Page 1

DAC eco M-Type

Instructions for use

Page 2

IMPORTANT:

READ CAREFULLY BEFORE USE

KEEP FOR LATER REFERENCE

All rights reserved.

Property of Dürkopp Adler AG and protected by copyrig

of these contents, including excerpts, is prohibited without the prior

written consent of Dürkopp Adler AG.

Copyright © Dürkopp Adler AG 2015

ht. Any reuse

Page 3

Table of Contents

1 About these instructions....................................................................3

1.1 Target group of these instructions.........................................................3

1.2 Representation conventions – symbols and characters........................3

1.3 Other documents..................................... ... ... ........................................5

1.4 Liability ..................................................................................................5

2 Performance description........................................................... ... .. .... 7

2.1 Characteristics.......................................................................................7

2.2 Declaration of conformity.......................................................................7

2.3 Technical data.......................................................................................7

3 Safety....................................................................................................9

3.1 Basic safety instructions........................................................................9

3.2 Signal words and symbols used in warnings.......................................10

4 Components and functions................................ ..............................13

4.1 Controller.............................................................................................13

4.2 Setpoint device........................................... .........................................14

4.3 Proper use....................................... ....................................................15

5 Operation ...........................................................................................17

5.1 Initial start-up........................................... ... .........................................17

5.2 Basic operation....................................................................................17

5.2.1 Switching the controller on and off......................................................17

5.2.2 Using buttons ......................................................................................19

5.2.3 Using the potentiometer......................................................................20

5.3 Programming.......................................................................................20

5.3.1 Setting the soft start stitch count.........................................................21

5.3.2 Setting the speed ................................................................................22

5.3.3 Set maximum speed............................................................................22

5.3.4 Setting the holding force......................................................................23

5.3.5 Setting positions..................................................................................24

6 Electrical connection........................................................................27

6.1 Connecting the power supply..............................................................27

7 Troubleshooting................................................................................29

7.1 Customer service ................................................................................29

7.2 Error messages...................................................................................29

8 Glossary.............................................................................................33

9 Appendix............................................................................................35

Instructions for use DAC eco M-Type - 01.0 - 10/2015 1

Page 4

Table of Contents

Instructions for use DAC eco M-Type - 01.0 - 10/20152

Page 5

About these instructions

1 About these instructions

These instructions for the DAC eco M-Type controller were compiled with the utmost care. They contain information and notes to

enable long-term and reliable operation.

Should you notice any discrepancies or if you have improvement

req

Customer service ( S. 30).

Consider these instructions part of the p

at all times.

1.1 Target group of these instructions

These instructions are intended for:

With regard to minimum qualification

be met by personnel, please also follow chapter Safety ( S. 9).

uests, we would be glad to receive your feedback through

roduct and keep it on hand

• Operating personnel:

This group is familiar with the co

the instructions for use.

Specifically, chapter Op

this group of employees.

• Technicians:

This group has the appropriate technical training for performing maintenance or repairing malfunctions.

Specifically, chapter Programmin

for this group of employees.

eration ( S. 17) is important for

ntroller and has access to

g ( S. 20) is important

and other requirements to

1.2 Representation conventions – symbols and characters

Various information in these instruction is represented or highlighted by the following characters in order to facilitate easy and

quick understanding:

Proper setting

Indicates proper setting.

Malfunctions

Specifies the faults that can occur due to an incorrect setting.

Instructions for use DAC eco M-Type - 01.0 - 10/2015 3

Page 6

About these instructions

1.

2.

etc.

•

Cover

Specifies which covers have to be removed in order to access the

mponents to be set.

co

Steps to be performed when operating the machine (sewing

and equipping)

Steps to be performed for service, maintenance, and

stallation

in

Steps to be performed via the software control panel

The individual steps are numbered:

1. First step

2. Second step

The sequence of the steps must always be followed.

Lists are identified by bullet points.

Result of performing an operation

Change to the machine or on the display/control panel.

