Page 1

878-M PREMIUM

Operating Instructions

Page 2

Všechna práva vyhrazena.

Vlastnictví společnosti Dürkopp Adler AG a chráněno autorskými právy.

Jakákoliv reprodukce těchto obsahů, a to i formou výňatků, je bez

předchozího písemného souhlasu společnosti Dürkopp Adler AG zakázána.

Copyright © Dürkopp Adler AG - 2018

Page 3

Obsah

1 About these instructions.................................. ..................................5

1.1 Scope of the instructions.......................................................................5

1.2 Applicable documentation.....................................................................5

1.3 Damage during transport.......................................................................5

1.4 Limitation of liability...............................................................................5

1.5 Symbols used........................................................................................6

1.6 Figures ..................................................................................................6

2 Technical Specifications ....................................................................7

2.1 Characteristics.......................................................................................7

2.2 Declaration of Conformity......................................................................7

2.3 Proper use................. ...................................................................... ......8

2.4 Technical data.......................................................................................9

2.4.1 Data overview by subclasses................................................................9

2.4.2 Additional equipment...........................................................................10

3 Safety..................................................................................................13

3.1 Basic safety instructions......................................................................13

3.2 Signal words and symbols used in warnings.......................................15

4 Machine Description .........................................................................19

5 Operation ...........................................................................................21

5.1 Switching power supply on and off......................................................21

5.2 Inserting and replacing the needle......................................................22

5.3 Threading the needle thread .......................................... ... ..................25

5.3.1 Tension plate electromagnetic ............................................................25

5.3.2 Tension plate electronic ......................................................................27

5.3.3 Tension plate rotary.............................................................................30

5.4 Inserting and winding on the hook thread .............................. ... ... ... ....31

5.5 Replacing the hook thread bobbin.......................................................34

5.6 Thread tension ......................................................... ...........................36

5.6.1 Setting needle thread tension for el. magnetic tension plate...............36

5.6.2 Setting hook thread tension.................................................................39

5.7 Setting the thread regulator.................................................................40

5.8 Lifting and folding the top roller...........................................................41

5.9 Holding the top roller in the upper position..........................................42

5.10 Electronic knee lever............................................. ... ... ........................43

5.11 Quick functions on the keypad............................................................44

5.11.1 Activating function keys.......................................................................44

5.11.2 Assigning key functions to the favorite button.....................................46

5.12 Operating the controller.......................................................................46

5.13 Sewing.................................................................................................47

6 Maintenance.......................................................................................49

6.1 Cleaning work......................................................................................49

6.2 Checking the oil level ..........................................................................51

6.3 Customer service ................................................................................52

Operating Instructions 878-M PREMIUM Verze 02.0 - 02/2018 1

Page 4

Obsah

7 Setup ..................................................................................................53

7.1 Checking the scope of delivery ...........................................................53

7.2 Removing the transport locks..............................................................54

7.3 Assembling frame components...........................................................54

7.4 Completing the table top ........................................................ ... ..........55

7.5 Fastening the table top to the frame....................................................56

7.6 Setting the working height...................................................................57

7.7 Controller.............................................................................................58

7.7.1 Fitting the control unit..........................................................................58

7.7.2 Fitting the pedal and setpoint device...................................................59

7.8 Mounting the machine head................................................................60

7.9 Fitting the oil extraction line.................................................................61

7.10 Fitting the tilt sensor............................................................................61

7.11 Installing the knee switch ....................................................................62

7.12 Fitting the control panel.......................................................................63

7.13 Electrical connection ...........................................................................63

7.13.1 Checking the mains voltage................................................................64

7.13.2 Fitting and connecting the sewing lamp and sewing lamp transformer64

7.13.3 Establishing equipotential bonding......................................................66

7.13.4 Connecting the control unit..................................................................67

7.14 Lubrication...........................................................................................67

7.15 Sewing test..........................................................................................69

8 Settings via the software..................................................................71

8.1 OP3000 control panel..........................................................................71

8.2 Switching the sewing machine on.......................................................72

8.3 Controller operating modes.................................................................73

8.4 Manual mode.......................................................................................74

8.4.1 Quick access function (softkey menu) .................................................76

8.4.2 Menu for other settings........................................................................77

8.4.3 Sewing.................................................................................................79

8.5 Automatic mode ..................................................................................79

8.5.1 Before starting sewing......................................................................... 80

8.5.2 Sewing.................................................................................................81

8.5.3 Canceling the program........................................................................82

8.6 Programming/edit mode......................................................................82

8.6.1 Creating programs...............................................................................82

8.6.2 Creating a program by keyboard input ................................................85

8.6.3 Creating a program by teach-in...........................................................85

8.6.4 Editing programs.................................................................................86

8.6.5 Changing further parameters for the current section...........................87

8.6.6 Changing further parameters for the selected program ......................89

8.6.7 Copying the program...........................................................................90

8.6.8 Deleting a program.................... ... ..................................... ..................91

8.7 Simplified display menu.......................................................................92

2 Operating Instructions 878-M PREMIUM Verze 02.0 - 02/2018

Page 5

Obsah

9 Disposal .............................................................................................93

10 Appendix............................................................................................95

10.1 Table top drawing...................... ..................................... ... ..................95

10.2 Component layout on underside of table top.......................................97

10.3 Interconnection diagram......................................................................98

Operating Instructions 878-M PREMIUM Verze 02.0 - 02/2018 3

Page 6

Obsah

4 Operating Instructions 878-M PREMIUM Verze 02.0 - 02/2018

Page 7

About these instructions

1 About these instructions

1.1 Scope of the instructions

These instructions describe the intended use and the setup of the

special sewing machine 878-M PREMIUM. It applies to all submodels listed in chapter 2.4 Technical data.

1.2 Applicable documentation

The device contains built-in components from other manufacturers, e.g. drive motors. Each manufacturer has performed a hazard

assessment for these purchased parts and confirmed their design

compliance with applicable European and national regulations.

The proper use of these components is described in each manufacturer's instructions.

1.3 Damage during transport

Dürkopp Adler cannot be held liable for any damage during transport. Inspect the delivery immediately upon receiving it.

Report any damage to the last transport manager.

This applies even if the packaging is undamaged.

Leave machines, equipment and packaging material in the condition in which they were found when the damage was discovered.

This will ensure any claims against the transport company.

Report all other complaints to Dürkopp Adler immediately after

receiving the product.

1.4 Limitation of liability

All information in these operating instructions was compiled with

consideration to the state of the art, and applicable standards and

regulations.

The manufacturer accepts no liability for any damage due to:

• Failure to observe the information given in these instructions

• Improper use

• Unauthorized modifications to the machine

• Use of untrained personnel

• Breakage and damage during transport

• Use of unapproved replacement parts

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 5

Page 8

About these instructions

1.

2.

etc.

1.5 Symbols used

Proper setting

Indicates proper setting.

Malfunctions

Specifies the faults that can occur due to an incorrect setting.

Steps to be performed when operating the machine (sewing

and equipping)

Steps to be performed for service, maintenance, and

installation

Steps to be performed via the software control panel

The individual steps are numbered:

1. First step

2. Second step

The sequence of the steps must always be followed.

Result of performing an operation

Change to the machine or on the display

Important

Special attention must be paid to this point when performing a step.

Information

Additional information, e.g. on alternative operating options.

Sequence

Specifies the work to be performed before or after a setting.

References

Reference to another section in these instructions.

1.6 Figures

Depending on the submodel, the appearance of the machine

varies in the following items:

Length of the machine arm, number of adjusting wheels, position

of the stitch adjustment lever, presence of the keypad, etc.

When this makes no difference to the handling steps, the figures

show only one machine version as an example.

6 Operating Instructions 878-M PREMIUM - 02.0 - 02/2018

Page 9

Technical Specifications

2 Technical Specifications

2.1Characteristics

The Dürkopp Adler 878-M PREMIUM is a post bed sewing machine for double lockstitches.

General technical characteristics

• 1-needle or 2-needles machine

• Large vertical hook

• Transport: Bottom wheel feed with driven top roller, without

• Programmable setting of the stitch length on control panel

• Programmable stroke adjustment of the top roller via stepper

• Programmable top roller pressure via stepper motor

• Programmable, electronically regulated thread tension (ETT)

• Electronic handwheel (jog dial)

• Direct drive for all subclasses

• Safety snap-on coupling for preventing any misadjustment of

• Automatic wick lubrication for machine and hook

• Maximum passage with lifted the top roller: 13 mm

• Electromagnetic thread cutter (length of remaining thread

• Keypad on the machine arm and favorite button for quick

• Thread monitor for the hook thread - on request

needle transport

with the possibility of differential between the top and bottom

feed.

motor

- on request

or damage to the hook in the event of a thread jamming

approx. 10 mm)

functions

2.2Declaration of Conformity

The machine complies with the European regulations specified in

the Declaration of Conformity or in the Declaration of Incorporation.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 7

Page 10

Technical Specifications

2.3Proper use

The Dürkopp Adler 878-M PREMIUM is intended for sewing light

to heavy material.

Depending on the subclass the following needle sizes are to be

used:

• Light to moderately heavy material: 70 – 80 Nm

• Moderately heavy material: 90 – 110 Nm

• Heavy material: 120 – 16 0 Nm

The maximum thickness of the sewing material thickness is

8 mm when pressed together under the top roller.

