Duplo Duprinter DP-203, Duprinter DP-205, Duprinter DP-205A, Duprinter DP-203A Instruction Manual

Page 1

For this machine to be used safely, it MUST be

operated correctly and serviced regularly. Therefore,

read this Instruction manual thoroughly before using

the machine.

Keep this manual in a safe place where it can be consulted at any time.

DUPLO CORPORATION

DUPRINTER

DP-203 /203A ,DP-205 /205A

Instruction Manual

Ver.1

Page 2

Complies with the provisions defined by the regulations listed below.

EC Low Voltage Directive ( 73 / 23 / EEC )

EC Electromagnetic Compatibility Directive ( 89 / 336 / EEC )

Copyright 2004

DUPLO SEIKO CORPORATION

All Rights Reserved

Page 3

- 1 -

Introduction

Thank you for your purchase of the

DUPRINTER DP-203

22

/ 203A22, DP-20522/ 205A

22

.

To ensure safe and efficient prolonged use of this machine, read and thoroughly unders

tand

this manual before using this machine. After using this manual, be sure to keep it in a

place to handy reference.

PLEASE NOTE

In the interest of upgrading our products, specifications and other data given in this

manual are subject to change without notice. If the manual contains anything that you

do not understand, contact the manufacturer for clarification.

Precautions for printing and duplicating

There are restrictions on what you may print on the printer.

Please be aware that there are some printed materials that are illegal

even to possess.

1. Printed matters banned by law

¡¡

Paper money, currency, government bonds and national and local

bonds cannot be duplicated, even if they are stamped with the

"sample" seal.

¡¡

Paper money, currency and bonds, etc. that are valid in foreign

country cannot be duplicated.

¡¡

Unused postage stamps and postcards cannot be duplicated

without governmental consent.

¡¡

Government-issued papers pertaining to stamps, liquor and sales

tax laws cannot be duplicated.

2. Printed matters that need caution

¡¡

Private-issued securities(stocks, bills and checks, etc.), passes and

tickets needs caution in duplicating unless a business is

duplicating them for needed amounts for their business needs.

¡¡

Government-issued passports, public-and private-issued driver`s

licenses, permits, identifications, food stamps, etc. will need

caution in duplicating.

3. Copyrighted materials

Books, music, artwork, prints, maps, diagrams, movies, photography,

etc. are banned from duplicating outside the limits of private home

use and their related non-sale usage.

Page 4

4

. Various functions 24

3

. Platemaking and printing procedure 19

2

. Easy printing 17

Safety Precautions 44

- 2 -

Contents

Making plates of text/photographs ………24

Adjusting the plate darkness ………………24

Changing the printing speed ………………25

Adjusting the printing position ……………25

Setting the enlargement and reduction …26

Setting the document size …………………27

Changing the image quality

in photograph mode………………………28

Entering the number of sets ………………29

Setting the number of copies

for separate documents …………………31

Using a thick or thin paper

(Adjusting the feeder pressure) ………33

When using a thick paper and/

or misfeed occurs …………………………33

When using a thin paper and/or

double feed occurs ………………………33

Confidential safeguard function……………34

To set confidential safeguard function ……34

To clear ………………………………………34

On-Line Print Function

(model :

DP-203A

22

/ 205A

22

only) ……35

Drum unit ……………………………………36

Changing the drum unit ……………………36

Setting the drum unit ………………………37

Tape cluster setting the tape cluster ……39

Setting the paper tray ………………………19

Setting the paper stacker …………………20

Turning the power on ………………………21

Checking the control panel …………………21

Setting the document ………………………22

Pressing the platemaking key ……………22

Entering the number of printed copies……23

Pressing the print key ………………………23

Easy printing …………………………………17

1

. Before using the machine 11

Part names and their functions ……………11

Control panel …………………………………14

Printing process………………………………16

Page 5

6

. Troubleshooting 46

5

. Replacing of consumable 40

- 3 -

Changing the ink pack………………………40

Changing the master roll……………………42

Changing the master ejection core ………45

OK Monitor……………………………………46

Removing a left paper jam

(feed tray side) ……………………………51

Removing a right paper jam

(print tray side) …………………………52

Removing a master(eject error) ……………54

Removing a master(set error)………………56

Removing a jammed document ……………58

Trouble shooting for machine malfunction

…59

2

3

4

5

1

6

7

8

7

. Maintenance and inspection 60

Maintenance …………………………………60 Total counter …………………………………61

8

. Specifications 62

Specifications …………………………………62 Original document/

copy paper specification …………………63

Page 6

- 4 -

Safety Precautions

Various symbols and pictures are used in this manual and on the stickers affixed

to the machine. These symbols and pictures provide warnings and instructions to

prevent danger to you or other personnel, and to prevent damage to office

property. The meanings of these symbols and pictures are explained below.

Indicates a high degree of potential danger. If the warning is

ignored, death or serious injury may result.

Indicates a medium degree of potential danger. If the

caution is ignored, medium injury or damage to property

may result.

WARNING:

CAUTION:

A circle with a line through it indicates a prohibited action. The particular

act prohibited

is indicated by a picture inside the circle. (In the example

shown here, the prohibited act is disassembly.)

A black disc indicates an instruction, or sometimes a prohibited action.

The instruction

itself is indicated by pictorial symbols drawn in white on

the disc. (In the example shown here, the instruction is "Remove the

plug from the outlet.")

About Machine Safety

Examples of pictorial symbols

Page 7

- 5 -

Safety Precautions

WARNING

¡¡

If the machine is used after foreign matter (metal fragments,

water, or other liquid) has gotten inside the machine, fire or

electrical shock can result.

aa

Turn the main unit`s power switch to OFF.

Pull the power plug from the outlet.

Contact the sales distributor (or maintenance service

company).

¡¡

If the machine is used after heat, smoke, strange smell, or other

abnormality is detected, fire or electrical shock can result.

aa

Turn the main unit`s power switch to OFF.

Pull the power plug from the outlet.

Contact the sales distributor (or maintenance service

company).

¡¡

Use only the power cord that is provided among the

accessories.

Insert the power cord plug firmly into the socket, so that

proper electrical contact is effected.

aa

Use of any other power cord could result in imperfect

grounding.

If grounding is imperfect and electrical leakage occurs, fire or

electric shock could result.

Page 8

¡¡

Do not modify the machine.

Fire or electrical shock can result.

¡¡

Do not remove the rear lid, cabinet, or cover from the

machine.

The interior contains high-voltage parts, which can cause

electrical shock.

¡¡

Do not remove or insert the power plug if your hands are wet.

You can get electrically shocked.

¡¡

Do not damage, break, or modify the power cord.

Do not place heavy objects on it, yank it, or unreasonably

bend it.

Fire or electrical shock can result.

- 6 -

WARNING

Page 9

¡¡

Do not insert or drop metal, burnable material, or other matter

through the ventilation holes into the machine interior.

Fire or electrical shock can result.

¡¡

Do not place flower vases, flowerpots, cups, or water

containers (including metal containers) on top of the

machine.

Fire or electrical shock can result if the liquid spills.

¡¡

Do not use a source voltage other than that specified.

Do not connect multiple loads to a single outlet.

Fire or electrical shock can result.

¡¡

Before cleaning, pull the power plug from the outlet.

¡¡

Prevent water and neutral cleansers from getting inside the

machine.

This action prevents not only breakdowns but electrical shock.

Maintenance

aa

Refer to page 60

- 7 -

Safety Precautions

WARNING

Page 10

¡¡

Before moving the machine, pull the power plug from the

outlet.

If the cord is damaged, fire or electrical shock can result.

¡¡

Pull the power plug itself, not the cord.

If you yank the cord, you can damage it (cause exposed

conductor, disconnection, etc.), resulting in fire or electrical

shock.

¡¡

Do not place the machine in an unstable position, such as on

an unsteady support or sloping area.

If the machine drops or falls over, a person could get injured.

¡¡

Do not place the machine in a humid or dusty area.

Fire or electrical shock can result.

- 8 -

WARNING

Page 11

- 9 -

Safety Precautions

1Caution Sticker 1M7-T3060

e

¡¡

Keep the WARNING and CAUTION stickers clean at all times.If stickers become

damaged or come off, replace them with new ones.

J3-T3200

q

Warning

¡Do not remove this cover. The

inside of the printer contains

movable cutting instruments,

contact with which could result

in injury.

w

L5-T3020

Do NOT touch the drum or rollers

when you operate the jog switch.

Do NOT put hands Inside

machine while it is operatung.

Hands could get caught up

or crushed.

WARNING

No. Parts No. Name Q´ty

q

J3-T3200 Warning Sticker 1 1

w

L5-T3020 Warning Sticker 2 1

Locations of warning stickers

e

M7-T3060

CAUTION

Page 12

- 10 -

Introduces instructions for correct operation of the machine.

If these instructions are ignored, the machine my not be able

to operate at optimum performance, or may break down.

Introduces information that is useful for operation and

maintenance of the machine, or information about the

machine’s performance, etc.

