Page 1

SUBMITTAL RECORD

UL 1978 - Grease Duct

Professional Series

Kitchen Ventilation

DCL Single Wall

DAS1 1-inch Air Insulated

DIS1 1-inch Insulated (AES WOOL)

DIS2 2-inch Insulated (AES WOOL)

DIS4 4-inch Insulated (AES WOOL)

DIS3Z 3-inch Insulated (AES WOOL)

SUBMITTAL RECORD

PREPARED FOR:

REFERENCE:

LOCATION:

CONTACT:

TELEPHONE: FAX:

EMAIL:

PREPARED BY:

Material Selection

FLUE (INNER WALL) CASING (OUTER WALL)

304 304

316 441

GALVALUME

DV-PRO REV. 1 09-26-17

Listed to standards:

UL 1978

UL 2221 - DIS3Z Only

CAN/ULC S662

Reference to the Installation Instructions will enable you to obtain a

safe, efficient and dependable installation of this vent system.

Do not alter or modify the components of this vent system under

any circumstances. Any modification or alteration of the vent system

or approved accessories, including but not limited to the appliance it

is connected to, may void the warranty, listings and approvals of this

system and could result in an unsafe and potentially dangerous

installation.

1

Page 2

Models: DCL, DAS1, DIS1,

UL 1978 - Grease Duct – All Models

5”- 36” ID

UL 2221 - Fire Resistant Enclosure DIS3Z ONLY

5”- 36” ID

ULC S662 - Grease Duct – All Models

5”- 36” ID

DIS2, DIS4, DIS3Z

SECTION A – CODE COMPLIANCE

UNDERWRITERS LABORATORIES

LISTINGS

Model D C L ( s i n g l e w a l l ) DAS1 ( 1 -i n ch air) , D I S 1 , DIS2, D IS4, D I S 3 Z

(Double wall, AES Insulation)

ULC S662 - Grease Duct

These requirements cover factory-built grease ducts and

grease duct assemblies that are intended to be installed as

alternatives to the grease ducts constructed of all welded 1.37

mm carbon steel or 1.09 mm stainless steel required by ULC-

S650, Standard

Ventilation and Fire Suppression Systems for Commercial

and Institutional Cooking Equipment. Grease ducts

by these requirements are intended to be installed in a fire

rated

enclosure when required by the provincial or territorial

regulations or bylaws, or in the absence of those

requirements by the National Building Code of Canada.

Grease duct assemblies that penetrate fire rated assemblies

which do not require the protection of a fire rated enclosure

are covered by the requirements contained in CAN/ULCS144,

Standard Method

Assemblies.

for the Installation and Performance of

of Fire R

esistance Test - Grease Duct

covered

COMPLIES TO THE FOLLOWING:

National Fire Protection Association (NFPA)

• Complies with NFPA 96 – “Standard for Ventilation

Control and Fire Protection of Commercial Cooking

Operations

International Code Congress (ICC)

• Complies with “International Mechanical Code” and

“International Building Code” if applicable to the

project or site

International Association of Plumbing and Mechanical

Officials (IAPMO)

• Complies with “Uniform Mechanical Code” if

applicable to the project or site

UL 1978 Grease Duct Listing:

DuraVents Model DCL, DAS1, DIS1, DIS2, DIS4

and DIS3Z are listed for continuous temperatures of 500°F

and intermittent temperatures of up to 2000°F, and are

ideally suited for use in commercial cooking installations

for the removal of smoke and grease laden vapors (Type I

or Type II kitchen exhaust hood). Grease duct system

size and capacity information may be obtained from the ”

ASHRAE Handbook – Fundamentals ” or from the ”

Air Pollution Engineering Manual ” of the ” US

Environmental Protection Agency. ”

UL 2221 Listing:

DuraVents Model DIS3Z is classified in accordance with

UL 2221 (Tests of Fire Resistive Duct Enclosure

Assemblies) as an alternate to a 2-Hr. fire resistive shaft

enclosure with a minimum zero clearance to combustibles

(sizes 5” to 36” diameters). Model DIS3Z has been

evaluated in accordance with the requirements for duct

enclosure Condition A.

MIXING PARTS

Model DCL, DAS1, DIS1, DIS2, DIS4 and DIS3Z

listed to UL 1978 may be intermixed within a system,

assuming proper clearances are maintained for

respective components. When penetrating a roof,

appropriate roof penetration components must be

used.

Do not use Model DCL to penetrate through a

wall, floor or roof.

2

Page 3

SECTION B

Clearance to Combustible (Unenclosed Surrounding)

Grease Duct UL1978 (500°F / 260°C)

Ø

DAS1

DIS1

DIS2 and DIS4

DIS3Z

5 4 2 1 0

18 6 5 2 1

0

18 7 5 2 1

0

18

8 5 2 1 0

18

9 5 2 1 0

18

10 5 2 1 0

18

11 5 2 1 0

18

12 6 2 1 0

18

13 6 2 1 0

18

14 6 2 1 0

18

16 6 3 1 0

18

18 7 3 2 0

18

20 7 3 2 0

18

22 7 3 2 0

18

24 8 3 2 0

18

26 8 4 2 0

18

28 8 4 2 0

18

30 9 4 2 0

18

32 9 4 3 0

18

34 9 4 3 0

18

36

10 5 3

0

18

– GENERAL INFORMATION

PART NUMBERS

This submittal identifies major model parts by name and part

number.

Material Code Designation:

B = Type 316 Stainless Steel (SS)

C = Type 304 Stainless Steel (SS)

E = Aluminum Zinc Coating (GALVALUME)

K = Type 441 Stainless Steel (SS)

Example:

DAS1 – 36” length with inside diameter of 14” made of SS 316

inner flue and SS 304 outer casing; Code = DAS1- 14 L36 BC

DAS1 14 L36 BC

Model Dia. Part Material

Model DCL) or the Outer Band BSE (for Model

DAS1, DIS1, DIS2, DIS4 and DIS3Z). See Figure 1

for the clearance distance.

For fire resistive non-combustible enclosure construction,

maintain clearance as required for installation access for

inspection or per local code. In buildings, more than one story

in height and in one-story buildings where the roof-ceiling

assembly is required to have a

fire resistance rating, the duct must be enclosed in a

continuous enclosure from the lowest fire-rated ceiling or floor,

through any concealed spaces, to or through the roof to

maintain the integrity of the fire separations required by the

applicable building code provisions. If the building is less than

4 stories in height, the enclosure shall have a fire resistance

rating of not less than 1 hour. If the building is 4 stories or more

in height, the enclosure shall have a fire resistance rating not

less than 2 hours.

DuraVent Models DCL, DAS1, DIS1, DIS2, DIS4 and DIS3Z

chimneys may penetrate a combustible floor, wall, or roof using

the appropriate parts and openings sizes.

