DuraMax Metal Garden Shed Owner's Manual/ Instructions For Assembly

TM

A Product of

ALL PURPOSE METAL STORAGE SHEDS

USP

US POLYMERS INC

Metal Garden Shed

OWNER’S MANUAL /

Instructions for Assembly

Size 6’ x 4’ with “Extension Kits”

• Tall Walk in Shed

• Quick & Easy Assembly

• Ridge Reinforced Walls

• Wide Double Doors

• Available in Various Sizes

Customer

Service Hotline

(800) 483-4674

www.uspolymersinc.com

PART 1

ASSEMBLING SHED WITH EXTENSION KIT

PART 2

ADDING EXTENSION KIT TO EXISTING SHED

Note: For shed with extension use this manual only.

Requires two people and takes 2-3 hours for Installation.

Call us for any missing or damaged parts.

Do not return to the store.

Duramax Storage Shed

Limited Fifteen Year Warranty

U.S. Polymer Inc. will send a replacement part free of charge, in the event of material defects and or

workmanship for a period of fifteen years from the date of purchase.

This warranty is extended only to the original purchaser. A purchase receipt or other proof of date of original

purchase will be required before warranty service is rendered. In no event shall we pay the cost of flooring,

labor, installation or any other costs related thereto.

This warranty only covers failures due to defects in material or workmanship which occurs during normal

use and does not extend to color change arising due to normal weathering or to damage resulting from

misuse or neglect, commercial use, failure to follow assembly instructions and the owner’s manual (including

proper anchoring of the shed), painting, forces of nature and other causes which is beyond our control.

Claims under this warranty must be made within the warranty period by calling 1-800-483-4674 or mail in

a dated sales slip and clear photograph of the part to:

U.S. Polymers, Inc.

6915 Slauson Avenue

Commerce, CA 90040

We reserve the right to discontinue or change components. If a component has been discontinued or is

not available,

U.S. Polymers, Inc. reserves the right to substitute a component of equal quality as may be compatible.

Limits and Exclusions

There are no express warranties except as listed above. The warrantor shall not be liable for incidental or

consequential damages resulting from the use of this product, or arising out of any breach of this warranty.

All express warranties are limited to the warranty period set forth above . Some states do not allow the

exclusion or limitation on how long an implied warranty lasts, so the above limitations may not apply to

you.

This warranty gives you specific legal rights and you may also have other rights which vary from state to

state or country to country.

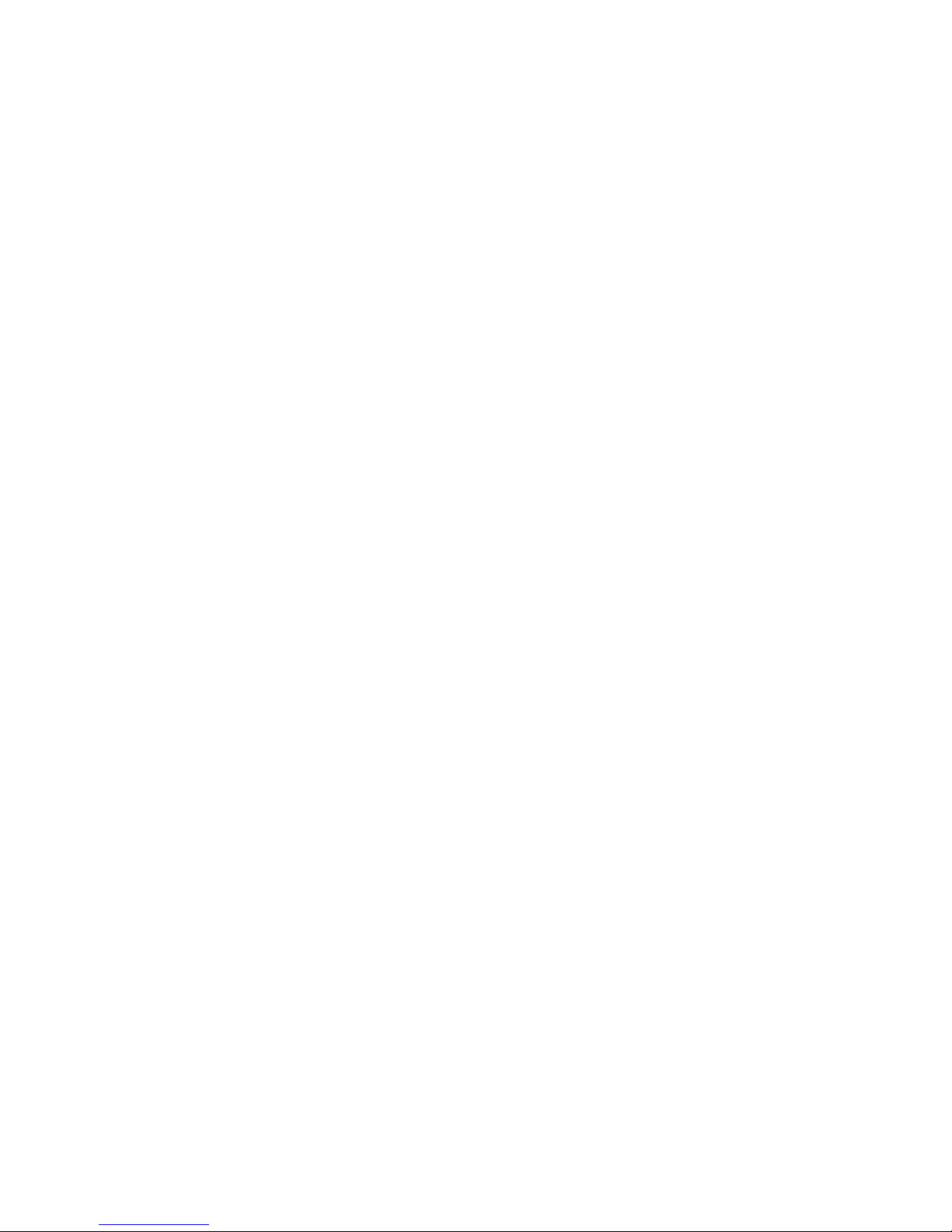

Parts List

Note: Check all parts prior to installation.

