Page 1

LP 2971

LP 2974

Industrial sewing machine

Instruction manual

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 521 / 9 25-00 • Telefax +49 (0) 521 / 9 25 24 35 • www.duerkopp-adler.com

CZ

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

06/2012 Rev. index: 00.0 Printed in Czech Republic 0791 888761

Page 2

All rights reserved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any manner, even

in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Copyright ©

Dürkopp Adler AG - 2012

Page 3

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

Page 4

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

instruction book and operated by persons with appropriate training.

2. Before putting into service also read the safety rules and

instructions of the motor supplier.

3. The machine must be used only for the purpose intended. Use of

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

5. Daily servicing work must be carried out only by appropriately

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Page 5

Contents Page:

Introduction and safety instructions

Part 1: Operating Instructions LP 2971, LP 2974 – Original Instructions

(Edition 06/2012)

1 Product description ........................................... 5

2 Designated use .............................................. 5

3 Subclasses ................................................. 6

4 Optional equipment ............................................ 7

5 Technical data ............................................... 7

5.1 Technicaldatasubclasses......................................... 8

6 Operation

6.1 Threading the needle thread ....................................... 9

6.2 Winding the hook thread .......................................... 10

6.3 Bobbin insertion and threading the hook thread ........................... 10

6.4 Adjustingthethreadtension........................................ 11

6.4.1 Adjusting the hook thread tension .................................... 11

6.4.2 Adjusting the needle thread tension ................................... 12

6.5 Switching on/off the thread tensioners ................................. 13

6.6 Adjusting the thread regulator....................................... 14

6.7 Changing the needle with single-needle machines with the hook on the right .......... 15

6.8 Changing the needle with double-needle machines ......................... 16

6.9 Liftingandfoldingtherollerpresser................................... 17

6.10 Sewing-foot pressure through the setting wheel............................ 18

6.11 Sewing backward (feeding backward; backtacking).......................... 19

6.12 Setting the stitch length .......................................... 19

6.13 Switching on the safety clutch at the hook blocking.......................... 20

6.14 Operating the machine equipped with the positioning motor .................... 21

6.14.1 Using the pedal ............................................... 21

6.14.2 Using the key................................................. 22

7 Positioning drive Efka DC1550/DA321G ............................... 23

8 Sewing w ith machine equipped w ith positioning motor

8.1 Machineautomaticfunction........................................ 24

8.2 Example of machine operation at sewing ............................... 25

9 Maintenance

9.1 Cleaning and checking .......................................... 26

9.2 Lubrication .................................................. 28

GB

Page 6

Notes:

Page 7

5

GB

1 Product description

The Dürkopp Adler LP 2971, LP 2974 is a special sewing machine for

universal use.

•

It is a double lockstitch post bed sewing machine .

•

It has a two step feed. A lower wheel feeder and a driven roller

presser feed in two steps, a needle feed feeds in the first step only.

In single and double needle machines, the first step represents 30%

of the total stitch length.

•

The machine is either single needle or double needle unit with

automatic functions such as thread trimming, automatic

backtacking, automatic foot lifting, or without them.

•

The machine is equipped with a large two part vertical hook.

•

Maximum foot lift is 12 mm.

•

The residual thread length after thread trimming is about 15 mm.

•

The hook is protected with a safety clutch against the

disarrangement of the adjusted position at the blocking of the

thread which interfered with its way.

•

The throat plate has replaceable inserts with the stitch hole

dimension difference, which are optional in dependence on the

needle number.

•

The machine has automatic wick lubrication from the central oil tank

with a visual check of the oil level by oil level indicator in the

machine arm. The part of the oil with which the hook is lubricated is

devaluated. The other part of the lubrication oil is returned to the

central tank by a pump.

•

Integrated bobbin winder.

2 Designated use

The class LP 2971, LP 2974 is designated for sewing shoe, leather,

and upholstery sewing. In general, the material sewn is leather (natural

or artificial). It is possible to use it for shoe fabrics too.

The equipment for light, medium or heavy sewing is mounted on the

machine as an option.

It is possible to sew dry material only which may not be thicker than

7 mm when pressed down with a roller presser. The material may not

contain hard objects, as the machine is not equipped with an eye

guard. This machine may be operated in dry rooms and by a trained

person only who is aware of the risks described in this instruction.

This special sewing machine may be set up and operated only

in dry, well-maintained premises. If the sewing machine is used in

premises which are not dry and well-maintained it may be

necessary to take further precautions (which should be agreed in

advance - see EN 60204-31:1999).

As manufacturers of industrial sewing machines we proceed on the

assumption that personnel who work on our products will have

received training at least sufficient to acquaint them with all normal

operations and with any hazards which these may involve.

Page 8

3 Subclasses

LP 2971 Single-needle double lockstitch post bed sewing

machine with feed wheel, needle feed with driven

roller foot and large hook, electro-magnetic thread

cutter, electro-magnetic seam bartacking and sewing

foot lifting.

LP 2974 Double-needle double lockstitch post bed sewing

machine with feed wheel, blocked needle feed with

driven roller foot and large hook, electro-magnetic

thread cutter, electro-magnetic seam bartacking and

sewing foot lifting.

6

Page 9

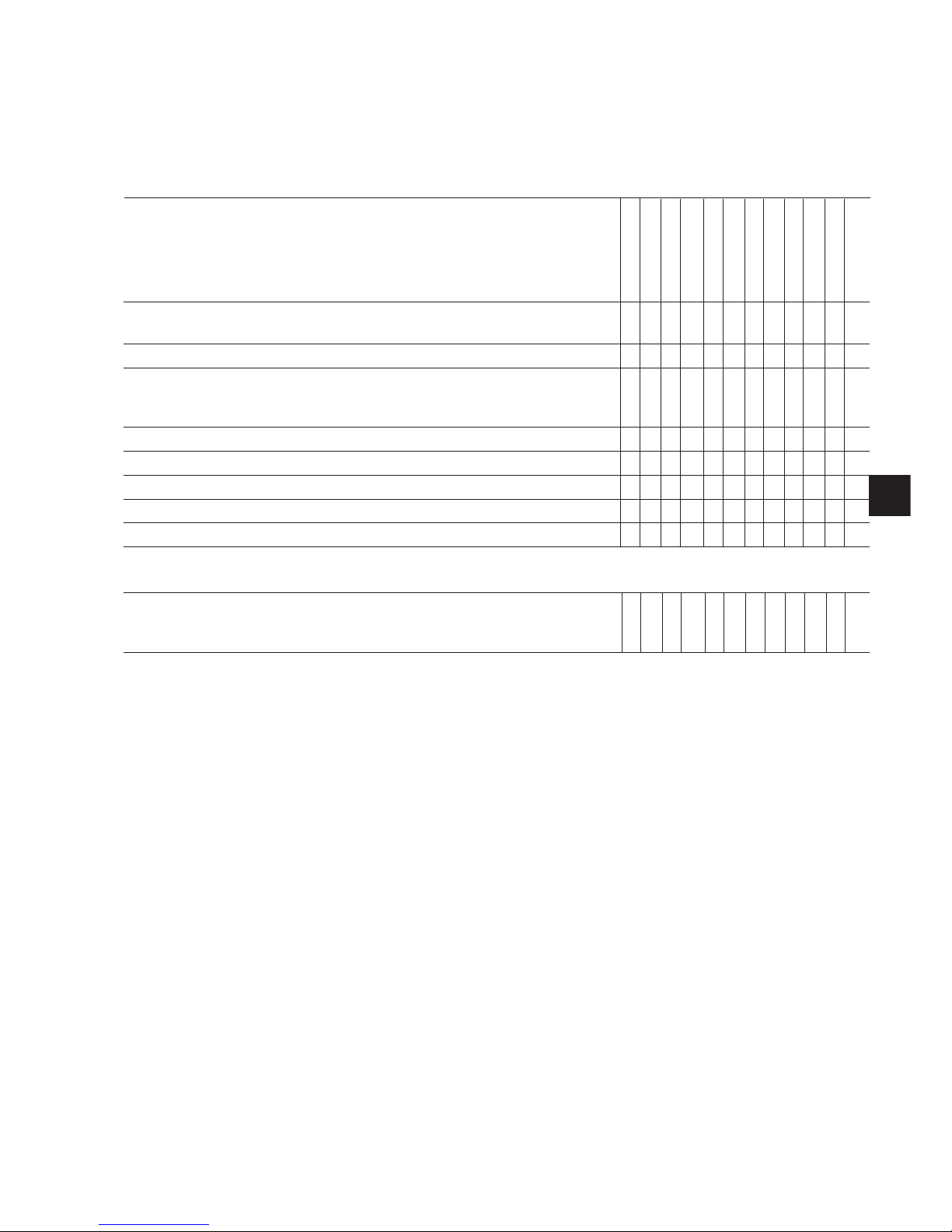

4 Optional equipment

The following optional equipments are available for the class LP 2971,

LP 2974 :