DIS2 - 30° elbow with inside diameter 22” made of SS 304

inner flue and Galvalume outer casing; Code = DIS2- 22 E30

CE

DIS2 22 E30 CE

Model Dia. Part Material

DCL – wall support for 8” diameter grease duct made

of Galvalume; Code = DCL- 8 WS E

DCL 8 WS E

Model Dia. Part Material

Use only factory supplied components. Failure to

do so will void the certification and the warranty of

the chimney system.

EFFECTIVE LENGTH AND MATERIAL

THICKNESS

The effective length is the length of the part when it is

assembled.

Effective Length Thickness for 5” to 36” diameters

L36 = 36-1/8” inner wall = 0.035”

L24 = 24-1/8” outer wall = 0.024”

L18 = 17-5/8”

L12 = 11-5/8”

NOTE: Model DIS3Z is equivalent to a 2-Hr fire rated

grease duct enclosure system.

NOTE: Do not completely enclose the chimney with

combustible materials.

In the case of a fire rated enclosure made of non-combustible

or limited combustible construction, the minimum

for Model

Model DIS3Z can be used for either combustible or noncombustible surroundings. When installed in an open room

where enclosure is not required, the duct may be located at a

minimum clearance to adjacent combustible walls

DCL is 6” or as required by local code.

clearance

(from the outer band)

DCL

CLEARANCE TO COMBUSTIBLE NON FIRE RATED UL 1978 LISTING

APPLICATION

Model DAS1, DIS1, DIS2, DIS4 and DIS3Z can be used for

either combustible or non-combustible surroundings. When

installed in an open room where enclosure is not required, the

chimney may be located at a minimum clearance to adjacent

combustible walls in accordance with Table 1. The chimney

may be located in corners formed by two combustible

constructions (walls, floor, ceiling, supports, etc.)

NOTE: The clearance distance with the wall is the

distance between the wall and the Inner V-Band (for

Table 1: Clearance to Combustible

Dimensions are in inches

NOTE: Clearance to non-combustible is 0” for all models / all

diameters

3

Page 4

Figure 01: Detail of Clearance to Combustible

!$& %"!'#'"#'#

'

&%#'!''

'

"#'

'

&''DCL, DAS1, DIS1, DIS2, DIS4,

DIS

3Z

''

'

DAS1, DIS1, DIS2, DIS4,

DIS

3Z

DIS1, DAS1, DIS2, DIS4, DIS3Z

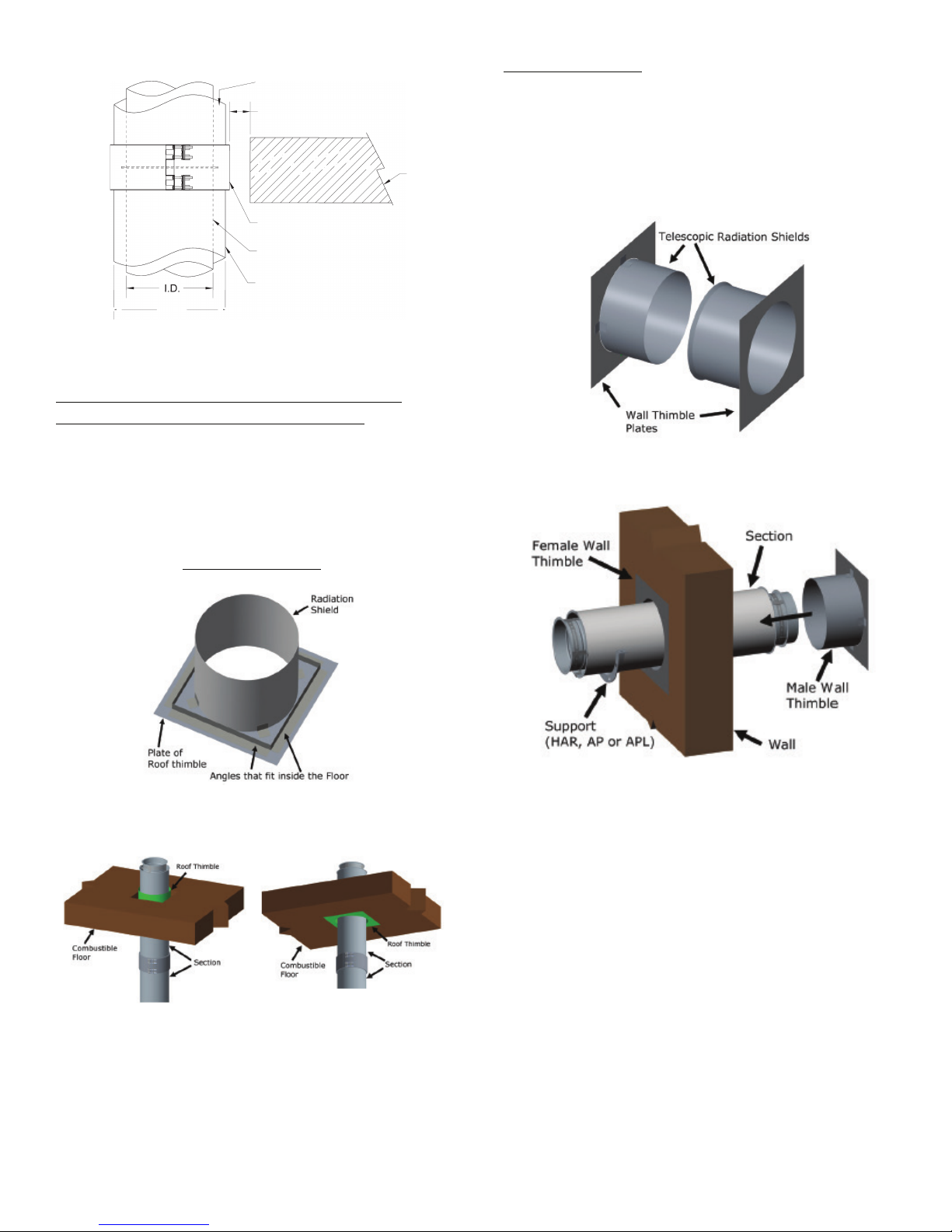

UL 1978 LISTING APPLICATION WALL,

FLOOR AND ROOF PENETRATION

A chimney that must penetrate through a wall, floor or roof

made of COMBUSTIBLE materials, must use a Wall Thimble

(WT) or Roof Thimble (RT). The minimum air space clearance

between the outer wall of the duct and the combustible

material of the wall, floor or roof must always be respected.

ROOF THIMBLE (RT)

WALL THIMBLE (RT)

The part consists of a roof thimble female half and a male roof

thimble that slide in each other to adjust wall thickness from 8”

to 12”. The minimum air space clearance between the outer

wall of the duct and the combustible material of the wall, floor

or roof must always be respected. The duct must be well

supported on both sides of the wall to prevent any load or

offset of the duct in the Wall Thimble.

Figure 4: Wall Thimble (WT)

Figure 2: Roof Thimble (RT)

Figure 3: Visualization Roof Thimble Installed

4

Figure 5: Visualization of Wall Thimble Installed

Page 5

Minimum Square OPENING for NON-Fire Rated Floor / Wall /

Roof for different Models

Duct

Flue

Through

Through

(in.)

