DuraLabel PRO 300, PRO User Manual

800.788.5572

DuraLabel.com

USER GUIDE

PRO/PRO 300

Graphic Products®, DuraLabel®, PathFinder®, Toro® and Lobo® are Registered Trademarks of Graphic Products, Inc.

© 2007, 2015 Graphic Products, Inc.

Minimum System Requirements

Operating System: Windows 2000 SP4, XP SP2, Vista, 7, 8

Memory: 128MB RAM

Hard Drive: 100MB

Additional Requirements: IT Administrator Privileges

Supplies

DuraLabel supplies and DuraLabel® PRO printers have been optimized for compatibility

and print quality. Use only DuraLabel supplies from Graphic Products with your

DuraLabel PRO/PRO 300 printer.

NOTE: The DuraLabel PRO/PRO 300 User Guide includes information for both the

DuraLabel PRO and DuraLabel PRO 300 printers. Reference to “DuraLabel PRO”

implies either the DuraLabel PRO or DuraLabel PRO 300 printer.

Copyright Information

No part of this guide, including the products and software described in it, may be

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any

language in any form or by any means, except as documentation kept by the purchaser

for backup purposes, without the express written permission of Graphic Products, Inc.

Products and corporate names appearing in this guide may or may not be registered

trademarks or copyrights of their respective companies, and are used only for

identification or explanation and to the owners’ benefit, without intent to infringe.

Specifications and other content contained in this guide are furnished for informational

use only and are subject to change at any time without notice, and should not be

construed as a commitment by Graphic Products. Graphic Products assumes no

responsibility or liability for any errors or inaccuracies that may appear in this guide.

DuraLabel.com | 800.788.5572

Introduction | 1

Introduction

Congratulations on the purchase of your DuraLabel® PRO/PRO 300 Printer.

You’ll be printing pipe markers, arc flash, NFPA Diamond, GHS, right-to-know, barcodes,

and custom labels in no time with your new DuraLabel Printer.

Call us at 800.788.5572 with any questions you may have about your DuraLabel PRO/

PRO 300 printer. We’re here to help with all your labeling needs!

