Page 1

667

Service Instructions

Page 2

IMPORTANT

READ CAREFULLY BEFORE USE

KEEP FOR FUTURE REFERENCE

All rights reserved.

Property of Dürkopp Adler AG and protected by copyright. Any reuse of these contents, including

extracts, is prohibited without the prior written approval of Dürkopp Adler AG.

Copyright © Dürkopp Adler AG 2016

Page 3

Table of Contents

1 About these service instructions..............................................3

1.1 Scope of the service instructions..................................................3

1.2 Representation conventions – symbols and characters............... 3

1.3 Other documents..........................................................................4

1.4 Liability..........................................................................................4

2 Safety...........................................................................................5

2.1 Basic safety instructions............................................................... 5

2.2 Signal words and symbols used in warnings................................6

3 Working basis............................................................................. 9

3.1 Order of the settings..................................................................... 9

3.2 Cable routing................................................................................9

3.3 Removing the covers..................................................................10

3.3.1 Tilting and erecting the machine head........................................10

3.3.2 Removing and placing the arm cover......................................... 11

3.3.3 Removing and placing the head cover.......................................12

3.3.4 Removing and placing the valve cover.......................................13

3.3.5 Removing and installing the throat plate ....................................14

3.3.6 Removing and installing the feed dog ........................................15

3.4 Flats on shafts ............................................................................16

3.5 Locking the sewing machine in place......................................... 16

3.6 Setting the handwheel into position............................................18

4 Positioning the arm shaft.........................................................19

5 Setting the handwheel scale ...................................................21

6 Positioning the toothed belt wheels....................................... 23

6.1 Setting the upper toothed belt wheel..........................................23

6.2 Setting the lower toothed belt wheel...........................................25

7 Setting the stitch length adjusting wheels............................. 27

7.1 Setting the upper stitch length adjusting wheel..........................28

7.2 Setting the lower stitch length adjusting wheel...........................30

7.3 Setting the stitch length limit.......................................................32

7.4 Setting the eccentric for the forward and backward stitches...... 33

8 Setting the feed dog................................................................. 35

8.1 Setting the feed dog position......................................................35

8.1.1 Moving the feed dog...................................................................36

8.1.2 Moving the feed dog carrier........................................................37

8.2 Setting the feed dog movement..................................................38

8.2.1 Setting the feed movement.........................................................38

8.2.2 Setting the feed dog height at top dead center...........................39

8.2.3 Setting the stroke movement......................................................40

9 Aligning the needle bar linkage...............................................43

9.1 Moving the needle bar linkage sideways....................................43

9.2 Aligning the needle bar linkage in the sewing direction..............45

10 Position of the hook and needle ............................................. 47

10.1 Setting the hook side clearance .................................................47

Service Instructions 667 - 00.0 - 04/2016 1

Page 4

Table of Contents

10.2 Setting the loop stroke position ..................................................49

10.3 Setting the needle bar height......................................................51

11 Sewing feet................................................................................53

11.1 Setting an even sewing foot stroke.............................................54

11.2 Setting the stroke movement for the feeding foot.......................55

11.3 Setting the sewing foot pressure................................................57

11.4 Setting the sewing foot lifting height........................................... 58

12 Setting the needle thread tension...........................................59

12.1 Setting the needle thread regulator............................................59

12.2 Setting the thread tensioning spring...........................................60

13 Winder .......................................................................................61

13.1 Setting the winder.......................................................................61

13.2 Setting the hook thread guide.....................................................64

14 Thread cutter............................................................................. 65

14.1 Setting the control cam position .................................................65

14.2 Setting the armature of the thread cutter magnet.......................66

14.3 Setting the position of the thread-pulling knife............................67

14.4 Setting the cutting pressure........................................................68

15 Setting the potentiometer........................................................ 71

16 Maintenance..............................................................................73

16.1 Cleaning .....................................................................................74

16.1.1 Cleaning the machine.................................................................74

16.1.2 Cleaning the motor fan mesh .....................................................75

16.2 Lubricating..................................................................................76

16.2.1 Lubricating the machine head ....................................................77

16.2.2 Lubricating the hook ...................................................................78

16.3 Servicing the pneumatic system.................................................79

16.3.1 Setting the operating pressure ...................................................79

16.3.2 Draining the water condensation................................................80

16.3.3 Cleaning the filter element..........................................................81

16.4 Servicing specific components...................................................82

16.5 Parts list......................................................................................82

17 Decommissioning.....................................................................83

18 Disposal.....................................................................................85

19 Technical data...........................................................................87

2 Service Instructions 667 - 00.0 - 04/2016

Page 5

About these service instructions

1.

2.

•

1 About these service instructions

These instructions for sewing machine 667 was compiled with the utmost

care. They contain information and notes intended to ensure long-term

and reliable operation.

1.1 Scope of the service instructions

The instructions describe the setting and maintenance work on the 967

sewing machine. They apply to all subclasses.

The proper use and setup is described in the Operating Instructions.

1.2 Representation conventions – symbols and characters

Various information in these instructions is represented or highlighted by the

following characters in order to facilitate easy and quick understanding:

Proper setting

Specifies proper setting.

Disturbances

Specifies the disturbances that can occur from an incorrect setting.

Steps to be performed when operating the machine (sewing and

equipping)

Steps to be performed for service, maintenance, and installation

Steps to be performed via the software control panel

The individual steps are numbered:

1. First step

2. Second step

The steps must always be followed in the specified order.

Lists are marked by bullet points.

Result of performing an operation

Change to the machine or on the display.

Important

Special attention must be paid to this point when performing a step.

Service Instructions 667 - 00.0 - 04/2016 3

Page 6

About these service instructions

Information

Additional information, e.g. on alternative operating options.

Order

Specifies the work to be performed before or after a setting.

References

Reference to another section in these instructions.

Safety Important warnings for the user of the machine are specifically marked.

Since safety is of particular importance, hazard symbols, levels of danger

and their signal words are described separately in 2 Safety.

Location

information

If no other clear location information is used in a figure, indications of right

or left are always from the user's point of view.

1.3 Other documents

The device contains built-in components from other manufacturers.

Each manufacturer has performed a hazard assessment for these

purchased parts and confirmed their design compliance with applicable

European and national regulations. The proper use of the built-in components is described in the corresponding manufacturer's instructions.

1.4 Liability

All information in these service instructions was compiled in accordance

with the current state of the art and the applicable standards and

regulations.

The manufacturer cannot be held liable for damages resulting from:

• Breakage and damage during transport

• Failure to follow the operating instructions

• Improper use

• Unauthorized modifications to the machine

• Use of untrained personnel

• Use of unapproved parts

4 Service Instructions 667 - 00.0 - 04/2016

Page 7

Safety

2 Safety

This chapter contains basic information for your safety. Read the instructions carefully before setting up or operating the machine. Make sure to

follow the information included in the safety instructions. Failure to do so

can result in serious injury and property damage.

2.1 Basic safety instructions

The machine may only be used as described in these instructions.

The instructions should be available at the machine's location at all times.

Work on live components and equipment is prohibited. Exceptions are de-

fined in the DIN VDE 0105.

For the following work, the machine must be disconnected from the power

supply using the main switch or by disconnecting the power plug:

• Replacing the needle or other sewing tools

• Leaving the workstation

• Performing maintenance work and repairs

• Threading

Missing or faulty parts could impair safety and damage the machine.

Therefore only use original parts from the manufacturer.

Transport Use a lifting carriage or forklift to transport the machine. Raise the machine

max. 20 mm and secure it to prevent it from slipping off.

Setup The connecting cable must have a power plug approved in the relevant

country. The power plug may only be connected to the power cable by

qualified specialists.

Obligations

of the operator

Follow the country-specific safety and accident prevention regulations and

the legal regulations concerning industrial safety and the protection of the

environment.

All the warnings and safety signs on the machine must always be in legible

condition, and must not be removed. Missing or damaged labels must be

replaced immediately.

Requirements

to be met by

the personnel

The machine may only be set up by qualified specialists.

Maintenance work and repairs may only be carried out by qualified

specialists.

Work on electrical equipment may only be carried out by qualified specialists.

Only authorized persons may work on the machine. Every person who

works on the machine must first have understood these instructions.

Service Instructions 667 - 00.0 - 04/2016 5

Page 8

Operation Inspect the machine for any externally visible damage during use.

Stop working if you notice any changes to the machine. Report any changes

to your supervisor. Machines must no longer be used if they are damaged.

Safety

Safety

equipment

Safety equipment should not be removed or deactivated. If it is essential

to remove or deactivate safety equipment for a repair operation, it must be

refitted and put back into service immediately afterward.

2.2 Signal words and symbols used in warnings

Warnings in the text are distinguished by color bars. The color scheme

based on the severity of the danger. Signal words indicate the severity of

the danger.

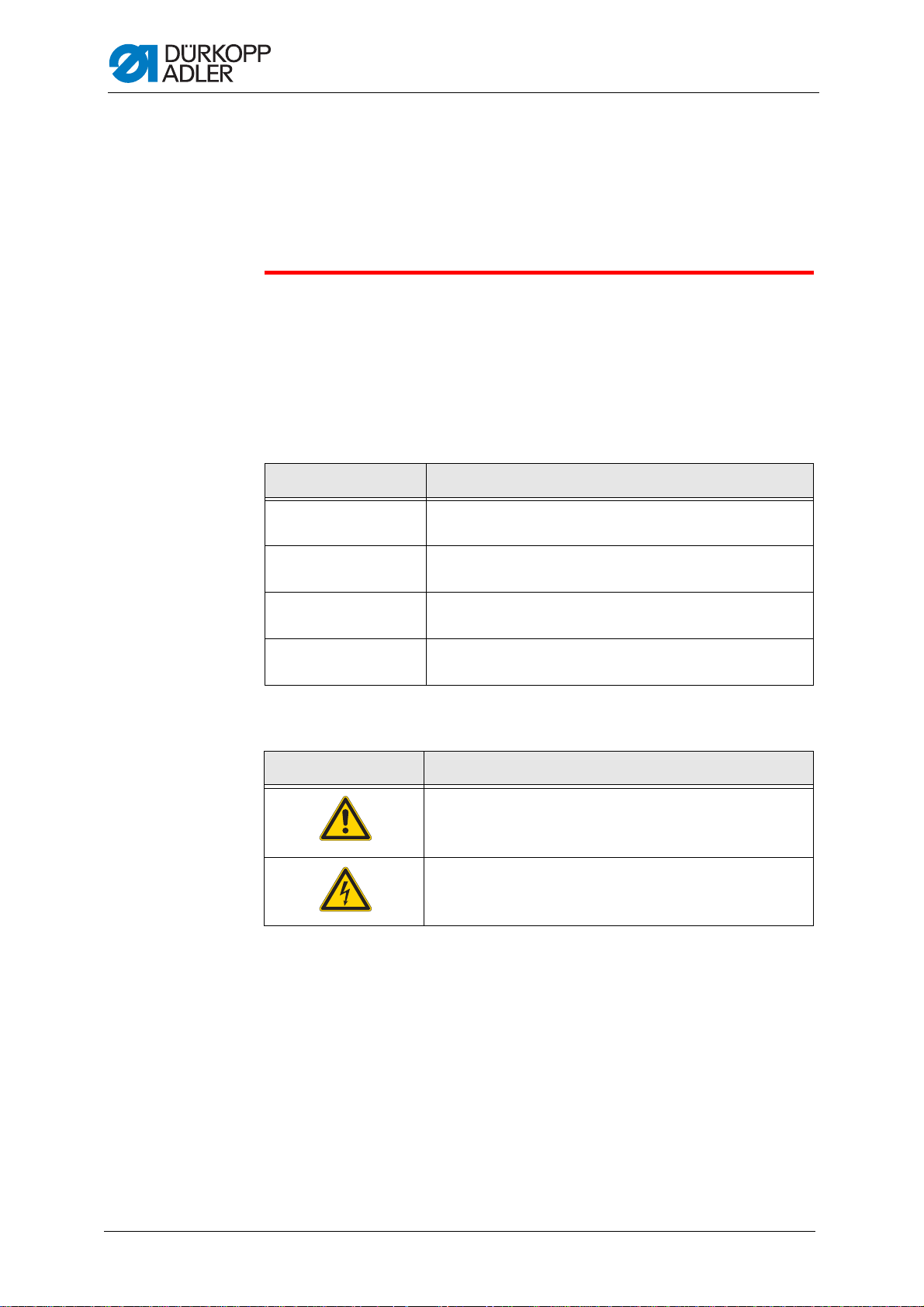

Signal words Signal words and the hazard they describe:

Signal word Meaning

DANGER (with hazard symbol)

If ignored, fatal or serious injury will result

WARNING (with hazard symbol)

If ignored, fatal or serious injury can result

CAUTION (with hazard symbol)

If ignored, moderate or minor injury can result

NOTICE (without hazard symbol)

If ignored, property damage can result

Symbols The following symbols indicate the type of danger to personnel:

Symbol Type of danger

General

Electric shock

6 Service Instructions 667 - 00.0 - 04/2016

Page 9

Safety

Symbol Type of danger

Sharp parts

Crushing

Environmental damage

Examples Examples of the layout of warnings in the text:

DANGER

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

This is what a warning looks like for a hazard that will result in serious

injury or even death if ignored.