5 to 36

ID + 37 1/4”

ID + 1 1/4”

5

ID + 8 3/4”

6 to 11

ID + 10 3/4”

12 to 16

ID + 12 3/4”

18 to 22

ID + 14 3/4”

24 to 28

ID + 16 3/4”

30 to 34

ID + 18 3/4”

36

ID + 20 3/4”

5 to 13

ID + 4 3/4”

14 to 24

ID + 6 3/4”

26 to 34

ID + 8 3/4”

36

ID + 10 3/4”

5 to 16

ID + 2 3/4”

18 to 30

ID + 4 3/4”

32 to 36

ID + 6 3/4”

5 to 16

ID + 2 3/4”

18 to 30

ID + 4 3/4”

32 to 36

ID + 6 3/4”

5 to 9

10 to 36

CLEARANCE TO COMBUSTIBLE (from the outer band -

BSE)

DIS3Z – 5” TO 36”

O”

DAS1: 0 8 = 0A + 2

DIS1: 08 = 0A + 2

DIS2: 08 = 0A + 4

DIS4: 08 = 0 A + 8

C = 0 B + 3/4

D = C + (2 x Clearance)

See Table for

Opening Dimensions

Outer Band (BSE)

For Models DAS1, DIS1, DIS2, DIS4

Floor

INNER WALL

DCL, DAS1, DIS1, DIS2, DIS4)

OUTER WALL

( DAS1, DIS1, DIS2, DIS4 )

Insulation (Air or Fiber Wool)

Figure 6: Openings for through Floor / Wall / Roof Models

DAS1, DIS1, DIS2, DIS4 made of combustible material

Grease Duct – UL1978

CLEARANCE TO COMBUSTIBLE FIRE

RATED

UL 2221

Model DIS3Z is equivalent to a 2 – Hour fire

rated grease duct enclosure system.

DIS3Z is “0” inch clearance to combustible

Table 3: DIS3Z Clearance to Combustible

Model DIS3Z may penetrate a combustible floor, wall or roof

using the appropriate parts and opening sizes. Refer to the

installation instructions for detailed information.

Whenever the DIS3Z grease duct passes through a fire rated

wall or floor, a DIS3Z Ø TPFK must be used to maintain the

fire rating.

Fire resistance rating: 2 hours (F & T)

Model

Diameter Ø

(in.)

Combustible

Roof / Floor /

Wall (in.)

Non-Combustible

But NOT-FIRE-

RATED

Roof / Floor / Wall

DCL

DAS1

DIS1

DIS2

DIS4

DIS3Z

ID + 6 3/4” ID + 6 3/4”

ID + 2 3/4”

ID + 2 3/4”

ID + 4 3/4”

ID + 8 3/4”

Table 2: Openings for through Floor / Wall / Roof – NON-Fire-

Rated

Grease Duct – UL1978

FIRE RATED (2-HR) FLOOR PENETRATION

Fig. 7: Through Penetration Firestop fire-rated Floor

Penetration

NOTE:

Must use S-TPFS (Spec Seal Triple S Intumescent

Firestop Sealant – SSS100). Ordered separately

from DIS3ZØTPFK based on duct diameter. Refer

to table 4 for tube coverage.

5

Page 6

Expected number of tubes of S-TPFS per hole Through

a 2 – Hr. Fire Rated Wall or Floor

Inner Duct Diameter

Number of Tube per hole

5

2 – ¼

6

2 – ½

7

2 – ¾

8

2 – ¾

9 3 10

3 – ¼

11

3 – ¼

12

3 – ½

13

3 – ¾

14

3 – ¾

16

4 – ¼

18

4 – ½

20

5

22

5 – ¼

24

5 – ½

26 6 28

6 – ¼

30

6 – ½

32

7

34

7 – ¼

36

7 – ¾

FIRE RATED (2-HR) WALL PENETRATION

PROPER STORAGE

All chimney components should be stored in a dry place until

installed.

Sealant shall be stored in a location where it will not freeze.

PRODUCT WEIGHT DIS3Z

The average weight of the duct, per foot of length, can be

estimated using the following formula:

Fig. 8: Through a fire-rated Wall / requires 2 X DIS3ZØTPFK

Table 4: required number of tubes S-TPFS

SYSTEM SIZING

The Grease Duct system sizing should be done by an

experienced person familiar with duct sizing. Not following the

equipment manufacturer’s instructions may result in

inadequate duct performance and/or a violation of the

equipment manufacturer’s installation requirements.

EXTERIOR CORROSION PROTECTION

It is recommended to apply an exterior grade high heat paint to

any plate support, full/half angle rings, wall supports/guides,

aluminized outer duct wall (Galvalume) corrosion protection

against the elements. Rust-Oleum V200 series High Heat

Industrial Aerosol is an example for proper protection of these

components.

THERMAL EXPANSION CALCULATIONS

Thermal expansion under normal operating temperatures can

fatigue welds and joints causing leakage. To calculate the

thermal expansion, use the following formula:

[Length (ft.) / 100] X [Temperature Rise Degrees F / 100]

Example: [50’ / 100] X 75° / 100] = .375” Expansion

If the computed expansion between the fixed points is greater

than .375” DuraVent recommends an adjustable length be

installed.

SLOPE FOR GREASE DUCT

For DuraVent factory-built grease ducts listed to UL1978,

install at a duct slope not less than 1/16” unit vertical slope in

12 units of horizontal toward the hood or toward the grease

reservoir. When DuraVent grease duct listed to UL1978

exceed 75 feet in length, the slope shall not be less than 1/8”

unit vertical slope in 12 units horizontal. The minimum slope is

a result of tests and/or analysis performed by Underwriters

Laboratories, where factory-built grease duct was compared to

rectangular field-applied grease duct for performance of flow

characteristics. Consult with AHJ for acceptance of this

alternate method.

6

Page 7

SECTION C

TYPICAL INSTALLATION for GREASE

DUCT

Figure 9: Sample Installation for Grease Duct

7

Page 8

SEISMIC REQUIREMENTS

PRODUCT LABELS

In certain areas of the country, local codes contain

requirements to address Seismic risks. Seismic requirements

for chimneys and Grease Duct usually include specifications

for additional “sway bars” / bracing, or similar devices to help

stabilize the system in the event of an earthquake.

Specific guidelines (including spacing, location, size and

method of attachment of bracing / sway bars or other devices)

for addressing seismic requirements may vary depending upon

the adopted code, seismic zone, duct size, location in building,

etc. and are not within the scope of this submittal.

Consult with a design professional to determine compliance

options for these potentially complex requirements when this

product is to be installed in a building where these additional

requirements apply.

PRODUCT LABELS

8

Page 9

SUPPORT METHODS AND HEIGHT LIMITS

Height Limits for each Type of Support

(ft.)

4

1

1

2

2

5

Ø24 to Ø36

64

32

28

24

18

17

WARNING: Do not attached any supports to combustible constructions.

