Duplo Duprinter DP-43E, Duprinter DP-43S, Duprinter DP-31S, Duprinter DP-33E, Duprinter DP-33S Service Manual

...Page 1

DUPRINTER

DP-43E/S

DP-33E/S

DP-31E/S

V er.2

SERVICE MANUAL

Be sure to read this manual carefully, so that you

repair and service this machine safely and

correctly. Do not begin work until you have

thoroughly understood the contents of this manual.

Repairing or servicing the machine with insufficient

knowledge about it could lead to unforeseen

accidents or falls in the machine's performance or

quality.

DUPLO SEIKO CORP.

Page 2

1

Introduction

The cause of most accidents is failure to adhere to basic safety rules and observe

safety instructions. It is important to prevent potential causes of accidents from

occurring. In order to do so, read this manual carefully, and be sure to understand

all the safety instructions and correct inspection and servicing procedures that it

provides before beginning repair or servicing work.

Repairing or servicing the machine with insufficient knowledge about it could

lead to unforeseen accidents.

It is not possible to anticipate and describe in a manual such as this every possi-

ble hazard that could arise in the course of repair and servicing. Therefore, besides

observing the safety instructions marked in this manual and on the machine's

labels, service personnel should be safety-conscious and take other safety precau-

tions as necessary. When performing repair or service work not covered by this man-

ual, you should obtain safety guidance from an appropriately knowledgeable person.

Copyright c 1999

DUPRO SEIKO CORPORATION

All Rights Reserved

Page 3

2

'Safety-related instructions

'Service work-related instructions

If the instructions accompanying this symbol are ignored and the

machine is operated incorrectly, death or serious injury is likely to

result.

If the instructions accompanying this symbol are ignored and the

machine is operated incorrectly, death or serious injury, or else material

damage, is likely to result.

WARNING:

COUTION:

Examples of pictorial symbols

A " " symbol tells you that a certain action is forbidden. Precisely what

is forbidden is indicated by a picture inside the symbol (in the example

here, the picture means that disassembly is forbidden), or in writing at the

side of the symbol.

A " " symbol means that a certain action is forbidden and/or that a specific instruction must be followed. The specific instruction is indicated by a

picture inside the symbol (in the example here, the instruction is "Remove

the power plug from the socket").

IMPORTANT:

NOTE:

Draws attention to important information. If this information is ignored and

the machine is operated or serviced incorrectly, the machine`s performance could drop, or it could break down.

Draws attention to information that is useful for operation or maintenance

of the machine, and to information about its performance, etc.

D Using the service manual

• This manual contains the following information: structure and function of major parts, disas-

sembly and reassembly procedures, specifications, and procedures for adjustment, mainte-

nance, inspection and corrective action. This information is current as of May 1999, and applies

basically to the model DP-43E/S,33E/S,31E/S Duprinter.

From time to time, parts are changed to improve quality, performance or safety. Note therefore

that in some cases, certain parts or machine structure aspects described in the text or illustra-

tions of this manual may not be precisely the same as the product being serviced.

• Safety instructions marked with a " " (WARNINGS and CAUTIONS) are very important for

safety and must be observed.

Page 4

3

Safety instructions

Safety instructions

Safety instructions

1. Cautions regarding the installation location

Installation environment

• Avoid installing the machine in places exposed to direct sunlight.

• Sunlight will cause the temperature in the machine's interior to rise, possibly leading to mal-

function of the control system.

• Sunlight could cause misoperation of the sensors.

• The heat of direct sunlight could cause deformation of the machine's plastic parts.

* Also avoid installation near to a ground glass window; light and heat penetrate such windows

although they are opaque.

• Avoid installing the machine in places subject to high or low temperature or humidity.

• High or low temperature or humidity could cause the machine to operate abnormally.

Suitable temperature and humidity ranges are:

Ambient temperature: 10y430y

Ambient humidity: 40%470%

Optimum temperature and humidity: 20y, 65%

• If the machine is installed near to faucets, water heaters or humidifiers, or in cool (sunless)

parts of a building or in the vicinity of water sources, the paper could absorb moisture and curl,

leading to misfeeds or poor image quality.

• Avoid installing the machine in places with open flames, or where reflected heat or other hot air

currents (from stoves, etc), or cold air currents from coolers, etc will strike it directly.

• Avoid installing the machine in poorly ventilated places.

• Avoid installing the machine in dusty places.

• The machine should not be tilting when it is used.

• Install the machine so that it is level.

(The machine should be level to within 5mm in the front-rear direction, and 5mm in the lateral

direction.)

•Do not install the machine on shaky, sloping or otherwise unstable surfaces.

• The machine could fall over on such surfaces, or fall off them, causing injury.

Page 5

4

Safety instructions

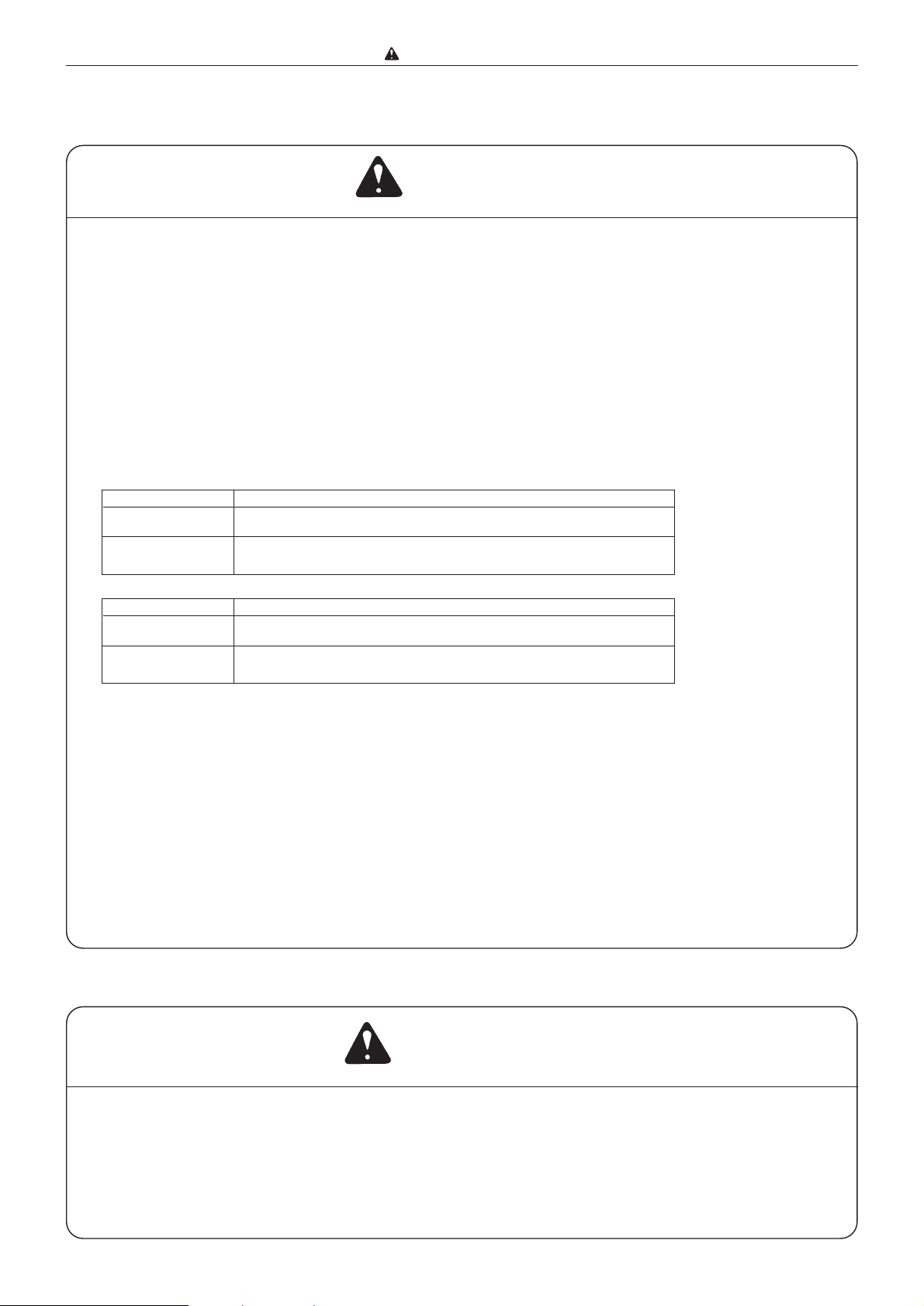

• The machine's power supply voltage and power consumption depend on the model. Details of this

are given in the tables below. The power supply voltage and power consumption for the machine

are given in the table below. The machine's power supply voltage is indicated on the identification

plate located on the machine's left side; the machine must be connected to a power supply of the

voltage indicated.

a Otherwise, fire or electric shock could result.

If the power supply voltage is unstable or if the power supply has insufficient capacity, the

machine may not operate normally.

Make sure that the power supply has sufficient capacity for the system as a whole, including

optional equipment.

Warning

Connect to outlet of 120V AC, 60Hz, at least 15A

With no load*

At full load

Power consumption

No more than 130V AC

At least 110V AC

During platemaking : 230W

During printing at speed 3 (printing speed) :110W

On standby : 30W

Power supply voltage

}

Use power supply meeting these requirements

Connect to outlet of 230V AC, 50Hz, at least 8A

With no load*

At full load

Power consumption

No more than 250V AC

At least 210V AC

During platemaking : 230W

During printing at speed 5 (printing speed) :300W

On standby : 30W

Power supply voltage

}

Use power supply meeting these requirements

* 120V AC model

* 230V AC model

* "With no load" - when the machine is on standby.

* "At full load" - when the machine is running at maximum power consumption.

• Use only the power cord that is provided among the accessories.

Insert the power cord plug firmly into the socket, so that proper electrical contact is effected.

• Install the machine close to its power supply. The outlet used should be exclusively for the

machine, and have no other equipment connected to it.

If an extension cord is necessary, it should have a ground terminal, and be of the following ratings:

* For a 120V AC model: 130V, at least 15A, length not exceeding 5m.

* For a 230V AC model: 250V, at least 8A, length not exceeding 5m.

• Never tread on the power cord or pinch it between other objects, or accidents could result.

2. Cautions for installation work

• Install the machine in accordance with the installation procedure appended to this manual.

• Lock the casters after the machine is installed.

a Otherwise, the machine could move or fall over, causing injury.

• To move the machine, push it by its mounting base.

a Pushing the printing (upper) part of the machine could make it fall over.

CAUTION

Page 6

5

Safety instructions

' Precautions for safe servicing

• Always remove the power cord plug from the outlet before starting work.

a Otherwise, you could get a shock or your hands/fingers could be injured.

• However, the plug must be left connected to the outlet when performing function checks (of indi-

vidual motors, a given series of operations, or electrical circuits). When motors are operated alone

in function checks, interlocks are deactivated, so be aware of the conditions and positions of relat-

ed equipment, and take great care not to put your hands or fingers into moving parts.

• The cutter unit contains hazardous sharp blades. Exercise great care when inspecting the cutter

unit or replacing it or its parts.

a Otherwise, your hands/fingers could be injured.

• Do not touch the drum or rollers after turning on the jog switch.

• Do not put your hands or fingers inside the machine while the drum is rotating.

a Otherwise, your hands/fingers could get caught and crushed between the drum and rollers.

' Working clothes

• Wear clothing than enables you to work safely.

Work clothing (overalls, etc) should be close-fitting.

Warning

' Tools

• Use tools that are appropriate for the work.

CAUTION

3. Cautions for maintenance, inspection and servicing

Page 7

6

Safety instructions

DLocations of warning stickers

The locations of the machine's warning stickers are shown below. To ensure safe work, read the

stickers and heed their instructions. Keep the stickers clean at all times. If they become damaged

or peel off, replace them with new ones.

No. Parts No. Name Q'ty

q

J3-T3200 Warning Sticker 1 1

w

L5-T3020 Warning Sticker 2 1

J3/-T3200

q

Warning

¡Do not remove this cover. The

inside of the printer contains

movable cutting instruments,

contact with which could result

in injury.

L5-T3020

2

Do NOT touch the drum or rollers

when you operate the jog switch.

Do NOT put hands Inside

machine while it is operatung.

Hands could get caught up

or crushed.

WARNING

Page 8

7

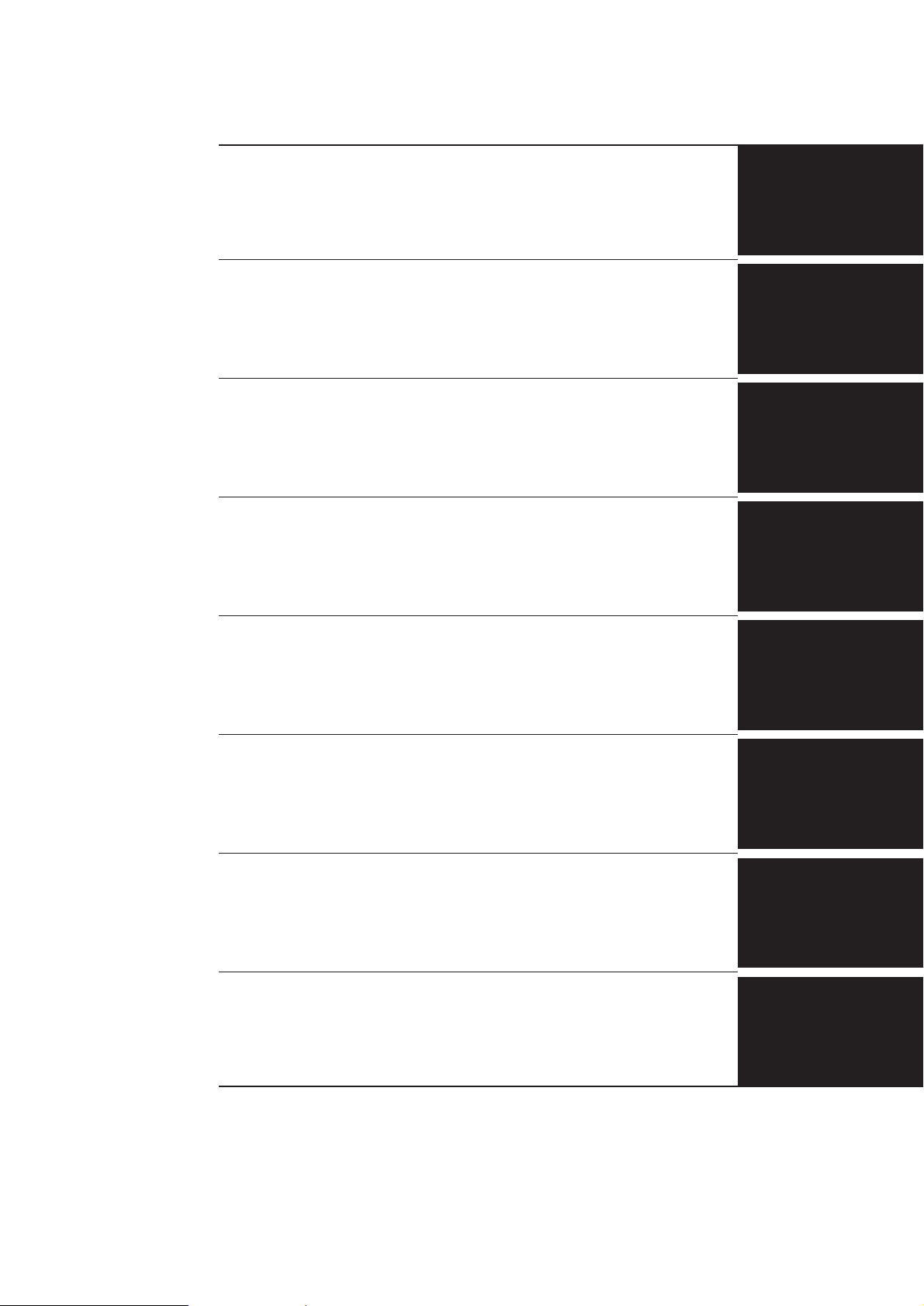

Chapter 8

Chapter 7

Chapter 6

Chapter 5

Chapter 4

Chapter 3

Chapter 2

Chapter 1

HELP Mode

Others

Countermeasures

Installation

Standard / Adjustment

Mechanism

Description of the Operation

Introduction

Page 9

8

Table of Contents

Chapter 1

z Features ................................................................................10

x Specifications ........................................................................14

c Dimensions ...........................................................................16

v Mechanism............................................................................17

b Master ...................................................................................18

n Ink .........................................................................................19

m System Setup ........................................................................20

, Part Names and Their Functions ........................................21

. Operation Procedures ..........................................................34

⁄0 Error Messages and Corrective Action ...............................38

⁄1 Option ...................................................................................60

Chapter 2

z

Scanner Section ..........................................................86

x

Platemaking/Master Feed/Ejection Section..............94

c

Paper Feed Section...................................................115

v

Drum Driving Section ..............................................129

b

Press Section.............................................................135

n

Paper Ejection Section .............................................142

m

Drum Section............................................................148

,

Option .......................................................................160

Chapter 3

z

Exterior .....................................................................164

x

Scanner Section ........................................................172

c

Platemaking/Master Feed/Ejection Section............180

v

Paper Feed Section...................................................188

b

Drum Driving Section ..............................................192

n

Paper Ejection Section .............................................194

m

Drum Section............................................................202

Chapter 4

z

Scanner Section ........................................................212

x

Platemaking/Master Feed/Ejection Section............214

c

Paper Feed Section...................................................222

v

Drum Driving Section ..............................................229

b

Press Section.............................................................231

n

Paper Ejection Section .............................................233

m

Drum Section............................................................235

,

Electrical System......................................................239

.

Option .......................................................................249

Chapter 5

z

DUPRINTER installation instructions...................252

x

Drum unit installation instructions........................262

c

KEYCARD COUNTER 3 installation procedure....266

v

A4 DRUM installation procedure............................270

Chapter 6

z

Troubleshooting Guide.............................................272

x

Error Display............................................................283

Chapter 7

Chapter 8

z

Electrical Parts Layout and Their Functions .........366

x

Overall Timing Chart...............................................375

c

Overall Wiring Layout

E type models...........................................................377

S type models ...........................................................378

z

HELP Mode List.......................................................286

x

Overview ...................................................................290

c HELP Mode Functions and Operation Procedures

........291

(1)Basic Procedure for Accessing HELP Modes ......291

(2)Guide to the HELP Mode Descriptions ...............291

• HELP Mode Descriptions.....................................292

Introduction.................................................................................1

Using the service manual ...........................................................2

Safety instructions ................................................................3

1.Cautions regarding the installation location.........................3

2.Cautions for installation work................................................4

3.Cautions for maintenance, inspection and servicing ............5

• Locations of warning stickers.................................................6

Countermeasures

Installation

Standards / Adjustment

HELP Mode

Others

Mechanism

Description of the Operation

Introduction

Page 10

9

Chapter 1 Introduction

z Features ........................................................................10

x Specifications................................................................14

c Dimensions ...................................................................16

v Mechanism....................................................................17

b Master ...........................................................................18

n Ink .................................................................................19

m System Setup................................................................20

, Part Names and Their Functions................................21

1. Machine exteriors ....................................................21

2. Sectional (structural) view of the machine.............24

3. Control Panel

E type models...........................................................26

S type models ...........................................................30

. Operation Procedures...................................................34

1. Printing

E type models...........................................................34

S type models ...........................................................35

2. Multiple Image Printing / 2 IN 1 Layout Mode

E type models...........................................................36

S type models ...........................................................37

⁄0 Error Messages and Corrective Action........................38

1. Error messages.........................................................38

2. Corrective action ......................................................41

(1) Replacing the Ink Pack ......................................41

(2) Replacing the Master Roll .................................43

(3) Replacing the Master Ejection Core..................46

(4) Supplying Paper ................................................48

(5) Replacing the Drum Unit ..................................51

(6) Paper Jam (Feeder side) ....................................53

(7) Paper Jam (Ejection side) ..................................54

(8) Master is Not Ejected.........................................57

(9) Master Set Incorrectly .......................................59

⁄1 Option............................................................................60

1. DUPRINTER Opion.................................................60

(1) TAPE CLUSTER 3 .............................................60

(2) KEYCARD COUNTER 3 ...................................61

(3) A4 DRUM (for DP-43E/S) ..................................80

1

Page 11

Chap.1 z Features

zFeatures

1. Size A3 printing

The DP-43E/S has size A3 (290X410mm)

printing area.