CODE DESCRIPTION QTY

BLC BASE BAR BACK LEFT 1

BRC BASE BAR BACK RIGHT 1

BSC BASE BAR SIDE LEFT & RIGHT 2

BBFC BASE BAR FRONT LEFT & RIGHT 2

ECC ENTRANCE TAPER CHANNEL 1

DCLC DOOR COLUMN PROFILE LEFT 1

DCRC DOOR COLUMN PROFILE RIGHT 1

ABLC TOP ANGLE BACK LEFT 1

ABRC TOP ANGLE BACK RIGHT 1

ASC TOP ANGLE SIDE LEFT & RIGHT 2

SCC SLIDING CHANNEL COVER 1

SSB SLIDING CHANNEL SUPPORT 1

SLC SLIDING CHANNEL LEFT 1

SRC SLIDING CHANNEL RIGHT 1

RSC ROOF SUPPORT LEFT & RIGHT 2

RF1C ROOF FLASHING (FRONT RIGHT / BACK LEFT) 2

RF2C ROOF FLASHING (FRONT LEFT / BACK RIGHT) 2

RFSA ROOF FLASHING SIDE LEFT & RIGHT 2

RFCC ROOF FLASHING CENTER 1

TSLC DOOR PANEL STRIP TOP LEFT 1

TSRC DOOR PANEL STRIP TOP RIGHT 1

BDSC DOOR PANEL STRIP BOTTOM LEFT/RIGHT 2

DSSC DOOR PANEL STRIP SIDE LEFT & RIGHT 2

DSCC DOOR PANEL STRIP CROSS 4

WCFC WALL PANEL CORNER FRONT LEFT & RIGHT 2

WCBC WALL PANEL CORNER BACK LEFT & RIGHT 2

WSC WALL PANEL SIDE 3

WFLC WALL PANEL FRONT LEFT 1

WFRC WALL PANEL FRONT RIGHT 1

GPLC GABLE PANEL FRONT LEFT/BACK RIGHT 2

GPRC GABLE PANEL FRONT RIGHT/BACK LEFT 2

GPS GABLE PANEL SUPPORT 2

RP1C ROOF PANEL FRONT LEFT / BACK RIGHT 2

RP2C ROOF PANEL FRONT RIGHT/BACK LEFT 2

DPLC DOOR PANEL LEFT 1

DPRC DOOR PANEL RIGHT 1

ACCESSORIES

CODE DESCRIPTION QTY

BS BOTTOM SLIDER 4

DH DOOR HANDLE 2

FC FLASHING END CAP 2

TC TOP CORNER 4

TS TOP SLIDER 4

VC VENTILATION COVER 4

PW PLASTIC WASHER 134

PC PLASTIC SCREW COVER 86

WST WEATHER STRIPPING TAPE 2.00 mtr

S1 DIA. 4.2 x 10mm. (5/32” x 3/8”)

SHEET METAL SCREW 160

S2 DIA. 4.2 x 16mm. (5/32” x 5/8”)

SHEET METAL SCREW 22

S3 M4 x 16mm. (5/32” x 5/8”)

MACHINE SCREW W/ NUT 53

ACCESSORIES

BOTTOM SLIDER

(BS)

TOP CORNERS

(TC)

PLASTIC WASHER

(PW)

DOOR HANDLE

(DH)

TOP SLIDER

(TS)

PLASTIC SCREW COVER

(PC)

PROFILES

BASE BAR

(BLC, BRC, BSC)

BASE BAR

(BBFC)

DOOR COLUMN PROFILE

LEFT (DCLC)

SLIDING CHANNEL COVER

(SCC)

SLIDING CHANNEL

(SLC, SRC)

ROOF SUPPORT

(RSC)

TOP ANGLE BACK

(ABLC, ABRC)

ENTRANCE TAPER

CHANNEL (ECC)

DOOR COLUMN PROFILE

RIGHT (DCRC)

TOP ANGLE SIDE

(ASC)

SLIDING CHANNEL

SUPPORT (SSB)

DOOR PANEL STRIP SIDE

AND CROSS

(DSSC, DSCC)

Tools You Will Need

Hand Gloves

Cordless Drill - Philips Head

Screw driver - Philips Head

Carpenters Square

Eye Protector

IMPORTANT: USE HAND GLOVES TO PREVENT INJURY.

8’ Step Ladder

Adjustable pliers

Level - 3ft.

Tape Measure

SHEET METAL SCREW

(S1),(S2)

FLASHING END CAP

(FC)

WEATHER STIPPING TAPE

(WST)

MACHINE SCREW WITH

NUT (S3)

VENTILATION COVER

(VC)

ROOF FLASHING

(RF1C, RF2C)

ROOF FLASHING CENTER

(RFCC)

DOOR PANEL STRIP

TOP AND BOTTOM

(TSLC, TSRC, BDSC)

GABLE PANEL SUPPORT

(GPS)