Maximum Vertical Spacing between any Guides/Supports and Maximum

Freestanding above the Roof

5

20’

8’ 6”

20’

7’ 3”

20’

6’ 6”

20’

6’

20’

6’ 6 20’

9’ 6”

20’

8’ 3”

20’

7’ 6”

20’

6’ 9”

20’

6’ 9” 7 20’

10’

20’

8’ 9”

20’

8’ 3”

20’

7’

20’

7’ 8 20’

11’

20’

9’

20’

8’ 6”

20’

7’ 3”

20’

7’ 3” 9 20’

11’ 6”

20’

9’ 3”

20’

8’ 9”

20’

7’ 6”

20’

7’ 6”

10

20’

12’

20’

9’ 6”

20’

9’

20’

7’ 9”

20’

7’ 9”

11

20’

12’ 6”

20’

9’ 9”

20’

9’ 3”

20’

8’

20’

8’

12

20’

13’

20’

10’

20’

9’ 6”

20’

8’ 3”

20’

8’ 3”

13

20’

13’ 6”

20’

10’ 3”

20’

9’ 9”

20’

8’ 6”

20’

8’ 6”

14

20’

14’

20’

10’ 6”

20’

10’

20’

9’

20’

9’

16

20’

14’ 6”

20’

11’

20’

10’ 6”

20’

9’ 6”

20’

9’ 6”

18

20’

15’

20’

11’ 6”

20’

11’

20’

10’

20’

10’

20

20’

15’

20’

12’

20’

11’ 6”

20’

10’ 9”

20’

10’ 9”

22

20’

15’

20’

12’ 3”

20’

11’ 9”

20’

11’

20’

11’

24

20’

15’

20’

12’ 9”

20’

12’ 3”

20’

11’ 6”

20’

11’ 6”

26

20’

15’

20’

13’

20’

12’ 6”

20’

12’

20’

12’

28

20’

15’

20’

13’ 6”

20’

13’

20’

12’ 3”

20’

12’ 3”

30

20’

15’

20’

13’ 9”

20’

13’ 6”

20’

12’ 9”

20’

12’ 9”

32

20’

15’

20’

14’ 3”

20’

13’ 9”

20’

13’ 3”

20’

13’ 3”

34

20’

15’

20’

14’ 6”

20’

14’ 3”

20’

13’ 6”

20’

13’ 6”

36

20’

15’

20’

15’

20’

14’ 6”

20’

13’ 9”

20’

13’ 9”

(ft.)

L

Half

Ring (HAR) /

Full Angle

Ring (FAR) /

Anchor

Support (AP) /

Anchor plate

with Length

(APL) /

Heavy Duty

Wall Guide

(HDWG)

1. Several support and guiding methods are used to

anchor a chimney against upward, downward and

angular displacement

2. These supports and guides used with thermal

expansion devices, prevent bending stresses on the

chimney elbows and joints

NOTE:

All the weight of the section must be supported by the

inner flue. Never support any chimney duct from the

outer wall.

* MVS = Maximum Vertical Spacing between two guides or support and guide in a vertical position.

** H = Maximum Freestanding Heigth above the roof. This limited height is due to wind loads.

Table 6: Support height limits

Parts

Flue

Diameter Ø

(in)

Ø5 to Ø22 26

Anchor Plate

(AP)

Anchor

Ø24 to Ø36 16

Ø5 to Ø22 28

Plate with

Length

(APL)

Base

supported

Tee

(T90 or

T45)

Wall Support

Ø24 to Ø36 17

Ø5 to Ø22 10

Ø24 to Ø36 63 32 27 23 17 16

Ø5 to Ø22 10

(WSHD)

Table 5: Support height limits

CL DA S1 / D IS1 DI S2 DI S4 DIS 3Z

in )

D

He igt h ( ft. ) Hei gth (ft .) Hei gth (f t.) He igt h ( ft. ) H eig th (ft .)

M

VS* H* * M VS* H* * M VS* H* * MV S* H* * M VS* H* *

Mo del

Fl ue Ø

(

Height

DSL DAS1 DIS1 DIS2 DIS4 DIS3Z

133 114 97 73 70

82 70 59 45 42

142 121 103 78 74

87 74 63 48 45

52 44 37 28 27

53 45 39 29 28

Figure 10: MVS and H limits

Maximum Horizontal Spacing between each Guides/Supports

Distance

Product

Flue

Diameter

Ø (in)

DS

DAS1 DIS1 DIS2 DIS4 DIS3Z

Angle

Ø5 to 12 23 23 19 16 12 12

Ø14 to 24 19 19 16 14 10 10

Ø26 to 36 15 15 13 11 8 8

NOTE: The Half Angle Ring (HAR) and Full Angle Ring (FAR) used in

horizontal installation must be installed with threaded rods having a

minimum of Ø1/2” or with structural steel provided by others.

Table 7: Maximum Horizontal Spacing between Guides /

Supports

9

Page 10

SECTION D

Joint installation is complete.

– PIPE & FITTING JOINT

ASSEMBLY

The ends of each inner pipe are made of flanges (1/2”). All the

joints between sections are a flange-to-flange connection of

the inner pipe.

SPECIAL FEATURE

All sections have an unattached “Alignment Sleeve”.

The alignment sleeve facilitates centering of adjacent sections

and provides backing for the sealant applied to the flange

keeping the sealant in the intended location. Typically, it is

inserted in the downstream end but may be removed.

Although not required, it aids in easier assembly, better sealing

and adds strength to the section joint

STEP 3:

Join the two flanged ends of the duct section together and

rotate slightly to ensure complete coverage of the sealant on

flanges.

Figure 14: Joint Assembly step 3

STEP 4:

Install the V-band around the flanges making sure the flanges

are located within the V-Clamp.

NOTE: do not locate V-band hardware at the bottom

side of horizontal ducts

NOTE: light tapping with a hammer all around the

band while tightening bolts helps align and pull

flanges together.

Figure 11: Feature of the Alignment Sleeve

JOINT ASSEMBLY

STEP 1:

Fill the channel of the inner V-band with S-650 sealant

supplied by DuraVent and place below the flange of the first

section.

Figure 12: Joint Assembly Step 1

STEP 2:

Apply a small continuous bead of S-650 sealant approximately

3/16” wide to one of the flanges to be joined.

Figure 15: Joint Assembly step 4

STEP 5:

Install the supplied AES insulation strips between sections to

ensure that all gaps are filled. Be sure that insulation is tightly

packed and completely fills the void between flue and closure

band when assembled

Figure 13: Joint Assembly Step 2

10

Figure 16: Joint Assembly step 5

STEP 6:

Secure the Outer Casing with the Outer Band (BSE).

Page 11

Expected number of tubes per joint assembly

for S-650 or S-375

Flue Diameter (in.)

Number of tubes per

Joint

5 to 10

1 / 5

11 to 16

1 / 4

18 to 22

1 / 3

24 to 28

1 / 2

30 to 32

2 / 3

34 to 36

3 / 4

SECTION E

– COMPONENTS

LENGTH (L)

Used as standard duct lengths.

