Page 1

DocuCutter CC-229

Service and Parts Manual

Revision Date: 09/16/18

Before operating the machine, read this manual. Follow all safety precautions.

Duplo USA Corporation

3050 S. Daimler St, Santa Ana, CA 92705

www.duplousa.com

Page 2

- 1 -

Revison History

Date Change/Add/

Delete

Reason

Page

Technical Bulletin

06/25/18 1. Add

2. Change

A die module to do crease/Perf/Emboss job

Model change from CC-228 to CC-229

Page 3

- 2 -

Declaration of Conformity

PrintFinishing Co. Ltd., located at 625 Sec. II, Wende Road, Hsin-Pu, Hsin-Chu 30544, Taiwan declares that the

product compliances with the provision defined in the regulations as below.

Product Name

Model

Regulation

UL / CSA Low Voltage Directive

2006/95/EC

RoHs Directive 2011/65/EU

Electromagnetic

Compatibility

Directive

2004/108/EC

Standard

DocuCutter

CC-229

UL60950-1, 2nd

Edition,

2007-03-27

CSA 22.2 No

60950-1-07, 2nd

Edition, 2007-03

EN60950-1: 2006/

A11: 2009/A1:2010

EN61000-3-2

EN61000-3-3

EN61000-6-2

EN61000-6-4

IEC61000-4-2

IEC61000-4-3

IEC61000-4-4

IEC61000-4-5

IEC61000-4-6

IEC61000-4-8

IEC61000-4-11

EN60950-1

IEC60950-1

EN50581

CISPR 16-2-3

CISPR 16-2-1

CISPR 16-2-2

Page 4

- 3 -

Conformity of FCC Class A

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Page 5

- 4 -

Contents

SAFETY PRECAUTIONS ......................................................................................................................................... 5

WEEE Informations ............................................................................................................................................. 6

Precautions in Maintenance and Handling ......................................................................................................... 7

Introduction ........................................................................................................................................................ 8

Specifications ...................................................................................................................................................... 8

Electric Connections – Main Board ..................................................................................................................... 9

Sensor Location and Trouble Shooting………………………………………………………………………………………………………..10

Electric Connections – Driver Board ................................................................................................................. 11

Motor Driver Trouble Shooting Procedure…………………………………………………………………………………………………..12

Firmware Upgrade ............................................................................................................................................ 13

Calibrations ....................................................................................................................................................... 18

Paper Weight ..................................................................................................... Error! Bookmark not defined.9

Top Margin Parallel Adjustment…………………………………………………………………………………………………………………..20

Error Message and Trouble Shooting ............................................................................................................... 21

Explosive View and WEEE ................................................................................................................................. 23

Recommended Spare Parts List……………………………………………………………………………………………………………………54

Page 6

- 5 -

SAFETY PRECAUTIONS

Always observe the cautions and Batch is given below to prevent personal injury or property damage.

Disposal of Waste Electrical and Electronics Equipment (WEEE)

This symbol (the symbol of the crossed out wheeled bin) indicates that in European countries this product should

not be disposed of as household waste.

Please recycle where facilities exist by checking with your local authority or supplier for recycle advice.

By ensuring this product is disposed of correctly through proper treatment, recovery and recycling, you will help

prevent potential negative effects on the environment and human health.

En

Entsorgung von alten elektrischen und elektronischen Ausrüstungsteilen

Dieses symbol (das Symbol mit dem durchgekreuzten fahrbaren Müllbehälter) zeigt an, dass dieses Produkt in

europ

äischen Länden nicht als Haushaltsmüll entsorgt werden, darf, Bitte informieren Sie sich bei lhren örtlichen

Beh

örden oder bei Ihren Händler hinsichtlich einer Empfehlung fü

r die Entsorgung und führen Sie die betreffenden

Teile dort, wo solche Einrichtungen vorhanden sind, einem Recycling-Prozess zu.

Indem sie sicherstellen, dass das betreffende Produkt durch richtige Behandlung, Rückführung und Recycling

entsorgt wird, tragen Sie dazu bei, möglichen negativen Auswirkungen auf die Umwelt und die menschliche

Gesundheit vorzubeugen.

Ge

Elimination du matériel électronique et électrique usagé

Ce symbole (une poubelle marquée d’une croix) indique que dans les pays européens, ce produit ne doit pas étre

éliminé comme des ordures ménagéres.

Recyclez-le dans les sites adaptés qui vous seront indiqués par les autorités locales ou reseignez-vous auprés de

votre fournisseur.

En veillant à ce que ce produit soit éliminé correctement avec un traitement, une collecte et un recyclage adaptés,

vous contributez

à éviter son action nocive potentielle sur I’ environnement et santé humaine.

Fr

Smaltimento di attrezzature elettriche ed elettroniche consummate

Questo simbolo (il simbolo della pattumiera con rotelle barrata) indica che nei paesi europei questo prodotto non

deve essere buttato nei rifiuti domestici.

Per favore smaltire in luogo addetto al riciclo, dove esistente, chiedendo informazioni alle autorità locali o a chi

fornisce consulenza a proposito.

Garantendo uno smaltimento adeguato di questo prodotto (trattamento, recupero e riciclo correto), aiuterete a

prevenire effetti negativi sull’ambiente e sulla salute dell’uomo.

It

Eliminación de residuos de aparatos eléctricos y electrónicos

Este símbolo (un cubo de basura tachado) indica que en los paises europeos este producto no deberá eliminarse

como si se tratara de un residuo doméstico. Solicite asesoramiento sobre reciclaje a las autoridades locales o a su

distribuidor, y siga la normativa en materia de gestión medioambiental y reciclaji de este tipo de residuos.

Si toma las medidas pertinentes para que este producto se elimine mediante un tratamiento, recuperación y

reciclaji adecuados, contribuir

á a evitar posibles efectos negativos en el medio ambiente y la salud humana.

SP

Page 7

- 6 -

WEEE information (for Europe)

As a minimum the following substances, preparations and components has to be removed from any separately

collected WEEE (Waste Electrical and Electronics Equipment).

In this parts catalogue, these WEEE symbols are appended to corresponding parts in this parts catalogue.

WEEE Symbol Meaning

ABS

(Poly Acrylonitrile Butadiene Styrene) Plastic Material

LCD

LCD Displays

Cables

Electric Cables

Battery

Batteries

PCBA

PCB’s over 10 square centimeters in size

Bromides

Plastic Containing Bromides

In considering of separate collection, plastics are subdivided into the following categories.

In this parts catalogue, these abbreviations are appended to corresponding parts in the parts catalogue.

Abbreviation Category

ABS

(Poly Acrylonitrile Butadiene Styrene) Plastic Material

NBR

Nitrile Rubber (Acrylonitrile-Butadiene Rubber)

PC

Polycarbonate

POM

Polyoxymethylene

PVC

Polyvinyl Chloride

PU

Polyurethane

EPDM

Synthetic Rubber

Mar

Marprene

Nylon

Nylon 6

IXEF

Fiber Glass

TEF

Tefl on

POA

PolyAcetal

Page 8

- 7 -

Precautions in Maintenance and Handling

1. Repairs should be performed by qualified service personnel.

2. WARNING:

2.1 To avoid the risk of touching to any hot spot on UV Curing section to cause injury, system has to

be cool down before performing any services procedure in curing section.

2.2 To avoid the risk of electrical shock, disconnect the machine from the A.C. power source before

performing any services procedure.

3. The hardware used is METRIC. Replace hardware only with the same size as was originally used.

4. Observe caution when cutting cable “ty-wraps” so as not damages the electrical wires.

5. Note the routing of wiring harnesses, cables and the position of parts and assemblies before

disassembly. They must be reassembled in the original configuration to avoid damage from moving

components during operation.

6. When using a tool generating heat such as soldering iron, take care not to damage the harnesses

and cables.

Page 9

- 8 -

Introduction

The DocuCutter CC-229 is designed to simplify business card, photo, post card cutting and creasing in letter

size which printed by digital press, color laser printer or inkjet image printer in one pass.

Specifications

Paper Size LT / Legal Size/ 9” x 14” (Max)

Paper Weight 120gsm ~ 300gsm {subject to change}

Feeder Capacity

75 sheets (200gsm)

Receiving Tray 500 business cards

Speed Up to 130 business cards per min

Accuracy ± 0.3 mm

Dimension 18.1” (W) x 18.3” (D) x 15.2” (H)

Net Weight 85 lbs (38.7Kgs)

Power 100~240VAC, 50/60Hz, 0.6A

Maximum Operation Temperature 40-degree C

Page 10

- 9 -

Electric Connections – Main Board

LED On LED Off while power is on and feed tray has paper

Connector

Connects to LED

On/OFF

Connector Connects to LED

On/OFF

DN1 Feed Tray Sensor S1 DN8 Waste Bin Switch S8

DN2 Transport Sensor S2

DN9 Rear Cover Switch S9

DN3 Top Margin/Mark Reader S3 DN10 Not in use

DN4 Die Home Position Sensor S4 CN2 Driver Board CN1

DN5 Cutter Sensor S5 CN6 Driver Board CN2

DN6 Cutter Index S6 CN4 24V Power Supply

DN7 Top Cover Switch S7

Page 11

- 10 -

Sensor Location

Sensor Trouble Shooting Procedure

1. Insert a piece of paper into 1

st

pick-up roller, press to move the paper forward, while paper

reaches to S2, S3 and S5, the sensor LED will be on; if not, the sensor is faulty.

