Page 1

INSTALLATION

INSTRUCTIONS

Boiler and Engine Exhaust Chimney Systems

Grease Duct Systems

Double Wall Construction Positive Pressure Chimney Systems

MODELS DIS / DAS

DIS: INSULATED

DAS: UNINSULATED

This installation manual will enable you to obtain a safe, efficient and

dependable installation of this positive pressure chimney system.

Please read and understand these instructions before beginning your

installation.

(DIS only)

Listed to standards:

UL 103 and ULC S604

UL-1978 (DIS only)

ULC/ORD-C959 540°C and 760°C

Report # 3162834

Do not alter or modify the components of this chimney system under any

circumstances. Any modification or alteration of the chimney system

or approved accessories, including but not limited to the appliance

it is connected to, may void the warranty, listings and approvals of

this system and could result in an unsafe and potentially dangerous

installation.

SUITABLE FOR POSITIVE PRESSURE VENTING APPLICATIONS WITH

MAXIMUM 60” WATER COLUMN INTERNAL STATIC PRESSURE AT

1000 DEGREES F.

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE

WARNINGS

FAILURE TO FOLLOW THESE INSTALLATION

INSTRUCTIONS COULD CAUSE FIRE, CARBON

MONOXIDE POISONING, OR DEATH. IF YOU ARE

UNSURE OF INSTALLATION REQUIREMENTS, CALL

THE PHONE NUMBER LISTED ON THE BACK OF

THESE INSTRUCTIONS.

A MAJOR CAUSE OF CHIMNEY RELATED FIRE IS

FAILURE TO MAINTAIN REQUIRED CLEARANCES

(AIR SPACES) TO COMBUSTIBLE MATERIALS. IT

IS OF UTMOST IMPORTANCE THAT THIS CHIMNEY

BE INSTALLED ONLY IN ACCORDANCE WITH THESE

INSTRUCTIONS.

PIDIS REV. 2 04/2013

Page 2

TABLE OF CONTENTS

Introduction ............................................................................ page 2

Testing / listing information .................................................... page 2

Section A - General information ................................ page 2

Features ............................................................................. page 2

Application ......................................................................... page 3

Surrounding / enclosure .................................................... page 3

Boiler and engine exhaust .......................................... page 3

Grease duct ................................................................ page 3

System sizing .................................................................... page 3

Part numbers ..................................................................... page 4

Effective length .................................................................. page 4

Clearances ......................................................................... page 4

Opening through combustible construction ....................... page 4

Chimney and fitting joint assembly .................................... page 5

Support methods and height limits .................................... page 6

Thermal expansion ............................................................ page 6

Chimney weight ................................................................. page 7

Chimney guying and spacing ............................................. page 7

Termination height ............................................................. page 8

Multi-engine exhausts not recommended .......................... page 8

Section B - Tees, elbows, increasers .......................... page 9

Tees ................................................................................... page 9

Increaser, step or tapered .................................................. page 10

Elbows ............................................................................... page 10

Offsets ............................................................................... page 11

Section C - Structural support and guiding .................... page 12

Anchor plate ..................................................................... page 12

Length Anchor Plate .......................................................... page 12

Anchor plate ventilated ...................................................... page 12

Wall support ..................................................................... page 14

Wall guide ......................................................................... page 14

Floor guide ........................................................................ page 15

Suspension band ............................................................... page 15

Roof brace ......................................................................... page 16

Guy wire ........................................................................... page 16

Section D - Roof and wall penetrations ........................ page 17

Roof / floor penetration .................................................... page 17

Wall penetration ................................................................. page 17

Section E - Terminations, starting adaptors, drain length

and relief valve ............................................ page 18

Single wall adaptor ............................................................ page 18

ANSI flange adaptor ........................................................... page 18

Flanged adaptor ................................................................. page 18

DIS/DAS to DCT and DCT to DIS/DAS adaptor .................. page 18

Rain cap ............................................................................. page 19

Finishing cone ................................................................... page 19

Flip top ............................................................................... page 19

Miter cut ............................................................................ page 19

Drain length ....................................................................... page 20

Relief valve ........................................................................ page 20

Section F - Thermal expansion ................................... page 21

Thermal expansion ............................................................ page 21

Expansion joints installation .............................................. page 21

Bellows expansion joint ..................................................... page 21

Adjustable length ............................................................... page 23

Variable length ................................................................... page 24

Section G - Grease duct application ................................page 26

Access ...............................................................page 26

Use and installation of individual parts ........................page 26

Horizontal drain length ...........................................page 26

Nozzle section ......................................................page 26

Square to round adaptor .........................................page 26

Grease tee 90° .....................................................page 27

Grease tee Y ........................................................page 27

No tool access door ...............................................page 28

Fan adaptor plate ..................................................page 29

Maintenance ........................................................page 29

Section H - Markings ..................................................page 30

2

Product reference information ......................................page 32

INTRODUCTION

Duravent Model DIS or DAS Chimney are cylindrical, prefabricated,

modular venting systems incorporating

designed for both quick assembly and pressure sealing capability. Model

DIS incorporates a

The circular cross section and high quality stainless steel inner

lated.

flue construction provide for a system with high strength-to-weight ratio

and low friction losses.

2” of mineral fiber insulation while DAS is air insu-

a unique extended inner flange

TESTING / LISTING INFORMATION

Duravent model DIS and DAS venting systems are listed with Intertek

Testing Services (ETL) to UL/ULC standards:

U.S.A.

• UL-103

- 60 in. Positive Pressure Chimney

- Building Heating Appliance Chimney

- 1400°F Chimney

• UL-1978 Grease Duct

(DIS only)

CANADA

• ULC/ORD C959

- 540°C (1000°F)

- 760°C (1400°F)

• ULC S604

Models DIS and DAS are code compliant when installed as per the

Installation Instructions with : NFPA211; NFPA31; NFPA37; NFPA96

and CSA-B149

When installed in accordance with it’s installation, Models DIS and DAS

comply with the following codes :

- NFPA (National Fire Protection Association)

- SBCCI (Southern Building Code Congress International)

- ICBO (International Conference of Building Officials)

- BOCA (Building Officials and Code Administrators)

- ICC (International Code Congress)

SECTION A - GENERAL INFORMATION

These instructions comprise both general guidelines and special requirements for all parts in the product line. Before specifying a design

or beginning an installation please carefully review these instructions.

Maintenance Notes:

Chimney Cleaning: This applies to cleaning other than standard natural

gas chimney applications where minimal maintenance is necessary.

Keep your chimney clean. Access should be provided for the inspection and cleaning of all sections of the chimney. Have your chimney

cleaned by qualified chimney sweep. It is recommended to use a nylon

chimney brush of the correct size. Do not use a brush that will scratch

the stainless steel interior of the chimney.

FEATURES

Models DIS and DAS are prefabricated modular venting systems design

for industrial and commercial applications. It has a unique extended inner flange for both quick assembly and pressure sealing capability. It

is a double wall construction with 2” of mineral fiber insulation for DIS

and 2” air space for model DAS. The inner flue is made of high quality

stainless steel plasma welded.

Page 3

APPLICATION

UL 103 Building Heating Appliance Chimney Listing:

Duravent models DIS and DIS chimney may penetrate a combustible

floor, wall or roof using the appropriate parts and openings sizes. See

section D “Roof & Wall Penetration” for more details.

Under this category, models DIS and DAS have been determined suitable

for venting flue gases at temperatures not exceeding 538°C (1000°F)

under continuous operating conditions from gas, liquid, oil or solid fuel

fired appliances. Also complies with operation (less than one hour)

at temperatures not exceeding 740°C (1400°F) and brief operation

(maximum 10 minutes) at temperatures not exceeding 906°C (1700°F).

Building Heating Appliance Chimneys are suitable for use with Building Heating Appliances and Low Heat Appliances as described in the

Chimney Selection Chart of National Fire Protection Association (NFPA)

Standard NO. 211.

UL 103 1400°F Chimney Listing:

Under this category, models DIS and DAS have been determined suitable

for venting flue gases at temperatures not exceeding 760°C (1400°F)

under continuous operating conditions from gas, liquid, oil or solid

fuel fired appliances. Also complies with brief operation (maximum 10

minutes) at temperatures not exceeding 906°C (1700°F). As such, it is

suitable for use with ovens and furnaces as described in the Chimney

Selection Chart of NFPA No. 211, in addition to other applications.

UL 103 Positive Pressure Listing:

Under this category, models DIS and DAS have been determined suitable for use at a maximum of 60 inch water column internal pressure.

ULC-C959 540°C and 760°C Industrial Chimneys Listing:

Under this category, models DIS and DAS have been determined suitable

for venting flue gases at temperatures not exceeding 760°C (1400°F)

under continuous operating conditions from gas, liquid, oil or solid

fuel fired appliances. Also complies with brief operation (maximum 10

minutes) at temperatures not exceeding 980°C (1800°F).

UL 1978 Grease Ducts Listing (DIS only):

Duravent model DIS chimney is tested in accordance with UL 1978

Standard and approved for Grease Duct applications when installed in

accordance with these installation instructions and National Fire Protection Association standard “NFPA 96, Standard for Ventilation Control

and Fire Protection of Commercial Cooking Operations”.

SURROUNDINGS / ENCLOSURE

Where, according to local code, no chase enclosure is necessary, models

DIS and DAS chimney may be placed adjacent to walls of combustible

construction at the clearance specified on each chimney section and

in the individual listing; see “CLEARANCES”. Contact local building or

fire officials about restrictions and installation inspection requirements

in your area.

Grease Ducts (DIS Only)

1. Model DIS grease ducts are primarily intended for installation in

noncombustible surroundings or in unenclosed installations.

2. Where model DIS grease ducts are installed in an open room and an

enclosure is not required, the minimum clearance to adjacent combustible walls shall be as shown in this section (see “CLEARANCES”). The

ducting may be located in a corner formed by two walls of combustible

construction, if the conditions above are met.

3. Other interior installations in all buildings should be as follows:

a) Where a grease duct penetrates a wall or ceiling rated for fire re-

sistance, it should be enclosed with a continuous non-combustible

enclosure extending from the lowest fire-rated ceiling or floor

above the hood, through any concealed space, to or through the

roof so as to maintain the integrity of the fire separations required

by the applicable building code provisions. The enclosure shall be

sealed around the duct at the point of penetration of the lowest

fire-rated ceiling or floor above the hood, in order to maintain the

fire resistance rating of the enclosure and shall be extended to

the exterior of the building through weather-protected openings.

b) A grease duct penetrating a ceiling, floor or wall which does not

have a fire resistance rating does not require to be enclosed, if

the clearances to combustibles are at the correct minimum for

unenclosed installations.

c) Where model DIS grease ducts extend through any story of a

building above the floor on which the connected appliances are

located, they shall be enclosed in the upper stories with walls

having a fire resistance rating of not less than one hour for

buildings of two or three stories. If the building is four stories

or more, the enclosure wall shall have a fire resistance rating of

not less than two hours.