Available in diameters 5” to 36”

L12, L18, L24 and L36

Figure 17: Joint Assembly step 6

NOTE:

Seal the BSE band (top) with S-375 sealant if exposed to

weather.

SEALANT USAGE

Part No. S-650

(Permatex® Red High Temp Silicone) is red and is

one of our UL approved sealants for temperatures up

to (650°F / 344°C). Can also be used for

weathering/sealing on outdoor seams and channel

bands where necessary.

Part No. S-375

(Nuflex 302 General Purpose) is a low temperature

grey silicone (450° / 232°C) only for

weathering/sealing on outdoor seams and Outer Band

(BSE) where necessary.

Figure 18: Standard Length

ADJUSTABLE LENGTH (LA) – THERMAL EXPANSION

AND ODD LENGTH

Adjust to fit odd lengths and compensate for Thermal

Expansion

Table 8: Tubes per Joint

Figure 19: Adjustable Length

VARIABLE LENGTH (LA) – ODD LENGTH - NO THERMAL

EXPANSION

Adjust to fit odd lengths only. Primarily used for space

between elbow offset when an odd length is required.

Figure 20: Variable Length

11

Page 12

DRAIN LENGTH (DL) – VERTICAL

Used to drain grease or condensate from the inner wall on

vertical runs. There is a channel inside the inner wall for

directing the flow. A 1” NPT nipple is provided.

NO TOOL ACCESS DOOR (ADL)

Used for inspection and cleaning. Greaseproof and fire-tight

seal.

Available in two lengths: 26” and 36” to accommodate spaces.

Figure 21: Vertical Drain Length

DRAIN LENGTH (HDL) – HORIZONTAL

Used as a horizontal drain in grease duct applications. There

is a DAM inside the inner wall for directing the grease to the

drain. A 1” NPT nipple is provided.

Figure 22: Horizontal Drain Length

NOZZLE LENGTH (NL)

Used to insert a fire-suppression or wash down nozzle. A 1”

NPT nipple is provided.

Figure 24: No Tool Access Door

NO TOOL ACCESS TEE CAP (NTTC)

Used to close and seal unused tee ports. Provides easy

access for inspection.

Figure 25: No Tool Tee Cap

ELBOWS – E3, E15, E30, E45 and E90

Used to change direction of the duct or to provide an offset.

Available in 3°, 15°, 30°, 45° and 90° configurations.

Elbows are not designed to take bending loads or thermal

expansion.

Figure 23: Nozzle Length

12

Figure 26: 3° elbow Figure 27: 15° elbow

Figure 28: 30° elbow Figure 29: 45° elbow

Page 13

Figure 30: 90° elbow

Diameter

5 3/8 2 4 1/8

6 1/4

13 1/4

6 3/8 2 4 1/4

6 5/8

14 1/4 7 3/8 2 4 3/8

6 7/8

15 1/4

8 3/8 2 4 1/2

7 1/8

16 1/4 9 3/8

2 1/8

4 5/8

7 1/2

17 1/4 10 3/8

2 1/8

4 3/4

7 3/4

18 1/4 11 3/8

2 1/8

4 7/8 8 19 1/4 12 3/8

2 1/8 5 8 3/8

20 1/4 13 3/8

2 1/4

5 1/8

8 5/8

21 1/4

14 3/8

2 1/4

5 1/4

8 7/8

22 1/4 16 3/8

2 3/8

5 1/2

9 1/2

24 1/4

18 3/8

2 3/8

5 3/4

10 1/8

26 1/4 20 3/8

2 1/2

6 1/8

10 5/8

28 1/4 22 3/8

2 1/2

6 3/8

11 1/4

30 1/4 24 3/8

2 5/8

6 5/8

11 7/8

32 1/4 26 3/8

2 5/8

6 7/8

12 1/2

34 1/4

28 3/8

2 3/4

7 1/8 13

36 1/4 30 3/8

2 3/4

7 3/8

13 5/8

38 1/4 32 3/8

2 7/8

7 5/8

14 1/8

40 1/4

34 3/8 3 8 14 3/4

42 1/4 36 3/8 3 8 1/4

15 3/8

44 1/4

Minimum (2) Elbow Offsets - DAS1 & DIS1

Diameter

Ø (in.)

5 1/2

2 1/2

5 1/4

8 1/4

18 1/2 6

1/2

2 1/2

5 3/8

8 1/2

19 1/2

7 1/2

2 5/8

5 1/2

8 3/4

20 1/2 8

1/2

2 5/8

5 3/4

9 1/8

21 1/2

9 1/2

2 5/8

5 7/8

9 3/8

22 1/2

10

1/2

2 5/8

6

9 5/8

23 1/2

11

1/2

2 3/4

6 1/8

10

24 1/2

12

1/2

2 3/4

6 1/4

10 1/4

25 1/2

13

1/2

2 3/4

6 3/8

10 1/2

26 1/2

14

1/2

2 3/4

6 1/2

10 7/8

27 1/2

16

1/2

2 7/8

6 3/4

11 3/8

29 1/2

18

1/2 3

7

12

31 1/2

20

1/2 3

7 1/4

12 5/8

33 1/2

22

1/2

3 1/8

7 5/8

13 1/8

35 1/2

24

1/2

3 1/8

7 7/8

13 3/4

37 1/2

26

1/2

3 1/4

8 1/8

14 3/8

39 1/2

28

1/2

3 1/4

8 3/8

14 7/8

41 1/2

30

1/2

3 3/8

8 5/8

15 1/2

43 1/2

32

1/2

3 3/8

8 7/8

16 1/8

45 1/2

34

1/2

3 1/2

9 1/8

16 3/4

47 1/2

36

1/2

3 1/2

9 1/2

17 1/4

49 1/2

Minimum (2) Elbow Offsets - DIS2

Diameter

Ø (in.)

5 1/2

2 5/8

5 1/2

8 3/4

20 1/2

6 1/2

2 5/8

5 3/4

9 1/8

21 1/2 7

1/2

2 5/8

5 7/8

9 3/8

22 1/2

8 1/2

2 5/8

6 9 5/8

23 1/2 9

1/2

2 3/4

6 1/8

10

24 1/2 10

1/2

2 3/4

6 1/4

10 1/4

25 1/2

11 1/2

2 3/4

6 3/8

10 1/2

26 1/2 12

1/2

2 3/4

6 1/2

10 7/8

27 1/2

13 1/2

2 7/8

6 5/8

11 1/8

28 1/2 14

1/2

2 7/8

6 3/4

11 3/8

29 1/2 16

1/2 3 7

12

31 1/2

18 1/2 3

7 1/4

12 5/8

33 1/2 20

1/2

3 1/8

7 5/8

13 1/8

35 1/2

22 1/2

3 1/8

7 7/8

13 3/4

37 1/2 24

1/2

3 1/4

8 1/8

14 3/8

39 1/2 26

1/2

3 1/4

8 3/8

14 7/8

41 1/2

28 1/2

3 3/8

8 5/8

15 1/2

43 1/2

30 1/2

3 3/8

8 7/8

16 1/8

45 1/2 32

1/2

3 1/2

9 1/8

16 3/4

47 1/2 34

1/2

3 1/2

9 1/2

17 1/4

49 1/2 36

1/2

3 5/8

9 3/4

17 7/8

51 1/2

OFFSETS

Various elbows will create a different configuration for the

offset and rise. The chart below (Table 9) provides information

for back-to-back elbows

3° 15° 30° 45° 90°

Table 9B: Offset chart of elbows

Figure 26A, 27A, 28A, 29A, 30A: Offset of 2 elbows

Minimum (2) Elbow Offsets - DCL

Ø (in.)

