Page 1

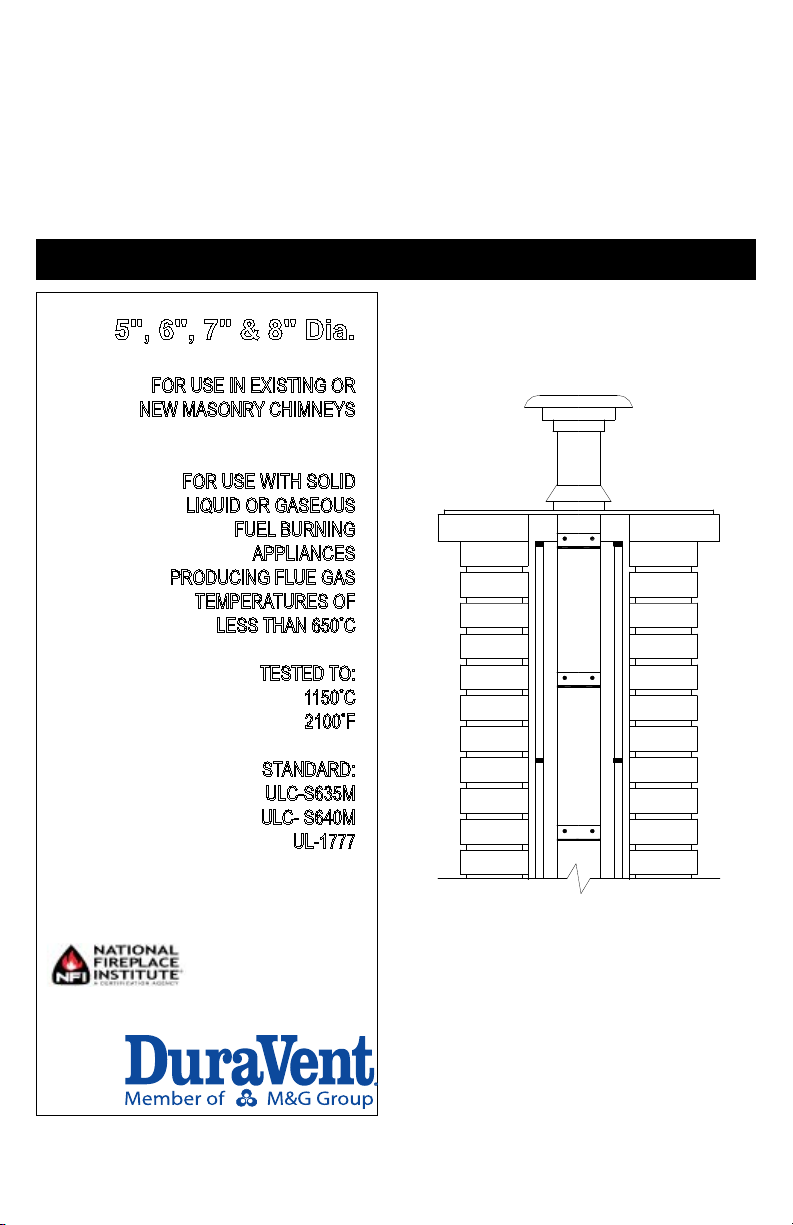

VENTINOX RIGID

FACTORY-BUILT LINING SYSTEM

INSTALLATION AND OPERATING INSTRUCTIONS

5", 6", 7" & 8" Dia.

FOR USE IN EXISTING OR

NEW MASONRY CHIMNEYS

FOR USE WITH SOLID

LIQUID OR GASEOUS

FUEL BURNING

APPLIANCES

PRODUCING FLUE GAS

TEMPERATURES OF

LESS THAN 650°C

TESTED TO:

1150°C

2100°F

STANDARD:

ULC-S635M

ULC- S640M

UL-1777

Printed in Canada REV1/JAN 2015 PIVENTINOX

Page 2

Installation and Operating Instructions

Read these instructions and keep them for future reference.

Before installing this liner, consult your local building

authority and obtain a building permit

Install the liner as described in these instructions. Only use parts supplied

by DURAVENT Ltd. Failure to do so will void the certication and the

guarantee of this chimney.

GENERAL NOTES

1. Ventinox Rigid lining system can be substituted to

the traditional clay tile liner in new masonry chimney

construction.

