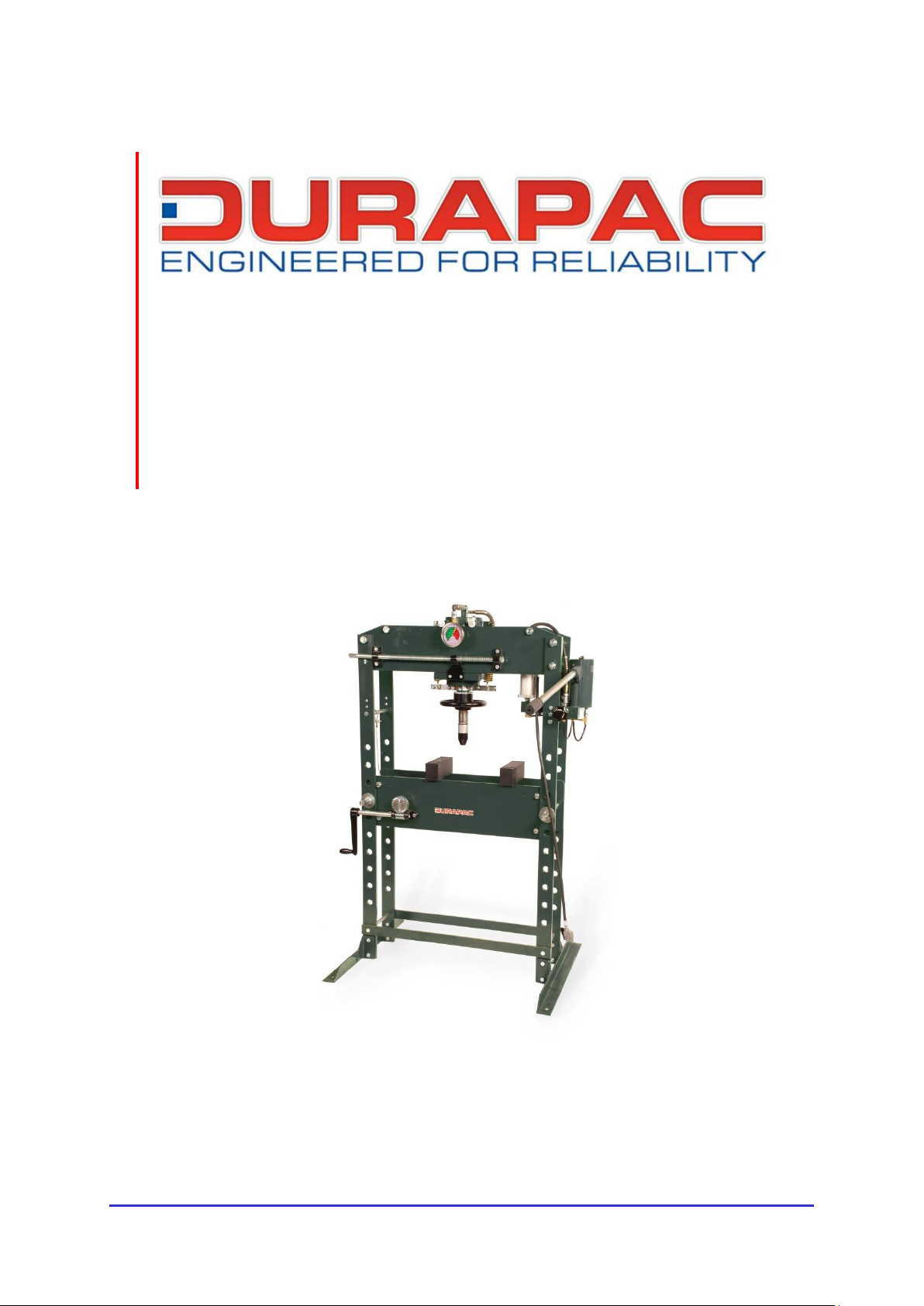

Durapac HP-35A Instruction Manual

Maximum Operating Pressure – 360 bar

Instruction Manual

35 Ton H-Frame Press

Model – HP-35A

ABSOLUTE EQUI P MENT PTY LTD – 2 /186 Granite Street, GEEBUNG QL D 40 34 – Aust r alia

sale s @abs o l utee q uipme nt.co m .au – P hone : +61 7 386 5 400 6 – Fax: + 61 7 3 102 6288

Instruction Manual

This is a safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid injury or death

DANGER:

To avoid personal injury keep hands and feet away from work area during operation

Do NOT handle pressurized hoses. Escaping oil under pressure can penetrate the skin

causing serious injury. If oil is injected under the skin, see a doctor immediately

Stay clear of loads supported by hydraulics. A cylinder, when used as a load lifting

device, should never be used as a load holding device. After the load has been raised

or lowered, it must always be blocked mechanically

1.0 Product Information

DURAPAC – H-Frame Presses are engineered to meet International Standards for Performance and

Safety. The HP-35A model is a 35 ton air and hand press that can operate up to 360 bar. Presses can

exert extremely high forces at moderate hydraulic pump pressure. If you have any questions

concerning how much force is exerted at a given pressure, contact a Durapac representative.

Special skill, knowledge and training may be required for a specific task and the product may not be

suitable for all jobs. The user must ultimately make the decision regarding suitability of the product

for any given task and assume the responsibility of safety for all in the work area. Contact a Durapac

representative if you are unsure of your press’ suitability for a particular application.