Important

Special attention must be paid to

this point when performing a step.

Information

Additional information, e.g. on alternative operating options.

Order

Specifies the work to be performed before or after a setting.

References

Reference to another section in the instructions.

Instructions for use DAC eco M-Type - 01.0 - 10/20154

Page 7

About these instructions

Safety Important warnings for the machine operator are specially desig-

nated. Since safety is of particular importance, hazard symbols,

levels of danger and their signal words are described separately

in the chapter Safety ( S. 9).

Orientation If the figure is unclear, indications of right or left ar

the operator's point of view.

1.3 Other documents

The controller includes components from other manufacturers.

Each manufacturer has performed a hazard assessment for these

purchased parts and confirmed their design compliance with applicable European and national regulations. The proper use of

se components is described in each manufacturer's instruc-

the

tions.

1.4 Liability

All information in these instructions were compiled with consideration to the state of the art, and applicable standards and regulations.

Dürkopp Adler cannot be held liable for damages resulting from:

• Breakage and transport damages

• Failure to follow the instructions provided

• Improper use

• Unauthorized modifications to the controller

• Use of untrained personnel

• Use of unapproved replacement parts

e always from

Transport

Dürkopp Adler will not be held liable for any damage during transport. Inspect the delivery immediately upon receiving it. Report

ny damage to the last transport manager. This applies even if

a

the packaging is undamaged.

Leave controllers, equipment and packaging material in the condition in which they were found when the damage was discovered.

his will ensure any claims against the transport company.

T

Instructions for use DAC eco M-Type - 01.0 - 10/2015 5

Page 8

About these instructions

Report all other complaints to Dürkopp Adler immediately after

receiving the product.

