Page 1

669 ECO / CLASSIC

Operating Instructions

Page 2

IMPORTANT

READ CAREFULLY BEFORE USE

KEEP FOR FUTURE REFERENCE

All rights reserved.

Property of Dürkopp Adler AG and protected by copyright.

Any reuse of these contents, including extracts, is prohibited without the

prior written approval of Dürkopp Adler AG.

Copyright © Dürkopp Adler AG 2019

Page 3

Table of Contents

1 About these instructions ....................................................................5

1.1 For whom are these instructions intended? .......................................... 5

1.2 Representation conventions – symbols and characters........................6

1.3 Other documents...................................................................................7

1.4 Liability .................................................................................................. 8

2 Safety....................................................................................................9

2.1 Basic safety instructions........................................................................9

2.2 Signal words and symbols used in warnings.......................................10

3 Machine description..........................................................................15

3.1 Components of the machine ...............................................................15

3.2 Proper use...........................................................................................17

3.3 Declaration of Conformity.................................................................... 18

4 Operation ...........................................................................................19

4.1 Preparing the machine for operation ...................................................19

4.2 Inserting or changing the needle.........................................................20

4.3 Threading the needle thread ............................................................... 22

4.4 Winding the bobbin thread .................................................................. 23

4.5 Changing the bobbin ...........................................................................24

4.6 Thread tension ....................................................................................26

4.6.1 Setting the needle thread tension........................................................ 27

4.6.2 Function of the main thread tension and the additional thread

tension depending on the sewing foot lift (optional) ............................29

4.6.3 Function of the additional thread tension depending on the stroke

adjustment and the Speedomat (optional) ..........................................30

4.6.4 Opening the needle thread tension .....................................................31

4.6.5 Switching on and off the supplementary thread tension (optional)......32

4.6.6 Setting the hook thread tension...........................................................33

4.7 Setting the needle thread regulator ..................................................... 34

4.8 Sewing feet.......................................................................................... 35

4.8.1 Lifting the sewing feet.......................................................................... 35

4.8.2 Locking the sewing feet at top dead center .........................................36

4.8.3 Setting the sewing foot pressure.........................................................37

4.8.4 Setting the sewing foot stroke ............................................................. 38

4.9 Setting the stitch length....................................................................... 42

4.10 Buttons on the machine arm ...............................................................43

4.11 Tilting the machine head .....................................................................45

4.12 Folding down the tabletop (optional) ...................................................46

4.13 Sewing.................................................................................................48

4.13.1 Sewing with machines using the F

IR clutch positioning drive ............. 48

4.13.2 Sewing with machines using the Efka DC1550/DA321G

positioning drive ..................................................................................49

Operating Instructions 669 - 00.0 - 08/2019 1

Page 4

Table of Contents

5 Maintenance....................................................................................... 53

5.1 Cleaning .............................................................................................. 54

5.2 Lubricating...........................................................................................56

5.2.1 Checking the oil level in the machine head .........................................57

5.3 Servicing the pneumatic system..........................................................58

5.3.1 Setting the operating pressure ............................................................ 58

5.3.2 Draining the water condensation......................................................... 59

5.3.3 Cleaning the filter element...................................................................60

5.4 Checking the V-belt tension ................................................................ 61

5.5 Parts list...............................................................................................62

6 Setup ..................................................................................................63

6.1 Checking the scope of delivery ...........................................................63

6.2 Removing the transport locks..............................................................63

6.3 Assembling the stand ..........................................................................64

6.3.1 Assembling the stand MG 55-3 ...........................................................64

6.3.2 Assembling the stand MG 56-3 ...........................................................65

6.4 Table top .............................................................................................66

6.4.1 Completing the tabletop for stand MG 55-3 with FIR clutch motor...... 66

6.4.2 Completing the tabletop for stand MG 55-3 with direct drive ..............68

6.4.3 Completing the tabletop for stand MG 56-3 with FIR clutch motor...... 69

6.4.4 Completing the tabletop for stand MG 56-3 with direct drive ..............71

6.4.5 Assembling the tabletop to the stand MG 55-3 ...................................72

6.4.6 Assembling the tabletop to the stand MG 56-3 ...................................73

6.4.7 Assemble support on table plate with cut-out (stand MG 55-3) .......... 74

6.5 Setting the working height ...................................................................75

6.6 Putting on the machine head...............................................................77

6.7 Assembling the operating panel ..........................................................78

6.8 Assembling the sewing light ................................................................79

6.9 Setpoint device for the Direct drive .....................................................81

6.9.1 Assembling the setpoint device to the stand MG 55-3 and aligning

the pedal.............................................................................................. 81

6.9.2 Assembling the setpoint device to the stand MG 56-3 and aligning

the pedal.............................................................................................. 82

6.10 Putting on and tightening the V-belt (clutch motor FIR) ......................83

6.11 Assembling the knee switch ................................................................85

6.12 Assembling the Direct Drive ................................................................ 87

.12.1 Assembling the motor and putting on the V-belt .................................87

6

6.12.2 Connecting the Hall sensor .................................................................88

6.13 Electrical connection ...........................................................................90

6.13.1 Creating the equipotential bonding...................................................... 90

6.13.2 Connecting the clutch motor FIR to the mains voltage........................ 93

6.13.3 Rotational direction of the clutch motor FIR ........................................93

6.13.4 Connecting the sewing light transformator .......................................... 95

2 Operating Instructions 669 - 00.0 - 08/2019

Page 5

Table of Contents

6.13.5 Connecting the DC positioning drive to the mains voltage .................. 96

6.13.6 Rotational direction of the DC positioning drive .................................. 98

6.13.7 Machine-specific parameters ............................................................100

6.13.8 Connecting the sewing light ..............................................................101

6.14 Pneumatic connection .......................................................................102

6.14.1 Assembling the compressed air maintenance unit ............................103

6.14.2 Setting the operating pressure ..........................................................103

6.15 Performing a test run.........................................................................104

7 Decommissioning ...........................................................................105

8 Disposal ...........................................................................................107

9 Troubleshooting .............................................................................. 109

9.1 Customer Service..............................................................................109

9.2 Errors in sewing process ...................................................................110

10 Technical data .................................................................................113

10.1 Data and characteristic values ..........................................................113

10.2 Requirements for trouble-free operation ...........................................113

Operating Instructions 669 - 00.0 - 08/2019 3

Page 6

Table of Contents

4 Operating Instructions 669 - 00.0 - 08/2019

Page 7

About these instructions

1 About these instructions

These instructions have been prepared with utmost care.

They contain information and notes intended to ensure long-term

and reliable operation.

Should you notice any discrepancies or if you have improvement

requests, then we would be glad to receive your feedback through

Customer Service ( p. 109).

Consider the instructions part of the product and store them in a

place where they are readily available.

1.1 For whom are these instructions intended?

These instructions are intended for:

Service Instructions are supplied separately.

With regard to minimum qualification and other requirements to be

met by personnel, please also follow the chapter Safety ( p. 9).

• Operators:

This group is familiar with the machine and has access to

the instructions. Specifically, chapter

Operation ( p. 19) is important for the operators.

•Specialists:

This group has the appropriate technical training for performing maintenance or repairing malfunctions. Specifically, the

chapter Setup ( p. 63) is important for specialists.

Operating Instructions 669 - 00.0 - 08/2019 5

Page 8

About these instructions

1.

2.

...

•

1.2 Representation conventions – symbols and characters

Various information in these instructions is represented or highlighted by the following characters in order to facilitate easy and

quick understanding:

Proper setting

Specifies proper setting.

Disturbances

Specifies the disturbances that can occur from an incorrect setting.

Cover

Specifies which covers must be disassembled in order to access

the components to be set.

Steps to be performed when operating the machine (sewing

and equipping)

Steps to be performed for service, maintenance, and

installation

Steps to be performed via the software control panel

The individual steps are numbered:

First step

Second step

The steps must always be followed in the specified order.

Lists are marked by bullet points.

Result of performing an operation

Change to the machine or on the display/control panel.

Important

Special attention must be paid to this point when performing a step.

6 Operating Instructions 669 - 00.0 - 08/2019

Page 9

About these instructions

Information

Additional information, e.g. on alternative operating options.

Order

Specifies the work to be performed before or after a setting.

References

Reference to another section in these instructions.

Safety Important warnings for the user of the machine are specifically

marked. Since safety is of particular importance, hazard symbols,

levels of danger and their signal words are described separately

in the chapter Safety ( p. 9).

Location

information

If no other clear location information is used in a figure, indications

of right or left are always from the user's point of view.

1.3 Other documents

The machine includes components from other manufacturers.

Each manufacturer has performed a hazard assessment for these

purchased parts and confirmed their design compliance with

applicable European and national regulations. The proper use of

the built-in components is described in the corresponding manufacturer's instructions.