2 | Contents

DuraLabel.com | 800.788.5572

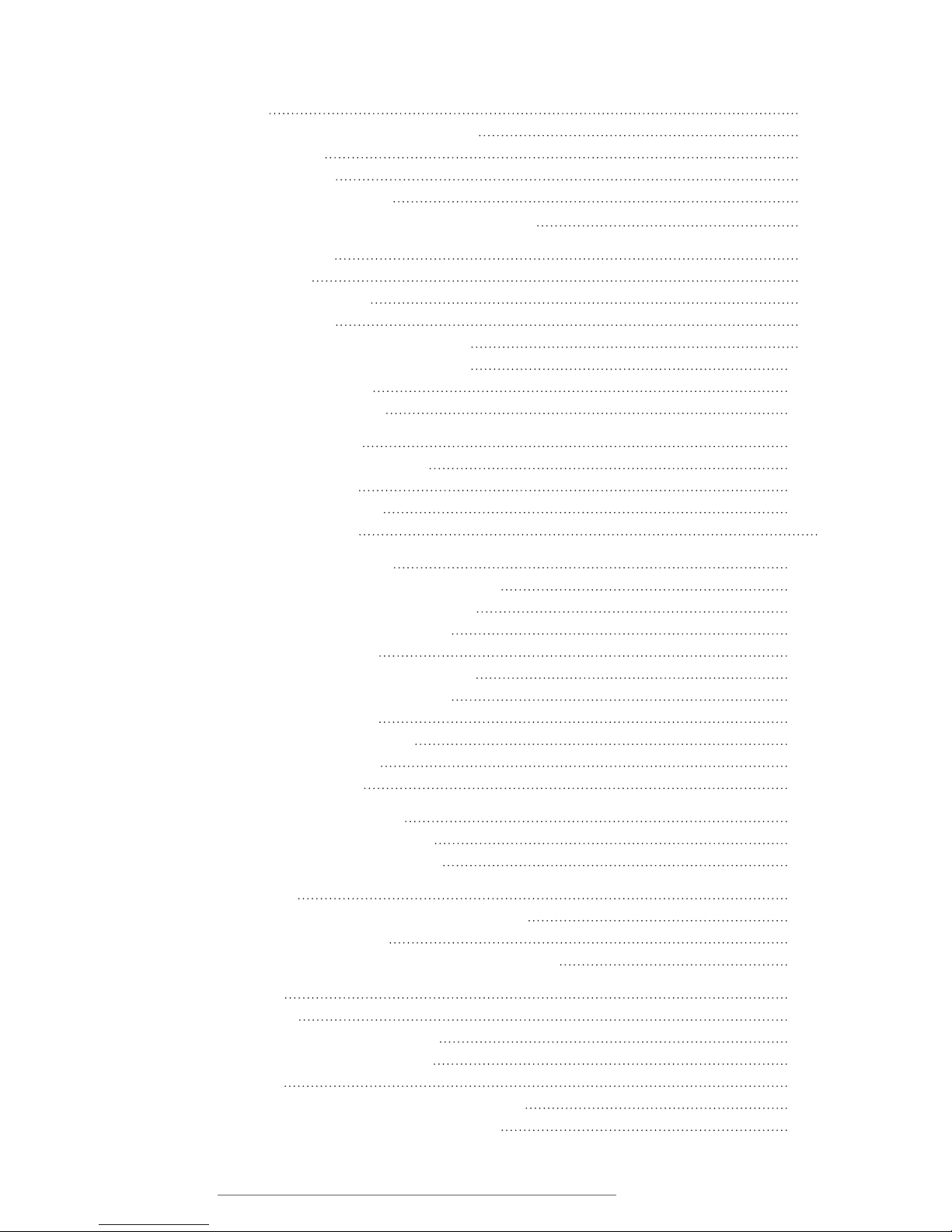

Contents

1. Warranties

4

1.1 5-Year DuraLabel Printer Warranty

4

1.1.1 Repairs

4

1.1.2 Batteries

4

1.1.3 Warranty Details

4

1.2

5-Year DuraLabel Premium Vinyl Warranty

5

2. Loading the Printer

6

2.1 Printer Parts

6

2.2 Printer Ribbon Parts

7

2.3 Loading Ribbon

8

2.3.1 Loading 4.3" ribbon supply

8

2.3.2 Loading 2.5" ribbon supply

11

2.4 Loading Vinyl Supply

12

2.5 Installing Tape Guides

14

3. Connecting the Printer

17

3.1 Inserting the Installation CD

17

3.2 Using a USB Cable

17

3.3 Using a Parallel Cable

20

3.4 Upgrading a Driver

22

4. Configuring Printer Drivers

23

4.1 Continuous Vinyl Printing Instructions

23

4.2 Die-Cut Label Printing Instructions

24

4.2.1 Label Supply Calibration

24

4.2.2 Driver Settings

25

4.3 B Mark Label Printing Instructions

25

4.3.1 Label Supply Calibration

25

4.3.2 Driver Settings

25

4.4 Cutting Labels in Intervals

26

4.5 Adjusting Print Speed

26

4.6 Adjusting Darkness

26

5. Installing Labeling Software

27

5.1 DuraSuite Labeling Software

27

5.2 LabelForge Labeling Software

27

6. Label Creation

28

6.1 Label Creation with Your Word Processor

28

6.1.1 Using Templates

28

6.1.2 Setting up a Microsoft Word Document

29

7. Label Design

30

7.1 Text Boxes

30

7.1.1 Changing Text Box Size

30

7.1.2 Positioning Text Boxes

31

7.2 Graphics

32

7.3 Merging Information, Sequencing Labels

33

7.3.1 Creating an Excel Spreadsheet

33

DuraLabel.com | 800.788.5572

Contents | 3

CONTENTS

8. Cleaning and General Maintenance

38

8.1 Print Head

39

8.2 Cutter

39

8.2.1 Cleaning Cutter from the Inside

39

8.3 Platen Roller

41

9. Troubleshooting

42

9.1 LED is Solid Red

42

9.2 Printing Suddenly Stops and LED Blinks Red

42

9.3 LED Quickly Blinks Red

42

9.4 Printing Stops While Printing Die-cut Labels and LED Blinks Red

43

9.5 LED Blinks Green after Label is Printed

43

9.6 After Printing a Label, Printer Dispenses Extra Supply and LED Blinks Red 43

9.7 Printing is not Aligned Correctly

43

9.8 Printing is Streaked

44

9.9 LED Blinks Amber and Red

44

9.10 Printer Cuts Labels Off-Center or into Next Label

45

10. Specifications

46

10.1 Printer

46

10.2 Indicators and Buttons

46

10.3 Communication Interface

46

10.4 Power Requirements

46

10.5 Environment

46

10.6 Label Supply

47

10.7 Ribbon Supply

47

10.8 Printer Body

47

4 | 1.1 5-Year DuraLabel Printer Warranty

DuraLabel.com | 800.788.5572

1. Warranties

1.1 5-Year DuraLabel Printer Warranty

Graphic Products’ DuraLabel printers are warrantied to be free from

defects in materials and workmanship for a period of five (5) years

from the date of purchase. Within this period, Graphic Products, Inc.