2. The liner is intended for use with solid, liquid and

gaseous fuel burning appliances at these allowable

ue gas temperatures :

U.S CANADA

Maximum continuous 1000 F

Brief forced ring 1400 F

Tested to 2100 F

540 C

760 C

1150 C

( 10 min)

TABLE 1

3. Size the liner in accordance with the appliance

manufacturer's instructions. The liner must not be

smaller than the appliance ue outlet.

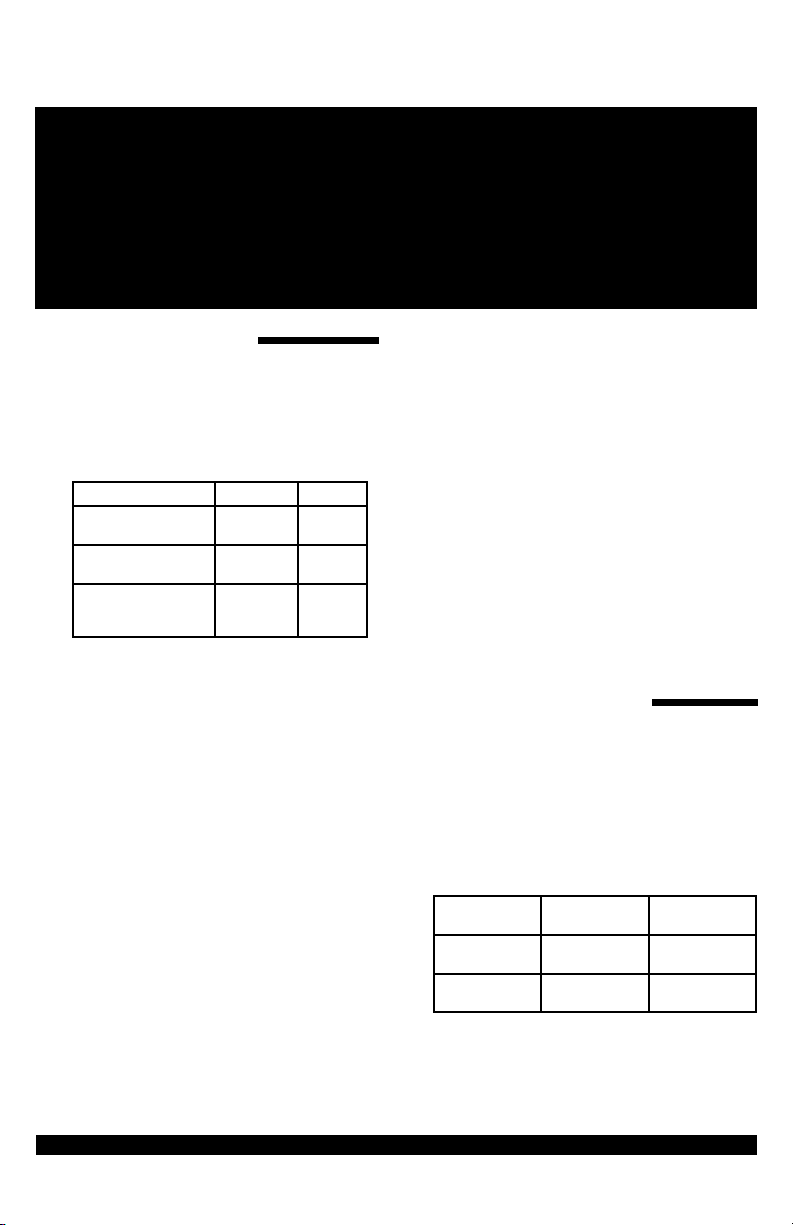

4. The chimney shall extend at least 3 ft (915 mm)

above its point of contact with the roof and at least

2 ft (10 mm) higher than any wall, roof or adjacent

building within 10 ft (3 m) of it (g. 1).

5. The clearance between single wall stove pipe and

unprotected combustible material must not be less

than 18" (457 mm) (See National Building Code or

NFPA).

6. A rain cap must be used on top of the liner to

prevent the entrance of debris, rain, birds or small

animals into the liner.

7. Homeowners must be reminded to check the rain

cap for icing during conditions of low ambient

temperatures due to the possibility of blockage

through freezing moisture. The local authority

having jurisdiction should be consulted if a rain cap

is considered in areas of low ambient temperature.

1200 F

650 C

1700 F

925 C

2100 F

1150 C

( 30 min)

8. Masonry chimney construction:

• The masonry chimney must be built with bricks

and mortar conformed to the Building Code.

The ue opening dimension must always leave

the liner free to expand.

9. The maximum height of liner that can be installed is

60 feet (18 m).

10. Special precaution should be taken in choosing the

correct size of liner system in colder climate region.

