DuraVent DuraTech 5-8 User Manual

Installation Instructions

All-Fuel Chimney System

5” to 8” diameter

DuraTech

A MAJOR CAUSE OF VENT RELATED FIRES IS FAILURE

TO MAINTAIN REQUIRED CLEARANCES (AIR SPACES) TO

COMBUSTIBLE MATERIALS. IT IS OF THE UTMOST IMPORTANCE

THAT DOUBLE WALL DURATECH BE INSTALLED ONLY IN

ACCORDANCE WITH THESE INSTRUCTIONS.

NOTE:

Read through all of these instructions before

beginning your installation. Failure to install

as described in this instruction will void the

manufacturer’s warranty, and may have an

effect on your homeowner’s insurance and

UL listing status. Keep these instructions for

future reference. This booklet also contains

instructions for installing a venting system

within an existing masonry chimney, and

for installations passing through a cathedral

ceiling.

Dear Customer, Installer, or End User:

We welcome any comments, ideas, input or

complaints regarding matters pertaining to our

DuraVent products.

If you are searching for tech support or product

information, please phone us at 800-835-4429.

Or email us at:

techsupport@duravent.com

LISTED

MH7399

ALL-FUEL CHIMNEY SYSTEM, 5” TO 8” DIAMETER

For the most up-to-date installation instructions, see www.duravent.com

CONTENTS

CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PERMITS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DURATECH CHIMNEY APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION NOTES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CHIMNEY HEIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CHIMNEY ENCLOSURE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SUPPORT REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

METHOD #1: CEILING SUPPORTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OFFSET ELBOW INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

EXTENDED ROOF BRACKET INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . .13

METHOD #2: ROOF SUPPORTED INSTALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

METHOD #3: TEE-SUPPORTED INSTALL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

METHOD #4: MASONRY FIREPLACE INSTALL . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

METHOD #5: ZERO-CLEARANCE FIREPLACE INSTALL. . . . . . . . . . . . . . . . . . 21

ADJUSTABLE CHIMNEY LENGTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

CHIMNEY MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

DuraTech

3

CLEARANCES

Always allow at least a 2-inch clearance

between DuraTech Chimney Pipe and any

combustible materials. Never ll any required

clearance space with insulation or any other

materials. Combustible materials include

lumber, plywood, sheetrock, plaster and lath,

furniture, curtains, electrical wiring and building

insulation. Keep single wall stovepipe at least

18 inches away from combustible materials,

unless a clearance reduction system that is

acceptable to the authority having jurisdiction

is used, or the appliance to be installed is

listed and the instructions specify a different

clearance.

PERMITS

Contact your local Building Ofcial or Fire

Ofcial regarding permits, restrictions, and

installation inspections in your area.

DURATECH CHIMNEY

APPLICATIONS

DuraTech Chimney (5”-8” Dia) is a complete

chimney system tested and listed to UL 103

HT for the United States, and ULC S604

in Canada. In the U.S., DuraTech 5”-8”

Chimney can be used with wood stoves,

replaces, reboxes, furnaces, boilers, or

other residential-type appliances fueled by oil,

gas, coal, or wood, that require a UL103 HT

chimney system. In Canada, DuraTech can

be used with oil & gas red appliances listed

for use with a Type A Chimney, in accordance

with ULC S604 . DuraTech is also listed for use

in Canada with some factory-built replaces;

check with your replace manufacturer.

Otherwise, DuraTech has not been approved

for use with solid fuel appliances in Canada.

Do not use with forced draft, positive-pressure

appliances. The DuraTech Chimney system

may have a maximum of two (2) offsets (four

elbows total) of 30° from vertical. DuraTech

Chimney is listed under UL FIle MH7399.

INSTALLATION NOTES

You must use only authorized DuraTech

Chimney parts to maintain a listed Chimney

system (not including the connector pipe).