Table 9A: Offset chart of elbows

3°

15°

30°

45°

3° 15° 30° 45° 90°

90°

Table 9C: Offset chart of elbows

13

Page 14

Minimum (2) Elbow Offsets - DIS4

Diameter

Ø (in.)

3° 15° 30° 45° 90°

5 1/2

2 3/4

6 1/8

10

24 1/2

6 1/2

2 3/4

6 1/4

10 1/4

25 1/2 7

1/2

2 3/4

6 3/8

10 1/2

26 1/2 8

1/2

2 3/4

6 1/2

10 7/8

27 1/2

9

1/2

2 7/8

6 5/8

11 1/8

28 1/2

10

1/2

2 7/8

6 3/4

11 3/8

29 1/2

11

1/2

2 7/8

6 7/8

11 3/4

30 1/2

12

1/2 3 7

12

31 1/2

13

1/2 3

7 1/8

12 1/4

32 1/2

14

1/2 3

7 1/4

12 5/8

33 1/2

16

1/2

3 1/8

7 5/8

13 1/8

35 1/2

18

1/2

3 1/8

7 7/8

13 3/4

37 1/2

20

1/2

3 1/4

8 1/8

14 3/8

39 1/2

22

1/2

3 1/4

8 3/8

14 7/8

41 1/2

24

1/2

3 3/8

8 5/8

15 1/2

43 1/2

26

1/2

3 3/8

8 7/8

16 1/8

45 1/2

28

1/2

3 1/2

9 1/8

16 3/4

47 1/2

30

1/2

3 1/2

9 1/2

17 1/4

49 1/2

32

1/2

3 5/8

9 3/4

17 7/8

51 1/2

34

1/2

3 3/4

10

18 1/2

53 1/2

36

1/2

3 3/4

10 1/4

19

55 1/2

Minimum (2) Elbow Offsets - DIS3Z

Ø (in.)

5 1/2

2 5/8

5 3/4

9 3/8

22 1/2

6 1/2

2 5/8

5 7/8

9 5/8

23 1/2

7 1/2

2 3/4

6 9 7/8

24 1/2 8

1/2

2 3/4

6 1/8

10 1/4

25 1/2 9

1/2

2 3/4

6 3/8

10 1/2

26 1/2

10

1/2

2 3/4

6 1/2

10 3/4

27 1/2

11

1/2

2 7/8

6 5/8

11 1/8

28 1/2

12

1/2

2 7/8

6 3/4

11 3/8

29 1/2

13

1/2

2 7/8

6 7/8

11 5/8

30 1/2

14

1/2

2 7/8

7 12

31 1/2

16

1/2

2 1/2

7 1/4

12 1/2

33 1/2

18

1/2

3 1/8

7 1/2

13 1/8

35 1/2

20

1/2

3 1/8

7 3/4

13 3/4

37 1/2

22

1/2

3 1/4

8 1/8

14 1/4

39 1/2

24

1/2

3 1/4

8 3/8

14 7/8

41 1/2

26

1/2

3 3/8

8 5/8

15 1/2

43 1/2

28

1/2

3 3/8

8 7/8

16

45 1/2

30

1/2

3 1/2

9 1/8

16 5/8

47 1/2

32

1/2

3 1/2

9 3/8

17 1/4

49 1/2

34

1/2

3 5/8

9 5/8

17 3/4

51 1/2

36

1/2

3 3/4

9 7/8

18 3/8

53 1/2

TEES - 90° TEES (T90) and 90° TEES with DAM (T90D1 or

T90D2)

Used to change direction at 90° breeching. Can be used as an

inspection access in horizontal runs. An optional DAM can be

ordered in position #1 or #2 for protection against fluids

running out.

Available with smaller snout (branch)

Table 9D: Offset chart of elbows

Diameter

3° 15° 30° 45° 90°

Figure 31: 90° Tee and 90° Tee with DAM

TEES - 90° TEES with NOZZLE (T90N)

Used to change direction at 90° breeching and provides

access for installation or inspection of a sprinkler head.

Available with smaller snout (branch)

Figure 32: 90° Tee with NOZZLE

TEES - 45° TEES (T45)

Used to change direction at 45° breeching at low resistance

flow.

Available with smaller snout (branch)

Table 9E: Offset chart of elbows

14

Figure 33: 45° Tee

Page 15

DOUBLE 45° TEE, AVAILABLE with SMALLER SNOUT

(TD45)

Used to centrally connect two appliance manifolds to a

common duct.

Available with smaller snout (branch)

TEE CAP (TC)

Used to close, seal or provide access for unused tee ports.

Figure 34: Double 45° Tee

Y TEE (TY)

Used to provide low-pressure drop joining two appliances.

Can be used as a single clean out toward each 90° direction

change. Offers the same diameter on all branches but is

available with a smaller snout (branch)

Figure 35: Y Tee

LATERAL TEE (BT)

NOTE: The lateral tee is only available up to 24” diameter.

For sizes 26” to 36” use a combination of 45° Tee and 45°

elbow.

Used to change direction at 90° at a lower resistance flow.

Figure 37: Tee Cap

DRAIN TEE CAP (DTC)

Used to close and seal unused tee ports and to provide a drain

port for grease or condensate at the base of a vertical duct. A

1” NPT nipple is provided

Figure 38: Drain Tee Cap

DRAIN BUCKET (DB)

Used at the base of a vertical riser as a drain reservoir and to

provide cleanout access. A 1” NPT nipple is provided.

Figure 39: Drain Bucket

TAPERED INCREASER (TIN)

Used when a pipe diameter change is required. Tapered

Increasers are typically used to provide an increase in duct

size, but they may also be used (in the opposite orientation) to

reduce the size of the duct. Caution should be exercised in

reducing duct sizes due to the resultant increase in flow

resistance.

NOTE: typically used in vertical applications to allow grease /

condensate flow.

Figure 36: Lateral Tee

Figure 40: Tapered Increaser

15

Page 16

ECCENTRIC TAPERED INCREASER (ETIN)

SECTION F

Used when a pipe diameter change and a flat bottom on

horizontal runs is required.

