Durant-Eaton AMBASSADOR SERIES Instruction Manual

Durant

®

INSTALLATION AND OPERATION

MANUAL Number 57600-905-03

AMBASSADOR SERIES COUNT CONTROL

MODELS:

57600-405 (10-15 VDC)

57600-415 (10-15 VDC)

57600-465 (10-15 VDC)

57601-405 (115 VAC)

57601-415 (115 VAC)

57601-455 (115 VAC)

57601-465 (115 VAC)

57602-405 (230 VAC)

57602-415 (230 VAC)

57602-465 (230 VAC)

• Six Digit, Four Preset Main Counter

• Six Digit, Single Preset Batch Counter

• Red or Green Display

• Eight Digit Totalizer

• 1/Tau Rate Meter

• Four User-Configurable Control Inputs

• Two Output Relays

• Two Solid State Outputs

• RS-485 Serial Communications

• Feet/Inches Control, Red or Green Display

Durant

®

C 123456

P1 10000

RST

CLR

EXIT ENT SEL

RUN

PGM

PRNT

•

N A E D

ASSOCIATE

TABLE OF CONTENTS

1 Introduction

2 Block Diagram

3 Installation Wiring and Programming - Quick Start

10 Rear Terminal Description

12 Program Mode

22 Description of Program Options

26 Wiring

29 Calculating Scale Factors

30 Run Mode

33 Feet/Inches Control

34 Troubleshooting

36 Specifications

37 Parts / Accessories

38 Dimensions

Durant

INTRODUCTION

This manual describes the Ambassador 5760X-405 count

control, and is intended to be a guide in the installation and

operation of the control.

The control itself is like an electronic erector set, full of

counter and ratemeter "parts" which the user must "assemble". The majority of this manual is concerned with

installation, describing the parts of the counter, helping the

user determine the wiring and programming necessary to

"assemble" his counter into the tool he needs to do a specific

job, and documenting those choices. The operation section,

which describes the operator functions, follows in the section

Run Mode. The following description of the control and the

block diagram is recommended reading for those new with

this device. Those installers who are familiar with controls

and counter terminology are welcome to attack the Quick

Start section after examining the block diagram. The Quick

Start uses a logical inputs-to-outputs approach to decide how

to wire and program this control to do the job. Detailed

programming and wiring information follow the Quick Start

section, providing guidance to the first time installer.

MAIN COUNTER

The main counter is a six digit, bi-directional count register

designated by the letter C on the display. The user can assign

up to four presets to this counter. The main counter is the

workhorse of this control. Note its central location in the block

diagram and the number of "connections" to it. This register

increments and decrements from scaled count input pulses.

The "favored" count direction is up in reset to zero mode and

down in reset to final preset mode. The favored count

direction feature affects only the function of the count inputs,

and the direction of the totalizer count, and the preset

selected for the current preset display. The main count

display screen can be customized to identify what type of

units are being counted.

RATEMETER

The control uses the frequency of the count pulses at input A

to calculate rate. The rate scaler accommodates the "weight"

of each pulse and the time units in order to display rates such

as revolutions per minute, barrels per hour, etc. The ratemeter average and zero times are programmable. Two alarm

setpoints are assigned to the ratemeter. The rate display text

can be customized.

OUTPUTS

Two form C relay and two open collector NPN transistor

outputs are available. Each output is individually assignable

to rate or count. Count outputs can turn on or off at any

combination of eight preset and control events. These outputs can be timed or latched, and each has a programmable

on-delay timer. Rate based outputs turn on based upon

comparison to one of two rate alarm setpoints. Rate outputs

turn off after timeout (pulsed), external control signal (latched),

or when the rate crosses the setpoint back to the non-alarm

state (follows).

COUNT INPUTS

Count inputs A and B are DIP switch settable to accept

sinking or sourcing single ended DC or differential count

signals. Input A is used by the ratemeter. Inputs A and B are

programmable to affect the main counter and totalizer in eight

count modes and three count/control modes.

CONTROL INPUTS/RESET KEY

Four control inputs are available. These inputs are single

ended DC, sink only and are programmable to one of 14

functions. The reset key may be programmed to reset one,

all, or none of the count registers.

TOTALIZER

The totalizer is an eight digit, bi-directional count register that

counts in parallel with the main counter. The totalizer counts

up when the main counter counts in the favored count

direction, and down when the main counter counts in the nonfavored direction. The totalizer display can be customized to

show units of count. The totalizer does not have preset or

output capability.

BATCH COUNTER

The batch counter counts the number of "batches" of the

main counter, incrementing every time the main counter

autocycles or reaches the final preset. This register is six

digits and counts up only. The batch counter has one preset,

and always autocycles whenever it reaches the setpoint. The

batch count display can be customized to show units of

count.

RS 485 SERIAL COMMUNICATIONS

The control uses RS-485 serial communications in either

host mode: to respond to a host computer, or printer mode:

to dump selected values to a printer. The print transmission

is initiated by either the Print key or a control input. The

communication capability is described in a separate manual.

If you need information on the serial communications, contact the Literature Department at 1-800-540-9242.

FEET/INCHES CONTROL

Models 57601-415 (green display) and 57601-465 (red display) have a readout in feet and inches with a fixed decimal

point separating them. These models also have a floating

prewarn that adjusts itself to the final preset. See page 33 for

more details.

