Page 1

SUBMITTAL RECORD

Single Wall or Double Wall AL29-4C® or 316L.

Special Gas Vent for Category I, II, III and IV.

TYPE L VENT Low temperature venting system

3” to 24” Diameter Vent For use on Positive, Neutral and

Negative Pressures up to 35” W.C.

Also for venting listed gas or oil fired appliances listed for

venting with TYPE L low temperature venting system

(DSD / DSID ONLY)

MODEL DuraSeal® DS/DSD/DSID

Listed to standards:

UL-1738

ULC-S636

UL-641

ULC-S609

Report # G100215896MTL-006

SUBMITTAL RECORD

PREPARED FOR:

REFERENCE:

LOCATION:

CONTACT:

TELEPHONE: FAX:

EMAIL:

PREPARED BY:

Material Selection

DSD / DSID ONLY

}

FLUE (INNER WALL)

AL29-4C

316L

MODEL DS MODEL DSD

MODEL DSID

Reference to the installation instructions will enable you to obtain a safe,

efficient and dependable installation of this vent system. Please read

and understand these instructions before beginning your installation.

Do not alter or modify the components of this chimney system under

any circumstances. Any modification or alteration of the vent system

or approved accessories, including but not limited to the appliance

it is connected to, may void the warranty, listings and approvals of

this system and could result in an unsafe and potentially dangerous

installation.

A. Examine all components for possible shipping damage prior to

installation;

B. Proper joint assembly is essential for a safe installation. Follow

these instructions exactly as written: Check severeness of joints

upon completion of assembly;

C. This venting system must be free to expand and contract. This venting

system must be supported in accordance with these instructions;

D. Check for unrestricted vent movement through walls, ceilings, and

roof penetrations;

E. Different manufacturers have different joint systems and adhesives.

Do not mix pipe, fittings, or joining methods from different manufacturers.

SFDS REV. 11 08-07-19

1

Page 2

TABLE OF CONTENTS

INTRODUCTION

Introduction ................................................................................. page 2

Testing / listing information ......................................................... page 2

Clearances to combustibles ......................................................... page 3

General installation requirements ................................................ page 3

Typical installations .................................................................... page 4-5

Chimney and fitting joint assembly .............................................. page 6

Chimney weight ........................................................................... page 6

Support methods and height ....................................................... page 7

Horizontal installation requirements ............................................ page 8

Maintain proper slope ................................................................. page 9

Vertical installation requirements ................................................ page 9

Wall penetration .......................................................................... page 10

Roof / floor penetration ............................................................... page 10

Condensate drains ...................................................................... page 10

DuraSeal as a liner ...................................................................... page 12

DuraSeal® single wall (DS) or double wall (DSD) or double wall insulated

(DSID) is a special stainless steel vent system for gas fired appliances listed

as Category I, II, III, and IV or in Canada as Type BH Gas Venting as noted

in ULC-636, with a maximum operating temperature of 550 Degrees F (288

Degrees C), and a maximum rated positive pressure of 35” Water Column. It

can also vent listed gas or oil fired appliance rated to be vent with TYPE L low

temperature venting system (DSD & DSID only). DuraSeal must be installed

by an experienced professional familiar with the operation and maintenance

of heating appliances and venting. Before installing this product, examine all

components for possible shipping damage and read the complete installation

manual. Failure to follow proper installation procedures, including vent pitch

and improper appliance connections, may cause unsafe conditions. DuraVent

recommends the system to be inspected once a year by a qualified service

technician

TESTING / LISTING INFORMATION

DuraVent DuraSeal model DS, DSD and DSID venting system is listed with

Intertek Testing Services (ETL) to UL/ULC standards:

U.S.A.

• UL-1738

Special Gas Vent for Category I, II, III

and IV appliances

• UL-641 (DSD & DSID only)

TYPE L VENT venting listed gas

or oil burning appliances

Adjustable length ........................................................................ page 13

DuraSeal Flex .............................................................................. page 14

Maintenance instructions ............................................................. page 15

DuraSeal Labels ........................................................................... page 16

Warranty ...................................................................................... page 44

Product reference information ...................................................... page 48

CANADA

• ULC-S636

Type BH Gas Vent Class I/II

• ULC-S609 (DSD & DSID only)

TYPE L VENT venting of flue gases with temperature not exceeding 300°C

from oil or gas burning appliances

This product must be installed in accordance with local building code requirements as well as National codes: USA - National Fuel Gas code ANSI-Z223.1

or NFPA Standard 54, or NFPA 211. In CANADA - CAN/CGA-B149.1 or CAN/

CGA-B149.2 Propane Installation Code as applicable.

2

Page 3

CLEARANCES TO COMBUSTIBLES

Table 1 shows the required MINIMUM AIRSPACE CLEARANCE TO COMBUS

TIBLES. “Combustibles” include framing lumber, drywall, plywood, paneling,

insulation, wiring and other building materials.

Minimum Clearance to Combustibles Single Wall DS

Enclosed

(4 sides)

Horiz. Vert. Horiz. Vert.

N/A N/A 2” 2”

N/A N/A 4” 4”

Diameter

3” to 12”

14” to 24”

Rated

operating

temperature

480º F

(250º C)

480º F

(250º C)

Max.

operating

temperature

550º F

(288º C)

550º F

(288º C)

Minimum Clearance to Combustibles Double Wall DSD / DSID

Enclosed

(4 sides)

Horiz. Vert. Horiz. Vert.

N/A 1” 1” 1”

N/A 1” 3” 1”

N/A 2” 2” 2”

N/A 2” 3” 2”

®

Diameter

3” to 12”

14” to 24”

3” to 12”

L-VENT

14” to

24”

L-VENT

Rated

operating

temperature

480º F

(250º C)

480º F

(250º C)

480º F

(250º C)

480º F

(250º C)

Max.

operating

temperature

550º F

(288º C)

550º F

(288º C)

550º F

(288º C)

550º F

(288º C)

Table 1 - Minimum Clearances for DuraSeal

Auxiliary parts such as combination Roof Supports, Roof Thimble, Flashings

and Wall Thimble outer shields are intended to be attached directly to the

framing or to ceilings, floors, or walls in accordance with their respective

instructions. These parts, which are installed in contact with wood or other

combustibles, are designed and tested to assure that they do not overheat

at points of contact.

Unenclosed

(2 sides Max.)

Unenclosed

(2 sides Max.)

GENERAL INSTALLATION REQUIREMENTS

-

When venting Category I, II, III, or IV appliances or TYPE L vented appliance,

DuraSeal must be used for the entire length of the system. Do not mix pipe,

fittings, or joining methods from different manufacturers. See the DuraSeal

catalog for a complete list of parts and products. Every vent system

must be planned and installed for optimum performance and safety. The

venting system must be free to expand and contract and must be supported

in accordance with these instructions. (Check for unrestricted vent movement

through walls, ceilings, and roof penetrations). Refer to the gas appliance

manufacturer’s instructions to determine venting requirements and limitations

with respect to installation and use of the appliance. It is the responsibility

of the installer to contact local building and fire officials concerning

any installation restrictions and/or inspection requirements that may

apply. Permits may be required before starting an installation.

• If required by the appliance manufacturer, a Drain Tee Cap must be

located as close as possible to the appliance flue outlet. Depending on

the arrangement of the vent, more than one drain may be required.

Unless a Drain Tee Cap is supplied with the appliance, install a DuraSeal

Drain Tee Cap.

• More than one Category II, III or IV appliance may not be connected into

the same vent system, unless the appliance manufacturer specifically

approved such a system and the appliance are designed for multiple

venting. Cat. II, III or IV appliances MAY NOT be common vented with Cat.

I, natural draft appliances. This limitation can be removed if an engineering

analysis demonstrates normal and safe operation of appliances.

• DuraSeal must not come in contact with plumbing or electrical systems.

• Maintain rated clearances to combustibles over the entire length of the

vent system.

• DuraSeal shall not be routed into, through, or within any vent, such as an

existing masonry or factory-built chimney, that is connected to another

appliance.

Notes:

1. Unenclosed requires at least two sides open.

2. Single Wall (DS) may be enclosed only in non-combustible enclosure.

3. Reduced clearances may be attained by using non-combustible enclosures.

4. Combustible Material is any material made of or surfaced with wood,

compressed paper, plant fibers or other materials that are capable of being

ignited or burned. Such material shall be considered combustible even

though it is flame-proofed, fire-retardant treated, or plastered. (Source:

NFPA 54/ANSI Z223.1)

5. Design any enclosure to permit inspection of the system.

6. Do not place insulation in any required clearance spaces surrounding the

vent system unless these instructions suggest otherwise and the insulation

is specified or supplied.

7. When using Viton caulking, follow the manufactures required drying times.

Material Thickness

*all seams are laser welded

DuraSeal DS DuraSeal DSD / DSID

Diameter Flue Diameter Flue Casing

3” to 9”

10” to 16”

18” to 24”

AL29-4C - .015”

316L - .015”

AL29-4C - .020”

316L - .019”

AL29-4C - .024”

316L - .024”

3” to 9”

10” to 16”

18” to 24”

AL29-4C - .015”

316L - .015”

AL29-4C - .020”

316L - .019”

AL29-4C - .024”

316L - .024”

441 stainless - .015”

441 stainless - .020”

441 stainless - .024”

PART NUMBERS

These instructions identify major model DS-DSD-DSID parts by name and part number.

Material Code Designations

B Type 316 Stainless Steel

H Type 430 Stainless Steel

K Type 441 Stainless Steel

P Type 439 Stainless Steel

U Type AL29-4C Stainless Steel

Example:

DSD 36” length with inside diameter 14” made of AL29-4C inner flue and

SS441 outer casting.

DSD 14 L36 UK

Model Dia. Part Material

DS 30° elbow with inside diameter 22” made of 316L.

DS 22 E30 B

Model Dia. Part Material

DSD wall support for 8” diameter chimney made of stainless 439.

DSD 8 WSHD P

Model Dia. Part Material

3

Page 4

TYPICAL INSTALLATION

Cables, rods or

braces By other

500 lbs rated

Maximum distance

suspended (S), see table 6

Suspension Band (SB)

Maximum distance between

support (MHS), see table 6

Anchor Plate HD

(APHD)

Minimum slope

1/4” per foot

Minimum Clearances

See table 1

Roof Support

(RS)

30º Termination

(STA)

Opening dimension

See table 6

Wall Thimble

(WT/WTI)

Refer to condensate drain

section for proper installation

Figure 1 - Horizontal

4

Appliance

Appliance

adaptor

Page 5

TYPICAL INSTALLATION

Exit Cone (EC)

Guy wires by others

500 lbs rated

Flashing

(F)

Roof

support

(RS)

Maximum freestanding height

See table 6 (H)

Maximum distance

between guides (MVS)

See table 6

Maximum distance

between supports

See table 4 & 5

Opening

dimension

See table

7,8 & 9

Maximum distance

between elbows without

any support or guide

See table 6 (MDE)

Maximum distance

between supports

See table 4 & 5

Roof

thimble

(RT/RTI)

Guy Support

(GS)

Minimum

Clearance

See table 1

Wall support

(WS)

Wall guide

(WG)

Figure 2 - Vertical

Appliance adaptor

Maximum distance

between guides

See table 6 (MVS)

Appliance

Wall guide

(WG)

Wall support HD

(WSHD)

5

Page 6

CHIMNEY AND FITTING JOINT ASSEMBLY

All components have a male and female end, the male end has the gasket.

The installation orientation is indicated on the labeling of each chimney section

with an arrow. The arrow indicated the direction of the flow.

DuraSeal® DS DuraSeal DSD / DSID

1. Add a thin film of

silicone lubricant

on the o-ring.