Operating Instructions 669 - 00.0 - 08/2019 7

Page 10

About these instructions

1.4 Liability

All information and notes in these instructions have been compiled

in accordance with the latest technology and the applicable standards and regulations.

Dürkopp Adler cannot be held liable for any damage resulting

from:

• Breakage and damage during transport

• Failure to observe these instructions

• Improper use

• Unauthorized modifications to the machine

• Use of untrained personnel

• Use of unapproved parts

Transport

Dürkopp Adler cannot be held liable for breakage and transport

damages. Inspect the delivery immediately upon receiving it.

Report any damage to the last transport manager. This also

applies if the packaging is not damaged.

Leave machines, equipment and packaging material in the condition in which they were found when the damage was discovered.

This will ensure any claims against the transport company.

Report all other complaints to Dürkopp Adler immediately after

receiving the product.

8 Operating Instructions 669 - 00.0 - 08/2019

Page 11

Safety

2 Safety

This chapter contains basic information for your safety. Read the

instructions carefully before setting up or operating the machine.

Make sure to follow the information included in the safety instructions. Failure to do so can result in serious injury and property

damage.

2.1 Basic safety instructions

The machine may only be used as described in these instructions.

The instructions should be available at the machine's location at

all times.

Work on live components and equipment is prohibited.

Exceptions are defined in the DIN VDE 0105.

For the following work, switch off the machine at the main switch

or disconnect the power plug:

• Replacing the needle or other sewing tools

• Leaving the workstation

• Performing maintenance work and repairs

• Threading

Missing or faulty parts could impair safety and damage the

machine. Only use original parts from the manufacturer.

Transport Use a lifting carriage or forklift to transport the machine. Raise the

machine max. 20 mm and secure it to prevent it from slipping off.

Setup The connecting cable must have a power plug approved in the

relevant country. The power plug may only be assembled to the

power cable by qualified specialists.

Obligations

of the operator

Operating Instructions 669 - 00.0 - 08/2019 9

Follow the country-specific safety and accident prevention regulations and the legal regulations concerning industrial safety and

the protection of the environment.

Page 12

Safety

All the warnings and safety signs on the machine must always be

in legible condition. Do not remove!

Missing or damaged warnings and safety signs must be replaced

immediately.

Requirements

to be met by

the personnel

Only qualified specialists may:

• set up the machine / put the machine in operation

• perform maintenance work and repairs

• perform work on electrical equipment

Only authorized persons may work on the machine and must first

have understood these instructions.

Operation Check the machine during operating for any externally visible

damage. Stop working if you notice any changes to the machine.

Report any changes to your supervisor. Do not use a damaged

machine any further.

Safety

equipment

Safety equipment should not be removed or deactivated. If it is

essential to remove or deactivate safety equipment for a repair

operation, it must be assembled and put back into operation

immediately afterward.

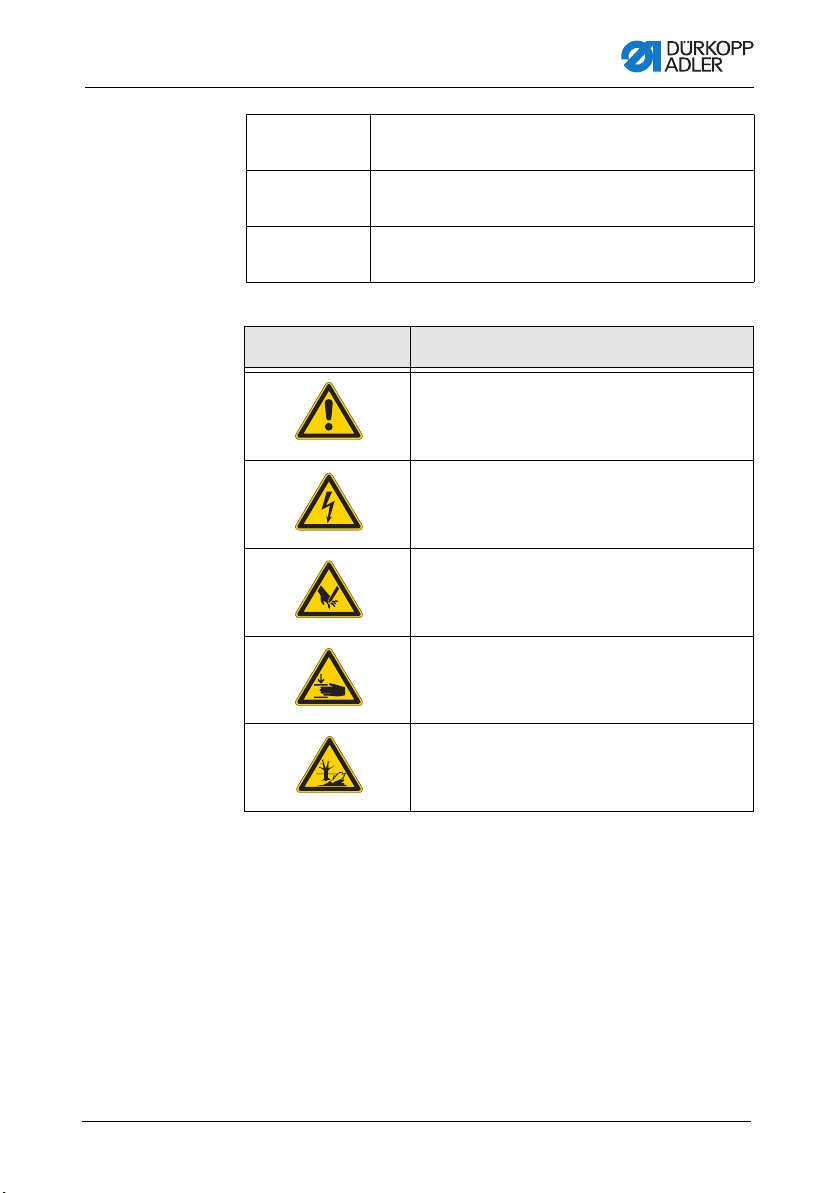

2.2 Signal words and symbols used in warnings

Warnings in the text are distinguished by color bars. The color

scheme is based on the severity of the danger. Signal words

indicate the severity of the danger.

Signal words Signal words and the hazard they describe:

Signal word Meaning

DANGER (with hazard symbol)

If ignored, fatal or serious injury will result

WARNING (with hazard symbol)

10 Operating Instructions 669 - 00.0 - 08/2019

If ignored, fatal or serious injury can result

Page 13

Safety

CAUTION (with hazard symbol)

If ignored, moderate or minor injury can result

CAUTION (with hazard symbol)

If ignored, environmental damage can result

NOTICE (without hazard symbol)

If ignored, property damage can result

Symbols The following symbols indicate the type of danger to personnel:

Symbol Type of danger

General

Electric shock

Puncture

Crushing

Environmental damage

Operating Instructions 669 - 00.0 - 08/2019 11

Page 14

Examples Examples of the layout of warnings in the text:

DANGER

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

This is what a warning looks like for a hazard that will result

in serious injury or even death if ignored.

WARNING

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

This is what a warning looks like for a hazard that could

result in serious or even fatal injury if ignored.

Safety

CAUTION

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

This is what a warning looks like for a hazard that could

result in moderate or minor injury if the warning is ignored.

12 Operating Instructions 669 - 00.0 - 08/2019

Page 15

Safety

NOTICE

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

This is what a warning looks like for a hazard that could

result in property damage if ignored.

CAUTION

Type and source of danger!

Consequences of non-compliance.

Measures for avoiding the danger.

This is what a warning looks like for a hazard that could

result in environmental damage if ignored.

Operating Instructions 669 - 00.0 - 08/2019 13

Page 16

Safety

14 Operating Instructions 669 - 00.0 - 08/2019

Page 17

Machine description

①

②

③

④

⑤

⑥

⑦

3 Machine description

3.1 Components of the machine

Fig. 1: Components of the machine (1), with stand MG 55-3

(1) - Stitch regulator

(2) - Knee switch

(3) - Pedal

(4) - Stand MG 55-3

(5) - Stitch length adjusting wheel

(6) - Reel stand

(7) - Winder

Operating Instructions 669 - 00.0 - 08/2019 15

Page 18

Machine description

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

Fig. 2: Components of the machine (2), with stand MG 56-3

(1) - Operating panel

(2) - Stitch regulator

(3) - Knee switch

(4) - Pedal

(5) - Compressed air maintenance

unit

(6) - Stand MG 56-3

(7) - Control

(8) - Stitch length adjusting wheels

(9) - Reel stand

(10)- Winder

16 Operating Instructions 669 - 00.0 - 08/2019

Page 19

Machine description

3.2 Proper use

WARNING

Risk of injury from live, moving and cutting

parts as well as from sharp parts!