4. Combustible roofs or roof-ceiling assemblies may be penetrated as

described in Section D – Roof and wall penetrations.

NOTE: Do not enclose with combustible materials. Refer to NFPA 96,

“ Standard For Ventilation Control And Fire Protection Of Commercial

Cooking Operations”, for installation and clearances of fire-rated

enclosures and definitions.

Boiler and Engine Exhaust

Duravent models DIS and DAS chimney are primarily intended to be

used in fire resistive noncombustible surroundings or installed unenclosed. They are not intended for use in one or two family residences.

(CAUTION: Do not enclose this chimney in a chase or passageway of

ordinary wood or other combustible material).

Where the chimney extends through any zone of a building (outside

that in which the heating appliance connected to it is located), it shall

be provided with an enclosure having a fire resistance rating equal to

or greater than that of the floor, wall or roof assemblies through which

it passes.

SYSTEM SIZING

Complete system sizing and capacity information maybe obtained from

the “Chimney, Gas Vent, and Fireplace Systems” chapter of the ASHRAE

Handbook (go to www.ashrae.org for more information). In spite of these

general sizing guidelines, it is most important that the heating appliance,

engine or turbine manufacturer’s installation instructions are followed.

Not following the equipment manufacturer’s instructions may result in

inadequate chimney performance and/or a violation of the equipment

manufacturer’s installation requirements.

3

Page 4

PART NUMBERS

OPENING THROUGH COMBUSTIBLE CONSTRUCTION

These instructions identify major model DIS / DAS parts by name and

part number.

Example:

DIS 36” length with inside diameter 14” made of ss316 inner flue and

ss304 outer casing.

DIS 14 L36 BC

Model Dia. Part Material

DAS 30° elbow with inside diameter 22” made of ss304 inner flue and

galvalume outer casing.

DAS 22 E30 CE

Model Dia. Part Material

DIS wall support for 8” diameter chimney made of galvalume.

DIS 8 WS E

Model Dia. Part Material

Use only factory-supplied components. Failure to do so will

void the certification and the warranty of the chimney system.

EFFECTIVE LENGTH

DIS / DAS

When assembling two parts together, the joint will overlap 5/8”. So effective length is nominal length minus 5/8”

Example:

Effective length

L36

L24

L18

L12

35-3/8”

23-3/8”

17-3/8”

11-3/8”

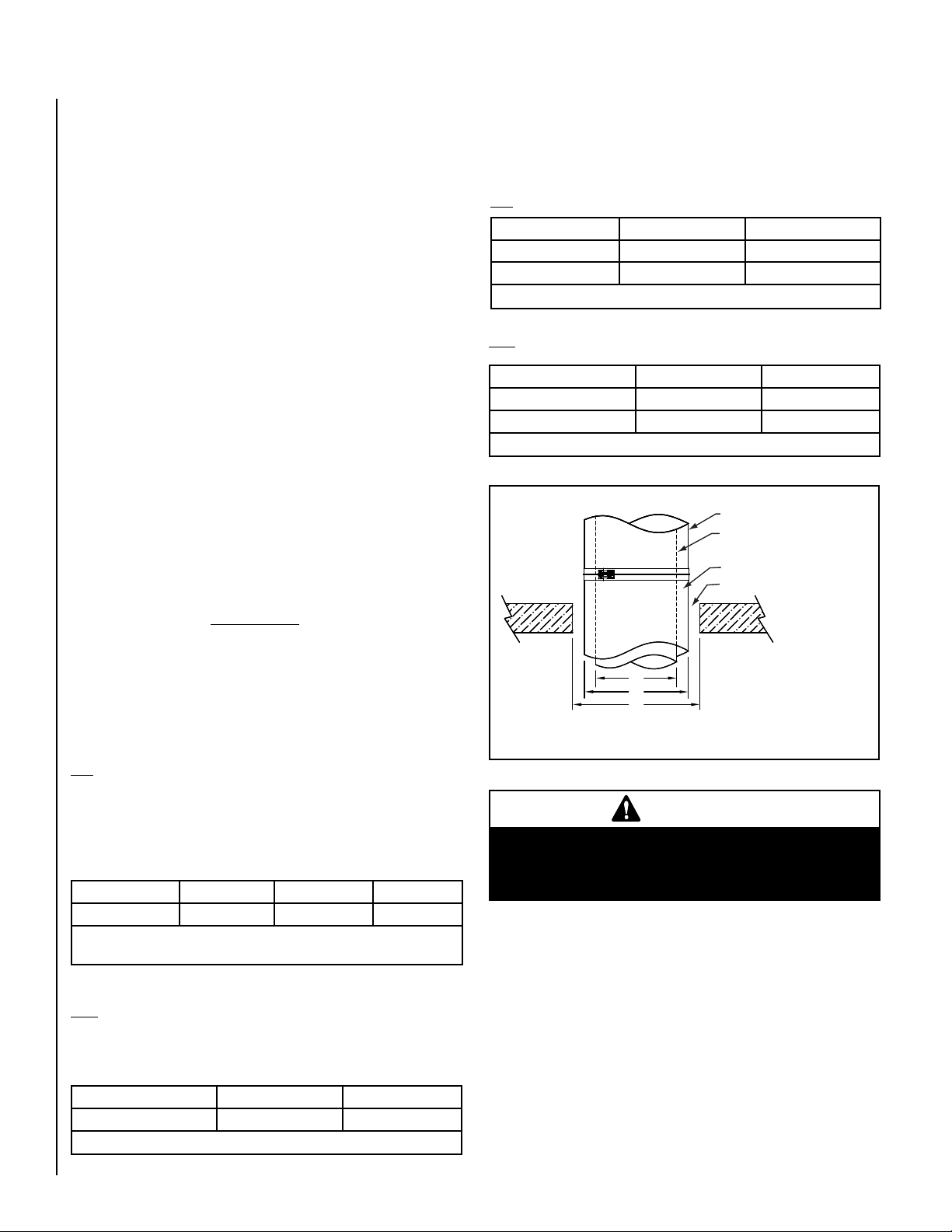

CLEARANCES

The following table serves to identify the minimum opening required when

installing a chimney through a floor, wall or roof made of combustible

material. See table 3 and figure 1.

DIS

Inside diameter (A) Roof / Floor (C) Wall (C)

Ø5” to Ø10” Inside Ø + 8” Inside Ø + 8”

Ø12” to Ø36” Inside Ø + 8” Not Listed

Table 3 - Minimum openings

DAS

Inside diameter (A) Roof / Floor (C) 1400°F Chimney (C)

Ø5” to Ø10” Inside Ø + 12” Inside Ø + 12”

Ø12” to Ø36” Inside Ø + 12” Not listed

Table 4 - Minimum openings

Chimney outside diameter

Chimney inside diameter

2” Insulation

Clearance opening

B = A + 4”

OPENINGS - Minimum open-

A

B

C

ing required when installing

a chimney through a floor,

wall or roof made of combustible material.

Figure 1

DIS

Minimum air space clearance to combustible construction to model

DIS Chimney is 1”.

For non-combustible construction, maintain clearances as required

for installation, access for inspection or per local code.

Inside diameter B.H.A Chimney 1400°F Chimney Grease Duct

Ø5” to Ø36” 1” 1” 2”

Table 1 - Minimum air space clearance to combustible construction model DIS

DAS

Minimum air space clearance to combustible construction to DAS

chimney is 4”.

Inside diameter B.H.A Chimney 1400°F Chimney

Ø5” to Ø36” 4” 4”

Table 2

4

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

WARNINGS

DO NOT INSTALL ANY TYPE OF INSULATION IN THE

REQUIRED CLEARANCE SPACES SURROUNDING

THE CHIMNEY.

Page 5

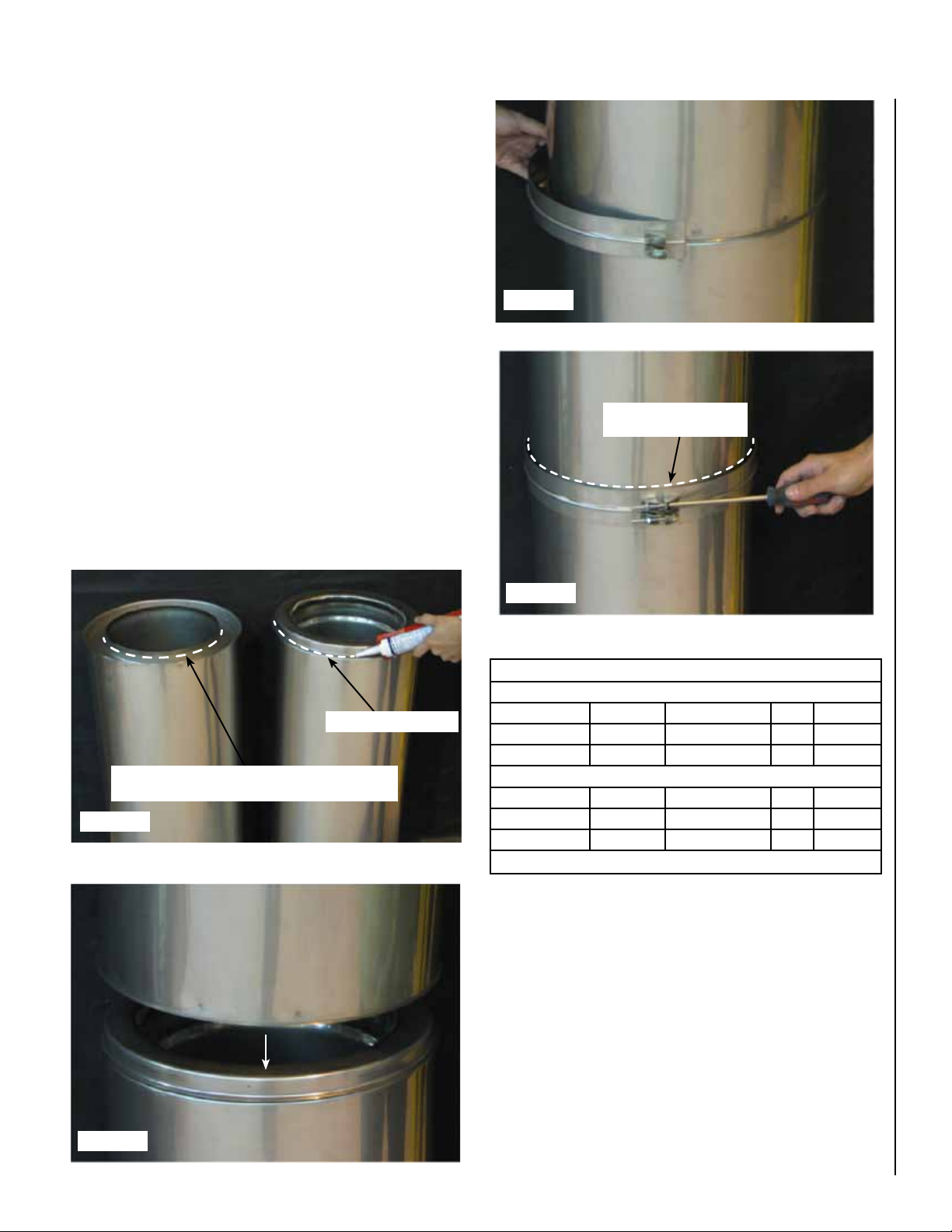

CHIMNEY AND FITTING JOINT ASSEMBLY

All components have a male and female end. The installation orientation

is indicated on the labeling of each chimney section with an arrow. The

arrow indicates the direction of the flow. Clean all inner and outer surfaces

of the male and female ends with an appropriate organic solvent, such

as acetone, Mek, or other commercial degreaser.

