Operating Instructions and Parts Reference

77C/107C DRILLS

107C DRILL - S.N. 101100017C & UP

77C DRILL - S.N. 77110001C & UP

0500146 • July 2018

TM

Product InformatIon

DuraTech InDusTrIes InTernaTIonal Inc.

Po Box 1940, JamesTown , nD 58402-1940

Tel: (701) 252-4601• Fax: (701) 252-0502

www.DuraTechInDusTrIes.neT • www.hayBusTer.com

A Tradition of Innovation Since 1966

77C/107C DRILLS

107C DRILL - S.N. 101100017C & UP

77C DRILL - S.N. 77110001C & UP

Operating Instructions

and Parts Reference

DuraTech Industries International Inc. (DuraTech Industries) has made every effort to assure

that this manual completely and accurately describes the operation and maintenance of the

77C/107C DRILLS™ as of the date of publication. DuraTech Industries reserves the right to

make updates to the machine from time to time. Even in the event of such updates, you should

still nd this manual to be appropriate for the safe operation and maintenance of your unit.

This manual, as well as materials provided by component suppliers to DuraTech Industries

are all considered to be part of the information package. Every operator is required to read

and understand these manuals, and they should be located within easy access for periodic

review.

and are registered trademarks of Duratech Industries

International, Inc. 77C DRILL and 107C DRILL are trademarks of Duratech Industries

International, Inc.

A Tradition of Innovation Since 1966

Foreword

All personnel must read and understand before operating unit

• Foreword and Section 1, important safety information.

• Section 2, ”Dealer Preparation,” to verify that the machine has been prepared for

use.

• Section 3, “Introduction,” which explain normal operation of the machine.

• Section 4.1, “Operating Instructions” Pre-Operation Inspection Check List.

Appropriate use of the unit

The 77C / 107C Grain Drill is designed to seed No-Till, Minimum Till, or convention-

ally tilled elds. The two compartment hopper offers the exibility of seeding with

fertilizer, seeding alone, or planting two different seeds.

Operator protection

As with all machinery, care needs to be taken by the operator in order to insure the

safety of the operator and those in the surrounding area.

WARNING: Operators and those observing the operation of the 77C / 107C

GRAIN DRILLS are required to wear head, eye, and ear protection. No loose

clothing is allowed.

77C/107C DRILLS OPERATING INSTRUCTIONS

i

TABLE OF CONTENTS

Part 1: Operating Instructions .........................................1

Introduction ................................................................................. 2

Purpose ....................................................................................... 2

Section 1: Safety ......................................................................... 3

1.1 SAFETY-ALERT SYMBOLS .......................................................................... 3

1.2 OPERATOR - PERSONAL EQUIPMENT ...................................................... 5

1.3 MACHINE SAFETY LABELS ........................................................................ 6

1.4 SHIELDING ...................................................................................................... 8

1.5 PERSONAL EQUIPMENT ............................................................................. 8

1.6 SAFETY REVIEW .......................................................................................... 8

Section 2: Dealer Preparation .................................................. 12

2.1 GAUGE WHEEL ATTACHMENT ................................................................. 12

2.2 DRILL LEGUME BOX ATTACHMENT ....................................................... 14

2.3 LEGUME HOPPER SHIPPING KIT (OPTIONAL) ...................................... 16

Section 3: Introduction .............................................................. 17

3.1 ORDERING PARTS ....................................................................................... 17

3.2 SERIAL NUMBER DECAL ........................................................................... 18

3.3 ABOUT YOUR 77C/107C GRAIN DRILL ................................................... 18

Section 4: Operating Instructions ............................................. 19

4.1 OPERATING INSTRUCTIONS ..................................................................... 19

4.2 GRAIN DRILL SETUP................................................................................... 20

4.3 PRESSURE SPRING ADJUSTMENT ........................................................... 20

4.4 PRESS WHEEL ADJUSTMENT ................................................................... 21

4.5 HAYBUSTER 77C/107C DRILL OPENER ................................................... 22

4.5A CONTROL PLATES .................................................................................... 22

4.6 FEED WHEEL SPACE ADJUSTMENT ........................................................ 23

4.7 DRILL CLEANOUT SLIDES ........................................................................ 24

4.8 CALIBRATION POINTER ADJUSTMENT ................................................. 25

4.9 SETTING AND CHECKING FEED RATE ................................................... 26

4.10 CHECKING FEED RATE ............................................................................ 27

4.11 DRILLING WITH THE GRAIN DRILL ...................................................... 33

4.12 SUGGESTIONS ............................................................................................ 35

4.13 REAR WHEEL SWIVEL AND ADJUSTMENT ......................................... 35

4.14 TRANSPORTING THE GRAIN DRILL ...................................................... 35

4.15 CLEANING GRAIN TANKS AND LEGUME BOXES ............................... 37

4.16 PREPARING FOR STORAGE ..................................................................... 37

4.17 REMOVING FROM STORAGE .................................................................. 37

ii

77C/107C DRILLS OPERATING INSTRUCTIONS

TABLE OF CONTENTS

Section 5: Grass Seeding Reference ......................................... 39

5.1 GRASS SEEDING ATTACHMENTS ............................................................ 39

5.2 LEGUME BOX APPLICATIONS .................................................................. 40

5.3 SINGLE AGITATOR APPLICATIONS.......................................................... 40

5.4 SPECIAL INSTRUCTIONS FOR WARM SEASON GRASSES .................. 40

5.5 PURE LIVE SEED CALCULATIONS .......................................................... 41

Section 6: Lubrication ............................................................... 43