Improper use can result in electric shock, crushing,

cutting and punctures.

Follow all instructions provided.

NOTICE

Non-observance will lead to property damage!

Improper use can result in material damage at the machine.

Follow all instructions provided.

The machine may only be used with sewing material that satisfies

the requirements of the specific application at hand.

The machine is intended only for use with dry sewing material.

The sewing material must not contain any hard objects.

The needle thicknesses permissible for the machine are listed in

the Technical data ( p. 43) chapter.

The seam must be completed with a thread that satisfies the

requirements of the specific application at hand.

The machine is intended for industrial use.

Operating Instructions 669 - 00.0 - 08/2019 17

Page 20

Machine description

The machine may only be set up and operated in dry conditions on

well-maintained premises. If the machine is operated on premises

that are not dry and well-maintained, then further measures may

be required which must be compatible with DIN EN 60204-31.

Only authorized persons may work on the machine.

Dürkopp Adler cannot be held liable for damages resulting from

improper use.

3.3 Declaration of Conformity

The machine complies with European regulations ensuring health,

safety, and environmental protection as specified in the declaration of conformity or in the declaration of incorporation.

18 Operating Instructions 669 - 00.0 - 08/2019

Page 21

Operation

4 Operation

The operating sequence consists of several different steps.

Fault-free operation is necessary in order to achieve a good

sewing result.

4.1 Preparing the machine for operation

WARNING

Risk of injury from moving, cutting and sharp

parts!

Crushing, cutting and punctures are possible.

If possible, make preparations only when the

machine is switched off.

Complete the following steps in preparation of sewing before

starting to work:

• Inserting/changing the needle

• Threading the needle thread

• Inserting and winding on the hook thread

• Setting the thread tension

Operating Instructions 669 - 00.0 - 08/2019 19

Page 22

4.2 Inserting or changing the needle

①

③

②

①②

WARNING

Risk of injury from sharp and moving parts!

Puncture possible.

Switch off the machine bevore changing the

needle.

NOTICE

Property damage may occur!

The insertion of a thinner needle can lead to skipped stitches

or damage to the thread!

The insertion of a thicker needle can result in damage to the

hook tip or the needle!

When switching to a different needle, adjust the clearance

between the hook and the needle.

Fig. 3: Inserting or changing the needle

Operation

(1) - Needle bar

(2) - Screw

20 Operating Instructions 669 - 00.0 - 08/2019

(3) - Groove

Page 23

Operation

To insert or change the needle:

1. Turn the handwheel until the needle bar (1) has reached its

highest position.

2. Loosen screw (2).

3. Pull the needle out from under the needle bar (1).

4. Push in the new needle until it reaches the limit stop in the

hole for the needle bar (1).

Important

The groove (3) must be pointing towards the hoo.

5. Tighten screw (2).

Operating Instructions 669 - 00.0 - 08/2019 21

Page 24

4.3 Threading the needle thread

⑥

⑦

⑧

⑨

⑩

⑪

①

②

③

④

⑤

WARNING

Risk of injury from sharp and moving parts!

Puncture or crushing possible.

Switch off the machine before threading the

needle thread.

Fig. 4: Thrading the needle thread

Operation

(1) - Guide

(2) - Guide

(3) - Pre-tensioner

(4) - Supplementary tensioner

(5) - Main tensioner

(6) - Guide

To thread the needle thread:

1. Put the reel on the reel stand and guide the needle thread

through the thread guide.

The thread guide must be perpendicular to the reel.

22 Operating Instructions 669 - 00.0 - 08/2019

(7) - Guide

(8) - Thread take-u p lev er

(9) - Guide

(10)- Needle thread regulator

(11)- Thread lever

Page 25

Operation

⑤⑥

①②②③④

2. Insert the thread through guide (1) and guide (2).

3. Pass the thread clockwise around the pre-tensioner (3).

4. Pass the thread counter-clockwise around the supplementary

tensioner (4).

5. Pass the thread clockwise around main tensioner (5).

6. Pull the thread under the thread take-up lever (8) and threafd

through the needle thread regulator (10) to the thread

lever (11).

7. Pass the thread through the needle thread lever (11) and

through guides (9) and (6) on the needle bar.

8. Pass the thread through the eye of the needle.

4.4 Winding the bobbin thread

Fig. 5: Winding the bobbin thread

(1) - Winder

(2) - bobbin winder lever

(3) - Guide

To wind the bobbin thread:

(4) - Tensioner

(5) - Guide

(6) - Blade

1. Put the reel on the reel stand. Guide the bobbin thread through

the thread guide.

2. Pull the thread through guide (5), tensioner (4), and guide (3).

3. Clamp the thread behind blade (6) and tear off.

Operating Instructions 669 - 00.0 - 08/2019 23

Page 26

Operation

①②③

4. Put the bobbin on the winder (1).

The thread does not need to be hand wound around the bobbin.

5. Press the bobbin winder lever (2) in the bobbin.

6. Sew.

The bobbin winder lever (2) ends the operation as soon as

the bobbin is full.

The bobbin winder (1) remains in position so that the blade (6)

is properly positioned

7. Take off the full bobbin. Clamp the thread behind the blade (6)

and tear off.

8. Put an empty bobbin on the bobbin winder for the next winding

process and press the bobbin winder lever (2) into the bobbin

4.5 Changing the bobbin

WARNING

Risk of injury from sharp and moving parts!

Puncture or crushing possible.

Switch off the machine before changing the

bobbin.

Fig. 6: Changing the bobbin (1)

(1) - Hook cover

(2) - Bobbin case retainer

24 Operating Instructions 669 - 00.0 - 08/2019

(3) - Bobbin enclosure

Page 27

Operation

②④⑤

③⑥⑦

To change the bobbin:

1. Raise the needle bar into its high position.

2. Pull out the hook cover (1) and fold dow.

3. Lift up the bobbin case retainer (2).

4. Take out the upper part of the bobbin enclosure (3) with the

bobbin.

5. Remove the empty bobbin from the upper part of the bobbin

enclosure (3).

Fig. 7: Changing the bobbin (2)

(2) - Bobbi n case retainer

(3) - Bobbin enclosure

(4) - Bobbin

(5) - Hole

(6) - Tension spring

(7) - Slot

6. Put a full bobbin in the upper part of the bobbin enclosure (3).

Please note the rotational direction of the bobbin.

The rotation is correct when the bobbin turns in the opposite

direction of the pulling direction of the thread.

7. Pull the hook thread through the slot (7) under the tension

spring (6) and then through the hole (5).

8. Pull out the tension spring (6) from the bobbin enclosure (3)

about 5 cm.

When the thread is being pulled out, the bobbin must rotate

in the direction shown by the arrow.

9. Replace bobbin enclosure (3).

10. Close bobbin case retainer (2).

11. Close the hook cover (1).

Operating Instructions 669 - 00.0 - 08/2019 25

Page 28

Operation

②

①

③

4.6 Thread tension

Together with the hook thread tension, the needle thread tension

influences the final seam pattern. With thin sewing material,

excessive thread tension can lead to undesired gathering and

thread breakage.