1

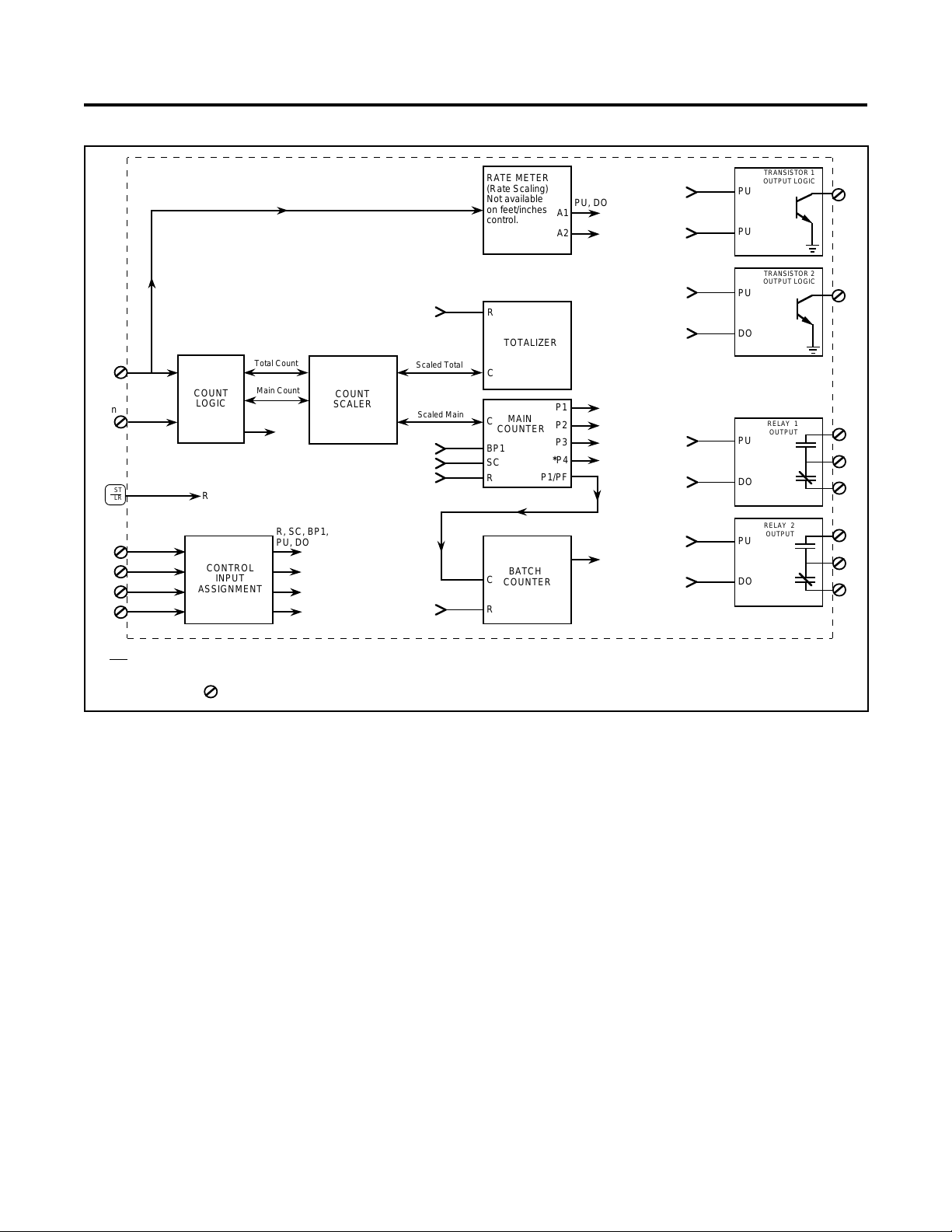

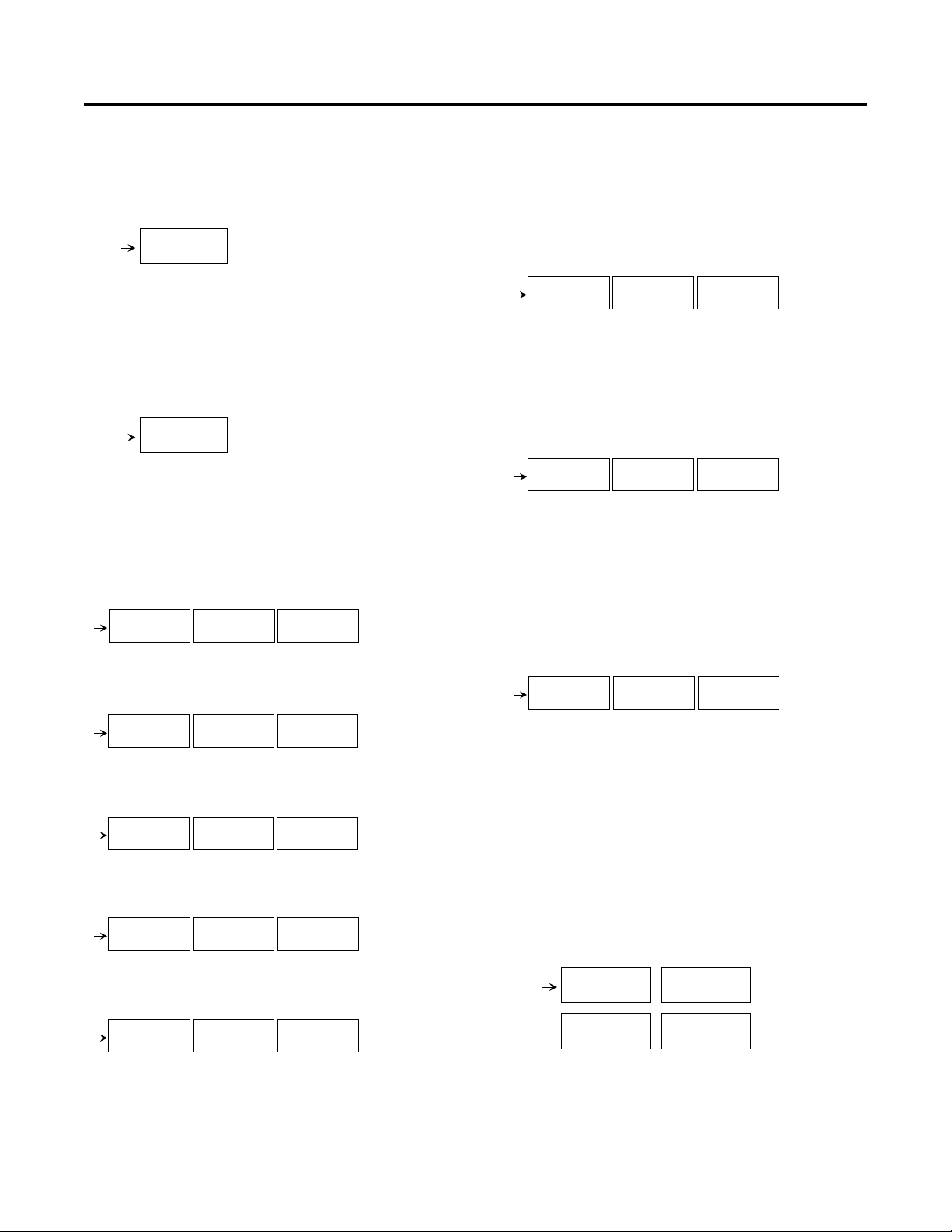

BLOCK DIAGRAM

A in

20

B in

19

15

16

17

18

RST

CLR

COUNT

LOGIC

R

CONTROL

INPUT

ASSIGNMENT

Total Count

Main Count

R

R, SC, BP1,

PU, DO

COUNT

SCALER

Scaled Total

Scaled Main

RATE METER

(Rate Scaling)

Not available

on feet/inches

control.