The machine is intended only for use with dry sewing material.

The sewing material must not contain any hard objects.

The sewing machine is intended for industrial use.

The manufacturer cannot be held liable for any damage

resulting from improper use.

8 Operating Instructions 878-M PREMIUM - 02.0 - 02/2018

Page 11

Technical Specifications

2.4Technical data

2.4.1 Data overview by subclasses

Subclasses: 878-M PREMIUM

-160722-M

Stitch type Double lockstitch 301

Hook type Vertical hook,

Number of needles 1

Needle system 134

Needle strength [Nm] 70 - 160

Maximum thread strength [Nm] 120/3 - 10/3

Stitch length, forwards / backwards

[mm]

-1

Maximum s.p.m. [min

stitch length [mm]

Maximum sewing foot stroke [mm] 13

Maximum stroke height [mm] 8

Mains voltage [V] 230

Mains frequency [Hz] 50 / 60

Length/width/height [mm] 640/220/550

] according to

2500/0-3.5; 2300/3.6-4; 2100/4.1-4.5; 2000/4.6-5;

1800/5.1-6; 1600/6.1-6.5; 1500/6.6-7

large (L)

7/7

-260722-M

2

Weight [kg] 55

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 9

Page 12

Technical Specifications

2.4.2 Additional equipment

A flexible system of additional equipment allows the sewing unit

to be optimally equipped for any application at low cost.

= Standard equipment

= Optional enhancement

Order

number

0888 220334

0888 220344

0888 220354

0888 220364

0888 220374

0888 220384

0888 220394

0888 220404

9880 888100 Diode sewing light 3W

0867 1 13504 Tension plat e electr onic

0867 1 13604 Tension plat e electr onic

0878 1 10064 Tension pl ate rot ary

0878 1 10074 Tension pl ate rot ary

0888 150234 Remaining thread monitor for the hook thread

Top roller

Top roller

Top roller

Top roller

Top roller

Top roller

Top roller

Top roller

∅ 25 mm knurled

∅ 25 mm smooth

∅ 25 mm rubberized

∅ 35 mm knurled

∅ 35 mm smooth

∅ 35 mm rubberized

∅ 45 mm, width 3.8 mm

∅ 45 mm, width 2.0 mm

Additional equipment

878-160722-M

878-260722-M

0888 150544 Remaining thread monitor for the hook thread

0888 150534 Blocking machine

0867 593504 Compressed air gun (feeding the thread through the hose guide,

cleaning the machine)

9081 300001 Tool kit M-type

10 Operating Instructions 878-M PREMIUM - 02.0 - 02/2018

Page 13

Technical Specifications

Order

number

0888 200464 Parts set for binding, tape width 2.0 mm

0888 200474 Parts set for binding, tape width 2.5 mm

0888 200614 Att achmen t for Fren ch binding

0888 200884 Tape roll holder, lower

0888 100294 Tape roll holder, top

N800 080030 Edge guide, tiltable

N800 080004 Roller and straight stop, swiveling

0878 590024 Sep ar ator, tiltable

Additional equipment

For additional instructions and further documentation, visit

the download section on the Dürkopp Adler website:

http://www.duerkopp-adler.com/de/main/Support/downloads.

878-160722-M

878-260722-M

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 11

Page 14

Technical Specifications

12 Operating Instructions 878-M PREMIUM - 02.0 - 02/2018

Page 15

Safety

3 Safety

This chapter contains basic information for your safety. Read the

instructions carefully before setting up or operating the machine.

Make sure to follow the information included in this section. Failure

to do so can result in serious injury and material damage.

3.1 Basic safety instructions

The machine may be used only as described in these operating

instructions.

The operating instructions should be available at the machine's

location at all times.

Work on live components and equipment is prohibited. Exceptions

are defined in the regulations set forth in DIN VDE 0105.

For the following work, the machine must be disconnected from

the power supply using the main switch or by disconnecting the

power plug:

• Replacing the needle or other sewing tools

• Leaving the workplace

• Performing maintenance work and repairs

• Threading (can be used the lock button)

Missing or faulty spare parts could impair safety and damage the

machine. Make sure you only use original replacement parts from

the manufacturer.

Transport Use a sturdy lifting carriage or stacker for transporting the ma-

chine. Raise the machine max. 20 mm and secure it against

slipping off.

Setup The power cable must have a plug authorized for the country in

which the machine is being used. The power plug may only be

connected to the power cable by a qualified specialist.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 13

Page 16

Safety

Obligations

of the operator

Observe the country-specific safety and accident prevention regulations and the legal regulations concerning industrial safety and

the protection of the environment.

All warnings and safety signs on the machine must always be in

legible condition and may not be removed. Missing or damaged

labels should be replaced immediately.

Requirements to

The machine may only be set up by qualified technicians.

be met by the

personnel

Maintenance work and repairs may only be carried out by qualified

technicians.

Work on electrical equipment may only be carried out by qualified

specialists.

Only authorized persons may work on the machine. Every person

who works on the machine must first have understood these

instructions.

Operation Inspect the machine while in use for any externally visible damage.

Stop working if you notice any changes to the machine. Report

any changes to your supervisor. A damaged machine must no

longer be used.

Safety

equipment

Safety equipment should not be removed or deactivated. If this

cannot be avoided for a repair operation, the safety equipment

must be refitted and put back into service immediately afterwards.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201814

Page 17

Safety

3.2 Signal words and symbols used in warnings

Warnings in the text are distinguished by color bars. The color

scheme is oriented towards the severity of the danger. Signal

words indicate the severity of the danger:

Signal words Signal words and the hazard that they describe:

Signal word Hazard

DANGER Will result in serious injury or death.

WARNING Can result in serious injury or death.

CAUTION Can result in minor or moderate injury.

NOTICE Can result in material damage.

CAUTION Pollution can result

Symbols The following symbols indicate the type of danger to personnel:

Symbol Type of danger

General

Electric shock

Pointed objects

Crushing

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 15

Page 18

Symbol Type of danger

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

DANGER

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

WARNING

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

CAUTION

Pollution

Examples Examples of the layout of the warnings in the text:

This is what a warning looks like for a hazard that will result

in serious injury or even death if ignored.

Safety

This is what a warning looks like for a hazard that could

result in serious injury or even death if ignored.

This is what a warning looks like for a hazard that could

result in moderate or minor injury if the warning is ignored.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201816

Page 19

Safety

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

NOTICE

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

CAUTION

This is what a warning looks like for a hazard that could

result in material damage if ignored.

This is a warning note for a hazard that could result in pollu-

tion if ignored.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 17

Page 20

Safety

Operating Instructions 878-M PREMIUM - 02.0 - 02/201818

Page 21

Machine Description

(1) - Control panel OP3000

(2) - Tension plate

(3) - Thread lever

(4) - Keypad on the machine arm

(5) - Top roller with needle

(6) - Hook (under throat plate)

(7) - Oil level indicator

(8) - Winder

(9) - Hand wheel

(10) - Electronic hand wheel

(11) - Reel stand

⑨

⑤

④

③

②

①

⑪

⑩

⑦

⑥

⑧

4 Machine Description

Fig. 1: Machine Description

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 19

Page 22

Machine Description

20 Operating Instructions 878-M PREMIUM - 02.0 - 02/2018

Page 23

Operation

+

–

(1) - Indicator lamp on the keypad

(2) - Switch for dimmable sewing lamp

(3) - Indicator lamp on the controller

(4) - Main power switch

(5) - Switch for the sewing lamp

①

②

④

③

⑤

5Operation

5.1 Switching power supply on and off

The lower main switch (4) on the controller regulates the power

supply.

Important

When you turn on the machine must not be under the top roller

sewn material!

Fig. 2: Switching power supply on and off

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 21

Switching power on

1. Press the main switch (4) down to position I.

Indicator lamps (1) and (3) light up.

Switching power off

1. Press the main switch (4) up to position 0.

Indicator lamps (1) and (3) turn off.

Switching on the dimmable sewing lamp

1. Press switch (5) to the left to position 1.

2. Press switch (2) up to position 1.

Dimmable sewing lamp illuminates.

Page 24

Operation

Switching off the dimmable sewing lamp

1. Press switch (2) down to position 0.

2. Press switch (5) to the left to position 0.

5.2 Inserting and replacing the needle

WARNING

Risk of injury from needle and moving parts!

Turn the sewing machine off before replacing the

needle.

Do not touch the tip of the needle.

Sequence

After switching to a different needle size, adjust the distance

between the hook and the needle, as well as the position of the

throat plate towards its post ( Service instructions).

NOTICE

Damage to the machine, needle breakage, or thread damage is possible due to incorrect distance between the

needle and hook tip.

A false orientation of the needle may damage the hook tip.

Check the distance to the hook tip and the position of the

throat plate towards its post after inserting a new needle with

a different size. Reset distance if necessary.

Faults caused by an incorrect hook clearance

After inserting a thinner needle:

• Missing stitches

• Thread damage

After inserting a thicker needle:

• Damage to the hook tip

• Damage to the needle

Operating Instructions 878-M PREMIUM - 02.0 - 02/201822

Page 25

Operation

(1) - Needle bar

(2) - Lever

(3) - Groove

(4), (5), (6) - Orientation of needle

②

①

③

④

⑤

⑥

m

a

x

.

