Page 1

Provided By

http://www.MyBinding.com

http://www.MyBindingBlog.com

Page 2

SERVICE TRAINING MANUAL

DocuCutter™

DC-545 & DC-545HC

Page 3

DocuCutter 545

Table Of Contents

Table Of Contents...............................................................................................................2

Product Overview ...............................................................................................................3

Programmable Memory...................................................................................................4

Automatic Operation via Barcode....................................................................................6

Automatic Registration Correction...................................................................................6

Safety .................................................................................................................................8

Cutter and Slitter Blades .................................................................................................9

Safety Notes..................................................................................................................10

Maintenance Safety ......................................................................................................11

Electrostatic Discharge (ESD) Protection Program.......................................................11

DocuCutter DC-545 Installation........................................................................................12

The Control Panel.............................................................................................................14

AF-100 OPERATOR CONTROLS ................................................................................17

PWB Locations.................................................................................................................19

Switch and Sensor Locations............................................................................................20

Paper Handling.................................................................................................................22

Paper Path....................................................................................................................23

Slitting ...........................................................................................................................24

Cutting...........................................................................................................................27

Creasing........................................................................................................................29

AF-100 Theory Of Operation ............................................................................................31

Programming Jobs........................................................................................................32

DC-545: AUTO CUT function........................................................................................34

DC-545 Theory of Operation.........................................................................................36

Reasons for JAM and ERROR messages........................................................................39

DocuCutter DC-545 Maintenance Procedures..............................................................41

DocuCutter DC-545 Service Mode ...................................................................................42

Documentation Review ........................................................................................................44

Conclusion............................................................................................................................45

2 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 4

Product Overview

DocuCutter 545

The DocuCutter DC-545 is a fully automatic four-sided

paper trimmer. In addition to four sided trimming, it can

also perform up to five parallel margin slits (a sixth slitter

is available as an option), multiple leading and trailing

edge cuts (up to 10) and multiple sheet creases (up to 4).

Full bleed color documents are finished in a single pass

with no operator intervention. The DocuCutter DC-545

produces postcards, greeting cards, photo albums,

business cards, and much more.

The optional DC-545HC configuration includes:

AF-100 autofeeder

Stand

The DC-545HC configuration is shown on the cover of this

manual. The DocuCutter DC-545 is shown in Figure 1

below.

Figure 1. The DocuCutter DC-545

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 3

Page 5

DocuCutter 545

Programmable Memory

The DocuCutter DC-545 is manually programmable so

additional jobs (up to 80 total) may be designed and

stored for future use. See Section 6 of the DocuCutter

DC-545 Service Manual for programming details.

4 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 6

DocuCutter 545

The major components of the DocuCutter DC-545 are

shown in Figure 2 below.

Figure 2. Major Components - View A

The remaining major components of the DocuCutter DC545 are shown in Figure 3 below.

Figure 3. Major Components - View B

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 5

Page 7

DocuCutter 545

Automatic Operation via Barcode

The operator places a single sheet of preprinted output

containing a properly formatted code 39 barcode in the

feed tray of the DocuCutter DC-545 (or in the feed tray of

the AF-100 on HC version systems). See the DC-545

Instruction Manual for bar code and registration mark

details. The preprinted output contains a barcode

indicating which preprogrammed job the DocuCutter DC545 needs to execute. The DocuCutter DC-545

automatically sets the slitter positions, activates the cutter

for lead/trail edge trimming and the creaser for any

required crease(s).

Automatic Registration Correction

The DC-545 reads a small 90-degree angle registration

mark, adjacent to the barcode. It is used for cutting,

creasing, and trimming registration correction. The REG

mark reference position is input during entry of each set of

programming parameters. Since the REG mark and image

shift proportionately, any error in the REG mark position is

used as error correction data for image registration. The

DocuCutter DC-545 automatically compares the actual

image position to the reference position and offsets the

cutting and creasing position (horizontal shift) and slit

position (vertical shift) to maintain precise trims—every

time.

6 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

REG Mark

Left Margin Slitter (LEFT SL)

Center Left Slitter (C.L. SL)

Center Slitter (OP1)

PAPER FEEDING DIRECTI ON

Bar Code

Right Margin Slitter (RGHT SL)

Center Right Slitter (C.R. SL)

Page 8

DocuCutter 545

DocuCutter DC-545 Specifications

The table below provides the specifications applicable to

the DocuCutter DC-545. This information is provided for

reference purposes only.

Paper size

Finishing size

Paper thickness

Front edge cutting width

Rear edge cutting width

Side cutting width

Cutting accuracy

Cutting speed

Feeding method

Stacker

Power supply

Maximum = 12.6" x 18"

Minimum = 8.5" x 11"

Minimum = 2" x 3.5"

(business card size)

28 lb bond to 10 pt cover

(80-230 gsm)

0.125" Minimum

0.125" Minimum

3" Maximum

0.125" Minimum

±0.762 mm

2 ppm Minimum

Manual feeding (3.93” stack

with AF-100 vacuum feeder

in the HC configuration)

Drop type

AC 120 V ±10 % @ 60 Hz

Current consumption

Machine dimensions

2.1A

44.5W x 22D x 11H in.

1130W x 559D x 279H mm

Machine weight

Main body: 127 lb. (58 kg)

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 7

Page 9

DocuCutter 545

Safety

The objective of this section is to familiarize you with the

safety requirements related to the operation and servicing

of the DocuCutter DC-545. By reading this section, you

will gain an understanding of the important safety

information relating to this product.

NOTE One of the most important goals of this section is to give

you enough information so that you will always take the

proper safety precautions when servicing this product.