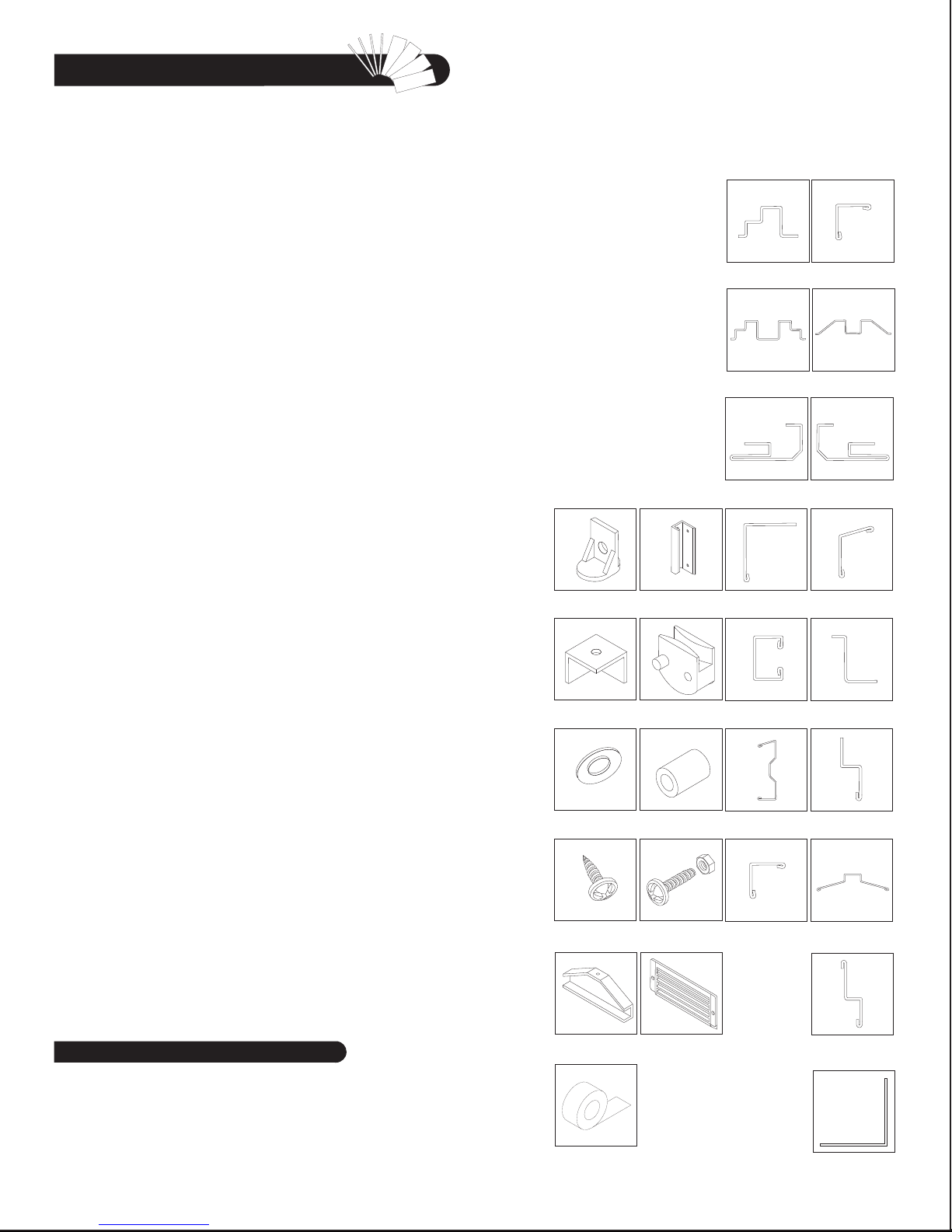

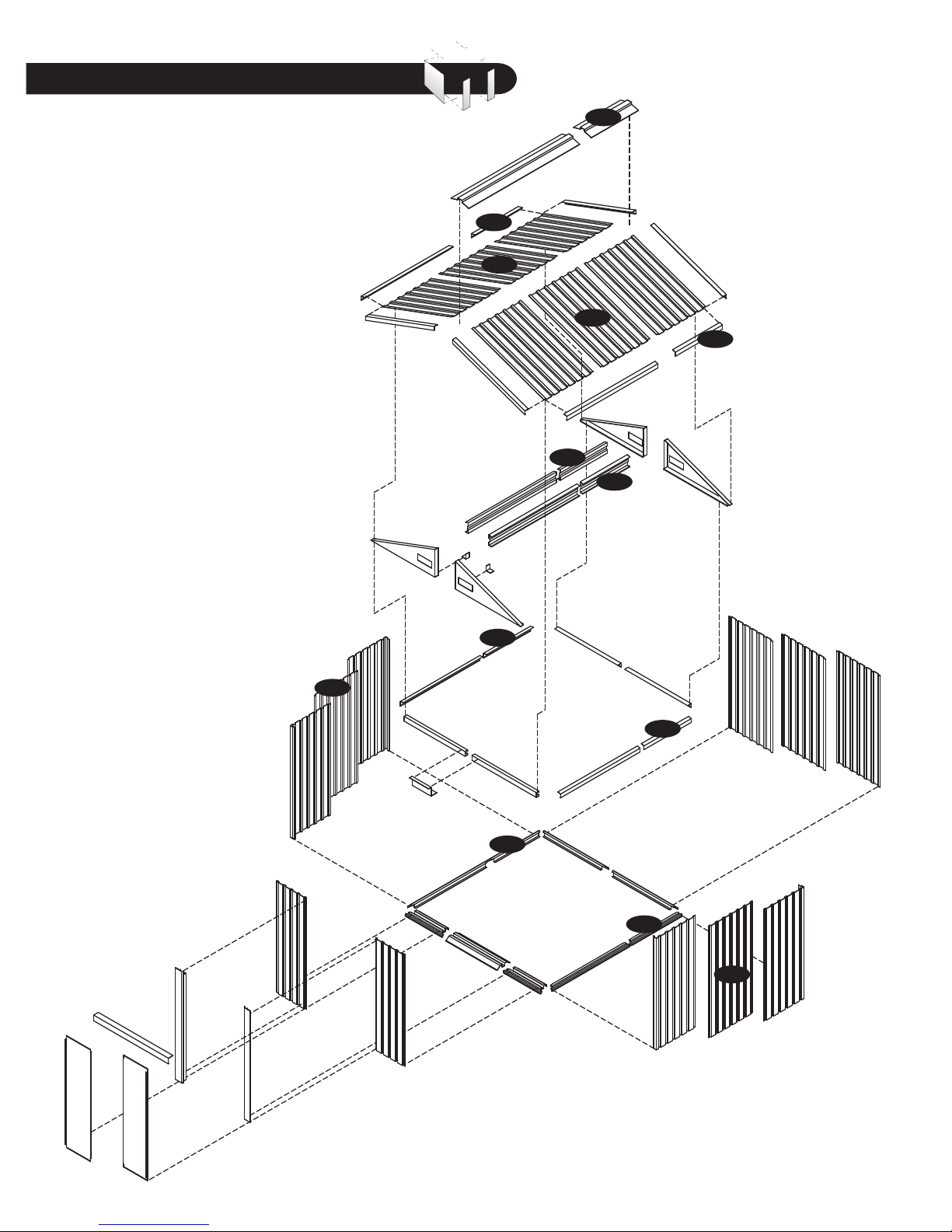

Exploded View

RFCC

RF1C

WCFC

WCBC

RFSA

RF2C

GPLC

RP1C

SSB

SLC

ASC

RF1C

RSC

RP2C

GPRC

SRC

RP2C

GPS

ABLC

RP1C

GPRC

RFSA

ASC

RF2C

ABRC

GPLC

WSC

WSC

WSC

WFLC

DCLC

SCC

DCRC

DPLC

DPRC

IMPORTANT: USE HAND GLOVES TO PREVENT INJURY.