APPENDIX A: WARRANTY .......................................................... 46

APPENDIX B: SPECIFICATIONS ................................................. 47

Part 2: Parts Reference ..................................................49

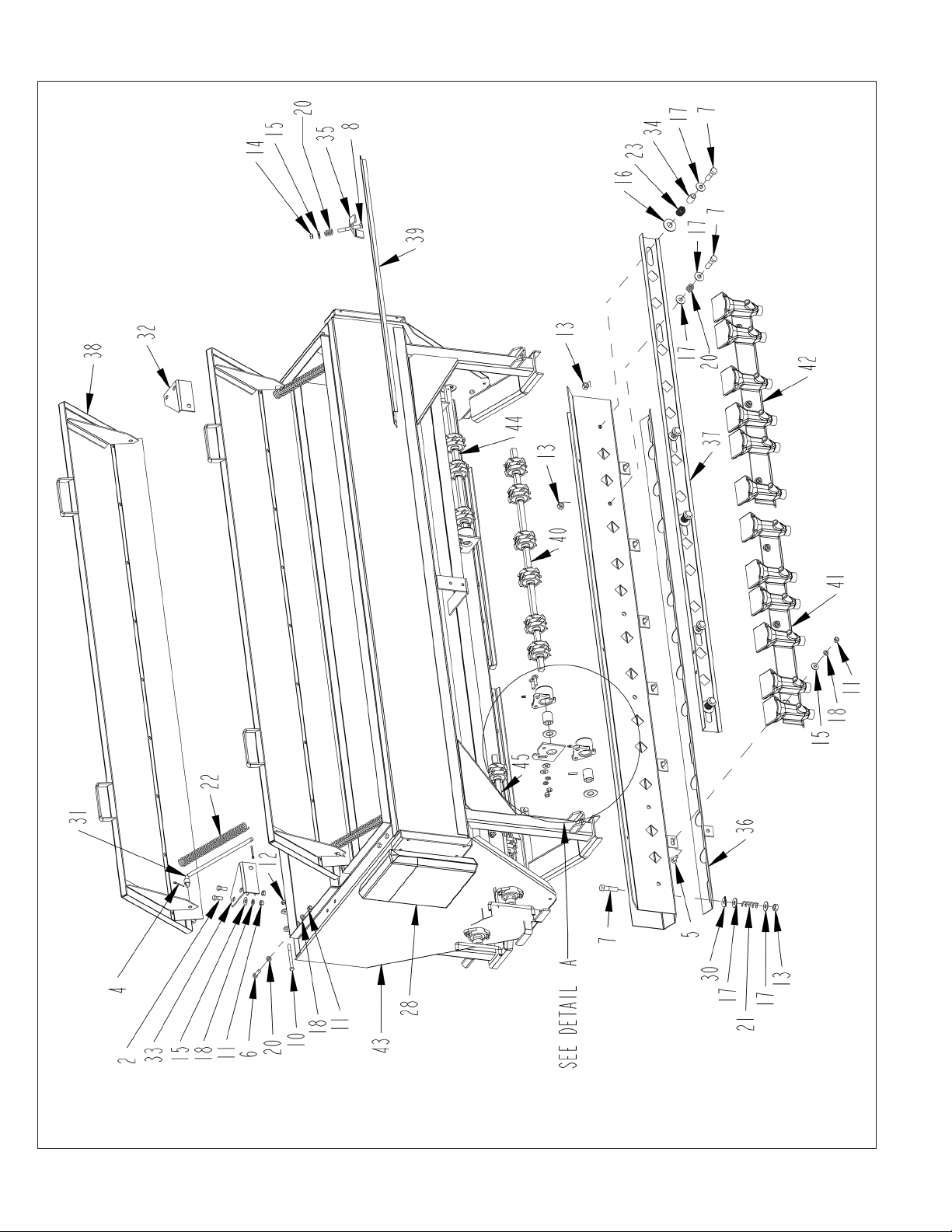

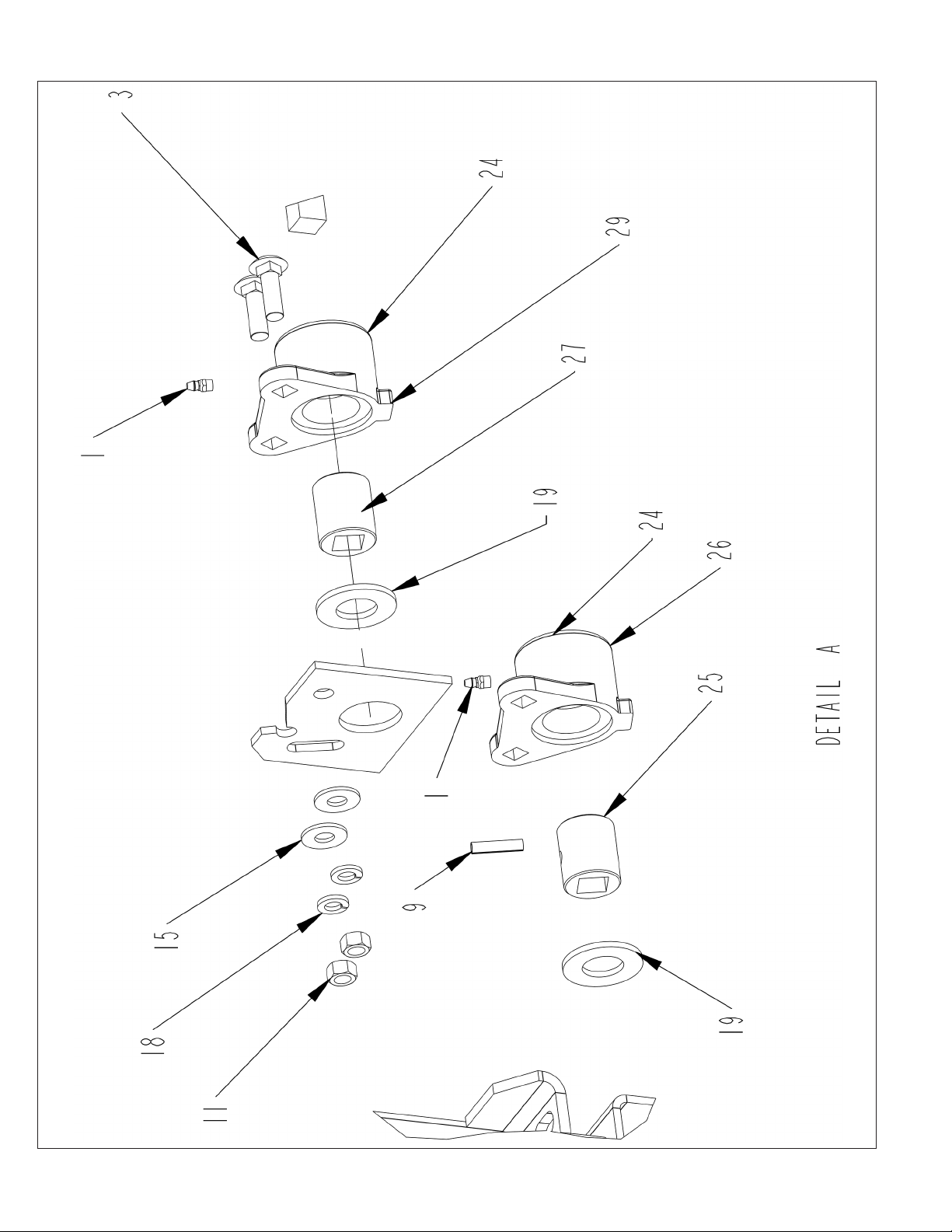

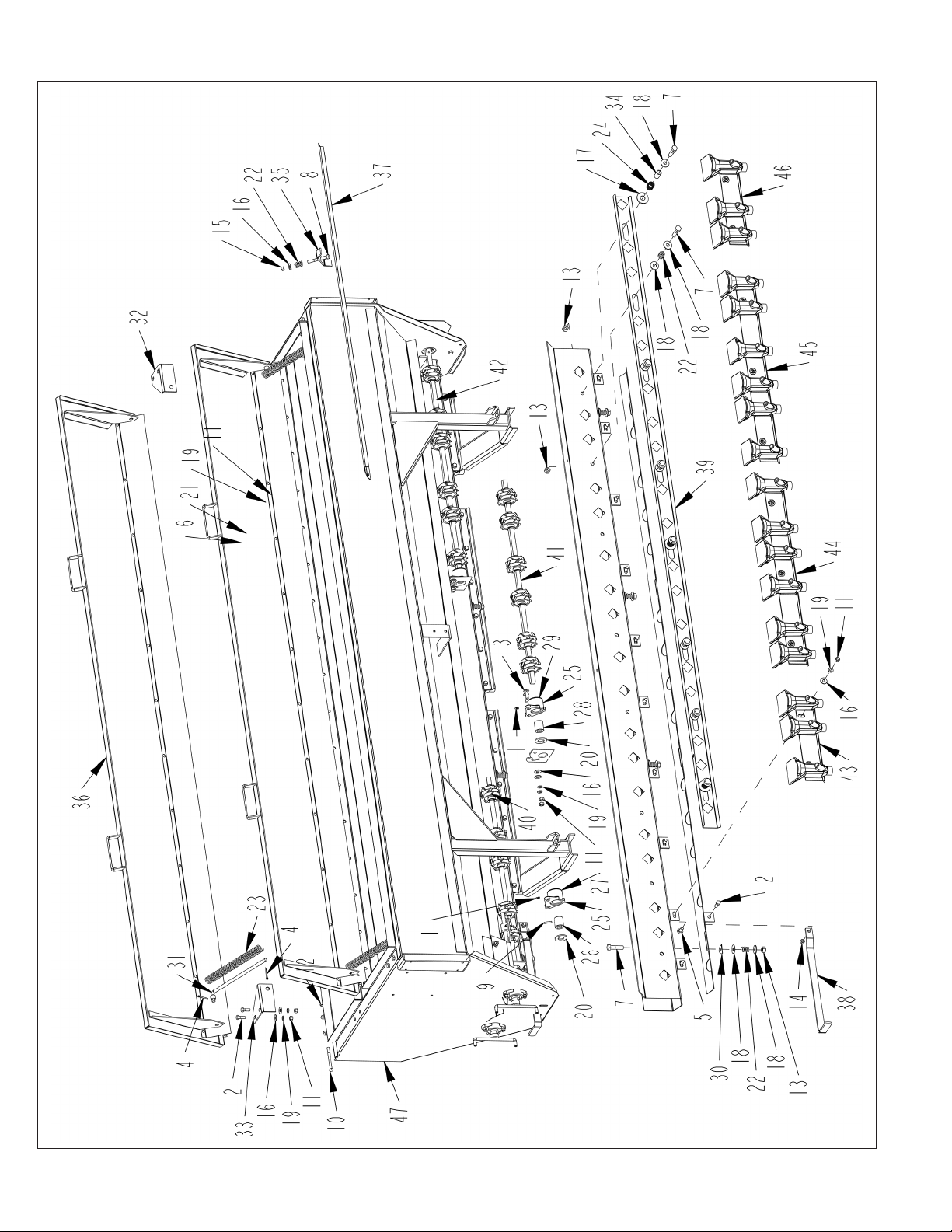

77C MAIN FRAME ASSEMBLY (FOR S.N. THRU 0075) ................................. 50

77C MAIN FRAME ASSEMBLY (FOR S.N. 0076 AND UP) ............................. 52

107C MAIN FRAME ASSEMBLY (FOR S.N. THRU 0880) ............................... 54

107C MAIN FRAME ASSEMBLY (FOR S.N. 0881 AND UP) ........................... 56

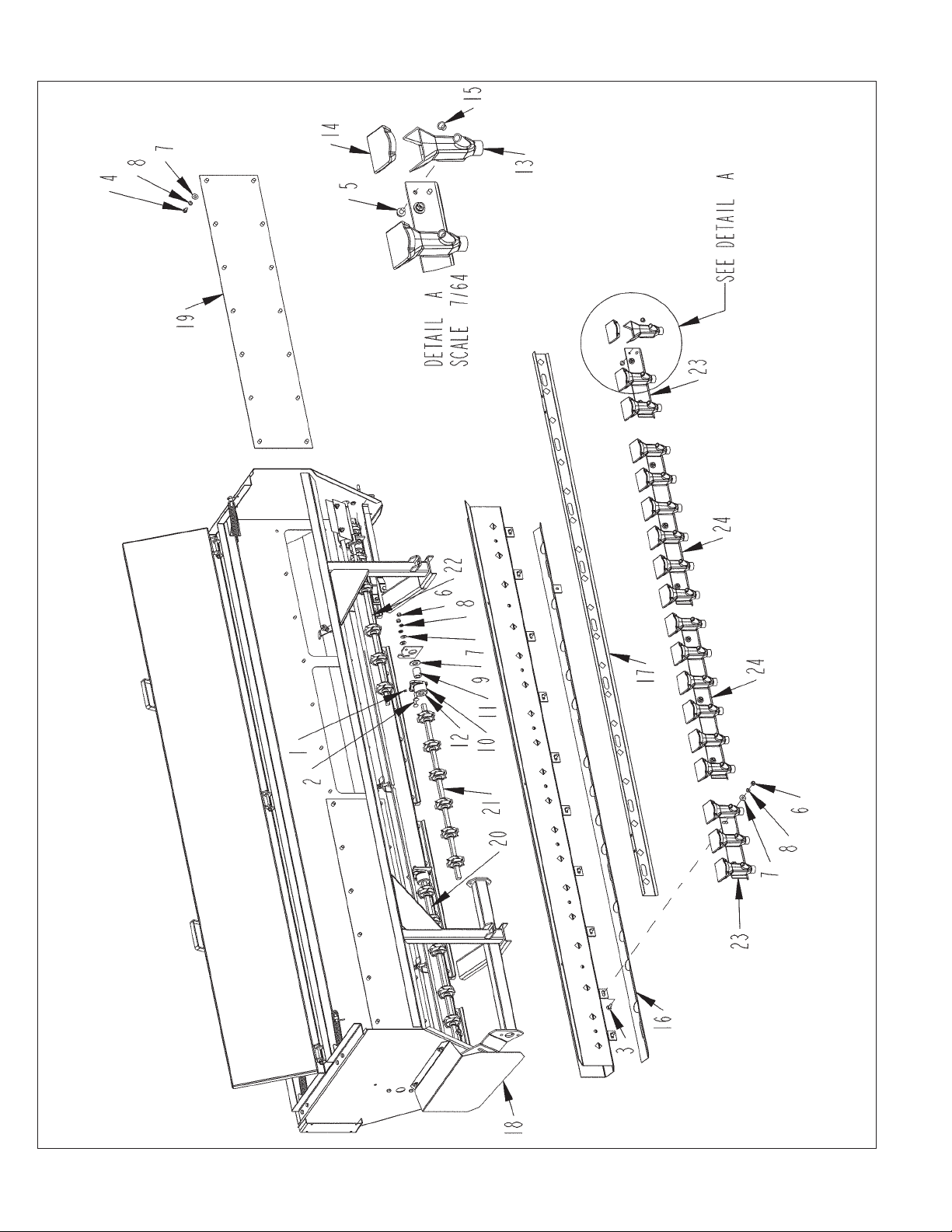

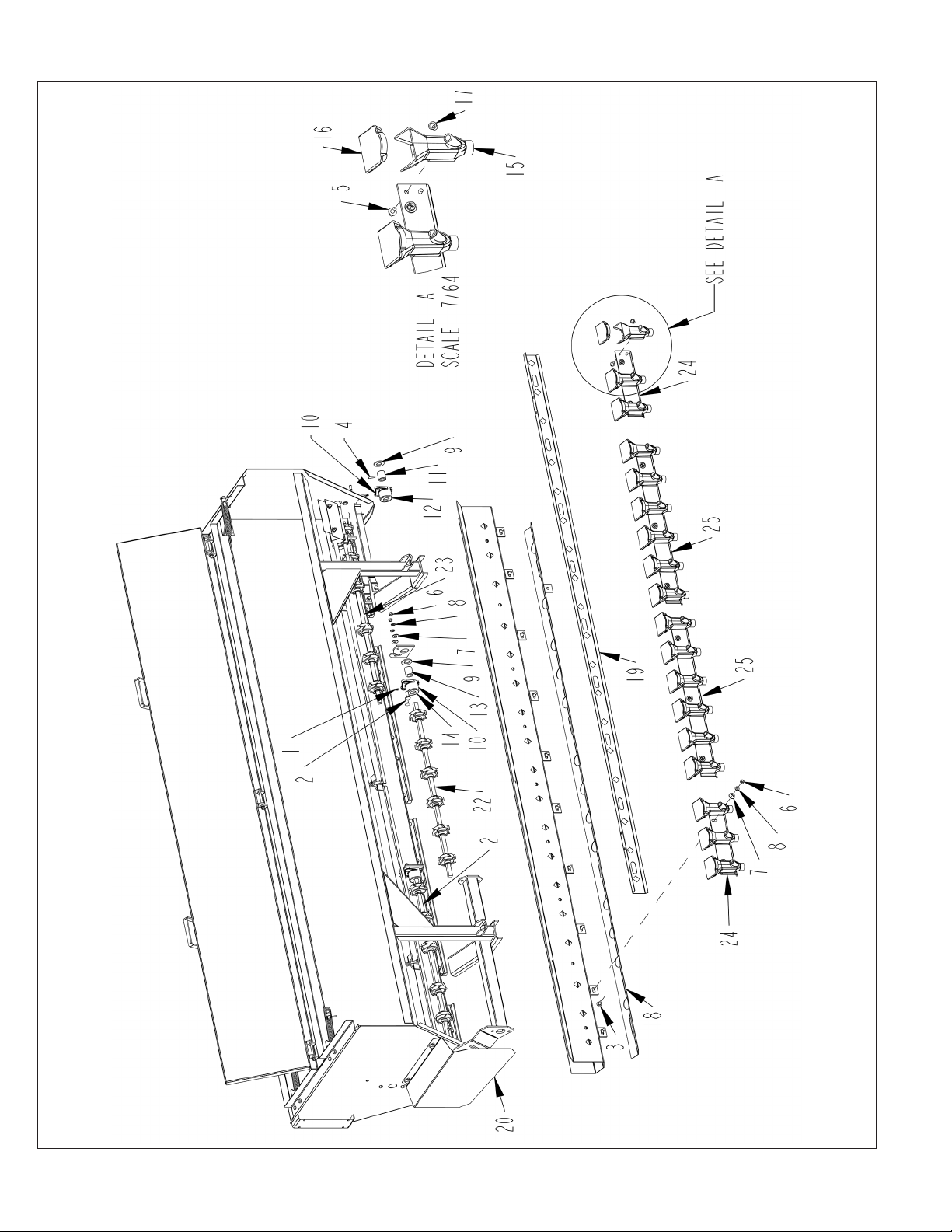

77C DRIVE ASSEMBLY ...................................................................................... 58

107C DRIVE ASSEMBLY .................................................................................... 60

77C & 107C DRIVE WHEEL ASSEMBLY .......................................................... 62

TANK END DRIVE (77C & 107C) ....................................................................... 64

RUN ASSEMBLY (77C & 107C) .......................................................................... 66

77C TANK ASSEMBLY - FRONT (FOR S.N. UP TO 0075) ............................... 68

77C TANK ASSEMBLY - FRONT (FOR S.N. 0076 AND UP) ........................... 70

77C TANK ASSEMBLY - BACK.......................................................................... 72

77C TANK ASSEMBLY - BACK - DETAIL A ..................................................... 74

107C TANK ASSEMBLY - FRONT (FOR S.N. UP TO 0500) ............................. 76

107C TANK ASSEMBLY - FRONT (FOR S.N. 0501 AND UP) ......................... 78

107C TANK ASSEMBLY - BACK........................................................................ 80

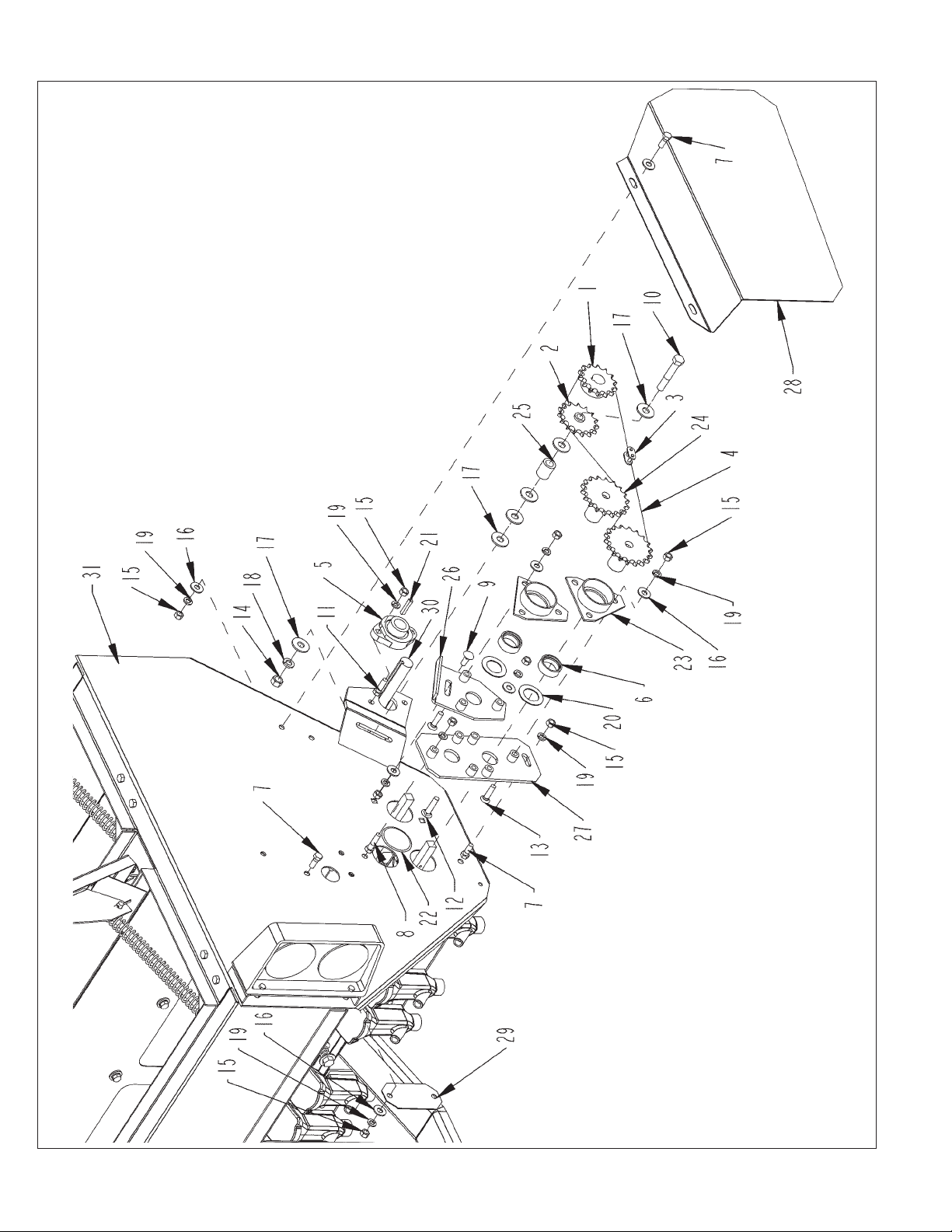

SEED & FERTILIZER SETTING ASSEMBLY ................................................... 82

SCRAPER ASSEMBLY ......................................................................................... 83

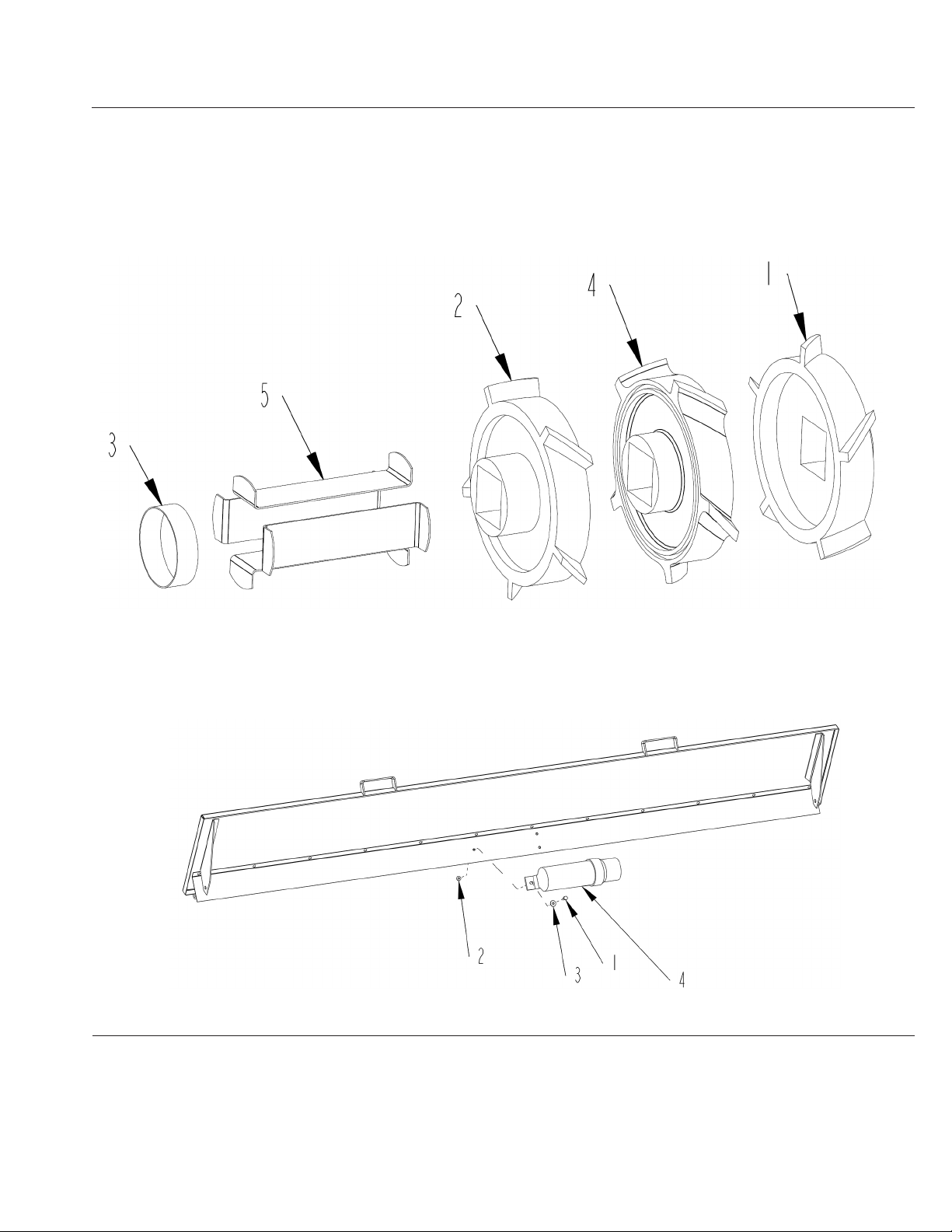

FEED WHEEL - DOUBLE .................................................................................... 84

FEED WHEEL - TRIPLE ...................................................................................... 85

MANUAL CANISTER .......................................................................................... 85

COULTER & DISK ASSEMBLY .......................................................................... 86

PRESS WHEEL ASSEMBLY ................................................................................ 87

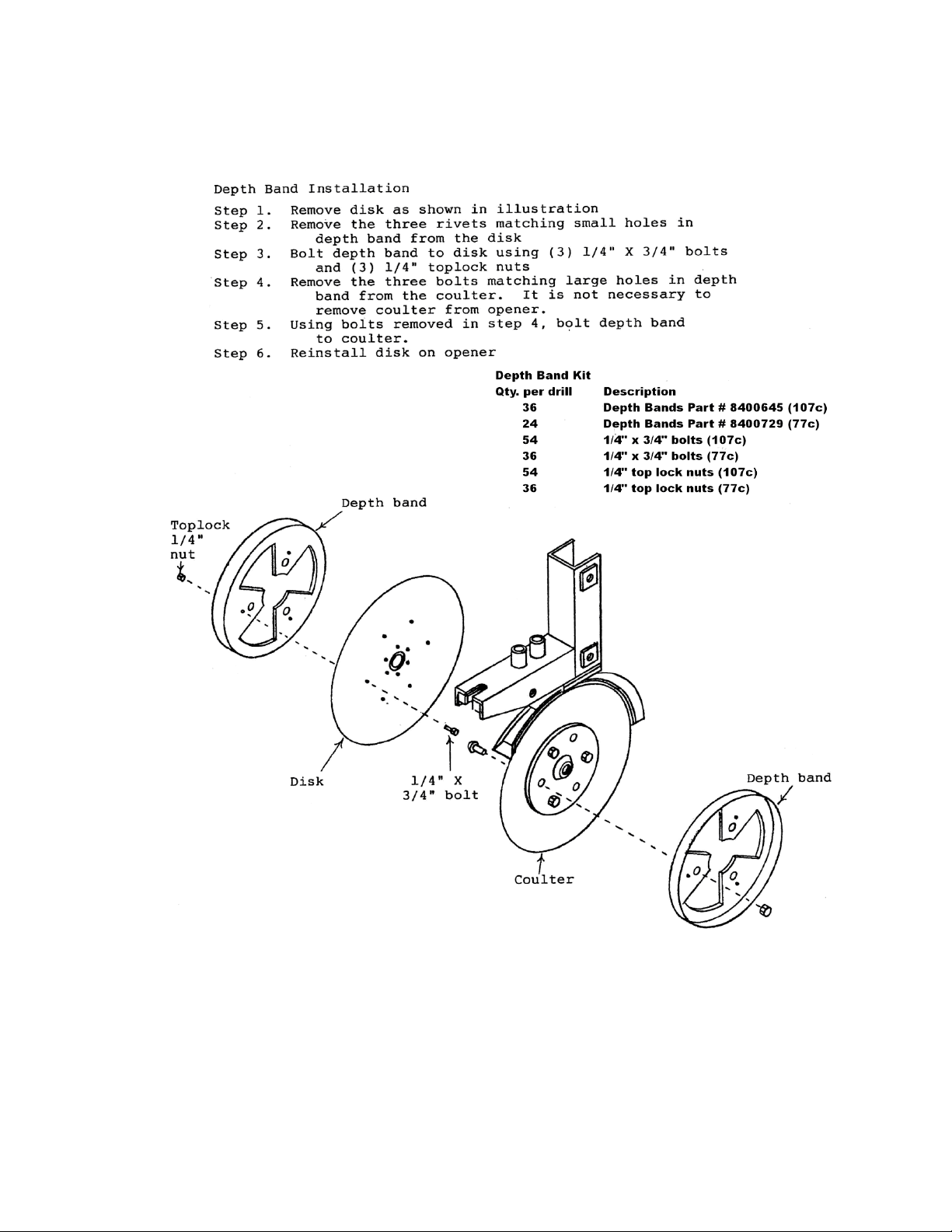

DEPTH BAND INSTALLATION ......................................................................... 89

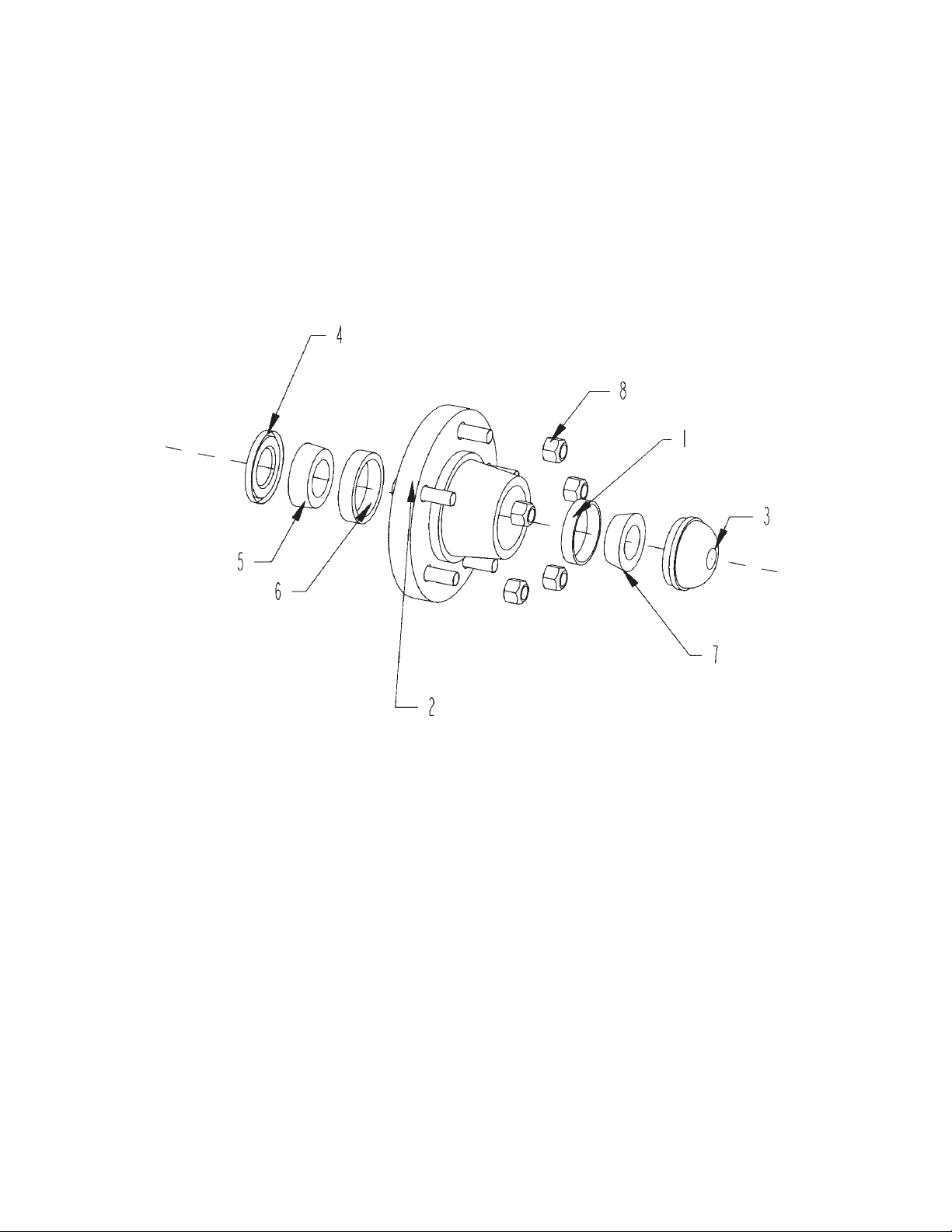

HUB ASSEMBLY .................................................................................................. 90

HUB FORK ASSEMBLY ...................................................................................... 92

FRONT STABILIZER OPTION (107C ONLY) .................................................... 93

REAR STABILIZER OPTION (107C ONLY) ...................................................... 94

TOW HITCH (107C ONLY) .................................................................................. 96

BALLAST BRACKET (77C & 107C) .................................................................. 97

77C/107C DRILLS OPERATING INSTRUCTIONS

iii

TABLE OF CONTENTS

HITCH LIFT (107C ONLY) .................................................................................. 98

DRILL SINGLE HITCH (77C & 107C) .............................................................. 100

SWIVEL HITCH (77C & 107C) .......................................................................... 101

STANDARD SINGLE DRILL HYDRAULICS (77C & 107C) .......................... 102

2-DRILL HITCH (107C ONLY) ......................................................................... 104

