Duracable J-MAXX Machine Manual

Read manual before operating

stop

keep manual for future reference

j-maxx

Right in there with you.

J-MAXX MACHINE MANUAL

Table of Contents

2 Warranty, Parts and Service

3 Safety Labels

4-7 J-Maxx Information and Specifications

8-9 J-Maxx Machine Schematics and Parts List

10 J-Maxx Reel Schematics and Parts List

11-12 Mini Power Cable Feed and Return Schematics and Parts List

13-14 J-Maxx Electrical Schematics and Safety Information

15 How to Splice DuraFlex® Cable and How to Bond End Fittings

WARRANTY

Duracable Manufacturing Company warrants the J-Maxx machine to be free from defects in material and workmanship for a period of two years

from the date of purchase. Warranty service can be obtained by contacting Duracable Manufacturing Company at the address listed below. If a defect

is covered by warranty, Duracable Manufacturing Company will repair or replace the defective machine or component without charge for labor or

materials (freight is not included).

Warranty of the machine is limited to the original purchaser. Duracable Manufacturing Company assumes no responsibility for damage or injury from

accident, neglect, abuse, misuse or from damage due to repair or alterations by others. This warranty does not cover damage to the machine from use

of parts other than genuine Duracable brand parts.

Duracable Manufacturing Company’s sole obligation and the original purchaser’s sole remedy under this warranty shall be for repair or replacement

as described above. All other warranties, expressed or implied, including but not limited to, implied warranties of merchantability and fitness for a

particular purpose, are disclaimed. In no event shall Duracable Manufacturing Company be liable for any incidental or consequential damages.

PARTS AND SERVICE INSTRUCTIONS

Parts can be purchased from Duracable Manufacturing Company. Service work is also available. Service is performed by trained factory personnel.

Machines sent to the factory for evaluation and repair can be estimated and quoted prior to service work. When sending a machine, be sure to include

the return address and include instructions on how the repair should be handled. Instructions can either be included with the machine, explained to your

account manager over the phone (800-247-4081), or faxed (515-223-6109).

IMPORTANT

Keep this manual in a safe, convenient place for future reference. Important information about this machine, its diagrams and warranty information are

included in this manual.

Serial Number: Date of Purchase:

Duracable Manufacturing Company

300 Ashworth Road • West Des Moines, IA 50265

2

Safety Labels

J-MAXX MACHINE MANUAL

Duracable Manufacturing uses three signal words on its

safety labels and instructions. These words have the following

definitions:

DANGER

A ‘Danger’ label indicates an imminently hazardous situation

that, if not avoided, will result in death or serious injury. This

signal word is to be limited to the most extreme situation,

typically for machine components that, for functional purposes,

cannot be guarded. The word ‘danger’ will be in white letters on

a red background.

WARNING

A ‘Warning’ label indicates a potentially hazardous situation

that, if not avoided, could result in death or serious injury, and

includes hazards that are exposed when guards are removed.

It may also be used to alert against unsafe practices. The word

‘warning’ will be in black letters on an orange background.

CAUTION

A ‘Caution’ label indicates a potentially hazardous situation that,

if not avoided, may result in minor or moderate injury. It may also

be used to alert against unsafe practices. The word ‘caution’ will

be in black letters on a yellow background.

The safety label format includes the signal word and symbol, a

picture (not required), and the message.

3

J-MAXX MACHINE MANUAL

Information and Specifications

Safe Machine Operation

Read this machine manual thoroughly before assembling or

operating the machine. Become familiar with its controls and

proper use before operating. Keep this manual in a handy place

for reference and parts replacement referral. This machine is

designed specifically for the purpose of opening and cleaning

drains. Use it for this purpose - do not use it for other purposes.

Use gloves to protect your hands. Wear them to feed and

retrieve cable. Use a material that cannot be easily grabbed by

the cable. Most leather gloves and certain rubber gloves work

well. Duracable Manufacturing has each type available through

the Duracable Product Catalog. Also, avoid the use of loosefitting clothes or jewelry when operating this machine.

Keep guards in place to protect the operator from the electric

motor and electrical wiring. These guards are for safety

protection and must be in place when running the machine.

Each machine is equipped with an air foot pedal. Use of the air

foot pedal to operate the machine is required for safe operation.

This allows the machine operator to turn the machine on or o

with the foot while keeping both hands on the cable.

Select a work area free from obstruction with room to work.

