Page 1

Installation Instructions

FNS 80/90

Combined Category I and

IV venting for Gas-Burning

Appliances

For the most up-to-date installation instructions, see www.duravent.com

CONTENTS

LISTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . 3

NOTES / A PPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CLEARANCES TABLE 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . 3

PRIOR TO INSTALLATION. . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . .3

INSTALLATION OF LINER. . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . .5

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

®

Page 2

A MAJOR CAUSE OF VENT RELATED FIRES IS FAILURE

TO MAINTAIN REQUIRED CLEARANCES (AIR SPACES)

TO COMBUSTIBLE MATERIALS. IT IS OF THE UTMOST

IMPORTANCE THAT DURAVENT PRODUCTS BE INSTALLED

ONLY IN ACCORDANCE WITH THESE INSTRUCTIONS.

WARNING

CARBON MONOXIDE POISONING

HAZARD. Failure to follow the steps

outlined below for each appliance

connected to the venting system being

placed into operation could result in

carbon monoxide poisoning or death.

• Examine all components for possible

shipping damage prior to installation;

• Read all instructions before beginning

the installation and follow these

instructions exactly as written.

• Proper joint assembly is essential for a

safe installation. Check the integrity of

ALL joints upon completion of assembly

• This venting system must be free to

expand and contract under normal

operation.

• Assure unrestricted vent movement

where required through walls, ceilings

and roof penetrations.

• This venting system must be supported

in accordance with these instructions.

• Do not mix pipe, ttings, or joining

methods from dierent vent system

manufacturers. Do not use adhesives

of any kind with this venting system.

Acceptance of the installed system is

dependant on full compliance with

these installation instructions.

WARNING

Risk of carbon monoxide poisoning

or re due to joint separation or pipe

breakage.

Keep these instructions for future

reference.

Dear Customer, Installer, or End User:

We welcome any comments regarding

matters pertaining to our DuraVent products.

We welcome any ideas, input or complaints

to help improve our product oering.

If you are searching for tech support or

product information, please phone us at

800-835-4429.

Or email us at:

techsupport@duravent.com

LISTED

MH6357

Page 3

LISTING

M&G DuraVent's FNS 80/90 Combination

Cat I and Cat IV gas vent system is designed

and UL listed for use with approved M&G

Duravent / Security Chimneys special gas

vent components only! Listed to applicable

portions of ULC S636/UL1738, UL1777, and

UL441.

GENERAL INSTALLATION NOTES

Read these instructions before beginning.

You must follow these installation

instructions when installing the FNS 80/90

system. This is a supplemental instruction to

other DuraVent listed instructions that are

used during this installation.

