DUPLO SEIKO CORPORATION Duprinter DP-460, Duprinter DP-340, Duprinter DP-440, Duprinter DP-330L, Duprinter DP-430 Service Manual

...

SERVICE MANUAL

V er.2

DUPRINTER

DP-460/DP-440

DP-430/DP-340

DP-330/DP-330L

N5-Y1071 2002.12

Be sure to read this manual carefully, so that you

repair and service this machine safely and

correctly. Do not begin work until you have

thoroughly understood the contents of this manual.

Repairing or servicing the machine with insufficient

knowledge about it could lead to unforeseen

accidents or falls in the machine's performance or

quality.

DUPLO SEIKO CORP.

1

Introduction

The cause of most accidents is failure to adhere to basic safety rules and observe

safety instructions. It is important to prevent potential causes of accidents from

occurring. In order to do so, read this manual carefully, and be sure to understand

all the safety instructions and correct inspection and servicing procedures that it

provides before beginning repair or servicing work.

Repairing or servicing the machine with insufficient knowledge about it could

lead to unforeseen accidents.

It is not possible to anticipate and describe in a manual such as this every possible hazard that could arise in the course of repair and servicing. Therefore, besides

observing the safety instructions marked in this manual and on the machine's

labels, service personnel should be safety-conscious and take other safety precautions as necessary. When performing repair or service work not covered by this manual, you should obtain safety guidance from an appropriately knowledgeable person.

Copyright 2002

DUPLO SEIKO CORPORATION

All Rights Reserved

2

'Safety-related instructions

If the instructions accompanying this symbol are ignored and the

machine is operated incorrectly, death or serious injury is likely to

result.

If the instructions accompanying this symbol are ignored and the

machine is operated incorrectly, death or serious injury, or else material

damage, is likely to result.

WARNING:

CAUTION:

Examples of pictorial symbols

A " " symbol tells you that a certain action is forbidden. Precisely what

is forbidden is indicated by a picture inside the symbol (in the example

here, the picture means that disassembly is forbidden), or in writing at the

side of the symbol.

A " " symbol means that a certain action is forbidden and/or that a

specific instruction must be followed. The specific instruction is indicated

by a picture inside the symbol (in the example here, the instruction is

"Remove the power plug from the socket").

IMPORTANT:

NOTE:

Draws attention to important information. If this information is ignored

and the machine is operated or serviced incorrectly, the machine`s

performance could drop, or it could break down.

Draws attention to information that is useful for operation or maintenance

of the machine, and to information about its performance, etc.

D Using the service manual

• This manual contains the following information: structure and function of major parts,

disassembly and reassembly procedures, specifications, and procedures for adjustment,

maintenance, inspection and corrective action. This information is current as of December

2002, and applies basically to the model DP-460/440/430/340/330/330L DUPRINTER.

From time to time, parts are changed to improve quality, performance or safety. Note therefore

that in some cases, certain parts or machine structure aspects described in the text or

illustrations of this manual may not be precisely the same as the product being serviced.

• Safety instructions marked with a " " (WARNINGS and CAUTIONS) are very important for

safety and must be observed.

3

Safety instructions

Safety instructions

Safety instructions

1. Cautions regarding the installation location

Installation environment

s Avoid installing the machine in places exposed to direct sunlight.

• Sunlight will cause the temperature in the machine's interior to rise, possibly leading to

malfunction of the control system.

• Sunlight could cause misoperation of the sensors.

• The heat of direct sunlight could cause deformation of the machine's plastic parts.

* Also avoid installation near to a ground glass window; light and heat penetrate such windows

although they are opaque.

s Avoid installing the machine in places subject to high or low temperature or humidity.

• High or low temperature or humidity could cause the machine to operate abnormally.

Suitable temperature and humidity ranges are:

Ambient temperature: 10y430y

Ambient humidity: 40%470%

Optimum temperature and humidity: 20y, 65%

• If the machine is installed near to faucets, water heaters or humidifiers, or in cool (sunless)

parts of a building or in the vicinity of water sources, the paper could absorb moisture and curl,

leading to misfeeds or poor image quality.

s Avoid installing the machine in places with open flames, or where reflected heat or other hot air

currents (from stoves, etc), or cold air currents from coolers, etc will strike it directly.

s Avoid installing the machine in poorly ventilated places.

s Avoid installing the machine in dusty places.

s The machine should not be tilting when it is used.

• Install the machine so that it is level.

(The machine should be level to within 5mm in the front-rear direction, and 5mm in the lateral

direction.)

sDo not install the machine on shaky, sloping or otherwise unstable surfaces.

• The machine could fall over on such surfaces, or fall off them, causing injury.

4

Safety instructions

Warning

• The machine's power supply voltage and power consumption depend on the model. Details of this

are given in the tables below. The power supply voltage and power consumption for the machine

are given in the table below. The machine's power supply voltage is indicated on the identification

plate located on the machine's left side; the machine must be connected to a power supply of the

voltage indicated.

a Otherwise, fire or electric shock could result.

If the power supply voltage is unstable or if the power supply has insufficient capacity, the

machine may not operate normally.

Make sure that the power supply has sufficient capacity for the system as a whole, including

optional equipment.

Connect to outlet of 120V AC, 60Hz, at least 15A

With no load*

At full load

Power consumption

No more than 130V AC

At least 110V AC

During platemaking : 250W

During printing at speed 3 (printing speed) :230W

On standby : 60W

Power supply voltage

}

Use power supply meeting these requirements

Connect to outlet of 230V AC, 50Hz, at least 8A

With no load*

At full load

Power consumption

No more than 250V AC

At least 210V AC

During platemaking : 250W

During printing at speed 3 (printing speed) :230W

On standby : 60W

Power supply voltage

}

Use power supply meeting these requirements

* 120V AC model

* 230V AC model

* "With no load" - when the machine is on standby.

* "At full load" - when the machine is running at maximum power consumption.

• Use only the power cord that is provided among the accessories.

Insert the power cord plug firmly into the socket, so that proper electrical contact is effected.

• Install the machine close to its power supply. The outlet used should be exclusively for the

machine, and have no other equipment connected to it.

If an extension cord is necessary, it should have a ground terminal, and be of the following ratings:

* For a 120V AC model: 130V, at least 15A, length not exceeding 5m.

* For a 230V AC model: 250V, at least 8A, length not exceeding 5m.

• Never tread on the power cord or pinch it between other objects, or accidents could result.

2. Cautions for installation work

• Install the machine in accordance with the installation procedure appended to this manual.

• Lock the casters after the machine is installed.

a Otherwise, the machine could move or fall over, causing injury.

• To move the machine, push it by its mounting base.

a Pushing the printing (upper) part of the machine could make it fall over.

CAUTION

Using the optional printer stand

5

Safety instructions

' Precautions for safe servicing

• Always remove the power cord plug from the outlet before starting work.

a Otherwise, you could get a shock or your hands/fingers could be injured.

• However, the plug must be left connected to the outlet when performing function checks (of

individual motors, a given series of operations, or electrical circuits). When motors are

operated alone in function checks, interlocks are deactivated, so be aware of the conditions and

positions of related equipment, and take great care not to put your hands or fingers into

moving parts.

• The cutter unit contains hazardous sharp blades. Exercise great care when inspecting the cutter

unit or replacing it or its parts.

a Otherwise, your hands/fingers could be injured.

• Do not touch the drum or rollers after turning on the jog switch.

• Do not put your hands or fingers inside the machine while the drum is rotating.

a Otherwise, your hands/fingers could get caught and crushed between the drum and rollers.

' Working clothes

• Wear clothing than enables you to work safely.

Warning

' Tools

• Use tools that are appropriate for the work.

CAUTION

3. Cautions for maintenance, inspection and servicing

• The tape clusters have hazardous blades. Exercise care when inspecting or replacing the

blades.

a Otherwise, your hands/fingers could be injured.