IMPORTANT

:

Note

:

Conventions Used in this Manual

Indicates a high degree of potential danger. If the warning is

ignored, death or serious injury may result.

Indicates a medium degree of potential danger. If the

caution is ignored, medium injury or damage to property

may result.

WARNING:

CAUTION:

GUIDE TO THIS MANUAL

Page 13

Before using the machine

1

MACHINE EXTERIORS

DOCUMENT RECEIVING TRAY

DOCUMENT GUIDE

DOCUMENT TRAY

SUPPORT TRAY

SUPPORT TRAY

CONTROL PANEL

FRONT COVER

INK PACK HOLDER RELEASE LEVER

DRUM HANDLE

FRONT COVER

DRUM UNIT

INK PACK

DRUM SECURING LEVER

POWER SWITCH

SUPPORT TRAY

DOCUMENT

TRAY

PAPER TRAY

ADF

¡¡

This lever is lock or unlocks the drum

in stopping the drum position.

- 11 -

Parts Names and Their Function

1. Before using the machine

Page 14

DOCUMENT RECEIVING TRAY

THERMAL HEAD ESCAPE LEVER

ROLL MASTER

MASTER HOLDER

FEED PRESSURE LEVER

PAPER TRAY

PAPER GUIDE

GUIDE LOCK SCREW

PAPER SET LEVER

PAPER FEED ROLLER

MASTER SET SWITCH

- 12 -

Page 15

Before using the machine

1

JOG SWITCH

PAPER STRIPPER FINGER

MASTER EJECTION CORE

DOCUMENT TRAY

MASTER EJECTION BOX

PAPER STACKER GUIDE

PAPER RECEIVING TRAY

MASTER EJECTION BOX

LID RELEASE LEVER

MASTER EJECTION BOX

RELEASE LEVER

PAPER EJECTION ROLLER

JUMP PLATE

PAPER STOPPER

- 13 -

Page 16

- 14 -

CONTROL PANEL

No. Components Functions

q

“

PLATE MAKING " key Starts plate making.

w

“

PRINT " key

Starts printing.This will not start plate making.When the tape cluster

have been installed,plate making will start automatically after end of

printing if the document is placed on the ADF.

e

“

TEST PRINT " key Prints one copy.This is used to check the image position and contrast.

r

“

STOP " key

Stops printing.If this key is pressed while the machine is stopped,the

number of copies and plates will be displayed.

t

“

ALL CLEAR " key

Returns the control panel settings back to the standard mode.Hold

down for at least 0.5 second.

y

Key pad Used for entering the number of prints.

u

“="

key

Enters the number of prints and number of sets.To enter the number of

prints per document after a clear,press the =key.

i

“

CLEAR " key Clears the display to “0" .Clears the number of prints only.

o

LCD panel

Displays number of prints and other machine settings.Displays error

messages when error is occurred.

!0

“

SELECT " key Selects magnification and other functions.

!8 !6 @0 o

!0!1!2!3!4!5!7!9

Page 17

- 15 -

Before using the machine

1

No. Components Functions

!1

“

MODE " key Switches between normal mode and function mode.

!2

“

TEXT/PHOTOGRAPH " key

Each press of this key switches between the text mode and photograph mode.

!3

Document mode indicator

lamp

The lamp for the specified document mode lights.

!4

“

PLATE DARKNESS ADJUSTMENT

"

key

The plate darkness is adjusted with this key.

!5

Plate darkness indicator

lamp

The lamp for the specified plate darkness lights.

!6

“

PRINTING SPEED ADJUSTMENT

"

key

The printing speed is adjusted with these keys.

!7

Printing speed indicator

lamp

The lamp for the specified printing speed lights.

!8

“

PRINTING POSITION ADJUSTMENT

"

key

The printing position(vertical) is adjusted with these keys.

!9

Printing position indicator

lamp

The lamp for the specified printing position lights.

@0

OK Monitor Indicates errors,LED to indicate the machine area.

ye q

rwtui

Page 18

- 16 -

"Printing"

In the "printing" process, the paper which is separated from the stack by the paper feed roller

and the paper separator unit are pressed to the drum by the pressure roller. There are small

holes in the image area of the master that is attached to the drum and ink that seeps from the

hole is transferred to the paper. The paper is separated from the drum unit by the stripper

finger. The paper is delivered to the paper receiving tray.

Printing Process

The DUPRINTER goes through a process of"platemaking" and "printing".

"Platemaking"

In the "platemaking" process, the old master on the drum is removed while the thermal head

creates the scanned image on new master and loads it on the drum.

DRUM

UNIT

ROLL MASTER

THERMAL HEAD

PAPER FEED ROLLER

PAPER

INK

DRUM UNIT

PAPER SEPARATOR UNIT

PRESSURE ROLLER

PAPER EJECTION ROLLER

PAPER STRIPPER FINGER

PAPER RECEIVING TRAY

MASTER EJECTION

BOX

Page 19

- 17 -

Easy Printing

1

2. Easy Printing

Preparation

Platemaking

Printing

Open the paper tray, set the paper,

and adjust the paper guide. (See page 19.)

1

Open the paper receiving tray; then adjust the paper stacker

guide, paper stopper, and jump plate. (See page 20.)

2

Turn on the power; then check the indication on the control

panel. (See page 21.)

3

Set the original document face down in the ADF; then adjust

the document guide. (See page 22.)

4

Press the PLATE MAKING key. One test-print will be

produced. (See page 22.)

5

Check the finished product. (See page 22.)

6

Enter the number of printed copies. (See page 23.)

7

Press the PRINT key. The number of copies entered will

be printed. (See page 23.)

8

2

Page 20

- 18 -

MEMO

Page 21

- 19 -

Platemaking and printing procedure

3

3. Platemaking and printing procedure

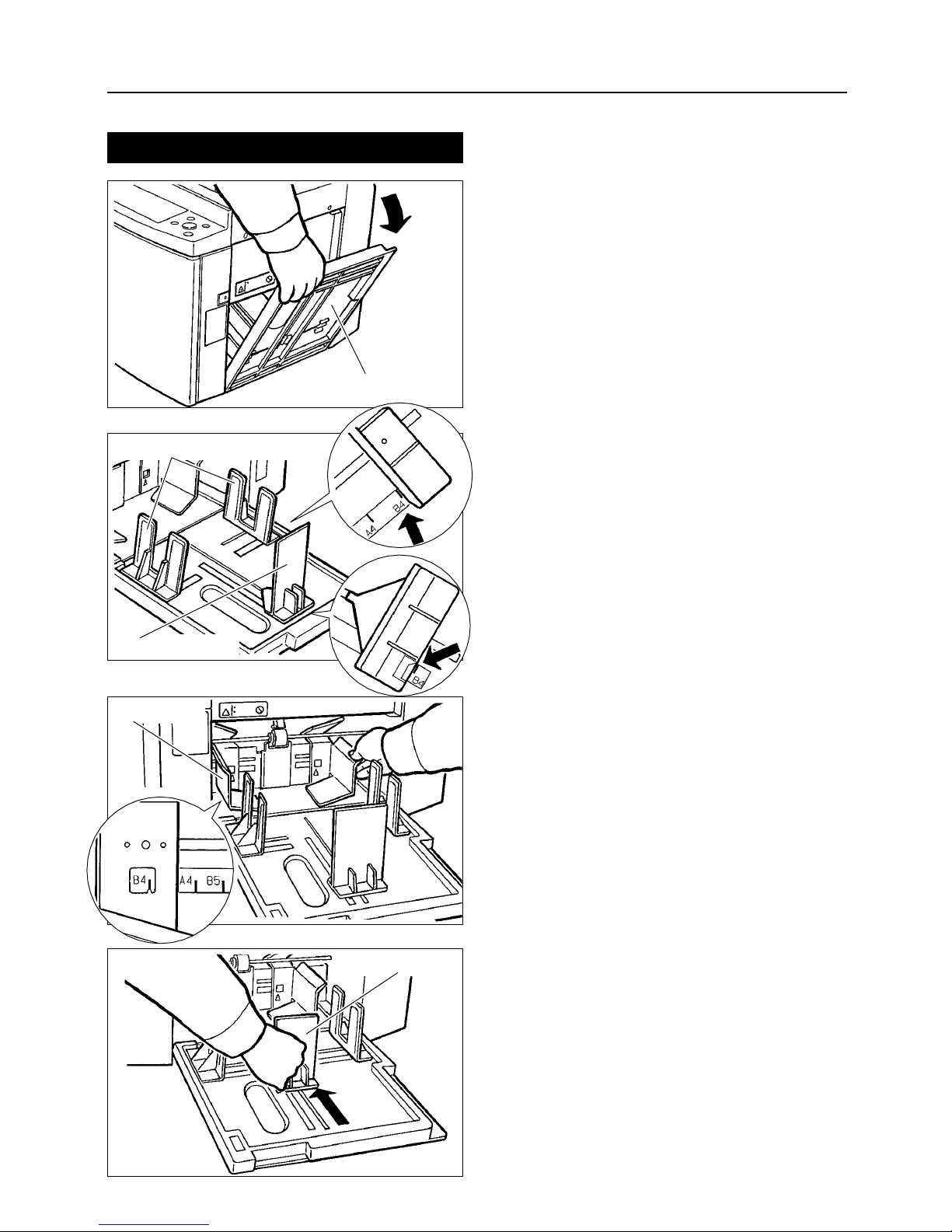

Setting the Paper Tray

Open the paper tray toward you Open

the paper tray toward you.