2. S4 is die module home position index sensor, if it is faulty, “Round Corner Sensor Error” will be showing

on display

3. S6 is cutter home position index sensor, if it is faulty, “Cutter Error” will be showing on display.

S1 Feed Tray Sensor

S2 Transport Sensor

S3 Mark/Margin Sensor

S5 Cutter Sensor

1st Pick Up Roller

Page 12

- 11 -

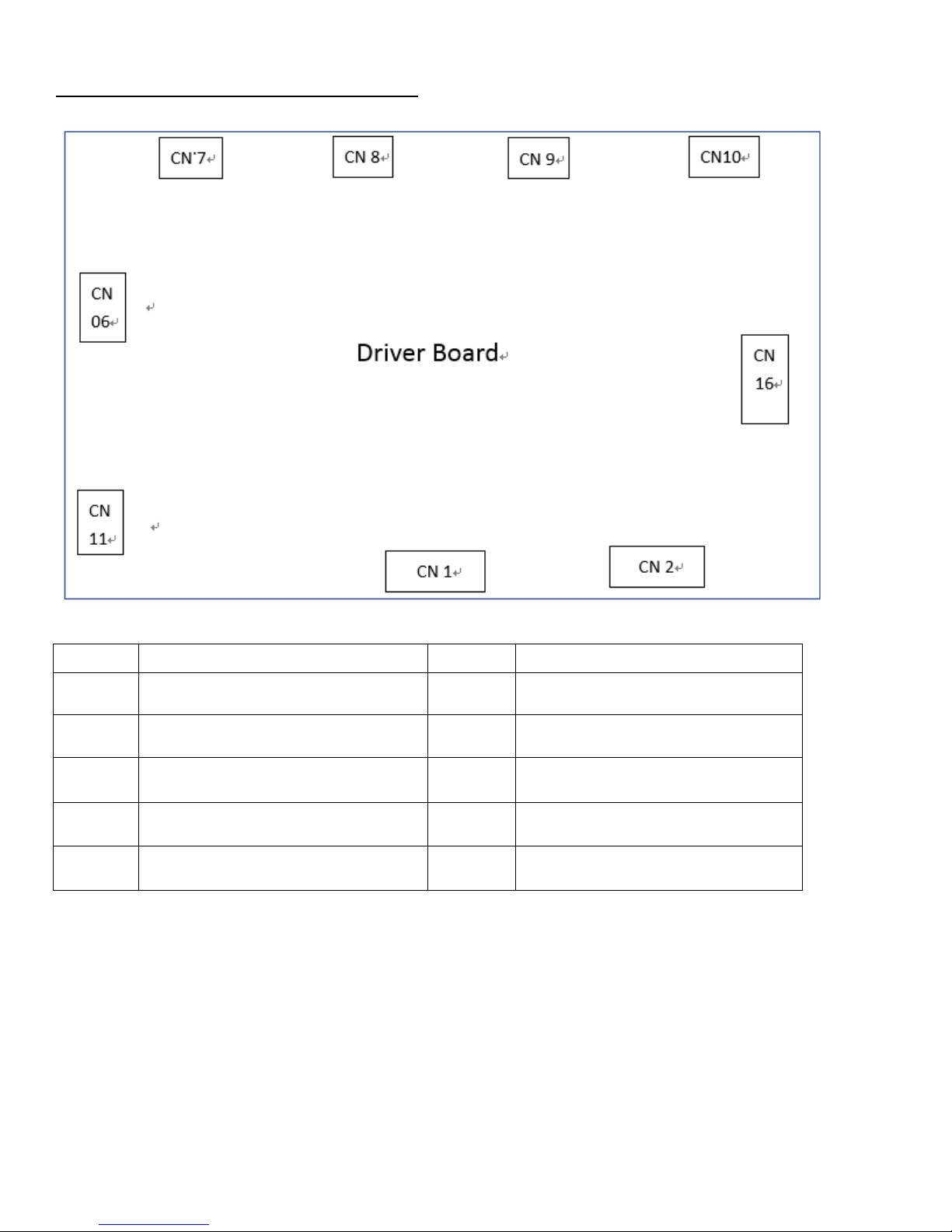

Electric Connections – Driver Board

Connector

Connects to Connector

Connects to

CN1 16-pin, Main Board CN2 CN9 4-pin, Die Module Motor

CN2 10-pin, Main Board CN6 CN10 4-pin, Cutter Motor

CN6 4-pin, 24V DC Power Supply CN11 16-pin, LCD Display

CN7 4-pin, Feed Motor CN16 10-pin, Control Panel Board

CN8 4-pin, Transport Motor

Page 13

- 12 -

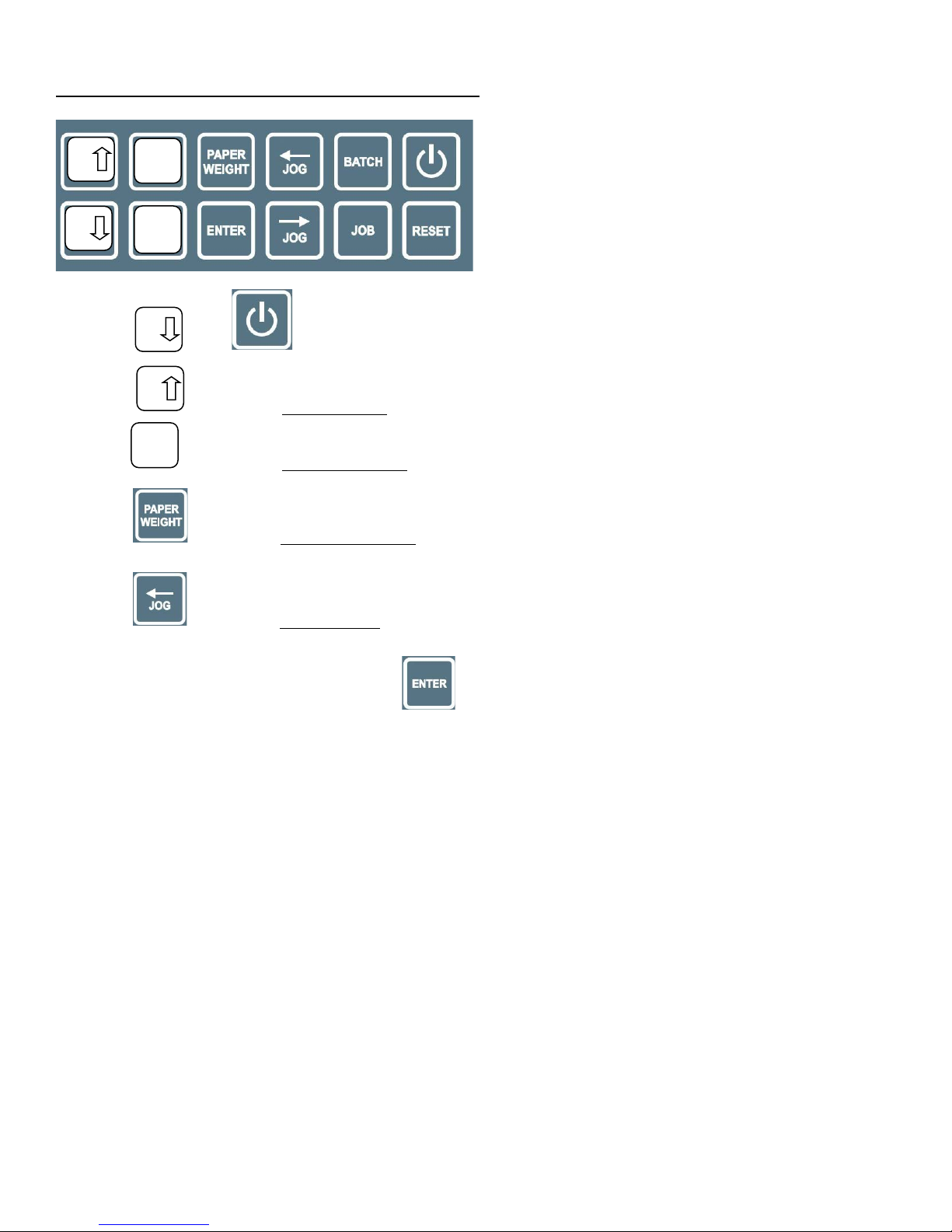

Driver Board Trouble Shooting Procedure

1. Hold and simultaneously for 2 seconds into Burn-in Test Mode

2. Press to activate Feeder Motor, if feed motor does not move, replace driver board

3. Press to activate Transport Motor, if motor does not move, replace driver board

4. Press to activate Die Driving Motor, if motor does not move, replace driver board

5. Press to activate Cutter Motor, if motor does not move, replace driver board

6. Once trouble shooting is complete, press to resume operation.

Up

Dn

Value+

Value-

Dn

Up

Value+

Page 14

- 13 -

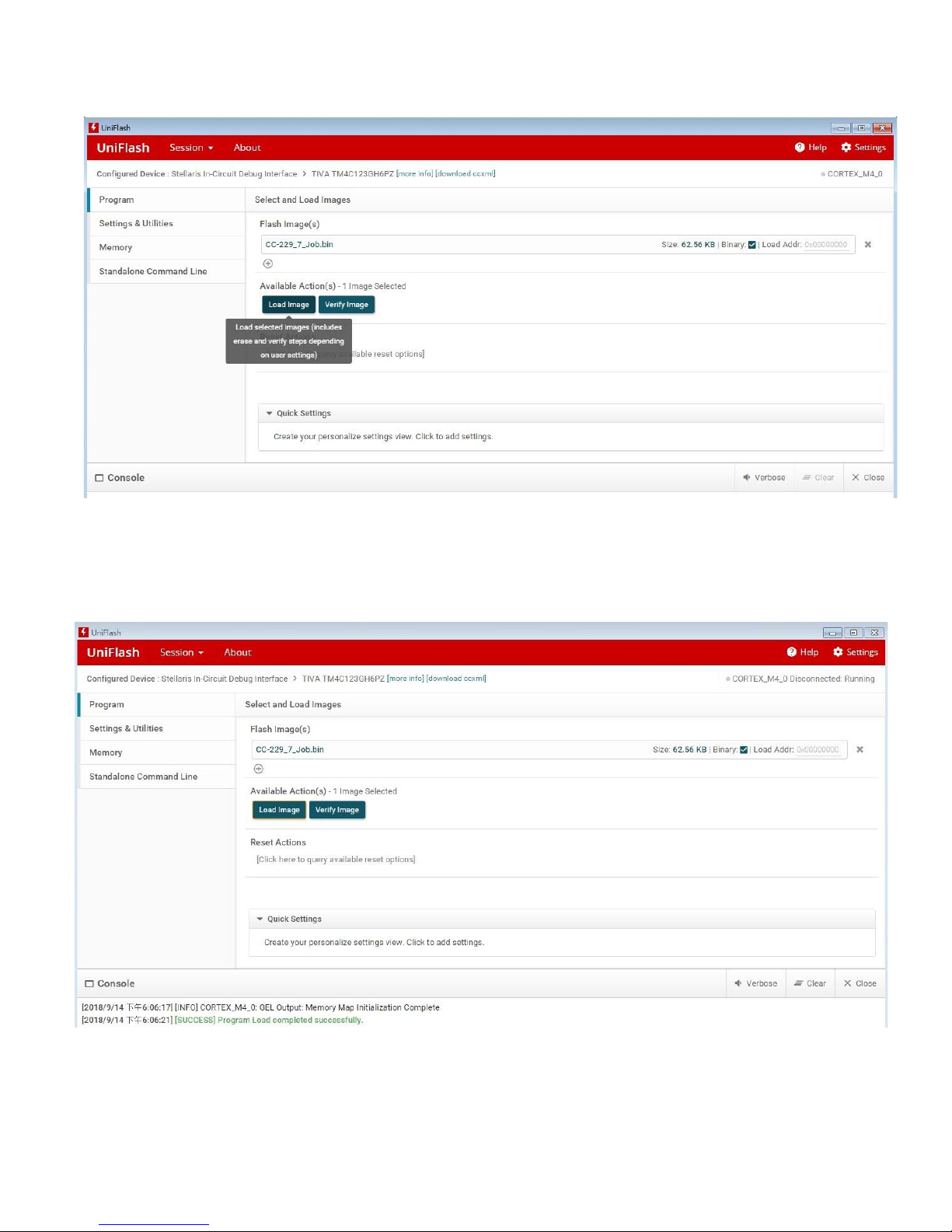

Firmware Upgrade

1. Power off

2. Using an adaptor board as shown below:

2.1 10-pin cable to CN 1 on main board and USB connector to USB port on Note Book

3. Power On

Firmware Upgrade Adaptor Board P/N 883-020-051A

4. Detail Procedure

4.1 Go to below website to download the software “Uniflash”

http://processors.wiki.ti.com/index.php/Category:CCS_UniFlash

4.2 Install the software “Uniflash” step by step on your laptop

Page 15

- 14 -

4.3 After install the software Uniflash. Please connect the EVM board (EPROM writer) and target board.

Double click the shortcut icon on the desktop to start.

4.4 “Choose Your Device” at Category “Tiva”

Page 16

- 15 -

4.4 Choose the MCU “TM4C123GH6PZ”

4.6 Choose Your Connection at “Stellaris In-Circuit Debug Interface”

Page 17

- 16 -

4.7 Click “START” to browse the file need to be upgrade.

4.8 Browse the file need to be upgrade.

Page 18

- 17 -

4.9 Click the “Load Image” icon to load the image file to the target board.

4.10 After load the image file successfully. The information line will show “<success>Program Load