Keep the machine within three feet of the pipe opening, allowing

only enough room to work. This is required to shorten the length

of exposed cable, thus providing maximum control in hightorque situations. Take a position that is comfortable to the left

or right side of the machine for feeding or retrieving cable. For

high work openings, the machine can be placed on its back as

conditions require.

When performing a job, use the smallest blade first. Rinse the

pipe after each blade is run through the line in order to clean out

loosened debris. Then follow with the increasing sizes of blades

until the size used is one that actually scrapes the side of the

pipe or sewer. The blades are flexible and can be compressed

to enter most cleanout openings. Centrifugal force created by

the spinning cable forces the blades to expand to their natural

diameter or to the walls of the pipe. It is advisable to maintain a

very keen cutting edge on the blades at all times.

Place two hands on the cable between the outlet of your

machine and the cleanout, and keep them there at all times

during operation. Your hands placed in the proper position, will

provide a guide for the cable. Keep the machine within three feet

of the pipe opening.

As the blade makes contact with an obstruction in the line, it

stops the blade from turning and builds torque in the cable.

Do not permit the blade to get hung up in an obstruction for

more than three seconds. Torque buildup can be both helpful

and dangerous. It is helpful when pulled from the obstruction

in a timely manner. When the cable is pulled away, the tension is

released and the blade turns at a high speed. When the blade is

free, feed it back into the obstruction to make use of the built-up

power to clean the line. It is dangerous because excess torque

can cause looping over of the cable. Serious injury to fingers

and hands is possible unless precautions are observed. When

retrieving cable from the line, feed the cable into the machine

until the blade is close to the cleanout opening. Shut o the

machine and hand-feed the remaining cable into the machine.

Unpacking Your Machine

The J-Maxx is shipped to you with the following parts: the base

machine, a drum, and a revolving arm. When it arrives, remove

the parts immediately and inspect for damage. If any of the

contents are damaged, contact your motor freight carrier

immediately.

Moving Your Machine

Break the machine down into lighter-weight components to

move it to and from the job site. To do this, wrap the GFCI cord

and the air foot pedal cord in a convenient spot on the machine,

remove the revolving arm from its assembled position (leave the

cable inside it and keep it with the drum), and remove the drum

assembly. Various accessories are available from Duracable

Manufacturing to assist and protect the operator during the

moving process.

Assembling Your Machine

• Attach the D3L Drum Attachment to the male end on one end

of the cable. Position the cable end with attachment inside the

cable and snap into place. Feed the cable into the drum.

• Set the base machine in a down position on its rails.

• Pick up the drum, loaded with cable, with the cone shape to

the front of the machine (toward the switches) and slide it

onto the drum shaft. Be sure the orange drive lugs slide into

the openings in the back of the drum and engage fully.

• Feed the cable through the revolving arm until it is flush with

the end of the arm.

• Position the revolving arm inside the drum.

• Position the extension shaft on the revolving arm into the

center of the drum bearing.

• Place the revolving arm with cable extended into the rear side

of the head bearing.

• Slide the collar forward using an Allen Wrench to loosen and

tighten the collar.

• Slide the cable through the head bearing.

Disassembling Your Machine

To disassemble the J-Maxx machine, reverse the assembly

process.

4

J-MAXX MACHINE MANUAL

Information and Specifications

Lubrication Maintenance

Caution: Do not over oil these points.

• Head Bearing Assembly - The roller bearing, located in the

front assembly, requires monthly lubrication. Use a grease

gun to lubricate the zerk fitting with multipurpose grease. A

lithium-base grease is recommended.

• Drum Shaft and Drum Bearings - The drum shaft requires

monthly lubrication. Use a multipurpose grease or heavy oil.

Keeping the shaft lubricated means the drum will slide and

will not ‘freeze’ to the shaft and need to be repaired. The drum

bearings require some light oil monthly.

• Belt - Check tension during the first 24 to 48 hours of operation.

• Belt Tension - Ideal deflection is 1/4”. Over tensioning shortens

belt and bearing life.

• Air Foot Pedal - Check for wear or stress cracks.