Poor draft, excessive condensation and creosote

build-up could occur if the liner system is too big for

the application.

11. Sharp bends that would crimp and restrict the crosssection of the liner are prohibited.

MASONRY CHIMNEY

Before installing the liner into an existing masonry

chimney, the chimney must be thoroughly cleaned

and examined. Check to ensure that the chimney is

structurally sound.

Check for cracked, loose or missing bricks, moisture

or other materials that could inhibit correct installation

of the liner.

Interior

installation

Exterior

installation

NFPA211 National

2``(50 mm) 2`` (50 mm)

1`` (25 mm) 1`` (25 mm)

TABLE 2

Building code

VENTINOX LINING SYSTEM - 2

Page 3

For a new masonry chimney liner installation make sure

that the masonry chimney construction and clearances

between the chimney exterior and combustible

materials are as specied in NFPA 211 (USA) or the

National Building Code (Canada) (See table 2).

Figure 1

YOU CAN DO IT ... STEP BY STEP !

Congratulations! You have made a wise choice in your selection of a VENTINOX lining system. You have purchased

a ne quality system researched, developed and tested to precise standards of quality in manufacturing.

It’s so easy to install…you can do it step by step. Each component is designed to t together perfectly and easily. If

you are handy with a few basic tools and have a general knowledge of carpentry, you can install your VENTINOX lining

system over a weekend or have a professional install it for you in a few hours.

Before you install your TUBINOX lining system, read these instructions carefully and follow them exactly.

DEAR CUSTOMER, INSTALLED, OR END USER

We welcome any comments regarding matters pertaining to our DURAVENT products.

We welcome any ideas, input or complaints and I`ill make sure thaht someone responds dirctly back to you.

Send your emails to: president@duravent.com

If you are searching for tech support or product information, please phone us at 800-835-4429.

Or email us at : techsupport@duravent.com

VENTINOX LINING SYSTEM - 3

Page 4

GENERAL INFORMATION

CREOSOTE

When wood is burned slowly, it produces tar and other organic vapours, which combine with expelled moisture to form

creosote. The creosote vapours condense in the relatively cool chimney ue of a slow burning re. As a result, creosote

residue accumulates on the ue lining. When ignited, this creosote makes an extremely hot re.

Creosote formation in a chimney cannot be eliminated, but it can be minimized by :

1. Keeping the temperature of the gases in the chimney above 300ºF.

2. Making small hot res rather than slow burning, smoldering res.

The chimney liner should be inspected periodically during the heating season to determine if a creosote build-up has occur.

If a signicant layer of creosote has accumulated ((1/8" (3 mm) or more)) it should be removed to reduce the risk of a

chimney re.

CHIMNEY OPERATION AND MAINTENANCE

Keep your chimney and liner clean.

Do not allow more than 1/8" build-up of creosote in your liner. Wood stoves can quickly create large deposits of creosote in

the liner. Some wood stoves can create enough creosote in two weeks to cause a chimney re.

When using a wood stove, we recommend that you :

1. Initially inspect the liner system weekly. From this you will learn how often it will be necessary to clean your

liner.

2. The liner should be inspected at least once every 2 months during the heating season to determine if a

creosote or soot build-up has occur. If creosote or soot has accumulated, it should be removed to reduce the

risk of a chimney re.

3. Have your liner cleaned by a qualied chimney sweep. If you want to clean your liner yourself, then use plastic, wood

or stainless steel brushes. Do not use a brush that will scratch the stainless steel interior of the liner.

4. Do not expect chemical chimney cleaners to keep your liner clean. Their use does not negate the necessity of

periodically inspecting and cleaning your liner.

COAL

Some coals contain large quantities of sulphur (up to 7%). When coal is burned, sulphur and coal ashes are deposited in

the liner. This deposit combines with moisture to form a highly corrosive acid (Sulphuric Acid). In order to protect your liner,

we recommend that you burn only low sulphur coals (less than 1% sulphur). Have your liner cleaned within 48 hours of

shutting down your stove at the end of the heating season. Be certain that all the soot is removed. Wipe the liner ue using

a strong solution of baking soda and water. This can be done by wrapping a rag around a chimney cleaning brush, dipping

it in the baking soda-water solution, then passing it through the liner three or four times.

CHIMNEY FIRES

If you are having a chimney re, follow these steps:

1. Close all heater doors and combustion air controls. For replaces, block the replace opening with a non-

combustible material (such as an asbestos or steel sheet).

