Page 1

INSTRUCTION MANUAL

Perfect Binder

DuBinder

Be sure to read this manual prior to use.

Please leave this manual at the site of use for easy reference.

DPB-500

Page 2

Direttiva sui macchinari 98/37/CE e 2006/42 CE in base a

EN 1010-1: 2004, EN 1010-4: 2004, EN 60204-1: 2006

Direttiva relativa alle apparecchiature a bassa tensione

2006/95/CE in base a IEC 60950-1: 2001 incluse deviazioni

EN 60950-1: 2001+ A11: 2004

Direttiva di compatibilità elettromagnetica 89/336/CEE e

2004/108/CE in base a EN 61000-3-2: 2006, EN 61000-3-3:

1995+A1: 2001+A2: 2005,

EN 61000-6-2: 2001,

EN 61000-6-4: 2001

It

Directiva sobre máquinas 98/37/CE y 2006/42/CE, según

EN 1010-1: 2004, EN 1010-4: 2004, EN 60204-1: 2006

Directiva sobre baja tensión 2006/95/CE, según IEC

60950-1: 2001, incluyendo las derogaciones EN 60950-1:

2001+ A11: 2004

Directiva sobre compatibilidad electromagnética 89/336/CEE

y 2004/108/CE, según EN 61000-3-2: 2006, EN 61000-3-3:

1995+A1: 2001+A2: 2005, EN 61000-6-2: 2001,

EN 61000-6-4: 2001

Sp

Directive Machines 98/37/CE et 2006/42/CE en application

des normes EN 1010-1: 2004, EN 1010-4: 2004 et

EN 60204-1: 2006

Directive Basse tension 2006/95/CE en application de IEC

60950-1: 2001, dérogations selon EN 60950-1: 2001

+A11: 2004 incluses

Directive sur la compatibilité électromagnétique 89/336/CEE

et 2004/108/CE en application des normes EN 61000-3-2:

2006, EN 61000-3-3: 1995+A1: 2001+A2: 2005,

EN 61000-6-2: 2001, EN 61000-6-4: 2001

Fr

Maschinenrichtlinie 98/37/EG und 2006/42 EG unter

EN 1010-1: 2004, EN 1010-4: 2004, EN 60204-1: 2006

Niederspannungsrichtlinie 2006/95/EG unter

IEC 60950-1: 2001 einschließlich EN 60950-1: 2001

+ A11: 2004 Abweichungen

Richtlinie zur elektromagnetischen Verträglichkeit

89/336/EWG und 2004/108/EG unter EN 61000-3-2: 2006,

EN 61000-3-3: 1995 + A1: 2001 + A2: 2005,

EN 61000-6-2: 2001, EN 61000-6-4: 2001

Ge

KONFORMITÄTSERKLÄRUNG

Die DUPLO CORPORATION mit Sitz in 1-6, Oyama 4-chome,

Sagamih ara -shi,

Kanagaw a-k en 229 -11 80, Japan , erklärt

hiermit, dass das folgende Produkt,

• Bezeichnung des Produkts :

Bindemaschine

• Modell :

DPB-500

den nachfolgend aufgelisteten Richtlinien entspricht:

• Richtlinien :

DICHIARAZIONE DI CONFORMITÁ

DU P L O CO RPORATI O N si ta a 1- 6 , Oy ama 4-chome ,

Sagamihara-shi, Kanagawa-ken 229-1180 Japan, dichiara che il

seguente prodotto,

• Nome del prodotto :

macchina cucitrice per legatoria

• Modello :

DPB-500

è conforme ai requisiti definiti dalle norme sotto elencate:

• Direttiva Bassa Tensione :

DECLARATION OF CONFORMITY

DUPLO CORPORATION, located at 1-6, Oyama 4-chome, Sagamihara-shi, Kanagawa-ken 229-1180, Japan, declares

that the following product,

• Name of product : Binder

• Model : DPB-500

complies with the provisions defined by the regulations listed below.

• Regulation : Machinery Directive 98/37/EC and 2006/42/EC under EN 1010-1: 2004, EN 1010-4: 2004, EN 60204-1: 2006

Low Voltage Directive 2006/95/EC under IEC 60950-1: 2001 including EN 60950-1: 2001+A11: 2004 deviations

Electromagnetic compatibility Directive 89/336/EEC and 2004/108/EC under EN 61000-3-2: 2006,

EN 61000-3-3: 1995+A1: 2001+A2: 2005, EN 61000-6-2: 2001, EN 61000-6-4: 2001

En

DECLARACIÓN DE CONFORMIDAD

DUPL O CORPORA TION, con domicilio en 1-6, Oyama

4-chome,

Sagamihara-shi, Kanagawa-ken 229-1180 Japan,

declara que el producto siguiente :

• Nombre del producto :

Encuadernadora

• Modelos :

DPB-500

cu m p le con l o dispues t o por lo s reglamen t o s que s e

in d i can a c o n tinuació n .

• Reglamentaciones :

DECLARATION DE CONFORMITE

DUPLO CORPORATION, située à 1-6, Oyama 4-chome,

Sagamihara-shi,

Kanagawa-ken 229-1180, Japon, déclare que le

produit suivant ;

• Nom du produit :

Relieuse

• Modèle :

DPB-500

est conforme aux dispositions définies par les réglementations

suivantes :

• Réglementations :

Page 3

Disposal of Old Electrical & Electronic Equipment

This symbol (the symbol of the crossed out wheeled

bin) indicates that in European countries this product

should not be disposed of as household waste.

Please recycle where facilities exist by checking with

your local authority or supplier for recycling advice.

By ensuring this product is disposed of correctly

through proper treatment, recovery and recycling,

you will help prevent potential negative e

ffects on the

environment and human health.

En

Entsorgung von alten elektrischen und

elektronischen

Ausrüstungsteilen

Dieses Symbol (das Symbol mit dem durchgekreuzten

fahrbaren Müllbehälter) zeigt an, dass dieses Produkt

in europäischen Länden nicht als Haushaltsmüll

entsorgt werden darf. Bitte informieren Sie sich bei

Ihren örtlichen Behörden oder bei Ihrem Händler

hinsichtlich einer Empfehlung für die Entsorgung

und führen Sie die betre

ffenden Teile dort, wo solche

Einrichtungen vorhanden sind, einem RecyclingProzess zu.

Indem sie sicherstellen, dass das betre

ffende Produkt

durch richtige Behandlung, Rückführung und Recycling

entsorg

t wird, tragen Sie dazu bei, möglichen negativen

Auswirkungen auf die Umwelt und die menschliche

Gesundheit vorzubeugen.

Ge

Elimination du matériel électronique et électrique

usagé

Ce symbole (une poubelle marquée d’une croix)

indique que dans les pays européens, ce produit ne

doit pas être éliminé comme des ordures ménagères.

Recyclez-le dans les sites adaptés qui vous seront

indiqués par les autorités locales ou renseignez-vous

auprès de votre fournisseu

r.

En veillant à ce que ce produit soit éliminé

correctement avec un traitement, une collecte et un

recyclage adaptés, vous contribuez à éviter son action

nocive potentielle sur l

’ environnement et la santé

humaine.

Fr

Smaltimento di attrezzature elettriche ed

elettroniche consumate

Questo simbolo (il simbolo della pattumiera con rotelle

barrata) indica che nei paesi europei questo prodotto

non deve essere buttato nei ri

fiuti domestici.

Per favore smaltire in luogo addetto al riciclo, dove

esistente, chiedendo informazioni alle autorità locali o

a chi fornisce consulenza a proposito.

Garantendo uno smaltimento adeguato di questo

prodotto (trattamento, recupero e riciclo corretto),

aiuterete a prevenire e

ffetti negativi sull’ambiente e

sulla salute dell’uomo.

It

Eliminación de residuos de aparatos eléctricos y

electrónicos

Este símbolo (un cubo de basura tachado) indica

que en los países europeos este producto no deberá

eliminarse como si se tratara de un residuo doméstico.

Solicite asesoramiento sobre reciclaje a las autoridade

s

locales o a su distribuido

r, y siga la normativa en

materia de gestión medioambiental y reciclaje de este

tipo de residuos.

Si toma las medidas pertinentes para que este

producto se elimine mediante un tratamiento,

recuperación y reciclaje adecuados, contribuirá a evitar

posibles efectos negativos en el medio ambiente y la

salud humana.

Sp

Page 4

Note: This symbol mark is for EU countries only.

This symbol mark is according to the directive 2006/66/

EC

Article 20 Information for end-users and Annex II.

This symbol means that batteries and accumulators, at

their end-of-life, should be disposed of separately from

your household waste.

If a chemical symbol is printed beneath the symbol

shown above, this chemical symbol means that the

battery or accumulator contains a heavy metal at a

certain concentration.

This will be indicated as follows:

Hg: mercury (0.0005%), Cd: cadmium (0.002%),

Pb: lead (0.004%)

In the European Union there are separate collection

systems for used batteries and accumulators.

Please, dispose of batteries and accumulators correctly

at your local community waste collection/recycling

centre.

Note:

You do not need to replace the battery for

this machine by yourself.

En

Nota: questo contrassegno interessa soltanto i

Paesi UE

It

Questo contrassegno è conforme alla direttiva

2006/66/CE Articolo 20 Informazioni per gli utenti finali

e Appendice II.

Indica che le batterie e gli accumulatori, una volta

esauriti, devono esssere gettati separatamente dai rifiuti

domestici.

Se sotto il simbolo mostrato qui sotto è stampato un

simbolo chimico, quest'ultimo indica che la batteria o

l'accumulatore contiene un metallo pesante in una

determinata concentrazione. Ciò verrà indicato come

segue:

Hg: mercurio (0.0005%), Cd: cadmio (0,0002%),

Pb: piombo (0.004%).

Nei Paesi dell'Unione Europea esistono sistemi di

raccolta diversi per le batterie e gli accumulatori usati.

Vi preghiamo di smaltire le batterie e gli accumulatori

correttamente presso il vostro centro di smaltimento

rfiuti/ riciclo locale.

Nota: non dovete sostituire da soli la batteria di

questa macchina.

Nota: Este símbolo sólo sirve para países de la UE.

Sp

Este símbolo cumple lo dispuesto en el Artículo 20 Información para los usuarios finales y el Anexo II de la

Directiva 2006/66/EC.

Este símbolo significa que las pilas y los acumuladores,

al finalizar su vida útil, deben eliminarse a parte de los

residuos habituales de su hogar.

Si debajo del símbolo que se muestra más arriba

aparece un símbolo de producto químico, entonces

este símbolo significa que la pila o el acumulador

contienen cierta concentración de metal pesado. Ello se

indica del siguiente modo:

Hg: mercurio (0,0005%), Cd: cadmio (0,002%),

Pb: plomo (0,004%).

En la Unión Europea existen sistemas separados para

la recogida de pilas y acumuladores usados.

Le rogamos que elimine las pilas y los acumuladores

correctamente en su centro local de recogida/reciclaje

de residuos.

Nota: No es necesario que usted mismo cambie la

pila de este aparato.

Hinweis: Diese Symbol-Markierung gilt nur für EULänder.

Ge

Diese Symbol-Markierung entspricht der Direktive

2000/66/EG Artikel 20 Informationen sowie Anhang II.

Dieses Symbol bedeutet, dass verbrauchte Batterien

getrennt vom Haushaltsmüll zu entsorgen sind.

Wenn ein chemisches Symbol unter das oben

dargestellte Symbol gedruckt ist, so bedeutet dieses

chemische Symbol, dass die Batterie oder der Akku ein

Schwermetall in einer bestimmten Konzentration

enthält, Dies wird wie folgt angezeigt:

Hg: Quecksilber (0,0005 %), CD: Cadmium (0,002 %),

Pb: Blei (0,004 %)

In der Europäische Union gibt es separate

Sammelsysteme für verbrauchte Batterien und Akkus.

Bitte entsorgen Sie die Batterien und Akkus

vorschriftsmäßig in Ihrem örtlichen

Müllsammel-/Müllrecycling-Zentrum.

Hinweis: Sie brauchen die Batterie für diese

Maschine nicht selbst auszutauschen.

Remarque : Ce symbole n’est valable que pour les

pays de l’UE.

Fr

Ce symbole est conforme à la directive 2006/66/CE,

Article 20 Informations destinées aux utilisateurs finaux

et Annexe II.

Ce symbole signifie que les batteries et accumulateurs,

une fois arrivés en fin de vie, ne doivent pas être jetés

avec les ordures ménagères.

Si un symbole chimique est imprimé au-dessous du

symbole indiqué ci-dessus, ce symbole chimique

signifie que la batterie ou l’accumulateur contient un

métal lourd atteignant une certaine concentration. Ceci

sera alors indiqué de la façon suivante :

Hg : mercure (0,0005 %), Cd : cadmium (0,002 %),

Pb : plomb (0,004 %)

Il existe dans l’Union Européenne des systèmes de

collecte distincts pour les piles et accumulateurs.

Veuillez déposer vos batteries et accumulateurs dans

votre centre local de recyclage ou de collecte des

déchets.

Remarque : Vous n’avez pas besoin de remplacer

vous-même la batterie de cette machine.

.

Page 5

Note:

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Page 6

Introduction

Thank you for purchasing a Duplo product.

Be sure to read this manual prior to using the product.

After reading, leave the manual at the site of use for easy reference whenever questions related to the

product arise in the future.