WFRC

BSC

BBFC

ECC

BLC

BBFC

BRC

BSC

WCBC

WCFC

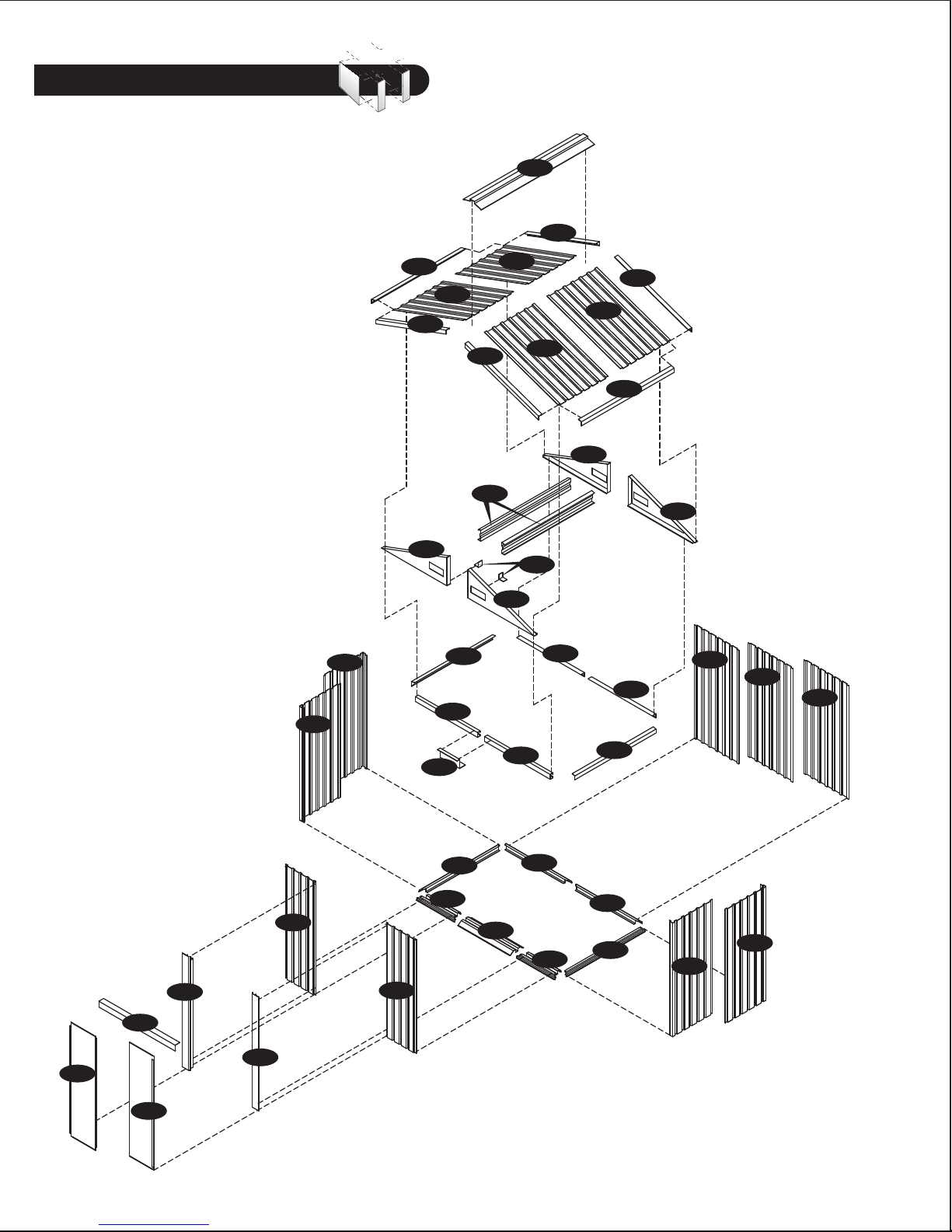

One Extension Parts List

Note: Check all parts prior to installation.

CODE DESCRIPTION QTY

EBS1 BASE BAR SIDE EXTENSION LEFT 1

EBS2 BASE BAR SIDE EXTENSION RIGHT 1

EAS1 TOP ANGLE SIDE EXTENSION LEFT 1

EAS2 TOP ANGLE SIDE EXTENSION RIGHT 1

ERS1 ROOF SUPPORT EXTENSION LEFT 1

ERS2 ROOF SUPPORT EXTENSION RIGHT 1

ERFS ROOF FLASHING SIDE EXTENSION LEFT/RIGHT 2

ERFC ROOF FLASHING CENTER EXTENSION 1

WSC WALL PANEL SIDE 2

RELC ROOF PANEL 1

RERC ROOF PANEL 1

ACCESSORIES

CODE DESCRIPTION QTY

PW PLASTIC WASHER 38

PC PLASTIC SCREW COVER 15

S1 DIA. 4.2 x 10mm. (5/32” x 3/8”)

SHEET METAL SCREW 40

S2 DIA. 4.2 x 16mm. (5/32” x 5/8”)

SHEET METAL SCREW 6

S3 M4 x 10mm. (5/32” x 3/8”)

MACHINE SCREW WITH NUT 6

WST WEATHER STRIPPING TAPE 1.5MTR

BASE BAR

(EBS1, EBS2)

ROOF SUPPORT

(ERS1, ERS2)

ACCESSORIES

PROFILES

TOP ANGLE SIDE

(EAS1, EAS2)

ROOF FLASHING SIDE

(ERFS)

ROOF FLASHING CENTER

(ERFC)

PLASTIC WASHER

(PW)

SHEET METAL SCREW

(S2)

WEATHER STRIPPING

TAPE

(WST)

PLASTIC SCREW COVER

(PC)

MACHINE SCREW WITH

NUT (S3)

IMPORTANT: USE HAND GLOVES TO PREVENT INJURY.

Exploded View with One Extension

ERFC

ERFS

RELC

RERC

ERFS

ERS1

ERS2

WSC

EAS1

EAS2

EBS1

EBS2

WSC

IMPORTANT: USE HAND GLOVES TO PREVENT INJURY.

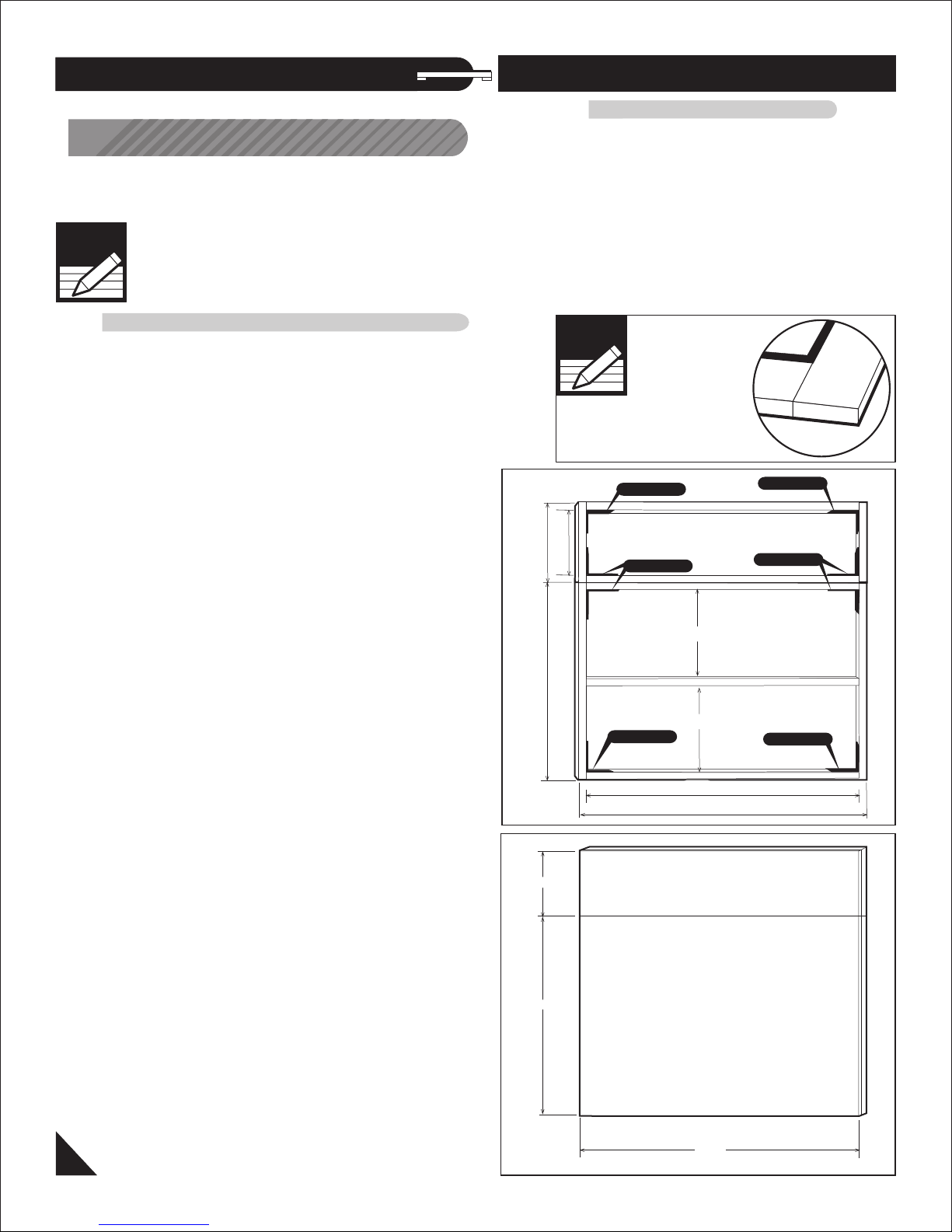

A. Foundation & Base Frame

Note: It is important that these instructions

are followed step by step.

DuraMax must be installed on a level wooden platform

or a level concrete foundation.

Note

Wooden platform is extra

and is not included.