If optional tape clusters are used

t

M7-T3060

1Caution Sticker 1

Caution Sticker 2

6

Safety instructions

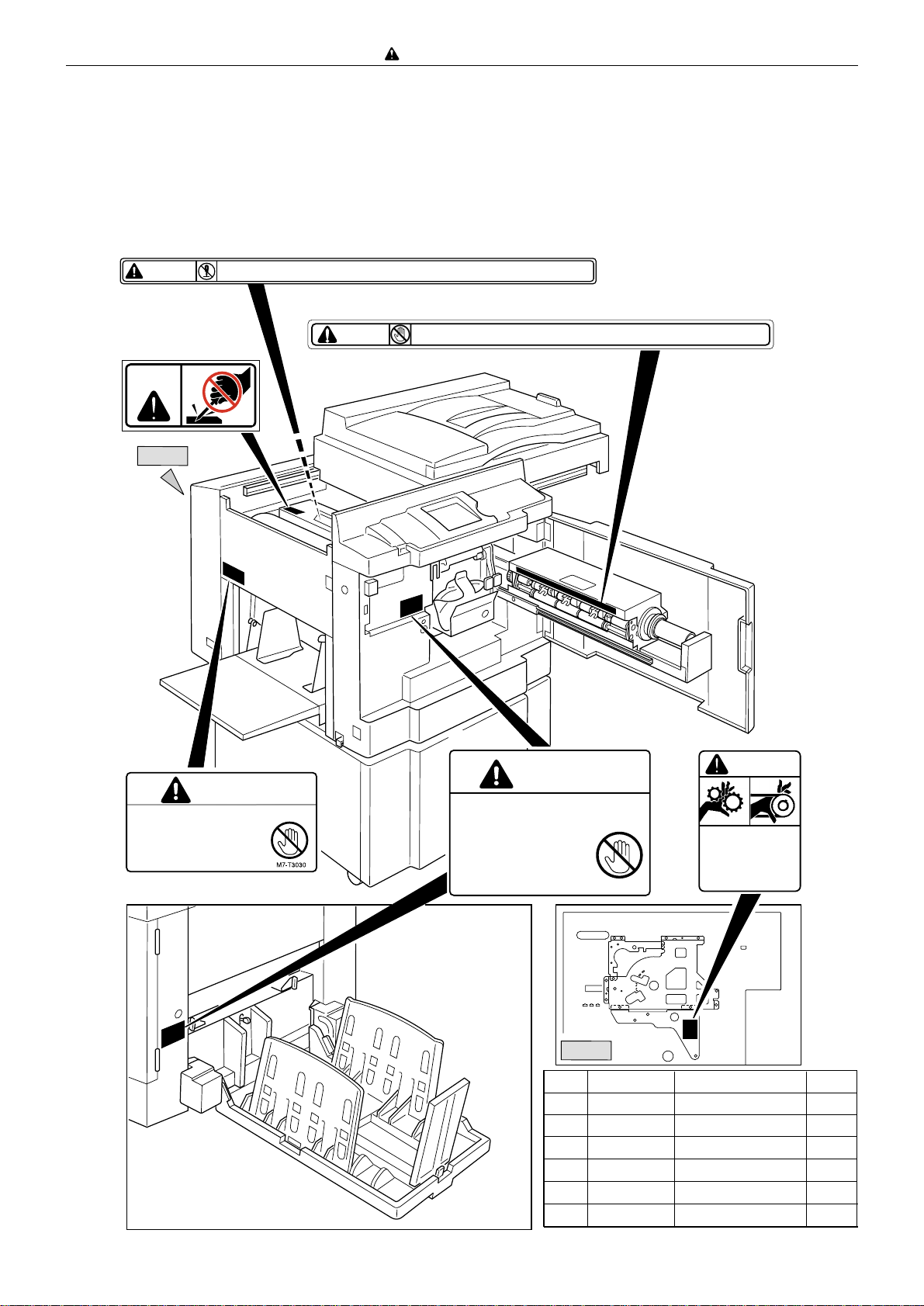

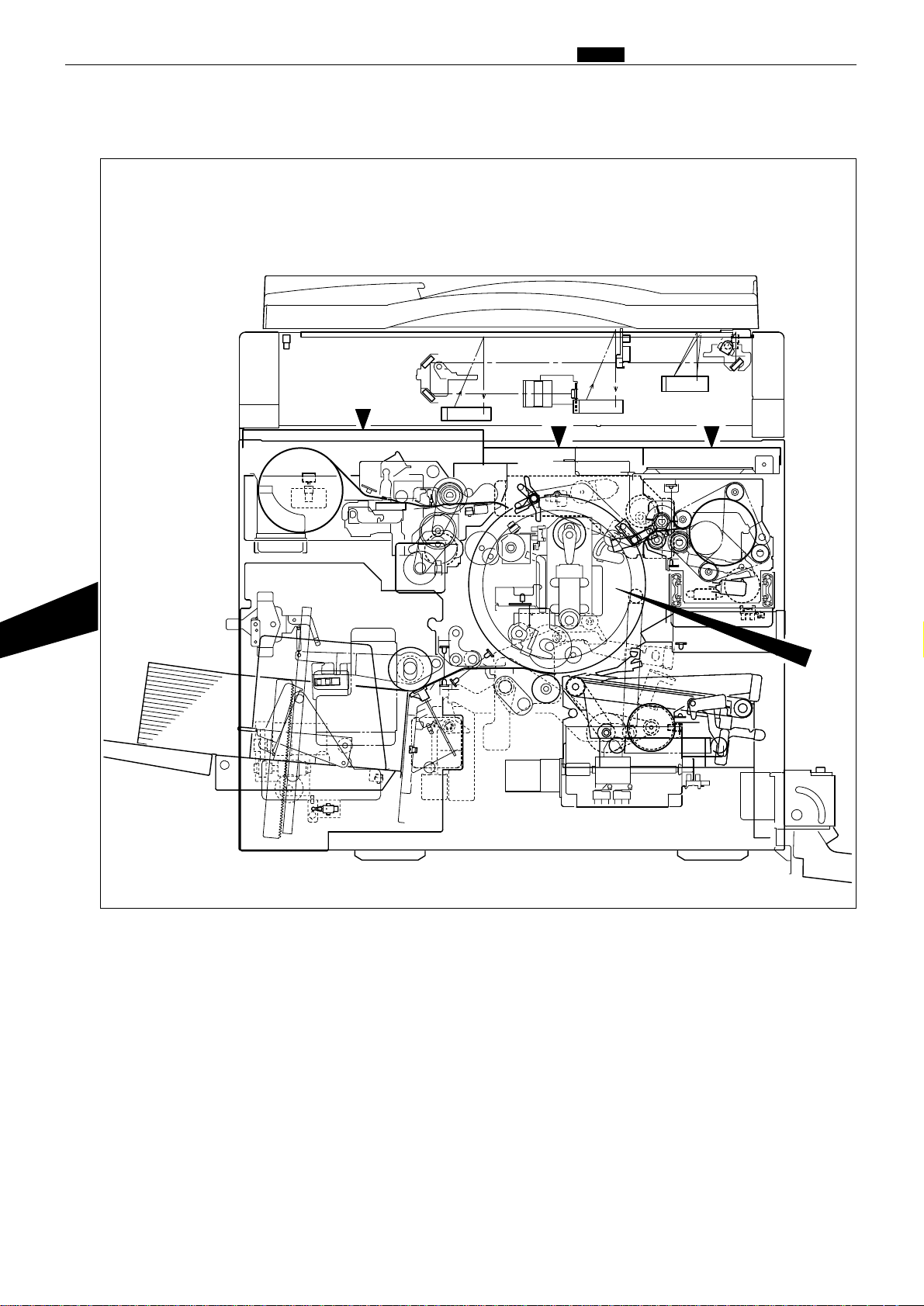

DLocations of warning stickers

The locations of the machine's warning stickers are shown below. To ensure safe work, read the

stickers and heed their instructions. Keep the stickers clean at all times. If they become damaged

or peel off, replace them with new ones.

No. Parts No. Name

Q'ty

q

L1-T3060 Warning Sticker 1

1

w

L5-T3020 Warning Sticker 2

2

e

r

M7-T3030

L8-T1090

Warning Sticker 3

Warning Sticker 4

1

1

View A

View A

M7-T3060

CAUTION

WARNING

Do NOT put hands inside machine

while it is operating.

Hands could get caught up

or crushed.

WARNING

● Do not remove this cover. The inside of the printer contains movable cutting instruments,

contact with which could result in injury.

L5-T3020

Do NOT touch the drum or rollers

when you operate the jog switch.

Do NOT put hands Inside

machine while it is operatung.

Hands could get caught up

or crushed.

WARNING

N5-T3010

Do not touch the roller below. Your clothes etc. may be stained with ink.

CAUTION

L8-T1090

WARNING

Use caution when working

near movable parts.

Disconnect power before

servicing.

q

t

y

e

w

r

y

N5-T3010

1

7

Chapter 8

Chapter 7

Chapter 6

Chapter 5

Chapter 4

Chapter 3

Chapter 2

Chapter 1

HELP Mode

Others

Troubleshooting

Maintenance / Check

Standard / Adjustment

Mechanism

Description of the Operation

Introduction

9

Table of Contents

Chapter 1

z Features................................................................................12

x Specifications ......................................................................14

c Dimensions ..........................................................................16

v System Setup.......................................................................18

b Part Names and Their Functions........................................19

n Operation Procedures.........................................................26

Chapter 2

z

Scanner Section.........................................................30

x

Platemaking/Master Feed/Ejection Section.............40

c

Paper Feed Section ...................................................66

v

Drum Driving Section................................................79

b

Press Section.............................................................85

n

Paper Ejection Section..............................................90

m

Drum Section .............................................................97

,

Option .......................................................................109

Chapter 3

z

Exterior .....................................................................112

x

Scanner Section.......................................................118

c

Platemaking/Master Feed/Ejection Section...........125

v

Paper Feed Section .................................................132

b

Drum Driving Section..............................................137

n

Paper Ejection Section............................................139

m

Drum Section ...........................................................144

Chapter 4

z

Scanner Section.......................................................154

x

Platemaking/Master Feed/Ejection Section...........156

c

Paper Feed Section .................................................164

v

Drum Driving Section..............................................169

b

Press Section...........................................................171

n

Paper Ejection Section............................................173

m

Drum Section ...........................................................175

,

Electrical System.....................................................179

.

Option .......................................................................188

Chapter 6

z

Troubleshooting Guide ...........................................194

x

Error Display ............................................................211

Chapter 7

Chapter 8

z

Electrical Parts Layout and Their Functions.........314

x

Overall Wiring Layout..............................................325

z

HELP Mode List .......................................................214

x

Overview...................................................................218

c HELP Mode Functions and Operation Procedures

.......219

(1)Accessing HELP Modes......................................219

(2)Guide to the HELP Mode Descriptions..............219

• HELP Mode Descriptions .....................................220

Introduction.................................................................................1

Using the service manual ..........................................................2

Safety instructions ...............................................................3

1.Cautions regarding the installation location........................3

2.Cautions for installation work...............................................4

3.Cautions for maintenance, inspection and servicing .........5

• Locations of warning stickers................................................6

Troubleshooting

Chapter 5

z

Guaranteed Periodical Maintenance......................190

x

Cleaning and Oiling.................................................190

c

Periodical Maintenance...........................................191

Maintenance / Check

Standards / Adjustment

HELP Mode

Others

Mechanism

Description of the Operation

Introduction

11

z Features........................................................................12

x Specifications...............................................................14

c Dimensions...................................................................16

v System Setup ...............................................................18

b Part Names and Their Functions................................19

1. Machine exteriors....................................................19

2. Sectional (structural) view of the machine ...........22

3. Control Panel ..........................................................24

n Operation Procedures .................................................26

1. Platemaking & Printing...........................................26

2. Multiple Image Printing / 2 IN 1 Layout Mode.......27

1

Chapter 1 Introduction

12

z Features

chap.1

zFeatures

Size A3/B4 printing(Printing area)

DP-460/440/430 : A3 ( 290X423mm )

DP-340/330/330L : B4 ( 250X355mm )

1.