Instructions for use DAC eco M-Type - 01.0 - 10/20156

Page 9

Performance description

2 Performance description

2.1 Characteristics

• Positioning drive for M-Type sewing motor

• Integration in the machine head of the M-Type

• Programmable parameters

• Transfer of machine-specific parameters during start-up

di

of the machine

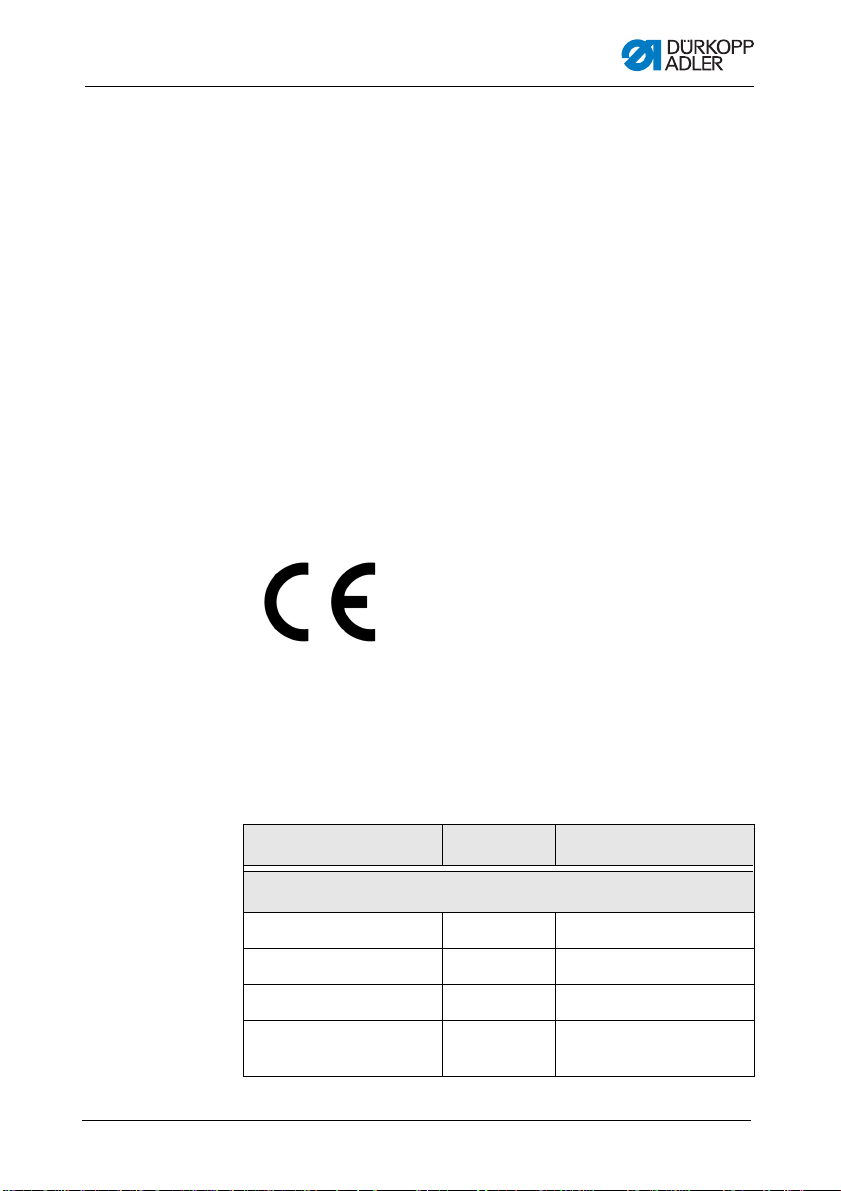

2.2 Declaration of conformity

The DAC eco M-Type complies with European regulations ensuring health, safety, and environmental protection as specified

in the declaration of conformity or low voltage directive.

rectl

y from the machine identification memory (machine ID)

2.3 Technical data

Rating and usage conditions

Data / motor type Unit Built-in motor

Rating

Line voltage [V] 190 – 250, single phase

Line frequency [Hz] 50/60

Rated power [W] 600

Speed

of the motor

Instructions for use DAC eco M-Type - 01.0 - 10/2015 7

[min

-1

]

3400

Page 10

Performance description

Data / motor type Unit Built-in motor

Operating mode S5

(Intermittent periodic duty with electric

braking,

relative duty cycle 40%, length 2.5 s)

IP class IP40

Insulation class

Usage conditions

Ambient temperature [°C] + 5 –

E

50

Instructions for use DAC eco M-Type - 01.0 - 10/20158

Page 11

Safety

3 Safety

This chapter contains basic information for your safety. Read the

instructions carefully before setting up or operating the controller.

Make sure to follow the information included in this chapter. Failure

to do so can result in serious injury and damage to the machine.

3.1 Basic safety instructions

The DAC eco M-Type controller may only be used as described

in these instructions.

The instructions should be available at

all times.

Work on live components is prohibited.

The controller was built and tested in compliance with all valid

rdinance and safety regulations, and left the factory in proper

o

working order.

The controller will only work safely and reliably when it is used as

ntended ( 4.3 Proper use, S. 15).

i

the controller's location at

Before leaving the workplace:

• Switch off the controller

• Wait until the machine stops

• Wait until the LEDs go out

Obligations

of the operator

Requirements to

met by the

be

personnel

Instructions for use DAC eco M-Type - 01.0 - 10/2015 9

Observe the country-specific safety and accident prevention regulations and the legal regulations concerning industrial safety and

protection of the environment.

the

All warnings and safety signs on the controller must always be in

egible condition and may not be removed. Missing or damaged

l

labels should be replaced immediately.

The controller may only be set up by qualified technicians. Qualified technicians are personnel with electronics and mechanical

training.

Page 12

Safety

The following work may only be performed by qualified technicians.

• Maintenance work

•Repairs

• Work on electrical equipment

Only authorized persons may work on the machine. Anyone working on the machine belongs to the operating personnel. Operating

ersonnel must have read and understand the instructions before

p

working on the system.

