Duralast T82454S Operating Manual

2-1/2 TON HYDRAULIC JACK

AND STAND KIT

Model T82454S

INTENDED USE

This trolley jack has a single hydraulic pump piston that effortlessly raises the lift arm. Pump piston dust shields and wiper

seals protect the hydraulic system from contaminants. The jack features an overload valve bypass system to prevent jack

damage and user injury. Compact design allows use in confined spaces. Easily fits under low vehicles. Meets ASME PASE

safety standards.

Jack Stands are designed to support rated capacity, partial vehicle loads consisting of one end of a vehicle. Use both stands

for each operation.

WARRANTY NOTICE

This equipment is covered under a 1-year limited warranty when used as recommended. Only those items listed with a Part #

are available for purchase. For assistance with the operation or the availability of replacement parts, contact our Parts and

Warranty Department at 1-888-448-6746. Please have available a copy of your receipt, the model number of the product,

serial number, and specific details regarding your question.

Not all equipment components are available for replacement; illustrations provided are a convenient reference of location and

position in the assembly sequence.

The manufacturer reserves the rights to make design changes and or improvements to product lines and manuals without

notice.

WARRANTY INFORMATION

We want to know If you have any concerns with our products. If so, please call toll-free for Immediate assistance. For additional

web customer support help inquiries visit the Customer Service section at: 1-888-448-6746.

TECHNICAL SPECIFICATIONS

Capacity

Item

T82454S 2.5TON

Trolley Jack

Jack Stands

Lifting Range

Min. (inch)

5-1/8 13-3/4 13 35

9-13/16 14-15/16 25 38

Lifting Range

Max. (inch)

Lifting Range

Min. (mm)

Lifting Range

Max. (mm)

WARNING

1. Study, understand, and follow all instructions before operating this device.

2. Do not exceed rated capacity.

3. Use only on hard, level surfaces, with less than 3 degrees of slope.

4. Lifting device only. Immediately after lifting, support the vehicle with appropriate

means.

5. Do not move or dolly the vehicle while on the jack.

6. Lift only on areas of the vehicle as specified by the vehicle manufacturer.

7. No alterations shall be made to this product.

8. Only attachments and/or adapters supplied by the manufacturer shall be used.

9. Do not get under or allow anyone under the vehicle until it has been supported by jack stands.

10. Center load on saddle prior to lifting.

11. Use wheel chocks or other blocking device on opposing wheels before using jack.

12. Never use on a lawn mower or lawn tractor.

13. Do not use this jack for any use other than the manufacturer specified usage.

14. Do not rock the vehicle while working on or around equipment.

15. The following are not recommended for supporting on this equipment: Foundations, Homes, Mobile Homes,

Trailers, RV’s, Campers, nor Fifth Wheels, etc...

16. Failure to heed these markings may result in personal injury and/or property damage.

FOR YOUR SAFETY

AND TO PREVENT INJURY:

Use Service Jack for

lifting purposes

ONLY.

Always support

vehicle with

jack stands.