The DP-33E/S and DP-31E/S has size B4

(250X350mm) printing area.

2. High-speed platemaking

With the DP-43E/S, it takes 17 seconds

*2

print the first sheet of paper

(size A3).

With the DP-33E/S and DP-31E/S, it takes

*1

15 seconds

*2

paper

*1: Time required to print the first sheet of paper

after the platemaking key is pressed.

*2: When the Fine Start mode is not activated.

to print the first sheet of

(size A4).

3. High print quality

A new, originally-developed superfine thermal head gives beautifully accurate reproductions of fine print and halftone photographs.

Resolution is 400dpi in the DP-43E/S,and

DP-33E/S.

*1

to

Resolution is 300dpi in the DP-31E/S.

4. Simple operation

In the E series, a touch panel provides simple

operation.

In the S series, operation is simplified by concealing occasionally-used keys under a panel,

leaving just the basic function keys permanently accessible.

5. Fine Start Mode

This mode automatically sets optimum values for the following start conditions: timing of ink roller actuation during platemaking, number of no-paper rotations with the

ink roller actuated. These optimum settings

*3

are based on the room temperature

, the

length of time the printer was out of use, and

the number of prints last time it was used.

They ensure clear printing right from the

first sheet.

*3: Room temperature of 10ºC or below can cause

insufficient ink supply, even in Fine Start

Mode.

6. High-performance lamp

A long-life, high-brightness xenon arc lamp

is used to illuminate the documents. Since

the lamp's intensity is not affected by tem-

*4

perature variation

temperatures is greatly enhanced

*4: The lamp is filled with xenon gas, which means

that it does not require heat to vaporize mercury, as a fluorescent lamp does, and therefore its intensity does not vary with temperature.

*5: Increased viscosity of the ink at low tempera-

tures results in fainter printing than at normal temperatures.

, printing quality at low

*5

.

10

Page 12

Chap.1 z Features

7. Full range of necessary functions

qDocuments are easily enlarged or re-

duced.

In addition to same-size printing, there are

three automatic settings for both enlargement and reduction. The margin function

(94% reduction) can be used with any setting.

• Size A/B models

• Free ratio setting (50-499%)

• Auto zoom settings

(70, 81, 86, 115, 122, 141%)

• Same-size (100%) printing

141% [A4/A3, B5/B4]

Enlargement

122% [A4/B4]

115% [B4/A3]

*6

86% [A3/B4]

Reduction

81% [B4/A4]

70% [A3/A4, B4/B5]

• Inch size model

• Free zoom range 50 to 499%

zoom (64, 74, 77, 121, 129, 141%)

• Same-size (100%)

141%

Enlargement

129% [LTR/LDG]

121% [LGL/LDG]

*6

*6

Reduction

77% [LGL/LTR]

74% [LDG/LGL]

67% [LDG/LTR]

*6: Maximum printing area of DP-33E/S and DP-

31E/S is B4(250X350mm).

wEditing functions

Editing functions are standard features of

E series printers (DP-43E,DP-33E,DP31E).

eMemory functions

The printers have memory functions that

can memorize frequently-used settings.

ySelf-diagnosis

The machines have self-diagnostic functions. Messages for self-diagnosed errors,

as well as consumable part replacement

prompt messages, appear on an LCD

panel.

uDocument modes

To the pre-existing Text and Photograph

Modes have been added the "Text-Photograph", "Text-Fine Lettering", "Photograph-Fine Lettering", "Screen 1 & 2" and

"Photo Dark" Modes, accommodating

printing of a wider variety of documents.

*6

Text-Photograph Mode:

Intermediate between the Text and Photograph Modes, this Mode is for documents

with mixed photographs and text.

Text-Fine Lettering Mode:

Emphasizes letter outlines more than the

regular Text Mode, providing better reproducibility of fine lettering.

Photograph-Fine Lettering Mode:

Emphasizes shape outlines more than the

regular Photograph Mode, providing better reproducibility of fine lines.

Screen Modes 1 & 2:

Add dots to images produced by the Photograph Mode, to bring out the contrast.

Mode 1 uses larger dots than Mode 2.

Photo Dark Mode:

Increases the number of gradations in

bright halftone portions of images produced by the Photograph Mode, to prevent

over-bright reproduction of bright documents.

iError message display

An LCD panel displays error messages and

messages prompting replenishment of

consumables.

DP-43E,33E,31E

3 types

DP-43S,33S,31S

2 types

rMultiple image printing

Multiple images (2, 4 or 8) of a single document can be printed on a single sheet of

paper.

tBook shadow erasure

Shadows in the middle or at the edges of

book documents can be erased.

11

Page 13

Chap.1 z Features

oSpecial functions

The following functions/modes, which formerly could only be changed/used by service personnel, have been made into user

functions/modes.

• Auto Clear

• Preprint

• Print Number Input Mode

• Change Initial Setting

• Fine Start

!0Adjusting the Printing Position

(vertical /horizontal)

In addition to vertical direction

adjustment,there is now a function for

adjusting the printing position in the horizontal direction as well.

!12 in 1 Layout Mode

In conjunction with an ADF (optional), this

mode makes possible continuous printing

of 2 documents onto single sheets of paper.

8. Options

qADF

Use of the ADF permits continuous platemaking and printing of 30 documents (64g/

2

paper). The ADF's tray fits completely

m

inside the ADF, so as not to interfere with

loading/removal of printing paper.

wTape cluster

This permits sectionized printing, by inserting tape automatically during printing.

eKey card counter

This magnetic card can control the numbers of prints and platemakings by up to

200 sections.

NOTE: Without this optional counter, the

number of sections controlled is 30 (standard).

rDrums

Replacing the drum with optional drums

permits printing with different colors.

!2Key card counter

Raises the number of sections controlled

*7

to up to 200

. Versions with internalized

control panel also available.

*7: Standard: 30 sections. Using the counter (op-

tional) raises the number to 200 sections.

tSorter

The newly-developed 25-bin tandem sorter

can sort up to 50 sets of sheets. A stapler

can be installed to staple the sets after

sorting.

yOn-line functions

*8

These enable data processed on a personal

computer or word processor to be directly

input and used for platemaking/printing.

*8: These functions require an IPC I/F kit and PC

interface.

12

Page 14

MEMO

Chap.1 z Features

13

Page 15

Chap.1 x Specifications

xSpecifications

• Specifications

Product name/model No.

Model Floor model

Platemaking method Thermal digital platemaking

Platemaking interval

Resolution 15.7 dots/mm (400 dpi)

Scanning method Fixed document

Printing method Stencil printing

Document type Sheet, Book (less than 10 kg)

Document size

Printing area

Feeding capacity 1000 sheets (64 g/m

Stacking capacity 1000 sheets (64 g/m2, duodecimo 55kg,high-grade paper)

Paper size

Paper thickness 53 g/m

Printing speed 120 pages par minute. (45 to 120 pages par minute, 5 step adjustment)

Print enlargement/reduction

A, B size model Same size 100%

Inch size model Same size 100%

Printing position adjustment

Image modes Text mode / Photograph mode / Text and photograph mode /

Contrast control Platemaking density 5 step adjustment

Ink supply method Complete automatic control (600 cc, 1000 cc)

Color printing Drum unit exchange method

Master feeder Roll master automatic feed

Plate ejection Complete automatic ejection plate rolling method

Power source

120VAC model 120VAC 60Hz, 5A

230VAC model 230VAC 50Hz, 2.5A

Power consumption

Size Operational Idle

Weight

Operating temperature

※ Specifications are subject to change without notice.

DP-43E / DP-43S DP- 33E / DP-33S

17 seconds (A3, same size)

Max. 297 mm×432 mm

Max. 290 mm×410 mm

2

, duodecimo 55kg,high-grade paper)

Max. 297 mm×432 mm (A3: 11” × 17”)

Min. 100 mm×150 mm (postcard)

2

to 210 g/m2(45 kg to 180 kg)

Fixed zoom ratios 70, 81, 86, 115, 122, 141%

Print with border 94%

Free zoom range 50 to 499%

Auto zoom 70, 81, 86, 115, 122, 141%

Fixed zoom ratios 64, 74, 77, 121, 129, 141%

Print with border 94%

Free zoom range 50 to 499%

Auto zoom 67, 74, 77, 121, 129, 141%

Vertical ±15 mm

Horizontal ±10 mm

Finelettering / Screen / Photo dark, Multiple printing (2, 4, 8 up)

Book shadow eraser

Printing density 3 step adjustment

230W(during platemaking), 110W(during3-speed printing),

30W(during standby)

1288mm(W)×670mm(D)×652mm(H)

675mm(W)×670mm(D)×652mm(H)

(cabinet height 350mm)

Machine 103kg

Base 12kg

10Y430Y

15 seconds (A4, same size)

Max. 250 mm×350 mm

1288

mm

(W)×655mm(D)×652mm(H)

675

mm

(W)×655mm(D)×652mm(H)

(cabinet height 350

Machine 96kg

Base 12kg

DP-31E / DP-31S

11.8 dots/mm (300 dpi)

mm

)

14

Page 16

• Specifications

Display panel

DP-43E/DP-33E/DP-31E DP-43S/DP-33S/DP-31S

320×240 dots, full dot matrix

LCD with Touch Panel (pressure

sensitive) input capabilities.

240×64 dots, full dot matrix LCD

Chap.1 x Specifications

Input

Strength

LCD

Recommended

viewing angle

range

Editing Functions

Other standard functions

※ Specifications are subject to change without notice.

Trimming

Makeup

Photograph Mode, Reversing,

Masking, Outline Type, Halftones,

Background Designs, Reversing

Background Designs, Mask Area

Exchange, Addtional Makeup

• OK monitor (graphical display,

Kanji characters/illustration

display)

• Memory ( 3 channels)

• Confidential Safeguard Function

• Entry of different number of

prints or sets

• Special function

• Fine start mode

By fingertip or special pen

Able to withstand maximum 29.4N (3kgf), a pplied

perpendicularly to the tablet surface for 1 minute

Recommended operating temperature: 0Y4 40Y

Vertical: up to 30Y above/below perpendicular

Horizontal: up to 30Y to either side of perpendicular

• OK monitor (graphical display,

Kanji characters/illustration

display)

• Memory ( 2 channels)

• Confidential Safeguard Function

• Entry of different number of

prints or sets

• Special function

• Fine start mode

• Option specifications

DUPRINTER DP-43E/DP-33E/DP-31E/DP-43S/DP-33S/DP-31S

Options

PC interface kit

※ Specifications are subject to change without notice.

ADF (Automatic Document Feeder)

Drum unit ,A4 Drum(DP-43E/S)

Keycard counter (built-in type)

Tape cluster

Sorter

PC interface kit

The printer driver must be installed in the PC.

• Compatible with Windows95 / Windows98

• Macintosh compatibility

(System 7.1 or later, MAC OS or later)

I/F board in main unit (on-line set III board unit)

SCSI cable (4 m)

15

Page 17

Chap.1 c Dimensions

cDimensions

103

DP-43E/S

DP-33E/S,31E/S

85

490(DP-43E/S)

675(DP-43E/S)

478(DP-33E/S,31E/S)

653(DP-33E/S,31E/S)

437

135

533(DP-43E/S)

513(DP-33E/S,31E/S)

1002

962

350

215 620 453

1288

(mm)