Setup Controller setup and start-up must be performed carefully by

qualified technicians to

sonnel.

The power cable must have a plug authori

which the machine is being used. The power plug may only be

connected to the power cable by a qualified specialist.

Operation Inspect the controller while in use for any externally visible dam-

age.

Stop working if you notice any changes. Report any changes to

your supervisor.

A damaged controller should no longer be used.

Conversions or changes to the controller are prohibited.

ensure no health risks for operating per-

zed for the country in

3.2 Signal words and symbols used in warnings

Warnings in the text are distinguished by color bars. The color

scheme is oriented towards the severity of the danger. Signal

words indicate the degree of risk:

Instructions for use DAC eco M-Type - 01.0 - 10/201510

Page 13

Safety

Signal words Signal words and the hazard that they describe:

Signal word Hazard

WARNING Performing an action can have se

consequences.

CAUTION Performing an action can have undesirable conse-

quences, such as loss of data or damage to hardware.

NOTE Tips or more detailed information

to make operation easier for the user.

rious or hazardous

Symbols The following symbols indicate the type of risk to personnel:

Symbol Type of danger

General risk

Electric shock

Puncturing

Crushing

Environmental damage

Instructions for use DAC eco M-Type - 01.0 - 10/2015 11

Page 14

Examples Examples of the layout of the warnings in the text:

Type and source of risk

Consequences of non-compliance.

Measures for avoiding the risk.

WARNING

Type and source of risk

Consequences of non-compliance.

Measures for avoiding the risk.

CAUTION

Tip.

NOTE

This is what a warning looks like where non-compliance

could result in serious or hazardous consequences.

is is what a warning looks like where non-compliance

Th

could result undesirable consequences, such as loss of data

or damage to hardware.

Safety

is is the more detailed information to simplify operation for

Th

the user.

Instructions for use DAC eco M-Type - 01.0 - 10/201512

Page 15

Components and functions

(1) - Button S1

(2) - Button S2

(3) - Potentiometer

②

③

①

4 Components and functions

When delivered the DAC eco M-Type consists of:

• Foot pedal rods

• Setpoint device

• Controller

4.1 Controller

Fig. 1: Controller front

Instructions for use DAC eco M-Type - 01.0 - 10/2015 13

Page 16

Components and functions

Buttons and functions

No. Button Function

Referenc

e

①

②

③

S1 Sewing mode

• Select needle stop

sition

po

Programming mode

• Confirm input

• Increase values

S2 Sewing mode

• Switch on soft start

Programming mode

• Terminate input

• Reduce values

Potentiometer • Adapt maximum

speed

S. 19

S. 19

S. 20

4.2 Setpoint device

The setpoint device converts the values from the foot pedal into

voltage values. The setpoint device indicates the speed.

The setpoint device is attached und

bracket.

The setpoint device includes:

• a push/pull rod (1) that is connected to the machine foot pedal

through the set of rods.

• a spring preload (2), enabling 3 settings for the push/pull rod

ne, 1/8, or 1/4 rotation)

(no

er the frame with a mounting

Instructions for use DAC eco M-Type - 01.0 - 10/201514

Page 17

Components and functions

(1) - Push/pull rod

(2) - Spring pre-load

(3) - Mounting parts

①

③

②

Improper use can result in hardware damage.

Follow all instructions provided.

CAUTION

Fig. 2: Setpoint device

4.3 Proper use

The DAC eco M-Type controller is not a standalone unit; instead,

it is intended for installation in a machine of the class M-Type with

the subclass’ suffix M. For additional information refer to

2.2 Declaration of conformity, S. 7.

The controller is intended for industrial use.

The controller may only operate in rooms that are clean and dry.

Do not operate the controller when ae

is in use.

Proper use includes compliance with

and repair conditions as specified by the manufacturer.