completed successfully”. Then you can hear the machine will initialize automatically.

Page 19

- 18 -

Calibrations

1. Hold and at same time for 2 seconds into Calibration mode

2. Press or one time the cursor will be move down or up one factor accordingly

Margin: Top margin

Offset: Last card is too long or to short to compensate

Mark: Cutting Mark

Leng: Card Length

3. The default value is 0, using or to set the number to compensate deviation, the value is –

99~+99.

After calibration is done, press to save.

Dn

Batch

Dn

Up

Value+

Value-

Up

Dn

Value+

Value-

Page 20

- 19 -

Paper Weight

Press into Paper Weight setting mode, then press or to do selection

Setting

Paper Weight

1, 2 120 – 210 (gsm)

3

211 – 300 (gsm)

4, 5 301 – 350 (gsm)

Page 21

- 20 -

Top Margin Parallel Adjustment

1. Power off

2. Remove the rear cover

3. Using a 300gsm or 14 pt. sheet as gauge, rotate the feed roller by hand to feed it into apex of

registration roller firm.

4. Underneath the feed tray has 5.5mm nut to hold the side guide, loosen the nut and align it against the

paper to make it straight. Fasten the nut.

5. Feed a sheet to cut, measure the left and right of the top margin cut is 12.7mm +/- 0.1mm, if not, re

adjust the side guide.

Side

Guide

Fastening

Side

Guide

Fastening

Screw

Page 22

- 21 -

Error Message and Trouble Shooting

Error Message/Symptom Trouble Shooting

Paper Out 1. Feed Tray is empty

2. Check S1 refer to page 8 and 9

3. Is feed motor belt broken? If not,

4. Check pulley screw loose, if not

5. Refer to page 12 to do motor driver trouble shooting

Jam in Sensor 2 1. Check S2 refer to page 8 and 9

2. Adjust the feed tray tension

3. Refer to page 12 to do motor driver trouble shooting

Jam in Sensor 3 1. Check S3 refer to page 8 and 9, if it is OK

2. Replace driver board

Mark Error 1. Check S3 mark/margin sensor refer to page 8 and 9

2. Replace S3 if seeing paper LED is not ON

3. Do mark, top margin calibration

Die Sensor Error 1. Refer to page 8 and 9 and rotate die motor allow index is

seen by S4

2. LED Din 4 needs to be on, if not

3. Replace S4 die index sensor

Top Cover Error 1. Refer to page 8, make sure Din Check top cover interlock

switch

Rear Cover Error Check rear cover interlock switch

Waste Bin Error Check waste bin interlock switch

Finish card not clean and neat 1. Adjust the cutting knife guiding plate, if problem still