• At no time will you ever be instructed to come in

contact with internal drive components or high

voltage electrical devices that are under power. In

fact, the first step in most service procedures is “disconnect power cords.”

• At no time should you ever instruct an operator to

touch any moving or powered internal components.

• The only time that power is left on during a service

procedure is when specific components are being

tested.

All safety devices and covers should be in place and in

working order before completing a service call. It is your

responsibility to follow safe work procedures at all times. If

you perform an unapproved service procedure, you may

run the risk of injuring yourself or the people nearby. Also,

you could be inadvertently demonstrating a dangerous

service procedure to a customer. This could result in a

severe injury and an expensive lawsuit.

8 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 10

DocuCutter 545

Cutter and Slitter Blades

Because the DocuCutter DC-545 contains a series of

Slitters and a Cutter, a variety of Warning Labels have

been placed on the machine. You should be aware of the

Warning Label locations, as shown in Figure 4 below.

WARNING The Cutter Blade and the Slitter Blades could cause

serious injury if not handled properly. Always use

caution when working near the Cutter or Slitters.

Keep the Warning Labels clean at all times. If Labels

become damaged, replace them.

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 9

Figure 4. Warning Label Locations

Page 11

DocuCutter 545

Safety Notes

The DocuCutter DC-545 has been designed and tested to

meet strict safety requirements. These include safety

agency examination and approval, and compliance to

established environmental standards. The following notes

and warnings will help to ensure your complete

understanding of the safety requirements for the

DocuCutter DC-545:

• ALWAYS follow all warnings and instructions marked

on, or supplied with, the equipment.

• ALWAYS disconnect the machine from the wall outlet

before cleaning.

• ALWAYS use the materials and supplies specifically

designed for this machine. Use of unsuitable materials

may result in poor performance and possibly create a

hazardous situation.

• ALWAYS ensure that the machine is located on a solid

support surface with adequate strength for the weight of

the machine.

• NEVER use any supplies or cleaning materials for

purposes other than what they were intended.

• NEVER push objects of any kind into the slots of the

machine as they may touch dangerous voltage points or

cause a short circuit in parts that could result in a risk of

fire or electric shock.

• NEVER push objects of any kind into the ventilation

openings in the back and bottom of the machine.

• NEVER allow anything to rest on the power cord.

• NEVER use a ground adapter plug to connect the copier

to a power source receptacle that lacks a ground

connection terminal.

• ALWAYS make sure that the total amperage of all

products plugged into the wall outlet does not exceed

the outlet protection.

10 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 12

DocuCutter 545

Maintenance Safety

• DO NOT use aerosol cleaners. Follow the instructions in

the Service Manual for proper cleaning methods.

• DO NOT use this machine near water, wet locations, or

outdoors.

• NEVER attempt any maintenance function that is not

specified in the Service Manual, or as directed by an

authorized service representative.

• NEVER spill liquid of any kind on the machine.

Electrostatic Discharge (ESD) Protection Program

The purpose of the Electrostatic Discharge (ESD)

Protection Program is to preserve the inherent reliability

and quality of electronic components that are handled by

field service personnel. This program is implemented as a

direct result of advances in micro circuitry technology, as

well as a new acknowledgment of the magnitude of the

ESD problem in the electronics industry today.

This program will reduce field service costs that are

charged to PWB failures. Approximately 90% of all PWB

failures that are ESD-related do not occur immediately.

Using the ESD Field Service Kit will eliminate these

delayed failures and intermittent problems caused by

ESD. This will improve product reliability and reduce

callbacks.

The ESD Field Service Kit should be used whenever

Printed Wiring Boards or ESD-sensitive components are

being handled. This includes activities like replacing or

reseating circuit boards or connectors. The kit should also

be used to prevent additional damage when circuit boards

are returned for repair.

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 11

Page 13

DocuCutter DC-545 Installation

These instructions are for installing the DC-545 base unit.

Refer to the Duplo AF-100 Installation Manual for details

on installing the DC-545HC configuration (including the

AF-100 autofeeder and the associated stand).

The following Installation notes are provided as a

reference.

• The DocuCutter DC-545 should be installed on a

• The Paper Tray should be attached to the main

DocuCutter 545

flat and stable surface (the machine weighs 127

pounds / 58 kg). As a precaution, on every service

call, be sure to verify that the customer has the

machine installed in an appropriate location.

body of the DocuCutter DC-545 as shown in Figure

5.

Figure 5. Attaching the Paper Tray

The power cord should be attached to the DocuCutter DC545 and a wall outlet, as shown in Figure 6.

12 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 14

DocuCutter 545

Figure 6. The Power Cord Location

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 13

Page 15

The Control Panel

DocuCutter 545

The Control Panel on the DocuCutter DC-545 performs

the following functions:

• Displays operation and machine status during

normal operation

• Indicates when problems with the machine have

occurred

• Allows for operator /service input to assist in jam

clearance

• Provides service personnel with a method of

accessing the Service Mode Diagnostic Tools

The location of the Control Panel on the DocuCutter DC545 is shown in Figure 7.

14 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Figure 7. Control Panel Location

Page 16

DocuCutter 545

Each of the Control Panel areas is shown in Figure 8

below. The function of each area is described in the table

that follows.

Cover Lamp

Jam Lamp

Paper Lamp

LCD Panel

F

Button

Power Lamp

Numerical

Clear

Button

Key Pad

Mode

Button

+ Button

- Button

Set

Button

Figure 8. The Control Panel

Start Button

and Start

Lamp

STOP

Button

The Liquid Crystal Display (LCD) Panel displays the

status of the machine. Messages are displayed when

an error or paper jam occurs.