16

Page 18

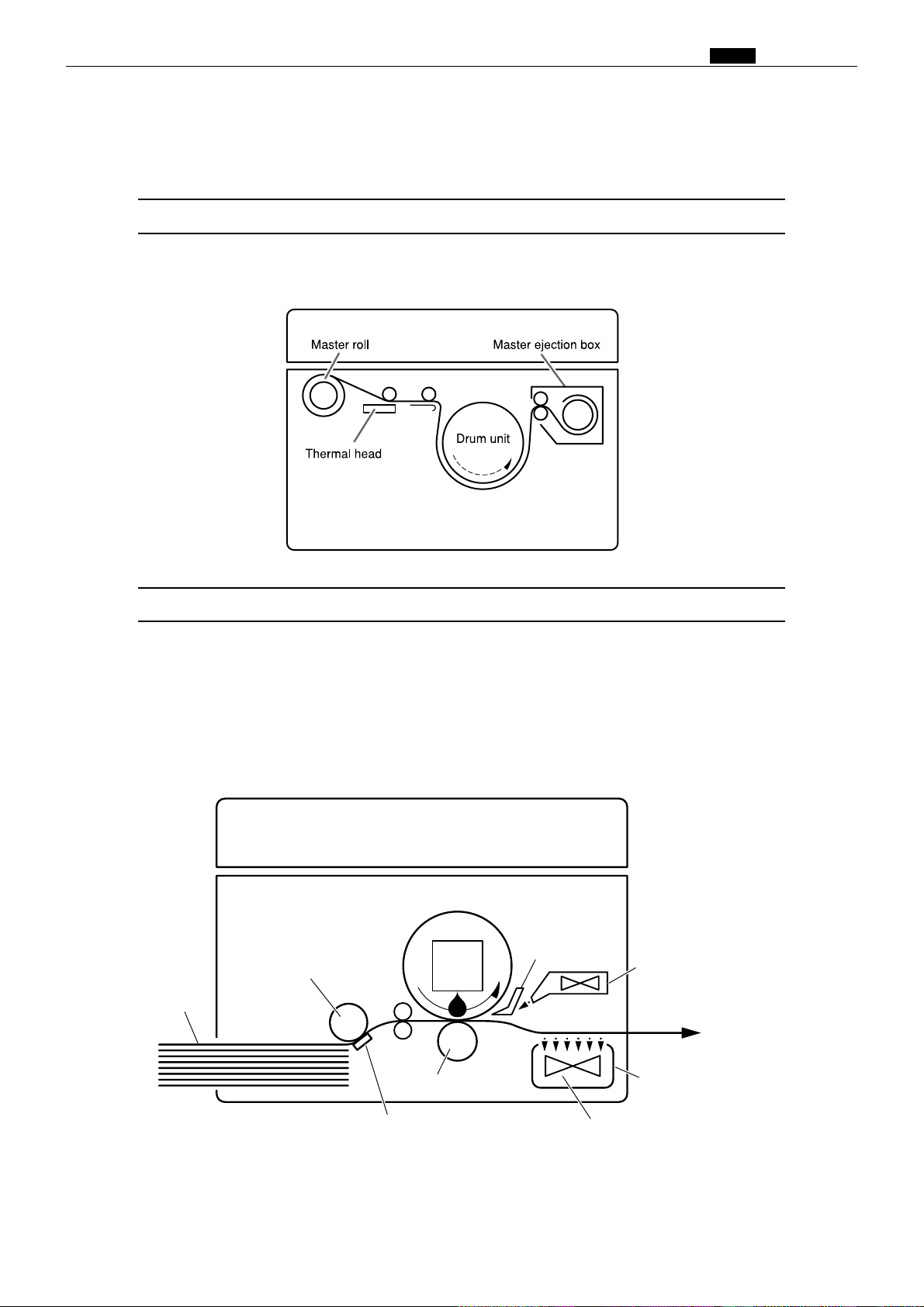

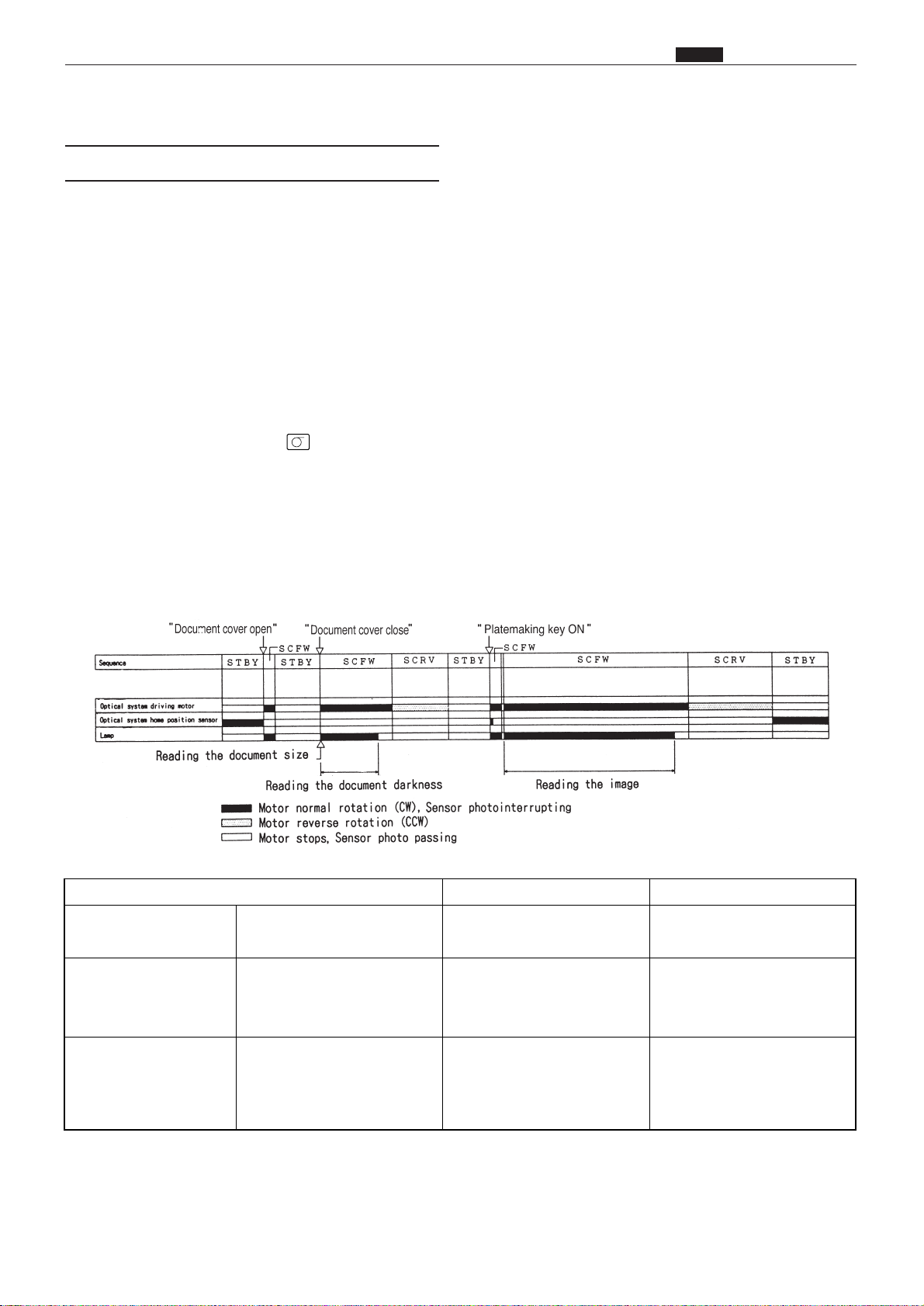

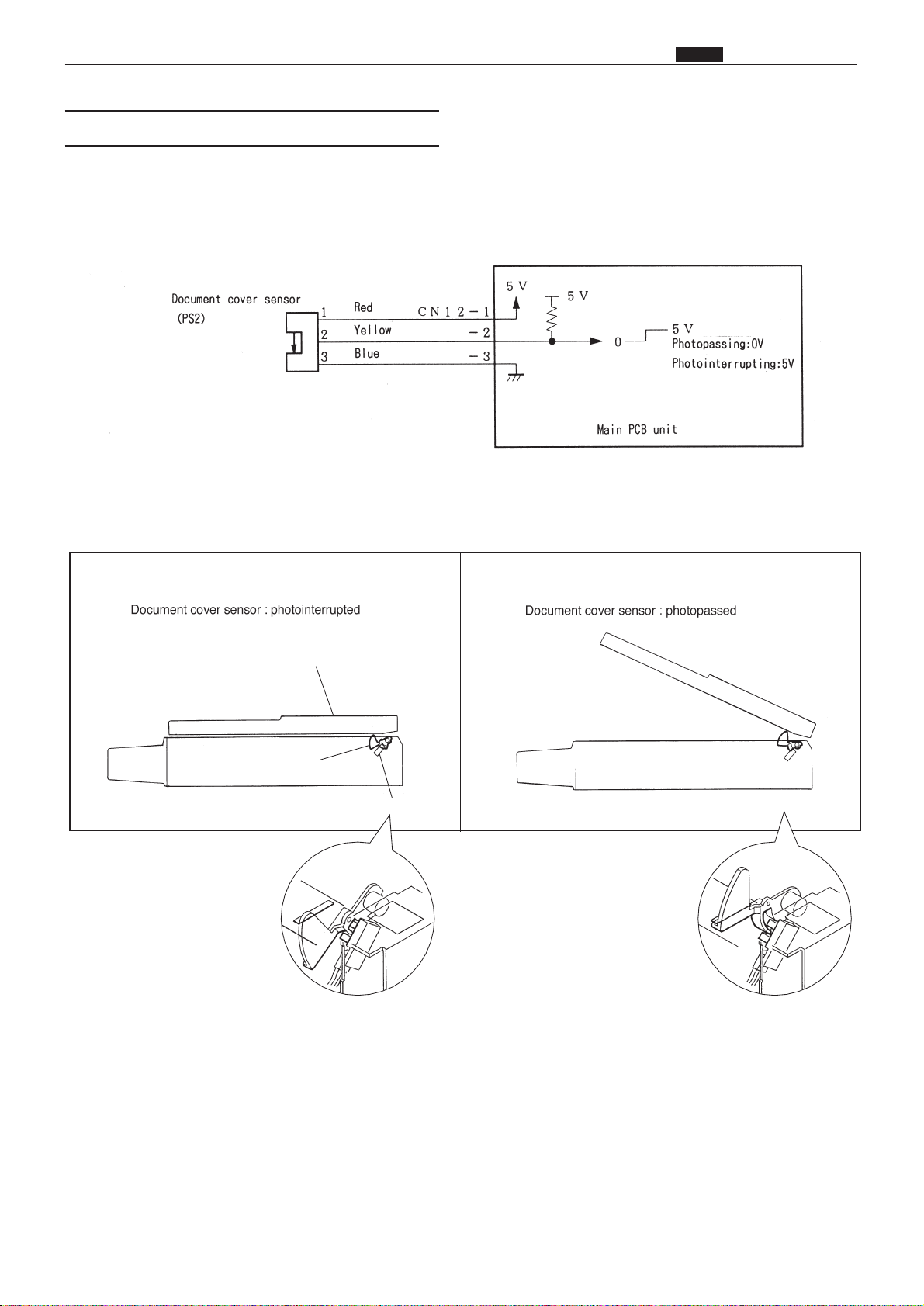

vMechanism

The machine carries out the processes of “platemaking” and “printing.”

Platemaking

In the “platemaking” process, the old master on the drum is removed while the

thermal head creates the scanned image on the new master and transfers it onto the

drum.

Chap.1 v Mechanism

Printing

In the “printing” process, paper separated from the stack by the paper feed roller and

the paper separator unit is pressed against the drum unit by the press roller. There are

small holes over only the image area of the master that is attached to the drum, and ink

that seeps from these holes is transferred to the paper. The paper is then peeled from

the master by the paper stripper finger and the top blow fan. The paper is directed onto

the paper ejection belt by a fan unit and discharged from the machine.

Drum unit

Paper stripper

finger

Top blow fan

Paper

Feeder roller

Ink

Press roller

Paper separator unit

17

Paper ejection belt

Fan unit

Page 19

Chap.1 b Master

bMaster

1) Characteristics of the master

(1) Structure of the thermal master

(2) Functions and materials of the layers

Coated surface …… Prevents the film from fusing, being damaged due to friction,being peeled,

and being conveyed defectively due to electric static charge.

Material: silicon fluorine mold lubricant

Thermal film …… Holes are made by the heat of the thermal head.

Material: Polyethylene terephthalate (polyester)

Adhesive ………… 1] Adheres the film to the base.

2] Does not prevent ink from seeping.

3] Increases impression endurance.

Base ……………… 1] Base material for the master. Fibrous layer

2] Ink seeps the base.

(3) Cross section of the master during platemaking

Holes are made on the coated surface, thermal film and adhesive, while base fiber, base material

for the master, is left.

A part of the film fused by the thermal head is stuck to the head or banks up.

(4) Printed image

As the image consists of innumerable dots, it is taken as a continuous line through our eye.

INPORTANT :

•Precautions to be taken in dealing in the master.

(1) Do not put a heavy thing on the box in which masters are packed.

•This may damage the master and may cause defective platemaking.

(2) Do not leave the master as it is after it is taken out.

•Foreign objects are stuck to the master and this may cause defective platemaking.

(3) Keep the master from direct sunlight, too high or low temperature and too high or low humidity.

(Desirable storage temperature and humidity: 5-35 °C, 20-80%)

• If the master curls, defective plate attachment may occur.

18

Page 20

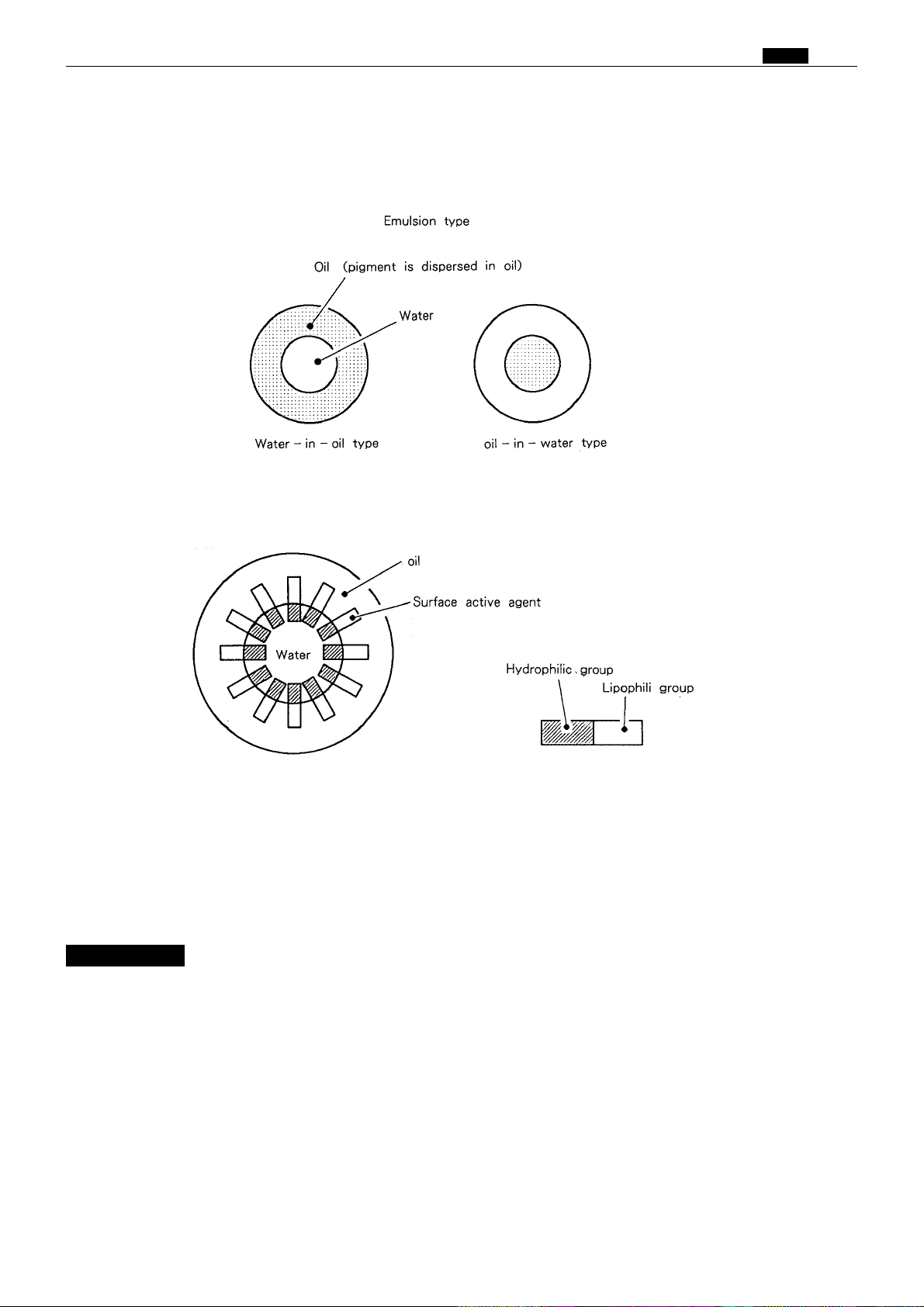

Chap.1 n Ink

nInk

1) Characteristics of ink

(1) Ink for the digital printer is an emulsion type. It has a water-in-oil type structure.

(2) The surface active agent has two characteristics: hydrophilic group and lipophilic group in one molecule.

Oil and water bond together by these two characteristics as shown in the figure.

(3) Ink

(3) Ink viscosity is high at a low temperature and it is low at a high temperature. So when ink is used at a

low temperature (10°C or less), the amount of ink transferred to the paper is smaller and the print

darkness is slightly lighter.

When ink is used at a high temperature (30°C or more), the amount of ink transferred to the paper is

larger and the print darkness is slightly darker.

INPORTANT :

• Precautions to be taken in handling ink

(1) Storage environment

• When an emulsion type ink is stored at too high or low temperature for a long time, oil and water in the

ink pack may be isolated. Keep the ink from too high or low temperature (5°C or less, 35°C or more).

Also keep the ink from direct sunlight since the temperature rises sharply in the direct sunlight.

• When the water content is frozen, the water content is solidified and the bond characteristics decreases.

• When ink is stored at a high temperature, the bond characteristics decreases due to the change of the

surface conditions (surface tension, solubility). The bond characteristics also decreases due to evaporatin

of the water content.

(2) Precautions to be taken in handling the ink pack

• When the ink pack is removed from the drum unit to store, put the ink pack with its mouth up, screw

the cap firmly after expelling air from the ink tube. (If air is in the ink pack, water content is generated.)

19

Page 21

Chap.1 m System Setup

mSystem Setup

The machine and its optional equipment are set up as follows:

ADF

Sorter

Dupulo Direct Print System

Personal computer

Key card counter

Drum unit

Tape cluster

Exclusive machine base

: Option

NOTE

• DDP system

Documents prepared on a personal computer can be printed on this machine. The

IPC board and PC interface kit are required to connect this machine to a personal

computer.

20

Page 22

,Part Names and Their Functions

1. Machine exteriors

Chap.1 , Part Names and Their Functions

21

Page 23

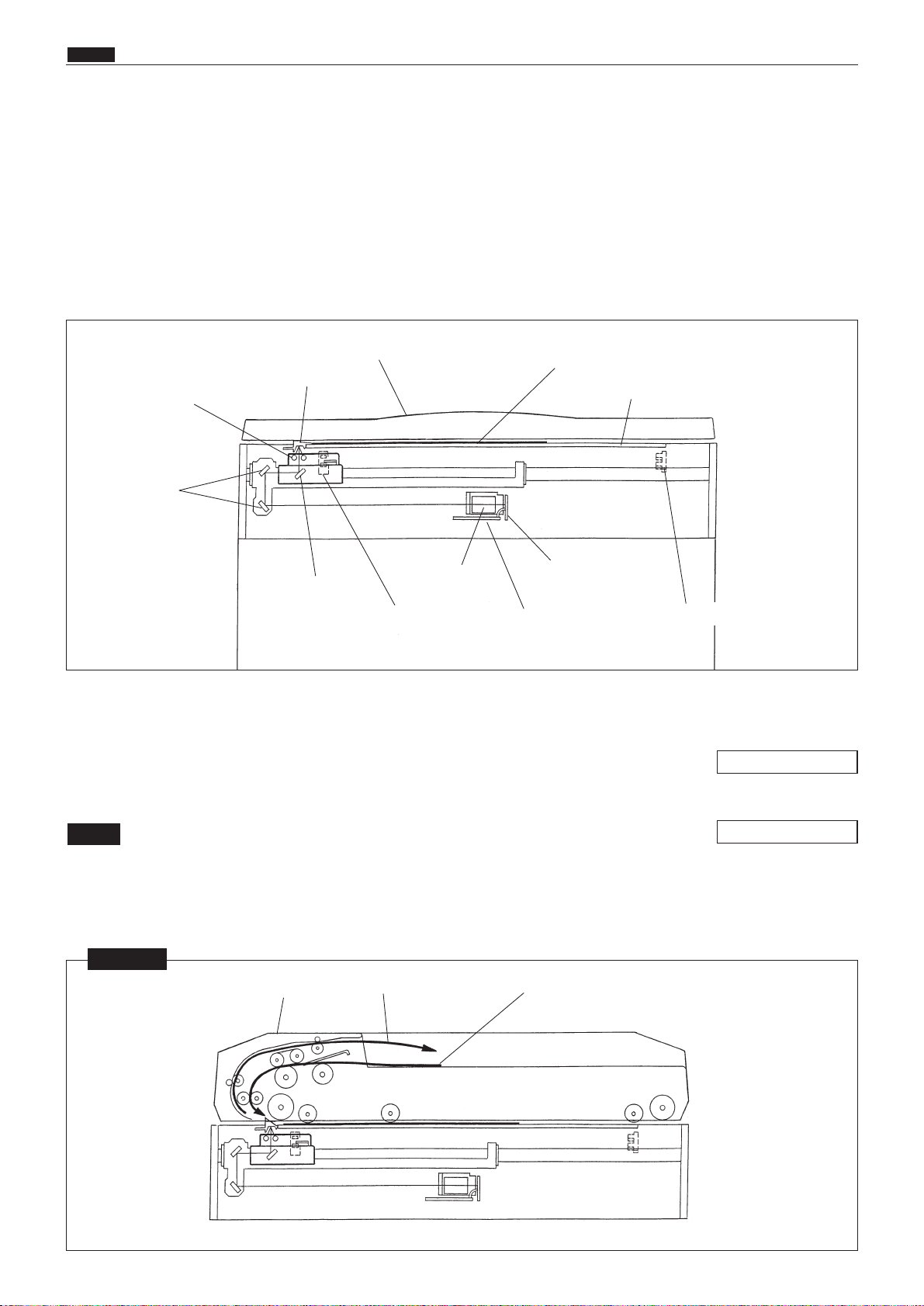

Chap.1 , Part Names and Their Functions

Thermal head escape lever

Master set switch

Master holder

Roll master

Paper tray

descending

switch

Lever

Scanner unit

(

Top cover

)

Paper tray descending switch

Feed pressure switching lever

Paper guide

Paper feed roller

Paper

tray

Supplemental paper tray

(Feeder tray)