2. Replace cutting knife

Finish card length uneven 1. Adjust the cutter Assy. frame mounting screw on the side

plates

2. Check driving belt tension

3. Tighten the compression spring

Cutter Error 1. Driving crane screw loose, if not

2. Check S6, if it is OK

3. Refer to page 12 to do motor driver trouble shooting

Top margin not even left and right 1. Adjust the side guide, make sure it is right angle to the first

set of rollers

Transport no function 1. Check motor pulley screw is loose, If not

2. Check pulley on driving shaft/roller is loose, if not

3. Refer to page 12 to do motor driver trouble shooting

Page 23

- 22 -

Slitting not good Replace the slitter

No Power 1. Check Fuse

2. Check power plug

3. Check main board has 5/24V or power supply has 5/24V

Paper buckled at feed ramp 1. Adjust the feed tray tension spring position

2. Set paper weight according the paper weight

Page 24

- 23 -

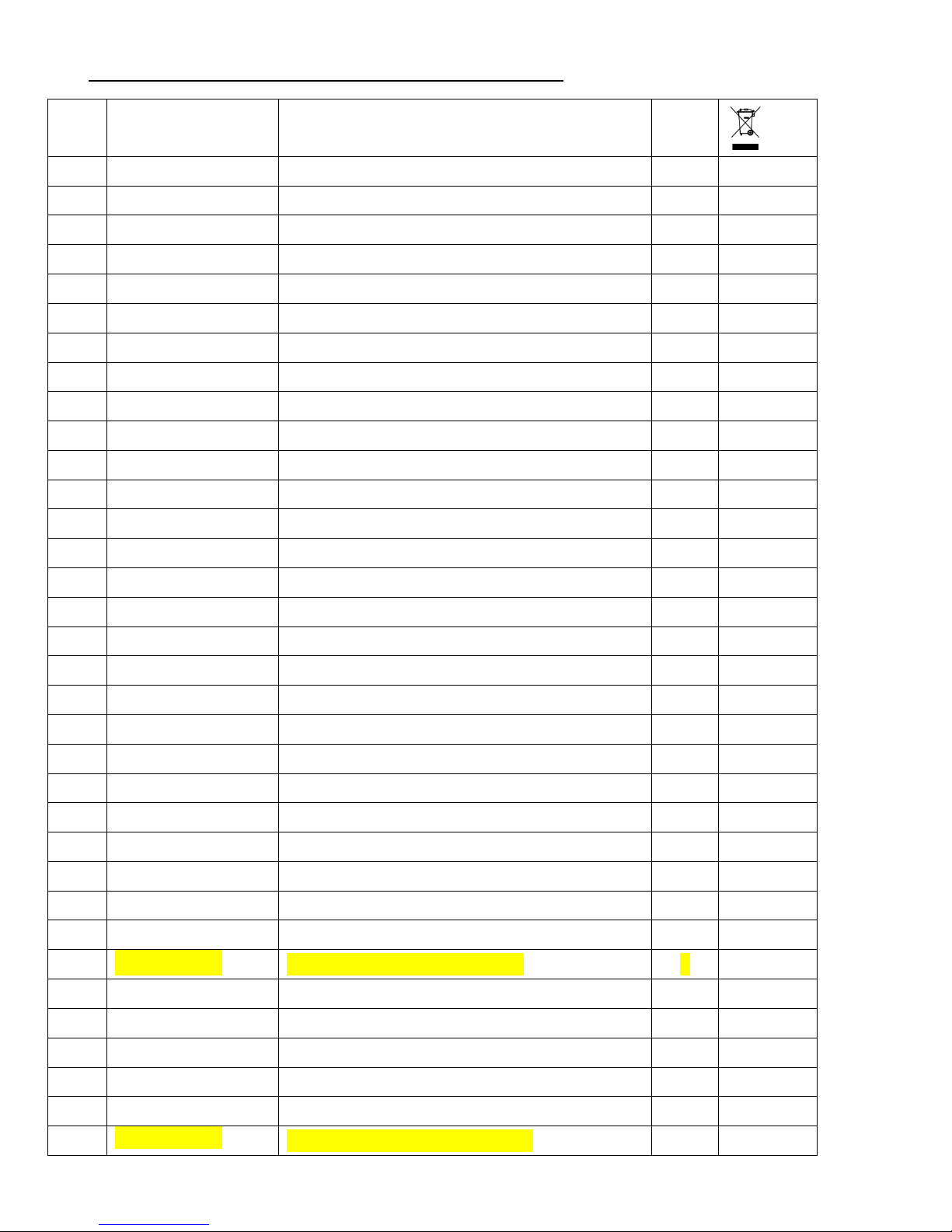

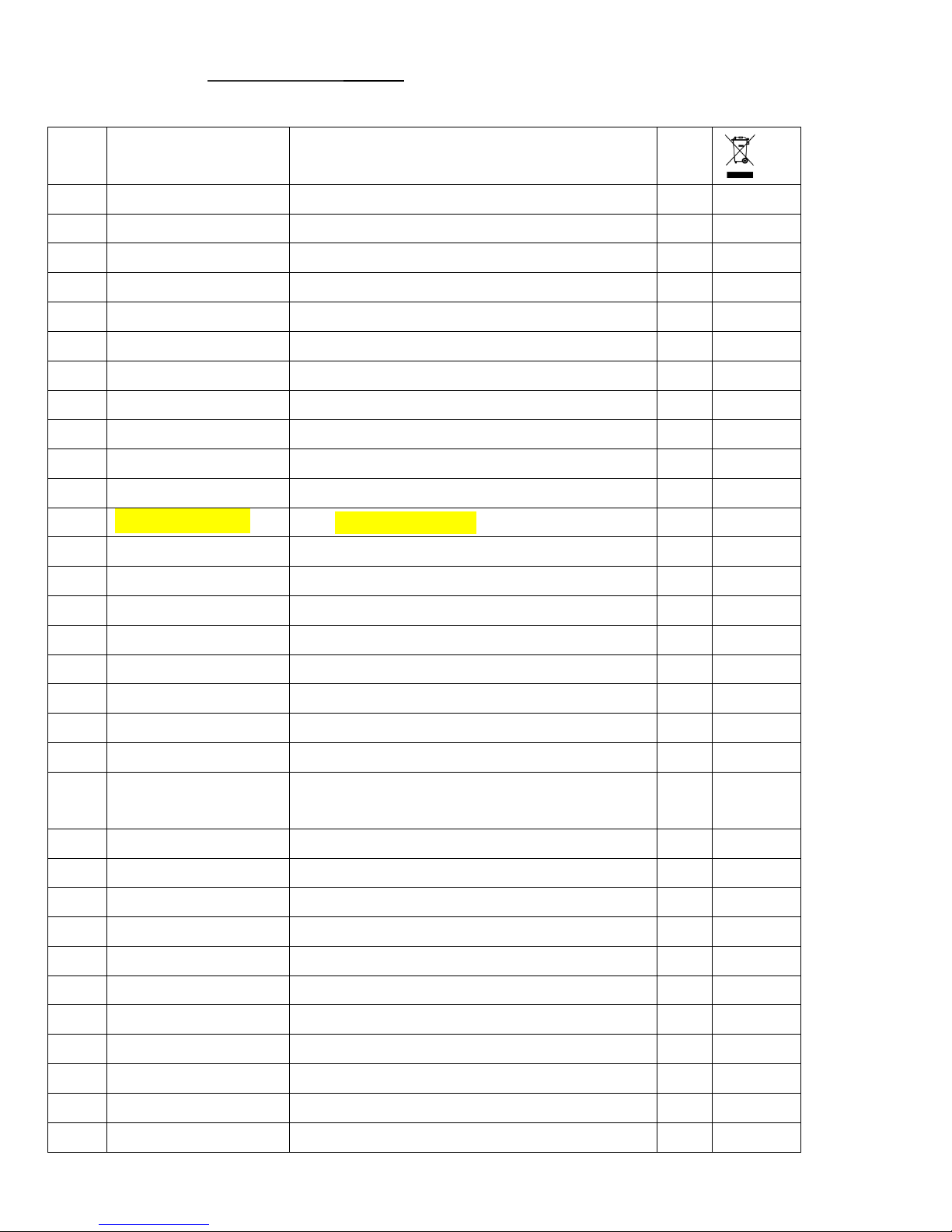

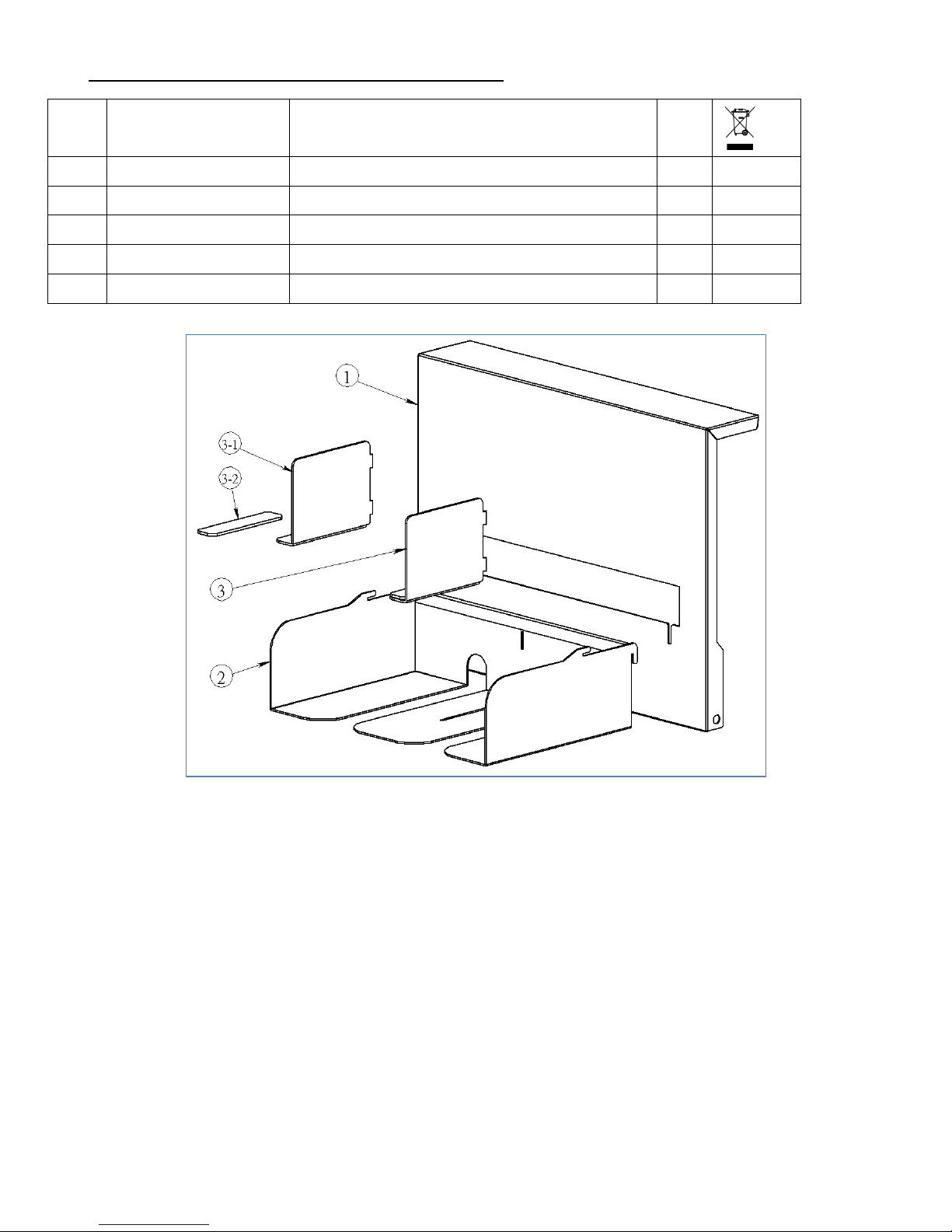

Explosive View and WEEE (Fig.1)

NO P/N Name Q’TY

1 883-010-000A

Asm, Side Plate, Non-Operating 1

2

883-020-000A

Asm, Side Plate, Operating

1

3 883-030-000A

Asm, Electric Panel 1

4 883-040-000A

Cover, Front Safety 1

5 883-050-000A

Asm, Feed Table 1

6 881-G00-000A

Bar, Tie 2

7 883-070-000A

Asm, Feed Ramp 1

8 881-N00-000A

Asm, Feed Roller 1

9 881-N10-000A

Asm, Transport Roller, Lowe, Front 1

10

881-N20-000A

Asm, Transport Roller, Lower, Middle 1

11

881-N30-000A

Asm, Transport Roller, Lower, Rear 1

12 881-L00-000A

Asm, Transport Roller, Upper, Front 1

13 881-M00-000A

Asm, Transport Roller, Upper, Rear 1

14 883-140-000A

Asm, Die Skew Adjustment 1

15 883-112-010A

Asm, Dummy Module 1

883-150-000A

Asm, Die Module

Option

16 881-Q00-000A

Asm, Upper Knife Driving 1

17 881-P00-000A

Asm, Lower Knife 1

18 883-180-000A

Asm, Slitter Mounting Chassis 1

19

883-190-000A

Asm, Slitter Alignment 1

20

881-112-0000

Module, Slitter, 2X3.5” 1

21 883-210-000A

Asm, Top, Safety Cover 1

22 883-220-000A

Asm, Cover, Rear 1

23 883-230-000A

Cover, Rear Lower Safety 1

24 00M-000-0003

Magnets 50 * 50 * 12T 1

25 883-250-000A

Asm, Waste Bin 1

Fig. 1

Page 25

- 24 -

Page 26

- 25 -

883-010-000A Non-Operating Side Plate Asm (Fig. 2)

NO P/N Name Q’TY

1 883-010-010A

Side Plate, Right 1

2 00R-000-1101

Rubber Foot 2

NBR

3 00B-000-0905

Angle Bracket 4

4 881-A04-000A

Stopper 1

5 00M-000-0427

Motor, 103H7823-1760 2

6 881-708-0000

Crank, Knife Driving 1

7

881-405-040A

Bushing, OD9, ID6.2 1

8

00B-000-1260

Ball Bearing, L-1260ZZ 1

9

883-010-090A

Idler 1

10 00B-000-1680

Ball Bearing, L-1680ZZ 1

11 00S-000-5904

Standoff, Idler 1

12 00N-000-0012

Nut, D Cut 1

13 883-010-130A

Asm, Rocker Tension Adjustment 3

883-010-131A

Block, Rocker Tension Adj 1

883-010-132A

Holder, Rocker Tension Spring 1

00S-M04-030R

Screw, M4x30 1

14

881-405-070A

Spring, Rocker Tension, Inner 1

00S-000-5611

Spring, Rocker Tension, Outer {Folder Black} 1

15

00G-M10-1912

Gear, M1.0, 19T, OD 12, Idler 1

00B-000-1280

