Durapac DBJ Series, DBJ-10S, DBJ-10, DBJ-20, DBJ-30:DBJ-30S Instruction Manual

...

ABSOLUTE EQUIPMENT PTY LTD – 2/186 Granite Street, GEEBUNG QLD 4034 – Australia

Instruction Manual

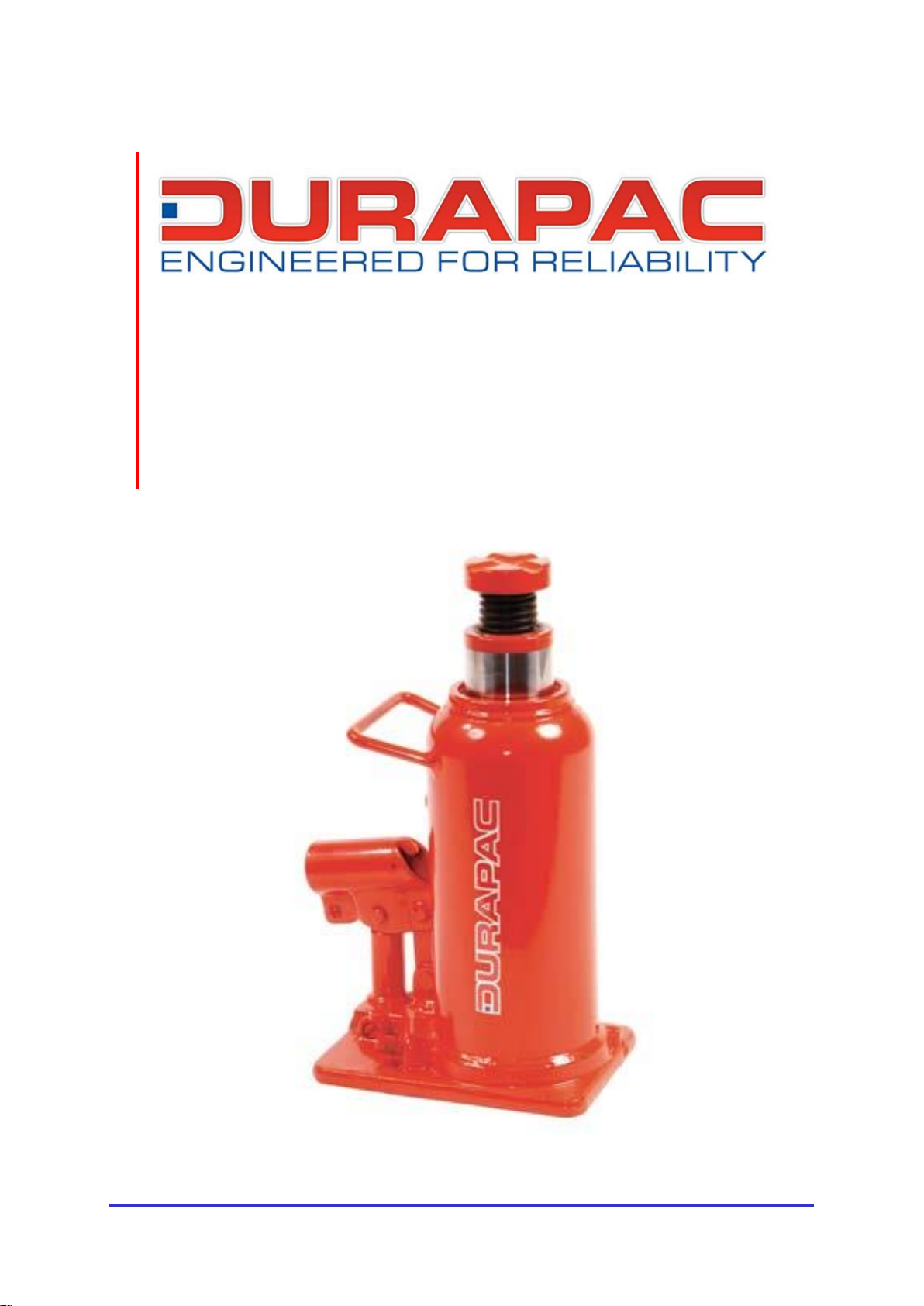

Manual Hydraulic Bottle Jacks

Model – DBJ Series

sales @abso l utee q uipme nt.co m .au – P hone: +61 7 3865 4006 – Fax: + 61 7 3102 6288

Instruction Manual

This is a safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid injury or death

DANGER:

To avoid personal injury keep hands and feet away from work area during operation

Do NOT handle pressurised hoses. Escaping oil under pressure can penetrate the skin

1.0 Product Information

DURAPAC – Hydraulic Bottle Jacks are engineered to meet Industrial Standards for Performance and

Safety. The DBJ Series of bottle jacks are a premium range ideally suited to most industrial lifting

and pushing applications. Models from 10-20 ton feature an additional screw extension and most

can be used in both the vertical and horizontal positions. All jacks are repairable and seal kits are

available.