The <+> Button ejects the document from the

machine at the time of paper jam. In the service

mode, this button is used to advance through the

various menus and increment adjustment values in a

positive direction.

The< –> Button ejects the document from the

machine at the time of paper jam. In the service

mode, this button is used to advance through the

various menus and increment adjustment values in a

negative direction.

The POWER Lamp lights up when the power is

switched on.

In the HC configuration, (AF-100 autofeeder attached)

the START Button is used to start processing.

While in the stand-alone configuration (DC-545 only,

no AF-100 autofeeder) the START button is not used.

The STOP Button stops cutting after the current sheet is

complete. The STOP Button also clears jam indication

after the paper is cleared. While in the service menu the

STOP Button is used to exit various menus.

During programming, the Numerical Key Pad enters

preset program numbers and job data.

During programming, the CLEAR Button clears data

values. It is also used to clear the total sheets processed

counter.

During programming mode, the SET Button enters data

values. In the HC configuration (AF-100 autofeeder

attached) the SET button is used to process only one

sheet for proofing purposes.

The MODE Button changes the main menu functions.

[RUN] Ready for processing

[SELECT] Manual job selection (as opposed to bar

code)

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 15

Page 17

DocuCutter 545

In the service mode, this button is used to enter

various service menus.

The COVER Lamp blinks when the front cover, rear

cover, or the waste cover is open.

The JAM Lamp blinks when a paper jam has

occurred.

[INPUT] Programming mode

[SELECT] Manual job selection (as opposed to

automatic job recall via a bar code)

BARCODE Used to toggle barcode mode on/off. When

the values is changed the REG mark and

autocut features are enabled.

In the HC configuration (AF-100 autofeeder attached)

the PAPER Lamp blinks when paper runs out.

16 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 18

DocuCutter 545

AF-100 OPERATOR CONTROLS

1. Level adjustment lever for adjusting the level of the

paper stack

2. Separator adjustment knob for adjusting the

amount of space between the mechanical paper

separators and the top sheet of paper

3. Airflow adjustment knob for adjusting the amount of

airflow used to separate the sheets in the paper

stack

4. Skew adjustment knob for adjusting the skew of the

paper stack

5. Stoppers for holding the rear edge of the paper

stack

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 17

Page 19

LCD Panel

DocuCutter 545

The LCD Panel located on the Control Panel displays the

status of the machine and displays messages when an

error or paper jam occurs.

A sample LCD Panel display is shown in Figure 9 below.

Figure 9. The LCD Panel

1. Status - Displays the current operating mode.

2. Preset Number - Displays the Program (P) number.

3. OPTION - An "*" is displayed when the AF-100 is

attached.

4. BAR CODE - When using bar codes "BC" is displayed;

"- -" is displayed when bar codes are not being used.

5. REGISTER MARK - When using register marks "REG"

is displayed; "- -" is displayed when REG marks are not

being used.

6. AUTO CUT - When using the autocut function, "AC" is

displayed; "- -" is displayed when autocut is not being

used.

7. COUNTER - Displays the number of pages processed.

18 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 20

PWB Locations

DocuCutter 545

The locations of each of the Printed Wiring Boards

(PWBs) in the DocuCutter DC-545 are shown in Figure

10.