Ball Bearing, L1280ZZ 2

16 881-A13-000A

Stud, Idle Gear 1

17 00E-M08-000E

E-Ring, 8mm 1

18 883-010-180A

Stud, Die Module Bottom Margin 1

19 883-010-190A

Bracket, R, Die Module Mounting Bracket 1

20 02P-17G-0800

Pulley, 0 .2 P, 17G, ID 8 1

21 02P-51G-1700

Pulley, 0 .2 P, 51G, ID 17 1

22

00G-M10-4017

Gear, M1.0, 40T, OD 17 1

23

00B-00R-1760

Ball Bearing, R-1760ZZ

1

24

883-010-230A

Bushing 1

25 00B-MXL-120C

Belt, 0.2P, 120 MXL, 8mm 1

MAR

26 883-010-260A

Case, R, CC-229 1

27

00S-000-6112

Power switch

1

28 00B-0NB-2430

Bushing, Cable Guard 1

Fig. 2

Page 27

- 26 -

Page 28

- 27 -

883-020-000A Operating Side- Side Plate Asm (Fig. 3)

NO P/N Name Q’TY

1 883-020-010A

Side Plate, Left 1

2 00R-000-1101

Rubber Foot 2

NBR

3 00B-000-0905

Angle Bracket 4

4 881-B04-000A

Stopper 1

5 883-020-050A

Main Board 1

883-020-051A

Adaptor Board, Firmware Upgrade 1

6

00M-000-0401

Motor, CKM245-01AH 1

7

02P-17G-0500

Pulley, 0 .2 P, 17G, ID 5.00 1

8

00B-MXL-132C

Belt, 0.2P, 132MXL, 8mm 1

MAR

9 00M-000-0427

Motor, 103H7823-1760 1

10 02P-17G-0800

Pulley, 0 .2 P, 17G, ID 8 1

11 00B-MXL-099C

Belt, 0.2P, 99 MXL, 8mm 1

MAR

12 883-010-090A

Idle Roller 1

13 00B-000-1680

Ball Bearing, L-1680ZZ 1

14 00S-000-5904

Standoff, Idler 1

15 00N-000-0012

Nut, D Cut 1

16

883-020-160A

Asm, Cutting Knife Home Position Sensor 1

00S-00E-ESV3

Sensor, Omron, EE-SV3 1

00W-883-2463

Wire, 24 AWG, 63cm 1

2PH-716-102F

Housing, Female, 2-pin 1

17 883-010-130A

Asm, Rocker Tension Adjustment 3

883-010-131A

Block, Rocker Tension Adj 1

883-010-132A

Holder, Rocker Tension Spring 1

00S-M04-030R

Screw, M4x30, Round Head 1

18 881-405-070A

Spring, Rocker Tension, Inner 1

00S-000-5611

Spring, Rocker Tension, Outer {Folder Black} 1

19

883-010-180A

Stud, Die Module Bottom Margin 1

20

883-020-200A

Asm, Die Home Position Sensor 1

00S-RX6-75NW

Sensor, RIKO RX675-NW 1

00W-883-2463

Wire, 24AWG, 63cm 1

2PH-716-102F

Housing, Female, 2-pin 1

21 883-020-210A

Co v er, RIKO RX675-NW 1

22 883-020-220A

Bracket, L, Die Module Mounting

23

883-020-231A

Asm, Interlock Switch, To p C o ver 1

Page 29

- 28 -

00B-000-0943

Bracket, Interlock Switch Mounting 1

00S-000-6105

Switch, Interlock, 1

00W-883-2233

Wire, 33cm, 22AWG 1

2PH-716-102F

Housing, Female, 2-pin 1

883-020-232A

Asm, Interlock Switch, Rear Cover 1

00B-000-0943

Bracket, Interlock Switch Mounting 1

00S-000-6105

Switch, Interlock 1

00W-883-2257

Wire, 57cm, 22AWG 1

2PH-716-102F

Housing, Female, 2-pin 1

883-020-233A

Asm, Interlock Switch, Waste Bin 1

00B-000-0943

Bracket, Interlock Switch Mounting 1

00S-000-6105

Switch, Interlock, 1

00W-883-2267

Wire, 67cm, 22 AWG 1

2PH-716-102F

Housing, Female, 2-pin 1

24 00C-000-2050

Cover, Interlock Switch 2

25

883-020-250A

Asm, PCB, Control Panel 1

PCBA

26 00D-000-0304

Display, LCD, 4 Row x 20 1

PC/PCBA

27 883-020-270A

Key Pad, CC-229 1

28 883-020-280A

Case, L, CC-229 1

29 00B-0NB-2430

Bushing, Cable Guard, ID24 OD30 3

Fig. 3

Page 30

- 29 -

Page 31

- 30 -

883-030-000A Electric Panel Asm (Fig. 4)

