Page 1

Installation Instructions

PolyPro Single-Wall Gas Vent

System for Category II & IV

Gas-Burning Appliances

PolyPro

®

Page 2

A MAJOR CAUSE OF VENT RELATED FIRES IS FAILURE

TO MAINTAIN REQUIRED CLEARANCES (AIR SPACES) TO

COMBUSTIBLE MATERIALS. IT IS OF THE UTMOST IMPORTANCE

THAT POLYPRO® BE INSTALLED ONLY IN ACCORDANCE WITH

THESE INSTRUCTIONS.

WARNING

CARBON MONOXIDE POISONING

HAZARD. Failure to follow the steps

outlined below for each appliance

connected to the venting system being

placed into operation could result in

carbon monoxide poisoning or death.

• Examine all components for possible

shipping damage prior to installation;

• Read all instructions before beginning

the installation and follow these

instructions exactly as written.

• Proper joint assembly is essential for a

safe installation. Check the integrity of

ALL joints upon completion of assembly

• This venting system must be free to

expand and contract under normal

operation.

• Assure unrestricted vent movement

where required through walls, ceilings

and roof penetrations.

• This venting system must be supported

in accordance with these instructions.

• Do not mix pipe, ttings, or joining

methods from dierent vent system

manufacturers. Do not use adhesives

of any kind with this venting system.

insurance and safety listing of your

appliance. Acceptance of the installed

system is dependant on full compliance

with these installation instrucitons

WARNING

Risk of carbon monoxide poisoning

or re due to joint separation or pipe

breakage.

Keep these instructions for future

reference.

Dear Customer, Installer, or End User:

We welcome any comments regarding

matters pertaining to our DuraVent products.

We welcome any ideas, input or complaints

to help improve our product oering. Send

your emails to:

president@duravent.com

If you are searching for tech support or

product information, please phone us at

800-835-4429.

Or email us at:

techsupport@duravent.com

PolyPro® is one of M&G DuraVent's line of

products.

Page 3

PolyPro Single-Wall Gas Vent System

For the most up-to-date installation instructions, see www.duravent.com

CONTENTS

LISTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . 4

APPLICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . 4

PERMITS . . . .. . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . 4

GENERAL INSTALLATION NOTES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CLEARANCES TABLE 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . 4

CONDENSATE DRAIN . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .4

JOINT CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . .. . . . 5

EQUIVALENT LENGTH CHART TABLE 2 . . . . . . . . . . . . . . . . . . . .. . . . . . . . . .. . . . 5

APPLIANCE CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . 6

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ENCLOSURE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

HORIZONTAL TERMINATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

WALL AND CEILING PENETR ATION TABLE 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

VERTICAL TERMINATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

MULTIPLE VENT RUNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ALUMINUM FLEX AIR INTAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

PolyPro

®

3

Page 4

LISTING

Listed to ULC S636

Rated Class IIA, IIB, and IIC vent system

maximum temperature 230°F (110 °C)

maximum positive pressure 15 in-w.c.

Massachusetts Plumbers Board,

# G1-0811-42

APPLICATION

ANSI Category II and IV gas-burning

appliances

Appliances specically tested and listed to

use M&G DuraVent PolyPro Venting

PERMITS

Check with your local Building Ocial, Fire

Ocial, or other authority having jurisdiction

regarding permits, restrictions, and

installation inspections in your area.

GENERAL INSTALLATION NOTES

Read these instructions before beginning.

You must use only authorized M&G DuraVent

PolyPro vent parts, or other parts specically

authorized in these instructions and/or listed

by the appliance manufacturer in order to

maintain a safe, approved system.

• Do not ll any air space clearance

(Table 1) with insulation.

• Do not mix parts or try to match with

other products or use improvised

solutions.

• Do not install damaged or modied

parts.