Symbols

In this manual, several symbols are used to indicate important warnings. Please make sure to read

instructions accompanied by these symbols. These symbols have the following

meanings.

Describes instructions which must be followed in use.

Be sure to read the instructions to avoid problems due to incorrect operations.

Indicates supplementary or useful information.

Describes names of related items and supplementary instructions.

Trademark

The product name and company name used in this manual are trademarks or registered trademarks

of the respective companies.

Page 7

i

Safety Precautions

Safety Precautions

In this manual, operations and handling of the unit which are hazardous are described using the

following marks to prevent personal injury or property damage to the user and others.

Ignoring this mark could result in the possibility of

serious injury or even death.

Ignoring this mark could result in the possibility of injury

or physical damage.

This mark indicates a “Warning” or “Caution”.

A graphic may be shown inside the mark to describe the warning or caution more specifically.

This mark indicates a forbidden action.

A graphic may be shown inside the mark to describe the forbidden action more specifically.

This mark indicates actions that must be performed.

A graphic may be shown inside the mark to describe the action to be performed more specifically.

Power Supply

● This unit shall be installed near the socket-outlet where the plug on the power supply cord is easily

accessible.

● Make sure the power supply used is always within the following range.

Power supply : Y208V,

240V AC (three-phase), 60 Hz (USA, Canada)

Y380 to Y415 V AC (three-phase), 50/60 Hz (Europe)

● When you power other appliances from the same AC outlet, make sure that the combined power

consumption does not exceed the power supply capacity.

Rated current (Rated power) : 3.2 kW AC (three-phase 208 V, 240 V 60Hz) 8 A/single-phase

(USA, Canada)

3.2 kW AC (three-phase 380 to 415 V 50/60Hz) 5 A/single phase (Europe)

Use only the power supply voltage specified on the main nameplate.

Using other voltages could result in a fire or an electrical shock.

Make sure that the combined power consumption of the appliances to be

connected does not exceed the capacity rating of the power outlets or plug

receptacles.

Exceeding the capacity rating could cause the power outlets, plug receptacles, or power extension

cords to overheat and catch a fire.

High touch current

Earth connection essential before connecting supply.

Page 8

ii

Safety Precautions

Operating Environment

Operate this unit in the following environment.

● where the temperature range is between 5 and 35°C/41 and 95°F (-10 to +50°C/ 14 to 122°F) in

storage)

● where the humidity range is between 10 and 85% RH (10 to 90% RH in storage, however no

condensation)

● which is not subject to direct sunlight

● which is reasonably free from dust

● which is subject to little or no vibration

● which is free from air-borne salt

● where there are no harmful chemicals

● where the unit is not exposed to water

Keep this unit and the power cord away from heaters and heater vents.

Excessive heat could melt the cover or power cord covering, and result in a fire or an electrical shock.

Do not place metal objects or vessels containing liquids on top of the unit.

The entry of any metal object or liquid could result in a fire or an electrical shock.

Do not insert any metal or easily-combustible object inside this unit.

This could result in a fire or an electrical shock.

Do not use flammable sprays inside or near the unit (e.g. when cleaning the

unit).

Such flammable gas may ignite and cause a fire or combustion.

Do not install this unit in a location where there is excessive humidity or where

contact with water is possible.

Poor choice of location could result in deterioration of the insulation, a fire or an electrical shock.

Install this unit on a level, stable stand or floor, with sufficient space around it.

Failure to do so could result in the unit overturning and causing injury.

Disconnect the power plug from the power outlet before attempting to move

this unit.

Failure to do so could result in power cord damage, a fire or an electrical shock.

Always disconnect the power plug from the power outlet when the unit is not

to be used for an extended period.

Failure to do so could result in a fire due to leakage current if the insulation should deteriorate.

Page 9

iii

Safety Precautions

Do not damage the power cord or power plug.

Do not scratch, alter, bend, twist, pull or place heavy objects on the power cord or power plug.

This could result in damage, a fire or an electrical shock.

Do not touch the power switch with wet hands.

Otherwise electric hazards may occur.

Do not remove the cover or back panel.

This unit contains high-voltage components that could cause an electrical shock.

Do not disassemble, modify or repair this unit.

There is a danger of fire, electrical shock or injury.

Contact your dealer when repairs are necessary.

If any foreign object such as metal or liquid should enter this unit, immediately

turn the unit off at the power switch and disconnect the power plug from the

power outlet.

Failure to do so could result in a fire or an electrical shock.

Contact your dealer immediately.

Before cleaning this unit, turn the unit off at the power switch and disconnect

the power plug from the power outlet.

Accidental operation of the unit during cleaning could result in injury.

Remove any dust that accumulates on the power plug prongs and the surface

of the plug from which the prongs extend.

Accumulated dust could result in a fire.

Always grip the plug when disconnecting the power plug from the power

outlet.

Forcibly pulling on the power cord could cause damage, resulting in a fire or an electrical shock.

Do not touch or insert foreign objects into any rotating part during operation.

This could result in injury.

Maintenance / Others

Page 10

iv

Safety Precautions

Hot Melt Glue

Do not block off the hume exhaust.

This unit exhausts vaporized hot melt glue to the outside of the unit using the fan. If the hume exhaust

is blocked off, the fumes that stay inside the unit may cause fire.

Attach a hume exhaust hose to the hume exhaust of this unit so that the fumes

can be exhausted outdoors or to a well-ventilated place.

The fumes are generated while the hot melt glue is being melted at high temperatures. The fumes

may irritate your eyes, nose and throat. If you do not feel well, go out into the fresh air. If you still feel

sick, get prompt medical attention.

Read carefully the precautions for handling the hot melt glue you are going to

use.

Because the hot melt glue is combustible, do not put the glue close to fire.

It may cause a burn injury or fire.

When you handle the hot melt glue, make sure that you wear protection

gloves, long-sleeved clothes, eye protectors to prevent burn injuries.

In case the liquefied or vaporized hot melt glue gets into your eye or is attach to your skin, cool it with

cold water immediately and get prompt medical attention.

Page 11

v

Safety Precautions

WARNING / CAUTION Labels

"WARNING" and "CAUTION" labels are pasted on the machine to ensure user safety.

Do not remove or change them.

When the labels become dirty or are lost, be sure to contact your dealer for a new one.

WARNING

Do not put hands inside

during operation.

It may injure you.

Page 12

vi

Safety Precautions

Details on Warning and Caution Label

Label Explanation

Do not touch the milling blade and roughening blade during

machine operation. This may cause you severe injury.

High voltage of electricity supplied to the glue tank may cause

an electric shock. Be careful.

Because the touch current is high, make sure that a ground

connection is provided before connecting the power cord.

The glue tank temperature is very high.

When pressing a book block against the support clamp, be

careful not to get your hand caught in it.

When opening a main cover, be careful not to get your hand

caught in it.

Do not touch the nipping section while the machine is in

operation. Your fingers may get caught in the nipper.

Do not touch the nipping section while the machine is in

operation. Your fingers may get caught in the nipper.

Do not put your hand inside the machine while the paper feed

tray is moving. It may injure you.

Do not take out booklets during machine operation. This may

cause unexpected injuries.

There are high voltage parts inside the machine. Do not

remove the cover.

Before discharging glue from the tank, switch the machine to

the glue discharge mode.

Leaving the tank without glue inside may cause a malfunction

to the machine.

Glue discharged from the tank is very hot. Be careful not to

burn yourself.

Page 13

vii

Safety Precautions

Contents

Safety Precautions .....................................i

Power Supply ...................................................... i

Operating Environment .......................................ii

Maintenance / Others .........................................iii

Hot Melt Glue .....................................................iv

WARNING / CAUTION Labels ...........................

v

Chapter 1

BEFORE OPERATION

1. Features .............................................1-2

2. Workflow ............................................

1-3

3. Names and Functions ......................1-4

3-1. External Parts ........................................ 1-4

3-2. Milling Section .......................................

1-5

3-3. Glue

Tank Section ................................. 1-6

3-4. Nipping Section .....................................

1-7

3-5. Scoring Section .....................................

1-8

3-6. Feed Section .........................................

1-9

3-7. Delivery Section .................................. 1-10

4. Screen Descriptions ....................... 1-11

4-1. Settings Screen for Binding ................. 1-11

4-2. Fine-adjustment Screen ......................

1-11

4-3. Motion Check Screen ..........................1-12

4-4. Option Setting Screen ......................... 1-13

5. Accessories ....................................1-14

7.

Precautions on Hot Melt Glue ...............1-16

8. Cautions for Handling ....................1-17

9. Emergency Stop .............................1-18

10. Paper Size .......................................1-19

10-1. Cover and Book Block Size ................. 1-19

10-2. Book Block Thickness and

Cover Weight ......................................1-19

10-3.

Using Single-folded or Double-folded

Paper ....................................................1-20

10-4 Cover Type ..........................................1-20

Chapter 2

PREPAR

ING FOR

OPERATIO

N

1. Turning On the Power ......................2-2

2. Preparing Hot Melt Glue ...................2-3

3. Preparing Each Section ...................2-6

3-1. Level Plate ............................................2-6

3-2. Glue Tank .............................................. 2-7

3-3. Nipping Section ..................................... 2-8

3-4. Replacing the Receiving Tray with

the Stacker Stopper ..............................2-9

3-5. Replacing the Stacker Stopper with

the Receiving Tray .............................. 2-10

4. Entering Job Information ...............2-12

4-1. Cover (With a cover/Without a

cover) .................................................. 2-12

4-2. Setting Double Feed Detection for

Cover .................................................. 2-14

4-3. Setting Book Block Size ...................... 2-16

4-4. Setting the Cover Size ........................2-18

4-5. Cover Base Spine Position .................2-19

4-6. Checking and Saving Settings ............ 2-21

Chapter 3

STARTING BINDING

OPERATIO

N

1. Placing a Book Block .......................3-2

2. Test-Feeding a Cover .......................3-6

3. Starting Binding ..............................3-14

4. Removing the Booklet ....................3-17

5. Adding Covers ................................3-20

6. Finishing Binding ...........................3-21

7. Using Supplied Parts .....................3-23

8. Using Wing Scoring ........................3-25

Page 14

viii

Safety Precautions

Chapter 4

FINE-ADJUSTMENT AND

OPTION SETTING

1.

Fine adjusting Each Part ..................4-2

1-1. Setting the Paper Feed Guide ............... 4-2

1-2. Setting the Scoring Width ...................... 4-4

1-3. Adjusting the Nipper Guide ................... 4-5

1-4. Setting the Nipper .................................4-7

1-5. Setting the Glue Cutting Position .......... 4-8

1-6. Setting the Width of Side Glue .............. 4-9

1-7. Adjusting Spine Glue Amount ............. 4-10

1-8. Adjusting Side Glue Amount ............... 4-11

1-9 Adjusting the Nipping Station .............. 4-12

2.

Using Motion Check .......................4-13

2-1. Ejecting Jammed Paper ...................... 4-13

2-2. Discharging Booklet ............................ 4-13

2-3. Adjusting the Height of Paper Feed

Tray ..................................................... 4-14

2-4. Moving the Clamp ...............................

4-14

3.

Setting the Options .........................4-15

3-1. Setting the Nipping Delay Time ........... 4-15

3-2. Setting the Nipping Time .....................4-15

3-3. Setting the Clamp Speed .................... 4-16

3-4. Setting the Glue Tank Temperature .....4-18

3-5. Setting the Standby Mode ...................4-18

3-6. Setting the Heater Schedule ............... 4-19

3-7. Setting the Auto Start ON/OFF ............4-21

3-8. Setting the Hispeed ON/OFF .............. 4-22

3-9. Setting the Receiving Tray ON/OFF ....4-23

3-10. Setting the Feed Guide and Nipper

Guide Synchronously .......................... 4-24

3-11. Setting the External Equipment

ON/OFF ............................................... 4-25

3-12. Setting the Contrast ............................4-26

3-13. Setting Opening Amount of Clamp

(for Normal Mode) ............................... 4-27

3-14. Setting Opening Amount of Clamp

(for Variable Mode) .............................. 4-28

3-15. Setting a Transparent Cover

ON/OFF ............................................... 4-29

Chapter 5

CLEANING THE UNIT

1.

Cleaning Each Section .....................5-2

1-1. Cleaning the Suction Belt ......................5-2

1-2. Cleaning the Level Plate .......................

5-3

1-3. Cleaning the Paper Path ....................... 5-4

2. Replacing Hot Melt Glue ..................5-6

3.

Adjusting the Date and Time ..............5-10

Chapter 6

TROUBLESHOOTING

GUIDE

1.

Solving Glue Problem ......................6-2

2.

Troubleshooting ................................6-6

2-1. Stacker Problem .................................... 6-6

2-2. Milling Problem ...................................... 6-6

2-3. Glue Problem ........................................ 6-7

2-4. Nipping Problem .................................... 6-8

2-5. Feeding Problem ...................................6-9

2-6. Scoring Problem .................................. 6-10

2-7. Booklet Quality Problem ...................... 6-11

3.

Error Messages ...............................6-12

3-1. Messages about Paper Jam ...............6-12

3-2. Messages about External Cover ......... 6-13

3-3. Messages about Motor and Sensor .... 6-13

3-4. Other Messages ..................................6-16

3-5. Other Error Codes ...............................6-18

Chapter 7 APPENDIX

1.

Specification .....................................7-2

Page 15

Chapter 1

BEFORE OPERATION

Page 16

1-2

CHAPTER 1 BEFORE OPERATION

1. Features

This machine enables you to make a book with or without a cover.