R

TOTALIZER

C

MAIN

C

COUNTER

BP1

SC

R

BATCH

C

COUNTER

R

P1

P2

P3

*P4

P1/PF

Pb

A1

A2

PU, DO

PU, DO

PU, DO

PU

PU

PU

DO

PU

DO

PU

DO

TRANSISTOR 1

OUTPUT LOGIC

TRANSISTOR 2

OUTPUT LOGIC

RELAY 1

OUTPUT

•

RELAY 2

OUTPUT

•

14

13

10

9

8

7

6

5

Key

R

SC

BP1

Reset

Stop Count

Bypass P1

Pick Up

PU

Drop Out

DU

Screw Terminal

C Count *P4 is the prewarn (Pw) on the

The block diagram shows the major internal "parts" of the

control. A general description of each block was given on the

previous page. The block diagram shows how the parts relate

to each other. The flow through the control is generally left to

right; inputs are designated by screw terminal number on the

left side of the block, and output terminals are shown on the

right side. In between, arrows lead from block to block from

the count inputs (19 and 20) to the count and rate registers.

The open ended arrows indicate "connections" that can be

made by programming.

Feet/Inches control.

The block diagram shows that the control will not respond to

the control inputs; (15, 16, 17, 18 and RST key) until they are

programmed to a specific function, and the outputs are also

oblivious to the count and rate registers until a programming

"connection" is made.

2

INSTALLATION WIRING AND PROGRAMMING - QUICK START

This section is a step-by-step process for determining program selections and I/O wiring. If the installer has a basic

knowledge of counter terminology and uses the block diagram for a reference, the configuration process should be

straightforward. Detailed descriptions of programming choices

are listed on pages 22 to 25. Detailed I/O wiring diagrams are

shown on pages 26 to 28. Instructions on calculating scale

factors are on page 29.

For each programming choice, a program item number is

listed. A selection space is provided to record the desired

selection. These numbers can be also recorded in the

programming menu chart on pages 14 to 21, in order to

D

document the application.

in the choice lists indicates

default setting.

I/O terminals used in the application can be labeled in the

space provided on page 10.

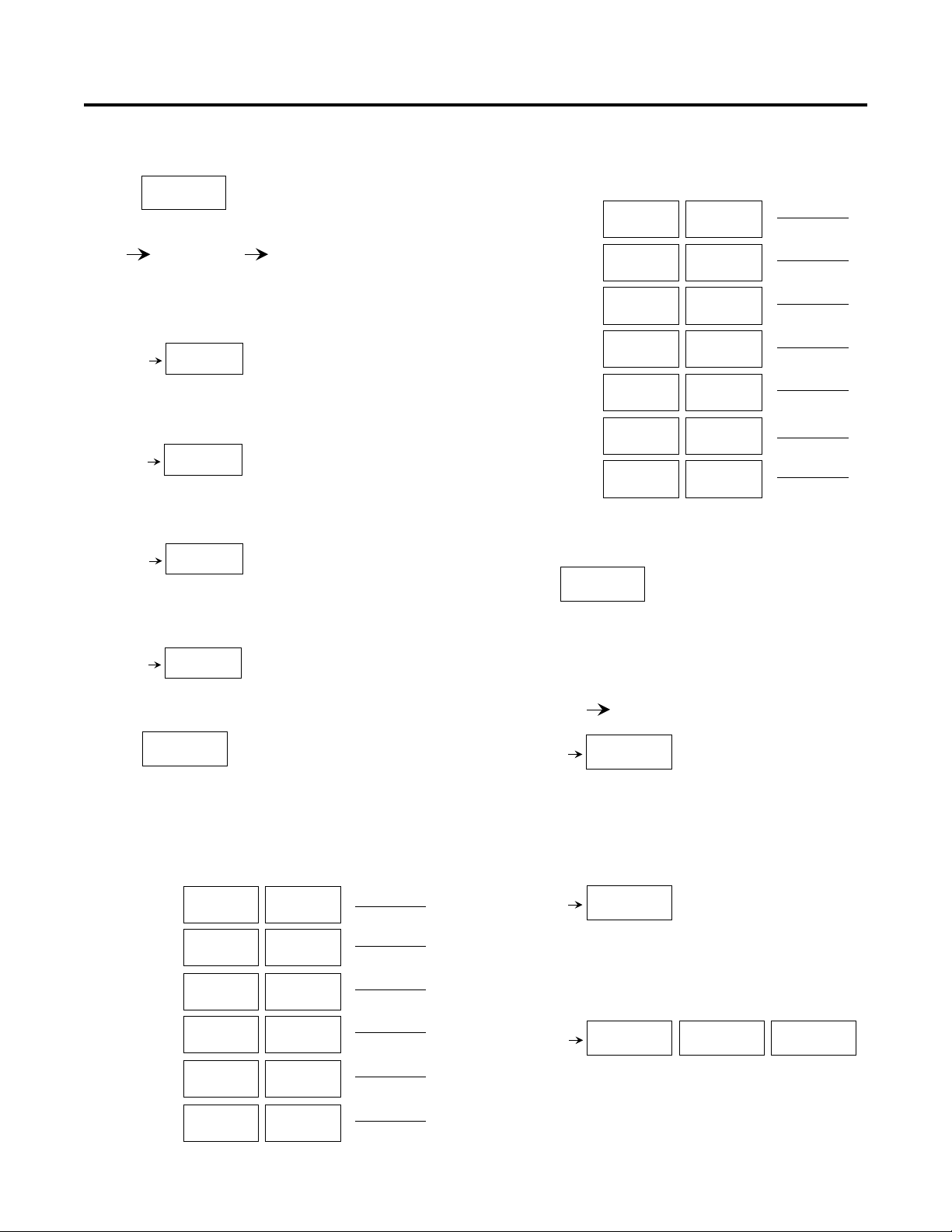

Phase I - The Vital Ingredients

1. Count Logic/Main Counter/Totalizer behavior determined

by:

PROGRAM

COUNT IN

A. Count Mode

Program Item 10 Selection __________

Consider: Type of count input sensor(s), main

counter and totalizer functions, and input B as a

count or control input.

Choices:

D

CNT + TOT

A-B

CNT + TOT

A, B DIR

CNT + TOT

QUAD X1

TOT A

CNT B

C. Input B Response

Program Item 12 Selection __________

Consider: Input speed <40Hz? If yes, use contact.

This item is not visible if a QUAD count mode or B

RST is selected (forced to SOLID ST) or if B DIR is

selected (forced to CONTACT).

Choices:

D

INPUT B

SOLID ST

INPUT B

CONTACT

D. Input B Reset

Program Item 13 Selection __________

Consider: Which count register(s) should input B

reset? This item is only visible if B RST count mode

is selected.