1

Lower the paper set lever.

2

Place the paper in the tray, and adjust

the paper guide to the width of the

paper.

3

Raise the paper set lever.

4

PAPER TRAY

PAPER SET LEVER

PAPER

PAPER SET LEVER

PAPER GUIDE

Page 22

- 20 -

Open the paper receiving tray.

1

Adjust the paper stacker guide and

paper stopper to the paper size marking.

2

Adjust the jump plate to the paper size

marking.

3

¡¡

After using the machine, push the paper

stopper inward as far as it will go, and

close the paper receiving tray back up.

Turning on the Power

Setting the Paper Stacker

PAPER RECEIVING

TRAY

PAPER STACKER GUIDE

PAPER STOPPER

JUMP PLATE

PAPER STOPPER

Page 23

- 21 -

Platemaking and printing procedure

3

Turning the power on

Turn the power switch to ON. The

power switch is ON when " I ", and OFF

when " K ".

1

Checking the Control Panel

Check the control panel. When the

power is ON, the control panel displays

the initial settings.

Magnification,

document

, and

plate darkness

can be changed as

needed.

¡¡

When the magnification is 100%, no

indication will appear on the liquid crystal

display (LCD).

¡¡

When the number of copies is set at 0, the

LCD will not indicate "0."

Note

:

1

POWER SWITCH

0sht 1set

ON OFF

Page 24

- 22 -

Setting the Document

Adjust the document guide to the size of

the document; then set the document

face down.

¡¡

Up to 10 original documents can be set at

one time.

¡¡

Set the DOCUMENT SIZE.

(See page 62 and 63.)

Note

:

2

Pressing the Platemaking Key

Press the

PLATE MAKING

key. The

document will be automatically

forwarded and platemaking will begin.

When platemaking is finished, one test

print will be produced.

Check the finished product. Check the

registration and copy quality.

1

2

¡¡

If the following settings are changed, return the document to the original position and make the plate again.

Magnification

a

100%, 94%, 86%, 81%, 70%, 115%, 122%, 141%

(A/B size specifications)

100%, 94%, 77%, 74%, 64%, 121%, 129%, 141%

(Inch size specifications)

Document mode

a

Text / Photograph

Plate darkness

a

Auto / Darker / Lighter

Photo mode

a

Dark / Soft

AUTO

S

¡¡

Magnification See page

26

¡¡

Document mode See page

24

¡¡

Plate darkness See page

24

¡¡

Photo mode See page

28

Open the support tray.

1

SUPPORT TRAY

Page 25

- 23 -

Platemaking and printing procedure

3

0sht 1set

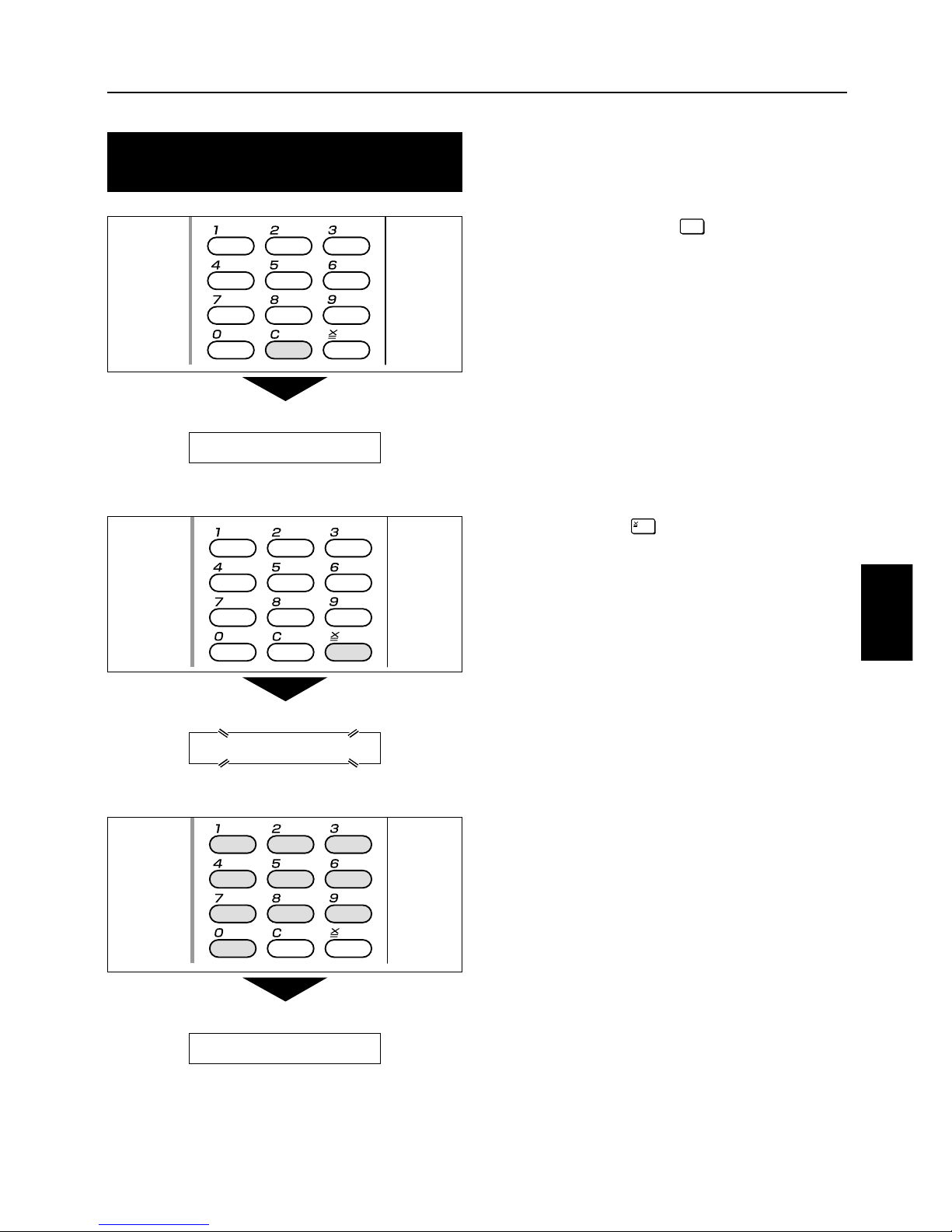

Entering the Number of Printed Copies

Using the number keys, enter the

number of copies you want to print.

1

Example:If you enter 1, 2, 3, and 4, the LCD

will look like this:

a

To enter numbers of sets : See page 29.

a

To enter numbers of copies for separate

documents : See page 31.

Pressing the Print Key

Press the

PRINT

key. When the

entered number of copies has been

printed, the machine will stop.

¡¡

When the following documents are in the

ADF, platemaking / printing will be

automatically executed.

Note

:

1

KEY PAD

1234sht 1set

Page 26

- 24 -

4. Various functions

Press the

DOCUMENT

key; then select

TEXT

or

PHOTOGRAPH .

: TEXT

TEXT

is appropriate for documents

containing characters only, and for blackand-white photograph documents that have

undergone dot processing.

: PHOTOGRAPH

PHOTOGRAPH

is appropriate for photograph

documents and color documents.

¡¡

You can change the image quality of

photograph mode. (See page 28.)

Note

:

S

S

Making Plates of Text / Photographs

Adjusting the Plate Darkness

There are three plate darkness settings; you

may select the desired darkness.

: STANDARD

Reads the darkness of the document, and

automatically makes plates with the optimal

darkness.

: DARKER

Makes plates darker.

: LIGHTER

Makes plates lighter.

STD

Page 27

- 25 -

Various functions

4

Changing the Printing Speed

Press or for print speeds.

FASTER : 120shts/min

STANDARD : 80shts/min

SLOWER : 60shts/min

Adjusting the Printing Position

Press or of the

PRINTING POSITION

key.

Print image moves up.

Print image moves down.

¡¡

Adjustments of up to approximately

20mm (from top to bottom) can be made.

¡¡

The lamp changes one position when a

shift of about 3mm is made.

Note

:

Page 28

- 26 -

Setting the Enlargement and Reduction

Press the

MODE

key and switch to

the enlargement and reduction selection

display.

1

Press the

SELECT

key; then select

the desired enlargement and reduction.

2

¡¡

Each time you press the key, the display

changes as shown in the figure below.