Power

PWB

Main

PWB

Panel

PWB

Memory

PWB

Switching

Power Supply

PWB

Figure 10. PWB Locations

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 19

Page 21

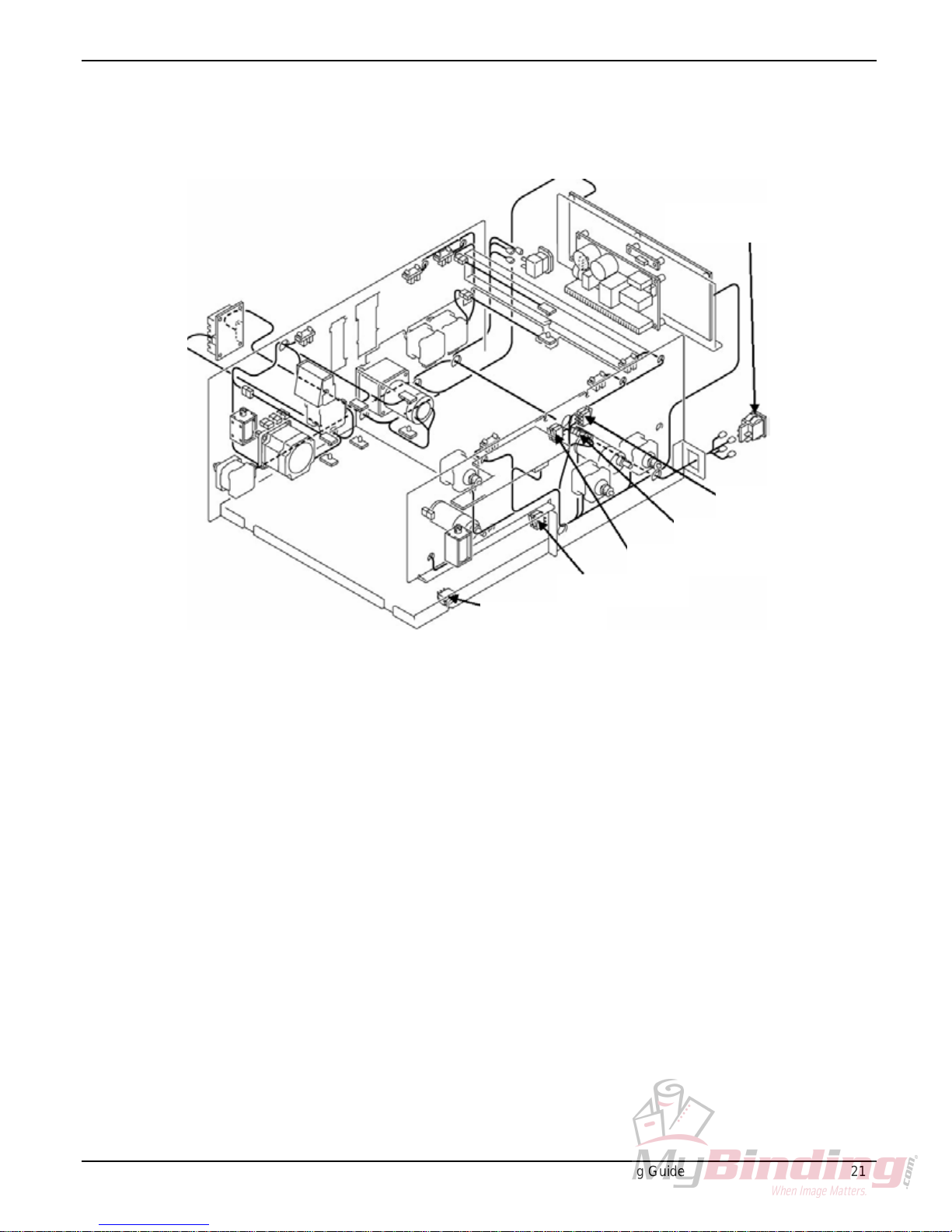

Switch and Sensor Locations

Slitter Sensor

Left Margin

Slitter Sensor

Center Slitter

Left Sensor

DocuCutter 545

The DocuCutter DC-545 contains a series of Switches

and Sensors to determine paper position. The locations of

the Slitter Sensors within the DocuCutter DC-545 are

shown in Figure 11.

Option 1

Figure 11. Slitter Sensor Locations

20 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Center Slitter

Right Sensor

Right Margin

Slitter Sensor

Page 22

DocuCutter 545

The remaining Switches and Sensors are shown below in

Figure 12.

Power Switch

Tray Switch

Door Switch

Figure 12. Switches and Sensors

Rear Cover Switch

Creaser Sensor

Front Cover Switch

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 21

Page 23

Paper Handling

DocuCutter 545

Throughout the following paragraphs, you will be reading

about Slitters, a Cutter, and a Creaser. These

components are used in various combinations to finish

documents in the DocuCutter DC-545. Figure 13 is

provided below to help you understand the paper handling

terms associated with the DocuCutter DC-545.

You should note that, by definition, a cut or a crease is

perpendicular to the direction of paper feed, while a slit

is parallel to the paper feed direction.

Cut

REG Mark

(Optional)

Bar Code

(Optional)

PAPER FEEDING DIRECTION

Slit

Crease

22 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Figure 13. Paper Handling Terms

Page 24

DocuCutter 545

Paper Path

All of the finishing operations within the DocuCutter DC545 take place along the Main Paper Path. The locations

of the main paper path components are shown in Figure

14.

1212 7345689101113141516

19

20

22 26

21

23

24

25

17 18

28

27

Figure 14. Main Paper Path Components

Names and Locations of Paper Path Components

Item

Number

1 Input Feed Rollers 19 Lower Primary Feed Roller

2 Input Roller 20 Lower Secondary Feed Roller

3 Upper Primary Feed Roller 21 Lower Margin Slitter Drive Gear

4 Upper Secondary Feed Roller 22 Lower Cutter Feed Roller

5 Right (Left) Margin Slitter Lead Screw 23 Lower Creaser Feed Roller

6 Upper Margin Slitter Drive Gear 24 Lower Center Slitter Feed Roller

7 Upper Cutter Feed Roller 25 Lower Center Slitter Drive Gear

8 Cutter Unit 26 Lower Rear Slitter Drive Roller

9 Upper Creaser Feed Roller 27 Lower Rear Slitter Drive Gear

10 Creaser Unit 28 Lower Exit Drive Roller

11 Upper Center Slitter Feed Roller

12 Left Center Slitter Lead Screw

13 Upper Center Slitter Drive Gear

14 Right Center Slitter Lead Screw

15 Upper Rear Slitter Feed Roller

16 Rear Slitter Drive Lead Screw

17 Upper Rear Slitter Drive Gear

18 Upper Exit Feed Roller

Descriptions Item

Descriptions

Number

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 23

Page 25

DocuCutter 545

Slitting

Standard configuration provides for five Slitters used in

the DocuCutter DC-545. An optional sixth slitter is

available. The five factory provided slitters are called:

• Right Margin Slitter

• Left Margin Slitter

• Center Left Slitter

• Center Right Slitter

• Option 1 Slitter

Two DC Slitter Drive Motors provide cutting energy to

each of the Slitters:

• One DC Slitter Drive Motor provides cutting energy for

the Left Margin Slitter and Right Margin Slitter

• One DC Slitter Drive Motor provides cutting energy for

the Center Left Slitter, Center Right Slitter, and the

Center Slitter.

Cutting Surfaces

Each Slitter consists of a two beveled edge cutting

wheels. Much like a pair of scissors, the two pieces

working together produce a fine cut. Furthermore, the

design provides for high performance with long life

characteristics (1,500,000 sheets).

Cutting Drive

The Slitter’s two cutting wheels are independently driven

by gear driven shafts. The hub of each wheel has a

removable key while the driving shafts have key-ways

located throughout the drive shafts length.

NOTE Use caution while removing the Cutter Units as the keys

can easily fall out.

24 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 26

DocuCutter 545

Position Detection

Each Slitter has a Sensor Plate mounted to the top of the

Slitter. The Sensor Plate has a slot that permits the Slitter

Sensor to activate when the Slitter is in the home position.