Choices:

D

B RST

CNT EDG

B RST

BCH EDG

B RST

TOT EDG

B RST

ALL EDG

E. Final Preset

Program Item 14 Selection __________

Consider: How many setpoints will be needed on

the main counter? Set Pf to that number.

Choices:

FINAL P f

D

P 4

FINAL P f

P 2

CNT + TOT

A+B

CNT + TOT

-A+B

CNT + TOT

2A, B DIR

CNT + TOT

A, B RST

CNT + TOT

QUAD X2

CNT + TOT

QUAD X4

TOT B

CNT B

Label the assignment of count inputs A + B (terminals 20 and 19) on the diagram on page 10.

B. Input A Response

Program Item II Selection __________

Consider: Input speed <40Hz? If yes, use contact.

This item is forced to SOLID ST and is not visible if

a QUAD count mode is selected.

Choices:

D

INPUT A

SOLID ST

INPUT A

CONTACT

FINAL P f

P 3

FINAL P f

P 1

F. Reset to Zero/Preset

Program Item 15 Selection __________

Consider: Reset to Preset is considered a down

counting mode for the main counter.

Choices:

D

RESET TO

ZERO

RESET TO

P f

G. Main Counter Auto Cycle

Program Item 16 Selection __________

Consider: Batch counter increments each time the

main counter auto cycles or Pf is reached.

3

INSTALLATION WIRING AND PROGRAMMING - QUICK START

D

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

Choices:

D

AUTO CYC

DISABLED

AUTO CYC

P 1

AUTO CYC

P f (0)

AUTO CYC

P1 P f (0)

2. When appropriate, adjust the count scaler and set up the

ratemeter in:

PROGRAM

SCALERS

Note: Calculation of scalers and decimal point selection

is explained on page 29.

A. Count Scaler

Program Item 0 Selection __________

C SCALER

D

1.00000

B. Count Decimal Point

Program Item 1 Selection __________

C DEC PT

D

- - - - - -

* * *AT THIS POINT, refer to the block diagram. We are

almost done with figuring out how the counters and ratemeter

are going to behave. All that's left to getting an output to occur

at the terminals on the right side when count pulses come in

at the terminals on the left is to program some "connections"

between the count/rate registers and the output blocks. This

is done in step 3.

3. Educating the outputs:

PROGRAM

OUT MODE

Note: All four output blocks (Relay 1, Relay 2, Trans 1,

and Trans 2) are included in PROGRAM OUT MODE.

The choices for all outputs are exactly the same. Only

Relay 1 choices will be shown here, but spaces for

recording the selections for the other outputs are provided.

RELAY 1

PROGRAM

A. Count or Rate Activated Output

Program Item 300 Selection __________

Consider: Should this output turn on or off based on

a ratemeter setpoint? If yes, choose rate.

C Rate Scaler

Program Item 2 Selection __________

R SCALER

D

1.0000

D. Rate Decimal Point

Program Item 3 Selection __________

R DEC PT

D

- - - - - -

E. Rate Zero Time

Program Item 4 Selection __________

Consider: Maximum ratemeter response time to

the process being considered "stopped".

R ZERO

D

TIME 1.0

F. Rate Average Time

Program Item 5 Selection __________

R AVG

D

TIME 1.0

Choices:

RELAY 1

D

COUNT

RELAY 1

RATE

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

* * * If RATE is selected, skip to N.

B. Output Operation

Program Item 303 Selection __________

Consider: Reverse mode is also known as contrary

mode. Pick Up events are really Drop Out events

and vise versa.

Choices:

RELAY 1

D

NORMAL

RELAY 1

REVERSE

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

C. Output Latch / Timeout

Program Item 304 Selection __________

Consider: Latched will require both a Pick Up and

Drop Out event.

Choices:

RELAY 1

LATCHED

RELAY 1

PULSED

4

INSTALLATION WIRING AND PROGRAMMING - QUICK START

* * * If LATCHED is selected, skip to E.

D. Output "On" Time

Program Item 305 Selection __________

RELAY 1

D

PUL 1.00

E. Output On Delay Time

Program Item 306 Selection __________

Consider: How many seconds should elapse after

a Pick Up event occurs before the output actually

picks up?

RELAY 1

D

DEL 0.00

F. Preset 1 Action

Program Item 307 Selection __________

Consider: Should the output Pick Up or Drop Out at

Preset 1 or ignore Preset 1 (No Action)?

Choices:

RELAY 1

D

P1 NA

RELAY 1

P1 PU

RELAY 1

P1 DO

G. Preset 2 Action

Program Item 308 Selection __________

RELAY 1

D

P2 NA

RELAY 1

P2 PU

RELAY 1

P2 DO

H. Preset 3 Action

Program Item 309 Selection __________

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

K. Output Control 1 Action

Program Item 30C Selection __________

Consider: This signal comes from a control input

programmed to Output Control 1 (OUT CTL 1).

Choices:

D

RELAY 1

OCTL1 NA

RELAY 1

OCTL1 PU

RELAY 1

OCTL1 DO

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

L. Output Control 2 Action

Program Item 30D Selection __________

Consider: This signal comes from a control input

programmed to Output Control 2 (OUT CTL 2).

Choices:

D

RELAY 1

OCTL2 NA

RELAY 1

OCTL2 PU

RELAY 1

OCTL DO

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

M. Counter Reset Action

Program Item 30E Selection __________

Consider: This signal comes from a control input

and/or the front panel reset key programmed to

Reset Count (RSC EDG, or RSC LVL).

Choices:

RELAY 1

D

RS C NA

RELAY 1

RS C PU

RELAY 1

RS C DO

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

* * * This completes the programming for Relay 1 when

it is programmed for count. Go back to choice A at the

beginning of this step and repeat the process for each

remaining output needed.

RELAY 1

D

P3 NA

I. Preset 4 Action

Program Item 30A Selection __________

RELAY 1

D

P4 NA

J. Batch Preset Action

Program Item 30B Selection __________

RELAY 1

D

PB NA

RELAY 1

P3 PU

RELAY 1

P4 PU

RELAY 1

PB PU

RELAY 1

P3 DO

RELAY 1

P4 DO

RELAY 1

PB DO

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

N. Output Setpoint Assignment

Program Item 301 Selection __________

Consider: Which setpoint, A1 or A2, should this

output respond to, and should it turn on above (hi)

or below (lo) the setpoint?