NO P/N Name Q’TY

1 883-030-010A

Plate, Electric Panel, CC-229 1

2

883-030-020A

Power Supply, 24V, RSP-320-24 1

3 00B-PWR-010A

Bracket, Power Supply 4

4 883-030-040A

Driver Board 1

PCBA

5

Cover, Dust, Driver Board 1

Not in Use

Page 32

- 31 -

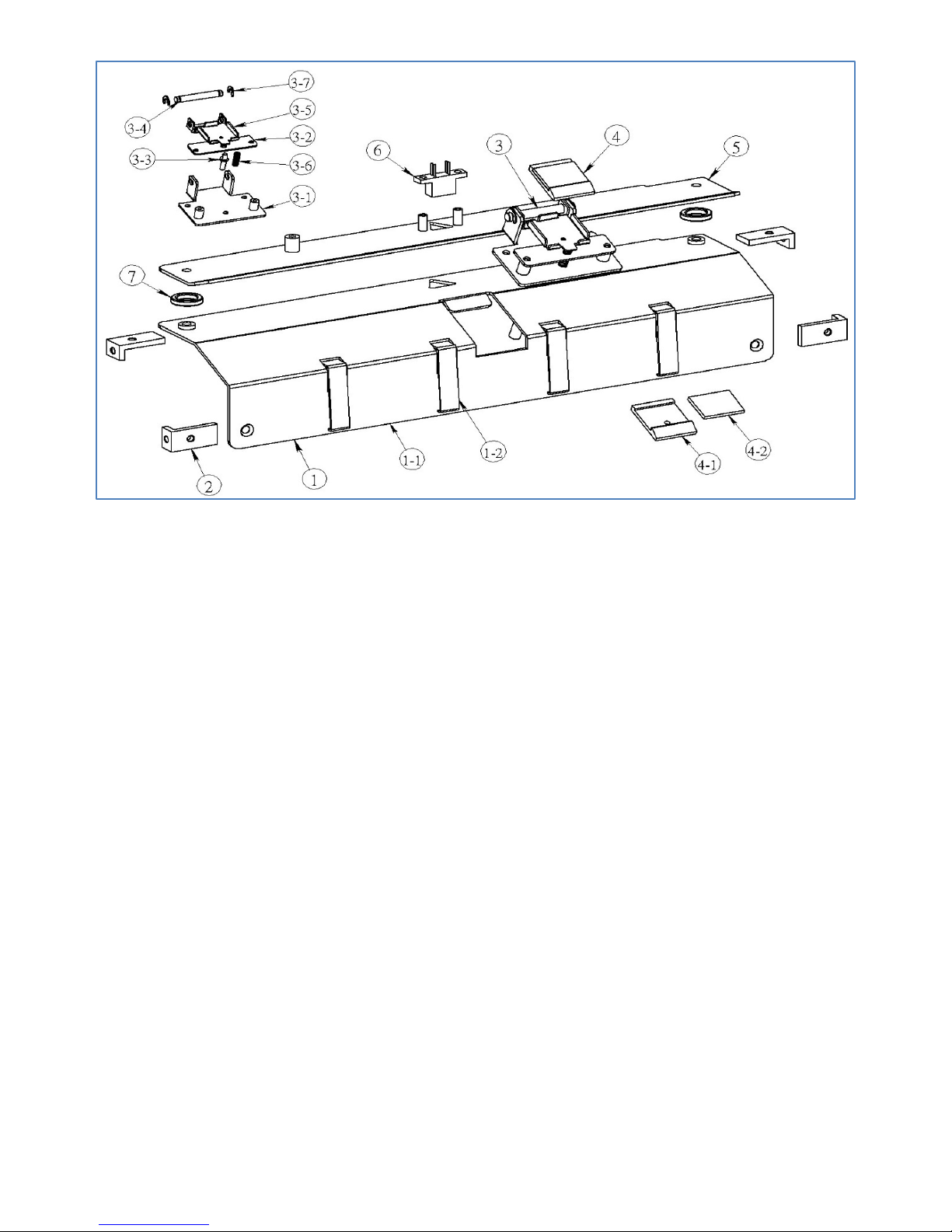

883-050-000A Feed Tray Asm (Fig. 5)

NO P/N Name Q’TY

1 881-211-000B

Tray, Feed, CC-228 1

2 881-E02-000A

Shaft, Side Guide Sliding 1

3 881-E03-000A

Bracket, Side Guide Mounting

2

4 00S-000-5901

Standoff, 6.35 x 2.2mm

4

5 881-105-000B

Side Guide, Feeder, CC-228

2

6

881-215-000A

Thumb Screw, Feeder Side Guide

2

7

881-406-000A

Shaft, Pivot, Feed Tray

1

8

881-217-000A

Bracket, Feed Tray Mounting

2

9

881-212-000B

Index, Center Alignment

1

10

883-050-100A

Asm, Feed Tray Sensor, CC-229

1

882-101-182A

Bracket, Paper Sensor Mounting

1

883-070-060A

Asm, Paper Sensor 1

00S-00E-ESB5

Sensor, EE-SB5 1

00W-883-2463

Wire, 63cm, 24 AWG 1

2PH-716-102F

Housing, Female, 2-pin

11

00C-000-1210

Collar, OD16, ID10

1

12

881-E12-000A

Nylon Graphite Gasket, OD16, ID10.1

1

Nylon

13

881-E13-000A

Nut, Center Alignment

1

14

881-104-0000

Knob, Center Alignment

1

15

881-E15-000A

Nylon Graphite Gasket, OD21, ID10.2

1

Nylon

16

881-E16-000A

Bushing, Ø10.1 x 2.5

2

POM

17

00C-000-1205

Collar, OD16, ID8(00C-000-1205)

1

18

881-E18-000A

Plate, Pressure Scale

1

19

881-E19-000A

Lever, Pressure Adjustment

1

20

881-E20-000A

Plate, spring Force Adjustment

1

21

881-E21-000A

Bushing, OD12, ID7.5

1

22

881-E22-000A

Plate, Spring

1

23

881-403-000B

Spring, Feed Tray Tension, Outer

1

24

881-403-000C

Spring, Feed Tray Tension, Inner

1

25

881-403-000D

Spring, Lever Tension

1

26

881-103-000B

Plate, Feed Tray Extension

1

27

00S-000-5902

Standoff, 6.35 x 4(00S-000-5902)