WARNING

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

This is what a warning looks like for a hazard that could result in seri-

ous or even fatal injury if ignored.

CAUTION

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

This is what a warning looks like for a hazard that could result in

moderate or minor injury if the warning is ignored.

Service Instructions 667 - 00.0 - 04/2016 7

Page 10

Safety

CAUTION

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

This is what a warning looks like for a hazard that could result in envi-

ronmental damage if ignored.

NOTICE

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

This is what a warning looks like for a hazard that could result in

property damage if ignored.

8 Service Instructions 667 - 00.0 - 04/2016

Page 11

Working basis

3 Working basis

3.1 Order of the settings

The setting positions for the sewing machine are interdependent.

Always comply with the order of individual setting steps as specified.

It is absolutely essential that you follow all notices regarding prerequisites

and subsequent settings that are marked with in the margin.

NOTICE

Property damage may occur!

Risk of machine damage from incorrect order.

It is essential to follow the working order specified in these instructions.

3.2 Cable routing

Ensure that all cables are laid in the machine such that the function of

moving parts is not hampered.

1. Lay any excess cabling neatly in proper cable snakes.

2. Bind together the cable loops with cable ties.

Tie loops wherever possible to fixed parts.

The cables must be secured firmly.

3. Cut off the extending ends of cable ties.

NOTICE

Property damage may occur!

Machine damage and malfunctions can be caused by laying the

cables incorrectly.

Lay excess cabling in such a way that moving parts are not impaired

in their ability to function correctly.

Service Instructions 667 - 00.0 - 04/2016 9

Page 12

Working basis

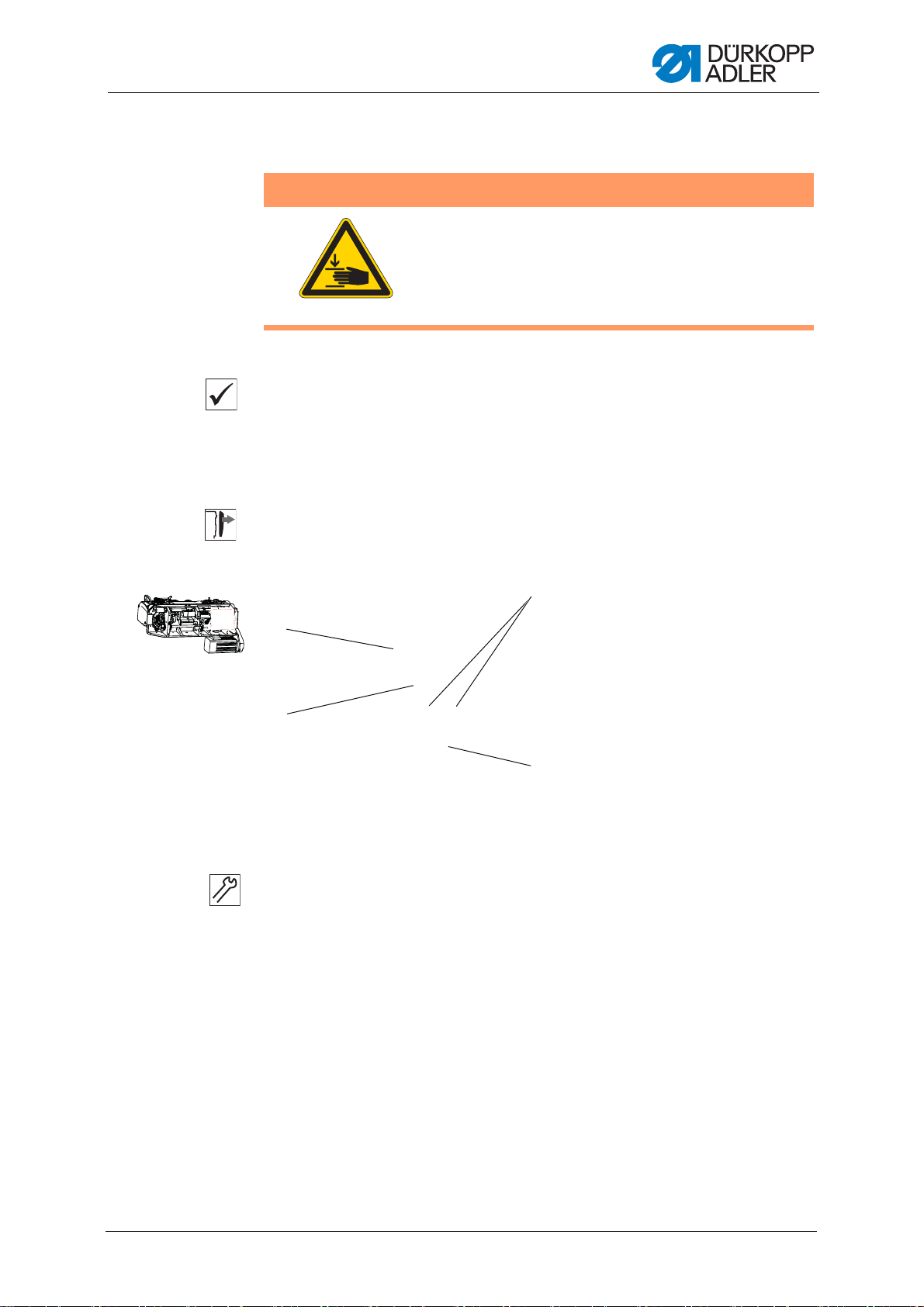

3.3 Removing the covers

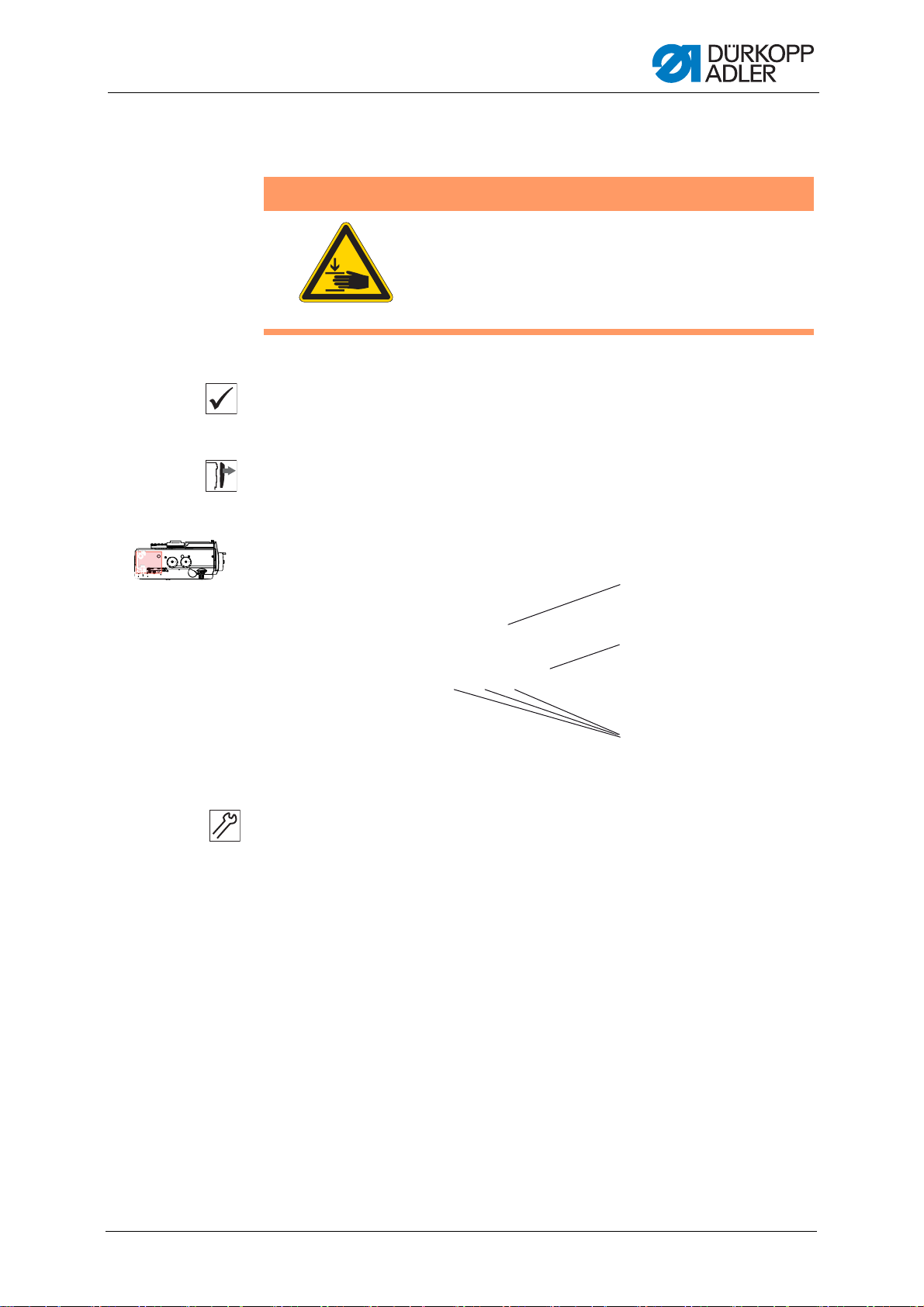

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before removing or

re-placing covers.

For many types of setting work, you will have to remove the machine covers first in order to access the components.

This chapter describes how to remove and then refit the individual covers.

The text for each type of setting work then specifies only the cover that

needs to be removed at that particular time.

3.3.1 Tilting and erecting the machine head

To access the components on the underside of the machine, swivel up the

machine head.