Don’t install under

windy conditions.

Wooden Platform (each Extension) (Not Included)

The following are a list of lumber and sizes

you will need.

Pressure Treated - Wood Studs:

2ea 2” x 4” x 71” (50mm x 88.9mm x 1803.4 mm)

2ea 2” x 4” x 24” (50mm x 88.9mm x 609.6 mm)

Exterior Grade (CDX) - 3/4” (19mm) plywood

1ea 3/4” x 24” x 78” (19mm x 609.6mm x 1981.2mm)

L-Brackets: 4ea

PART 1: Assembling Shed With Extension Kit

Wooden Platform (Not Included)

The following are the list of lumber and sizes

you will need.

Pressure Treated - Wood Studs:

3ea 2” x 4” x 71” (50mm x 88.9mm x 1803.4mm)

2ea 2” x 4” x 47” (50mm x 88.9mm x 1193.8mm)

Exterior Grade (CDX) - 3/4” (19mm) plywood

1ea 3/4” x 47” x 78” (19mm x 1193.8mm x 1981.2mm)

L-Brackets: 4ea

Note

Lay 50 x 88.9mm Flat

L- BRACKET

L- BRACKET

Parts needed:

(1) Base bar back left (BLC)

(1) Base bar back right (BRC)

(2) Base bar side (BSC)

(2) Base bar front (BBFC)

(1) Entrance Taper channel (ECC)

(12) Sheet metal screw (S1)

(18) Sheet metal screw (S2)

Parts needed for each Extension:

(1) Base bar side extension left (EBS1)

(1) Base bar side extension right (EBS2)

(8) Sheet metal screw (S1)

(6) Sheet metal screw (S2)

1. Use pressure treated wood studs 2” x 4”

(50mm x 88.9mm) to create a platform frame that

has an outside dimension of 47” x 78”

(1193.8mm x 1981.2mm).

1a. Use pressure treated wood studs 2” x 4”

(50mm x 88.9mm) to create a platform frame that

has an outside dimension of 24” x 78”

(609.6mm x 1981.2mm) for each extension.

17” (431.8mm)

24” (609.6mm)

47” (1193.8mm)

24” (609.6mm)

L- BRACKET

L- BRACKET

L- BRACKET

18 1/4” (463.55mm)

18 1/4” (463.55mm)

L- BRACKET

71” (1803.4mm)

78” (1981.2mm)

OR 1b. Use pressure treated wood studs 2”x 4”

(50mm x 88.9mm) to create a platform frame that

has an outside dimension of 71”x 78”

(1803.4mm x 1981.2mm)

for shed one extension.

2. Using exterior grade CDX 3/4” (19mm) plywood,

cut and fit together the sheets to form solid foundation

as shown. Foundation must be square and level.

1

IMPORTANT: USE HAND GLOVES TO PREVENT INJURY.

47” (1993.8mm)

78” (1981.2mm)