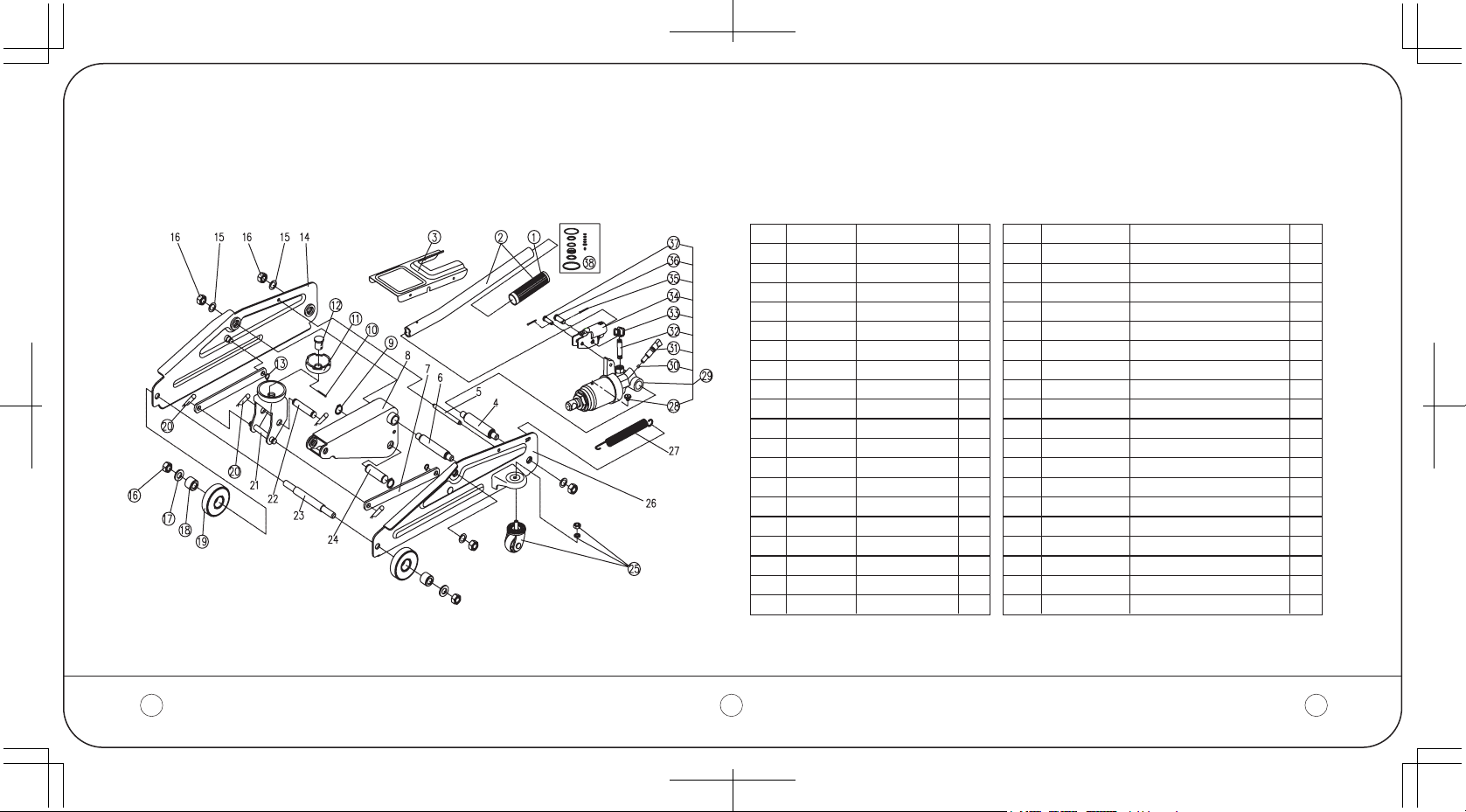

ASSEMBLY DIAGRAM-Trolley Jack

Safe Operating Temperature is between 40°F – 105°F (4°C - 41°C)

REF#

PART#

QLQD2A.1-1

1

T82004C.4

2

T82000-1a

3

4

5

6

7

8

GB894.1

9

GB91

10

QLQD2A.7-2

11

QLQD2C.5-2a

12

GB894.1

13

14

15

GB6170

16

GB97.1

17

T820013-7

18

T820033XE-4

19

DESCRIPTION QTY

Handle cover

Handle

Cover plate

Supporting shaft

Pin for frame

Supporting shaft

Connecting rod

Lifting arm assembly

C-clip Ø 18mm

Cotter pin Ø 2x20mm

Saddle

Saddle pin

C-clip Ø 13mm

Right frame assembly

Washer M12

Nut M12

Washer M12

Sleeve for front wheel

Front wheel

1

1

1

1

1

1

2

1

2

1

1

1

2

1

4

6

2

2

2

REF#

PART#

QLQD2B-3

20

21

22

23

24

T820033XE.2(asm)

25

26

27

TF1201C-29

28

TA82504D.1

29

GB308-6

30

T83003.2-10(asm)

31

QLQD2A.2-5(asm)

32

QLQD2A.2-7b

33

QLQD2A.2-8b

34

TA820012.1-23

35

QLQD2A.2-19

36

QLQD2A.2-20

37

TA82504D.MF

38

DESCRIPTION QTY

Roundwire snap ring Ø 1.4x26mm

Saddle base assembly

Pin for saddle base

Shaft for front wheel

Pin for lifting arm

Rear caster assembly

Left frame assembly

Return spring

Oil plug

Power unit assembly

Steel ball bearing Ø 6mm

Release value assembly

Pump plunger assembly

U-Bracket for plunger

Handle socket

Cotter pin Ø 2X14mm

Pin for pump plunger

Pin for unit base

Seal kit

4

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

Loading...

Loading...