APPLICATION

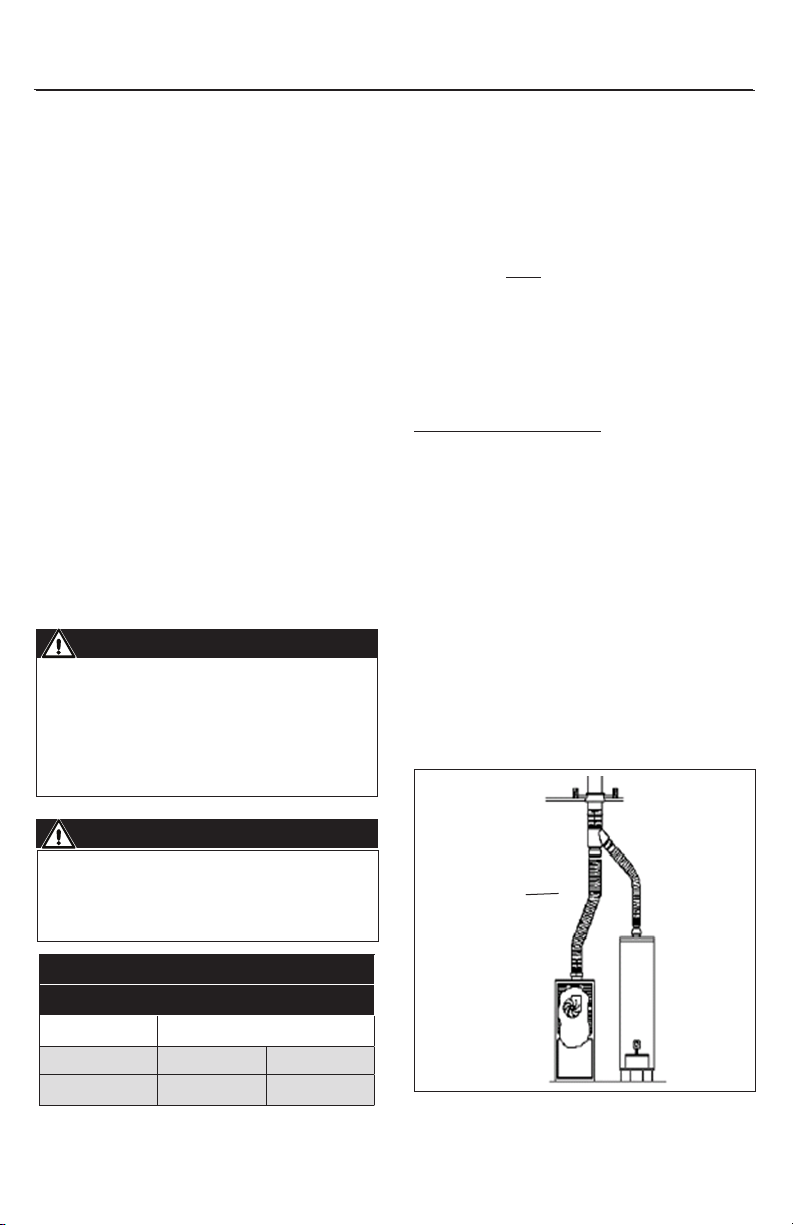

The FNS 80/90 system is a tested and listed

exhaust vent for the replacement of one

Category I gas red appliance with a high

eciency appliance in an existing Type B

common vent system. In a typical common

IMPORTANT

The vent system must be installed in

accordance with local code requirements

and appropriate National Codes: In the

US: NFPA 54 / ANSI Z223.1 National Fuel

Gas Code or the International Fuel Gas

Code.

vent Type B setup (Fig.1), two Category I

(Cat I) appliances vent into one common

vent that conveys ue products outside the

building. In many appliance retrots, one

Cat I appliance is removed, and replaced

with a higher eciency (typically a Cat

IV) condensing appliance. The new Cat IV

appliance is NOT permitted to be vented with

B Vent, but requires a vent system engineered

for a dierent exhaust requirement.

Condensing appliances have much lower

exhaust temperatures, which create

signicant amounts of acidic condensate.

Using the FNS 80/90 solution, a special

stainless steel Cat IV liner is installed within

the existing Cat I vent. This ex handles the

Cat IV ue products, while the remaining

Cat I appliance uses the annular space

around the liner to exhaust ue products

to the outside via natural draft (Fig.2). A

patent pending termination is engineered

to provide separate exhaust exit paths for

each appliances's exhaust system (Fig.2). The

combination of these systems helps both

operate more eectively.

PRIOR TO INSTALLATION: RELINING

COMMON VENTED B VENT SYSTEMS

When relining common vented B-Vent (or

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow these installation

instructions could result in personal

injury or death

Table 1

Clearance to Combustibles

Type B Gas Vent Unchanged Unchanged

VENT PIPE ORIENTATION

Vertical Horizontal

3

TYPICAL

COMMON

VENTED

CATEGORY I

INSTALLATION

Figure 1

Page 4

CAT I EXHAUST

PATH

CAT IV EXHAUST

PATH

Figure 2

other approved factory built vent), special

care must be taken. Prior to reline work

being started:

BIRDSCREEN

FNS FLEX

COLLAR

TERMINATION

CAP

CAP MOUNT

STRAPS /

HARDWARE

FNS FLEX

B VENT

PRE-EXISTING

CAT IV

FIRESTOP /

HARDWARE

POLYPRO

TO FNS FLEX

ADAPTER

CATEGORY

IV EXHAUST

ENTRY

FIG.5

CAT I

EXHAUST

ENTRY

Ensure the new proposed vent system

Figure 3

is appropriate for the two appliances in

question. For the Category IV appliance,

reference the OEM Appliance manual for

information on min/max vent run and vent

diameter requirements. OEM guidance

should include maximum number of elbows

and related pressure-drops. The total vent

length from the appliance to the termination

should not be greater than the maximum

Table 2 - Equivalent Length Chart

2" Equivalent Length 3" Equivalent Length 4" Equivalent Length 5" Equivalent Length

1-ft Rigid Pipe 1-ft 1-ft 1-ft 1-ft

1-ft SS FNS (or

Secure Seal)Flex

1-ft Flex Pipe

45 Elbow 3-ft 3-ft 5-ft 6-ft

90 Elbow 5-ft 7-ft 12-ft 14-ft

Tee 9-ft 12-ft 19-ft 21-ft

Same as rigid pipe (or

elbows)

0.4-ft

(updsized one diameter)

Same as rigid pipe (or

elbows)

0.6-ft

(updsized one diameter)

Same as rigid pipe (or

elbows)

0.6-ft

(updsized one diameter)

Same as rigid pipe (or

elbows)

N/A

4

Page 5

Equivalent Vent Length (EVL) specied by the

appliance manufacturer. If specic guidance

is not oered by the appliance manufacturer

regarding EVL for vent components, the

general guidelines in Table 2 may be used for

PolyPro, FNS, FNS W2 and Security Chimney

Secure Seal product.

For sizing of the remaining Cat I appliance

into the B Vent, reference Table 3. This Table

shows B Vent diameter, inner Cat IV liner

diameter, and the resulting annular space in

terms of an "Equivalent" diameter. This data

takes into account ow restriction on the Cat

I ue introduced from the inner ex and has

been experimentally conrmed. Ensure this

"equivalent" diameter is appropriate for your

remaining Cat I appliance via use of Type B

Gas Vent sizing tables / NFPA54 (Chapter 13).

Treat the connector from the Cat I appliance

and the common vent as a single appliance

vent with the height, length, osets, etc

and verify that the tables conrm adequate

capacity of this annular space before

proceeding.

After conrming the combination vent

system is appropriate for your installation,

inspect the physical condition of existing

B Vent. The B vent must be inspected for

evidence of damage, internal ue blockage,

appropriateness of components including

restops, supports, etc. The inspection must

also ensure the original installation meets

current codes for termination location,

height, etc. Clean and repair as needed to

bring the vent system into compliance.

4a

4b 4c

Figure 4

INSTALLATION OF LINER WITHIN B VENT

Reference Fig.3 for the components required.

Inspect the area where the Cat I exhausts

come together- typically a "Tee" or "Wye". It is

critical that when the Cat IV liner is installed,

it maintain a slope of at least 45° downward

towards the appliance (Fig.4) throughout

the vent run- This is to ensure proper ow of

condensate back to the appliance / drain. If

the inlet end of the existing (common) B vent

is a tee, either the ex for the Cat IV appliance

vent must route through the bottom end of

the tee (Fig.4a) or the tee should be replaced

with a "wye" (Fig.4b), so the ex can route

through the inclined snout of the wye (to

maintain proper slope). Do not install per

Fig.4c!

Table 3 - Annular Space- Effective Remaining B Vent Diameter

2" Cat IV Liner Dia 3" Cat IV Liner Dia 4" Cat IV Liner Dia 5" Cat IV Liner Dia

5" B Vent 4" 3" N/A N/A

6" B Vent 5" 4" 4" N/A

7" B Vent 6" 5" 5" 4"

8" B Vent 6" 6" 6" 5"

5

Page 6

APPLY SEALANT

BIRD-SCREEN

SLIDE FLEX

UP TO

SEAL

Figure 5a- 2" Flex

APPLY SEALANT

APPROX 3/4"

FROM TOP

BIRD-SCREEN

Figure 5b- 3"-5" Flex

If the lower tee or wye needs to be replaced,

determine the existing brand of B Vent. If

the B Vent is DuraVent, the appropriate Tee

or Wye can be purchased and connected as

is. If the B Vent is not DuraVent, purchase a

"Female Adapter" which allows connection to

non-DuraVent B Vent, and the DuraVent tee

or wye desired.