2. Insert the male

end into the

female end.

ASSEMBLY JOINT DS/DSD/DSID LUBE REQUIREMENT

Inside diameter Qty (oz)

3” 0.1

4” 0.1

5” 0.1

6” 0.1

7” 0.1

8” 0.2

9” 0.2

10” 0.2

12” 0.3

14” 0.3

16” 0.3

18” 0.4

20” 0.4

22” 0.5

24” 0.5

Table 2

CHIMNEY WEIGHT

3.Close the clips to

secure the joint.

NOTE:

Clips are self-locking

Figure 3 - Joint assembly steps

To open clips, push the secondary catch while pulling up the lever

Push

Pull Up

Figure 4 - Opening clips

Chimney weight is given in pounds per foot of each diameter. It is important

to know the weight of the chimney section for chimney support or guiding.

Chimney weight (table 3) along with the maximum chimney height (table 4)

is necessary to calculate the proper anchor strength needed with supports.

CHIMNEY WEIGHT IN LB/FT

INSIDE DIAMETER DS DSD DSID

3” 0.7 1.7 2.1

4” 0.9 2.1 2.6

5” 1.1 2.6 3.0

6” 1.3 3.0 3.4

7” 1.5 3.4 3.9

8” 1.7 3.8 4.3

9” 1.9 4.3 N/A

10” 2.1 4.7 5.5

12” 2.6 6.2 7.0

14” 3.6 7.7 8.2

16” 4.1 8.7 9.3

18” 4.6 9.8 10.3

20” 5.1 10.8 11.3

22” 5.7 11.8 12.4

24” 6.2 12.8 N/A

Table 3 - Chimney weight

Example: Model DuraSeal DSD 6” diameter section of 25 feet in length from

table 3, weight in lb/ft = 3. Total length 3 x 25 = 75lbs.

6

Page 7

SUPPORT METHODS AND HEIGHT

1. Several support and guiding methods are used to anchor a chimney

against upward, downward and angular placement.

2. These supports and guides prevent bending stresses on the chimney

elbows and joints.

3. Certain limitations apply for proper installation of supports and guides.

See tables 4 and 5.

4. See figure 1 and 2 for typical installations.

MAXIMUM CHIMNEY HEIGHTS AND SUPPORT METHOD FOR

Inside

Anchor

dia.

3” 200 200 200 100 200 100 250

4” 200 200 200 100 200 100 250

5” 195 195 195 97.5 195 97.5 225

6” 190 190 190 95 190 95 190

7” 185 185 185 92.5 185 92.5 160

8” 180 180 180 90 180 90 140

9” 175 175 175 87.5 175 87.5 130

10” 170 170 170 85 170 85 115

12” 160 160 160 80 160 80 90

14” 150 150 150 75 150 75 65

16” 140 140 140 70 140 70 60

18” 130 130 130 65 130 65 55

20” 120 120 120 60 120 60 50

22” 110 110 110 55 110 55 45

24” 100 100 100 50 100 50 40

MAXIMUM CHIMNEY HEIGHTS AND SUPPORT METHOD FOR

Inside

Anchor

dia.

3” 100 100 100 50 100 50 115

4” 100 100 100 50 100 50 115

5” 97.5 97.5 97.5 48.75 97.5 48.75 95

6” 95 95 95 47.5 95 47.5 80

7” 92.5 92.5 92.5 46.25 92.5 46.25 70

8” 90 90 90 45 90 45 65

9” 87.5 87.5 87.5 43.75 87.5 43.75 55

10” 85 85 85 42.5 85 42.5 50

12” 80 80 80 40 80 40 40

14” 75 75 75 37.5 75 37.5 30

16” 70 70 70 35 70 35 27

18” 65 65 65 32.5 65 32.5 25

20” 60 60 60 30 60 30 22

22” 55 55 55 27.5 55 27.5 21

24” 50 50 50 25 50 25 20

Plate

(AP)

Plate

(AP)

Anchor

Plate

HD

(APHD)

Anchor

Plate

HD

(APHD)

Anchor

Plate

Length

(APL)

Anchor

Plate

Length

(APL)

Wall

Support

(WS)

Wall

Support

(WS)

Wall

Support

HD

(WSHD)

Wall

Support

HD

(WSHD)

MODEL DS

Roof

support

(RS)

MODEL DSD

Roof

support

(RS)

Guy

support

(GS)

Guy

support

(GS)

Table 4 - Dimensions are in feet

MAXIMUM CHIMNEY HEIGHTS AND SUPPORT METHOD FOR

Inside

Anchor

dia.

3” 95 95 95 47.5 95 47.5 80

4” 95 95 95 47.5 95 47.5 80

5” 92.5 92.5 92.5 46.25 92.5 46.25 70

6” 90 90 90 45 90 45 65

7” 87.5 87.5 87.5 43.75 87.5 43.75 55

8” 85 85 85 42.5 85 42.5 50

9” N/A N/A N/A N/A N/A N/A N/A

10” 80 85 85 42.5 85 42.5 40

12” 75 75 75 37.5 75 37.5 30

14” 70 70 70 35 70 35 27

16” 65 65 65 32.5 65 32.5 25

18” 60 60 60 30 60 30 22

20” 55 55 55 27.5 55 27.5 21

22” 50 50 50 25 50 25 20

24” N/A N/A N/A N/A N/A N/A N/A

Plate

(AP)

Anchor

Plate

HD

(APHD)

Anchor

Plate

Length

(APL)

Wall

Support

(WS)

Wall

Support

HD

(WSHD)

MODEL DSID

Roof

support

support

(RS)

Table 5 - Dimensions are in feet

Guy

(GS)

7

Page 8

SUPPORT AND GUIDE SPACING FOR

Inside

diameter

3” 10 8 12 12 10 50

4” 10 8 12 12 10 100

5” 10 8 12 12 10 100

6” 10 8 12 12 10 100

7” 10 8 12 12 10 100

8” 10 8 12 12 10 100

9” 10 8 12 12 10 100

10” 10 8 12 12 10 100

12” 10 8 12 12 10 100

14” 10 8 12 12 10 100

16” 10 8 12 12 10 100

18” 10 8 12 12 10 100

20” 10 8 12 12 10 100

22” 10 8 12 12 10 100

24” 10 8 12 12 10 100

SUPPORT AND GUIDE SPACING FOR

Inside

diameter

3” 10 8 12 12 10 50

4” 10 8 12 12 10 50

5” 10 8 12 12 10 50

6” 10 8 12 12 10 50

7” 10 8 12 12 10 50

8” 10 8 12 12 10 50

9” 10 8 12 12 10 50

10” 10 8 12 12 10 50

12” 10 8 12 12 10 50

14” 10 8 12 12 10 50

16” 10 8 12 12 10 50

18” 10 8 12 12 10 50

20” 10 8 12 12 10 50

22” 10 8 12 12 10 50

24” 10 8 12 12 10 50

MVS

Interior Exterior

MVS

Interior Exterior

MODEL DS

MHS MDE H S

MODEL DSD & DSID

MHS MDE H S

Table 6 - Dimensions are in feet

MVS : Maximum Vertical Spacing between Guides/Supports

MHS: Maximum Horizontal Spacing between Guides/Supports

MDE: Maximum Distance between Elbows

H: Maximum Freestanding Height above the Roof

S: Maximum Suspended Length

*Important Notes:

1. For Anchor Plate (AP) / Anchor Plate Heavy Duty (APHD) / Wall Support

Heavy Duty (WSHD), the support must be installed below a bead. See

figure 5.

2. For Wall Support (WS) / Roof Support (RS) , the support can be installed

anywhere on the part.

3.

For Anchor plate length, the support is already integrated to a length. Directly

attached to the building structure or supported by non combustible structural

elements (not included). No other installation is required than the standard

installation for a regular length.

Anchor plate,

Bead

A. Pass the female end through the

B. Install the two parts plate below

Figure 5 - Position of support

HORIZONTAL INSTALLATION REQUIREMENTS

• When venting through a sidewall, terminate the system not less than 12” (.3m)

• Terminate the system at least 7’ (2.1m) above a public walkway or driveway,

• The total horizontal vent length from the appliance flue collar to the outside

Anchor plate HD or

Wall support HD

hole of the one part plate.

a bead and bolt it to the one part

plate.

Bead

One part plate

Two parts

plate

Bolts and

nuts

above the ground and above the snow line in geographical areas where snow

accumulates. The termination area must be kept clear of snow and ice at all

times.

no less than 6’ (1.8m) from the combustion air intake of any appliance or 3’

(.9m) from any other building opening, gas utility meter, service regulator or

the like. Less distance is permitted if specified in the appliance’s installation

instructions. It also shall terminate at least 3’ (.9M) above any forced air inlet

within 10’ (3.1m) and shall terminate at least 4’ (1.2m) below, 4’ horizontally

from, or 1’ (.3m) above any door, window, or gravity air inlet into any building

as provided in the National Fuel Gas Code ANSI Z223.1 and NFPA 54. See

figure 6. Proper judgment may require greater distances depending on the

side of the equipment installed or to allow for snow drifting or falling from

falling from overhead roofs or trees. The termination should be far enough

away from trees, shrubs, or decorative items to prevent damage.

termination shall be in accordance with the appliance manufacturer’s instructions.

8

Page 9

MAINTAIN PROPER SLOPE

VERTICAL INSTALLATION REQUIREMENTS

• Install with a continuous 1/4” per foot (minimum) slope, as is required by the

National Fuel Gas Code for all gas-fired appliances.

• Vent systems for condensing appliances must have a continuous 1/4” per foot

(minimum) slope toward the appliance or a condensate drain. Always check

the appliance manufacturer’s instructions for proper drain requirements.

•

DuraSeal

degree slope, we recommend that you use these to generate your slope.

• Some appliances require the venting system to be sloped toward the horizontal

termination.

• Remember, if you raise the appliance or lower the ceiling you must adjust

the slope of the vent to maintain the 1/4” per foot minimum.

®

offers a range of tees and elbows that are built incorporating a 2

1 ft. above doors and windows

4 ft. horizontally from

door and windows

4 ft below any

window or fresh

air inlet

1 ft. above ground

or snow line

7 ft above

public

walkways

and drives

Sidewalk

Figure 6 - Horizontal termination requirements

1. The vent system must terminate at least 3 feet above the roof line and

at least 2 feet higher than any portion of the building within 10 feet.

See figure 7. This limitation can be removed if an engineering analysis

demonstrates normal and safe operation of appliance.

2. When terminated at a height of more than 10 feet, the stack must be

supported by a Guy Section.

3. The vent system must terminate with one of the

DuraSeal

®

terminations.

Except;

a) Category I appliances (natural draft) must use a Rain Cap. It is optional

on Category II. This limitation can be removed if an engineering analysis

demonstrates normal and safe operation of appliance.

b) Vent systems without provisions for draining rain water must use a Rain

Cap.

c) Terminations or approved mechanical vent devices specified or provided

by the appliance manufacturer are permitted.

4. The total continuous distance of the vent system from the appliance flue

collar to the termination shall not exceed that specified in the appliance

manufacturer’s installation instructions. When venting natural draft appliances the termination must be at least 5 feet above the topmost draft

hood. Otherwise a listed mechanical draft inducing device is required.

This limitation can be removed if an engineering analysis demonstrates

normal and safe operation of appliance.

5. In general, systems installed in cold climates perform best, and condensation is reduced, when the system is fully enclosed by some part of the

building structure or by using insulated SSID venting system.

6. In cold climates do not install a condensate drain on the exterior of the

building. Doing so may result in dangerous icy conditions on surfaces near

the drain and may cause damage to the vent system and/or the building

exterior. Security Chimneys will NOT be held liable for any personal injury

or property damage due to any formation of ice.