Only authorized persons may work on

3 Safety, S. 9).

rosols (sprays) or oxygen

the operating, maintenance,

the controller (chapter

Instructions for use DAC eco M-Type - 01.0 - 10/2015 15

Page 18

Components and functions

Instructions for use DAC eco M-Type - 01.0 - 10/201516

Page 19

Operation

CAUTION

Hardware damage due to faulty connecti on.

An overload is possible due to a faulty connection.

Only qualified technicians may perform the

connection.

5 Operation

Operation of the DAC eco M-Type controller is provided exclusively by using buttons S1 and S2 as well as the potentiometer.

You set the foundation for the sewing process with the settings

the controller.

on

5.1 Initial start-up

Before initial start-up of the controller, make sure to follow all

information in chapter 3 Safety, S. 9.

Ensure the following:

• Setting the positions ( S. 24)

5.2 Basic operation

In this section you will learn the basics for working with the controller. These basics are:

• Switching the controller on and off ( S. 17)

• Using buttons ( S. 19)

• Using the potentiometer ( S. 20)

5.2.1 Switching the controller on and off

Important

Before operating the controller, make sure to follow all information

in chapter 3 Safety, S

Instructions for use DAC eco M-Type - 01.0 - 10/2015 17

. 9.

Page 20

Risk of injury by the needle tip.

Accidentally switching on the system may result in

minor puncture injuries.

When there are longer standstill periods,

disconnect the power cable before leaving the

workplace.

WARNING

(1) - POWER-LED

(2) - MESSAGE-LED

(3) - Main switch

(4) - LED S2

(5) - LED S1

①

⑤

②

③

④

Operation

The controller is located below the tabletop of the frame.

Fig. 3: Switching the controller on and off

Instructions for use DAC eco M-Type - 01.0 - 10/201518

Page 21

Operation

Switching on the controller

1. Press the main switch (3) down to position I.

e POWER LED (1) illuminates green.

Th

You can begin sewing and pushing the foot pedal forward.

Switching off the controller

When you are finished your work switch off the controller.

1. Press the main switch (3) up to position 0.

The M

ESSAGE LED (2) illuminates red.

5.2.2 Using buttons

While in sewing mode, you can select the following machine

functions with the buttons:

Buttons and use

Button Use

S1 • Select needle stop position:

up = LED illuminates

down = LED off

S2 • Switch on soft start

To select a machine function:

1. Briefly press the corresponding button.

e machine beeps briefly.

Th

You will recognize whether a machine function has been

activated by the LED in the respective button.

When the POWER LED is on you can sew. Pro

gramming is

possible outside of sewing only ( S. 20).

Instructions for use DAC eco M-Type - 01.0 - 10/2015 19

Page 22

Operation

5.2.3 Using the potentiometer

You can use the potentiometer to adjust the maximum speed of

the current sewing process. The set values are retained, even

when you switch off the controller.

To adjust the maximum speed:

1. Turn the potentiometer:

• Clockwise = increase speed

• Counterclockwise = decrease speed

5.3 Programming

You can program the controller within a reduced scope using

buttons S1 and S2.

Buttons and use

Button Use

S1 • Confirm input (press and hold)

• Increase values (press briefly)

S2 • Terminate input (press and hold)

• Reduce values (press briefly)

Programmable parameters

No. Parameters Min. Max.

1 Soft start stitch count 1 20 10 1

2 Soft start speed 100 1000 100 [rpm]

3 Max. speed 100 3400 1000 100 [rpm]

4 Holding force 0 6 0.1 1 [A]

5 Needle position

Instructions for use DAC eco M-Type - 01.0 - 10/201520

Flashing

LED

S1 ≙

Flashing

S2 ≙

LED

Unit

Page 23

Operation

Important

The programming mode has to be activated first.

To activate the programming mode:

1. When switching on the controller press and hold button S1

until

the machine beeps a second time.

The M

ESSAGE LED flashes.

Select the corresponding parameter by

briefly pressing button S1.

The S1 LED indicates which parameter has been preselected

through frequent flashing.