3

°

Changing the needle

Fig. 3: Inserting and replacing the needle - 1-needle machine

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 23

1. Turn the handwheel until the needle bar (1) reaches the upper

end position.

2. Draw the lever (2) in your direction to loosen the screw fixing

the needle.

3. Pull the needle out towards the bottom.

4. Insert the new needle.

5. Important: Align the needle so that the groove (3)

is facing the hook according to section (4) or (5). The needle

may not be oriented as shown at section (6).

6. Turn the lever (2) back to tighten the screw.

Page 26

Operation

(1) - JNeedle bar

(2) - Lever

(3) - Groove

(4), (5), (6) - Orientation of needle

②

①

③

④

⑤

⑥

m

ax

. 3°

Fig. 4: Inserting and replacing the needle - 2-needles machine

1. Turn the handwheel until the needle bar (1) reaches the upper

end position.

2. Loosen the screws (2).

3. Pull the needle out towards the bottom.

4. Insert the new needle.

5. Important: Align the needles so that the groove (3)

is facing the hook according to section (4) or (5). The needles

may not be oriented as shown at section (6).

6. Tighten the screws (2).

Operating Instructions 878-M PREMIUM - 02.0 - 02/201824

Page 27

Operation

①

(1) - Pin

5.3 Threading the needle thread

WARNING

Risk of injury from needle and moving parts!

Turn off the sewing machine before threading the

thread.

5.3.1 Tension plate electromagnetic

In all machines the thread from the thread reel is fed through the

thread guide and to the machine via the unwinding bracket.

Fig. 5: Threading the needle thread - 1-needle machine

1. Thread the machine according to picture.

2. If the machine is equipped for heavy sewing, wind the thread

around the pin (1).

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 25

Page 28

Operation

(1) - Pin

(2) - Left thread

(3) - Thread lever

②

①

②

③

Fig. 6: Threading the needle thread - 2-needles machine

1. Thread the machine according to the picture. The thread (2)

designed for the left needle is to be threaded in the left tensioners and in the upper hole in the thread lever (3).

2. Threading the side by side arranged needles is in the picture

above.

Fig. 7: Threading the diagonally arranged needles

3. If the machine is equipped for heavy sewing, wind the thread

around the pin (1).

Operating Instructions 878-M PREMIUM - 02.0 - 02/201826

Page 29

Operation

(1) - Thread guide

(2) - Reel stand

(3) - Guide on unwinding bracket

①

②

③

5.3.2 Tension plate electronic

Informace

Tension plate electronic is optional equipment.

In all machines the thread from the thread reel is fed through the

thread guide and to the machine via the unwinding bracket.

Fig. 8: hread guide on the unwinding bracket and machine arm

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 27

1. Fit the thread reel on the reel stand (2).

2. Insert the thread from the rear to the front through the thread

guide on the unwinding bracket (3).

3. Use e.g. a compressed air gun to feed the thread through the

thread guide (1).

Page 30

Operation

+

(1) - Tightening lever

(2) - Spring tip

(3) - Thread tensioning spring

(4) - Diverter pin

(5) - Tensioner 2

(6) - Tensioner 1

(7) - Preliminary tensioner

(8) - Thread guide

①

②

③

④

⑤

⑥

⑧

⑦

Fig. 9: Threading procedure for needle thread - part 1

4. Feed the thread clockwise from the thread guide (8) around

the preliminary tensioner (7).

5. Feed the thread counterclockwise around tensioner 1 (6).

6. Feed the thread clockwise around tensioner 2 (5).

7. Guide the thread under the diverter pin (4) to the thread

tensioning spring.

8. Lift the tightening lever (1) with the thread.

9. Pull the thread under the spring tip (2).

Operating Instructions 878-M PREMIUM - 02.0 - 02/201828

Page 31

Operation

(9) - Upper thread guide

(10) - Lower thread guide

(11) - Thread guide on the

needle bar

(12) - Needle eye

(13) - Thread regulator

(14) - Thread lever

⑨

⑩

⑪

⑩

⑭

⑬

⑫

Fig. 10: Threading procedure for needle thread - part 2

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 29

10.Inser t the thread from bottom to top through the hole on the

thread regulator (13).

11.Inser t the thread from the right to the left through the thread

lever (14).

12.Inse r t the thread through the upper thread guide (9).

13.Insert the thread through a hole in the lower thread guide (10).

14.Inse r t the thread through the thread guide on the needle

bar (11).

15.Inser t the thread through the needle eye (12) in such a way

that the loose thread end faces the hook.

Page 32

Operation

(1) - Thread guide

(2) - Thread guide

(3) - Auxiliary tensioner

(4) - Primary rotary tensioner

(5) - Thread regulator

(6) - Tightening spring

①

②

③

④

⑤

⑥

5.3.3 Tension plate rotary

Information

Tension plate rotary is optional equipment, uses the control on

the display and all the setting as an tension plate electronic.

Fig. 11: Threading of needle thread

1. Insert the thread from thread stand through (1) and (2).

2. Guide the thread from the thread guide (2)

around auxiliary tensioner

3. Wind the thread once clockwise arou nd primary tensioner (4).

4. Guide the thread to tightening spring (6).

5. Lift the tightening spring (6) with the thread and pull the thread

under the spring arm.

6. Insert the thread from the bottom up through the thread regulator hole (5) and then to the thread lever.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201830

(3).

counterclockwise

Page 33

Operation

(1) - Guide on unwinding bracket (2) - Reel stand

1

2

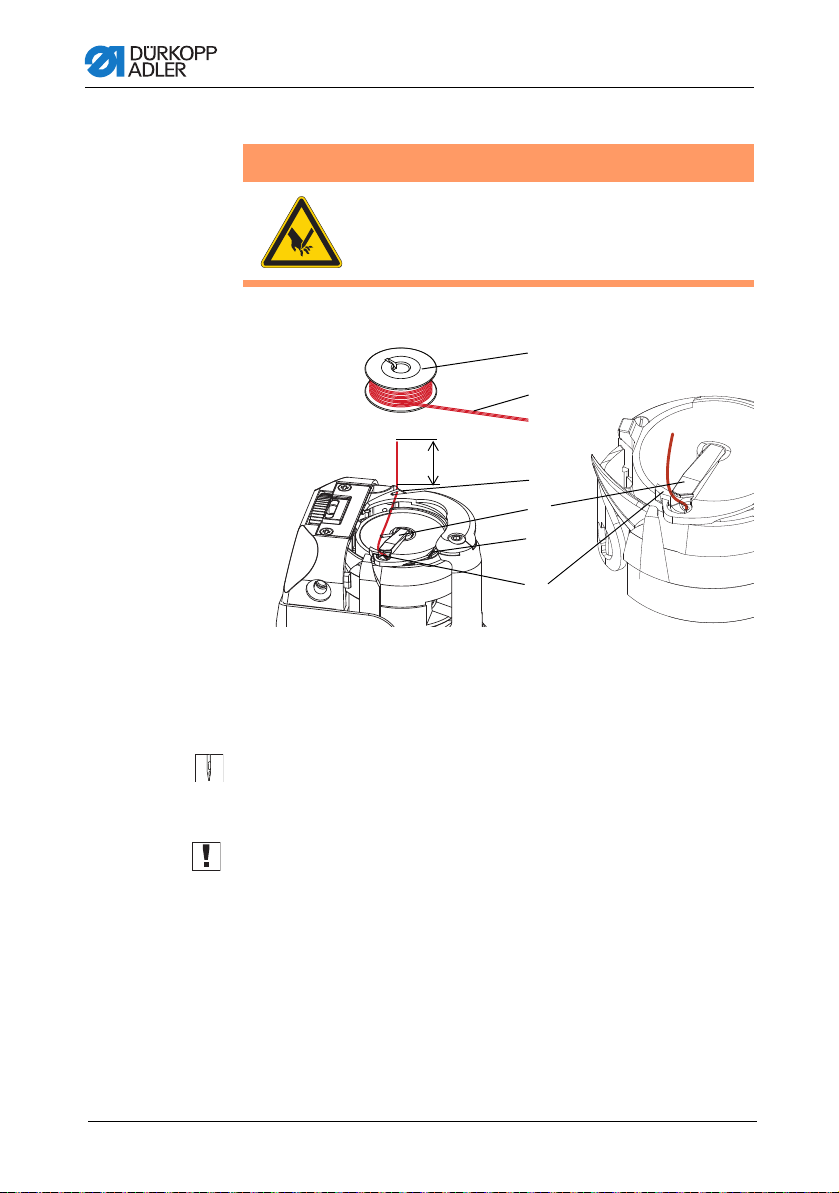

5.4 Inserting and winding on the hook thread

WARNING

Risk of injury from needle and moving parts!

Turn off the sewing machine before threading the

thread.

Fig. 12: Thread guide on the unwinding bracket and machine arm

1. Fit the thread reel on the reel stand (2).

2. Insert the thread from the rear to the front through the thread

guide on the unwinding bracket (1).

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 31

Page 34

Operation

(1) - Thread guide

(2) - Pre-tensioner

(3) - Winder

(4) - Hook thread guide

①

②

③

④

(5) - Bobbin lever

(6) - Bobbin shaft

(7) - Cutter

⑤

⑥

⑦

Fig. 13: Winding on the hook thread - part 1

3. Insert the thread in a wavelike manner through the 3 holes of

the thread guide (1): from top to bottom through the left hole,

from bottom to top through the hole in the middle and finally

from top to bottom through the right hole.