2

Page 33

- 32 -

Fig. 5

Page 34

- 33 -

883-070-000A Feed Ramp Asm

NO P/N Name Q’TY

1 881-116-000A

Ramp, Feed 1

881-F01-010A

Plate, Ramp, Feed 1

881-F01-020A

Paper Registration 4

2 00B-000-0905

Angle Bracket 4

3 881-F03-000A

Asm, Separator 1

881-F03-010A

Base, Separator Asm 1

881-F03-020A

Lower Limit Plate, Separator 1

881-F03-030A

Pin, Separator Compression Spring Holding 1

881-F03-040A

Shaft, Pivot, Separator Holding Plate 1

881-F03-050A

Holder, Separator 1

881-F03-060A

Shaft, Pivot, Separator Holder 1

00E-M04-000E

E-Ring M4 2

4

00S-000-1604

Separator, CC-228

1

SEPERATOR MTG 1

POM

SEPERATOR PAD 1

PU

5 881-225-000A

Guide, Feed Ramp

1

6 883-070-060A

Asm, Paper Sensor 1

00S-00E-ESB5

Sensor, EE-SB5 1

00W-883-2463

Wire, 63cm, 24 AWG 1

2PH-716-102F

Housing, Female, 2-pin 1

7

00S-881-0003

Spacer, TXP PLATE 3MM 2

Page 35

- 34 -

Page 36

- 35 -

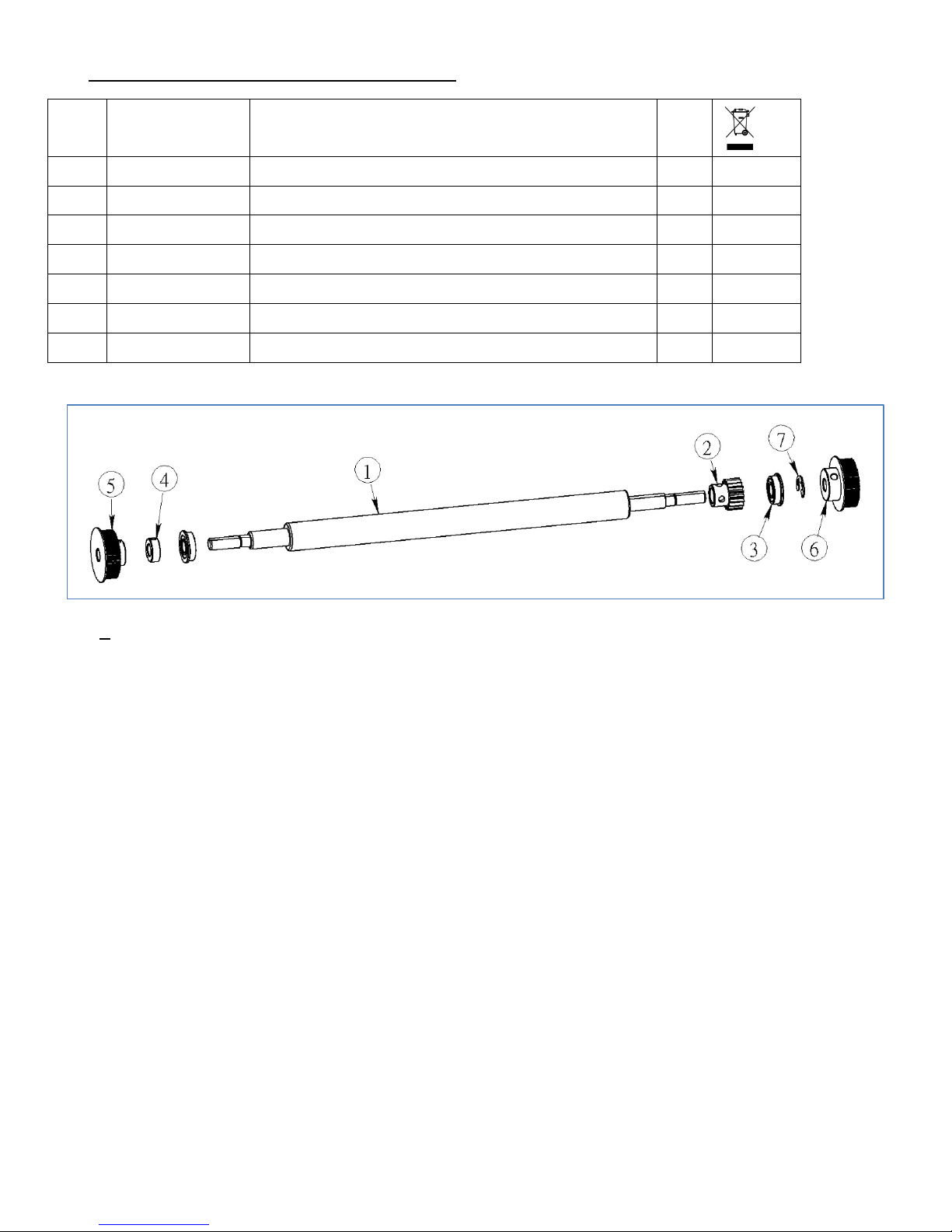

Feed Roller Asm (Fig. 7)

NO P/N Name Q’TY

1 881-N01-000A

Shaft, Feed Roller 1

2 00B-0UF-L001

Pillow Block Ball Bearings, UFL-001 1

3 00R-000-1502

Feed Roller, CC-228 3

881-N03-000A

Core, Feed Roller 1

00R-010-520A

Feed Roller 1

PU

4 881-N04-000A

Shaft, Feed Driving 1

5

162-107-0400

Bushing, OD7, ID6(162-107-0400) 4

6

00B-000-6201

Ball Bearing, 6201ZZ 1

7

881-N07-000A

Housing, Ball Bearing 6201ZZ 1

8 881-N12-000A

Bushing, OD16, ID12.1 1

9 881-N08-000A

Gasket 1

Nylon

10 00A-51G-FC12

Asm, Pulley/Clutch, 51G/FC12 1

02P-51G-180A

Pulley, 0 .2 P, 51G,ID18 1

00O-000-FC12

One Way Clutch, OD18, ID12, FC-12 1

11 00B-000-1209

Hardening Bushing, OD12, ID9(LRT-91216) 1

Fig. 7

Page 37

- 36 -

Front Lower Trasport Roller Asm (Fig. 8)

NO P/N Name Q’TY

1 881-H01-000A

Roller, Transport, CC-228 1

2 00G-M10-1910

Gear, M1, 19T, ID10 1

3 00B-00F-1980

Ball Bearing, LF-1980ZZ 2

4 00C-000-1205

Collar, OD16, ID 8

1

5 02P-51G-08WK

Pulley, 0 .2 P, 51G, ID 8-WK 1

6 02P-51G-080A

Pulley, 0 .2 P, 51G, ID 8 1

7

00E-M08-000E

E-Ring, 8mm 1

Fig. 8

Page 38

- 37 -

Middle Lower Trasport Roller Asm (Fig. 9)

NO P/N Name Q’TY

1 881-H01-000A

Roller, Transport, CC-228 1

2 00G-M10-1910

Gear, M1, 19T, ID 10 1

3 00B-00F-1980

Ball Bearing, LF-1980ZZ 2

4 00C-000-1205

Collar, OD16, ID 8

1

5 02P-51G-08WK

Pulley, 0 .2 P, 51G, ID 8-WK 1

6 00B-MXL-099C

Belt, 0.2P, 99MXL, 8mm 1

MAR

7

00E-M08-000E

E-Ring, 8mm 1

8

00B-MXL-132C

Belt, 0.2P, 132MXL, 8mm 1

MAR

Fig. 9

Page 39

- 38 -

Rear Lower Transport Roller Asm (Fig. 10)

NO P/N Name Q’TY

1 881-H01-000A

Roller, Transport, CC-228 1

2 00G-M10-1910

Gear, M1.0, 19T, ID10 1

3 00B-00F-1980

Ball Bearing, LF-1980zz 2

4 00C-000-1205

Collar, OD16, ID8

1

5 02P-51G-080A

Pulley, 0.2, P51G, ID 8 1

6 00E-M08-000E

E-Ring, 8mm 1

MAR

Fig. 10

Page 40

- 39 -

Front UpperTransort Roller Asm (Fig. 11)

NO P/N Name Q’TY

1 881-L01-000B

Roller, Upper, Transport 1

2 00G-M10-1910

Gear, M1, 19T, ID10 1

3 881-L03-000A

Nylon Graphite Gasket, OD14, ID8.2

1

Nylon

4 883-120-040A

Rocker Asm 2

00H-000-1280

Housing, 1280 Ball Bearing, Transport Rocker 1

00B-00F-1280

Ball Bearing, LF-1280ZZ 1

00B-000-1280

Ball Bearing, L-1280ZZ 1

Page 41

- 40 -

Rear Upper Transnsport Roller Asm (Fig. 12)

NO P/N Name Q’TY

1 881-M01-000B

Roller, Transport 1

2 00G-M10-1910

Gear, M1.0, 19T, ID10 1

3 881-L03-000A

Nylon Graphite Gasket, OD14, ID8.2

1

Nylon

4 883-120-040A

Rocker Asm 2

00H-000-1280

Housing, 1280 Ball Bearing, Transport Rocker 1

00B-00F-1280

Ball Bearing, LF-1280ZZ 1

00B-000-1280

Ball Bearing, L-1280ZZ 1

Fig. 12

Page 42

- 41 -

883-140-000A Die Module Fine Tuning Asm (Fig. 13) {Need to add a Mark Reader}

NO P/N Name Q’TY

1 883-140-010A

Bar, Die Module Fine Tuning 1

2 883-140-020A

Bracket, Die Module Sensor Mounting 1

3

883-070-060A

Asm, Paper Sensor

1

00S-00E-ESB5

Sensor, EE-SB5

1

00W-883-2463

Wire, 63cm, 24 AWG 1

2PH-716-102F

Housing, Female, 2-pin 1

4

883-140-040A

Bracket, Die Skew Adjustment 1

5

883-140-050A

Thumb Screw, 1

6

883-14—060A

Nut, Thumb Screw, Skew Adjustment 1

7 00B-0NB-1419

Bushing, NB-1419 1

Fig. 13

Page 43

- 42 -

883-150-000A Die Module (Fig. 14)