The Sensor Plates are shown in Figure 15.

NOTE The Slitter Sensor Plate can be moved side-to-side

several millimeters when the mounting screws are

loosened. The available movement is for factory setup

and should not be changed. Slitter calibration position is

performed through the service menu.

LEFT SLITTER UNIT POSITION SHAFT

SENSOR PLATE

TO LEFT SLITTER STEPPER MOTOR

LEFT SLITTER UNIT

KEYWAYS

RIGHT SLITTER UNIT

RIGHT SLITTER UNIT POSITION SHAFT

SLITTER DRIVE GEARS

Figure 15. Slitter Components

BEARING

SENSOR PLATE

TO RIGHT SLITTER STEPPER MOTOR

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 25

Page 27

DocuCutter 545

Slitter Position Drive

Each Slitter has its own positioning drive motor (stepper

motor). The use of a stepper motor ensures highly

accurate positioning of the slitter unit. Each stepper motor

drives a lead screw. The Slitters contain a bearing that

rides on the lead screw, so as the lead screw turns, the

Slitter is driven from side to side. Direction of the Slitter

movement is determined by the stepper motor control

signal.

Slitter Positioning

Each job contains position information for the Slitters. The

program information sets the Slitter position each time a

sheet is processed. This method provides extremely

accurate performance.

When a job is executed, each stepper motor is driven until

the Slitters arrive at the home position (home position is

next to the side frame where each sensor is located).

Next, the stepper motors drive the Slitters in the opposite

direction, away from the side frame, until the desired

position is obtained. Position information is monitored by

the stepper motor drive signal.

Once the Slitter positions are correct, the DocuCutter

begins to drive the Slitter cutting drive gears, thus

providing slitting energy. Then the drive rollers convey the

paper through the machine.

26 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 28

DocuCutter 545

Cutting

The DocuCutter DC-545 uses an integrated Cutter to

produce a cut (or multiple cuts) perpendicular to the paper

path, as determined by the program data. The Cutter

specifically enables lead and trail edge cuts so custom

finished sizes and full bleed documents are obtainable. It

also enables multiple cut applications such as business

cards to be produced in a single pass. Cutting is

accomplished using the components listed below:

• A high torque DC motor with a self-contained torque

enhancing transmission

• Long life (2,000,000 cuts), replaceable, precision

upper cutting blade

Cutter Construction

The Cutter Unit consists of a movable, precisely beveled,

Upper Cutting Blade and a counter-cutting surface. Much

like a pair of scissors, the two pieces working together

produce a very fine cut. The design provides for high

performance with long life characteristics.

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 27

Page 29

DocuCutter 545

Cutting Drive

Energy is supplied to the Cutter Unit by a high torque

drive configuration. The Motor, via a self-contained gear

drive to the Cutter Drive Cam, supplies rotational energy.

The Cam causes the Upper Blade to move towards the

bottom surface, cutting the paper, and then returns the

blade to the home position.

Operational Status

The Cam activates a Micro switch. The Micro switch

signals the Microprocessor that the Cutter Unit has

reached the home position. The Cutter Unit is cycled each

time the DocuCutter DC-545 is powered on. If the

Microprocessor fails to receive the home position signal, a

jam is declared and the LCD indicates CUTTER LOCK.

Cutting Position Detection

The preset job data indicates where the paper requires

cutting. When the lead edge of the paper triggers Paper

Path Sensor #3 (PPS3), the Microprocessor calculates the

distance the paper travels via the Stepper Motor Control

pulses. When the desired distance is reached, the Cutter

Drive Motor is activated and the paper is cut.

28 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 30

DocuCutter 545

Creasing

The DocuCutter DC-545 uses an integrated Creaser to

produce a crease (or multiple creases) perpendicular to

the paper path, as determined by the program data. The

crease enables smooth, even forming of finished paper so

it may be folded easily after processing. Creasing also

permits folding of color printed documents with minimal

toner cracking or flaking.

Creasing is accomplished in the DocuCutter DC-545 with

the following components:

• A high torque DC Motor with a self-contained torque

enhancing transmission

• Long life, high-precision male and female paper

creasing surfaces

Creaser Construction

The upper and lower surfaces of the Creaser are

designed to mesh when they are pressed together. One

surface has a channel and the other surface has a ridge

that fits into the channel.

Creasing Drive

Energy is supplied to the Creaser by a high torque drive

configuration. Rotational energy is supplied by the motor,

through a self-contained gear drive, to a Drive Belt and

ultimately to the Creaser Drive Pulley. The Pulley is

directly connected to an Eccentric Shaft. When the Shaft

is driven, the eccentricity causes the upper creasing

surface to move towards the lower creasing surface, thus

creasing the paper.

Operational Status

The Camshaft activates a Photo Interrupter. The Photo

Interrupter signals the Microprocessor that the Creaser

Unit has reached the home position. The Creaser Unit is

cycled each time the DocuCutter DC-545 is powered on. If

the Microprocessor fails to receive the home position

signal, a jam is declared and the LCD indicates

CREASER LOCK.

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 29

Page 31

DocuCutter 545

Creasing Position Detection

The preset job data indicates where the paper requires a

crease. When the lead edge of the paper triggers PPS3,

the microprocessor calculates the distance the paper

travels via the Stepper Motor control pulses. When the

desired distance is reached, the Creaser Drive Motor is

activated and the paper is creased.

30 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 32

AF-100 Theory Of Operation

DocuCutter 545

The following describes the operating principle of the AF100 Autofeeder.

1. The operator loads a stack of paper in the AF-100

feed tray and then presses the START button on

the DC-545.