Fig. 1: Tilting and erecting the machine head

Tilting the machine head

To tilt the machine head:

1. Tilt the machine head as far as it will go.

Erecting the machine head

To erect the machine head:

1. Erect the machine head.

10 Service Instructions 667 - 00.0 - 04/2016

Page 13

Working basis

(1) - Screws

(2) - Left adjusting wheel for sewing

foot stroke

(3) - Arm cover

②

③

①

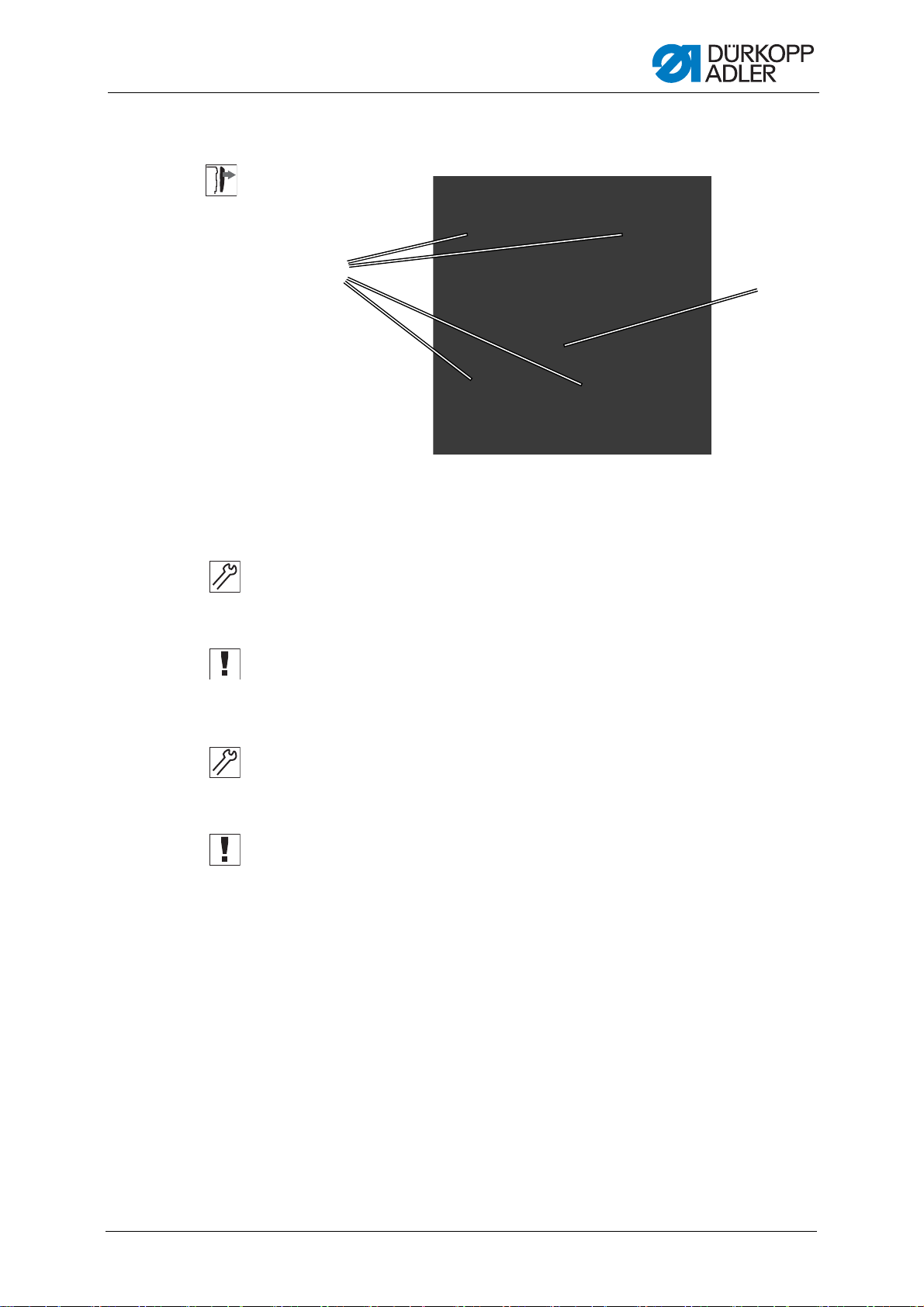

3.3.2 Removing and placing the arm cover

Fig. 2: Removing and placing the arm cover

Removing the arm cover

To remove the arm cover:

1. Position the left adjusting wheel for the sewing foot stroke (2) to 2.

2. Loosen the screws (1).

3. Hold the arm cover (3) at the adjusting wheels and remove it.

Placing the arm cover

To place the arm cover:

1. Position the left adjusting wheel for the sewing foot stroke (2) to 2.

2. Place the arm cover (3).

3. Tighten the screws (1).

Service Instructions 667 - 00.0 - 04/2016 11

Page 14

3.3.3 Removing and placing the head cover

(1) - Screws (2) - Head cover

②

①

Fig. 3: Removing and placing the head cover

Working basis

Removing the head cover

To remove the head cover:

1. Loosen the screws (1).

2. Remove the head cover (2).

Placing the head cover

To place the head cover:

1. Place the head cover (2).

2. Tighten the screws (1).

12 Service Instructions 667 - 00.0 - 04/2016

Page 15

Working basis

(1) - Screws (2) - Valve cover

②

①

3.3.4 Removing and placing the valve cover

Fig. 4: Removing and placing the valve cover

Removing the valve cover

To remove the valve cover:

1. Loosen all 4 screws (1).

2. Remove the valve cover (2).

Important

When removing the valve cover, be sure not to pull off any cables.

Placing the valve cover

To place the valve cover:

1. Place the valve cover (2).

2. Tighten all 4 screws (1).

Important

When placing the valve cover, be sure not to pull off any cables.

Service Instructions 667 - 00.0 - 04/2016 13

Page 16

3.3.5 Removing and installing the throat plate

(1) - Screws (2) - Throat plate

①

②

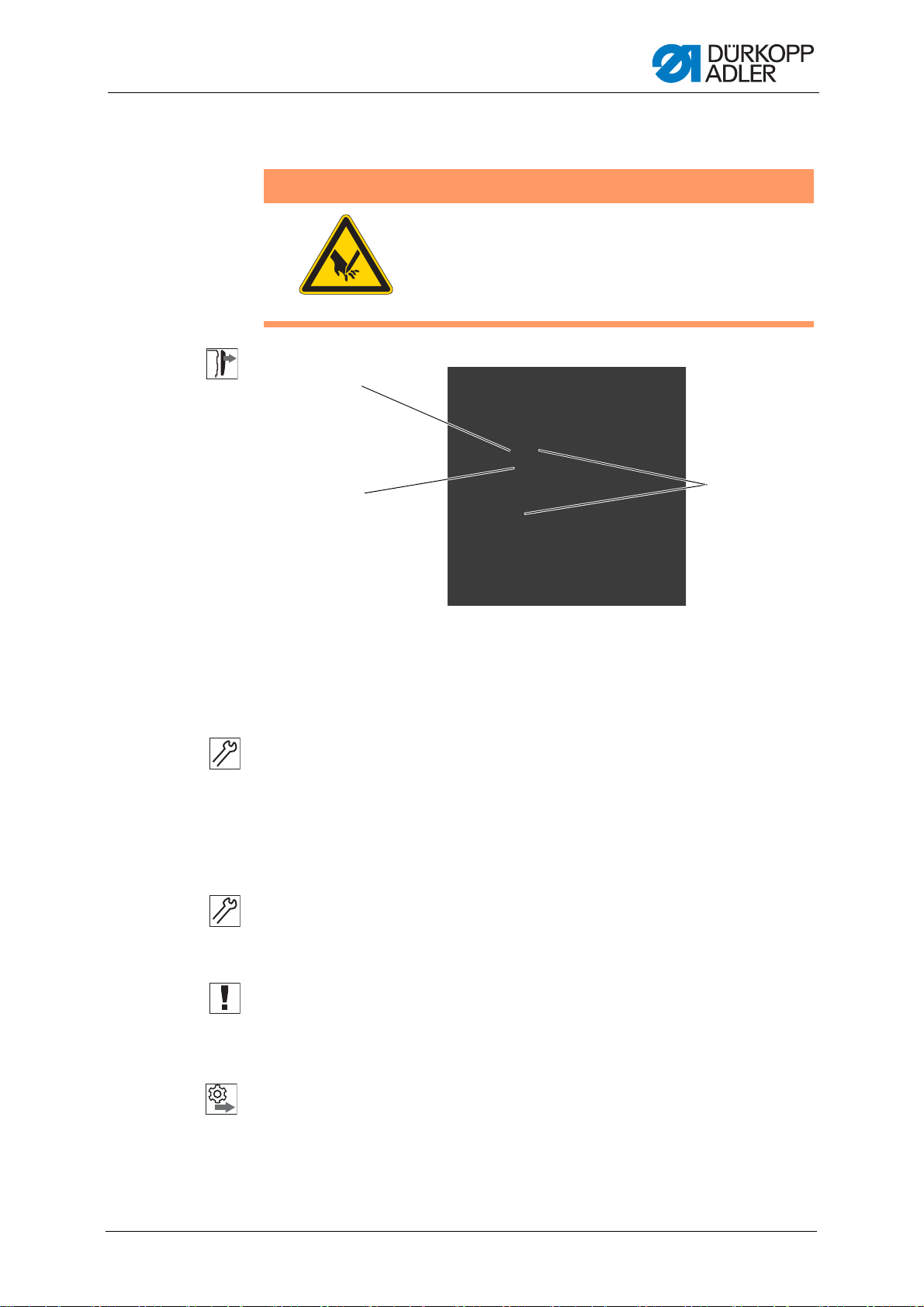

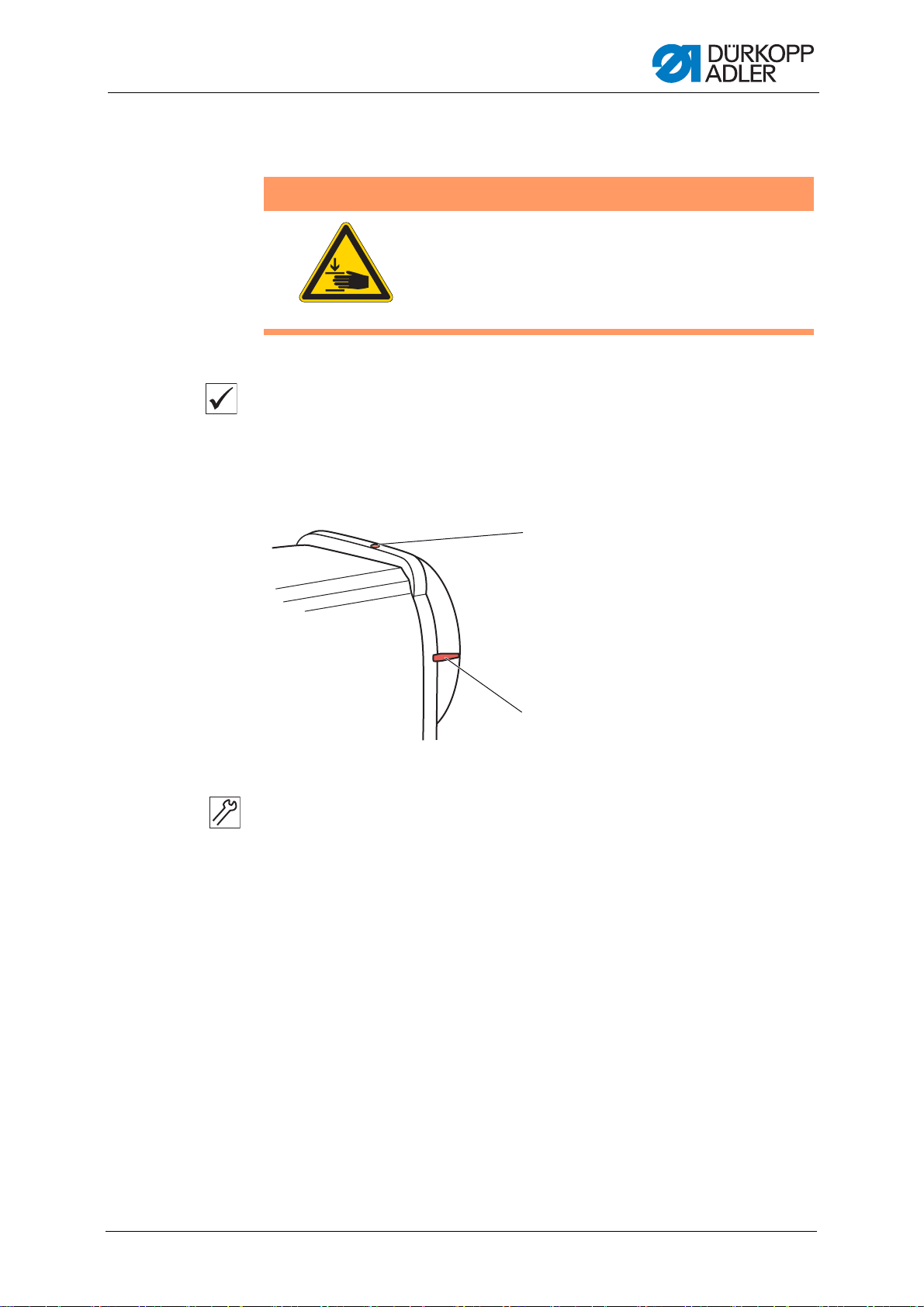

WARNING

Risk of injury from sharp and moving parts!