Paper guide lock lever

Printing position adjustment dial

22

Page 24

Chap.1 , Part Names and Their Functions

Master ejection core

Master ejection box

release lever

Jamp stands

Master ejection box lid

release lever

Master ejection box lid

Master ejection box

Paper stacker guide

Paper stopper

Drum rotator switch

Print tray

23

Page 25

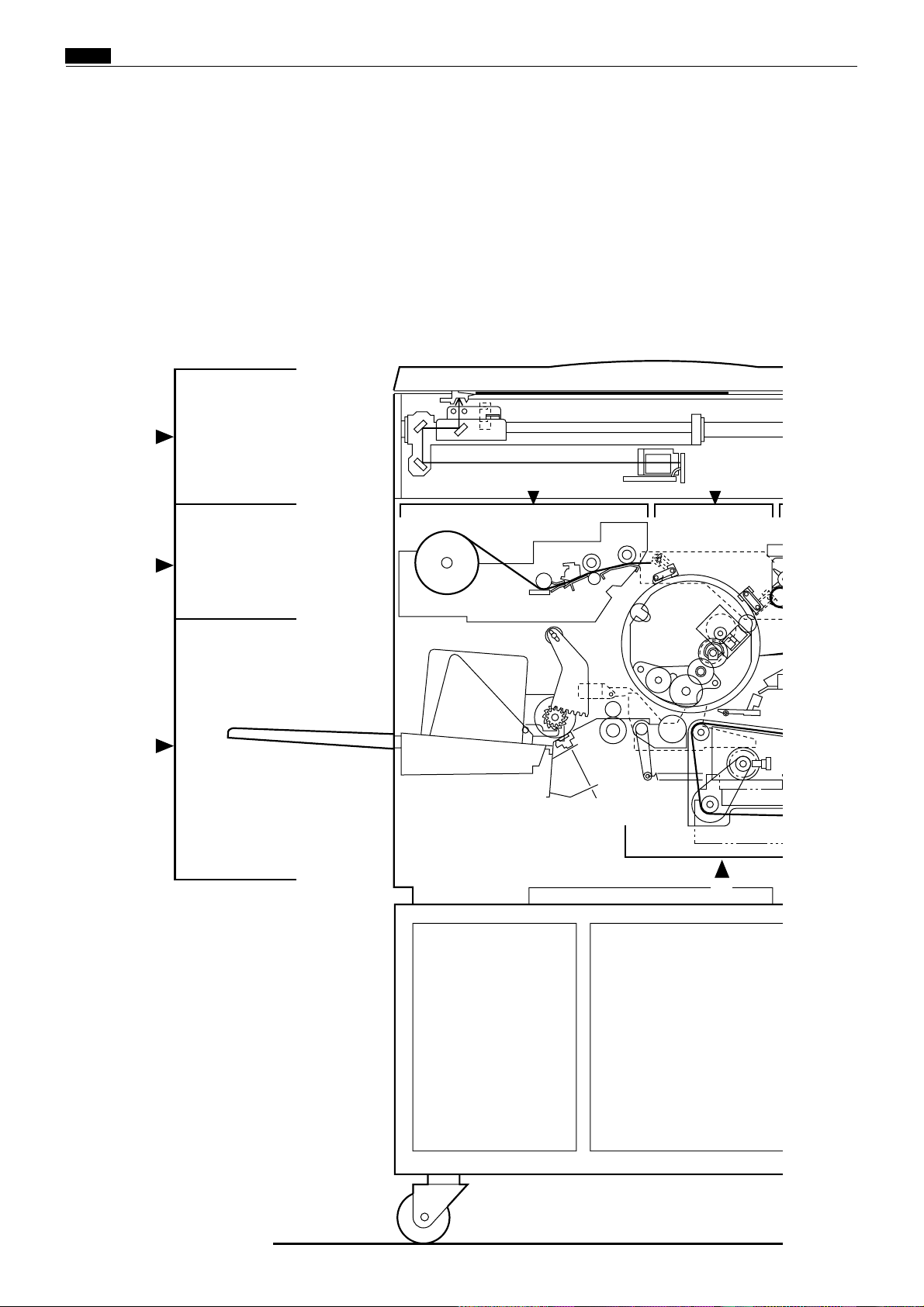

Chap.1 , Part Names and Their Functions

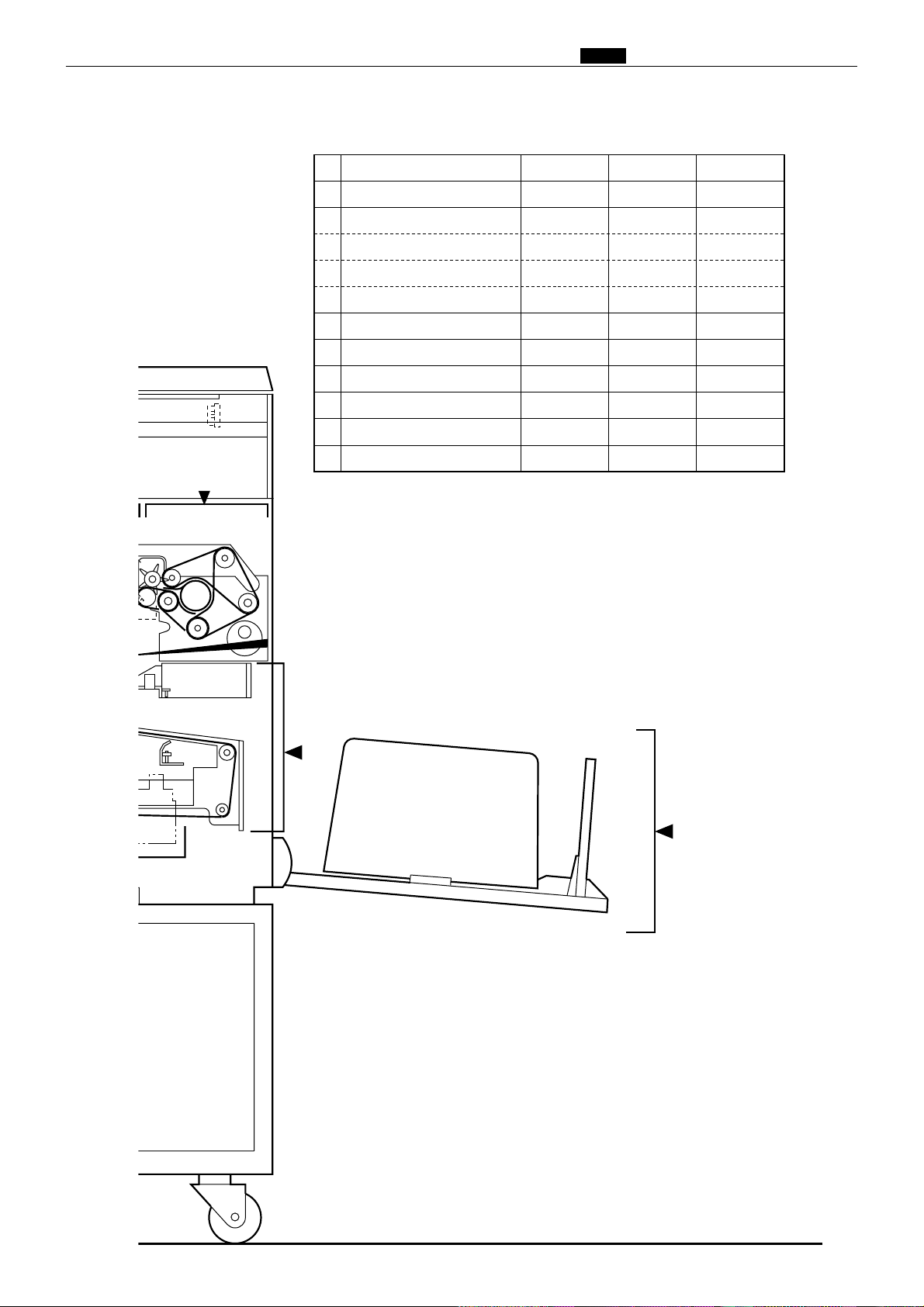

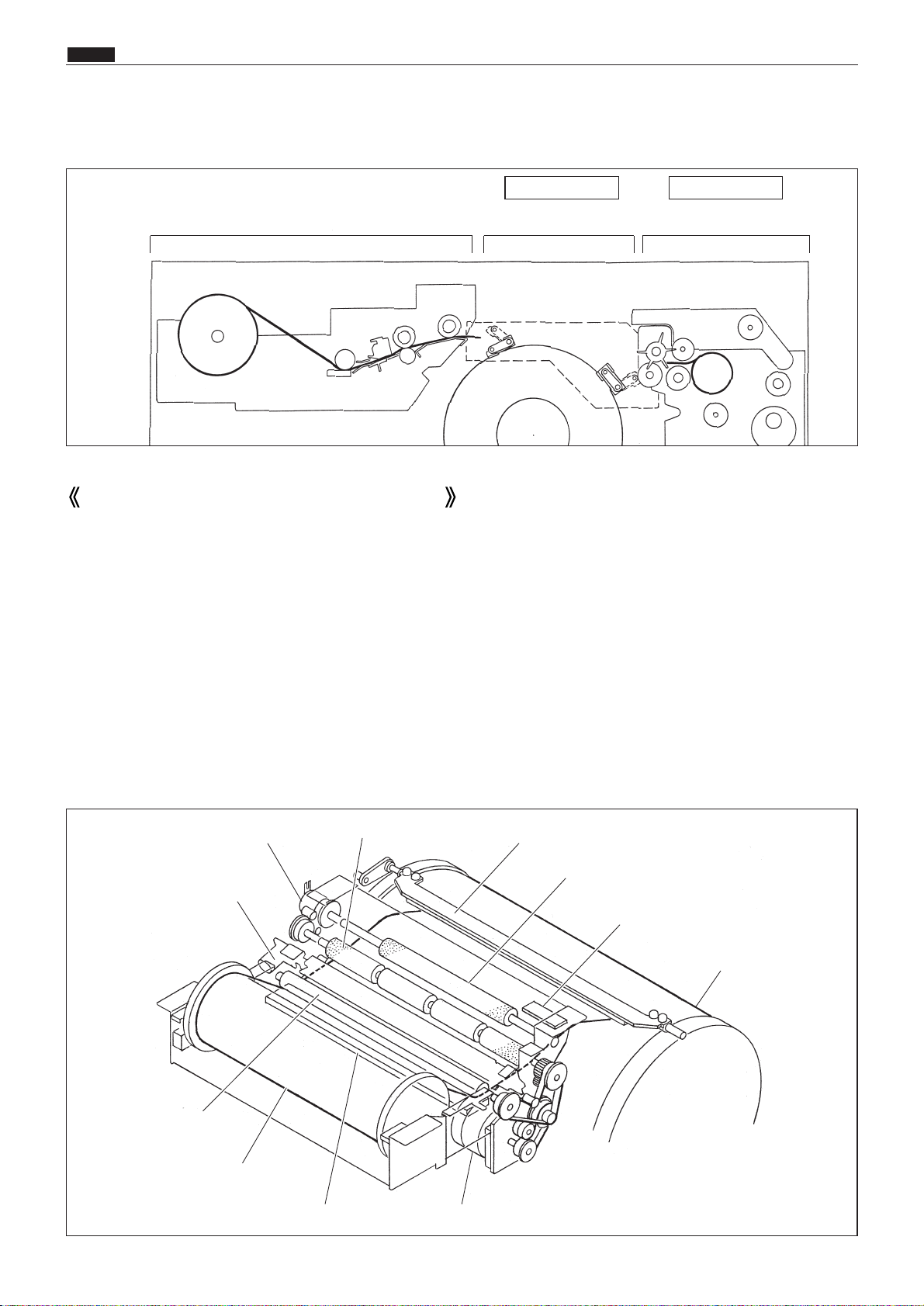

2. Sectional (structural) view of the machine

1

2A

2C

2

3

5

24

Page 26

Chap.1 , Part Names and Their Functions

2B

No.

Section Name

1

Scanner section

Platemaking/Master feed/ejection section

2

Platemaking/Master feed section

2A

Master ejection section

2B

Master clump opening/closing section

2C

Paper feed section

3

Drum driving section

4

Press section

5

Paper ejection section

6

Print tray

7

Drum section

8

Description of

the Operation

86page

94page

94page

107page

109page

115page

129page

135page

142page

4

148page

Mechanism

172page

180page

180page

185page

186page

188page

192page

4

194page

4

202page

Srandard/Adjustment

212page

214page

214page

215page

217page

222page

229page

231page

233page

4

235page

4,8

6

7

25

43E00001

Page 27

!091

2

3

4

5

678

EDIT

F-SET

MENU

PRINTING

1

×

A4

100%

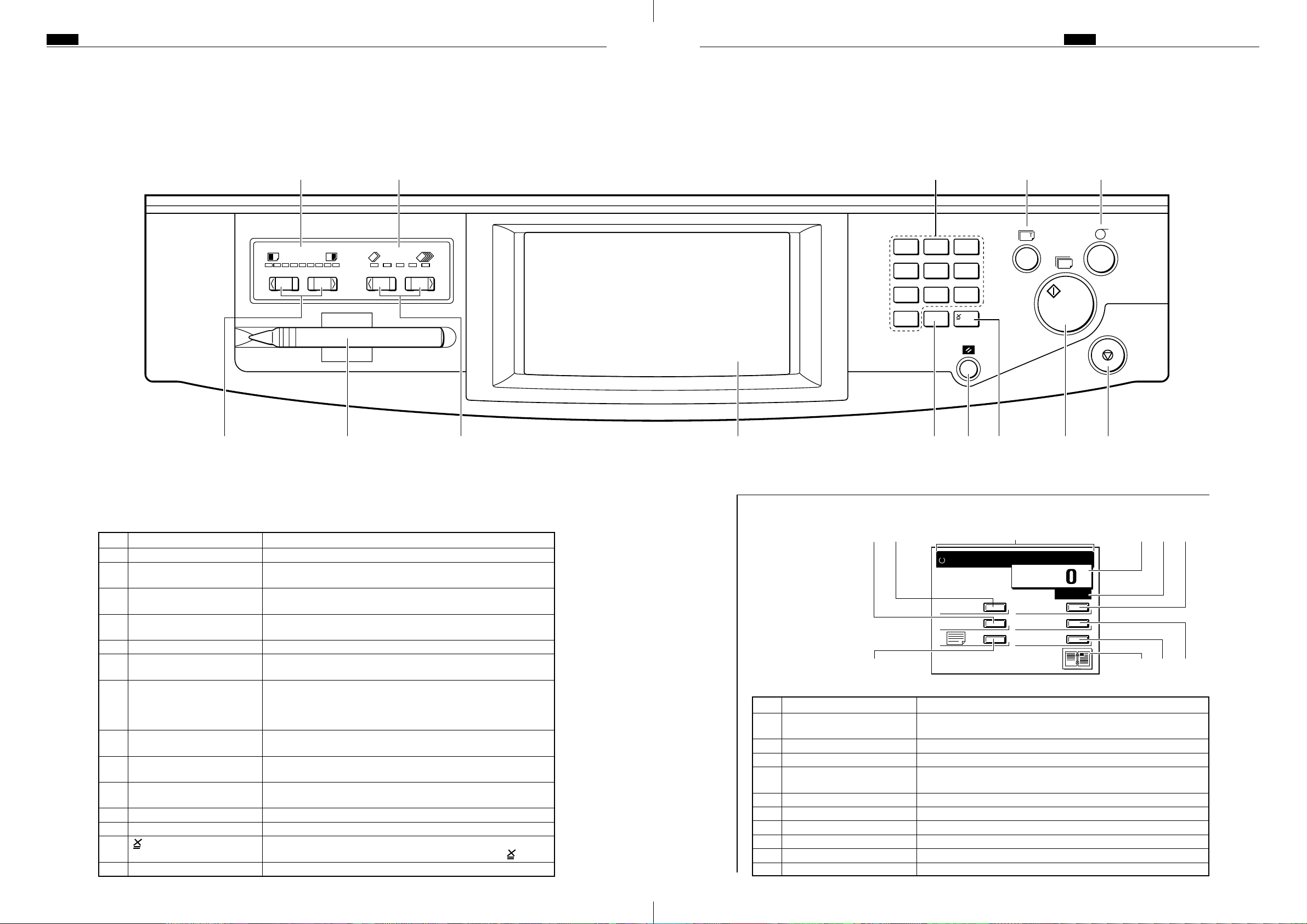

3. Control panel

<<E type models>>

1. Keys of the control panel

Chap.1 , Part Names and Their FunctionsChap.1 , Part Names and Their Functions

e q !1 y t

1 2 3

4 5 6

7 8 9

0 C

No. Name Functions

Printing speed indicator lamp

q

“PRINTING SPEED The printing speed is adjusted with these keys.

w

ADJUSTMENT” keys

Printing position indicator The lamp for the specified printing position lights.

e

lamp

“PRINTING POSITION The printing position (vertical) is adjusted with these keys.

r

ADJUSTMENT” keys

“PLATEMAKING” key Starts platemaking.

t

“TEST PRINT” key Prints one copy. This is used to check the image position and

y

“PRINT” key Starts printing. This will not start platemaking. When the tape

u

“STOP” key Stops printing. If this key is pressed while the machine is

i

“ALL CLEAR” key Returns the control panel settings back to the standard made.

o

LCD panel Displays number of prints and other machine settings. Displays

!0

Key pad Used for entering the number of prints.

!1

“CLEAR” key Clears the display to “0”. Clears the number of prints only.

!2

!3

Input Pen Used with the Edit Functions.

!4

key Enters the number of prints and number of sets. To enter the

The lamp for the specified printing speed lights.

contrast.

cluster or ADF have been installed, platemaking will start

automatically after end of printing if the document is placed on

the ADF .

stopped, the number of copies and plates will be displayed.

Hold down for at least 0.5 second.

error messages when error is occurred.

number of prints per document after a clear, press the key.

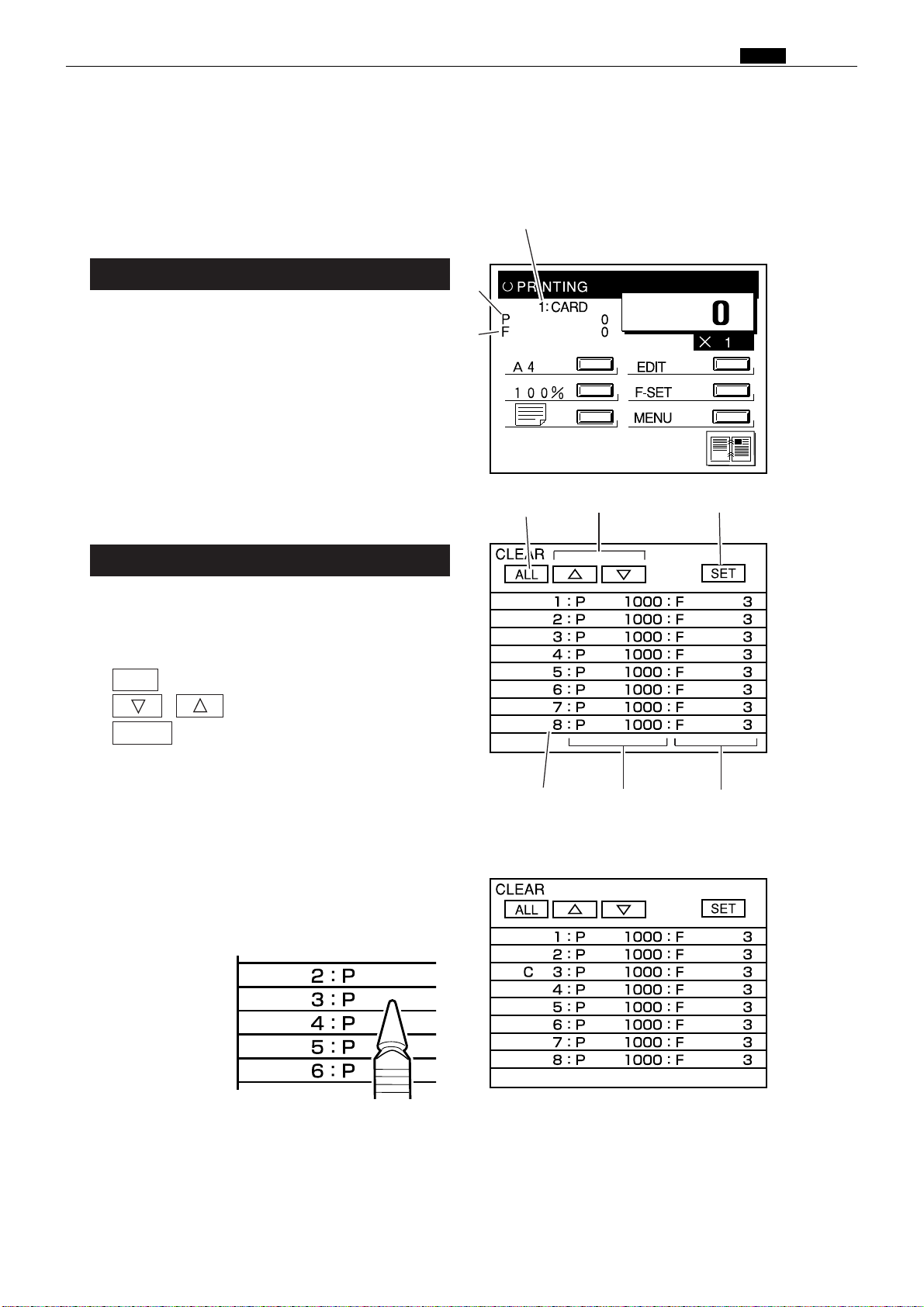

2. LCD Panel main screen

No. Name Functions

Message Display Area Displays "PRINT" and other messages related to the operation of

q

the printer.

Paper Size This button is used to select the size of the paper for printing.

w

Enlargement/Reduction This button is used to set the enlargement/reduction ratio.

e

Photograph Mode This button is used to set the Photograph Mode and other

r

Edit This button is used to select Editing Functions.

t

F Settings This button is used to select Function modes.

y

Menu This button is used to display and manipulate the Menu Screen.

u

Status This button displays the current settings.

i

Counter Displays the number of copies remaining to be printed.

o

Number of Sets Displays the number of sets.

!0

Platemaking methods.

2726

iuo!2 !3!0wr!4

Page 28

Chap.1 , Part Names and Their Functions

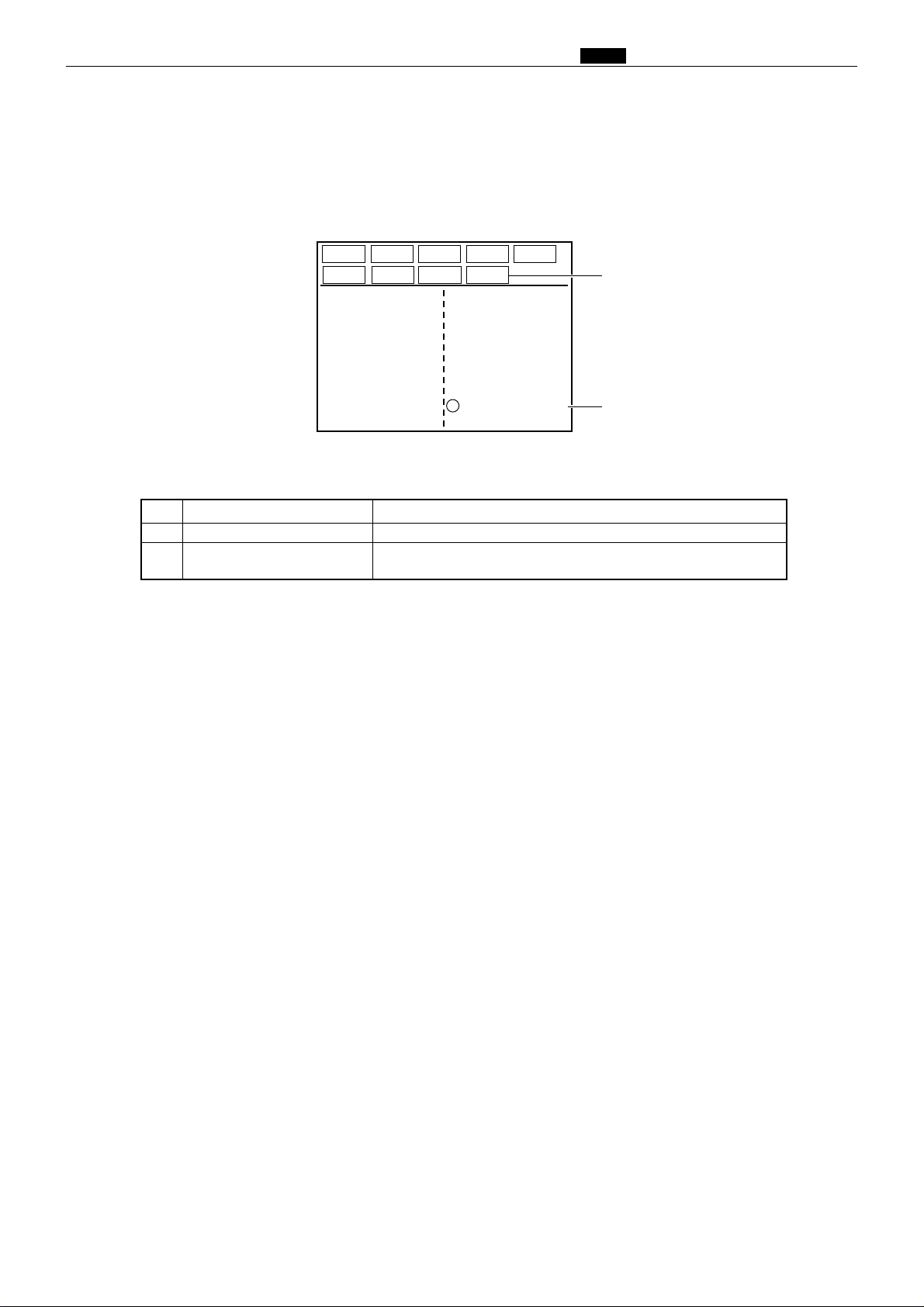

3. Function Mode Screen

Screen A

o Function Keys (F1-F3)

Normal key q

Page Cgange key w

Save key e

No. of Copies/No. of Sets indicator r

Paper Size indicator t

Document Mode indicator y

Enlargement/Reducation indicator u

94% indicator i

No. Name Feature

Normal key Clears the Function Mode.

q

Page Change key Changes from Screen A to Screen B and vice versa.

w

Save key Stores settings under Function keys F1 through F3.

e

No. of Copies/No. of Sets indicator

r

Paper Size indicator Indicates the Paper Size setting.

t

Document Mode indicator Indicates the Document Mode setting

y

Enlargement/Reduction indicator

u

94% indicator A black dot "•" indicates the 94% Reduction Mode is ON.

i

Function Keys (F1-F3) Allow information pertaining to enlargement/reduction, paper

o

End key Terminates Function setting operation.