4. Guide the thread counterclockwise around the pretensioner (2).

5. Insert the thread in a wavelike manner through the 2 holes of

the hook thread guide (4): from bottom to top through the left

hole and from top to bottom through the right hole.

6. Guide the thread to the winder (3).

Fig. 14: Winding on the hook thread - part 2

7. Clamp the thread behind the cutter (7) and tear off the loose

end behind it.

8. Fit the bobbin on the bobbin shaft (6).

9. Turn the bobbin clockwise until it clicks.

10.Pull the bob bin lever (5) up.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201832

Page 35

Operation

Damage to the sewing feet or needle plate possible if the

thread is wound on without material.

Lock the top roller in place in the highest position.

ATTENTION

The hook thread is normally wound on when sewing is in progress. However, you can also wind on the hook thread without

sewing, e.g. if you require a full bobbin in order to start sewing.

Winding procedure

1. Switch on the sewing machine.

2. Press the foot pedal forwards.

The machine sews and winds the hook thread from the

thread reel onto the bobbin.

When the bobbin is full, the machine automatically stops

winding. The bobbin lever moves down.

The cutter is automatically moved into its basic vertical

position.

3. Pull off the full bobbin.

4. Tear off the thread behind the cutter.

5. Insert the full bobbin in the hook

( Replacing the hook thread bobbin, p. 34).

6. Repeat the winding-on procedure with an empty bobbin, as

described above.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 33

Page 36

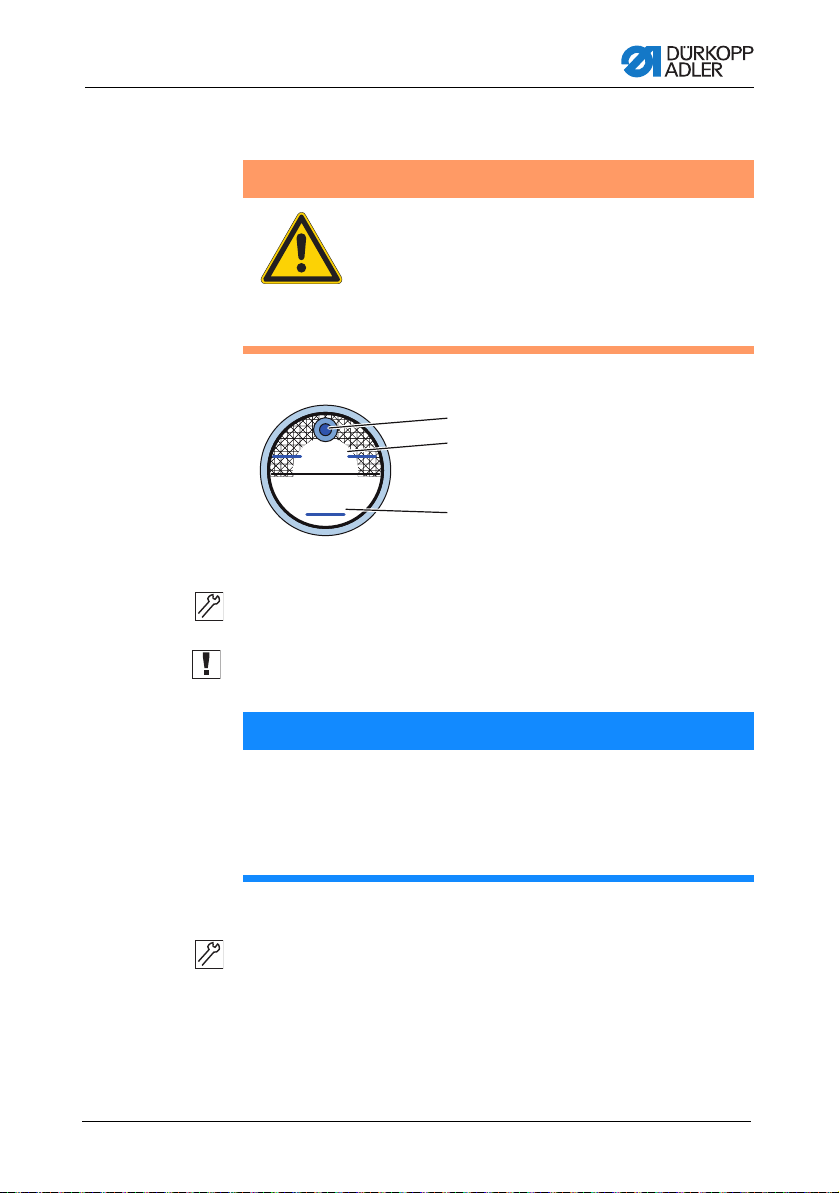

5.5 Replacing the hook thread bobbin

(1) - Bobbin

(2) - Thread end

(3) - Tensioning spring

(4) - Bobbin housing flap

(5) - Slot

(6) - Slot

①

10

②

③

④

⑤

⑥

WARNING

Risk of injury from needle and moving parts!

Switch off the sewing machine before replacing

the hook thread bobbin.

Fig. 15: Replacing the hook thread bobbin

Operation

1. Push up the bobbin housing flap (4).

2. Remove the empty bobbin.

3. Insert a full bobbin (1):

Important: Insert the bobbin (1) with the thread end (2) orient-

ed according to the picture.

4. Thread the thread through the slot (5) and slot (6).

5. Close up the bobbin housing flap (4) and fasten the thread

under the tensioning spring (3).

6. Trim the thread end according to the picture.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201834

Page 37

Operation

+

–

(1) - LEDs on the machine arm

①

Automatic

remaining thread

monitor

For machines with automatic remaining thread monitor:

If the hook thread needs to be replaced, the LED indicator lamps

(2) light up on the machine arm. The left light is for the left-hand

hook, and the right light is for the right-hand hook.

Fig. 16: Remaining thread monitor

Each of the bobbins has a thread supply groove that is embedded

in the bobbin core.

Important: Insert the bobbin in the hook in such a way that the

thread supply groove faces down. Otherwise, the remaining thread

monitor will not work.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 35

Page 38

Operation

(1) - Equal tension of the needle and hook threads

(2) - Hook thread tension greater than needle thread tension

(3) - Needle thread tension greater than hook thread tension

①

②

③

5.6 Thread tension

There tension of the needle thread and hook thread determines

where the thread interlaces.

Correct setting

The threads should normally interlace in the exact middle of the

material. When setting, typically only the tension of the needle

thread is altered, while the tension of the hook thread remains

unchanged.

5.6.1 Setting needle thread tension for el. magnetic

tension plate

General

To increase tension:

1. Turn regulator clockwise.

To reduce tension:

1. Turn regulator counter-clockwise.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201836

Page 39

Operation

①

②

(1) - Pre-tensioner

(2) - Auxiliary tensioner

(3) - Primary tensioner

(4) - Lever

③

④

Fig. 17: Setting needle thread tension

Setting pre-tensioner (1)

Set the pre-tensioner (1) so that it has the lowest tension possible,

but so high that, when taking out the sewn material after the

preceding trimming (when the tensioners (2) and (3) are switched

off), the thread is not pulled out of the pre-tensioner (1). (Pretensioner (1) is not switched off at the top roller lifting).

Setting tensioners (2) and (3)

The machine can be equipped with a lever (4) for the auxiliary

tensioner (2) temporary switching off. In this case, two thread

tension values can be pre-selected and a good stitch tightening

can be achieved when sewing over a varia b l e nu mb er of layers

of the sewn material with one seam.

1. Switch the auxiliary tensioner off (2) with the lever (4) and sewn

on a smaller numbers of layers.

2. Regulate the thread tension on the primary tensioner (3), until

a proper thread interlacing is achieved (see picture p. 36).

3. Switch the auxiliary tensioner on (2) by the lever (4) shifting

out and sew on a greater number of layers.

4. Regulate the thread tension on the auxiliary tensioner (2) until

a proper thread interlacing is achieved (see picture p. 36).

5. If the machine is not equipped with the lever (4), regulate the

tension by both tensioners (2) and (3) at the same time so that

their nuts are screwed approximately in the same height.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 37

Page 40

Switching on/off thread tensioners

①

②

③

④

(1) - Pre-tensioner

(2) - Auxiliary tensioner

(3) - Primary tensioner

(4) - Lever

Obr. 18: Switching on/off thread tensioners

Via hand lever

1. Pull the hand lever (4).

Tensioners (2) and (3) are switched off.

Pre-tensioner (1) is never switched off.

Operation

Via electromagnet

Tensioners (3) and (4) are switched off with an electromagnet at

the automatic top roller lifting. If the automatic top roller lifting at

the machine stop is pre-selected, the tensioners are switched off,

but temporarily only, so that the switching off electric magnet does

not overheat.

• Tensioners (3) and (4) are switched off temporarily during

the trimming cycle.

• Tensioners (3) and (4) are not switched off at the top roller

lifting with hand lever.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201838

Page 41

Operation

①

②

(1) - Adjusting screw (2) - Hole

5.6.2 Setting hook thread tension

WARNING

Risk of injury from needle and moving parts!

Switch off the sewing machine before adjusting

the hook thread tension.

Fig. 19: Setting hook thread tension

The hook thread tension is adjusted using the adjusting screw (1).