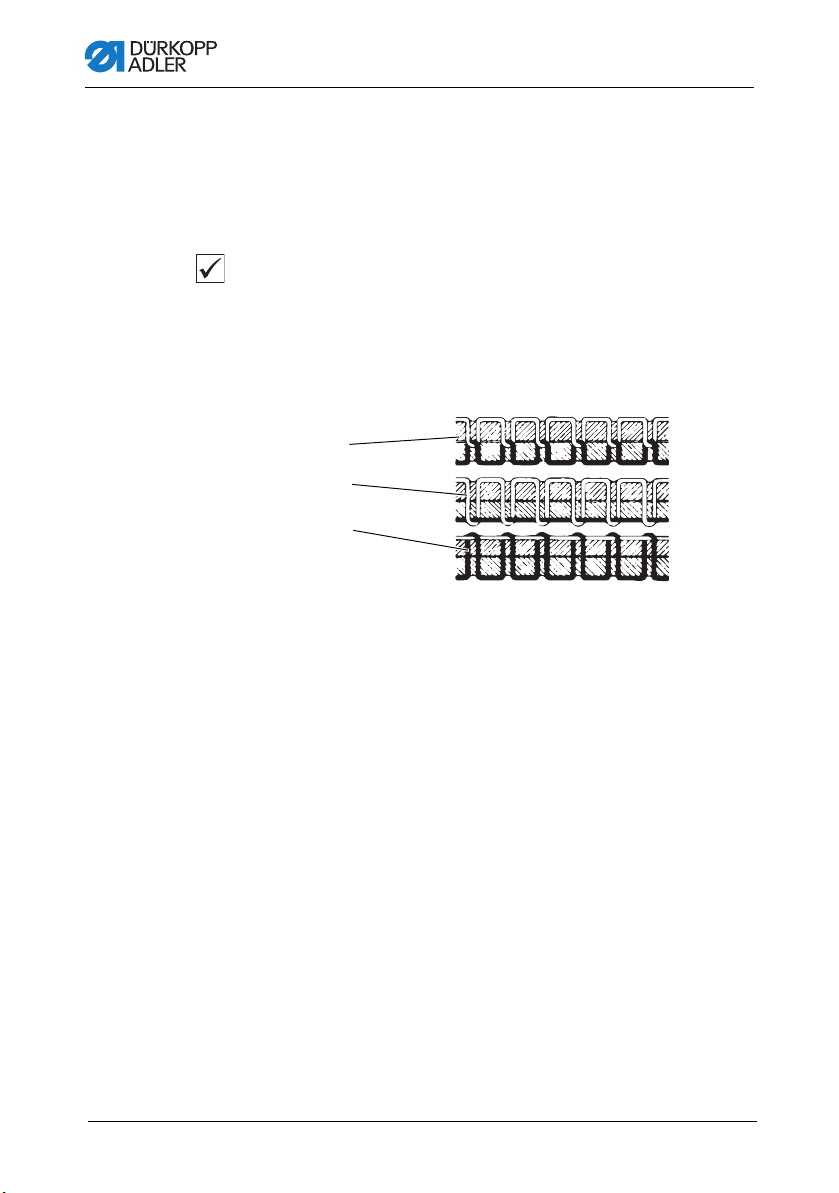

Proper setting

If the tension of needle thread and hook thread is identical, the

thread interlacing lies in the middle of the sewing material.

Set the needle thread tension so that the desired seam pattern is

achieved with the lowest possible tension.

Abb. 8: Thread tension

(1) - Iden tical needle thread and hook thread tension

(2) - Hook t hread tension higher than needle thread tension

(3) - Needle thread tension higher than hook thread tension

26 Operating Instructions 669 - 00.0 - 08/2019

Page 29

Operation

①

②③⑤④

4.6.1 Setting the needle thread tension

Fig. 9: Setting the needle thread tension

(1) - Pre-Tensioner

(2) - Main tensioner

(3) - Supplementary tensioner

Pre-tensioner

When the main thread tensioner (2) and the supplementary

tensioner (3) are open, there must still be a slight tension remaining on the needle thread.

This residual tension is created by the pre-tensioner (1).

The pre-tensioner (1) influences both the length of the cut needle

thread and the starter thread for the next seam

To set the basic adjustment:

1. Turn adjusting wheel (4) until its front side is flush with the

bolt (5).

To set a shorter starter thread:

1. Turn the adjusting wheel (4) clockwise.

To set a longer starter thread:

1. Turn the adjusting wheel (4) counter-clockwise.

(4) - Adjusting wheel

(5) - Bolt

Operating Instructions 669 - 00.0 - 08/2019 27

Page 30

Operation

Main tensioner

The main tensioner (2) should be adjusted as little as possible.

The threads’ cross-over point should be in the centre of the material. If the thread tension is too strong, crimping and thread

tearing canoccur when working with a thin material.

To set the main tensioner:

1. Adjust the main tensioner 2 so that you attain a consistent

stitch pattern.

• Increasing the tension: turn the adjusting wheel clockwise

• Decrease the tension: turn the adjusting wheel counterclockwise

Supplementary tensioner

The switchable supplementary tensioner (3) is used for quick

changes to the thread tension (for example, when working with

thicker seams).

To set the supplementary tensioner:

1. The supplementary tension (3) should be set lower than the

main tension (2).

28 Operating Instructions 669 - 00.0 - 08/2019

Page 31

Operation

4.6.2 Function of the main thread tension and the

additional thread tension depending on the

sewing foot lift (optional)

This option applies to the subclass 669-180312.

Button on the machine’s row of buttons can be used to activate

or deactivate the supplementary thread tension at any time. The

parameter F-299 must be set to 1 for this to work. .

Sewing-foot lift in the seam

Parameter

setting

F-196 = 0 0 0 0 0

F-196 = 1 1 1 0 0

F-196 = 2 0 0 1 1

F-196 = 3 1 1 1 1

1 = Thread tension opened mechanicall

0 = Thread tension closed mechanically

Main thread

tension

Supplementary thread

tension

Sewing-foot lift lift after

the thread has been cut

Main thread

tension

Supplementary thread

tension

If the supplementary thread tensioner is open, the state of the

sewing-foot lift does not change

If the machine is turned off, the supplementary thread tension

remains at its previously set state.

Operating Instructions 669 - 00.0 - 08/2019 29

Page 32

Operation

4.6.3 Function of the additional thread tension

depending on the stroke adjustment and the

Speedomat (optional)

This option applies to the subclass 669-180312.

Button on the machine’s row of buttons can be used to activate

or deactivate the supplementary thread tension at any time. The

parameter F-255 must be set to 7 for this to work.

Stroke adjustment via

knee button

Parameter

setting

F-197 = 0 1 1

F-197 = 1 0 1

F-197 = 2 1 (*) 0

F-197 = 3 0 0

(*) If the stroke adjustment (max.) is activated via the knee switch and

the HP speed from parameter F-117 has been reached by the

Speedomat, then the supplementary thread tensioner is automatically

activated.

Max. strike adjustment

via adjusting wheel

when the HP speed from

parameter

F-117 is reached

(Speedomat)

0 = Supplementary thread tension closed mechanicall

1 = Supplementary thread tension opened mechanically

If the supplementary thread tensioner is closed, the state of the

stroke adjustment does not change.

If the machine is turned off, the supplementary thread tension

remains at its previously set state.

30 Operating Instructions 669 - 00.0 - 08/2019

Page 33

Operation

Initial control-box settings for the automatic stepped reduction of

the stitch count (Speedomat), using the adjusting wheel for the

height of the alternating feed stroke:

Parameter 188

Stufe 01-21 Entire Speedomat range

Stufe 01-10 Maximum allowed stitch count, parameter F-111 =

3000 min

Stufe 11-18 Linear step-wise reduction of the maximum stitch count

(Speedomat)

Stufe 19-21 Maximum allowed stitch count, parameter F-117 =

1.800 min

1

1

4.6.4 Opening the needle thread tension

Suibclass 669-180010

When raising the sewing feet by means of the knee lever, the main

and supplementary tensioners are automatically opened.

Subclasses 669-180112, 669-180312

The needle-thread tensioner is automatically opened when the

thread is cut.

Operating Instructions 669 - 00.0 - 08/2019 31

Page 34

Operation

②

①

4.6.5 Switching on and off the supplementary thread

tension (optional)

This option applies to the subclasses 669-180010 and

669-180112.

Fig. 10: Switching on and off the supplementary thread tension

(1) - Leve r (2) - Knob

To switch on and off the supplementary thread tension:

Switch on

1. Push the knob (2) on the lever (1) to the left.

Switch off

1. Push the knob (2) on the lever (1) to the right.

32 Operating Instructions 669 - 00.0 - 08/2019

Page 35

Operation

①

②③

4.6.6 Setting the hook thread tension

WARNING

Risk of injury from sharp and moving parts!

Puncture or crushing possible.

Switch off the machine before setting the hook

thread tension.

Fig. 11: Setting the hook thread tension

(1) - Brak e spring

(2) - Screw

Brake spring

The brake spring (1) is responsible for preventing a bobbin overrun

during a machine stop and when the hook thread is being cut.

It cannot be adjusted!

To set the tension spring:

1. Adjust the tension spring (3) with the screw (2). Turn until the

required tension force is present.

Operating Instructions 669 - 00.0 - 08/2019 33

To increase the hook thread tension:

1. Turn the screw (2) clockwise.

To decrease the hook thread tension:

1. Turn the screw (2) counter-clockwise.

(3) - Tension spring

Page 36

4.7 Setting the needle thread regulator

①②③

Fig. 12: Setting the needle thread regulator

Operation

(1) - Needle thread regulator

(2) - Screw

The neelde thread regulator (1) is used to control the quantity of

the needle thread required by the stitch formation.

The best sewing results can only be ensured when using a precisely adjusted needle thread regulator (1).

At the properly adjusted setting, the needle thread loop must be

able to slide over the thickest section of the hook.

To set the needle thread regulator:

1. Loosen screw (2).

2. Change the position of the needle thread regulator (1).

• Thread regulator to the left: more thread

• Thread regulator to the right: less thread

3. Tighten screw (2).

34 Operating Instructions 669 - 00.0 - 08/2019

(3) - Thread take-up lever

Page 37

Operation

①②

Information

At the point where the most thread is required, the thread take-up

lever (3) must be pulled up about 0.5 mm from its lower end

position.