Do not mix parts or try to match with other

products, or use improvised solutions. Do

not install damaged or modied parts. Follow

the appliance manufacturer’s instructions to

determine: chimney diameter, clearances

between combustible materials and your

heating appliance, and to ensure maximum

system efciency and safety. Connect only

one appliance per chimney. Never choose

a chimney with an inside diameter smaller

than your appliance’s outlet. Practice good

workmanship, sloppy work could jeopardize

your chimney’s safety. Keep electrical wiring

and insulation away from all chimneys and

stovepipes. If you have any questions, be

sure to contact either your dealer or DuraVent

directly.

Fuels: Do not burn driftwood, plastic, or

chemically treated wood such as railroad

ties. They are corrosive to your appliance,

stovepipe and chimney. Follow the appliance

manufacturer’s instructions and safety manual

in regards to fuels. Not all appliances are

equipped to burn coal. Coal with a low sulfur

content will reduce the possibility of corrosion.

Care must be taken to avoid overring, which

can damage the appliance, stovepipe and

chimney system.

Mobile Homes: Please read the appliance

manufacturer’s instructions and safety manual

carefully. Not all appliances are listed for use

in mobile homes.

4

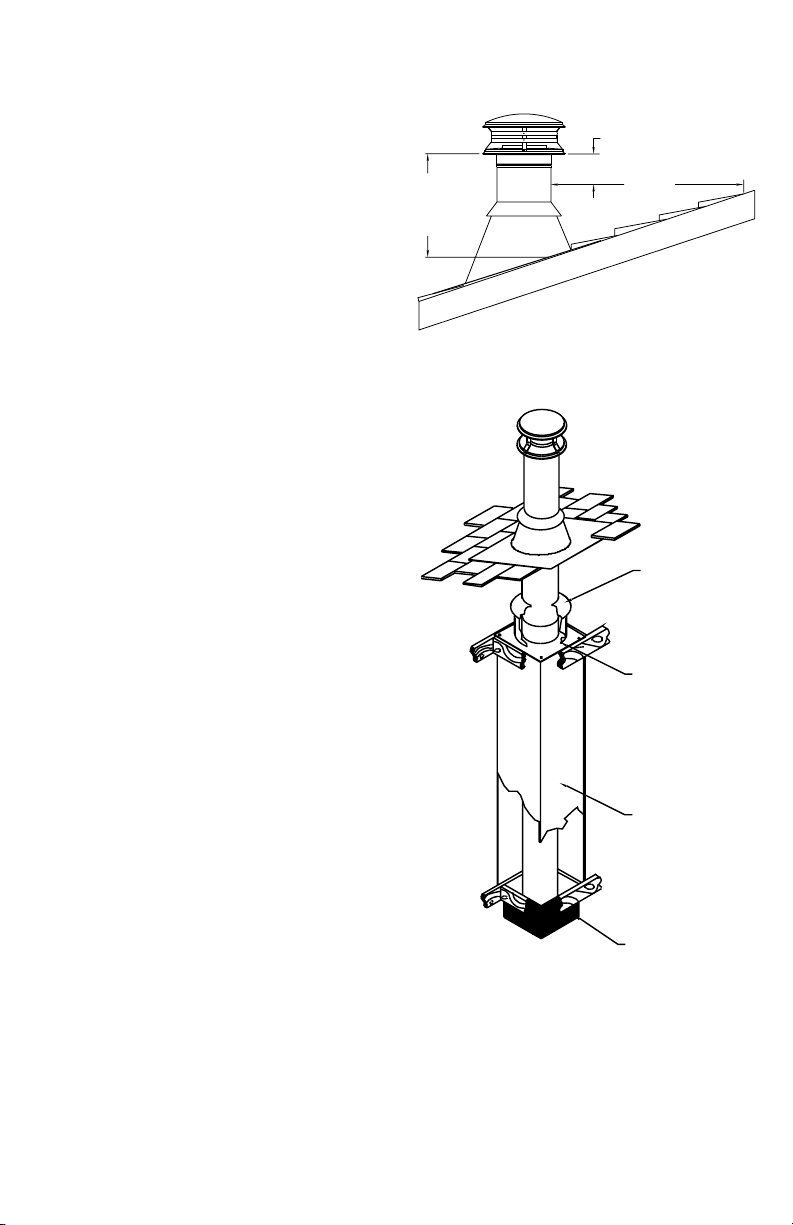

CHIMNEY HEIGHT

The National Fire Protection Association

Standard #211 states: “Chimneys shall extend

at least three feet above the highest point

where it passes through the roof of a building,

and at least two feet higher than any portion

of a building within ten feet.” (Fig.1) DuraTech

Chimney may be installed up to 60 feet high. If

the chimney extends more than 5 feet above

the roof, an Extended Roof Bracket must be

used (see page 12). Due to the overlap of the

joints, subtract 1-1/4 inches from each Chimney

Section’s height to calculate installed height.

CHIMNEY PLACEMENT

When deciding the location of your chimney,

try to avoid modications to roof beams and

other structural components of the building.

CHIMNEY ENCLOSURE REQUIREMENTS