2-DRILL HITCH HYDRAULICS (107C ONLY) .............................................. 106

3-4 DRILL HITCH (107C ONLY) ....................................................................... 108

3 DRILL HYDRAULICS (107C ONLY) ............................................................ 109

4 DRILL HYDRAULICS (107C ONLY) ............................................................ 110

DECALS .............................................................................................................. 112

DECAL LOCATIONS ......................................................................................... 114

107C LEGUME BOX OPTION ......................................................................... 118

77C LEGUME BOX OPTION ........................................................................... 120

SEED INDEX ASSEMBLY LEGUME BOX (DETAIL C) ............................... 122

CUP ASSEMBLY LEGUME BOX (DETAIL D) ............................................... 123

LEGUME DROP TUBE ASSEMBLY ................................................................. 124

LEGUME BOX MOUNTING BRACKET (77C & 107C) ................................. 126

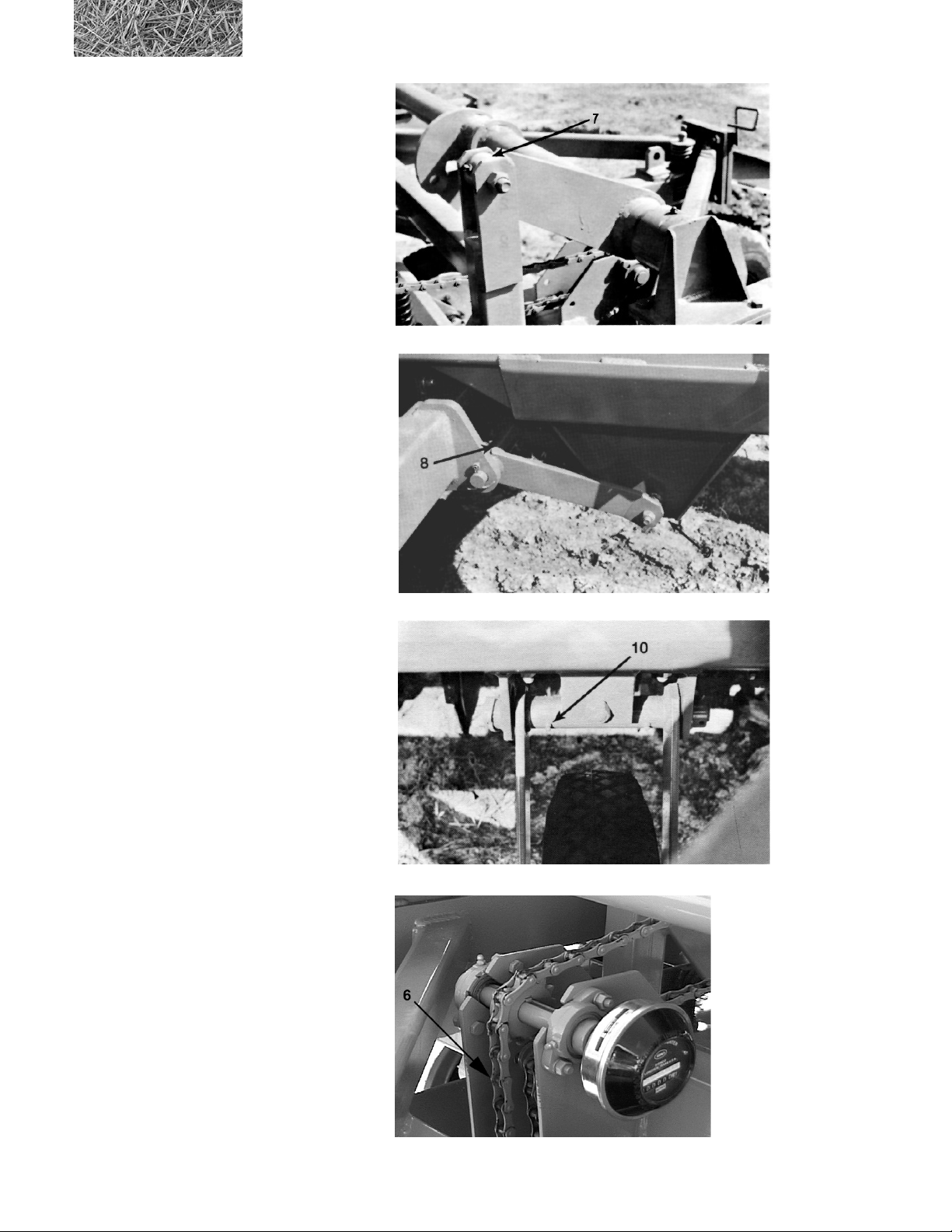

ACRE COUNTER (OPTION) (77C & 107C) ..................................................... 127

GAUGE WHEELS OPTION (107C ONLY) ....................................................... 128

DRILL LIGHT KIT & SMV (77C & 107C) ........................................................ 130

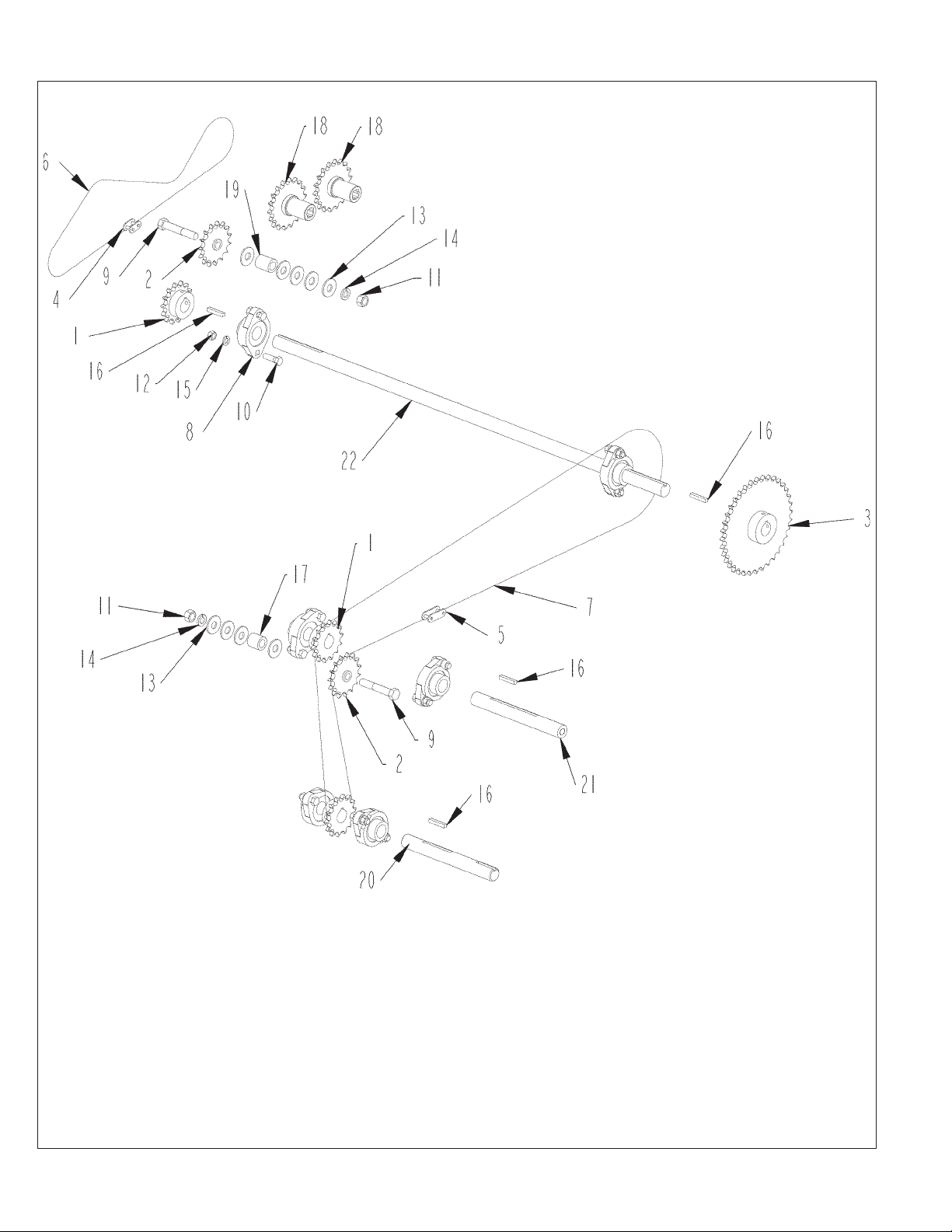

77C NATIVE GRASS KIT OPTION - ADDITIONAL AGITATOR SHAFTS... 134

107C NATIVE GRASS KIT - ADDITIONAL AGITATOR SHAFTS ................ 136

NATIVE GRASS KIT - SEED CUPS .................................................................. 138

107C NATIVE GRASS KIT - TANK, EXISTING SHAFT MODIFICATIONS 140

NATIVE GRASS KIT - TANK END DRIVE ASSEMBLY (77C & 107C) ........ 142

iv

NATIVE GRASS KIT - SEED AND FERTILIZER SETTING ASSEMBLY

(77C & 107C) ....................................................................................................... 144

NATIVE GRASS KIT - DROP TUBE AND HOSE (77C & 107C) .................... 145

77C NATIVE GRASS KIT FIELD INSTALLATION FOR SINGLE AND

DOUBLE AGITATORS ....................................................................................... 146

107C NATIVE GRASS KIT FIELD INSTALLATION FOR SINGLE AND

DOUBLE AGITATORS ....................................................................................... 148

CHAIN ROUTING (77C & 107C) ...................................................................... 150

NATIVE GRASS KIT - SINGLE AGITATOR MASTER PARTS LIST

(77C ONLY) ......................................................................................................... 151

NATIVE GRASS KIT - SINGLE AGITATOR MASTER PARTS LIST

(107C ONLY) ....................................................................................................... 153

77C / 107C DRILL DOCUMENTATION COMMENT FORM .......... 157

77C/107C DRILLS OPERATING INSTRUCTIONS

77C/107C DRILLS

107C DRILL - S.N. 101100017C & UP

77C DRILL - S.N. 77110001C & UP

PART 1: Operating

Instructions

1

77C /107C DRILLS OPERATING INSTRUCTIONS

1

Introduction

The 77C/107C Grain Drills are designed to seed No-Till, Minimum Till, or conventionally tilled elds. Two 30 gallon

tanks are available for added ballast to penetrate the tough no-till conditions.

The two compartment hopper offers the exibility of seeding with fertilizer, seeding alone, or planting two different

seeds. The metering system for each hopper is innitely adjustable.

Field hitches are available for one or multiples of two, three, and four of the model 107C Drill only. A tow hitch is also

available for the 107C Drill to allow the towing of two or more drills in transport.

Purpose

The purpose of this owner’s manual is to explain maintenance requirements and routine adjustments for the most

efcient operation of your 77C/107C Grain Drill. There is also a trouble shooting section that may help in case of

problems in the eld. Any information not covered in this manual may be obtained from your dealer.

