Page 1

Installation Instructions

PolyPro Double-Wall Flex

Gas Vent System for Category II &

IV Gas-Burning Appliances

PolyPro

®

Flex

Page 2

A MAJOR CAUSE OF VENT RELATED FIRES IS FAILURE

TO MAINTAIN REQUIRED CLEARANCES (AIR SPACES)

TO COMBUSTIBLE MATERIALS. IT IS OF THE UTMOST

IMPORTANCE THAT POLYPRO

® BE INSTALLED ONLY IN

ACCORDANCE WITH THESE INSTRUCTIONS.

• Assure unrestricted vent movement

IMPORTANT

Throughout this manual you will see

special attention boxes intended to

supplement the instructions and make

special notice of potential hazards.

In the judgement of M&G DuraVent,

these categories mean:

WARNING

Indicates a condition or hazard which

may cause severe personal injury, death

or major property damage.

CAUTION

Indicates a condition or hazard which

will or can cause minor personal injury

or property damage.

WARNING

Risk of carbon monoxide poisoning

or re due to joint separation or pipe

breakage.

• Examine all components for possible

shipping damage prior to installation;

• Read all instructions before beginning

the installation and follow these

instructions exactly as written.

• Proper joint assembly is essential for a

safe installation. Check the integrity of

ALL joints upon completion of assembly

• This venting system must be free to

expand and contract under normal

operation.

where required through walls, ceilings

and roof penetrations.

• This venting system must be supported

in accordance with these instructions.

• Do not mix pipe, ttings, or joining

methods from dierent vent system

manufacturers. Do not use adhesives of

any kind with this venting system.

Keep these instructions for future

reference.

Dear Customer, Installer, or End User:

We welcome any comments regarding

matters pertaining to our DuraVent products.

We welcome any ideas, input or complaints

to help improve our product oering. Send

your emails to:

president@duravent.com

If you are searching for tech support or

product information, please phone us at

800-835-4429.

Or email us at:

techsupport@duravent.com

PolyPro® is one of M&G DuraVent's

GreenVent® line of products.

2

Page 3

PolyPro Flex Gas Vent System

For the most up-to-date installation instructions, see www.duravent.com

CONTENTS

APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

MINIMUM CLEARANCE TO COMBUSTIBLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GENERAL INSTRUCTION NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . 4

INSTALLATION OF FLEX GASKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

MASONRY / SHEET ROCK ENCLOSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

B VENT / RELINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

PolyPro

®

Flex

3

Page 4

APPLICATION / LISTING

For specic information on application,

equivalent length of ttings, listings, etc.,

please reference M&G Duravent's installation

instructions for rigid pipe (Document L273).

M&G Duravent's PolyPro vent pipe should not

be installed in areas where the temperature

could exceed 230 F / 110 C.

PERMITS

Check with your local Building Ocial, Fire

Ocial, or other authority having jurisdiction

regarding permits, restrictions, and

installation inspections in your area.