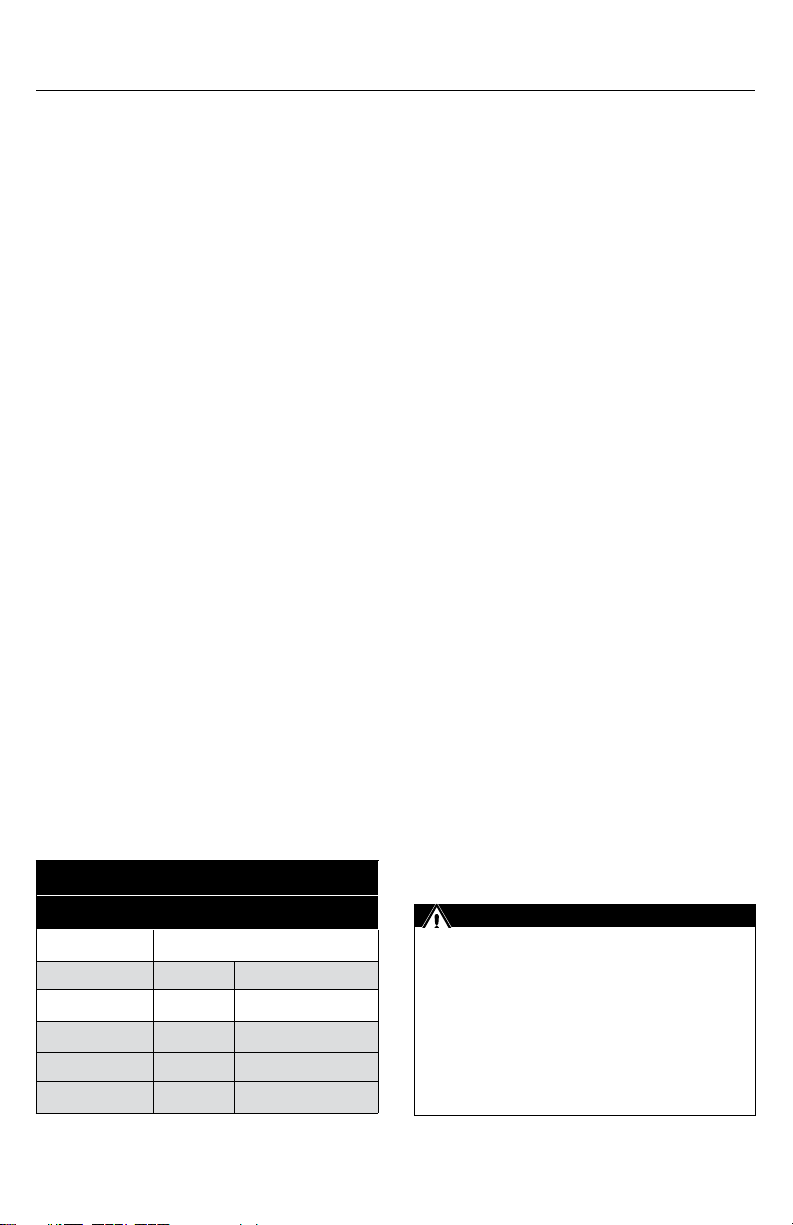

Table 1

• Use soapy water to lubricate gaskets.

• Never use Petroleum base lubricants.

If these directions and those of the appliance

manufacturer dier, follow the more

conservative requirements. If you have any

questions, contact either your dealer or M&G

DuraVent directly. A venting system must

not be routed into, through, or within any

other vent, such as an existing masonry or

factory-built chimney ue, unless that vent

or chimney is not being used to vent another

appliance and is only used as a conduit for

the gas-vent system. Plastic venting systems

shall not pass through re rated separations

without approved restopping.

Refer to the appliance manufacturer's

instructions for maximum and minimum

vent lengths permitted with your specic

appliance model. This information should

include guidance on the maximum number

of elbows and related pressure-drops. The

total vent length from the appliance to

the termination shall not be greater than

specied by the appliance manufacturer.

If specic guidance is not oered by the

appliance manufacturer as to Equivalent

Vent Lengths (EVL) for vent components, the

general guidelines in Table 2 can be used.

CONDENSATE DRAIN (Fig.1)

Refer to the appliance manufacturer’s

installation instructions for requirements of

condensate drainage. Ensure proper system

slope for drainage. (Fig.7)

Clearance to Combustibles

VENT PIPE ORIENTATION

Single Wall Vertical Horizontal

Up to 190°F 0" 0"

Up to 230°F 0" ¼" (6mm) all around

Concentric

Up to 230°F 0" 0"

4

IMPORTANT

The vent system must be compliant in

accordance with local code requirements

and appropriate National Codes: In

the US: NFPA 54 / ANSI Z223.1 National

Fuel Gas Code or the International Fuel

Gas Code. In Canada: CAN/CGA-B149.1

Natural Gas Installation Code or CAN/CGA-

149.2 Propane Installation Code.

Page 5

IMPORTANT

To prevent possible recirculation of ue

gases, the installer must consider the

eects of prevailing wind conditions,

eddy zones, nearby buildings,

obstructions, or other obstacles such as

shrubs when planning exhaust and air

intake locations. M&G DuraVent can not

be held responsible for poor appliance

performance or damage to buildings

due to an incorrect installation. The

minimum clearances detailed within our

instructions may not be adequate in some

circumstances depending on the specics

of the installation. For this reason we

always recommend vertical venting.

