Page 1

867

867-M

867-M PREMIUM

Additional Instructions

Remaining thread monitor

Page 2

IMPORTANT

READ CAREFULLY BEFORE USE

KEEP FOR FUTURE REFERENCE

All rights reserved.

Property of Dürkopp Adler AG and protected by copyright. Any reuse of these contents,

including extracts, is prohibited without the prior written approval of Dürkopp Adler AG.

Copyright © Dürkopp Adler AG 2018

Page 3

Table of Contents

1 General information ...................................................................3

1.1 Components of the kit...................................................................3

1.2 Kits for M-TYPE PREMIUM..........................................................5

2 Assembling the remaining thread monitor .............................. 6

2.1 Assembling the remaining thread monitor....................................6

2.2 Connecting the remaining thread monitor ....................................7

2.2.1 Connecting the remaining thread monitor

on Classic machines.....................................................................7

2.2.2 Connecting the remaining thread monitor

on PREMIUM machines ............................................................. 10

2.3 Setting the remaining thread monitor electrically........................ 12

2.4 Software settings........................................................................14

2.4.1 Parameter settings for classes 867 and 867-M..........................14

2.4.2 Parameter settings for class 867-M PREMIUM..........................16

Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018 1

Page 4

Table of Contents

2 Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018

Page 5

General information

1 General information

The remaining thread monitor (RTM) can be used with all 1-needle and

2-needle machines equipped with a thread cutter.