1. Remove the Cat I appliance being

replaced, the associated B Vent pipe, and

existing termination cap.

2. Measure vent run, cut ex to length,

ensure 1 ft of excess ex. Remove burrs from

ex for ease of install.

4. Connect ex to termination cap:

4a. If installing 2" Flex: Flip the

termination cap upside down and apply

a generous amount of high temperature

non-hardening silicone around the outer

ange edge of the FNS Flex Collar (Fig.5a).

Once applied, ip the termination cap back

upright and carefully lower cap onto ex

so that the silicone ange is seated inside

the 2” ex. Tighten hose clamp to secure

the ex to the termination cap.

4b. If installing 3”-5” ex: Run the ex

through the termination cap until ex is

¾” from exit at the top of the cap. Tighten

the hose clamp to secure the ex into

position. Apply a generous bead of high

temperature non-hardening silicone

(Fig.5b) to seal ex to the inner diameter

of the termination cap.

5. Lower cap to B-Vent and ax with

hardware / mount straps to the vent pipe.

Strap can be trimmed if desired.

6. Compress / Install Bird Screen Ring into

Flex collar groove. (Fig.5a/b)

3"-5"

APPLY

SEALANT

TOP (CAP) side of install:

3. Route ex through B Vent, leave 8" excess

at top. Ensure ex does not go beyond 45

degree anywhere along the vent run for

proper condensate handling. Ensure ex is

installed so the arrow goes in direction of

exhaust ow

POLYPRO

/ FLEX

ADAPTER

FIRESTOP

Figure 6- Appliance Side

Connection

6

Page 7

IMPORTANT

When installing FasNSeal Flex, the

direction of exhaust ow is away

from the appliance. There is an arrow

printed on each section of liner and

components that will point in the

direction of the exhaust gas. You can

conrm the liner is installed correctly

by running your ngernails up the

inside wall of the liner. If the direction

is correct your nails will catch at the

seams of the inner wall. If it is incorrect

your nails will slide smoothly across

the inner surface.

LOWER (Appliance) side of install (Fig.6)

1. Flex should stick outside B Vent minimum

3”, maximum 5” (trim if needed).

2. Apply generous amount of silicone to ex

and PolyPro / Flex adapter (or other approved

DuraVent or Security Chimneys product).

Insert ex into adapter and tighten hose

clamp.

3. Install restop onto adapter, fasten to

B-Vent using supplied hardware.

4. Continue vent run to the appliance per the

appropriate instruction.

MAINTENANCE

Have your venting system checked annually.

This can be done by the same technician

who inspects & services the appliance.

Recommended areas to inspect are as

follows:

- Check areas of the Venting System which

are exposed to the elements for wear or

damage. If damage is found, the components

should be replaced immediately.

- Where possible, look into the Termination

Cap to verify no foreign material is there to

block the vent. Remove any foreign material

found.

- Where practical, inspect joints to verify

Figure 7- Disassembly of Cap

that no Pipe Sections or Fittings have been

disturbed, and consequently loosened. Also

check mechanical supports such as Wall

Straps, support plates, etc for rigidity.

Should the termination need to be removed,

loosen ex hose clamp and unfasten from

B-Vent. If internal access is needed, the four

screws holding the termination top to the

termination base may be removed and the

termination top will lift o (Fig.7).

7

Page 8

M&G DURAVENT LIMITED LIFETIME WARRANTY

M&G DuraVent, Inc. (“DuraVent”) provides this limited lifetime warranty for all of its products with the exception of Ventinox® (lifetime), and

PolyPro® (ten years). Subject to the limitations set forth below, DuraVent warrants that its products will be free from defects in material or

manufacturing, if properly installed, maintained and used. DuraVent products are fully warranted if installed only by a professional installer.