This occurs when the needle thread loop passes the section of

the hook with the widest diameter.

4.8 Sewing feet

4.8.1 Lifting the sewing feet

Fig. 13: Lifting the sewing feet

(1) - Knee s w itch (2) - Peda l

Subclass 669-180010

The sewing feet can be lifted mechanically by pressing the knee

switch (1).

Subclasses 669-180112, 669-180312

The sewing feet can be lifted electro-pneumatically by pressing

the pedal (2) or the knee switch (1).

Operating Instructions 669 - 00.0 - 08/2019 35

Page 38

Operation

①①

Lifting the sewing feet mechanically (knee switch)

To lift the sewing feet machanically:

1. Push the knee switch (1) to the right in order to move the

sewing material (for example, when making corrections).

The sewing feet remain in the lifted position as long as the

knee switch (1) is pressed.

Lifting the sewing feet electro-pneumatically (pedal)

To lift the sewing feet electro-pneumatically:

1. Press the pedal (2) half way back.

The sewing feet are lifted when the machine is stopped.

2. Press the pedal (2) all the way back.

The thread trimmer will then be activated and the sewing

feet will be lifted.

4.8.2 Locking the sewing feet at top dead center

Fig. 14: Locking the sewing feet at the top dead center

(1) - Lever

To lock the sewing feet at the top dead center:

1. Swivel lever (1) downwards.

The sewing feet are locked at top dead center.

36 Operating Instructions 669 - 00.0 - 08/2019

Page 39

Operation

①

1. Swivel the lever (1) up.

The lock of the sewing feet has been removed.

OR

1. Lift the sewing feet pneumatically using the pedal.

The lever (1) swivels back to its initial position.

4.8.3 Setting the sewing foot pressure

NOTICE

Property damage may occur!

If the sewing foot pressure is too high, the material could

tear.

If the sewing foot pressure is too weak, the material could

slip.

Set the sewing foot pressure in such a way that the sewing

material slides smoothly over the base without slipping.

Fig. 15: Setting the sewing foot pressure

(1) - Adju sting wheel

Operating Instructions 669 - 00.0 - 08/2019 37

Page 40

Operation

①②③

To set the sewing foot pressure:

1. Set the sewing foot pressure using the adjusting wheel (1).

• Increase sewing foot pressure: turn clockwise

• Decrease sewing foot pressure: turn counterclockwise

4.8.4 Setting the sewing foot stroke

NOTICE

Property damage may occur!

It is not possible to set a lower sewing foot stroke on the right

adjusting wheel than on the left adjusting wheel.

Do not attempt to use force to set a smaller sewing foot

stroke on the right adjusting wheel.

Fig. 16: Setting the sewing foot stroke (1)

(1) - Adju sting wheel

(2) - Adju sting wheel

(3) - Knee switch

Use the adjusting wheel (2) on the left to select the standard

sewing foot stroke from1 to 9.

Use the adjusting wheel (1) on the right to set a higher sewing foot

stroke from 1 to 9.

38 Operating Instructions 669 - 00.0 - 08/2019

Page 41

Operation

To set the sewing foot stroke:

1. Turn adjusting wheel (1) and (2) (from 1 to 9).

• 1: minimal sewing foot stroke

• 9: maximum sewing foot stroke

Automatic stitch rate limit

Machines without a thread trimmer

The speed is not verified on these machines.

Machines with a thread trimmer

The sewing-foot stroke and stitch count are interdependent. A

potentiometer is connected mechanically with the adjusting wheel.

The control unit detects what foot-stroke has been set by means

of this potentiometer and restricts the speed of rotation accordingly.

Machines with electro-pneumatic rapid stroke adjustment

When processing thick sections of material or when sewing over

transversal seams, the higher sewing-foot stroke (adjusting

wheel (1)) can be activated while sewing by means of the knee

switch (3) (under the table plate).

A potentiometer is used here just as in the machines with thread

trimmers.

Operating mode for the rapid stroke adjustment

The activation time for the maximum sewing-foot stroke depends

on which operating mode is set. You can select between three

different operating modes.

Operating Instructions 669 - 00.0 - 08/2019 39

Page 42

Operation

③

④

The particular modes are specified on the operating panel by

setting the parameters F-138 a nd F-184 (refer to the instructions

from the motor manufacturer).

Operating

mode

momentary

contact

F-138 = 0

F-184 = 0

maintained

contact

F-138 = 1

momentary

contact with

minimum

stitch count

F-138 = 0

F-184 0 < 100

Operation/Explanation

The maximum sewing-foot stroke remains activated as

long as the knee switch is being pressed.

The maximum sewing-foot stroke is activated when the

knee switch is pressed.

Pressing the knee switch again will then deactivate the

maximum sewing-foot stroke.

The maximum sewing-foot stroke remains activated as

long as the knee switch is being pressed.

After releasing the knee switch, the machine continues

to sew with the maximum sewing-foot stroke until the

specified minimum stitch count (parameter F-184) is

reached. Afterwards, sewing continues with the standard sewing-foot stroke.

Information

Fig. 17: Setting the sewing foot stroke (2)

(3) - Knee switch (4) - Switch

The switch (4) on the rear of the knee switch (3) can also be used

to switch between the maintained contact and momentary contact

modes.

40 Operating Instructions 669 - 00.0 - 08/2019

Page 43

Operation

Maximum stitch count

Stitch length range

adjusting wheel

position

0 - 6 1 - 3

6 - 9 1 - 4

Sewing foot stroke

[mm]

4

5

6 - 9

5

6 - 9

max. stitch count

-1

]

[min

3000

2500

2100

1800

2500

2100

1800

Important

Do not exceed the max. stitch count limits specified in the table.

Observing these limits will ensure safe operations and a long

lifespan for the machine.

Operating Instructions 669 - 00.0 - 08/2019 41

Page 44

4.9 Setting the stitch length

①②③④

NOTICE

Property damage may occur!

It is not possible to set a lower stitch length on the upper

adjusting wheel than on the lower adjusting wheel.

Do not attempt to force the top adjusting wheel to set a lower

stitch length.

Fig. 18: Setting the stitch length

Operation

(1) - Adju sting wheel

(2) - Adju sting wheel

(3) - Stitch regulator

(4) - Button

The machine is equipped with two adjusting wheels, depending

on the subclass. This allows two different stitches to be used when

sewing. They can be selected using button 4 ( p. 43).

The stitch lengths are set using the adjusting wheels (1) and (2)

on the machine arm.

To set the stitch length:

1. Set the longer stitch length with the upper adjusting wheel (1).

• Position 1: min. stitch length

• Position 9: max. stitch length

2. Set the shorter stitch length with the lower adjusting wheel (2).

• Position 1: min. stitch length

• Position 9: max. stitch length

42 Operating Instructions 669 - 00.0 - 08/2019

Page 45

Operation

⑦

⑧

①②③④⑤⑥

Stitch lengths are equal for both forward and reverse sewing.

3. Push the stitch regulator (3) down in order to manually sew

bartacks.

The machine will sew backwards as long as the stitch

regulator (3) is pressed down

Information

in order to facilitate the process of adjusting the stitch lengths, the

button (4) should be used to fix the stitch lengths so that they do

not shift.

4.10 Buttons on the machine arm

Fig. 19: Buttons on the machinearm

(1) - Button supplementary thread

tension

(2) - Button 2. stitch length

(3) - Butt on start/final bartack

(4) - Butt on needle position

Operating Instructions 669 - 00.0 - 08/2019 43

(5) - Button sew backwards

(6) - Screw

(7) - Key

(8) - LED

Page 46

Taste Funktion

Operation

①

②

③

④

⑤

Supplementary tread tension

Button is back-lit:

the supplementary thread tension is activated.

Button is not back-lit:

the supplementary thread tension is not activated.

2. stitch length

Button is back-lit:

long stitch length (upper adjusting wheel) is activated

Button is not back-lit:

small stitch length (lower adjusting wheel) is activated

Invoke or suppress the start/final bartacks.

If the start and final bartacks are activated, then the

next bartack is deactivated when the button is pressed.

If the start and final bartacks are not activated, then the

next bartack is activated when the button is pressed.

Move the needle to the upper or lower position. The

function of the button can be set with the parameter

F-242.

1 = needle up/down

2 = needle up

3=singlestitch

4 = full stitch

5 = needle to position 2

The factory default setting is 1 (needle up/down

Sew backwards manually

The machine sews backwards for as long as the button

is held down.

⑧

LED display Power On

The key (7) can be assigned a function using the screw (6)( found

under the switch.

1. Select a function.

For example: 6 = sew backwards manually.

2. Press in the screw under key (5) and turn 90° to the right (the

slot is vertical).