Magnification Display

A / B size Specifications Inch size Specifications

Press the

MODE

key and return to

the main display. The enlargement and

reduction is shown to the right of the

number of copies.

Example: If you select a reduction of 64%:

3

0sht 1set 64%

Enlargement and Reduction

Main Display

1. ZOOM

1 0 0 %

9 4 %

8 6 %

8 1 %

7 0 %

1 4 1 %

1 2 2 %

1 1 5 %

1 0 0 %

9 4 %

7 7 %

7 4 %

6 4 %

1 4 1 %

1 2 9 %

1 2 1 %

Page 29

- 27 -

Various functions

4

Setting the Document Size

Press the

MODE

key and switch to

the document size selection display.

1

Press the

SELECT

key; then select

the document size.

2

¡¡

Each time you press the key, the display

changes as shown in the figure below.

Document Size Display

Press the

MODE

key and return to

the main display.

3

A / B size Specifications Inch size Specifications

Document Size

2.DOCUMENT SIZE

Main Display

Osht 1set

B 4

A 4

B 5

A 5

P O S T

A 4

B 5

A 5

P O S T

1 0 9 1 4

L G

L T

S T

P O S T

L G

L T

S T

P O S T

DP - 205 / 205A DP - 203

/

203A DP - 205 / 205A DP - 203 / 203A

Page 30

- 28 -

Changing the Image Quality in

Photograph Mode

Photograph Mode Image Quality

Image Quality

3. PHOTO MODE

NORMAL

dd

DARK

dd

SOFT

Press the

MODE

key and switch to

photograph mode (indicated in image

quality selection display).

1

Press the

SELECT

key; then select

the image quality.

2

¡¡

Each time you press the key, the display

changes as shown in the left-hand

figure.

DARK

Darkens the half-tone light areas.

SOFT

Softens the outline`s highlighting.

Press the

MODE

key and return to

the main display.

3

Main Display

Osht 1set

Page 31

- 29 -

Various functions

4

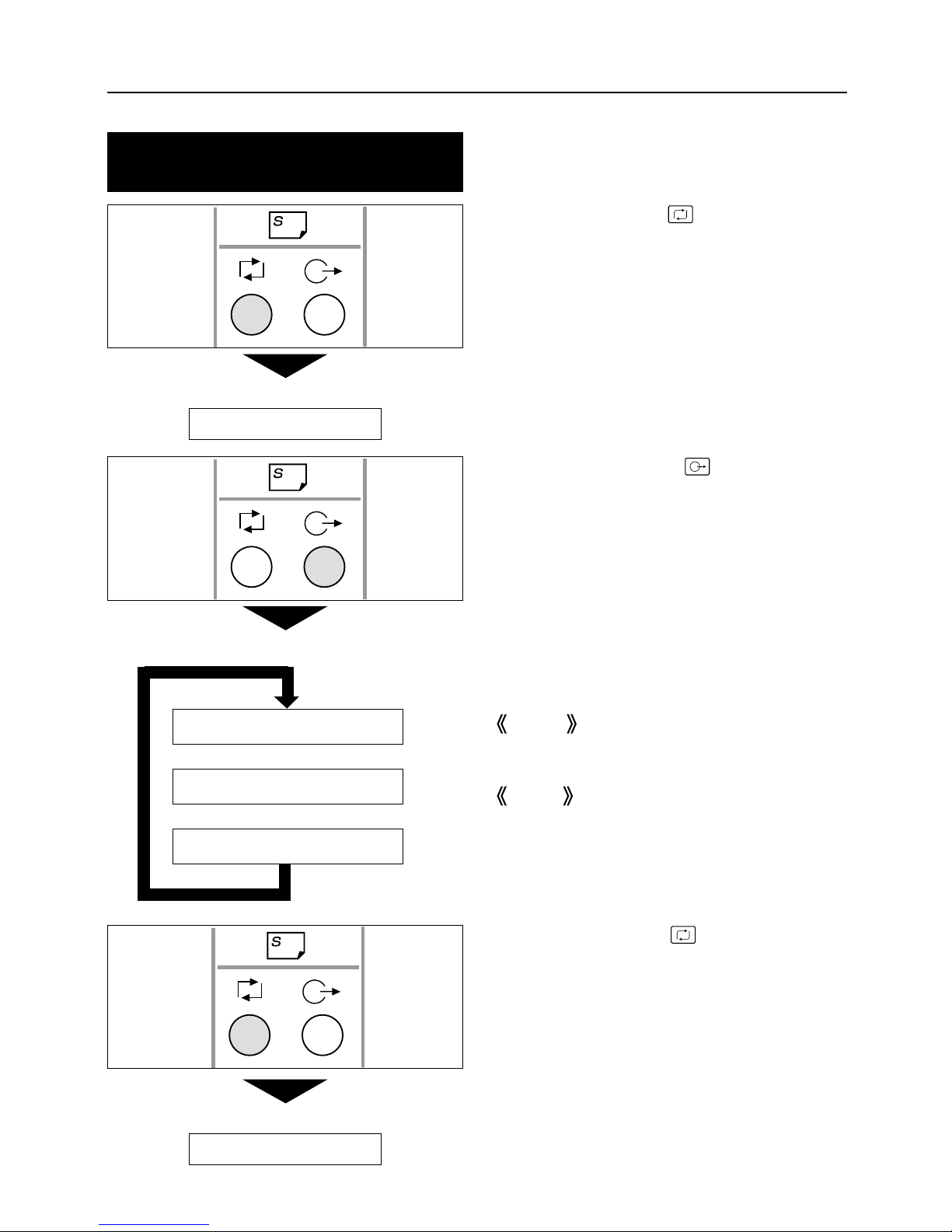

Entering the Number of Sets

Press the

CLEAR

key to clear the

main displayed.

C

1

Using the number keys, enter the

desired number of copies.

2

Press the

=

key.

3

Example: If you enter 1, 2, 3, and 4,

the LCD will look like this:

Main Display

0sht 1set

Main Display

1234sht 1set

Main Display

1234sht 0set

Page 32

- 30 -

Using the number keys, enter the

desired number of sets.

4

Example: If you enter 5, the LCD will

look like this:

Press the

=

key.

5

¡¡

When continuously inputting, repeat steps

2

thru 5.

¡¡

Up to 15 original documents can be entered.

¡¡

Printing stops after one set of copies are finished. Press the PRINT key to

restart printing. (Using the optional tape cluster permits continuous printing.).

¡¡

If two or more documents are set in the ADF,after all copies entered are

printed, platemaking and printing of the next document is automatically

executed.

Main Display

1234sht 5set

Main Display

1234sht 5set

Note

:

Page 33

- 31 -

Various functions

4

0sht 1set

Setting the Number of Copies for

Separate Documents

Press the

CLEAR

key to clear the

main displayed.

C

1

Press the

=

key, and the indication

will flash.

2

Using the number keys, enter the

desired number of copies. Starting from

the document set at the top of the ADF,

enter the number of copies.

3

Example: If you enter 1, 2, 3, and 4,

the LCD will look like this:

Main Display

0sht 1set

Main Display

Main Display

1234sht 1set

Page 34

- 32 -

Press the

=

key.

4

Using the number keys, enter the

desired number of sets.

5

Press the

=

key.

6

Example : If you enter 5, the LCD will

look like this:

Main Display

1234sht 5set

Main Display

1234sht 0set

Main Display

1234sht 5set

¡¡

Repeat steps

2

thru 6(for numbers of original documents only).

¡¡

Up to 15 original documents can be entered.

¡¡

Printing starts from the last group entered.

¡¡

Printing stops after one set`s copies are finished. Press the PRINT key to

restart printing. (Using the optional tape cluster permits continuous printing.)

¡¡

After one document is printed, platemaking and printing of the next document

is automatically executed.

Note

:

Page 35

- 33 -

Various functions

4

Using a thick or thin paper(Adjusting the feeder pressure)

Adjust the feed pressure if you encounter a feeding error with thick or thin paper:

When using a thick paper and / or

Misfeed occurs

Set the feed pressure lever to

"HEAVY PAPER".

When using a thin paper and / or

Double feed occurs

Set the feed pressure lever to

"LIGHT PAPER".

¡¡

After the printing.

Please return the pressure lever to

"NORMAL PAPER"

for the next person.

Note

:

HEAVY

PAPER

NORMAL

PAPER

LIGHT

PAPER

FEED

PRESSURE

Page 36

- 34 -

Confidential safeguard function

By a simple procedure, the Printer can be programmed to confidential documentation.

¡¡

When confidential safeguard is set, printing can not be performed with

PRINT

or

TEST

PRINT

keys.

¡¡

Turning power off will not turn the confidential safeguard off.

¡¡

Even with the confidential safeguard is on, plate making still functions.

Normal operation other than print or test print, can be performed.

¡¡

Once the plate is made, the confidential safeguard will be cleared.

To Set Confidential Safeguard Function

Press and hold the

CLEAR

key, and

press the

STOP

key.

Beep tone will sound when confidential

safeguard is set.