Crushing and puncture possible.

Switch off the machine before you remove or install

the throat plate.

Fig. 5: Removing and installing the throat plate

Working basis

Removing the throat plate

To remove the throat plate:

1. Loosen the screws (1).

2. Remove the throat plate (2).

Installing the throat plate

To install the throat plate:

1. Insert the throat plate (2).

2. Tighten the screws (1).

14 Service Instructions 667 - 00.0 - 04/2016

Page 17

Working basis

①

②

③

3.3.6 Removing and installing the feed dog

WARNING

Risk of injury from sharp and moving parts!

Crushing and puncture possible.

Switch off the machine before you remove or install

the feed dog.

Fig. 6: Removing and installing the feed dog

(1) - Feed dog (2) - Feed dog carrier

(3) - Screws

Removing the feed dog

To remove the feed dog:

1. Tilt the machine head.

2. Loosen the screws (3).

3. Take the feed dog (1) off the feed dog carrier (2).

Installing the feed dog

To install the feed dog:

1. Place the feed dog (1) onto the feed dog carrier (2).

2. Tighten the screws (3).

Important

Check the feed dog position in its movement at maximum stitch length

(depending on the equipment: 6, 9 or 12) by turning the handwheel.

The feed dog must not hit against the throat plate.

Order

Then check the following setting:

• Feed dog ( p. 36)

Service Instructions 667 - 00.0 - 04/2016 15

Page 18

Working basis

2

1

(1) - Flat (2) - Shaft

(1) - Arresting pin

(2) - Large arresting groove

(3) - Small arresting groove

(4) - Arm shaft crank

①

②

③

5 mm

3 mm

④

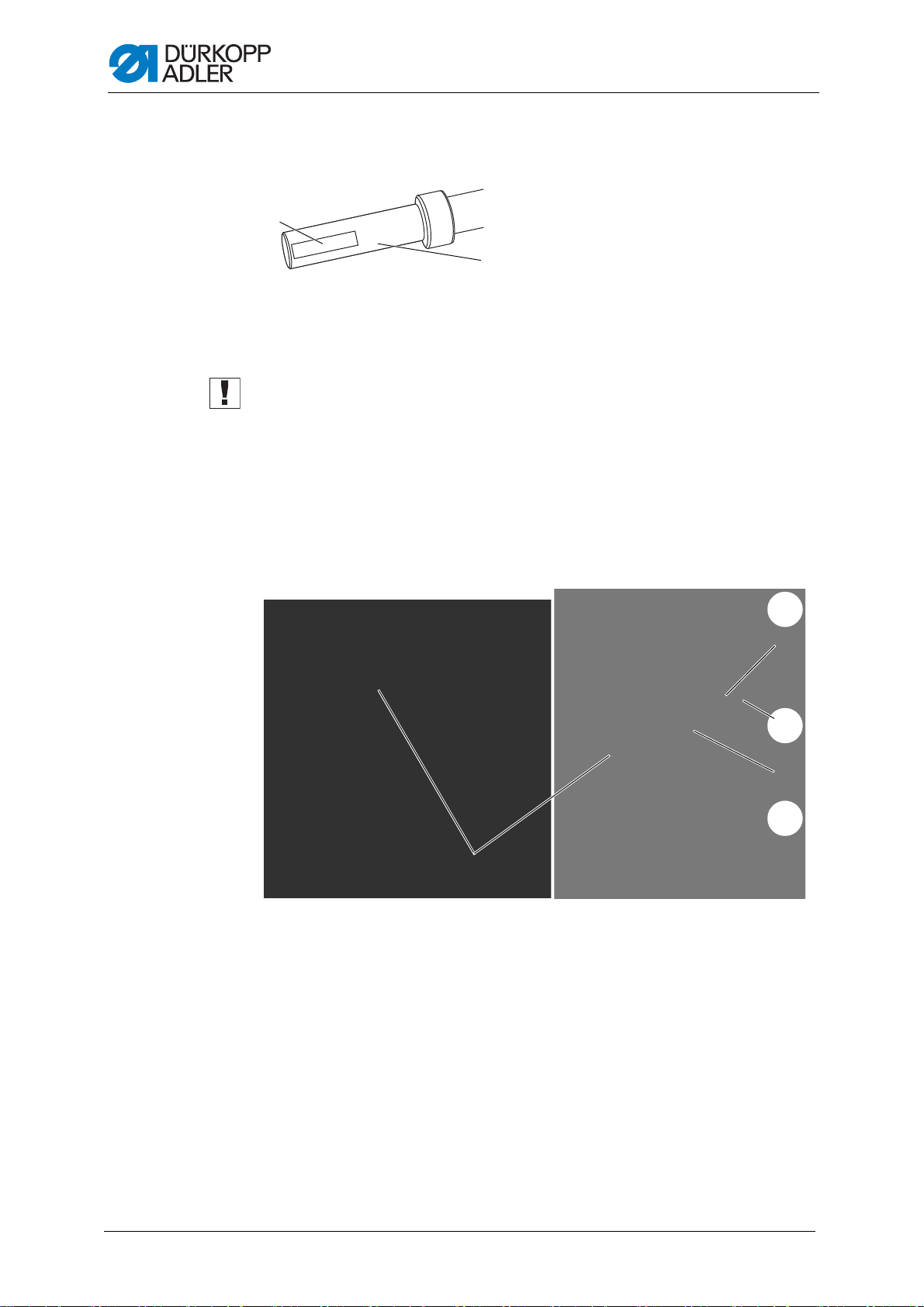

3.4 Flats on shafts

Fig. 7: Flats on shafts

Some shafts have flat surfaces at the points where the components are

screwed on. This stabilizes the connection and makes adjustment easier.

Important

Always ensure that the screws are completely flush with the surface.

3.5 Locking the sewing machine in place

For some settings, the machine must be locked in place. To do this, the

arresting pin from the accessory pack is inserted into a slot on the arm

shaft crank, blocking the arm shaft.

Fig. 8: Locking the sewing machine in place (1)

16 Service Instructions 667 - 00.0 - 04/2016

Page 19

Working basis

(1) - Slot

(2) - Locking opening

(3) - Arresting pin

①

②

③

There are 2 securing positions:

• Position 1: Loop stroke position

• 5 mm end in the large slot

• Setting the loop stroke and needle bar height

• Position 2: Handwheel zero position

• 3 mm end in the small slot

• Setting the handwheel position and checking the top dead center

for the needle bar

Fig. 9: Locking the sewing machine in place (2)

Locking the machine in place

1. Remove the plug from the locking slot (2).

2. Turn the handwheel until the appropriate groove (1) is in front of the

locking opening (2):

• Small slot at handwheel position 0°

• Large groove at handwheel position 200 – 205°

3. Insert the arresting pin (3) with the appropriate end in the groove (1).

Removing the positional lock

1. Pull the arresting pin (3) out of the groove (1).

2. Insert the plug into the locking opening (2).

Service Instructions 667 - 00.0 - 04/2016 17

Page 20

Working basis

(1) - Graduated

scale

(2) - Marking

①

②

3.6 Setting the handwheel into position

For some settings, the graduated scale on the handwheel has to be moved

to a certain position.

Fig. 10: Setting the handwheel into position

To set the handwheel into position:

1. Turn the handwheel until the specified number on the graduated

scale (1) is next to the marking (2).

18 Service Instructions 667 - 00.0 - 04/2016

Page 21

Positioning the arm shaft

(1) - Arm shaft crank

(2) - Machine casting

(3) - Threaded pins

4 Positioning the arm shaf t

Proper setting

The 3 threaded pins (3) on the arm shaft crank (1) are seated completely

on the flat. The arm shaft crank (1) is flush with the machine casting (2).

Cover

• Arm cover ( p. 11)

Fig. 11: Positioning the arm shaft

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before you check and set

the position of the arm shaft crank.

1

2

3

To position the arm shaft:

1. Loosen all threaded pins (3) on the arm shaft crank (1).

2. Turn the arm shaft crank (1) such that the threaded pins (3) are seated

completely on the flat of the arm shaft.

3. Push the arm shaft (1) to the right as far as it will go and flush with the

machine casting.

4. Tighten all the threaded pins (3) on the arm shaft crank (1).

Service Instructions 667 - 00.0 - 04/2016 19

Page 22

Positioning the arm shaft

20 Service Instructions 667 - 00.0 - 04/2016

Page 23

Setting the handwheel scale

(1) - Screw opening (2) - Marking

5 Setting the handwheel scale

Checking the proper setting

1. Lock the machine in place at position 2 ( p. 16).

The handwheel is at position 0°.

If a different degree number is next to the marking (2) then you will

have to reset the graduated scale.

Fig. 12: Setting the handwheel scale

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before you check and set

the position of the handwheel on the arm shaft.

1

2

To set the handwheel scale:

The handwheel is fastened using 2 threaded pins, which you can see

through the screw opening (1).

1. Turn handwheel until the first threaded pin is under the opening (1).

2. Loosen the threaded pin through the opening (1).

3. Turn the handwheel by 50° such that the second threaded pin is under

the opening (1).

4. Loosen the threaded pin through the opening (1).

5. Lock the machine in place at position 2 ( p. 16).

6. Turn the handwheel scale so that the 0° is at the center of the

marking (2).

7. Tighten the threaded pin through the opening (1).

8. Removing the lock ( p. 16).

9. Move the handwheel into the 50° position.

10. Tighten the threaded pin through the opening (1).

Service Instructions 667 - 00.0 - 04/2016 21

Page 24

Setting the handwheel scale

22 Service Instructions 667 - 00.0 - 04/2016

Page 25

Positioning the toothed belt wheels

6 Positioning the toothed belt wheels

The two toothed belt wheels must be positioned one on top of the other

such that the toothed belt can run correctly. In machines with normal

lengths, the winder wheel is directly next to the upper toothed belt wheel

and determines its alignment. In long arm machines, the winder wheel is

fastened farther away in the center of the arm.