will, at its sole option, repair or replace any components which fail in

normal use. Such repairs or replacement will be made at no charge to the purchaser for

parts or labor, provided that the purchaser shall be responsible for any transportation

cost. This warranty does not cover loss, damages from accident, or equipment or parts

which have been misused, altered, neglected, carelessly handled, used for purpose

other than those for which the printer was manufactured, or damages resulting from

unauthorized service.

1.1.1 REPAIRS

Repairs are warrantied for 90 days. If the original warranty is still in effect, repaired

units will remain under their original warranty or for 90 days from the date of service,

whichever is longer.

1.1.2 BATTERIES

The optional battery packs for the DuraLabel Toro and Lobo portable systems are

warrantied for three years from the date of purchase.

The battery for the DuraLabel 2000 PLUS system is warrantied for one year from the

date of purchase.

1.1.3 WARRANTY DETAILS

The warranties and remedies contained herein are exclusive and in lieu of all other

warranties whether express, implied, or statutory, including any liability arising under any

warranty of merchantability or fitness for a particular purpose, statutory or otherwise.

This warranty gives the purchaser specific legal rights, which may vary from state to

state.

In no event shall Graphic Products be liable for any incidental, special, indirect, or

consequential damages, whether resulting from the use, misuse, or inability to use

the product for any reason including defect. Some states do not allow the exclusion of

incidental or consequential damages, so the above limitation may not apply in all areas.

Graphic Products retains the exclusive right within all warranty periods to repair, replace,

or offer a full refund of the purchase price at its sole discretion. Such remedy shall be

the purchaser’s sole and exclusive remedy for any breach of warranty.

DuraLabel.com | 800.788.5572

1.2 5-Year DuraLabel Premium Vinyl Warranty | 5

WARRANTIES

General maintenance and cleaning of the DuraLabel printer is the purchaser’s

responsibility and is not covered by the warranty. Expendable items or parts such as

label supply and ribbon are not covered by this warranty.

NOTE:6SHFLÀFSUHSDUDWLRQPD\EHUHTXLUHGEHIRUHVKLSSLQJ3OHDVHFRQWDFW\RXU

Graphic Products representative to ensure correct return procedure: please call

800.788.5572 for details. Graphic Products, Inc. shall not be responsible for any loss

or damages incurred during shipping.

1.2 5-Year DuraLabel Premium Vinyl Warranty

DuraLabel supplies are tested for durability under various conditions, including UV

exposure, moisture, heating and cooling cycles, abrasion, and chemical exposures.