High-speed platemaking2.

High print quality3.

Align paper4.

High-performance lamp5.

Simple operation6.

Full range of necessary functions

q

Documents are easily enlarged or reduced.

In addition to same-size printing, there are three

automatic settings for both enlargement and

reduction. Further, the margin (94% reduction)

function can be used for these automatic settings.

7.

• Zoom settings : (70, 81, 86, 115, 122, 141%)

• Same-size : (100%) printing

Size A/B models

• Free zoom : 50% -500% ( 1% )

Enlargement :141% [A4/A3, B5/B4]

*

4

122% [A4/B4, A5/B5]

115% [B4/A3, B5/A4]

*

4

Reduction : 86% [A3/B4, A4/B5]

*

4

81% [B4/A4, B5/A5]

70% [A3/A4, B4/B5]

*

4

*4:

Maximum printing area of DP-340 and DP-330

is B4(2509355mm).

• Zoom settings : (64, 74, 77, 121, 129, 141%)

• Same-size : (100%) printing

Inch size models

• Free zoom : 50% -500% ( 1% )

Enlargement :141%

129% [LTR/LDG]

121% [LGL/LDG]

Reduction : 77% [LGL/LTR]

*

5

74% [LDG/LGL]

*

5

67% [LDG/LTR]

*5:

Maximum printing area of DP-340 and DP-330

is 11"914"(2509355mm).

w

Self-diagnosis

The machines have self-diagnostic functions.

Messages for self-diagnosed errors, as well as

consumable part replacement prompt messages,

appear on an LCD panel.

e

Book shadow erasure

Shadows in the middle or at the edges of book

documents can be erased.

r

Adjusting the Printing Position(vertical)

In addition to vertical direction adjustment.

Print the first sheet of paper.(document size : A4R )

DP-460 : 24 seconds*

1

DP-440/340 : 19 seconds*

1

DP-430 : 24 seconds*

1

DP-330/330L : 23 seconds*

1

*1:Time required to print the first sheet of paper

after the platemaking key is pressed.

A new, originally-developed superfine thermal

head gives beautifully accurate reproductions of

fine print and halftone photographs.

Its resolution is 600dpi in the primary scanning

and 600dpi in the secondary scanning.

Its resolution is 400dpi in the primary scanning

and 400dpi in the secondary scanning.

Its resolution is 300dpi in the primary scanning

and 600dpi in the secondary scanning.

DP-430/330/330L

DP-440/340

DP-460

Adjusting the eject enables both thin and thick

sheets of paper to be aligned neatly.

A long-life, high-brightness xenon arc lamp is

used to illuminate the documents. Since the

lamp's intensity is not affected by temperature

variation*2, printing quality at low temperatures

is greatly enhanced*3.

*2: The lamp is filled with xenon gas, which means

that it does not require heat to vaporize mercury,

as a fluorescent lamp does, and therefore its

intensity does not vary with temperature.

*3: Increased viscosity of the ink at low temperatures

results in fainter printing than at normal

temperatures.

Operation is simplified by concealing

occasionally-used keys under a panel, leaving

just the basic function keys permanently

accessible.

13

z Features

chap.1

User setting

q

Memory Function

Equipped with a memory function (for 9

items) able to memorize frequently used

settings.

w

Optimize Print

Optimal images can be printed in times of

low/high temperature by setting the

temperature and the print speed.

e

Initial Paper Size setting

The paper size and print speed, etc., that

are valid when the power is turned on can

be set.

r

Document Memory

The last platemaking image can be

memorized, and used later for platemaking

without having to read it out again.

8.

Special functions

The HELP mode items listed below can now also be

used in the user mode. And the power save mode can

cut power consumption.

q

Fine Start

w

Auto Clear

e

Pre-print

r

Batch Print

t

Auto Power Off

y

Auto LCD Off

u

Long Paper mode

(OP: when mounting the long paper unit)

i

Ink Circulation

o

Tape Cluster ( tape inserter )

(OP: when mounting the tape cluster)

!0

Double Feed Detection

!1

Drum selection ( A3/A4 )

(OP: when mounting the A3/A4 drum unit)

9.

Option

q

S2-ADF

w

Drum unit

e

A3/A4 Drum unit

r

Tape Cluster

t

PC Interface kit 2

y

Key card counter 4

u

Postcard stacker

i

Long paper unit

10.

t

Document modes

The "Text-Photograph", "Text-Fine Lettering",

"Photograph-Fine Lettering", "Screen 1 & 2" and

"Photo Dark" Modes selecting, accommodating

printing of a wider variety of documents.

y

Adjusting the contrast control

The degree of contrast for printing can be

adjusted.

14

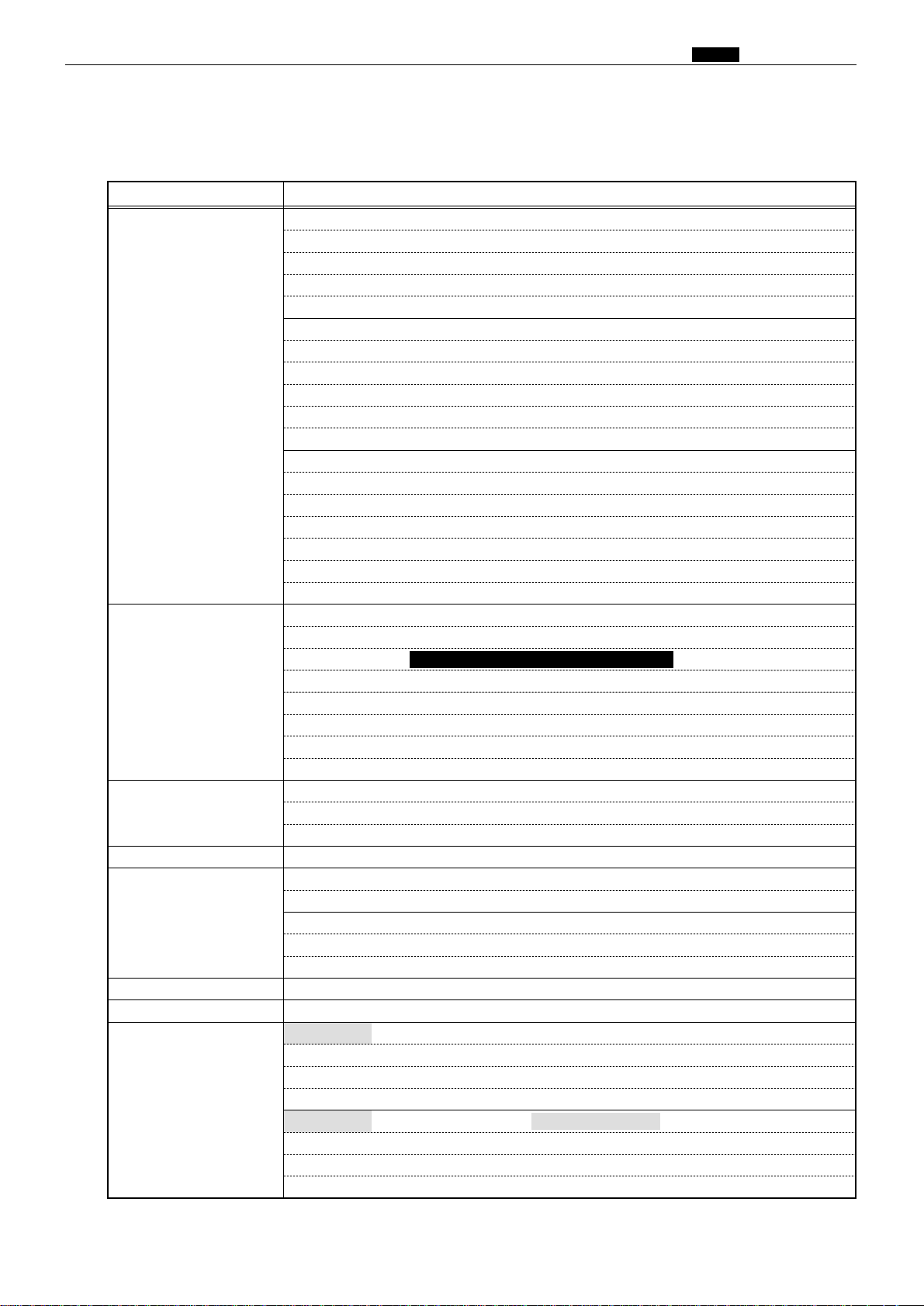

x Specifications

chap.1

xSpecifications

• Specifications

Model

Model name

DUPRINTER

DP-460 DP-440 DP-430 DP-340 DP-330 DP-330L

Floor model

Thermal digital master making

24 sec ( A4R 100% )

600dpi

19 sec ( A4R 100% )

400dpi

400dpi

19 sec ( A4R 100% )

24 sec ( A4R 100% )

300 dpix 600 dpi

23 sec ( A4R 100% )

300 dpix 600 dpi

Flat bed scanner

100 sheets (64 - 128gsm)

Stencil print

MAX. 297mm x 432mm

290mm x 423mm

290mm x 423mm (A3) (11.4"x16.6")

250mm x 355mm (B4) (9.8"x14") 8.3"x14" (LGL)

1,500 sheets(64gsm)

1,500 sheets (64gsm)

MAX: 297mm x 432mm

With Long paper unit (service part) : Max: 540mm

MIN: 100mm x 150mm

Master making method

Master making interval

Resolution

Scanning method

ADF (Optional)

Printing method

Sheets, book ( max: 10kg)Document type

Document size

Scanning area

Image area ( max)

Feeding capacity

Stacking capacity

Paper size

53gsm -210gsm (45kg-180kg)Paper weight

13lb - 110lb (Index)

Feeding pressure adj.( 3 steps )

Separator adj. ( 3 steps )

120 ppm ( 45-120 ppm, 5 steps) 130 ppm ( 45-130 ppm, 5 steps)

Print speed

100%Zoom A/B size

Inch size

Preset reduction/enlargement: 70, 81, 86, 115, 122, 141%

94%

Zoom: 50 - 500%

Auto zoom: 70, 81, 86, 115, 122, 141%

100%

Preset reduction/enlargement: 64, 74, 77, 121, 129, 141%

94%

Zoom: 50 - 500%

Auto zoom: 64, 74, 77, 121, 129, 141%

Vertical : +/- 15mm [ shown on the LCD by 0.5(mm)]Registration adjustment

Horizontal: +/- 10mm [shown on the LCD by 0.5(mm)]

Text,Photo,Text/Photo,Text Fine,Photo Fine,Screen1,Screen2,Photo DarkImage modes

Contrast control : Text mode, Photo mode, Text/Photo mode

Master making density: 5stepsContrast control

Print density: 11 steps

Automatic control (600ml, 1000ml)Ink supply method

Drum unit exchangeColour print

Roll master automatic feed Master feeding method

Automatic ejection/ master rolling-up method Master ejection method

50sheetsUsed master capacity

320 x 240 dot matrix full- dot matrix LCD ( with contrast control) LCD

OK monitor ( LCD graphic)

Remainig master display function, remainig master ejection display function

* Specifications are subject to change without notice.