Through Rooms: Interior chimneys shall be

enclosed where they extend through closets,

storage areas, occupied spaces, or anyplace

where the surface of the chimney could be

contacted by persons or combustible materials.

Maintain at least a 2-inch air space between

the outer wall of the chimney and the enclosure

(Fig.2).

Multi-Story: Consult local building codes for

requirements in your area. In the U.S., the

National Fire Protection Association Standard

#211 states: “Factory-built chimneys that

pass through oors of buildings requiring the

protection of vertical openings shall be enclosed

with approved walls having a re resistance

rating of not less than one hour when such

chimneys are located in a building less than

4 stories in height, and not less than 2 hours

when such chimneys are located in a building

more than 4 stories in height.” In Canada,

2 FT MIN ABOVE HIGHEST

POINT OF ROOF WITHIN

10 FT

3 FT MIN

ABOVE

ROOF

10 FT

Figure 1

ATTIC

INSULATION

ATTIC /

UNOCCUPIED

SPACE

OCCUPIED

SECOND

FLOOR

FIRST

FLOOR

SHIELD

FIRESTOP

RADIATION

SHIELD

(INSIDE)

ENCLOSURE

MUST HAVE 2

INCHES OF

CLEARANCE

BETWEEN

CHIMNEY AND

WALL

SUPPORT

BOX

Figure 2

except in single-family and two-family dwellings,

chimneys which extend through another story

must have an enclosure with a re resistance

rating equal to or greater than that of the oor or

5

roof assembly through which they pass.

Cold Climates: In cold climates, chimneys

mounted on an outside wall should be

enclosed in a chase. Exterior chases reduce

condensation and creosote formation, and

enhance draft. Include an access door by the

Tee Cap for chimney cleaning (Fig.26,27).

TABLE 1: Framing Dimensions

Chimney Diameter

5” 6” 7” 8”

CATHEDRAL CEILING

SUPPORT BOX

FLAT CEILING

SUPPORT BOX

ROUND CEILING

SUPPORT BOX

FIRESTOP RADIATION

SHIELD

WALL THIMBLE 11- 1/4” 12-1/4” 13-1/4” 14-1/4”

CAS CEILING

SUPPORT

CAS WALL THIMBLE NA 12-1/4” NA 14-1/4”

REDUCED

CLEARANCE

SUPPORT BOX

11-1/4” 12-1/4” 13-1/4” 14-1/2”

11-1/4” 12-1/4” 13-1/4” 14-1/2”

11-1/4” 12-1/4” 13-1/4” 14-1/4”

11-1/4” 12-1/4” 13-1/4” 14-1/4”

NA 12-1/4” NA 14-1/2”