Order No. Optional equipment Subclasses

LP 2971

LP 2974

9880 888101 Integrated sewing light with 2 LED, incl. x x

dimmer transformer

9880 888100 Diode sewing light 3W x x

0888 320254 Variator for a continuous regulation of x x

the difference between the feed wheel and

thedrivenrollerfoot

0888 310134 Needle feed blocking x o

0867 490013 Bracket for the control panel x x

N800 080030 Rectractable material guide x x

N800 080040 Retractable roller material guide x x

9081 300001 Tool kits M-type x x

Stand

MG 55 400334 Stand set MG 55-3 xxxxxxxxxxx

for toothed belt drive, with pedal

Table top size 1060 x 500 mm

x = Optional equipment

o = Standard equipment

Additional optional equipments can be requested:

E-Mail: sales@minerva-boskovice.com

marketing@duerkopp-adler.com

5 Technical data

Noise: Workplace-related emission value in accordance with DIN 45635-48-A-1-KL2

LP 2971 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

LP 2974 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

7

GB

Page 10

8

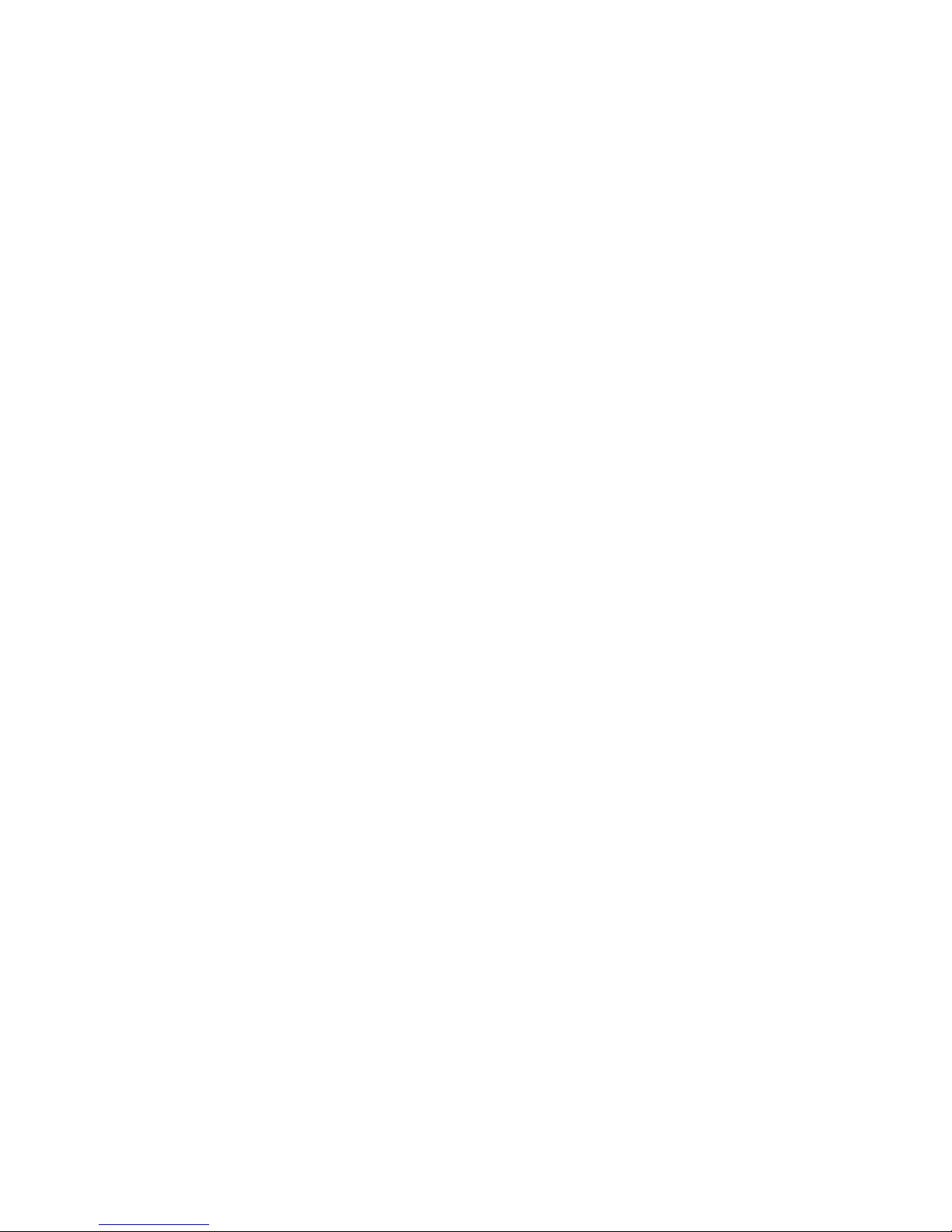

5.1 Technical data of the subclasses

Subclasses

LP 2971

LP 2974

Type of stitch Lock stitch 301

Hook type

large

large

Number of needles 1 2

Needle system 134

Needle size 160

(depending on E-No.) [Nm]

Max. thread thickness [Nm] 10/3

Stitch length [mm]

Forwards 7 (5 for E55/2.0 and E56/2.4)

Backwards 7 (5 for E55/2.0 and E56/2.4)

Max. Speed [min-1] 3000

Number of stitches with

factory setting [min

-1

] 2500

Max. sewing foot stroke [mm] 12

Dimensions (H x W x D) [mm] 550 / 220 / 600

Page 11

6 Operation

6.1 Threading the needle thread

Caution! Risk of injury!

Turn off the main switch.

The needle thread may only be threaded with the sewing machine

switched off.