2. Alert your family to the possible danger.

3. If you require assistance, alert your re department.

4. If possible, use a dry chemical re extinguisher, baking soda or sand to control the re. Do not use water, as it may

cause a dangerous steam explosion.

5. Watch for smouldering or re on combustibles next to the stove, stove pipe and chimney. Check outside to ensure

that sparks and hot embers coming out of the chimney are not igniting the roof.

6. Do not use the stove again until your chimney and stove pipe have been inspected by a qualied chimney sweep

or Fire Department inspector. The TUBINOX lining system has been designed to withstand the intense heat of a

chimney re. Nevertheless, chimney res are dangerous and should be avoided.

VENTINOX LINING SYSTEM - 4

Page 5

INSTALLATION GUIDELINES

DuraVent Liners venting gas or oil appliances do not require a minimum clearance or

insulation between the outside of the liner and inside of the masonry shell*. Leave enough

clearance for the liner to slide into place without difculty.

For Venting Solid Fuel Appliance, a minimum of ½` clearance is require between the outside

of the liner and inside of the masonry. To meet Zero Clearance to combustible, insulation must

be used. (See insulating liner section for instruction).

*Please note: While insulation is not required for every installation (refer to UL1777 or ULC-S635 for appropriate

listings or standards), the performance of the entire heating system is greatly enhanced when installing insulating materials.

The venting system acts and reacts in step with the heating unit`s operation. Insulation improves draft and minimizes

condensation, helping ue surfaces warm up more quickly to achieve a heater’s rated efciency. Insulation is particularly

important for exterior chimneys.

Read the sections outlining insulating procedures before beginning the installation.

INSTALLATION INSTRUCTIONS

• The chimney lining system can be installed in a masonry or concrete chimney that complies with the building code.

• In Canada, a new masonry or concrete chimney construction must comply with CAN/CSA A405: Design and

Construction of Masonry Chimneys and Fireplaces.

INSTALLATION

• NEW CHIMNEY LINING (g.4)

1. To install a liner into a new masonry chimney, we

suggest that you install the liner as the chimney is

being constructed.

2. Start the masonry chimney construction, making

sure that the dimension and manufacture of the

bricks and mortar conform to the Building Code.

If you choose to insulate the liner.

See insulating liner section (Page 8) to

size the masonry chimney.

Fig. 2

Fig. 3

3. To start the liner installation, attach the tee to the

rst length. Insert the liner with the male (smaller

connection) end down. Twist lock the part together

(g.2). Attach the tee cap to the base of the tee.

• NOTE: Each joint takes 1 1/2" (38 mm) overlap.

4. Place the tee and length assembly on the support

base, then add lengths along the chimney

construction until the liner protrudes about 10 in.

(254 mm) above the masonry chimney (g.3).

5. Install the top support on top of the masonry

chimney using lag bolts and/or cement (Fig. 5).

6. Slip the support collar over the liner until it rests on

the support.Tighten the bolt to fasten it to the liner.

(Fig. 5)

7. Twist lock the rain cap to the top of the liner.

VENTINOX LINING SYSTEM - 5

Fig. 4 - New masonry liner installation for interior chimney

Page 6

8. Installation of wall radiation shield through a

combustible wall.

• From inside, frame a hole14 1/2" x 14 1/2" (368

mm x 368 mm) in the wall where the vent will pass

through.

• Adjust the insulated wall radiation shield length to

t the wall thickness and lock the two parts together

with three (3) screws supplied.

CAUTION: Make sure the wall radiation shield is

always in contact with the masonry chimney.

• Slide the wall radiation shield over the length and x

it to the wall using four (4) screws supplied (g. 6).

Note: The void in the four corners between the wall

radiation shield and the wall frame can be lled with

berglass insulation.

EXISTING CHIMNEY RELINING (g.7) :

1. At the bottom of the masonry chimney, set up a brick

or other non-combustible support on which the liner

will rest.

Note: On an installation lower than 30 feet, you may

support the liner from the top support.

2. Attach the tee to the rst liner length. Insert the liner

with the male (smaller connection) end down. Twist

lock the parts together (g. 2 page 4).

3. You may remove the horizontal branch to facilitate

lowering the liner into the chimney, then attach it

when in place. If you keep it, make sure it is solidly

attached.

4. To lower the liner into the chimney, we suggest that

you tie a small hook to a long rope and grip the hook

on the tee. Make sure the rope is on the outside

of the liner, so you will be able to add lengths and

lower the assembly down the chimney (g. 10). Add

lengths until the liner protrudes about 10" above the

masonry chimney top.