Choices:

RELAY 1

D

A 1 HI

RELAY 1

A 1 LO

RELAY 1

A 2 HI

RELAY 1

A 2 LO

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

5

INSTALLATION WIRING AND PROGRAMMING - QUICK START

O. Output Duration

Program Item 302 Selection __________

Consider: Once the output turns on, by what means

will it turn off?

Choices:

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

D

RELAY 1

DISABLED

RELAY 1

FOLLOWS

RELAY 1

LATCHED

RELAY 1

PULSED

* * * If PULSED is selected, continue to choice P; if not,

go back to choice A and repeat the process for each

remaining output needed.

P. Output "On" Time

Program Item 305 Selection __________

RELAY 1

D

PUL 1.00

RELAY 2 ______

TRANS 1 ______

TRANS 2 ______

* * * This completes the programming for Relay 1 when

it is programmed for rate. Go back to choice A at the

beginning of this step and repeat the process for each

remaining output needed.

Choices:

D

INPUT 1

DISABLED

INPUT 1

BYP P 1

INPUT 1

OUT CTL 1

INPUT 1

OUT CTL 2

INPUT 1

RS C EDG

INPUT 1

RS C LVL

INPUT 1

RS B EDG

INPUT 1

RS T EDG

INPUT 1

RS A EDG

INPUT 1

STOP CNT

INPUT 1

PRINT

INPUT 1

LOCK PGM

INPUT 1

LOCK ALL

INPUT 1

UNL ALMS

INPUT 2 ______

INPUT 3 ______

INPUT 4 ______

Label the assignment of control inputs 1, 2, 3, and 4

(terminals 15, 16, 17 and 18) on the diagram on page 10.

2. Allow the operator to view what's important in:

PROGRAM

DISPLAY

A. Count with text

Program Item 40 Selection __________

Consider: If all items are set to hide, CNT and TXT

will show.

Choices:

Record the assignments of the outputs (terminals 5, 6,

7, 8, 9, 10, 13, 14) on the diagram on page 10.

* * *This completes the wiring and programming selec-

tions for a "bare bones" application. If you check the

block diagram, you can see that count inputs are getting

converted to relay and transistor outputs at this point.

Most applications will need further dressing up before

the control is ready for use by the operator. This is done

in Phase 2.

Phase 2 - Finishing Touches

1. Assigning the control inputs in:

PROGRAM

INPUTS

Input 1 Function

Program Item 20 Selection __________

Consider: Use control inputs wisely and save one for

one of the lock functions.

D

CNT + TXT

HIDE

CNT + TXT

SHOW

B. Rate with text

Program Item 41 Selection __________

Choices:

D

RATE + TXT

HIDE

RATE + TXT

SHOW

C. Batch count with text

Program Item 42 Selection __________

Choices:

D

BCH + TXT

HIDE

BCH + TXT

SHOW

D. Totalizer count with text

Program Item 43 Selection __________

Choices:

D

TOT+ TXT

HIDE

TOT+ TXT

SHOW

6

INSTALLATION WIRING AND PROGRAMMING - QUICK START

D

D

E. Count and current preset

Program Item 44 Selection __________

Choices:

CNT+ Pc

D

HIDE

CNT + Pc

SHOW

F. Count and preset 1

Program Item 45 Selection __________

Choices:

CNT+ P1

D

HIDE

CNT + P1

SHOW

G. Count and preset 2

Program Item 46 Selection __________

Choices:

CNT+ P2

D

HIDE

CNT + P2

SHOW

H. Count and preset 3

Program Item 47 Selection __________

L. Rate and alarm setpoint A1

Program Item 4B Selection __________

Choices:

RATE + A1

HIDE

RATE + A1

SHOW

M. Rate and alarm setpoint A2

Program Item 4C Selection __________

Choices:

D

RATE + A2

HIDE

RATE + A2

SHOW

N. Count scaler

Program Item 4D Selection __________

Choices:

D

C SCALER

HIDE

C SCALER

SHOW

O. Count decimal point position select

Program Item 4E Selection __________

Choices:

CNT+ P3

D

HIDE

CNT + P3

SHOW

I. Count and preset 4

Program Item 48 Selection __________

Choices:

CNT+ P4

D

HIDE

CNT + P4

SHOW

J. Batch and batch preset

Program Item 49 Selection __________

Choices:

BCH + Pb

D

HIDE

BCH + Pb

SHOW

K. Count and rate

Program Item 4A Selection __________

Choices:

D

CNT + RATE

HIDE

CNT + RATE

SHOW

Choices:

D

C DEC PT

HIDE

C DEC PT

SHOW

3. If you intend to use the front panel reset and/or print

keys, enable them in:

PROGRAM

OPTIONS

A. Reset key function

Program Item 80 Selection __________

Choices:

D

RST KEY

DISABLED

RST KEY

RS C EDG

RST KEY

RS C LVL

RST KEY

RS B EDG

RST KEY

RS T EDG

RST KEY

RS D EDG

RST KEY

RS A EDG

B. Print key enable

Program item 81 Selection __________

Consider: If you enable the print key, be sure to

program the item(s) to be printed in PROGRAM

SER OUT.

Choices:

PRNT KEY

DISABLED

PRNT KEY

ENABLED

7

INSTALLATION WIRING AND PROGRAMMING - QUICK START

4. Identify what you're counting in:

PROGRAM

TEXT

You have up to eight characters; select each to be alpha

A Z, numeric 0 9, or space, comma, dash,

decimal point, or slash.

