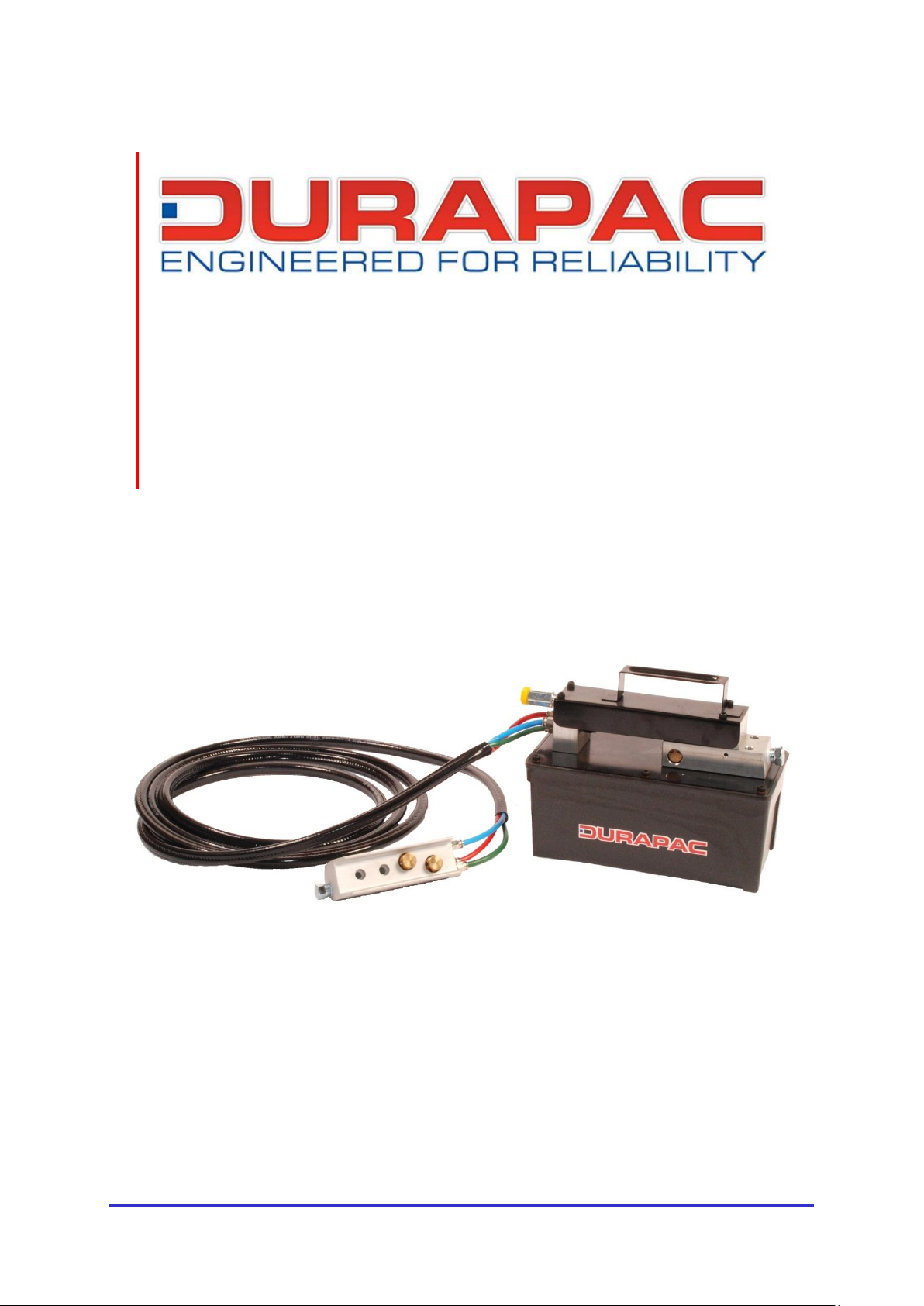

Durapac DPA-15R Instruction Manual

Instruction Manual

Reciprocating Air Hydraulic Power Unit

Model – DPA-15R

Maximum Operating Pressure – 700 bar

ABSOLUTE EQUI P MENT PTY LTD – 2 /186 Granite Street, GEEBUNG QL D 4034 – A u stralia

sale s @abs o l utee q uipme nt.co m .au – P hone : +61 7 386 5 400 6 – Fax: + 61 7 3 102 6288

Instruction Manual

This is a safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid injury or death

1.0 Product Information

DURAPAC – Remote Equipped Reciprocating Air Hydraulic Power Units are engineered to meet

Industrial Standards for Performance and Safety. The DPA-15R’s unique hydraulic circuit allows the

quick displacement of hydraulic fluid under no load conditions and easy pumping in loaded

conditions. The remote has an advance-hold-retract button and a three metre long hand lead. These

air actuated power units supply compressed hydraulic fluid to a compatible single-acting cylinder,

anywhere that 700 bar of fluid pressure is needed.