NA 10-1/4” NA NA

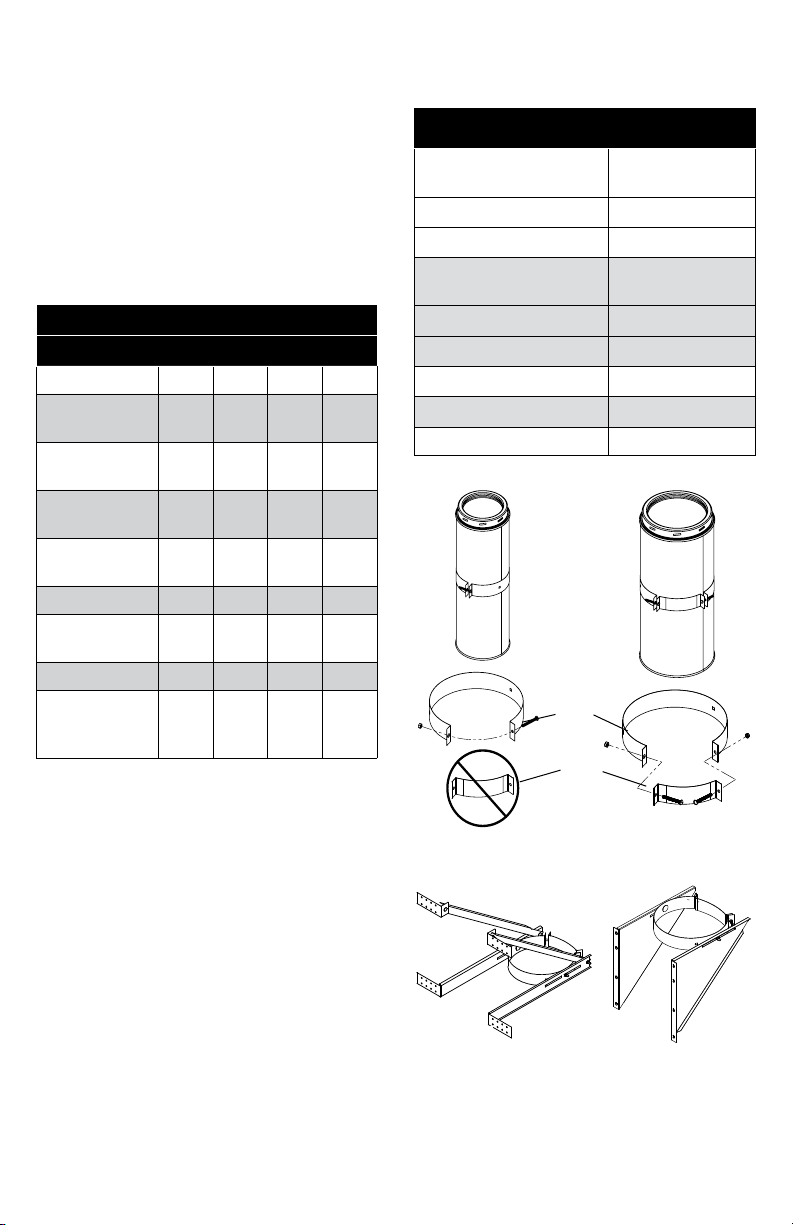

TABLE 2: Chimney Support

DURATECH SUPPORT COMPONENT

ADJUSTABLE ELBOW STRAP EA ELBOW/PIPE

ADJUSTABLE WALL STRAP N/A - USE EVERY 8’ MIN

SUPPORT BOX (SQUARE OR

ROUND)

TEE SUPPORT 60-FT

EXTENDED ROOF BRACKET N/A

EXTENDED WALL SUPPORT 20-FT

RE-SUPPORT 20-FT

ROOF SUPPORT 30’ TOTAL, 10’ ABOV E

5” AND 6” DIA 7” AND 8” DIA

UNIVERSAL

SUPPORT

BAND

SPACER

CHIMNEY HEIGHT

SUPPORTED 5”-8” DIA

60-FT

SUPPORT REQUIREMENTS

There are two “styles” of support connection

to the chimney pipe: Dedicated dia supports,

and Universal supports shown in Fig.3, 4.