(1) With a cover

Glue is applied to the side and spine of a book block, then a cover is applied to the pasted area.

Book block

Cover

(2) Without a cover (Pad binding)

Glue is applied only to the spine of a book block. You can make a note pad or scratch pad.

Book block

Page 17

1-3

CHAPTER 1 BEFORE OPERATION

2. Workflow

1 Turn on the power

2 Prepare for hot melt glue

4 Enter job information

6 Start binding

7 Take out a booklet

9 Finish binding

Chapter 2 “1. Turning on the Power” ( p.2-2)

Chapter 2 “3. Preparing Each Section” ( p.2-6)

Chapter 2 “4. Entering Job Information” ( p.2-12)

Chapter 3 “3.Starting Binding” ( p.3-14)

Chapter 3 “6. Finishing Binding” ( p.3-21)

Chapter 3 “5. Adding Covers” ( p.3-20)

Chapter 3 “4. Removing the Booklet” ( p.3-17)

Chapter 3 “1. Placing a Book Block” ( p.3-2)

Chapter 3 “2. Test-Feeding a Cover” ( p.3-6)

10 Fine adjust

Chapter 4 Fine-adjustment and Option Setting ( p.4-2)

8 Add covers

5 Test feed

3 Prepare each section

Chapter 2 “2.Preparing Hot Melt Glue” ( p.2-3)

Page 18

1-4

CHAPTER 1 BEFORE OPERATION

3. Names and Functions

3-1. External Parts

T

ouch Panel Angle Adjustment Knob

Adjusts the angle of the touch panel.

Main Cover

Prevents the user from

touching inside of the

machine during operation.

Fume Exhaust Opening

Exhausts steam from inside the

machine.

Safety Sensor

The machine stops if the light

between the sensors is

interrupted.

Touch Panel

Use this panel to enter information

to operate the machine.

Clamp

Holds a book block and moves horizontally

during the binding operation.

Support clamp

When placing a book block on the clamp, the

support clamp is used as an aid in holding its

shape.

Emergency Stop Button

Press this button to stop the

machine urgently.

Start Button

Starts the binding operation.

Glue Drain Access

Open this cover to place a

container before draining the glue

in the glue tank.

Nipper Level Adjustment Access

Open this access to access to the

adjustment lever to raise or lower

the nipping station.

Spine Meter Roller Adjustment

Adjusts the amount of spine glue

applied to the booklet.

No.2 Glue Drum Meter Adjustment

Adjusts the amount of glue provided

to the No. 2 drum.

No.1 Glue Drum Meter Adjustment

Adjusts the amount of glue provided

to the No. 1 drum.

Main Switch

Turns on or off the

machine.

Jam Removing Knob

When a paper jam occurs

during the transportation of

a cover, rotate this knob to

move the feed roller and

remove the jammed cover.

Page 19

1-5

CHAPTER 1 BEFORE OPERATION

3-2. Milling Section

Milling Adjustment Label

Refer to the label when

adjusting the height of the level

plate using the milling

adjustment bar.

Milling Adjustment Bar

Use this bar to adjust the

milling depth.

Level Plate

To change the milling depth, move up or down

the level plate.

Milling Guide

This guide prevents paper chips from

scattering. The guide moves automatically

according to the thickness of the book block.

Page 20

1-6

CHAPTER 1 BEFORE OPERATION

3-3. Glue Tank Section

Side Glue Meter

(non-operator’ s side)

Adjusts the side glue

amount provided to the

side glue roller according

to the position of the side

glue meter adjustment.

No.2 Meter

Adjusts the glue amount

provided to the application

No.2 drum.

Application No.1 Drum

Provides glue that penetrates

into the spine.

Application No.2 Drum

Applies additional glue to the

spine.

Side Glue Meter (operator’ s side)

Adjusts the side glue amount provided to the

side glue roller according to the position of

the side glue meter adjustment.

Side Glue Roller Adjustment (non-operator’ s side)

Adjusts the position of the side glue roller.

Side Glue Roller

(non-operator’ s

side)

Applies the glue to

the non-operator’ s

side of the book

block.

Side Glue Roller

(operator ‘s side)

Moves automatically

according to the

thickness of the book

block and applies the

glue to the operator’ s

side.

Side Glue Meter Adjustment

(operator’ s side)

Adjusts the position of the side glue

meter and side glue amount provided

to the side glue roller.

Side Glue Meter

Adjustment

(non-operator’ s side)

Adjusts the position of the

side glue meter and side

glue amount provided to

the side glue roller.

No.1 Meter

Adjusts the glue amount

provided to the application

No.1 drum.

Spine Meter Roller

Evens out the glue

applied to the spine.

Page 21

1-7

CHAPTER 1 BEFORE OPERATION

3-4. Nipping Section

Skewing

Adjustment

Cover Stopper

Prevents the

cover from

moving by

holding down its

leading edge.

Scale Label

Use this label to decide

the position of the

cover stopper.

Positioning Fingers

Prevents the cover from

moving by holding down its

tail edge.

Nipper Guide

Moves automatically

according to the size

of a cover and holds

down its both sides.

Skewing Adjustment Label

Adjusts the position of the

cover and the book block so

that they are parallel to each

other.

Positioning Fingers Adjustment

Adjusts the position of the positioning fingers.

Nipping

Station

Nips the cover

transported

from the paper

feed tray to

form a spine.

Skewing

Adjustment

Page 22

1-8

CHAPTER 1 BEFORE OPERATION

3-5. Scoring Section

Secondary Feed Roller Pressure Adjustment

Adjusts the pressure of the feed roller.

Scoring Depth Adjustment

Adjusts the depth of a score

applied to a cover.

Primary Feed Roller Pressure

Adjustment

Adjusts the pressure of the

feed roller.

Page 23

1-9

CHAPTER 1 BEFORE OPERATION

3-6. Feed Section

Cover Feeder Skewing

Adjustment

Adjust the angle of the feed

guide to align them with the

cover edge.

Scoring Line Label

Indicates the standard

scoring line on the

non-operator s side.

Feeder

Feeds covers automatically.

Feed Guide

Moves automatically

according to the cover size

and holds the both sides of

the cover.

Suction Belt

Sucks and

transports each

cover.

Stack Height Sensor

Adjustment

Select 1 or 2 to decide the

stop position of the cover

according to the thickness

of the cover.

Separating Air Adjustment

Adjusts the amount of air sent to

between each cover.

Separator Adjustment

Adjusts the gap between the

separator and suction belt to

separate covers from each other.

Test Feed Button

Press this switch to

perform a test feed

or size change.

Guide Adjustment Switch A

Fine-adjusts the width of the

feed guide and the nipper

guide.

Guide Adjustment Switch B

Fine-adjusts the position of the

feed guide and the nipper guide.

Feed Tray Down

Button

Press this

switch to lower

the feed tray.

Back stopper

Holds the tail

edge of the

cover.

Error Release Button

When the paper feed

tray has exceeded the

upper limit, press this

button to clear the error

message “E-025.”

Separator

Prevents double-feed of

covers.

Page 24

1-10

CHAPTER 1 BEFORE OPERATION

3-7. Delivery Section

Book Exit Damper

Adjustment Lever

Adjusts the angle of the book

exit damper.

Book Exit Damper

Serves as a cushion for

the booklets delivered

from the exit.

Stacker Stopper

Supports the delivered booklets

on the stacker to keep them

upright.

Knob Screw

Used to secure the

stacker stopper to the

machine.

Movable Stacker

Aligns the finished

booklets.

Page 25

1-11

CHAPTER 1 BEFORE OPERATION

4. Screen Descriptions

4-1. Settings Screen for Binding

After you turn the power on, the main menu screen appears on the panel. You can set the details of

the binding process on this menu.

Press other tabs on the screen to switch to other menus. Press the setting button to set up a binding

process. Refer to Chapter 2 "Preparing for Operation" “4.Entering Job Information" ( p.2-12) for details.

Glue Tank Temperature Button

The current glue tank temperature

is displayed. When pressed, the

temperature setting screen appears.

Main Menu Tab

Pressing this tab opens the main

menu screen.

Fine-adjustment Tab

Pressing this tab opens the fine-adjustment screen.

Motion Check Tab

Pressing this tab opens the motion check screen.

Option Tab Pressing this tab opens the

option tab screen.

Memory No.

You can save up to 20 job information.

Date and Time Setting Button

The current date and time are

displayed. When pressed, the date

and time setting screen appears.

Memory No. Switching Button

Use this button to select a desired memory No.

Setting Button

Pressing this button opens a

screen to enter job information.

Size Change Button

Pressing this button executes a

size change.

Test Feed Button

Pressing this button starts test feeding.

Clear Button

Keep pressing this button returns

the counter to zero.

Counter

Displays the number of sets that

was already bound.

Setting Value Data

The job information of the memory

currently selected is displayed.

2007-04-05 15:29

4-2. Fine-adjustment Screen

Press the fine adjustment tab to switch to the fine-adjustment screen.

Select a section you want to fine adjust.

Refer to Chapter 4 "Fine-adjustment and Option Setting"

“1. Fine adjusting Each Part" ( p.4-2) for details.

Feed Guide

Select Button

Scoring Width

Select Button

Nipper Select

Button

Nipping Guide

Select Button

Side Glue Width

Select Button

Glue-cutting Position

Select Button

Page 26

1-12

CHAPTER 1 BEFORE OPERATION

4-3. Motion Check Screen

Press the motion check tab to discharge finished booklets or

jammed paper, to change the level of the paper feed tray,

or to move the clamp.

Refer to Chapter 4 "Fine-adjustment and Option Setting" "2.Using Motion Check" ( p.4-13) for details.

Paper Ejection Button

Booklet Exit Button

Paper Feed

Tray Up/Down Button

Clamp Horizontal

Movement Button

Page 27

1-13

CHAPTER 1 BEFORE OPERATION

4-4. Option Setting Screen

Press the option tab to select optional menus.

Press the next or previous button to change the screen.

Refer to Chapter 4 "Fine-adjustment and Option Setting"

"3.Setting the Options" ( p.4-15) for details.

Nipping

Delay Time

Nipping Time

Clamp Speed

Next Button

20

External Equipment

ON/OFF

Contrast

Adjustment

Synchronous

Adjustment

ON/OFF

Auto Start

ON/OFF

Receiving Tray

ON/OFF

Next

Button

Previous

Button

Hispeed Mode

ON/OFF

Auto Start Time

Next Button

Previous Button

Glue Tank

Temperature

Standby Mode

Shift Time

Heater

Schedule

Next Button

Previous Button

Next Button

Barcode Setting

(for an option)

Clamp opening

amount (for normal

mode)

Clamp opening

amount (for

variable mode)

Transparent Cover

ON/OFF

Page 28

1-14

CHAPTER 1 BEFORE OPERATION

5. Accessories

Supplied (quantity)

[2]

[5] [6]

[3]

[4]

[1]

[7]

[8]

[9] [10] [11] [12]

[13]

[14] [15] [16]

No. Name Qty. Explanation

[1] Guide 2 Used when a cover does not go to the nipper

guides smoothly because of a curled edge.

[2] Small Cover Guide L 1 Holds the tail edge of a small cover when feeding

it to the machine.

[3] Small Cover Guide R 1 Holds the tail edge of a small cover when feeding

it to the machine.

Page 29

1-15

CHAPTER 1 BEFORE OPERATION

No. Name Qty. Explanation

[4] Stabilizer Plate Lite Weight

Cover

1 Used when covers flaps fanned by separating air.

[5] Small Cover Guide 1 Attached to the suction part when feeding a small

cover.

[6] Small Cover Feed Belt

Accessory

1 Attached to the suction part when feeding a small

cover.

[7] Book Block Support Guide 1 Attached to the clamp when a book block is thin

and big to prevent it from bending over.

[8] Scale Label 1 Attach the label to the most suitable location

(sticker).

[9] Receiving Tray 1 Attached to the book exit when necessary. This is

attached to the machine at the factory.

[10] Knob Bolt 2 Used to attach the receiving tray to the book exit.

This is attached to the machine at the factory.

[11]

Instruction Manual 1 This manual

[12] Stacker Stopper 1 Attached to the book exit when necessary.

[13] Knob Screw 4 Used to attach the stacker stopper to the book

exit.

[14] Milling Adjustment Bar 1 Adjusts a milling depth.

[15] Wrench

(opposite side distance 3 mm)

1 Used to adjust the side glue meters and side glue

roller adjustment.

[16] Spanner 1 Used to adjust the side glue meters and side glue

roller adjustment.

Page 30

1-16

CHAPTER 1 BEFORE OPERATION

6. Wing Scoring (Optional)

[1] Wing Scoring (1) ------Used when applying a wing score to a cover.

[2] Wrench (opposite side distance 2 mm) (1) ------Used to attach the wing scoring to the ma-

chine.

Chapter 3 "Starting Binding Operation" "8.Using Wing Scoring" ( p.3-25)

Page 31

1-17

CHAPTER 1 BEFORE OPERATION

7.

Precautions on Hot Melt Glue

a. Precautions

Before you use the hot melt glue, read "Hot Melt Glue" in "Safety Precautions" ( p.iv). Also, read

carefully the handling precautions supplied with hot melt glue you are going to use.

1) When you handle the hot melt glue, make sure that you wear protection gloves, long-sleeved

clothes, eye protectors to prevent burn injuries.

2) In case the hot melt glue gets into your eye, cool it with cold water immediately and get prompt

medical attention.