+/- 5mm

(Within operating temperature)

x Specifications

chap.1

15

Other function

Model name

DUPRINTER DP-460/440/430/340 /330/330L

Image Rotation ( 90 & 180 degree)

Colour Separation (equipped in online printer driver)

Document Size Auto Scan

Multiple Exposure ( 2, 4, 8, & 16- up.)

Book Shadow Erasure ( adjustable)

Memory Function ( 9 pattern of settings of control panel can be stored.)

Confidential Safeguard

Initial setting (when the power is turned on.)

Optimize Print (

P-roller control according to user’s input of temperature and speed.

)

Online (IEEE1284 standard bi-directional parallel interface)

NB:For USB connection, optional interface kit II is required.

Document Memory , Auto Clear

Fine Start , Pre-print

Batch Print

Auto LCD Off

Auto Power Off

Ink Circulation

Double Feed Detection

S2-ADF [100sheets (64gsm)]Option

Drum unit

Tape inserter

PC interface kit II

Key card counter 4 ( built-in type)

Cabinet( with front door)

Cabinet( open )

Power source Domestic:100V +/- 10%, 50/60Hz, 3.0A

120V :120VAC60Hz, 2.5A

230V :230VAC50Hz, 1.3 A

250W(

during plate making

),230W(

during 3rd speed printing

),60W(

during standby

)Power consumption

In use: 1374mm(W) x 738mm(D) x 1089mm(H)Dimension

Folded: 753mm(W) x 738mm(D) x 1089mm(H)

With optional ADF attached:

In use: 1374mm(W) x 738mm(D) x 1228mm(H)

Folded: 753mm(W) x 738mm(D) x 1228mm(H)

119kgWeight

10 -30 degree(C)Operating temperature

Standard : Parallel bi-directional interfaceOnline

Confirmed with IEEE1284 (compatibility mode, nibble mode)

Printer driver must be installed in computer

[Windows95/98/Me, Windows NT4.0,Windows 2000/XP Professional/Home Edition]

Printer driver must be installed in computer

[Windows95/98/Me, Windows NT4.0,Windows 2000/XP Professional/Home Edition]

I/F PCB must be installed in the main unit.

* Specifications are subject to change without notice.

A3/A4 drum unit (Attachable to DP-460/440/430 only)

Optional : USB, SCSI interface (

PC interface kit II)

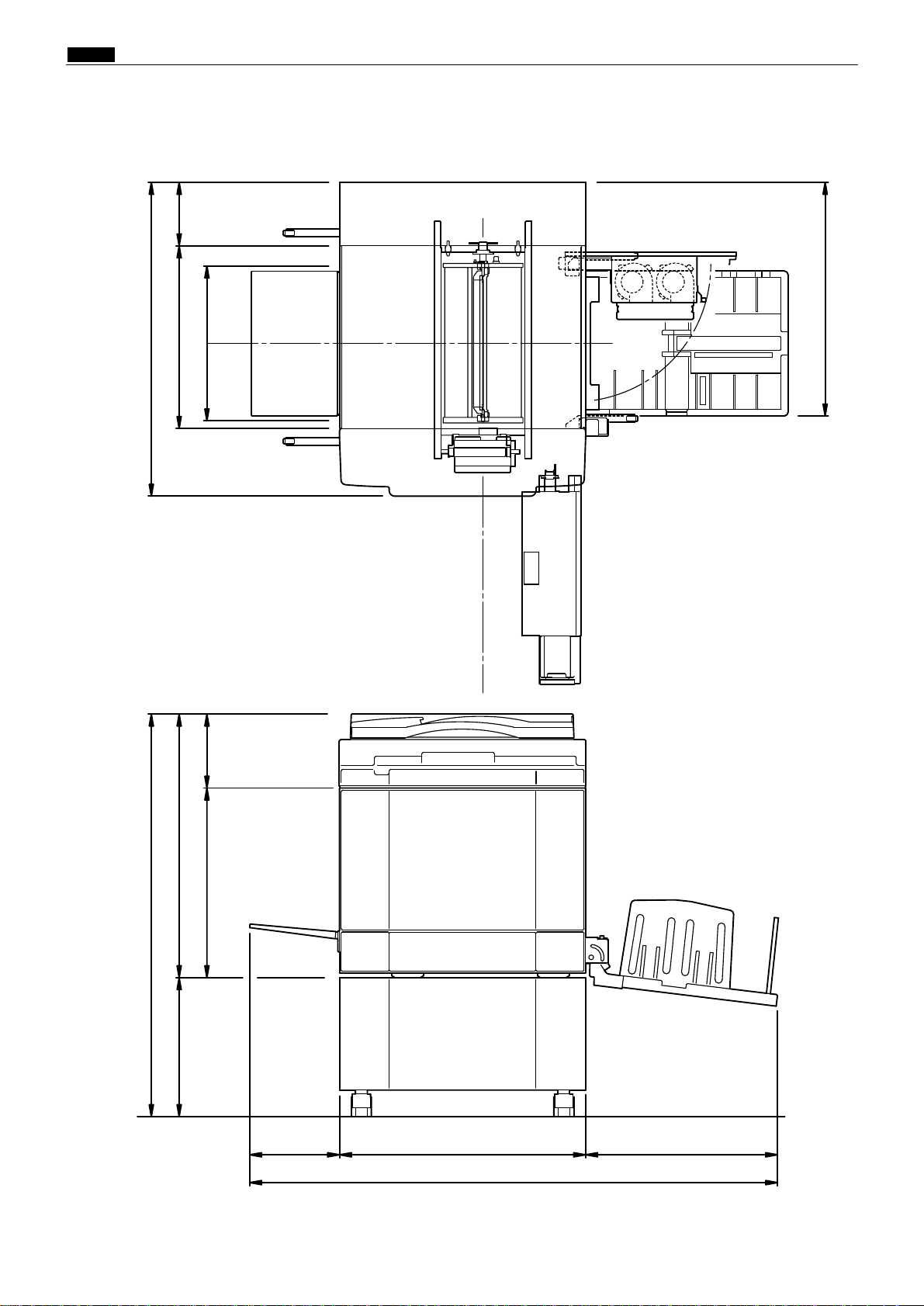

c Dimensions

chap.1

16

44000B

cDimensions

790.6

160

790.6

460

390

588.5

1013.9

664350

186.5477.5

226.5

483.5

620

1330

( mm )

c Dimensions

chap.1

17

MEMO

v System Setup

chap.1

18

vSystem Setup

1. Before Installation

The machine and its optional equipment are set up as follows:

Documents prepared on a personal computer can be printed on this machine.

The PC interface kit is required to connect this machine to a personal computer.

DDP system

NOTE :

KEYCARD COUNTER 4

: Option

TAPE CLUSTER 4

Cabinet (Printer stand)

Personal computer

S2-ADF

Duplo Direct Print System

Drum unit

A3/A4 drum (Attachable to DP-460/440/430 only)

44000C

Panel cover

Contrast adjusting dial

Scanner switch

Feed tray descend switch

(Elevator down switch)

Inlet

Feed tray

Feed pressure

adjuster lever

Supplemental

paper tray

Power switch

Document cover

Glass

Vertical size scale plate

Control panel

Caster locks

Cabinet

(Optional)