1. Apply a bead of S-650 sealant about 1/8” thick around the male end

of chimney and for Grease duct application, add a bead of S-2000

sealant at the edge of the female chimney (see figure 2). See table

5 for approved sealants.

2. Insert the female end, of another section of chimney, over male end

with sealant (see figure 3).

3. Insert the assembly band (see figure 4) around the joint of the two

sections assembled in step 2. A small bead of S-650 can be applied

on the inner groove of the band prior to installation for better leak

tightness.

4. Using a phillips screwdriver, connect the two ends of the band as

shown in figure 5.

5. Where the chimney is installed outside, an exterior sealant S-375

must be applied at the upper joint of the band and the outer casing,

see figure 5.

Figure 4

Apply S-375 sealant here

for exterior installation

Grease Duct Application: Add a bead of S-2000 sealant

at the edge of the female end.

Figure 2

Add S-650 sealant here

Figure 5

SEALANT USAGE

Interior Installation

Sealant Application Supplier Model Color Max. Temp.

Joints Duravent S-650 red 650°F

Inner Flue Duravent S-2000 White 2000°F

Exterior Installation

Sealant Application Supplier Model Color Max. Temp.

Joints Duravent S-650 red 650°F

Outer Band Duravent S-375 gray 375°F

Table 5

CAUTIONS

A. DO NOT ALLOW SCREWS TO PENETRATE THE INNER FLUE.

THIS CAN CAUSE CORROSION, GAS LEAKAGE OR EXPANSION

FAILURE.

B. NEVER USE SCREWS THROUGH THE OUTER CASING OF AN

ADJUSTABLE LENGTH OR EXPANSION JOINT.

Figure 3

C. OBSERVE ADEQUATE SAFETY MEASURES WHEN USING A

DEGREASER.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

5

Page 6

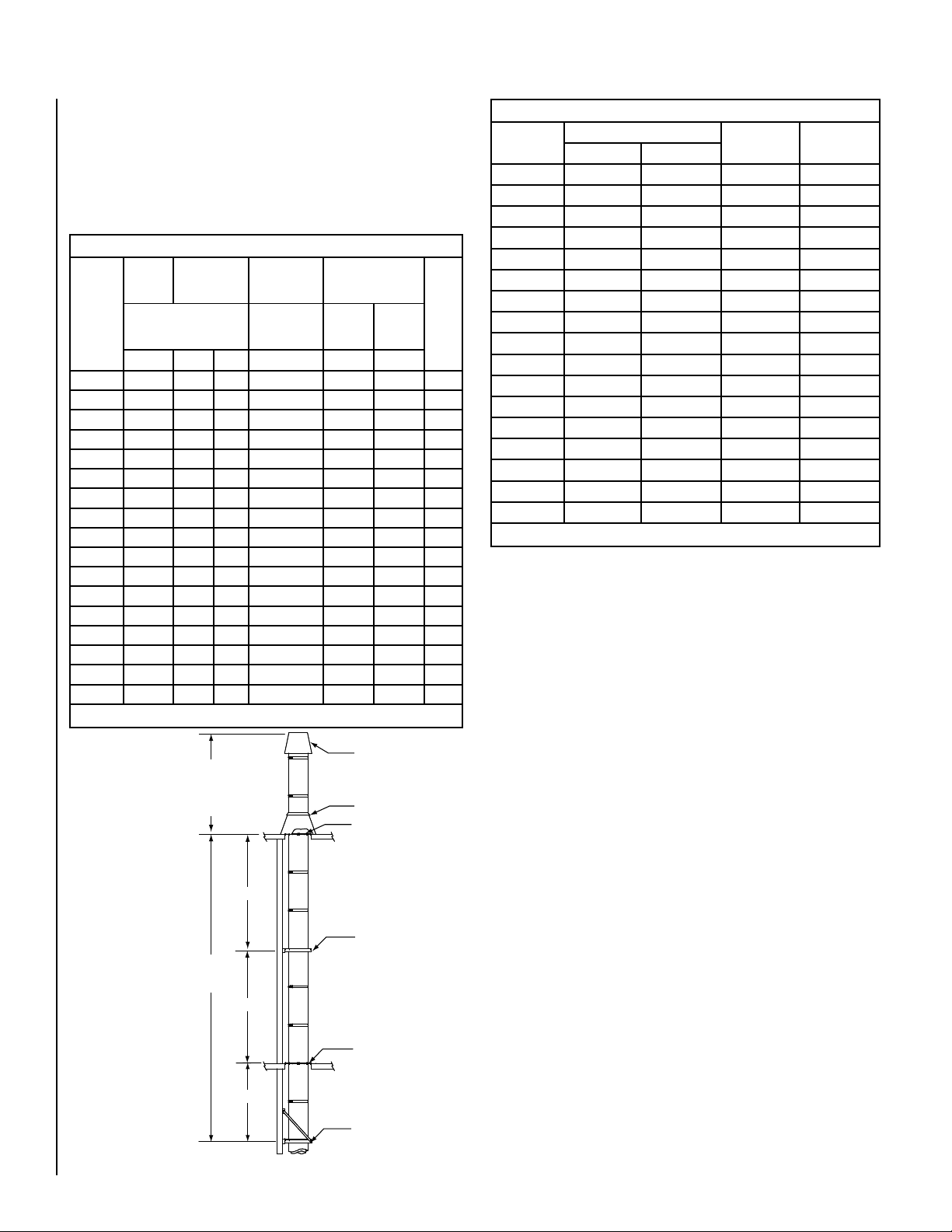

SUPPORT METHODS AND HEIGHT LIMITS

1. Several support and guiding methods are used to anchor a chimney

against upward, downward and angular displacement.

2. These supports and guides used with thermal expansion devices,

prevent bending stresses on the chimney elbows and joints.

3. Supports and guiding methods and installation are described in Section C. Certain limitations apply for proper installation of supports

and guides. See tables 6 and 7.

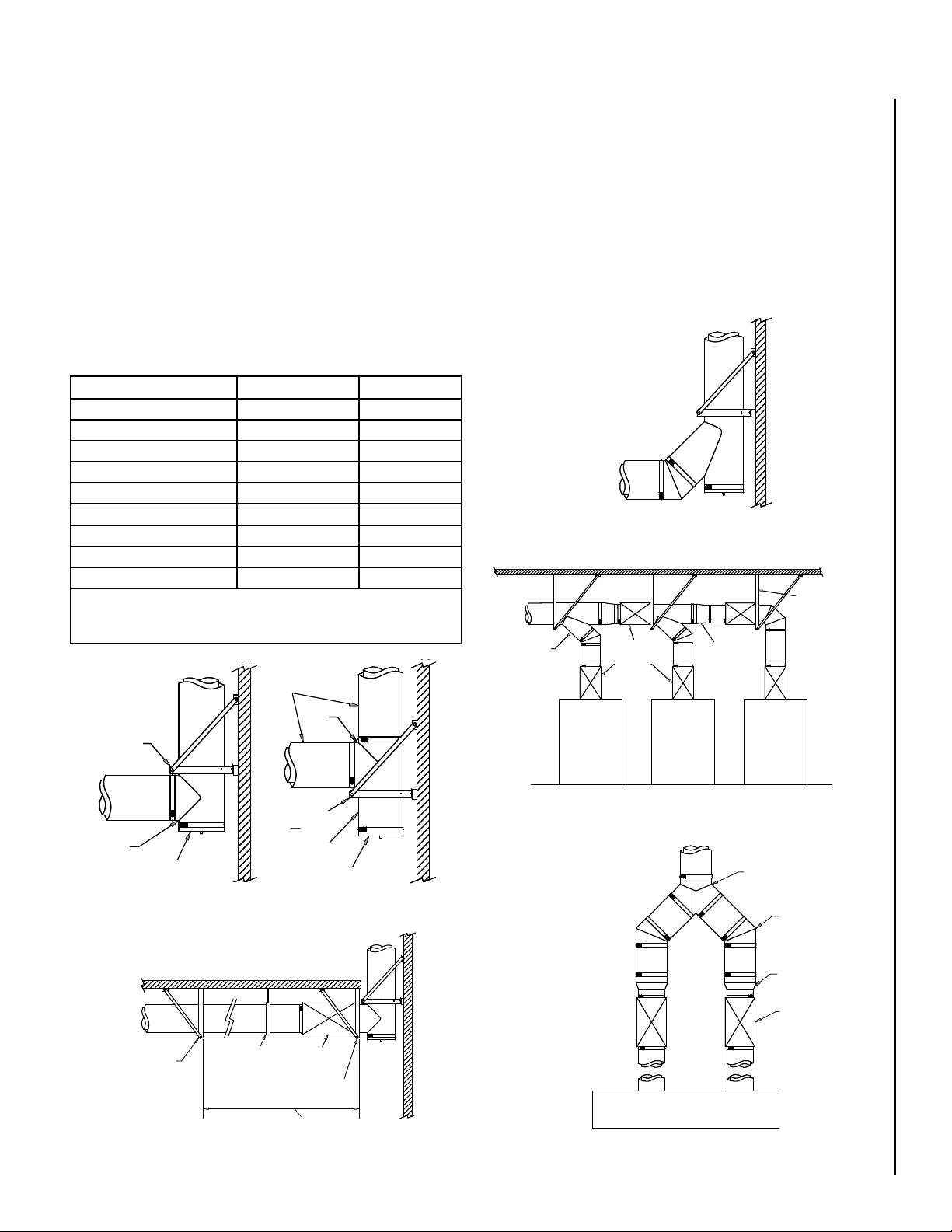

MAXIMUM CHIMNEY HEIGHTS AND SUPPORT METHOD FOR MODEL DIS AND DAS

Anchor

Inside

Diameter

(in)

DIS/DAS

5

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

Anchor Plate

Plate

with Length

(AP)

Metal Frame Only

DIS DAS

200 200

147

128

200 200

200 200

103

177 200

86

73

152 194

64

133 175

57

118 146

106 135

53

97 125

48

44

89 117

76 92

37

35

71 88

33

66 83

63 76

31

59 73

29

56 70

27

53 65

26

(APL)

Ventilated

Anchor Plate

(APV)

Metal Frame

OR Wood

Frame

DIS/DAS DIS/DAS

133 147

116 128

93 106

78 86

66 73

58 64

52 57

48 53

43 48

40 44

34 37

32 35

30 33

28 31

26 29

25 27

23 26

Wall Support (WS)

Frame

Metal

Wood

Frame

DIS/DAS

61 105

53

43

35

30

27

24

22

20

18

15

14

13

13

12

11

11

Tee

(T)

92

74

61

53

46

41

38

34

31

27

25

23

22

21

20

18

Table 6 - Dimensions are in feet

See Dim. “H” figure 7

and Chimney Guying

and Bracing in this

section.