–

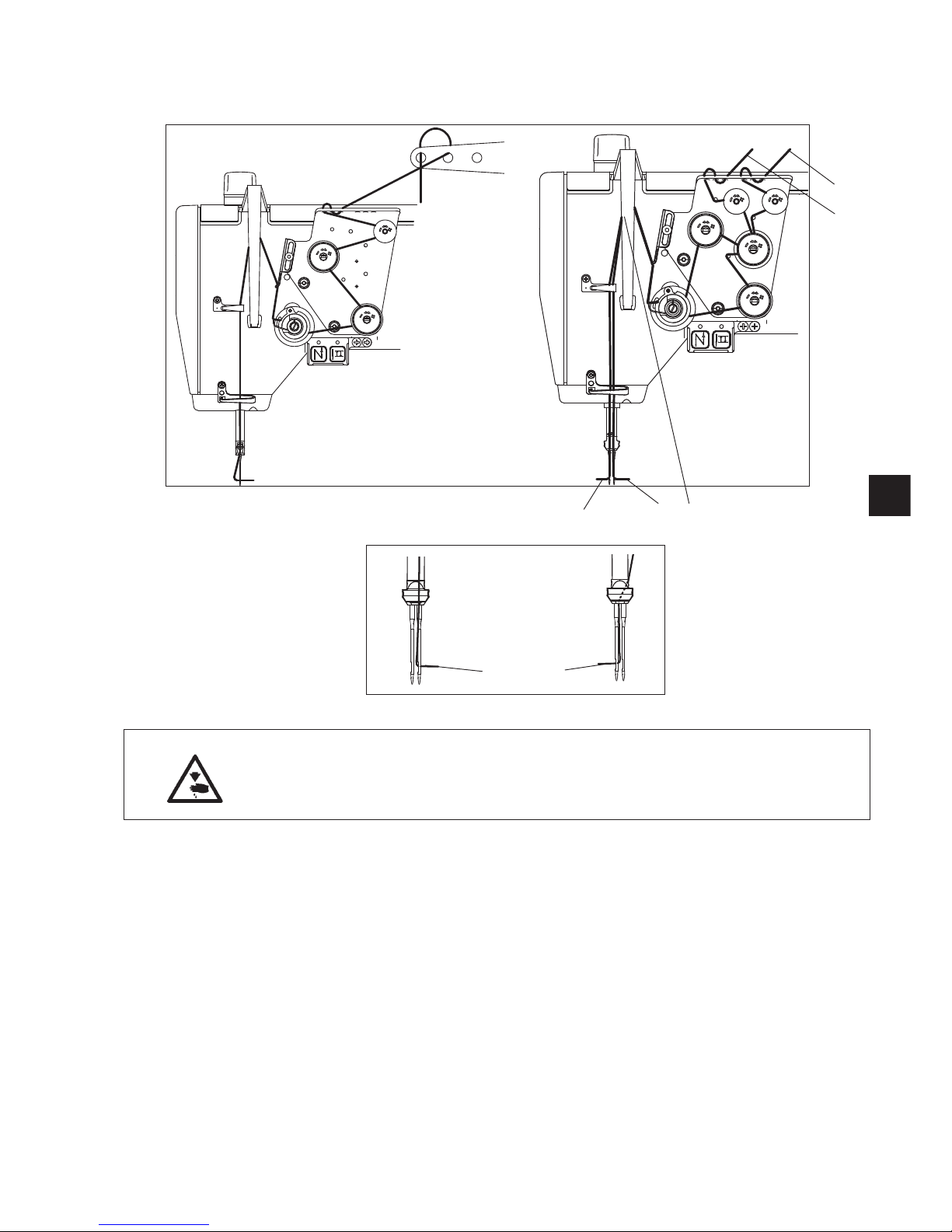

Thread the single needle machine according to fig. (A).

–

Thread the double needle machine according to fig. (B). The

thread (1) designed for the left needle is to be threaded in the left

tensioners and in the upper hole in the thread lever (3).

The thread (2) designed for the right needle is to be threaded in the

right tensioners and in the upper hole in the thread lever (3).

–

Thread the needles arranged side by side according to fig. (B).

–

Thread the diagonally arranged needles according to fig. (C-right

needle) and fig. (D-left needle).

9

GB

2

1

DC

B

A

3

2

1

21

Page 12

6.2 Winding the hook thread

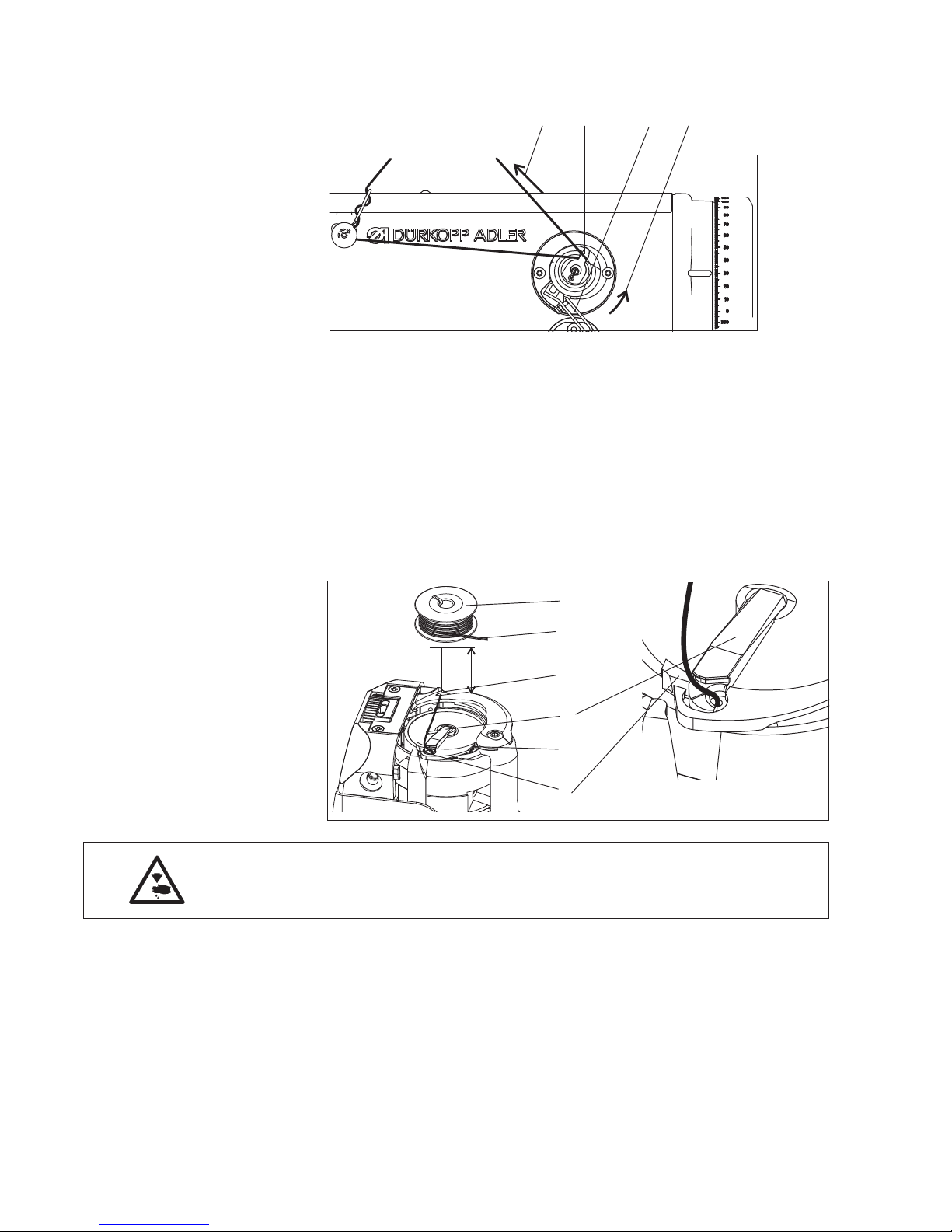

–

Thread the thread according to the picture.

–

Insert the thread under the knife (1) and tear off by pulling in the

arrow direction (2).

–

Fix the bobbin and press the lever (3) in the direction (4).

–

Start the machine up.

–

After the thread winding, slide the thread under the knife again (1)

and tear it off.

–

Insert another bobbin immediately and press the lever (3).

6.3 Inserting the bobbin and threading the hook thread

Caution! Risk of injury!

Switch the main switch off and wait till the motor stops.

–

Tilt the shutter (1) up.

–

Insert the bobbin (2) with the thread end (3) oriented according to

the picture.

–

Thread the thread through the slit (4) and space (5), hook upon the

shutter (1) and fasten it under the spring (6).

–

Trim the thread ends according to the picture.

–

If the hook is located to the left of the needle, fix the bobbin and do

the threading in a similar way.