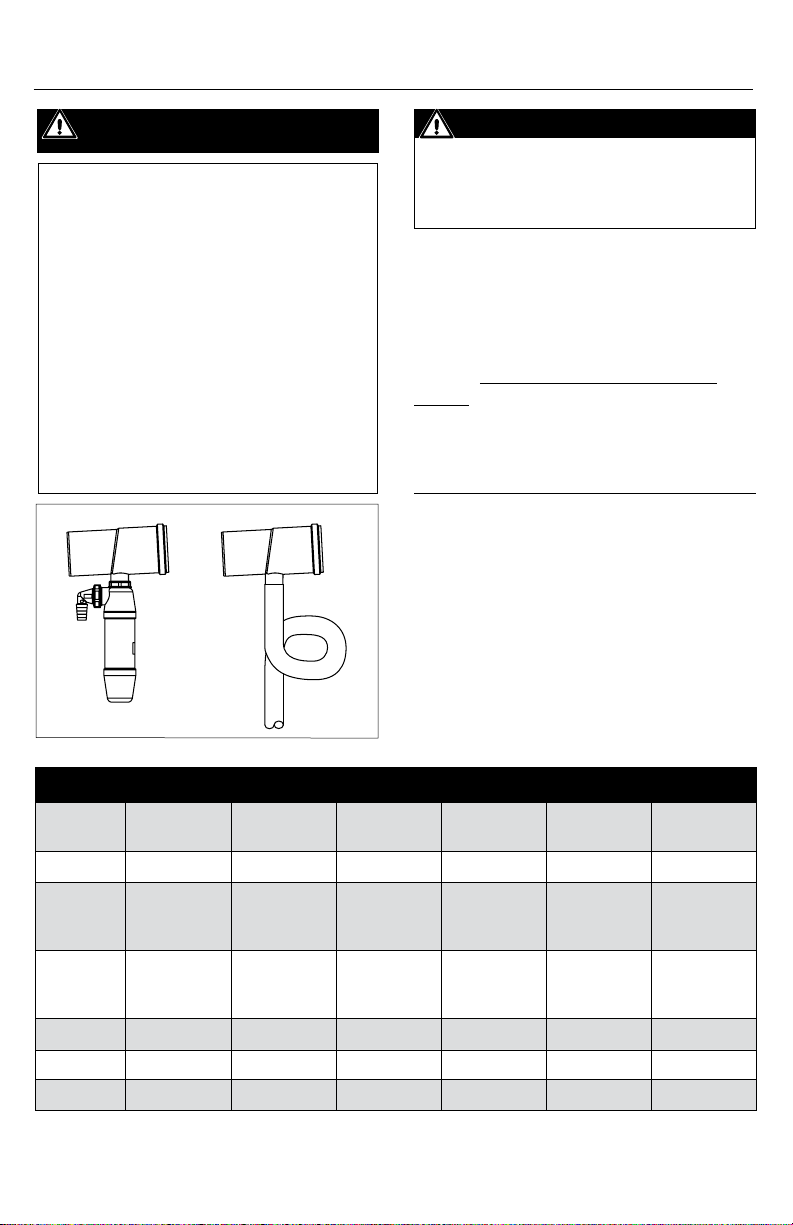

SIPHON

P-TRAP

Figure 1

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow these installation

instructions could result in personal

injury or death

JOINT CONNECTIONS

Verify the gasket is seated evenly inside the

groove in the female end. There are two

versions of locking band available, one with

stando legs (Fig.2), one without (Fig.3).

For both: Slide Locking Band on male pipe

section. Fig.2: For pipe without Locking

Button: Slide pipe sections together until

joint is bottomed out then slide apart

¼”

to 5/8” (7.5 - 15 mm) for expansion. Clip the

locking band clasp onto the female hub.

Fig.3: For PP/Metal pipe with Locking Button:

Insert locking button into locking band

recess, rotate button away from Locking

Band Clasp, insert pipe sections, push

lock band clamp downward into socket,

disengage button 1/4" from socket. Screws

are not allowed for joint connection.

Never penetrate the wall of PolyPro vent

pipe. (Exception- a SS screw may be

used outside the building on exterior

termination ttings to orient an elbow,

etc).