Insert a screwdriver through the hole (2).

To increase the tension:

1. Turn the adjusting screw (1) clockwise.

To reduce the tension:

1. Turn the adjusting screw (1) counterclockwise.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 39

Page 42

Operation

+

+

–

(1) - Regulator screw (2) - Thread regulator

5.7 Setting the thread regulator

WARNING

Risk of injury from needle and moving parts!

Switch off the sewing machin e be fore sett ing t he

thread regulator.

The thread regulator determines the tension applied to guide the

needle thread around the hook.

Proper setting:

The loop of the needle thread slides at low tension over the thickest

point of the hook.

Fig. 20: Setting the thread regulator

1

1234

1. Loosen the regulator screw (1).

• To increase the tension:

Slide the thread regulator (2) to the right

• To reduce the tension:

Slide the thread regulator (2) to the left

2. Tighten the regulator screw (1).

2

Operating Instructions 878-M PREMIUM - 02.0 - 02/201840

Page 43

Operation

1

(1) - Pedal

①

(1) - Top roller

5.8 Lifting and folding the top roller

Fig. 21: Electronic top roller lifter with pedal

1. Press the pedal (1) halfway back.

The machine stops and lifts top roller.

The top roller remain up as long as the pedal

is pressed halfway back.

or

1. Press the pedal (1) fully back.

The thread cutter is activated and

the top roller is lifted.

Top roller folding

Fig. 22: Top roller folding

1. Fold the top roller (1) in the direction of the arrow.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 41

Page 44

Operation

(1) - Top roller in upper position

(2) - Upper position canceled

Risk of crushing when lowering the top roller!

Do not hold your hands under the top roller when

the upper position is released via the pedal or lever.

CAUTION

5.9Holding the top roller in the upper position

There is a lever at the back of the machine for holding the top

roller in the upper position.

Fig. 23: Holding the top roller in the upper position with the lever

1

2

To hold the top roller in the upper position:

1. Push the lever down.

To cancel the lock:

1. Push the lever up.

You can also use the pedal to cancel the upper position:

1. Press the pedal halfway back as when lifting the top roller.

The lever swivels back up and the lock is removed.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201842

Page 45

Operation

(1) - Knee switch

(2) - Switch

5.10Electronic knee lever

The electronic knee lever can be used to control the different

functions of the machine for example switch between two different

stitch lengths or two values of the upper thread tension. You can

also lift the top roller while sewing. The switch on the back of the

knee lever specifies whether the feature is enabled permanently,

or only for the knee lever is pressed.

Fig. 24: Elements of the knee lever

1

2

For permanent switch:

1. Set the switch (2) to the upper position.

• To switch the relevant function:

Push the knee switch (1) to the right.

• To switch off the relevant function:

Push the knee switch (1) to the right again.

For temporary switch:

1. Set the switch (2) to the lower position.

• To switch:

Push the knee switch (1) to the right and keep it pressed.

A new state is retained as long as the knee switch is

pushed to the right.

• To switch off:

Release the knee switch (1).

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 43

Page 46

Operation

+

+/–

(1) - Favorite button func tions

Keys for:

(2) - Reverse sewing

(3) - Needle position

(4) - Start and end bar tack

(inversion)

(5) - Stitch length preselection

(great/small)

(6) - Auxiliary thread tensioner

(7) - Switch to the next seam section

(customizable)

(8) - Screws for configuring the

favorite button (1)

①

④②⑤③

⑥

⑦

⑧

5.11Quick functions on the keypad

The machine has a keypad on the machine arm for activating

specific functions while sewing.

5.11.1 Activating function keys

Fig. 25: Keypad for quick functions

+/–

Activating a key function

1. Press the key.

Function is activated. The key illuminates.

Deactivating a key function

1. Press the key again.

Function is deactivated. The key turns off.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201844

Page 47

Operation

+/–+/–

④

②

⑤

③

⑥⑦

Fig. 26: Functions keys

Reverse sewing key (2):

When this key (2) is activated, the machine sews in reverse.

Needle positioning key (3):

When this key (3) is activated, the needle moves to a specific

position. This position is determined individually via the parameter

settings. For more information, refer to the Service instructions.

The machine comes configured so that selecting the key (3) will

bring the needle up.

Start and end ba r tack key (4):

This key (4) cancels the general setting for sewing start and end

bar tacks. If bar tacks are on, pressing the key (4) skips the next

bar tack. If bar tacks are off, pressing the key (4) sews the next

bar tack.

Stitch length key (5):

When this key (5) is selected, the machine sews with the greater

stitch length that was programmed for this stitch length on the

control panel.

Auxiliary thread tensioning key (6):

This key (6) activates the programmed auxiliary thread tensioner.

Switch to the next seam section (7):

The key (7) switches to the next seam section. The key is fully

customizable. It is possible to implement other functions as

necessary.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 45

Page 48

Operation

+

+/–

(1) - Favorite button

(2) - Screws for the assignment of the favorite button (1)

(3) - Screw in basic position: slot horizontal

(4) - Screw activates the favorite button (1): slot vertical

①

④

③

②

5.11.2 Assigning key functions to the favorite button

You can assign one of the key functions to the favorite button.

Select a function that you frequently use so that you can switch it

on faster while sewing.

Fig. 27: Assigning a key function to the favorite button

+/–

The key function is assigned by turning the screw under the key

until it is vertical. Only one function at a time can be assigned to

the favorite button (1). Therefore, only one of the screws (4) may

be in the vertical position.

All screws must be turned back to their original horizontal position

before a new function is assigned.

To assign a key function:

1. Turn all screws to their original position (2) so that the slots

are horizontal.

2. Turn the screw under the desired key 90° so that the slot is

vertical (3).

5.12Operating the controller

The machine is operated with a DAC Comfort controller

( Settings via the software, p. 71).

Operating Instructions 878-M PREMIUM - 02.0 - 02/201846

Page 49

Operation

(1) - Pedal position +1:

sewing active

(2) - Pedal position 0:

rest position

(3) - Pedal position -1:

moves the sewing feet up

(4) - Pedal position -2:

sewing the end bar tack and

cutting off the thread

5.13Sewing

WARNING

Risk of injury from the needle tip when sewing

is started unintentionally!

Take care not to accidentally press the foot pedal

when your fingers are in the needle tip area.

The pedal starts and controls the sewing process.

Fig. 28: Sewing with the peda

1

2

3

4

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 47

Initial position:

• Pedal position 0:

Machine stationary, needles up, top roller down.

To position the material to be sewn:

1. Press the pedal halfway back in pedal position -1:

The sewing feet are lifted.

2. Push the material to be sewn into the initial position.

Sewing:

1. Press the pedal forwards in pedal position +1:

The machine sews.

The sewing speed increases the further forward the pedal

is pressed.

Page 50

Operation

To interrupt sewing:

1. Release the pedal in pedal position 0:

The machine stops, needles and top roller are down.

To continue sewing:

1. Press the pedal forwards in pedal position +1:

The machine continues to sew.

To sew over thickened seams:

1. Switch on the elevated top roller stro ke w it h th e knee le ve r

( Electronic knee lever, p. 43).

To change the stitch length:

1. Switch on the 2nd stitch length using the key for the quick

function ( Quick functions on the keypad, p. 44).

To increase the thread tension:

1. Switch on the auxiliary thread tensioner using the key for the

quick function ( Quick functions on the keypad, p. 44).

To sew intermediate bar tacks:

1. Press the reverse sewing button on the keypad

( Quick functions on the keypad, p. 44).

To finish a seam:

1. Press the pedal back completely in pedal position -2:

The machine sews the end bar tack, and the thread cutter

cuts the thread.

The machine stops, needles and sewing feet are up.

2. Remove the sewing material.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201848

Page 51

Maintenance

6 Maintenance

This chapter describes simple maintenance work that needs to be

carried out on a regular basis. The maintenance work can be

carried out by the operating personnel. Advanced maintenance

work may only be carried out by qualified specialists. Advanced

maintenance work is described in the Service instructions.

6.1 Cleaning work

Cleaning the machine

Lint and thread remnants should be removed after every 8 hours

of operation using a compressed air gun or a brush. When

sewing very fluffy material, the machine should be cleaned more

frequently.

WARNING

Risk of injury from flying particles!

Switch off the machine at the main switch before

cleaning the machine.

Flying particles can enter the eyes, causing

injury.

Hold the compressed air gun so that the particles

do not fly close to people.

Make sure no particles fly into the oil sump.

NOTICE

Malfunctions can occur due to a dirty machine.

Lint and thread remnants can impair the operation of the

machine.

Clean the machine at regular intervals as described in the

instructions.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 49

Page 52

Maintenance

(1) - Area around the needle

(2) - Area under the throat plate

(3) - Hook

(4) - Cutter on the bobbin winder

①

②

④

③

Fig. 29: Areas requiring special cleaning

Areas particularly susceptible to soiling:

• Cutter on the bobbin winder for the hook thread (4)

• Area under the throat plate (3)

• Hook (2)

• Area around the needle (1)

Cleaning steps:

1. Shut off power by turning off main switch.

2. Remove any lint and thread remnants using a compressed air

gun or a brush.

50 Operating Instructions 878-M PREMIUM - 02.0 - 02/2018

NOTICE

Damage to paintwork may occur when using solventbased cleaners.