7. Vertical supports are required after every transition to vertical. Vertical

supports are also required after every offset elbow.

8. Unless DuraSeal is installed in a fire rated shaft, a roof thimble and support

is required when penetration fire rated floors, walls or ceilings.

10’

2’

2 ft. above structures within 10 ft.

Figure 7 - Vertical installation requirements

9

Page 10

WALL PENETRATION

ROOF / FLOOR PENETRATION

1. Prior to installation, determine proper location of wall thimble (WT) or wall thimble

insulated (WTI) so that a minimum slope of 1/4” (6mm) per foot is maintained in

the horizontal section of vent to ensure proper flow of condensation.

2. Prepare the wall by cutting a square opening. See table 6 for opening dimension.

3. Install the wall thimble by inserting the larger of the two parts on the appliance

(interior side). See figure 8.

4. Next, apply a bead of sealant around the edges of the exterior (smaller of the

two parts) wall thimble component. Then install this part of the wall thimble by

inserting the smaller collar into the other component from the previous step.

NOTE: The two horizontal cylinders of the thimble must engage a

minimum of two inches.

5. Fasten both sides of the wall thimble using screws or nails.

6. Once the thimble is installed, DuraSeal

®

vent pipe can be inserted into

the thimble.

7. Close the gap between the thimble and the vent by installing the two half

plate and fasten it using screws or nails.

8. Install horizontal termination to complete the assembly.

9. Once assembly is completed, apply a bead of high-temp sealant around

the pipe and the exterior two half plates of the thimble to protect against

weather.

10. The air gap is filled with insulation when using the insulated wall thimble

(WTI).

1. A roof thimble (RT) or roof thimble insulated (RTI) for cold climate must be installed

every time the vent system passes through a floor or roof.

2. Prepare the roof / floor by cutting a square opening. See table 6.

3. Install the roof thimble. You may cut the radiation sleeve if it is too long. See

figure 9.

4. For roof installation, install a flashing.

Flashing

Roof support

Air gap

or insulated

Roof thimble

Opening dimension

See table 6

Figure 9 - Roof penetration

2” Minimum overlap

Opening dimension

See table 6

Air gap or

insulated

Figure 8 - Wall penetration

Add sealant

Two half plate

Wall Thimble

(WT/WTI)

Termination

CONDENSATE DRAINS

When an internal condensate drain is NOT part of the appliance:

1. A Drain length (DL) or a Tee with a drain tee cap (DTC) is strongly recommended.

Install this drain as close as possible to the appliance flue collar.

2. A condensate drain is required for every 30 feet of horizontal vent and at the bottom

of a vertical stack.

3. Use the Drain length for a straight horizontal run. Rotate the fitting so that the

drain tube is as vertical as possible.

4. Use a Tee at a transition from horizontal to vertical, and attach the Drain Tee Cap

to the appropriate branch of the tee.

5. A condensate drain tube kit is available to direct the condensate to an appropriate

location. A trap loop must be formed into the drain hose and must be a diameter

that is at least four times the appliance’s rated stack pressure in inches of water

column or minimum 3 inches. Secure the loop with a cable tie.

6. Flue gas condensate can have a low (3 to 5) PH level, follow all local and national

codes and regulations for the draining of acidic condensate.

7. In cold climate, do not install a condensate drain on the exterior of the building.

Doing so may result in dangerous icy conditions on surfaces near the drain and

may cause damage to the vent system and the building exterior. DuraVent will

NOT be held liable for any injury or property damage due to formation of ice.

10

Page 11

OPENING DIMENSIONS FOR WALL/ROOF PENETRATION

FOR MODEL DS

Inside

diameter

3” 8x8 9x9 7x7 11x11

4” 9x9 10x10 8x8 12x12

5” 10x10 11x11 9x9 13x13

6” 11x11 12x12 10x10 14x14

7” 12x12 13x13 11x11 15x15

8” 13x13 14x14 12x12 16x16

9” 14x14 15x15 13x13 17x17

10” 15x15 16x16 14x14 18x18

12” 17x17 18x18 16x16 20x20

14” 22x22 22x22 22x22 22x22

16” 24x24 24x24 24x24 24x24

18” 26x26 26x26 26x26 26x26

20” 28x28 28x28 28x28 28x28

22” 30x30 30x30 30x30 30x30

24” 32x32 32x32 32x32 32x32

Table 7 - Dimensions are in inches

Wall

Thimble

(WT)

Wall

Thimble

Insulated

(WTI)

Roof

Thimble

(RT)

Roof

Thimble

Insulated

(RTI)

OPENING DIMENSIONS FOR WALL/ROOF PENETRATION

FOR MODEL DSID

Inside

diameter

3” 10x10 11x11 7x7 11x11

4” 13x13 14x14 10x10 14x14

5” 14x14 15x15 11x11 15x15

6” 15x15 16x16 12x12 16x16

7” 16x16 17x17 13x13 17x17

8” 17x17 18x18 14x14 18x18

9” N/A N/A N/A N/A

10” 19x19 20x20 16x16 20x20

12” 22x22 22x22 18x18 22x22

14” 24x24 24x24 20x20 24x24

16” 26x26 26x26 22x22 26x26

18” 28x28 28x28 24x24 28x28

20” 30x30 30x30 26x26 30x30

22” 32x32 32x32 28x28 32x32

24” N/A N/A N/A N/A

Table 9 - Dimensions are in inches

Wall

Thimble

(WT)

Wall

Thimble

Insulated

(WTI)

Roof

Thimble

(RT)

Roof

Thimble

Insulated

(RTI)

OPENING DIMENSIONS FOR WALL/ROOF PENETRATION

FOR MODEL DSD

Inside

diameter

3” 12x12 13x13 9x9 13x13

4” 11x11 12x12 8x8 12x12

5” 12x12 13x13 9x9 13x13

6” 13x13 14x14 10x10 14x14

7” 14x14 15x15 11x11 15x15

8” 15x15 16x16 12x12 16x16

9” 16x16 17x17 13x13 17x17

10” 17x17 18x18 14x14 18x18

12” 19x19 20x20 16x16 20x20

14” 22x22 22x22 18x18 22x22

16” 24x24 24x24 20x20 24x24

18” 26x26 26x26 22x22 26x26

20” 28x28 28x28 24x24 28x28

22” 30x30 30x30 26x26 30x30

24” 32x32 32x32 28x28 32x32

Table 8 - Dimensions are in inches

Wall

Thimble

(WT)

Wall

Thimble

Insulated

(WTI)

Roof

Thimble

(RT)

Roof

Thimble

Insulated

(RTI)

11

Page 12

INSTALLING DURASEAL® AS A LINER IN A MASONRY CHIMNEY OR

AS A LINER IN AN EXISTING VENT

* Stainless Steel Wire Rope (by others) is to be used to hang the vent

system from the top of the masonry chimney or from the top of the

existing vent.

- The stainless wire rope is attached to the Guy Support Band and is

secured with cable clamps (by others).

- The Stainless Steel Wire Rope is secured in a similar manner to the

top platform of the masonry chimney or existing vent.

- Use the appropriate size of Stainless Steel Wire Rope to accommodate

the required total loads of the vent system.

Note: When installed as a liner in a masonry chimney or to reline an existing vent no other appliance

can be vented into the same chimney or vent.

Exit cone (EC)

Storm Collar (SC)

Flat Flashing (F)

1” Minimum

It may be necessary to fabricate a platform (at top of chimney / vent

- by others).

Consult DuraVent for guidelines.

DO NOT USE GALVANIZED WIRE ROPE.

Masonry chimney

Combustible wall

Stainless steel

wire rope *

(by other)

Centering band

(CB)

Guy support (GS)

Elbow or tee

Maximum distance

between guides

See table 6 (MVS)

Maximum distance

between supports

See table 4 & 5

Maximum distance

between guides

See table 6 (MVS)

12

Figure 10 - Installing DuraSeal as a liner

Page 13

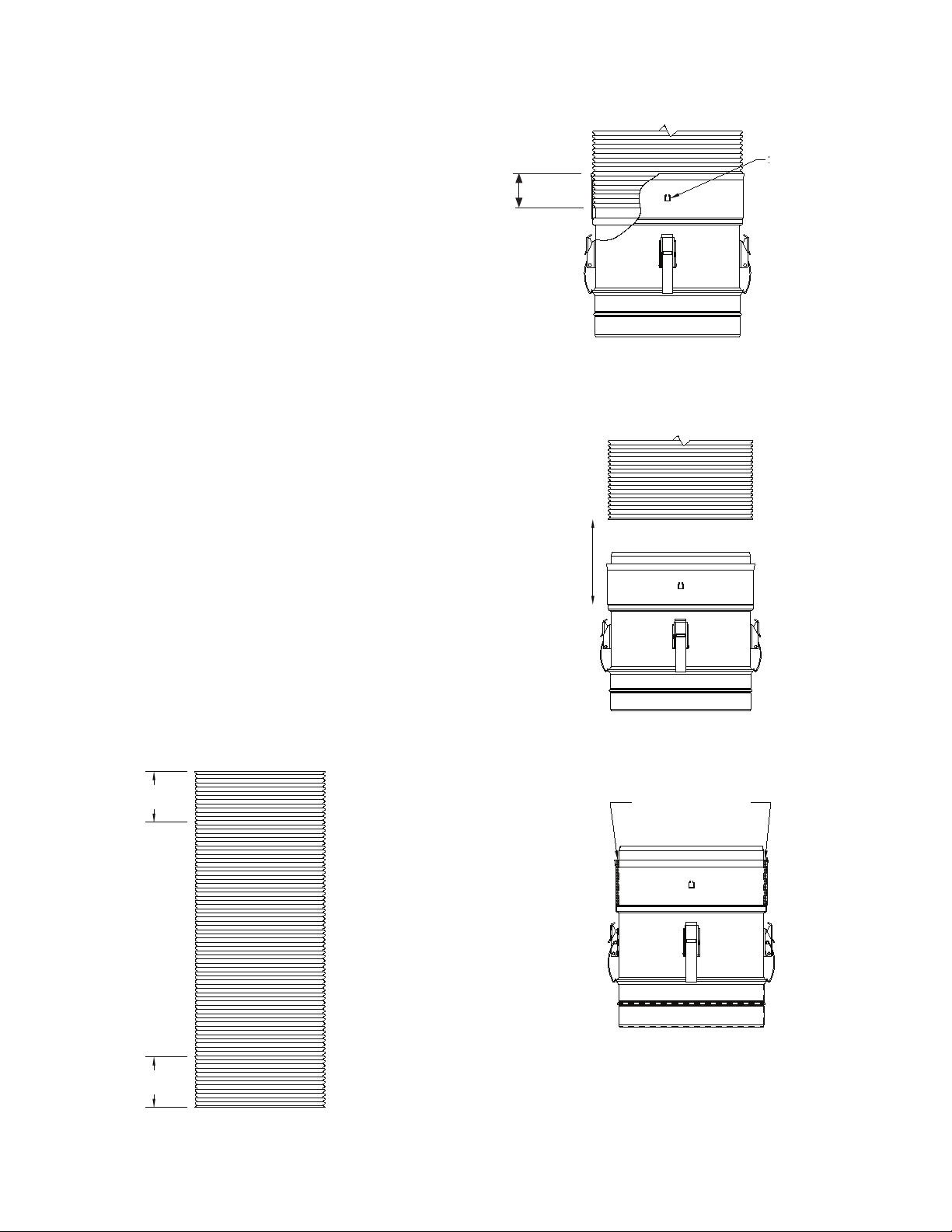

ADJUSTABLE LENGTH

For installations that requires non-standard vent lengths,

(AL) should be used.