• IMPORTANT: Locking bands are

Table 2 - Equivalent Length Chart

2" Equivalent

Length

1-ft Vent Pipe 1-ft 1-ft 1-ft 1-ft 1-ft 1-ft

2-ft

1-ft Flex Pipe

1-ft Flex Pipe

45 Elbow 3-ft 3-ft 5-ft 6-ft 6-ft 13-ft

90 Elbow 5-ft 7-ft 12-ft 14-ft 14-ft 19-ft

Tee 9-ft 12-ft 19-ft 21-ft 22-ft 29-ft

(same diameter

as rigid)

0.4-ft

(updsized one

diameter)

3" Equivalent

Length

2-ft

(same diameter

as rigid)

0.6-ft

(updsized one

diameter)

4" Equivalent

Length

2-ft

(same diameter

as rigid)

0.6-ft

(updsized one

diameter)

5" Equivalent

Length

2-ft

(same diameter

as rigid)

N/A N/A N/A

6" Equivalent

Length

N/A N/A

8" Equivalent

Length

5

Page 6

MALE

FEMALE

END

LOCKING

BUTTON

END

Figure 2

LOCKING

BAND RECESS

LOCKING

BAND CLASP

LOCKING BAND

PUSH DOWN

TO LOCK

VERIFY GASKET IS

SEATED IN FEMALE

END OF PIPE

PRY OUT

TO UNLOCK

CLICK!

APPLIANCE CONNECTION: 2" - 4"

1. If the appliance has a PVC/CPVC female

outlet use the Appliance Adapter/ PVC

Adapter and Clamp. (Fig.4)

• If the appliance has a PVC/CPVC

Male outlet use a matching PVC/

CPVC coupling to convert to a

female outlet.

2. If the appliance outlet has a rubber

boot or Fernco-style appliance adapter,

then the PolyPro vent pipe may attach

directly to the appliance (Fig.5).

3. If the appliance has a FasNSeal outlet

then use the FasNSeal to PolyPro

adapter.

1/4"

POLYPRO PIPE

APPLIANCE

ADAPTER CLAMP

APPLIANCE ADAPTER/

PVC ADAPTER

APPLIANCE

EXHAUST OUTLET

OR PVC UNION

Figure 3

mandatory on all exhaust vent joints

on pipe sizes from 2" up to 4". (Fig.2, 3)

• For 5"-8" diameter, Locking Bands are

not required but strongly recommended

at every exhaust vent joint.

(Fig.2, 3)

• Locking bands are optional for air inlet

vent joints.

POLYPRO TO DURAVENT / SECURITY

CHIMNEY METAL VENT CONNECTION

Approved M&G Duravent / Security Chimney

1738/636 metal vent ttings can be used with

PolyPro. For PolyPro (female) to Metal Vent

(Male) connections, the metal ttings will have

a Locking Button or Protrusion, and will be

connected simliar to Fig. 3.

6

(Fig.2, 3)

APPLIANCE

Figure 4

Figure 5

POLYPRO

VENT PIPE

TIGHTEN CLAMPS ON

RUBBER COUPLER

ADAPTER OR FERNCO

STYLE ADAPTER TO

SECURE VENT

PIPE TO APPLIANCE

APPLIANCE

OUTLET

Page 7

INSTALLATION

1. Pipe lengths may be cut to length

(Fig.6). Use an alternate clamp (Fig.4PPS-PAC / PPS-LBC) for the connection

if a locking button (Fig.3) is removed.

• Cut square (not at an angle) to the

end of the pipe.

• Remove burrs before assembly.

MARK

CUT WITH

HACKSAW

TO APPLIANCE

5/8"

1/4" 5/8"

7.5mm 15mm

MIN

12"

Figure 7

IMPORTANT

PP Pipe sections must be disengaged 1/4"5/8" per joint (to allow for expansion) and

sloped 3°(5/8"per ft) back to the appliance

per Fig.7 for proper condensate flow.

DEBURR

Figure 6

2. Check with appliance manufacturer for

any restrictions or limits on vent length,

number of elbows, etc.

3. The slope of the vent pipe must be at

least 3° (5/8" per ft, 50mm per meter)

back to the appliance. (Fig.7)

4. Every horizontal section must be

supported. (Fig.8)

5. The venting system shall be securely

supported using suitable hangers.