Special Note: When reference is made as to front, rear, right hand or left hand of this machine, the

reference is always made from standing at the rear end of the machine and looking towards the hitch.

Always use serial number and model number when referring to parts or problems. Please obtain your

serial number and write it below for your future reference.

MODEL: 77C DRILL SERIAL NO. ________________________

107C DRILL

2

77C /107C DRILLS OPERATING INSTRUCTIONS

Section 1: Safety

The safety of the operator is of great importance to DuraTech Industries/Haybuster. We have provided decals, shielding

and other safety features to aid you in using your machine safely. In addition, we ask you to be a careful operator who

will properly use and service your Haybuster equipment.

WARNING: FAILURE TO COMPLY WITH SAFETY INSTRUCTIONS THAT FOLLOW

WITHIN THIS MANUAL COULD RESULT IN SEVERE PERSONAL INJURY OR DEATH.

BEFORE ATTEMPTING TO OPERATE THIS MACHINE, CAREFULLY READ ALL

INSTRUCTIONS CONTAINED WITHIN THIS MANUAL. ALSO READ THE INSTRUCTION

MANUAL PROVIDED WITH YOUR TRACTOR.

THIS MACHINE IS NOT TO BE USED FOR ANY PURPOSE OTHER THAN THOSE

EXPLAINED IN THE OPERATOR’S MANUAL, ADVERTISING LITERATURE OR OTHER

DURATECH INDUSTRIES WRITTEN MATERIAL PERTAINING TO THE 77C/107C GRAIN

DRILL.

1.1 Safety-alert symbols

Decals are illustrated in Part 2: Parts Reference.

The safety decals located on your machine contain important and useful information that will help you operate your

equipment safely.

To assure that all decals remain in place and in good condition, follow the instructions below:

• Keep decals clean. Use soap and water - not mineral spirits, adhesive cleaners and other similar cleaners

that will damage the decal.

• Replace all damaged or missing decals. When attaching decals, surface temperature of the machine must

be at least 40° F (5° C). The surface must be also be clean and dry.

• When replacing a machine component to which a decal is attached, be sure to also replace the decal.

• Replacement decals can be purchased from your Haybuster dealer.

77C /107C DRILLS OPERATING INSTRUCTIONS

3

DuraTech Industries uses industry accepted ANSI standards in labeling its products for safety and operational

characteristics.

Safety-Alert Symbol

Read and recognize safety information. Be alert to

the potential for personal injury when you see this

safety-alert symbol.

DANGER: Indicates an imminently

hazardous situation that, if not avoided, will

result in death or serious injury. This signal

word is to be limited to the most extreme

situations, typically for machine components

that, for functional purposes, cannot be

guarded.

WARNING: Indicates a potentially hazardous

situation that, if not avoided, could result in

death or serious injury, and includes hazards

that are exposed when guards are removed.

It may also be used to alert against unsafe

practices.

CAUTION: Indicates a potentially hazardous

situation that, if not avoided, may result in

minor or moderate injury. It may also be used

to alert against unsafe practices.

This manual uses the symbols to the right to denote

important safety instructions and information.

The DANGER, WARNING and CAUTION symbols

are used to denote conditions as stated in the text above.

Furthermore, the text dealing with these situations is

surrounded by a box with a white background, will begin

with DANGER, WARNING, or CAUTION.

The INFORMATION symbol is used to denote important

information or notes in regards to maintenance and use of

the machine. The text for this information is surrounded

by a box with a light grey background, and will begin with

either Important or Note.

DANGER

WARNING

CAUTION

INFORMATION

4

77C /107C DRILLS OPERATING INSTRUCTIONS

1.2 Operator - personal equipment

THE OPERATOR

Physical Condition

You must be in good physical condition and mental health and not under the inuence of any substance (drugs, alcohol)

which might impair vision, dexterity or judgment.

Do not operate a 77C/107C DRILL when you are fatigued. Be alert - If you get tired while operating your 77C/107C

DRILL, take a break. Fatigue may result in loss of control. Working with any farm equipment can be strenuous. If

you have any condition that might be aggravated by strenuous work, check with your doctor before operating

Proper Clothing

Clothing must be sturdy and snug-tting, but allow complete freedom of movement.

Avoid loosetting jackets, scarfs, neckties, jewelry, ared or cuffed pants, unconned

long hair or anything that could become entangled with the machine.

Protect your hands with gloves when handling discs and coulters. Heavy duty, nonslip

gloves improve your grip and protect your hands.

Good footing is most important. Wear sturdy boots with nonslip soles. Steel-toed safety

boots are recommended.

To reduce the risk of injury to your eyes never operate a 77C/107C DRILL unless

wearing goggles or properly tted safety glasses with adequate top and side protection.

Tractor noise may damage your hearing. Always wear sound barriers (ear plugs or ear

mufers) to protect your hearing. Continual and regular users should have their hearing

checked regularly.

77C /107C DRILLS OPERATING INSTRUCTIONS

5

1.3 Machine safety labels

The safety decals located on your machine contain important information that will help you operate your equipment.

Become familiar with the decals and their locations.

WARNING: FOR YOUR PROTECTION AND

PROTECTION OF OTHERS, PRACTICE THE

FOLLOWING SAFETY RULES.

1. BEFORE OPERATING THIS MACHINE, READ THE

OPERATOR’S MANUALS SUPPLIED WITH THIS

MACHINE AND YOUR TRACTOR.

2. CHECK OPERATORS MANUALS TO BE SURE

YOUR TRACTOR MEETS THE MINIMUM

REQUIREMENTS FOR THIS MACHINE.

3. READ ALL DECALS PLACED ON THIS MACHINE

FOR YOUR SAFETY AND CONVENIENCE.

4. NEVER ALLOW RIDERS ON THIS IMPLEMENT OR

THE TRACTOR.

5. KEEP OTHERS AWAY FROM THIS MACHINE

WHILE IN OPERATION.

6. KEEP ALL SHIELDS IN PLACE WHILE MACHINE IS

OPERATING.

7. KEEP HANDS, FEET, LOOSE CLOTHING, ETC.,

AWAY FROM POWER DRIVEN PARTS.

8. ALWAYS SHUT OFF MACHINE AND ENGINE

BEFORE SERVICING, UNCLOGGING,

INSPECTING, OR WORKING NEAR THIS MACHINE

FOR ANY REASON. ALWAYS PLACE

TRANSMISSION IN PARK OR SET PARK BRAKE

AND WAIT FOR ALL MOVEMENT TO STOP

BEFORE APPROACHING THIS MACHINE.

WARNING: FOR YOUR PROTECTION KEEP ALL

SHIELDS IN PLACE AND SECURED WHILE MACHINE

IS OPERATING MOVING PARTS WITHIN CAN CAUSE

SEVERE PERSONAL INJURY.

6

77C /107C DRILLS OPERATING INSTRUCTIONS

WARNING: CHEMICALS MAY CAUSE EYE, SKIN AND

BREATHING PROBLEMS.

WEAR FACE MASK, GLOVES AND GOGGLES .

READ AND FOLLOW SAFETY INSTRUCTIONS ON THE

CHEMICAL SUPPLIERS LABEL.

WARNING: NO RIDERS.

SERIOUS PERSONAL INJURY COULD RESULT FROM

RIDING ON STEP.

WARNING: DISC BLADES ARE EXTREMELY SHARP!

WEAR HEAVY GLOVES WHEN SERVICING.

77C /107C DRILLS OPERATING INSTRUCTIONS

7

1.4 Shielding

Shields are installed for your protection. Keep them in place, and replace damaged shields.

1.5 Personal equipment

Operators of this machine are encouraged to wear head, eye, and ear protection. Loose clothing is discouraged.

1.6 Safety review

BEFORE OPERATING

• Read and follow all instructions contained in:

A. This 77C/107C DRILL Operator’s Manual.

B. Tractor operator’s manual.

C. Decals placed on the 77C/107C Drill and Tractor.

NOTE: Additional copies of the above mentioned materials can be obtained from your dealer.

• Be sure all safety shields and covers are securely in place when machine is running.

• Read all warning and instructional decals placed on the machine for your safety and convenience.

• Allow only responsible, properly instructed individuals to operate machine. Carefully supervise

inexperience operators.

• Make no modications to this equipment unless specically requested or recommended by DuraTech

Industries.

• Tighten or replace any loose or cracked bolts, chains, hoses or connections.

• The towing vehicle must be of equal or greater weight than the grain drill for adequate braking capacity.

8

77C /107C DRILLS OPERATING INSTRUCTIONS

DURING OPERATION

• Exercise extreme caution with operating the drill on steep slopes or grades.

• Be sure all spectators are clear of the area where the drill is in operation or raised and lowered.

• Be sure the tractor operator is the only person riding the tractor. Allow no one to ride the drill at any time.

• Remember, loose clothing, necklaces and similar items are more easily caught in moving parts. Avoid the

use of these items if possible and keep long hair conned.

• Never work under the drill when the drill is lifted up unless the safety stop bar is in position.

• Watch out for and avoid any object that might interfere with the proper operation of the machine.

DURING SERVICE & MAINTENANCE

CAUTION: Before performing any maintenance or adjustments make sure machine is NOT running.

• Before working on or near drill for any reason including servicing, lubricating, cleaning, inspecting or

relling, or if working under drill or detaching from tractor, install safety stop bar (next to hydraulic

cylinder).

• When replacing any part on your drill, be sure to use only DuraTech Industries authorized parts.

• Relieve all pressure in the hydraulic system before disconnecting the lines or performing other work

on the system. Make sure all connections are tight and the hoses and lines are in good condition before

applying pressure to the system.

CAUTION: Hydraulic uid escaping under pressure can be invisible and have enough force to

penetrate the skin. When searching for a suspected leak, use a piece of wood or cardboard rather than

your hands. If injured, seek medical attention immediately to prevent serious infection or reaction.

• Be careful when using a hoist or other lifting device. Use only devices that have adequate lifting capacity

and be sure the chain or cable is securely attached.

77C /107C DRILLS OPERATING INSTRUCTIONS

9

WHEN TRANSPORTING ON PUBLIC ROADS

• Use good judgment and drive carefully, especially over rough or uneven roads.

• Be sure tractor brakes are properly adjusted and foot pedals locked together.

• Check your state laws regarding the use of lights, slow moving vehicle sign, safety chain and other

possible requirements.

• Do not tow drills at speeds over 20 mph. It is recommended that drills be empty of seed or fertilizer when

transporting.

10

77C /107C DRILLS OPERATING INSTRUCTIONS

IMPORTANT WINCH SAFETY INFORMATION

• The winch is built for multipurpose hauling and lifting operations. It is not to be used as a hoist for

lifting, supporting or transporting people, or for loads over areas where people could be present.

• Respect the winch. High forces are created when using a winch, creating potential safety hazards. It

should be operated and maintained in accordance with instructions. Never allow children or anyone who

is not familiar with the operation of the winch to use it. A winch accident could result in personal injury.

• Check winch for proper operation on each use. Do not use if damaged. Seek immediate repairs.

• Never exceed rated capacity. Excess load may cause premature failure and could result in serious

personal injury.

• Never apply load on winch with cable fully extended. Keep at least three full turns of cable on the reel.

• Secure load properly. When winching operation is complete, do not depend on winch to support load.

• Operate with hand power only. This winch should not be operated with a motor of any kind. If the winch

cannot be cranked easily with one hand, it is probably overloaded.

FAILURE TO COMPLY WITH ANY OF THE ABOVE SAFETY INSTRUCTIONS OR

THOSE THAT FOLLOW WITHIN THIS MANUAL MAY RESULT IN SEVERE INJURY

OR DEATH.

THIS DRILL IS NOT TO BE USED FOR ANY PURPOSE OTHER THAN THAT FOR

WHICH IT IS INTENDED AS EXPLAINED IN THE OPERATOR’S MANUAL,

ADVERTISING MATERIALS AND OTHER PERTINENT WRITTEN MATERIAL.

PREPARED BY DURATECH INDUSTRIES.

77C /107C DRILLS OPERATING INSTRUCTIONS

11

Section 2: Dealer Preparation

2.1 Gauge Wheel Attachment

The heavy duty gauge wheels mount on the tool bar in front of the drill. The gauge wheels are adjustable to maintain a

uniform planting depth when on side hills.

INSTALLATION

Step 1: Place the gauge wheel mount assembly in front of the second run assembly from either tool bar end.

See the accompanying illustration.

Step 2: Mount the gauge wheel mount assembly to the tool bar by using two gauge wheel mount straps and

four 5/8” x 6-1/2” hex bolts, lock washer and nuts provided. See accompanying illustration.

Step 3: Repeat Step 1 and Step 2 for the gauge wheel on the other side of the tool bar.

Step 4: Lift the tool bar using the drill’s hydraulics and insert both gauge wheels into the bottom of the

gauge wheel mount assemblies. See the accompanying illustration.

Step 5: If conditions prevent Step 4 from being done, the gauge wheels can be inserted into the front of

the gauge wheel mount assemblies. To do this, remove all four bolt sleeves (two per gauge wheel

mount assembly) by unbolting the four 3/4” x 6” hex bolts, lock washers and nuts and push the

gauge wheels into the mount assemblies. Bolt the bolt sleeves on to the gauge wheel mount

assemblies again.

Step 6: Adjust the gauge wheels to the desired position by inserting the adjustment handle through the

proper gauge wheel adjustment with the hair pin. This adjustment determines the gauge wheel

height that maintains the uniform planting depth on side hills. See the accompanying illustration.

12

77C /107C DRILLS OPERATING INSTRUCTIONS

Gauge Wheel (Option) Installation

77C /107C DRILLS OPERATING INSTRUCTIONS

13

2.2 Drill Legume Box Attachment

The legume box attachment features uted-feed cups which are capable of accurately metering small seeds even at very

low rates. The hopper will hold up to 150 lbs. of seed.

INSTALLATION

Step 1: Drill four 7/16” diameter holes in the front (grain) box as shown in Figure 1. Measure these holes

carefully and use a good center punch to mark locations before drilling. Loosely bolt the mounting

bracket to the grain box observing left hand and right hand parts.

Step 2: Remove the convoluted grain hoses and unbolt the cup assemblies from the grain tank. Replace

with modied cup assemblies provided with the legume box kit. Reattach the convoluted grain hoses

to the cups.

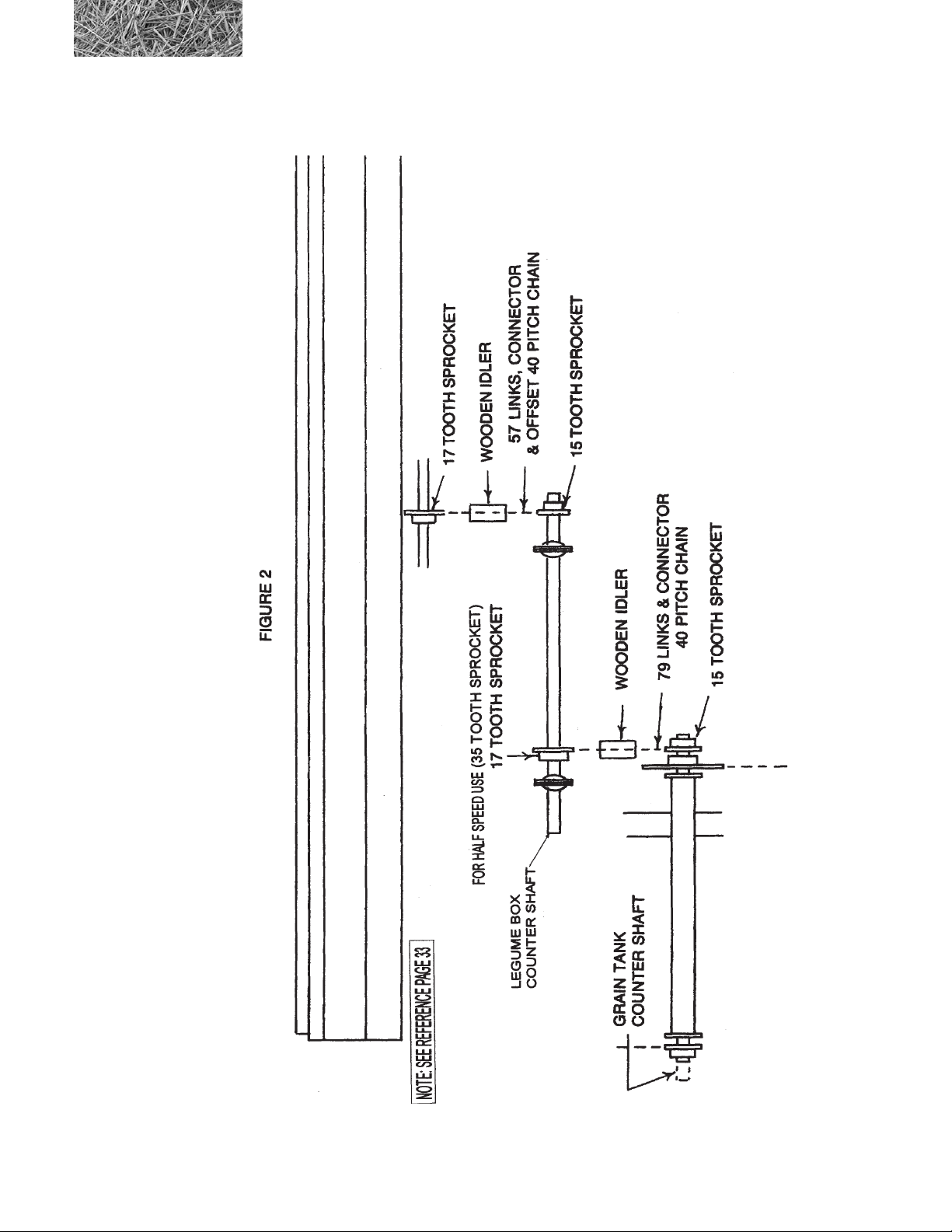

Step 3: Loosen chains, sprockets and bearings and move countershaft on grain tank. Reinstall existing

bearings, sprockets and chains and install 15 tooth sprocket as shown in Figure 2.