The part consists of an inner conduit that slips into the downstream part and over the

upstream part, a collar holds the conduit in place and an outer shell (for double wall

only). See figure 11 for installation steps.

Note: The inner conduit may be cut to desired length to limit interference with downstream part.

DuraSeal

®

Adjustable Length

DuraSeal DS

1. Keep a play about

1/8” to 1/4” to

allow thermal

expansion

2. Apply a 1/8” to 1/4”

bead (may vary) of

Viton caulking to fill

the gap between the

adjustable length

inner wall and

the female end of

the standard part.

Please allow 24-36

hours for Viton to

cure.”

3. Slide the collar

down over the

female end of the

downstream part

and tighten the

collar

ADJUSTABLE LENGTH DS/DSD CAULKING REQUIREMENT

Inside diameter Qty (oz)

3” 0.2

4” 0.3

5” 0.4

6” 0.5

7” 0.6

8” 0.7

9” 0.8

10” 0.9

12” 1.0

14” 1.2

16” 1.4

18” 1.5

20” 1.7

22” 1.9

24” 2.1

Table 10

DuraSeal DSD

1. Keep a play about

1/8” to 1/4” to

allow thermal

expansion

2. Apply a 1/8” to 1/4”

bead (may vary) of

Viton caulking to fill

the gap between the

adjustable length

inner wall and

the female end of

the standard part.

Please allow 24-36

hours for Viton to

cure.

3. Slide the collar

down over the

female end of the

downstream part

and tighten the

clamp

4. Install the outer shell over end of

downstream part and under the

end of upstream part and tighten

the clamps. Need to cut outer

shell to correct length.

Figure 11 - Adjustable length installation steps

13

Page 14

DURASEAL FLEX

*IMPORTANT NOTE

When installing DuraSeal Flex, the direction of exhaust flow is always from the ap-

pliance. There is an arrow printed on each section of liner and component that will

point in the direction of the exhaust gas. If the inner liner is installed correctly the

proper direction can be determined by running your fingernails up the inside wall of

the liner. If the direction is correct, your nails will catch at the seams of the inner

wall. If it is incorrect, your nails will slide smoothly across the inner surface.

Attaching adapters to DURASEAL FLEX liner

1- The adapter without the latches is the Female Flex Adapter and designed for the

top of the flex liner. The Adapter with the latches and the black Viton O-ring is

the Male Flex Adapter and is designed for the bottom of the flex liner. If cutting

the liner on the field is required, make sure the cut is square.

2- Make a mark on both ends of liner at 1 5/8” from each end. (Figure 12a) That

mark will act as a reference point when the adapters are fully seated onto the flex

liner. (Figure 12b)

3- To be sure everything is right before putting the sealant between both tubes, do a

dry fit test by pushing the liner into the adapter until it reach the bottom between

the inner tube and the outer tube, then remove it. (Figure 13)

4- Add the sealant S-650 in the channel of the Male Flex Adapter. Put enough sealant

so the channel gap is evenly covered all around. (Figure 14)

Small cut / catch

1 5/8 min

1 7/8 MAX

Figure 12b - Flex Adapter small cut / catch

5- Push the adapter on the liner (the inner tube fits inside the liner and the outer tube

fits outside the liner) all the way in. (Figure 15)

6- Push the little natches. (Figure 16)

7- Repeat steps 3 through 6 for the other end with the female flex adapter or the flex

to flex adapter.

8- Before installation, cure for a minimum of 24 hours or follow the cure time called

out by the silicone manufacturer.

1 5/8”

Figure 13 - Flex Adapter dry fit test

apply sealant

1 5/8”

Figure 12a - DuraSeal Flex liner

14

Figure 14 - Flex Adapter apply sealant

Page 15

Figure 15 - Flex Adapter, seating flex

Small cut / catch

Push natches

Guy support (GS)

Figure 16 - Flex Adapter push natch to lock

BASIC DURASEAL FLEX LINER INSTALLATION

1- Determine the required location and opening in the masonry chimney. For a

basic DuraSeal Flex installation the opening must be large enough for the mortar

sleeve and Male Flex Adapter and the DuraSeal Flex to easily pass through. If a

Tee application is necessary, a larger hole may be required.

2- Make sure the DuraSeal Flex is supported at the bottom of the chimney. Refer to

Figure 10 for guiding and support installation in the masonry chimney.

3- The DuraSeal Flex liner must be installed from the top of the masonry chimney.

To prevent damage, one person should feed the liner through the chimney and

another person should pull the liner from the bottom. To ease the installation, you

can attach a rope to the DuraSeal Flex liner above the Male Flex Adapter. Doing

this will reduce the chance of breaking the seal between the DuraSeal Flex and

the Male Flex Adapter.

4- The DuraSeal Flex must stay within the masonry chimney; however the Elbow or

other DuraSeal components will extend beyond the masonry chimney. (Figure

16)

5- It is strongly recommended to use a drain between the Male Flex Adapter and the

appliance (refer to Condensate Drains section).

Figure 17 - Flex Adapter Elbow in masonry

MAINTENANCE INSTRUCTIONS

As with all vents, the DuraSeal vent system should be inspected at least annually for

the presence of deposits or debris and any accumulation should be removed. The vent

system should also be inspected at regular periods for signs of leakage of condensate

or combustion products at any joints.

If the vent system incorporates a drain hose from either a Drain length or a Drain tee

cap, the hose must be inspected periodically to ensure that water is in the trap loop.

If a proper trap loop is not maintained, exhaust from the connected appliances may

accumulate in the building area.

15

Page 16

DS, DSD / DSID DURASEAL® CHIMNEY LABELS

The labels supplied for product identification are shown here and indicates the flow of the flue gases in the venting system.

16

Page 17

DSD / DSID VENT LENGTHS

Ø

EFFECTIVE

Effective

length

Effective

length

Ø

3-5/8”

Ø

DSD & DSID Lengths

Ø

(in.)

3 to 24 6-5/8 DSDØL9 DSIDØL9

3 to 24 9-5/8 DSDØL12 DSIDØL12

3 to 24 15-5/8 DSDØL18 DSIDØL18

3 to 24 21-5/8 DSDØL24 DSIDØL24

3 to 24 33-5/8 DSDØL36 DSIDØL36

NOTE: DSID 9” and 24” not available.

Effective Length

(in.)

Product Code

DSD

Product Code

Figure 18

DSID

Effective

length

DSD & DSID Test Port Lengths

Ø

(in.)

3 to 24 6-5/8 DSDØTPL DSIDØTPL

Drain Ø4–Ø24, 1/4 NPT, 1/2 O.D.

NOTE: DSID 9” and 24” not available.

Effective Length

(in.)

Product Code

DSD

Product Code

DSID

Figure 20

Effective

Ø

DSD & DSID Drain Lengths

Ø (in.) Effective Length

(in.)

3 to 24 6-5/8 DSDØDL DSIDØDL 0.25

Drain Ø4–Ø10, 1/4 NPT, 1/2 O.D.

Drain 12–Ø24, 1/2 NPT, 5/8 O.D.

Product Code

DSD

Product Code

DSID

length

3-1/4”

K

Factor

Ø

DSD & DSID Adjustable Lengths

Ø

(in.)

3 to 24 3 to 5 DSDØAL9 DSIDØAL9

3 to 24 3 to 14 DSDØAL18 DSIDØAL18

NOTE: DSID 9” and 24” not available.

Effective Length

(in.)

Product Code

DSD

Product Code

Figure 19

DSID

NOTE: DSID 9” and 24” not available.

Figure 21

LENGTH

MAX

DSD Telescopic Lengths

Ø (in.) Effective Length (in.) Product Code

3 to 24 14 to 20 DSDØLAT20

3 to 24 20 to 32 DSDØLAT32

NOTE: Not available for DSID.

Figure 21a

17

Page 18

Plate for

actuator

DSD & DSID VENTING ELBOWS

Offset

Effective

length

Ø

DSD & DSID Damper Lengths

Ø

Effective Length

(in.)

3 to 24 15-5/8 DSDØDAMP DSIDØDAMP 0.60-9999

Figure 22

Cross Section View

Ø

(in.)

3 to 24 6-5/8 DSDØDAMPS DSIDØDAMPS 0 to 9999

(in.)

NOTE: DSID 9” and 24” not available.

DSD

& DSID

Effective Length

(in.)

Figure 23

Cross Section View

DSD

Ø

Effective Length

(in.)

3 to 24 5-7/8 DSDØVFR DSIDØVFR 0 to 9999

Figure 24

(in.)

NOTE: DSID 9” and 24” not available.

Product Code

DSD

6-5/8

Damper Length Short Manual

Product Code

DSD

NOTE: DSID 9” and 24” not available.

7-5/8

& DSID

Vent Flow Regulator

Product Code

DSD

Product Code

DSID

4

Product Code

DSID

4-3/4

Product Code

DSID

Factor

Ø INT.

Factor

Ø INT.

Factor

2º

Rise

Ø

DSD 2-Degree Elbow

Ø (in.) Offset (in.) Rise (in.) Product Code SSD K Factor

3 1/8 7-3/4 DSD3E2 .04

4 1/8 7-3/4 DSD4E2 .04

K

5 1/8 7-3/4 DSD5E2 .04

6 1/8 7-7/8 DSD6E2 .04

7 1/8 7-7/8 DSD7E2 .04

8 1/8 7-7/8 DSD8E2 .04

9 1/8 8 DSD9E2 .04

10 1/8 8 DSD10E2 .04

12 1/8 8 DSD12E2 .04

14 1/8 8-1/8 DSD14E2 .03

16 1/8 8-1/4 DSD16E2 .03

18 1/8 8-1/4 DSD18E2 .03

20 1/8 8-3/8 DSD20E2 .03

22 1/8 8-3/8 DSD22E2 .03

24 1/8 8-1/2 DSD24E2 .03

Figure 25

K

Ø (in.) Offset (in.) Rise (in.) Product Code SSID K Factor

3 1/8 7-3/4 DSID3E2 .04

4 1/8 7-3/4 DSID4E2 .04

5 1/8 7-3/4 DSID5E2 .04

6 1/8 7-7/8 DSID6E2 .04

7 1/8 7-7/8 DSID7E2 .04

8 1/8 7-7/8 DSID8E2 .04

9 N/A N/A N/A N/A

10 1/8 8 DSID10E2 .04

12 1/8 8 DSID12E2 .04

14 1/8 8-1/8 DSID14E2 .03

16 1/8 8-1/4 DSID16E2 .03

18 1/8 8-1/4 DSID18E2 .03

K

20 1/8 8-3/8 DSID20E2 .03

22 1-3/4 8-3/8 DSID22E2 .03

24 N/A N/A N/A N/A

Figure 26

DSID 2-Degree Elbow

NOTE: DSID 9” and 24” not available.