Remote actuation for adv/hold/retract functions

1.5 L usable oil reservoir

3 position treadle for adv/hold/retract functions

Dust cover protection for the release control valve

Release detent function enhances productivity

Convenient carry handle included

Recommended air pressure range 4-12 bar

Special skill, knowledge and training may be required for a specific task and the product may not be

suitable for all jobs. The user must ultimately make the decision regarding suitability of the product

for any given task and assume the responsibility of safety for all in the work area. Contact a Durapac

representative if you are unsure of your power unit’s suitability for a particular application.

2.0 Receiving Instructions

It is recommended prior to use that an inspection be done by qualified personnel and that any

missing or damaged parts, decals, warning/safety labels or signs are replaced with Durapac

authorised replacement parts only. Any power unit that appears to be damaged in any way, is worn,

leaking or operates abnormally should be removed from service immediately until such time as

repairs can be made. Any power unit that has been or suspected to have been subject to a shock

load should be removed from service immediately until inspected by a Durapac authorised service

centre. Owners and operators of this equipment should be aware that the use and subsequent

repair of this equipment may require specialised training and knowledge.

3.0 Safety

Save these instructions. For your safety, read and understand the information contained within. The

owner and operator should have an understanding of this product and safe operating procedures

before attempting to use this product. Instructions and safety information should be conveyed in the

operator's native language before use of this product is authorised. Make certain that the operator

thoroughly understands the inherent dangers associated with the use and misuse of the product. If

any doubt exists as to the safe and proper use of this product as outlined in this factory authorised

manual, remove from service immediately.

DPA-15R Air Hyd. Power Unit - V1.1 www.durapac.com Page 2 of 10

Instruction Manual

DANGER:

To avoid personal injury keep hands and feet away from work area during operation

Do NOT handle pressurized hoses. Escaping oil under pressure can penetrate the skin

causing serious injury. If oil is injected under the skin, see a doctor immediately

Stay clear of loads supported by hydraulics. A cylinder, when used as a load lifting

device, should never be used as a load holding device. After the load has been raised

or lowered, it must always be blocked mechanically

WARNING:

The system operating pressure must not exceed the pressure rating of the lowest

rated component in the system. Install pressure gauges in the system to monitor

operating pressure. It is your window to what is happening in the system

Always wear protective gear when operating hydraulic equipment. The operator must

take precaution against injury due to failure of the tool or work piece(s)

Do NOT hold or stand directly in line with any hydraulic connections while pressurising

Do NOT attempt to disconnect hydraulic connections under pressure. Release all line

pressure before disconnecting hoses

All personnel must be clear before lowering load or depressurising the system

Do NOT attempt to lift a load weighing more than the capacity of the cylinder

IMPORTANT:

If at any stage, the safety related decals become hard to read, these must be replaced

Minimum age of the operator must be 18 years. The operator must have read and

understood all instructions, safety issues, cautions and warnings before starting to

operate the equipment. The operator is responsible for this activity towards other

persons

Do NOT lift hydraulic equipment by the hoses or couplers. Use the carrying handle or

other means of safe transport

Hydraulic equipment must only be serviced by a qualified hydraulic technician. For

repair service, contact the Durapac authorised service centre in your area. To protect

your warranty, use only high quality hydraulic oil

CAUTION:

KEEP HYDRAULIC EQUIPMENT AWAY FROM FLAMES AND HEAT. Hydraulic fluid can

ignite and burn. Excessive heat will soften packings and seals, resulting in fluid leaks.

Heat also weakens hose materials and packings. For optimum performance do not

expose equipment to temperatures of 65°C (150°F) or higher. Protect all equipment

from weld spatter

No alteration should be made to this device

3.1 Hydraulic Power Units

Do use a gauge or other load measuring instrument to verify load

DPA-15R Air Hyd. Power Unit - V1.1 www.durapac.com Page 3 of 10

Loading...

Loading...