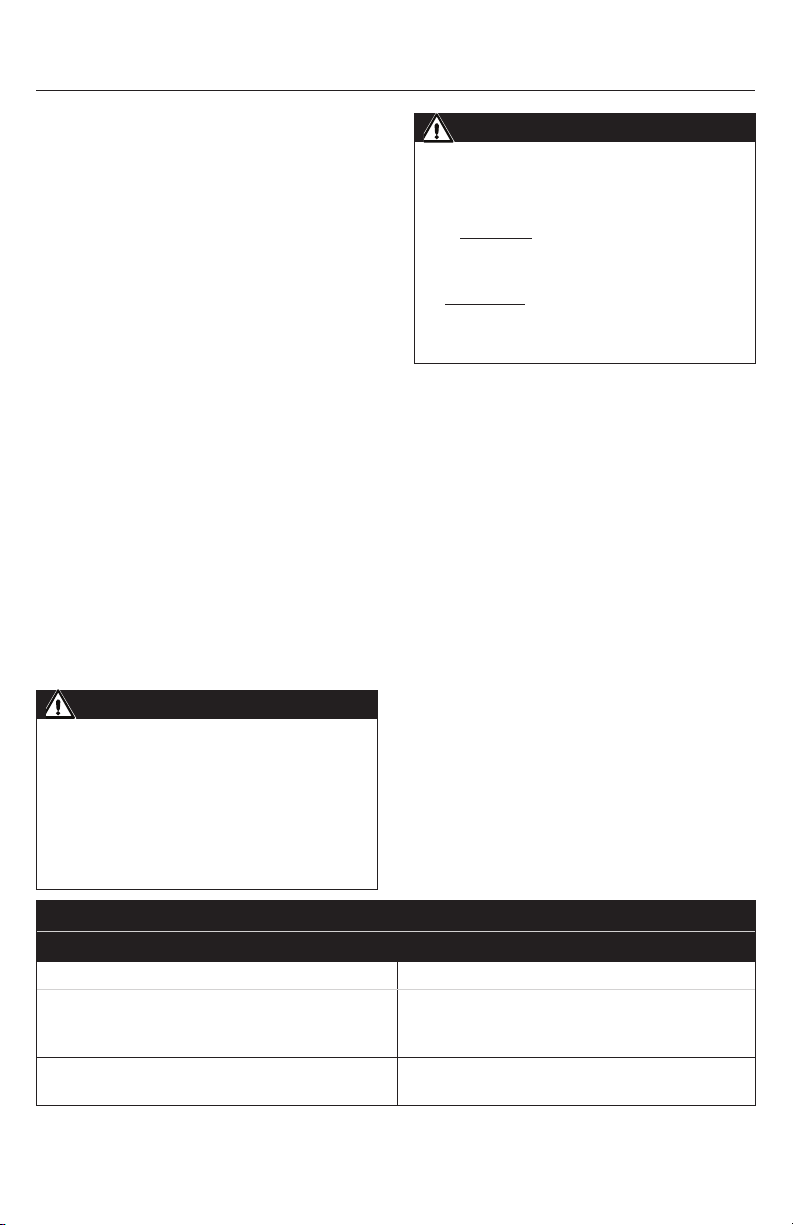

MINIMUM CLEARANCE TO

COMBUSTIBLES

Refer to Table A for minimum clearances

to combustible materials. Use the values

shown in this table unless the appliance

manufacturer species otherwise. If there

is a conict between the two, the greater

clearance shall apply. It is prohibited to place

any type of insulation around the venting

system within these clearances.

CAUTION

Installation applications and

terminations shown in these

instructions must be approved by

the manufacturer of the appliance to

which it is applied. Use only listed M&G

DuraVent terminations with PolyPro

Venting.

Table A

Minimum Clearance To Combustibles Table

VENT ORIENTATION

Horizontal Single Wall: 0" for ue temperatures up to 194*F (90*C).

Vertical Single Wall: 0"

IMPORTANT

The vent system must terminate in

accordance with local code requirements

and appropriate National Codes:

In the US: NFPA 54 / ANSI Z223.1

National Fuel Gas Code or the

International Fuel Gas Code.

In Canada: CAN/CGA-B149.1 Natural

Gas Installation Code or CAN/CGA-149.2

Propane Installation Code.

GENERAL INSTALLATION NOTES

Reference the Installation Instructions

provided with M&G Duravent's rigid pipe

(L273) for general instructions. PP Flex must

be enclosed, and used in conjunction with

rigid PP pipe to connect to an appliance.

• When used to conduct ue gases, PP ex

must not be installed at an angle greater

than 45 degrees from vertical. This will

ensure proper condensate ow back

towards the appliance outlet.

• PP Flex may be used to bring

combustion air into the appliance. In

these instances, pipe can be unenclosed

and oriented in a vertical or horizontal

position.

• PP ex must be treated carefully to

prevent damage when being installed

during low temperatures (<41°F, < 5 °C).

In colder weather, pre-warm ex prior

to installation. When relining, it may be

easier to insert ex from the bottom up

CLEARANCE

1/4" (6mm) for ue temperatures up to 230*F (110*C).

Flex: N/A- NOT ALLOWED

Flex: 0" (Must be enclosed)

4

Page 5

rather the top down.

• Always use soapy water to lubricate

gaskets prior to joint assembly. Do

not use Petroleum based lubricants!

• Plastic venting systems shall not pass

through rated re separations.

ADDITIONAL INSTRUCTIONS FOR

TERMINATION

M&G Duravent's PP Flex terminations are

specically designed for use with higheciency appliances that are known to

produce high volumes of uid due to

condensation of moisture within ue gases.

DO NOT modify these terminations.

IMPORTANT: Unless the appliance is designed

to address ow of condensates from the

vent system, a drain must be incorporated

within the vent to allow condensates and

rainwater to escape. This drain must include

a trap to prevent combustion gases from

entering living spaces. Be sure to check

the appliance manufacturer's installation

instructions closely in regards to condensate

management.

PP Flex pipe must always have gaskets

installed on both ends of any installation.

Gaskets are installed on the ex pipe, with the

gasket seating inside the ex pipe grooves

(Fig.1). Use soapy water to assist installation.