Feed pressure adjuster lever

Feeder guide F

Paper feed roller

Feeder guide R

Paper separator unit

Paper feed section

Feeder guide lock leverSeparat pressure adjuster screw

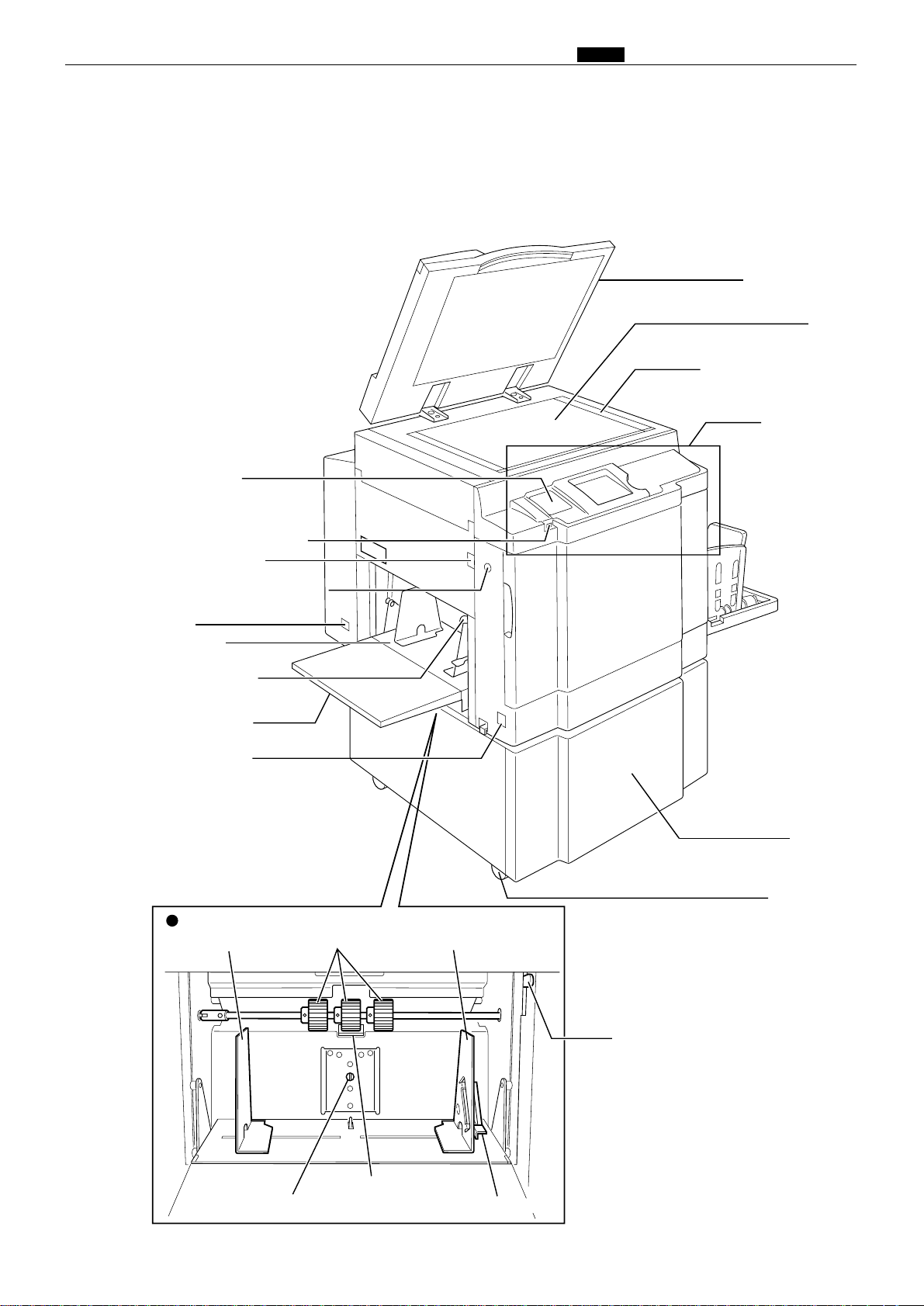

b Part Names and Their Functions

chap.1

19

440AAe

bPart Names and Their Functions

1. Machine exteriors

b Part Names and Their Functions

chap.1

20

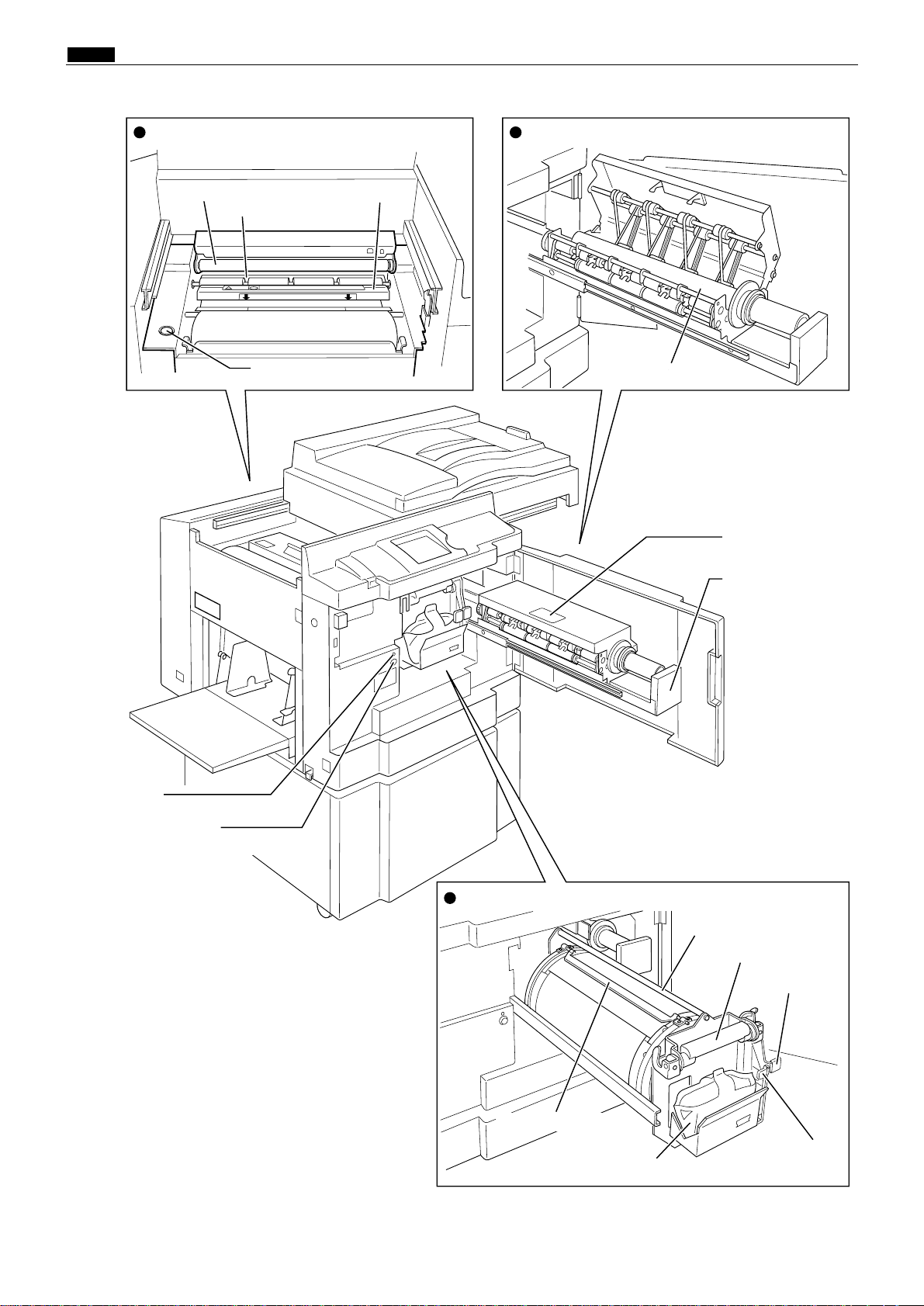

Master ejection box

lid release lever

Master ejection box

lever

LED

JOG switch 1

(Drum rotator switch 1)

Master ejection core

Master ejection sectionMaster feed section

Drum bar

Drum handle

Drum securing

lever

Ink puck holder

release lever

Ink puck

Master clump

Drum section

Master roll cut switch

Cutter

Platen roller

Thermal head

440BBe

b Part Names and Their Functions

chap.1

21

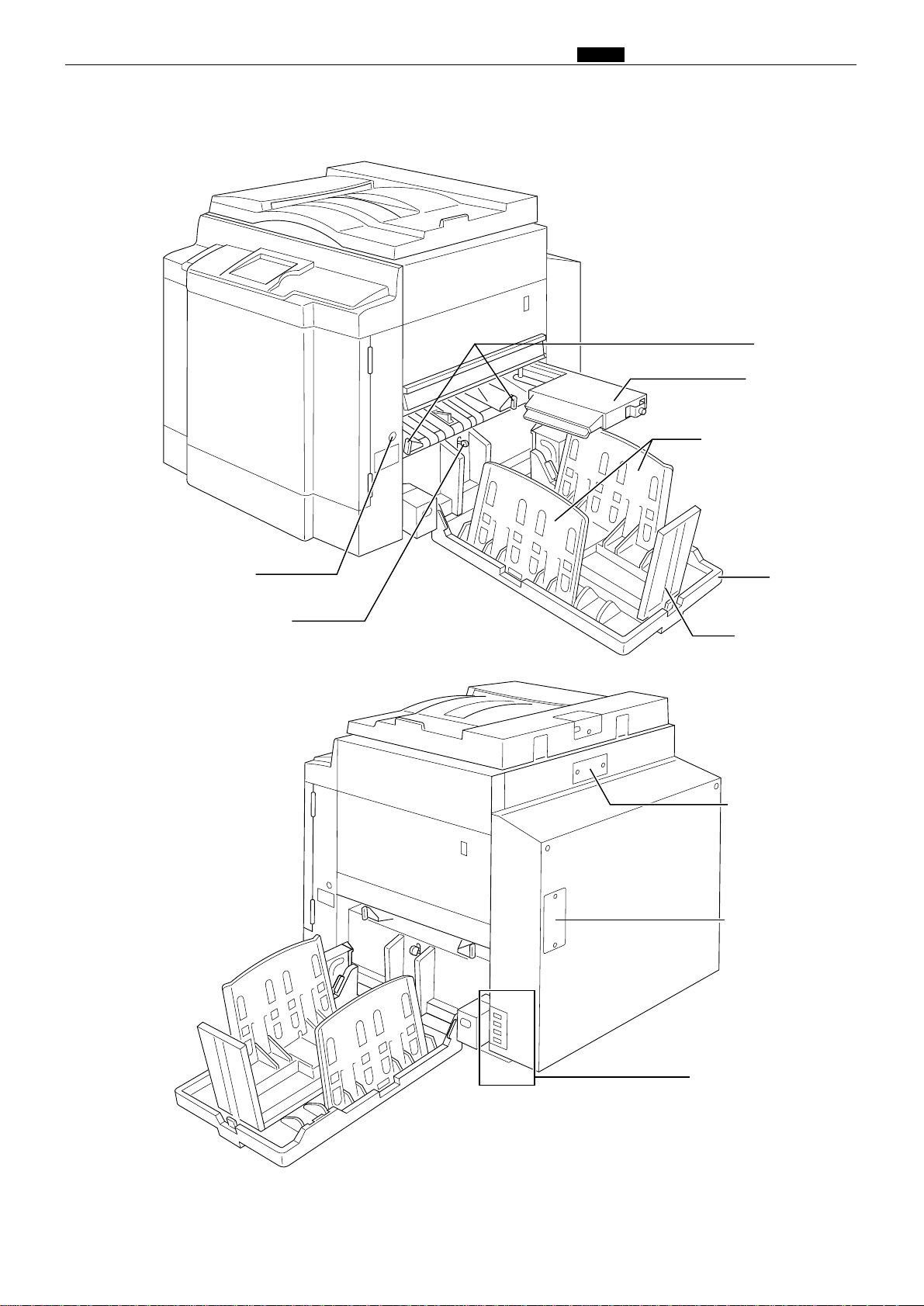

JOG switch 2

(Drum rotator switch 2)