Order

• Always check the position of the other toothed belt wheel after making a

change on either of the toothed belt wheels.

The position of the upper toothed belt wheel is defined by the distance to

the winder wheel.

Therefore, you must first align the upper toothed belt wheel on the winde r

wheel and then align the lower toothed belt such that the toothed belt runs

correctly over both wheels.

6.1 Setting the upper toothed belt wheel

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before you check and set

the upper toothed belt wheel.

Proper setting

The 2 threaded pins for the upper toothed belt wheel are seated flush on

the flat.

The distance between the winder wheel and the upper toothed belt wheel

is 0.8 mm.

Cover

• Arm cover ( p. 11)

Service Instructions 667 - 00.0 - 04/2016 23

Page 26

Positioning the toothed belt wheels

3

4

5

2

1

(1) - Upper toothed belt wheel

(2) - Threaded pins

(3) - Winder wheel (position in machines

with normal lengths)

(4) - Toothed belt

(5) - Surface of arm shaft

Fig. 13: Setting the upper toothed belt wheel

To set the upper toothed belt wheel:

1. Using the screwdriver, push the toothed belt (4) sufficiently far to the

side so that the 2 threaded pins (2) can be reached.

2. Loosen the threaded pins (2).

3. Turn the upper toothed belt wheel (1) such that the threaded pins (2)

are seated flush on the flat (5) of the arm shaft.

4. Move the upper toothed belt wheel (1) to the side such that the dista nce

to the winder wheel (3) is 0.8 mm.

5. Tighten the threaded pins (2).

6. Use the screwdriver to push the toothed belt (4) back again.

24 Service Instructions 667 - 00.0 - 04/2016

Page 27

Positioning the toothed belt wheels

2

1

3

4

(1) - Toothed belt

(2) - Retaining ring

(3) - Lower toothed belt wheel

(4) - Threaded pins

6.2 Setting the lower toothed belt wheel

Proper setting

The 2 threaded pins for the lower toothed belt wheel are seated flush on

the flat of the lower shaft.

The toothed belt runs correctly without running against the retaining ring

or slipping off.

Cover

• Tilt the machine head ( p. 10)

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before you check and set

the lower toothed belt wheel.

Fig. 14: Setting the lower toothed belt wheel

To set the lower toothed belt wheel:

1. Loosen the threaded pins (4).

2. Turn the lower toothed belt wheel (3) such that the threaded pins (4)

are seated on the flat of the arm shaft.

3. Move the lower toothed belt wheel (3) sufficiently far to the side so that

the toothed belt (1) makes contact with the retaining ring (2) without

being pushed away.

4. Tighten the threaded pins (4).

Service Instructions 667 - 00.0 - 04/2016 25

Page 28

Positioning the toothed belt wheels

26 Service Instructions 667 - 00.0 - 04/2016

Page 29

Setting the stitch length adjusting wheels

0

1

2

4

3

5

6

7

8

9

10

11

12

0

1

2

4

3

5

6

7

8

9

10

11

12

+/–+/–

3

1

2

(1) - Button for the stitch length

on the machine arm

(2) - Upper stitch length adjusting wheel

(3) - Lower stitch length adjusting wheel

7 Setting the stitch length adjusting wheels

Fig. 15: Setting the stitch length adjusting wheels

The 2 adjusting wheels on the machine column determine the stitch length.

• Upper adjusting wheel: larger stitch length

• Lower adjusting wheel: smaller stitch length

It is not possible to set a larger stitch length on the lower adjusting wheel

than on the upper adjusting wheel.

To switch over between the stitch lengths: Press the button for the stitch

length on the machine arm (1).

If the upper adjusting wheel is activated, then the button (1) lights up.

Upon switching on the machine, the stitch length adjusting wheel activated

most recently is always active.

An automatic switchover to the upper adjusting wheel is made when you

switch off the machine at the main switch.

Order

Set the upper stitch length adjusting wheel first, then the lower stitch length

adjusting wheel.

Service Instructions 667 - 00.0 - 04/2016 27

Page 30

Setting the stitch length adjusting wheels

(1) - Upper stitch length adjusting wheel

(2) - Screw

(3) - Lower stitch length adjusting wheel

(4) - Adjusting mark

(5) - Shaft

(6) - Scale

(7) - Wrench

②

①

④

③

⑤

⑥

⑦

7.1 Setting the upper stitch length adjusting wheel

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before you set the upper

toothed belt wheel.

Proper setting

Upper stitch length adjusting wheel to 0:

No play on the stitch regulator gear. The plates for the gear are parallel;

the frame cannot be moved.

Cover

• Tilt the machine head ( p. 10)

To set the upper stitch length adjusting wheel:

1. Switch off the machine at the main switch.

The machine switches over to the upper stitch length adjusting

wheel.

Fig. 16: Setting the upper stitch length adjusting wheel (1)

2. Hold the upper stitch length adjusting wheel (1) in place using a

wrench (7).

3. Loosen the screw (2).

4. Remove the upper stitch length adjusting wheel (1) from the shaft (5).

28 Service Instructions 667 - 00.0 - 04/2016

Page 31

Setting the stitch length adjusting wheels

(8) - Frame for the stitch regulator gear

(9) - Plates for the stitch regulator gear

(10) - Hole

(11) - Tension spring

(12) - Screw

⑨

⑧

⑪⑩ ⑫

NOTICE

Property damage may occur!

Risk of machine damage if the shaft is turned too hard.

If you turn the shaft too far, parts on the stitch regulator gear may

bend or get stuck.

Turn the shaft carefully and stop as soon as you feel a slight

resistance.

5. Carefully turn the shaft (5) clockwise using a size 10 wrench.

Fig. 17: Setting the upper stitch length adjusting wheel (2)

6. Check whether the frame (8) for the stitch regulator gear can be moved.

Information

In machines that have a stitch adjustment lever, check this by pressing

the stitch adjustment lever.

In machines that do not have a stitch adjustment lever, insert the arresting pin or a hex key into the opening (10) and try to move the frame (8) up

and down.

7. As soon as the frame (8) stops moving: Remove the wrench from the

shaft (5).

8. Turn the scale (6) so that the 0 is exactly next to the adjusting mark (4).

9. Place the upper stitch length adjusting wheel (1) onto the shaft (5) and

tighten it with a wrench (7).

10. Tighten the upper stitch length adjusting wheel (1) using screw (2).

11. Check whether the plates for the stitch regulator gear (9) are parallel

to one another.

Service Instructions 667 - 00.0 - 04/2016 29

Page 32

Setting the stitch length adjusting wheels

(1) - Button for the stitch length

on the machine arm

(2) - Upper stitch length adjusting wheel

(3) - Lower stitch length adjusting wheel

+/–

Important

If the plates (8) are not parallel to one another:

12. Remove the tension spring (11).

13. Loosen the screw (12).

14. Manually position the plates (9) so that they are parallel.

15. Tighten the screw (12).

16. Attach the tension spring (11).

7.2 Setting the lower stitch length adjusting wheel

WARNING

Risk of injury from moving parts!

Crushing possible.

The lower stitch length adjusting wheel has to be

set when the machine is switched on because

a switchover is automatically made to the upper

stitch length adjusting wheel when the machine is

switched off.

Carry out all work with extreme caution.

Checking the proper setting

Sewing with 2 different stitch lengths:

• The stitch lengths on the seam correspond with the set stitch lengths.

• The lower stitch length adjusting wheel can only be turned up to the

stitch length set on the upper stitch length adjusting wheel.

Cover

• Tilt the machine head ( p. 10)

Fig. 18: Setting the lower stitch length adjusting wheel (1)

0

1

2

3

4

5

6

7

9

8

3

2

4

5

6

7

8

9

10

11

2

3

1

12

11

10

1

+/–

0

12

30 Service Instructions 667 - 00.0 - 04/2016

Page 33

Setting the stitch length adjusting wheels

(1) - Upper stitch length adjusting wheel

(2) - Screw

(3) - Lower stitch length adjusting wheel

(4) - Adjusting mark

(5) - Shaft

(6) - Scale

(7) - Wrench

②

①

④

③

⑤

⑥

⑦

To set the lower stitch length adjusting wheel:

1. Position the upper stitch length adjusting wheel (2) > 3.

2. Switch the machine to short stitch length.

The button for the stitch length (1) does not light up.

If the button lights up, press button (1) again.

Fig. 19: Setting the lower stitch length adjusting wheel (2)

3. Hold the lower stitch length adjusting wheel (3) in place using the

wrench (7).

4. Loosen the screw (2).

5. Remove the lower stitch length adjusting wheel (3) from the shaft (5).

NOTICE

Property damage may occur!

Risk of machine damage if the shaft is turned too hard.

If you turn the shaft too far, parts on the stitch regulator gear may

bend or get stuck.

Turn the shaft carefully and stop as soon as you feel a slight

resistance.

6. Carefully turn shaft (5) clockwise with a size 10 wrench until you feel

significant play on the frame for the stitch regulator gear.

7. Carefully turn shaft (5) counterclockwise with a size 10 wrench until

you no longer feel any play.

8. As soon as the frame stops moving: Remove the wrench from the

shaft (5).

9. Turn the scale (6) so that the 0 is exactly next to the adjusting mark (4).

10. Place the lower stitch length adjusting wheel (3) onto the shaft (5) and

tighten it with a wrench (7).

11. Tighten the lower stitch length adjusting wheel (3) using screw (2).

Service Instructions 667 - 00.0 - 04/2016 31

Page 34

Setting the stitch length adjusting wheels

2

3

1

(1) - Upper stitch length adjusting wheel

(2) - Screw

(3) - Mark-off openings

7.3 Setting the stitch length limit

If not all of the stitch lengths are available during sewing operation, a limit

can be placed on the maximum stitch length that can be set.

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before setting the maximum

stitch length limit.

9 or 6 mm can be selected as the maximum stitch length. The appropriate

throat plate must be selected for the selected maximum stitch length.

The throat plate cut-out must be large enough to prevent the feed dog

from hitting the edges of the throat plate at the front and rear d ead center.

NOTICE

Property damage may occur!

Risk of damaging the feed dog due to incorrect throat plate size.

If the throat plate cut-out is too small, the feed dog may hit against

the edges.

Make sure that an appropriate throat plate is used for the selected

maximum stitch length.

Proper setting

Turn the upper stitch length adjusting wheel clockwise as far as it will go.

The upper stitch length adjusting wheel can only be turned up to the

set maximum stitch length.

Fig. 20: Setting the stitch length limit

32 Service Instructions 667 - 00.0 - 04/2016

Page 35

Setting the stitch length adjusting wheels

To set the stitch length limit:

1. Position the upper stitch length adjusting wheel (1) to 0.

2. Hold the upper stitch length adjusting wheel (1) in place using a wrench.

3. Loosen the screw (2).

4. Remove the upper stitch length adjusting wheel (1).

5. Loosen the threaded pin from one of the 3 mark-off openings (3).

6. Screw the threaded pin into the mark-off opening for the required maximum stitch length. The openings are marked with numbers for the

stitch length.

7. Turn the scale so that the 0 is exactly next to the adjusting mark.

8. Place the upper stitch length adjusting wheel (1) and hold it in position

using a wrench.

9. Tighten the screw (2).

7.4 Setting the eccentric for the forward and backward

stitches

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before setting the eccentric

screw.

Proper setting

The forward and backward stitches are the same length.

As a test, sew a seam forward, stop, and sew a seam backward. The inser-

tions of the forward and backward stitches have to lie within one another.