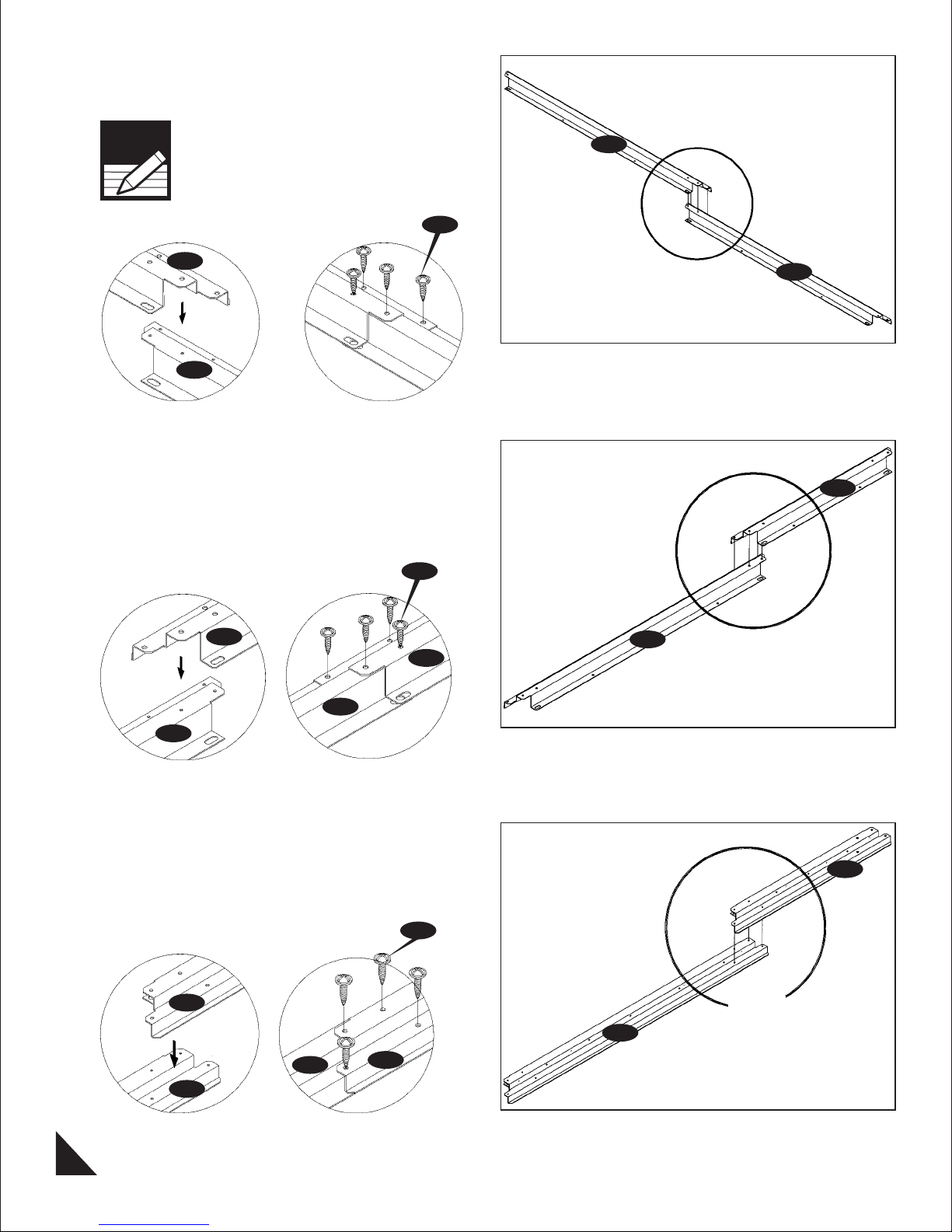

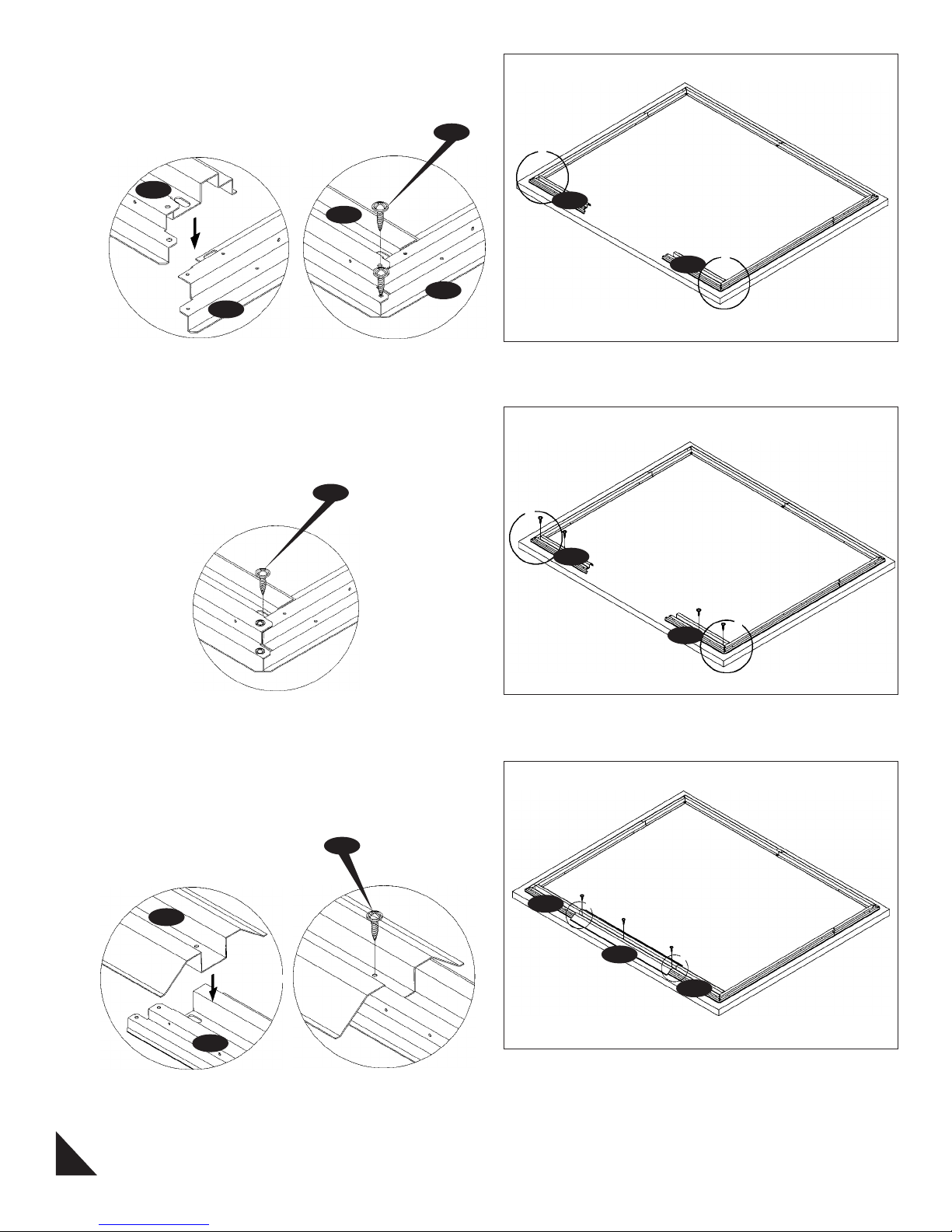

3. Assemble base bar back left (BLC) and base

bar back right (BRC) with four (S1) screws.

See fig. 1 & 2.

Note

Step 1

Take care of sharp edges.

Step 2

BLC

BRC

S1

Fig.1 Fig. 2

4. Assemble the base bar side (BSC) & extension

(EBS1) with (S1) screws.

Add one (EBS1) for each extension.

Step 1 Step 2

S1

BLC

1 & 2

BRC

EBS1

EBS1

EBS1

BSC

BSC

Fig.1 Fig. 2

5. Assemble the base bar side (BSC) & extension

(EBS2) with (S1) screws.

Add one (EBS2) for each extension.

Step 1 Step 2

EBS2

BSC

BSC

S1

EBS2

BSC

1 & 2

EBS2

1&2

BSC

Fig.1 Fig. 2

2

IMPORTANT: USE HAND GLOVES TO PREVENT INJURY.

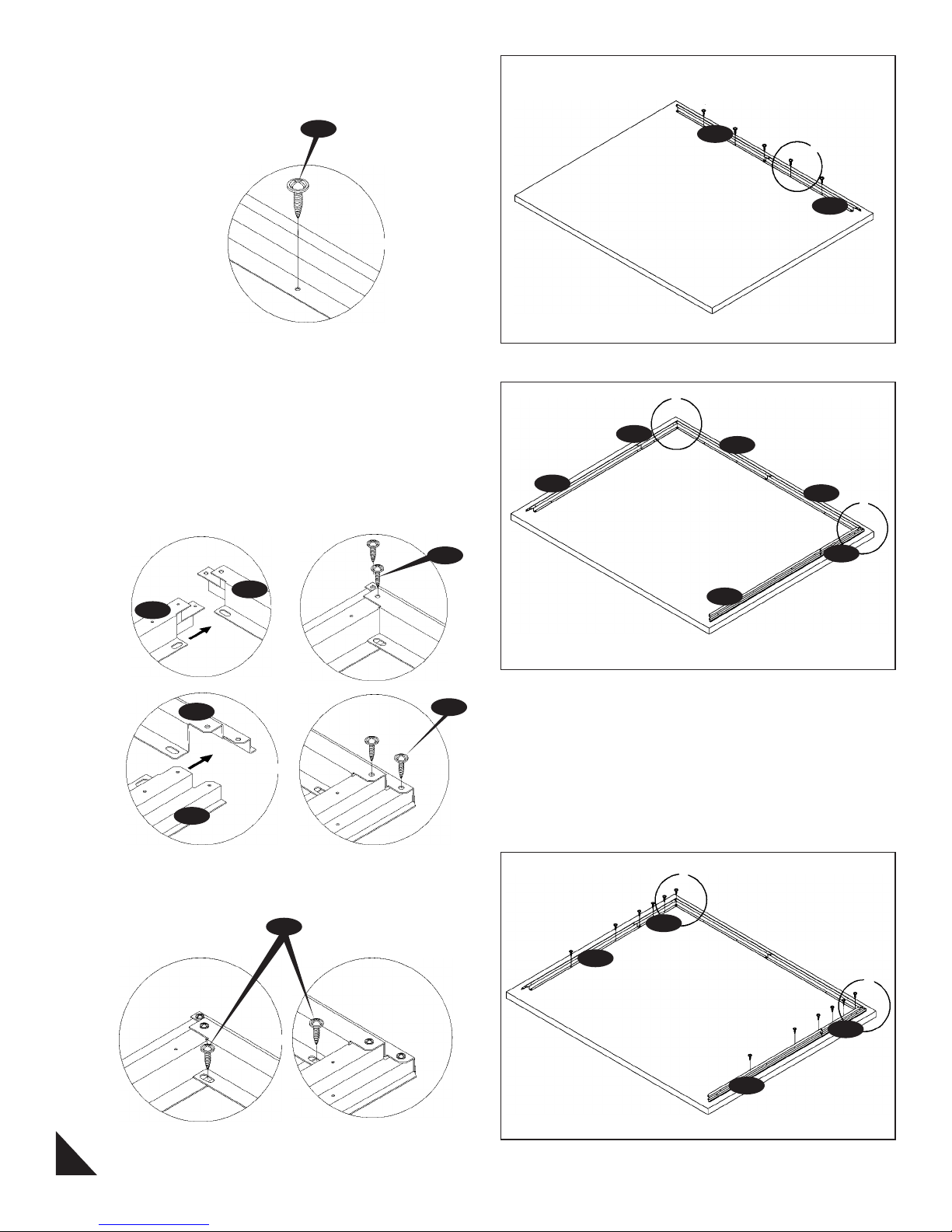

6. Place the base bar back assembly (BLC) &

(BRC) on top of the foundation. Use (S2) screws

to fix the assembly to foundation.