1. Cut PP ex pipe (knife, saw, etc) to

desired length. Special care should be taken

to ensure cut is square, and the edge is

deburred.

2. Place Flex Gasket over Flex pipe and install

in the rst whole groove nearest the end.

3. Open the locking tabs (x2) of the

appropriate ex tting to accept the ex pipe

(Fig.2)

4. Apply soapy water to the gasket, and push

pipe/gasket into appropriate ex tting,

seating pipe down until it bottoms out

(Fig.2).

Gasket in

fiRst

GRooVe

INSTALLATION OF FLEX GASKET:

PP flex PiPe

PP flex Gasket

flex aDaPteR

flex to coRRect

lenGth, clean eDGe

install Gasket, use

soaPy wateR

Figure 2, Installing Gasket / Flex Adapter

Figure 1, Mounting the Gasket

inseRt into

aDaPteR

lock PiPe to

aDaPteR

(click!)

5

Page 6

5. Close locking tabs on ex adapter so

tabs seat in the ex pipe. Slight adjustment

of pipe may be needed to ensure proper

engagement.

that is lined with a clay or concrete liner,

check to see if a short portion of the tile is

sticking out of the top of the chimney. If so,

this short top portion must be broken o to

permit the termination's ashing to sit down

ush on the chimney's crown. It is best to do

this prior to beginning the installation.

1. Determine the required location of the

opening within the enclosure. Ensure the ue

access cut-out meets the minimum specied

size to allow manual assembly of connections

within the ue. With masonry chimneys, the

breech opening may have to be enlarged

FLEX CHIMNEY LINING KIT

RoPe

Figure 3, Flex Puller

FLEX PULLER

A ex puller is an optional component

available to help ease installation of PP

Flex through enclosures (Fig.3). The

2"(60mm) version is of dierent design than

3"-5"(80mm-130mm).

2" Dia: Unscrew ceramic holder from cone.

Install ceramic holder around PP Flex pipe,

and re-install into cone.

3"-5" Dia: Connected using bayonet style

connection with a rotating movement of 1/4

turn to lock in.

MASONRY / SHEET ROCK

ENCLOSURE:

Examine the chimney or enclosure

carefully for obstructions prior to starting

an installation. Any structural defects or

potential safety problems must be repaired

prior to relining, and the enclsoure should be

clean. If working with a masonry chimney

1. Wall Plate

2. Support Elbow

3. Flex Chimney Support

4. Flex Male Adapter

5. Clamp (or Tie)

6. Flex Coupler

7. Gasket

8. Flex Liner

9. Spacer

10. Support Bracket

11. Flex

Female Adapter

12. Flex Chimney

Cap Flashing

13. Termination

Pipe

6

1

13

12

11

10

7

9

8

7

5

4

3

2

6

Page 7

to permit proper access. If this is the case,

patch up the opening after the installation

is completed using best practices. The slope

of the rigid connecting ue pipe must have a

minimum of 3° (equivalent 5cm/m) (5/8" per

foot).

2. Fix the Flex Chimney Support

(Fig.4) with 4 screws on the wall of the

enclosure.

6. Install PP Flex liner into the enclosure. A

second person is required to help feed the

exible liner into position (feeding either

from the top or bottom of the enclosure).

This will also help prevent damage from

occurring.

7. After installing the required length of liner,

remove the Flex Puller (if applicable)

8a. Position the Support Elbow on the Flex

Chimney Support (see 2 and 3, Fig.5)

8b. Secure the Support Elbow with the clamp

around the Flex Male Adapter and through

the slot of the Flex Chimney Support (see 1,

Fig.6).

1

2

1

3

Figure 4, Mounting Flex Chimney Support

3. The length of the exible liner can be

determined in two ways: use a rope with

a weight to measure the shaft length, add

16" (40cm) extra length for each bend. The

exible liner can be shortened with a saw or

scissors by cutting in a groove. The correct

length can also be determined after installing

the liner in the shaft and cutting it at the top

of the chimney, see Fig.8, dimension B.

4. Mount the Gasket into the ex pipe, and

attach to the appropriate coupler as detailed

above.

5. Mount the Spacers with a maximum

distance between them of 6 feet (2m).

Figure 5,

Installation

Support Elbow

Figure 6,

Securing

Support Elbow

9. Mount the Wall Plate on the wall of the

shaft (Fig.7). Pay attention to the correct

slope of 3°. The pipe of the Support Elbow

must be in the centre of the hole in the Wall

Plate.

10. The Support Elbow can be shortened if

required- For single wall, Dim A (Fig.7) must

have a minimum length of 1.6" (40mm).