3) The glue attached to your skin may cause a burn injury. Cool the affected area with cold water

immediately and get prompt medical attention.

4) Fumes, which comes out of the machine while the glue is being melted, may irritate your eyes,

nose and throat. If you do not feel well, go out into the fresh air.

5) Because the hot melt glue is combustible, do not put the glue close to fire.

b. Recommended Hot Melt Glue

Destination: 208 V, 240V 60 Hz (USA)

Manufacturer: US ADHESIVE COMPANY

Model: HM-53-R

Destination: 380 to 415 V 50/60 Hz (Europe)

Manufacturer: NATIONAL STARCH&CHEMICAL

Model: COOL BIND 1450

c. Ventilation

This machine will exhaust fumes to the outside of the machine using the fan while the hot melt glue

is being melted at high temperatures. The fumes may irritate your eyes, nose and throat.

Make sure that you let the fumes exhausted from the machine go outside or to a well-ventilated

place. If you feel sick, go out into the fresh air.

Page 32

1-18

CHAPTER 1 BEFORE OPERATION

8. Cautions for Handling

1) Do not put your hand inside the machine during machine operation. This may cause you

severe injury.

2) Do not touch blades (milling blade and roughening blade) during machine operation. This

may cause you severe injury.

Milling guide

Roughening blade

Milling blade

Protect cover

3) Do not touch the hot melt glue while it is being melted. This will cause burn injuries.

4) While the clamp is moving, keep your hand and head out of the book block feeding

section.

Page 33

1-19

CHAPTER 1 BEFORE OPERATION

9. Emergency Stop

This machine is equipped with the emergency stop functions for the safety of an operator.

When you need to stop the machine for emergency, press the emergency stop button. Turning the

button to the right will release the emergency stop.

The machine will also stop automatically when the main cover is opened or the light between the

safety sensors is interrupted. To start the machine again, close the main cover when it is open or

leave your hand from the safety sensor when you have interrupted it.

Main cover

Safety sensor

Emergency stop button

Turn the button to the right

to release the emergency stop.

2007-04-05 10:30

Page 34

1-20

CHAPTER 1 BEFORE OPERATION

10. Paper Size

10-1. Cover and Book Block Size

This machine can handle a cover and book block of the following sizes.

Book block length: 120 to 360 mm (4.72 to 14.17 inches)

Book block height: 120 to 320 mm

(4.72 to 12.6 inches)

Cover length: 120 to 360 mm

(4.72 to 14.17 inches)

Cover width: 250 to 696 mm (9.84 to 27.4 inches)

Feed direction

Book block thickness: 1 to 51 mm

(0.04 to 2.01 inches)

10-2. Book Block Thickness and Cover Weight

Depending on the book block thickness, the appropriate cover weight changes. Refer to the table

below to select a book block thickness and cover weight.

Book block thickness (Fine A4 81.4 g/m²)

1 mm/

0.04 inch

10 mm/

0.39 inch

20 mm/

0.79 inch

30 mm/

1.18

inches

40 mm/

1.58

inches

50 mm/

1.97

inches

Cover

weight

Coat

104.7g/m²

O O O O X X

Coat

127.9 g/m²

O O O O O X

Coat

157 g/m²

O O O O O O

Coat

210 g/m²

X O O O O O

Coat

260 g/m²

X O O O O O

Coat

310 g/m²

X O O O O O

O=Binding available

X=The booklet may has a curled edge or twists or creases on its spine.

Page 35

1-21

CHAPTER 1 BEFORE OPERATION

10-3.

Using Single-folded or Double-folded Paper

You can use single-folded or double folded paper for a book block. The book block thickness of the

folded side (spine) should be 50 mm (1.97 inches) or less when you place the book block on a flat

surface.

● If the book block thickness is more than 51 mm (2.01 inches), the clamp cannot hold

the book block.

● Depending on the condition of the fold, the clamp may not be able to hold the book

block.

10-4. Cover Type

You can use transparent paper as a cover.

When using transparent paper, note that the part shown below must be opaque.

5.0 mm (0.20 inch)

25.0 mm

(0.98 inch)

Feed direction

Opaque area

Scoring base line

Chapter 4 "Fine-adjustment and Option Setting" ”3-15.15.Setting a Transparent Cover ON/OFF”

( p.4-29)

Page 36

1-22

CHAPTER 1 BEFORE OPERATION

Memo

Page 37

Chapter 2

PREPARING FOR

OPERATION

Page 38

2-2

CHAPTER 2 PREPARING FOR OPERATION

1. Turning On the Power

1.

Turn the power switch to the right to turn on the power of the machine.

OFF

Power switch

OFF

The hot melt glue in the glue tank will be ready for binding in about 30 minutes at earliest after you

turn on the power.

The time for the machine to be ready for a binding operation after turning on the power

varies depending on the hot melt glue you are using and the environment.

2.

Turn the panel angle adjustment knob to adjust the angle of the touch panel.

Touch panel

Panel angle

adjustment knob

3.

Tighten the panel angle adjustment knob to fasten the touch panel.

Page 39

2-3

CHAPTER 2 PREPARING FOR OPERATION

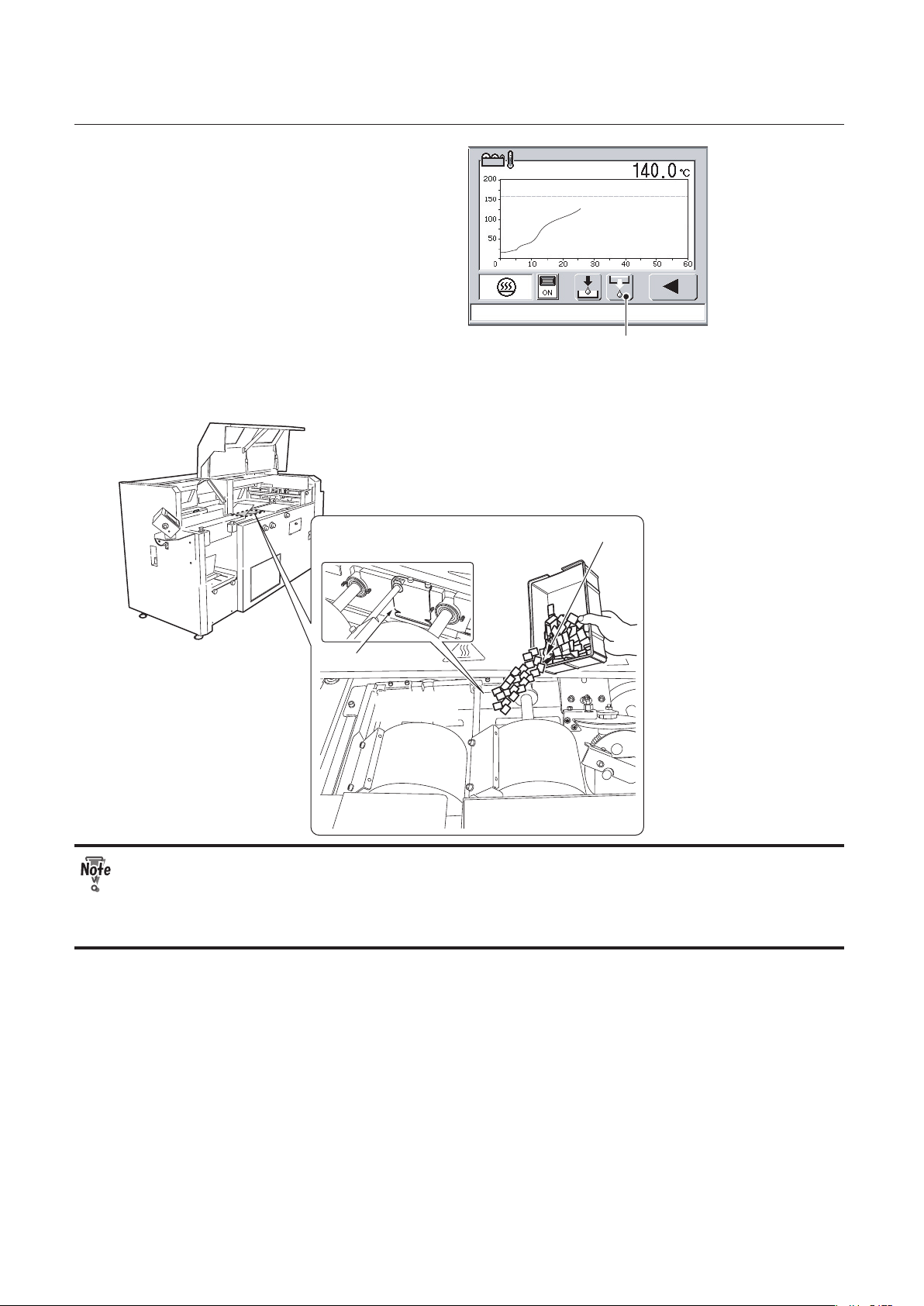

2. Preparing Hot Melt Glue

Glue Tank Temperature Button

2007-04-05 10:35

1.

Press the glue tank temperature

button.

The temperature graph will be displayed.

● Check the melt temperature of the hot

glue.

The temperature of the glue tank is set at

150°C/302°F by default. Check the melt

temperature of the hot melt glue you use

and change the glue tank temperature if

necessary.

Chapter 4 "Fine-adjustment and Option

Setting" ”3-4.Setting the Glue Tank

Temperature” ( p.4-18)

20.0

Heater Switch

ON/OFF Button

2.

Press the ON/OFF button of the

heater switch.

Either of the two following icons is

displayed.

OFF ON

The ON/OFF position of the heater

switch will be maintained even after the

machine is turned off. If you turn off the

machine with the heater switch ON, the

heater switch will be ON next time when

you turn on the machine.

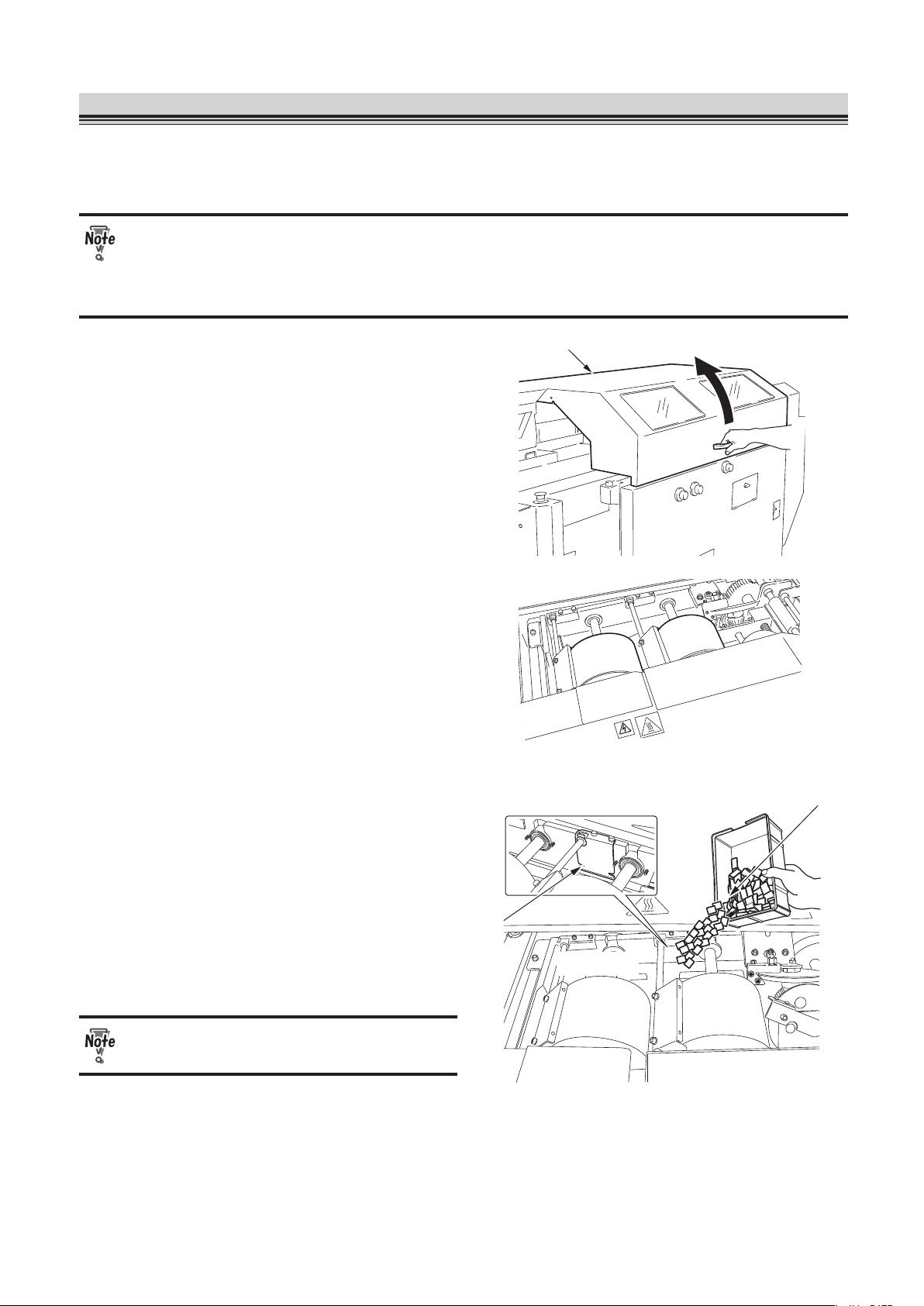

Main cover

3.