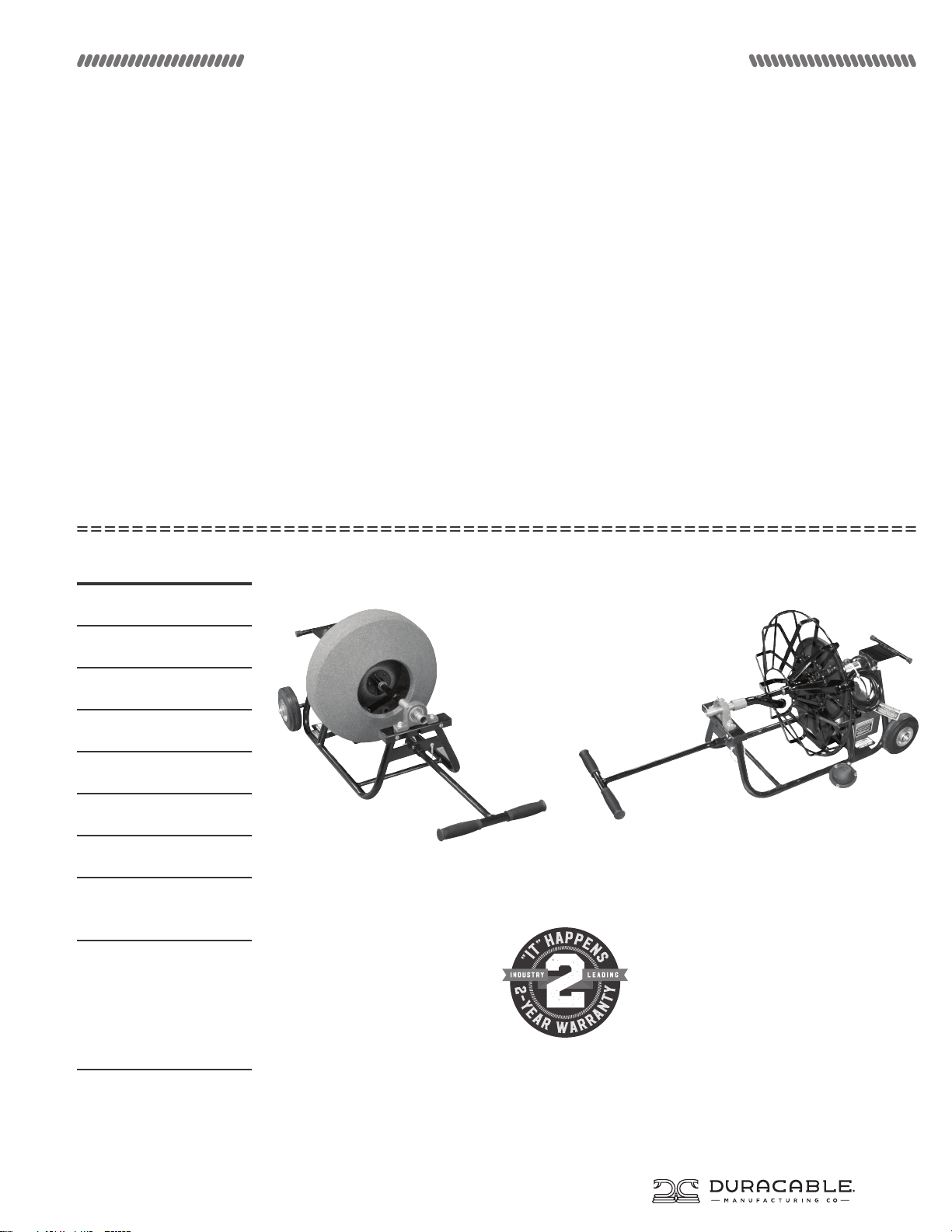

j-Maxx

1/3 HP Motor

Cable Care Instructions

Take care of your cable for optimum performance. The

recommended care procedure is as follows:

• Break in a new cable. To relieve the stress on new cable that

has been coiled since its manufacture, put it in a clean line and

run it for 10 minutes.

• Oil the cable once a week.

• Rinse the cable immediately after each use with the hottest

water available. This is especially important if the cable was in

acid or alkali during use.

• When one end of the cable begins to show wear, rewind and

use the opposite end. (Tip: order the same kind of end fittings

on both ends of the cable.)

• If the cable kinks, cut out the kink and splice the cable ends

together.

200 RPM

Belt Drive

19” Reel

1/2” x 75’ Cable

Detachable “T” Handle

2-Year Warranty

Continuous Weld

Uni-body Frame

USES:

1-1/4” to 3” lines,

Residential, Sinks,

Roof Vents,

Floor Drains

The J-Maxx with 16PRS, 16” enclosed polyethylene reel The J-Maxx with D1S1, 19” open spoke reel (standard package)

5

Loading...

Loading...