Duravent hardware is recommended; eld

supplied support hardware suitable to

the AHJ is acceptable, hardware must not

deform or damage the vent. (Fig. 7 and 8)

Make sure the load of the vent system is not

supported by the appliance.

• On Duravent and other certain clamp

styles, ¼” or greater All-thread may be

used as an extension.

6. Vertical installations must be supported

every 10 feet (3 meters) or less. (Fig.8)

7. Do not install / enclose PolyPro in the stud

space of a wall.

8. Elbows and Tees are suciently supported

when a bracket is xed at the female end of

the connected straight section. (Fig.8)

ALLTHREAD

LOCKING BANDS

REQUIRED AT EVERY

EXHAUST JOINT

MAX

10FT

3m

WALL STRAP

MINIMUM 1PER

HORIZONTAL PIPE

SECTION

Figure 8

9. Vertical components can be insulated in

unconditioned space or when ran outside.

10. Use black UV protected components on

venting installed on the exterior.

ENCLOSURE REQUIREMENTS

Through Rooms: Interior vents shall be

enclosed where they extend through closets,

storage areas, occupied spaces, or anyplace

where the surface of the vent could be

contacted by persons or combustible materials

except when installed in the room with the

appliance.

7

Page 8

Multi-Story: Consult local building or other

applicable codes for requirements in your

area. In the U.S., NFPA 211 10.6.3 (2013)

states: “Vents that pass through the oors

of buildings requiring the protection of

vertical openings shall be enclosed within an

approved enclosure. The enclosure walls shall

have a re resistance rating of not less than

1 hour where a vent is located in a building

less than four stories in height. The enclosure

walls shall have a re resistance rating of not

less than 2 hours where a vent is located in a

building four or more stories in height."

If the vent system is not exposed to wind or

lateral load within the enclosure and joints

cannot buckle, wall straps are not required

provided upper and lower supports are

proper.

ENCLOSURE

FIRESTOP

FIRESTOP

FIRESTOPS (Fig. 9)

1. Firestops are required at each ceiling/

oor penetration including an attic.

Firestops are not required at the roof

deck penetration.

2. Cut and/or frame hole. (Table 3)

3. Slide the two halves together and attach

to the ceiling.

INTERIOR

WALL PLATE

ALIGN TABS WITH

MOUNTS

EXTERIOR

WALL PLATE

GASKET

Figure 10

TERMINATIONS:

Horizontal Single Pipe (Fig.10)

1. Locate penetration in wall.

2. Cut or cut and frame hole. (Table 3)

3. Attach Inner Plate to wall.

4. Attach / seal Outer Plate to outside wall.

5. Line up keyway, slide black pipe (UV

Protected) or termination through

plates.

6. If termination is used, attach with

screws. Align tabs with pipe mounts.

REMOVE GASKET

FIRESTOP

INSERT BIRD GUARD

Figure 9

Figure 11

8

Page 9

Table 3 - Wall & Ceiling Penetration Sizing Table

VENT DIAMETER

Termination 2" 3" 4" 5" 6" 8"

CONCENTRIC

VERTICAL OR HORIZONTAL

TWIN PIPE HORIZONTAL

CLASS IIB

TWIN PIPE HORIZONTAL

CLASS IIC (Framing Dimensions)

4 ⁄"

105mm

7 ⁄" x 2⁄"

187mm x

65mm

8" x 3"

200 x 77mm

5 ⁄"

130mm

8 ⁄" x 3⁄"

212 x 85mm

8 ⁄" x 3⁄"

225 x 98mm

6 ⁄"

155mm

9" x 4⁄"

228 x 100mm

9 ⁄" x 4 ⁄"

238 x 112mm

N/A N/A N/A

N/A N/A N/A

N/A N/A N/A

SINGLE HORIZONTAL

CLASS IIB

SINGLE HORIZONTAL

CLASS IIC (Framing Dimensions)

SINGLE WALL W/ LOCKING BAND

VERTICAL

SINGLE PIPE NO LOCKING BANDS

VERTICAL

2⁄"

65mm /

3"

77mm

3 ⁄" "

85mm

3 ⁄

98mm

3 ⁄" 4 ⁄" 5 ⁄" 6 ⁄" 7 ⁄" 9 ⁄"

3" 3 ⁄" 4 ⁄" 5 ⁄" 6 ⁄" 7 ⁄"

7. Add additional components to raise vent

level if desired (vent to be 12" above

grade or average snow level).

8. Remove gasket and install Bird Guard

into end of pipe. (Fig.11)

9. Install Poly Pro venting system to/from

termination to appliance.