All jacks have been designed for ease of use and handling

Operating handle is included with all models

Carbon steel base is automatically welded to ensure increased resistance to high pressure

and provide greater durability

Chrome plated steel piston rod resists corrosion and extends life

Internal stroke limiter prevents piston rod over-extension

Special skill, knowledge and training may be required for a specific task and the product may not be

suitable for all jobs. The user must ultimately make the decision regarding suitability of the product

for any given task and assume the responsibility of safety for all in the work area. Contact a Durapac

representative if you are unsure of your bottle jack’s suitability for a particular application.

2.0 Receiving Instructions

It is recommended prior to use that an inspection be done by qualified personnel and that any

missing or damaged parts, decals, warning/safety labels or signs are replaced with Durapac

authorised replacement parts only. Any bottle jack that appears to be damaged in any way, is worn,

leaking or operates abnormally should be removed from service immediately until such time as

repairs can be made. Any bottle jack that has been or suspected to have been subject to a shock

load should be removed from service immediately until inspected by a Durapac authorised service

centre. Owners and operators of this equipment should be aware that the use and subsequent

repair of this equipment may require specialised training and knowledge.

3.0 Safety

Save these instructions. For your safety, read and understand the information contained within. The

owner and operator should have an understanding of this product and safe operating procedures

before attempting to use this product. Instructions and safety information should be conveyed in the

operator's native language before use of this product is authorised. Make certain that the operator

thoroughly understands the inherent dangers associated with the use and misuse of the product. If

any doubt exists as to the safe and proper use of this product as outlined in this factory authorised

manual, remove from service immediately.

DBJ Series Bottle Jacks - V1.1 www.durapac.com Page 2 of 11

Instruction Manual

causing serious injury. If oil is injected under the skin, see a doctor immediately

Stay clear of loads supported by hydraulics. A cylinder, when used as a load lifting

device, should never be used as a load holding device. After the load has been raised

or lowered, it must always be supported mechanically

WARNING:

The system operating pressure must not exceed the pressure rating of the lowest

rated component in the system. Install pressure gauges in the system to monitor

operating pressure. It is your window to what is happening in the system

Always wear appropriate personal protective equipment (PPE) when operating

hydraulic equipment. The operator must take precaution against injury due to failure

of the tool or work piece(s)

Do NOT hold or stand directly in line with any hydraulic connections while pressurising

Do NOT attempt to disconnect hydraulic connections under pressure. Release all line

pressure before disconnecting hoses

All personnel must be clear before lowering load or depressurising the system

Do NOT attempt to lift a load weighing more than the capacity of the cylinder

IMPORTANT:

If at any stage, the safety related decals become hard to read, these must be replaced

Minimum age of the operator must be 18 years. The operator must have read and

understood all instructions, safety issues, cautions and warnings before starting to

operate the equipment. The operator is responsible for this activity towards other

persons

Do NOT lift hydraulic equipment by the hoses or couplers. Use the carrying handle or

other means of safe transport

Hydraulic equipment must only be serviced by a qualified hydraulic technician. For

repair service, contact the Durapac authorised service centre in your area. To protect

your warranty, use only high quality hydraulic oil

CAUTION:

KEEP HYDRAULIC EQUIPMENT AWAY FROM FLAMES AND HEAT. Hydraulic fluid can

ignite and burn. Excessive heat will soften packings and seals, resulting in fluid leaks.

Heat also weakens hose materials and packings. For optimum performance do not

expose equipment to temperatures of 65°C (150°F) or higher. Protect all equipment

from weld spatter

No alteration should be made to this device

3.1 Hydraulic Bottle Jacks

Do NOT exceed the rated capacity of the jack or any equipment in the system

Do NOT tamper with the adjustment of the jacks internal relief valve screw. To do so