11. At the top of the shaft, shorten the

exible liner to the required length and make

sure that dimension B in Fig.8 is between 1½

- 2½" (between 38 and 64 mm).

7

Page 8

15. Install the Termination Pipe(see 1 ,

Fig.10). Assemble the storm collar portion of

the Flex Chimney Flashing (see 2, Fig.10).

16. Connect the appliance to the exible vent

=

=

=

system with M&G DuraVent rigid PolyPro vent

system.

=

1

A

Figure 7, Mounting the Wall Plate

13. Fit the Support Bracket (see 1, Fig.8)

over the liner and let it rest on the wall of the

shaft. Mount the Gasket as detailed above

(see Fig.1). Push the Flex Female Adapter on

the liner and close the latching tabs. Allow

the assembly to rest on the Support Bracket.

14. Seal the edge of the chimney shaft with

water-resistant sealant (see 1, Fig.9) and push

the Flex Chimney Flashing (see 2, Fig.9) on

the shaft and x it with four masonry anchors

(see 3, Fig.9).

B

1

3

2

1

Figure 9, Installing Vent Cap

1

2

Figure 8, Required Liner Length

8

Figure 10, Installing Termination Pieces

Page 9

B VENT RELINE:

From within the room where the appliance is located, remove any existing horizontal or angled

sections of B Vent. PP Flex cannot be installed at an angle greater than 45 degrees from vertical.

The B Vent Adapter-Lower will t over the bottom of the existing B Vent's vertical stack at or

near the ceiling. Carefully inspect the B Vent to ensure integrity. Ensure any visible screws or

obstructions are removed. PP Rigid pipe must be used to complete install to the appliance-

Instructions- 2" (60mm) PP Flex in B Vent

1. Remove existing B Vent termination cap

2. Carefully feed ex down through B Vent so

approx 2' of ex extends beyond the bottom

of the B Vent (Flex puller or rope aid optional)

3. Cut to length the top of Flex pipe and

insert ex through B Vent Adapter- Upper, and

through the Termination Base.

4. Install the PP Flex Gasket and Flex Female

Adapter onto Flex pipe using instructions in

previous pages.

5. Lower the B Vent Adapter- Upper onto the

top of the existing B Vent and secure using

screws (x3) supplied with the hardware kit.

6. Attach the Termination Top to the

Termination Cap (clicks when engaged),

then insert the Flex Female Adapter into the

Termination Cap. Push the assembly onto the

Termination Base (clicks when engaged, see

Fig.12).

7. Push the completed assembly down onto

the B-Vent Adapter- Upper. When level, secure

with three screws provided.

8. At the bottom end, cut the PP Flex to

length 3" below the bottom of the vertical B

Vent still portruding from the ceiling.

9. Install the Flex Gasket

and Flex Male Adapter onto

the Flex pipe

10. Install B Vent Adapter-

Lower. (Flex Male Adapter

should protrude beyond

per Fig.13)

(click!)

11. Secure the B Vent

Adapter- Lower to the B

Vent using three screws

from the supplied

hardware.

Figure 12

Figure 11- (2" Flex / B Vent)

teRMination toP

teRMination caP

flex feMale aDaPteR

2" (60MM) flex Gasket

2" (60MM) flex

teRMination Base

MountinG haRDwaRe

B Vent aDaPteR- uPPeR

B Vent PiPe

2" (60MM) flex Gasket

flex Male aDaPteR

MountinG haRDwaRe

B Vent aDaPteR- loweR

9

Page 10

B Vent

aDaPteR-

loweR

flex Male

aDaPteR

B Vent PiPe

MountinG

haRDwaRe

flex

feMale

aDaPteR

B Vent

aDaPteR-

uPPeR

B Vent

PiPe

c suPPoRt

BRacket

Figure 13

Instructions- 3" (80mm) PP Flex in B Vent

1. Remove existing B Vent termination cap

2. Carefully feed ex down through B Vent so

approx 2' of ex extends beyond the bottom

of the B Vent (Flex puller or rope aid optional)

3. Cut to length the top of Flex pipe and

insert ex through B Vent Adapter- Upper

4. Install PP Flex Gasket and Flex Female

Adapter onto Flex pipe per instructions

detailed above

5. Lower B Vent Adapter- Upper to the top

of the B Vent and secure with screws (x3)

supplied

6. Install C Support Bracket as shown in Fig.14

and lower Flex Female Adapter into B Vent

Adapter- Upper

7. Attach Termination Top to Termination Cap

(clicks when engaged), insert 3" Rigid Pipe

into Termination Cap, and attach Termination

Insert into Termination Cap (clicks). Then

connect Termination Insert to Termination

Transition (click).