Graphic Products warranties labels made from its Premium vinyl supplies for a period of

five (5) years.

Within five years of purchase and after proper application, Graphic Products will replace

labels made with DuraLabel Premium Vinyl which become unreadable or fail to maintain

adhesion with the labeled surface. In such instance, Graphic Products, Inc. will provide

a one-time replacement roll of the same supply.

6 | 2.1 Printer Parts

DuraLabel.com | 800.788.5572

2. Loading the Printer

DuraLabel Ribbon and Vinyl Supplies have been optimized for compatibility and print

quality. Only authorized DuraLabel Supplies from Graphic Products will print correctly in

the DuraLabel PRO/PRO 300 printer.

An instructional video demonstrating how to load DuraLabel Ribbon and Supplies can be

viewed at DuraLabel.com/duralabel-videos.

2.1 Printer Parts

A

B

D

F

G

H

I

C

E

Figure 1 Inside of printer, with ribbon mechanism open in upright position

A. Supply loading diagram

B. Label supply roll

C. Label roll mounts

D. Fixing tabs

E. Teflon bar (white)

F. Adjustable label guides (turquoise)

G. Media sensor/B Mark sensor

(turquoise)

H. Platen roller (black)

I. Printed label opening

DuraLabel.com | 800.788.5572

2.2 Printer Ribbon Parts | 7

LOADING THE PRINTER

2.2 Printer Ribbon Parts

Rear Spring-Loaded Hub

for Ribbon Supply Spindle

Rear Hub for Flange Side of

Ribbon Supply Spindle

Front Hub for Flange Side of

Ribbon Rewind Spindle

Front Spring-Loaded Hub

for Ribbon Rewind Spindle

(with paper core)

Figure 1

NOTE:6SLQGOHÁDQJHVVKRXOGEHLQVHUWHGRQULJKWVLGHZKHQIDFLQJSULQWHU6HH

diagram under the ribbon supply.

Ribbon Spindle Flange

Ribbon Rewind Spindle

with Paper Core Applied

Ribbon Supply Spindle

Figure 2

8 | 2.3 Loading Ribbon

DuraLabel.com | 800.788.5572

LOADING THE PRINTER

2.3 Loading Ribbon

IMPORTANT! Always turn the printer OFF when loading supplies. Always wait at least 5

seconds before turning power back ON.

Open the ribbon mechanism cover by pressing down and in to unlatch it, then lift it up

and back to open.

NOTE: To load 4.3" ribbon, follow the instructions in section 2.3.1. To load 2.5" ribbon,

follow instructions in section 2.3.2.

2.3.1 LOADING 4.3" RIBBON SUPPLY

A. With spindle flange on right side, load ribbon onto an empty ribbon supply spindle,

with the ribbon leader extended over the top and toward the back.

B. Slide the ribbon onto the spindle until it touches the spindle flange.

C. Apply the paper core to the other empty ribbon rewind spindle.

D. Apply the ribbon supply spindle to the rear hub, with the ribbon leader dropped

down. Insert the left side of the spindle first, fitting it onto the left hub, then fitting

the right (flanged) side onto the right hub.