!0

Clear key Clears settings stored in memory under Function Keys F1-F3.

!1

Plate Darkness indicator Indicates the Plate Darkness (contrast) setting.

!2

Print Darkness indicator Indicates the Print Darkness setting

!3

Trimming indicator A black dot "•" indicates the Trimming Mode is ON.

!4

Makeup indicator A black dot "•" indicates the Makeup Mode is ON.

!5

Book Shadow Eraser indicator

!6

Sorter indicator Indicates the Sorter Mode setting. (Indicator only functions when

!7

Multiple Printing indicator Indicates the Multiple Printing Mode setting.

!8

NORMAL

PAGE

0 ✕ 1

F 1 F 2 F 3

SAVE CLEAR

A 4

100%

✕ 94%

END

!0 End key

!1 Clear key

!2 Plate Darkness indicator

!3 Print Darkness indicator

!4 Trimming indicator

!5 Makeup indicator

!6 Book Shadow Eraser indicator

!7 Sorter indicator

!8 Multiple Printing indicator

Indicates the number of copies and sets that have been set.

Indicates the Enlargement/Reduction setting.

size, multiple printing, number of copies, makeup, etc. to be

stored in advance, and then called up as needed for printing

operations.

Pressing the Clear key returns the Function Keys to their default

settings.

A black dot "•" indicates the Book Shadow Eraser Mode is ON.

the sorter is hooked up.)

28

Page 29

Screen B

Chap.1 , Part Names and Their Functions

NORMAL

PAGE

1: 1 ✕ 1

2: 2 ✕ 2

3: 3 ✕ 3

4: 4 ✕ 4

5: 5 ✕ 5

6: 6 ✕ 6

7: 7 ✕ 7

8: 8 ✕ 8

F 1 F 2 F 3

SAVE CLEAR

MODIFY

9: 9 ✕ 9

A: 10 ✕ 10

B: 11 ✕ 11

C: 12 ✕ 12

D: 13 ✕ 13

E: 14 ✕ 14

F: 15 ✕ 15

NUMBER OF PRINTS

END

!9

@0

No. Name Feature

Modify key Allows the No. of Copies/No. of Sets to be revised.

!9

Number of Prints

@0

A black dot "•" indicates that the Print Number Input Mode is

NUMBER.

29

Page 30

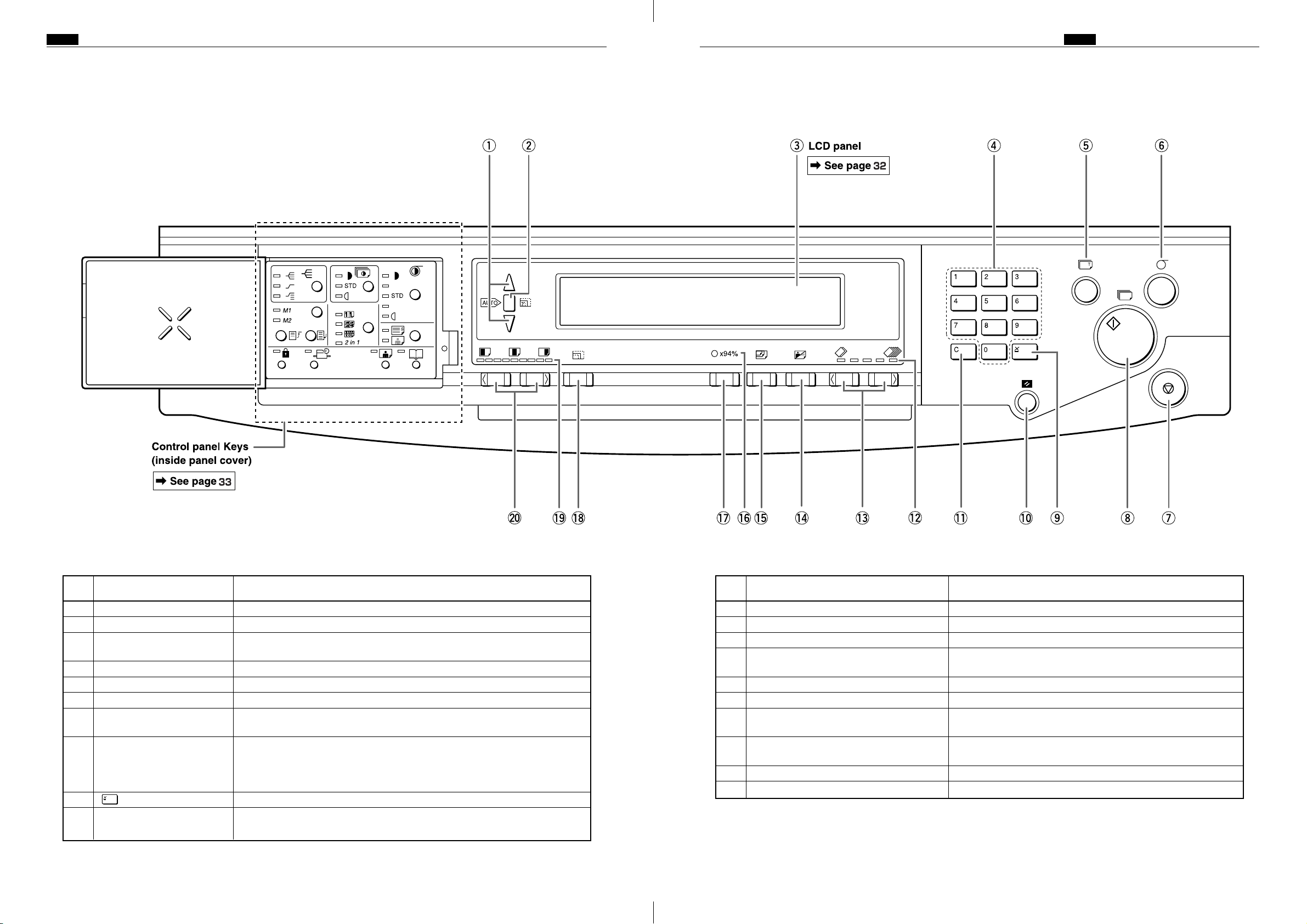

<<S type models>>

1. Keys outside of the panel cover

Chap.1 , Part Names and Their FunctionsChap.1 , Part Names and Their Functions

No. Name Function

q “ZOOM” key Adjusts the zoom factor in 1% increments.

w “AUTO ZOOM” key Turns the auto zoom function ON.

e LCD panel Displays the number of prints and other settings. Displays error messages

when an error has occurred.

r Key pad Used for entering the number of prints.

t “TEST PRINT” key Prints one copy. This is used to check the image position and darkness.

y “PLATE MAKING” key Starts platemaking.

u “STOP” key Stops printing. If this key is pressed while the machine is stopped, the total

number of prints and plates will be displayed.

i “PRINT” key Starts printing. This will not start platemaking. Printing cannot start when

the print key lamp is red; press this key only when the lamp is blue. When

the ADF has been installed, platemaking will start automatically after the

end of printing if there is a document on the ADF.

o key Enters the number of prints and number of sets.

!0 “ALL CLEAR” key Returns the control panel settings to the standard mode settings. Press and

hold for at least 1 second.

No. Name Function

!1 “CLEAR” key Clears the display to “0”. Clears the number of prints only.

!2 Printing speed indicator lamp The lamp for the specified printing speed lights.

!3

“PRINTING SPEED ADJUSTMENT” keys

!4 “TEXT/PHOTOGRAPH” key Each press of this key switches between the text mode,

!5 “PAPER SIZE” key Selects the paper size.

!6 94% reduction LED Lit when in the x94% Reduction Mode.

!7 “94%” key Toggles the x94% reduction mode ON/OFF. When ON, 94%

!8 “PRINT SIZE” key Selects Reduction/Enlargement (standard size ➞ standard

!9 Printing position indicator lamp The lamp for the specified printing position lights.

@0

“PRINTING POSITION ADJUSTMENT” keys

The printing speed is adjusted with these keys.

photograph mode, and text/photograph mode.

reduction is applied to the selected zoom ratio.

size) percentage.

The printing position (vertical) is adjusted with these keys.

3130

Page 31

Chap.1 , Part Names and Their Functions

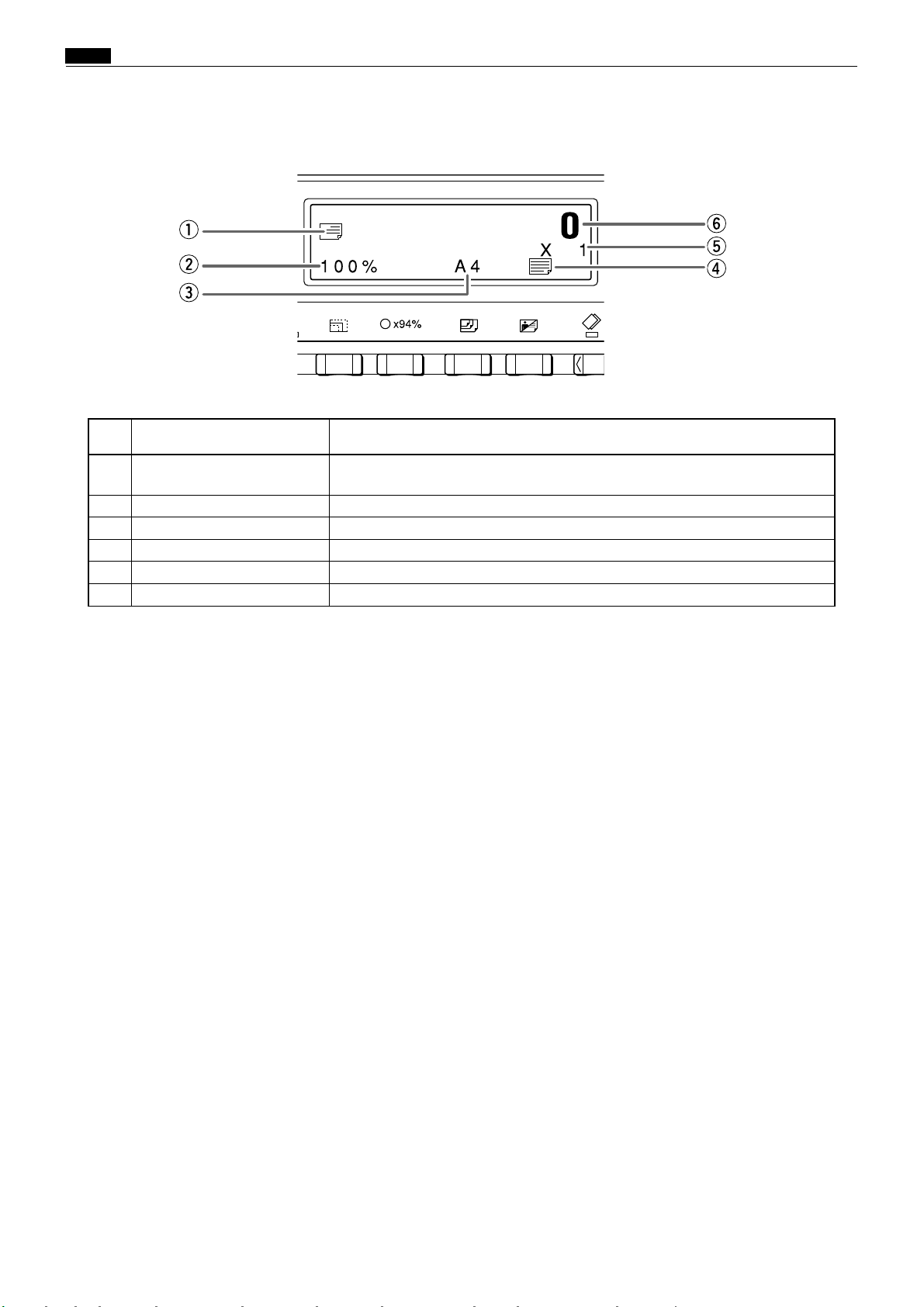

2. LCD Panel

No. Name Function

q Prints per page Displays the icon for the selected number of prints per page (multiple

printing).

w Zoom ratio Displays the selected zoom (enlargement/reduction) ratio.

e Paper size Displays the selected paper size.

r Document mode Displays the print mode.

t Sets Displays the number of sets to be printed.

y Print count Displays the number of prints to be made.

32

Page 32

Chap.1 , Part Names and Their Functions

3. Keys inside of the panel cover

No. Name Function

q “PRINTING DARKNESS” key Adjusts the print darkness (ink transfer amount). The position of the

lit print darkness adjustment lamp changes each time the key is

pressed.

Print darkness adjustment indicator lamp

w “SORTER” key When the optional sorter is installed, this key selects the sorter mode.

Sorter mode indicator lamp The lamp for the specified sorter mode lights when the sorter option

e “MEMORY” key Selects the memory channel to read settings from or save settings to.

Memory indicator lamp The lamp for the selected memory channel lights.

“SAVE” key Saves settings to the currently selected memory.

“RETRIEVE” key Reads the settings from the selected memory.

r “CONFIDENTIAL” key Selects Confidential Mode. Prints cannot be made unless a plate is

Confidential safeguard indicator lamp Lights when the confidential safeguard mode is ON.

t “SPECIAL FUNCTION” key Allows use of special functions.

Special function indicator lamp Lights when special functions are in use.

y “MULTIPLE PRINTING” key Selects the number of prints per page (2 up, 4 up, 8 up, or 2in1).

Multiple printing indicator lamp The lamp for the specified number of multiple printing lights.

u “PLATE DARKNESS” key The plate darkness is adjusted with this key. The position of the lit

Plate darkness indicator lamp The lamp for the specified plate darkness lights.

i “FINE TEXT/SCREEN” key Selects the optimum text mode for fine text documents or the

Fine text/screen mode indicator lamp The lamp for the specified mode lights.

o Function in-use lamp Lights when functions controlled by keys under the panel cover are

!0 “BOOK SHADOW ERASER” key Selects Book Shadow Eraser mode.

Book shadow eraser mode indicator lamp

!1 “PHOTO DARK” key Press to adjust the gradations in dark photographic documents.

Photo dark indicator lamp Lights when Photo Dark is selected.

The lamp for the specified printing darkness lights.

The position of the lit sorter mode lamp changes each time the key is

pressed.

is installed.

made.

Each press of the key changes the number of prints per page. The

multiple printing indicator lamp changes accordingly.

plate darkness indicator lamp changes each time this key is pressed.

optimum screen mode for photographic documents that have not

been screen processed. Each time the key is pressed, the fine text/

screen mode lamp lighting changes.

in use.

Lights when Book Shadow Eraser Mode is selected.

33

Page 33

Chap.1 . Operation Procedures

.Operation Procedures

1. Printing <<E type models>>

1 Set document

• LCD panel

PAPER SIZE key

PRINT SIZE key

PHOTOGRAPH MODE key

Menu key•Multiple Image Printing icon

Menu key• icon•Platemaking Density(darkness) icon

Menu key•Erasing Book Shadow icon

2

PLATEMAKING

PRINTING POSITION ADJUSTMENT key

Selects the paper size

Selects the magnification factor

(including auto zoom and zoom)

Selects Text/Photograph/Text-Photograph/

Fine Lettering/Halftone Dot/Dark Photo Mode

2in 1

If the number of prints is set in advance,

printing will start automatically at the end

of platemaking

Adjusts the printing position

Multiple Image and 2 in 1 printing are only

possible when the optical ADF is used

selects image-taking dencity

(darkness)

Erases shadows from book documents

PRINTING SPEED ADJUSTMENT key

Menu key• icon•Print Density(ink transfar amount) icon

TEST PRINT key

Input the number of prints and

3

the number of sheets

PRINT key

4

5

END

Adjusts the printing speed

Adjusts the print density

Executes test printing (of 1 sheet)

Input the number of prints and the number

of sets (using the numeric keys)

34

Page 34

<<S type models>>

Chap.1 . Operation Procedures

35

Page 35

Chap.1 . Operation Procedures

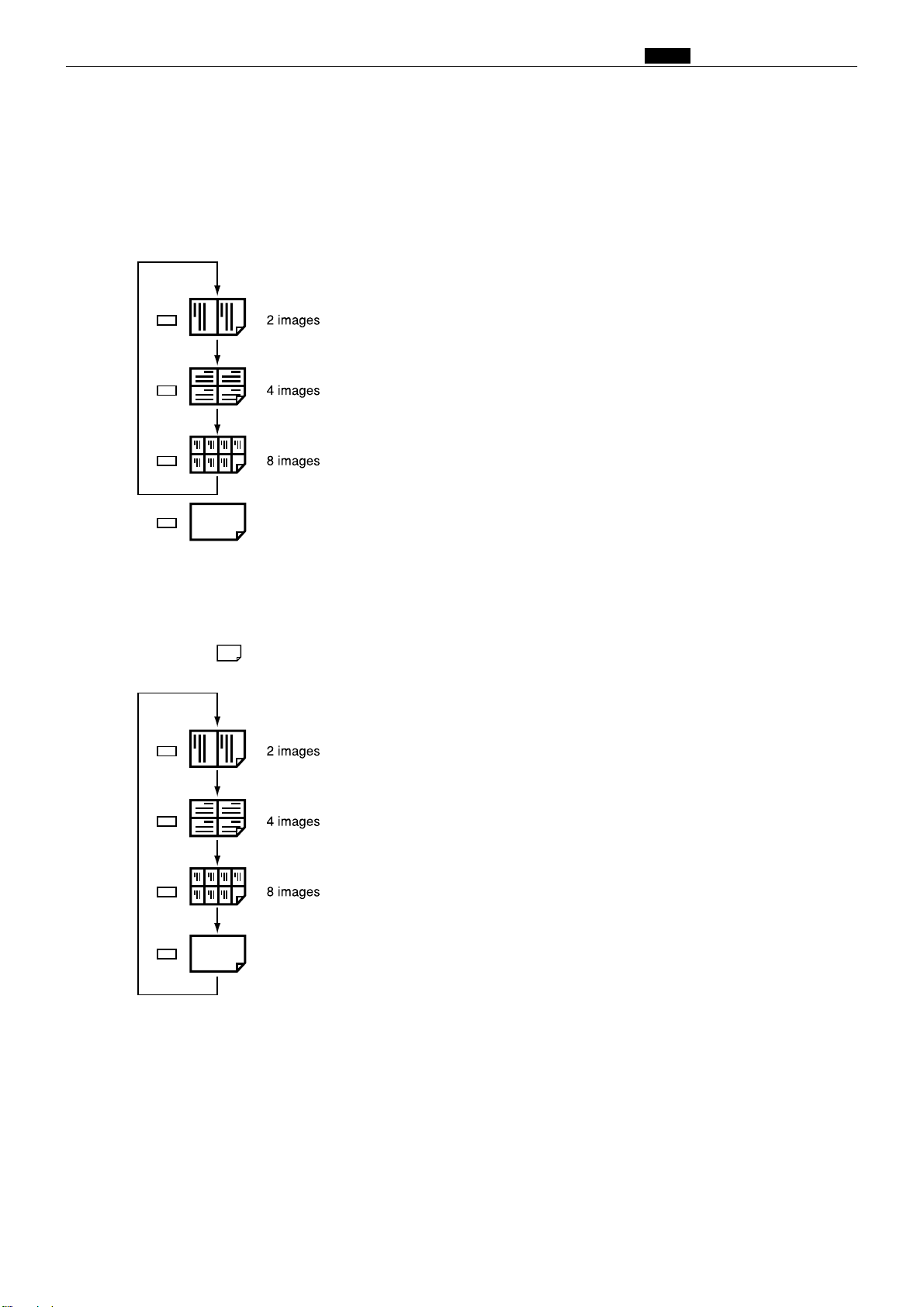

2. Multiple Image Printing / 2 IN 1 Layout Mode

<<E type models>>

In the normal state (when the ADF is not connected), the screen shown below appears

when the Multiple Image Printing " " icon is selected after the MENU key is pressed.