Solvent-based cleaners will damage paintwork on the machine.

Use only solvent-free substances for cleaning the machine.

Page 53

Maintenance

MAX

MIN

1

2

3

(1) - Filler opening

(2) - Maximum level marking

(3) - Minimum level marking

6.2 Checking the oil level

WARNING

Skin damage due to contact with oil!

Oil can cause a rash if it comes into contact with

skin.

Avoid any skin contact with the oil.

If oil has come into contact with your skin, wash

the affected areas thoroughly.

Fig. 30: Oil level indicator

Checking the oil level

1. Check the oil level indicator every day:

Important: The oil level must always be between the minimum

level marking (3) and the maximum level marking (2).

NOTICE

Machine damage possible due to incorrect oil level.

Too little or too much oil can damage the machine.

Check the oil level on a daily basis, adding enough oil so oil

level is always between the minimum and maximum

markings.

Refilling oil

Pour in oil through the filler opening (1) as required:

1. Switch off the sewing machine at the main switch.

2. Add oil up to but not past the maximum level marking (2).

3. Press the main switch again to turn the sewing machine

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 51

back on.

Page 54

Maintenance

Required oil:

Only DA 10 or equivalent oil should be used for the machine, which

has the following properties:

• Viscosity at 40 °C: 10 mm²/s

• Flash point: 150 °C

NOTICE

Machine damage possible due to incorrect oil.

An incorrect oil type can cause damage to the machine.

Only use oil specified in the operating instructions.

CAUTION

Risk of pollution from oil.

Oil is a pollutant and must not enter the sewage

system or the soil.

Collect waste oil carefully and dispose of it and

oily machine parts in accordance with the

applicable statutory regulations.

6.3 Customer service

Contact for repairs if machine is damaged:

Dürkopp Adler AG

Potsdamer Str. 190

33719 Bielefeld, Germany

Tel. +49 (0) 180 5 383 756

Fax +49 (0) 521 925 2594

Email: service@duerkopp-adler.com

Internet: www.duerkopp-adler.com

52 Operating Instructions 878-M PREMIUM - 02.0 - 02/2018

Page 55

Setup

7Setup

WARNING

Risk of injury!

The machine may only be set up by trained

specialists.

Wear safety gloves and safety shoes when

unpacking and setting up.

7.1 Checking the scope of delivery

Important: The scope of delivery depends on your specific order.

1. Check that all parts are present before setup.

Standard equipme nt:

• Machine head

• Oil sump

• Reel stand with unwinding bracket

• Control unit

• Control panel

• Sewing lamp

Optional additional equipment:

•Table top

•Drawer

•Frame

• Pedal

• Knee switch

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 53

Page 56

Setup

(1) - Upper sections of the inner bars

(2) - Inner bars

(3) - Frame bars

(4) - Cross bar

(5) - Frame foot struts

(6) - Cross strut

(7) - Adjusting screw

(8) - Oil can holder

7.2 Removing the transport locks

All transport securing devices must be removed prior to setup.

1. Remove the lashing straps and wooden blocks from the

machine head, the table, and the frame.

2. Remove the support wedges between the machine arm and

throat plate.

7.3 Assembling frame components

Fig. 31: Assembling frame components

1

2

6

3

5

8

7

2

1

3

4

4

5

1. Screw the cross bar (4) onto the frame bars (3).

2. Screw the oil can holder (8) at the rear to the upper cross

bar (4).

3. Screw the cross strut (6) to the foot struts (5).

4. Insert the inner bars (2) in such a way that the longer end of

the head section (1) is above the longer end of the foot struts

(5).

5. Screw the inner bars (2) down so that both head sections (1)

are at the same height.

Important: Turn the adjusting screw (7) so that the frame has

even contact with the ground.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201854

Page 57

Setup

(1) - Cable duct

(2) - Recesses for lower

hinge parts

(3) - Drawer

(4) - Oil sump

(5) - Corner protrusions

(6) - Hole

(7) - Reel stand

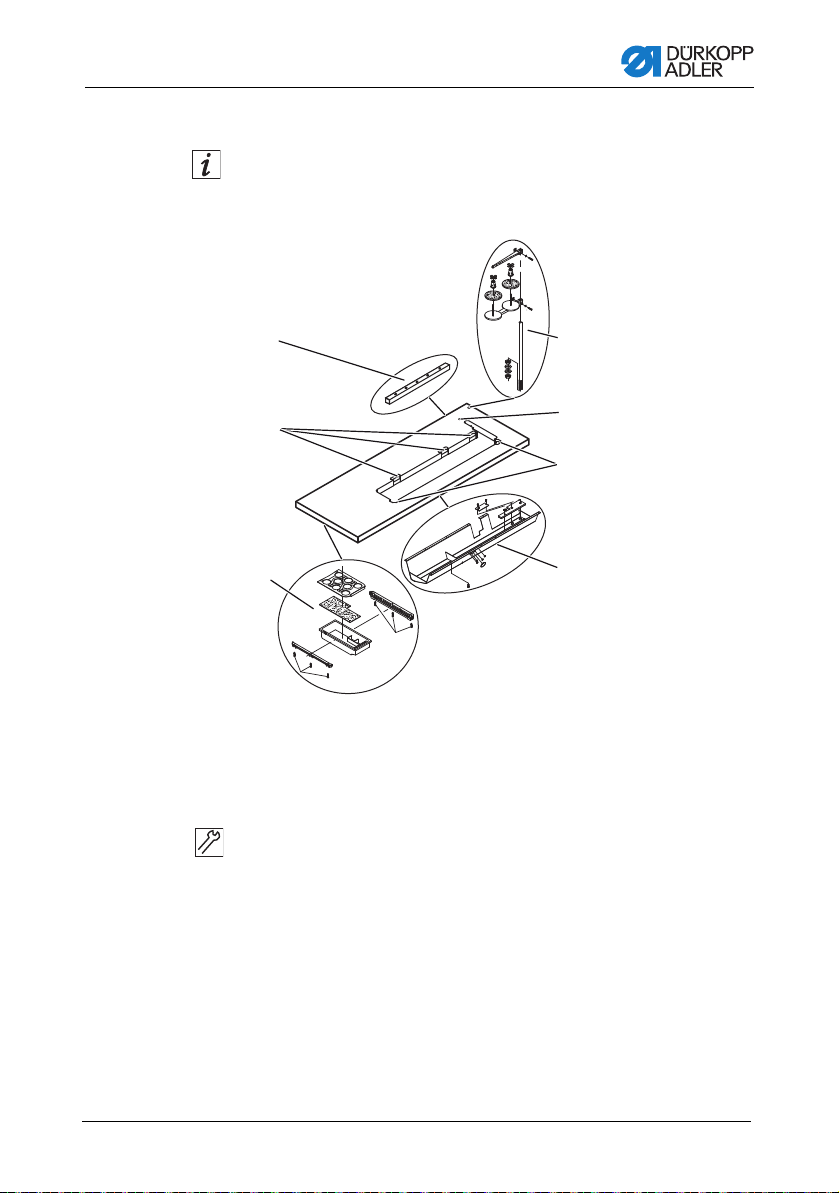

7.4 Completing the table top

The table top is optional.

For drawings that allow you to independently assemble a table

top, refer to the Appendix, p. 87.

Fig. 32: Completing the table top

1

2

3

7

6

5

4

1. Screw the drawer (3) with the left-hand bracket to the underside

of the table top.

2. Screw the oil sump (4) in place under the recess for the

machine.

3. Screw the cable duct (1) to the underside of the table top.

4. Insert the reel stand (7) into the hole.

5. Fasten the reel stand (7) with nut and washer.

6. Screw the thread reel holder and the unwinding bracket onto

the reel stand (7) in such a way that they are exactly on top of

each other.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 55

Page 58

7. Insert the blind plug to the hole (6).

1

1

(1) - Screw holes and screws

8. Fit the lower hinge parts into the recesses (2).

9. Fit the rubber corners in the corner protrusions (5).

7.5 Fastening the table top to the frame

Fig. 33: Fastening the table top to the frame

Setup

1. Place the table top on the head sections of the inner bars.

2. Screw the table top firmly with the screws (1) according to the

marks on the table top Tabl e top drawing, p. 95.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201856

Page 59

Setup

1

(1) - Screws

7.6 Setting the working height

The working height is continuously adjustable between 750 and

900 mm (clearance between the floor and upper edge of the table

top).

Fig. 34: Setting the working height

CAUTION

Risk of crushing!

The table top can sink under its own weight when

the screws on the frame bars are released. This

applies even more when the machine head is

already fitted.

Ensure that your hands are not jammed when

releasing the screws.

1. Release the screws (1) on the frame bars.

2. Set the table top to the desired height.

Important: Pull out or push in the table top evenly at both

sides to prevent it from jamming.

3. Tighten the screws (1) on the frame bars.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 57

Page 60

Setup

3

2

1

(1) - Strain relief (2) - Control unit

(3) - Screw holder

7.7 Controller

7.7.1 Fitting the control unit

Fig. 35: Fitting the control unit

1. Screw the control unit (2) onto the 4 screw holders (3) under the

table top.

2. Clamp the power cable of the control unit (2) into the strain

relief mechanism (1).