– SUPPORTS

Refer to Table 5 for MAXIMUM HEIGHT / SPACING

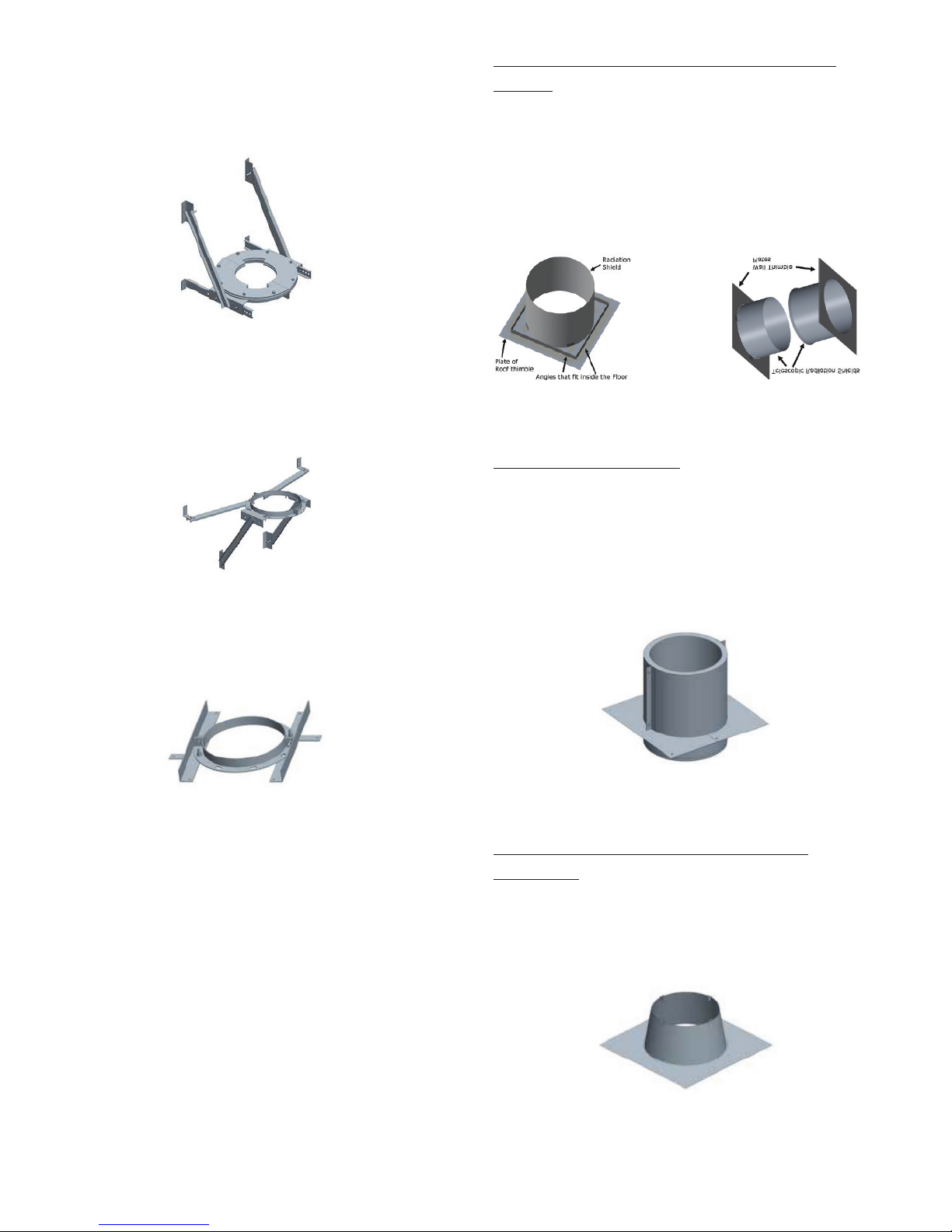

HALF ANGLE RING (HAR)

Used for supporting and guiding the duct in horizontal runs.

Hardware by others.

Figure 41: Eccentric Tapered Increaser

ROUND FLANGED HOOD ADAPTER (RFHA)

Used to connect the first duct section to the hood. Can be field

welded or supplied to the HOOD manufacturer for installation

(by others)

Figure 42: Round Flanged Hood Adapter

SQUARE TO ROUND ADAPTER – CUSTOM PART

Used to connect a round duct to a hood with a

square/rectangular collar or to connect to a square duct.

STR’s are a custom component and all requests need to go

through the DuraVent Design Group at layouts@duravent.com.

Figure 43: Square to Round Adapter

ECCENTRIC SQUARE TO ROUND ADAPTER – CUSTOM

PART

Used to connect a round duct to a hood with a

square/rectangular collar or to connect to a square duct.

ESTR’s are a custom component and all requests need to go

through the DuraVent Design Group at layouts@duravent.com.

Figure 44: Eccentric Square to Round Adapter

Figure 45: Half Angle Ring

FULL ANGLE RING (FAR)

Used for guiding on a vertical run and allows movement for

thermal expansion.

Figure 46: Full Angle Ring

LENGTH ANCHOR PLATEE (APL)

Used for supporting the duct in vertical or horizontal runs and

to provide a fixed point for thermal expansion consideration.

Must not be in contact with combustible material.

Figure 47: Length Anchor Plate

ANCHOR PLATEE (AP)

Used for supporting the duct in vertical or horizontal runs and

to provide a fixed point for thermal expansion consideration.

Must not be in contact with combustible material.

Figure 48: Anchor Plate

16

Page 17

WALL SUPPORT HEAVY DUTY (WSHD)

SECTION G

SECTION H

Used for supporting the vent in vertical runs and to provide a

fixed point for thermal expansion consideration. It can

maintain a clearance from the outer wall of the vent from 2-1/2”

to 10”.

– PENETRATION ROOF /

WALL

A chimney that must penetrate through a floor, roof or wall

made of COMBUSTIBLE materials, must use a Roof Thimble

(RT) or a Wall Thimble (WT). The minimum air space

clearance between the outer wall of the chimney and the

combustible material of the roof / floor / wall listed in the Table

1 must always be respected when using a Roof Thimble (RT)

or a Wall Thimble (WT).

Figure 49: Wall Support Heavy Duty

WALL GUIDE HEAVY DUTY (WGHD)

Used for guiding in vertical installation attached to the wall. It

can maintain a clearance to the outer wall of the vent from 21/2” to 10”.

Figure 50: Wall Guide Heavy Duty

FLOOR GUIDE HEAVY DUTY (FGHD)

Used for guiding in vertical installation when passing through a

floor or roof. Must not be in contact with combustible material.

Figure 51: Floor Guide Heavy Duty

Figure 52: Roof Thimble Figure 53: Wall Thimble

2-HOUR FIRESTOP THROUGH PENETRATION

FIRESTOP KIT (TPFK) DIS3Z ONLY

Used to maintain the fire resistance rating of a floor or a wall

when the grease duct DIS3Z is penetrating a 2-hour fire-rated

floor or wall (UL System No. C-AJ-7160). One kit required for

a floor penetration and two kits required for a wall penetration.