This function can now be activated using either key (5)

or (7).

44 Operating Instructions 669 - 00.0 - 08/2019

Page 47

Operation

①③ ②

4.11 Tilting the machine head

WARNING

Risk of injury from moving parts!

Crushing possible.

DO NOT reach between base and machine arm

when tilting the machine head.

NOTICE

Property damage may occur!

Oil leakage possible.

Tilt the machine head only briefly.

Fig. 20: Tilting the machine head

(1) - Lever

(2) - Strap

To tilt the machine head:

1. Press lever (1) upwards.

The locking mechanism is then released.

(3) - Machine head

Operating Instructions 669 - 00.0 - 08/2019 45

Page 48

Operation

①

①②

2. Tilt the machine head (3) to the rear

The machine head (3) will be supported by the strap (2).

To erect the machine head:

1. Tilt the machine head (3) forwards.

2. Pull lever (1) back up.C

3. Carefully tilt the machine head (3) downwards

4.12 Folding down the tabletop (optional)

This option applies to the stand MG 56-2.

WARNING

Risk of injury from moving parts!

Crushing possible.

Hold the table top with both hands when pulling it

off.

Fig. 21: Folding down the tabletop (1)

(1) - Tabl etop latch (2) - Tabl etop

To fold down the tabletop:

1. Loosen the tabletop latch (1) located under the tabletop (2).

46 Operating Instructions 669 - 00.0 - 08/2019

Page 49

Operation

③④

2. Pull out the tabletop (2) to the left and fold out.

Fig. 22: Folding down the tabletop (2)

(3) - Bolt (4) - Diagonal brace

3. Hook in the diagonal brace (4) to the bolt (3).

4. Fold down the tabletop (2).

Follow these steps in the opposite order to raise the table plate.

Operating Instructions 669 - 00.0 - 08/2019 47

Page 50

Operation

4.13 Sewing

4.13.1 Sewing with machines using the FIR clutch

positioning drive

Fig. 23: Sewing with machines using the FIR clutch positioning drive

(0) - At rest

(1) - Sewing forwards with minimum speed

(2) - Sewing forwards with higher speed

(3) - Sewing forwards with maximum speed

You can find a comprehensive description of the control unit in

the current operating instructions from the motor manufacturer.

48 Operating Instructions 669 - 00.0 - 08/2019

Page 51

Operation

4.13.2 Sewing with machines using the Efka DC1550/

DA321G positioning drive

The DA321G control unit contains all required operational interfaces for switching functions and setting parameters.

It is possible to operate without an operating panel, but the seam

programming can no longer be carried out.

The V810 and V820 operating panels can also be connected to

the control unit. They are deliverable as accessories.

Seam programming can be performed with the V820 operating

panel.

The EFKA DC1550 – DA321G Operating Manual contains a more

detailed description of the control unit (also refer to

www.efka.net).

Fig. 24: Sewing with machines using the Efka DC1550/DA321G positioning drive (1)

Pedal

position

-2 Completely back-

-1 Half backwards Command for raising the sewing foot

0 Neutral rest posi-

1 Slightly forwards Command for lowering the sewing foot

2 More forwards Sew with miminal speed (first level)

3 More forwards Sew with more speed (second level)

13 Entirely forwards Sew with maximal speed (twelfth level)

Operating Instructions 669 - 00.0 - 08/2019 49

Pedal movement Function

Command for cutting the thread (end of

wards

tion

seam)

Page 52

Operation

①②③④

Information

The following functions can be programmed to correspond with

the rest position:

• Needle position (down/up) and sewing-foot position (down/up)

when stop in seam

• Sewing-foot position (up/down) after end of seam

Fig. 25: Sewing with machines using the Efka DC1550/DA321G positioning drive (2)

(1) - Button supplementary thread

tension

(2) - Button 2. stitch length

Sewing

Sewing process Operation

Before sewing start

Starting position • Pedal in resting position

Position material at

seam start

Sewing • Press the pedal forward and hold

50 Operating Instructions 669 - 00.0 - 08/2019

The machine is at rest

The needle is up

The sewing feet are down

• Move pedal back halfway

The sewing feet lift

• Push the material to the needle

The machine then continues to sew with the

speed determined by the pedal

(3) - Button sew backwards

(4) - Stitch regulator

Page 53

Operation

Sewing process Operation

In the middle of the

seam

Interrupt sewing

operation

Continue sewing

operation (after

releasing the pedal)

Sewing an intermediate lockstitch

Sewing over transverse seams (maximum sewing-foot

stroke)

nd

set stitch length

2

during sewing

(max. stitch length)

Raise the thread

tension during

sewing

• Release pedal (return to rest position)

The machine stops in the first position (needle

down)

The sewing feet are down

• Press the pedal forward

The machine then continues to sew with the

speed determined by the pedal

• Press the stitch regulator (4) downwards.

The machine sews in reverse as long as the

stitch regulator (4) is pressed.

The speed is determined by the pedal.

OR

• Press button (3)

The maximum sewing-foot stroke is activated.

-1

The speed is limited to 1600 min

.

Operating modes for maximum sewing-foot

stroke

• Briefly press the knee switch for activating the

maximum sewong foot stroke

• Briefly press the knee switch again for deactiva-

ting the maximum sewing foot switch

• Press the button (2)

• Press the button (1)

At seam end

Remove sewing

materia

• Press the pedal completely backwards and

hold

The final bartack is sewn (when activated).

The thread is cut.

The machine stops in the second position.

The needles are up (reverse rotation). T

he sewing feet are down.

• Take out the material

Operating Instructions 669 - 00.0 - 08/2019 51

Page 54

Operation

52 Operating Instructions 669 - 00.0 - 08/2019

Page 55

Maintenance

5 Maintenance

WARNING

Risk of injury from sharp parts!

Punctures and cutting possible.

Prior to any maintenance work, switch off the

machine or set the machine to threading mode.

WARNING

Risk of injury from moving parts!

Crushing possible.

Prior to any maintenance work, switch off the

machine or set the machine to threading mode.

This chapter describes maintenance work that needs to be carried

out on a regular basis to extend the service life of the machine

and achieve the desired seam quality.

Advanced maintenance work may only be carried out by qualified

specialists ( Service Instructions).

Maintenance intervals

Work to be carried out Operating hours

8 40 160 500

Removing lint and thread remnants

Cleaning the motor fan sieve

Servicing the pneumatic system

Checking the V-belt tension

Operating Instructions 669 - 00.0 - 08/2019 53

Page 56

5.1 Cleaning

WARNING

Risk of injury from flying particles!

Flying particles can enter the eyes, causing injury.

Wear safety goggles.

Hold the compressed air gun so that the particles

do not fly close to people.

Make sure no particles fly into the oil pan.

NOTICE

Property damage from soiling!

Lint and thread remnants can impair the operation of the

machine.

Clean the machine as described.

NOTICE

Maintenance

Property damage from solvent-based cleaners!

Solvent-based cleaners will damage paintwork.

Use only solvent-free substances for cleaning.

54 Operating Instructions 669 - 00.0 - 08/2019

Page 57

Maintenance

②① ③

Fig. 26: Cleaning

(1) - Hook

(2) - Area under the throat plate

(3) - Motor fan sieve

Points that need to be cleaned particularly thoroughly:

• Area under the throat plate (2)

• Area around the hook (1)

• Bobbin case

• Thread cutter

• Area around the needle

• Motor fan sieve (3)

To clean the machine:

1. Blow out dust and thread residues with the compressed air

gun.

Operating Instructions 669 - 00.0 - 08/2019 55

Page 58

Maintenance

5.2 Lubricating

CAUTION

Risk of injury from contact with oil!

Oil can cause a rash if it comes into contact with

skin.

Avoid skin contact with oil.

If oil has come into contact with your skin, wash

the affected areas thoroughly.

NOTICE

Property damage from incorrect oil!

Incorrect oil types can result in damage to the machine.

Only use oil that complies with the data in the instructions.

CAUTION

Risk of environmental damage from oil!

Oil is a pollutant and must not enter the sewage

system or the soil.

Carefully collect up used oil.

Dispose of used oil and oily machine parts in

accordance with national regulations.

The machine is equipped with a central oil-wick lubrication system.

The bearings are supplied from the oil reservoir.

For topping off the oil reservoir, use only lubricating oil DA 10 or

oil of equivalent quality with the following specifications:

• Viscosity at 40 °C:10 mm2/s

• Flash point: 150 °C

56 Operating Instructions 669 - 00.0 - 08/2019

Page 59

Maintenance

②

③

①

④

You can order the lubricating oil from our sales offices using the

following part numbers.

Container Part no.