Cover

• Tilt the machine head ( p. 10)

Service Instructions 667 - 00.0 - 04/2016 33

Page 36

Setting the stitch length adjusting wheels

2

4

3

1

2

(1) - Block

(2) - Threaded pin

(3) - Eccentric

(4) - Recess

Fig. 21: Setting the eccentric for the forward and backward stitches

To set the eccentric for forward and backward stitches:

1. Loosen the threaded pin (2).

2. Turn the eccentric screw (3) from the right through the opening in the

base plate:

Initial position:

The slot in the eccentric screw (3) is parallel to the threaded pin (2),

the recess (4) faces the front.

If the forward and backward stitches are not the same length:

• Turn clockwise:

The forward stitch becomes larger, the backward stitch smaller.

• Turn counterclockwise:

The forward stitch becomes smaller, the backward stitch larger.

3. Tighten the threaded pin (2).

34 Service Instructions 667 - 00.0 - 04/2016

Page 37

Setting the feed dog

8 Setting the feed dog

The position and the movement of the feed dog and needle bar have to be

coordinated such that the needle pierces exactly in the center of the needle hole of the feed dog.

Order

First, check the following setting:

• Needle bar linkage ( p. 43)

8.1 Setting the feed dog position

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before you set the feed dog

position.

Proper setting

The feed dog is exactly in the center of the throat plate cut-out, both sideways and in the sewing direction.

If the stitch length is 0, the needle pierces exactly in the center of the ne edle hole.

Various settings can be made depending on how far the position of the

feed dog differs from the correct setting:

• For minimal deviations, it suffices to move the feed dog on the carrier

( p. 36).

• If this is not sufficient, move the entire feed dog carrier on the sliding

shaft ( p. 36).

Service Instructions 667 - 00.0 - 04/2016 35

Page 38

8.1.1 Moving the feed dog

①

②

③

Cover

• Throat plate ( p. 14)

Fig. 22: Moving the feed dog

Setting the feed dog

(1) - Feed dog

(2) - Feed dog carrier

To move the feed dog:

1. Loosen the screws (3).

2. Move the feed dog (1) on the feed dog carrier (2).

Place the removed throat plate next to it as an aid for orientation so

that the feed dog can be screwed on straight.

3. Tighten the screws (3).

(3) - Screws

36 Service Instructions 667 - 00.0 - 04/2016

Page 39

Setting the feed dog

①

⑧

②

③

④

⑤

⑥

⑦

8.1.2 Moving the feed dog carrier

The feed dog carrier is connected to the stitch regulator gear via the sliding

shaft, and can be moved on this shaft.

Cover

• Tilt the machine head ( p. 10)

Fig. 23: Moving the feed dog carrier

(1) - Adjusting rings

(2) - Threaded pins

(3) - Lever

(4) - Stroke eccentric

To move the feed dog carrier:

1. Position the upper stitch length adjusting wheel to 0.

2. Loosen threaded pins (2), (5), (7) and screw (6).

3. Move the feed dog carrier perpendicular to the sewing direction so that

the feed dog is exactly in the center of the throat plate cut-out.

4. Push the adjusting rings (1) toward each other as far as they will go.

Important

Make sure that the sliding shaft (8) is tightened by the clamping rings.

5. Tighten the threaded pins (2).

6. Tighten the threaded pins (5) for the stroke eccentric (5).

7. The stroke eccentric (4) and the slot of the lever (3) must be in a line.

8. Move the feed dog carrier in the sewing direction such that the feed

dog is exactly in the center of the throat plate cut-out.

9. Tighten screw (6) and threaded pin (7).

In the process, make sure that the feed dog height has the correct set-

ting ( p. 39).

(5) - Threaded pins

(6) - Screw

(7) - Threaded pins

(8) - Sliding shaft

Service Instructions 667 - 00.0 - 04/2016 37

Page 40

Setting the feed dog

(1) - Pusher eccentric

(2) - Threaded pins

(3) - Connecting rod

①

②

③

8.2 Setting the feed dog movement

The feed dog moves in an elliptical cycle. To align this correctly, the feed

movement and the stroke height and the stroke movement of the feed dog

all have to be set.

Order

First, check the following setting:

• Feed dog ( p. 35)

8.2.1 Setting the feed movement

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before you check and set

the feed movement of the feed dog.

The proper setting for the feed movement is checked at standstill and set

using the pusher eccentric.

Proper setting

Lock the machine in place at position 1 and position the upper stitch length

wheel to stitch length 0.

The slots of the feed dog eccentric and of the connecting rod are in a

line.

Cover

• Tilt the machine head ( p. 10)

Fig. 24: Setting the feed movement

38 Service Instructions 667 - 00.0 - 04/2016

Page 41

Setting the feed dog

(1) - Stroke eccentric

(2) - Threaded pins

(3) - Lever

(4) - Locking ring

①

②

③

④

To set the feed movement:

1. Position the upper stitch length adjusting wheel to 0.

2. Lock the machine in place at position 1.

3. Loosen the threaded pins (2) on the pusher eccentric (1).

4. Turn the pusher eccentric (1) such that the slot is in a line with the slot

of the connecting rod.

5. Tighten the threaded pins (2).

8.2.2 Setting the feed dog height at top dead center

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before you check and set

the feed dog height.

The feed dog reaches the maximum stroke height at top dead center when

the handwheel is positioned at 190°.

Proper setting

Place the feed dog in the uppermost position by turning the handwheel.

The upper edge of the feed dog protrudes 0.5 mm above the throat

plate.

Cover

• Tilt the machine head ( p. 10)

Fig. 25: Setting the feed dog height at top dead center

Service Instructions 667 - 00.0 - 04/2016 39

To set the feed dog height at top dead center:

1. Position the upper stitch length adjusting wheel to 0.

2. Place the feed dog in the uppermost position by turning the handwheel.

Page 42

Setting the feed dog

(1) - Stroke eccentric (2) - Lever

(3) - Stroke eccentric

①

②

③

3. Loosen the threaded pins (2).

4. Turn the stroke eccentric (1) such that the upper edge of the feed dog

protrudes 0.5 mm above the throat plate.

5. Move the stroke eccentric (1) to the left such that the feed dog has no

play in relation to the lever (3).

6. Tighten the threaded pins (2).

8.2.3 Setting the stroke movement

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before you check and set

the stroke movement of the feed dog.

Order

First, check the following setting:

• Feed dog height ( p. 39)

Proper setting

Machine locked in place at position 1 and upper stitch length adjusting

wheel set to 0.

Cover

• Tilt the machine head ( p. 10)

Fig. 26: Setting the stroke movement

To set the feed stroke:

1. Position the upper stitch length adjusting wheel to 0.

2. Lock the machine in place at position 1.

40 Service Instructions 667 - 00.0 - 04/2016

Page 43

Setting the feed dog

3. Loosen the threaded pins (3).

4. Turn the stroke eccentric (1) such that the slot is in a line with the slot

of the lever.

5. Tighten the threaded pins (3).

Service Instructions 667 - 00.0 - 04/2016 41

Page 44

Setting the feed dog

42 Service Instructions 667 - 00.0 - 04/2016

Page 45

Aligning the needle bar linkage

1

2

4

3

(1) - Threaded pins

(2) - Adjusting rings

(3) - Throat plate

(4) - Needle bar linkage

9 Aligning the needle bar linkage

Order

First, check the following setting:

• A straight and undamaged needle must be inserted

( Operating Instructions, chap. Inserting and replacing the needle)

Proper setting

Position the upper and lower stitch length adjusting wheel to 0.

The needle pierces exactly in the center of the feed dog needle hole.

9.1 Moving the needle bar linkage sideways

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before aligning the needle

bar linkage sideways.

Cover

• Arm cover ( p. 11)

• Head cover ( p. 12)

Fig. 27: Moving the needle bar linkage sideways (1)

Service Instructions 667 - 00.0 - 04/2016 43

To move the needle bar linkage sideways:

1. Set the upper and lower stitch length adjusting wheel to 0.

2. Loosen the threaded pins (1) on the two adjusting rings (2) at the righthand end of the shaft for the needle bar linkage.

Page 46

Aligning the needle bar linkage

5

6

7

(5) - Arm shaft crank

(6) - Threaded pins

(7) - Thread lever

Fig. 28: Moving the needle bar linkage sideways (2)

3. Loosen both threaded pins (6) on the arm shaft crank (5). Make sure

that the threaded pins stay on the surface.

4. Move the needle bar linkage (4) sideways such that the needle pierces

exactly in the center of the needle hole (3) for the feed dog.

5. Push the two adjusting rings (2) inwards as far as they will go and

tighten them.

6. Tighten the threaded pins (1) on the two adjusting rings (2).

7. Align the thread lever (7) exactly in the middle of the slot.

8. Tighten both threaded pins (6) on the arm shaft crank (5).

Order

Then check the following settings:

• Loop stroke position ( p. 49)

• Distance of the hook to the needle ( p. 47)

44 Service Instructions 667 - 00.0 - 04/2016

Page 47

Aligning the needle bar linkage

(1) - Arm surface

(2) - Center of bolt

(3) - Lever

(4) - Threaded pins

(5) - Screw

①

③

②

④

⑤

9.2 Aligning the needle bar linkage in the sewing direction

Cover

• Valve cover ( p. 13)

• Tilt the machine head ( p. 10)

Fig. 29: Aligning the needle bar linkage in the sewing direction

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before you check and set

the position of the needle bar linkage in the sewing

direction.

126,6 mm

Proper setting

Stitch length adjusting wheels to 0.

The lever (3) is positioned such that the distance from the surface of

the arm (1) to the middle of the bolt (2) is 126.6 mm.

To align the needle bar linkage in the sewing direction:

1. Position the lower stitch length adjusting wheel to 0.

2. Position the upper stitch length adjusting wheel to 0.

3. Loosen the threaded pins (4).

4. Loosen the screw (5).

5. Position the lever (3).

6. Tighten the threaded pins (4).

7. Tighten the screw (5).

Service Instructions 667 - 00.0 - 04/2016 45

Page 48

Order

Then check the following setting:

• Loop stroke position ( p. 49)

Aligning the needle bar linkage

46 Service Instructions 667 - 00.0 - 04/2016

Page 49

Position of the hook and needle

10 Position of the hook and needle

10.1 Setting the hook side clearance

Order

First, check the following settings:

• A straight and undamaged needle has been inserted

( Operating Instructions, chap. Inserting and replacing the needle)

• Needle bar linkage ( p. 43)

• Loop stroke position ( p. 49)

WARNING

Risk of injury from moving parts!

Crushing possible.

Switch off the machine before you check and set

the hook side clearance.

NOTICE

Property damage may occur!

Damage to the machine, needle breakage, or thread damage due to

an incorrect clearance between the needle and hook tip.

Check and, if necessary, readjust the distance to the hook tip after

inserting a new needle with a different size.

Proper setting

Machine locked in place at position 1 ( p. 16).

Maximum 0.1 mm distance between the hook tip and the groove for

the needle.

Cover

• Tilt the machine head ( p. 10)

• Throat plate ( p. 14)

• Feed dog ( p. 15)

Service Instructions 667 - 00.0 - 04/2016 47

Page 50

Position of the hook and needle

(1) - Threaded pins

(2) - Slot for screw

(3) - Hook tip

(4) - Needle groove

①

②

③

④

Fig. 30: Setting the hook side clearance

To set the hook side clearance:

1. Position the upper stitch length adjusting wheel to 0.

2. Lock the machine in place at position 1.

3. Remove the middle section from the hook.

4. Loosen the threaded pins (1) through the slot (2).

5. Move the hook sideways such that the distance between the hook

6. Tighten the threaded pins (1).

7. Remove the lock.

st

The 1

tip (3) and the groove for the needle (4) is 0.1 mm at most, without the

hook tip (3) touching the needle.

screw in the direction of rotation is located on the flat.