18

Page 19

Offset

Offset

15º

Ø

DSD 15-Degree Elbow

Ø (in.) Offset (in.) Rise (in.) Product Code SSD K Factor

3 1 8-3/4 DSD3E15 .31

4 1 8-3/4 DSD4E15 .31

5 1 8-3/4 DSD5E15 .30

6 1-1/8 9 DSD6E15 .30

7 1-1/8 9-3/8 DSD7E15 .29

8 1-1/4 9-5/8 DSD8E15 .29

9 1-1/4 9-7/8 DSD9E15 .28

10 1-1/4 10-1/8 DSD10E15 .28

12 1-3/8 10-5/8 DSD12E15 .27

14 1-3/8 11-1/8 DSD14E15 .27

16 1-1/2 11-5/8 DSD16E15 .26

18 1-1/2 12-1/8 DSD18E15 .26

20 1-5/8 12-5/8 DSD20E15 .26

22 1-5/8 13-1/4 DSD22E15 .26

24 1-3/4 13-3/4 DSD24E15UK .26

Figure 27

Rise

30º

Ø

DSD 30-Degree Elbow

Ø (in.) Offset (in.) Rise (in.) Product Code SSD

3 2-3/8 9-5/8 DSD3E30

4 2-3/8 9-5/8 DSD4E30

5 2-3/8 9-5/8 DSD5E30

6 2-5/8 10-1/8 DSD6E30

7 2-3/4 10-5/8 DSD7E30

8 2-7/8 11-1/8 DSD8E30

9 3 11-5/8 DSD9E30

10 3-1/8 12-1/8 DSD10E30

12 3-3/8 13-1/8 DSD12E30

14 3-5/8 14-1/8 DSD14E30

16 3-7/8 15-1/8 DSD16E30

18 4-1/8 16-1/8 DSD18E30

20 4-1/2 17-1/8 DSD20E30

22 4-3/4 18-1/8 DSD22E30

24 5 19-1/8 DSD24E30UK

Figure 29

Rise

K Factor

.61

.61

.60

.59

.58

.57

.56

.55

.54

.54

.53

.52

.52

.51

.51

DSID 15-Degree Elbow

Ø (in.) Offset (in.) Rise (in.) Product Code SSID K Factor

3

4

5

6

7

8

9

10

12

14

16

18

20

22

24

Figure 28

1-1/8 9 DSID3E15UK .31

1-1/8 9 DSID4E15UK .31

1-1/8 9-3/8 DSID5E15UK .30

1-1/4 9-5/8

1-1/4 9-7/8 DSID7E15UK .29

1-1/4 10-1/8 DSID8E15UK .29

N/A N/A N/A N/A

1-3/8 10-5/8 DSID10E15UK .28

1-3/8 11-1/8 DSID12E15UK .27

1-1/2 11-5/8 DSID14E15UK .27

1-1/2 12-1/8 DSID16E15UK .26

1-5/8 12-5/8 DSID18E15UK .26

1-5/8 13-1/4 DSID20E15UK .26

1-3/4 13-3/4 DSID22E15UK .26

N/A N/A N/A N/A

DSID6E15UK

NOTE: DSID 9” and 24” not available.

.30

DSID 30-Degree Elbow

Ø (in.) Offset (in.) Rise (in.) Product Code SSID K Factor

3 2-5/8 10-1/8 DSID3E30UK 0.61

4 2-5/8 10-1/8 DSID4E30UK 0.61

5 2-3/4 10-5/8 DSID5E30UK 0.60

6 2-7/8 11-1/8 DSID6E30UK 0.59

7 3 11-5/8 DSID7E30UK 0.58

8 3-1/8 12-1/8 DSID8E30UK 0.57

9 N/A N/A N/A N/A

10 3-3/8 13-1/8 DSID10E30UK 0.55

12 3-5/8 14-1/8 DSID12E30UK 0.54

14 3-7/8 15-1/8 DSID14E30UK 0.54

16 4-1/8 16-1/8 DSID16E30UK 0.53

18 4-1/2 17-1/8 DSID18E30UK 0.52

20 4-3/4 18-1/8 DSID20E30UK 0.52

22 5 19-1/8 DSID22E30UK 0.51

24 N/A N/A N/A N/A

Figure 30

NOTE: DSID 9” and 24” not available.

19

Page 20

45º

Offset

Offset

Ø

DSD 45-Degree Elbow

Ø (in.) Offset (in.) Rise (in.) Product Code SSD K Factor

3 3-7/8 10-1/8 DSD3E45 .26

4 3-7/8 10-1/8 DSD4E45 .26

5 3-7/8 10-1/8 DSD5E45 .22

6 4-1/4 10-7/8 DSD6E45 .17

7 4-1/2 11-1/2 DSD7E45 .16

8 4-7/8 12-1/4 DSD8E45 .14

9 5-1/8 13 DSD9E45 .13

10 5-3/8 13-5/8 DSD10E45 .12

12 6 15-1/8 DSD12E45 .11

14 6-5/8 16-1/2 DSD14E45 .11

16 7-1/8 17-7/8 DSD16E45 .10

18 7-3/4 19-3/8 DSD18E45 .09

20 8-3/8 20-3/4 DSD20E45 .08

22 8-7/8 22-1/8 DSD22E45 .08

24 9-1/2 23-5/8 DSD24E45 .08

Figure 31

Rise

88º

Ø

DSD 88-Degree Elbow

Ø (in.) Offset (in.) Rise (in.) Product Code SSD K Factor

3 8-3/8

4 8-3/8

5 8-3/8

6

7

8

9

10

12

14

16

18

20

22

24

9-1/4 10-1/4 DSD6E88

10-1/4 11-1/4 DSD7E88

11-1/4 12-1/4 DSD8E88

12-1/4 13-1/4 DSD9E88

13-1/8 14-1/4 DSD10E88

15-1/8 16-1/4 DSD12E88

20-7/8 22-1/4 DSD18E88

22-7/8 24-1/4 DSD20E88

24-3/4 26-1/4 DSD22E88

26-5/8 28-1/4 DSD24E88

17 18-1/4 DSD14E88

19 20-1/4 DSD16E88

9-1/4 DSD3E88

9-1/4 DSD4E88

9-1/4 DSD5E88

Figure 33

Rise

.54

.54

.48

.42

.39

.37

.34

.32

.29

.27

.25

.24

.23

.21

.20

DSID 45-Degree Elbow

Ø (in.) Offset (in.) Rise (in.) Product Code SSID K Factor

3

4

5

6

7

8

9 N/A N/A N/A N/A

10

12

14

16

18

20

22

24 N/A N/A N/A N/A

Figure 32

4-1/4 10-7/8 DSID3E45

4-1/4 10-7/8 DSID4E45

4-1/2 11-1/2 DSID5E45

4-7/8 12-1/4 DSID6E45

5-1/8 13 DSID7E45

5-3/8 13-5/8 DSID8E45

6 15-1/8 DSID10E45

6-5/8 16-1/2

7-1/8 17-7/8 DSID14E45

7-3/4 19-3/8 DSID16E45

8-3/8 20-3/4 DSID18E45

8-7/8 22-1/8 DSID20E45

9-1/2 23-5/8 DSID22E45

DSID12E45 0.11

NOTE: DSID 9” and 24” not available.

0.26

0.26

0.22

0.17

0.16

0.14

0.12

0.11

0.1

0.09

0.08

0.08

DSID 88-Degree Elbow

Ø (in.) Offset (in.) Rise (in.) Product Code

3

4

5

6

7

8

9 N/A N/A N/A N/A

10

12

14

16

18

20

22

24 N/A N/A N/A N/A

Figure 34

9-1/4 10-1/4 DSID3E88

9-1/4 10-1/4 DSID4E88

10-1/4 11-1/4 DSID5E88

11-1/4 12-1/4 DSID6E88

12-1/4 13-1/4 DSID7E88

13-1/8 14-1/4 DSID8E88

15-1/8 16-1/4 DSID10E88

17 18-1/4 DSID12E88

19 20-1/4 DSID14E88

20-7/8 22-1/4 DSID16E88

22-7/8 24-1/4 DSID18E88

24-3/4 26-1/4 DSID20E88

26-5/8 28-1/4 DSID22E88

NOTE: DSID 9” and 24” not available.

SSID

K Factor

0.54

0.54

0.48

0.42

0.39

0.37

0.32

0.29

0.27

0.25

0.24

0.23

0.21

20

Page 21

Offset

DSD & DSID VENTING TEES

Offset

90º

Ø

DSD 90-Degree Elbow

Ø (in.) Offset (in.) Rise (in.) Product Code SSD K Factor

3 8-1/2

4 8-1/2

5

6

7

8

9

10

12

14

16

18

20

22

24

8-1/2 9-1/8 DSD5E90 .48

9-1/2 10-1/8 DSD6E90 .42

10-1/2 11-1/8 DSD7E90 .39

11-1/2 12-1/8 DSD8E90 .37

12-1/2 13-1/8 DSD9E90 .34

13-1/2 14-1/8 DSD10E90 .32

15-1/2 16-1/8 DSD12E90 .29

17-1/2 18-1/8 DSD14E90 .27

19-1/2 20-1/8 DSD16E90 .25

21-1/2 22-1/8 DSD18E90 .24

23-1/2 24-1/8 DSD20E90 .23

25-1/2 26-1/8 DSD22E90 .21

27-1/2 28-1/8 DSD24E90 .20

9-1/8 DSD3E90 .54

9-1/8 DSD4E90 .54

Figure 35

DSID 90-Degree Elbow

Ø (in.) Offset (in.) Rise (in.) Product Code SSID

3

4

5

6

7

8

9 N/A N/A N/A N/A

10

12

14

16

18

20

22

24 N/A N/A N/A N/A

Figure 36

9-1/2 10-1/8 DSID3E90 .54

9-1/2 10-1/8 DSID4E90 .54

10-1/2 11-1/8 DSID5E90 .48

11-1/2 12-1/8 DSID6E90 .42

12-1/2 13-1/8 DSID7E90 .39

13-1/2 14-1/8 DSID8E90 .37

15-1/2 16-1/8 DSID10E90 .32

17-1/2 18-1/8 DSID12E90 .29

19-1/2 20-1/8 DSID14E90 .27

21-1/2 22-1/8 DSID16E90 .25

23-1/2 24-1/8 DSID18E90 .24

25-1/2 26-1/8 DSID20E90 .23

27-1/2 28-1/8 DSID22E90 .21

NOTE: DSID 9” and 24” not available.

K Factor

Rise

Rise

Height

43º

Ø

DSD 43-Degree Tee

Ø (in.) Height (in.) Offset (in.) Rise (in.) Product Code K Factor

3

16-1/2 8-1/4 13-3/8 DSD3T43 0.4

4

16-1/2 8-1/4 13-3/8 DSD4T43 0.4

5

18-1/2 8-7/8 14-3/8 DSD5T43 0.4

6

19-1/2 9-5/8 15-3/8 DSD6T43 0.4

7

20-1/2 10-1/4 16-1/4 DSD7T43 0.4

8

22-1/2 11-5/8 18 DSD8T43 0.4

9

23-1/2 12-1/4 18-7/8 DSD9T43 0.4

10

12

14

16

18

20

22

24

Available with smaller snout and custom height.

25-1/2 13 19-3/4 DSD10T43 0.4

28-1/2 15 22-3/8 DSD12T43 0.4

31-1/2 16-3/8 24-1/4 DSD14T43 0.4

33-1/2 18-1/2 26-1/4 DSD16T43 0.4

38-1/4 20-1/2 29-3/8 DSD18T43 0.4

42-1/4 23-7/8 33-1/2 DSD20T43 0.4

45-1/4 23-7/8 33-7/8 DSD22T43 0.4

51-1/4 27-7/8 38-1/2 DSD24T43 0.4

Figure 37

DSID 43-Degree Tee

Ø (in.)

Height (in.)

3

19-1/2 9-5/8 15-3/8 DSID3T43 0.4

4

19-1/2 9-5/8 15-3/8 DSID4T43 0.4

5

20-1/2 10-1/4 16-1/4 DSID5T43 0.4

6

22-1/2 11-5/8 18 DSID6T43 0.4

7

23-1/2 12-1/4 18-7/8 DSID7T43 0.4

8

25-1/2 13 19-3/4 DSID8T43 0.4

9

10

12

14

16

18

20

22

24

Available with smaller snout and custom height.