2. The paper sensor (11) detects the presence of

paper and allows the blower (13) and vacuum fan

(13) to turn ON.

3. The paper level sensor (15) determines the paper

pile height is at the desired level. The elevator is

raised if the paper pile is not high enough. When

the paper pile reaches the proper height the

elevator stops raising the stack and the vacuum

shutter solenoid (12) turns ON, allowing vacuum

pressure to pick up the top sheet on the pile.

4. The feed motor turns ON and drives the feed belts

in order to feed the sheet into the DC-545. PPS1,

located in the DC-545, senses the paper and

causes the feed motor (13) and the vacuum feed

shutter solenoid to turn OFF.

5. When the finished sheet of paper passes PPS4,

signaling the sheet has exited the DC-545, the feed

process repeats until the paper pile is depleted.

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 31

Page 33

DocuCutter 545

Programming Jobs

The DocuCutter DC-545 is manually programmable with 80 sets of

available finishing program numbers. An individual set of cutting

dimensions are stored and recalled by a finishing program number.

You may be required to change or add finishing programs

depending upon customer requirements. Follow the steps below to

manually enter a finishing program:

NOTE The information provided here is also available in General

Procedure GP-5 of the DocuCutter DC-545 Field Service Manual. It

is presented in this document for reference purposes only.

1. Power On the DocuCutter.

2. Repeatedly push the <MODE> button until the display indicates

[INPUT].

3. Push and hold the <SET> button until the display appears.

4. Enter the desired program number using the numerical

keypad (01 ~ 80). In this example the program number is 52.

5. Press the [SET] button.

6. Place a PREPRINTED (with a REG mark) sample sheet in the

DocuCutter DC-545.

7. While observing the number on the lower left of the LCD display panel,

push the <+> button until the number changes (a typical change is

approximately 500 to 50, depending on the REG mark position). If the

REG mark goes past the image sensing area, press the <-> button to

move the paper (REG mark) back.

8. Enter the three-digit value from the lower left of the display using the

appropriate key on the keypad. In this example, the value is 52.

9. Press the [SET] button.

10. Remove the sample paper by pressing the <-> button.

11. Measure the distance (in millimeters) between the leading edge of the

paper and the horizontal portion of the REG mark. The value must be

between 5 and 50 millimeters.

12. Enter the value from step 11 using the 10 key keypad.

13. Press the [SET] button.

14. Enter the distance from the left side of the paper to the position for the

15. Press the [SET] button.

16. Enter the distance from the left side of the paper to the position for the

32 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

left margin slit (LEFT SL) location. This value must be between 0 and

120 millimeters.

right margin slit (RGHT SL) location. This value must be between 200

and 320 millimeters.

Page 34

DocuCutter 545

17. Press the [SET] button.

18. Enter the distance from the left side of the paper to the position for the

center left slit (C.L. SL) location. This value must be between 0 and

160 millimeters.

19. Press the [SET] button.

20. Enter the distance from the left side of the paper to the position for the

center right slit (C.R. SL) location. This value must be between 0 and

320 millimeters. However, the C.R. SL value must be 50 mm greater

than the value of the C.L. SL. This is due to both slitters are on the

same set of cutting drive shafts.

21. Press the [SET] button.

22. Enter the distance from the left side of the paper to the position for the

center (OP1 SL) slit location. This value must be between 0 and 320

millimeters.

23. Press the [SET] button.

24. Enter the distance from the leading edge of the paper to the position

for the first cut (CUT 1) location. This value must be between 0 and

999 millimeters.

25. Press the [SET] button.

26. Enter the distance from the leading edge of the paper to the position

for the second cut (CUT 2) location. This value must be between 0 and

999 millimeters. If a second cut is not required, enter a value of zero.

27. Press the [SET] button.

NOTE: If attempting to enter a lower CUT value than the previous value is

attempted, the DocuCutter will not permit the lower

value to be entered.

28. Enter the distance from the leading edge of the paper to the position

for the first score (SCR. 1) location. This value must be between 0 and

650 millimeters. If a second score is not required, enter a value of zero.

29. Press the [SET] button.

NOTE: If attempting to enter a lower SCR value than the previous value is

attempted, the DocuCutter will not permit the lower

value to be entered.

30. Enter the total length (in millimeters) of the sample paper.

31. Press the [SET] button.

32. Press the <SET> button to retain the settings or <STOP> to discard

the settings. The display will indicate “Memory Please Wait” while the

information is written to the DocuCutter memory circuit. The

memorization process will take approximately 10 seconds.

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 33

Page 35

DocuCutter 545

A

DC-545: AUTO CUT function

When AUTO CUT is ON, it works under the following

conditions

:

The first cut in the preset program is longer than 17.0

mm.

The distance between the total length entered in the

program and the last cut position entered in the program

is longer than 21.0 mm.

IMPORTANT NOTE ON AUTO CUT

Auto cut works on:

a) The section between the lead edge and CUT 1

and/or

b) The section between the last CUT in the preset

program and the trail edge only. If you want to

have the any other margin cut into pieces, make

sure to add ‘dummy’ cuts of less than 17 mm in the

program. Otherwise, the margin cut can be left in

the machine or ejected on the paper tray.

UTOCUT is

possible in

these

sections only

Lead edge

CUT1

To cut this part into pieces, add

‘dummy’ cuts of less than 17.0mm

in the program.

Last CUT

34 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 36

DocuCutter 545

IMPORTANT NOTE ON DATA ERROR

When the total number of Scores, Cuts, and AUTO

CUTS exceeds 17, ‘---E6--- DATA ERROR’ is

indicated on the LCD.

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 35

Page 37

DocuCutter 545

DC-545 Theory of Operation

The following describes the DC-545 base model theory of

operation without the AF-100 autofeeder. For details of

the AF-100 theory, see the AF-100 Theory of Operation.