3. Screw the strain relief mechanism (1) under the table top.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201858

Page 61

Setup

SWG DAC

10°

1

2

3

6

5

4

(1) - Pedal rod

(2) - Screw

(3) - Cross strut

(4) - Pedal

(5) - Setpoint device

(6) - Bracket

7.7.2 Fitting the pedal and setpoint device

Fig. 36: Fitting the pedal and setpoint device

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 59

1. Fit the pedal (4) on the cross strut (3) and align it in such a

way that the middle of the pedal is under the needle. The cross

strut has elongated holes to allow alignment of the pedal.

2. Screw the pedal (4) firmly onto the cross strut (3).

3. Screw the bracket (6) under the table top so that the pedal rod

(1) runs to the pedal (4) at right-angles to the setpoint device

(5).

4. Screw the setpoint device (6) onto the bracket (5).

5. Hang the pedal rod (1) with the ball socket on the setpoint

device (5) and attach to the pedal (4).

6. Pull the pedal rod (1) to the correct length:

Proper setting: 10° inclination with pedal (4) released

7. Tighten the screw (2).

Page 62

7.8 Mounting the machine head

(3) - Locking plate

①

②

③

Fig. 37: Mounting the machine head

CAUTION

Risk of crushing!

The machine head is very heavy.

Take care not to jam your hands when fitting the

machine head.

This especially applies when fitting the upper

hinge parts into the rubber inlays.

Setup

1. Screw the upper hinge parts (1) onto the machine head.

2. Insert the machine head vertically in the recess in the table top.

3. Insert the upper hinge parts (1) into the rubber inlays (2).

4. Above the right hinge place the locking plate (3) and screw it

with two screws to the table.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201860

Page 63

Setup

(1) - Tube of the oil extraction line (2) - Filter

(1) - Tilt sensor (2) - Screws

①

②

7.9 Fitting the oil extraction line

Fig. 38: Fitting the ooil extraction line

1

2

1. Tilt the machine head.

2. Screw the filter (2) into the oil sump with the plastic adapter

to the right.

3. Insert the tube of the oil extraction line (1) into the plastic

adapter.

7.10Fitting the tilt sensor

Fig. 39: Fitting the tilt sensor

1. Tilt the machine head.

2. Place the tilt sensor (1) into the groove in the table top.

3. Screw the tilt sensor (1) with two screws (2).

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 61

Page 64

Setup

(1) - Knee switch

(2) - Connecting cable

(3) - Plug

7.11Installing the knee switch

Fig. 40: Installing the knee switch

1

2

3

1. Screw the knee switch (1) in front of the oil sump firmly in place

under the table top.

2. Guide the connecting cable (2) to the back between the oil

sump and the control unit.

3. Insert the plug (3) of the connecting cable in the socket of

the control unit.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201862

Page 65

Setup

(1) - Control panel

(2) - Connecting cable plug

(3) - Control panel bracket

①

②

③

7.12Fitting the control panel

Fig. 41: Fitting the control panel

1. Screw the control panel (1) firmly onto the control panel bracket

(3).

2. Insert the plug (2) of the connecting cable in the socket of the

control panel (1).

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 63

7.13Electrical connection

DANGER

Risk of death from electric shock!

The machine may only be connected by trained

electricians.

Disconnect the power plug before carrying out

work on the electrical equipment.

Make sure the power plug cannot be accidentally

plugged back in.

The voltage on the type plate of the sewing drive

must correspond to the mains voltage.

Page 66

Setup

(1) - Sewing lamp transformer

①

7.13.1 Checking the mains voltage

Important: The voltage on the type plate of the sewing drive must

correspond to the mains voltage.

1. Check the mains voltage before connecting the machine.

7.13.2 Fitting and connecting the sewing lamp and

sewing lamp transformer

DANGER

Risk of death from electric shock!

When you disconnect the sewing machine from

the power supply at the main switch, the supply

voltage for the sewing lamp remains active.

Pull out the power plug before fitting and

connecting the sewing lamp and sewing lamp

transformer.

Make sure the power plug cannot be accidentally

plugged back in.

Fitting the sewing lamp transformer

Fig. 42: Fitting the sewing lamp transformer

1. Screw the sewing lamp transformer (1) in place at the predrilled holes under the table top.

2. Fasten the connecting cable under the table top using cable ties.

3. Establish the plug connection to the supply line for the sewing

lamp.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201864

Page 67

Setup

4

1

2

2

3

(1) - Screw holder

(2) - Adapter cover screws

(3) - 24V/X5 port

(4) - X3 port

Connecting the sewing lamp transformer

Fig. 43: Connecting the sewing lamp transformer

1. Loosen the screw holder(4) for the controller far enough to

allow the controller to be removed..

2. Remove the controller.

3. Loosen the adapter cover screws (3).

4. Connect the supply line:

• for additional sewing lamps to be fitted to the

X3 port (1)

• f or integrated LED sewing lamps connected to

the 24V/X5 port (2)

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 65

Page 68

Setup

(1) - Nut (2) - Protective earth connection

①

②

7.13.3 Establishing equipotential bonding

DANGER

Risk of death from electric shock!

Disconnect the power plug before establishing

equipotential bonding.

Make sure the power plug cannot be accidentally

plugged back in.

The protective earth conductor conducts away any static charging

of the machine head.

Fig. 44: Establishing equipotential bonding

1. Unscrew the nut (1).

2. Place the loop of grey motor cable on the protective earth

connection (2).

3. Screw and tighten the nut (1).

Information

If is mounted the knee switch with the protective earth cable on

the machine, it must be connect to control unit in the same way.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201866

Page 69

Setup

7.13.4 Connec ting the control unit

NEBEZPEČÍ

Risk of death from electric shock!

Disconnect the power plug before connecting the

control unit.

Make sure the power plug cannot be accidentally

plugged back in.

Connect the control unit as follows:

• Insert the plug of each connecting cable into the sockets on

the back of the control unit.

• Connect the control unit to the power supply using the power

cable.

1. Connect the control unit as specified in the interconnection

diagram, Interconnection diagram, p. 88

7.14Lubrication

WARNING

Skin damage due to contact with oil!

Oil can cause a rash if it comes into contact with

skin.

Avoid any skin contact with the oil.

If oil has come into contact with your skin, wash

the affected areas thoroughly.

All wicks and felt bits of the machine head are soaked in oil at the

factory. This oil is conveyed to the reservoir during use. This is

why you should avoid filling too much oil during initial filling.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 67

Page 70

Setup

MAX

MIN

1

2

3

(1) - Filler opening

(2) - Maximum level marking

(3) - Minimum level marking

Fig. 45: Oil level indicator

1. Fill oil through the filler hole (1) to a maximum of 2 mm below

the maximum level marking (2).

NOTICE

MMachine damage possible due to incorrect oil level.

Too little or too much oil can damage the machine.

During initial filling, only pour in oil up to 2 mm below the

maximum level marking.

Required oil:

Only DA 10 or equivalent oil should be used for the machine, which

has the following properties:

• Viscosity at 40 °C: 10 mm²/s

• Flash point: 150 °C

NOTICE

Machine damage possible due to incorrect oil.

An incorrect oil type can cause damage to the machine.

Only use oil specified in the operating instructions.

CAUTION

Risk of pollution from oil.

Oil is a pollutant and must not enter the sewage

system or the soil.

Collect waste oil carefully and dispose of it and

oily machine parts in accordance with the

applicable statutory regulations.

Operating Instructions 878-M PREMIUM - 02.0 - 02/201868

Page 71

Setup

7.15Sewing test

Conduct a sewing test before starting up the machine. Adjust the

machine to the sewing material requirements.

To do this, read the corresponding sections in the Instructions

for use. Read the corresponding chapters in the Service instructions in order to make adjustments to the machine if the

sewing results do not conform to the requirements.

WARNING

Risk of injury from needle and moving parts!

Switch off the sewing machine before replacing

the needle, inserting the thread, inserting the

hook thread bobbin, and adjusting the hook

thread tension and the thread regulator.

Performing a sewing test

1. Insert needle.

2. Wind on the hook thread.

3. Insert the hook thread bobbin.

4. Thread hook thread.

5. Thread needle thread.

6. Set thread tension to material being sewn.

7. Adjust the thread regulator to the material to be sewn.

8. Set top roller pressure to material being sewn.

9. Set top roller stroke to material being sewn.

10.Set stitch length.

11.Transfer the desired quick function from the keypad to the

additional switch.

12.Start sewing test at low speed.