To verify that confidential safeguard is

working. Hit

PRINT

or

TEST PRINT

key and it will not print with confidential

safeguard on.

C

PLS MAKE MASTER

To Clear

Press

PLATEMAKING

key.

Once the plate making is performed, the

confidential safeguard is automatically

turned off.

Page 37

- 35 -

Various functions

4

On-Line Print Function (model : DP-205A

22

only)

Set the size of the printing paper.

aa

See page 27

2

Connect the cable from the computer

into the printer as left figure.

3

Firmly fasten the locks on both sides of

the connector.

5

CONNECTOR

LOCK

¡¡

When platemaking ends and printing

starts,you can again use the keys on the

control panel.

Note

:

¡¡

For details on connection and settings, and refer to the Printer Driver Operation Manual.

IMPORTANT

:

Check that the top menu is displayed.

1

This function allows you to make prints of documents directly from on-line data from personal computers.

Insert the cable from the computer into

the connector on the printer.

4

Use the print command of the computer

applications according to the manual.

Refer to the Printer Driver Operation

Manual about operation.

Platemaking and printing start automatically.

6

CABLE

DUPRINTER

(REAR SIDE)

LOCK

On-line Print Function

Page 38

- 36 -

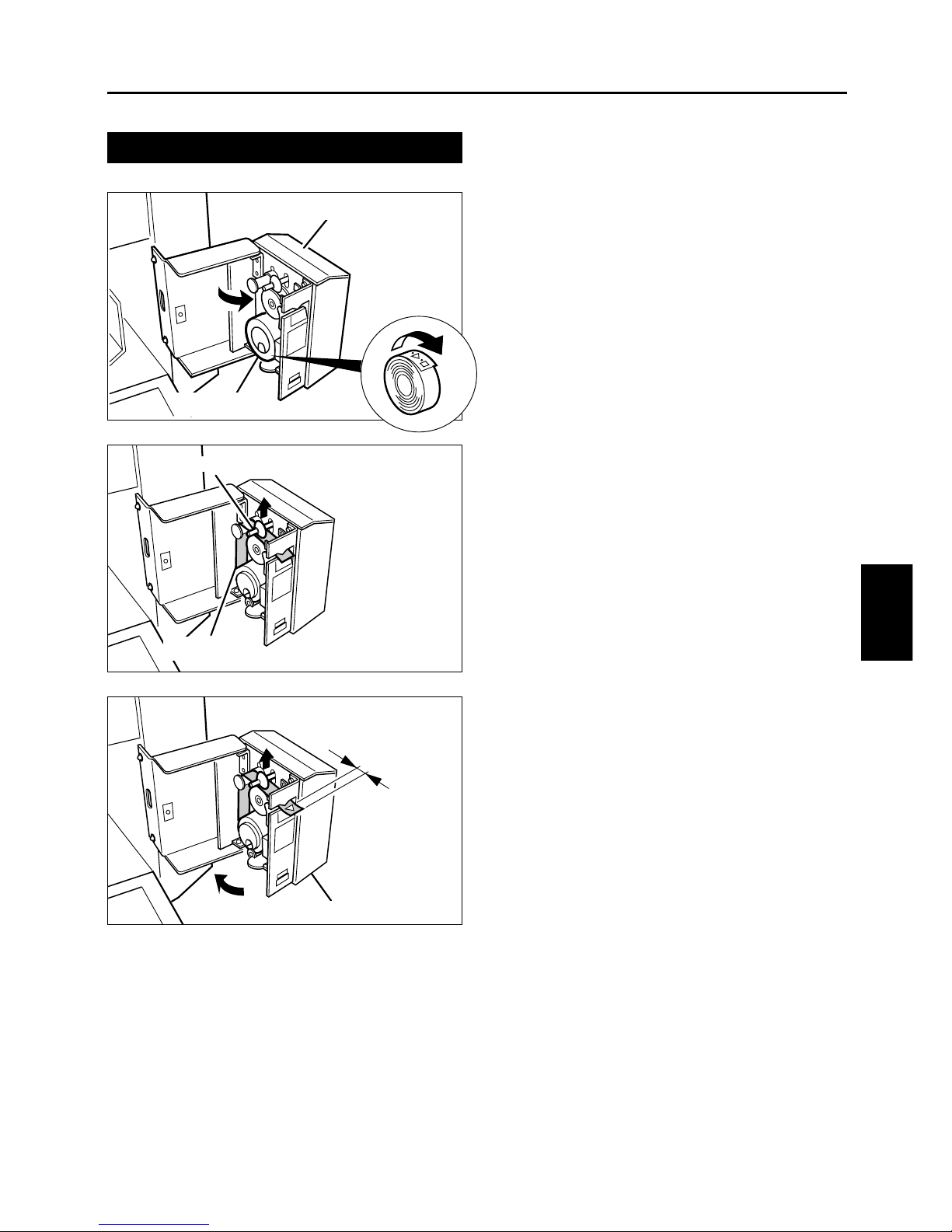

Changing the drum unit

Drum unit

Press the

JOG switch.

Hold down until the drum stops with a beep.

1

WARNING

¡¡

Do NOT touch the drum or rollers when

you operate the jog switch.

¡¡

Do NOT put hands inside machine while

it is operating.

Hands could get caught up or crushed.

Open the front cover.

2

Lift up the drum securing lever.

While lifting the lever up, pull out the

drum handle toward you, pulling it

straight out until it stops.

3

Taking the upper drum shaft with your

other hand, slightly lift up the front of the

drum and pull the drum out toward you.

4

JOG SWITCH

FRONT COVER

DRUM SECURING LEVER

q Upper drum shaft

w

e

CAUTION

¡¡

Do not touch the drum surface; the

ink will get on your clothes.

¡¡

Hold the drum level and place it on a

flat, solid surface.

Page 39

- 37 -

Various functions

4

Setting the drum unit

Hold the drum level and place the drum

guide roller onto the rail in the machine.

1

Holding the front up slightly, push in

about 10cm.

2

Hold the drum level and push it in

gently until it stops.

3

Lift the drum securing lever toward you

while pushing the drum in.

4

ROLLER

RAIL

DRUM

DRUM SECURING LEVER

Page 40

- 38 -

Push down the securing lever tightly

with the drum inside the machine.

5

Close the front cover.

6

Press the

JOG switch.

Keep pressing until the drum stops with

a beep.

7

WARNING

¡¡

Do NOT touch the drum or rollers when

you operate the jog switch.

¡¡

Do NOT put hands inside machine

while it is operating.

Hands could get caught up or crushed.

DRUM SECURING LEVER

FRONT COVER

JOG SWITCH

Slowly and gently

CAUTION

¡¡

Avoid pressing and damaging the drum

surface with fingers etc.

It can stain your clothes, and the warp in

the drum surface may cause bad prints.

¡¡

Always place the drum unit on flat and

stable surface.

Otherwise, the drum surface may be

damaged or warped and may cause bad

prints.

Page 41

- 39 -

Various functions

4

Setting the tape cluster

Tape cluster

Open the tape cluster body.

1

Lift up the lever and pass the tape

through the slot.

3

Make about

1cm

of tape protrude out of

the slot.

4

Tape cluster body

CLUSTER TAPE

1cm

COVER

Lever

CLUSTER TAPE

Install the new tape.

Make sure it will wind off in the correct

direction.

2

Swing the tape cluster body back in.

a

For sectional printing, see p.29,

"Entering the Number of sets"