S2

Left

BLC

Back

1

BRC

Fig.1

7. Place the base bar left side assembly (BSC) &

(EBS1)on left side. Insert the edge of (EBS1) into

the back base bar (BLC) and secure with (S1)

screws. See fig. 1.

Place the base bar right side assembly (BSC) &

(EBS2) on right side. Insert the edge of (EBS2) into

the back base bar (BRC) and secure with (S1)

screws. See fig. 2.

Step 1

S1

BLC

EBS1

Fig.1

Step 2

BRC

S1

BSC

Front

EBS1

Right

1

BLC

BRC

BSC

2

EBS2

EBS2

Fig.2

8. Using a carpenter square, line up the corners

secure base bar side assembly to the foundation

with (S2) screws.

S2

Step 1

Fig.1

3

IMPORTANT: USE HAND GLOVES TO PREVENT INJURY.

Step 2

1

EBS1

BSC

2

EBS2

BSC

Fig. 2

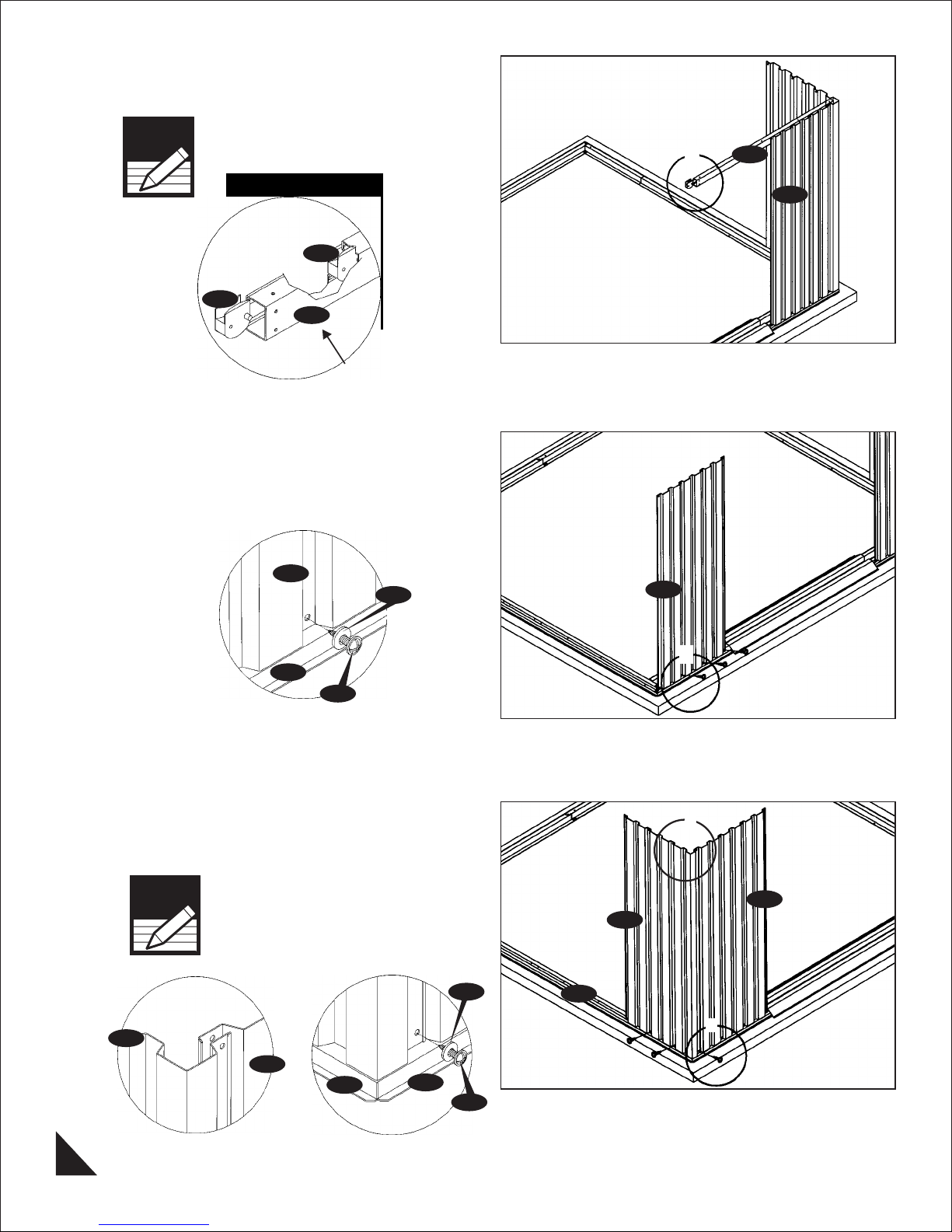

9. Place the base bar (BBFC) on top of (BSC) on

both sides. Secure with (S1) screw to (BSC) on

both corners. See fig. 1 & 2.

Step 1

BBFC

BSC

Step 2

BBFC

BSC

Fig.1 Fig.2

10. Using the carpenter square, line up the corners.

Secure the base (BBFC) to the foundation with (S2)

screws.

S2

S1

1&2

BBFC

1&2

BBFC

1

BBFC

Fig.1

11. Place the entrance taper channel (ECC) on

top of the (BBFC). Secure with (S2) screws to the

foundation. See fig. 1 & 2.

S2

Step 1

ECC

BBFC

Step 2

BBFC

1&2

ECC

BBFC

1

1&2

BBFC

Fig.1 Fig.2

4

IMPORTANT: USE HAND GLOVES TO PREVENT INJURY.

12. Measure in all direction as shown in figure.

Make the base bar assembly in a perfect square.

Concrete foundation

12a. (Concrete foundation) Using a carpenter’s

square, line up corners. Align Base bars, mark the

concrete at the holes in the base and drill concrete

with 1/4” (dia. 6mm) concrete bit to accept anchor

bolts to a 1 3/4” (44mm) depth. Replace base and

secure with 1/4” x 1 3/8” (M6 x 35mm) anchor bolts

(not provided).

B. Walls & Columns

BSC

BBFC

1560mm

(

(

ECC

EBS1

)

1830m

m)

BBFC

BLC

(

1830m

1560mm

(

BSC

m)

BRC

)

EBS2

Note

All panels are clearly marked

and care should be taken to

use the correct one.