“ M V S” d imen sion see table 7 for

Maximum Vertical

Spacing between two

guides or a support

and a guide.

NOTE: W h en t he

maximum height from

table 6 is exceeded, resupport using another

support and expansion

joint.

Maximum

height - See

table 6

MVS

MVS

MVS

Termination

Storm collar (SC)

Roof support (RS)

Wall guide (WG)

Floor guide (FG)

SUPPORT AND GUIDE SPACING FOR MODEL DIS AND DAS

Inside

Diameter (in)

5 10 8 10 12

6 10 8 10 12

8 10 8 10 12

10 10 8 10 12

12 10 8 10 12

14 10 8 10 12

16 10 8 10 12

18 10 8 10 12

20 10 8 10 12

22 10 8 10 12

24 10 8 10 12

26 10 8 10 12

28 10 8 10 12

30 10 8 10 12

32 10 8 10 12

34 10 8 10 12

36 10 8 10 12

Table 7

- Dimensions are in feet

MVS*

Interior Exterior

H** MHS***

* MVS = Maximum Vertical Spacing between two guides or a support and

a guide in a vertical position.

** H = Maximum freestanding Height above the roof.

*** MHS = Maximum Horizontal Spacing between two guides or a support

and a guide is 12 feet.

THERMAL EXPANSION

Good installation practice requires that any length of exhaust system

between two fixed points subject to more than 1/4 inch expansion must

have an Adjustable Length (LA) or Bellows Joint (LB) to compensate

for expansion. Models DIS and DAS will expand approximately 1 inch

for every 100°F temperature rise per 100 feet of chimney. To accommodate chimney movements, any wall guide or floor guide must be

located away from the locking band.

It is essential that these parts be properly installed and provided with

adequate support and guidance to prevent binding or excessive bending forces. (See detailed installation information contained on page 19,

Thermal Expansion).

Figure 6 - Maximum chimney heights and support

6

Wall support (WS)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 7

CHIMNEY WEIGHT

Chimney weight is given in pounds per foot of chimney for each diameter.

It is important to know the weight of the chimney section for chimney

support or guiding. Chimney weight (table 8) along with maximum

chimney height (table 6) are necessary to calculate the proper anchor

strength needed with wall supports (WS), Anchor Plate (AP) supports

and Suspension Bands (SB).

CHIMNEY WEIGHT IN LB/FT

Inside diameter Model DIS Model DAS

5 7 4

6 8 5

8 10 6

10 12 8

12 14 9

14 16 10

16 18 12

18 20 13

20 22 14

22 24 15

24 28 19

26 30 20

28 32 21

30 34 23

32 36 24

34 38 25

36 40 27

Table 8

Example: Model DIS, 6” diameter section of 25 feet in length from table 8,

weight in lb/ft = 8. Total weight 8 x 25 = 200 lbs

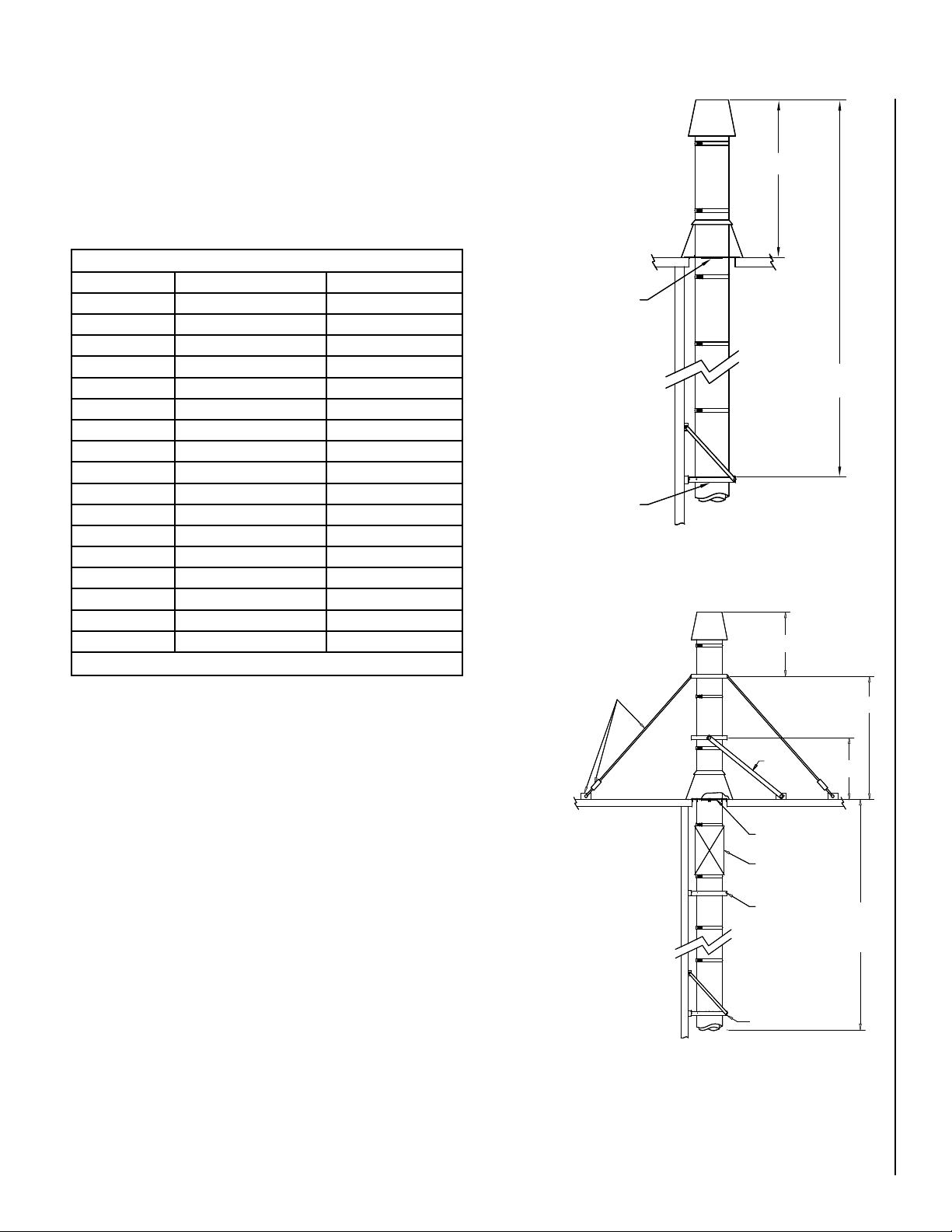

CHIMNEY GUYING AND BRACING

* If Dimension “H” exceeds the

value in table 7, use bracing or

cable guying to stabilize chimney section above the roof. See

notes 3, 4, 5 and figure 8.

Guide

Support

No guying or bracing required

Figure 7 - Maximum freestanding chimney height

See table 7 for “H” dimensions

Guy Cable * tensioners and

roof anchors * (by others)

H*

Maximum Height

See table

H

Brace

H

5’ MAX

1. Proper guying and bracing is essential for part of the chimney that

extends above the roof or parapet wall. The chimney at this point is

subject to wind conditions and needs special attention for proper

stabilization.

2. If the stack above the roof does not exceed dimension H, no special

guying or bracing is required. However, to protect the flashing from

lateral movement, a guide must be installed at the roof level. See figure

7).

3. For stack height above the roof that needs guying or bracing, a support,

a small length and a expansion length must be installed near the roof

level to absorb the thermal expansion and minimise this effect on the

guy wires or brace.

4. When using guy wire, the cable must be slightly slack or loose to allow

thermal expansion.

5. When using rigid bracing, the maximum vertical height between supports must be reduced to 5’ to compensate thermal expansion.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Support

* Cables and roof anchors

designed for 30 lb. per

sq. ft. force on chimney

projected area.

Expansion Length

Guide

See table 6

Support

Figure 8 - Chimney height with rigid bracing or guying option

Maximum

height -

7

Page 8

TERMINATION HEIGHT

MULTI-ENGINE EXHAUST SYSTEMS

Chimneys and vents shall terminate above the roof level in accordance

with the following requirements:

1. Five feet above the roof level or any adjacent flat roof, wall parapet

or air intakes, and/or in accordance with the following NFPA 211

requirements.

2. Where chimney terminates at less than 10 feet from any adjacent

ridge, wall or parapet, the chimney shall terminate at minimum of 3

feet above the ridge, wall, or parapet.

3. Where chimney terminates at more than 10 feet from ridge, wall, or

parapet, a minimum height of 2 feet shall be required above the ridge

wall or parapet.

A common exhaust system for multiple engine or turbine installations

is generally not recommended. A separate exhaust system should be

provided for each engine or turbine.

Check with your engine or turbine manufacturer prior to common exhaust system design. Exhaust gas from operating units tends to flow to

non-operating units where condensation may form. WATER IN ENGINE

OR TURBINES AT START-UP MAY CAUSE DAMAGE. IN GENERAL,

A SEPARATE EXHAUST SYSTEM SHOULD BE PROVIDED FOR EACH

ENGINE OR TURBINE.

8

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 9

SECTION B - TEES, ELBOWS, INCREASERS

90° TEE (T90)

1. Generally used to connect the horizontal length from the appliance to the

vertical length when clean-outs access or drain is required.

2. 90° should not be used for changing flow direction in diesel or turbine

exhaust.

3. For supporting the tee, the preferred location is above the tee (see figure

9).

4. If it is not possible to suspend the tee, it may be supported from the

base (see figure 10). When this is necessary, a short length should be

installed between the tee and the tee cap or Drain-Tee Cap for a good

clean-out or inspection access.

IMPORTANT NOTE:

If more than 1/4” of thermal expansion is expected between a stationary

point and the tee, the use of an expansion length and a two axis support

is recommended to minimize bending moments on the tee (see figure 11

and table 9).