This Warranty is transferable from the original homeowner to the buyer of the home. This warranty does not cover normal wear and tear,

smoke damage or damage caused by chimney res, acts of God, or any product that was: (1) purchased other than from an authorized

DuraVent dealer, retailer or distributor; (2) modied or altered; (3) improperly serviced, inspected or cleaned; or (4) subject to negligence or

any use not in accordance with the installation instructions included with the product as determined by DuraVent. Installation instructions are

available online at www.duravent.com under Support/Literature and through our Customer Service Department 800-835-4429 or

customerservice@duravent.com. This limited lifetime warranty applies only to parts manufactured by DuraVent.

DuraVent provides the following warranties for its products: One Hundred Percent (100%) MSRP 15 years from the date of purchase, and Fifty

Percent (50%) thereafter, except for the following limitations on: all Termination Caps and DuraBlack® are warranted at One Hundred Percent

(100%) for ve years.

All warranty obligations of DuraVent shall be limited to repair or replacement of the defective product pursuant to the terms and conditions

applicable to each product line. These remedies shall constitute DuraVent’s sole obligation and sole remedy under this warranty. This warranty

provides no cash surrender value. The terms and conditions of this warranty may not be modied, altered or waived by any action, inaction or

representation, whether oral or in writing, except upon the express, written authority of an executive ocer of DuraVent.

Corn, bio-fuels, driftwood or other wood containing salt, preservative-treated lumber, plastic and household trash or garbage, or wood pellets

containing such materials must not be burned in the appliance or replace. In case of a chimney re, the chimney must be inspected and

approved by a certied Chimney Sweep before reuse. After each annual inspection, maintenance, and cleaning, the certied Chimney Sweep

must ll out and date the appropriate section of the warranty card provided with the chimney liner.

LIMITATIONS ON INTERNET SALES: Notwithstanding any other terms or conditions of this Limited Lifetime Warranty, DuraVent provides no

warranty for the following specic products if such products are not installed by a qualied professional installer: DuraTech®, DuraPlus HTC®,

DuraChimney® II, PelletVent Pro®, DirectVent Pro®, FasNSeal®, FasNSeal® W2, FasNSeal® Flex, and PolyPro®, and M&G DuraVent’s relining

products including DuraLiner®, DuraFlex® (SW, Pro, 316, 304), and Ventinox®. For purposes of this warranty, a trained professional installer is

dened as one of the following: licensed contractors with prior chimney installation experience, CSIA Certied Chimney Sweeps, NFI Certied

Specialists, or WETT Certied Professionals.

DuraVent must be notied and given the opportunity to inspect defective product prior to replacement under the terms of this limited lifetime

warranty. All warranty claims must be submitted with proof of purchase. Labor and installation costs are not covered under this warranty. To

obtain warranty service contact: DuraVent Warranty Service, 877 Cotting Ct., Vacaville CA 95688, or call 800-835-4429.

WHERE LAWFUL, DURAVENT DISCLAIMS ALL OTHER WARRANTIES, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT WILL DURAVENT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL,

PUNITIVE OR SPECIAL DAMAGES OR DIRECT OR INDIRECT LOSS OF ANY KIND, INCLUDING BUT NOT LIMITED TO PROPERTY DAMAGE AND

PERSONAL INJURY. DURAVENT’S ENTIRE LIABILITY IS LIMITED TO THE PURCHASE PRICE OF THIS PRODUCT. SOME STATES DO NOT ALLOW

LIMITATIONS ON IMPLIED WARRANTIES, OR THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS AND EXCLUSIONS MAY NOT APPLY TO YOU. THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS THAT VARY FROM STATE TO STATE.

For the most up-to-date installation instructions, see

www. duravent.com

REV 3.22.2012

Manufactured in Vacaville CA and Albany NY

Customer Service Support 800-835-4429 707-446-4740 FAX www.duravent.com

PolyPro® and GreenVent® are registered trademarks of M&G DuraVent, Inc.

All rights reserved, ©2012 M&G DuraVent is a member of M&G Group.

820014370- L273C 11/2014

Loading...

Loading...