For Universal components, the spacer is

discarded for 5”-6” Dia. Table 2 details the

chimney height supported by the various

components and must be followed throughout

this instruction, this data applies to both styles.

Items in Table 2 noted N/A are not load bearing

components.

6

UNIVERSAL

EXTENDED

WALL SUPPORT

Figure 3

UNIVERSAL

RE-SUPPORT

Figure 4

BAND-BRACKET CONNECTIONS

For Universal components, use the carriage

bolt through the band and through the leg.

Use (1) at washer, (1) locking washer, and (1)

nut per side to secure to carriage bolt (Fig.5).

Ensure carriage bolts are directly across from

each other.

CARRIAGE BOLT

FLAT WASHER

LOCKING WASHER

NUT

UNIVERSAL

SUPPORT BAND

Figure 5

MOUNTING

HARDWARE- #8

WOOD SCREWS

WITH WASHER

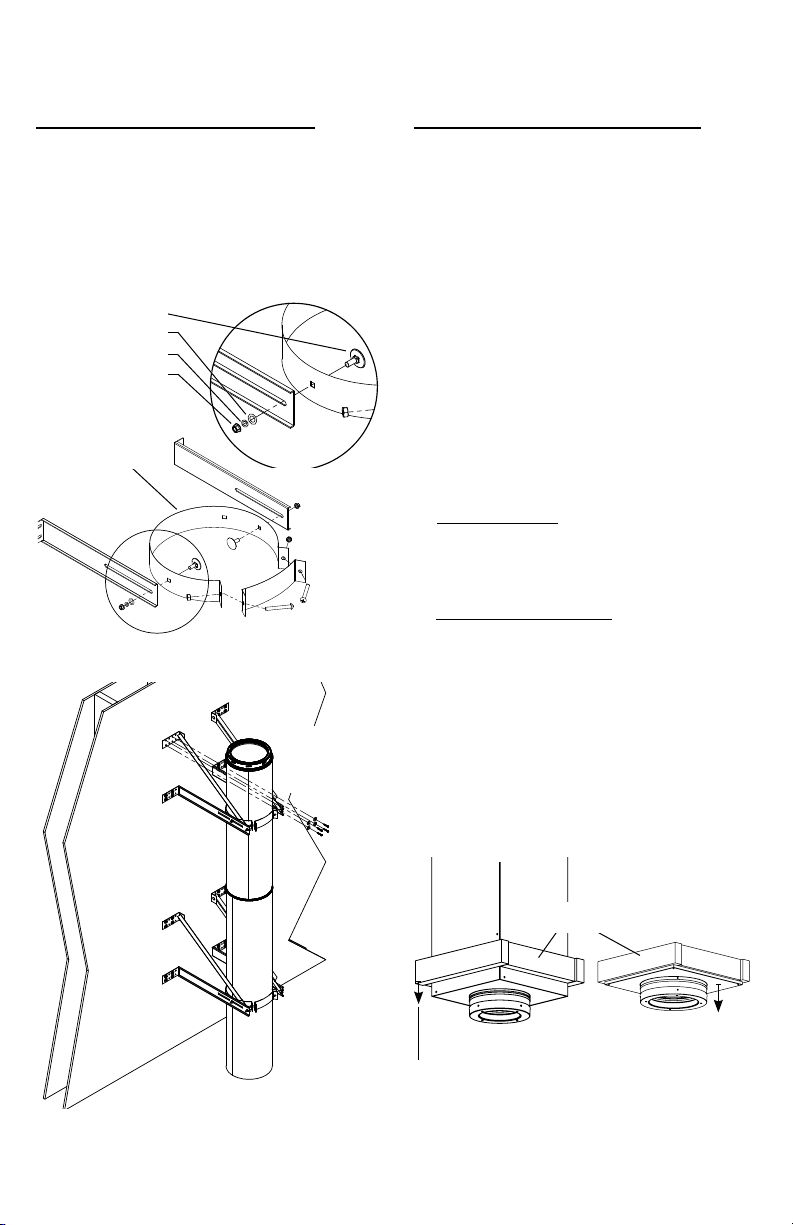

WALL SUPPORTS/RE-SUPPORTS

Wall Supports, Re-Supports, and Tee Supports

can be used interchangeably (Fig.6) to support

the chimney on vertical runs.

STEP-BY-STEP DIRECTIONS

There are ve general types of DuraTech

Chimney installations- Review the step-by-step

directions before beginning your installation.

1.Ceiling-supported (p.7)

2.Roof-supported (p.14)

3.Tee-supported-through-the-wall (p.16)

4.Masonry Fireplace (p.20)

5.Zero-Clearance Fireplace (p.21)

METHOD 1: CEILING SUPPORTED

1. Place Appliance: Position the appliance

according to the manufacturer’s instructions.

The ue outlet collar should be placed

between the rafters or joists above, if possible.

2. Frame Support Opening: Drop a plumb bob

to the center of the appliance’s ue outlet and

mark this center point on the ceiling. Refer

to Table 1 for specic framing and clearance

dimensions. Mark appropriate cutting lines

around the center point. Cut a square hole in

the ceiling for the Support Box. Frame a level,

square opening centered over the hole which

you have cut. (Fig.7 and 8).

SQUARE SUPPORT

BOX

ROUND SUPPORT

BOX- SQ TRIM

EXTENDED

WALL SUPPORT

Figure 6

JOISTS & FRAMING

PER TABLE 1

SQUARE MUST

EXTEND MIN 2” BELOW

FINISHED CEILING

(MIN POINT IF ANGLED)