Gas Temperature Rise Maximum Length Expansion

200°F 12’0” 0.25”

300°F 8’0” 0.25”

400°F 6’0” 0.25”

500°F 5’0” 0.25”

600°F 4’0” 0.25”

700°F 3’6” 0.25”

800°F 3’0” 0.25”

900°F 2’6” 0.25”

1000°F 2’0” 0.25”

Note: 60°F - 70°F ambient T°

Table 9 - Maximum allowable length between two fixed points

without expansion length

Lengths

45° TEE (T45)

1. For systems where flow resistance must be minimized like engine or

turbine exhaust. The use of a 45° tee is suggested. It can be combined

with a 45° elbow to make a smooth 90° turn (see figure 12). To support

this tee, use similar method as a 90° tee.

2. When using 45° tee to connect multiple appliances together, thermal

expansion must be considered. Thus prepared to prevent bending moments on the tee, an expansion length must be installed between the tees

(see figure 13).

45° TEE Y (TY)

1. This kind of tee is useful where the stack is located between two application or with a double exhaust system. Use the same support method and

thermal expansion considerations from the other tees (see figure 14).

Figure 12 - Smooth 90° Turn

Stationary / Fix

Support

45° Tee

Expansion

Length

Increaser

Wall

Support

Tee

Tee Cap or

Drain-Tee Cap

Figure 9 - Suspended Tee

Stationary

Support

Suspension

Figure 11 - Two Axis Support

Tee

Wall Support

Short Length

Tee Cap or

Drain-Tee Cap

Figure 10 - Base Supported Tee

Expansion

Band

expansion between two stationary points

Length

Stationary

Support

More than 1/4” of expected thermal

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Appliance Appliance

Appliance

Figure 13 - Multiple appliance connection with 45° tees

45° Tee Y

45° Elbow

Increaser

Expansion

Length

Appliance

Figure 14 - 45° Tee Y

9

Page 10

TEE CAP (TC)

ELBOWS

1. Use to block one of the openings of horizontal or vertical tee.

2. Removable, it facilitates access for inspection and maintenance of

the chimney.

3. The installation is the same as for lengths.

4. When removed, the old silicone must be cleaned out and a new bed

of sealant must be applied.

DRAIN-TEE CAP (DTC)

1. Use as a drain for vertical stack.

2. Connect to a suitable drain fitting to allow rain entering the chimney

to wash down, dilute and remove any corrosive residue.

3. Same installation as a tee cap.

Tee cap

Drain-Tee Cap

Figure 15 - Tee cap and Drain-Tee Cap

INCREASER, STEP OR TAPERED

1. Use to increase the diameter of the chimney flue.

2. The tapered increaser induce less pressure drop than the step increaser, but requires more space. It has a 15° side angle and provides

increases of one, two or three size. The height of the fitting varies

depending on the diameters to be increased (see figure 17).

3. The tapered increaser have the same load strength as a standard

length, but the step increaser is a non-structural part and must be

protected from axial and lateral load.

1. Elbows are used for changes in direction in horizontal or vertical

portions of a chimney system.

2. All elbows feature the standard joint assembly as described in Section

A - Chimney and Fitting Assembly.

3. Elbows are used in combination to make different angles ranging

from 3° to 90° in horizontal and vertical breechings of the chimney

system.

4. Elbows are not designed to take bending loads and must be structurally

supported (see figure 17). Structural parts such as posts or beams

may also be needed to hold chimney supports in position.

2X 45° Elbows

Anchor plate (A P) and

frame (by others)

Wall support (WS)

Expansion length

Ø B

2”

C*

2”

Ø A

* See table 10

6”

Figure 16 - Increaser height

STEP 1 Diameter 2 Diameters 3 Diameters

C 4” 8” 12”

Table 10 - Tapered increaser height

Ø B

Figure 17 - Supported elbow

Ø A

10

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 11

OFFSETS

1. Sloped or horizontal offsets in the vertical portion of a chimney above

the breeching should be avoided except where absolutely necessary.

2. Sloped offsets require more expansion joints and secure bracing

above and below elbows.

3. With solid fuel burning appliance, the slope must not be greater than

30° from the vertical. Appliances which are capable of burning solid

fuel or are convertible to solid fuel are limited to the same 30° slope.

4. The length of the offset is determined by strength considerations. The

maximum dimension between supports, given as the MHS dimension

in table 7, is applicable to all horizontal and sloped orientations (see

figure 18)

5. The minimum offset is accomplished with two elbows directly connected to each other (see Figure 34 and table 9).

6. With frequent re-support, there is no structural or operating limit to

the length of horizontal or sloped portions of model DIS chimney,

providing the system meets the capacity, pressure drop of available

equipment.

7. The carrying capacity of supports and their structural attachments

must take into account the weight of the offset plus whatever vertical

chimney is carried by that support.

8. Height limits for supports ar tabulated in Section A of these instructions.

9. The ends of any sloped or horizontal offset must be anchored to

prevent overstressing elbows and to assure proper operation of

expansion joints.

10. The vertical sections of chimney above the offset must also be supported or anchored and guided where necessary.

11. Models DIS and DAS Roof Support (RS), Wall Support (WS), Wall

Guide (WG) may be used in a variety of ways for offset support to

achieve the structural stability of the chimney system. Preferred

methods of using model DIS and DAS supports are shown in Section

C.

12. Re-supports such as those shown in Figure 31 must be securely

anchored to walls, posts, or locally fabricated rigid framework. This

framework must be designed to assure stability of attached model DIS

supports, such as Anchor Plate (AP) supports and Wall Supports (WS).

13. Supports suspended by threaded rods or from small size angles or

straps are usually not satisfactory to resist bending moments due

to offsets.

Offset *

* See table 11

Figure 19 - Minimum offset

Ø 3° 15° 30° 45°

5” n/a 1-3/8” 3-5/16” 5-5/8”

6” n/a 1-7/16” 3-7/16” 5-15/16”

8” n/a 1-1/2” 3-3/4-” 6-1/2”

10” n/a 1-9/16” 4” 7-1/16”

12” n/a 1-5/8” 4-1/4” 7-11/16”

14” n/a 1-11/16” 4-1/2” 8-1/4”

16” n/a 1-3/4” 4-13/16” 8-7/8”

18” n/a 1-7/8” 5-1/16” 9-7/16”

20” n/a 1-15/16” 5-5/16” 10”

22” n/a 2” 5-5/8” 10-5/8”

24” n/a 2-1/16” 5-7/8” 11-3/16”

26” n/a 2-1/8” 6-1/8” 11-3/4”

28” n/a 2-3/16” 6-3/8” 12-3/8”

30” n/a 2-1/4” 6-11/16” 12-15/16”

32” n/a 2-5/16” 6-15/16” 13-1/2”

34” n/a 2-3/8” 7-3/16” 14-1/8”

36” n/a 2-7/16” 7-1/2” 14-11/16”

Table 11 - Minimum offset

MHS

Figure 18 - Offsets MHS (refer to table 7)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

11

Page 12

SECTION C - STRUCTURAL SUPPORT AND GUIDING

LENGTH ANCHOR PLATE (APL)

ANCHOR PLATE ASSEMBLY (AP)

1. The anchor plate support assembly is designed to provide maximal

support to vertical sections and to provide fixed point support for

horizontal sections.

2. The plate support must be attached to the building structure or supported with rigid structural members (see figure 22 and table 12 for

bracing dimensions)

3. DO NOT ATTACH THE ANCHOR PLATE TO COMBUSTIBLE CON-

STRUCTION. If unavoidable, use the Ventilated Anchor Plate support

assembly.

4. The anchor plate consists of a plate and eight clamp flange. See

figure 21 for sectional details for plate support.

5. IMPORTANT: The surfaces of the male and female couplings

in contact with the plate of the anchor plate assembly must be

coated with inner joint sealant.

6. There are two ways of assembling parts on the support. You may

choose your method depending on your situation.

6.1 The first method consists of assembling two parts and the anchor

plate on the side and then installing this assembly on the support

structure. This method is easier and faster to install, but requires

enough clearance to insert the complete assembly through the support structure opening. If there is a tee or elbow upstream of the

anchor plate, you may not have enough clearance. Also consider

the weight of the assembled parts and make sure you have a safe

manner of lifting the assembly.

INSTALLATION STEPS FOR FIRST METHOD (refer to figure 23)

1. Place the part that will be upsteam of the support on the floor.

2. Apply a bead of inner joint sealant on the male coupling flange.

3. Slide the plate of the anchor plate support over the coupling.

4. Apply a second bead of sealant on the plate around the male

coupling where the flange of the female coupling of the next part

will mate.

5. Place the second part over the plate. Make sure the sealant completely fills joints between the plate and the female coupling.

6. Use eight clamp flanges and bolts to tightly clamp the parts to

the support.

7. Insert the assembly on the support structure and fix the plate to

the structure using the supplied hardware.

6.2 The second method is applicable when the plate of the anchor plate

support needs to be installed first, as when there is a tee or elbow

upstream of the support. May require at least two persons to complete

the installation.

INSTALLATION STEPS FOR SECOND METHOD (refer to figure 24)

1. Fix the plate of the anchor plate support to the structure using

the supplied hardware.

2. Apply a bead of inner joint sealant on the male coupling flange

of the part before the support.

3. Insert the male coupling of the part in the plate opening.

4. You may hold it using two clamp flanges placed at 180° and

bolted to the anchor plate.

5. Apply a bead of sealant on the plate around the male coupling.

6. Place the second part over the plate. Make sure the sealant completely fills the joint between the plate and the female coupling.

7. Fix the assembly by clamping it with four clamp flanges on the

unused flange positions.

8. Remove the first two clamp flanges and finish clamping the assembly.

1. Use for same application as the anchor plate (AP).

2. It is composed of a straight section - with an effective length of

3 3/4” integrated into a support plate (see Figure 20 for the detail of

the part).

3. Unlike the anchor plate (AP), the Length Anchor Plate (APL) doesn’t

need any clamp flange (and its hardware) for its installation, so it is

easier and faster to isntall.

4. The APL must be attached to the building structure or supported by

rigid NON-COMBUSTIBLE structural members (see Figure 22 and

Table 12 for bracing dimensions).

Installation steps for the APL

1. Fix the plate of the APL to the structure using the supplied hardware.

2. Follow the steps of the «Chimney and fitting assembly» section in

the section A on page 5 to connect the couplings to the APL with

the parts downstream and upstream.