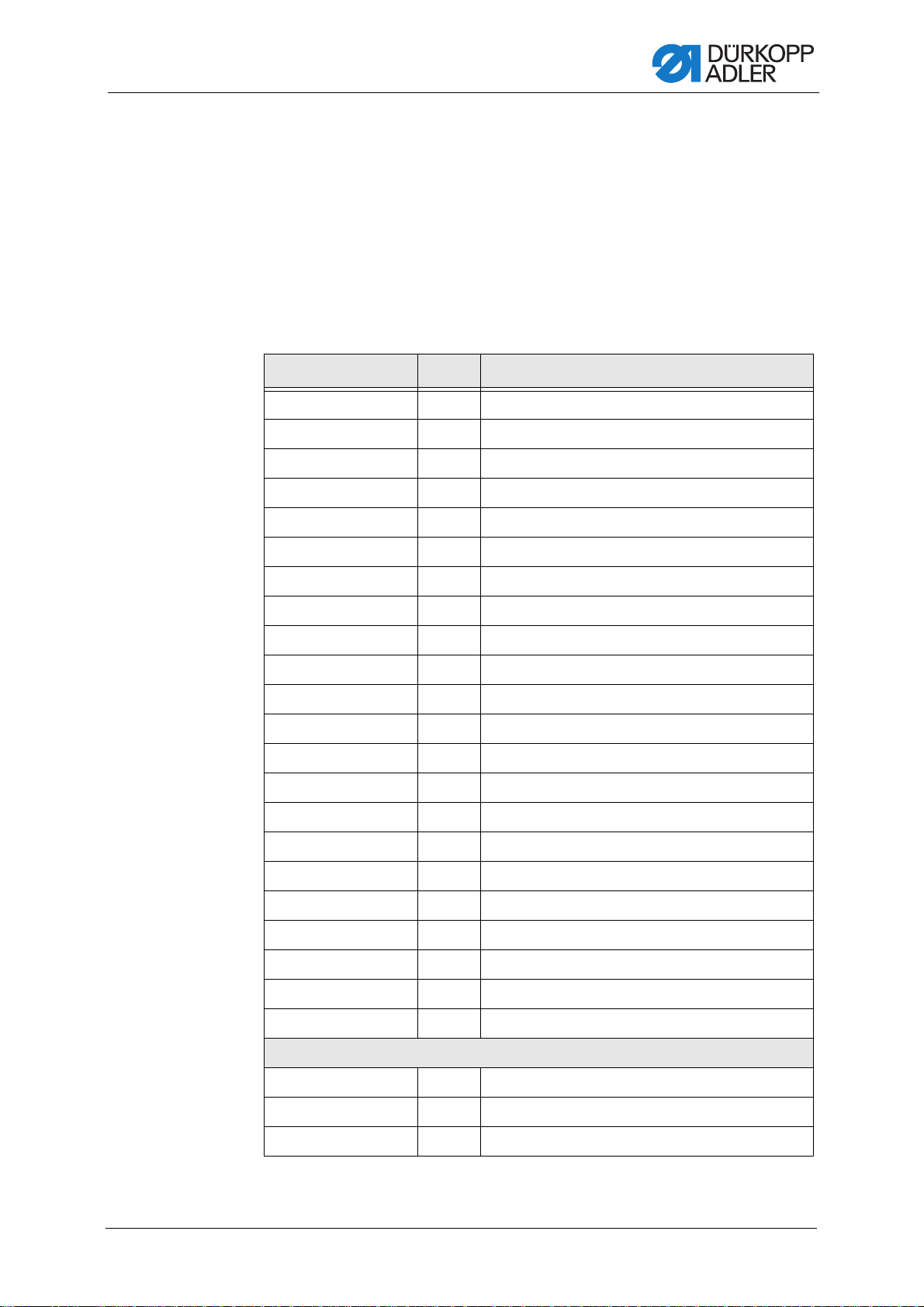

1.1 Components of the kit

Check whether the scope of delivery for the kit is correct prior to installation.

The different kits for the remaining thread monitor differ in some parts, which

are listed separately below.

Part number Quantity Description

0667 155824 1 RTM carrier

0699 979265 1 Hose PUR, 0.9 m

9840 120106 3 Cable holder

9815 925002 1 Light barrier

9850 867003 1 Circuit board

9870 867003 1 Cable (RTM cable machine head)

9870 367003 1 Cable (367 valve)

0667 155840 1 Holder

9204 201667 8 Pan-head screw M4x10-H

9830 501010 4 Spacer

9710 900031 1 Connection plate

091 1 000478 1 O-ring

0999 240389 1 Hose connector

9203 003097 2 Cylinder-head bolt M3x16

9204 200517 2 Pan-head screw M2x20-H

9710 061200 1 Magnet valve

0667 155930 1 Cover

9203 003157 2 Cylinder-head bolt M3x30

9710 982003 1 Silencer

9840 121002 3 Cable tie

9840 120025 2 Mounting clip

0791 867720 EN 1 Additional Instructions

Kit 0867 590104

9202 002077 1 Cylinder-head bolt M4x10

0767 150170 3 Bobbin

0867 150240 3 Bobbin

Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018 3

Page 6

Part number Quantity Description

0867150170 1 Compression spring

0570 001847 1 Blanking plug

9203 003177 2 Cylinder-head bolt M3x40

9231 000347 2 Hexagon nut

Kit 0867 590114

0667 156014 1 Bobbin case

0667 155614 1 Bobbin case

9202 002078 1 Cylinder-head bolt M4x10

0667 150880 3 Bobbin

0867 150560 3 Bobbin

0867 150170 1 Compression spring

0570 001847 1 Blanking plug

General information

9203 003177 2 Cylinder-head bolt M3x40

9231 000347 2 Hexagon nut

Kit 0867 590124

9202 002077 2 Cylinder-head bolt M4x10

0767 150170 6 Bobbin

0867 150240 6 Bobbin

9790 030020 1 Y-connection

0667 155594 2 Bobbin case

0867 150170 2 Compression spring

Kit 0867 590134

0667 156014 2 Bobbin case

0667 155614 2 Bobbin case

9202 002078 2 Cylinder-head bolt M4x10

0667 150880 6 Bobbin

0867 150560 6 Bobbin

9790 030020 1 Y-connection

0867 150170 2 Compression spring

4 Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018

Page 7

General information

1.2 Kits for M-TYPE PREMIUM

Important

Machines of the M-TYPE PREMIUM class are not equipped with

compressed air. If you want to assemble the remaining thread monitor

to a PREMIUM machine, you will need the following additional kits:

(see Parts List):

• 9780 000108: Compressed air maintenance unit

• 0867 593534: Pneumatic connection PREMIUM

• 0797 003031: Pressure line K

Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018 5

Page 8

Assembling the remaining thread monitor

①

②

③

④

①

①

②

③

2 Assembling the remaining thread monitor

WARNING

Risk of injury from sharp and moving parts!

Puncture or crushing possible.

Switch off the machine before assembling the

residual thread monitor.

2.1 Assembling the remaining thread monitor

Fig. 1: Assembling the remaining thread monitor (1)

(1) - Remaining thread monitor

(2) - Hose

To assemble the remaining thread monitor:

1. Remove old bobbin case and replace it with the new bobbin case from

the kit.

2. Tighten the pre-assembled carriers (4) using the screws (3).

As a rule, the front edge of the remaining thread monitor (1) must be

assembled parallel to the front edge of the carrier (4).

3. Connect the hose (2) used for the blow-off.

(3) - Screws

(4) - Carrier

6 Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018

Page 9

Assembling the remaining thread monitor

②③

①

ABC

4. Set the position of the remaining thread monitor (1) so that the light

beam hits the reflective surface of the bobbin through the slot in the

bobbin case.