POSITIONED

HORIZONTALLY

INTERIOR

WALL PLATE

EXTERIOR WALL PLATE

EXHAUST PIPE

APPLY BEAD OF SILICON SEALANT

AROUND FEMALE END OF PIPE TO

SEAL AGAINST EXTERIOR WALL PLATE

EXHAUST TIP

4" "

100mm

4 ⁄

112mm

N/A N/A N/A

N/A N/A N/A

Horizontal Twin Pipe (Fig.12)

1. Locate penetration.

2. Cut or cut and frame hole. (Table 3)

3. Attach interior wall plate to inside wall.

4. Attach and seal exterior wall plate to

outside wall.

5. Slide pipes through outer plate.

6. Rotate pipes to slide pipe past keyway.

POSITIONED

VERTICALLY

AIR INLET PIPE

OUTER COVER PLATE

Figure 12

9

Page 10

7. Slide exhaust tip into exhaust pipe.

8. Mount outer cover plate to exterior wall

plate.

9. install Poly Pro venting system to/from

termination to appliance.

Horizontal Concentric (Fig.13)

1. Locate penetration.

2. Cut hole. (Table 3)

3. Attach and seal exterior exterior wall

plate onto outside wall.

4. Slide cap through exterior wall plate into

hole from outside building. Cap must

not be installed sloped downward.

5. Orient termination so air intake slots

face down.

6. Seal termination to exterior wall plate

with silicone sealant.

7. Slide interior wall plate over termination

and attach to wall from inside the room.

8. Attach interior wall plate to termination

with provided hardware.

9. Install gaskets into Co-Linear Adapter.

10. Attach Co-Linear Adapter to Horizontal

Termination.

11. Install Poly Pro venting system to/from

termination to appliance.

INSTALL

GASKETS

INTERIOR

WALL PLATE

EXTERIOR

WALL PLATE

POLYPRO PIPE

W/PVC ADAPTER

SUPPLIED WITH

TERMINATION KIT

BRACKET

Figure 14

Lochinvar 2" installation (Fig.14)

1. Slide PolyPro pipe w/ PVC adapter into

oblong hole and down. Brackets will

point away from the wall, on the exterior

of the house, and rest between the two

outward beads.

2. Install the termination assembly

in accordance with appliance

manufacturer’s instructions.

3. Verify exhaust pipe cannot be removed

from termination cap.

POLYPRO PIPE

W/PVC ADAPTER

SUPPLIED WITH

TERMINATION KIT

COLINEAR

EXHAUST

AIR INTAKE

10

ADAPTER

SCREW TO

TERMINATION

Figure 13

HORIZONTAL

TERMINATION

Figure 15

Lochinvar 3" & 4" installation (Fig.15)

1. Slide PolyPro Pipe w/ PVC adapter into

small hole of retaining plate until it stops

on the adapter collar.

2. Finish installing the termination

assembly in accordance with appliance

manufacturer’s instructions. PolyPro

Page 11

pipe is to be installed on the exhaust

outlet.

3. Once securely installed to exterior, verify

exhaust pipe cannot be removed from

termination cap.

Stainless Horizontal (Fig.16)

1. Cut opening in the wall.

2. Add Trim Plates and locking band (if

applicable) to nal pipe length before

installing. Make sure anges are facing

towards the wall. Use non-hardening

sealant where necessary.

3. After exterior trim plate is mounted to

wall, measure 3" from exterior plate and

cut o female pipe end. Duburr. Seal

pipe to exterior plate. Slide Bird screen

over cut pipe end and tighten clamp.

THROUGH HOLE SIZING

4PPS: 4.125" 5PPS: 5.25"

6PPS: 6.125" 8PPS: 8.00"

EXTERIOR PLATE

FLANGES

CUT LINE

INTERIOR PLATE

INITIAL

TERMINATION

CAP

STORM COLLAR

FLASHING

SUPPORT CLAMP

Figure 18

EXHAUST

AIR INLET

BIRD

SCREEN

CLAMP

Figure 16

Figure 17

PP PIPE

CENTERLINE OF

EXHAUST OUTLET

OF APPLIANCE

FINAL

Figure 19

Vertical Concentric (Fig.18)

1. Locate penetration. (Fig.17)

2. Cut hole in roof. (Table 3)

3. Cut hole in ceiling above appliance.

• Cut hole(s) big enough for pipe in all

ceilings above appliance if installing

in a multi story installation.