Figure 20 - Length Anchor Plate (APL)

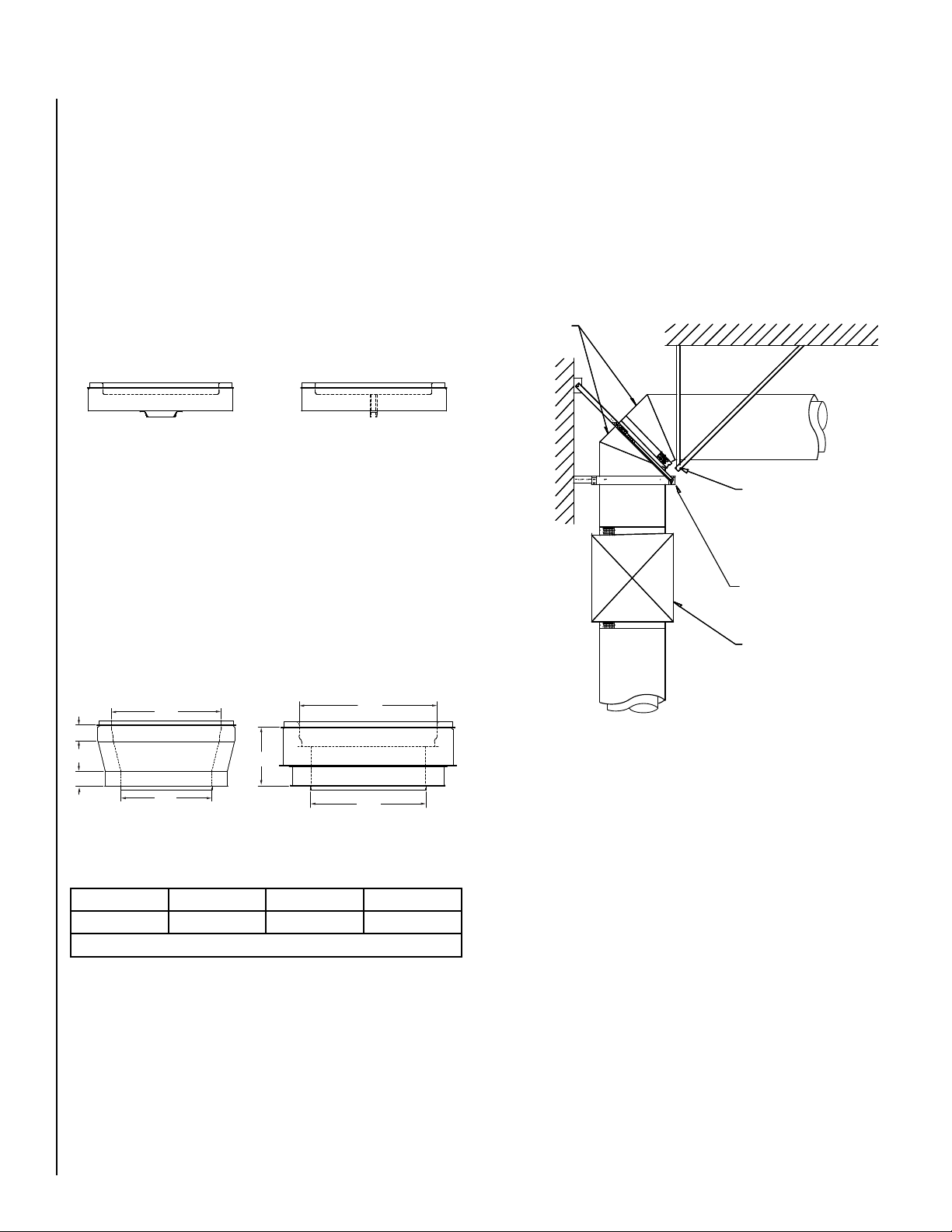

VENTILATED ANCHOR PLATE (APV)

1. Use for same application as the anchor plate, but can be attached to

combustible construction.

2. Usually uses as roof support. See section D for details on how to

install at the roof level.

3. Installation is done the same manner as the anchor plate.

4. See Figure 25 for opening dimensions through combustible construction.

5. Do not block or obstruct openings in the plate. They are intended to

minimize heat accumulation.

12

Figure 21 - Sectional detail for plate support

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 13

Height Limits - See Section A,

Table 6 for maximum support

height of Anchor Plate (AP).

NOTE: If bracing is used, minimum “X” angle is 30°. If there

is no bracing, the framework

must be attached to structural

members to provide equivalent

rigidity.

Figure 22 - Homemade brace

Method #2 - Step 1

Sealant

bead

Method #2 - Step 2

Sealant

bead

Method #1 - Step 1 and 2

Method #1 - Step 5

Sealant

bead

Method #1 - Step 3 and 4

Method #1 - Step 6

Method #2 - Step 3 and 4

Method #2 - Step 6 and 7

Method #2 - Step 5

Method #2 - Step 8

Figure 24 - Method #2 installation Steps

I.D. FRAMEWORK BRACING

5” – 20” 3” X 2” X 3/16” 2” X 2” X 1/4”

22” – 36” 4” X 2” X 1/4” 3” X 3” X 1/4”

Table 12 - Bracing DIS / DAS

Method #1 - Step 7

Figure 23 - Method #1 installation Steps

I.D. + 8” (DIS)

I.D. + 12” (DAS)

Figure 25 - Ventilated anchor plate (APV)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

I.D. + 8” (DIS)

I.D. + 12” (DAS)

13

Page 14

WALL SUPPORT (WS)

1. The wall support consists of an Anchor Plate and a prefabricated frame

with mounting brackets and angled struts for bracing.

2. Used to support the chimney in vertical runs, it maintains the chimney

at an adjustable distance between 2-1/2” and 7-1/2” from the wall (see

Figure 26).

3. The maximum weight allowable on the wall support depends if the

support is attached to a metal structure or a wood structure (see table

6 for maximum chimney height).

4. The installation begins by attaching the frame of the wall support to a

rigid metal or wood structure. Adjust the braces to have a minimum

of 45° angle from horizontal. Once the frame of the wall support is

fixed to a rigid structure, the installation is the same as the Anchor

Plate.

Height Limit - See Section A, table 6 for

maximum height of Wall Support (WS)

1”

(25mm)

Figure 27 - Wall guide (WG)

Wall

guide

Adjustable braces

45° Min.

Figure 26 - Adjustable wall support (WS)

WALL GUIDE (WG)

1. The wall guide is used as a lateral guide to resist lateral or side load

only, it is not designed for carrying the weight of a vertical chimney.

It also ensure a minimum clearance of 1” to combustibles for model

DIS and 4” for model DAS. See Figure 27 (wall guide).

2. The proper location to install the wall guide is immediately below a

locking band. The locking band must be able to move without interfering with the guide when thermal expansion occurs. See Figure 28

(wall guide location).

3. The wall guide can be installed with a wall band extension for greater

clearances up to 4-1/4” for model DIS and up to 7-1/4” for DAS. See

Figure 29 (wall guide extension).

4. Special considerations must be taken when installing on exterior wall.

A wall guide must be installed between 6’ and 10’ below the highest

wall support to stabilize the free standing portion of the chimney. Do

not install a expansion length in this area due to bending forces induced

by the freestanding portion. See Figure 30 (special considerations).

MVS

Wall

guide

MVS

Wall support

Figure 28 - Wall guide location

14

2” to 4-1/4” (51mm to 108mm) (DIS)

5” to 7-1/4” (127mm to 184mm) (DAS)

Figure 29 - Wall guide extension

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 15

Freestanding = H max

SUSPENSION BAND (SB)

1. Suspension band is used to support and guide the chimney in

horizontal runs. It consists of a band, a flexible strap (by others), a

trolley and a rail.

2. The trolley and rail allow up to 4” of travel to compensate thermal

expansion.

3. See section A, Table 7 for maximum distance between two supports

or guide.

4. Important: The flexible strap must be at least 3/4” wide and 0.036”

thick made of galvanized or stainless steel. YOU MUST USED TWO

LAYERS OF FLEXIBLE STRAP to attach the band to the trolley.

Rail

Do not install expansion

length in this area

6’ to 10’

Wall guide

Expansion length

Figure 30 - Special considerations for exterior installation

FLOOR GUIDE (FG)

1. The floor guide is used the same manner as the wall guide but it is

modified for use at floor penetrations. See Figure 30 (floor guide).

I.D. + 8” (DIS)

I.D. + 12” (DAS)

Trolley

Flexible strap

2X Layer (By others)

4”

Travel

THERMAL

EXPANSION

DIRECTION

Band

Figure 32 - Trolley

CRADLE SUPPORT (CS)

1. Cradle support is used to support and guide the chimney in horizontal

runs. It consists of a cradle support and suspension rod (by others).

2. The suspension rods must attached to the structural members to

provide rigidity.

3. Cradle support allows to stack two (or more) horizontal chimney

runs (See Figure 33).

4. Cradle support does not allow movement for thermal expansion.

This support should be used for low temperature application.

Figure 31 - Floor guide (FG)

I.D. + 8” (DIS)

I.D. + 12” (DAS)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Rods (by others)

Cradle Support

Figure 33 - Cradle Support

15

Page 16

ROOF BRACE (RB)

GUY WIRE (GW)

1. The roof brace is used to stabilize the chimney where it extends more

than 15’ above the roof.

2. It consists of one band (RB) and two braces (supplied by the installer).

3. To minimize loads induced by thermal expansion on braces and support, the maximum distance between the last fixed support and the

band of the roof brace must be reduced to 5’.

4. Begin by attaching the braces to the band with supplied bolts and

nuts. Next, install the band on the chimney and tighten the band. Fix

the braces to the roof at 120°. Make sure you have a rigid structure

on the roof.

H

1-1/4” Rigid galvalume tube

or 1-1/2” x 3/16” angle iron

(by others)

5’ Max

1. The guy wire is used where the chimney extends more than 15’ above

the roof.

2. It consists of a band designed to receive 3 guy wire (supplied by others)

at 120° apart or 6 guy wire at 60° apart for diameter larger than 24”.

The guy wires are fixed to the roof by mean of tensioner and anchor

(also by others).

3. When installing guy wire, the cable must be slightly slack or loose to

allow thermal expansion or be equipped with tensioning springs (by

others). The tensioning springs are mandatory only when there is

more than one level of guy wire needed.

4. To minimize the effect of thermal expansion, good practice implies

installing a fixed support and an expansion length at the roof level

(see Figure 35 ’guy wire’).

* Cables and roof anchors

designed for 30 lb. per

sq. ft. force on chimney

projected area.

Guy wire band (GW)

Guy Cable * tensioners and

roof anchors * (by others)

Fixed support

H

Fixed support

Expansion length

120°

Figure 35 - Guy Wire

Figure 34 - Roof brace assembly

16

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 17

SECTION D - ROOF AND WALL PENETRATIONS

WALL PENETRATION

ROOF/FLOOR PENETRATION

1. The roof/floor penetration consist of a firestop radiant shield (FS), a

flashing (F) with a storm collar (SC) and a floor guide (FG) or ventilated

anchor plate (APV) (see Figure 36 roof/floor penetration).

2. Those components allows the chimney to penetrate a combustible roof

or floor at 2 inches clearance to combustible. See table 3 – Minimum

openings for framing dimension.

3. The radiant shield of the firestop may need to be trimmed to fit the

height of the roof. Nominal height is 10 inches.

4. Roof/floor penetration components are designed to be installed on a

flat roof. They may be installed on a pitch roof if a curb is installed

to provide a flat surface.