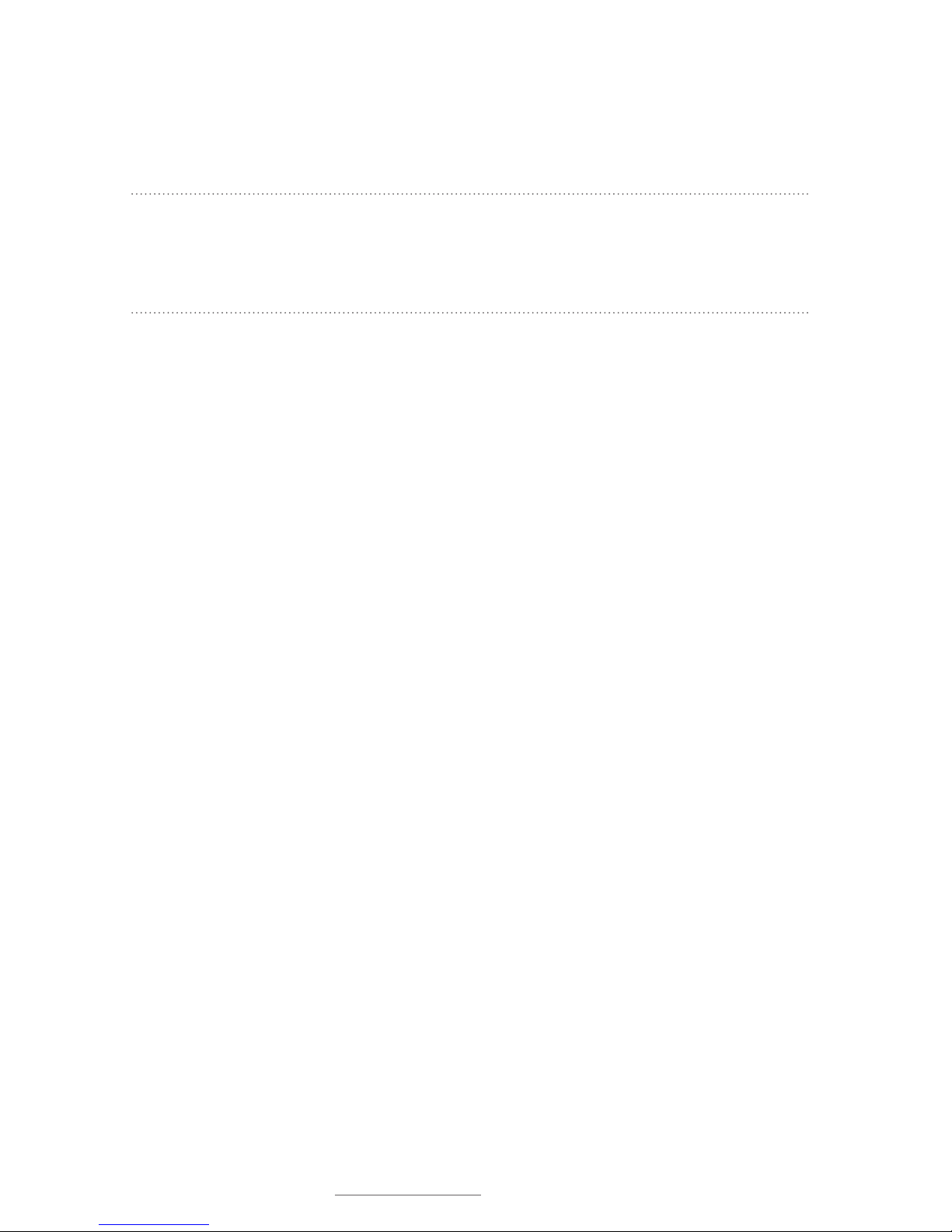

Figure 1 Press down and in to unlatch. Figure 2 Lift up and back to open.

Ribbon Leader

Spindle Flange

Figure 3 Correct ribbon application for spindle

DuraLabel.com | 800.788.5572

2.3 Loading Ribbon | 9

LOADING THE PRINTER

E. Place the ribbon rewind spindle (with paper core) on the front hubs by inserting the

left side of the spindle first, fitting it onto the front spring-loaded hub. Then fit the

right (flanged) side of the spindle onto the right hub.

F. Open the printer cover by pulling

the release levers on the sides of

the printer toward you.

Figure 7 Ribbon supply (4.3") spindle being inserted

at rear hubs

Figure 8 Ribbon supply (4.3") spindle inserted at rear hubs

Figure 9 Ribbon rewind spindle with paper core (4.3") being applied to the front spring-loaded hub

Figure 10

Ribbon supply

(2.5") spindles

loaded and aligned

with each other

Figure 11 Printer release lever being pulled forward

10 | 2.3 Loading Ribbon

DuraLabel.com | 800.788.5572

LOADING THE PRINTER

G. Grab the ribbon leader that is hanging down.

H. Pull it toward you and underneath the ribbon mechanism and print head, up to the

front hub and ribbon rewind spindle.