10

2

3

6

4

5

10

1

2

31

4

Page 13

6.4 Adjusting the thread tension

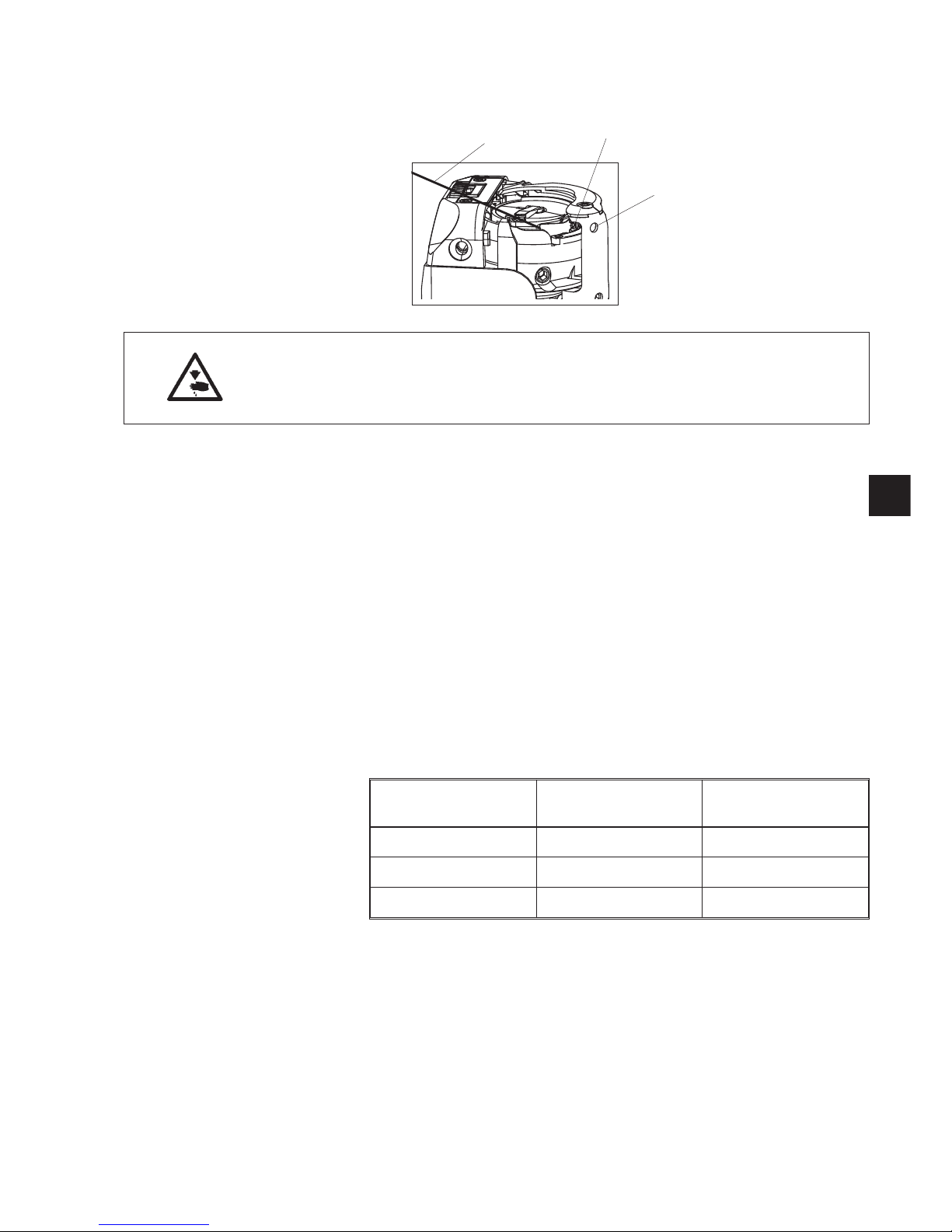

6.4.1 Adjusting the hook thread tension

Caution! Risk of injury!

Turn off the main switch.

The hook thread tension may only be adjusted with the machine

switched off.

–

Adjust the hook thread tension via the screw (1). Insert a

screwdriver through the hole (2).

Increase the tension by tightening the screw.

–

Measure the thread tension with a dynamometer. Thread the

thread according to the picture and pull in the arrow direction (3).

This tension is adjusted in the factory in dependence on the

selected sewing equipment according to the table below, and it is

suitable for the usual sewing operations.

For sewing thin soft materials, it is necessary to reduce the

tension. If the seam is to be tightened strongly, it is necessary to

increase the tension and reduce the sewing speed at the same

time.

–

Thread tension of the hook located to the left of the needle is

adjusted and measured in a similar way. For this hook, the tension

is set up by 10 - 20 % lower than for the hook on the right.

Hook thread tension mean value

Sewing category Used needle-Number Thread tension in

grams

light 70 - 80 50

medium 90 - 110 65

heavy 120 - 160 90

11

GB

1

2

3

Page 14

6.4.2 Adjusting the needle thread tension

Adjusting the pre-tensioner (1)

–

When the main tensioner (3) and supplementary tensioner (2) are

open, the needle thread must be under slight residual tension. This

residual tension is produced by the pre-tensioner (1).

The pre-tensioner (1) simultaneously affects the length of the end

of the severed needle thread, the starting thread for the next seam.

(Tensioner (1) is not switched off at the foot lifting).

Adjusting tensioners (2) and (3) with electro-magnetic control

–

Regulate the thread tension with the tensioner (3), till a good

thread loop is achieved (see below).

–

Regulate the thread tension with a tensioner (2), till a good thread

loop is achieved (see below).

–

Regulate the tension by both tensioners (2) and (3) at the same

time so that their nuts are screwed approximately in the same

height.

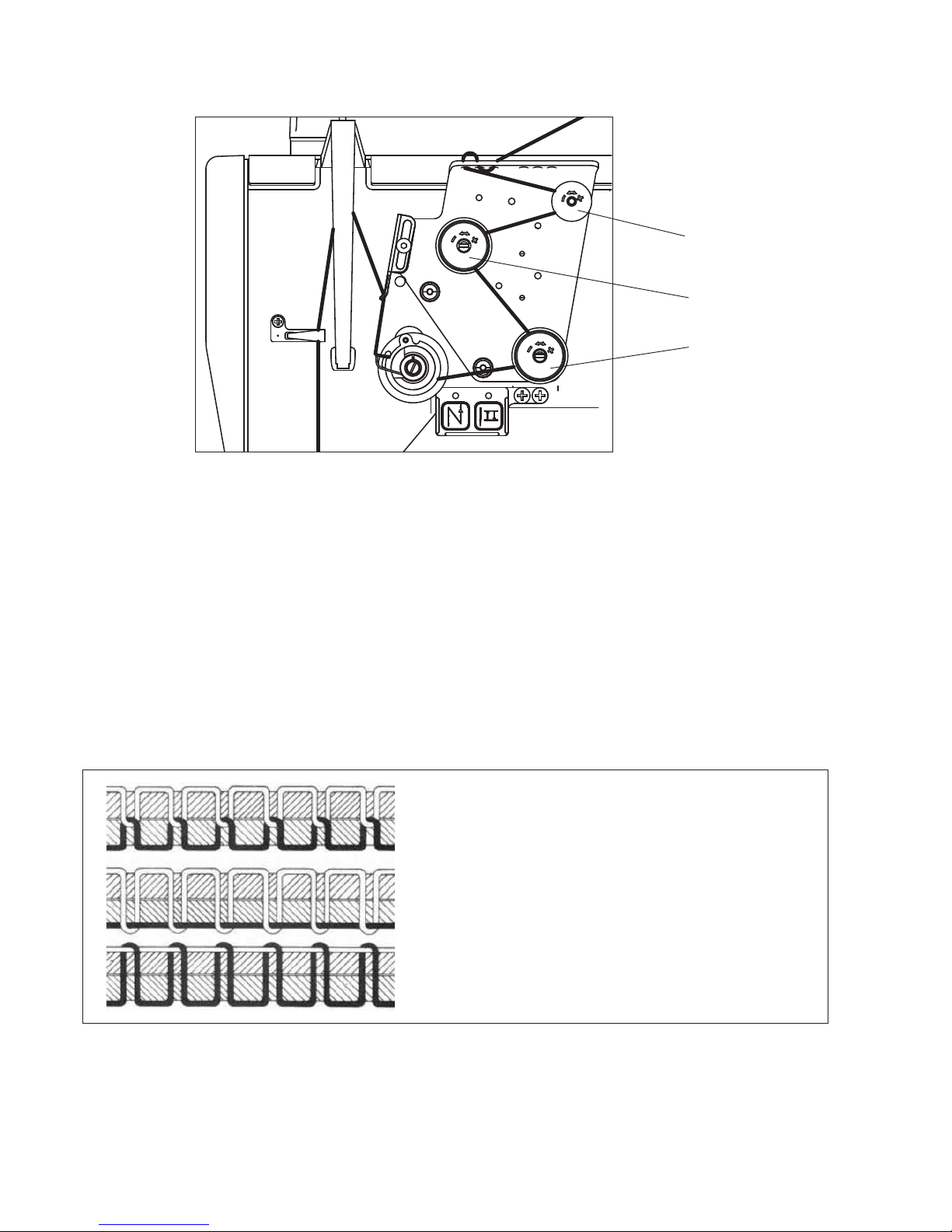

Correct interlacing of threads in the center

of the material

Needle-thread tension too weak

or

Hook-thread tension too strong

Needle-thread tension too strong

or

Hook-thread tension too weak

12

3

2

1

Page 15

6.5 Switching on/off the thread tensioners

–

Tensioner (1) is never switched off.