2.2 Connecting the remaining thread monitor

2.2.1 Connecting the remaining thread monitor on Classic machines

Fig. 2: Connecting the remaining thread monitor on Classic machines (1)

(1) - Remaining thread monitor carrier plate

(2) - Circuit board

(3) - Spacer

To connect the remaining thread monitor:

1. Insert spacer (3) into the holes of the remaining thread monitor carrier

plate (1).

2. Attach the circuit board (2).

3. Connect the cables to the circuit board (2):

• A = Valve circuit board

• B = Light barrier, left needle

• C = Light barrier, right needle

Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018 7

Page 10

Assembling the remaining thread monitor

④⑤

⑥

⑦

X24

Fig. 3: Connecting the remaining thread monitor on Classic machines (2)

(4) - Cable clamps (5) - Screw

4. Fasten the cables with the cable clamps (4) to the base plate of the

remaining thread monitor control.

5. Screw the remaining thread monitor carrier plate (1) with the circuit

board (2) into the base plate using the screws (5).

Fig. 4: Connecting the remaining thread monitor on Classic machines (3)

(6) - Cable (7) - Cable holder

6. Route the cable (6) through the cable holder (7) in the machine arm:

8 Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018

from the remaining thread monitor control to the valve circuit board.

7. Connect the cable (6) to plug connection X24 of the valve circuit board.

8. Guide the cables of the remaining thread monitors through the holes

in the base plate and fix them to the existing cables with cable tie.

Page 11

Assembling the remaining thread monitor

⑩

⑧⑨

X22

9. Roll up the remaining thread monitor cables that are too long and fix

them to the base plate of the remaining thread monitor control with

cable ties.

Fig. 5: Connecting the remaining thread monitor on Classic machines (4)

(8) - Y-connection

(9) - Hoses

10. Assemble the valve (10).

Ensure that the sealing washer is in the correct position when doing this.

11. Disassemble the valve unit.

12. Screw the valve (10) to the valve rail.

13. Assemble the valve unit.

14. Connect the hoses (9) of the remaining thread monitor to the valve.

With right AND left remaining thread monitor: Connect hoses (9)

to Y-connection (8).

15. Assemble hoses and cables with clips to the oil return line and to the

knee lever shaft.

16. Connect the magnet valve electrically to the valve circuit board.

• X22, PIN 1/7/8 (+) and PIN4 (FL)

OR

• X22, PIN 1/7/8 (+) and PIN2 (FA)

(10) - Valve

Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018 9

Page 12

Assembling the remaining thread monitor

①

2.2.2 Connecting the remaining thread monitor on PREMIUM machines

To connect the remaining thread monitor:

• For XXX PREMIUM machines: Remove the valve cover

• For XXX-M PREMIUM machines: Remove the motor cover

Fig. 6: Connecting the remaining thread monitor on PREMIUM machines (1)

(1) - Circuit board

1. Loosen the circuit board (1).

To do so, push the circuit board (1) down and off the white spacers.

2. Screw the connection plate and magnet valve together.

10 Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018

Page 13

Assembling the remaining thread monitor

②

③

④

①

⑤⑥⑦

Fig. 7: Connecting the remaining thread monitor on PREMIUM machines (2)

(1) - Circuit board

(2) - Magnet valve

3. Insert the magnet valve (2) into socket X16 on the circuit board (1).

If socket X16 is already occupied, use socket X17 or socket X18.

4. Assemble the circuit board (1).

5. Tighten the connection plate (4) on the holder (3).

Fig. 8: Connecting the remaining thread monitor on PREMIUM machines (3)

(3) - Holder

(4) - Connection plate

(5) - Compressed air maintenance unit

(6) - Hose

(7) - Valve

Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018 11

Page 14

Assembling the remaining thread monitor

①②③

⑦⑧④⑤⑥

6. Assemble the compressed air maintenance unit (5) to the stand.

7. Use an R 1/4” hose coupling to connect the connection hose to

the compressed air supply.

8. Set the operating pressure to 6 bar.

9. Connect the hose (6) to the valve (7).

2.3 Setting the remaining thread monitor electrically

Important

The remaining thread monitor is delivered with a basic setting.

As a rule, the sensitivity of the residual thread monitor does NOT have

to be set!

The pre-set sensitivity of the remaining thread monitor may only be

changed if the remaining thread monitor is not working properly.

Fig. 9: Setting the remaining thread monitor electrically

(1) - Plug connection light barrier,

right hook

(2) - Plug connection light barrier,

left hook

(3) - Plug connection inputs and outputs

of the control

(4) - Plug connection switched output

(5) - Potentiometer left hook

(6) - LED

(7) - Potentiometer right hook

(8) - Plug connection auxiliary output

After the machine has been switched on and before it starts sewing, the

remaining thread monitor is in setting mode.