• Icons for a single image " ", 2 images " ",

4 images " " and 8 images " " are

displayed on the screen. Press the icon for the

desired number of images.

aThe menu screen will reappear, with the se-

lected icon displayed in the status field.

If the optional ADF is connected, the screen shown below appears when the Multiple Im-

age Printing icon " " is selected after the MENU key is pressed. Selecting the " " icon

from this screen will activate the 2 in 1 Layout Mode.

2in1

2in1

36

Page 36

<<S type models>>

In the normal state (when the ADF is not connected) the mode is switched by pressing the

multiple printing selection key as follows.

Chap.1 . Operation Procedures

Every time the key is pressed, the mode is switched

and the relevant multiple printing indicator lamp

lights up.

• Each press of the multiple printing selection key makes

a different multiple printing indicator light up, in

sequence. To set the number of images, press the key

until the indicator for the desired number of images is

lit.

2in1

When the ADF is connected, the multiple printing selection key can also be used to select

the 2 in 1 Layout Mode, as shown below. To activate the 2 in 1 Layout Mode, press the key

until the " " icon is lit.

2in1

2in1

37

Page 37

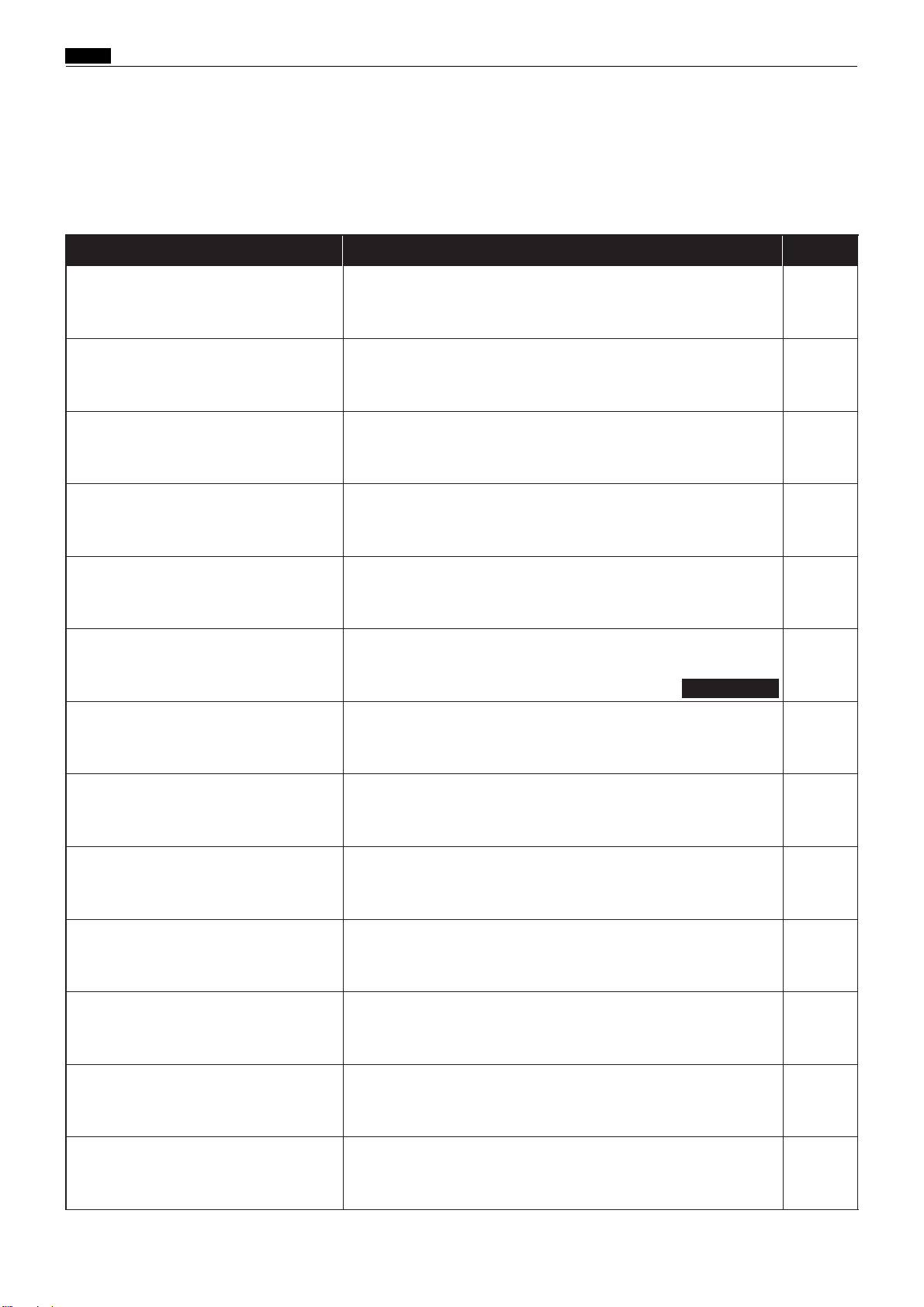

Chap.1 ⁄0 Error Messages and Corrective Action

⁄0Error Messages and Corrective Action

1. Error messages

Error messages are displayed as text illustrations.

Message

CHANGE INK

CHANGE MASTER

CHANGE MASTER

EJECTION CORE

ADD PAPER

NO DRUM

DRUM CHANGE

A3<=>A4

Cause and corrective action

There is no ink. Replace the old ink pack with a new one.

There is no master. Replace the master roll with a new one.

The master ejection core is full. Replace the core with a new

one.

There is no paper in the feed tray. Load the feed tray with

printing paper.

There is no drum. Install a drum in the machine.

The installed drum is not the specified drum. Install the correct drum for this machine.

For DP-43E/S

See page

41

43

46

48

51

51

FRONT COVER OPEN

TOP COVER OPEN

PAPER JAM ON THE FEEDER SIDE

PAPER JAM ON THE EJECTION SIDE

PLATE EJECTION

ERROR

MASTER SETTING ERROR

ADF PAPER JAM

The front cover is open. Close the front cover.

The scanner unit is open. Close the scanner unit.

A paper jam has occurred in the feeder side. Inspect the feeder

side, and remove the jammed paper.

A paper jam has occurred on the ejection side. Inspect the

ejection side and remove the jammed paper.

There is an old master on the drum. Remove all the masters

from the drum.

There is an error during master setting. Open the top cover

and remove the master that is left in the plate feeder.

The document is jammed on the ADF. Remove the jammed

document in accordance with the ADF instruction manual.

4

4

53

54

55,57

59

ADF

Instruction

manual

13

38

Page 38

Chap.1 ⁄0 Error Messages and Corrective Action

C

T

Message

PLEASE WAIT

PLEASE INSERT CARD

RE-INSERT CARD

NOW READING CARD PLEASE WAIT

CANNOT USE THIS CARD

MAXIMIZING CARD

Cause and corrective action

The printer is not ready. Please wait with the power ON.

If the message remains after a few minutes, turn the power

OFF and ON again. If the message still remains after a few

minutes, turn the power OFF and contact your service person.

Insert the key card into the key card counter.

Please insert card.

Cannot read key card. Please reinsert the card.

Key card reading is in progress. Please wait.

You have inserted an unusable card. Check the card for dirt

and scratches, then reinsert the card.

Insert the highest-numbered of the cards that are to be used.

See page

4

62,78

62,78

62,78

62,78

62,77

CARD IS WRITE PROTECTED

CANNOT PRINT

PRINTING

You inserted suspended card. Use a different card or cancel

the card's suspension.

Cannot print.

This message is displayed if you press (PRINT) or

(TEST PRINT) keys without making a plate immediately

after a master setting error or master ejection error, or when

the confidential safeguard function is ON.

Printing is not complete. Either press (PRINT) key to

resume printing or press (CLEAR) key to clear the

counter.

E type : 65

S type : 71

4

4

39

Page 39

Chap.1 ⁄0 Error Messages and Corrective Action

Message

[C301A]

SORTER JAM1

[C302]

SORTER JAM3

[C303B]

SORTER JAM2

[C304]

SORTER DOOR OPEN

[C305]

STAPLER DOOR OPEN

[C306A]

NO STAPLES

Cause and corrective action

A paper jam has occurred in the paper path of sorter A.

Remove the jammed paper.

For details, see the Sorter Instruction Manual.

A paper jam has occurred in the sorter bridge. Remove the

jammed paper.

For details, see the Sorter Instruction Manual.

A paper jam has occurred in the paper path of sorter B.

Remove the jammed paper.

For details, see the Sorter Instruction Manual.

The sorter door is open. Close the sorter door.

For details, see the Sorter Instruction Manual.

The stapler door is open. Close the stapler door.

For details, see the Sorter Instruction Manual.

The stapler of sorter A is out of staples. Load staples.

For details, see the Sorter Instruction Manual.

See page

Sorter

Instruction

Manual

Sorter

Instruction

Manual

Sorter

Instruction

Manual

Sorter

Instruction

Manual

Sorter

Instruction

Manual

Sorter

Instruction

Manual

[C307]

NO STAPLES2

[C306A]

STAPLES JAM

[C307B]

STAPLES JAM2

[EXXX]

CALL THE SERVICE PERSON

The stapler of sorter B is out of staples. Load staples.

For details, see the Sorter Instruction Manual.

The staplers have jammed in sorter A. Remove the jammed

staples.

For details, see the Sorter Instruction Manual.

The staplers have jammed in sorter B. Remove the jammed

staples.

For details, see the Sorter Instruction Manual.

Note error code (EXXX).

Turn the power OFF and back ON again.

If the machine does not operate normally, call the service

person and describe the error code and conditions that led to

the situation as clearly as possible.

Sorter

Instruction

Manual

Sorter

Instruction

Manual

Sorter

Instruction

Manual

283

40

Page 40

2. Corrective action

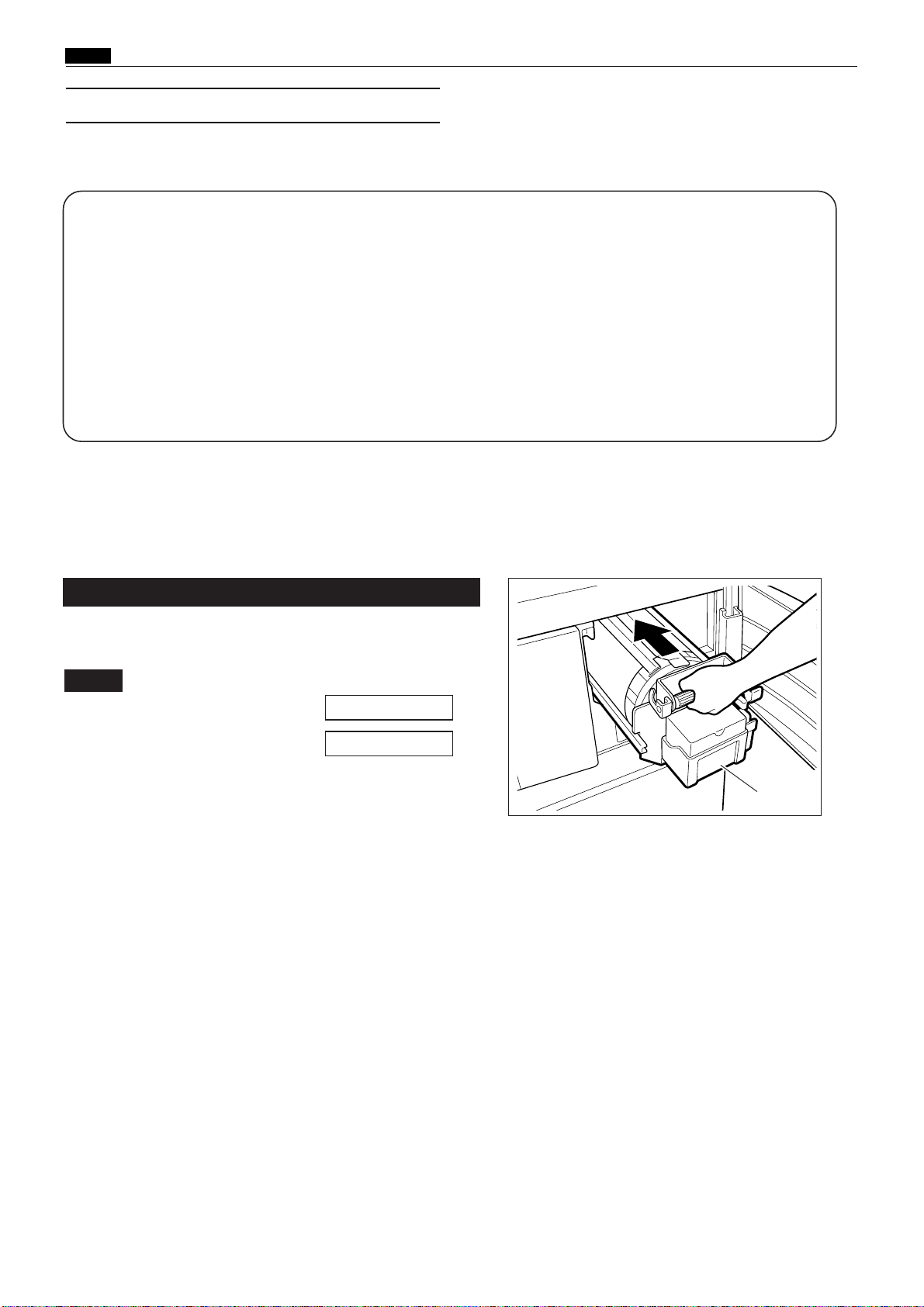

(1) Replacing the Ink Pack

IMPORTANT

•Only use ink packs designed for this machine.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Chap.1 ⁄0 Error Messages and Corrective Action

Open the front cover.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Grasp the lever and pull it toward you.

Front cover

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Lift out the empty ink pack.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Remove the cap from a new ink pack.

IMPORTANT

•Do not leave an ink pack uncapped for longer

than necessary.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

41

Page 41

Chap.1 ⁄0 Error Messages and Corrective Action

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Insert the ink pack so that the groove on the lip

fits onto the “U” groove of the holder.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Push the ink pack in to the set line on the ink

pack.

Set line

Set line

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the back of the holder in with the palm of

your hand.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Close the front cover.