4. Firestop each ceiling penetration.

5. Attach ashing to roof. (Fig.18)

• Slide storm collar onto ashing if

using the Adjustable Roof Flashing.

6. Slide vertical termination into ashing

from above until seated on ashing.

7. Plumb Termination and mount support

bracket to structure.

11

Page 12

8. Install gaskets into Co-Linear Adapter (if

applicable). (Fig.13)

9. Connect Co-Linear Adapter to

termination (if applicable). (Fig.19)

10. Install Poly Pro venting system to/from

Co-Linear Adapter or termination to

appliance.

BIRD GUARD

BLACK

UV PROTECTED PIPE

max length rectangle, 4 vent runs max per

support. The listing requires clearance holes

no larger than 5 1/8" Dia, with spacing 1 3/4"

apart.

The upper support plate (with a ange for

B vent and factory built chimney, Fig.22)

must be axed to the top of the conduit via

screws. Anchor bolts must be used when

attaching a at support plate to the top of

Masonry or other chase (not shown). Support

plate must be weather tight. The SS Hanger

Bracket is installed under the Gasket Plate

and axed to the top of the support plate

with screws (Fig.22). Use non-hardening

sealant as required.

RUBBER FLASHING

Figure 20- Vertical Pipe Termination

Vertical single pipe (Fig.20)

1. Follow instructions for Vertical Concentric

Termination.

2. Attach ashing to roof. (Fig.20)

• Rubber boot ashing or similar,

ensure an eective, leak-proof seal

is maintained.

• Use BLACK UV protected pipe.

3. Maintain 12 in. (305mm) min. clearance

above highest anticipated snow level,

max 24 in. (610mm) above roof.

MULTIPLE VENTS IN ONE CONDUIT Fig.21

Multiple PolyPro Rigid/Flex vent systems may

be installed within one conduit. Listed 2"-4"

M&G components must be used, and the

conduit (if pre-existing) must be inspected

and deemed sound.

Upper supports may be eld supplied and

listed, the listing requires: Min thickness of 24

ga (0.020") SS, no larger than 18" Dia or 18"

The lower portion of the vent system must

be supported and restopped as detailed

earlier in these and/or the PP Flex instructions

(provided separately).

GASKET PLATE

/ HANGER

MOUNT

HARDWARE

GASKET

PLATE

1.75" MAT'L

SPACE MIN

CLEARANCE

HOLE

STAINLESS

RELINE

HANGER

BRACKET

POLYPRO

FLEX LINER

RIGID BLACK

UV PROTECTED

POLYPRO

STAINLESS

UPPER

SUPPORT

PLATE

FLANGE

RIGID

POLYPRO

Figure 21

12

Page 13

Figure 22

HANGER

MOUNTED

TO TOP OF

SUPPORT,

BELOW

GASKET

PLATE

SEAL AS

REQ'D

M&G DURAVENT

POLYPRO

CHIMNEY CAP

TERMINATION

COMBUSTION

AIR INTAKE

FLEX HANGER

BRACKET AND

HARDWARE

FLEX CLAMP

STORM COLLAR

M&G DURAVENT

POLYPRO

EXHAUST SYSTEM

ALUM FLEX AIR INTAKE (Fig.23)

Important: This section only applies to

sourcing combustion air!

Reference Fig.23 for installation of air intake

ex when used with the M&G DuraVent

Chimney Cap Termination. Combustion air

is drawn in under the storm collar. Ensure

Aluminum ex is approx 1"-2" below

termination base for unrestricted operation.

See Fig.24 for the lower install.

MAINTENANCE

Have your venting system checked annually.

This can be done easily by the same

technician who inspects & services the

appliance. Recommended areas to inspect

are as follows:

- Check areas of the Venting System which

are exposed to the elements for wear or

damage. If damage is found, the components

should be replaced immediately.

- Where possible, look into the Termination

Cap to verify no foreign material is there to

block the vent. Remove any foreign material

found.

- Where practical, inspect joints to verify

that no Pipe Sections or Fittings have been

disturbed, and consequently loosened. Also

check mechanical supports such as Wall

Straps, support plates, etc for rigidity.