Diameter of penetration is outer casing + 2” (Ø ID + 8”). Must

use the firestop caulking S-TPFS (Spec Seal Triple S

Intumescent Firestop Sealant – SSS100). Refer to Table 2

Figure 54: Through Penetration Firestop

– FLASHING / STORM

COLLAR

FLASHING (F)

Used in conjunction with storm collar (included) for

weatherization at the roof.

Figure 55: Flashing

17

Page 18

SECTION I

ADJUSTABLE FLASHING (F30)

Used in conjunction with storm collar (included) for

weatherization at the roof 5° to 30° pitch.

Figure 56: Adjustable Flashing

STORM COLLAR (SC)

Used above the Flashing or Adjustable Flashing for complete

weatherization above the roof. To be sealed with outer joint

sealant (ordered separately).

Figure 57: Storm Collar

– TERMINATIONS

FAN ADAPTER (FAN)

Used to connect to the inlet of an UPBLAST fan.

NOTE: Plate size (A B) must be specified. Hardware for

connection is not included and is by others.

Figure 58: Fan Adapter

CONE RAIN CAP (CRC) / CONE RAIN CAP with

BIRDSCREEN (CRCB)

Used to provide the greatest degree of rain protection for a

standard vertical termination without fan.

Figure 59: Cone Rain Cap

MITER CUT (MC)

Used for horizontal exhaust with INLINE fan.

Figure 60: Miter Cut

18

Page 19

This DuraVent Limited Lifetime Warranty warrants your DIS3Z grease duct

system to be free from defects in material and workmanship at the time of

manufacture when properly connec ted to and included as a part of a codecompliant commercial kitchen ventilation system for cooking appliances. This

Limited Lifetime Warranty includes all components and ttings. After installation,

if covered components manufactured by DuraVent are found to be defective

in materials or workmanship during the Limited Lifetime Warranty period and

while the Product remains at the site of the original installation, DuraVent will

replace the covered components. DuraVent reserves the right to replace covered

components with an equivalent product and the replacement must be carried

out in accordance with DuraVent recommendations. If replacement is not

commercially practical, DuraVent will, at its option, refund the purchase price

or wholesale price of the DuraVent Product, whichever is applicable. Labor or

freight costs to remove or replace DuraVent components are not included. THERE

ARE EXCLUSIONS AND LIMITATIONS to the Limited Lifetime Warranty as described

herein.

Coverage Commencement Date

Warranty coverage begins on the date of shipment from DuraVent.

Exclusions and Limitations

This Limited Lifetime Warranty applies only if the Product is installed in the United

States or Canada and only if used for the application for which it was designed

and intended. The Product must be installed and maintained in accordance with

the design, installation and maintenance instructions for the Product and in

compliance with all applicable installation and building codes and high-quality,

industry accepted trade practices.

This warranty is non-transferable and extends to the original owner only. The

Product must be purchased through an DuraVent Agent/Representative and proof of

purchase must be provided.

Components and ttings (excludes labor):

Year 1-10 – Replacement of all components and ttings.

Year 11-15 – Replacement at 75% o of the prevailing list price in eect at the

time of replacement (25% of the retail list price paid by the consumer).

Year 16+ – Replacement at 50% o of the prevailing list price in eect at the time

of replacement (50% of the retail list price paid by the consumer).

Limitation on Liability

It is expressly agreed and understood that the sole obligation of DuraVent and

the purchaser’s exclusive remedy under this warranty, under any other warranty,

expressed or implied, or in contract, tort or otherwise, shall be limited to

replacement, repair, or refund, as specied herein.

In no event shall DuraVent be liable for any incidental or consequential damages

caused by defec ts in the Product, whether such damage occurs or is discovered

before or after replacement or repair, and whether such damage is caused by

DuraVent negligence. DuraVent makes no expressed warranties except as stated

in this Limited Lifetime Warranty. The duration of any implied warranty is limited

to the duration of this expressed warranty. No one is authorized to change this

Limited Lifetime Warranty or to create for DuraVent any other obligation or

liability in connection with the Product. Some states and provinces do not allow

the exclusion or limitation of incidental or consequential damages, so the above

limitations or exclusions may not apply to you. The provisions of this Limited

Lifetime Warranty are in addition to and not a modication of or subtrac tion from

any statutory warranties and other rights and remedies provided by law.

Investigation of Claims Against Warranty

DuraVent reserves the right to investigate any and all claims against this Limited

Lifetime Warranty and to decide, in its sole discretion, upon the method of

settlement. DuraVent shall in no event be responsible for any warranty work

done by a contractor that is not approved without rst obtaining DuraVent’s prior

written consent.

For the most up-to-date installation instructions, see

www.duravent.com

REV 8.30.2016

Manufactured in Laval, Quebec

DuraVent will not be responsible for: (a) damages caused by normal wear and

tear, corrosion from salt air, accident, riot, re, ood, high wind or acts of God;

(b) damages caused by abuse, negligence, misuse, or unauthorized alteration or

repair of the Product aecting its stability or performance; (c) damage resulting

from failure to reasonably clean, care for or maintain products in accordance with

the printed design, installation and maintenance instructions for the Product;

(d) damages caused by failing to provide proper maintenance and service in

accordance with the design, installation and maintenance instructions for the

Product, including damage to the nish of the Product caused by the use of

improper solvents/chemicals or improper cleaning methods; (e) damages, repairs

or ineciency resulting from faulty installation or application of the Product; (e)

replacement of system sealants as a result of improper installation or a system

grease re.

This Limited Lifetime Warranty covers only par ts as provided herein. DuraVent’s

entire liability is limited to the purchase price of this Product. In no case shall

DuraVent be responsible for materials, components or construction which are not

manufactured or supplied by DuraVent or for the labor necessary to install, repair

or remove such materials, components or construction. All replacement or repair

components will be shipped F.O.B. from the DuraVent manufacturing facility.

19

Page 20

WARRANTY

This product has a 15 year limited warranty. Please read the warranty to be

familiar with its coverage.

Retain this manual. File it with your other documents for future reference.

PRODUCT REFERENCE INFORMATION

Please contact DuraVent for the phone number of your nearest DuraVent dealer

who will answer your questions or address your concerns.

Normally, all parts should be ordered through your Security Chimneys International distributor or dealer. Parts will be shipped at prevailing prices at

time of order.

When ordering repair parts, always give the following information:

1. The model number of the vent system.

2. The part number.

3. The description of the part.

4. The quantity required.

5. The installation date of the chimney system.

If you encounter any problems or have any questions concerning the installation

or application of this system, please contact your dealer.

DuraVent reserves the right to make changes at any time, without notice, in design, materials, specifications, prices.

877 Cotting Court • Vacaville, CA • 95688

800-835-4429; www.DuraVent.com

Consult your local distributor for chimney system code information.

Printed in Canada © 2011, 2017 DuraVent

DV_PRO REV. 1 09-26-17

20

Loading...

Loading...