5.3.1 Setting the soft start stitch count

Soft start refers to starting the machine at a slower speed. This

machine function prevents the motor from overheating during long

work processes. After a certain stitch count, the machine runs at

the set soft start speed ( S. 22).

You set the stitch count for s

1. Briefly press button S1 once.

LED S1 fl

ashes briefly once.

2. Press and hold button S1.

The M

ESSAGE LED illuminates.

3. Press button S1

obtained.

You can reduce the value by briefly pressing button S2.

e value increases or decreases incrementally by one

Th

step.

LED S1 fl

ashes for the tens digit, and LED S2 for the units

digit.

4. Press and hold button S1 t

oft start as follows:

repeatedly until the required value is

o confirm input.

Press and hold button S2 t

Instructions for use DAC eco M-Type - 01.0 - 10/2015 21

o return to sewing mode.

Page 24

5.3.2 Setting the speed

You can also set the speed for soft start.

To set the soft start speed:

Operation

1. Briefly press button S1 twice

LED S1 fl

2. Press and hold button S1.

The M

3. Press button S1

obtained.

You can reduce the value by briefly pressing button S2.

Th

one-hundredth step.

LED S1

units digit.

4. Press and hold button S1 t

Press and hold button S2 t

ashes briefly twice.

ESSAGE LED illuminates.

repeatedly until the required value is

e value increases or decreases incrementally by one

flashes for the hundreds digit, and LED S2 for the

.

o confirm input.

o return to sewing mode.

5.3.3 Set maximum speed

A reduced speed protects the sewing motor with an ongoing lower

speed. The maximum speed depends on the machine class.

To set the speed:

1. Briefly press button S1 three times.

LED S1 fl

2. Press and hold button S1.

The M

3. Press button S1

obtained.

You can reduce the value by briefly pressing button S2.

Th

one-hundredth step.

LED S1 fl

hundreds digit.

4. Press and hold button S1 t

ashes briefly three times.

ESSAGE LED illuminates.

repeatedly until the required value is

e value increases or decreases incrementally by one

ashes for the thousands digit, and LED S2 for the

o confirm input.

Instructions for use DAC eco M-Type - 01.0 - 10/201522

Page 25

Operation

Hardware damage due to incorrect setting.

Setting too strong a holding force can overheat the

sewing motor.

Only qualified technicians may make this setting.

CAUTION

Press and hold button S2 to return to sewing mode.

Example for setting the speed

The value is set by pressing the button (button S1 or

button S2).

The following example assumes an initial value of 3400 rpm :

To set the speed to 1700 rpm (

1. Briefly press button S2

LED S1 fl

ashes once, LED S2 7 times.

2. Press and hold button S1 t

= 3400 - 1700):

17 times ( ≙ 1700 / 100).

o confirm input.

5.3.4 Setting the holding force

This function prevents unintended needle movement when the

machine is stopped. You can check whether it is working by turning

the handwheel.

Holding force works when the machine is stopped:

• when stopping during sewing

• at the end of sewing

The effect can be adjusted.

To set the holding force:

1. Briefly press button S1 four

LED S1 fl

ashes briefly four times.

times.

2. Press and hold button S1.

ESSAGE LED illuminates.

eatedly until the required holding force is

obtained.

The M

3. Press button S1 rep

Instructions for use DAC eco M-Type - 01.0 - 10/2015 23

Page 26

Operation

Hardware damage due to incorrect setting.

An incorrect setting can cause problems in the

sewing process.

Only qualified technicians may make this setting.

CAUTION

You can reduce the holding force by briefly pressing

button S2.

e holding force increases or decreases in increments of

Th

0.5 A.

LED S1 fl

ashes for the digit before the decimal point, and

LED S2 for the decimal digit.

The higher the set value, the stronger the holding force.

4. Press and hold button S1 t

o confirm input.