1. The document is placed in the Feed Tray and

PPS1 detects the presence of the document.

2. After 1.5 seconds, the Feed Solenoid drives down

the Input Rollers.

3. After 100msec, the Gate is driven down by the

Gate Solenoid, and the Feed Motor is turned on to

feed the document.

4. Next, the Main Motor feeds the document.

Note: If PPS2 cannot detect the document, after it has

been fed 30mm since feed initiation, “J2 - FEED JAM” is

displayed.

<When using sheet with a Bar Code>

5. The document is fed from the PPS2 location until

the CCD detects the Bar Code.

6. Note: If the CCD cannot read the Bar Code after

the document is fed 50mm, “E3 - BARCODE

ERROR” will be displayed.

<When using a sheet without a Bar Code>

7. After the document is fed 50mm from the PPS2

location, the slitters return to their home positions

and then move to the positions indicated by the

program number.

36 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

8. After the slitters are in position, the job is

performed. Go to step 13.

Page 38

DocuCutter 545

Note: If the slitters do not move to their indicated positions

within approximately 5 seconds, “E5 - SLITTER ERROR”

will be displayed.

9. When the CCD scans the Bar Code, the document

feeding stops, and each slitter returns to its home

position.

Note: If the slitters do not return to their home positions

(all slitter sensors aren’t blocked) within approximately 5

seconds, “E5 - SLITTER ERROR” will be displayed.

10. After the slitters return to their home positions, the

slitters move to their indicated positions according

to the preset job data detected by scanning the Bar

Code.

Note: If the slitters do not move to their indicated

positions within approximately 5 seconds, “E5 SLITTER ERROR” will be displayed.

11. After the slitters are positioned properly, the

document is fed until the CCD detects the vertical

line of the REG Mark.

Note: If the CCD cannot scan the vertical line within 10

mm of feeding, “E4 - REG MARK ERROR will be

displayed.

12. Each slitter is adjusted for any registration error.

13. The document is fed backwards until PPS2 detects

its leading edge.

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 37

14. The document is fed by 0.1mm increments until the

CCD detects the horizontal line of the REG Mark.

Page 39

DocuCutter 545

Note: If the CCD cannot scan the horizontal line within

50mm of feeding, “E4 - REG MARK ERROR” will be

displayed.

15. After the horizontal component of the REG Mark is

scanned, any required error correction is

calculated. Horizontal registration correction is

performed during the cutting and creasing

processes.

16. The document processing begins.

38 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 40

DocuCutter 545

Reasons for JAM and ERROR messages

1. When turning on the power, if any Paper Path

Sensor (PPS1 – PPS4) is blocked, “J1 - REJECT

PAPER” will be displayed.

2. If PPS3 cannot detect the document, after it is fed

10 cm since PPS2 detects it, “J3 - CENTER JAM”

will be displayed.

3. If PPS3 has been blocked, after document is fed its

entire length since PPS3 detects it, “J3 - CENTER

JAM” will be displayed.

4. If PPS4 cannot detect the document, after it is fed

44 cm since PPS3 detects it, “J4 - SLITTER JAM”

will be displayed.

5. If PPS4 has been blocked, after the document is

fed its entire length since the PPS4 detected it, “J4

- SLITTER JAM” will be displayed.

6. If the Upper Blade of the cutter unit does not return

to the home position (the Cutter Position Switch is

not closed) within 400msec since the cutter

movement initiation, “J7 - CUTTER LOCK” will be

displayed.

7. If the Upper Blade of the score unit does not return

to the home position (the Score Position Switch is

not blocked) within 3 seconds since the score

movement initiation, “J8 - CREASE LOCK” will be

displayed.

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 39

8. If the covers are opened while the machine is

running, “E1 - COVER OPEN” will be displayed.

Page 41

DocuCutter 545

9. If the CCD does not communicate with the Main

PWB, “E2 - RS232C ERROR” will be displayed.

10. If the number of cuts exceeds 10, “E6 - DATA

ERROR will be displayed.

40 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 42

DocuCutter 545

DocuCutter DC-545 Maintenance Procedures

The following Maintenance procedures are available in the

DocuCutter DC-545 Field Service Manual. They are

presented here for information only.

;Q W YKNN WUG VJ G IWK FGNK PGU UJ QYP K P 6C DNG VQ RGTHQTO

OC K PVGPC PEG VY K EG C [GC T QP VJ G &Q EW %W VVGT &%

DC UGF QP PQ OQTG VJ C P GK IJ V J QWTU WUG C FC [ J GC XK GT

WUG YKNN TGSWK TG OQTG H TGSWGPV OC K PVGPC PEG

ITEM ACTION

PPS1 (Paper Path Sensor 1) Use a brush to clean any paper dust, etc. from the

upper and lower sensor portions.

PPS2 (Paper Path Sensor 2) Use a brush to clean any paper dust, etc. from the

upper and lower sensor portions.

PPS3 (Paper Path Sensor 3) Use a brush to clean any paper dust, etc. from the

upper and lower sensor portions.

PPS4 (Paper Path Sensor 4) Use a brush to clean any paper dust, etc. from the

upper and lower sensor portions.

PAPER LEVEL SENSOR Use a brush to clean any paper dust, etc. from the

sensor.

ROLLERS Use a lint free cloth moistened with water to clean the

Rollers.

ROLLER BEARINGS Clean and oil the Roller Bearings.

SUCTION BELTS Clean the Belts with rubber belt cleaner.

SLITTERS Clean and oil the Slitters.

CUTTER Clean and oil the Cutter Assembly.