N/A N/A N/A N/A N/A

28-1/2 15 22-3/8 DSID10T43 0.4

31-1/2 16-3/8 24-1/4 DSID12T43 0.4

33-1/2 18-1/2 26-1/4 DSID14T43 0.4

38-1/4 20-1/2 29-3/8 DSID16T43 0.4

42-1/4 23-7/8 33-1/2 DSID18T43 0.4

45-1/4 23-7/8 33-7/8 DSID20T43 0.4

51-1/4 27-7/8 38-1/2 DSID22T43 0.4

N/A N/A N/A N/A N/A

Figure 38

Offset (in.) Rise (in.) Product Code

NOTE: DSID 9” and 24” not available.

K Factor

21

Page 22

Offset

Offset

Rise

Height

45º

Ø

DSD 45-Degree Tee

Ø (in.) Height (in.) Offset (in.) Rise (in.) Product Code K Factor

3

4

5

6

7

8

9

10

12

14

16

18

20

22

24

Available with smaller snout and custom height.

16-1/2 8-1/4 13-1/4 DSD3T45 .04

16-1/2 8-1/4 13-1/4 DSD4T45 .04

18-1/2 9-1/4 14-1/8 DSD5T45 .04

19-1/2 9-7/8 15-1/8 DSD6T45 .04

20-1/2 10-5/8 16 DSD7T45 .04

22-1/2 12 17-5/8 DSD8T45 .04

23-1/2 12-3/4 18-1/2 DSD9T45 .04

25-1/2 13-1/2 19-1/2 DSD10T45 .04

28-1/2 15-5/8 22 DSD12T45 .04

31-1/2 17 23-7/8 DSD14T45 .04

33-1/2 19-1/8 26-3/8 DSD16T45 .04

38-1/4 21-1/4 28-7/8 DSD18T45 .04

42-1/4 24-3/4 32-7/8 DSD20T45 .04

45-1/4 24-3/4 33-1/4 DSD22T45 .04

51-1/4 28-7/8 37-3/4 DSD24T45 .04

Rise

Height

88º

Ø

DSD 88-Degree Tee

Ø (in.) Height (in.) Offset (in.) Rise (in.) Product Code K Factor

3

4

5

6

7

8

9

10

12

14

16

18

20

22

24

Available with smaller snout and custom height.

13-1/2 7 6-5/8 DSD3T88 1.21

13-1/2 7 6-5/8 DSD4T88 1.21

14-1/2 8 7-1/4 DSD5T88 1.21

15-1/2 8 7-5/8 DSD6T88 1.21

16-1/2 9 8-1/4 DSD7T88 1.21

17-1/2 9 8-5/8 DSD8T88 1.21

18-1/2 10 9-1/4 DSD9T88 1.21

19-1/2 10 9-5/8 DSD10T88 1.21

21-1/2 11 10-5/8 DSD12T88 1.21

23-1/2 12 11-5/8 DSD14T88 1.21

25-1/2 13 12-5/8 DSD16T88 1.21

27-1/2 14 13-5/8 DSD18T88 1.21

29-1/2 15 14-5/8 DSD20T88 1.21

31-1/2 16 15-5/8 DSD22T88 1.21

33-1/2 17 16-5/8 DSD24T88 1.21

Figure 39

DSID 45-Degree Tee

Ø (in.) Height (in.) Offset (in.) Rise (in.) Product Code K Factor

3

4

5

6

7

8

9

10

12

14

16

18

20

22

24

Available with smaller snout and custom height.

19-1/2 9-7/8 15-1/8 DSID3T45 .04

19-1/2 9-7/8 15-1/8 DSID4T45 .04

20-1/2 10-5/8 16 DSID5T45 .04

22-1/2 12 17-5/8 DSID6T45 .04

23-1/2 12-3/4 18-1/2 DSID7T45 .04

25-1/2 13-1/2 19-1/2 DSID8T45 .04

N/A N/A N/A N/A N/A

28-1/2 15-5/8 22 DSID10T45 .04

31-1/2 17 23-7/8 DSID12T45 .04

33-1/2 19-1/8 26-3/8 DSID14T45 .04

38-1/4 21-1/4 28-7/8 DSID16T45 .04

42-1/4 24-3/4 32-7/8 DSID18T45 .04

45-1/4 24-3/4 33-1/4 DSID20T45 .04

51-1/4 28-7/8 37-3/4 DSID22T45 .04

N/A N/A N/A N/A N/A

Figure 41

DSID 88-Degree Tee

Ø (in.) Height (in.) Offset (in.) Rise (in.) Product Code

3

4

5

6

7

8

9

10

12

14

16

18

20

22

24

Available with smaller snout and custom height.

15-1/2 8 7-5/8 DSID3T88 1.21

15-1/2 8 7-5/8 DSID4T88 1.21

16-1/2 9 8-1/4 DSID5T88 1.21

17-1/2 9 8-5/8 DSID6T88 1.21

18-1/2 10 9-1/4 DSID7T88 1.21

19-1/2 10 9-5/8 DSID8T88 1.21

N/A N/A N/A N/A N/A

21-1/2 11 10-5/8 DSID10T88 1.21

23-1/2 12 11-5/8 DSID12T88 1.21

25-1/2 13 12-5/8 DSID14T88 1.21

27-1/2 14 13-5/8 DSID16T88 1.21

29-1/2 15 14-5/8 DSID18T88 1.21

31-1/2 16 15-5/8 DSID20T88 1.21

33-1/2 17 16-5/8 DSID22T88 1.21

N/A N/A N/A N/A N/A

K Factor

Figure 40

22

NOTE: DSID 9” and 24” not available.

Figure 42

NOTE: DSID 9” and 24” not available.

Page 23

Offset

Rise

Height

90º

Ø

DSD 90-Degree Tee

Ø (in.) Height (in.) Offset (in.) Rise (in.) Product Code K Factor

3

4

5

6

7

8

9

10

12

14

16

18

20

22

24

Available with smaller snout and custom height.

13-1/2 7 6-1/2 DSD3T90 1.21

13-1/2 7 6-1/2 DSD4T90 1.21

14-1/2 8 7 DSD5T90 1.21

15-1/2 8 7-1/2 DSD6T90 1.21

16-1/2 9 8 DSD7T90 1.21

17-1/2 9 8-1/2 DSD8T90 1.21

18-1/2 10 9 DSD9T90 1.21

19-1/2 10 9-1/2 DSD10T90 1.21

21-1/2 11 10-1/2 DSD12T90 1.21

23-1/2 12 11-1/2 DSD14T90 1.21

25-1/2 13 12-1/2 DSD16T90 1.21

27-1/2 14 13-1/2 DSD18T90 1.21

29-1/2 15 14-1/2 DSD20T90 1.21

31-1/2 16 15-1/2 DSD22T90 1.21

33-1/2 17 16-1/2 DSD24T90 1.21

Offset

45º

Ø

SSD 90-Degree Tee Y

Ø (in.) Offset (in.) Rise (in.) Product Code K Factor

3

4

5

6

7

8

9

10

12

14

16

18

20

22

24

Available with smaller snout.

5 10-3/8 DSD3TY90 0.6

5 10-3/8 DSD4TY90 0.6

5-5/8 11-1/8 DSD5TY90 0.6

5-5/8 11-1/8 DSD6TY90 0.6

6-3/8 11-3/4 DSD7TY90 0.6

6-3/8 11-3/4 DSD8TY90 0.6

7-1/8 13-1/2 DSD9TY90 0.6

7-1/8 13-1/2 DSD10TY90 0.6

7-3/4 14-1/4 DSD12TY90 0.6

8-1/2 15-7/8 DSD14TY90 0.6

9-1/4 17-5/8 DSD16TY90 0.6

9-7/8 18-3/8 DSD18TY90 0.6

10-5/8 21 DSD20TY90 0.6

11-3/8 21-3/4 DSD22TY90 0.6

12 22-1/2 DSD24TY90 0.6

Rise

Figure 43

DSID 90-Degree Tee

Ø (in.)

Available with smaller snout and custom height.

3

4

5

6

7

8

9

10

12

14

16

18

20

22

24

Height (in.)

15-1/2 8 7-1/2 DSID3T90 1.21

15-1/2 8 7-1/2 DSID4T90 1.21

16-1/2 9 8 DSID5T90 1.21

17-1/2 9 8-1/2 DSID6T90 1.21

18-1/2 10 9 DSID7T90 1.21

19-1/2 10 9-1/2 DSID8T90 1.21

N/A N/A N/A N/A N/A

21-1/2 11 10-1/2 DSID10T90 1.21

23-1/2 12 11-1/2 DSID12T90 1.21

25-1/2 13 12-1/2 DSID14T90 1.21

27-1/2 14 13-1/2 DSID16T90 1.21

29-1/2 15 14-1/2 DSID18T90 1.21

31-1/2 16 15-1/2 DSID20T90 1.21

33-1/2 17 16-1/2 DSID22T90 1.21

N/A N/A N/A N/A N/A

Figure 44

Offset (in.) Rise (in.) Product Code

NOTE: DSID 9” and 24” not available.

K Factor

Figure 45

DSID 90-Degree Tee Y

Ø (in.) Offset (in.) Rise (in.) Product Code K Factor

3

4

5

6

7

8

9

10

12

14

16

18

20

22

24

Available with smaller snout.

Figure 46

5-5/8 11-1/8 DSID3TY90 0.6

5-5/8 11-1/8 DSID4TY90 0.6

6-3/8 11-3/4 DSID5TY90 0.6

6-3/8 11-3/4 DSID6TY90 0.6

7-1/8 13-1/2 DSID7TY90 0.6

7-1/8 13-1/2 DSID8TY90 0.6

N/A N/A N/A N/A

7-3/4 14-1/4 DSID10TY90 0.6

8-1/2 15-7/8 DSID12TY90 0.6

9-1/4 17-5/8 DSID14TY90 0.6

9-7/8 18-3/8 DSID16TY90 0.6

10-5/8 21 DSID18TY90 0.6

11-3/8 21-3/4 DSID20TY90 0.6

12 22-1/2 DSID22TY90 0.6

N/A N/A N/A N/A

NOTE: DSID 9” and 24” not available.

23

Page 24

Offset

Offset

Offset

Offset

Height

4 to 8

DSD Lateral Tee

Ø (in.)

Available with smaller snout and custom height.

Height

3

4

5

6

7

8

9

10

12

14

16

18

20

22

24

14-3/8 11-5/8 10 DSD3BT 0.55

14-3/8 11-5/8 10 DSD4BT 0.55

16-3/8 12-1/4 11 DSD5BT 0.55

17-3/8 13-3/4 12-1/4 DSD6BT 0.55

19-3/8 14-3/4 13-1/4 DSD7BT 0.55

20-3/8 16 14-3/8 DSD8BT 0.55

23-3/8 14-1/4 14-1/4 DSD9BT 0.55

25-3/8 15-1/4 15-1/4 DSD10BT 0.55

27-3/8 16-7/8 17 DSD12BT 0.55

30-3/8 18-7/8 18-7/8 DSD14BT 0.55

33-3/8 20-3/4 20-3/4 DSD16BT 0.55

38-1/8 22-1/2 22-1/2 DSD18BT 0.55

42-1/8 24-3/8 24-3/8 DSD20BT 0.55

45-1/8 26-1/4 26-1/4 DSD22BT 0.55

51-1/8 28 28-1/8 DSD24BT 0.55

Offset (in.) Rise (in.) Product Code K Factor

(in.)

Figure 47

Rise

Height

9 to 24

Rise

Height

DSD Lateral Tee 88-Degree

Ø (in.)