–

Tensioners (2) and (3) are switched off with an electric magnet at

the foot automatic lifting. If the automatic foot lifting at the machine

stop is pre-selected, the tensioners are switched off, but

temporarily only, so that the switching off electric magnet does not

overheat.

–

Tensioners (2) and (3) are also switched off temporarily during the

trimming cycle.

–

Tensioners (2) and (3) are not switched off at the foot lifting with

the hand lever.

13

GB

2

3

1

Page 16

6.6 Adjusting the thread regulator

The thread regulator (2) controls the quantity of needle thread required

for stitch formation.

The thread regulator must be precisely adjusted for an optimum result.

–

Loosen the screw (1), shift the thread regulator (2), and tighten the

screw (1).

14

2

1

Page 17

6.7 Changing the needle with single-needle machines with the hook on the right

Caution! Risk of injury!

Replace the needle with the main switch switched off and the motor

stopped.

–

Turn the hand wheel, until the needle bar (1) has reached its

highest position.

–

Loosen screw (2).

–

Remove the needle and insert a new one with the needle scarf (3)

to the right [see section (4) or (5)]. The needle may not be oriented

as shown at section (6).

–

Tighten screw (2).

Caution! Danger of breakage!

A false orientation of the needle may damage the hook point.

When changing to another needle size, the distance between hook

and needle, as well as the position of the throat plate towards its post

must be readjusted (see service instructions).

15

GB

1

2

3

4

5

6

MAX. 3°

Page 18

6.8 Changing the needle with double-needle machines

Caution! Risk of injury!

Turn off the main switch.

The needles may only be changed with the sewing machine

switched off.

–

Loosen the screws (1).

–

Remove the needle and insert new ones with the needle scarf (2)

oriented as shown above [see section (3) or (4)]. The needles may

not be oriented as shown at section (5).

–

Tighten the screws (1).

Caution! Danger of breakage!

A false orientation of the needle may damage the hook point.

When changing to another needle size, the distance between hook

and needle, as well as the position of the throat plate towards its post

must be readjusted (see service instructions).

16

MAX. 3°

5

4

3

1

2

Page 19

6.9 Lifting and folding the roller presser

Lifting the roller presser with a hand lever

–

Lift the roller presser by the lever turning (1) in the arrow direction

to the stop (the roller presser remains lifted, the lever (1) remains

tilted).

–

Lower the roller presser by putting the lever (1) to the initial

position.

–

After the roller presser lifting with the hand lever, the machine may

be started up (e.g. for hook thread winding).

Caution!

At the roller presser lifting higher than 6 mm over the throat plate the

machine may not operate, otherwise the needle bar with the needle

holder hits the roller presser, or the needle guides of the double needle

machines.

Roller presser lifting with a pedal - automatically

–

The roller presser lifting in the machines equipped with a

positioning motor (drive) can be controlled by the pedal (4)

treading in the position -1 (see chap. 6.14.1). The roller presser is

lifted to the upper dead point by means of an integrated electric

magnet. After the pedal is released, the roller presser is lowered.

–

It is possible to pre-select the automatic roller presser lifting at

each machine stop without the necessity to tread the pedal in the

position to the position -1.

In this case, the roller presser is lowered at the pedal treading in

the position +1. After the finishing of the seam, the roller presser

remains lifted permanently (see chapter 8).

17

GB

1

2

Page 20

Roller presser folding

Caution! Risk of injury!

Roller presser folding to be done at main switch off and standing

motor.

–

Lift the roller presser with the hand lever.

–

Lift the roller presser by pressing in the signed direction.

6.10 Sewing-foot pressure through the setting wheel

–

The required sewing-foot (roller) pressure is set with the setting

wheel (1).

–

To increase the roller pressure = turn the setting wheel (1)

clockwise.

To decrease the roller pressure = turn the setting wheel (1)

anti-clockwise.

–

The roller pressure is to be as small as possible, but strong enough

so that the roller presser is not lifted by the needle friction in the

material during the upward movement and that the feeding is

reliable.

–

The maximum roller presser pressure is 100 N in the machine

equipped with solenoid.

18

1

+

Page 21

6.11 Sewing backward (backtacking)

Backtacking with the lever

–

Push the stitch regulator lever (1) downwards. The machine sews

backward stitches as long as the stitch regulator lever (1) is being

pushed.

Automatic backtacking (bartacking)

–

In the machines equipped with the positioning motor it is possible

to pre-select the backtacking by a pre-selected backstitches

number both at the beginning and at the seam end. At the seam

beginning (after the preceding thread trimming) after the pedal

treading forwards the machine sews the pre-selected bartack

entirely automatically. The same at the seam end after the pedal

treading in the position –2 the machine sews the pre-selected end

bartack and then trims the threads (see chapter 8).

6.12 Setting the stitch length

–

Turn the button (1) so that the number (2) indicating the required

stitch length in mm corresponds to the mark (3).

19

GB

1

2

3

1

Page 22

6.13 Switching on the safety clutch at the hook blocking

–

If the thread gets in the hook way, the hook gets blocked and it is

subsequently disconnected from the motor by the safety clutch.

Caution! Risk of injury!

Turn off the main switch.

Switch the safety clutch on, with the sewing machine switched off.

–

Turn the hand wheel until you hear a switching click (snapping) of

the safety clutch.

–

Turn the hand wheel in the opposite direction until the hook gets

released.

–

If the safety clutch remains switched off accidentally, insert a

screwdriver (1) in the hole (2) and turn the hand wheel until the

safety clutch gets switched.

–

Free up the blocked hook by removing the cause of disturbance.

20

1

2

Page 23

6.14 Controlling the machine equipped with a positioning motor

6.14.1 Using the pedal

The pedal position is scanned by a sensor distinguishing 16 levels.

The meaning is given in the table:

Pedal position Pedal motion Meaning

-2 Over heel fully backwards Command for thread trimming (seam finishing)

-1 Over heel slightly backwards Command for foot lifting

0 Neutral position See notes

1 Slightly forwards Command for foot lowering

2 Further forwards Sewing at minimum speed (1. speed gear)

3 Further forwards Sewing - 2. speed gear

:::

13 Fully forwards Sewing at maximum speed (12. speed gear)

Note:

In addition to the neutral position, it is possible to pre-select the needle

position (down/up) and the foot position (down/up) at the stopping in

the seam (by the pedal positioning in the neutral position), the foot

position (down/up) after the seam finishing (by the pedal treading fully

backwards and positioning the pedal in the neutral position).

21

GB

-1

13

2

1

0

-2

Page 24

6.14.2 Using the key

Key Function

1 Manual sewing backward

The machine sews backward stitches as long as the key is being pushed.

2 Needle positioning to the upper or lower position

By parameter F-242 (DA321) the following key functions can be defined:

1 = needle up/down

2 = needle up

3 = one stitch

(factory setting is 1)

22

12

Page 25

7 Positioning drive Efka DC1550/DA321G

DA321G control contains all necessary operating elements to switch

the functions over and to set the parameters. The operation is possible

without the control panel, it is not possible only to program the sewing.

It is possible to connect the control panel V810 and V820, which are

available as an attachment. It is possible to program the sewing by the

control panel V820.

A detailed description of the control is included in the operating manual

of the motor manufacturer of Efka DC1500 – DA321G drive (see also

www.efka.net).

23

GB

Page 26

8 Sewing with machine with positioning motor

8.1 Machine automatic functions

The machine has the below functions which are automatically

performed during the seam sewing depending on:

–

Pre-selection

–

Pedal position (according to the machine operator´ s selection)

–

Working phase of seam sewing

Automatic function Pre-selection

Needle positioning

•

Needle down at machine stopping in seam

•

Needle up at machine stopping in seam

Note: after the seam * finishing the machine stops always

with the needle up.