To set the remaining thread monitor:

1. Switch on the machine.

2. Insert an empty bobbin into the hook.

3. Turn the hook to a position that the light beam falls through the slot in

the hook housing onto the bobbin.

4. Set the potentiometer (5) or (7) to the highest sensitivity.

To do this, turn the potentiometer clockwise.

12 Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018

Page 15

Assembling the remaining thread monitor

5. Turn the hook until the light beam hits the reflective surface on the

bobbin.

The LED (6) lights up for 1 second with each reflection in the setting

mode.

The output to the control and the auxiliary output are switched on.

6. Turn potentiometer (5) or (7) counterclockwise to reduce the sensitivity

until the reflection can just be detected.

When sewing begins, the system leaves setting mode automatically.

Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018 13

Page 16

Assembling the remaining thread monitor

2.4 Software settings

2.4.1 Parameter settings for classes 867 and 867-M

DAC classic control

Parameter Value Function

Operator level

o 06 00 4 Remaining thread monitor

o 06 05 0 - 9999 Number of stitches for the remaining thread

monitor

o 06 06 0 - 1 Stop sewing motor when the counter

reaches 0

0 = No

1 = Yes

o 06 07 0 - 1 Sewing foot stays down after thread cutting

0 = No

1 = Yes

Technician level

t 06 00 0 - 2 Activation of the remaining thread monitor

0 = Off

1 = Right

2 = Left & right

t 06 01 0 - 1 Remaining thread monitor mode

0 = Dynamic

1=Static

t 06 02 0.0 - 3.300 V Threshold right

t 06 03 0.0 - 3.300 V Intensity right

t 06 04 0.0 - 3.300 V Threshold left

t 06 06 0.0 - 3.300 V Intensity left

t 06 06 0 - 1 Confirmation required after warnings

0 = No

1 = Yes

14 Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018

Page 17

Assembling the remaining thread monitor

Efka control (class 867 only)

Recommended mode for remaining thread monitor function:

Parameter F-195 on value "3"

Parameter Value Function

F-195 0 Remaining thread monitor off

F-195 1 No stop after 1st detection Bobbin empty,

F-195 2 With stop after 1st detection Bobbin empty,

F-195 3 With stop after 1st detection Bobbin empty,

F-195 4 Hook thread monitoring via preset number

F-195 1 - 3

after thread cutting, sewing foot down

after thread cutting, sewing foot up

after thread cutting, sewing foot down

of stitches

Light barrier remaining thread monitor control

without function

085 0 - 9990 Number of stitches for remaining thread

Count from 1st detection Bobbin empty

until stop

F-195 4

085 0 - 9990 Number of stitches A for hook thread

monitoring

Pre-set number of stitches is counted

downwards to "0". When the value "0" is

reached: Stop at value 0 and after thread

cutting sewing foot down.

086 0 - 9990 Number of stitches B for hook thread

monitoring

Pre-set number of stitches is counted

downwards to "0". When the value "0" is

reached: Stop at value 0 and after thread

cutting sewing foot down.

086 0 - 9990 Number of stitches C for hook thread

monitoring

Pre-set number of stitches is counted

downwards to "0". When the value "0" is

reached: Stop at value 0 and after thread

cutting sewing foot down.

Information

A detailed functional description of the remaining thread monitor functions

and the stitch counts can be found in the instructions for use of the DA82GA

or DA321G controls.

Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018 15

Page 18

Assembling the remaining thread monitor

2.4.2 Parameter settings for class 867-M PREMIUM Important

PREMIUM machines require that the valve output be enabled for electropneumatic needle cooling via software.

To enable the valve output via software:

1. Call up the Technician level.

• Switch on the machine.

• Press the P and S buttons at the same time.

• Enter password (25483).

You are on the Technician level:

2. Open the submenu User config. > Output Config and select

the parameter T 56 00.

3. Assign mode 2 (cleaning signal for RTM) to the output to which the

remaining thread monitor is connected.

Machine output signal Output

RA (X16) X120B.12

STL (X17) X120B.22

STL (F A) (X18) X120B.23

16 Additional Instructions 867/867-M PREMIUM - 00.0 - 07/2018

Page 19

Page 20

DÜRKOPP ADLER AG

Potsdamer Str. 190

33719 Bielefeld

Germany

Phone: +49 (0) 521 925 00

Email: service@duerkopp-adler.com

www.duerkopp-adler.com

Subject to design changes - Part of the machines shown with additional equipment - Printed in Germany

© Dürkopp Adler AG - Additional Instructions - 0791867720 EN - 00.0 - 07/2018

Loading...

Loading...