DuraMax 10 Ft WoodBridge Owner's Manual

• All Weather Durable PVC

• Won’t Dent, Rust, Rot or Mildew

• Tall Walk In Shed

• Never Needs Painting

• 61 Inch Wide Double Doors

• Easy Assembly

• High Wind Tested

• Snow Load Tested 20lbs/sq. foot

• Pad Lock Ready (Lock not included)

• Wooden or Cement Foundation Needed

Call us for any missing or damaged parts.

Do not return to the store.

Your Total Solution To Maintenance Free Storage Sheds.

Available Kits

• Foundation Kit Available

• Modular 2.5 Ft Extension Kits Available

• 10 Ft x 8 Ft Window Kits Available

Ver: 4.0

Building Dimensions :

Approximate

Size

Storage

Exterior Dimension Interior Dimension

10 Ft x 8 Ft

79 Sq. Ft

480 Cu.Ft

Roof Edge to Edge

Base Dimension

Door Opening

3.2 m x 2.4 m

7.3 Sq.m

13.6 Cu.m

Width

Depth

Height

inch cm

125 3/8 318.4

inch cm

94 1/4

239.3

125 1/2

318.7

95 1/8

241.6

85 1/2

217.1

inch cm

123 3/8 313.3

inch cm

92 1/4

234.3

60 5/8

154

71 1/2

181.6

73

185.5

Wall to Wall

Area Volume

OWNER’S MANUAL /

Instructions for Assembly ‘10 Ft WoodBridge’

Size 10 Ft x 8 Ft / 3.2 m x 2.4 m

(Approx.)

Vinyl Garden Shed

Vinyl Garden Shed

A Product of

TM

ALL PURPOSE VINYL GARDEN SHEDS

Customer

Service Hotline

(800) 483-4674

www.duramaxbp.com

Patent #416.091

Duramax Garden Shed

Limited Fifteen Year Warranty

U.S. Polymer Inc. will send a replacement part free of charge, in the event of material defects and or

workmanship for a period of fifteen years from the date of purchase.

This warranty is extended only to the original purchaser. A purchase receipt or other proof of date of

original purchase will be required before warranty service is rendered. In no event shall we pay the cost

of flooring, labor, installation or any other costs related thereto.

This warranty only covers failures due to defects in material or workmanship which occurs during normal

use and does not extend to color change arising due to normal weathering or to damage resulting from

misuse or neglect, commercial use, failure to follow assembly instructions and the owner’s manual

(including proper anchoring of the shed), painting, forces of nature and other causes which is beyond

our control.

Claims under this warranty must be made within the warranty period by calling 1-800-483-4674 or mail

in a dated sales slip and clear photograph of the part to:

U.S. Polymers, Inc.

1057 S. Vail Ave,

Montebello, CA 90640.

We reserve the right to discontinue or change components. If a component has been discontinued or

is not available,

U.S. Polymers, Inc. reserves the right to substitute a component of equal quality as may be compatible.

Limits and Exclusions

There are no express warranties except as listed above. The warrantor shall not be liable for incidental

or consequential damages resulting from the use of this product, or arising out of any breach of this

warranty. All express warranties are limited to the warranty period set forth above . Some states do not

allow the exclusion or limitation on how long an implied warranty lasts, so the above limitations may not

apply to you.

This warranty gives you specific legal rights and you may also have other rights which vary from state

to state or country to country.