Bartacks

•

Standard

•

Decorative**

Initial bartack

•

Single

•

Double

•

Standard bartack stitch number forwards

•

Decorative bartack stitch number forwards

•

Standard bartack stitch number backwards

•

Decorative bartack stitch number backwards

End bartack

•

Single

• Double

•

Standard bartack stitch number backwards

•

Decorative bartack stitch number backwards

•

Standard bartack stitch number forwards

•

Decorative bartack stitch number forwards

Thread trimming

•

ON

•

OFF

Automatic foot lifting

•

Foot lowered at stopping in seam

•

Foot lifted at stopping in seam

* The seam is finished after the pedal shifting to the position -2 (if the thread trimming is pre-selected, then after

the trimming).

** The decorative bartack is characterized by the fact that the needle sews stitch in stitch in the previous seam at

the bartacking. At the sewing direction change the machine stops for a moment.

24

Page 27

Automatic function codes are described in the attached drive

manufacturer´ s Instruction Leaflet.

The drive manufacturer’s Instruction Leaflet for Efka DA321G drive is

available on website www.efka.net. Some automatic functions can be

preset by means of push buttons. Their description is included in the

booklet “Efka Operation Instructions”.

Other automatic functions can be preset through the drive parameter

change. Every function like this has its parameter number. It is

possible then to preset the parameter value for the particular

parameter number. The parameter change is described in the booklet

“Efka Operation Instructions".

List of parameters for the operator level is included in the booklet

“Efka List of Parameters”.

8.2 Example of machine operation at sewing

Pre-selection:

•

Needle down at machine stopping in seam

•

Standard bartacks

•

Double initial bartack

•

Double end bartack

•

Thread trimming on

•

Foot lowered at stopping in seam

•

Foot lifted at seam finishing

Operation Sewing procedure

Machine stopped. Needle in upper position. Foot lifted.

Insert the material.

Pedal treading to position +1. Foot lowering.

Pedal release to position 0. Foot lifting.

Material position correction.

Pedal treading to position +1. Foot lowering.

Pedal treading to position +3. Sewing of standard double bartack (at speed pre-selected by producer and

subsequent sewing at speed corresponding with third speed level +3.

Pedal release to position 0. Machine stopping with needle down.

Pedal treading to position -1. Foot lifting.

Turning of sewing material on needle

Pedal treading to position +5. Foot lowering and subsequent machine running to fifth speed

grade of sewing.

Pedal treading to position -2. Speed reduction. Sewing of standard double bartack.

Thread trimming under throat plate and machine stopping with needle up.

Foot lifting.

Pedal release. (Foot remains lifted).

Remove the material.

25

GB

Page 28

9. Maintenance

9.1 Cleaning and checking

Caution! Risk of injury!

Turn off the main switch.

Maintenance may only be carried out with the machine switched off!

Maintenance work must be carried out no less frequently than at the

intervals given in the tables (see ”operating hours” column).

Maintenance intervals may need to be shorter when processing

heavy-shedding materials.

A clean machine is a trouble-free machine.

Maintenance work Explanation Operating

to be carried out hours

Machine head

- Remove lint, pieces of

thread (e.g. with an air

blow gun)

Places in special need of cleaning:

- Area under the throat plate, feeding

roller (2), top roller and its surrounding.

- Area around the hook (1)

- Bobbin housing (6)

- Thread trimmer

- Area around the needle

CAUTION !

Be sure to hold the blow air gun so that no

sewing dust is blown into the oil sump.

8

- Remove lint, pieces of

thread (e.g. with an air

blow gun)

Remove the throat plate. Remove the thread

puling knife (4). Remove the hook plunger

ring (5). Remove the bobbin housing (6) from

the hook. Clean the inner area of the hook.

Clean the bobbin housing - particularly look

for glue remainder on the surface (7).

20

- Check the hook Check the clearance on the track between

bobbin housing (6) and the hook (1)

500

26

3

2

6

4

7

5

1

Page 29

Maintenance work Explanation Operating

to be carried out hours

- Clean the oil sump Clean the oil sump (1) of dirt and

contaminated oil.

(you may use a special vacuum cleaner.)

20

- Clean fan grille Remove lint and pieces of thread from

air-intake openings (2)

(e.g. with an air blow gun).

20

27

GB

1

2

Page 30

9.2 Lubrication

Caution! Risk of injury!

Oil can cause skin eruptions.

Avoid protracted contact with the skin.

In the event of contact, thoroughly wash the affected area.

Caution!

The handling and disposal of mineral oils is subject to legal regulation.

Deliver used oil to an authorised collection point.

Protect your environment.

Take care not to spill oil.

To lubricate the special sewing machine use only DA-10 lubricating oil

or an equivalent oil of the following specification:

–

Viscosity at 40° C: 10 mm˛/s

–

Flashpoint: 150° C

DA-10 is available from DÜRKOPP ADLER AG retail outlets under the

following part numbers:

250-ml container:9047 000011

1-litre container: 9047 000012

2-litre container: 9047 000013

5-litre container: 9047 000014

All points of the sewing machine head lubricated with oil are supplied

from the central tank (1).

–

If the oil volume drops to the level (3), supply the oil through the

hole (2) to the “MAX” level.

–

Check the oil level every day!

Caution! Risk of failure!

The oil may be supplied only into the central tank or in the hook path.

The other points must not be lubricated separately, so that the oil does

not penetrate to the spots, which must not be lubricated.

28

1

2

3

Page 31

GB

Contents Page:

Part 2: Installation Instructions LP 2971, LP 2974 – Original Instructions

1 Scope of delivery ............................................. 3

2 Transport packing of assembled machine ............................. 4

3 Assembling the stand

3.1 Assembling the stand components ................................... 4

3.2 Assemblingthetabletop(directdrive).................................. 5

3.3 Settingtheworkingheight......................................... 6

4 Assembling the machine head

4.1 Fitting the machine head ......................................... 7

4.2 Fitting the belt guards ........................................... 8

4.3 Adjustment of pedal position ....................................... 9

4.4 Fittingtheoilpumppipe .......................................... 10

4.5 Fitting the connecting cable, control panel

and sewing diode lamp on the machine head ............................. 11

5 Electrical connection

5.1 Electrical connection to low voltage network ............................. 12

5.1.1 Sewing light transformer connection to network voltage ....................... 13

5.2. Grounding .................................................. 14

5.3 Connection of head to Efka DC1550/DA321G drive ......................... 15

6 Adjustment of Efka positioning motor (drive)

6.1 Settingofpositioningmotor(drive)parameters ............................ 16

6.1.1 Settingofparametersbythe“autoselect”function .......................... 16

6.1.2 Setting of Efka drive parameters specific for LP 2971, LP 2974 .................. 16

6.1.3 Values of parameters specific for LP 2971, LP 2974 ......................... 17

6.2 Settingofmachinepositioning ...................................... 17

6.2.1 Positiondefinition.............................................. 17

6.2.2 Setting the machine positioning for DC1550/DA321G drive ..................... 17

6.2.3 Checkingofsetpositions ......................................... 18

6.3 Masterreset ................................................. 18

7 Lubrication ................................................. 19

8 Sewing test ................................................. 19

Page 32

Notes:

Page 33

1 Scope of delivery

The purchaser can order a complete machine, or some components

only. Prior to setting up, please check that all the required parts are

present.

This description refers to a special sewing machine, of which all

individual components can completely be delivered by

Dürkopp Adler AG.

Machine with the direct drive on the machine head

Obligatory components:

Machine head (1)

Accessories (includes oil tank (2), yarn stand (3), tools and other items

Set of parts with motor (includes direct drive (5), belt guard (4) and

other parts)

Optional components:

Stand (6)

Control panel (8)

3

GB

1

3

7

4

8

6

5

2

Page 34

2 Transport packing of assembled machine

If the machine is supplied in assembled condition, the following

transport packing must be removed:

–

Safety straps and wooden battens on the machine head and stand.

–

Safety blocks and straps on the sewing drive.

3 Assembling the stand

3.1 Assembling the stand components

–

Mount the frame according to the picture. Mount the pedal (1)

provisionally. Its position will be adjusted after the whole machine

is complete.

–

Adjust the screw (2) so that the stand is stable.