Open the main cover.

When some hot melt glue is left in the

glue tank.

Go to step 4.

When the glue tank is empty.

Go to step 5.

Page 40

2-4

CHAPTER 2 PREPARING FOR OPERATION

Glue Supply Button

4.

Press the glue supply button.

The side glue rollers will open to the

maximum. If the hot melt glue temperature

has not reached a temperature that is

20°C/68°F lower than the set temperature,

the side glue rollers will not move.

5.

Add hot melt glue in the glue tank.

Add the hot melt glue little by little being careful not to exceed the upper limit.

The upper limit of the hot melt glue

Cutout

Glue tank

Hot melt glue

● When you add hot melt glue, be careful not to put it on the application drums or the

side glue rollers. Make sure that you put it in the glue tank.

● If you added hot melt glue when the glue tank is empty, you need to add the glue

several times until the melted glue reach the upper limit.

Page 41

2-5

CHAPTER 2 PREPARING FOR OPERATION

6.

Close the main cover.

● Be careful not to get your hand caught when you close the main cover.

● When the main cover is open, the heater will be turned OFF automatically. Make sure

that you close the main cover during heating.

Timing for adding glue

● When the message below appears on

the touch panel screen, add hot melt

glue.

Touching the screen will clear the message.

Even after adding hot melt glue, the

icon to the right will blink on the main

menu screen until the glue is melted

completely.

● When the adhesivity of the spine glue

is weak or when the surface of the glue

on the application drums is lumpy, the

remaining amount of the glue may be

low in the glue tank.

● Be careful not to boil dry the glue tank.

● When you add hot melt glue, be careful not to put it on the application drums or the

side glue rollers. Make sure that you put it in the glue tank.

● The temperature around the glue tank is very high. Be careful when you add hot melt

glue.

● High voltage of electricity supplied to the glue tank may cause an electric shock. Be

careful.

Previous Button

7.

Press the previous button to return

to the main menu.

Page 42

2-6

CHAPTER 2 PREPARING FOR OPERATION

3. Preparing Each Section

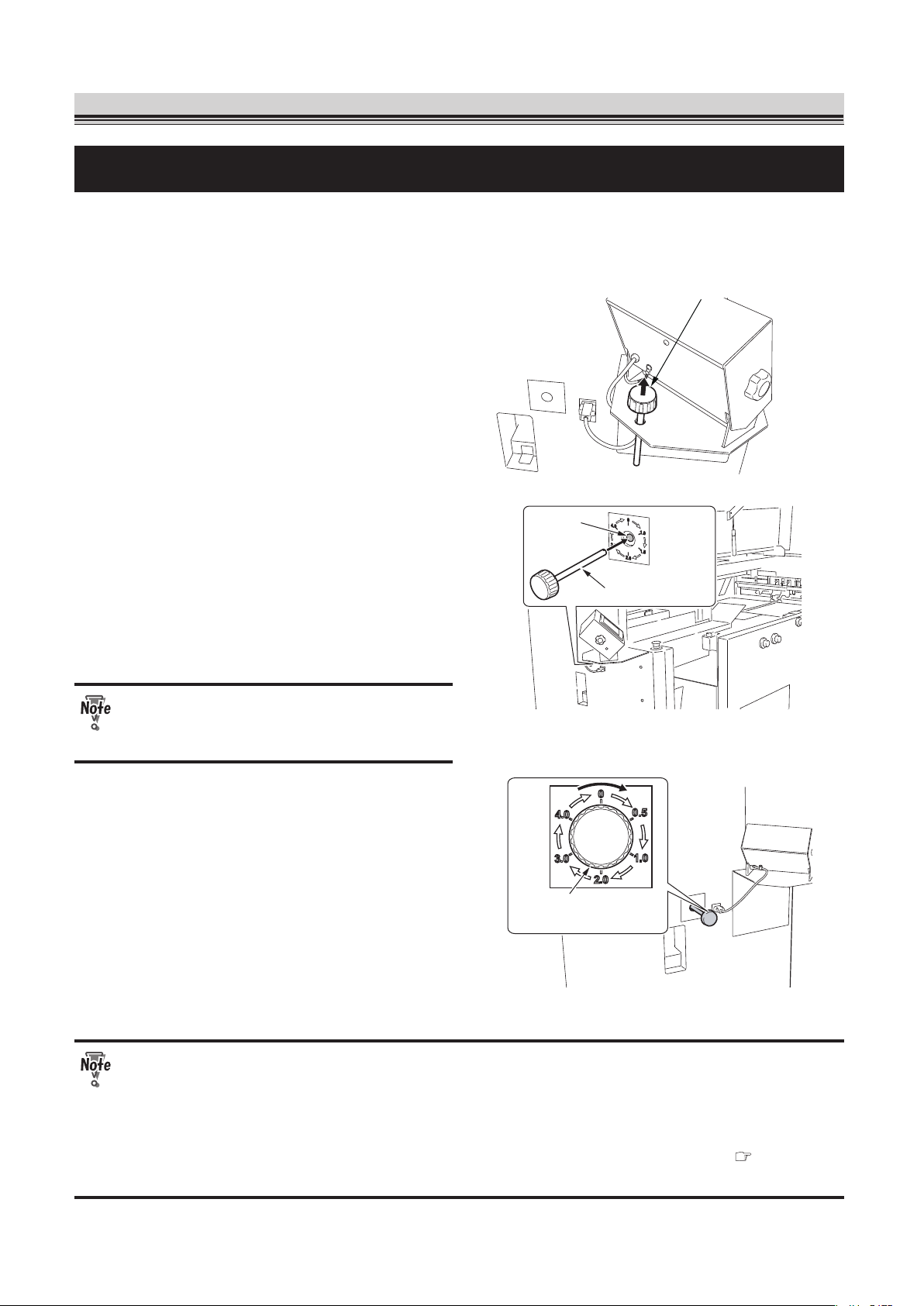

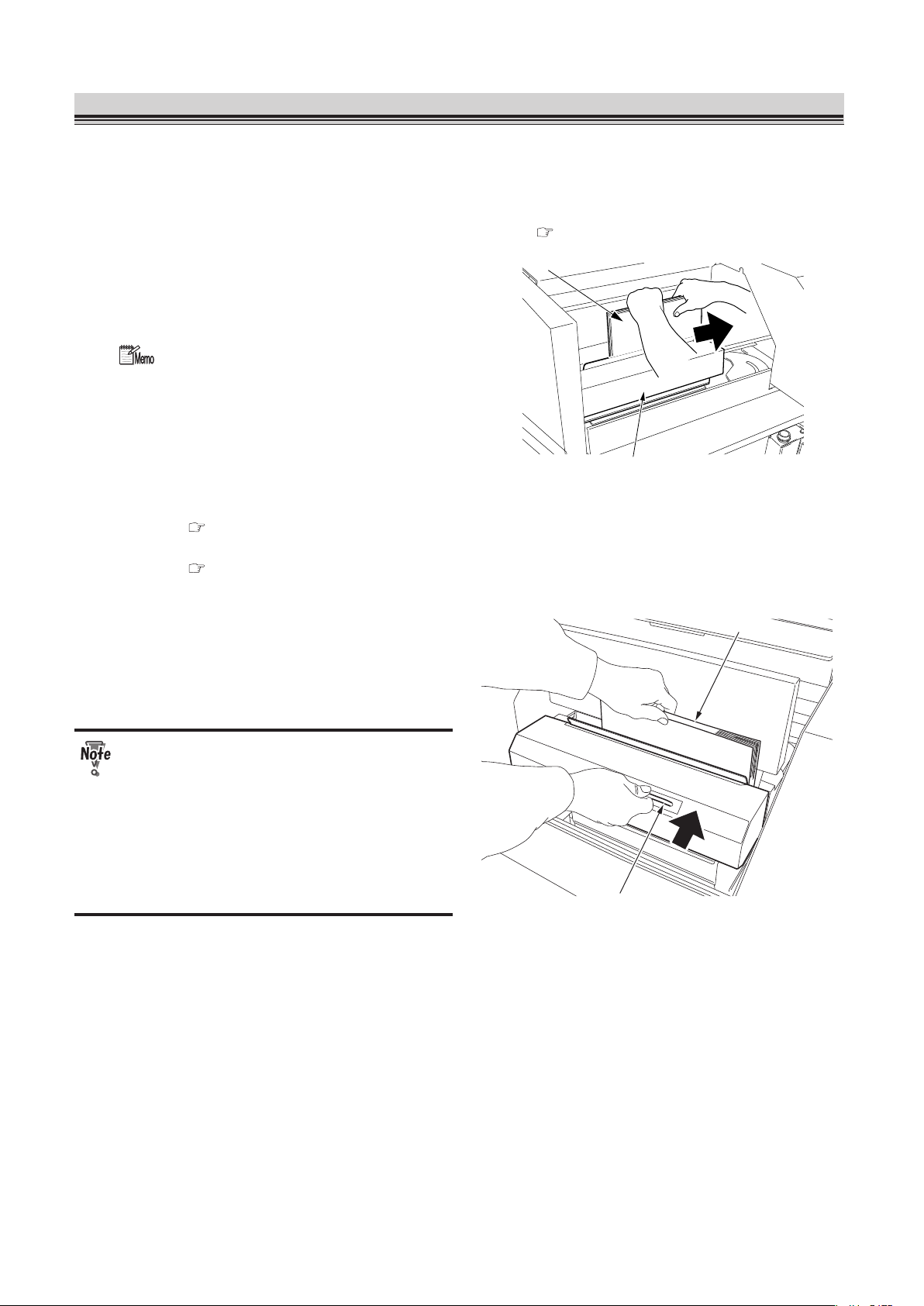

3-1. Level Plate

To change the milling depth, adjust the height of the level plate. The milling operation jags a spine for

better penetration of the glue. When milling depth is set to 0, a milling function is disabled and only

notches by the roughening blade are applied to the spine, resulting in poor adhesivity.

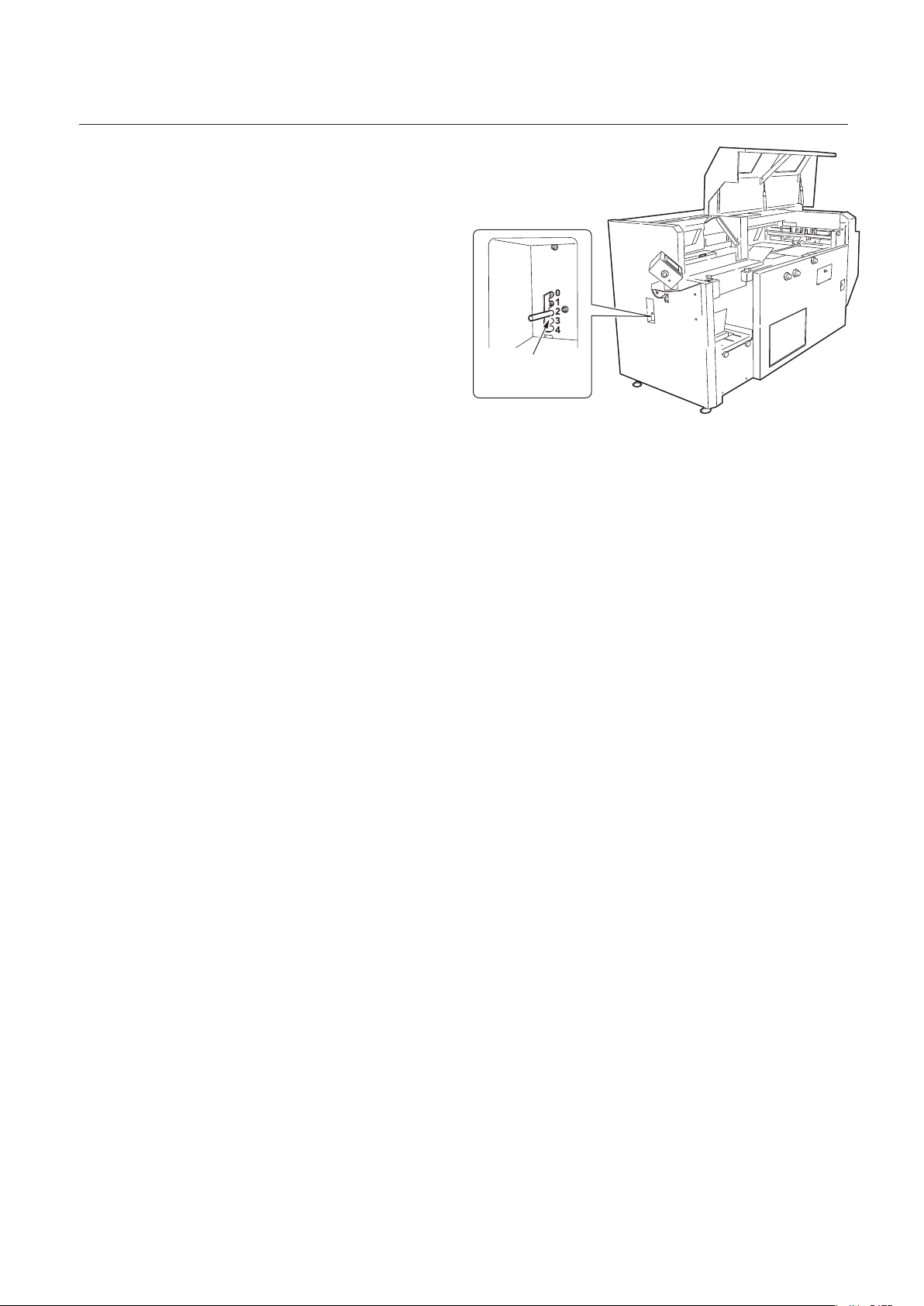

Milling adjustment bar

1.