13.Gradually increase sewing speed until working speed is

reached.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 69

Page 72

Setup

Operating Instructions 878-M PREMIUM - 02.0 - 02/201870

Page 73

Settings via the software

A

B

8 Settings via the software

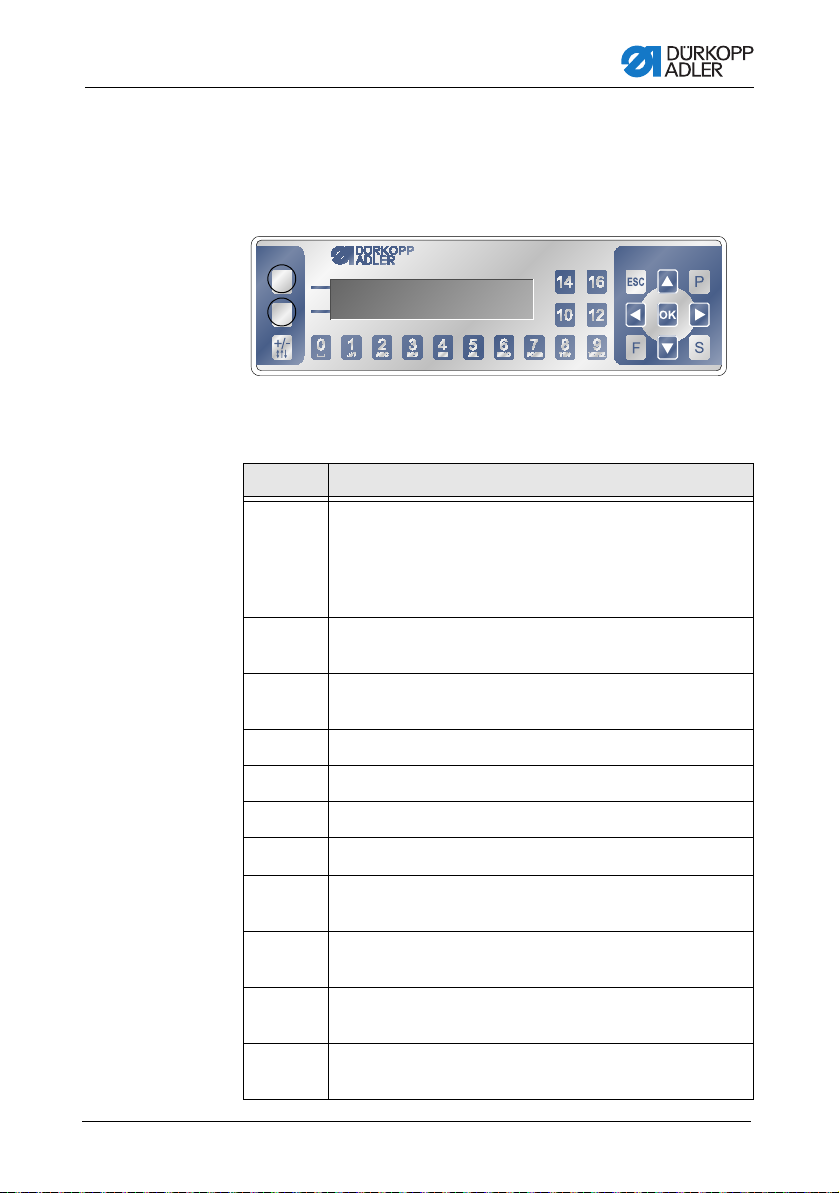

8.1 OP3000 control panel

Fig. 46: Control panel

All settings in the controller for the 878-M PREMIUM are performed

using the OP3000 control panel.

Key Function

0 to 9 Inputting the parameter value (if the field for the parameters

ESC Cancel the function

is activated)

Selection of a parameter that is shown on the display

• Press the key under the desired symbol.

The function is selected.

Exit the menu (changes remain saved)

OK Confirm the settings

Activate the input

P Function is different for each menu

S Function is different for each menu

F Function is different for each menu

A Upper softkey

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 71

Selection to the right

Selection to the left

Back one menu level

Increase the value

Scroll through the list (upwards)

Decrease the value

Scroll through the list (downwards)

Assignment is different for each menu

Page 74

Settings via the software

878

2016

2016

Key Function

B Down softkey

+/- Altering sense of difference feed

Information

For more information on setting control DAC Comfort can be found

in the relevant parameter sheets.

8.2 Switching the sewing machine on

Fig. 47: Display of the firmware and software version

1. Switch the main switch on.

The displ ay show s the software version:

• On the left of the screen the control panel firmware

• On the right of the screen the controller software version

The machine performs a reference run:

The display shows the program last used, or manual mode.

Fig. 48: Display of the program last used

Fig. 49: Display in Manual mode

Operating Instructions 878-M PREMIUM - 02.0 - 02/201872

Page 75

Settings via the software

8.3 Controller operating modes

The controller of the 878-M PREMIUM has 3 available

operating modes:

• Manual mode (program 000)

• Automatic mode (program 001 - 999)

• Programming/edit mode

Manual mode is the simplest operating mode.

There are no sewing programs and no inputs for individual

sewing sections.

Changes to the top roller pressure, stroke height, stitch

length, thread tension and also the activation of other functions are always implemented immediately.

All the major sewing parameters can be changed manually

during the sewing process.

Automatic mode allows for the execution of setups (seam

program comprised of only one seam section) or complex

seam programs.

Seam programs are divided into individual sections. Each

section is assigned its own individual stitch length, thread tension, etc.

Programming mode allows the operator to create a new

seam program in a quick and easy manner (P flashes above

the program number).

Edit mode can be used to change, delete and copy seam

programs.

Operating Instructions 878-M PREMIUM - 02.0 - 02/2018 73

Page 76

Settings via the software

8.4 Manual mode

Fig. 50: Parameters in manual mode

The following table shows the individual symbols (parameters) on

the display and the functions of the keys on the control panel.

When a parameter is selected, its color on the display changes.

When a parameter is changed, its new value is loaded immediately.

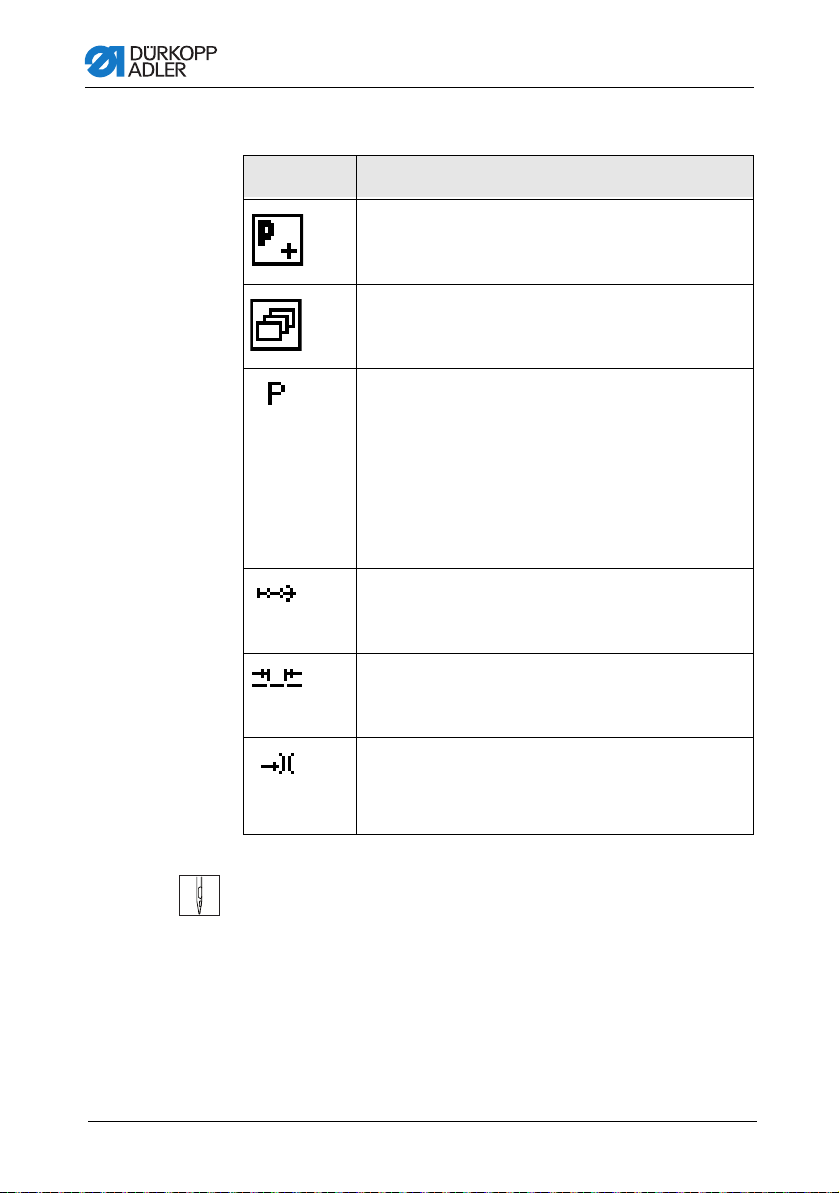

Symbol Meaning

(depending on the assignment)

Programming

• Press the upper softkey

Quick access function (softkey menu)

• Press the lower softkey,

tion (softkey menu), str. 76.

Program number

Value range: 000 to 999

Program 000 indicates that the controller is in Manual

mode.

/ to select the Program parameter.

•Use

/ to change the program number.

•Use

Or:

• Input the program number directly using the keys

0 to 9 and confirm with OK as required.

This takes you into Automatic mode.

8.4.1 Quick access func-

Stitch length

Value range: 0.0 to 7.0 mm (depending on the sewing

equipment)

/ to select the Stitch length parameter.

•Use

/ to change the stitch length

•Use

Thread tension (only for electronic tension plate)

Value range: 1 to 99

•Use

/ to select the Thread tension parameter.

/ to change the thread tension

•Use

Operating Instructions 878-M PREMIUM - 02.0 - 02/201874

Page 77

Settings via the software

Symbol Meaning

P Creating a program

Top roller pressure

Value range: 1 to 14

/ to select the Top roller pressure parame-

•Use

ter.

•Use

/ to change the top roller pressure