Table 1. Recommended Maintenance Schedule

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 41

Page 43

DocuCutter 545

DocuCutter DC-545 Service Mode

Entering the Service Mode in the DocuCutter DC-545

enables you to perform a variety of diagnostic tests.

NOTE The information provided here is also available in General

Procedure GP-4 of the DocuCutter DC-545 Field Service

Manual. It is presented in this document for reference

purposes only.

The procedure for entering the Service Mode follows:

1. If the machine is already powered on, power off the

machine.

2. While depressing the STOP button, power on the

machine. A buzzer will sound to indicate you are

entering the Service Mode.

3. Press the <+> or <-> buttons to scroll through the

available Service Mode diagnostic selections.

4. When you locate the appropriate Service Mode

diagnostic selection, press the START button.

To exit the Service Mode, press the STOP button and

switch the power off.

42 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 44

DocuCutter 545

The Service Modes are described in Table 2.

HELP CODE Content

H-00 ROM version indication

H-01 Total cut counter

H-02 Total feed counter

H-03 P.P.S.1 check

H-04 P.P.S.2 check

H-05 P.P.S.3 check

H-06 P.P.S.4 check

H-07 P.P.S.5 check

H-08 Sensor & switch check

H-09 DIP SW status check

H-10 Feed motor check

H-11 Feed solenoid check

H-12 Left margin slitter check

H-13 Right margin slitter check

H-14 Left center slitter check

H-15 Right center slitter check

H-16 OP1 slitter check

H-17 Main motor check

H-18 Score check

H-19 Cutter check

H-20 Slitter blade drive check

H-21 LED check

H-22 CCD performance check

H-23 Total score counter

H-24 Slitter position adjustment

H-25 RAM initialize

H-26 Score distance adjustment

H-27 P.P.S.2 & CCD distance adjustment

H-28 OP2 slitter check (Option slitter 2)

H-29 Elevator check (Optional AF-100)

H-30 Fan Check (Optional AF-100)

H-31 Solenoid & Feed check (Optional AF-100)

H-32 Feeder Total check (Optional AF-100)

H-33 SPEED UP – Prevents slitters from returning home

while in REG mark correction mode.

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 43

Table 2

Page 45

Documentation Review

DocuCutter 545

You will be required to use DocuCutter DC-545 Field

Service Manual when servicing the DocuCutter DC-545

machine. The Manual contains the following sections:

• Section 1 - Service Call Procedures

• Section 2 - Status Indicator RAPs

• Section 3 – Output Quality RAPs

• Section 4 - Repairs/Adjustments

• Section 5 - Parts List

• Section 6 - General Procedures

• Section 7 - Wiring Data

Many of the topics described in this training guide are

described in detail in the Field Service Manual. As always,

you should make the Field Service Manual your main

source for obtaining service information.

When servicing the DocuCutter DC-545, you should also

be aware of the information available in the Duplo

DocuCutter DC-545 Instruction Manual. The Duplo

DocuCutter DC-545 Instruction Manual provides a variety

of information for customers, including both operating and

troubleshooting information.

44 DocuCutter 545 Training Guide © 2002, Duplo USA Corporation

Page 46

Conclusion

DocuCutter 545

Congratulations!! You have completed the DocuCutter

DC-545 Training Guide. You should now be able to:

• Understand and describe the main components and

features of the DocuCutter DC-545.

• Be able to operate the DocuCutter DC-545.

• Be familiar with all of the documentation available

for servicing and operating the DocuCutter DC-545.

• Understand the important safety precautions

required when servicing the DocuCutter DC-545.

• Be familiar with the steps required to program jobs

in to the DocuCutter DC-545.

• Be able to enter the Service Mode of the

DocuCutter DC-545.

• Understand how to set the adjustments on the AF-

100 autofeeder

• Understand the AF-100 operation theory.

If you have any questions about the features and

functions of the DocuCutter DC-545, or this manual,

review the appropriate Service Manual, or the Product

Operation Manual as required.

© 2002, Duplo USA Corporation DocuCutter 545 Training Guide 45

Page 47

Guaranteed Lowest Prices on an

Endless Selection of Binding Systems, Laminators,

Paper Shredders, Supplies and Accessories.

We have you covered with Expert Advice

and Support. Our popular blog keeps you up to

date on the latest tips and techniques to make

your most important binding and laminating

tasks a success.

Call Us Today

1-800-944-4573

Our Trusted Partners

GBC / Ibico

Fellowes

Powis Fastback

Unibind

Akiles

Renz

Tamerica

Rhin-O-Tuff

DFG

Pro-Bind

Martin Yale

MBM

Formax

Intimus

Dahle

HSM

Standard

Xyron

Challenge

Lasko-Wizer

GBC Shredmaster

Avery

Wilson Jones

Cardinal

Samsill

Universal

Binding Machines

Binding Supplies

Laminators

I.D. Accessories

Boards & Easels

Paper Shredders

Xyron Laminators

Coil Binding machines

Unibind Binding Machines

Fastback Binding Equipment

Paper Folding Machines

Laminating Pouches

Rotary Trimmers

Clear Covers

Twin Loop Wire

Regency Covers

Plastic Binding Covers

Velobind Binding Machines

Paper Handling Equipment

Thermal Binding Machines

Proclick Binding Systems

Comb Binding Machines

Comb Binding Supplies

Wire Binding Machines

Pouch Laminators

Laminating Rolls

3-Ring Binders

Roll Laminators

Velobind Spines

Paper Cutters

Paper Joggers

Letter Openers

Thermal Covers

Unibind Supplies

Proclick Spines

Zipbind Spines

Linen Covers

Spiral Coil

Index Tabs

Loading...

Loading...