Pull out the milling adjustment bar

from the machine.

Hole

Milling adjustment bar

2.

Insert the milling adjustment bar to

the hole located on the back of the

touch panel.

After inserting the bar, turn the bar

clockwise until the notch on the tip of the

bar meets the convex part of the hole.

Make sure that you do not insert

anything other than the milling

adjustment bar into the hole.

Milling adjustment

bar

3.

Turn the milling adjustment bar

referring to the label.

You can choose from the six levels: 0, 0.5,

1.0, 2.0, 3.0 or 4.0 mm (0, 0.02, 0.04, 0.08,

0.12, 0.16 inch).

Select a lower level for non-folded paper

and a higher level for folded paper. When

using double-folded paper, select a higher

level than you select for the single-folded

paper.

● When a book block is thick and larger than the A4 size, actual milling depth may be

deeper than the depth you have selected. Do not select a higher level at first.

● Be sure to turn the milling adjustment bar clockwise.

● Do not insert the milling adjustment bar to the hole while the machine is in operation.

● Once you change the milling depth, check the appropriate clamp speed. (

p.4-17)

● Do not turn the milling adjustment bar when a book block is in the clamp.

Page 43

2-7

CHAPTER 2 PREPARING FOR OPERATION

Milling adjustment bar

4.

Pull out the milling adjustment bar

from the hole and put it back to its

original place.

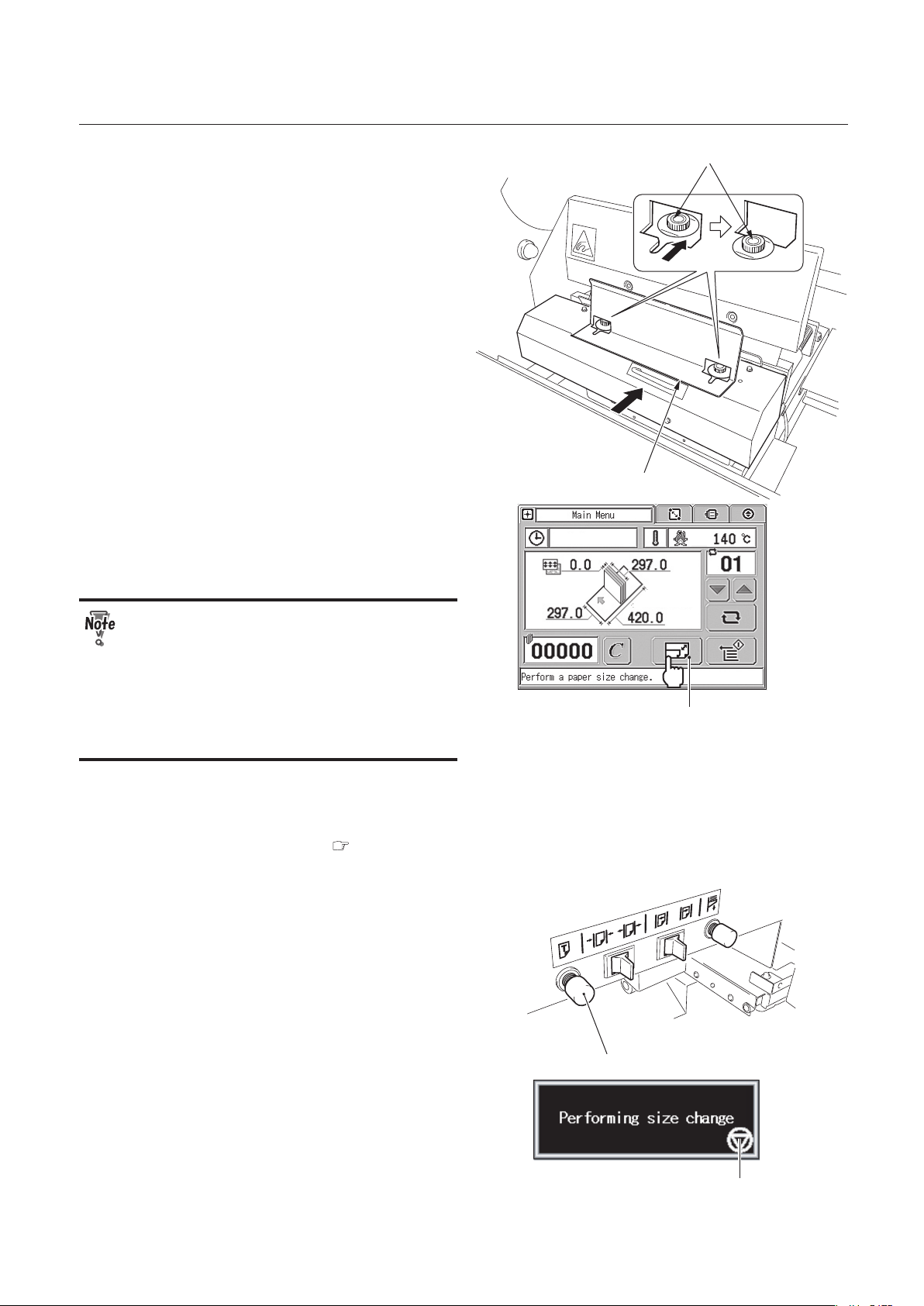

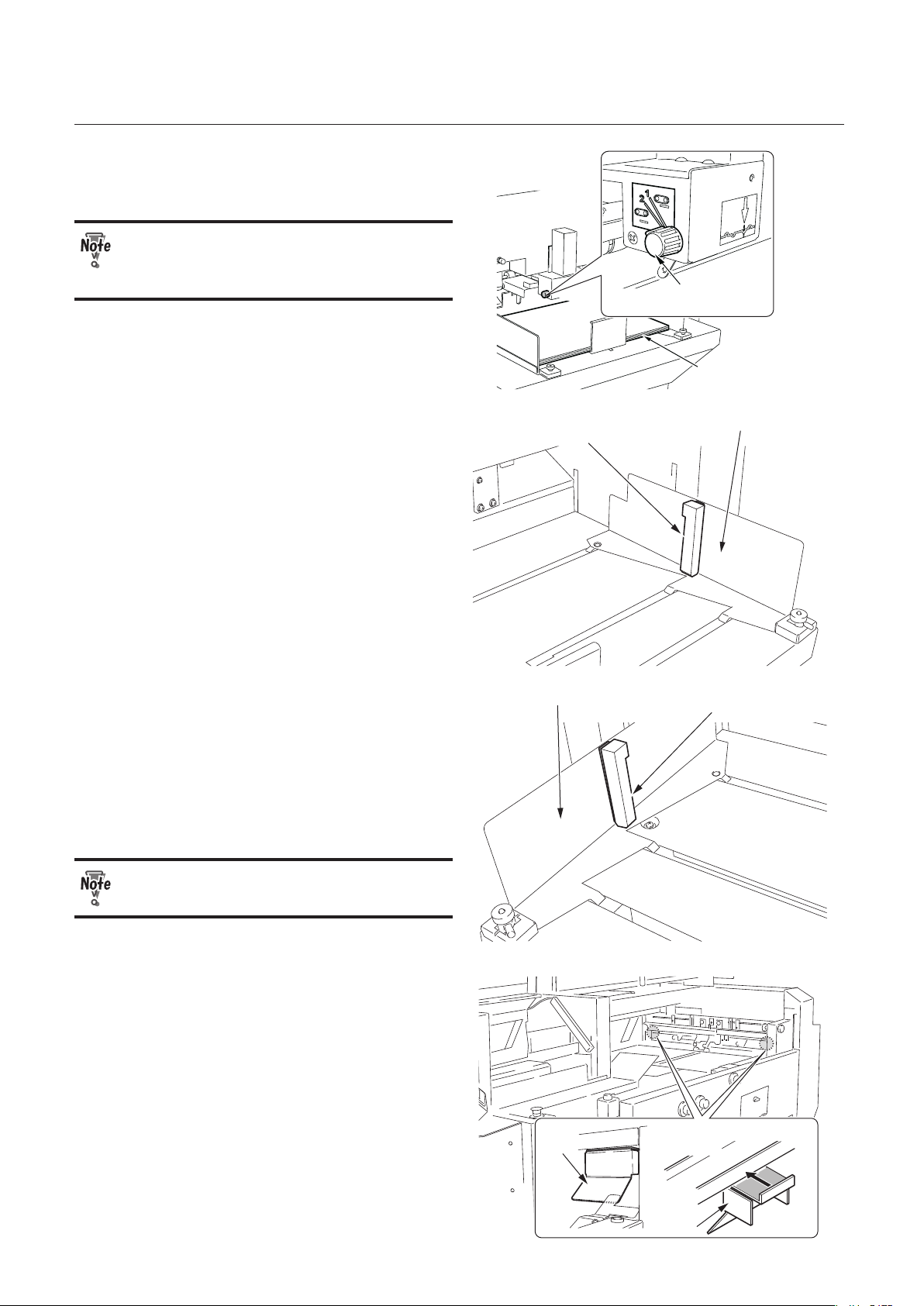

3-2. Glue Tank

The position of the side glue rollers need to be changed depending on whether binding a book block

with a cover or without a cover.

Screw

Wrench

Screw

1.

Loosen the screws (3) using the

supplied wrench (opposite side

distance 3 mm).

Side glue roller

adjustment

Spanner

2.

Turn the side glue roller adjustment

using the supplied spanner to adjust

the position of the side glue rollers.

The iron spanner gets hot. Do not

continue to use it for a long time.

Page 44

2-8

CHAPTER 2 PREPARING FOR OPERATION

Side glue roller

adjustment

A d j u s t a b l e

r a n g e 6 0 °

O p e r a t o r ’ s s i d e

Base position

You can turn the side glue roller adjustment

within the range of 60°.

When binding a book block without a

cover, turn the adjustment 60° to the nonoperator's side from the base position

to move the side glue rollers to the nonoperator's side.

When binding a book block with a cover,

move the adjustment to its base position to

move the side glue rollers to the operator's

side.

If the leading edge of the cover bends,

move the adjustment a bit to the nonoperator's side.

If you turn the adjustment too much to

the non-operator's side when binding a

book block with a cover, side glue may

not be applied to the book block.

3.

Tighten the screws (3) using the

supplied wrench (opposite side

distance 3 mm).

● Before turning the side glue roller adjustment, make sure that the hot melt glue is

completely melted.

● Touching the inside and outside of the glue tank will cause burn injuries.

● Be careful not drop the supplied tools inside the glue tank.

● High voltage of electricity supplied to the glue tank may cause an electric shock. Be

careful.

3-3. Nipping Section

Move the cover stopper to the position for the largest cover size.

Cover stopper

Cover stopper

Cover stopper

adjustment

Cover stopper

adjustment

To a larger size

1.

Loosen the cover stopper

adjustments.

2.

Move the cover stopper to the

position for the largest cover size.