4

1

2

3

Page 35

5

GB

3.2 Assembling the table top (direct drive)

–

Turn the table top (1) upside down.

–

Screw the electric cable channel (2).

–

Screw the pedal position sensor (3).

–

Screw the electric cable clip (4).

–

Put the oil s ump on (5) and slide it in the arrow direction (6) till the

relevant protrusions of the oil sump are seated on the recess

contour. Screw the oil sump.

–

Screw the drawer (7).

–

Pre-bore the holes for wood screws and screw the drive control

box (8).

–

Screw the sewing lamp transformer (9) – if there is any.

–

Mount electric cables according to the instructions in chapter 5.

–

Pre-bore the holes (10). Attach the table plate to the stand with

woodscrews (B8 x 35). Then turn the stand to normal position.

–

Insert the yarn stand (11) in the hole in the table plate and secure it

with the nuts and washers. Fit and align the yarn reel and

unwinding holders.

–

Insert the machine head support pin (12).

–

Place the hinge bottoms (13) for the machine head into the cutout

of the table plate (1) and tighten the screws.

–

Insert the wedges (14) in the recess corners.

–

Insert the rubber cushions (15).

328

30

80

770

30

72

185

15

368

80

15

4

10 2 69 58 13 10

14

12

15

11

260

13

460

180

15

7

50

Page 36

3.3 Setting the working height

–

The stand height is adjustable between 750 and 900 mm.

–

Loosen the screws (1).

–

Set the required table top height and make sure that it is identical

on both sides. To do that, use the scale on the stand feet. Set the

stand height so that it corresponds with the operator ’s body

proportions.

–

Tighten both screws (1).

Caution! Risk of injury!

Failure to adjust the stand height to the operator ’s body proportions

can cause damage to the operator ’s locomotion system.

6

1

Page 37

4 Assembling the machine head

4.1 Fitting the machine head

–

Tilt the machine head (1) and insert it in the table top recess.

–

After the head insertion, screw the locking plate (2) immediately to

secure the machine head against falling out at its tilting. The

locking plate is part of the machine head accessories.

7

GB

2

1

Page 38

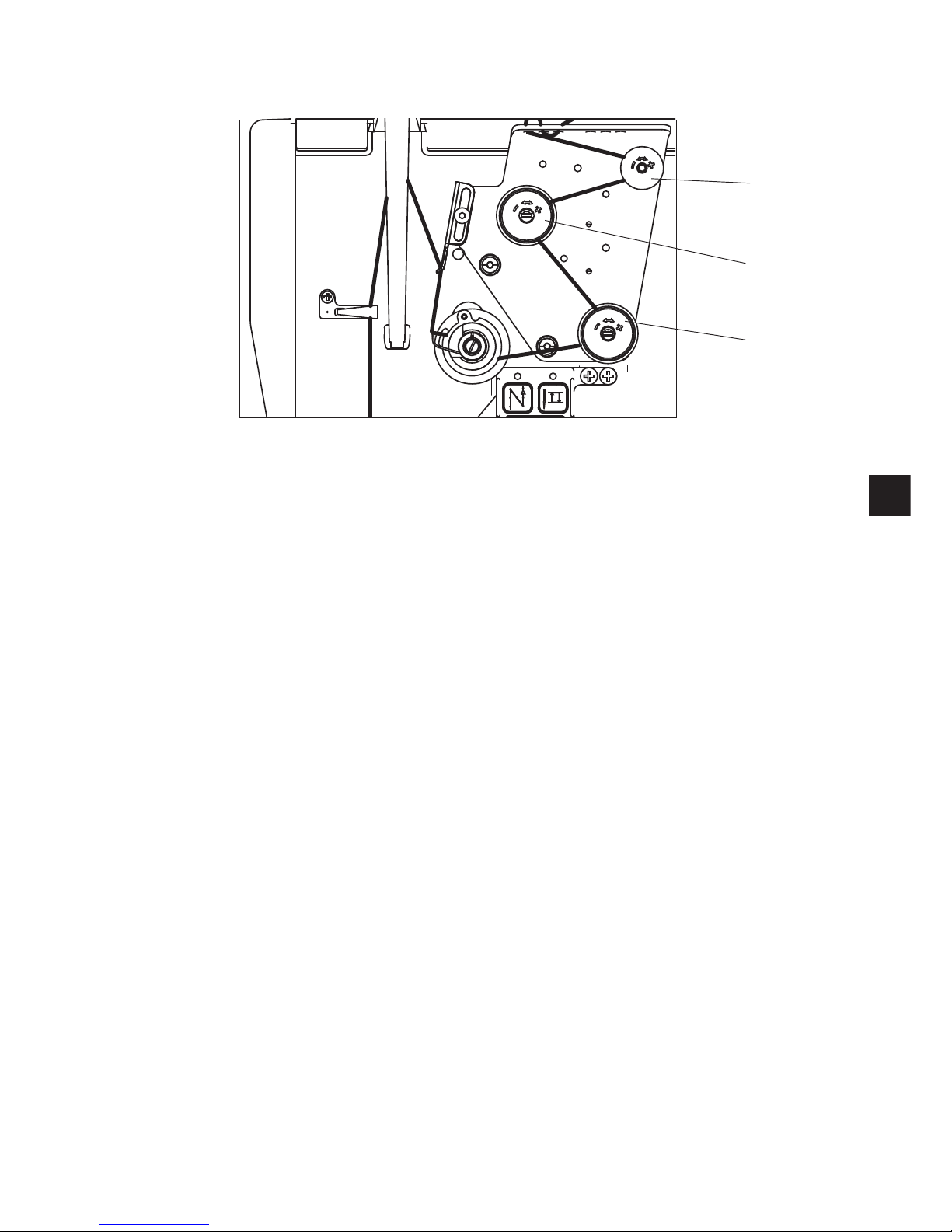

4.2 Fitting the belt guards

–

Disassembly the hand wheel (1).

–

In the machines with the motor on the sewing head and with 1,55:1

toothed belt driving gear, mount the proximity switch (3). It is

included in the “kit for motor“.

–

In all machines with the motor on the machine head mount the

guard (2) (it is included in of the motor part set).

–

Mount the hand wheel (1). Doing this, observe the correct angle

position: if the needle is in the upper dead point, there should be

the 0° value on the hand wheel scale.

8

1

2

3

Page 39

4.3 Adjustment of pedal position

–

Adjust the side position of the pedal (1) so that its center lies on

the needle axis.

–

Adjust the draw rod (2) so that the foot axis is perpendicular to the

pedal surface.

Caution! Risk of injury!

Failure to keep the determined pedal position can cause damage to

the operator’s locomotion system.

9

GB

2

1

2

90°

3

Page 40

4.4 Fitting the oil pump pipe

–

Tilt the machine head (1).

–

Attach the pipe (2) with the clips (3) and install the suction

basket (4).

–

TIlt the machine head.

10

3

4

2

1

Page 41

4.5 Fitting the connecting cable, control panel and sewing diode lamp

on the machine head

–

The connecting cable (1) is supplied with every machine with the

positioning motor (drive).

–

The control panel (2) had to be ordered separately (optional

equipment). When ordering a control panel, a bracket (3) is always

supplied together with it. The sewing lamp LED (5) is an optional

equipment. Two types of brackets are supplied together with it

to enable the installation of the lighting body in two positions.

Position (5) is the basic one. Position (7) should be used if a guide

for sewing material is mounted on the machine.

–

Dismantle the upper cover and back cover of the machine head.

–

Install the connecting cable with the connector (1) according to the

picture.

–

Install the control panel (2) with the bracket (3) and install the

cable (4) according to the picture.

–

Mount the sewing lamp (5) and install the cable (6) according to the

picture.

–

Push the cables through the table top and attach them with a

self-sticking clip (8).

11

GB

3

7

2

41

8

6

5

9

Page 42

5 Electrical connection

The machine drive is supplied from the low voltage network.

Caution!

All work on the electrical equipment of this special sewing

machine may only be carried out by qualified electricians or

other appropriately trained persons.

Remove the mains plug before carrying out any work!

5.1 Electrical connection to low voltage network

According to the selected type the machine drive has a one-phase or

three-phase supply. If the drive has the three-phase supply, it has an

asynchronous motor. In that case it is necessary to adjust the

connection of the coils in the motor terminal board (star or triangle) to

the voltage of the local electric network.