Step 4: Bolt legume box to grain tank using the four 3/8” x 1” bolts provided. The mounts welded to the

rear of the legume box should go between the mounting brackets installed in Step 1. Tighten all

mounting bolts securely.

Step 5: Bolt the two bearing standards to the brackets on the legume box using six 5/16 x 3/4” carriage

bolts, at washers, lock washers and nuts. Align the bearing standards before tightening bolts.

Loosely bolt the bearings to the outside of the bearing standards using the four 5/16”’ x 3/4” carriage

bolts. Install the 29” shaft with the 17 tooth sprocket BETWEEN the bearings as shown in Figure

2. Install two wooden block chain tightener using 3/8” x 2-1/2” bolts, two at washers, lock washer

and nuts. Tighten the drive chains.

Step 6: Cut 5/8” I.D. clear plastic hose to 22” lengths. Eighteen are required. Install hoses on the grain

cups rst and then on legume box cups. Dipping the ends in a liquid soap solution (one part soap to

one part water) will ease installation of the hoses.

14

77C /107C DRILLS OPERATING INSTRUCTIONS

Legume Box (Option) Installation

77C /107C DRILLS OPERATING INSTRUCTIONS

15

2.3 Legume Hopper Shipping Kit (Optional)

ITEM PART NO. QTY. DESCRIPTION

1 8700001 1 BRKT\LEGUME\LH\LEG-BOX

2 8700002 1 BRKT\LEGUME\RH\LEG-BOX

3 8700003 4 STRAP\LEGUMEBOX

4 8700008 1 BRG\BOX\LEGUME\RH

5 8700009 1 BRG\BOX\LEGUME\LH

6 2000002 2 BRG\1” W/LOCK\COLLAR

7 2000703 4 FLGETT\1\2BOLT\PLTD

8 2000016 2 BLK\WD\IDLER

9 8700011 1 SHFT\1X29\LEGUMEBOX

10 1000111 1 SPKT\B\40\17\1\1/4KW\SOFT

11 1000112 2 SPKT\B\40\15\1\1/4KW

12 6200010 3 KEY\SQ\1/4X1

13 1100232 1 CHAIN\40NP\53

14 1100246 1 CHAIN\40NP\79

15 1100224 2 CHAIN\40NP\CL

16 1100225 2 CHAIN\40NP\OL

17 3700129 18 HOSE\PVC\5/8IDX22-1/2\CLR

18 4800098 4 BOLT\HEX\3/8X1-1/4\NC

19 4800156 4 BOLT\HEX\3/8X3

20 4800029 2 BOLT\HEX\3/8X2-1/2

21 4800003 4 BOLT\HEX\3/8X1

22 4900002 14 NUT\HEX\3/8\NC

23 5000019 14 WASH\LOCK\3/8

24 500000 1 4 WASH\FLAT\3/8

25 4800153 10 BOLT\CRG\5/16X3/4\NC

26 4900003 10 NUT\HEX\5/16\NC

27 5000022 10 WASH\LOCK\5/16

16

77C /107C DRILLS OPERATING INSTRUCTIONS

Section 3: Introduction

Every effort has been made to ensure that the information contained in this manual is correct at the date of publication;

but, due to continuous improvements, DuraTech Industries reserves the right to make changes in the contents without

notice or obligation.

This manual is shipped with each machine to familiarize the operator with the proper operating, maintenance and

lubrication instructions to insure the best possible performance and service from the machine. Study and understand

these instructions thoroughly before operating the machine. We recommend that this manual be readily available for

reference at all times. Consult your DuraTech Industries dealer if any items in this manual are not understood.

DuraTech reserves the right to make changes in engineering, design and specications, add improvements, or

discontinue manufacture at any time without notice or obligation.

3.1 Ordering Parts

When ordering parts always specify your model number, serial number, and the number of the parts you wish to order.

IMPORTANT: WHEN REPLACEMENT PARTS ARE NEEDED, USE THE LISTED PART

NUMBERS AND DESCRIPTIONS TO INSURE FAST AND ACCURATE SHIPMENT OF YOUR

ORDER. WHEN ORDERING PARTS ALWAYS SPECIFY UNIT SERIAL NUMBER.

ONLY AUTHORIZED PARTS SHOULD BE USED FOR REPAIR AND/OR REPLACEMENT.

77C /107C DRILLS OPERATING INSTRUCTIONS

17

3.2 Serial Number Decal

The serial number and the machine model number are stamped on the decal. The model number and serial number are

important when service and/or parts are required.

3.3 About your 77C/107C Grain Drill

The 77C/107C Grain Drill is designed to seed No-Till, Minimum Till, or conventionally tilled elds. Two 30 gallon

tanks are available for added ballast to penetrate the tough no-till conditions.

The two compartment hopper offers the exibility of seeding with fertilizer, seeding alone, or planting two different

seeds. The metering system for each hopper is innitely adjustable.

Field hitches are available for one or multiples of two, three, and four of the model 107C Drill only. A tow hitch is also

available for the 107C Drill to allow the towing of two or more drills in transport.

18

77C /107C DRILLS OPERATING INSTRUCTIONS

Section 4: Operating Instructions

To insure long life and economical operation, we highly recommend the operator of the 77C/107C Grain Drill be

thoroughly instructed in the maintenance and operation of the machine. There is no substitute for a sound, preventative

maintenance program and a well-trained operator.

Prior to operating the Grain Drill, we recommend the operator make a visual inspection of the unit. This can be done as

the lubrication is being carried out.

4.1 Operating Instructions

Check the following:

q Hydraulic components for leaks or damage.

WARNING: Hydraulic uid escaping under pressure can be almost invisible and can have sufcient

force to penetrate the skin. When searching for suspected leaks, use a piece of wood or cardboard

rather than your hands.

If injured, seek medical attention immediately to prevent serious infection or reaction.

q Lug nuts for tightness.

q Condition of tire rims.

q Tires for proper air pressure.

q Condition of rubber convoluted hoses.

q Adjustment of all chains.

q Installation and condition of shields.

q Installation of Slow Moving Vehicle (SMV) sign.

q Condition of decals.

WARNING: Before attempting to operate this machine, refer again to Section 1 (pages 3-11) for

important safety information.

77C /107C DRILLS OPERATING INSTRUCTIONS

19

4.2 Grain Drill Setup

The 77C/107C Grain Drill may be shipped without the hydraulic lift cylinder, since the grain drill used a standard 3”

x 8” cylinder. The retracted length must be 20-1/4”, measured from the center of the mounting holes. When multiple

grain drills are used, a cylinder will be required for each grain drill.

• Set the wheels on your tractor out as wide as possible for maximum stability.

• Hitch the grain drill to the tractor.

• Connect the hydraulic hoses to the tractor’s hydraulic system.

4.3 Pressure Spring Adjustment

To gain versatility for all types of terrain and soil conditions, it is important to have a considerable amount of up and

down travel built into each individual run. When seeding on level terrain, adjust hydraulic cylinder stroke to lower

Movable Frame so openers penetrate soil approximately two (2) inches and Parallel Bars are about level when viewed

from the side. The toolbar height will be about 20” when discs are new. This will allow runs to move up or down

according to terrain.

If parallel bars are not level, it will be necessary to adjust pressure spring, or press wheel adjustment.

Proper tension of the pressure spring varies with conditions. No-till seeding may require more down pressure; loose

soil requires less. Since the pressure springs work together with the opener depth adjustment controlled by the

hydraulic cylinder, make sure that the opener depth adjustment is set correctly.

pressure spring adjustment

20

77C /107C DRILLS OPERATING INSTRUCTIONS

In extremely loose soils such as freshly worked summer fallow, it will be necessary to lessen tension on pressure spring

instead of lessening hydraulic cylinder stroke.

To adjust the pressure springs:

1. Make sure the movable frame is raised completely

up and the safety stop bar is secured.

2. Using the adjustment nut on each pressure spring,

adjust the spring to the desired length. See table

at right showing the opener pressure obtained at

various spring lengths. Under no circumstances

should the spring be adjusted to less than 10 inches.

This may damage the spring and related parts and

SPRING

LENGTH

12¼ IN.

11½ IN.

11 IN.

10½ IN.

10 IN.

OPENER

PRESSURE

135 LBS.

180 LBS.

205 LBS.

235 LBS.

300 LBS.

will also void the warranty on these parts.

4.4 Press Wheel Adjustment

In addition to rming the soil around the seed, the press wheels serve as gauge wheels for the openers. The relationship

of each press wheel and opener will remain consistent regardless of terrain or soil density. If the seed is too deep, lower

the press wheel. If the seed is too shallow, raise the press wheel.

To adjust the press wheel height:

1. Remove quick attachment pin.

2. To lower the press wheel, relocate shim washers from top to bottom. To raise the press wheel, relocate

shim washers from bottom to top.

3. Install quick attachment.

depth adjustment washer for

serial numbers 401 and up

77C /107C DRILLS OPERATING INSTRUCTIONS

21

4.5 Haybuster 77C/107C Drill Opener

The 77C/107C Drill uses a coulter-disk offset opener. The coulter blade leads the disk by 1-1/2”. Both blades are the

same size and due to the offset, there is some sliding action where the blades contact. This sliding or scissor action

provides excellent residue cutting action at ground level, especially in wet residue. The scissor action causes some

wear into the coulter blade at the point of contact. This wear is normal and the heavier coulter blade is bolted to the

bearing cage to allow easy replacement.

depth adjustment washer for

serial numbers 401 and up

One complete turn changes points A and B (DWG. 1) the amount shown in DWG. 2. It takes 6 turns to bring points A

and B back together.

4.5A Control Plates

Control plates are mounted using a spring, bolt, guide tube, washers and nut assemblies. The two outer and center

assemblies use a larger washer, guide tube, washer, bolt and top locknut. When installing these assemblies, tighten

the bolt until the guide tube is tight against the tank. The remaining assemblies use a spring, washers, bolt and a top

locknut. On these remaining assemblies, the springs should be tightened to 1-1/16” - 1-1/8”.

remaining bolt assemblies

outer bolt assemby

control plate

22

77C /107C DRILLS OPERATING INSTRUCTIONS

control plate

remaining bolt assemblies

center bolt assembly

4.6 Feed Wheel Space Adjustment

Large seeds require more space between feed wheel lugs and tank wall than small seeds to prevent cracking. Small

seeds require less space to provide an even ow. Therefore each seed listed in the feed rate chart, pages 28 to 31, shows

a required wheel space.

feed wheel space

adjustment.

FEED WHEEL SPACE ADJUSTMENT

bolt B

bolt A

1. Remove the feed wheel covers.

2. Loosen the eight bolts A and B. There are four sets

of bolts for each feed wheel - two on the outer end

of the hopper and six inside the hopper.

3. Select the proper space gauge using the wheel

space chart.

4. Install the proper space gauge as shown.

5. Slide the feed wheel toward the gauge until the

feed wheel lugs, gauge and hopper are pressed

together. Tighten the eight bolts.

6. Recheck the feed wheel space adjustment.

7. Install the feed wheel covers.

one set of feed wheel space

adjustment bolts

The feed wheel space adjustment provides the proper clearance for the type of seed or fertilizer

being used.

77C /107C DRILLS OPERATING INSTRUCTIONS

23

4.7 Drill Cleanout Slides

Cleanout slides are provided on both grain and fertilizer

tanks. Handles for opening and closing the slides are

located on the left side of the drill.

drill cleanout slides

handles

24

77C /107C DRILLS OPERATING INSTRUCTIONS

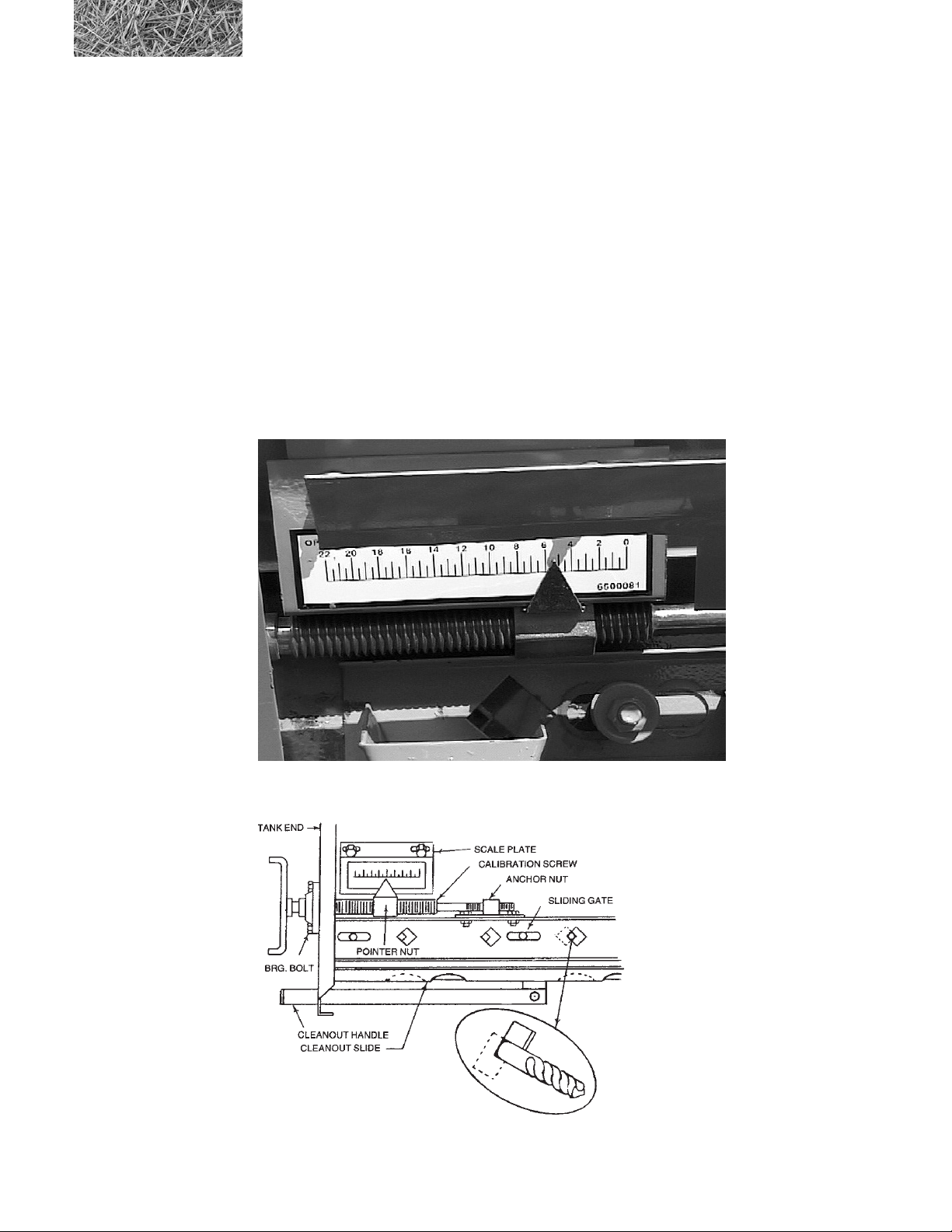

4.8 Calibration Pointer Adjustment

Grain and fertilizer sliding gates are preadjusted at the factory. In the event any part of the calibrating mechanism is

removed or replaced, it can be recalibrated in this order:

1. Place both pointer nut and anchor nut in the center of their respective thread.

2. Insert a short length of 7/16” rod or the shank end of a 7/16” drill bit into the square hole in sliding gate

as shown.(gure 4.1)

3. Tighten bearing bolts securing calibration screw to end of tank.

4. Tighten bolts securing anchor nut to sliding gate.

5. Place scale plate on tank so number 8 is directly in line with top of pointer. This will insure pointer

setting to coincide with chart. Scale plate must be parallel with calibration screw to allow pointer to

operate smoothly along plate.

calibration pointer

adjustment

gure 4.1

77C /107C DRILLS OPERATING INSTRUCTIONS

25

4.9 SETTING AND CHECKING FEED RATE

front feed wheel alignment

For most seeding, the front feed wheel should be aligned as shown above. Set the pointer on number 8. The center of

the front feed wheel should be centered in the opening as viewed from outside of the box.

Rear feed wheel alignment

Setting the rear feed wheel, set pointer on number 22. The right edge of the rear feed wheel should line up with the right

point of the diamond as viewed from outside of the box.

The rates shown on the charts serve only as a starting point. Due to variations in material size and density the rates may

vary from the chart. The following methods may be used to determine the proper setting for your particular seed or

fertilizer.

Setting and checking feed rate using wheat as an example.