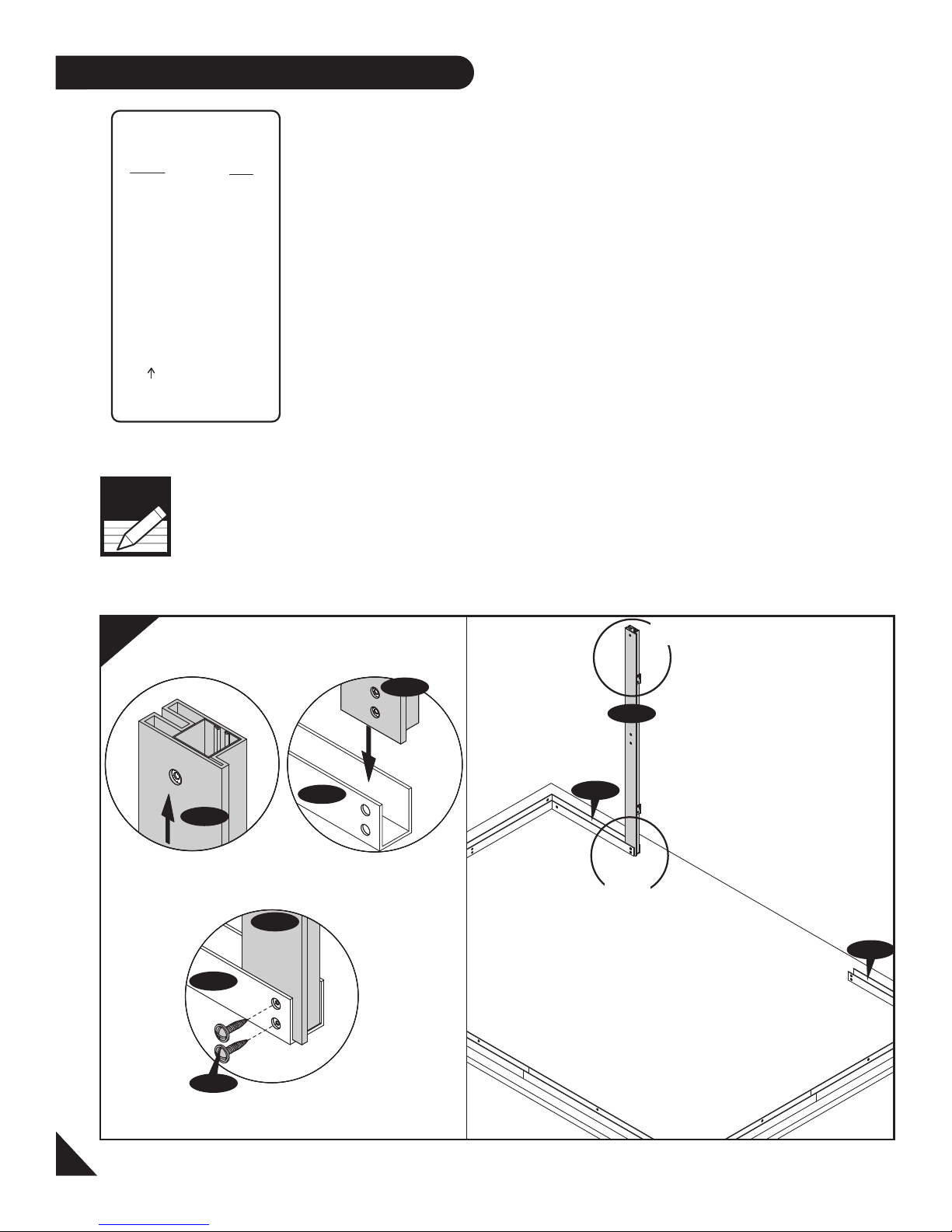

Behind left Door Panel for Basic Shed.

Location of Product Labels

On Side Panel for Extensions.

1

2

SAFETY & PRECAUTIONS

Before You Begin...

1. Check your local building codes regarding footings, location, etc.

2. Select a site that allows enough working space around the shed.

3. Determine building foundation and anchor system.

4. Read and understand the Owner’s manual enclosed in the package.

5. Follow all directions and dimensions thoroughly.

6. Follow the steps given in the manual carefully for correct assembly.

7. Make sure all parts are present before you start assembling.

8. BE SAFE : Follow safety instructions and avoid injury.

(See inside page).

9. GROUND MUST BE EVEN : Make sure the foundation frame lies flat on

the ground. If the earth bed is uneven, remove sod and other debris and

level it with a flat shoval.

10. Separate contents of the carton by the part number and review the list.

Be sure you have all the necessary parts for your shed.

Refer Owner’s manual for part list.

CAUTION

Sharp

Edges

3

SAFETY & PRECAUTIONS

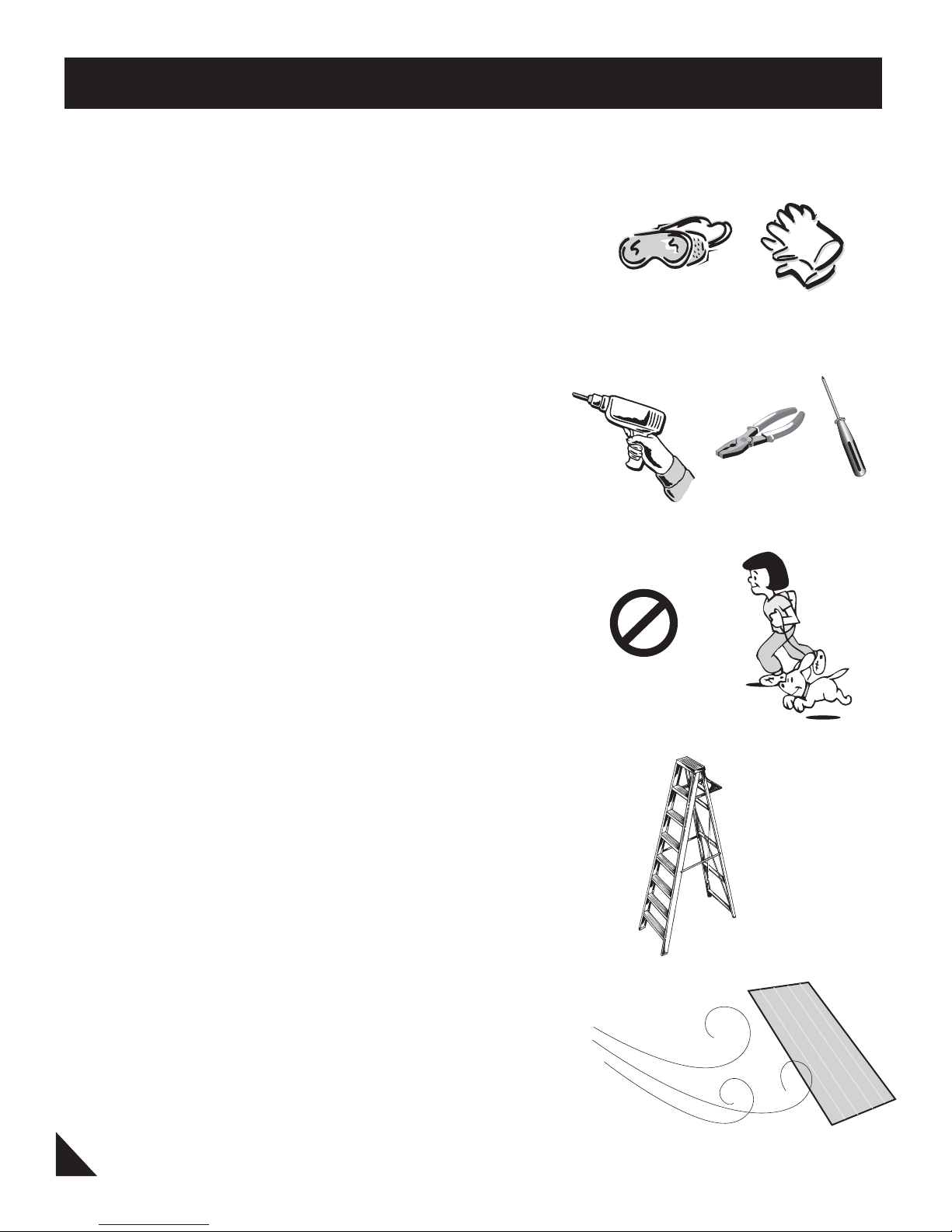

For your own safety, please read and follow these instructions during the shed assembly.