AIR INTAKE

AIR INTAKE

FLEX

AIR INTAKE

FLEX TO

POLYPRO

ADAPTER

FLEX

Figure 23- Upper Assy

Figure 24- Lower Assy

ENCLOSURE

M&G DURAVENT

POLYPRO

EXHAUST SYSTEM

POLYPRO PIPE TO

APPLIANCE AIR

INTAKE

13

Page 14

THIS PAGE INTENTIONALLY LEFT BLANK

Page 15

THIS PAGE INTENTIONALLY LEFT BLANK

Page 16

POLYPRO WARRANTY

M&G DuraVent, Inc. (“ DuraVent”) provides t his warranty for Po lyPro® for ten years. Subj ect to the limitati ons set forth b elow, DuraVent warrants that it s

produc ts will be free fr om defects in m aterial or manufac turing, if proper ly installed, mainta ined and used. DuraVent pro ducts are fully wa rranted if install ed

only by a profe ssional installer. This War ranty is transf erable from the or iginal homeowner to t he buyer of the home wit hin the warranted ten ye ars. This

warrant y does not cover norma l wear and tear, smoke damage or damage c aused by chimney re s, acts of God, or any pr oduct that was: (1) purchase d

other than f rom an authorized D uraVent dealer, retailer or distr ibutor; (2) modied or a ltered; (3) improperly ser viced, inspec ted or cleaned; or (4) subjec t to

negligence o r any use not in accordance wit h the installation in structions i ncluded with the pr oduct as determin ed by DuraVent.

Installation instruc tions are available online at www.duravent.com under Support /Literature and th rough our Customer Se rvice Depart ment

800 -835-4429

or customerservice@duravent.com.

DuraVent provide s the following warr anties for PolyPro: On e Hundred Percent (100%) MSRP 10 years f rom the date of purchase .

All warrant y obligations of Dur aVent shall be limi ted to repair or replaceme nt of the defecti ve product pursu ant to the terms and condi tions applicable to

each produc t line. These reme dies shall constitu te DuraVent’s sole obligatio n and sole remedy under t his warranty. This war ranty provides n o cash surrender

value. The ter ms and conditions of th is warranty may not be m odied, altered or w aived by any action, ina ction or represe ntation, whether or al or in

writing , except upon the exp ress, written au thority of an exe cutive ocer of DuraVent.

This produc t is intended for ven ting only categor y II & IV appliances burni ng Natural Gas, Propan e and Oil. All other fuels ar e not covered under this

warranty.

LIMITATIONS ON POLYPRO INTE RNET SALES: Notw ithstanding any ot her terms or conditio ns of this PolyPro Warrant y, DuraVent provides no warra nty for

PolyPro® if it is n ot installed by a qualie d professional ins taller.

DuraVent must be no tied and given the op portunity t o inspect defe ctive produc t prior to replacement und er the terms of this limit ed lifetime warra nty.

All warrant y claims must be subm itted with proo f of purchase. Labor an d installation cost s are not covered under t his warranty. To obtain warr anty service

contact : DuraVent Warranty Ser vice, 877 Cotting Ct., Vaca ville CA 95688, or call 8 00-835-442 9.

WHERE LAWFUL , DURAVENT DISCLAIMS AL L OTHER WARRANTIES, INCLUD ING BUT NOT LIMITED TO IMPLIED WARR ANTIES OF MERCHAN TABILIT Y AND

FITNESS F OR A PARTICULAR PURPOSE. IN N O EVENT WILL DURAVENT BE L IABLE FOR INCIDENTAL, CONSE QUENTIAL, PUNITIVE O R SPECIAL DAMAGES OR

DIRECT OR I NDIRECT LOSS OF ANY KIND, INCLU DING BUT NOT LIMITED TO PROPE RTY DAMAGE AND PERSONAL I NJURY. DURAVENT’S ENTIRE LIABIL ITY

IS LIMITED TO THE P URCHASE PRICE OF THIS PRO DUCT. SOME STATES DO NOT ALLOW LIMITATIONS ON IMPLIE D WARRANT IES, OR THE EXCLUSION OR

LIMITATION OF INCIDEN TAL OR CONSEQUE NTIAL DAMAGES, SO THE ABOVE L IMITATIONS AND E XCLUSIONS MAY NOT APPLY TO YOU. THIS LIMIT ED

WARRANTY GI VES YOU SPECIFIC LEGAL RI GHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS THAT VARY FROM STATE TO STATE.

For the mos t up-to-date ins tallation instr uctions, see www. duravent.com

REV 9.4.2012

Customer Service Support 800-835-4429 707-446-4740 FAX www.duravent.com

PolyPro® is a registered trademark of M&G DuraVent, Inc.

All rights reserved, ©2014 M&G DuraVent is a member of M&G Group.

820003161- L273 08/2014

Loading...

Loading...