5.3.5 Setting positions

The following positions can be set:

• Reference position

• Position 1

• Position 2

The positions have to be set once:

• during initial start-up ( S. 17)

• after replacing the controller

• after replacing the motor or setpoint device

Setting the reference position

The reference position establishes a reference between the synchronizer and the actual mechanical position.

To set the reference position:

1. Briefly press button S1 five

LED S1 fl

ashes briefly five times.

2. Press and hold button S1.

The M

ESSAGE LED, LED S1, and LED S2 illuminate.

Instructions for use DAC eco M-Type - 01.0 - 10/201524

times.

Page 27

Operation

Risk of injury by the needle tip.

Accidentally pressing the foot pedal may result in

minor puncture injuries.

Secure the sewing area.

WARNING

3. Press the foot pedal forward.

LEDs S1 and S2 flash.

4. Turn the handwheel until the needle tip

is on the throat plate.

5. Press and hold button S1 to confirm input.

LED S2 fl

ashes.

Either continue by setting position 1 or exit the parameter while

eping button S2 pressed.

ke

Setting the position 1

Position 1 (lower dead center) indicates the position where it

needle is at its lowest point.

To set the position 1:

1. Turn handwheel until the needle below changes direction.

2. Press and hold button S1 t

o confirm input.

LED S1 flashes.

Either continue by setting position 2 or exit the parameter while

eping button S2 pressed.

ke

Instructions for use DAC eco M-Type - 01.0 - 10/2015 25

Page 28

Operation

Setting the position 2

Position 2 (upper dead center) indicates the position where it

eedle is at its highest point.

n

To set the position 2:

1. Turn handwheel until the needle above changes direction.

2. Press and hold button S1 t

Press and hold button S2 t

o return to sewing mode.

o confirm input.

Instructions for use DAC eco M-Type - 01.0 - 10/201526

Page 29

Electrical connection

Electric shock due to live parts.

Serious or fatal injuries possible.

Work on the electrical system must ONLY be

performed by technicians or appropriately trained

and authorized personnel.

WARNING

6 Electrical connection

6.1 Connecting the power supply

1. Connect the controller to grounded AC line power per the wiring

diagram ( 9 Appendix, S. 35). Always use a multi-prong

plug with protective ground co ntact.

The following are suitable power supply nets:

• TN net

•TT net

•IT net

Instructions for use DAC eco M-Type - 01.0 - 10/2015 27

Page 30

Electrical connection

Instructions for use DAC eco M-Type - 01.0 - 10/201528

Page 31

Troubleshooting

7 Troubleshooting

7.1 Customer service

Contact for problems, repairs, or if the controller is damaged:

Dürkopp Adler AG

Potsdamer Str. 190

33719 Bielefeld, Germany

Tel: +49 (0) 180 5 383 756

Fax: +49 (0) 521 925 2594

E-Mail: service@duerkopp-adler.com

Internet: www.duerkopp-adler.com

7.2 Error messages

The DAC eco M-Type controller has 3 types of error messages

displayed with the MESSAGE LED. The codes are displayed by

means of the MESSAGE LED flashing for an appropriate period

at specific intervals. After a brief pause the flashing repeats.

Instructions for use DAC eco M-Type - 01.0 - 10/2015 29

Page 32

Types of error messages

Type Description Remedial action

Troubleshooting

Error Serious error:

Work cannot be continued

Warning Error

Work cannot be continued

Information Information:

Work can be continued

• Switch off the controller

• Correct the state that resulted in

he error

t

• If nec., contact customer service

• Correct the state that resulted in

he error

t

• Switch the controller off and on

gain

a

• If nec., correct the state that

esulted in the message

r

Listing of codes

Code Type Description Remedial action

1 Warning Operation lock • Check tilt sensor on

machine

2 Information Low voltage warning

3 Warning Foot pedal not in 0

shold):