5

Page 42

- 40 -

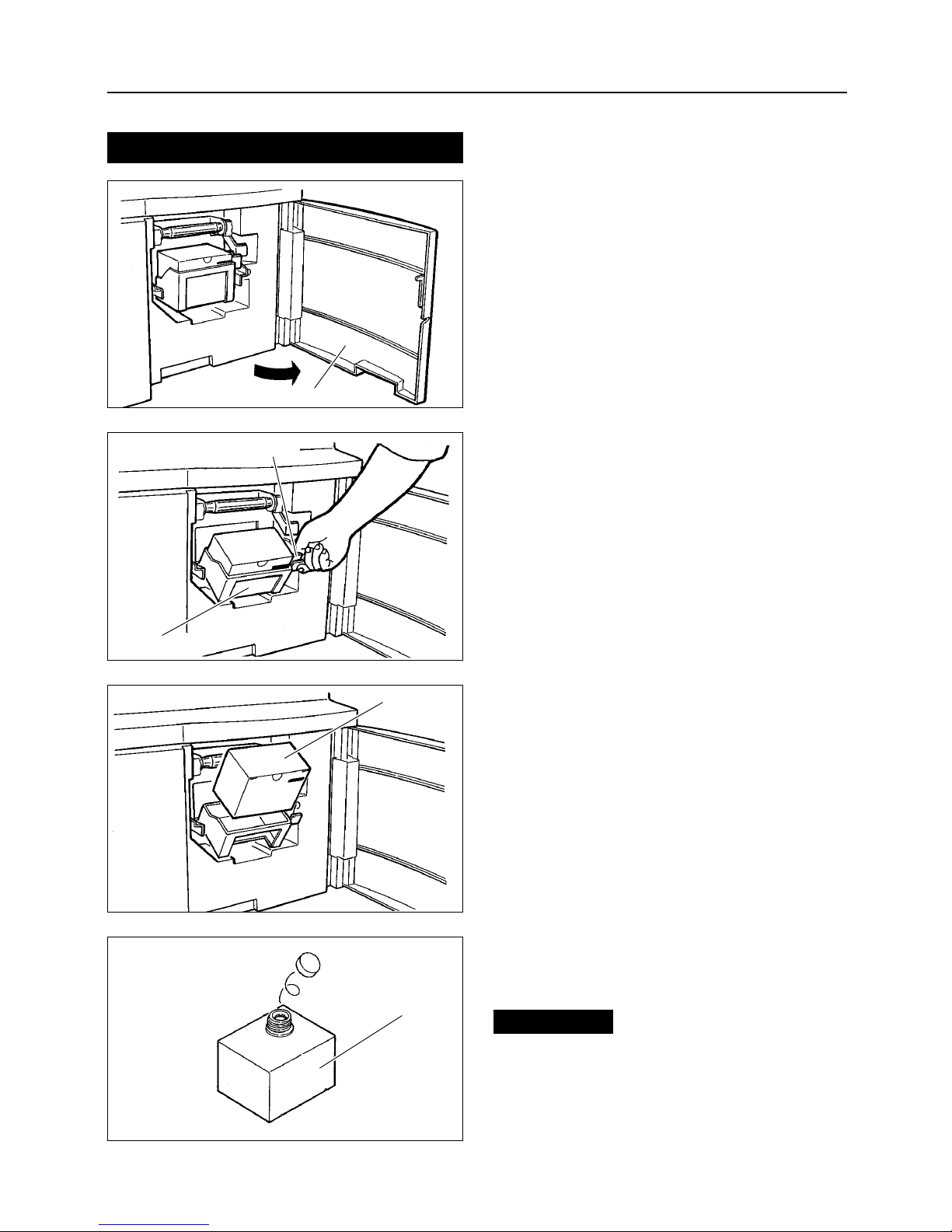

Changing the ink pack

Open the front cover.

1

Hold the ink pack holder release lever

and pull it toward you.

2

Pull up and remove the empty ink pack.

3

Twist open the cap of the new ink pack.

4

FRONT COVER

HOLDER RELEASE LEVER

INK PACK

INK PACK

INK PACK

¡¡

Do NOT leave an uncapped INK PACK for

a period longer then necessary.

IMPORTANT

:

5. Replacing of consumable

Page 43

- 41 -

Replacing of consumable

5

Insert the ink pack so that the groove on the

LIP fits into the "U" groove of the holder.

5

Push the ink pack to the set line on the

ink pack.

6

Push the side of the holder in with the

palm of your hand.

7

Close the front cover.

8

LIP

"u" GROOVE OF HOLDER

SET LINE

INK PACK

FRONT COVER

INK PACK INK PACK

HOLDER HOLDER

CAUTION

¡¡

Do not operate the machine without

setting the ink pack.

Page 44

- 42 -

MASTERHOLDER

Open the document receiving tray.

1

Remove the master roll to pull up.

3

Remove the master holder from the

master roll.

4

Turn the master holder toward you while

pushing the thermal head escape lever.

Pull out the master.

2

Changing the master roll

DOCUMENT RECEIVING TRAY

THERMAL HEAD ESCAPE LEVER

MASTER HOLDER

WARNING

¡¡

Do not remove the cover affixed with

Warning Label 1.

Personnel can get injured by the

movable cutter installed inside.

Page 45

- 43 -

Replacing of consumable

5

¡¡

Do not peel off the yellow label.

IMPORTANT

:

MASTERROLL

Take out a new master roll from a bag.

5

Insert the master roll into the machine

so that the green line on the roll is facing

the control panel.

7

Insert the master holders deeply into

both ends of the master roll. (Holders are

interchangeable.)

6

Peel off the seal.

8

GREEN LINE

YELLOW LABEL

SEAL

Page 46

- 44 -

Push the

master set switch.

The master will be pulled in, and cut

automatically.

If the master does not go in, push the

yellow label slightly back.

10

Pull out the master and insert the arrow

on the yellow label until it contacts the

roller.

9

¡¡

If the master is wrinkled:push and hold the

master set switch

again, and push down

the

thermal head escape lever

2 or 3 times.

¡¡

When the master stops, make sure that

you remove the trimmed piece of the

master.

IMPORTANT

:

Remove the trimmed piece of the

master.

11

Close the document receiving tray

gently.

12

¡¡

The cutter will operate and stop after the

master is cut.

Remove the cut piece left inside the

machine.

IMPORTANT

:

MASTER SET SWITCH

THERMAL HEAD

ESCAPE LEVER

YELLOW LABEL

DOCUMENT RECEIVING TRAY

Page 47

- 45 -

Replacing of consumable

5

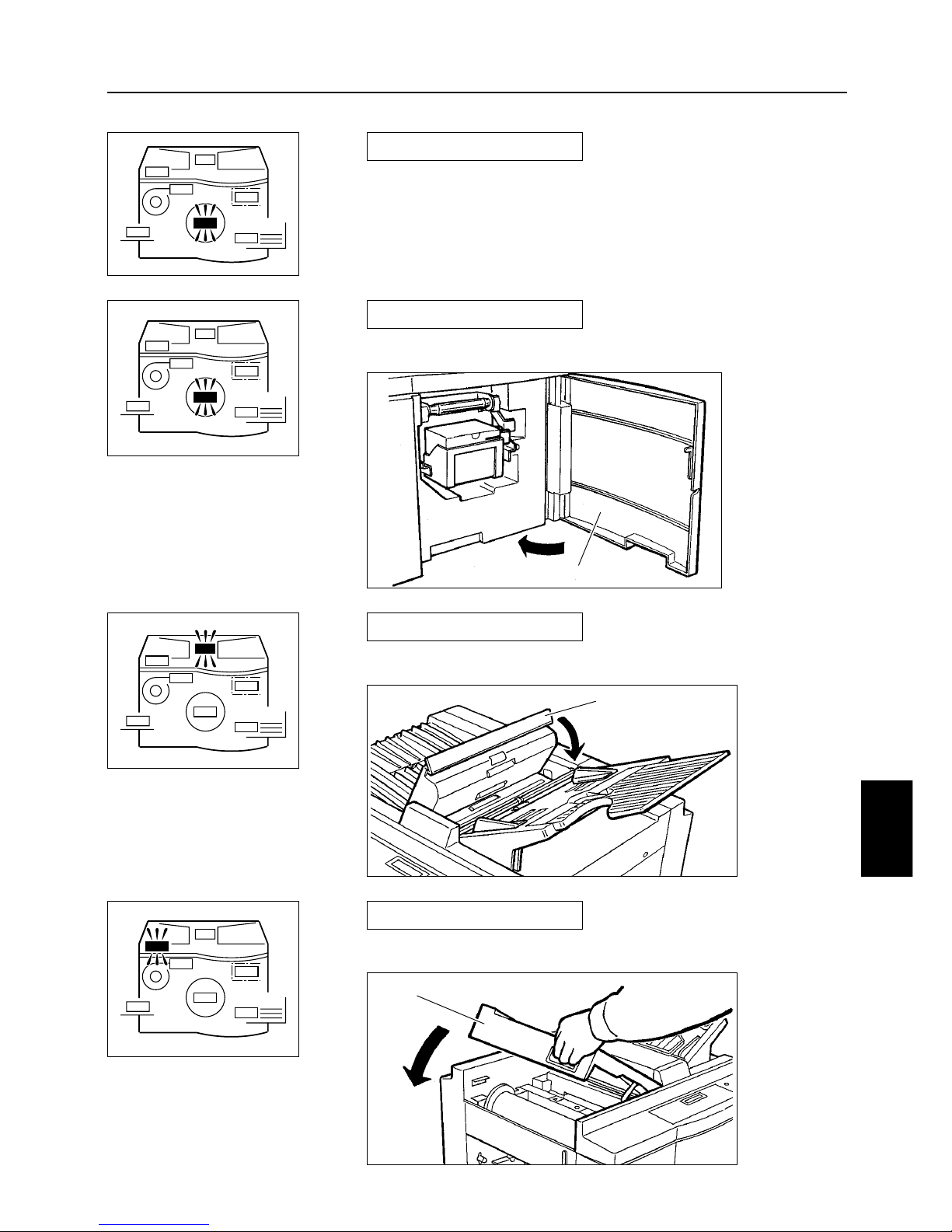

Open the paper receiving tray.(See page

20

.)

Push the master ejection box release

lever. The master ejection box will open.

Open the box all the way until it stops.

1

Open the lid up by pushing the release

lever of the master ejection box lid.

2

Pull out the core and discard it by holding

the edges of the master ejection core.