1. Always wear work gloves, long sleeves and eye

protection during assembly of the shed. Some pieces

of the shed contain sharp edges and can cause injury.

2. Be cautious with the tools used for the assembly of

the shed. Familiarize yourself with the operation of all

the power tools.

3. Children and pets should be kept away from the

assembly site to avoid any distractions and accidents.

4. When using a step ladder, make sure it is on even

ground and fully open with the safety latch in place.

Never concentrate your full weight on the roof or any

part of the shed.

5. Do not attempt to assemble the shed on a windy day.

Shed panels can be whipped across by the wind

making the worksite difficult and dangerous.

4

IMPORTANT

Wear eye protection when using any form of power tools. Do not use voltage power tools in a wet or damp

enviornment to avoid electric shock.

Do not use any part of the shed as a means of personal support while attaching components during assembly.

The shed must be constructed on a solid base foundation. A concrete pad or a large size concrete patio

stone squares is recommended for suitable floor base. Make sure it is firm and level and will allow drainage

away from the site. The base foundation should be at least 4 inches (100mm) larger than the shed dimensions.

Please refer to the front page of your owner’s manual for the exterior dimensions of the shed. Manufacturer is

not responsible for the choice and construction of the foundation.

For a concrete pad base, prepare a level bed for a firm footing layer of crushed stone. The concrete pad

should then be poured to a thickness of 4 inches (100mm) to 5 inches (125mm). Allow to dry thoroughly

for at least 48 hours

Your shed must be firmly anchored to the concrete pad or large concrete patio stone squares, to help protect

against damage in high winds.

Care & Maintenance

Although this unit does not require any maintenance, care should be taken to prolong the life

of your shed.

ROOF : Keep roof clean of leaves and snow with long handled, soft bristled broom. Heavy amounts

of snow on the roof can damage the shed making it unsafe. Do not step on the roof.

WALLS : Do not rest any object against the wall panels of the shed.

DOORS : Keep doors closed to prevent wind damage.

FASTENERS : Regularly check your shed for loose screws, bolts, nuts, etc. And retighten them as

necessary.

MOISTURE : With changing temperatures, condensation will accumulate inside the shed. Good

ventilation will help in regulating and avoid moisture.

TIP : A noncorrosive caulking is helpful to seal the shed.

DO NOT store swimming pool chemicals in your building.

Combustibles and corrosive must be stored in

air tight containers

Parts List

Cordless Drill - Philips Head

Hammer or Rubber mallet

Carpenters Square

8’ Step Ladder

Adjustable pliers

Level -

3ft.

Tape Measure

Caulk Gun

Waterproof Clear Silicon

Sealant

Hand Gloves

Tools You Will Need

2. Maximum no. of Extension can be build

upto 10’x13’ (ie. Two Extension).

Note

3. Shed with more than two extensions

require Roof Super Support.

Recomended Qty of Roof Super Support

For 10’x8’ Vinyl Shed - 2Nos.

For additional each Extension - 1No.

1. Before starting installation, please refer

Safety & Precautions.