NOTE: The ribbon should rotate with ease as you unroll it.

I. Tape the entire width of the end of the ribbon leader to the ribbon rewind spindle’s

paper core, placing one piece of tape horizontally.

J. Roll the ribbon rewind spindle (top side of spindle moving away from you) to secure

the ribbon supply and eliminate wrinkles, fingerprints or flaws. Your ribbon supply

should now be loaded.

NOTE: The ribbon-loading process is the same for all ribbon sizes in steps D – J.

Figures 7, 8, 9, 12, 13, 14 and 15 illustrate 4.3" ribbon supply.

Figure 12 Ribbon supply (4.3") being pulled down

Figure 13 Ribbon supply (4.3") being pulled up to the ribbon

rewind spindle

Figure 14 Ribbon supply (4.3") taped to ribbon rewind

spindle

Figure 15 Ribbon supply (4.3") rolled tight

DuraLabel.com | 800.788.5572

2.3 Loading Ribbon | 11

LOADING THE PRINTER

2.3.2 LOADING 2.5" RIBBON SUPPLY

A. With spindle flange on the right side, load ribbon onto the ribbon supply spindle,

with the ribbon leader extended over the top and toward the back.

B. Align the ribbon supply in the center of the ribbon spindle using the measurement

marks.

C. Apply the paper core to the ribbon rewind spindle, centering it using the

measurement marks.

Now refer to Steps D – J under “Loading 4.3" ribbon supply.”

Figure 5 Ribbon supply (2.5")

centered on ribbon supply spindle

Figure 6 Paper core (2.5")

centered on ribbon rewind

spindle

Ribbon Leader

Spindle Flange

Figure 4 Correct ribbon application for spindle

12 | 2.4 Loading Vinyl Supply

DuraLabel.com | 800.788.5572

LOADING THE PRINTER

2.4 Loading Vinyl Supply

IMPORTANT! Always turn the printer OFF when loading supplies. Always wait at least 5

seconds before turning power back ON.

A. Load the vinyl supply onto the label supply spindle, centering and securing it with

the fixing tabs located on each end.

B. Place loaded label supply spindle into the label roll mount slots, with the label

supply extending over the top of the roll and toward the front of the printer.

C. Lead the label supply underneath the

white Teflon bar, over the platen roller

and through the printed label opening,

leaving at least ½" of supply extended

out to help prevent loading errors.