3

Insert a new master ejection core and close

the master ejection box lid.Gently push

the master ejection box lid until it locks.

Close the master ejection box, and push

until it locks.

4

Changing the master ejection core

MASTER EJECTION BOX

RELEASE LEVER

MASTER EJECTION BOX

LID RELEASE LEVER

MASTER EJECTION BOX

MASTER EJECTION CORE

MASTER EJECTION CORE

CAUTION

¡¡

There is ink on the master ejection

core; take care not to get it on your

clothing.

Page 48

- 46 -

6.

Troubleshooting

OK MONITOR

When a disposable part needs a replacement or the operator`s help is necessary due to an error,

the display will show a message and the

OK MONITOR

will show the area that needs attention.

CHANGE INK

There is no ink. Replace the old ink pack with a new one.

See p.40, "Changing the ink pack" for more details.

CHANGE MASTER

There is no master. Replace the master roll with a new one.

See p.42, "Changing the master roll" for more details.

EJECT.ROLL FULL

The master ejection core is full. Replace the core with a new

one. See p.45, "Changing the master ejection core" for more

details.

LOAD PRINT PAPER

There is no printing paper.

See p.19, "Setting the paper tray" for more details.

SET PAPER TRAY

The paper tray is not set. To set, lift the paper set lever.

Page 49

- 47 -

Troubleshooting

6

NO DRUM

There is no drum or it is installed incorrectly. Set the drum

unit on the machine.

See p.37"Setting the drum unit" for more details.

ADF OPEN

The ADF cover is open. Close the cover.

TOP COVER OPEN

Document receiving tray is open. close the receiving tray.

FRONT COVER OPEN

Front cover is open. Close the cover.

ADF COVER

DOCUMENT RECEIVING TRAY

FRONT COVER

Page 50

- 48 -

PAPER LEFT JAM

Check the feeder side and remove the jammed paper.Follow

the instructions on p.51, "Removing a left paper jam (feed

tray side)".

PAPER RIGHT JAM

Check the delivery side and remove the jammed paper.

Follow the instructions on p.52, "Removing a right paper jam

(print tray side)".

MAST.EJECT ERROR

There is an old master on the drum. Remove all the masters

on the drum.

See p.54, "Removing the master(ejection error)" for more

details.

MASTER SET ERROR

There is an error during master Setting. Open the top cover

and remove the master that is left in the machine.

See p.56, "Removing a master (set error)" for more details.

ADF JAM

The document is jammed on the ADF. Remove the jammed

document in the ADF.

Page 51

- 49 -

Troubleshooting

6

--- WAIT ---

MASTER MAKING

Printer is not ready. Please wait with the power

on. If the message remains after a few minutes,

turn the power off and contact your service

person.

Appears while platemaking is in progress. Please

wait until platemaking is finished.

-- PRINTING --

Appears if you press while printing is not

finished. Please finish printing. When you want

to make a plate, press

CLEAR

and then

PLATEMAKING

.

C

PLS MAKE MASTER

Execute platemaking. Appears after you press

PRINT

and

TEST-PRINT

in the

following situations: qwhen in confidential

safeguard mode, or wright after master set

error, or eright after distribution error.

SET KEYCARD

Insert the card into the keycard counter. If you

do not insert the card while the keycard counter

is connected, the printer cannot be operated.

Page 52

- 50 -

DRUM LOCK

Drum does not rotate. Turn off the power and

contact your service person.

CUTTER LOCK

Master cutter does not operate. Turn off the

power and contact your service person.

POWER(T.H)NG

Thermal head power is abnormal. Turn off the

power, wait for a few seconds, and then turn on

the power again. If this indication appears again,

turn off the power and contact your service

person.

ONLINE ERROR

Communication error occurred during on-line

platemaking. Check the connection cord and

retry. Turn off the power, wait for a few seconds,

and then turn on the power again. If this

indication appears again, turn off the power and

contact your service person.

Page 53

- 51 -

Troubleshooting

6

PAPER LEFT JAM.

If this message is indicated in the display

panel check the feeder side and remove the

jammed paper by following these steps:

Removing a left paper jam (feed tray side)

Push down the paper set lever to down

the paper tray.

1

Pull out the jammed paper as shown in

the diagram.

2

Press the

JOG switch

until the drum

stops with a beep.

3

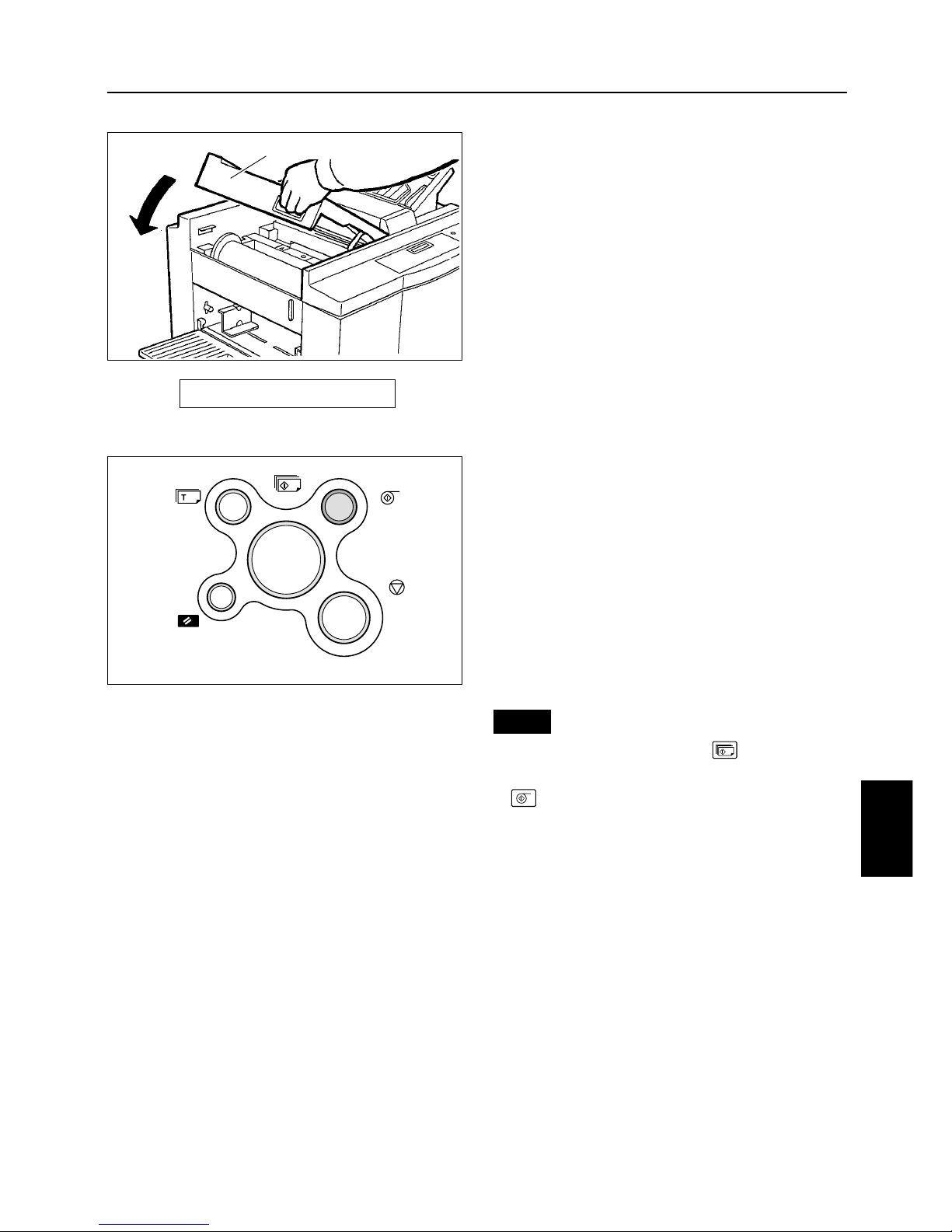

WARNING

¡¡

Do NOT touch the drum or rollers when

you operate the jog switch.

¡¡

Do NOT put hands inside machine

while it is operating.

Hands could get caught up or crushed.

PAPER SET LEVER

JOG SWITCH

Page 54

- 52 -

PAPER RIGHT JAM.

If this message is indicated in the error

display panel check the delivery side and

remove the jammed paper by following these

steps:

Removing a right paper jam (print tray side)

Push the master ejection box release

lever. The box will open toward you.

1

Remove the jammed paper.

Eject the paper that is printed halfway

by pressing the

JOG switch.

2

Paper adhering to drum

Press the

JOG switch

to find the edge of

the paper; stop the drum at the position

shown in the diagram.

1

WARNING

¡¡

Do NOT touch the drum or rollers when

you operate the jog switch.

¡¡

Do NOT put hands inside machine

while it is operating.

Hands could get caught up or crushed.

