DuraVent DuraChimney II Shroud User Manual

Installation Instructions

DuraChimney II 10" - 16"

Chimney Shroud

DuraChimney II Shroud

A MAJOR CAUSE OF CHIMNEY RELATED FIRES IS FAILURE

TO MAINTAIN REQUIRED CLEARANCES (AIR SPACES) TO

COMBUSTIBLE MATERIALS. IT IS OF THE UTMOST IMPORTANCE

THAT THIS CHIMNEY BE INSTALLED ONLY IN

ACCORDANCE WITH THESE INSTRUCTIONS.

NOTE:

Read through all these instructions

before beginning your installation. Failure

toinstall the chimney as described in these

instructions will void the manufacturer’s

warranty and may have an effect on your

homeowner insurance and UL listing status.

Refer to the DuraChimney II Installation

Instructions for complete details on

installing the DuraChimney II system. Keep

these instructions for future use.

Dear Customer, Installer, or End User:

We welcome any comments regarding matters

pertaining to our DuraVent products.

We welcome any ideas, input or complaints

and I’ll make sure that someone responds

directly back to you.

Send your emails to:

president@duravent.com

If you are searching for tech support or product

information, please phone us at 800-835-4429.

Or email us at:

techsupport@duravent.com

APPLICATION AND LISTING

As specied in these instructions, Shrouds are

approved for use with DuraChimney II (10”16” diameter). A Shroud built and installed in

compliance with these instructions is UL listed

for use with DuraChimney II (listing number

MH7399).

INSTALLATION NOTES

Practice good workmanship. Exercise extreme

caution when working on roofs. Be

sure to wear appropriate safety gear and

clothing as needed. Refer to the DuraChimney

II Installation Instructions for further safety

details.

MH7399

SHROUD REQUIREMENTS

Shrouds can either be eld-fabricated or

factory-fabricated, but they must meet the

requirements as specied in these instructions.

Shrouds must be constructed of a minimum

24 gauge (.024”) stainless steel, aluminized

steel, galvanized steel, or copper. Other

materials may also be used, such as brick,

mortar, stucco, stone, etc., provided they

are completely non-combustible. Check with

your local building code authorities for any

additional shroud requirements. Shrouds

must be able to be removed to allow chimney

access to properly clean the chimney.

DuraChimney II installations which include the

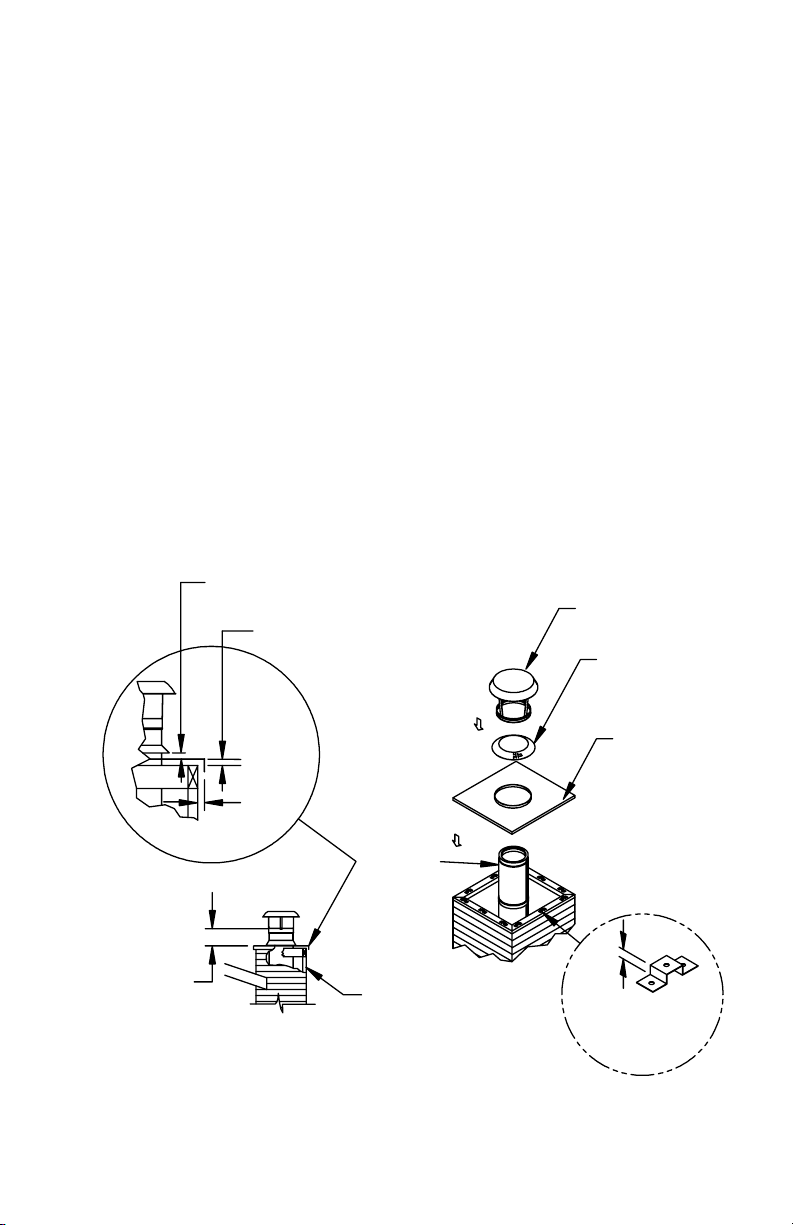

use of a shroud must comply with the following

requirements (Figure 1):

ALLOW A 1-INCH AIR GAP BETWEEN STORM

COLLAR AND CHASE TOP FLASHING

1/2” AIR SPACE ESTABLISHED

BY SPACERS

▪ DuraChimney II must maintain at least 2”

clearance from combustible materials.

▪ The chase enclosure must be ventilated.

▪ The Chase Top Flashing or eld-fabricated

chase pan must be used. Fieldfabricated

chase pans are acceptable if they meet these

requirements:

▪ Material must be 24 gauge (.024”)

Galvanized steel or equivalent.

▪ Chase pan must have opening 3”

larger than outside diameter of

chimney pipe with at least a 1/2”

upturned ange/collar.

▪ Chase pan must overhang chase

by 1/2” per side for proper air ow.

▪ Chase pan must have a 1” down

turned outside edge (weather

protection).

CHIMNEY CAP

STORM COLLAR

10”-16” DIAMETER

CHIMNEY MUST

EXTEND AT LEAST 6-

INCHES ABOVE CHASE

TOP FLASHING.

1/2-INCH

OVERHA NG

DURA

CHIMNEY II

PI PE

MAINTAIN 2-INCH

CLEARANCE BETWEEN

DURACHIMNEY I I AND

CHASE ENCLOSURE

Figure 1

CHASE TOP

FLASHING OR

CHASE PAN

1/2-INCH

FIELD-FABRICATED

SPACERS FOR CHASE

TOP FLASHING

3

Loading...

Loading...