5

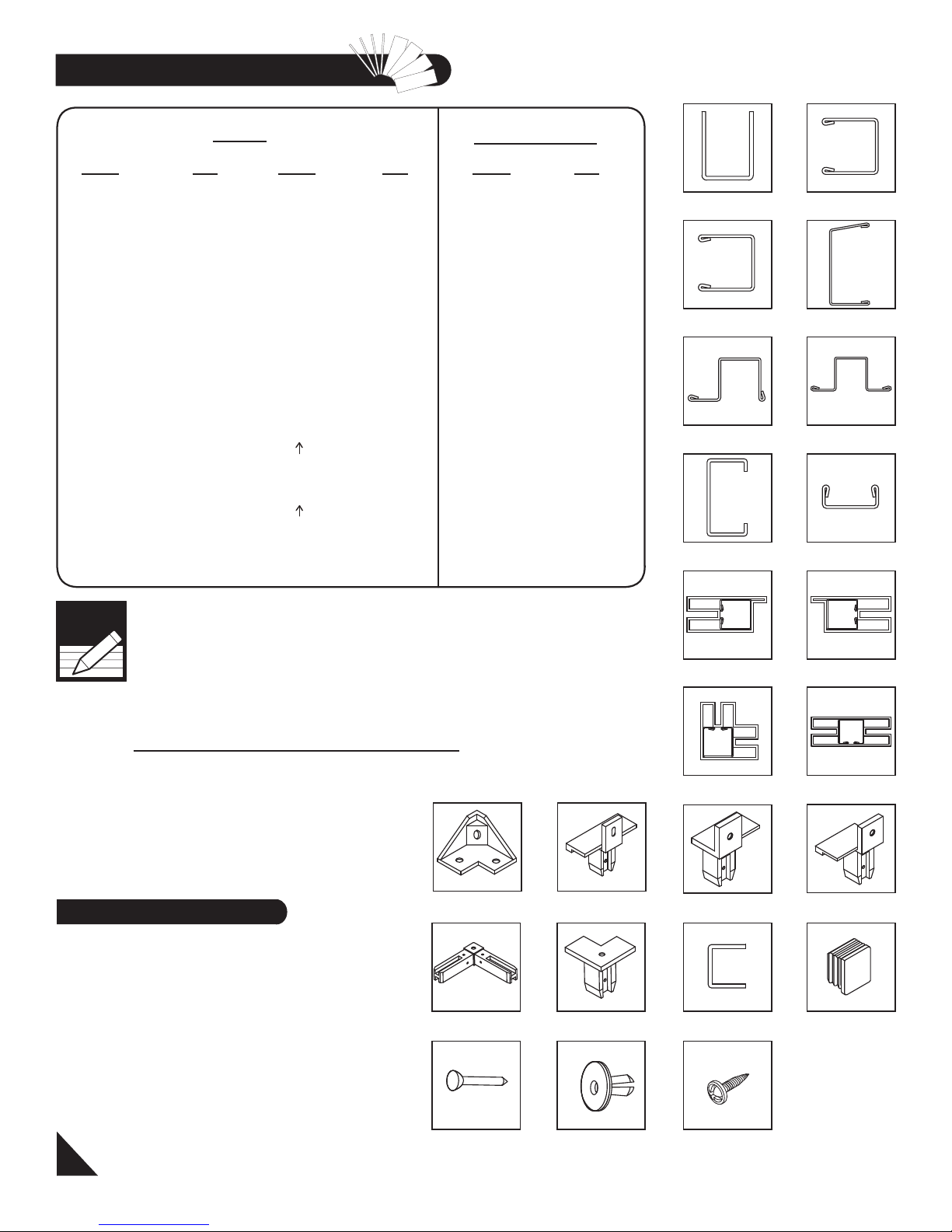

B1LA, B1RA, B21,

B22, B3LA, B3RA

CB1A, CB2A,

CB3XA, CB4A, MJ

RS1A, RS3XA,

RS3LA, RS8A, RS9A

RS5A, RS6XA,

RS7XA

RS2A, RS10A, RS4XA, RS11A,

RS12A

DSH RS14A

CDLA CDRA

CCA CMA

FDCL

FDCR

FCB FMC

FCCRJ

EPS

CBC

PIN PPG & PWS S1, S2, S7

CODE

QTY

B1LA 1

B1RA 1

B21 2

B22 2

B3LA 1

B3RA 1

CB1A 2

CB2A 2

CB3XA 4

CB4A 2

RS1A 4

RS2A 4

RS3LA 2

RS3XA 2

RS4XA 4

RS5A 4

RS6XA 2

RS7XA 2

CODE

QTY

FDCL 1

FDCR 1

FCC 4

FMC 7

FCB 4

RJ 4

EPS 4

CBC 3

PPG 80

PIN 80

S1 253

S2 8

S7 16

CODE

QTY

RS8A 4

RS9A 4

MJ 7

RS10A 2

RS11A 2

RS12A 2

RS14A 12

DSH 1

CMA 7

CCA 4

CDLA 1

CDRA 1

SP 12

FPL 2

FPR 2

RP 6

RRS 3

DL 1

DR 1

PARTS ACCESSORIES