JOG SWITCH

MASTER EJECTION BOX

RELEASE LEVER

MASTER EJECTION BOX

Page 55

- 53 -

Troubleshooting

6

Peel off the paper from the drum.

2

Pull the paper toward the ejection side

while pressing the

JOG switch

to peel

the paper off.

3

Press the

JOG switch

until the drum

stops with a beep.

4

Close the master ejection box until it is

locked.

5

DRUM

JOG SWITCH

JOG SWITCH

MASTER

EJECTION BOX

CAUTION

¡¡

Make sure that the peeled paper do

not stick to your clothing.

Page 56

- 54 -

MAST.EJECT ERROR

If this message is indicated in the error

display panel, there is an old master on the

printing drum. Remove it by following these

steps:

Removing a master (eject error)

Push the master ejection box release

lever. The box will open toward you;

continue opening until the box stops.

1

Press the

JOG switch

to stop the drum at

a position shown in the diagram.

2

WARNING

¡¡

Do NOT touch the drum or rollers when

you operate the jog switch.

¡¡

Do NOT put hands inside machine

while it is operating.

Hands could get caught up or crushed.

Lift the lever toward you.

The master clamp will open and the edge

of the master will be released from the

clamp.

If the master is stuck, release it by hand.

3

MASTER CRAMP

LEVER

JOG SWITCH

w REMOVE MASTER

e CLOSE THE CLAMP

q OPEN THE

CLAMP

MASTER EJECTION BOX

RELEASE LEVER

MASTER EJECTION BOX

Page 57

- 55 -

Troubleshooting

6

Pull the front end of the master toward

you and press the

JOG switch

intermittently.

Continue until the master peels off.

4

Press the

JOG switch

until the drum

stops with a beep.

5

WARNING

¡¡

Do NOT touch the drum or rollers when

you operate the jog switch.

¡¡

Do NOT put hands inside machine

while it is operating.

Hands could get caught up or crushed.

Close the master ejection box until it is

locked.

6

Make a plate again.

7

JOG SWITCH

JOG SWITCH

MASTER

EJECTION BOX

CAUTION

¡¡

Discard the old master, making sure

that it does not touch your clothing.

Page 58

- 56 -

Removing a master (set error)

MASTER SET ERROR

If this message is indicated in the error display panel, remove the master and remake

the plate by following these steps:

Open the document receiving tray.

1

Remove the master out of the machine.

2

DOCUMENT RECEIVING TRAY

Page 59

- 57 -

Troubleshooting

6

PLS MAKE MASTER

Close the document receiving tray

gently. Verify that the OK monitor

indicator has switched off.

3

Make the master and print again.

4

¡¡

If you press the

PRINT

key without

executing platemaking,

PLS PLATEMAKING

key will be displayed.

Note

:

DOCUMENT RECEIVING TRAY

Page 60

- 58 -

Removing a jammed document

ADF JAM

If this message is indicated in the error display panel, check the ADF and remove the

jammed document by following these steps:

Pull out the jammed document as shown

in the diagram.

2

Close the ADF cover gently.

3

Open the ADF cover.

1

ADF COVER

Page 61

- 59 -

Troubleshooting

6

Trouble shooting for machine malfunction

The machine doesn't TURN ON.

Is power plug inserted?

Insert the power

plug securely.

Is power switch ON?

Turn the power

switch ON.

Cannot make plates / print

Is a Massage displayed on

the ERROR DISPLAY?

Is the OK MONITOR lamp lit?

See "OK MONITOR"

on page 46.

Please contact your service person.

YES

YES

YES

NO

NO

NO

Page 62

- 60 -

¡¡

Before cleaning, pull the power plug from the outlet.

¡¡

Prevent water and neutral cleansers from getting inside

the machine. This action prevents not only breakdowns

but electrical shock.

Clean the exterior as described in the

following procedure. Tightly wring a soft

cloth that has been soaked in water or

neutral detergent, and wipe dirt from the

surface.

Then, using a dry soft cloth, wipe away

remaining moisture.

Dust and clean the machine at least once a

week to avoid breakdowns.

Before cleaning, turn the power switch to

OFF and then pull out the power plug.

To clean the reader glass, use a dry soft cloth

and lightly wipe off any dirt.

WARNING

Alcohol

thinner

7.

Maintenance and inspection

Maintenance

Page 63

- 61 -

Maintenance and inspection

7

P1234500 F.12345

Example : Print amount, 1,234,500

Platemaking amount, 12,345

Total amount of print and platemaking can be shown on display panel.

Press the

STOP

key while the Machine

is stopped. Print and platemaking amount

will be shown on Display Panel.

Total counter will appear while

STOP

key is being pressed.

Total counter

Page 64

- 62 -

Product name / Model No.

Model Table top

Platemaking method Thermal digital system

Platemaking time 27 seconds (A4, same size)

Resolution 11.8 dot/mm (300dpi)

Scanning method ADF / movable document

ADF capacity 10 sheets (64g/m

2

,17 Ib)

Document type Sheets

Image reading size 250mm 9350mm

Document size

MAX. 271mm 9382mm, 10.6"915"

M I N. 100mm 9148mm, 4" 96"

Document weight 64g/m

2

4

128g/m

2

, 17Ib 434Ib

Image area

A/B size : 250mm 9 350mm

Paper capacity

(Feed and receiving trays)

500Sheets (64g/m

2

, 17 Ib)

Paper size

MAX. 271mm 9382mm, 10.6"915"

M I N . 100mm 9148mm, 4"96"

Paper weight 53g/m

2

4

210g/m

2

, 14 Ib 456 Ib

Printing speed 120 pages/minute (60 4120 pages/minute , 3 steps adjustment)

Reduction size

A / B size : 141%,122%,115%,94%, 86%, 81%, 70%

Inch size : 141%,129%,121%,94%, 77%, 74%, 64%

Printing position adjustment 20mm, 13/16"(Top4bottom direction total adjustment)

Image modes Text mode, Photograph mode

Contrast control 3 steps

Ink supply method Full automatic control

Color printing Drum unit exchange control (600cc)

Master feeder Roll master automatic feed

Plate ejection Complete automatic ejection plate rolling method

Option

¡

Drum units

¡

Tape cluster

¡

I/F kit (mountable to

DP-205 / 203

only) :

Compatible with an IEEE1284 compliant bi-directional parallel interface only

Power source

120V Type; 120V

±

10%, 60Hz, 2.0A

230V Type; 230V

±

10%, 50Hz, 1.2A

Size of machine

Closed 600mm(W)

9

598mm(D)

9

524mm(H)

23.6"(W) 9 23.5"(D) 9 20.6"(H)

Opened 1004mm(W)

9

598mm(D)

9

600mm(H)

39.5"(W) 9 23.5"(D) 9 23.6"(H)

Weight 68kg

Operating temp. 10tC 430tC

On-line

DP-205A / 203A

includes as standard equipment :

Compatible with Windows 95/98/Me ,Windows 2000/XP professional/home edition

A/B size : 204mm 9 288mm

Inch size : 10" 9 13.8" Inch size :

8" 9 13.6" (204mm 9 347mm )

DUPRINTER DP-205 / DP-205A DUPRINTER DP-203 / DP-203A

8. Specifications

Specifications

Page 65

- 63 -

Specifications

8

88

Acceptable Document

¡¡

Document Weight: 64g/m

2

4

128g/m

2

, 17Ib434Ib

¡¡

Document Size: MAX. 271mm 9382mm, 10.6" 915"

MIN. 100mm 9148mm 4" 96"

¡¡

ADF Capacity: 10sheets (64g/m

2

, 17Ib)

88

Acceptable Copy paper

¡¡

Copy Paper Weight: 53g/m

2

4

210g/m

2

, 14Ib456Ib

¡¡

Copy Paper Size: MAX. 271mm 9382mm, 10.6" 915"

MIN. 100mm 9148mm 4" 96"

¡¡

Copy Paper Capacity: (Feed and Receiving Trays) 500Sheets (64g/m

2

, 17Ib)

Do not place the following types of documents in the ADF:

¡¡

Documents with tears or large binding holes.

¡¡

Severely curls documents or documents with sharp folds.

¡¡

Clipped or stapled documents.

¡¡

Carbon-backed paper or other documents which might not feed smoothly.

¡¡

Transparencies and other highly transparent documents.

Note

:

Do not use the following types of Copy Paper:

¡¡

Copy paper with tears or large binding holes.

¡¡

Severely curled paper or paper with sharp folds.

¡¡

Clipped or stapled paper.

¡¡

Carbon-backed paper or other paper which might not feed smoothly.

¡¡

Coat paper or other copy paper that does not absorb ink well.

Note

:

Original document/Copy paper Specification

Page 66

- 64 -

MEMO

Page 67

J8-Y1320 2004. 10

Duplo building, 1-6, Oyama 4 chome, Sagamihara, Kanagawa 229-1180,Japan

TEL : +81-42-775-3602

FAX : +81-42-775-3606

E-mail : info@duplo.com

DUPLO CORPORATION

Loading...

Loading...