Front cover

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

42

Page 42

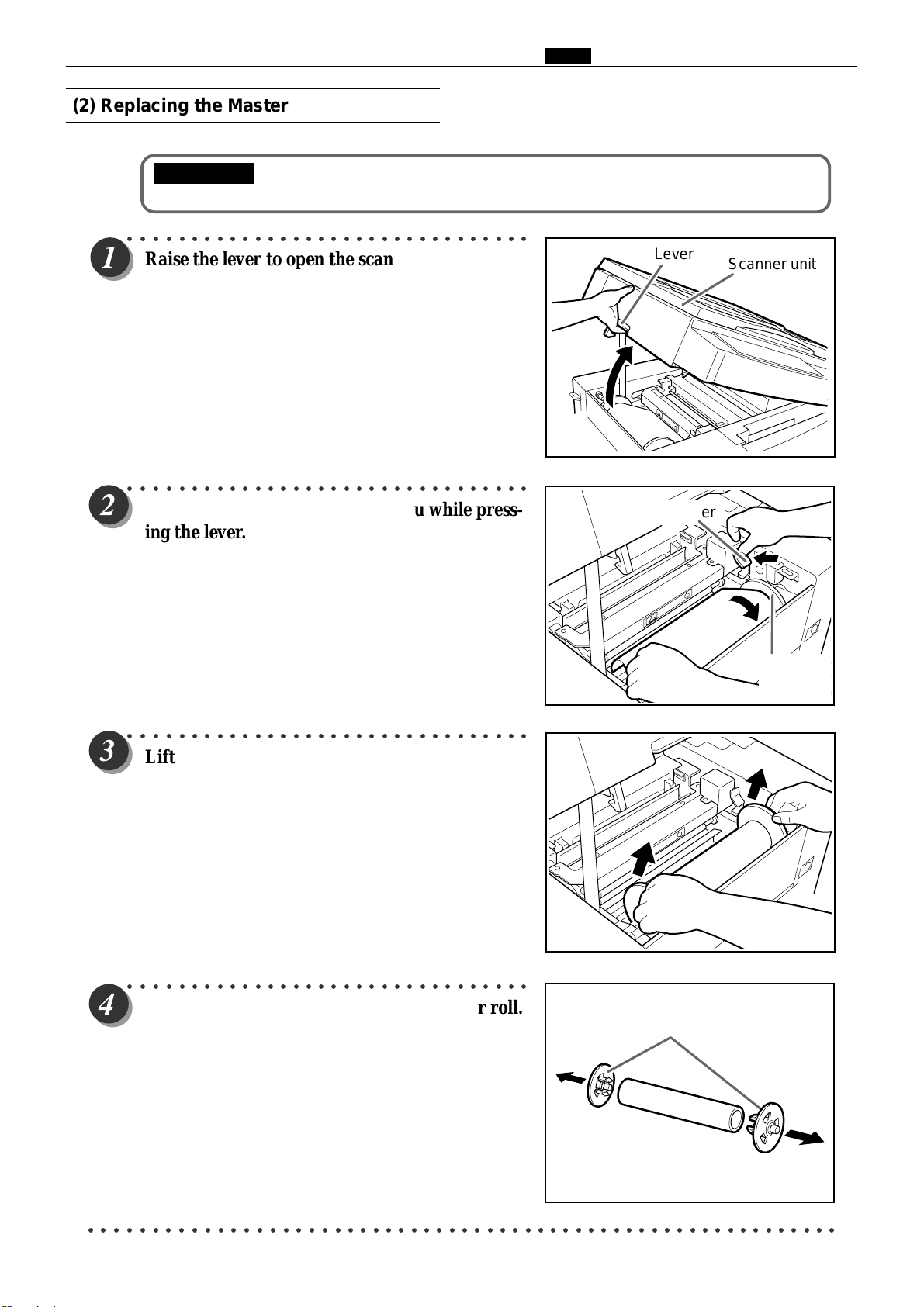

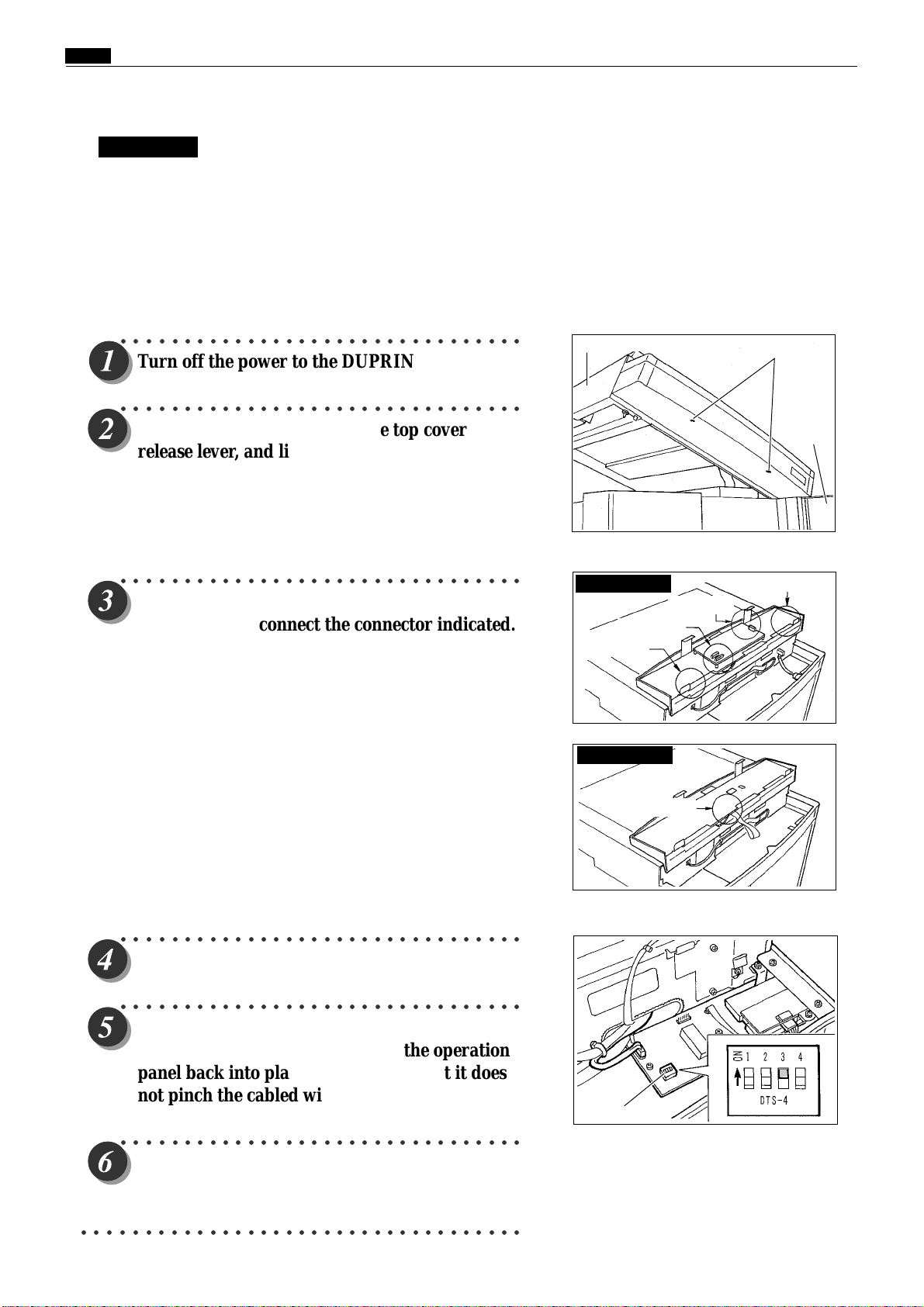

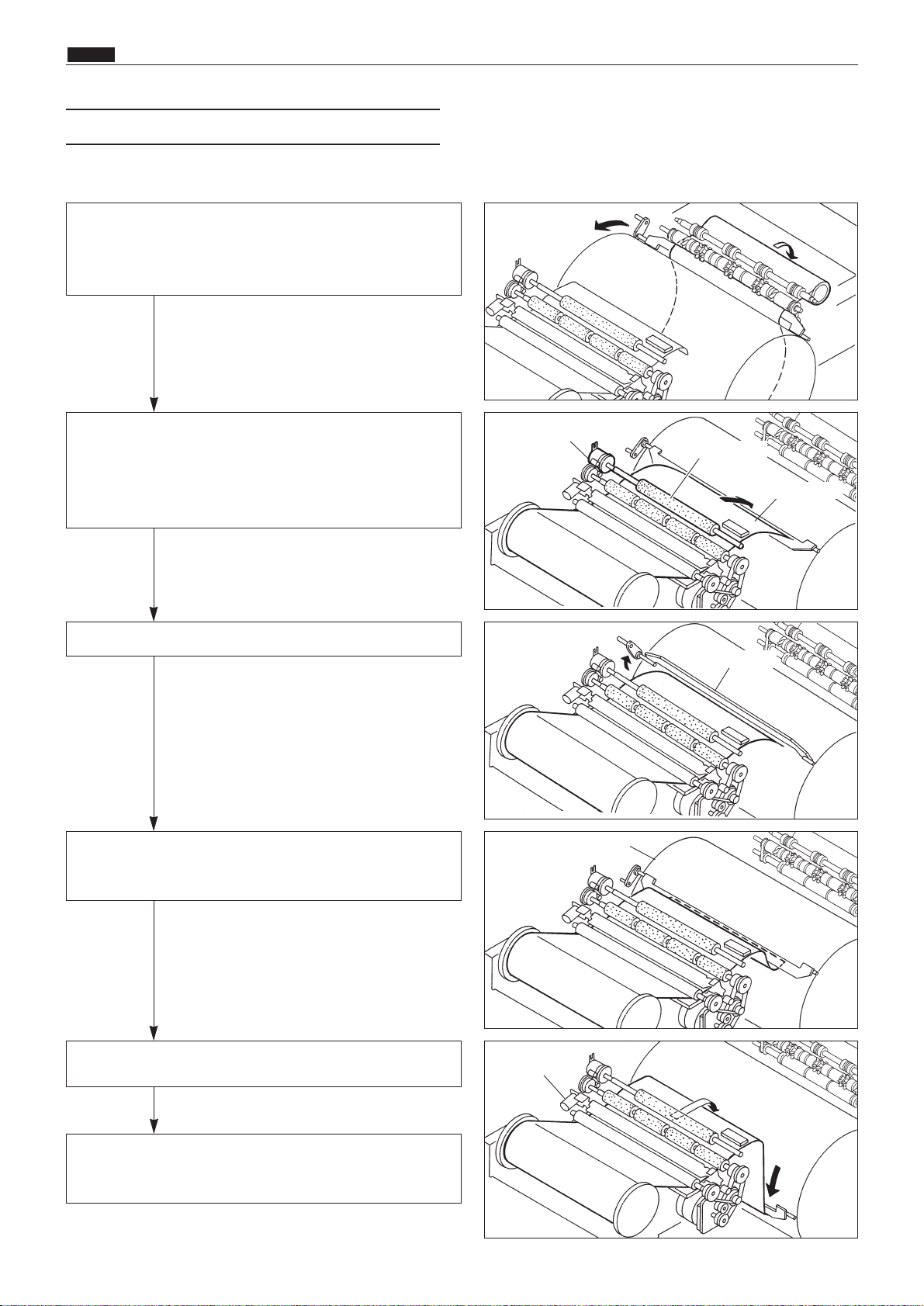

(2) Replacing the Master Roll

IMPORTANT

•Only use a master roll designed for use in this machine.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Raise the lever to open the scanner unit.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Chap.1 ⁄0 Error Messages and Corrective Action

Lever

Scanner unit

Turn the master holder toward you while pressing the lever.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Lift out the master roll.

Lever

Master

Holder

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Remove the master holder from the master roll.

Holder

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

43

Page 43

Chap.1 ⁄0 Error Messages and Corrective Action

Green line

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

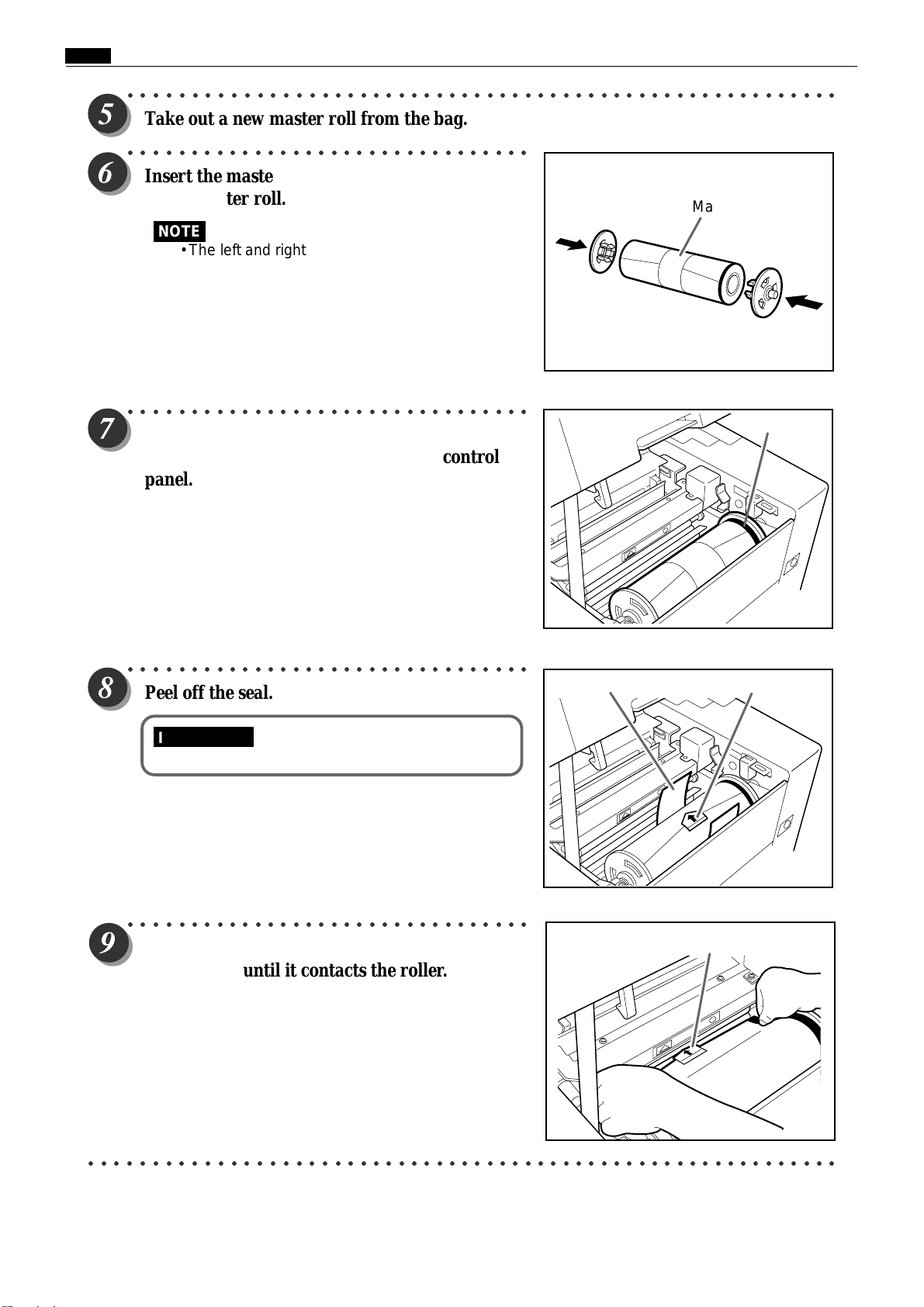

Take out a new master roll from the bag.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Insert the master holder deeply into both ends

of the master roll.

NOTE

• The left and right holders are identical.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Insert the master roll into the machine so that

the green line on the roll is facing the control

panel.

Master roll

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Peel off the seal.

IMPORTANT

•Do not peel off the yellow label.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Pull out the master and insert the arrow on the

yellow label until it contacts the roller.

Yellow labelSeal

Yellow label

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

44

Page 44

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the master set switch.

The master is pulled in and automatically cut.

IMPORTANT

• If the master is not pulled in, press the yellow

label lightly toward the back.

• If the master is not installed correctly, it will

not be cut. Remove the master and reinstall it.

• If the master is wrinkled, press the lever in

step 2 two or three times while pressing and

holding the master set switch.

• When there are no more wrinkles in the

master, release your finger from the master

set switch.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Remove the trimmed piece of the master.

IMPORTANT

• Do not forget to remove the cut end of the

master. Leaving cut master scraps in the

machine may result in machine trouble.

Chap.1 ⁄0 Error Messages and Corrective Action

Master set switch

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Gently close the scanner unit and press it down

until it locks.

WARNING

• Do not remove the cover with Warning

Label 1.

• You may be injured by the movable cutter

inside the machine.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

45

Page 45

Chap.1 ⁄0 Error Messages and Corrective Action

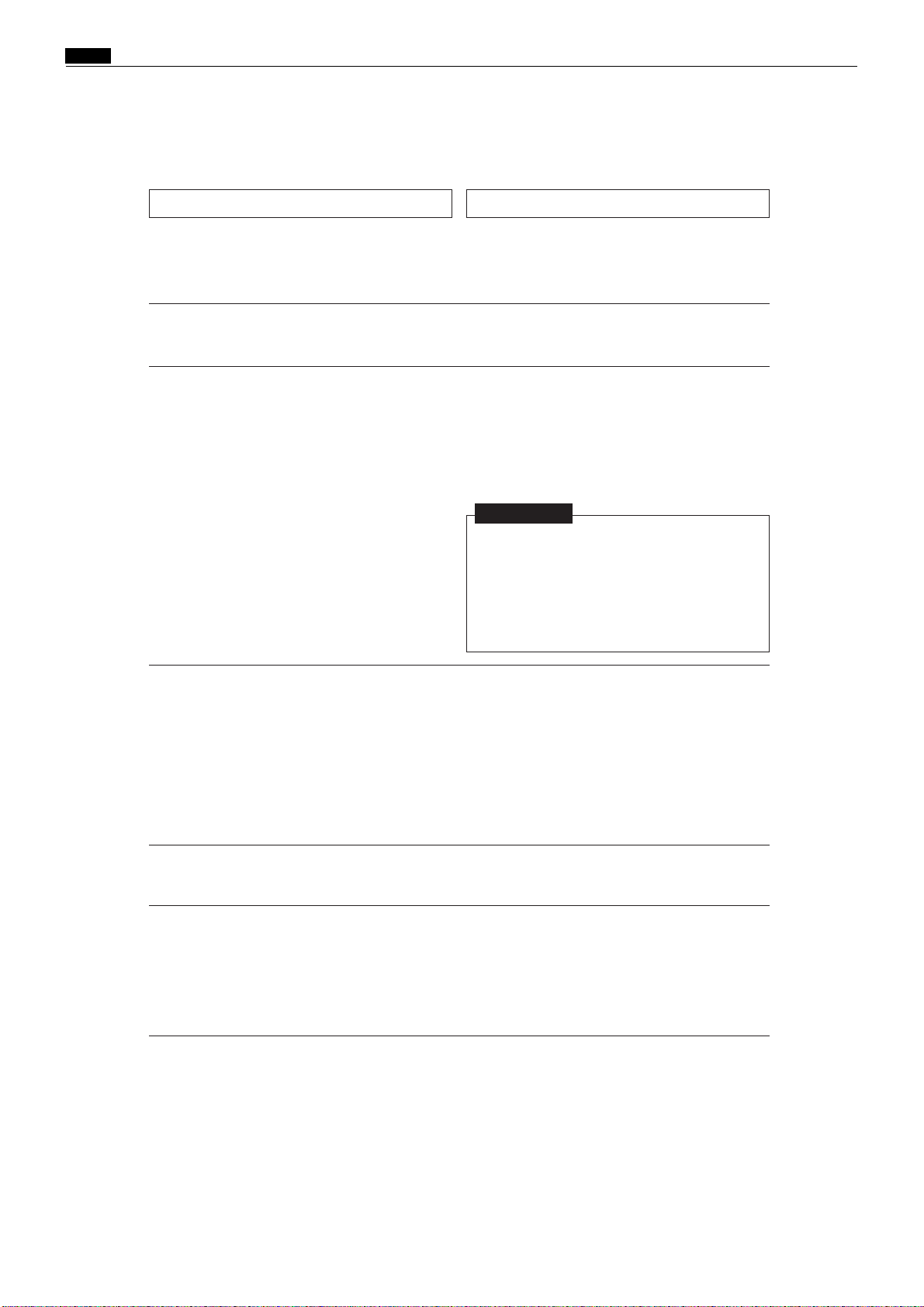

(3) Replacing the Master Ejection Core

IMPORTANT

• Use only a master ejection core designed for use in this machine.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the lever to open the master ejection box.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Open the master ejection box until it stops.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Open the cover while pressing and holding the

release lever.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Holding the edges of the master ejection core,

pull out the core and discard it.

IMPORTANT

• Ink adheres to the master ejection core. Take

care to prevent ink from getting onto your

clothing.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

46

Page 46

Chap.1 ⁄0 Error Messages and Corrective Action

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

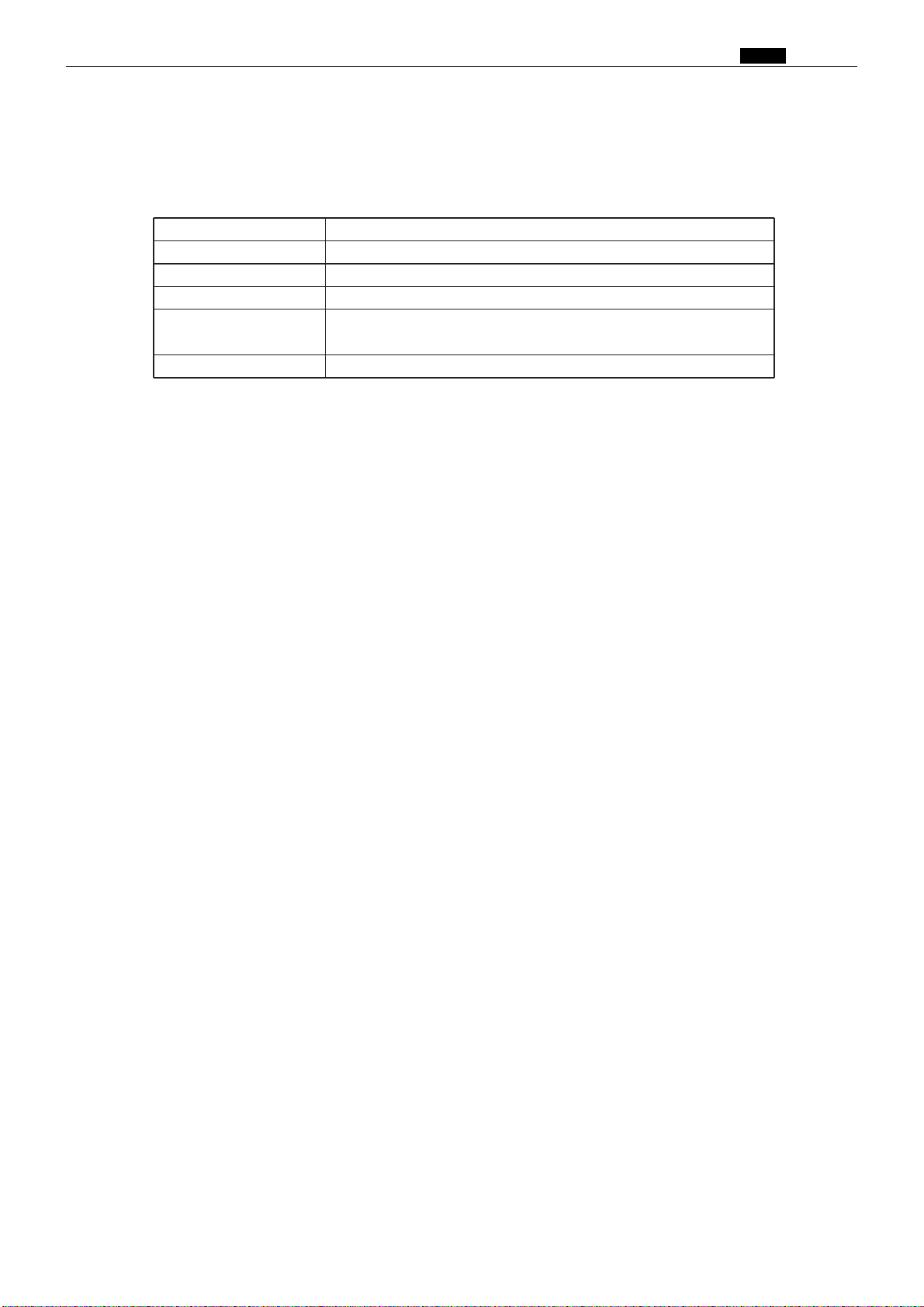

Insert a new master ejection core.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Gently close the master ejection box cover,

pressing it until it locks.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Close the master ejection box, pressing it until it

locks.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

47

Page 47

Chap.1 ⁄0 Error Messages and Corrective Action

(4) Supplying Paper

Supplying Paper

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Open the supplemental paper tray if it is closed.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Paper guides

Raise the paper guide lock lever to manually

move the paper guides.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Set the paper guides to the size of the paper to be used.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Load a stack of aligned sheets between the

paper guides and press the stack lightly toward

the machine.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Lower the paper guide lock lever to lock the

paper guides in place.