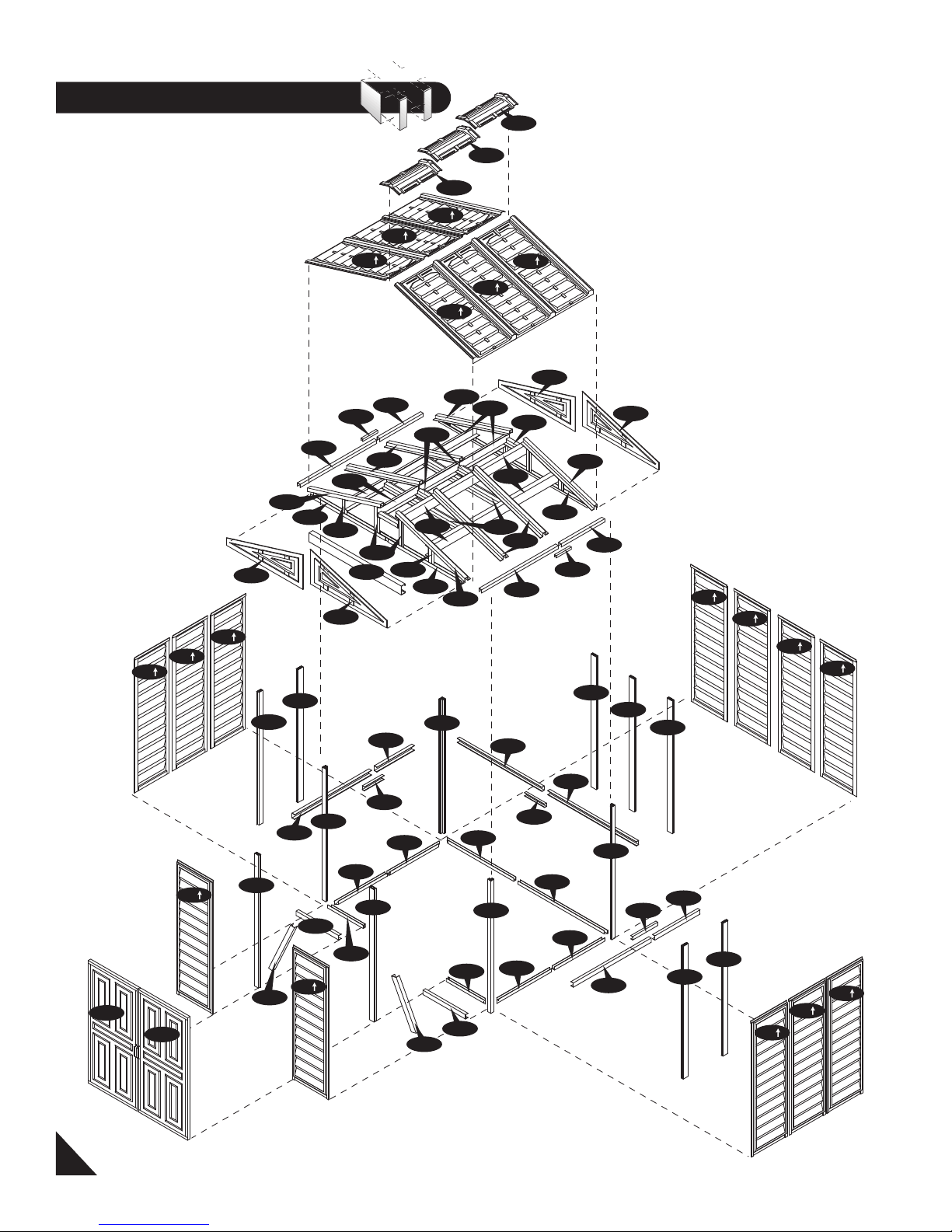

Exploded View

SP

CB4A

CB1A

B1LA

B1RA

B21

B22

B22

B21

B3LA

B3RA

6

RP

RP

RP

RP

RP

FPL

FPR

FPR

FPL

RS3LA

RS3XA

MJ

RS3LA

RS3XA

MJ

RS1A

DSH

RS1A

RRS

RRS

RRS

RP

RS8A

RS9A

RS2A

RS4XA

RS9A

RS2A

RS4XA

RS6XA

RS7XA

RS12A

RS10A

RS11A

RS2A

RS1A

RS2A

RS5A

RS5A

SP

SP

SP

SP

SP

SP

SP

SP

SP

DL

DR

CMA

CMA

CMA

SP

SP

CMA

CMA

CMA

CMA

CCA

CCA

CCA

CCA

CDLA

CDRA

CB3XA

CB2A

MJ

CB3XA

MJ

CB2A

CB3XA

MJ

CB3XA

CB1A

CB4A

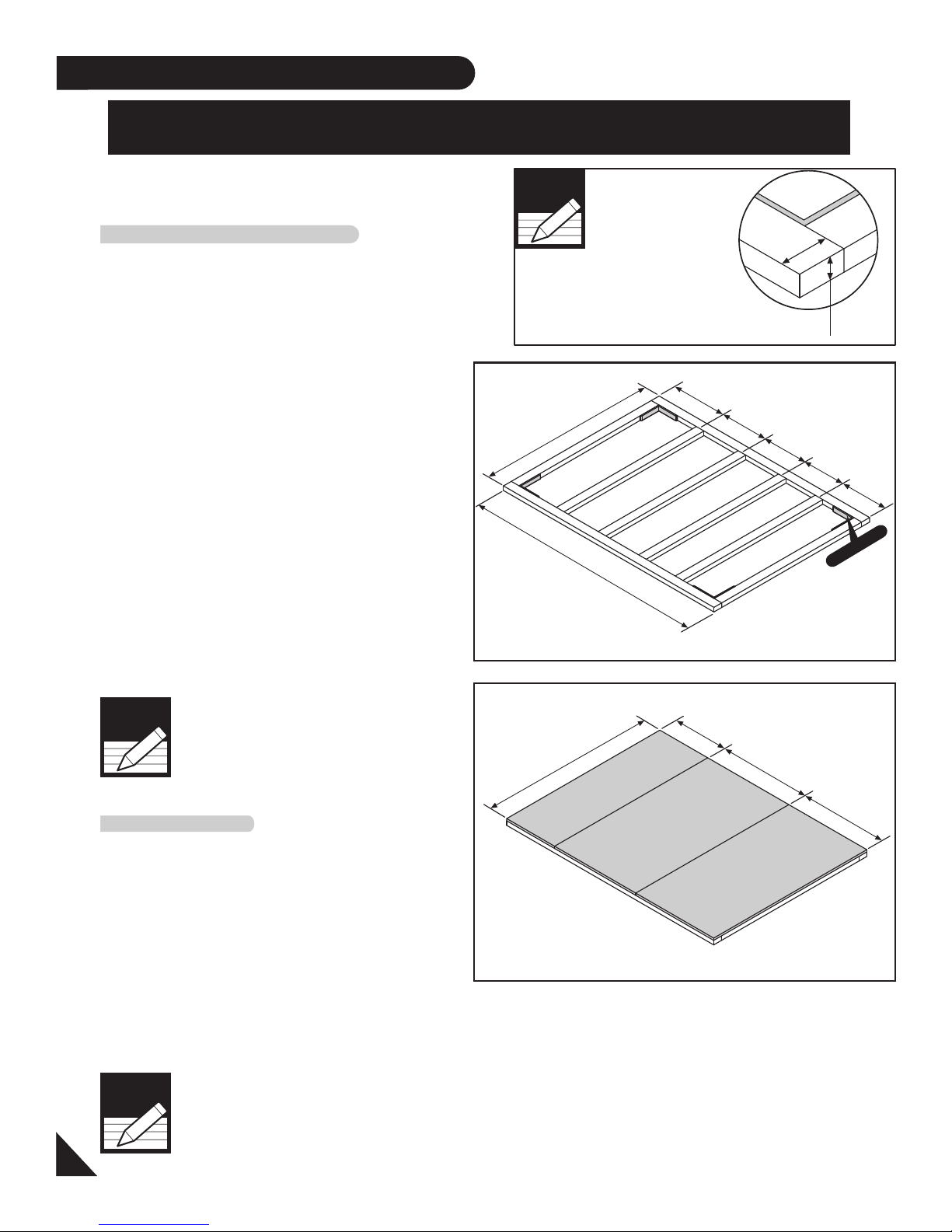

A. Foundation

7

1. Use pressure treated wood studs 2 x 4 (Actual

size 2” x 3 1/2”, 50mm x 88.9mm) to create a

platform frame that has an outside dimension of

94 7/8” x 126” (2410mm x 3200mm).