Page 45

2-9

CHAPTER 2 PREPARING FOR OPERATION

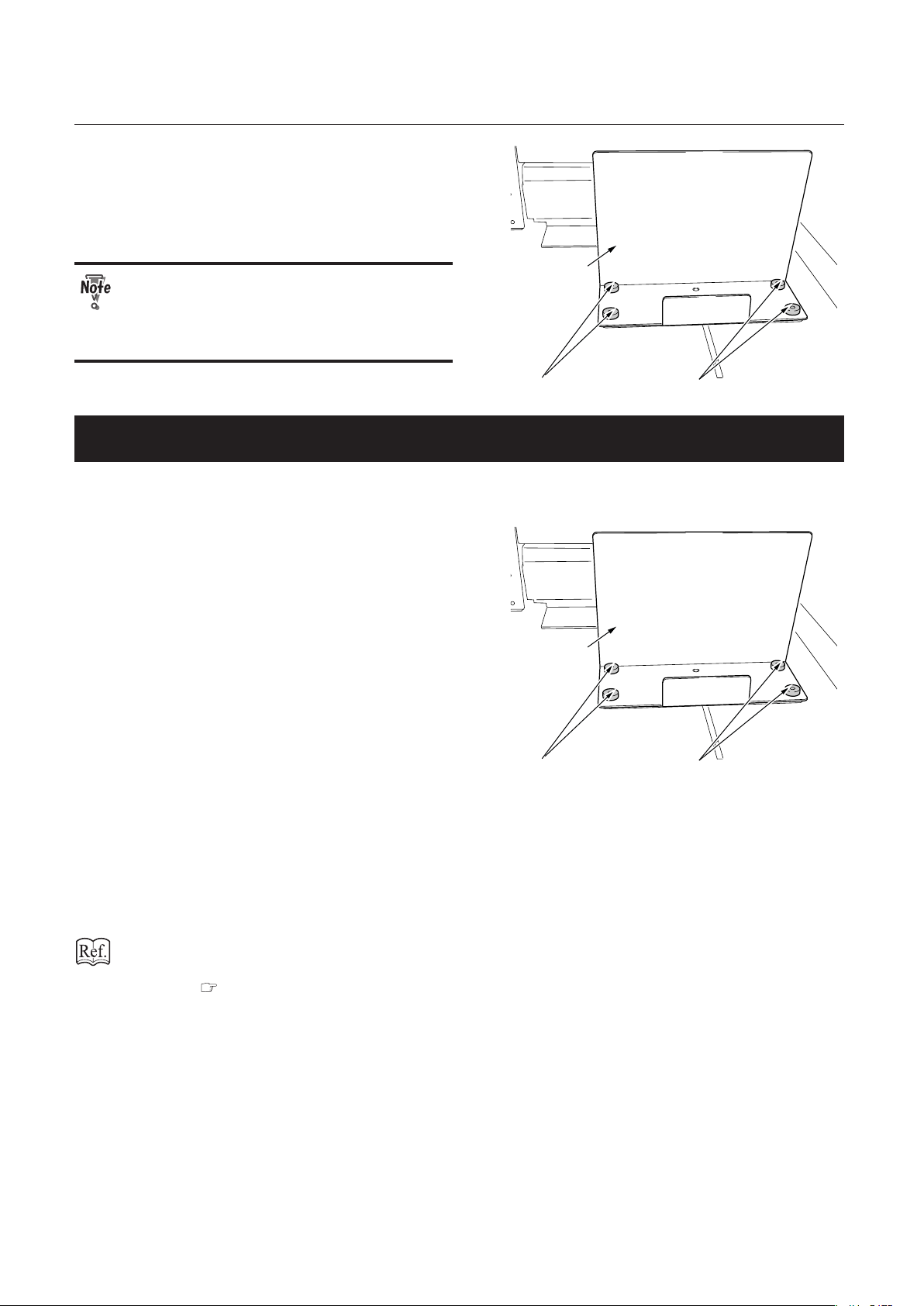

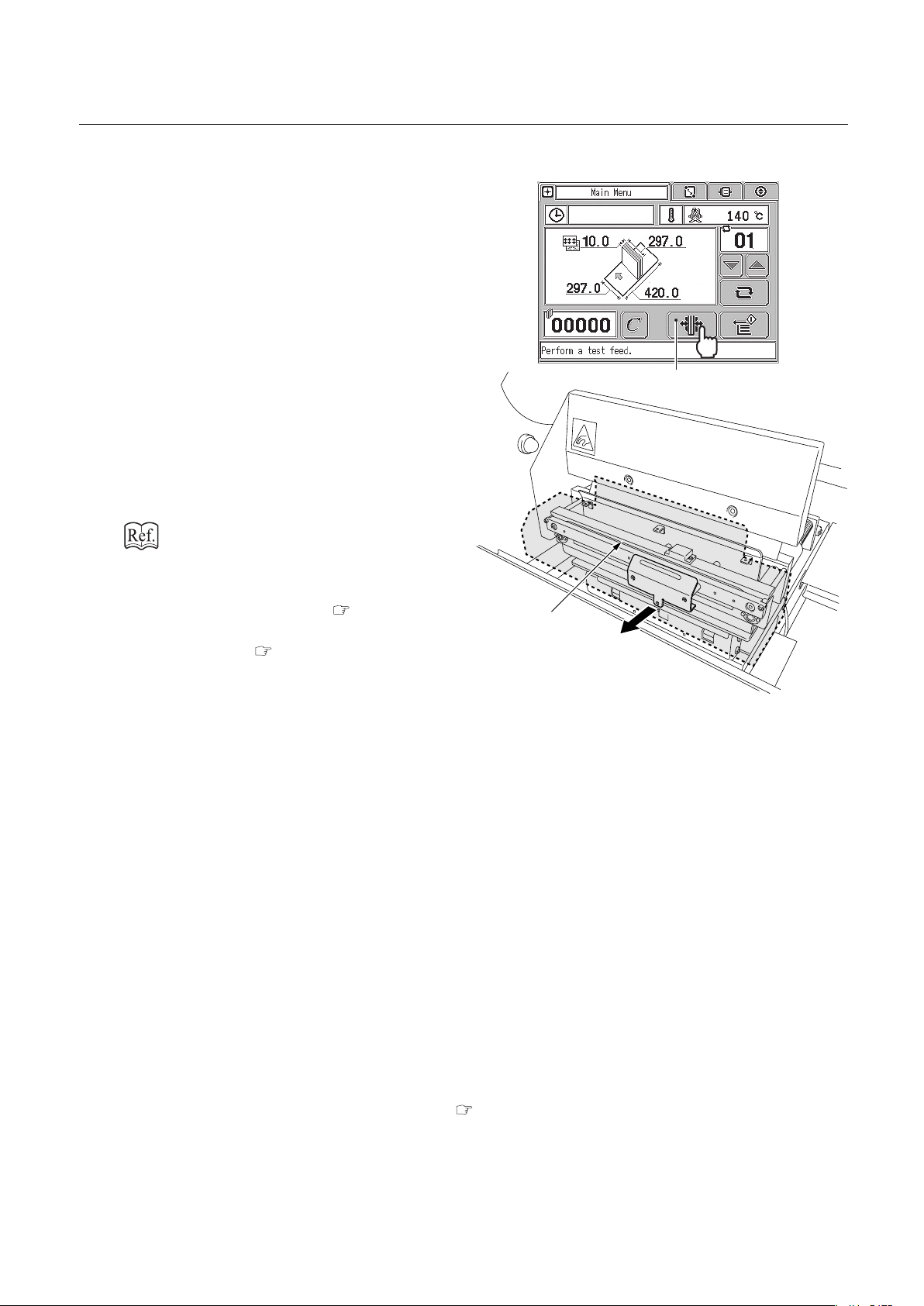

3-4.

Replacing the Receiving Tray with the Stacker Stopper

You can use the stacker stopper for the booklet size of A5, B5, A4 and legal size or for the booklet with

a height of 148 to 216 mm (5.83 to 8.50 inches). To replace the receiving tray with the stacker stopper,

follow the procedures below.

Knob bolt

Receiving

tray

1.

Remove the knob bolts (2) from the

receiving tray.

2.

Raise the receiving tray and pull it

toward you to remove it from the

machine.

3.

Put back the knob bolts (2) removed

in step 1 to their original places.

4.

Select OFF on the paper receiving

tray ON/OFF setting screen of the

touch panel.

Chapter 4 "Fine-adjustment and Option

Setting" "3-9. Setting the Receiving Tray

ON/OFF" ( p.4-23)

Movable stacker

5.

Check that the movable stacker has

been pushed forward (operator's

side).

Stacker stopper

Stacker stopper base

6.

Place the supplied stacker stopper

on the position as shown in the

figure.

Page 46

2-10

CHAPTER 2 PREPARING FOR OPERATION

Stacker stopper

Knob screw

Knob screw

7.

Secure the stacker stopper to the

machine using the supplied knob

screws (4).

When both a book block and cover is

thin, the booklet may hit the movable

stacker and be curled up. Use the

receiving tray when the booklet is limp.

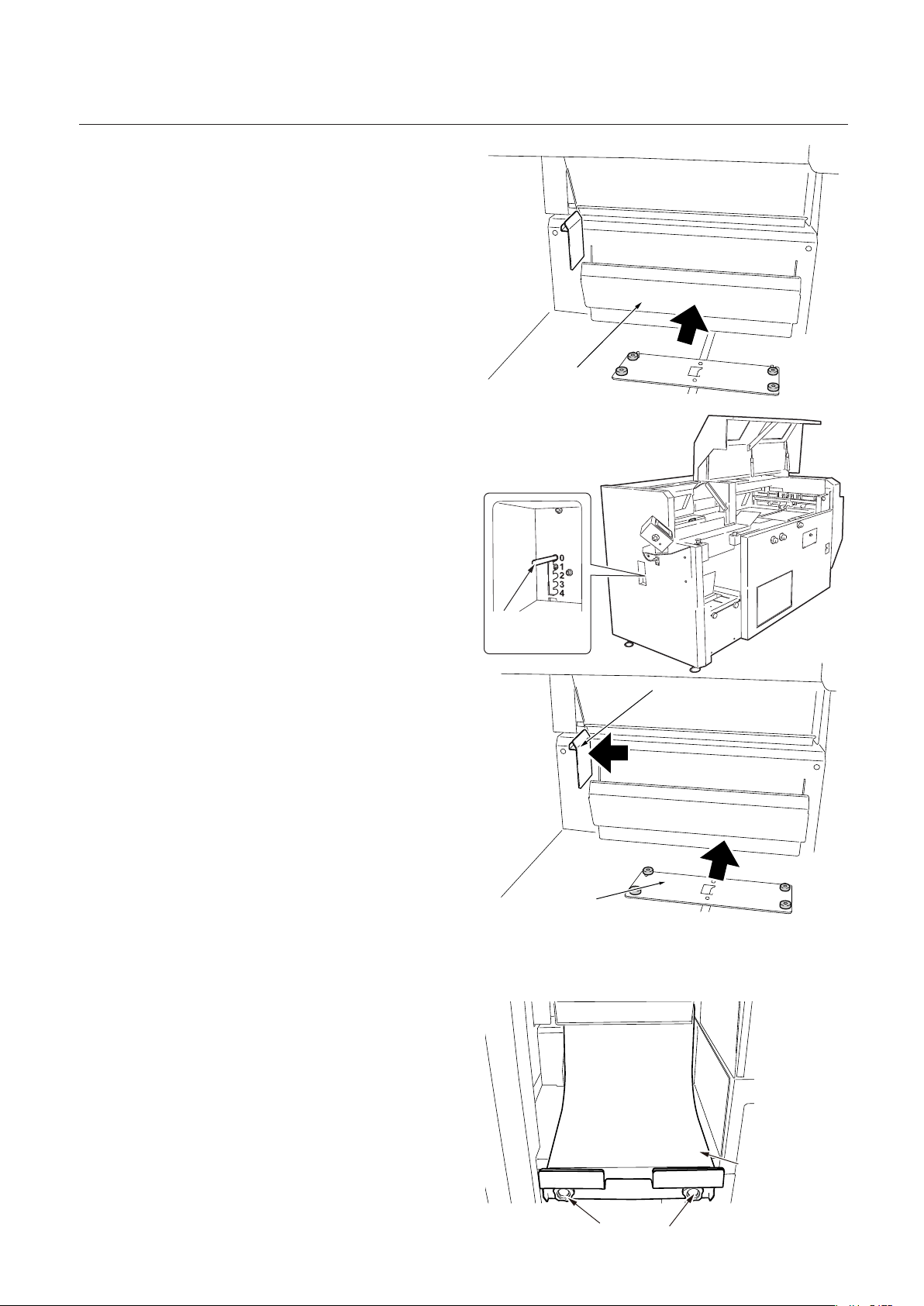

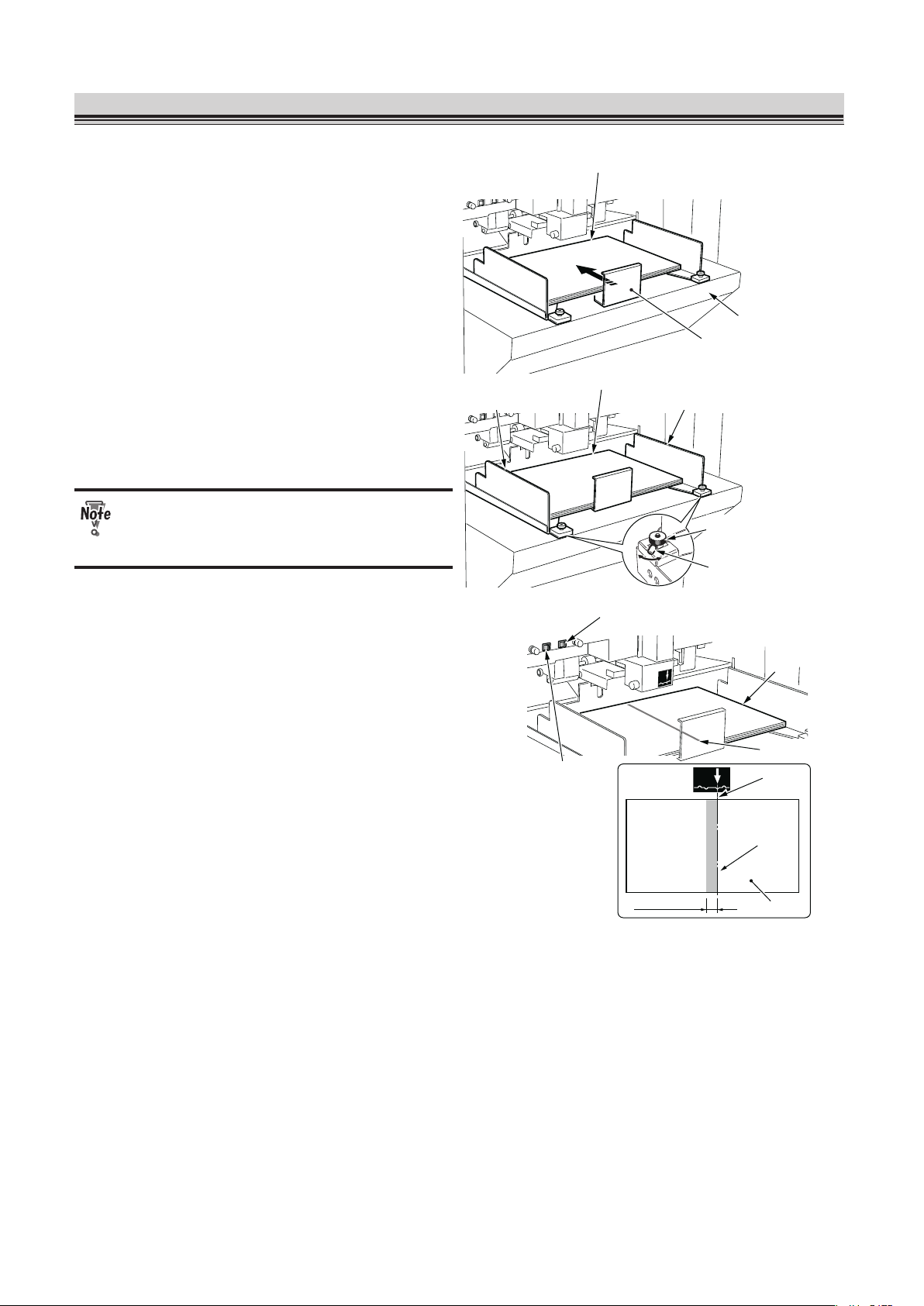

3-5.