5. Install the support plate on top of the masonry

chimney using lag bolts and /or cement.

6. Slip the support collar over the liner until it rests on

the support plate. Tighten the bolt to fasten it to the

liner.

Fig. 5

Fig. 6

If you choose to insulate the liner

See insulating liner section (Page8).

VENTINOX LINING SYSTEM - 6

Fig. 7 - Existing masonry relining installation

Page 7

Fig. 8 - Lining sustem for new replace installation

Fig. 10

7. Twist lock the rain cap to the top of the liner.

8. From inside the house, twist lock the masonry

adaptor to the tee. Now fasten the adaptor’s collar to

the masonry wall.

Be sure there is at least 18 inch clearance between

the single wall pipe and any combustible material.

INTERIOR SUPPORT

A liner installed in a replace chimney will require an

interior support at the top of the replace.

• NEW CHIMNEY LINING (g.8)

• Install the support plate on top of the replace

• Proceed with the erection of the liner along the

chimney construction as described before.

• EXISTING FIREPLACE (g.9)

• Install the liner as described previously

• (see "existing chimney lining"). With the liner

hanging in the replace, place the interior support in

position and mark its location on the liner.

• Remove the support and attach the support collar

around the liner slightly above your mark.

• Attach the support to the replace wall using four

bolts and lags.

• Continue connection to your stove.

Fig. 9 - Existing replace relining installation

VENTINOX LINING SYSTEM - 7

Page 8

INSULATING DURAVENT LINERS

General Guidelines:

Duravent Liners have been tested and are listed to

UL 1777 and ULC-S635 standard at zero clearance to

combustibles and for use with all fuels. When venting

wood red heaters or replaces, a minimum of one inch

TherMix® or at least 1/2" of ProFoil are needed to conform

to the UL1777 and ULC-S635, zero clearance listing.

All temperature tests were performed on chimneys

featuring a 4” nominal masonry shell and a Security Liner

with or without the specied insulation between the liner

and interior of the chimney (no clay tiles). The outside of

the chimney was surrounded with a wood enclosure at

zero clearance as specied by the standard.

METHOD #1: INSULATING WITH

THERMIX

TherMix® is poured into the chimney AFTER the liner is

installed. TherMix® is a pre-mixed insulation material and

only requires the addition of water at the job site. Review

TherMix® literature to determine the volume of TherMix®

needed to ll a specic chimney.

Empty a TherMix® bag into a mortar trough or

wheelbarrow. Add 7 to 9 gallons of water and mix with a

hoe. Proper consistency is achieved when the material

feels damp but is still granular. Little or no water should

appear between ngers when a handful of TherMix® is

squeezed. Correctly prepared TherMix® pours like “loose

ll” into the void between the liner and the chimney.

Complete instructions are on each TherMix® bag.

During the pouring process, distribute the insulation

evenly into the available space. Spacers may be used

every 5 ft. to center the liner. Vibrate the liner by rmly

tapping it. Continue to pour TherMix® until the chimney is

lled to the top and nish as described previously. Inspect

the liner at this time to ensure that no TherMix® has fallen

inside the venting system.

All heaters or replaces can be red up right after the

installation is complete. Keep ue gas temperatures below

700 degrees F for three weeks. This allows for TherMix® to

dry gradually. The operator is responsible for making sure

that the heater is not over red during this initial period.

METHOD #2: INSULATING WITH

PROFOIL OR FLEXWRAP CERAMIC

BLANKETS.

Ceramic blankets are attached to DuraVent Liners as

the liner is installed into the chimney. Blankets are 1/2" in.

thick, 8 pounds density, and faced with a 2 mil. aluminum

®

Bag of TherMix

foil. The 1/2" thick blanket is the minimum amount of

insulation needed when using ProFoil. If using 1/4" ProFoil

blankets, two wraps are necessary to achieve the required

1/2" insulation. Aluminum tape, wire mesh and clamps are

needed for proper installation.

VENTINOX LINING SYSTEM - 8

Page 9

METHOD #1:THERMIX

BENEFITS AT-A-GLANCE:

• No Health Risks: Non-brous, non-toxic, inert and

manufactured under stringent quality controls. Safe

to the installer and homeowner, today and into the

future.

• Adds Safety: Chimneys insulated by TherMix reduce

creosote build-up, the chance of a chimney re is

minimized and its dangers are decreased.

• Superior Performance: Featuring high “R” values,

ue surface temperatures are balanced and react

quickly to ring cycles of heating units. Aiding in

optimal heating efciencies.