48

Page 48

Changing Paper Selection

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press (STOP) key.

Printing stops.

Chap.1 ⁄0 Error Messages and Corrective Action

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the paper tray descend switch

continuously. Release the switch when the paper

tray is at the proper height.

The paper tray will stop.

.

IMPORTANT

• If the sheet is still in the paper feed roller, pull it

out and align it with the stack.

Paper tray descending switch

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Remove paper from the paper tray.

The paper tray will automatically descend.

49

Page 49

Chap.1 ⁄0 Error Messages and Corrective Action

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Load paper.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

a a

a See page 48

a a

T

Press (PRINT) key.

Printing resumes.

NOTE

•When you press (PLATEMAKING) key,

“PRINTING” is displayed on the LCD panel.

•When you press (STOP) key, printing stops.

If Paper Runs Out During Printing

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

If paper runs out during printing, printing stops and the paper tray is Lowered

automatically.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

a a

a See page 48

a a

Adding Paper While Printing

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press (STOP) key.

Printing stops.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the paper tray descend switch

continuously. Release the switch when the paper

tray reaches the proper height.

The paper tray will stop.

Paper tray descending switch

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

50

Page 50

(5) Replacing the Drum Unit

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press and hold the JOG switch until the drum

comes to a stop with a beep.

WARNING

•Do not touch the drum or rollers when you

operate the JOG switch.

•Do not put your hands or fingers inside the

machine while it is operating. Your hands

may be pulled in or nipped.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Open the front cover toward you.

Chap.1 ⁄0 Error Messages and Corrective Action

JOG switch

(Drum rotator switch)

Front cover

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Lift the drum securing lever toward you and,

holding it there, then pull out the drum handle

straight toward you until it stops.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Hold the handle on the far end of the drum, and

lift the front end of the drum slightly to pull the

drum toward you.

IMPORTANT

•Do not touch the drum surface. Ink may

transfer to your clothes.

•Hold the drum level and place it on a flat,

solid surface.

LeverDrum handle

Handle far end of

drum

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

51

Page 51

Chap.1 ⁄0 Error Messages and Corrective Action

Installing the Drum Unit

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Hold the drum level and place the drum guide

roller onto the rail in the machine.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Release the handle at the far end of the drum

and press the drum in about 10cm while lifting

up the front end slightly.

Roller

Rail

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Hold the drum level and press it in gently until it comes to a stop.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Lift the drum securing lever toward you while

Lever

pressing the drum in.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Lower the lever.

Lever

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Close the front cover.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

52

Page 52

(6) Paper Jam (Feeder Side)

If the message "PAPER JAM ON THE FEEDER SIDE" is

indicated in the error display panel, check the feeder side and

remove the jammed paper by following the procedure below.

Chap.1 ⁄0 Error Messages and Corrective Action

PAPER JAM ON THE FEEDER SIDE

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the paper tray descending switch to lower

the paper tray slightly.

The paper tray is lowered for the time that the

switch is pressed.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Pull out the jammed paper as shown in the

diagram.

Paper tray descending switch

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press and hold the JOG switch until the drum

comes to a stop with a beep.

WARNING

•Do not touch the drum or rollers when you

operate the JOG switch.

•Do not put your hands or fingers inside the

machine while it is operating. Your hands

may be pulled in or nipped.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

JOG switch

(Drum rotator switch)

53

Page 53

Chap.1 ⁄0 Error Messages and Corrective Action

(7) Paper Jam (Ejection Side)

If the message "PAPER JAM ON THE EJECTION SIDE" is

indicated in the error display panel, check the ejection side and

remove the jammed paper by following the procedure below.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the lever to open the master ejection box.

PAPER JAM ON THE EJECTION SIDE

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Open the master ejection box until it stops.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Remove the jammed paper.

Press the JOG switch to eject the partially printed paper.

WARNING

•Do not touch the drum or rollers when you

operate the JOG switch.

•Do not put your hands or fingers inside the

machine while it is operating. Your hands

may be pulled in or nipped.

JOG switch

(Drum rotator switch)

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Close the master ejection box, pressing it until it

locks.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

54

Page 54

Paper Adhering to Drum

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the lever to open the master ejection box.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Open the master ejection box until it stops.

Chap.1 ⁄0 Error Messages and Corrective Action

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the JOG switch to find the edge of the

paper, then stop the drum at the position shown

in the diagram.

WARNING

•Do not touch the drum or rollers when you

operate the JOG switch.

•Do not put your hands inside the machine

while it is operating. Your hands may be

pulled in or nipped.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Peel off the edge of the paper from the drum.

Paper edge

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

55

Page 55

Chap.1 ⁄0 Error Messages and Corrective Action

J

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Pull the paper toward the ejection side while

pressing the JOG switch to peel the paper off.

IMPORTANT

•Make sure that the peeled paper does not

stick to your clothing.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Hold the JOG switch down until the drum

comes to a stop with a beep.

OG switch

(Drum rotator switch)

JOG switch

(Drum rotator switch)

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Close the master ejection box, pressing it until it

locks.

JOG switch

(Drum rotator switch)

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Make another plate.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

56

Page 56

(8) Master is Not Ejected

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

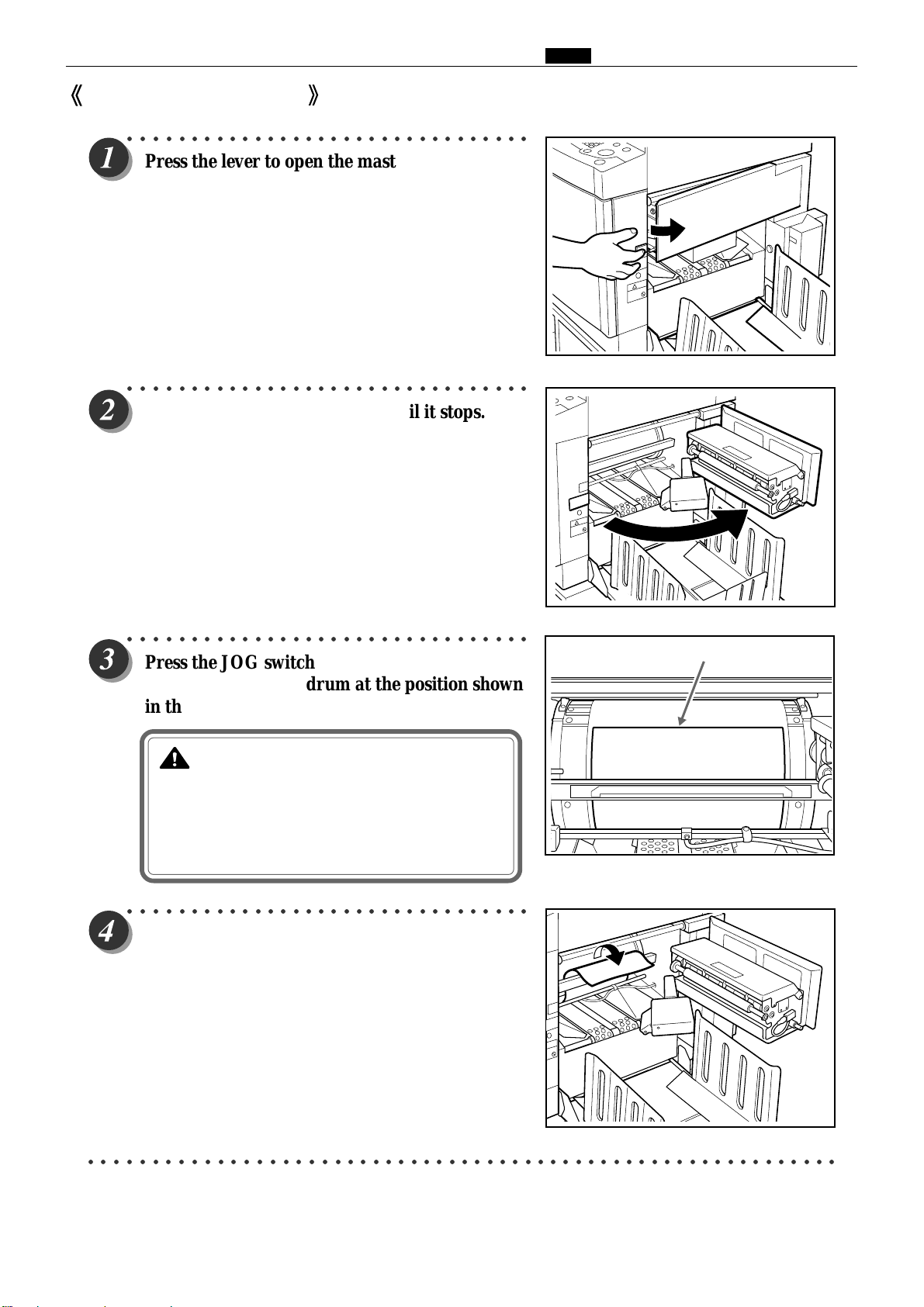

Press the lever to open the master ejection box.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Open the master ejection box until it stops.

Chap.1 ⁄0 Error Messages and Corrective Action

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the JOG switch to find the edge of the

paper, then stop the drum at the position shown

in the diagram.

WARNING

•Do not touch the drum or rollers when you

operate the JOG switch.

•Do not put your hands inside the machine

while it is operating. Your hands may be

pulled in or nipped.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Lift the lever toward you.

The master clump opens and the edge of the master will be

released from the clump. If the master is stuck, release it

manually.

Master clump

Master clamp

Master

Lever

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

57

Page 57

Chap.1 ⁄0 Error Messages and Corrective Action

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Return the lever.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Pull the front end of the master toward you and

press the JOG switch intermittently.

Hold the switch down until the master peels off.

IMPORTANT

•Discard the old master, making sure that it

does not touch your clothing.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Hold the JOG switch down until the drum comes to a stop with a beep.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Close the master ejection box, pressing it until it

locks.

JOG switch

(Drum rotator switch)

JOG switch

(Drum rotator switch)

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press (STOP) key.

The message is deleted.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Make another plate.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

58

Page 58

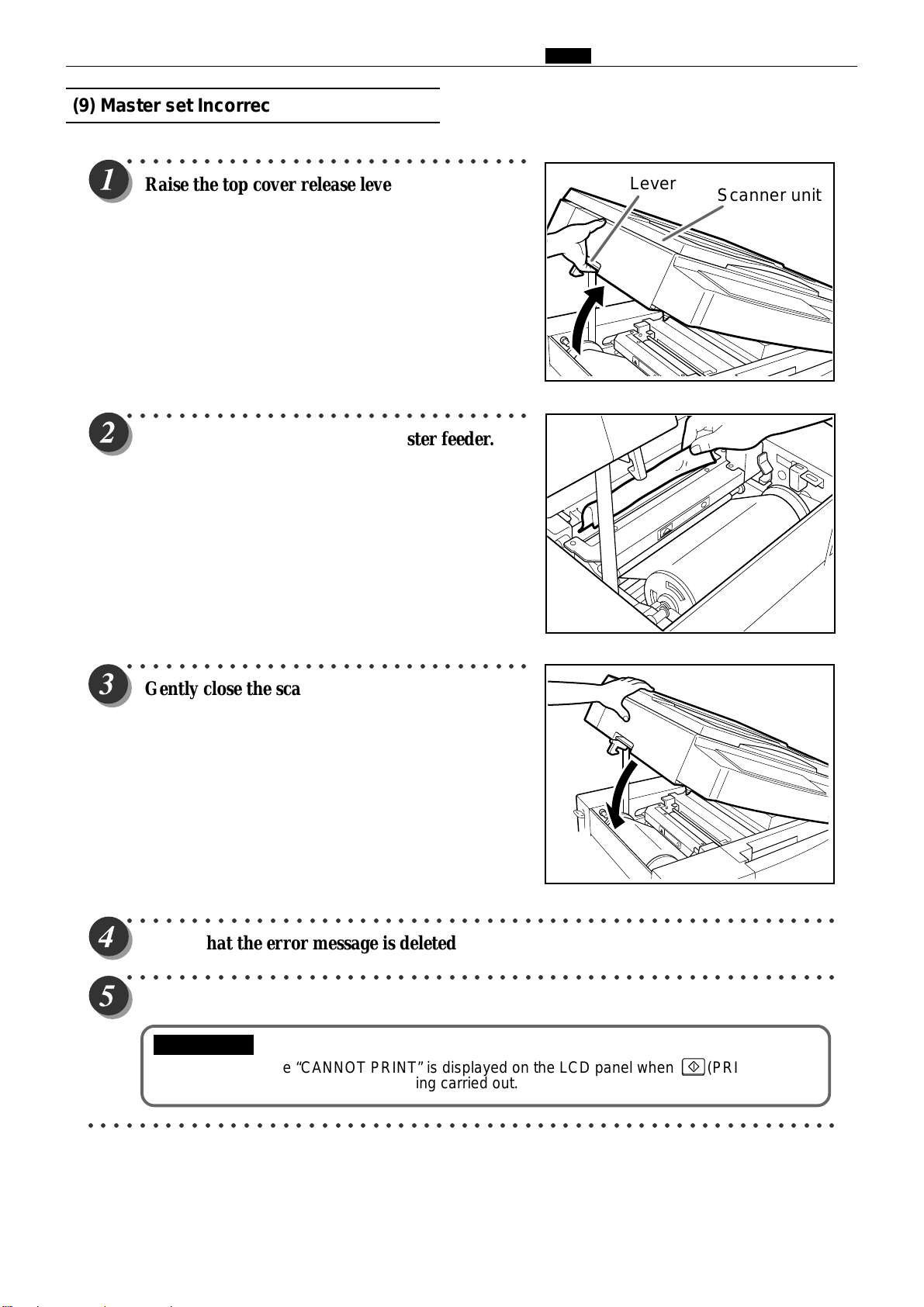

(9) Master set Incorrectly

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Chap.1 ⁄0 Error Messages and Corrective Action

Raise the top cover release lever to open the

scanner unit.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Remove the master left in the master feeder.

Lever

Scanner unit

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Gently close the scanner unit and press it until

it locks.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Check that the error message is deleted.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Make a new plate and start printing.

IMPORTANT

•The message “CANNOT PRINT” is displayed on the LCD panel when (PRINT) key is

pressed without platemaking being carried out.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

59

Page 59

Chap.1 ⁄0 Error Messages and Corrective Action

⁄1Option

1. DUPRINTER Option

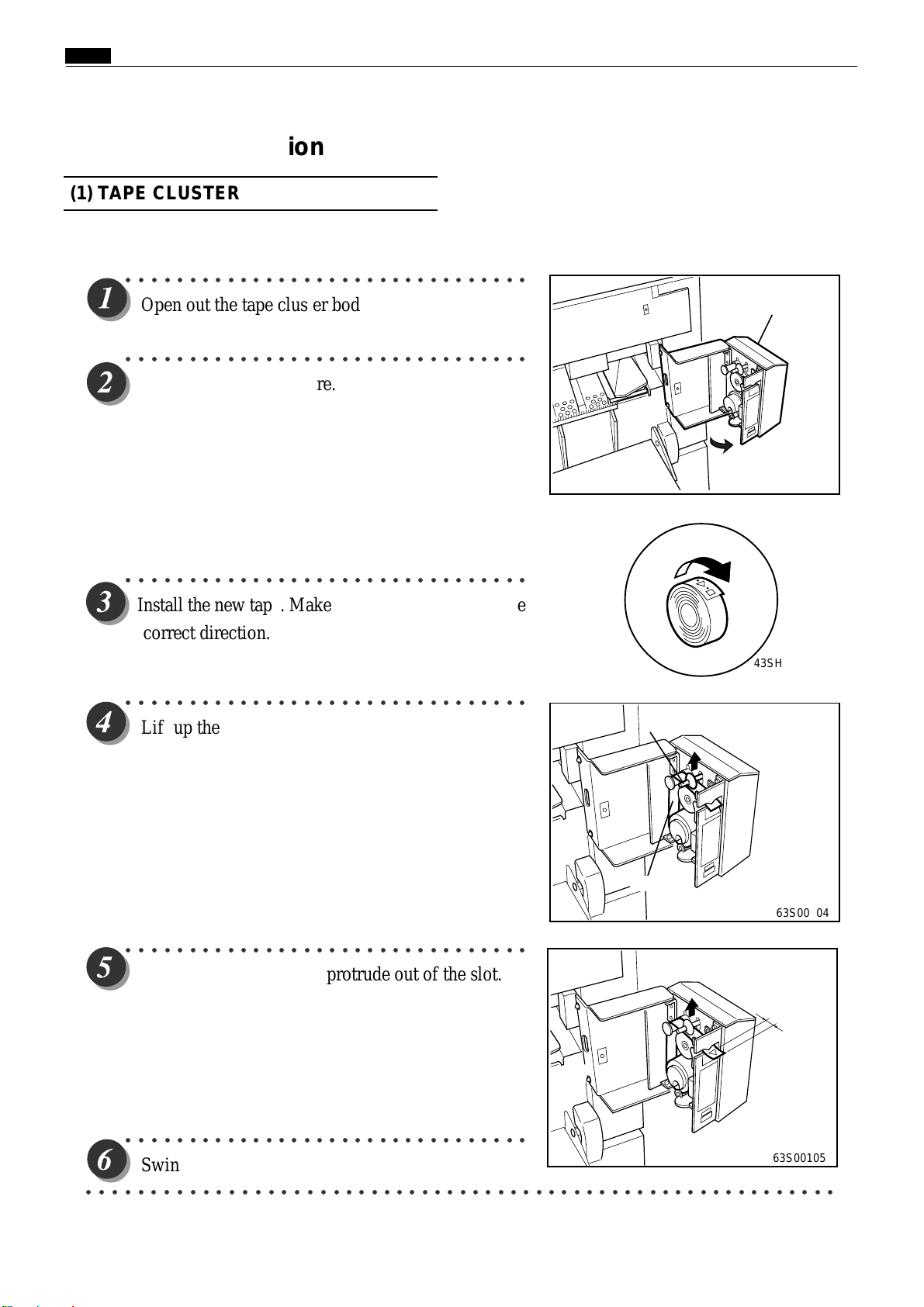

(1) TAPE CLUSTER

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Open out the tape cluster body.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Remove the old tape core.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Install the new tape. Make sure it will wind of f in the

correct direction.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Lift up the lever and pass the tape through the slot.

Tape cluster body

63S00103

43SH0104

Lever

Tape

63S00104

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Make about 1cm of tape protrude out of the slot.

BB

1

B

BB