250 ml 9047 000011

1 l 9047 000012

2 l 9047 000013

5 l 9047 000014

5.2.1 Checking the oil level in the machine head

Fig. 27: Checking the oil level in the machine head

(1) - Oil reservoir

(2) - Hole

Proper setting

The oil level must not raise above the MAX marking (4) or drop

below the MIN marking (3).

To top off the oil:

(3) - MIN marking

(4) - MAX marking

1. Fill oil through the hole (2) up to the MAX marking (4).

Operating Instructions 669 - 00.0 - 08/2019 57

Page 60

Maintenance

②

①

5.3 Servicing the pneumatic system

5.3.1 Setting the operating pressure

NOTICE

Property damage from incorrect setting!

Incorrect operating pressure can result in damage to the

machine.

Ensure that the machine is only used when the operating

pressure is set correctly.

Proper setting

Refer to the Technical data ( p. 43) chapter for the permissible

operating pressure. The operating pressure cannot deviate by

more than ± 0.5 bar.

Check the operating pressure on a daily basis.

Fig. 28: Setting the operating pressure

(1) - Pres sure controller (2) - Pressure gage

To set the operating pressure:

1. Pull the pressure controller (1) up.

58 Operating Instructions 669 - 00.0 - 08/2019

Page 61

Maintenance

①

③

②

2. Turn the pressure controller until the pressure gage (2)

indicates the proper setting:

• Increase pressure = turn clockwise

• Reduce pressure = turn counterclockwise

3. Push the pressure controller (1) down.

5.3.2 Draining the water condensation

NOTICE

Property damage from excess water!

Excess water can cause damage to the machine.

Drain water as required.

Water condensation accumulates in the water separator (2) of the

pressure controller.

Proper setting

Water condensation must not rise up to the level of the filter

element (1).

Check the water level in the water separator (2) on a daily basis.

Fig. 29: Draining the water condensation

(1) - Filter element

(2) - Water separator

Operating Instructions 669 - 00.0 - 08/2019 59

(3) - Drain screw

Page 62

Maintenance

①

③

②

To drain water condensation:

1. Disconnect the machine from the compressed air supply.

2. Place the collection tray under the drain screw (3).

3. Loosen the drain screw (3) completely.

4. Allow water to drain into the collection tray.

5. Tighten the drain screw (3).

6. Connect the machine to the compressed air supply.

5.3.3 Cleaning the filter element

NOTICE

Damage to the paintwork from solvent-based cleaners!

Solvent-based cleaners damage the filter.

Use only solvent-free substances for washing out the filter

tray.

Fig. 30: Cleaning the filter element

(1) - Filter element

(2) - Water separator

To clean the filter element:

1. Disconnect the machine from the compressed air supply.

2. Drain the water condensation (( p. 59)).

3. Loosen the water separator (2).

60 Operating Instructions 669 - 00.0 - 08/2019

(3) - Drain screw

Page 63

Maintenance

①

4. Loosen the filter element (1).

5. Blow out the filter element (1) using the compressed air gun.

6. Wash out the filter tray using benzine.

7. Tighten the filter element (1).

8. Tighten the water separator (2).

9. Tighten the drain screw (3).

10. Connect the machine to the compressed air supply.

5.4 Checking the V-belt tension

Fig. 31: Checking the V-belt tension

(1) - V-belt

Proper setting

You should be able to press down with your finger on the V-belt (1)

so that the belt moves about 10 mm down.

Operating Instructions 669 - 00.0 - 08/2019 61

Page 64

Maintenance

5.5 Parts list

A parts list can be ordered from Dürkopp Adler. Or visit our website

for further information at:

www.duerkopp-adler.com

62 Operating Instructions 669 - 00.0 - 08/2019

Page 65

Setup

6Setup

WARNING

Risk of injury from cutting parts!

Cutting injuries may be sustained while

unpacking and setting up the machine.

Only qualified specialists may set up the machine.

Wear safety gloves

WARNING

Risk of injury from moving parts!

Crushing injuries may be sustained while

unpacking and setting up the machine.

Only qualified specialists may set up the machine.

Wear safety shoes.

6.1 Checking the scope of delivery

The scope of delivery depends on your specific order.

Check that the scope of delivery is correct after taking delivery.

6.2 Removing the transport locks

Remove all transport locks before setting up the machine:

• Safety straps and battens from the upper machine head

• Safety straps and battens from the table

• Safety straps and battens from the stand

• Safety blocks and straps from the sewing drive

Operating Instructions 669 - 00.0 - 08/2019 63

Page 66

Setup

③

①

②

④

6.3 Assembling the stand

There are two stand sets with different table plates available:

• MG 55-3: not separated, with or without cut-out

• MG 56-3: separated, hinged

6.3.1 Assembling the stand MG 55-3

Fig. 32: Assembling the stand MG 55-3

(1) - Stand brace

(2) - Pedal

To assemble the stand:

1. Assemble the stand according to the illustration.

2. Fasten the pedal (2) to the stand brace (1).

3. Mount the stand brace (1) to the stand.

4. Align the pedal.

5. Screw on the holder for the oil can (3).

6. Turn the adjusting screw (4) to ensure a secure mount on the

stand.

The stand must be resting with all 4 feet on the floor.

64 Operating Instructions 669 - 00.0 - 08/2019

(3) - Oil can

(4) - Adjusting screw

Page 67

Setup

③

④

④

⑥

⑤

①②

6.3.2 Assembling the stand MG 56-3

Fig. 33: Assembling the stand MG 56-3

(1) - Stand brace

(2) - Pedal

(3) - Pedal rods

To assemble the stand:

1. Assemble the stand according to the illustration.

2. Fasten the pedal (2) to the stand brace (1).

3. Mount the stand brace (1) to the stand.

4. Turn the adjusting screws (4) to ensure a secure mount on

the stand

The stand must be resting with all 6 feet on the floor.

5. Align the pedal (2).

6. Screw on the holder for the oil can (5).

7. Assemble the rod (6) and pedal rod (3) (only for FIR clutch

motor).

(4) - Adjusting screws

(5) - Oil can

(6) - Rod

Operating Instructions 669 - 00.0 - 08/2019 65

Page 68

Setup

①

②

③④

⑤⑥⑦

(3,5x17) x2 (4x20) x2

(4x20) x2

(5x25) x2

(3,5x17) x2

6.4 Table top

Ensure that the tabletop has sufficient load-bearing capacity and

strength.

6.4.1 Completing the tabletop for stand MG 55-3 with

FIR clutch motor

Fig. 34: Completing the tabletop (1)

(1) - Cable duct

(2) - Main switch

(3) - Power supply

(4) - Tabletop

66 Operating Instructions 669 - 00.0 - 08/2019

To complete the tabletop:

1. Turn over the tabletop (4).

2. Screw on the cable duct (1).

3. Screw on the main switch (2).

4. Screw on the power supply (3).

5. Screw on the drawer (5).

6. Screw on the sewing light transformer (6).

(5) - Drawer

(6) - Sewing light transformer

(7) - Clutch motor

Page 69

Setup

⑦

④

⑧

Fig. 35: Completing the tabletop (2)

(4) - Tabletop

(7) - Clutch motor

7. Mount the clutch motor (7).

For this, screw the 3 hexagon bolts with washers into the

anchor nuts on the table plate.

The belt pulley (8) must point to the right when the tabletop

is mounted.

(8) - Belt pulley

Operating Instructions 669 - 00.0 - 08/2019 67

Page 70

Setup

⑥⑦⑧①

(3,5x17) x6 (4x20) x2 (3,5x17) x2

②③④⑤

(4x20) x2

6.4.2 Completing the tabletop for stand MG 55-3 with

direct drive

Fig. 36: Completing the tabletop

(1) - Cable duct

(2) - Motor control

(3) - Power supply

(4) - Knee switch

(5) - Tabletop

(6) - Drawer

(7) - Sewing l ight transformator

(8) - Setp oint device

To complete the tabletop:

1. Turn over the tabletop (5)

2. Screw on the cable duct (1).

3. Screw on the motor control (2).

4. Screw on the power supply (3).

5. Screw on the knee switch (4).

6. Screw on the setpoint device (8).

7. Screw on the drawer (6).

8. Screw on the sewing light transformer (7).

68 Operating Instructions 669 - 00.0 - 08/2019

Page 71

Setup

④⑤⑥⑦⑧

⑦①② ③

(5x25) x2 (4x20) x2

(3,5x17) x2

(5x25) x2 (4x20) x2 (5x25) X2

(3,5x17) x6

6.4.3 Completing the tabletop for stand MG 56-3 with

FIR clutch motor

Fig. 37: Completing the tabletop (1)

(1) - Sewing light transformator

(2) - Clutch motor

(3) - Cable duct

(4) - Drawer

To complete the tabletop:

(5) - Main switch

(6) - Power supply

(7) - Flap trays

(8) - Tabletop

1. Turn over the tabletop (8).

2. Screw on the sewing light transformer (1).

3. Screw on the cable duct (3).

4. Screw on the drawer (4).

5. Screw on the main switch (5).

6. Screw on the power supply (6).

7. Screw on flap trays (7) using two wood screws per tray.

Operating Instructions 669 - 00.0 - 08/2019 69

Page 72

Setup

⑨

②

Fig. 38: Completing the tabletop (2)

(2) - Clutch motor (9) - Belt pulley

8. Mount the clutch motor (2).

For this, screw the three hexagon bolts with washers into the

anchor nuts on the table plate

The belt pulley (9) must point to the left when the table plate

is mounted.