DuraMax must be installed on a level wooden

platform or a level concrete foundation.

2. Using exterior grade CDX 3/4” (19mm)

plywood, cut and fit together the sheets to form

solid foundation as shown. Foundation must

be square and level.

The following are the list of lumber and sizes

you will need.

Wooden Platform (Not Included)

Pressure Treated - Wood Studs:

2ea 2” x 3 1/2” x 126” (50mm x 88.9mm x 3200 mm)

6ea 2” x 3 1/2” x 87 7/8” (50mm x 88.9mm x 2232.2 mm)

Exterior Grade (CDX) - 3/4” (19mm) plywood

2ea 3/4” x 48” x 94 7/8” (19mm x 1219.2mm x 2410mm)

1ea 3/4” x 30” x 94 7/8” (19mm x 761.6mm x 2410mm)

L-Brackets: 4ea

The shed must be constructed on a solid

base foundation. A concrete pad or a large

size concrete patio stone squares is

recommended for suitable floor base. Make

sure it is firm and level and will allow drainage

away from the site.

The base foundation should be at least 4

inches(100mm)larger than the shed

dimensions. Please refer to the front page of

your owner’s manual for the exterior

dimensions of the shed. Manufacturer is not

responsible for the choice and construction

of the foundation

Concrete Platform

Note

For a concrete pad base, prepare a level bed for a

firm footing layer of crushed stone. The concrete

pad should then be poured to a thickness of 4

inches (100mm) to 5 inches (125mm). Allow to dry

thoroughly for at least 48 hours

If the shed is assembled with

wooden foundation on soil, use the

soil anchor kit.

Note

30”

761.6mm.

48”

1219.2mm.

48”

1219.2mm.

94 7/8”

2410mm.

Note : If you have DURAMAX Foundation, please follow instruction manual

in that package. If not, follow below wooden platform instruction.

Lay 2 x 4

(Actual size 2”x 3 1/2”, 50mm x 88.9mm)

Note

50

mm (2”)

88.9

mm (3 1/2”)

30”

761.6mm.

24”

609.6mm.

24”

609.6mm.

24”

609.6mm.

24”

609.6mm.

94 7/8”

2410mm.

126”

3200mm.

L- BRACKET

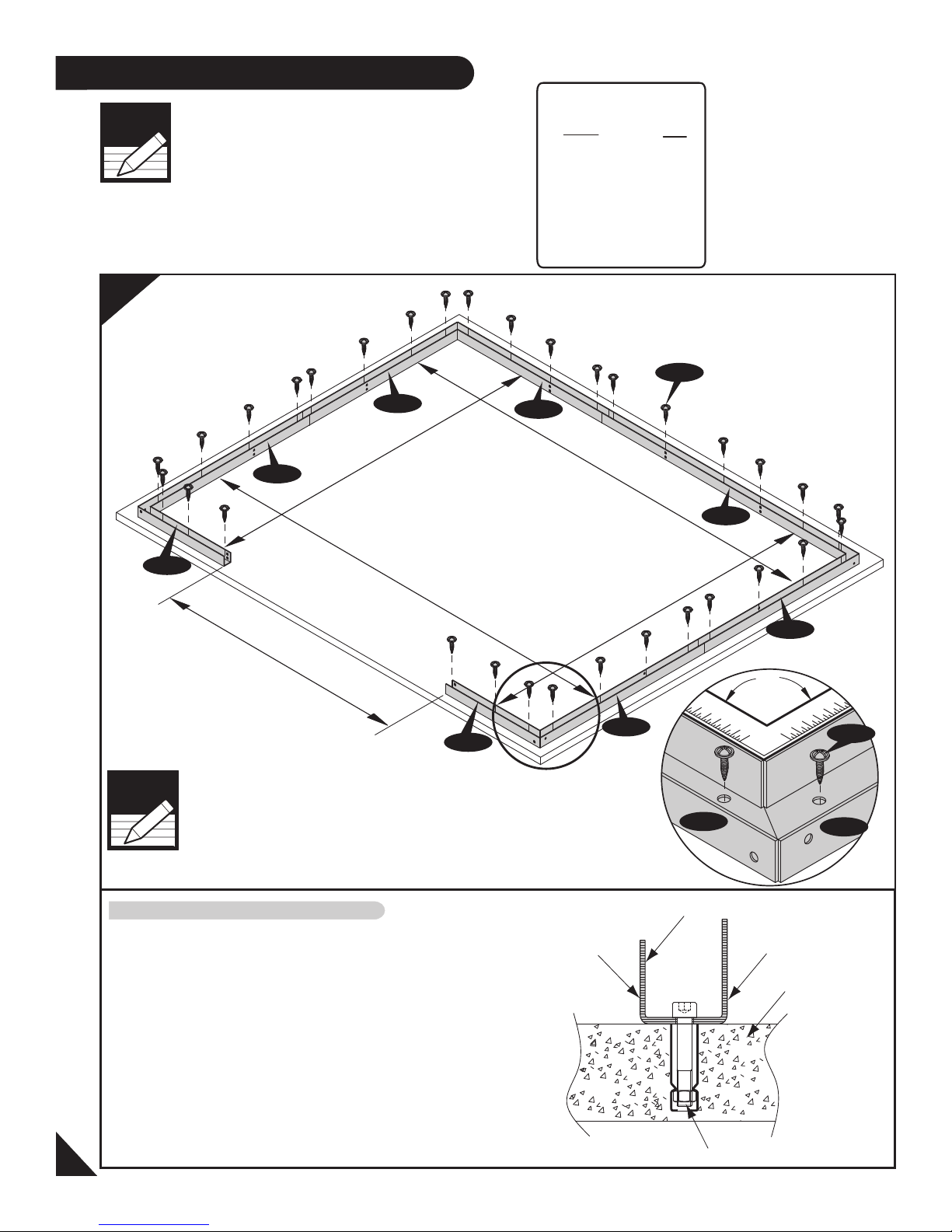

8

Parts Needed:

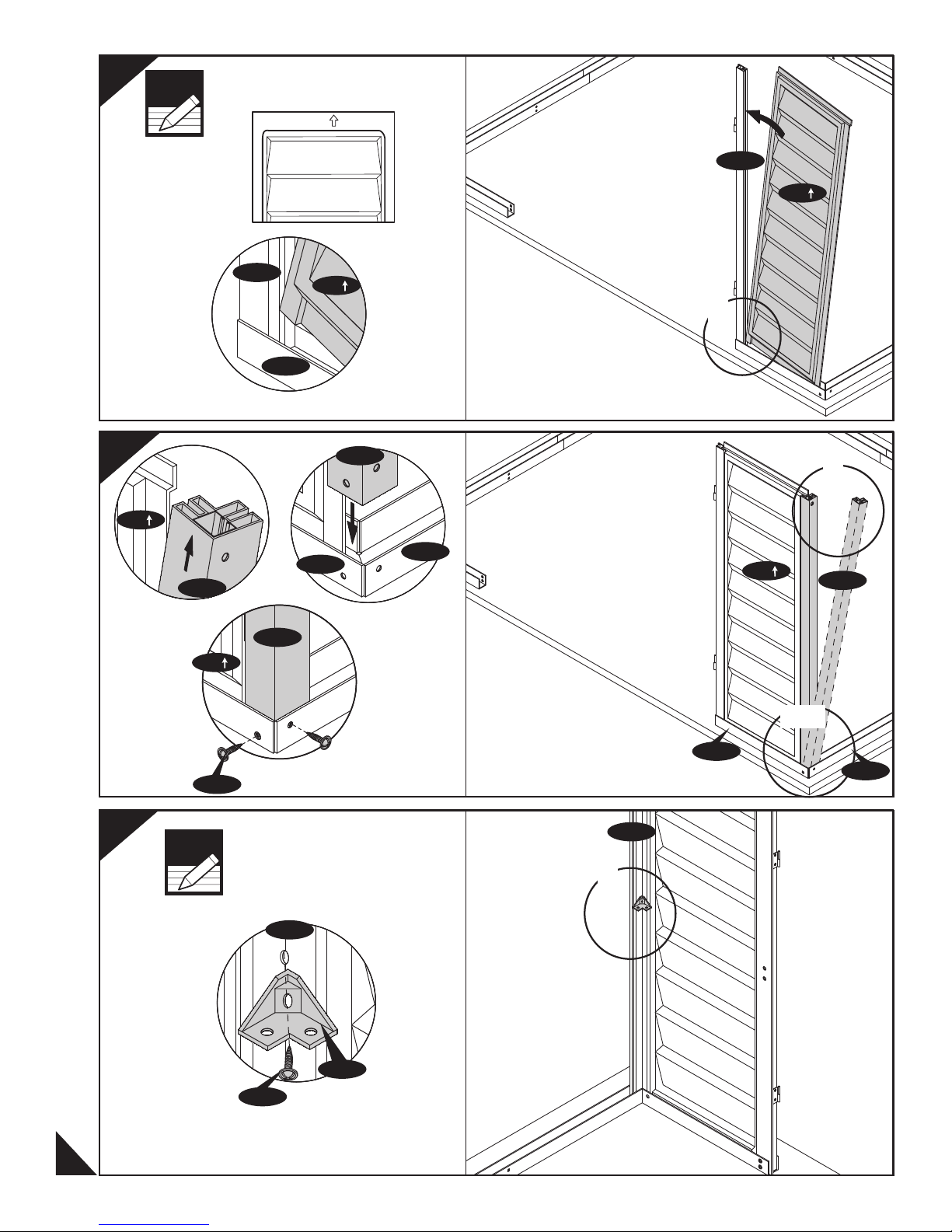

B. Base Frame

Code Qty

B1LA 1

B1RA 1

B3LA 1

B3RA 1

B21 2

B22 2

S1 32

Note

S1

B22

B1RA

90

O

Using a carpenter square, line up corners. Align

base bars, mark the concrete at the holes in the

base and drill concrete with suitable concrete bit to

accept 1/4” x 1 1/2” (M6 x 40mm) anchor bolts.

(Qty - 32Nos. not provided).

Assembly on concrete foundation

Note

Measure in all direction as shown in

figure to make the base channel

assembly in a perfect.

1

1. It is important that these instructions

are followed step by step.

2. All parts are clearly marked and care

should be taken to use the correct one.

3. Don’t install under windy conditions.

4. If you are building the shed against a wall,

build it 2.5 ft. away then slide it in.

M6 Anchor Bolt

Base ‘U’ Channel

Concrete

Outside

Inside

S1

123 3/8”

3133mm.

123 3/8”

3133mm.

92 1

/4”

2343

mm.

92 1

/4”

2343

mm.

61 1/4”

1556mm.

B1RA

B22

B21

B3RA

B3LA

B22

B21

B1LA

9

C. Wall & Columns

1

Front

Fig.3

Fig.1

CDRA

Fig.2

CDRA

B1RA

Right

Back

Left

1

2&3

B1RA

CDRA

B1LA

B1RA

CDRA

S1

Parts Needed:

Code Qty

CMA 7

CCA 4

CDLA 1

CDRA 1

CB1A 2

CB2A 2

CB3XA 4

MJ 3

CB4A 2

FCB 4

CBC 3

SP 12

S1 63

S2 4

1. All parts are clearly marked and

care should be taken to use the

correct one.