Paper aligning lever

Jump plate

Top blow fun

Paper stacker guide

Paper stopper

S2-ADF

connector cover

(Optional)

Interface kit II

(Optional)

Connectors (Optional)

Print tray

440CCe

b Part Names and Their Functions

chap.1

22

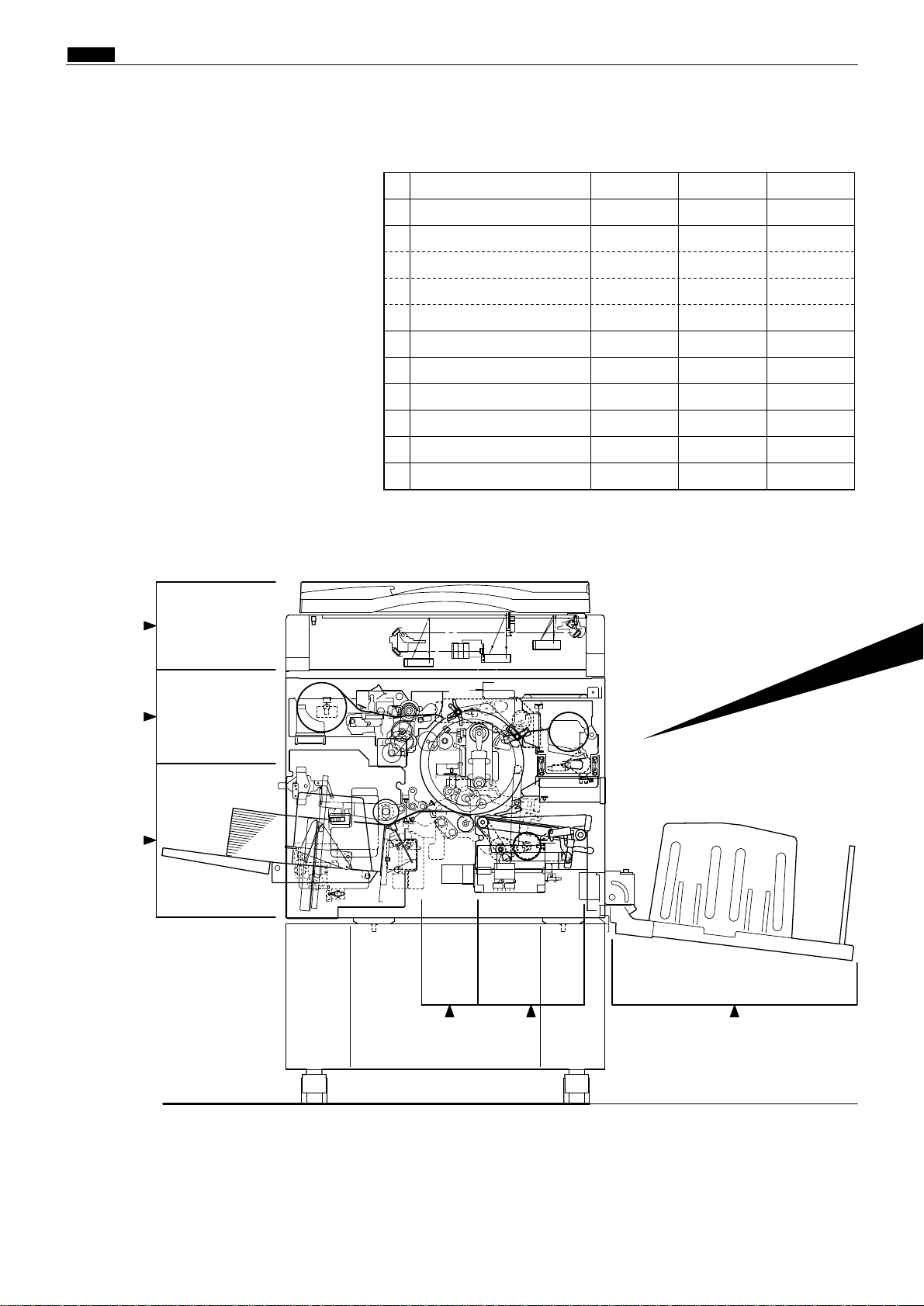

2. Sectional (structural) view of the machine

1

2

3

56 7

No.

1

2

2A

2B

2C

3

4

5

6

7

8

Section Name

Scanner section

Platemaking/Master feed/ejection section

Platemaking/Master feed section

Master ejection section

Master clamp opening/closing section

Paper feed section

Drum driving section

Press section

Paper ejection section

Print tray

Drum section

30page

40page

40page

52page

54page

66page

79page

85page

90page

4

97page

Mechanism

118page

125page

125page

129page

130page

132page

137page

4

139page

4

144page

Srandard/Adjustment

154page

156page

156page

157page

159page

164page

169page

171page

173page

4

175page

Description of

the Operation

44000Ae

4,8

2A

2B

2C

44000A1e

b Part Names and Their Functions

chap.1

23

b Part Names and Their Functions

chap.1

24

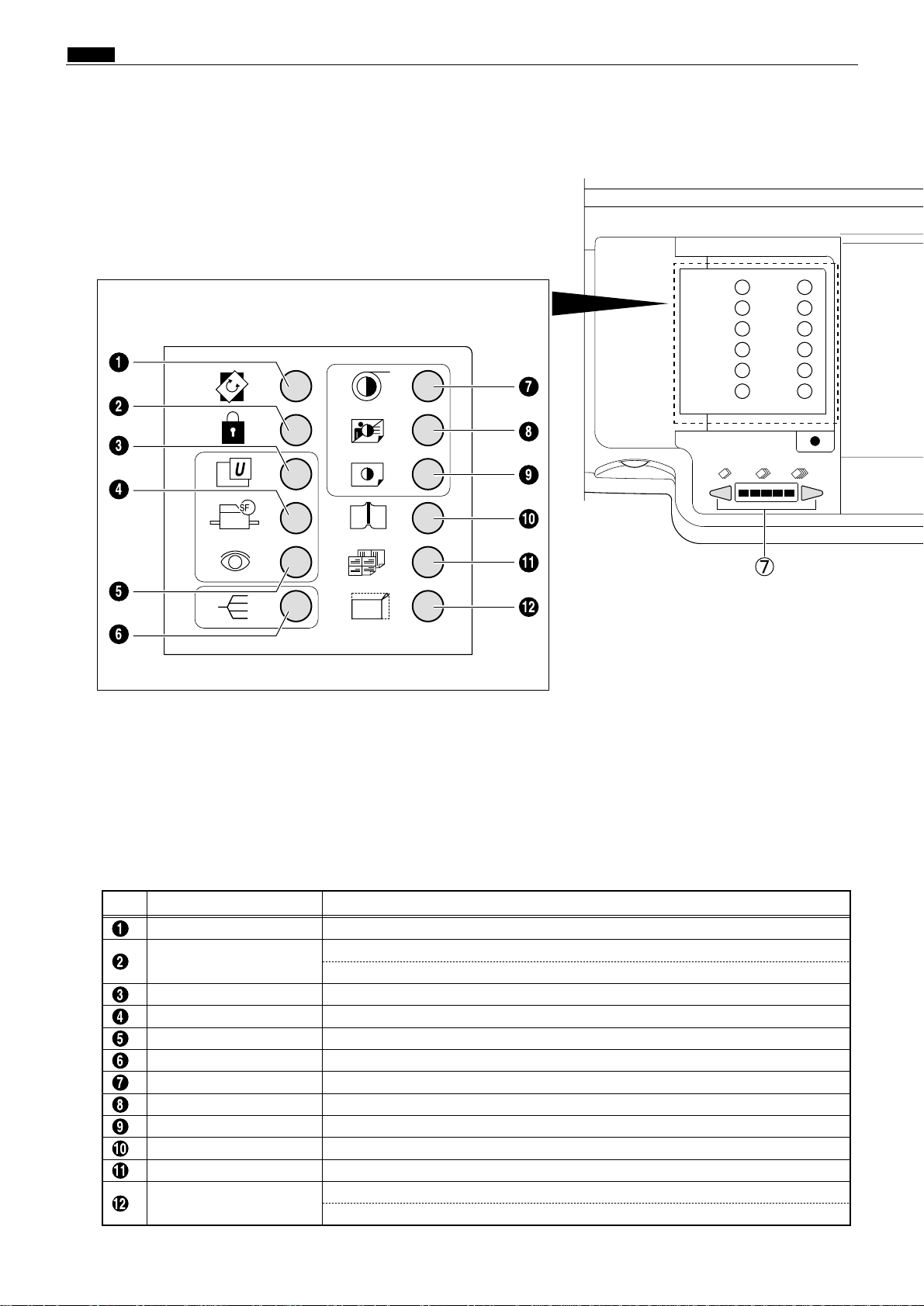

3. Control Panel

EDIT key

NameNo. Function

Switches to rotate the document image for plate.

CONFIDENTIAL SAFEGUARD key

Enables confidential safeguard function.