70 Operating Instructions 669 - 00.0 - 08/2019

Page 73

Setup

⑤⑦④③ ②

⑦⑥ ⑧①

(5x25) x2 (4x20) x2 (3,5x17) x2

(3,5x17) x6

(5x25) x2 (4x20) x2

6.4.4 Completing the tabletop for stand MG 56-3 with

direct drive

Fig. 39: Completing the tabletop

(1) - Drawer

(2) - Motor control

(3) - Power supply

(4) - Knee switch

To complete the tabletop:

(5) - Tabletop

(6) - Sewing l ight transformator

(7) - Flap trays

(8) - Cable duct

1. Turn over the table plate (5)

2. Screw on the drawer (1).

3. Screw on the motor control (2).

4. Screw on the power supply (3).

5. Screw on flap trays (7) using two wood screws per tray.

6. Screw on the knee switch (4).

7. Screw on the sewing light transformer (6).

8. Screw on the cable duct (8).

Operating Instructions 669 - 00.0 - 08/2019 71

Page 74

Setup

④

①

②

③

6.4.5 Assembling the tabletop to the stand MG 55-3

Fig. 40: Assembling the tabletop to the stand

(1) - Reel stand

(2) - Tabeltop

To assemble the tabletop to the stand:

1. Place the table top (2) on the floor upside down.

2. Fasten the stand 4 to the tabletop (2) using wood screw

Be sure to note the marking for the stand ( p. 66),

( p. 68).

3. Set up stand (4) with tabletop (2).

4. Attach the rod (3) onto the pedal and motor.

5. Put the reel stand (1) into the drilled hole in the tabletop (2).

Fasten with nut and washer.

6. Mount and align the reel holders and thread guide.

The thread guide must be positioned above the reel holders.

72 Operating Instructions 669 - 00.0 - 08/2019

(3) - Rod

(4) - Stand

Page 75

Setup

⑥

⑦

⑧

①

②

③

④

⑤

6.4.6 Assembling the tabletop to the stand MG 56-3

Fig. 41: Assembling the tabletop to the stand

(1) - Reel stand

(2) - Tabletop

(3) - Rod

(4) - Actuating lever

To assemble the tabletop to the stand:

1. Fasten the tabletop (2) to the stand (5) using woodscrews.

Pre-drill the holes for the wood screws.

2. Fasten the tableplate (8) to the latch (7) using woodscrews.

3. Attach the rod (6) onto the pedal and the actuating lever (4)

(only for FIR clutch motor).

4. Attach the rod (3) onto the actuating lever (4) and motor.

5. Put the reel stand (1) into the drilled hole in the tabletop (2).

Fasten with nut and washer.

6. Mount and align the reel holders and thread guide.

The thread guide must be positioned above the reel holders.

(5) - Stand

(6) - Rod

(7) - Latch

(8) - Tabletop

Operating Instructions 669 - 00.0 - 08/2019 73

Page 76

Setup

①

②

③

6.4.7 Assemble support on table plate with cut-out

(stand MG 55-3)

In order to increase the stability of the right side of the tabletop (1),

the plate is support by a junction bar (2).

Fig. 42: Assemble support on table plate with cut-out

(1) - Righ t side of tabletop

(2) - Junction bar

To assemble the support:

1. Fasten junction bar (2) to the stand using screw (3).

2. Fasten junction bar (2) to the bottom of the tabletop (1) using

wood screws.

(3) - Screw

74 Operating Instructions 669 - 00.0 - 08/2019

Page 77

Setup

6.5 Setting the working height

WARNING

Risk of injury from moving parts!

The tabletop can sink under its own weight when

the screws on the stand bars are loosened.

Crushing possible.

Ensure that your hands are not jammed when

loosening the screws.

CAUTION

Risk of musculoskeletal damage from

incorrect setting!

The operator can sustain musculoskeletal

damage if failing to comply with the ergonomic

requirements.

Adjust the working height to the body height of the

person who will operate the machine.

The working height of the stand MG 55-3 is adjustable between

750 mm and 900 m.

Operating Instructions 669 - 00.0 - 08/2019 75

Page 78

Fig. 43: Setting the working height

①

(1) - Screws

To set the working height:

Setup

1. Loosen screws (1).

2. Adjust the table plate vertically to your required height.

Important

Make sure that the table top is the same height on both sides.

To prevent tilting, pull out or push in the table top evenly on both

sides.

3. Fasten screws (1).

76 Operating Instructions 669 - 00.0 - 08/2019

Page 79

Setup

②

①

②

6.6 Putting on the machine head

Fig. 44: Putting on the machine head

(1) - Screws (2) - Washers

To put on the machine head:

1. Put the machine head on the table plate.

2. Tighten the machine head from the underside of the tabletop

with screws (1) and washers (2).

Operating Instructions 669 - 00.0 - 08/2019 77

Page 80

6.7 Assembling the operating panel

①②③④

Fig. 45: Assembling the operating panel

Setup

(1) - Operating panel

(2) - Thre ad guide

(3) - Valve cover

(4) - Cable

To assemble the operating panel:

1. Screw on operating panel (1) along with the thread guide (2).

2. Take off the valve cover (3).

3. Route the cable (4) in the machine arm and then downwards

through the opening in the tabletop.

4. Plug in the cable plug into the B776 socket on the control.

5. Put the valve cover (3) back on.

78 Operating Instructions 669 - 00.0 - 08/2019

Page 81

Setup

①⑤ ②

②④③

②

⑥

⑦

6.8 Assembling the sewing light

Fig. 46: Assembling the sewing light (1)

(1) - Sewing light

(2) - Arm cover

(3) - Holes

To assemble the sewing light:

1. Screw off the arm cover (2).

2. Use a 4.5-mm Ø bit to drill the fastening holes (3).

3. Screw the retainer piece (5) using screw (4).

Fig. 47: Assembling the sewing light (2)

(2) - Arm cover

(6) - Valve cover

(4) - Screws

(5) - Retainer piece

(7) - Main switch

Operating Instructions 669 - 00.0 - 08/2019 79

Page 82

Setup

4. Put the sticker with the safety notice on the front of the main

switch (7)

5. Put the sewing light (1) onto the retainer piece (5).

6. Unscrew the valve cover (6).

7. Route the sewing light’s (1) supply cable into the cut-out on

the machine arm.

8. Guide the the connection cable downwards through the

opening in the tableplate.

9. Fasten the sewing light transformer under the tabletop.

10. Connect the cable of the sewing light (1) to the sewing light

transformer.

11. Put the valve cover (6) back on.

12. Put the arm cover (2) back on.

80 Operating Instructions 669 - 00.0 - 08/2019

Page 83

Setup

①

②

④

③

6.9 Setpoint device for the Direct drive

6.9.1 Assembling the setpoint device to the stand

MG 55-3 and aligning the pedal

Fig. 48: Assembling the setpoint device to the stand and aligning the

pedal

(1) - Setp oint device

(2) - Rod

To assemble the setpoint device to the stand:

1. Screw the angle bracket (3) under the tabletop (4).

2. Screw the setpoint device (1) onto the angle bracket (3).

3. Hang the rod (2) on the setpoint device (1) and pedal.

To align the pedal:

1. Loosen screw on the rod (2).

2. Adjust the height of the pedal rod so that the released pedal

has a decline of about 10°.

3. Tighten the screw on the rod (2).

Operating Instructions 669 - 00.0 - 08/2019 81

(3) - Angle bracket

(4) - Tabletop

Page 84

Setup

⑤

④

②③①

6.9.2 Assembling the setpoint device to the stand

MG 56-3 and aligning the pedal

Fig. 49: Assembling the setpoint device to the stand and aligning the

pedal

(1) - Stand

(2) - Rod

(3) - Setp oint device

To assemble the setpoint device to the stand:

1. Screw the setpoint device (3) onto the plate (5) on stand (1).

2. Hang the rod (2) on the setpoint device (3) and pedal.

To align the pedal:

1. Loosen screw on the rod (2).

2. Adjust the height of the pedal rod so that the released pedal

has a decline of about 10°.

3. Tighten the screw on the rod (2).