Height

3

14-3/8 11-5/8 10-1/4 DSD3BT88 0.55

4

14-3/8 11-5/8 10-1/4 DSD4BT88 0.55

5

16-3/8 12-1/4 11-3/8 DSD5BT88 0.55

6

17-1/2 13-3/4 12-3/4 DSD6BT88 0.55

7

19-3/8 14-7/8 13-3/4 DSD7BT88 0.55

8

20-3/8 16-1/8 15 DSD8BT88 0.55

9

23-3/8 14-1/2 15-1/4 DSD9BT88 0.55

10

12

14

16

18

20

22

24

Available with smaller snout and custom height.

25-3/8 15-3/8 16-1/8 DSD10BT88 0.55

28-3/8 17 17-7/8 DSD12BT88 0.55

31-3/8 19-1/8 20-1/8 DSD14BT88 0.55

33-3/8 21 22 DSD16BT88 0.55

38-3/8 22-7/8 24 DSD18BT88 0.55

42-1/8 24-3/4 26 DSD20BT88 0.55

45-1/8 26-5/8 28 DSD22BT88 0.55

51-1/8 28-1/2 29-7/8 DSD24BT88 0.55

Offset (in.) Rise (in.) Product Code K Factor

(in.)

Figure 49

4 to 8

Rise

Rise

Height

9 to 24

DSID Lateral Tee

Ø (in.)

Available with smaller snout and custom height.

Height

3

17-3/8 13-3/4 12-1/4 DSID3BT 0.55

4

17-3/8 13-3/4 12-1/4 DSID4BT 0.55

5

19-3/8 14-3/4 13-1/4 DSID5BT 0.55

6

20-3/8 16 14-3/8 DSID6BT 0.55

7

23-3/8 14-1/4 14-1/4 DSID7BT 0.55

8

25-3/8 15-1/4 15-1/4 DSID8BT 0.55

9

10

12

14

16

18

20

22

24

N/A N/A N/A N/A N/A

27-3/8 16-7/8 17 DSID10BT 0.55

30-3/8 18-7/8 18-7/8 DSID12BT 0.55

33-3/8 20-3/4 20-3/4 DSID14BT 0.55

38-1/8 22-1/2 22-1/2 DSID16BT 0.55

42-1/8 24-3/4 24-3/8 DSID18BT 0.55

45-1/8 26-1/4 26-1/4 DSID20BT 0.55

51-1/8 28 28-1/8 DSID22BT 0.55

N/A N/A N/A N/A N/A

Figure 48

Offset (in.) Rise (in.) Product Code K Factor

(in.)

NOTE: DSID 9” and 24” not available.

DSID Lateral Tee 88-Degree

Ø (in.)

Height

3

17-1/2 13-3/4 12-3/4 DSID3BT88 0.55

4

17-1/2 13-3/4 12-3/4 DSID4BT88 0.55

5

19-3/8 14-7/8 13-3/4 DSID5BT88 0.55

6

20-3/8 16-1/8 15 DSID6BT88 0.55

7

23-3/8 14-1/2 15-1/4 DSID7BT88 0.55

8

25-3/8 15-3/8 16-1/8 DSID8BT88 0.55

9

10

12

14

16

18

20

22

24

Available with smaller snout and custom height.

N/A N/A N/A N/A N/A

28-3/8 17 17-7/8 DSID10BT88 0.55

31-3/8 19-1/8 20-1/8 DSID12BT88 0.55

33-3/8 21 22 DSID14BT88 0.55

38-3/8 22-7/8 24 DSID16BT88 0.55

42-1/8 24-3/4 26 DSID18BT88 0.55

45-1/8 26-5/8 28 DSID20BT88 0.55

51-1/8 28-1/2 29-7/8 DSID22BT88 0.55

N/A N/A N/A N/A N/A

Figure 50

Offset (in.) Rise (in.) Product Code K Factor

(in.)

NOTE: DSID 9” and 24” not available.

24

Page 25

Offset

DSD Barometric Tee

Ø (in.)

Height

3

4

5

6

7

8

9

10

12

14

16

18

20

22

24

Available with smaller snout and custom height.

13-1/2 5 6-1/2 DSD3BMT

13-1/2 5 6-1/2 DSD4BMT

14-1/2 5 7 DSD5BMT

15-1/2 6 7-1/2 DSD6BMT

16-1/2 7 8 DSD7BMT

17-1/2 8 8-1/2 DSD8BMT

18-1/2 9 9 DSD9BMT

19-1/2 10 9-1/2 DSD10BMT

21-1/2 12 10-1/2 DSD12BMT

23-1/2 14 11-1/2 DSD14BMT

25-1/2 16 12-1/2 DSD16BMT

27-1/2 18 13-1/2 DSD18BMT

29-1/2 20 14-1/2 DSD20BMT

31-1/2 22 15-1/2 DSD22BMT

33-1/2 24 16-1/2 DSD24BMT

Offset (in.) Rise (in.) Product Code K Factor

(in.)

Figure 51

DSID Barometric Tee

Ø (in.)

Height

3

4

5

6

7

8

9

10

12

14

16

18

20

22

24

Available with smaller snout and custom height.

15-1/2 6 7-1/2 DSID3BMT

15-1/2 6 7-1/2 DSID4BMT

16-1/2 7 8 DSID5BMT

17-1/2 8 8-1/2 DSID6BMT

18-1/2 9 9 DSID7BMT

19-1/2 10 9-1/2 DSID8BMT

N/A N/A N/A N/A N/A

21-1/2 12 10-1/2 DSID10BMT

23-1/2 14 11-1/2 DSID12BMT

25-1/2 16 12-1/2 DSID14BMT

27-1/2 18 13-1/2 DSID16BMT

29-1/2 20 14-1/2 DSID18BMT

31-1/2 22 15-1/2 DSID20BMT

33-1/2 24 16-1/2 DSID22BMT

N/A N/A N/A N/A N/A

Figure 52

Offset (in.) Rise (in.) Product Code K Factor

(in.)

NOTE: DSID 9” and 24” not available.

Height

Rise

Ø

4-1/8

Ø

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

Ø (in.)

3 to 24

Height

Figure 53

Ø (in.)

3 to 24

Drain Ø4 – Ø10, 1/4 NPT, 1/2 0.D

Drain Ø12 – Ø24, 3/8 NPT, 5/8 0.D

Height

DSD & DSID Tee Cap

(in.)

4-1/8 DSDØTC DSIDØTC

Product Code DSD Product Code DSID

Ø

Drain NPT

DSD & DSID Drain Tee Cap

(in.)

4-1/8 DSDØDTC DSIDØDTC

Product Code DSD Product Code DSID

3-3/4

Figure 54

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

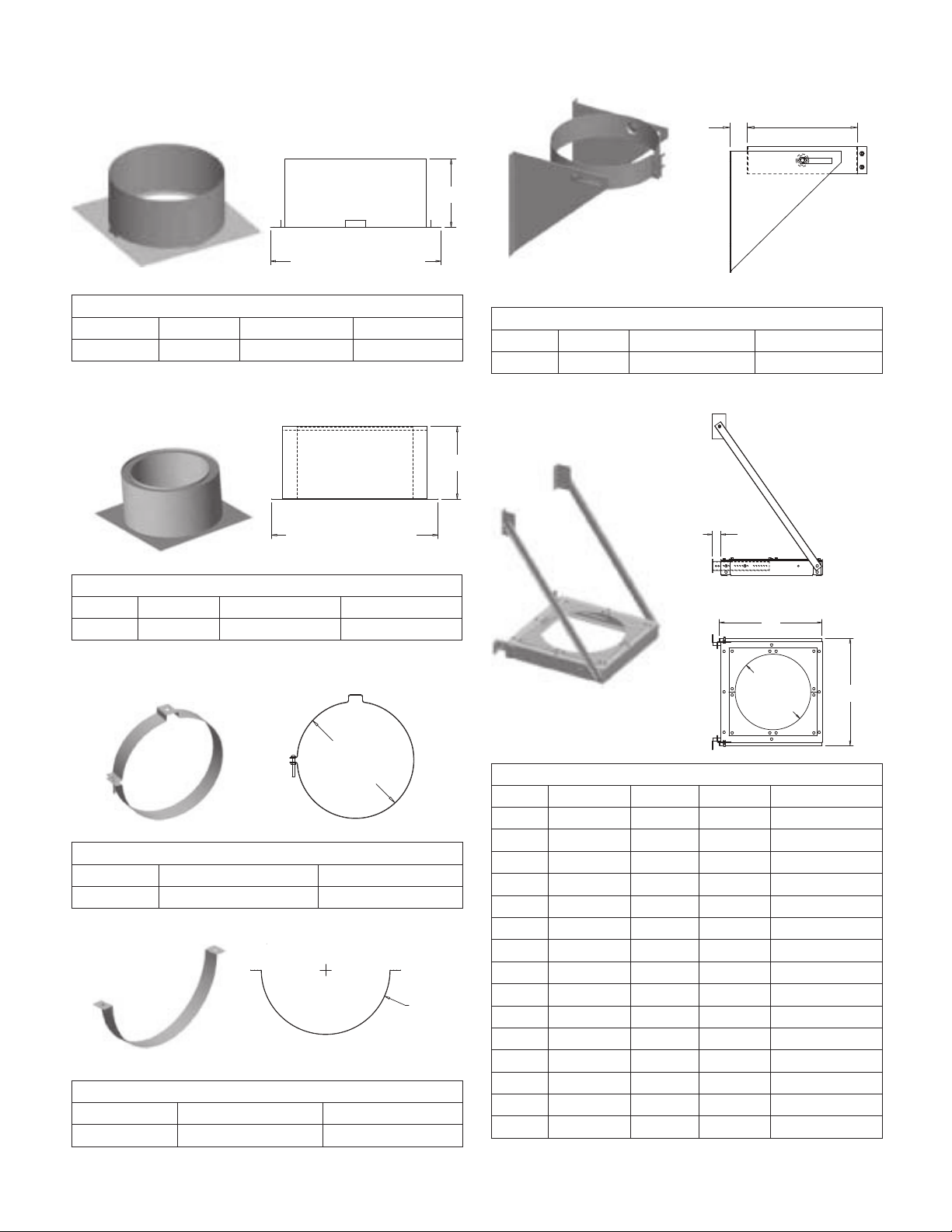

SSD & SSID VENTING ACCESSORIES

ØB

Height

Ø

DSD & DSID Tapered Increaser

Ø (in.) ØB

Available

(in.)

3 to 9 Ø+1 12-1/8 DSDØTIN(ØB) DSIDØTIN(ØB) 0.05

3 to 22 Ø+2 13-1/8 DSDØTIN(ØB) DSIDØTIN(ØB) 0.10

3 to 9 Ø+3 14-1/8 DSDØTIN(ØB) DSIDØTIN(ØB) 0.15

3 to 20 Ø+4 15-1/8 DSDØTIN(ØB) DSIDØTIN(ØB) 0.20

3 to 7 Ø+5 16-1/8 DSDØTIN(ØB) DSIDØTIN(ØB) 0.25

3 to 18 Ø+6 17-1/8 DSDØTIN(ØB) DSIDØTIN(ØB) 0.30

Figure 55

Height

(in.)

NOTE: DSID 9” and 24” not available.

Product Code

DSD

Product Code

DSID

Factor

K

25

Page 26

ØB

Ø

ØB

Height

Height

DSD & DSID Step Increaser

Ø

ØB Available

(in.)

3 to 22 5 to 24 8 DSDØSIN(ØB) DSIDØSIN(ØB)

(in.)

Figure 56

Height

(in.)

Product Code

DSD

Product Code

NOTE: DSID 9” and 24” not available.