Prints cannot be made unless a new master is made.

USER SETTING key Switches to User setting list display.

SPECIAL FUNCTION key

Switches to Special function list display.

CURRENT SETTING key

Shows a list of current setting of the machine.

SORTER MODE key Switches to sorter mode display.

MASTER DARKNESS key

Switches to Master darkness control display.

MASTER CONTRAST key

Switches to Master contrast control display.

PRINT DARKNESS key Switches to Print Darkness control display.

BOOK SHADOW ERASURE key

Switches to Book Shadow erasure setting display.

MULTIPLE EXPOSURE key

Switches to multiple exposure setting display.

94% key

Reduces image to 94%.

94% key can be used in conjunction with preset zoom setting.

94 %

2Keys inside of the panel cover

b Part Names and Their Functions

chap.1

25

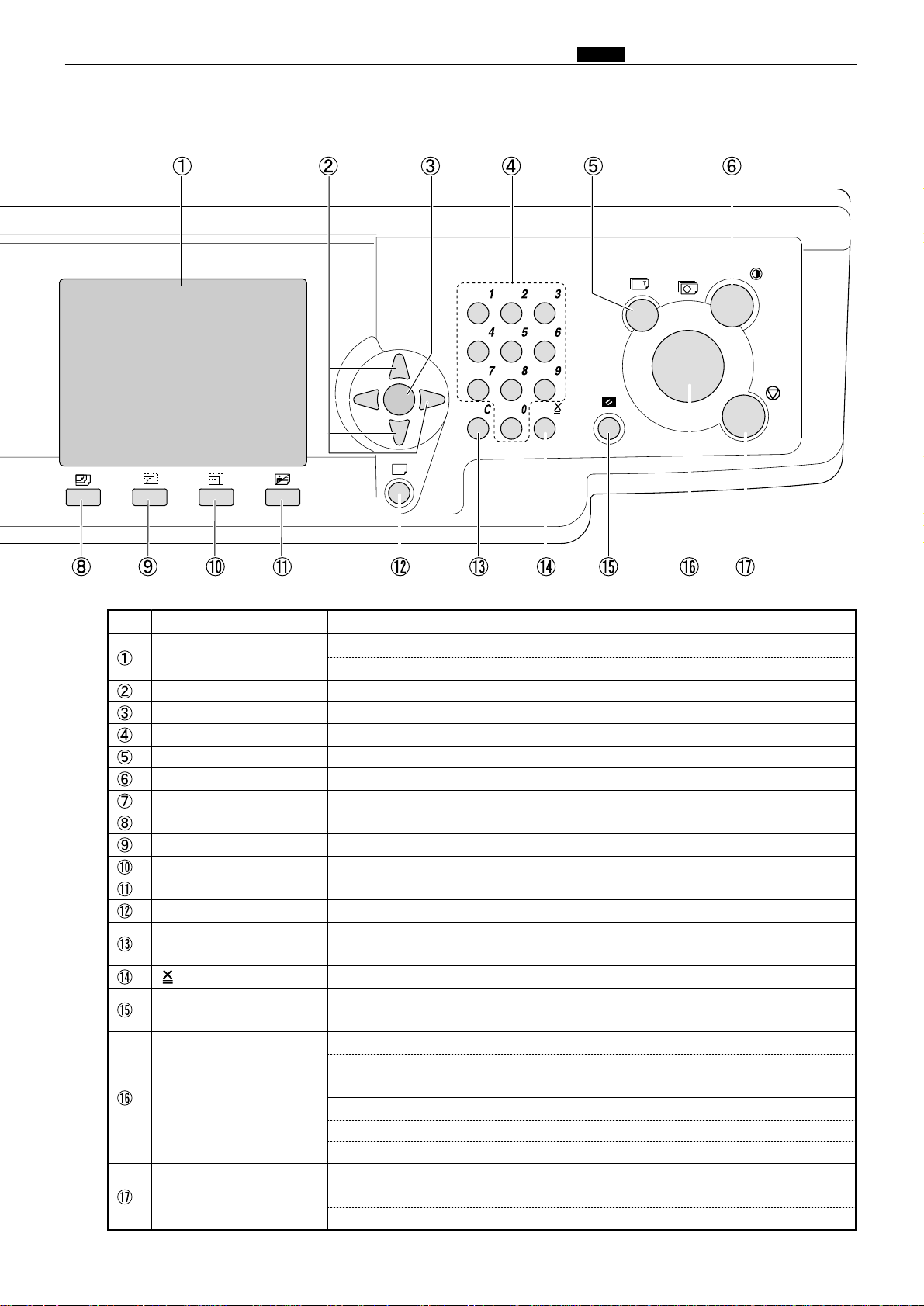

LCD

NameNo. Function

Displays current settings and status of the machine e.g. print volume,

and error messages in case of error.

Cursor keys Selects setting item and adjusts printing position.

OK key Enters specified setting.

Ten keys Enter the print volume etc.

TEST PRINT key Prints 1 copy to check the image position and density etc.

PLATE MAKING key Starts making a master.

PRINT SPEED key Switches to Print speed control display.

PAPER SIZE key Switches to Paper size selection display.

ZOOM key Switches to Zoom setting display.

PRINT POSITION key Switches to Print Position control display.

IMAGE MODE key Switches to image mode selection display.

CANCEL key

Cancels settings in Special Functions etc and returns to main display.

CLEAR key

Returns the print volume to 0.

Other settings on the control panel are not changed.

key Enters the print and group number in batch printing.

ALL CLEAR key

Return all settings on the control panel to default.

( Press and hold at least 1 second.)

PRINT key

Starts printing. This key does not start making a master.

Printing cannot start when the lamp o the key is red.

Confirm that the light is Blue before pressing.

When equipped with optional ADF unit:

When next document is set on the ADF, next master making starts automatically

after a printing is finished.

STOP key

Stops printing.

*While the machine is not working, indicates the total print quantity

and the total master quantity.