A. Main counter text

Program Item 50 Selection __________

CNT TXT

D

COUNT

B. Ratemeter text

Program Item 51 Selection __________

RATE TXT

D

RATE

C. Batch counter text

Program Item 52 Selection __________

BCH TXT

D

BATCH

D. Totalizer text

Program Item 53 Selection __________

TOT TXT

D

TOTAL

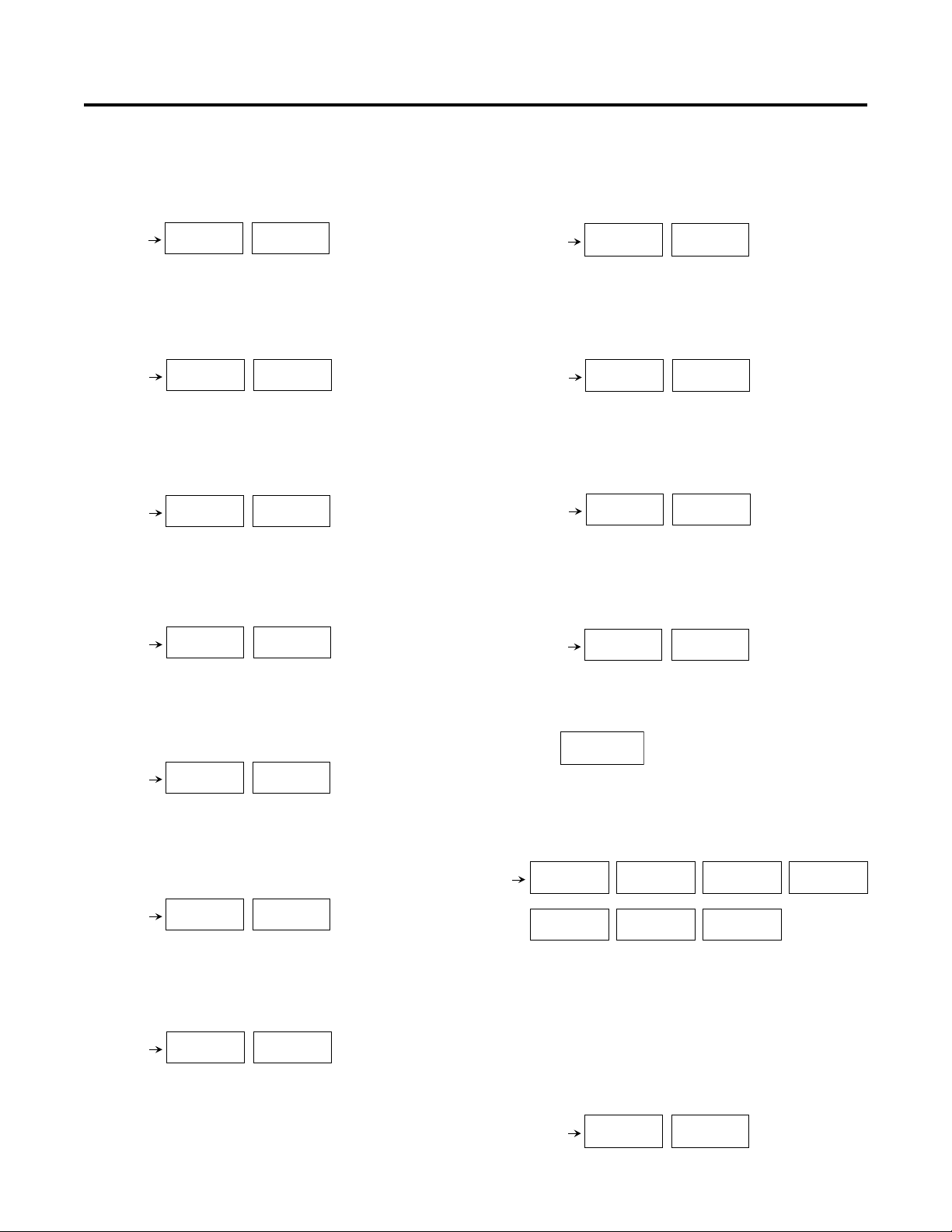

5. Set up your print list in:

Cont.

PROGRAM

ITEM

76

77

78

79

7A

7B

7C

DEFAULT CHOICE

P3

SKIP

P4

SKIP

PB

SKIP

A1

SKIP

A2

SKIP

C SCALER

SKIP

C DEC PT

SKIP

P3

SEND

P4

SEND

PB

SEND

A1

SEND

A2

SEND

C SCALER

SEND

C DEC PT

SEND

SELECTION

6. Configure the serial communications for use with a host

computer or a dumb printer in:

PROGRAM

SER PORT

A. Counter ID number

Program Item 60 Selection __________

Consider: When more than one counter is used in

a system, assign a unique number from the range

of 0 99 to each counter.

PROGRAM

SER OUT

Remember to set the baud rate and parity and set the

port to PRINTER in PROGRAM SER PORT if you are

going to initiate a transmission from the counter.

PROGRAM

ITEM

70

71

72

73

74

75

DEFAULT CHOICE

COUNT

SKIP

BATCH

SKIP

TOTAL

SKIP

RATE

SKIP

P1

SKIP

P2

SKIP

COUNT

SEND

BATCH

SEND

TOTAL

SEND

RATE

SEND

P1

SEND

P2

SEND

SELECTION

SER PORT

D

ID 0

B. Baud rate

Program Item 61 Selection __________

Consider: Choices are 19200, 9600, 4800, 2400,

1200 and 300.

BAUD

D

19200

C. Parity

Program Item 62 Selection __________

Choices:

PARITY

D

NONE

PARITY

ODD

PARITY

EVEN

8

INSTALLATION WIRING AND PROGRAMMING - QUICK START

D. Transmission delay time

Program Item 63 Selection __________

D

Tx DELAY

0.002

Tx DELAY

0.100

E. Host or printer port

Program Item 64 Selection __________

Consider: Should the counter initiate the transmis-

sion (printer), or should the counter respond to a

serial command (host)?

Choices:

HOST

D

PORT

PRINTER

PORT

Label the serial port (terminals 21 and 22) on the

diagram on page 10.

***This completes Phase 2 wiring and programming

selections. All the necessary selections have been made.

Record the selections you have made that are not the default

value in the program menu chart on pages 14 to 21. After you

wire the counter up according to the diagram on page 10, go

into the program mode and give your counter the personality

to do your application.

Phase III - Above and Beyond

A phase 3 installation uses the serial communications port in

the host mode. This capability allows a host computer to read

all programming and run mode information and to write all

programming selections. Furthermore, all of the control input

functions are available through the serial port.

A separate manual describing the serial communications is

available. If you would like a copy, call 1-800-540-9242.