DSID

ØB

Offset

Ø

DSD & DSID Eccentric Tapered Increaser

Ø (in.) ØB

Available

3 to 9 Ø+1 12-1/2 1/2 DSDØETIN(ØB) DSIDØETIN(ØB)

3 to 22 Ø+2 13-1/2 1 DSDØETIN(ØB) DSIDØETIN(ØB)

3 to 9 Ø+3 14-1/2 1-1/2 DSDØETIN(ØB) DSIDØETIN(ØB)

3 to 20 Ø+4 15-1/2 2 DSDØETIN(ØB) DSIDØETIN(ØB)

3 to 7 Ø+5 16-1/2 2-1/2 DSDØETIN(ØB) DSIDØETIN(ØB)

3 to 18 Ø+6 17-1/2 3 DSDØETIN(ØB) DSIDØETIN(ØB)

Figure 57

Height

Offset

(in.)

(in.)

(in.)

NOTE: DSID 9” and 24” not available.

Product Code

DSD

Product Code

DSID

ØB

Offset

K

Factor

KØ = (1-β

KØB = KØ/β

β = Ø/ØB

Height

Factor

0.05

0.10

0.15

0.20

0.25

0.30

Ø

2)2

4

Ø (in.) ØB

Available

(in.)

5 to 10 Ø-1 12-7/16 DSDØTRD(ØB) DSIDØTRD(ØB)

6 to 24 Ø-2 13-7/16 DSDØTRD(ØB) DSIDØTRD(ØB)

6 to 12 Ø-3 14-7/16 DSDØTRD(ØB) DSIDØTRD(ØB)

8 to 24 Ø-4 15-7/16 DSDØTRD(ØB) DSIDØTRD(ØB)

9 to 24 Ø-5 16-7/16 DSDØTRD(ØB) DSIDØTRD(ØB)

10 to 24 Ø-6 17-7/16 DSDØTRD(ØB) DSIDØTRD(ØB)

Figure 59

DSD & DSID Tapered Reducer

Height

(in.)

Product Code

DSD

Product Code

NOTE: DSID 9” and 24” not available.

DSID

K

Factor

0.07

0.09

0.11

0.13

0.15

0.17

ØB

K

Height

Ø

DSD & DSID Step Reducer

Ø (in.) ØB

Available

5 to 24 3 to 22 8 DSDØSRD(ØB) DSIDØSRD(ØB)

Figure 60

Height

(in.)

(in.)

Product Code

DSD

NOTE: DSID 9” and 24” not available.

Product Code

DSID

K Factor

KØB = 0.5 (1-β2)

KØ = KØB/β

β = ØB/Ø

4

Ø

DSD & DSID Eccentric Step Increaser

Ø

(in.)ØBAvailable

3 to 22 5 to 24 8 (ØB-ØA)/2 DSDØESIN(ØB) DSIDØESIN(ØB)

Figure 58

Height

Offset

(in.)

(in.)

(in.)

NOTE: DSID 9” and 24” not available.

Product Code

DSD

Product Code

DSID

26

Height

K

Factor

KØ = (1-β2)

KØB = KØ/β

β = Ø/ØB

2

4

Page 27

ØB

Offset

Ø

DSD

& DSID

Eccentric Tapered Reducer

Ø

(in.)ØBAvailable

5 to 10 Ø-1 12-1/2 1/2 DSDØETRD(ØB) DSIDØETRD(ØB)

6 to 24 Ø-2 13-1/2 1 DSDØETRD(ØB) DSIDØETRD(ØB)

6 to 12 Ø-3 14-1/2 1-1/2 DSDØETRD(ØB) DSIDØETRD(ØB)

8 to 24 Ø-4 15-1/2 2 DSDØETRD(ØB) DSIDØETRD(ØB)

9 to 24 Ø-5 16-1/2 2-1/2 DSDØETRD(ØB) DSIDØETRD(ØB)

10 to 24 Ø-6 17-1/2 3 DSDØETRD(ØB) DSIDØETRD(ØB)

(in.)

Height

(in.)

Offset

(in.)

Product Code

DSD

Product Code

DSID

K

Factor

0.07

0.09

0.11

0.13

0.15

0.17

Height

Width

DSD & DSID Wall Thimble

Ø (in.) Width (in.) Product Code DSD Product Code DSID

3 to 24

Figure 63

9 to 17 DSDØWT DSIDØWT

NOTE: DSID 9” and 24” not available.

DSD Ø + Clearance + 5

DSID Ø + Clearance + 7

Figure 61

NOTE: DSID 9” and 24” not available.

ØB

Offset

Ø

DSD

& DSID

Eccentric Step Reducer

Ø (in.) ØB Available (in.) Height (in.) Offset (in.)

5 to 24 3 to 22 8 (ØA-ØB)/2

Product Code DSD Product Code DSID K Factor

DSDØESRD(ØB) DSIDØESRD(ØB)

Figure 62

NOTE: DSID 9” and 24” not available.

KØB = 0.5 (1-

KØ = KØB/

4

=ØB/Ø

DSD Ø + Clearance +9

DSID Ø + Clearance +11

Width

Height

DSD & DSID Wall Thimble Insulated

Ø (in.) Width (in.) Product Code DSD Product Code DSID

3 to 24

Figure 64

2

)

9 to 17 DSDØWTI DSIDØWTI

NOTE: DSID 9” and 24” not available.

27

Page 28

DSD Ø + Clearance + 5

DSID Ø + Clearance + 7

DSD Ø + 2

DSID Ø + 4

A

10

DSD & DSID Roof Thimble

Ø (in.) Width (in.) Product Code DSD Product Code DSID

3 to 24

Figure 65

10 DSDØRT DSIDØRT

NOTE: DSID 9” and 24” not available.

DSD Ø + Clearance +5

DSID Ø + Clearance +7

DSD & DSID Roof Thimble Insulated

Ø (in.) Width (in.) Product Code DSD Product Code DSID

3 to 24

Figure 66

10 DSDØRTI DSIDØRTI

NOTE: DSID 9” and 24” not available.

SSD Ø+2

SSID Ø+4

10

DSD & DSID Wall Support

Ø (in.) A (in.) Product Code DSD Product Code DSID

3 to 24

Figure 69

1 to 3 DSDØWS DSIDØWS

NOTE: DSID 9” and 24” not available.

A

B

DSD Ø+2

DSID Ø+4

C

DSD & DSID Suspension Band

Ø (in.) Product Code DSD Product Code DSID

3 to 24

Figure 67

Ø (in.) Product Code DSD Product Code DSID

3 to 24

Figure 68

DSDØSB DSIDØSB

NOTE: DSID 9” and 24” not available.

DSD & DSID Cradle Support

DSDØCS DSIDØCS

NOTE: DSID 9” and 24” not available.

28

SSD Ø+2

SSID Ø+4

DSD Wall Suort HD

Ø (in.) A (in.) B (in.) C (in.) roduct Code

3 1-1/2 to 6-1/2 9 12 DSD3WSHD

4 1-1/2 to 6-1/2 9 12 DSD4WSHD

5 1-1/2 to 6-1/2 10 12 DSD5WSHD

6 1-1/2 to 6-1/2 11 12 DSD6WSHD

7 1-1/2 to 6-1/2 12 14 DSD7WSHD

8 1-1/2 to 6-1/2 13 14 DSD8WSHD

9 1-1/2 to 6-1/2 14 14 DSD9WSHD

10 1-1/2 to 6-1/2 15 16 DSD10WSHD

12 1-1/2 to 6-1/2 17 16 DSD12WSHD

14 1-1/2 to 6-1/2 19 22 DSD14WSHD

16 1-1/2 to 6-1/2 21 22 DSD16WSHD

18 1-1/2 to 6-1/2 23 26 DSD18WSHD

20 1-1/2 to 6-1/2 25 30 DSD20WSHD

22 1-1/2 to 6-1/2 27 30 DSD22WSHD

24 1-1/2 to 6-1/2 29 30 DSD24WSHD

Figure 70

Page 29

A

A

B

DSD Ø+2

DSID Ø+4

DSID Wall Support HD

Ø (in.) A (in.) B (in.) C (in.) Product Code

3 1-1/2 to 6-1/2 11 12 DSID3WSHD

4 1-1/2 to 6-1/2 11 12 DSID4WSHD

5 1-1/2 to 6-1/2 12 14 DSID5WSHD

6 1-1/2 to 6-1/2 13 14 DSID6WSHD

7 1-1/2 to 6-1/2 14 14 DSID7WSHD

8 1-1/2 to 6-1/2 15 16 DSID8WSHD

9 N/A N/A N/A N/A

10 1-1/2 to 6-1/2 17 16 DSID10WSHD

12 1-1/2 to 6-1/2 19 22 DSID12WSHD

14 1-1/2 to 6-1/2 21 22 DSID14WSHD

16 1-1/2 to 6-1/2 23 26 DSID16WSHD

18 1-1/2 to 6-1/2 25 30 DSID18WSHD

20 1-1/2 to 6-1/2 27 30 DSID20WSHD

22 1-1/2 to 6-1/2 29 30 DSID22WSHD

24 N/A N/A N/A N/A

Figure 71

NOTE: DSID 9” and 24” not available.

B

DSD Ø+2

DSID Ø+4

A

DSD & DSID Roof Support

Ø (in.) A (in.) B (in.) Product Code DSD Product Code

3 to 24 6-1/2 7-5/8 DSDØRS DSIDØRS

DSID

C

Figure 73

NOTE: DSID 9” and 24” not available.

A

DSD Ø+2

DSID Ø+4

DSD & DSID Anchor Plate

Ø (in.) A (in.) Product Code DSD Product Code DSID

3 to 24 Ø+7 DSDØAP DSIDØAP

Figure 74

NOTE: DSID 9” and 24” not available.

A

DSD Ø+2

DSID Ø+4

2-1/2

9-9/32

DSD Anchor Plate Length (APL)

Ø (in.) A (in.) Product Code

3 to 24

Ø (in.) A (in.) Product Code

3 to 22

Figure 72

Ø

+ 7 DSDØAPL

DSID Anchor Plate Length (APL)

Ø + 9

NOTE: DSID 9” and 24” not available.

Ø

A

DSIDØAPL

DSD & DSID Anchor Plate HD

Ø (in.) A (in.) Product Code DSD Product Code DSID

3 to 24 Ø+7 DSDØAPHD DSIDØAPHD

Figure 75

NOTE: DSID 9” and 24” not available.

29

Page 30

Flexible strap by other

DSD Ø+2

DSID Ø+4

DSD & DSID Roof Brace

Ø (in.) Product Code DSD Product Code DSID

3 to 24 DSDØRB DSIDØRB

Figure 76

Ø (in.) Product Code DSD Product Code DSID

3 to 24 DSDØGWB DSIDØGWB

Figure 77

NOTE: DSID 9” and 24” not available.

DSD & DSID Guy Wire Band

NOTE: DSID 9” and 24” not available.

DSD Ø+2

DSID Ø+4

DSD Ø+2

DSID Ø+4

DSD & DSID Wall Guide

Ø (in.) A (in.) Product Code DSD Product Code DSID

3 to 24 1 to 4-1/2 DSDØWG DSIDØWG

Figure 79

NOTE: DSID 9” and 24” not available.

3/4

DSD Ø+2

DSID Ø+4

3

DSD & DSID Guy Support

Ø (in.) Product Code DSD Product Code DSID

3 to 24 DSDØGS DSIDØGS

Figure 80

NOTE: DSID 9” and 24” not available.

A

6

DSD & DSID Centering Band

Ø (in.) Product Code DSD Product Code DSID

3 to 24 DSDØCB DSIDØCB

Figure 78

NOTE: DSID 9” and 24” not available.

Effective

Length

Ø

DSD & DSID Double Male Adaptor

Ø

(in.)

3 to 24 7-1/8 DSDØDMAU DSIDØDMAU

Figure 81

Effective Length

(in.)

NOTE: DSID 9” and 24” not available.