5. Floor guide is used to protect the flashing from lateral movement. The

ventilated anchor plate is used to protect the flashing and to provide

a re-support.

6. Do not install a chimney joint or a expansion length in the roof/floor

space.

7. For installation on non-combustibles materials, the minimum opening

can be reduced to I.D. + 6 inches. The anchor plate can also be used

instead of the ventilated version.

8. Always seal, with outer joint sealant, between storm collar and outer

chimney casing.

9. Installation step:

a. Cut opening to dimensions specify in table 3.

b. Install the Firestop under the roof/floor and attach it with screw.

c. Slide DIS / DAS chimney trough the firestop.

d. Install the floor guide or the ventilated anchor plate on top of the

roof/floor.

e. Install flashing over the chimney and the guide/support and

screw it.

f. The storm collar is placed around the chimney and sealed to the

casing with outer joint sealant. The storm collar should not quite

rest on the flashing when the chimney is cold (1/4” gap between

the collar and the top of the flashing).

1. This part is used to allow model DIS / DAS chimney to pass trough a

wall made of combustible construction.

NOTE: Crossing a combustible wall is not permitted for diameters

larger than 10” inside diameter.

2. The wall penetrator (FSW) consist of a firestop female half and a male

half that slide in each other to adjust wall thickness from 7.8” to 12.1”,

see Figure 37.

3. Installation step:

a. Cut opening to dimension indicated in table 3.

b. Slide the firestop female half into the opening and fix it to the

wall with screws.

c. On the other side of the wall, slide the male half into the opening

and fix it.

d. Insert the chimney trough the opening of the wall firestop. Make

sure there is no chimney joint or expansion length in the wall

opening.

e. The chimney section must be well supported and guided to

prevent any load on the wall firestop.

Firestop

female half

Chimney

length

Firestop

Male half

Storm Collar (SC)

Floor guide or

ventilated anchor

plate

No joint or expansion

length in this area

Figure 36 - Roof / floor penetration

Sealant

Flashing

Combustible

roof / floor

Firestop radiant shield

2” Clearances (DIS)

4” Clearances (DAS)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Figure 37 - Wall firestop

17

Page 18

SECTION E - TERMINATIONS, STARTING ADAPTORS, DRAIN

LENGTH AND RELIEF VALVE

STARTING ADAPTORS

Single Wall Adaptor (SWA)

1. The Single Wall Adaptor is used as an appliance connector. It is designed to be clamped with a Retaining Band and a locking band over

a shank type flue gas outlet.

2. First, slide the retaining band over the appliance outlet and tighten it

with supplied bolt. (See figure 38).

3. Add a bead of sealant about 1/8” on the flange of the retaining band

and one on the flange of the adaptor (SWA) and mate those two flanges

together. Be sure to fill all the gaps with S-2000 sealant. (See figure

39 and figure 40).

4. Tighten the Locking Band to hold and seal the adaptor in place. See

Figure 41 for typical installation.

ANSI Flange Adaptor (FA)

Female Flanged Adaptor (FFHA)

1. The Flanged Adaptor (FFHA) is used to connect the DIS chimney to

flanged appliance outlets other than those with ANSI pipe flanges.

2. The adaptor is designed to sandwich an 1/2 inch flange between two

half ring and the appliance flanged outlet. The Flange Adaptor comes

with beam clamps to clamp the FFHA to the appliance. See Figure 43.

Insert and tighten

the band in place

INLET

APPLIANCE

OUTLET

Insert and tighten

the band in place

1. The Flange Adaptor (FA) is intended for use as a connection to a class

125 or 150 ANSI pipe flange.

2. This type of connection requires a flange gasket and bolt set provided

by the installer. The gasket and bolts are typically sold by pipe, valve

and fittings houses as ‘NBG’ set. Figure 42 illustrates a typical instal-

lation.

3. An outer band with insulation is included to close the installation.

Flanged Adaptor (FHA)

1. The Flanged Adaptor (FHA) is used to connect the DIS / DAS chimney

to flanged appliance outlets other than those with ANSI pipe flanges.

2. The adaptor is designed to sandwich an 1/2 inch flange between two

half ring and the appliance flanged outlet. The Flange Adaptor comes

with beam clamps to clamp the FHA to the appliance. See Figure 43.

DIS/DCT, DCT/DIS, DAS/DCT, DCT/DAS Adaptor

1. Used to connect model DIS / DAS chimney to model DCT chimney.

See Figure 44.

OTHER ADAPTORS

Female Single Wall Adaptor (FSWA)

1. The Female Single Wall Adaptor is used as a connector to specialised

component or existing chimney connection. It is designed to be

clamped with a Retaining Band and a locking band over a shank type

flue gas inlet.

2. First, slide the retaining band over the system inlet and tighten it with

supplied bolt. (See figure 38a).

3. Add a bead of sealant about 1/8” on the flange of the retaining band

and one on the flange of the adaptor (SWA) and mate those two flanges

together. Be sure to fill all the gaps with S-2000 sealant. (See figure

39a and figure 40a).

4. Tighten the Locking Band to hold and seal the adaptor in place. See

Figure 41a for typical installation.

Figure 38 - Single wall adaptor

Apply bead

of sealant

APPLIANCE

OUTLET

Figure 39

Insert the

coupling end

APPLIANCE

OUTLET

Figure 40

Tighten the

locking band

Figure 38a - Female Single wall

adaptor

INLET

Apply bead

of sealant

Figure 39a

INLET

Insert the

coupling end

Figure 40a

INLET

Female ANSI Flange Adaptor (FFA)

1. The Female Flange Adaptor (FFA) is intended for use as a connection

to a class 125 or 150 ANSI pipe flange.

2. This type of connection requires a flange gasket and bolt set provided

by the installer. The gasket and bolts are typically sold by pipe, valve

and fittings houses as ‘NBG’ set. Figure 42 illustrates a typical instal-

lation.

3. An outer band with insulation is included to close the installation.

18

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Figure 41

APPLIANCE

OUTLET

Tighten the

locking band

Figure 41a

Page 19

Flange adaptor

Bolts and nuts

(by other)

Gasket

(by other)

ANSI 125 or 150

pipe flange

Appliance outlet

Figure 42 - ANSI flange adaptor (FA illustrated)

Flanged adaptor

Half ring

Beam clamp

Appliance

flanged

outlet

Figure 43 - Flanged adaptor (FHA illustrated)

TERMINATIONS

Note: Installation of model DIS / DAS chimney can be completed

without any terminations if not necessary.

Rain Cap (RC)

1. Installed at the top of the chimney, it provides the greatest degree of

rain protection.

2. Three models of rain cap are available dependently of the diameter,

see Figure 45.

3. Do not use with turbine or engine exhaust.

4. Installation is done the same manner as a standard length except for

model 3. For this model, there are 3 additional steel straps to be screwed

to the chimney outer casing to ensure resistance to high wind.

Finishing Cone (FC)

1. Used to create a better draft when installed at the top of the chimney,

see Figure 46.

2. Requires a drain at the bottom of the stack to collect rain entering

the chimney.

3. Installation is done as a standard length.

Flip Top (FT) (DIS only)

1. Used in diesel or turbine exhaust, it prevents moisture and debris

from entering the system. See Figure 47.

2. Flip top opens with internal pressure and closes when no pressure.

3. Install as a standard length.

Miter Cut (MC)

1. Used in diesel or turbine exhaust as an horizontal termination. See

Figure 48.

2. Installation is done as a standard length.

DCT female connection

DIS / DAS female connection

Figure 44 - DIS / DCT, DCT / DIS adaptor

DIS / DAS male connection

DCT male connection

5” to 10” Ø

20” to 36” Ø

5” to 18” Ø

Figure 45 - Rain Cap models

Optional bird screen

12” to 18” Ø

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

19

Page 20

Figure 46 - Finishing Cone (FC)

Flip top

Figure 47 - Flip Top (FT)

Better draft

RELIEF VALVE (DIS ONLY)

Relief Valve (RV)

1. The relief valve is intended for use with diesel engines to provide extra

protection to the chimney in case of a delayed ignition of backfire.

2. The connection of the Relief valve and the DIS chimney is done with

the use of the ANSI Female Flange Adaptor (FFA).

3. The valve is factory calibrated to open at 27 in. wc.

4. The relief valve must be supported independently of the rest of the

exhaust system. The best way to accomplish this is to locate an

Anchor Plate (AP) support at the joint between the ANSI Flange

adaptor and the adjacent fitting. See Figure 50.

5. It is crucial that the support be properly secured to building structure

so that it can withstand the forces generated in case of delayed fuel

ignition.

6. It must be installed in combination with a Tee 45° Relief Valve (T45RV).

Drain length

Drain

Drain tubing

(by others)

Bird screen

Figure 48 - Miter Cut Termination (MC)

DRAIN LENGTH

Drain Length (DL)

1. Used to drain rain or condensate from the chimney.

2. The chimney flue is equipped with an annular catch ring and a 1” NPT

nipple extending through the outer casing for attachment of drain

tubing.

3. The drain tubing should include a water trap of a height at least equal

to the maximum expected operating pressure at the appliance outlet

to avoid allowing flue gases to vent through the drain. See Figure 49.

4. Drain length should be installed indoors to prevent freezing.

Trap height equal to max

appliance outlet pressure

Figure 49 - Drain length

Flue direction

Relief valve

Anchor plate (AP)

in frame by others

ANSI Female Flange adaptor (FFA)

Figure 50 - Relief Valve installation

Tee 45 RV (T45RV)

20

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 21

SECTION F - THERMAL EXPANSION

BELLOWS EXPANSION JOINT (LB)

Thermal Expansion :

1. When Model DIS / DAS is in use, thermal expansion will occur on

the inner flue and outer casing.

2. A good estimation for thermal expansion is approximately 1” per

100’ chimney length per 100°F rise.

Thermal expansion [inch] = (length[feet]/100)x(

∆T[°F]/100)

3. Thus, the thermal expansion is dependant on the inner flue temperature

and the length of the chimney between two (2) fixed points.

4. Good installation requires that expansion greater that 1/4” must be

compensated with either a bellow joint (LB) or an adjustable length

(LA). Depending on the pressure of the system.

5. Tees and elbows are not designed to withstand bending moment,

make sure to compensate thermal expansion before connecting to a

tee or a elbow.

6. Expansion joints are not designed to withstand lateral forces so they

must be accurately supported and guided.

7. Because the amount of outer casing movement is the same as the

inner flue, the outer casing must slide to avoid excessive forces on

tees, elbows or fixed points. To accommodate outer casing movements, wall guide, floor guide and suspension bands must allow

movement of the chimney.

8. When supporting a system with considerable height and thermal

expansion, adjustable lengths or bellow joints must be used just

below every fixed support above the first to compensate for thermal

expansion.