9

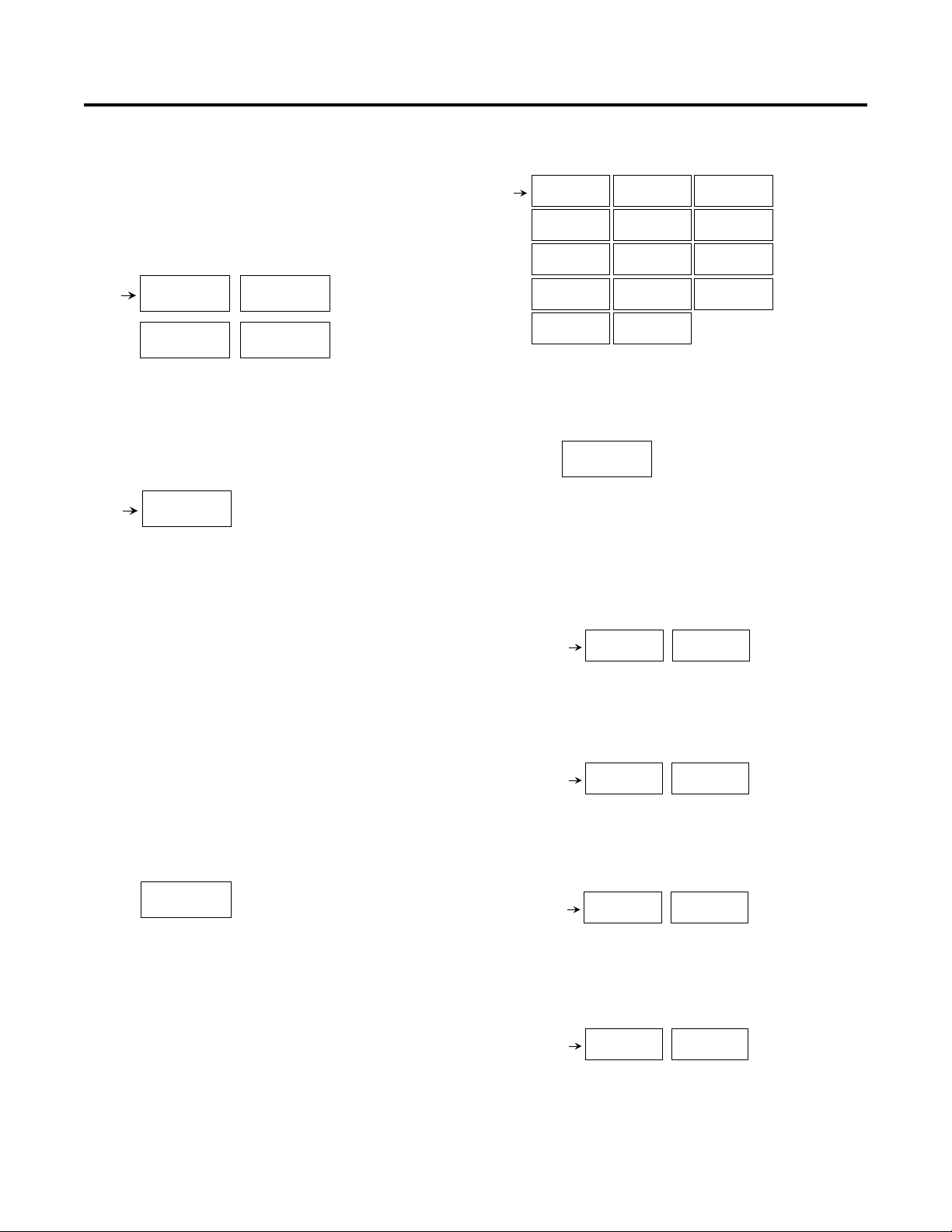

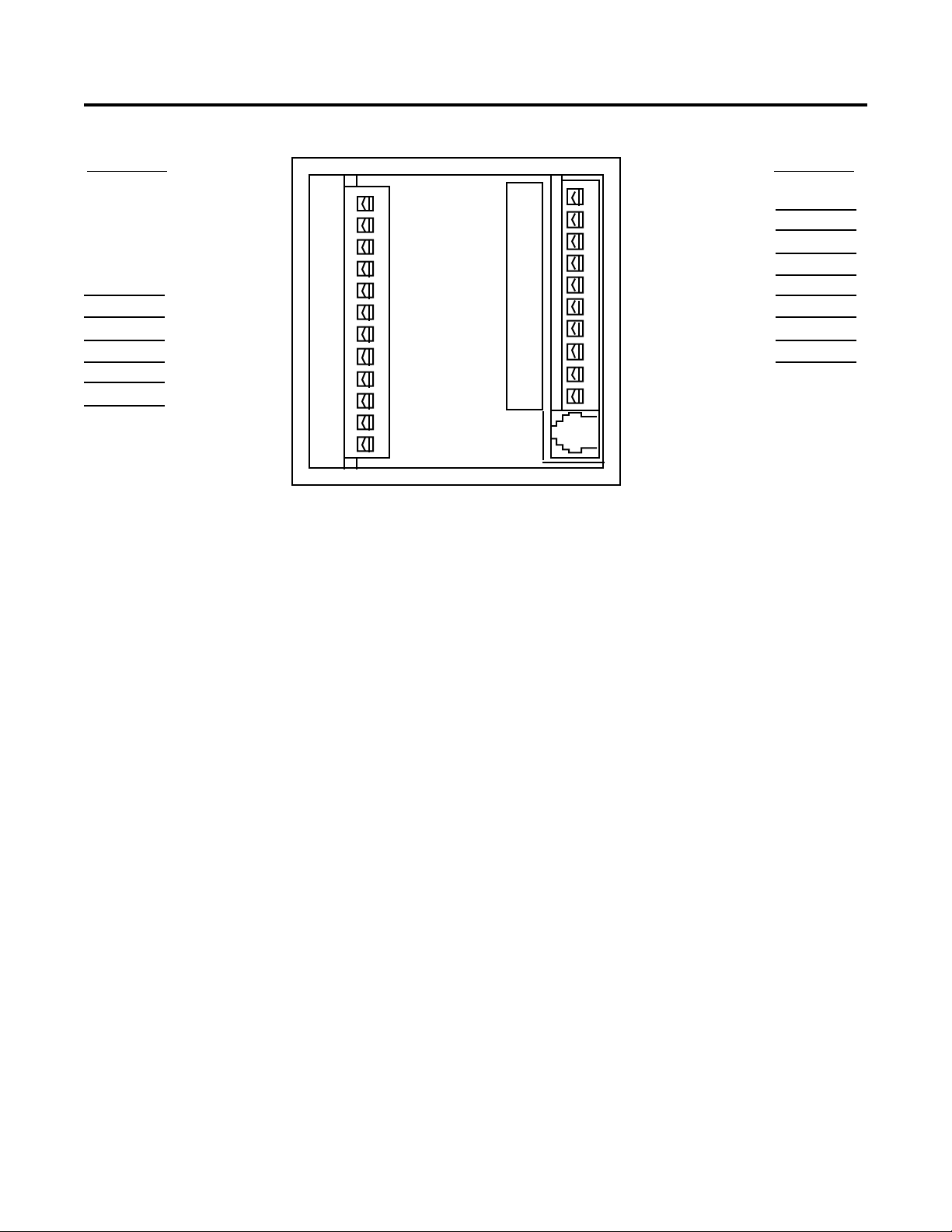

REAR TERMINAL DESCRIPTION

Assignment Assignment

+12 Volt DC

DC Common

DC Common

DC Common

Relay 2 N.C.

Relay 2 Com.

Relay 2 N.O.

Relay 1 N.C.

Relay 1 Com.

Relay 1 N.O.