may cause the jack to fail

DBJ Series Bottle Jacks - V1.1 www.durapac.com Page 3 of 11

Instruction Manual

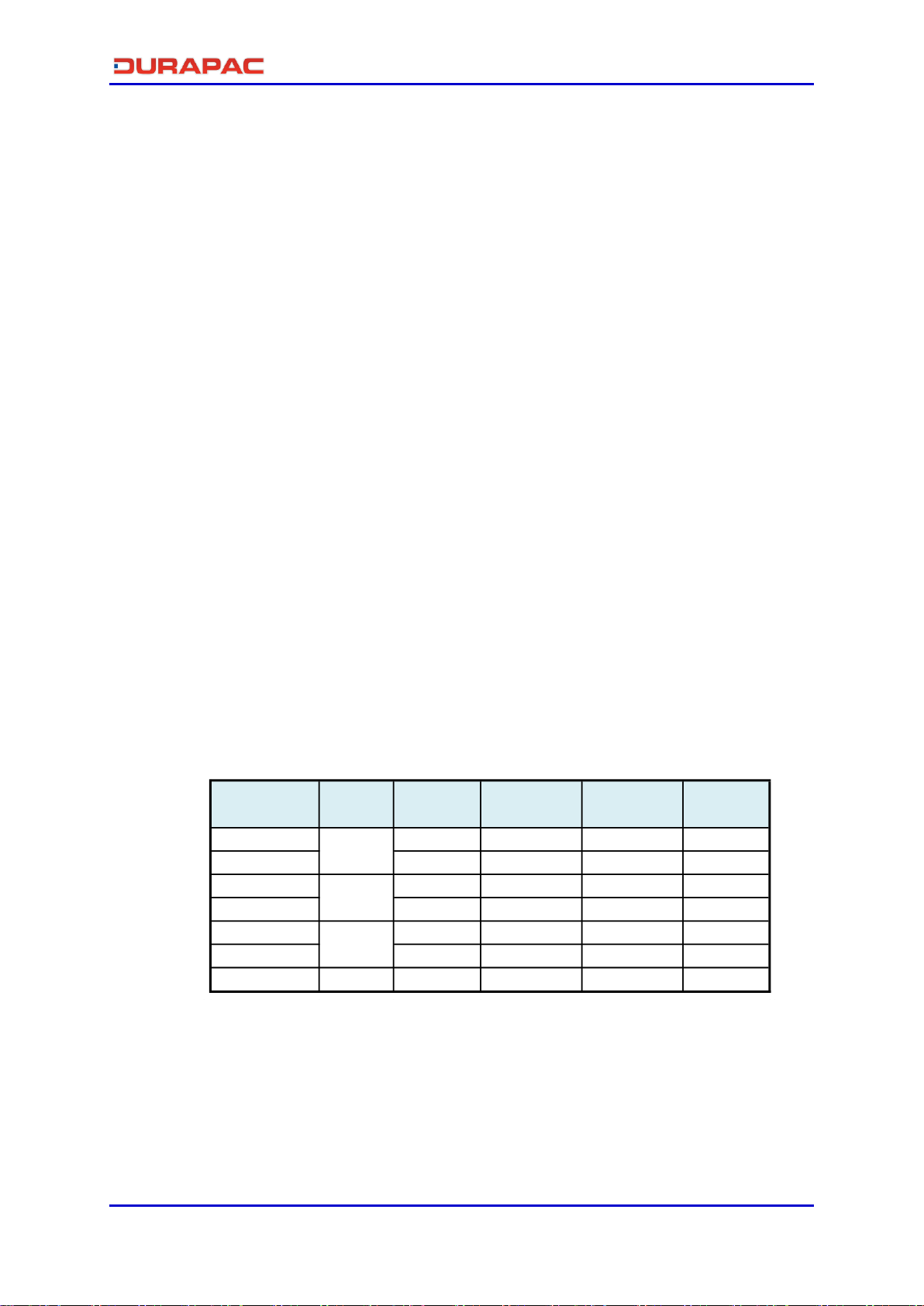

Model

Number

Capacity

(ton)

Stroke

(mm)

Collapsed

Height (mm)

Extended

Height (mm)

Weight

(kg)

DBJ-10 147 240 387 8.2

DBJ-10S 95 170 265 6.4

DBJ-20 152 265 417 13.3

DBJ-20S 85 187 272 10.0

DBJ-30 155 282 437 19.6

DBJ-30S 80 182 262 13.8

DBJ-50 50 155 305 460 42.3

102030

Do NOT use in an unstable or hazardous position

Always use the jack on solid and level surface that is capable of carrying the load. If

used to lift a vehicle, set the vehicle’s parking brake and chock the tyres

Keep the load stable during lifting. An unstable load may cause the jack or load to slip

Centre the load on the jack. Off centre loads can damage seals and cause hydraulic

failure

Keep non-essential personnel at a safe distance when using the jack

Do NOT carry the jack by the jacking lever

Do NOT lift people or loads with people on them

Ensure that the jack is undamaged and in good working order. Do not use the jack if it

is damaged

Do NOT use the jack for any purpose other than that for which it is intended

Keep the jack clean, particularly the head

Do NOT operate the system with bent or damaged couplers or damaged threads

Do NOT subject the jack and its components to shock loads

Use only Durapac approved accessories and components

FAILURE TO HEED THESE WARNINGS MAY RESULT IN PERSONAL INJURY AS WELL AS PROPERTY DAMAGE.

4.0 Installation

4.1 Familiarise yourself with the specifications and illustrations in this owner’s manual.

Know your bottle jack, its limitations and how it operates before attempting to use.

Refer to the specification chart below or if in doubt, contact a Durapac representative.

4.2 Check oil level in reservoir before operating the jack.

4.3 Remove air from the system – Air can accumulate in the hydraulic system during the

initial setup or after prolonged use, causing the cylinder to respond slowly or in an

unstable manner. Should removal of air from the jack be required, please follow the

steps in 6.2 – Bleeding Air from the System in the Maintenance Section.

4.4 Lubrication - Oil the pivots of the manual pump mechanism.

DBJ Series Bottle Jacks - V1.1 www.durapac.com Page 4 of 11

Loading...

Loading...