8. Line up inner pipe connections and push

termination assembly down onto B Vent

Adapter- Upper and secure with screws (x3)

provided

9. Cut Flex to length 3" below the bottom of

the B Vent

10. Install Flex Gasket and Flex Male Adapter

on Flex

11. Install B Vent Adapter- Lower. (Flex Male

Adapter should protrude beyond per Fig.13)

12. Secure B Vent Adapter- Lower to B Vent

with hardware provided

Figure 14

teRMination toP

teRMination caP

3" (80MM) RiGiD PiPe

teRMination inseRt

teRMination tRansition

c suPPoRt BRacket

B Vent aDaPteR- uPPeR

flex feMale aDaPteR

3" (80MM) flex Gasket

3" (80MM) flex

B Vent PiPe

3" (80MM) flex Gasket

flex Male aDaPteR

MountinG haRDwaRe

B Vent aDaPteR- loweR

Figure 15- (3" Flex / B Vent)

10

Page 11

11

Page 12

POLYPRO WARRANTY

M&G DuraVent, Inc. (“DuraVent”) provides this warranty for PolyPro® for ten years. Subject to the limitations set fort h below, DuraVent

warrants that its products will be free from defects in material or manufacturing, if properly installed, maintained and use d. DuraVent

product s are fully warranted if installe d only by a professional installer. This Warrant y is transferable from t he original homeowner to the

buyer of the home within the warranted ten years. This warranty does not cover normal wear and tear, smoke damage or damage caused

by chimney res, ac ts of God, or any product that was: (1) purchased other than from an authorized DuraVent dealer, retailer or distributor;

(2) modied or altered; (3) improperly serviced, inspec ted or cleaned; or (4) subject to negligence or any use not in accordance with the

installation ins tructions included with the product as deter mined by DuraVent.

Installation ins tructions are available online at w ww.duravent.com under Support/Literature and through our Cus tomer Service Department

800-835- 4429 or customerser vice@duravent.com.

DuraVent provides the following warranties for PolyPro: One Hundred Percent (100%) MSRP 10 years from the date of purchase.

All warranty obligations of DuraVent shall be limited to repair or replacement of the defective pro duct pursuant to the terms and conditions

applicable to each pro duct line. These remedies shall constitute DuraVent’s sole obligation and sole remedy under this warranty. This

warranty provides no cash surrender value. The terms and conditions of this warranty may not be modie d, altered or waived by any action,

inaction or representation, whether or al or in writing, except upon the ex press, written author ity of an executive ocer of DuraVent.

This product is intended for venting only category IV appliances burning Nat ural Gas, Propane and Oil. All other fuels are not covered under

this warranty.

LIMITATIONS ON POLYPRO INTERNET SALES: Not withstanding any other terms or conditions of this PolyPro Warrant y, DuraVent provides no

warranty f or PolyPro® if it is not installed by a qualied professional installer.

DuraVent must be notied and given the opportunity to inspect defective product prior to replacement under the terms of this limited

lifetime warranty. All warranty claims must be submitted with pro of of purchase. Labor and installation costs are not covered under this

warranty. To obtain warranty service contac t: DuraVent Warranty Ser vice, 877 Cotting Ct., Vacaville CA 9568 8, or call 800-835-4429.

WHERE LAWFUL, DURAVENT DISCLAIMS ALL OTHER WARRANTIES, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF

MERCHANTABILITY AND FIT NESS FOR A PARTICULAR PURPOSE. IN NO EVENT WILL DURAVENT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL,

PUNITIVE OR SPECIAL DAMAGES O R DIRECT OR INDIRECT LOSS OF ANY KIND, INCLUDING BUT N OT LIMITED TO PROPERTY DAMAGE AND

PERSONAL INJURY. DURAVENT’S ENTIRE LIABILITY IS LIMITED TO THE PURCHASE PRICE OF THIS PRODUCT. SOME STATES DO NOT ALLOW

LIMITATIONS ON IMPLIED WARRANTIES, OR THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS AND EXCLUSIONS MAY NOT APPLY TO YOU. THIS LIMITED WARRANTY GIVE S YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS THAT VARY FROM STATE TO STATE.

For the most up-to-date installation instructions, se e www. duravent.com

REV 3.22.2012

Customer Service Support 800-835-4429 707-446-4740 FAX www.duravent.com

PolyPro® and GreenVent® are registered trademarks of M&G DuraVent, Inc.

All rights reserved, ©2012 M&G DuraVent is a member of M&G Group.

9/2012 l272

Loading...

Loading...