48 Service Instructions 667 - 00.0 - 04/2016

Page 51

Position of the hook and needle

(1) - Vertical center line of the needle (2) - Hook tip

①

②

10.2 Setting the loop stroke position

The loop stroke is the path length from the lower dead center of the needle

bar up to the position where the hook tip is exactly on the vertical center

line of the groove for the needle.

Fig. 31: Setting the loop stroke position (1)

WARNING

Risk of injury from sharp and moving parts!

Crushing and puncture possible.

Switch off the machine before you check and set

the loop stroke position.

The loop stroke is precisely 2 mm.

Order

First, check the following settings:

• Needle bar linkage ( p. 43)

• A straight and undamaged needle must be inserted

( Operating Instructions, chap. Inserting and replacing the needle)

Proper setting

Machine locked in place at position 1 and stitch length set to 0.

The hook tip (2) points exactly to the vertical center line (1) of the

needle.

Disturbance caused by an incorrect setting

• Missing stitches

Service Instructions 667 - 00.0 - 04/2016 49

Page 52

Cover

(1) - Threaded pins

(2) - Hook tip

(3) - Needle groove

①

③

②

• Tilt the machine head ( p. 10)

• Throat plate ( p. 14)

• Feed dog ( p. 15)

Fig. 32: Setting the loop stroke position (2)

Position of the hook and needle

To set the loop stroke position:

1. Lock the machine in place at position 1 ( p. 16).

2. Position the upper stitch length adjusting wheel to 0.

3. Loosen the threaded pins (1).

4. Turn the hook such that the hook tip (2) points exactly to the vertical

center line of the groove (3).

5. Tighten the threaded pins (1).

6. Remove the lock.

Order

Then check the following settings:

• Timing of cutting by the thread cutter ( p. 65)

50 Service Instructions 667 - 00.0 - 04/2016

Page 53

Position of the hook and needle

1

4

3

2

(1) - Needle bar

(2) - Screw

(3) - Needle groove

(4) - Hook tip

10.3 Setting the needle bar height

Order

First, check the following settings:

• Loop stroke position ( p. 49)

• A straight and undamaged needle must be inserted

( Operating Instructions, chapter Inserting and replacing the needle)

Proper setting

Machine locked in place at position 1 and upper stitch length adjusting

wheel set to 0.

WARNING

Risk of injury from sharp and moving parts!

Crushing and puncture possible.

Switch off the machine before you check and set

the needle bar height.

The hook tip is level with the lower third of the groove on the needle.

Disturbances caused by an incorrect needle bar height

• Damage to the hook tip

• Jamming of the needle thread

• Missing stitches

• Thread breaking

• Needle breakage

Cover

• Head cover ( p. 12)

Fig. 33: Setting the needle bar height

To set the needle bar height:

1. Lock the machine in place at position 1 ( p. 16).

2. Position the upper stitch length adjusting wheel to 0.

Service Instructions 667 - 00.0 - 04/2016 51

Page 54

Position of the hook and needle

3. Loosen the screw (2) of the needle bar (1).

4. Move the height of the needle bar (1) such that the hook tip (4) is in

the middle of the lower third of the groove for the needle.

Important

When doing so, take care not to twist the needle to the side.

The groove (3) must face toward the hook.

5. Tighten the screw (2) for the needle bar (1).

6. Remove the lock ( p. 16).

Order

Then check the following setting:

• Position of the needle guard ( p. 51)

52 Service Instructions 667 - 00.0 - 04/2016

Page 55

Sewing feet

5

6

4

1

2

9

1

2

3

(1) - Presser foot

(2) - Feeding foot

(3) - Adjusting wheels for the sewing foot

stroke

11 Sewing feet

The two adjusting wheels (3) on the machine arm determine how high the

presser foot (1) and feeding foot (2) are raised during the sewing process.

The left adjusting wheel determines the normal sewing foot stroke.

The right adjusting wheel determines the elevated sewing foot stroke.

The elevated sewing foot stroke must not be lower than the normal sewing

foot stroke.

Fig. 34: Sewing feet

NOTICE

Property damage may occur!

Machine can be damaged if the adjusting wheels are forced.

Do not attempt to use force to set a smaller sewing foot stroke at the

right adjusting wheel.

Service Instructions 667 - 00.0 - 04/2016 53

Page 56

Sewing feet

1

2

3

4

(1) - Presser foot

(2) - Feeding foot

(3) - Screw

(4) - Sewing foot lever

11.1 Setting an even sewing foot stroke

WARNING

Risk of injury from sharp and moving parts!

Crushing and puncture possible.

Switch off the machine before you check and set

the sewing foot stroke.

Proper setting

For sewing foot stroke 3, the presser foot and feeding foot are raised by

the same height.

Cover

• Arm cover ( p. 11)

Fig. 35: Setting an even sewing foot stroke

To set the even sewing foot stroke:

1. Set the handwheel to the 0° position.

2. Loosen the screw (3).

3. Lower the presser foot (1) and feeding foot (2) together down to the

throat plate.

Important

While doing so, make sure that the feeding foot is only lowered down to

the throat plate. Do not inadvertently lower the feeding foot through the

throat plate cut-out down to the feed dog.

4. Tighten the screw (3).

54 Service Instructions 667 - 00.0 - 04/2016

Page 57

Sewing feet

2

1

3

(1) - Feeding foot

(2) - Feed dog

(3) - Needle tip

11.2 Setting the stroke movement for the feeding foot

WARNING

Risk of injury from sharp and moving parts!

Crushing and puncture possible.

Switch off the machine before you check and set

the stroke movement for the feeding foot.

In order to ensure a correct feed, the stroke movement for the feeding foot

must be aligned to the stroke movement for the feed dog.

Order

First, check the following settings:

• Feed dog movement ( p. 38)

• Even sewing foot stroke ( p. 54)

Proper setting

Left adjusting wheel for the sewing foot stroke set to 9 and the upper stitch

length adjusting wheel to 0.

The feeding foot (1) touches down exactly on the feed dog (2) when

the downward movement of the needle tip (3) reaches the upper

edge of the feeding foot. This will occur when the handwheel is in the

95° position.

Fig. 36: Setting the stroke movement for the feeding foot (1)

Service Instructions 667 - 00.0 - 04/2016 55

Cover

• Arm cover ( p. 10)

Page 58

Sewing feet

1

2

3

(1) - Stroke eccentric

(2) - Threaded pins

(3) - Threaded pin

Fig. 37: Setting the stroke movement for the feeding foot (2)

Proper setting

The feeding foot reaches the level of the throat plate at the same time as

the following elements:

• The feed dog moving up

• The needle tip moving down

To set the stroke movement for the feeding foot:

1. Screw in the threaded pin (3) so that there is a stroke.

2. Loosen the threaded pins (2).

3. Turn the stroke eccentric (1) such that the feeding foot reaches the

level of the throat plate at the same time as the feed dog and the tip

of the needle.

Important

When doing so, ensure not to move the stroke eccentric (1) laterally on the

axle.

4. Tighten the threaded pins (2).

5. Unscrew the threaded pin (3) far enough so that there is no longer any

contact with the clamp.

56 Service Instructions 667 - 00.0 - 04/2016

Page 59

Sewing feet

1

(1) - Adjusting wheel for the sewing foot pressure

11.3 Setting the sewing foot pressure

The adjusting wheel at the top left of the machine arm determines the

pressure for the sewing feet on the sewing material. The pressure can be

adjusted continuously by turning the adjusting wheel.

The correct pressure depends on the sewing material:

• Lower pressure for soft materials, e. g. silk

• Higher pressure for harder materials, e. g. leather

Proper setting

The sewing material does not slip and is correctly transported.

Fig. 38: Setting the sewing foot pressure

To set the sewing foot pressure:

1. Turn the adjusting wheel for the sewing foot pressure (1):

• greater pressure: turn clockwise

• lower pressure: turn counterclockwise

Service Instructions 667 - 00.0 - 04/2016 57

Page 60

Sewing feet

(1) - Adjusting screw

(2) - Counternut

11.4 Setting the sewing foot lifting height

WARNING

Risk of injury from moving parts!

Crushing possible

The machine must remain switched on so that the

sewing feet can be raised.

Work very carefully when you check and set the

lifting height for the sewing feet.

Do not put your hands under the sewing feet when

they are being lowered.

When the pedal is pressed back halfway, the sewing feet can be raised

during sewing, e. g. to move the sewing material.

When the pedal is pressed completely back, the sewing feet will be raised

after the thread is cut so that the sewing material can be exchanged.

Proper setting

The distance between the raised sewing feet and the throat plate is preset

to 25 mm on delivery.

Fig. 39: Setting the sewing foot lifting height

1

2

Setting steps

1. Loosen the counternut (2) for the adjusting screw (1).

2. Turn the adjusting screw (1) to set the distance between the raised

sewing feet and the throat plate:

• Raise the sewing feet to a lesser height: turn clockwise

• Raise the sewing feet higher: turn counterclockwise

58 Service Instructions 667 - 00.0 - 04/2016

3. Tighten the counternut (2) for the adjusting screw (1).

Page 61

Setting the needle thread tension

+

1234

+

–

2

1

(1) - Needle thread regulator

(2) - Screw

12 Setting the needle thread tension

12.1 Setting the needle thread regulator

The needle thread regulator determines the tension applied to guide the

needle thread around the hook. The required tension depends on the

thickness of the sewing material, thread strength, and stitch length.

Lower thread tension for

• thin sewing material

• low thread strengths

Greater thread tension for

• thick sewing material

• high thread strengths

Proper setting

The loop of the needle thread slides at low tension over the thickest point

of the hook, without forming loops or snagging.

Cover

• Throat plate slide ( p. 14)

Fig. 40: Setting the needle thread regulator

To set the needle thread regulator:

1. Turn the handwhee l and observe the cycle of the needle thread around

the hook.

2. Loosen the screw (2).

3. Moving the needle thread regulator

• Reduce tension: slide to the left

• Increase tension: slide to the right

4. Tighten the screw (2).

Service Instructions 667 - 00.0 - 04/2016 59

Page 62

Setting the needle thread tension

2

3

4

1

(1) - Stop collar

(2) - Spring

(3) - Tension disk

(4) - Screw

12.2 Setting the thread tensioning spring

The thread tensioning spring holds the needle thread under tension from

the top dead center of the thread lever up to the point when the needle eye

plunges into the sewing material.

Proper setting

Initial position: The thread tensioning spring does not contact the stop

until the needle eye has plunged into the sewing material.

Important

The setting for the thread tensioning spring must be varied according to

the sewing material and the required sewing result.

Fig. 41: Setting the thread tensioning spring

To set the thread tensioning spring:

1. Loosen the screw (4).

2. Setting the spring travel: Turn the stop collar (1):

• Longer spring travel: turn counterclockwise

• Shorter spring travel: turn clockwise

3. Setting the spring tension: Turn the tension disk (3):

• Greater spring tension: turn counterclockwise

• Lower spring tension: turn clockwise

Important

Do not twist the stop collar in doing so.

4. Tighten the screw (4).

60 Service Instructions 667 - 00.0 - 04/2016

Page 63

Winder

(1) - Screws

(2) - Screw

(3) - Winder lever

(4) - Arm

13 Winder

13.1 Setting the winder

Proper setting

The winder wheel runs smoothly and without axial play.

The winding process will stop automatically when the required filling quan-

tity of the bobbin is reached.