Replacing the Stacker Stopper with the Receiving Tray

If the stacker stopper does not align the discharged booklets, replace the stacker stopper with the

receiving tray.

Stacker stopper

Knob screw

Knob screw

1.

Remove the knob screws (4) from the

stacker stopper.

2.

Remove the stacker stopper.

3.

Put back the know screws (4)

removed in step 1 to their original

places.

4.

Select ON on the paper receiving tray

ON/OFF setting screen of the touch

panel.

The movable stacker will be pushed

backward (non-operator's side).

Chapter 4 "Fine-adjustment and Option

Setting" "3-9. Setting the Receiving Tray

ON/OFF" ( p.4-23)

Page 47

2-11

CHAPTER 2 PREPARING FOR OPERATION

Movable stacker

5.

Check that the movable stacker

has been pushed backward (nonoperator's side).

Book exit

damper

adjustment

6.

Check that the book exit damper

adjustment lever is set to "0."

Stacker stopper base

Stacker side guide

7.

Move the stacker side guide to the

left side.

8.

Move the stacker stopper base to the

non-operator's side by hand.

Knob bolt

Receiving

tray

9.

Place the supplied receiving tray as

shown in the figure and secure it to

the machine using the supplied knob

bolts (2).

Page 48

2-12

CHAPTER 2 PREPARING FOR OPERATION

4. Entering Job Information

Setting

Button

2007-04-05 10:40

You can make the following settings on the

main menu screen.

1. Cover (With a cover/Without a cover)

2. Double feed detection (ON/OFF)

3. Book block size

4. Cover size

5. Cover base position

6. Checking and saving settings for the above

items (1-5)

Press the setting button on the main menu screen to go to the cover (with a cover/without a cover)

setting screen.

4-1. Cover (With a cover/Without a cover)

Select whether binding a book block with a cover or without a cover.

Book block

Cover

Without a Cover

With a Cover

Book block

With a Cover Button

Without a Cover Button

Cover

1.

Select whether to bind a book with or

without a cover.

When you press the button, the color of the

button will change as follows.

Select "With a cover" for binding a book

block with a cover and proceed to the step 3.

Select "Without a cover" for pad binding

and proceed to the step 2.

Page 49

2-13

CHAPTER 2 PREPARING FOR OPERATION

Nipping

ON/OFF

button

Next Button

2.

Select whether to apply nipping to

the book block using the nipping ON/

OFF button.

Nipping (ON) Nipping (OFF)

When nipping is ON, the nipping station will

go up during operation.

Press the next button to go to "4-3. Setting

Book Block Size" ( p.2-16).

Press the cancel button to delete all the

settings you made so far and to go back to

the main menu.

● Before binding without a cover, wipe

the gray-colored part shown in the

figure using a cloth with silicon spray

applied. This will prevent hot melt

glue from adhering to the nipping

surface.

● When nipping is set to ON, short

nipping time may cause glue to

adhere to the nipping station. Check

the open time of the hot melt glue you

use and change the time if necessary

( p.3-15, 4-15).

Cancel Button

Next Button

Double Feed

Detection Button

3.

Turn ON or OFF the double feed

detection.

When set to ON, the double feed detection

button is displayed. Press this button to go

to "4-2. Setting Double Feed Detection for

Cover" ( p.2-14).

When set to OFF, press the next button to

go to "4-3. Setting Book Block Size"

( p.2-16).

Press the cancel button to delete all the

settings you made so far and to go back to

the main menu.

Page 50

2-14

CHAPTER 2 PREPARING FOR OPERATION

4-2. Setting Double Feed Detection for Cover

To make the machine detect double feed, decide and input the detection value. Change the double

feed detection settings when detection error occurs frequently at the default setting (standard value).

1.

Press or to select the LED luminescence amount.

Example

LED

luminescence

amount

“0” will be indicated

as shown above.

255

128

Setting range: AUTO (0) to 255 (standard value: Auto)

When the cover is thin or the print is light: Decrease the value.

When the cover is thick or the print is dark: Increase the value.

2.

Press or to select the double feed detection level.

Using the sensor for measuring paper thickness, the thickness of a cover fed at test feed is read

as the reference data, and is compared with the data of the cover fed at the subsequent feed.

When the difference between those data exceeds the double feed detection level (%) you

specified, the machine determines that a double-feed has occurred.

Setting range: 5 to 100 (standard value: 50)

Example

Double feed

detection level

50

20

75

If the double feed is detected when no double feeds are present: Increase the value.

If the double feed is not detected when double feeds are present: Decrease the value.

Page 51

2-15

CHAPTER 2 PREPARING FOR OPERATION

3.

Press or to select the starting point of the double feed detection.

The starting point is a distance from the leading edge of the cover.

Setting range: 20.0 mm (0.79 inch) to cover length minus 40.0 mm (1.57 inches) (standard

value: 40.0 mm (1.57 inches))

Example

Starting point

of double feed

detection

28.0

24.0

20.0

The double-feed detection sensor is located at 5.0 mm (0.20 inch) down to the operator's side

from the scoring base line.

Spine

Scoring base line

Cover

Double-feed detection sensor

5.0 mm (0.2 inch)

Operator’ s side

Feed direction

Detection errors may frequently occur on a solid black area of the cover. Do not

choose the solid black area as the starting point. Detection error hardly occurs

on a white area or light-color print area.

Previous Button

4.

Press the previous button.

The screen shown in step 3 of "4-1.Cover

(With a cover/Without a cover)"

( p.2-13) will appear.

Next Button

5.

Press the next button.

The screen for "4-3.Setting Book Block Size"

( p.2-16) will appear.

Page 52

2-16

CHAPTER 2 PREPARING FOR OPERATION

4-3. Setting Book Block Size

Select whether to change a book block thickness for each process.

Normal mode

Variable mode

Book blocks Book blocks

Normal: The thickness of book blocks is

same for each process

Variable: The thickness of book blocks

varies for each process.

Next Button

Previous Button

Selector Button

1

. Press the selector button to select

normal or variable.

: Normal

The sensor detects the thickness of the first book block. The same thickness is

applied to the following book blocks.

: Variable

The sensor detects the thickness of the book block each time you feed it.

When the variable mode is selected, the processing speed will slow down.

Next Button

Previous Button

Booklet Length Button

2.

Press the book block length button.

The numeric keypad screen will appear.

If you do not need to change the book

block length, press the next button.

When "With a Cover" is selected

You will go to "4-4. Setting the Cover Size"

( p.2-18).

When "Without a Cover" is selected

You will go to "4-6. Checking and Saving

Settings" ( p.2-21).

Press the previous button to return to the previous screen.

Page 53

2-17

CHAPTER 2 PREPARING FOR OPERATION

Numeric Keypad

Clear Button

Input value

297. 0

3.

Input the book block length using the

numeric keypad.

Setting range: 120 to 360 mm (4.72 to

14.17 inches)

Book block

Book block length

To clear the input value, press the clear button.

Return Button

Cancel Button

297. 0

297. 0

4.

Press the return button to confirm

the value.

Press the cancel button to return to the

previous screen.

Next Button

297. 0

5.

Press the next button.

When "With a Cover" is selected

You will go to "4-4. Setting the Cover Size"

( p.2-18).

When "Without a Cover" is selected

You will go to "4-6. Checking and Saving

Settings" ( p.2-21).

Page 54

2-18

CHAPTER 2 PREPARING FOR OPERATION

4-4. Setting the Cover Size

Next Button

Previous Button

Cover Width Button

Standard Size

Select Button

Cover Length

Button

1.

Press the cover width button for

specifying a cover width and the

cover length button for specifying

the cover length.

The screen to input the value will appear.

If you use a standard-sized cover, press the

standard size select button and proceed to

"Selecting the standard size."

Numeric Keypad

Clear Button

Input value

297. 0

2.

Input the size using the numeric

keypad.

Setting range:

Cover length:

120 to 360 mm (4.72 to 14.17 inch)

Cover width:

250 to 696 mm (9.84 to 27.40 inches)

To clear the input value, press the clear

button.

Return Button

Cancel Button

297. 0

297. 0

3.

Press the return button to confirm

the value.

You will go to "4-5. Cover Base Spine

Position" ( p.2-19).

To delete the input data and return to the

screen shown in step 1, press the cancel

button.

Selecting the standard size

1.

Press the button of a size you use.

When you press the button, its color will

change.

Page 55

2-19

CHAPTER 2 PREPARING FOR OPERATION

Return Button

Cancel Button

2.

Press the return button to confirm

the settings.

You will go to "4-5. Cover Base Spine

Position" ( p.2-19).

To cancel the selection and return to the

screen shown in step 1, press the cancel

button.

4-5. Cover Base Spine Position

There are two types of base spine position: side base and center base.

Book block

Feed guide

Feed guide

Scoring base line

Specified value

Non-operator’ s side

Operator’ s side

Side base (based on a specified value):

If the distance between the scoring position

and cover edge has been decided, use

"side base."

After a size change ( p.3-3), the side

guides will move to align the scoring base

line with the specified base line.

Feed guide

Cover center line

Feed guide

Book block

center line

Non-operator’ s side

Operator’ s side

Center base:

Use "center base" to align the cover center

line with the book block center line.

After a size change ( p.3-3), the side

guides will move to align the cover center

line with the book block center line.

The acceptable cover length for a center

base is 342 to 651 mm (13.46 to 25.63

inches).

Base Spine Position Button

1.

Press the base spine position button.

A value that is equal to half the cover width

will be displayed.

Page 56

2-20

CHAPTER 2 PREPARING FOR OPERATION

2.

For side base

Return Button

Cancel Button

Clear

Button

190. 0

The range you can input

Input the length between the scoring

position and cover edge using the

numeric keypad.

The range you can input will be displayed

on the lower right of the screen. Press the

cancel button or clear button, then input an

appropriate value.

Cover width: 250 to 696 mm/9.84 to 27.40 inches

Specified value:

125 to 325.5 mm/4.92 to 12.82 inches

Cover width – specified value:

125 to 376.5 mm/4.92 to 14.82 inches

Spine

Base Spine Position

Next Button

190. 0

The specified position will align with the

scoring base line.

When you press the next button, you will go

to "4-6. Checking and Saving Settings"

( p.2-21).

Page 57

2-21

CHAPTER 2 PREPARING FOR OPERATION

For center base

0

Return button

Input “0” using the numeric keypad and

press the return button.

Base Spine Position Button

Next Button

The base spine position button will be

displayed as shown in the figure.

The icon means that the scoring base line

will align with the book block center line

when you perform the size change in a later

step.

When you press the next button, you will go

to "4-6.Checking and Saving Settings"

( p.2-21).

When you input a cover length other than 342 to 651 mm (13.46 to 25.63 inches) in

"4-4.Setting the Cover Size," "0" will not be accepted.

4-6. Checking and Saving Settings

You will confirm the settings you made so far for a book block size, cover size, and double feed

detection and save them to a memory.

1.

Check the settings of before and

after changing.

Book block length

Cover (With a cover,

Without a cover

Cover width

Cover length

Base spine position

LED luminescence amount

Double feed detection level

Starting point of the double

feed detection

Book block thickness (variable/normal)

Before Change

Before Change

After Change

After Change

Page 58

2-22

CHAPTER 2 PREPARING FOR OPERATION

Memory No.

Cancel Button

Previous Button

2.

Press or to select the

destination to save the settings.

The number of memories is 20 and all of

them contains the same setting data by

default.

Book block length: 297.0 mm (11.69 inches)

Book block thickness: variable

Cover (with or without a cover): With a cover

Book block width: 420.0 mm (16.54 inches)

Cover length: 297.0 mm (11.69 inches)

Base spine position: 210.0 mm (8.27 inches)

LED luminescence amount: 0 (Auto)

Double feed detection level: 50%

Starting point of the double feed detection: 40.0 mm (1.57 inches)

When you press the cancel button, the

setting data will be deleted and you will

return to the main menu.

To return to previous screen, press the

previous button.

Memory Button

3.

Press the memory button for more

than one second.

The message “Do you want to clear the fine

adjustment data?” will appear. Press "Yes"

if you want to clear the data.

When you press "Yes," the fine-adjustment

data you set in the past will be erased.

You will return to the main menu.

Page 59

Chapter 3

STARTING BINDING

OPERATION

Page 60

3-2

CHAPTER 3 STARTING BINDING OPERATION

1. Placing a Book Block

When binding with a cover:

Follow the procedures below.

When binding without a cover:

After completing the step 2, go to "3. Starting Binding" ( p.3-14).

Clamp Section