• Durable & Tested: When properly installed, TherMix

does not leak, separate or deteriorate. Field tested

since 1984.

• Reinforces: Insulates the liner & ue gas while

providing a strong bond for the masonry chimney.

THERMIX: THE “THERMAL

BRIDGE” BETWEEN

FLEXIBLE CHIMNEY

LINERS AND MASONRY

TherMix lowers temperatures on liners during over ring

or chimney res: Allows heat to be slowly absorbed into

the entire mass of a chimney, where it is safely dissipated

over a large surface area.

TherMix maintains higher temperatures on liners

when ue gas temperatures are low: Maintaining ue gas

temperatures above dew point, (~128°F), is essential

to avoid condensation. The insulating mass of TherMix

retains the maximum available heat close to the liner:

the ue stays warm for a longer period of time after the

appliance shuts down. With oil and gas appliances,

keeping the ue warmer between ring cycles greatly

reduces the possibility of momentary ue gas spillage

which occur at the start of the next cycle. With wood

burning applications, warmer ues help eliminate back

pufng and other draft related problems.

TherMix minimizes uctuations of liner surface

temperatures during heating cycles. This is critical when

draft must be established quickly each time an appliance

res up and when minimizing condensation within the

entire height of the ue is important.

NOTE: To comply with the specications

zero clearance solid ue installation, a

minimum thickness of 1” of TherMix must

be installed between a listed stainless steel

liner and a 4” thick masonry chimney wall.

ProFoil ceramic blanket

There is no change in consistency of TherMix over

time. Even after exposure to many high temperature

tests, the structural integrity, chemical composition, and

insulating qualities remained consistent over time, every

time.

• TherMix insulated chimneys can be used right after

the installation is complete, as long as ue gas

temperatures do not exceed 1000°F during the rst

48 hours of actual use. Please note that drying and

curing are two separate processes:

• Curing or hardening of TherMix takes place over

a 28-day period, with 65% to 75% of this process

occurring the rst week.

• Drying time depends on the thickness TherMix, the

permeability of the chimney, and weather conditions.

The drying process :

• Curing or hardening of TherMix takes place over

a 28-day period,with 65% to 75% of this process

occuring the rst week.

• Drying time depends on the thickness TherMix, the

permeability of the chimney, and weather conditions.

The drying process is enhanced and completed over

time by using the heating appliance.

VENTINOX LINING SYSTEM - 9

Page 10

TherMix Field Benets TherMix Ceramic Blankets

Zero-clearance to combustibles Yes Yes

Ease-of-installation Yes Yes

Diculties with Osets No Yes

Seals dangerous cracks and voids in chimneys Yes No

Eliminates air leakage into chimney Yes No

Eliminates moisture buildup between liner & chimney structure Yes No

Ships UPS/FedEx (Boxes Only) Yes Yes

Accepted by building code ocials Yes Yes

Can be removed Yes Yes

Avoids reliance on respirator during installation Yes No

Eliminates the need for reective surfaces to reduce heat transfer Yes No

Poured method means one size ts all insulation Yes No

Holds liner in place Yes No

Figure 2

WHEN USING THERMIX

There is no need to purchase spray adhesives, tapes,

wire, mesh, and/or sheet metal parts which add to the cost

and time to complete a job (Figure 2.)

• TherMix can be used to insulate modular masonry

replaces.

• TherMix stays in place when installed but can be

easily removed. Dry weight per cubic foot installed

is ~20lbs.

TherMix is delivered in a strong poly-lined bag or

box containing all ingredients except water, which must

be added to moisten the material (Figure 3.) Proper

consistency is achieved when the material feels damp but

still granular (~7 to 9 gallons of water per bag/box). *When

a handful of properly moistened TherMix is squeezed hard,

little to no water appears between the ngers.

During the installation, correctly prepared TherMix pours

like “loose ll.” TherMix is distributed within the chimney

cavity by vibrating the liner. *Do not tamp or compress

TherMix.