Cover

• Arm cover ( p. 11)

Removing the winder

Fig. 42: Removing the winder

1

4

2

3

To remove the winder:

1. Loosen the screws (1).

2. Remove the winder.

Setting the winder filling quantity

To set the winder filling quantity:

The position of the arms on the screw (2) determines the filling quantity:

• Parallel: Automatic winding stop at 0.5 mm below the edge of the

winder

• Closer together: Automatic stop with larger filling quantity

• Further apart from each other: Automatic stop with smaller filling

quantity

3. Turn the screw (2):

• Arms closer together: turn counterclockwise

• Arms further apart from each other: turn clockwise

4. Put the completely filled bobbin onto the winder.

5. Fold the winder lever (3) upwards as far as it will go to the thread.

Service Instructions 667 - 00.0 - 04/2016 61

Page 64

Setting the winder spacing

6

^

<

+

5

,

3

(3) - Bobbin lever

(5) - Block

(6) - Winder wheel

(11) - Thread-pulling knife

(12) - Winder spindle

(13) - Right-hand screw hole

(14) - Locking disk

6

8

9

9

0

5

7

(5) - Block

(6) - Winder wheel

(7) - Threaded pin

(8) - Threaded pin

(9) - Switch cam

(10) - Leaf spring

Fig. 43: Setting the winder spacing

To set the winder spacing:

Winder

1. Turn the winder spindle (12) such that the thread-pulling knife (11) is

at the top right and is facing the right-hand screw hole (13).

2. Loosen the threaded pin in the block (5).

3. Set the winder lever (3) such that the upper arm is above the marking

for the XXL hook (15).

The distance between the winder lever and the outer thread on the

bobbin is 2 – 3 mm.

4. Set the block (5) such that it is resting against the locking disk (14).

5. Set the block (5) such that its distance to the winder wheel (6) is 0.5 mm.

6. Tighten the threaded pin in the block (5).

Setting the winder run

Fig. 44: Setting the winder run

62 Service Instructions 667 - 00.0 - 04/2016

Page 65

Winder

(1) - Screws (15) - Marking for XXL hook

To set the winder run:

1. Loosen the threaded pin (8).

2. Set the switch cam (9) such that it is just contacting the leaf spring (10)

when the block (5) has engaged in the locking disk.

3. Set the switch cam (9) such that the winder lever (3) has no axial play.

4. Tighten the threaded pin (8).

Installing the winder

Fig. 45: Installing the winder

1

.

To install the winder:

1. Place the winder on the machine arm.

2. Tighten the screws (1).

Service Instructions 667 - 00.0 - 04/2016 63

Page 66

Winder

2

1

(1) - Screw (2) - Hook thread guide

13.2 Setting the hook thread guide

The position of the hook thread guide determines how the thread is wound

onto the winder.

Proper setting

The thread is wound on evenly over the entire width of the bobbin.

Fig. 46: Setting the hook thread guide

To set the hook thread guide:

1. Loosen the screw (1).

2. Turn the hook thread guide (2):

• To the front: The thread will be wound on further to the front

• To the rear: The thread will be wound on further to the rear

64 Service Instructions 667 - 00.0 - 04/2016

Page 67

Thread cutter

①

②③

14 Thread cutter

WARNING

Risk of injury from sharp and moving parts!

Cutting and crushing possible.

Switch off the machine before setting the thread

cutter.

14.1 Setting the control cam position

Fig. 47: Setting the control cam position

(1) - Hook pinion

(2) - Control cam

Proper setting

The control cam (2) makes contact with the hook pinion (1).

The first screw (3) in the hook's direction of rotation must be located on the

flat of the shaft. This defines the timing of the knife movement.

To set the position of the control cam:

1. Loosen the screw (3) on the control cam (2).

2. Rotate the control cam (2).

The first screw in the direction of rotation is located on the flat of the

shaft.

3. Tighten the screw (3).

Service Instructions 667 - 00.0 - 04/2016 65

(3) - Screw

Page 68

Thread cutter

①

②

③

④⑤

⑥

14.2 Setting the armature of the thread cutter magnet

Fig. 48: Setting the armature of the thread cutter magnet

(1) - Block

(2) - Pull rod

(3) - Roller

Proper setting

When the magnet is at rest, the distance between the roller (3) and the

highest point of the control cam (4) must range between 0.2 and 0.3 mm.

To check the armature of the thread cutter magnet:

1. Slide the pull rod (2) with the block (1) all the way to the left.

2. Check the distance between the roller (3) and the control cam (4) using

a feeler gage.

To set the armature of the thread cutter magnet:

3. Turn the nut (6) on the armature (5).

4. Check the setting and correct it if necessary.

(4) - Control cam

(5) - Armature

(6) - Nut

66 Service Instructions 667 - 00.0 - 04/2016

Page 69

Thread cutter

①③

②

⑥

⑦

④

⑤

14.3 Setting the position of the thread-pulling knife

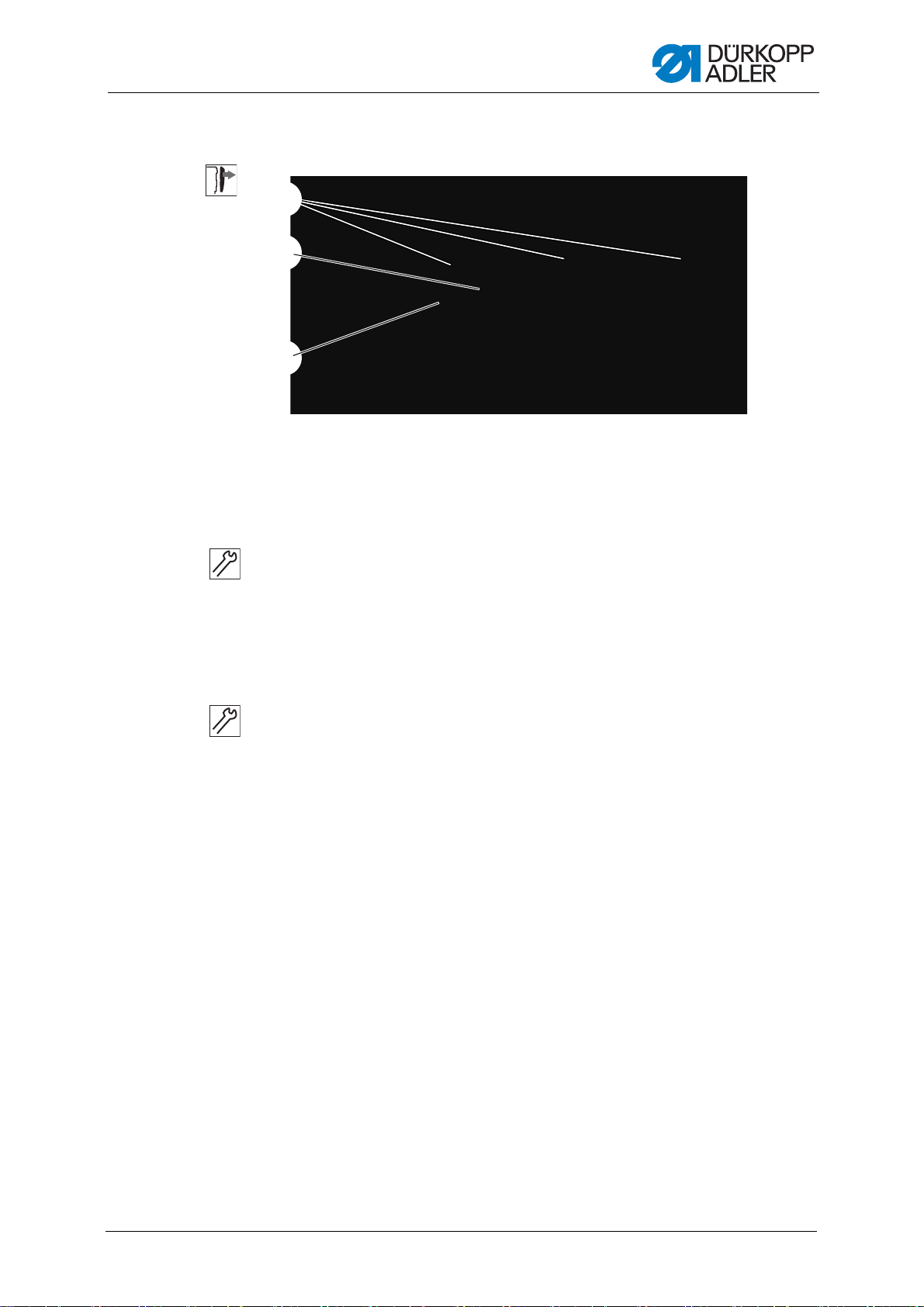

Fig. 49: Setting the position of the thread-pulling knife (1)

(1) - Tip

(2) - Stationary knife

Fig. 50: Setting the position of the thread-pulling knife (2)

(4) - Block

(5) - Pull rod

(3) - Thread-pulling knife

(6) - Roller

(7) - Screw

Proper setting

When the knife is at rest, the tip (1) of the thread-pulling knife (3) must be

positioned flush below the cutting edge of the stationary knife (2).

To set the position of the thread-pulling knife:

1. Turn the handwheel until the thread lever is positioned slightly beyond

its highest point.

2. Loosen the screw (7).

3. Set the thread-pulling knife (3).

Service Instructions 667 - 00.0 - 04/2016 67

Page 70

Thread cutter

① ②

③

④

⑤

4. Slide the pull rod (5) to the left under slight pressur e to keep the play

inside the mechanics of the thread cutter at a minimum.

5. Position the block (4) with the roller (6) against the control cam.

6. Tighten the screw (7).

7. Check the setting and correct it if necessary.

14.4 Setting the cutting pressure

Fig. 51: Setting the cutting pressure (1)

(1) - Screw (2) - Thread-pulling knife

Fig. 52: Setting the cutting pressure (2)

(3) - Block

(4) - Roller

(5) - Control cam

Proper setting

The thread should be cut at a pressure that is as low as possible.

A low cutting pressure will keep knife wear at a minimum.

Two of the thickest threads used must be reliably cut at the same time.

68 Service Instructions 667 - 00.0 - 04/2016

Page 71

Thread cutter

Important

If the cutting pressure is too high, the thread cut ter magnet will not swivel

out the thread-pulling knife. The thread will not be cut.

To check the cutting pressure:

1. Turn the handwheel until the threa d-pulling knife (2) can be swung out

by hand.

2. To do this, press the block (3) with the roller (4) to the right against the

control cam.

The thread-pulling knife (2) swivels out.

3. Insert 2 threads to be cut into the thread-pulling knife (2).

4. Turn the handwheel further until the thread-pulling knife (2) is swiveled

down.

5. Check whether the threads have been cleanly cut.

To set the cutting pressure:

1. Turn the screw (1).

• greater cutting pressure: turn clockwise

• lower cutting pressure: turn counterclockwise

2. Check the setting and correct it if necessary.

Service Instructions 667 - 00.0 - 04/2016 69

Page 72

Thread cutter

70 Service Instructions 667 - 00.0 - 04/2016

Page 73

Setting the potentiometer

ESC

ABCD

OK

++++

––––

P

RESET

1

2

3

4

5

(1) - ESC button

(2) - P button

(3) - Plus/Minus buttons

(4) - Reset button

(5) - OK button

15 Setting the potentiometer

The potentiometer adjusts the number of stitches to the set sewing foot

stroke and reduces the number of stitches if the sewing foot stroke is too

much.

Proper setting

After accessing the technician level and pressing the OK button, the left

display will show 1 in the first instance and the relevant maximum speed

next to it.

WARNING

Risk of injury from moving parts!