D. Move the adjustable label guides to hold the label supply in place.

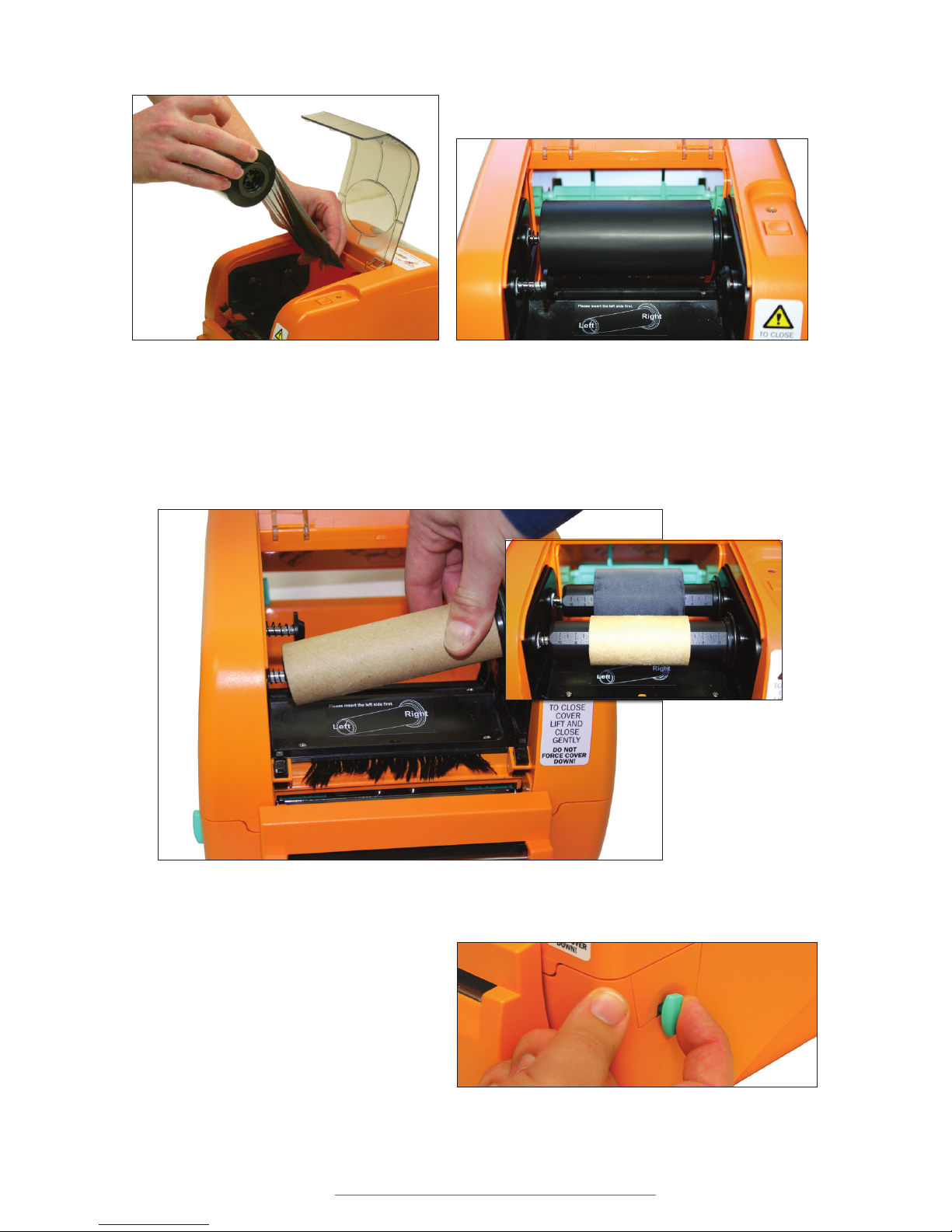

Figure 1 Loaded label supply spindle set in label roll

mount slots

Figure 2 Label supply loaded in the correct direction

Figure 4 Label supply held in place by adjustable label guides

Figure 3 Label supply loaded correctly, with printable

surface facing up and liner facing down

DuraLabel.com | 800.788.5572

2.4 Loading Vinyl Supply | 13

LOADING THE PRINTER

E. Close the printer cover by slowly lifting up, then pressing down until it

latches shut.

F. Close the ribbon mechanism cover by pressing down and in until it latches shut.

Your printer is now loaded and ready to print.

Figure 5 Lift printer cover all the way up,

then press down until it latches shut.

Figure 6 Printer cover closed, with ribbon

mechanism cover open

Figure 7 Press down and in to close.