1. You want to seed wheat at a rate of 95 lbs. per acre on 7” spacing.

2. Seed rate charts calls for a wheel space of 1/8” (page 28). Pointer set on 8 (see illustration above). The

adjustment should be made before lling grain tank.

3. Make sure feed wheel cover is in place. Put grain in tank.

4. Seed far enough so you can visually check grain owing into seed cups.

26

77C /107C DRILLS OPERATING INSTRUCTIONS

The addition of the single agitator to the standard drill box will prevent these seeds from bridging above the feed

wheels. The single agitator may be added to all 77C/107C drills.

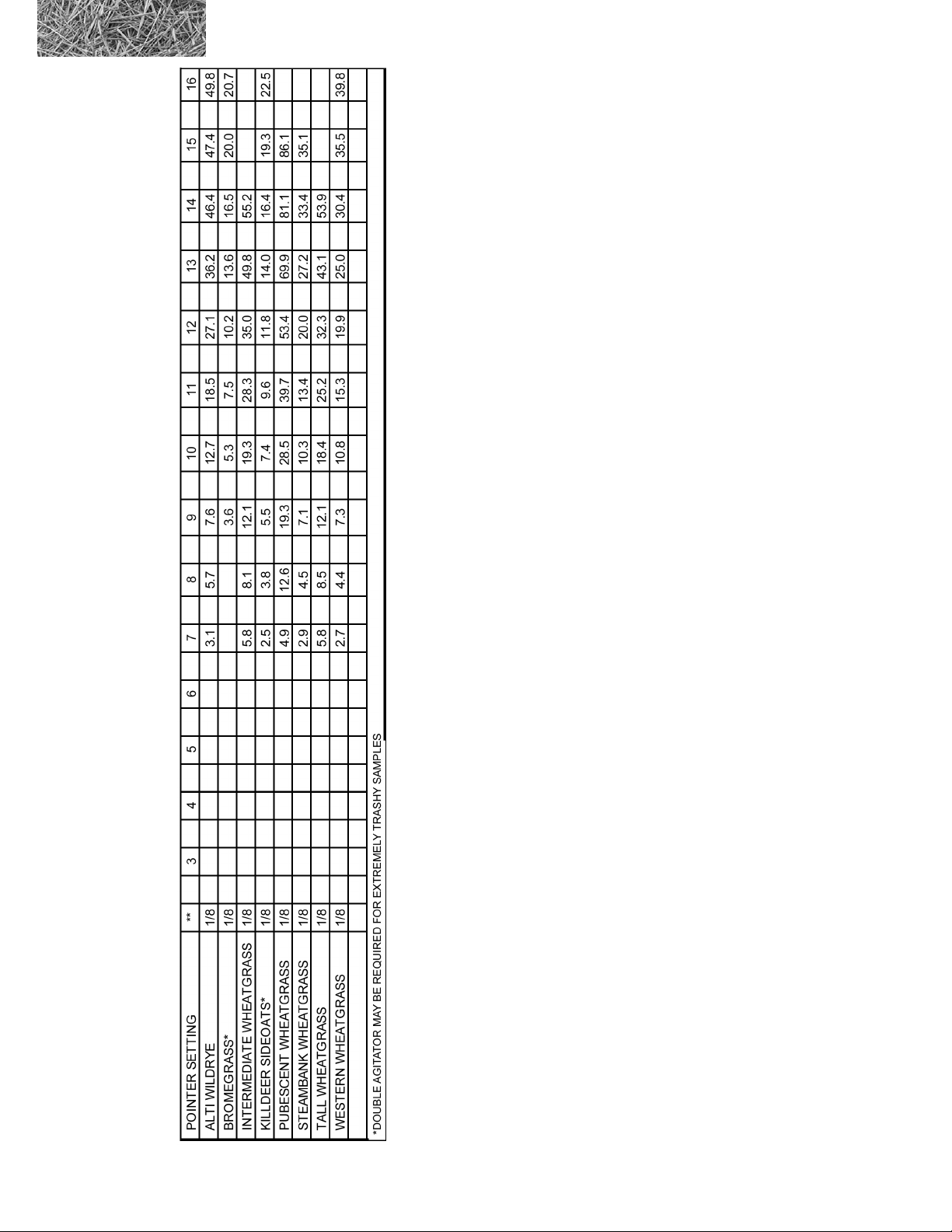

Alti wildrye

Bromegrass #

Intermediate wheatgrass

Killdeer sideoats #

Pubescent wheatgrass

Streambank wheatgrass

Tall wheatgrass

Western wheatgrass

# Extremely trashy samples may require the double agitator.

4.10 CHECKING FEED RATE

1. Measure a distance of 415’ on a drill with 7” spacing and mark. Remove one hose from seed hopper

on each drill. Attach a container (cloth or plastic bag) to hopper to collect seed.

2. Operate drill at intended planting speed through entire length of test track.

3. Weigh the sample in ounces (less weight of sample container). Use the following formula to determine

lbs./acre for your particular shank spacing.

7” Spacing - oz. x 11.25 = lbs./acre

EXAMPLE

Sample and container weighs 9.9 ounces

Container weighs - 1.5 ounces

Weight of sample only 8.4 ounces

4. Use formula No. 1 to gure pounds per acre. 8.4 ounces x 11.25 = 94.5 pounds per acre.

5. To calibrate a seed not shown on the chart or a mix of different seeds, compare to a similar charted

seed to obtain a trial setting. Recalibrate as necessary.

6. The same method may be used to determine fertilizer rates.

77C /107C DRILLS OPERATING INSTRUCTIONS

27

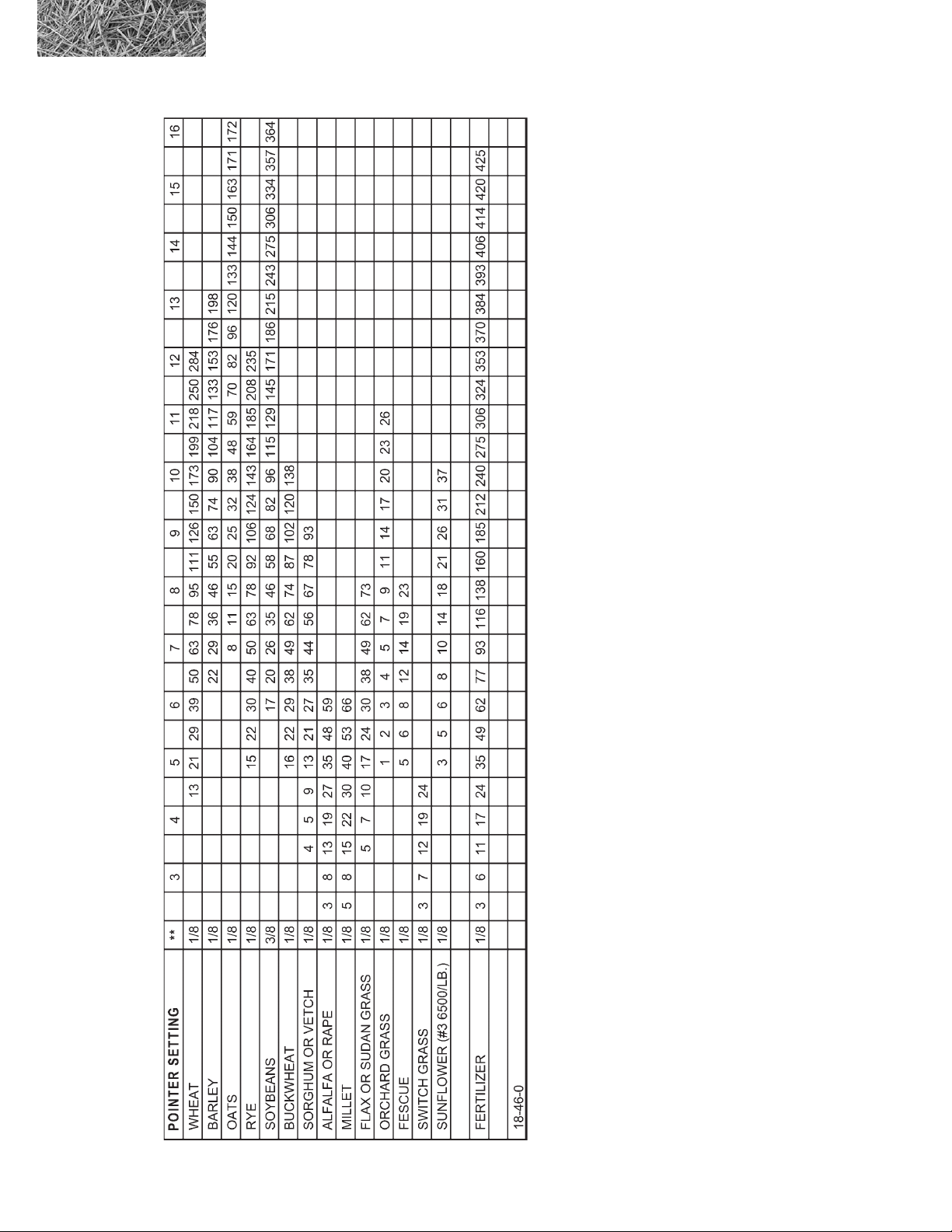

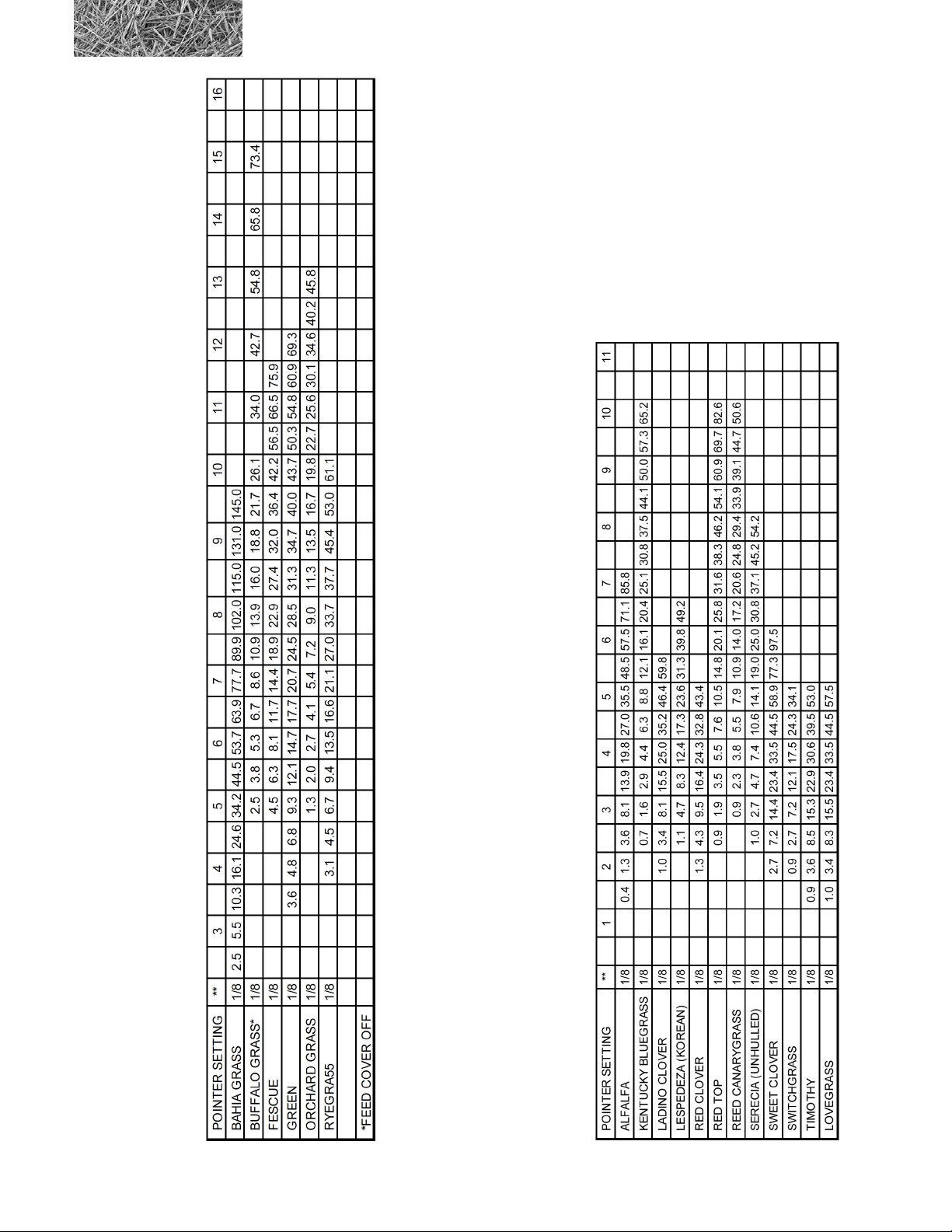

POINTER SETTING

CHART FOR DRILLING GRAIN IN POUNDS PER ACRE

100 DRILL DETERMINING SEED POPULATION

28

Series 100

Spacing 7”

Model No. 77C/107C

The 107C Drill seeds 10.50’ / 126” per pass; the 77C Drill seeds 7’/ 84” per pass.

The 107C Drill travels 4149 feet to seed 1 acre; the 77C Drill travels 6223’ to seed 1 acre.

Following is the lineal feet of seeded row to seed 1 acre.

7” rows - 74,700 ft/acre

EXAMPLE:

150,000 bean plants desired per acre on 7” row spacing

** = indicates wheel spacing

77C /107C DRILLS OPERATING INSTRUCTIONS

150,000 divided by 74,700 = 2.0 beans per ft.

10 ft. of row - 20 beans.

POINTER SETTING

POINTER SETTING

CHART FOR DRILLING GRAIN IN POUNDS PER ACRE

Spacing 7 Inch

77C /107C DRILLS OPERATING INSTRUCTIONS

** = indicates wheel spacing

CHART FOR DRILLING GRAIN IN POUNDS PER ACRE

Spacing 7 Inch

** = indicates wheel spacing

29

POINTER SETTING

CHART FOR DRILLING GRAIN IN POUNDS PER ACRE

30

Spacing 7 Inch

** = indicates wheel spacing

77C /107C DRILLS OPERATING INSTRUCTIONS

IN POUNDS PER ACRE

LEGUME BOX ATTACHMENT FOR 77C/107C DRILL ON 7” SPACING

SEED MIXTURES

SELECT THE SETTING FOR THE DESIRED

QUANTITY OF EACH SEED.

ADD INDIVIDUAL SETTINGS.

EXAMPLE:

LBS/ACRE NOTCH

ALFALFA 5 2

SWEET CLOVER 5 2

TIMOTHY 2 1

TOTAL 5

WHEN USING HALF SPEED DRIVE DIVIDE

CHARTED RATES BY TWO. REPLACE 17

TOOTH SPROCKET ON COUNTERSHAFT

WITH 35 TOOTH. (SEE MANUAL FOR

DETAILS.)

DENSITY OF THE SAMPLES USED TO

PREPARE THIS CHART ARE GIVEN IN THE

FIRST COLUMN TO THE RIGHT OF THE

CROP NAME IN POUNDS PER BUSHEL.

CHART FOR DRILLING LEGUMES AND SMALL GRASSES

77C /107C DRILLS OPERATING INSTRUCTIONS

31

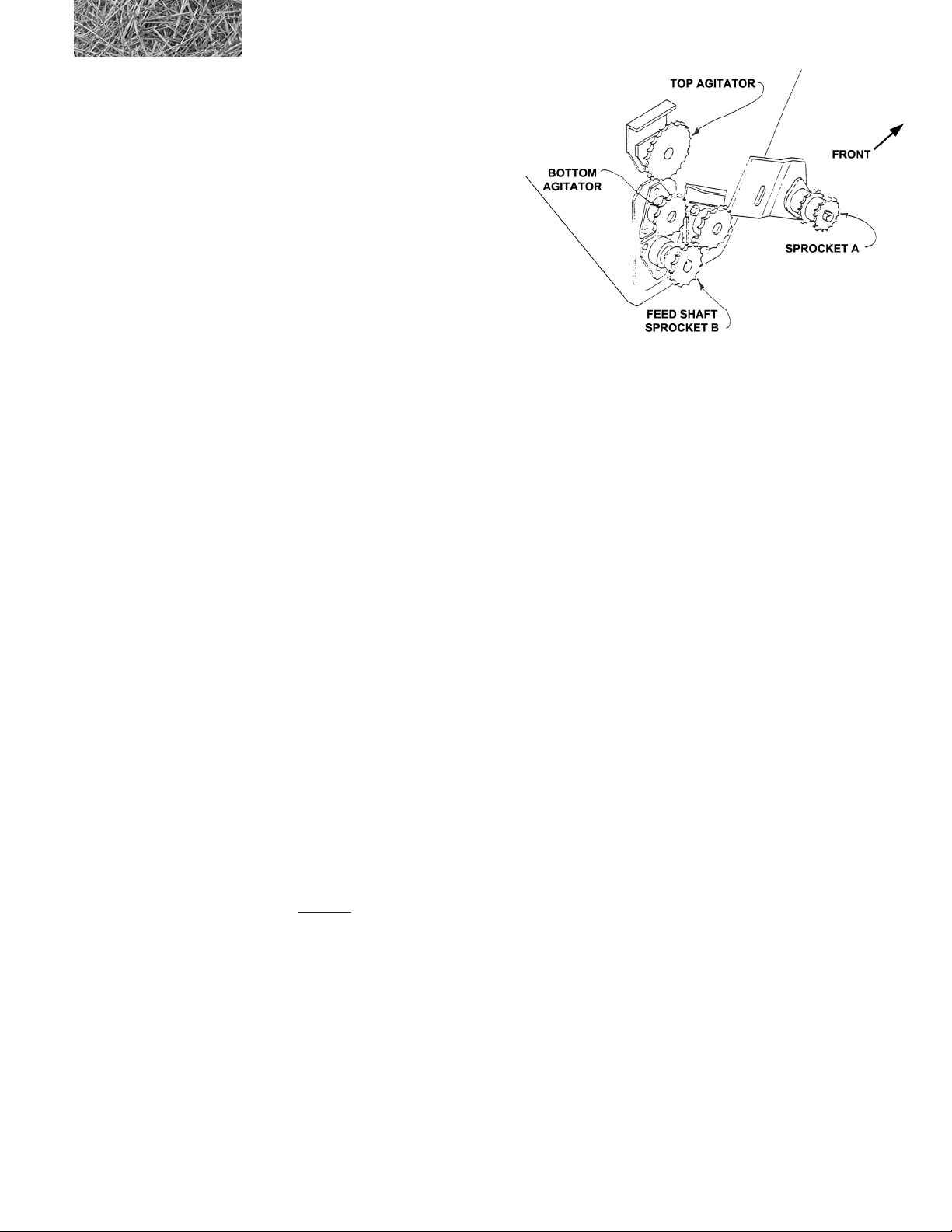

CHART FOR DRILLING GRASS IN POUNDS PER ACRE

To obtain the desired seeding rate of the chaffy native

grasses it may be necessary to adjust the feed shaft speed.