Note

2. Set the Torque limit of your Screw drill to

#3 or #4 to ensure the screws do not

strip the metal reinforcements.

2

Note

Check the stamped label on top of

all panels inside.

SP

CDRA

SP

3

SP

CCA

Fig.1

SP

CDRA

B1RA

Fig.1

CCA

B1RA

SP

CCA

Fig.2

B22

Front

1

1

SP

CCA

2&3

10

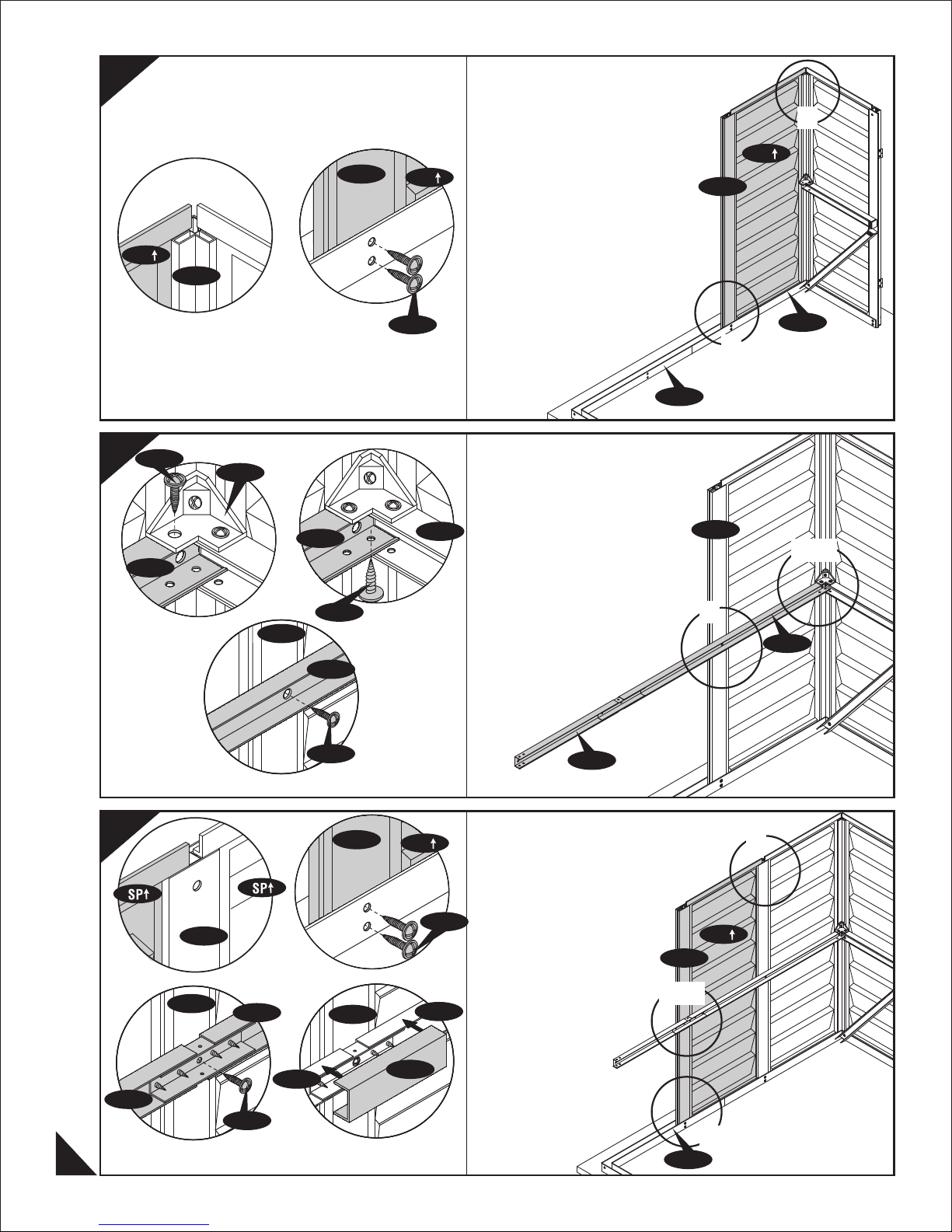

4

Note

S1

Fig.3

Do not tighten the screw.

Leave it loose

CCA

FCB

S2

Fig.1

B1RA

B22

CCA

1

5

6

FCB

S1

Fig.1

CB4A

S1

B1RA

CB1A

S1

S1

CB1A

CB4A

CDRA

Fig.2

CDRA

1

CDRA

CB1A

2

CDRA

7

Fig.1

CB2A

S1

CB1A

CB4A

Fig.3

MJ

EPS

Fig.2

CB3XA

S1

CB3XA

MJ

S1

2&3

CB4A

1

B1RA

CB3XA

S1

CB3XA

CB2A

11

MJ

CB3XA

CB2A

CB3XA

MJ

8

9

SP

CCA

Fig.1 Fig.2

S1

FCB

CB3XA

CB3XA

CMA

S1

SP

CB1A

Right Wall

B21

CMA

1

SP

CMA

B22

2

1&2

10

Fig.1

Fig.1

CMA

CMA

Fig.3

CB3XA

CMA

CB3XA

S1

Fig.2

S1

CMA

CMA

Fig.2

SP

CB3XA

3

CB3XA

CB2A

1

S1

SP

CMA

3&4

CB2A

CB2A

S1

12

Fig.3

Fig.4

CBC

2

B21

Loading...

Loading...