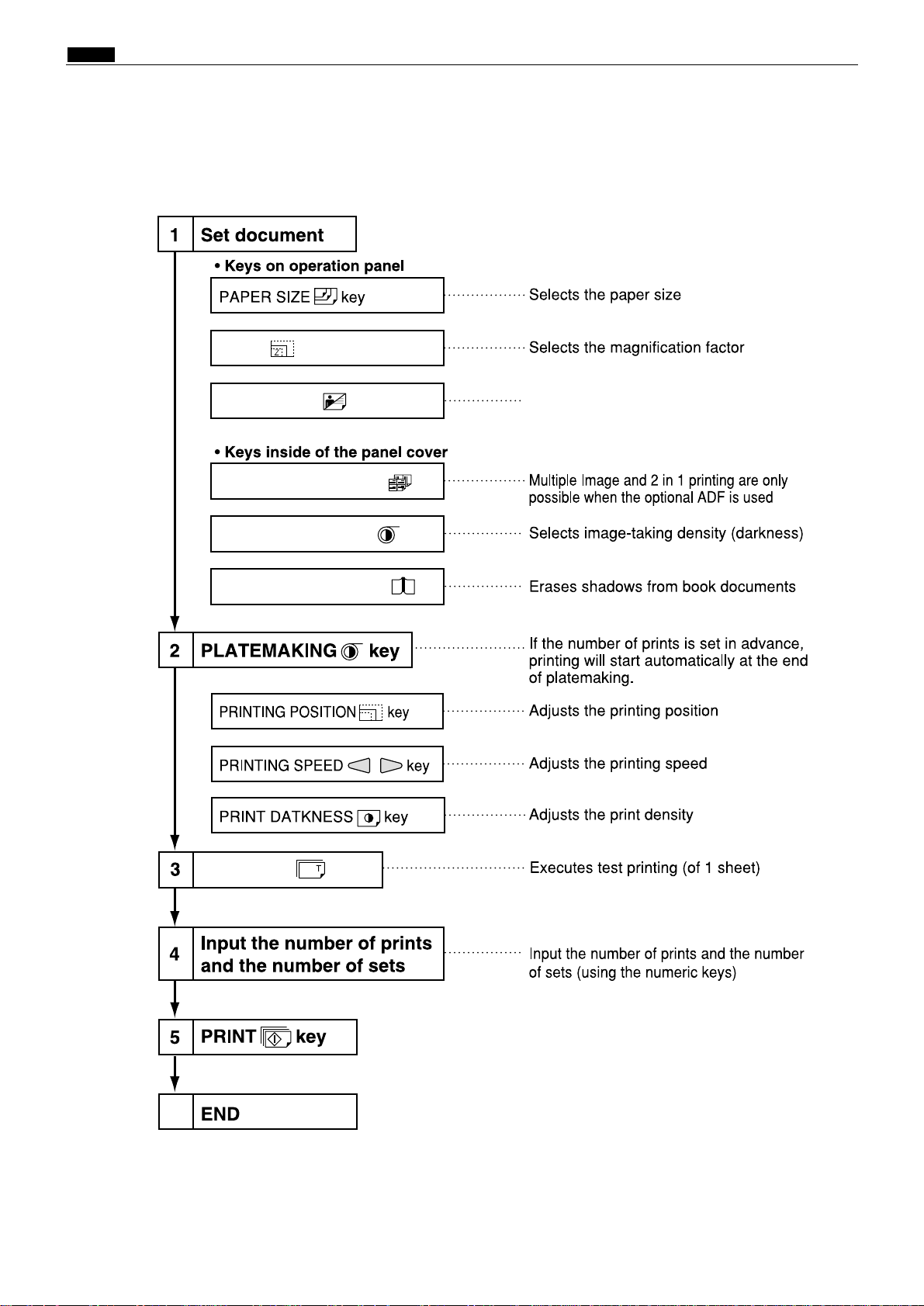

n Operation Procedures

chap.1

26

nOperation Procedures

1. Pratemaking & Printing

ZOOM key

IMAGE MODE key

MULTIPLE EXPOSURE key

MASTER DARKNESS key

TEST PRINT key

6

BOOK SHADOW ERASER key

Selects Text , Photograph ,

Text / Photograph Mode

n Operation Procedures

chap.1

27

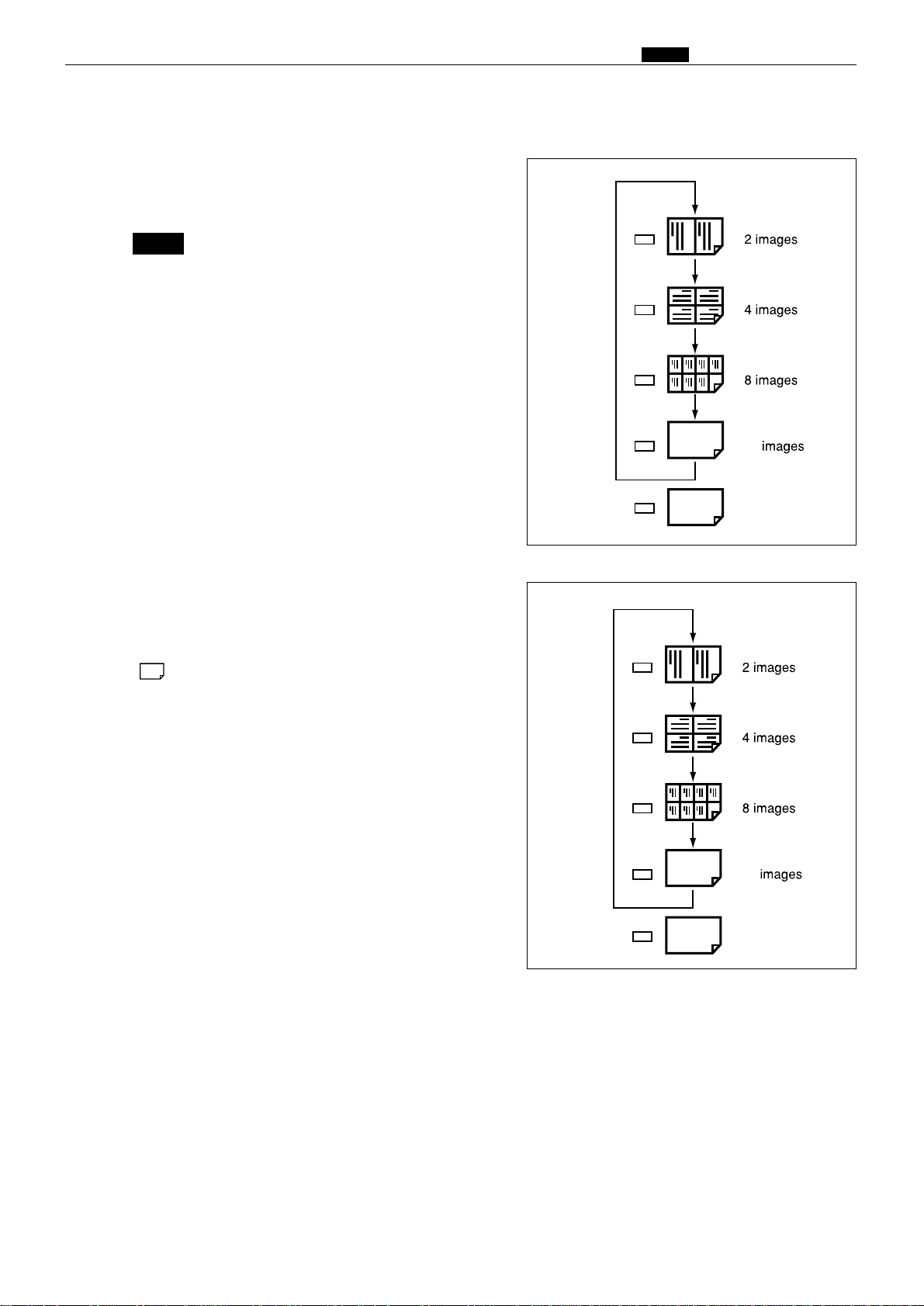

2. Multiple Image Printing / 2 IN 1 Layout Mode

In the normal state (when the ADF is not connected) the

mode is switched by pressing the multiple printing

selection key as follows.

Each press of the multiple printing selection key

makes a different multiple printing indicator

light up, in sequence.

To set the number of images, press the key until

the indicator for the desired number of images

is lit.

2in1

16

NOTE :

When the ADF is connected, the multiple printing selection

key can also be used to select the 2 in 1 Layout Mode, as

shown below.

To activate the 2 in 1 Layout Mode, press the key until the

" " icon is lit.

2in1

16

2in1

28

Chapter 2 Description of the Operation

z Scanner Section...........................................................30

1. Description...............................................................30

2. Sequence of Operation...........................................31

(1) Sequence of the Scanner Operation ..................31

(2) Sequence of the Scanner Operation (ADF).......31

(3) Operation with the Document

Cover Open / Closed ..........................................32

1. Reading the Document Size...........................32

2. Reading the Document Darkness..................32

2

Platemaking Area for the Selected Paper.....33

2

Platemaking Area for the Book Shadow

Erasing Mode..................................................33

3. Function of Parts and Circuit.............................34

(1) Home Position Sensors ......................................34

(2) Document Sensor ..............................................35

(3) Document Cover Sensor.....................................37

(4) CCD / Lamps ......................................................38

(5) Scanner Unit Open / Close Detection................39

x Platemaking / Master Feed / Ejection Section...........40

Platemaking /

Master Feed Section

........................40

1. Description...............................................................40

2. Sequence of Operation...........................................41

(1) Operation when the master set ........................41

(2) Platemaking / Master Feeding ..........................42

3. Function of Parts ....................................................43

(1) Thermal Head.....................................................43

(2) End Mark Sensor ...............................................46

1. Master Setting Error Detection......................47

2. Master End Detection......................................47

(3) Master top sensor...............................................48

(4)

Master Detect Sensor ........................................49

(5) Cutter Unit.........................................................50

(6)

Master Feed Clutch (Electromagnetic clutch)..51

Master Ejection Section ...........................................52

1. Description...............................................................52

2. Circuit.......................................................................52

3. Function of Parts ....................................................53

(1) Master Ejection Sensor......................................53

1. Master Ejection Error Detection.....................53

2.

Rotation Control of the Eject(Roll-up) Motor

.........53

Master Clamp Opening/Closing Section ...............54

1. Description...............................................................54

2.

Operation of Master Clamp Open / Close Lever

........55

(1) Structure.............................................................55

(2) Master Attach / Detach Operation....................56

(3) Clamp Opening / Closing

Lever Position (A / B / C Mode) .........................57

3. Function of Parts ....................................................58

(1) A / B / C Mode Detect Sensor.............................58

4. Returning Operation Flowchart

When the Power is Cut Off Accidentally...............59

Master Clamp Opening/Closing Section ...............60

1. Description...............................................................60

2.

Operation of Master Clamp Open / Close Lever

........61

(1) Structure.............................................................61

(2) Master Attach / Detach Operation....................62

(3) Clamp Opening / Closing

Lever Position (B / C Mode)...............................63

3. Function of Parts ....................................................64

(1) B / C Mode Detect Sensor ..................................64

4. Returning Operation Flowchart

When the Power is Cut Off Accidentally...............65

Product No.: initial lot - 020455313

Product No.: 020455314 -

29

2

c Paper Feed Section .....................................................66

1. Description...............................................................66

2. Operation .................................................................67

(1) Rotation of the Paper Feed Roller and

Timing Roller.....................................................67

(2) Paper Feed Roller Drive.....................................68

(3) Driving of the Timing Roller..............................69

(4) Escape the Guide Roller.....................................70

(5) Paper Feed Length.............................................71

3. Function of Parts.....................................................72

(1) Printing Position Adjustment Mechanism .......72

(2) Double Feed Detect Mechanism........................74

(3) Elevator Top Limit Sensor.................................75

(4) Elevator Lower Limit Switch ............................76

(5) Paper Sensor.......................................................77

(6) Elavator Encoder Sensor ..................................78

(7) Long Paper Unit Mechanism( Option ) ............78

v Drum Driving Section ..................................................79

1. Description...............................................................79

2. Function of Parts ....................................................80

(1) Drum Stop / JAM Detect Position Sensor.........80

(2) Master Attach / Detach Position Sensor...........81

(3) JOG Switch 1,2(Drum Rotation Switch 1,2).....82

(4) Control of the Main Motor.................................83

1. Rotation Speed Control by Encoder Sensor ...84

2. Selecting the Speed..........................................84

b Press Section ...............................................................85

1. Description...............................................................85

(1) Press Roller Timing & Printing Area................85

2. Function of Parts ....................................................87

(1) P-Roll Sensor......................................................87

(2) Switching the Contact Pressure........................88

1. Contact pressure position sensing..................89

n Paper Ejection Section................................................90

1. Description...............................................................90

2. Function of Parts ....................................................91

(1) Paper Stripper Finger........................................91

(2) Top Blow Fan......................................................92

(3) Paper Ejection Jam Sensor ...............................93

1. Paper JAM Detection Timing .........................94

(4) Paper Ejection Belt ............................................95

1. Paper ejection belt speed.................................95

(5) Paper aligning mechanism ................................96

m Drum Section ...............................................................97

1. Description...............................................................97

2. Circuit.......................................................................98

3. Function of Part.......................................................99

(1) Ink Detection......................................................99

1. LED Display and Output Signal on

the Ink Detection PCB Unit..........................100

2. "CHANGE INK" Display Timing..................101

(2) Ink Roller Up / Down Mechanism...................102

(3) Ink Pump..........................................................104

(4) Drum Switch.....................................................105

(5) Fine Start Mode................................................106

(6) Drum Shift Mechanism....................................107

(7) Front Cover Detection Switch .........................108

, Option .........................................................................109

(1) TAPE CLUSTER..............................................109

Loading...

Loading...