Figure 8 Loaded DuraLabel PRO 300 printer, ready to print

14 | 2.5 Installing Tape Guides

DuraLabel.com | 800.788.5572

LOADING THE PRINTER

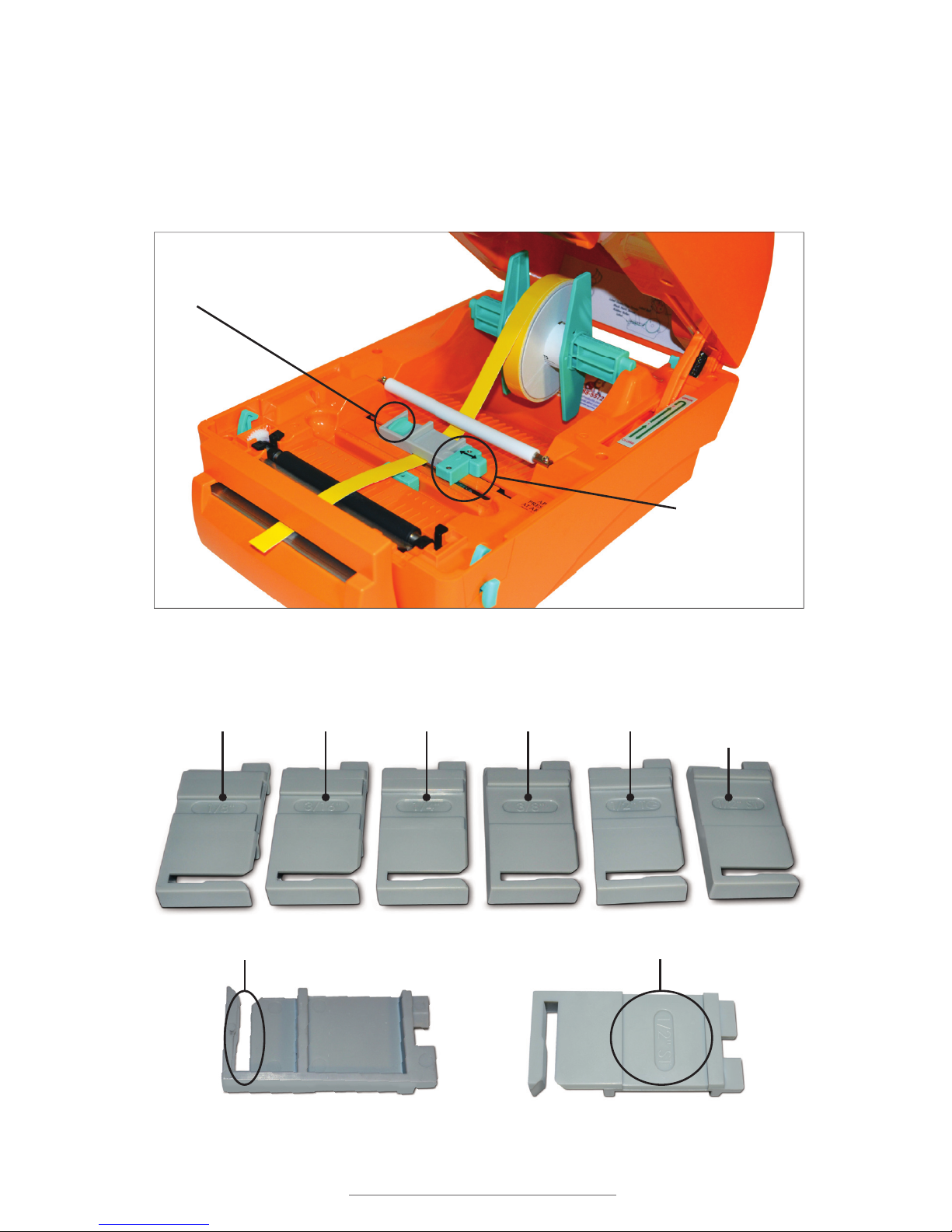

2.5 Installing Tape Guides

Tape guides are required for ½" label supply and shrink tube sizes ½" and smaller.

Larger vinyl and shrink tube supply are held in place by the adjustable label guides.

A. Load shrink tube or ½" label supply and thread it through the cutter.

B. Find the tape guide to match the size of label or shrink tube supply loaded in your

printer.

Left Adjustable Label Guide

Right Adjustable

Label Guide

Figure 1 Loaded shrink tube supply

1/2"1/8" 3/16" 1/4" 3/8"

Figure 2

1/2"

Shrink Tube

Figure 3 Tape guide, with cutout opening facing

up, toward supply spindle

Figure 4 Tape guide showing grooved section

(Tape guide is shown upside down.)

Cutout Opening Grooved Section

Loading...

Loading...