The charts on page 32 list the sprocket combinations and

relative speed in revolutions per acre. Use these charts as

a guideline in choosing the correct sprocket combinations.

On a standard drill box, sprocket A has 14 teeth and

sprocket B has 18 teeth. There are 12 tooth and 24 tooth

sprocket included in the shipping kit for the native grass

attachment.

Also see information in section 5.4

32

Spacing 7 Inch

** = FOR BEST RESULTS OBTAIN THE MOST TRASH-FREE SEED AVAILABLE.

77C /107C DRILLS OPERATING INSTRUCTIONS

4.11 Drilling with the Grain Drill

If the grain drill was transported using the optional end hitch, the rear wheels will need to be rotated as follows:

1. Use the hydraulic system to lower the openers onto solid soil or use a jack to raise the drill frame and

remove the weight from the rear wheels.

2. Remove the bolts from each wheel.

rotating the wheels for

drilling (wheel shown in

drilling position)

3. Rotate the wheels 90° and insert bolts.

4. Using a tape measure, align the wheels so that they are parallel with each other and the frame as shown.

Adjust and secure the stop bolt #2.

77C /107C DRILLS OPERATING INSTRUCTIONS

NOTE: Step 4 covers alignment of the wheels. Once this adjustment is set, it should not

normally be necessary to readjust it. Alignment of the wheels in the working position is less

critical than in the transport position because of the softer surfaces and slower speeds.

33

5. Tighten the bolts.

6. Remove the jack, if used.

7. After the tractor is hitched to the front hitch, move the drill ahead slowly until the front swivel wheels are

properly positioned.

At this point the grain drill should be properly set up and adjusted according to the instructions in the preceding

sections.

Load the tanks with seed and/or fertilizer. Rotate the drive wheel by hand to make sure that the feed wheel shafts are

free to turn. This is particularly important if the drill was transported with fertilizer and seed in the hoppers.

Start the tractor, retract the cylinder completely, and begin drilling.

Periodically check for proper seed depth and feed rate.

When the seeding operation is nished, park the drill over a sheet of plastic, canvas, etc. Pull one of the cleanout side

control levers out to empty the remaining seed or fertilizer. Collect the seed or fertilizer. Repeat the procedure for the

other hopper.

34

77C /107C DRILLS OPERATING INSTRUCTIONS

4.12 SUGGESTIONS

When preparing to sow damp fertilizer that has been sitting in the tank for several hours, stir the fertilizer all the way to

the bottom to break up any blocks of fertilizer which have become cemented together.

The amount of fertilizer sown will vary with the moisture content and quality of the fertilizer.

4.13 REAR WHEEL SWIVEL AND ADJUSTMENT

Both rear wheels are designed to swivel 90° for the purpose of transporting drills endways. Adjusting bolts are

provided for aligning wheels in transport position as well as in forward position. Transport position is most critical for

tire wear due to hard surface roads and faster speeds.

CAUTION: Transporting drills with seed and fertilizer in the tanks is not recommended. If drills

are moved any distance with seed or fertilizer in tanks, either in transport or eld position, materials

will settle around feed wheels. Before starting to seed, operator should check with a wrench on drive

end of feed wheel shaft to make sure they are free to turn. Shaft may be turned either clockwise or

counterclockwise with openers in raised position.

WARNING: Maximum transport speed should never exceed 20 M.P.H., and should be less where

conditions demand.

4.14 TRANSPORTING THE GRAIN DRILL

The rear wheels swivel 90° to transport the drill end ways with the optional end hitch. These wheels must be carefully

aligned before transporting the drill because of the hard surfaces.

To rotate the rear wheels:

1. Use the hydraulic system to lower the openers onto solid soil or use a jack to raise the drill frame and

remove the weight from the rear wheels.

2. Remove the lock bolts from each wheel.

3. Rotate the wheels 90° and insert the lock bolts.

NOTE: Step 4 covers alignment of the wheels. Once this adjustment is set, it should not normally be

necessary to readjust it.

77C /107C DRILLS OPERATING INSTRUCTIONS

35

rotating the wheels for

drilling (wheel shown in

drilling position)

4. Using a string, align the wheels as shown. Adjust and secure the stop bolts.

5. Tighten the lock bolts.

6. Raise the openers or

remove the jack. Secure

the torque bar in the

transport position with

the safety stop bar.

rear wheel alignment - transport position

7. After the tractor is hitched to the end hitch, move the drill ahead slowly until

the front swivel wheels are properly positioned.

36

step # 4

stop bolt

77C /107C DRILLS OPERATING INSTRUCTIONS

4.15 CLEANING GRAIN TANKS AND LEGUME BOXES

CLEAN grain tanks and/or legume boxes on the 77C/107C Drill after using inoculated, treated or

coated seeds. Failure to clean tanks will cause damage to moving parts. This damage is NOT covered

by warranty. Always add graphite to treated seeds.

4.16 PREPARING FOR STORAGE

To prepare the 77C/107C Drill for storage, perform the following steps:

1. Install safety stop bar to keep planting units off the ground and to minimize rusting. Before drill is stored,

clean out slides should be opened to remove as much seed and fertilizer as possible. Both tanks should

be ushed out thoroughly to prevent any caking of seed or fertilizer. Open and close slides while ushing

to allow any fertilizer that might be under the calibration slide to work its way free. Fertilizer can be

damaging if left in contact with metal parts for a prolonged period.

2. Clean all mud, dirt, grease and other foreign material from the exterior of the machine. Wash the complete

machine. Repaint places where bare metal is exposed - this will inhibit rusting.

3. After inside of the tank is thoroughly dry, apply a coat of oil or diesel fuel to calibration slide, bearings

and other parts that have been in contact with fertilizer or seed.

4. Remove the chains and wash them in solvent. Using a clean cloth, wipe off the chains. Soak the chains

in engine oil. Drain off the excess oil and install the chains on the grain drill.

5. Coat all chains and exposed hydraulic cylinder rod with a Valvoline Tectyl 506 oil or equivalent.

6. Lubricate machine thoroughly according to the lubrication instructions.

7. Drain water from ballast tanks, if installed.

8. If possible, store the machine in a dry, protected place. If it is necessary to store the machine outside,

cover it with plastic, waterproof canvas, or other suitable protective material.

9. Check the machine for any worn or broken parts. By ordering parts now, you will avoid delays when it

is time to remove the machine from storage. When ordering parts always specify machine serial number

and the part number of the replacement part. Part numbers can be found in the Parts List Manual.

4.17 REMOVING FROM STORAGE

To remove the 77C/107C Drill from storage, perform the following steps:

1. Remove all protective coverings.

2. Remove all excess oil from chains and cylinder rods. Lubricate machine in accordance with lubrication

instructions found in this manual.

3. Check all hydraulic hoses for deterioration and, if necessary, replace. Tighten any loose bolts, nuts and

hydraulic ttings.

4. Follow prestarting inspection.

77C /107C DRILLS OPERATING INSTRUCTIONS

37

A Tradition of Innovation Since 1966

38

77C /107C DRILLS OPERATING INSTRUCTIONS

Section 5: Grass Seeding Reference

All Haybuster 77C/107C Grain Drills are very versatile. These base drills are capable of accurately metering most

common seeds and fertilizer. The seed will be placed at the correct depth in conventional and minimum tillage and

most zero-tillage situations. Through the use of special attachments, Haybuster 77C/107C Grain Drills can be used for

seeding of various types of grass seeds including small-seed legumes and chaffy native grasses. When grass seeding is

complete, each of these drills are capable of seeding and fertilizing your conventional crops. For more information on

operating the drill, settings and procedures, please see Section 4: Operating Instructions.

5.1 Grass Seeding Attachments

The following attachments are available for grass seeding:

• Legume box

• Single agitator

• Double agitator

• 2” I.D. seed tubes

• Depth bands

Many grasses can be metered through the standard seed box with no additional equipment. However, some of the

grasses listed below can be metered more accurately by using some of the special attachments listed on the following

pages.

*Alfalfa *Alsike clover @Altiwild rye *Bahiagrass

*Birdsfoot trefoil @Bromegrass Buffalograss Fescue

Green needlegrass @Intermediate wheatgrass *Kentucky bluegrass @Killdeer sideoats

*Ladino clover *Lespedeza (unhulled) *Lovegrass Orchard grass

@Pubescent wheatgrass Ryegrass *Red clover *Red top

*Reed cararygrass *Serecia (unhulled) *Sweet clover *Switchgrass

@Streambank wheatgrass *Timothy @Tall wheatgrass @Western wheatgrass

* See legume box section, page 40

@ See single agitator section, page 40

77C /107C DRILLS OPERATING INSTRUCTIONS

39

5.2 Legume Box Applications

The legume box attachment is designed to accurately meter the small seeds listed below.

Alfalfa Alsike clover Bahia grass Birdsfoot trefoil

Fescue Kentucky bluegrass Ladino clover Lesoedeza (Korean)

Lovegrass Orchard grass Red clover Red top

Reed canarygrass Rye grass Serecia (unhulled) Sweet clover

Switchgrass Tibbet clover Timothy Vetch

For more information please see the Chart for drilling legumes and small grasses on page 31.

5.3 Single Agitator Applications

The addition of the single agitator to the standard drill box will prevent these seeds from bridging above the feed

wheels.

Alti wildrye Bromegrass # Intermediate wheatgrass

Killdeer sideosts # Pubescent wheatgrass Streambank wheatgrass

Tall wheatgrass Western wheatgrass

# Extremely trashy samples may require the double agitator.

For more information please see the Chart for drilling grain on page 30.

5.4 Special Instructions for Warm Season Grasses

Warm season grasses tend to be very low bulk and are very trashy or chaffy in appearance. Special equipment required

to properly meter these grasses is listed below.

• Double agitator (top and bottom)

• Larger opening in drill box (1-1/2 inch)

• 2 inch I.D. grass tube kit

• Sprocket set (feed shaft speed adjustment)

Obtain the best quality seed available for best results. Trashier samples may need to be blended with heavier seed to

improve metering capabilities. Center the feed wheels as shown on page 23. Be sure to check the feed wheels as shown

on page 23.

Blue grammagrass Big bluestem Indian grass Little bluestem Prairie sandreed

40

77C /107C DRILLS OPERATING INSTRUCTIONS

To obtain the desired seeding rate of the chaffy native

grasses it may be necessary to adjust the feed shaft speed.

The charts on page 32 list the sprocket combinations and

relative speed in revolutions per acre. Use these charts as

a guideline in choosing the correct sprocket combinations.

On a standard drill box, sprocket A has 14 teeth and

sprocket B has 18 teeth. There are 12 tooth and 24 tooth

sprocket included in the shipping kit for the native grass

attachment.

5.5 Pure Live Seed Calculations

Any sample of bulk seed always has a certain percentage of non-viable seed and inert matter. In cereal grains, this

percentage is quite small and can usually be ignored when determining seeding rates. Grass seeds can have a very

high percentage of dormant and non-viable seed, and inert matter. These high percentages must be considered when

determining grass seeding rates.

For example: You wish to plant Big Bluestem (Chart pg 32) at a rate of 12 ponds of pure live seed (pls) per acre.

A typical grass seed tag might appear as follows:

Big Bluestem

Weed seed……………..0.10% Lot No………….83101

Noxious weed seed…….0.00% Germ……………52.0%

Other crops…………….0.05% Date of test………3-86

Inert matter……………40.05% Grown…………Kansas

Step 1. Determine the total percentage of inert matter from the seed tag

Weed seed 0.10%

Noxious weed seed 0.00%

Other crops 0.05%

Inert matter 40.05%

40.20%

Step 2. Subtract the percentage of inert matter from 100% to nd pure seed percentage.

100.0% - 40.20% = 59.80%

Step 3. Divide the pounds of pure live seed desired by the percent pure seed.

12 lbs pls/0.5980= 20.07 lbs pure seed

77C /107C DRILLS OPERATING INSTRUCTIONS

41

Step 4. Divide pounds of pure seed by the germination percentage to get bulk seed.

20.07/0.52 = 38.6 lbs of bulk seed

So 38.6 lbs of bulk seed per acre must be sown to get 12 lbs of pure live seed per acre.

For most seeding, the feed wheel should be aligned as shown above. Set the pointer on number 8. The center of the

feed wheel should be centered in the opening as viewed from outside of the box.

When seeding the grasses listed on page 32, move the feed wheel as shown above. Set the pointer on number 22,

the center of the feed wheel should be centered in the opening as viewed form outside of the box. Generally, a small

screwdriver or similar tool may be inserted through the opening into the tank and used to push the wheel into position.

The agitator blades inside the drill box may need to be re-centered over the feed wheels to prevent interference.

42

77C /107C DRILLS OPERATING INSTRUCTIONS

Section 6: Lubrication

All 77C/107C Grain Drills are completely serviced at the factory before shipping. However, the operator should make

a check of all grease ttings on the unit before beginning to operate it so as to become familiar with their location and

the correct service schedule.

Use only a high quality, multi-purpose grease when lubricating the unit. Make sure all ttings and the nozzle of the

grease applicator are clean before applying the grease. If any grease ttings are missing, replace them immediately.

Lubricating of all pillow block and ange-type self-aligning ball or roller bearings should be done slowly to help

prevent bearing seal damage. Use caution when using a high pressure, high volume gun.

Description Type Frequency No. Zerks

1. Swivel Wheel Pivot Grease 20 Hrs. 2

2. Torque Tube Bushings Grease 40 Hrs. 2

3. Universal Joints Grease 40 Hrs. 2

4. Square Drive Line Grease 40 Hrs. 2

5. Feed Wheel Shaft Grease 100 Hrs. 6

6. Roller Chains Oil Daily In Dusty Conditions

7. Tool Bar Bushing Grease 20 Hrs. 2

8. Lift Arm Bushing Grease 20 Hrs. 2

9. Lift Arm Grease 20 Hrs. 2

10. Drive Wheel Frame Grease 20 Hrs. 2

11. Packer Wheel Bearings and Coulter-Disk Bearings are Non-Relubable.

12. Cylinder Clevis Pin Grease 20 Hrs. 1

swivel wheel pivot

lubrication zerk

77C /107C DRILLS OPERATING INSTRUCTIONS

43

torque tube bushings

lubrication points

universal joints and

square drive line

lubrication zerks

feed wheel shaft

lubrication zerk

44

77C /107C DRILLS OPERATING INSTRUCTIONS

tool bar bushing

lubrication zerk

lift arm bushing

lubrication zerk

drive wheel frame

lubrication zerk

roller chains lubrication

77C /107C DRILLS OPERATING INSTRUCTIONS

45

APPENDIX A: WARRANTY

Duratech Industries International, warrants to the original purchaser for one year from purchase date that this product

will be free from defects in material and workmanship when used as intended and under normal maintenance and

operating conditions. This warranty is limited to the replacement of any defective part or parts returned to our factory

in Jamestown, N.D., within thirty (30) days of failure.

This warranty shall become void if in Duratech Industries International’s judgment the machine has been subject to

misuse, negligence, alterations, damaged by accident or lack of required normal maintenance, or if the product has been

used for a purpose for which is was not designed.

All claims for warranty must be made through the dealer which originally sold the product and all warranty adjustments

must be made through same.

This warranty does not apply to tires or bearings or any other trade accessories not manufactured by Duratech

Industries International. Buyer must rely solely on the existing warranty, if any, of these respective manufacturers.

Duratech Industries International shall not be held liable for damages of any kind, direct, contingent, or consequential

to property under this warranty. Duratech Industries International cannot be held liable for any damages resulting from

causes beyond its control. Duratech Industries International shall not be held liable under this warranty for rental costs

or any expense or loss for labor or supplies.

Duratech Industries International reserves the right to make changes in materials and/or designs of this product at any

time without notice.