Caution!

The voltage in the electric network must agree with the voltage on the

motor label!

The connection of the coils of the asynchronous motor must

correspond with the voltage in the local network.

The low voltage circuit includes the following items:

–

Supply plug

–

Main switch (with the drive on the machine head the main switch is

incorporated in the drive)

–

Drive

–

Sewing lamp transformer (option)

–

Cables

Part of these items is included in the drive package. The other part is

included in the package of the motor part set obligatorily supplied with

the machine head. The division of the items can be seen in the parts

list.

The low voltage circuit connection will be made according to the wiring

diagram, which is included in the package of the motor part set.

Caution! Risk of electric current injury!

The drives may be operated only with a safety conductor connected to

the functional protective system in accordance with the regulations

and rules to avoid personal injuries by electric current or fire.

The drive operation will become dangerous if the s afety conductor

inside or outside the drive is disrupted. The protection must not be

disrupted with e.g. an extension cord without the protective conductor.

12

Page 43

5.1.1 Sewing lamp transformer connection to network voltage

Caution! Risk of electric current injury!

The sewing lamp transformer is not switched off by the main switch

(EN 60 204-31)! At the sewing lamp installation and repair inside the

transformer box, e.g. at a fuse replacement, the mains plug must be

disconnected from the power outlet.

The machine is equipped with the Efka DC1550/DA321G drive

–

Pull the mains plug from the power outlet.

–

Screw out 4 screws on the front panel of the control box.

–

Dismantle the front panel.

–

Pull the transformer cable through the channel (1) in the control

box.

–

Remove the black rubber bushing (2).

–

Pierce the bushing with a screwdriver.

–

Pull the sewing lamp transformer cable through the arisen hole.

–

Insert the rubber bushing back again.

–

Press the clip openers (3) and (4) with a small screwdriver slightly

until the clips (5) and (6) open.

–

Connect the blue conductor to the terminal (6) and the brown

conductor to the terminal (5).

–

Screw the front panel back again.

–

Fix the light transformer cable against pulling off (e.g. with a

fastening band to a supply mains cable).

13

GB

26 5 1

65 4 3

Page 44

5.2 Grounding

–

The grounding conductor (1) is included in the accessory package

of the machine head.

–

Connect the conductor (1) to the plug (2) and pull its opposite end

under the table top.

–

Screw the opposite end of the grounding conductor to the relevant

grounding point of the drive (indicated ).

–

Attach the conductor with a c lip on the bottom side of the table top.

Caution!

Make sure that the grounding conductor does not touch the driving

V-belt (if there is any).

Note:

If the machine has the direct drive with the motor drive on the machine

head, it is not necessary to ground the head. In that case the head is

grounded with the motor on the head.

14

1

2

Page 45

5.3 Connection of the head to Efka DC1550/DA321G drive

Efka DC1550/DA321G direct drive is fixed directly on the machine

head. The motor synchronizer is incorporated in the motor body and it

is not located on the hand wheel (this applies, however, only for the 1:1

gear reduction motor – machine).

–

Connect the machine head connecting cable to the connector (1).

–

Connect the control panel to the connector (2).

–

Connect connector (3) of the motor synchronizer (6) to

connector (4).

–

Connect the connector (5) of the motor (6) to the connector (7).

–

Connect the pedal position sensor (8) to the connector (9).

–

Connect hand wheel position in connector B18.

15

GB

741 2 935 6 8

B 7 7 6

V 8 . .

B 1 8

L S M ...

B 2

M

B 8 0

E B . ..

B 4 1

M

A

Page 46

6 Adjustment of Efka positioning motor (drive)

The function of the positioning motor (drive) is defined by its program,

drive parameter setting, and the machine stopping positions. If the

machine is supplied in the disassembled condition, the drive setting

must be carried out by the purchaser. If the sewing machine is supplied

in assembled condition, the drive is already set by the sewing machine

manufacturer.

6.1 Setting of positioning motor (drive) parameters

The setting of the drive parameters is carried out in two steps. In the

first step, the parameters for the family of sewing machine class

groups are set by the function “autoselect“. In the second step, some

of the set parameters are changed to be adjusted to the particular

class.

6.1.1 Setting of parameters by the “autoselect” function

The drive control system is equipped with the “autoselect“ device,

which is able to identify what sort of the sewing machine was

connected to the drive (with a connection cable). At the drive switching

on, the value of the resistance of the resistor located inside the sewing

machine head for this purpose is measured automatically. As a result

of this, the required parameter values are set automatically. If the

control system is not able to identify the valid resistance, the drive

control will run with so-called safety operation functions only to avoid

the sewing machine damage.

6.1.2 Setting of Efka drive parameters specific for LP 2971, LP 2974

Caution!

Change of the parameter value must be performed with consideration

and in a responsible way. A false setting of the control may cause the

machine damage!

Warning!

By the so-called master-reset (see chapter 6.3) it is possible to reset

all parameter values back to the preset values again.

For a detailed description of the various parameters of the control unit,

please consult the enclosed current issue of the instructions of the

motor manufacturer (see also www.efka.net).

16

Page 47

6.1.3 Values of parameters specific for LP 2971, LP 2974

Parameter change for machines with gear rate of 28/28 teeth

Parameter Original value New value Parameter description

290* 0 3 Class of the machine

111 - - Max. sewing speed

170 - - Reference position (see chapter 6.2.2)

Parameter change for machines with gear rate 18/28 teeth

Parameter Original value New value Parameter description

290* 0 4 Class of the machine

111 - - Max. sewing speed

170 - - Reference position (see chapter 6.2.2)

* The parameter must be entered first.

Attention: to set up parameters higher as 200, it is necessary to enter

the control with a programmer ’s level (via code 3112).

6.2 Setting of machine positioning

6.2.1 Position definition

Position 1

The needle is down at the stopping in the seam. The angle 225° is on

the hand wheel scale.

Position 2

The needle is up after trimming. The angle 35° is on the hand wheel

scale.

6.2.2 Setting the machine positioning for DC1550/DA321G drive

For the needle and other elements positioning the incremental sensor

located on the hand wheel is applied which gives 512 impulses

(increments) /value in ° is displayed on the display/ and one additional

impulse per rotation. In general, the particular position is defined by

the angle between this position and the reference position. The angle

is set by the corresponding parameter value (it is not, however,

identical with the parameter value). The position parameter values

have already been set – see chapter 6.1.3. The reference position still

remainstobeset.

The reference position is defined by the angle 105° on the hand wheel

scale.

After dismantling, mounting, or replacement of the motor drive the

reference position must be set again.

A reference position setting is described in the operating manual of the

motor manufacturer Efka.

17

GB

Page 48

6.2.3 Checking of set positions

Position 1

–

Switch on the network switch.

–

Tread the pedal forwards shortly and release. The machine is

stopped in the position 1 (see chapter 6.2.1).

–

Check the angle on the hand wheel scale (225° ± 5°).

Position 2

–

Tread the pedal forwards shortly at first and then entirely

backwards with the heel until the machine stops. The machine

stops in the position 2 (see chapter 6.2.1).

–

Check the angle on the hand wheel scale (35° ± 5°).

6.3 Master reset

By means of the so-called master-reset all changed values are set

back to the preset ones again.

How to proceed with the master reset is described in the instructions of

the motor manufacturer Efka.

18

Page 49

7 Lubrication

Before start, the machine must be lubricated properly with oil

according to chapter 9.2 in the operating instructions.

8 Sewing test

This test can be carried out only after the machine is set completely.

–

Thread in the bobbin-winder thread. (see operating instructions).

–

Turn on the main switch.

–

Lock the sewing foot in the lifted position (see operating

instructions).

–

Fill the bobbin at low speed.

–

Turn off the main switch .

–

Thread in needle thread and bobbin thread (see operating

instructions).

–

Select the material to be sewn.

–

Carry out the s ewing test first at low speed and then gradually

increase the speed.

–

Check whether the seams are of the desired quality.

–

If the quality requirements are not met change the thread tensions

(see operating instructions).

19

GB

Loading...

Loading...