Parts Needed:

(1) Wall panel front right (WFRC)

(1) Wall panel front left (WFLC)

(2) Wall panel corner front (WCFC)

(2) Wall panel corner back (WCBC)

(3) Wall panel side (WS)

(1) Sliding channel right (SRC)

(1) Sliding channel left (SLC)

Parts Needed for each extension:

(2) Wall panel (WSC)

(1) Top angle side extension left (EAS1)

(1) Top angle side extension right (EAS2)

(15) Plastic washer (PW)

(16) Sheet metal screw (S1)

(2) Machine screw (S3)

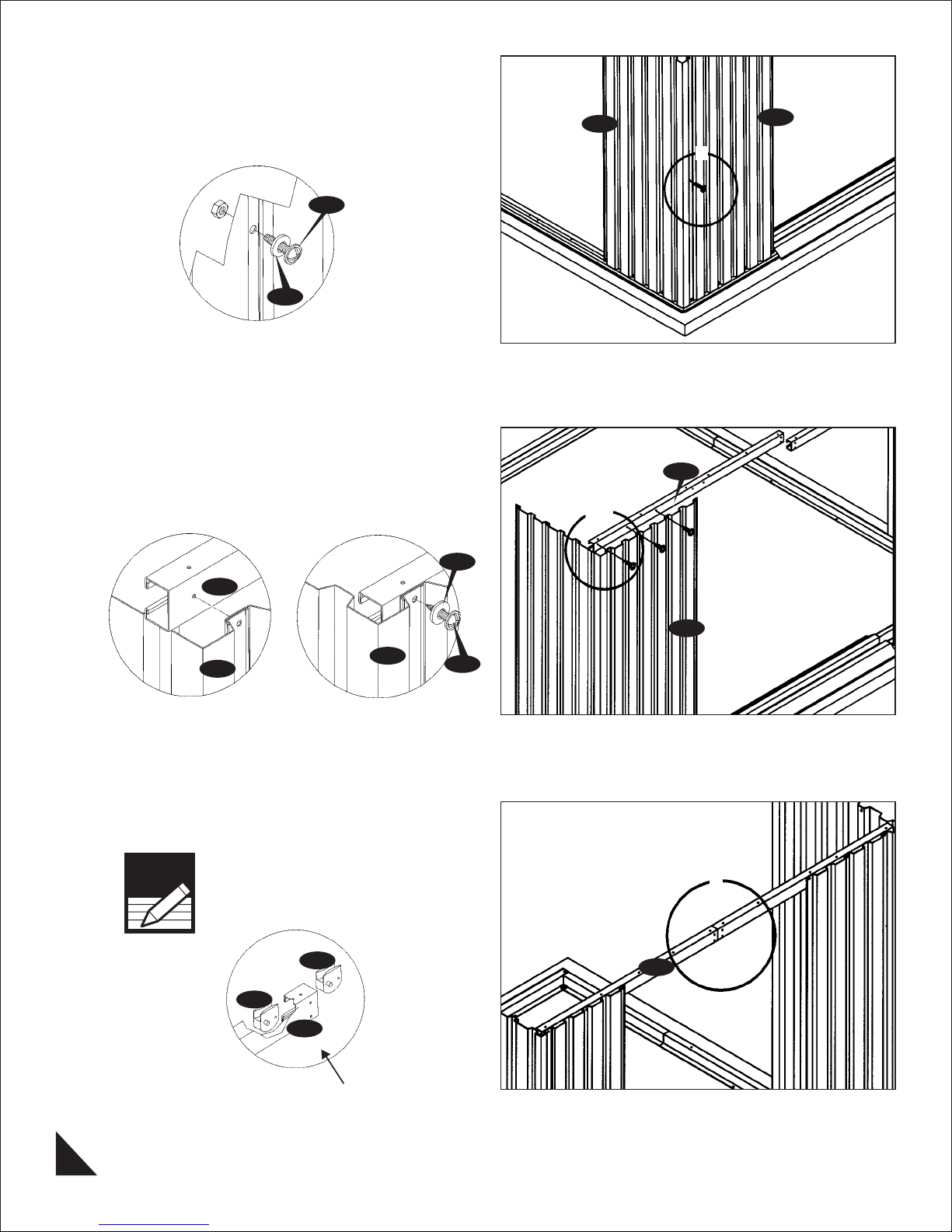

1. Place the wall panel (WFRC) on the base bar

(BBFC). Front right side of the shed line up the holes

with base bar. Secure with (S1) screws with washers

from outside.

(2) Top angle side (ASC)

(1) Sliding channel support (SSC)

(1) Sliding channel cover (SCC)

(4) Top slider (TS)

(1) Door column profile left (DCLC)

(1) Door column profile right (DCRC)

(1) Top angle back left (ABLC)

(1) Top angle back right (ABRC)

(54) Plastic washer (PW)

(64) Sheet metal screw (S1)

(8) Machine screw (S3)

PW

S1

WFRC

BBFC

Fig.1

5

IMPORTANT: USE HAND GLOVES TO PREVENT INJURY.

WFRC

1

Front

2. Place the wall panel corner front (WCFC) on the

base bar (BSC). Line up the holes with base bar and

use (S1) screws with washers to Secure.

1

Note

WFRC

Make sure the overlapping

position is as shown in fig.1.

S1

WCFC

BBFC

PW

BSC

Fig.1 Fig.2

3. Use (S3) bolt and nut with washer to join together

the wall panels.

PW

WFRC

WFRC

WCFC

BSC

2

WCFC

1

S3

Fig.1

4. Place the sliding channel right (SRC) on top of

the wall panel (WFRC) from inside. See the position

in fig. 1. Line up the holes with wall panel. Use (S1)

screw with washers to fix. See fig. 2.

S1

SRC

WCFC

Fig.1 Fig.2

SRC

WCFC

PW

SRC

WFRC

1&2

WCFC

6

IMPORTANT: USE HAND GLOVES TO PREVENT INJURY.

5. Insert the 2 pieces of (TS) Top slider into the

sliding channel. See blowup.

Note

Make sure the position of the

projection on (TS) towards

inside.

TS

TS

SRC

Front

Fig.1

6. Place the wall panel (WFLC) on the base bar

(BBFC). Front left side of the shed. Line up to holes

with base bar. Secure with (S1) screws with washers

from outside.

WFLC

PW

WFLC

1

SRC

WFRC

BBFC

S1

Fig.1

7. Place the wall panel corner front (WCFC) on the

base bar (BSC). Line up the holes with base bar

and use (S1) screws with washers to secure.

Note

WCFC

Make sure the overlapping

position is as shown in fig.1

WFLC

BSC

BBFC

PW

S1

1

Front

1

WFLC

WCFC

BSC

2

7

Fig.1 Fig.2

IMPORTANT: USE HAND GLOVES TO PREVENT INJURY.

8. Use (S3) bolt and nut with washer to join together

the wall panels.

S3

PW

Fig.1

9. Place the sliding channel left (SLC) on top of the

wall panel (WFLC) from inside. See the position in

fig1. Line up the holes with wall panel use (S1) screw

with washers to fix. See fig. 2

SLC

PW

WCFC

1&2

WFLC

1

SLC

WFLC

WFLC

Fig.1 Fig.2

10. Insert the 2 pieces of (TS) Top slider into the

sliding channel. See blowup.

Note

Make sure the position of the

projection on top slider towards

inside.

TS

TS

SLC

WFLC

S1

1

SLC

Fig.1

8

IMPORTANT: USE HAND GLOVES TO PREVENT INJURY.

Front

Loading...

Loading...