AC Power Neut

AC Power Hot

TERMINAL DESCRIPTIONS

1 - On models 57601 and 57602 this terminal is the +12 VDC

power output. It is used to supply 12 VDC (+/- 25% 100 mA

max) for accessories. DC Common is the negative side of this

supply.

On the model 57600 this terminal is used for the 10-15 VDC

power input. Connect the positive lead of the power supply to

terminal 1 and the negative lead to DC Common.

The DC POWER OUTPUT contains a series Positive Temperature Coefficient (PTC) resistor that undergoes a large

and abrupt increase in resistance when an over-current

condition occurs. This resistance change limits the fault

current to several milliamps. The PTC device will reset when

the unit power has been removed for a time sufficient to cool

the device. The overload condition should be removed before unit power is reapplied.

2, 3, and 4 - DC Common: These terminals are connected

to the negative side of the counter’s internal DC power

supply. Count inputs must be referenced to DC Common.

Control inputs are on when connected to DC Common.

Transistor outputs conduct to DC Common when picked up.

5, 6 and 7 - Relay 2 contacts

8, 9 and 10 - Relay 1 contacts

Each relay output consists of one electrically isolated form C

set of contacts. The user must supply power through a

contact to the external load. The contacts remain in the

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

normal state until a pickup signal occurs. The relay remains

picked up (on) until a dropout signal occurs (see output

programming diagram page 16 and block diagram page 2).

11 and 12 - AC Power Inputs:

Model 57601-405 115VAC

Model 57602-405 230VAC

Model 57600-405 Not used

13, 14 - Transistor Outputs 2 and 1: These terminals are

separate open collector NPN transistor outputs. Each output

conducts to DC Common when picked up (see output programming diagram page 16 and block diagram page 2).

15, 16, 17, and 18 - Inputs 1, 2, 3, and 4: Programmable

inputs. The user can assign one of 14 functions to each

individual input. The inputs require a current sinking signal

(contact or solid state) to DC Common (see input programming diagram page 15 and block diagram page 2).

19, 20 - Count Inputs B and A: Connect the count input

signal(s) to these terminals. The count input can operate with

either a current sinking signal (contact or solid state) to DC

Common or a current sourcing signal. (See specifications,

programming diagram page 14, and block diagram page 2.)

Rate calculations are made from count pulses into Input A

only.

21, 22 - RS-485 serial I/O port: Connect terminal 21 to the

positive lead of the communications bus. Connect terminal

22 to the negative lead of the communications bus.

Transistor 2 Output

Transistor 1 Output

Input 1

Input 2

Input 3

Input 4

Count Input B

Count Input A

Communication +

Communication -

RS-485 communication connector, RJ-11 modular telephone style.

10

REAR TERMINAL DESCRIPTION continued

MODULAR COMMUNICATION JACK

The modular phone jack is an alternate connection to the RS485 communications port. Pin 3 is positive and is the same

as terminal 21. Pin 2 is negative and is the same as terminal

22. Pins 1 and 4 are connected to DC Common and should

be used for any shield connections.

Note: This jack is intended only for connection to Ambassador and other RS-485 communication networks. It should

not be connected to any telephone system - damage or hazard may result.

!

TERMINAL BLOCKS

Connections to the Ambassador are made through deplugable, screw terminal blocks to allow for ease of wiring and

removal of the counter. The terminals can accommodate

stranded, solid or fused wire (preferred) from 14 to 22 gauge.

To remove the terminal block, remove AC power and pry

gently underneath each end of the terminal block with small

screwdriver. Press straight on to re-install.

GENERAL WIRING PRACTICES

1. Disconnect all power before wiring terminals. A

safety hazard exists if this precaution is not

observed. Treat all control and count inputs as

hazardous since they may carry line voltage.

2. Use shielded cables for count signals, control input and

communications signals. Connect shield to common

(terminal 2, 3 or 4) of counter to terminate properly.

3. Keep all signal lines as short as possible.

4. Do NOT bundle or route signal lines with power or

machine control wiring. Use separate conduit for power

and signal wires.

5. Provide "clean" power to the counter. In severe cases,

power may have to be filtered or a separate power

source used. Do not use the same power source that is

supplying the loads.

6. Use 18 ga. minimum (0.97mm

maximum (2.1mm2, 600V) wire for AC power wiring.

7. See page 26, top drawing, for the correct fuse to be used

in the power input wiring.

DIP SWITCH FUNCTIONS

Switch 1: Input A sink/source

Off: input A requires a current sinking input signal.

On: input A requires a current sourcing input signal.

Switch 2: Input B sink/source

Off: input B requires a current sinking input signal.

On: input B requires a current sourcing input signal.

2

, 600V) and 14 ga.

Switch 3: Input A threshold level

Off: high threshold level — use with DC sensors.

On: low threshold level — use with mag pickups. Turn

switch 1 on.

Switch 4: Input B threshold level

Off: high threshold level — use with dc sensors.

On: low threshold level — use with mag pickups. Turn

switch 2 on.

Dip switches may be set through an opening on the bottom

of the unit. It is located towards the rear of the control.

PANEL MOUNTING

The panel mounting kit includes:

(1) mounting gasket, (2) mounting clips and (4) screws.

Refer to the dimension diagram on page 37 for a drawing of

the correct installation of these parts.

The mounting gasket is coated on one side with a contact

adhesive and a paper backing. Care should be taken during

the gasket installation that the gasket be correctly positioned

on the panel at the first attempt. Attempting to re-position the

gasket once the adhesive has come in contact with the panel

is likely to deform or tear the gasket.This may result in an

improper seal. For best results, follow these directions:

1. Stand the Ambassador counter on a desk or table with

its display down, screw terminals up.

2. Remove and discard the center square of the gasket at

the scribe marks in the gasket and paper backing. Do not

remove the backing from the remaining outer rim.

3. Slide the gasket down the unit until it is in position at the

rear of the unit's front bezel. The paper backing side

should be up.

4. Insert the tip of a knife between the paper and the gasket

and, while holding the gasket down to the unit with the

knife, peel off the paper backing.

5. Slide the unit through the panel cutout until the gasket

firmly adheres to the panel.

6. Install the mounting clips and screws as shown in the

diagram on page 37. Do not overtighten the mounting

screws. The screws should be tight enough to firmly hold

the unit in place, but not so tight as to squeeze the gasket

out from behind the front bezel.

7. A switch shall be included in the building installation:

• It shall be in close proximity to the equipment and

within easy reach of the operator.

• It shall be marked as the disconnecting device for the

equipment.

• Switches and circuit breakers in Europe must comply

with IEC 947.

11

Loading...

Loading...