This warranty is void if Duratech Industries International does not receive a valid warranty registration card at its ofce

in Jamestown, N.D., within 10 days from date of original purchase.

All other warranties made with respect to this product, either expressed or implied, are hereby disclaimed by Duratech

Industries International.

46

77C /107C DRILLS OPERATING INSTRUCTIONS

APPENDIX B: SPECIFICATIONS

77C Drill 107C Drill

Overall Width: 91” 125”

Seeding Width: 84” 126”

End Transport Width: 155”

Height: 73” 73”

Weight: 3,600 lbs 4,200 lbs

Tire Size- Front: 9.5x14 Implement 9.5x14 Implement

Tire Pressure 44 PSI 44 PSI

Tire Size- Rear: 7.6x15 implement 7.6x15 implement

Tire Pressure 32 PSI 32 PSI

Tire Size- Drive: 20X8-10 4-Ply 20X8-10 4-Ply

Tire Pressure 28 PSI 28 PSI

Hopper Capacity:

Grain- Front: 10 Bu. 14 Bu.

Granulated Fertilizer: 10 Bu. 14 Bu.

Grain- Front & Rear: 20 Bu. 28 Bu.

Legume Box: 1.5 Bu. 2 Bu.

Feed System: innitelyadjustablemeter innitelyadjustablemeter

Hoses: rubber convoluted rubber convoluted

Row Spacing: 7” 7”

Openers - Double Disc: 14” 14”

Press Wheels - Standard: 2” x 15-1/2” 2” x 15-1/2”

Press Wheels - Optional: 2” x 13” 2” x 13”

Options:

Swivel Hitch 1-2-3-4 Drill Hitch and Components

Acre Counter Swivel Hitch

Legume Box Acre Counter

Native Grass Kit Hitch Winch

Ballast Tanks Ballast Tanks

Gauge Wheels End Hitch

Stabilizer - Front and Rear

Legume Box

Native Grass Kit

Gauge Wheels

False Bottom

77C /107C DRILLS OPERATING INSTRUCTIONS

47

A Tradition of Innovation Since 1966

48

77C /107C DRILLS OPERATING INSTRUCTIONS

77C/107C DRILLS

107C DRILL - S.N. 101100017C & UP

77C DRILL - S.N. 77110001C & UP

Part 2:

Parts Reference

49

77C MAIN FRAME ASSEMBLY (FOR S.N. THRU 0075)

50

77C/107C DRILLS PARTS REFERENCE

77C MAIN FRAME ASSEMBLY (FOR S.N. THRU 0075)

ITEM PART QTY. PART DESCRIPTION

1 2600008 2 TIRE\7:60X15\8PLY;IMP

2 2600013 1 TIRE\9.5LX14\8PLY

3 2600601 1 WHL\6-BOLT\14X8

4 2600606 2 WHL\5-BOLT\15X5

5 2600825 1 WHL\IMP\9.5X14\TIRE&RIM (includes 2600013 and 2600601)

6 2600834 2 WHL\IMP\7.60X15\TIRE&RIM (includes 2600008 and 2600606)

7 2900004 2 CUP\INNER\WHEEL HUB

8 2900011 2 HUB\COMPLETE (includes 2900004, 2900013, 2900014, 2900015, 2900016, 2900018)

9 2900013 2 CAP\DUST\WHL;HUB(DC-13)

10 2900014 2 SEAL\GREASE(517) (15190)

11 2900015 2 CONE\INNER/WHL HUB(48548)

12 2900016 2 CUP\INNER\WHL:HUB(48510

13 2900018 2 CONE\OUTER\WHL;HUB(67048

14 2900084 2 SPACER\HUB\WHEEL

15 2900085 2 SEAL\WHL;HUB(20078)

16 2900086 2 CONE\2788\WHL;HUB

17 2900087 2 CUP\BRG\HUB\WHL\2720

18 2900089 1 HUB\H-628(FORK)\COMPLETE

19 3000018 1 SPNDL\FORK

20 3800041 4 FTG\LUB\1/8MPXZERK\ADAPT

21 3800082 5 FTG\LUB\1/4NFXZERK\ADAPT

22 3800111 1 FTG\1/8MPX1/8FP\90\ST;EL

23 3800126 1 FTG\LUB\1/8MPXZRK\2-5/8

24 4800017 1 BOLT\HEX\3/4X3

25 4800018 4 BOLT\HEX\1/2X1-1/4

26 4800068 4 BOLT\HEX\1/2X3

27 4800082 60 BOLT\HEX\1/2X1-1/2

28 4800100 4 BOLT\HEX\5/8X4

29 4800115 3 BOLT\HEX\3/4X2-1/2

30 4800120 1 PIN\COT\3/16X1-3/4

31 4800141 4 BOLT\HEX\1/2X4-1/2

32 4800157 4 PIN\COT\3/16X2

33 4800158 2 BOLT\HEX\5/8X4-1/2

34 4800626 2 BOLT\HEX\1X11\NC

35 4900001 66 NUT\HEX\1/2\NC

36 4900004 4 NUT\HEX\3/4\NC

37 4900005 5 NUT\HEX\5/8\NC

38 4900012 4 NUT\TPLCK\5/8\NC

39 4900014 6 NUT\TPLCK\1/2\NC

40 4900015 2 NUT\NYLCK\1\NC

41 4900115 2 NUT\CASTLE\1\1”-14

42 4900054 2 NUT\CASTLE\1/2\NF

43 4900094 10 NUT\TAPER\WHEEL\1/2\NF\

44 4900127 2 NUT\TPLCK\1\NC

45 5000002 4 WASH\FLAT\5/8

46 5000003 3 WASH\LOCK\5/8

47 5000004 16 WASH\FLAT\1/2

48 5000006 64 WASH\LOCK\1/2

49 5000012 4 WASH\LOCK\3/4

50 5000032 1 WASH\MACH\2IDX10GA

51 5000040 2 WASH\BUSH;MACH\1

52 5000055 2 WASH\SPINDLE\7/8

53 5000075 1 WASH\MACH\3X2-1/16X1/4

54 6100044 1 SPRNG\2-1/16X3/8WIRE2”LG

55 7500134 4 GROM 1.25ODX 17/32IDX1.25

56 7500858 1 GRMT\RBBR\2-1/4X2IDX1/4T

57 8400032 1 GOOSENECK

58 8400036 2 TUBE\TORQUE\PIVOT

59 8400038 2 ARM\LIFT

60 8400039 2 BUSH\ARM\LIFT\1X5/8X2-1/8

61 8400041 2 SPNDL\REAR\WHL

62 8400042 2 BOLT\PIVOT\REAR\WHL

63 8400130 1 STEP\REAR\RH

64 8400131 1 STEP\REAR\LH

65 8400132 2 STRAP\REAR\STEP;MOUNT

66 8400150 2 BUSH\TOOL_BAR\1-1/4X3/4X2

67 8400272 1 TUBE\TORQUE

68 8400281 1 CAP\RECESSED\WHL\SWIVEL

69 8400282 1 ROD\THRDD\5/8X4

70 8400283 1 FORK\WHL\SWVL

71 8400701 1 BAR\TOOL\7”SPCNG

72 8400702 1 WALKWAY\100_SERIES

73 8400742 1 FRM\MAIN\77

74 8400785 1 BRKT\HOSE\MINDER

75 8400799 1 PIN\CLEVIS\1X3\GREASE

76 8800021 2 RETAINER\SPNDL

77C/107C DRILLS PARTS REFERENCE

51

77C MAIN FRAME ASSEMBLY (FOR S.N. 0076 AND UP)

52

77C/107C DRILLS PARTS REFERENCE

77C MAIN FRAME ASSEMBLY (FOR S.N. 0076 AND UP)

ITEM PART QTY. PART DESCRIPTION

1 2600008 2 TIRE\7:60X15\8PLY;IMP

2 2600013 1 TIRE\9.5LX14\8PLY

3 2600601 1 WHL\6-BOLT\14X8

4 2600606 2 WHL\5-BOLT\15X5

5 2600825 1 WHL\IMP\9.5X14\TIRE&RIM (includes 2600013 and 2600601)

6 2600834 2 WHL\IMP\7.60X15\TIRE&RIM (includes 2600008 and 2600606)

7 2900004 2 CUP\INNER\WHEEL HUB

8 2900011 2 HUB\COMPLETE (includes 2900004, 2900013, 2900014, 2900015, 2900016, 2900018)

9 2900013 2 CAP\DUST\WHL;HUB(DC-13)

10 2900014 2 SEAL\GREASE(517) (15190)

11 2900015 2 CONE\INNER/WHL HUB(48548)

12 2900016 2 CUP\INNER\WHL:HUB(48510

13 2900018 2 CONE\OUTER\WHL;HUB(67048

14 2900084 2 SPACER\HUB\WHEEL

15 2900085 2 SEAL\WHL;HUB(20078)

16 2900086 2 CONE\2788\WHL;HUB

17 2900087 2 CUP\BRG\HUB\WHL\2720

18 2900089 1 HUB\H-628(FORK)\COMPLETE

19 3000018 1 SPNDL\FORK

20 3800041 4 FTG\LUB\1/8MPXZERK\ADAPT

21 3800082 5 FTG\LUB\1/4NFXZERK\ADAPT

22 3800111 1 FTG\1/8MPX1/8FP\90\ST;EL

23 3800126 1 FTG\LUB\1/8MPXZRK\2-5/8

24 4800017 1 BOLT\HEX\3/4X3

25 4800018 4 BOLT\HEX\1/2X1-1/4

26 4800068 4 BOLT\HEX\1/2X3

27 4800082 60 BOLT\HEX\1/2X1-1/2

28 4800100 4 BOLT\HEX\5/8X4

29 4800115 3 BOLT\HEX\3/4X2-1/2

30 4800141 4 BOLT\HEX\1/2X4-1/2

31 4800157 4 PIN\COT\3/16X2

32 4800158 2 BOLT\HEX\5/8X4-1/2

33 4800559 1 PIN\LYNCH\5/16X2-1/2\W/SQ;WIRE;KEEPER

34 4800626 2 BOLT\HEX\1X11\NC

35 4900001 66 NUT\HEX\1/2\NC

36 4900004 4 NUT\HEX\3/4\NC

37 4900005 5 NUT\HEX\5/8\NC

38 4900012 4 NUT\TPLCK\5/8\NC

39 4900014 6 NUT\TPLCK\1/2\NC

40 4900015 2 NUT\NYLCK\1\NC

41 4900115 2 NUT\CASTLE\1\1”-14

42 4900054 2 NUT\CASTLE\1/2\NF

43 4900094 10 NUT\TAPER\WHEEL\1/2\NF\

44 4900127 3 NUT\TPLCK\1\NC

45 5000002 4 WASH\FLAT\5/8

46 5000003 3 WASH\LOCK\5/8

47 5000004 16 WASH\FLAT\1/2

48 5000006 64 WASH\LOCK\1/2

49 5000012 4 WASH\LOCK\3/4

50 5000014 2 WASH\FLAT\1

51 5000032 1 WASH\MACH\2IDX10GA

52 5000040 2 WASH\BUSH;MACH\1

53 5000055 2 WASH\SPINDLE\7/8

54 5000075 1 WASH\MACH\3X2-1/16X1/4

55 6100044 1 SPRNG\2-1/16X3/8WIRE2”LG

56 7500134 4 GROM 1.25ODX 17/32IDX1.25

57 7500858 1 GRMT\RBBR\2-1/4X2IDX1/4T

58 8101352 1 BOLT\HEX\1X6\GREASE

59 8400032 1 GOOSENECK

60 8400036 2 TUBE\TORQUE\PIVOT

61 8400038 2 ARM\LIFT

62 8400039 2 BUSH\ARM\LIFT\1X5/8X2-1/8

63 8400041 2 SPNDL\REAR\WHL

64 8400042 2 BOLT\PIVOT\REAR\WHL

65 8400130 1 STEP\REAR\RH

66 8400131 1 STEP\REAR\LH

67 8400132 2 STRAP\REAR\STEP;MOUNT

68 8400150 2 BUSH\TOOL_BAR\1-1/4X3/4X2

69 8400281 1 CAP\RECESSED\WHL\SWIVEL

70 8400282 1 ROD\THRDD\5/8X4

71 8400283 1 FORK\WHL\SWVL

72 8400701 1 BAR\TOOL\7”SPCNG

73 8400702 1 WALKWAY\100_SERIES

74 8400785 1 BRKT\HOSE\MINDER

75 8400808 1 FRM\MAIN\77C

76 8400809 1 TUBE\TORQUE\107C\77C

77 8400901 1 STOP\CYL\PVT

78 8800021 2 RETAINER\SPNDL

77C/107C DRILLS PARTS REFERENCE

53

107C MAIN FRAME ASSEMBLY (FOR S.N. THRU 0880)

54

77C/107C DRILLS PARTS REFERENCE

107C MAIN FRAME ASSEMBLY (FOR S.N. THRU 0880)

ITEM PART QTY. PART DESCRIPTION

1 2600008 2 TIRE\7:60X15\8PLY;IMP

2 2600013 1 TIRE\9.5LX14\8PLY

3 2600601 1 WHL\6-BOLT\14X8

4 2600606 2 WHL\5-BOLT\15X5

2600825 WHL\IMP\9.5X14\TIRE&RIM (includes #2 & #3)

2600834 WHL\IMP\7.60X15\TIRE&RIM (includes #1 & #4)

5 2900004 2 CUP\INNER\WHEEL HUB

6 2900013 2 CAP\DUST\WHL;HUB(DC-13)

7 2900014 2 SEAL\GREASE(517) (15190)

8 2900015 2 CONE\INNER/WHL HUB(48548)

9 2900016 2 CUP\INNER\WHL:HUB(48510

10 2900018 2 CONE\OUTER\WHL;HUB(67048

2900011 HUB/WHL;HUB-517-1 COMP (includes #5, #6, #7, #8, #9 & #10)

11 2900084 2 SPACER\HUB\WHEEL

12 2900085 2 SEAL\WHL;HUB(20078)

13 2900086 2 CONE\2788\WHL;HUB

14 2900087 2 CUP\BRG\HUB\WHL\2720

15 2900089 1 HUB\H-628(FORK)\COMPLETE

16 3000018 1 SPNDL\FORK

17 3800041 4 FTG\LUB\1/8MPXZERK\ADAPT

18 3800082 5 FTG\LUB\1/4NFXZERK\ADAPT

19 4800017 1 BOLT\HEX\3/4X3

20 4800018 4 BOLT\HEX\1/2X1-1/4

21 4800044 1 PIN\COT\5/32X1-1/2

22 4800068 4 BOLT\HEX\1/2X3

23 4800082 12 BOLT\HEX\1/2X1-1/2

24 4800100 4 BOLT\HEX\5/8X4

25 4800107 1 PIN\HAIR\1/8(#9)

26 4800115 3 BOLT\HEX\3/4X2-1/2

27 4800120 1 PIN\COT\3/16X1-3/4

28 4800141 4 BOLT\HEX\1/2X4-1/2

29 4800157 4 PIN\COT\3/16X2

30 4800158 2 BOLT\HEX\5/8X4-1/2

31 4800527 2 PIN\CLEVIS\3/4X2

32 4800626 2 BOLT\HEX\1X11\NC

33 4900001 17 NUT\HEX\1/2\NC

34 4900004 4 NUT\HEX\3/4\NC

35 4900005 5 NUT\HEX\5/8\NC

36 4900012 4 NUT\TPLCK\5/8\NC

37 4900014 6 NUT\TPLCK\1/2\NC

38 4900015 2 NUT\NYLCK\1\NC

39 4900115 2 NUT\CASTLE\1\1”-14

40 4900054 2 NUT\CASTLE\1/2\NF

41 4900094 10 NUT\TAPER\WHEEL\1/2\NF\

42 4900127 2 NUT\TPLCK\1\NC

43 5000002 4 WASH\FLAT\5/8

44 5000003 3 WASH\LOCK\5/8

45 5000004 16 WASH\FLAT\1/2

46 5000006 16 WASH\LOCK\1/2

47 5000012 4 WASH\LOCK\3/4

48 5000032 1 WASH\MACH\2IDX10GA

49 5000040 2 WASH\BUSH;MACH\1

50 5000055 2 WASH\SPINDLE\7/8

51 5000075 1 WASH\MACH\3X2-1/16X1/4

52 6100044 1 SPRNG\2-1/16X3/8WIRE2”LG

53 7500134 4 GROM 1.25ODX 17/32IDX1.25

54 7500858 1 GRMT\RBBR\2-1/4X2IDX1/4T

55 8400742 1 FRM\MAIN

56 8400032 1 GOOSENECK

57 8400036 2 TUBE\TORQUE\PIVOT

58 8400038 2 ARM\LIFT

59 8400039 2 BUSH\ARM\LIFT\1X5/8X2-1/8

60 8400040 1 WALKWAY\100_SERIES

61 8400041 2 SPNDL\REAR\WHL

62 8400042 2 BOLT\PIVOT\REAR\WHL

63 8400103 1 BAR\HOLDUP\TRANSPORT

64 8400130 1 STEP\REAR\RH

65 8400131 1 STEP\REAR\LH

66 8400132 2 STRAP\REAR\STEP;MOUNT

67 8400150 2 BUSH\TOOL_BAR\1-1/4X3/4X2

68 8400272 1 TUBE\TORQUE