Page 1

Installation Instructions

FasNSeal Fixed Blade Damper

instruction- Fixed Damper

FasNSeal- Supplemental

®

A MAJOR CAUSE OF VENT RELATED FIRES IS

FAILURE TO MAINTAIN REQUIRED CLEARANCES

(AIR SPACES) TO COMBUSTIBLE MATERIALS. IT IS

OF THE UTMOST IMPORTANCE THAT FASNSEAL

BE INSTALLED ONLY IN ACCORDANCE WITH

THESE INSTRUCTIONS.

LISTED

Page 2

INTRODUCTION

The purpose of the Fixed Blade Damper is

to ensure optimum pressures through an

appliance. The Damper will aid in the proper

operation and eciency of the appliance

by preventing higher than desired draft

readings.

INSTALLATION

• IMPORTANT: The max rated temperature

for the xed blade damper is 392°F

(200°C). When the damper is installed,

the entire FNS system is to be de-rated in

maximum temperature to this value.

• Always follow appliance manufacturer’s

installation instructions for proper appliance

setup and venting requirements.

• Refer to the FasNSeal SW & W2 Installation

Instructions for correct installation to

FasNSeal vent lengths and adapters.

• It is important to note that the Damper

can be installed vertically, diagonally and

horizontally.

• If the Damper is going to be installed

horizontally, make sure the Damper Axis is

horizontal (Fig.1). Make sure the venting is

pitched towards the boiler by a value of ¼”

drop for every foot of vent length (Fig.2 and

Fig.3) for proper condensate management.

The weight on the damper is a fail safe to

make certain that the damper will be open in

the event of failure. Ensure that the weight is

at the top of the damper plate when closed in

the Horizontal (Fig.1).

Horizontal Installation (Fig.1, Fig.2, Fig.3)

• To prevent the build up of condensation in

horizontal installations, it is required to use

an Eccentric Increaser rather than Tapered

Increasers at the male connection of the

damper (Fig.2).

• Installation of the Damper in the ue

venting of an appliance should be at the

breech of the appliance or as close as

possible.

• Lock the Damper position to the 90 degree

value so that it is in the full open position.

• Ensure the female end is pointing away

from the appliance.

• Once the damper has been correctly

installed in the venting ue, lock the damper

to 90° and then operate the burner until

the appliance is suciently warmed up and

chamber pressure has stabilized.

• After the chamber pressure is lower than

what is prescribed by the OEM, proceed

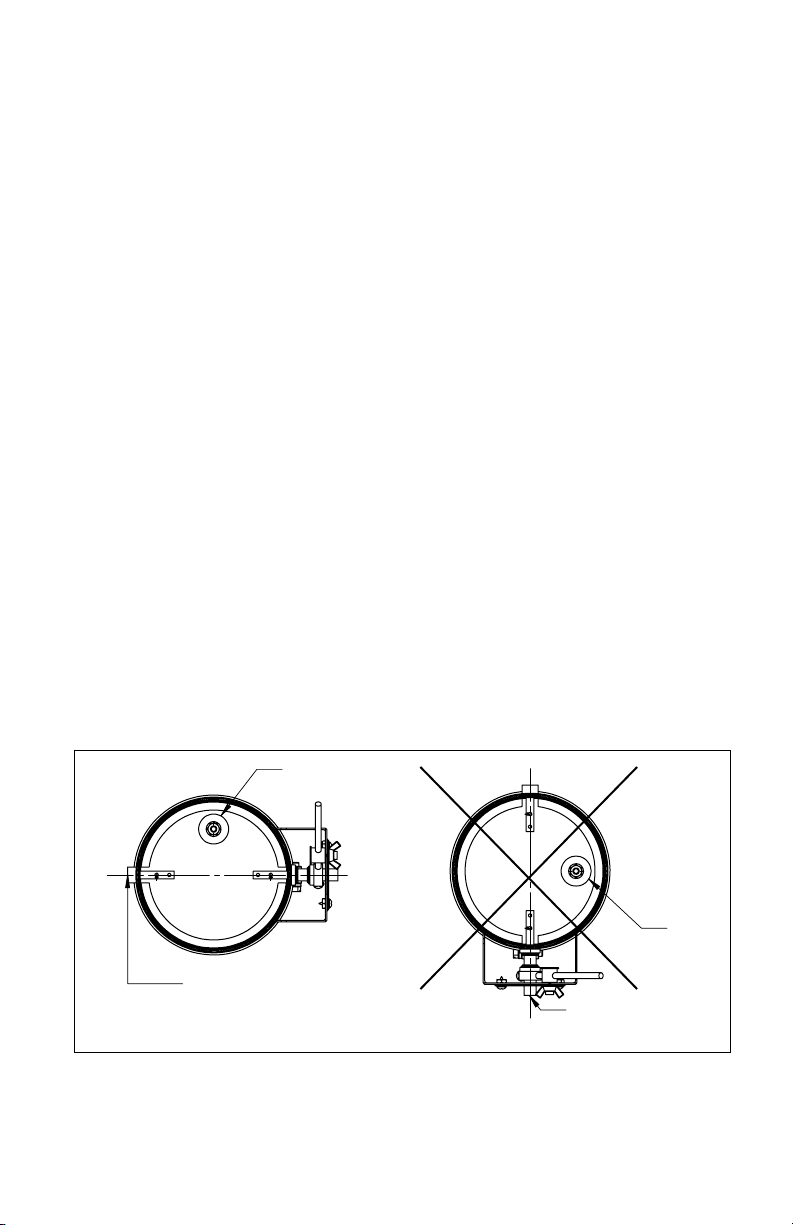

WEIGHT

WEIGHT

CORRECT

ORIENTATION OF

SHAFT AXIS

INCORRECT

ORIENTATION OF

SHAFT AXIS

Figure 1

2

Page 3

with closing o the damper until the desired

chamber pressure has been achieved.