9. For engine or turbine exhaust system requiring pressures up to 60

inches of water column, or where the construction must be absolutely gas tight, all welded bellows length (LB) are recommended for

expansion and vibration movements of the exhaust.

10. Low pressure systems, such as boilers (up to 6 inches water column),

can effectively use the Adjustable Length (LA).

11. Spacing of guides and supports, when a thermal expansion part is

used, should not be greater than that specified in Section A, table 7.

12. Proper guiding and support of expansion parts often requires closer

spacing.

1. Used in diesel or turbine exhaust installation for expansion and vibration

movements.

2. Good for exhaust pressure up to 60 inches of water column, it will compensate for up to 3” max of expansion. See table 14 for maximum run with one

bellow.

3. Bellow joints comes with a liner to protect the bellow and to have a smooth

flow.

4. We suggest to always install a 12” length chimney downstream and upstream

the bellow to insure clearance for the liner and adding accessibility for supporting and guiding. See Figure 51 ‘’bellowjoint’’ for good positioning of the

bellow expansion joint.

5. It is of the most important that the bellow joint be properly supported and

guided in vertical and horizontal orientation.

6. Installation is done the same way as described in section A: Chimney and

fitting joint assembly.

Operating temp. [°F] Max distance with one bellow joint [feet]

700 42.8

800 37.5

900 33.3

1000 30.0

1100 27.3

1200 25.0

1300 23.1

1400 21.4

Table 14 - Maximum run with bellow between each fixed point

EXPANSION JOINTS INSTALLATION

Bellows Expansion Joint (LB) and Adjustable Length (LA) in vertical

runs

1. A Bellows Expansion Joints or Adjustable Length installed vertically

should be installed directly below one chimney length of the highest

support, between fixed points (see Figure 51).

2. Always use Bellows Expansion Joints or Adjustable Lengths between

fixed points when expansion is over 1/4”. See table 14 and Table 15

for maximum run between fixed points.

3. Install proper guiding between fixed points when using Bellows

Expansion Joint or Adjustable Length, to allow chimney vertical

movement due to expansion.

Bellows Expansion Joint and Adjustable Length in horizontal runs

1. Same guidelines apply as for vertical run with respect to expansion

estimate and proper support and guiding with the use of Bellows

Expansion Joint and Adjustable Length.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

21

Page 22

3” Max.

Expansion

Flip top (FT)

Anchor plate ventilated (APV)

12” Long length minimum with bellows (L12)

Bellow joint (LB)

Wall guide (WG)

UP TO 60 INCH W.C.

INTERNAL PRESSURE

Wall support (WS)

12” Long length minimum with bellows (L12)

Bellow joint (LB)

3” Max.

Expansion

12” Long length minimum with bellows (L12)

Wall guide (WG)

Wall support (WS)

Suspension band (SB)

Bellow joint (LB)

Fixed support (AP)

3” Max.

Fixed

Support (AP)

Relief

Valve (RV)

Fixed

Support (AP)

Expansion

Suspension band (SB)

Bellow joint (LB)

Fixed support (AP)

MUFFLER

ENGINE

Figure 51 - Bellow Joint installation on Diesel Engine

22

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 23

ADJUSTABLE LENGTH

1. The adjustable length (LA) is used for two functions, one is to make

odd lengths and the other to serve as an expansion joint.

2. The adjustable length may be used when internal pressure do not

exceed 6” water column or in well ventilated areas. See Figure 66

for good positioning of the adjustable length.

3. The adjustable length assembly includes a sliding inner section, two

containing rings, one compression band, a graphite packing gasket,

an insulation band (DIS only) and a telescopic outer casing. There

is a tool supplied with this assembly. (see Figure 67).

4. For proper installation, the adjustable length must have adequate

overlap and sufficient allowance for thermal expansion. (see Figure

56 - Adjustable length (LA), and table 15).

5. Installation steps (see Figure 57):

a. Adjust the length of the chimney as required. If outer casing

or inner flue are too long, they may be cut to length. You must

keep the overlap of the outer casing to at least 1”. You are only

authorised to cut on the outer casing section attached to the

female coupling. See Figure 52.

b. Move up the sliding section of the outer wall to access inner

wall. See Figure 53.

c. Tighten the compression band so that the graphite packing is

firmly registered against the inner flue. See Figure 54.

d. Tighten all the bolts of the containing ring. For each bolt, use

the supplied tool as a guide between the two containing rings

(see Figure 55).

e. Fill the gap between the inner flue and outer casing with the

supplied insulation band. See Figure 56 (DIS only).

f. Move down the sliding section of the outer wall to the flange of

the female coupling and install the locking band as described in

section A: Chimney and fitting joint assembly. See Figure 57.

Compression band

Graphite packing

Containing ring

Telescopic

outer casing

Insulation band (DIS only)

1” Min.

overlap

X Min.

Figure 58 - Adjustable length

X min. = EXPANSION + 3 [inch]

∆

EXPANSION = (length[feet]/100)x(

Operating Temp. [°F] Max distance with one Adjustable length [feet]

200 200

300 133

400 100

500 80

800 50

1000 40

1200 33

1400 29

Table 15 :

Maximum run with Adjustable length between two fixed points

T[°F]/100)

Desired length

Figure 52 - Adjustable length, INSTALLATION STEP A

Wrench

Supplied tool

Figure 55 - Adjustable length, INSTALLATION STEP D

Desired length

Move outer casing

Figure 53 - Adjustable length, INSTALLATION STEP B

Figure 56 - Adjustable length, INSTALLATION STEP E

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Figure 54 - Adjustable length, INSTALLATION STEP C

Figure 57 - Adjustable length, INSTALLATION STEP F

23

Page 24

VARIABLE LENGTH

1. The variable length (LV) is used only to make odd lengths, it doesn’t

compensate thermal expansion. See figure 65 for typical location.

2. The variable length assembly includes a sliding flanged female coupling, a flanged retaining band, a locking band, a insulation band and

split outer casing. Inner flue sealant S-2000 or S-650 is necessary

depending on the flue gas temperature.

3. Installation steps :

a. Measure the distance required for the variable length. See figure

59.

b. Cut the inner wall at the dimension found at point ‘a.’ plus 1”.

Cut the split outer casing at dimension plus 5/8”. Then cut the

insulation band at dimension (DIS only). See figure 60.

c. Install the interior assembly between the two parts. Put one

bead of sealant between the couplings flanges as a regular length

installation. See figure 61.

d. Slide down the female coupling over the male coupling of down-

stream part and fill the gap between the female coupling and the

inner wall with S-2000 or S-650 sealant. See figure 62.

e. Slide down the retaining band to the female coupling to mate

their flanges and tighten the band. Then, install the locking band

over those flanges. See figure 63.

f. Install the insulation over the inner wall (DIS only). See figure

64.

Slide down the female coupling

and fill the gap with sealant

Figure 62 - Variable length, Installation step D

Slide down the retaining band and

tighten the band and install the locking

band over the flanges

Figure 63 - Variable length, Installation step E

Distance X

Figure 59-

Variable length, Installation step A

Cut to X + 1”

Cut 1.25” in the bend to

clear the locking band

Figure 60 - Variable length, Installation step B

Install interior assembly

between two parts

Figure 61 - Variable length, Installation step C

Cut to

X + 5/8”

Cut to X

(DIS only)

Figure 64 - Variable length, Installation step F

Install the outer shell by inserting

the crimped end under the male

coupling first

Figure 65 - Variable length, Installation step G

Install the insulation (DIS only)

Tighten the bolts

and install the

locking bands

24

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 25

Finishing cone (FC)

Adjustable length

(LA)

UP TO 6 INCH W.C.

INTERNAL PRESSURE

Adjustable length

(LA)

Wall guide (WG)

Wall support

(WS)

Drain tee cap

(DTC)

Wall firestop

(FSW)

Increaser

(TINS)

Suspension band

(SB)

Appliance

Adjustable length

(LA)

Fixed support (AP)

45° Tee (T45)

Tee cap (TC)

45° Elbow (E45)

Length (L)

Locking band (BS)

Variable length (LV)

Starting adaptor

(SWA, FA or FHA)

Appliance

Figure 66 - Adjustable and Variable length typical location

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

25

Page 26

SECTION G - GREASE DUCT APPLICATION (DIS ONLY)

ACCESS

Grease Duct installations require provisions for cleaning the interior of

the duct. NFPA 96 clean-out requirements are as follows:

1. A clean-out must be provided at each change of direction except

where the entire length of the duct can be inspected and cleaned

from either the hood or the discharge end.

2. On horizontal duct runs, at least one (1) 20” (508) diameter opening

must be provided. Where the duct is smaller than 20” (610) diameter, openings large enough to permit cleaning must be provided at

intervals of not more than 12’ (3.66m).

3. Openings may be at the side or the top of the duct whichever is more

accessible. When the opening is on the side of the duct, the lower

edge of the opening must be at least 1-1⁄2” (38) above the bottom

of the duct. For Model DIS Grease Duct, this is accomplished by the

use of the Grease Tee (GT90) with a Tee Cap (TC).

4. On vertical duct where personnel entry is possible, access must be

from the top of the riser. Where entry is not possible, access must

be provided at each floor.

NOTE: ACCESS REQUIREMENTS ARE SUBJECT TO CHANGE IN ACCORDANCE WITH LOCAL CODE. LOCAL AUTHORITIES SHOULD BE

CONSULTED FOR EXACT REQUIREMENTS.

Drop to hood

Plan view

Horizontal

drain length

Clean-out cap

Standard 90° tee

Hood (by others)

Up to fan

Figure 68 - Horizontal drain length typical location

USE AND INSTALLATION OF INDIVIDUAL PARTS

1. Duravent Model DIS parts numbering and parts usage are discussed

under chimney applications beginning on page 4 of these installation

instructions.

2. Those parts specific to grease duct, which are not normally used in

chimney applications, are discussed in the following sections.

3. Installation is the same as described for standard application on page

5, but a additional bead of sealant must be applied. See figure 2.

HORIZONTAL DRAIN LENGTH (HDL)

1. Horizontal Drain length is equipped with a 1” (25) NPT nipple, which

is attached to the inner flue and extends through the outer casing to

provide a path to drain grease, condensate or wash water from the

duct. See Figure 67.

2. A dam is attached to the inside of the inner flue adjacent to the nipple

to channel the effluent to the drain.

3. The duct drain is intended for use at the end of a horizontal run where

access and drainage is needed (See Figure 68).

4. The drain coupling must be connected to a grease trap or approved

container (supplied by others).

NOZZLE SECTION

1. The nozzle section is used when the duct is required to be equipped

with a fire suppression system or washdown is desired.

2. The nozzle section allows a spray head or nipple to be attached to

the duct through a 1” (25) NPT coupling attached to the inner flue

and when the chimney section is in a vertical orientation, the nozzle

may be located at the most convenient place. See Figure 69.

3. Local authorities should always be consulted regarding the need for