Figure 3

VENTINOX LINING SYSTEM - 10

Page 11

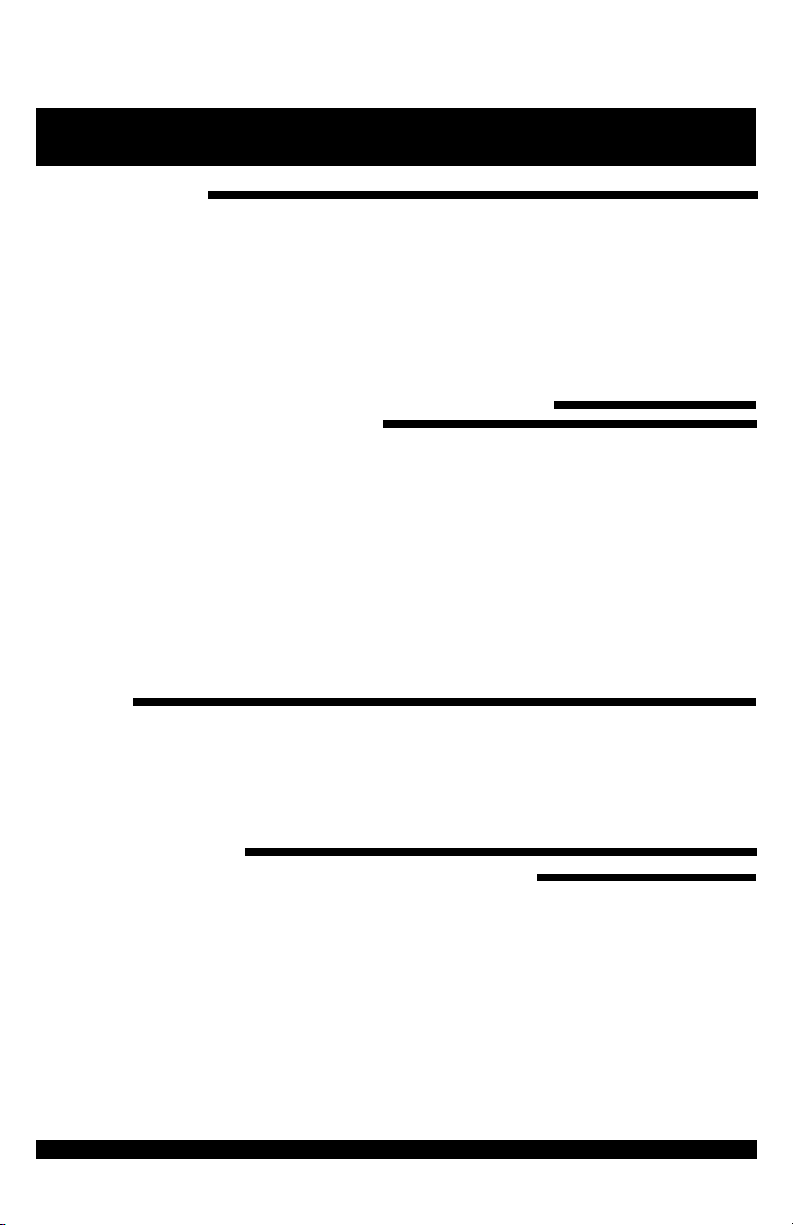

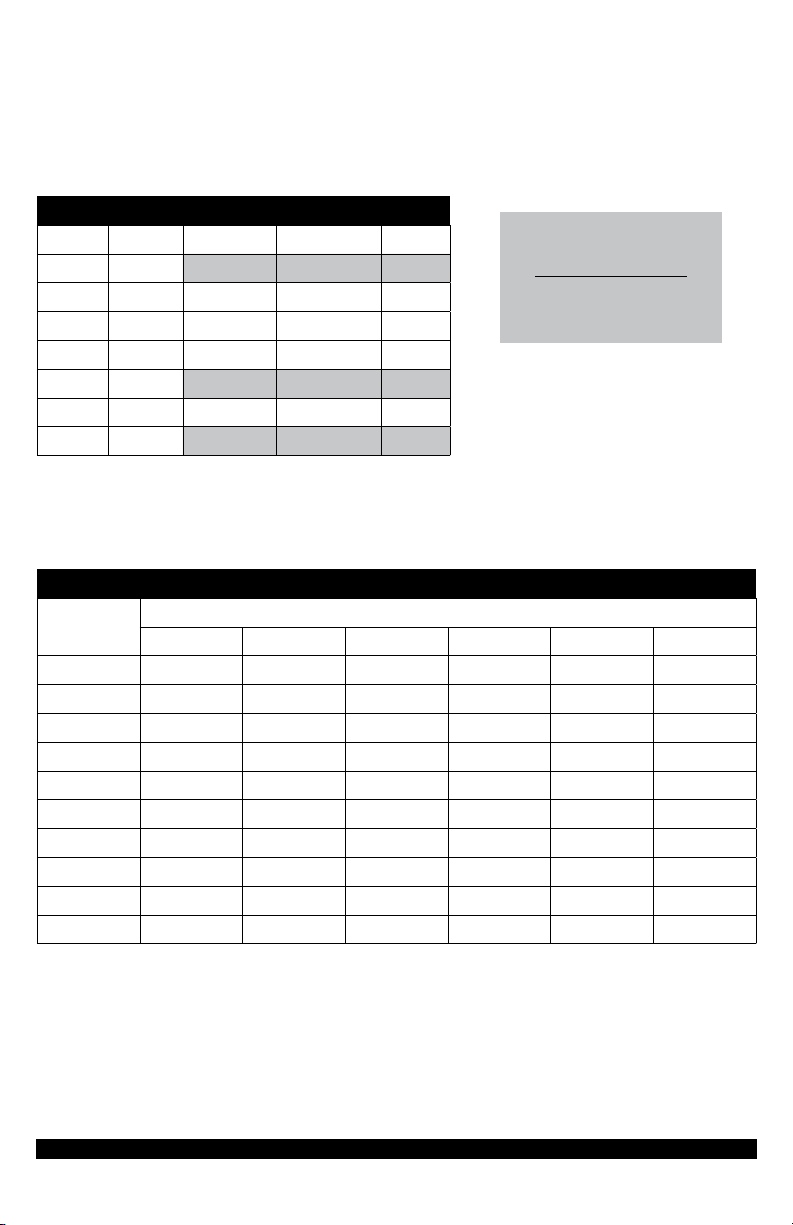

TABLE 2: CROSS SECTION AREA OF LINER

Liner Size CS Area Oval Liner Size Oval Dimensions CS Area

Round 5" 19.62in 2

Round 6" 28.46in2 Oval 6" (4.2" x 7.2") 24.60in2

Round 7" 38.46in2 Oval 7" (4.2" x 9.1") 32.20in2

Round 8" 50.25in2 Oval 8" (4.2 x 10.3") 37.20in2

Round 9" 62.50in2

Round 10" 78.50in2 Oval 10" (4.2" x 13.3") 49.5 0in2

Packages of TherMix

=

(W" x D" x H") - (CS x H")

1728 cu. in.

÷

3.25

W = Width of flue opening (in inches)

D = Depth of flue opening (in inches)

H = Height of flue (in inches)

CS = Cross Section areas (table 2)

Round 12" 113. 22i n2

TABLE 1: THERMIX VOLUME PER ONE FOOT OF CHIMNEY HEIGHT

Flue Opening

5" 6" 7" 8" 10" 12"

Diameter of Liner

7.5" x 7. 5" .25 .20 - - - - - - - -

7.5" x 11.5" .46 .40 (Ovalized) .38 (Ovalized) .32 - - - -

8.5" x 8.5" .36 .30 .23 - - - - - -

8.5" x 11.5" .54 .48 .41 (Ovalized) .36 (Ovalized) .33 - -

9.5" x 9.5" .49 .43 .36 .27 - - - -

11.5" x 11.5" .78 .72 .65 .60 .37 - -

11.5" x 16.5" 1.18 1.12 1.05 .96 .77 - -

12.5" x 12.5" .95 .88 .82 .73 .53 - -

14.5" x 14.5" 1.30 1.26 1.20 1.10 .92 .65

14.5" x 18.5" 1.70 1.66 1.60 1.50 1.30 1.04

VENTINOX LINING SYSTEM - 11

Page 12

METHOD #2 PROFOIL ATTACHING CERAMIC BLANKETS TO A

DURAVENT LINER:

Roll out the insulation blanket on a clean surface, foil

face down. Lay the liner on top and trim the blanket so that

it is about 1 1/2" shorter than the liner.

Wrap the insulation around the liner lengthwise and trim

it so that a butt joint is formed. Seal the joint with aluminum

foil tape. Spray adhesive may be used to hold the blanket

in place until it can be secured with the foil tape. A

minimum of 1/2" of insulation is required. If a double layer

of blanket is needed, install it with the butt joint on the

opposite side.

Install ProMesh protective wire mesh over the

blanket(s). The ProMesh is used to protect the ProFoil

insulation as the liner is lowered into the chimney. Slip the

ProMesh over the insulated liner and secure one end with

a stainless steel band clamp. Pull the ProMesh towards

the other end of the liner so that it tightens snugly around

the insulation, then trim off the excess. Secure this end

with a stainless steel band clamp.

1/2" of ProFoil

Attaching a ceramic blanket

VENTINOX LINING SYSTEM -12

Loading...

Loading...