(1st thre

Live voltage < 180 V

AC

position

• Check the line voltage

• Stabilize the line

age

volt

• Use generator

• Remove foot from

edal

foot p

4 Error Foot pedal not con-

nected

5 Error Sewing motor

encoder plug (

9 pin) is not connected

6 Error Sewing motor

blocked

7 Error Sewing motor over-

load

Instructions for use DAC eco M-Type - 01.0 - 10/201530

sub D,

• Connect foot pedal

• Connect encoder

to the control

cable

system, use the correct connector

• Eliminate stiff movement in the machine

• Eliminate stiff movement in the machine

Page 33

Troubleshooting

Code Type Description Remedial action

8 Error Sewing motor not

connected

9 Error Sewing motor insula-

10 Error High-voltage error:

11 Error EEprom communica-

tion error

Live voltage for

nded period >

exte

290 V

tion error

• Check the connection

• Test sewing motor

phases (R = 2.8 Ω,

high impedance to

PE)

• Replace sewing

motor

• Replace controller

• Check motor phase

and PE for

impedance connection

• Replace sewing

motor

• Check line voltage,

if line volt

exceeds continuously:

• Stabilize or use generator

• Check machine ID

connection

• Switch off the controller, wait until the

LEDs are

then switch on

again

low-

age

off and

12 Information No valid data on

rnal

exte

EEprom

13 Error Low voltage warning

reshold):

(2nd th

Live voltage < 150 V

AC

Instructions for use DAC eco M-Type - 01.0 - 10/2015 31

• Check machine ID

connection

• Switch off the controller, wait until the

LEDs are

then switch on

again

• Update the software

• Check the line voltage

• Stabilize the line

volt

• Use generator

off and

age

Page 34

Troubleshooting

Code Type Description Remedial action

14 Error Incorrect sewing

motor direction of

rotation

15 Error Sewing motor over-

16 Error Maximum speed

17 Error AC-RDY Timeout:

18 Information No valid data on

current:

Internal current rise >

25 A

exceeded

intermediate circuit

age did not reach

volt

the defined threshold

in the specified time

rnal

exte

EEprom

• Exchange encoder

• Check motor plug

assignment and

change, if necessary

• Check wiring on

machine distributor

and change if necessary

• Test motor phases

and check for correct value

• Replace controller

• Replace encoder

• Check the line voltage

• If the line voltage is

OK, replace the

controller

• Check machine ID

connection

• Switch off the controller, wait until the

LEDs are

then switch on

again

• Update the software

off and

19 Information No valid data on

Instructions for use DAC eco M-Type - 01.0 - 10/201532

rnal

exte

EEprom

• Check machine ID

connection

• Switch off the controller, wait until the

LEDs are

then switch on

again

• Update the software

off and

Page 35

Glossary

8 Glossary

Term Explanation

Machine function Identifies an equipment feature of a machine

Parameters Numerical values that activate or set a machine

function

Potentiometer Continuous adjustment wheel for setting the maxi-

mum speed

Soft start Machine starts at a lower speed

Setpoint device Converts the values from the foot pedal into volt-

Stitch count Indicates the number of stitches per minute

age values

Instructions for use DAC eco M-Type - 01.0 - 10/2015 33

Page 36

Glossary

Instructions for use DAC eco M-Type - 01.0 - 10/201534

Page 37

Appendix

9 Appendix

Fig. 4: TN net wiring diagram

Fig. 5: TT net wiring diagram

Instructions for use DAC eco M-Type - 01.0 - 10/2015 35

Page 38

Fig. 6: IT net wiring diagram

Appendix

Instructions for use DAC eco M-Type - 01.0 - 10/201536

Page 39

Page 40

DÜRKOPP ADLER AG

Potsdamer Str. 190

33719 Bielefeld, Germany

Germany

Phone: +49 (0) 521 925 00

E-Mail: service@duerkopp-adler.com

www.duerkopp-adler.com

Subject to design changes - Printed in Germany - © Dürkopp Adler AG - Original instructions - 0791 100632 EN - 01.0 - 10/2015

Loading...

Loading...