ROUND MUST EXTEND

MIN 3” BELOW

FINISHED CEILING

Figure 7

7

REF FIG. 7 FOR MIN

DISTANCE BELOW

CEILING FOR

SUPPORT USED

18 INCHES

MINIMUM FOR

SINGLE WALL

STOVEPIPE

CHIMNEY CAP

STORM

COLLAR

ROUND SUPPORT

BOX

Figure 8

ADJUSTABLE FLASHING

CHIMNEY SECTIONS

ATTIC INSULATION SHIELD

FRAMED OPENING

ROUND TRIM COLLAR

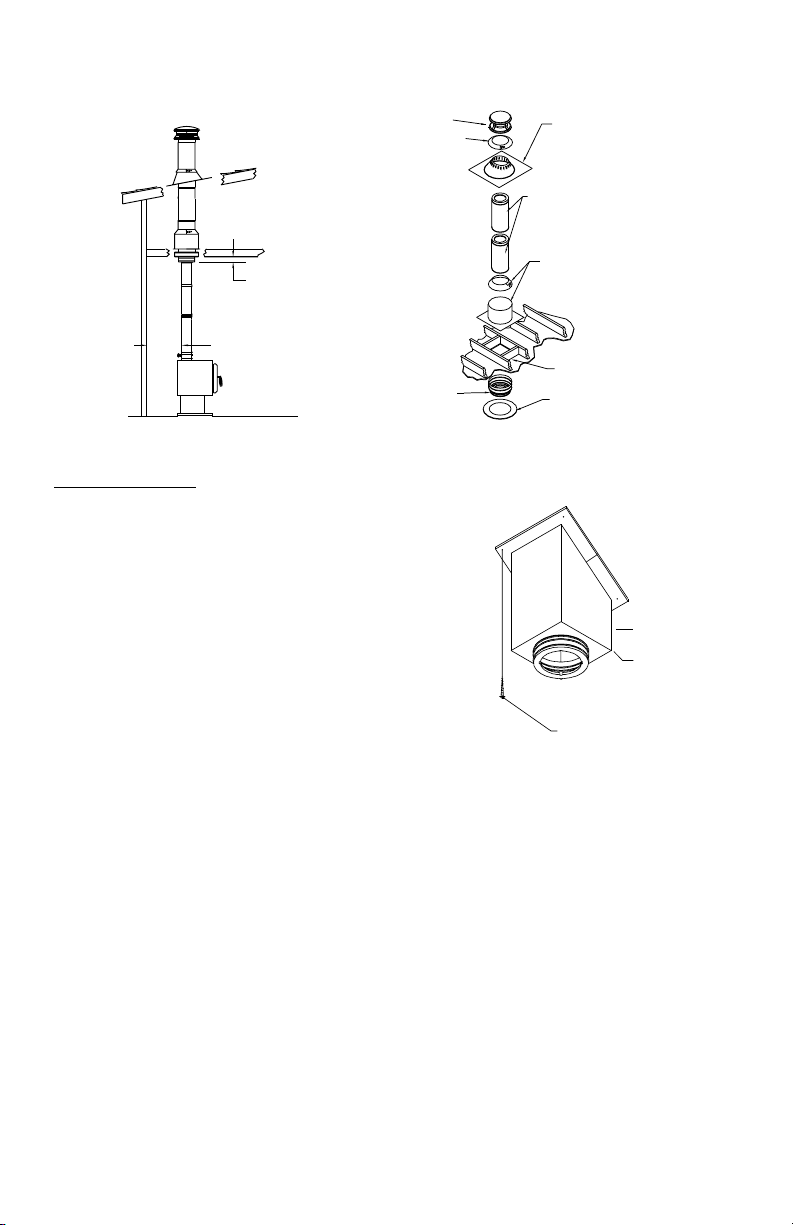

3. Install Support Box: For installation into a

at ceiling, there is the option of the Round

Support Box (Round or Square Trim Collar),

Flat Ceiling Support Box, Square Ceiling

Support Box, Reduced Clearance Support

Box, or the Combustion Air System (CAS)

Ceiling Support Box. The CAS Ceiling

Support is only used when installing the

CAS system, refer to the DuraTech CAS

Installation Instructions for directions on how

to install the remainder of the system. The Flat

Ceiling Support Box is primarily used for Oil

Appliances and comes unpainted.

For the Round support box, the trim mounts

ush to the ceiling with the bottom protruding

a min of 3” below the ceiling (Fig.7). For the

Square support box, the square face must

protrude a min of 2” below the ceiling (Fig.7).

Level the Support Box and secure it to the

framing using at least three 8-penny nails

per side (min. of 12 total). Alternatively, you

may use 1-1/2” #8 wood screws (min. of 12

total), instead of nails. After the Support Box

is mounted, secure the Trim Collar (round or

square) to the framing members using the (4)

1” long, round-head wood screws provided

SQUARE SUPPORT BOX

WITH TRIM FRAME IN

PLACE

MINIMUM OF

2” BELOW

CEILING

WOOD SCREWS ARE

REQUIRED

Figure 9

(Fig.9). For installation into a cathedral ceiling,

you must use the Square Ceiling Support

Box or Reduced Clearance Support Box (or

the CAS Ceiling Support if installing the CAS

system) and the two-piece Trim. The bottom

of the square portion of the Support Box must

be a minimum of 2” lower (round portion is

then an additional 3” lower) than the nished

ceiling at the lowest side of the penetration

(Fig.9). Level the Support Box and secure it

to the framing using at least three (3) 8-penny

nails per side (minimum of 12 nails total), or a

minimum of (3) #8, 1-1/2” wood screws. Adjust

8

Loading...

Loading...