2.0 Receiving Instructions

It is recommended prior to use that an inspection be done by qualified personnel and that any

missing or damaged parts, decals, warning/safety labels or signs are replaced with Durapac

authorised replacement parts only. Any press that appears to be damaged in any way, is worn,

leaking or operates abnormally should be removed from service immediately until such time as

repairs can be made. Any press that has been or suspected to have been subject to a shock load

should be removed from service immediately until inspected by a Durapac authorised service centre.

Owners and operators of this equipment should be aware that the use and subsequent repair of this

equipment may require specialised training and knowledge.

Locate the press in an isolated area, or shield the press to minimize danger to others.

Hydraulic pressure can cause materials to break, possibly resulting in personal injury

3.0 Safety

Save these instructions. For your safety, read and understand the information contained within. The

owner and operator should have an understanding of this product and safe operating procedures

before attempting to use this product. Instructions and safety information should be conveyed in the

operator's native language before use of this product is authorised. Make certain that the operator

thoroughly understands the inherent dangers associated with the use and misuse of the product. If

any doubt exists as to the safe and proper use of this product as outlined in this factory authorised

manual, remove from service immediately.

HP-35A Press - V1.0 www.durapac.com Page 2 of 11

Instruction Manual

WARNING:

The system operating pressure must not exceed the pressure rating of the lowest

rated component in the system. Install pressure gauges in the system to monitor

operating pressure. It is your window to what is happening in the system

Always wear protective gear when operating hydraulic equipment. The operator must

take precaution against injury due to failure of the tool or work piece(s)

Do NOT hold or stand directly in line with any hydraulic connections while pressurising

Do NOT attempt to disconnect hydraulic connections under pressure. Release all line

pressure before disconnecting hoses

All personnel must be clear before lowering load or depressurising the system

Do NOT attempt to lift a load weighing more than the capacity of the cylinder

IMPORTANT:

If at any stage, the safety related decals become hard to read, these must be replaced

Minimum age of the operator must be 18 years. The operator must have read and

understood all instructions, safety issues, cautions and warnings before starting to

operate the equipment. The operator is responsible for this activity towards other

persons

This device is not suitable for use as a support device! As the system load is lifted, use

blocking and cribbing to guard against a falling load

Do NOT lift hydraulic equipment by the hoses or couplers. Use the carrying handle or

other means of safe transport

Hydraulic equipment must only be serviced by a qualified hydraulic technician. For

repair service, contact the Durapac authorised service centre in your area. To protect

your warranty, use only high quality hydraulic oil

CAUTION:

KEEP HYDRAULIC EQUIPMENT AWAY FROM FLAMES AND HEAT. Hydraulic fluid can

ignite and burn. Excessive heat will soften packings and seals, resulting in fluid leaks.

Heat also weakens hose materials and packings. For optimum performance do not

expose equipment to temperatures of 65°C (150°F) or higher. Protect all equipment

from weld spatter

No alteration should be made to this device

3.1 Hydraulic Presses

To avoid personal injury and possible equipment damage, make sure all hydraulic

components withstand the maximum pressure of 360 bar (5,220psi)

Work pieces must be well supported and aligned so when pressure is exerted;

parts being pressed do not slip out or break

To prevent accidental slippage, do not place work pieces on the press bed, or

apply hydraulic force until all bolster pins are in place and all tension has been

removed from the bolster lift cables

Do NOT overload equipment. Overloading can cause equipment failure and

possible personal injury. The presses are designed for a maximum pressure of 360

bar (5,220psi)

Do NOT stress adapters beyond their capacities. Any pushing or pulling adapters

used with this press must have a maximum tonnage rating equal to, or higher

than, the maximum tonnage rating of the press, or breakage can occur

HP-35A Press - V1.0 www.durapac.com Page 3 of 11

Instruction Manual

IMPORTANT:

It is mandatory that the operator has a full understanding of all instructions, safety

regulations, cautions and warnings, before starting to operate any of this high force

tool equipment

To reduce the risk of personal injury and/or property damage, hydraulic connections

must be securely fastened before building pressure in the system. Release all system

pressure before loosening any hydraulic connection in the system

Always monitor pressure, load or position using suitable equipment. Pressure may be

monitored by means of a manifold and gauge. Correct application position can only be

determined by the operator of the equipment

Do NOT operate the press while the cables are under tension

It is impossible for Durapac to provide practical “all purpose” shielding because

this is a general all-purpose press that can be used in many different applications.

The owner of the press must supply shielding that is practical and necessary for

each application. Some safety can be provided by wrapping the piece in a

protective blanket before applying pressure

FAILURE TO HEED THESE WARNINGS MAY RESULT IN PERSONAL INJURY AS WELL AS PROPERTY DAMAGE.

4.0 Installation

Do NOT adjust safety valve pressure – safety valve pressure is set at 360 bar (5,220 psi)

4.1 Familiarise yourself with the specifications and illustrations in this owner’s manual.

Know your press, its limitations and how it operates before attempting to use. If in

doubt, contact Durapac.

4.2 Remove all banding from the press and shipping pallet and remove all cartons. Stand

the press upright and attach feet to the press.

4.3 Check all hydraulic connections.

4.4 Check oil level and change drilled bolt to vent cap/plug in the reservoir before

operating the pump.

4.5 Air from the System. Air can accumulate in the hydraulic system during the initial setup

or after prolonged use, causing the cylinder to respond slowly or in an unstable

manner. Should removal of air from pump be required, please follow the steps in 6.2 –

Bleeding Air from the System in the Maintenance Section.

5.0 Operation

5.1 Before using - check the air pressure range is between 7-10 kgf/cm2 (Figure 1).

Figure 1

HP-35A Press - V1.0 www.durapac.com Page 4 of 11

Loading...

Loading...