• At this point lock the damper blade in

position and begin the burner set up as

prescribed by the OEM.

ECCENTRIC

INCREASER

EXHAUST FLOW

TAPERED

INCREASER

EXHAUST FLOW

Figure 2

1/4" PER FT

PROPER

SLOPE

EXHAUST FLOW

Figure 3

1/4" PER FT

PROPER

SLOPE

3

Page 4

M&G DURAVENT LIMITED LIFETIME WARRANTY

M&G DuraVent, Inc. (“DuraVent”) provides this limited lifetime warranty for all of its products with the exception of Ventinox® (lifetime), and

PolyPro® (ten years). Subject to the limitations set forth below, DuraVent warrants that its products will be free from defects in material or

manufacturing, if properly installed, maintained and used. DuraVent products are fully warranted if installed only by a professional installer.

This Warranty is transferable from the original homeowner to the buyer of the home. This warranty does not cover normal wear and tear, smoke

damage or damage caused by chimney res, acts of God, or any product that was: (1) purchased other than from an authorized DuraVent

dealer, retailer or distributor; (2) modied or altered; (3) improperly serviced, inspected or cleaned; or (4) subject to negligence or any use not

in accordance with the installation instructions included with the product as determined by DuraVent. Installation instructions are available

online at www.duravent.com under Support/Literature and through our Customer Service Department 800-835-4429 or customerservice@

duravent.com. This limited lifetime warranty applies only to parts manufactured by DuraVent.

DuraVent provides the following warranties for its products: One Hundred Percent (100%) MSRP 15 years from the date of purchase, and Fifty

Percent (50%) thereafter, except for the following limitations on: all Termination Caps and DuraBlack® are warranted at One Hundred Percent

(100%) for ve years.

All warranty obligations of DuraVent shall be limited to repair or replacement of the defective product pursuant to the terms and conditions

applicable to each product line. These remedies shall constitute DuraVent’s sole obligation and sole remedy under this warranty. This warranty

provides no cash surrender value. The terms and conditions of this warranty may not be modied, altered or waived by any action, inaction or

representation, whether oral or in writing, except upon the express, written authority of an executive ocer of DuraVent.

Corn, bio-fuels, driftwood or other wood containing salt, preservative-treated lumber, plastic and household trash or garbage, or wood pellets

containing such materials must not be burned in the appliance or replace. In case of a chimney re, the chimney must be inspected and

approved by a certied Chimney Sweep before reuse. After each annual inspection, maintenance, and cleaning, the certied Chimney Sweep

must ll out and date the appropriate section of the warranty card provided with the chimney liner.

LIMITATIONS ON INTERNET SALES: Notwithstanding any other terms or conditions of this Limited Lifetime Warranty, DuraVent provides no

warranty for the following specic products if such products are not installed by a qualied professional installer: DuraTech®, DuraPlus HTC®,

DuraChimney® II, PelletVent Pro®, DirectVent Pro®, FasNSeal®, FasNSeal® W2, FasNSeal® Flex, and PolyPro®, and M&G DuraVent’s relining

products including DuraLiner®, DuraFlex® (SW, Pro, 316, 304), and Ventinox®. For purposes of this warranty, a trained professional installer is

dened as one of the following: licensed contractors with prior chimney installation experience, CSIA Certied Chimney Sweeps, NFI Certied

Specialists, or WETT Certied Professionals.

DuraVent must be notied and given the opportunity to inspect defective product prior to replacement under the terms of this limited lifetime

warranty. All warranty claims must be submitted with proof of purchase. Labor and installation costs are not covered under this warranty. To

obtain warranty service contact: DuraVent Warranty Service, 877 Cotting Ct., Vacaville CA 95688, or call 800-835-4429.

WHERE LAWFUL, DURAVENT DISCLAIMS ALL OTHER WARRANTIES, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT WILL DURAVENT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL,

PUNITIVE OR SPECIAL DAMAGES OR DIRECT OR INDIRECT LOSS OF ANY KIND, INCLUDING BUT NOT LIMITED TO PROPERTY DAMAGE AND

PERSONAL INJURY. DURAVENT’S ENTIRE LIABILITY IS LIMITED TO THE PURCHASE PRICE OF THIS PRODUCT. SOME STATES DO NOT ALLOW

LIMITATIONS ON IMPLIED WARRANTIES, OR THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS AND EXCLUSIONS MAY NOT APPLY TO YOU. THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS THAT VARY FROM STATE TO STATE.

For the most up-to-date installation instructions, see

www. duravent.com

REV 3.22.2012

Manufactured in Vacaville CA and Albany NY

Customer Service Support 800-835-4429 707-446-4740 FAX www.duravent.com

FasNSeal is a registered trademark of the M&G DuraVent, Inc.

All rights reserved. Made in the USA. M&G DuraVent is a member of M&G Group. ©2012

820013661 - L1150SUP 04/2014

Loading...

Loading...