NO P/N Name Q’TY

1 883-150-010A

Bracket, Die Module 1

2 883-150-020A

Sie Plate, Die Module 2

3 881-R17-000A

Handle 2

4 883-150-040A

Thumb Screw 2

5 00E-M04-000E

E-Ring M4 5

6 883-150-060A

Bracket, Lower Die Base Mounting 1

7

883-150-070A

Base, Lower Die 1

8

00M-000-0002

Magnet, Rear Cover Position 10

9

883-150-090A

Pin, ψ4*6, Die Plate Positioning

4

10 00B-0LM-06UU

Linear Bearing, LM-06-UU 4

11 883-150-110A

Bar, Upper Die Base Mounting 1

12 883-150-120A

Base, Upper, Die Module 1

13 883-150-130A

Pin, Die Module Sliding 4

14

883-150-140A

Plate, Cam Contact 2

15

883-150-150A

Bracket, Spring Holding 2

16

883-150-160A

Spring,

2

17 883-150-170A

Shaft, Die Module Driving 1

18 883-150-180A

Cam 2

19 00B-000-6005

Ball Bearing, 6005ZZ 2

20 00C-000-4025

Collar, OD 40, ID 25 2

21 00B-00F-6901

Ball Bearing, LF-6901ZZ 2

22 00G-M10-3112

Gear, M1.0, 31T, ID 12 1

23 883-150-230A

Triger 2

24

883-150-240A

Guide Plate 1

25

883-150-250A

Die Plate, Crease, Lower 1

26

883-150-260A

Die Plate, Crease, Upper

1

Fig. 14

Page 44

- 43 -

Page 45

- 44 -

881-Q00-000A Upper Knife Driving Asm (Fig. 15)

NO P/N Name Q’TY

1 881-704-000A

Knife, Upper. CC-228 1

2 881-P02-000A

Plate, Upper KNIFE MOUNTING 2

3 881-719-000A

Link 2

4 881-701-000A

Bushing, OD7.9, ID6.1 2

5 881-P05-000A

Shaft, Knife Driving 1

6 00B-00F-1910

Ball Bearing, LF-1910zz 2

7

881-721-000A

Arm, R, Knife Driving 1

881-P07-010A

Plate, Knife Driving 1

881-P07-020A

Block, Arm Link 1

8 881-720-000A

Arm, L, Knife Driving 1

881-P08-010A

Plate, Knife Driving 1

881-P07-020A

Block, Arm Link 1

9 881-722-000A

Shutter, Index, CC-228 1

10 00E-M10-000E

E-Ring, 10mm 1

11

00C-000-1201

Collar, OD16, ID10

1

12 00B-00R-1560

Ball Bearing, R-1560ZZ 2

13

00B-000-1101

Anti-Static Brush 3” 2

Page 46

- 45 -

881-P00-000A Lower Knife Asm (Fig. 16)

NO P/N Name Q’TY

1 881-711-000A

Chassis, Cutting Knife Mounting CC-229 1

2 881-705-000A

Knife, Lower, CC-228 1

3 881-714-000A

Asm, Middle, Upper Knife Holding Spring 1

881-714-010A

Spring, Middle, Upper Knife Holding Spring 1

881-714-020A

Pin, Middle, Upper Knife Holding Spring 1

881-714-030A

Bushing, Middle, Upper Knife Holding Spring 1

00B-000-L940

Ball Bearing, L940ZZ 2

00E-M04-000E

E-Ring, 4mm 2

4

881-717-000A

Nut, Middle, Upper Knife Holding Spring 1

5 881-715-000A

Asm, Left, Upper Knife Holding Spring 1

881-715-010A

Spring, Left, Upper Knife Holding Spring Asm 1

881-716-020A

Pin, R/L, Upper Knife Holding Spring Asm 1

881-716-030A

Bushing, R/L, Upper Knife Holding Spring Asm 1

00B-000-L940

Ball Bearing, L940ZZ 2

00E-M04-000E

E-Ring, 4mm 2

6 881-716-000A

Asm, Right, Upper Knife Holding Spring 1

881-716-010A

Spring, Right, Upper Knife Holding Spring 1

881-716-020A

Pin, R/L, Upper Knife Holding Spring 1

881-717-030A

Bushing, R/L, Upper Knife Holding Spring 1

00B-000-L940

Ball Bearing, L940ZZ 2

00E-M04-000E

E-Ring, 4mm 2

7 881-718-000A

Nut, L/R Upper Knife Holding Spring Asm 2

8 Not in use

9 883-070-060A

Asm, Paper Sensor 1

00S-00E-ESB5

Sensor, EE-SB5 1

00W-883-2463

Wire, 63cm, 24 AWG 1

2PH-716-102F

Housing, Female, 2-pin 1

Fig. 16

Page 47

- 46 -

Page 48

- 47 -

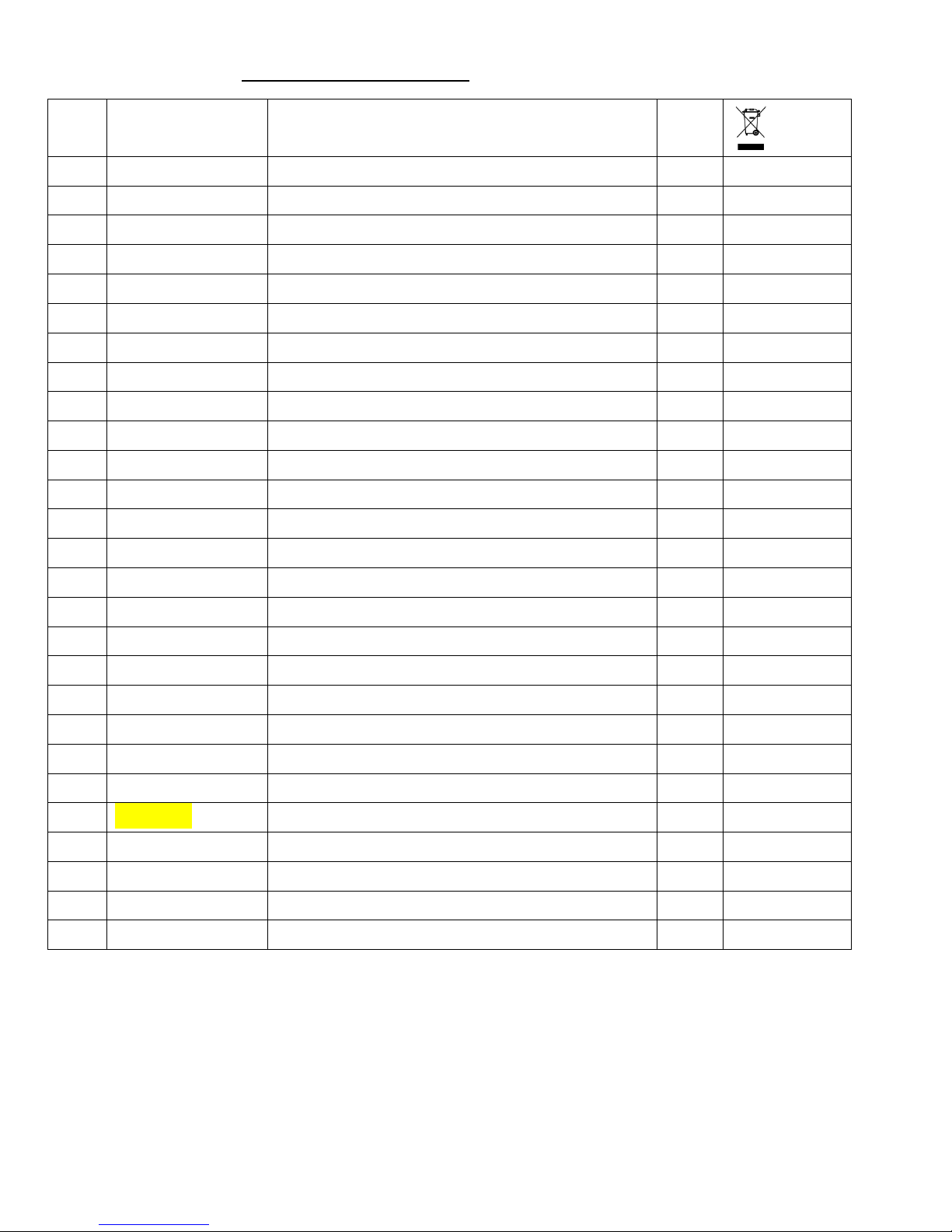

883-180-000A Slitter Mounting Chassis Asm (Fig. 17)

NO P/N Name Q’TY

1 883-180-010A

Chassis, Slitting Module Mounting , CC-229 1

2 881-S02-000A

Stud, Rear Safety Cover 2

3 00M-000-0002

Magnet, Rear Cover Position 2

4 883-180-040A

Thumb Screw, Slitting Module Fastening CC-229 1

5 881-111-010A

Spring, Compression, Slitting Module Fastening 1

6 00E-M08-000E

E-Ring, 8mm 1

7

00W-M05-000F

FLAT WASHER M5 1

Fig. 17

Page 49

- 48 -

883-190-000A Slitter Left/Right Adj Asm (Fig. 18)

NO P/N Name Q’TY

1 883-190-010A

Nut, Slitter Left/Right Adj 1

2 883-190-020A

Screw, Driving, Slitter Left/Right Adj 1

3 00B-00F-1260

Ball Bearing, LF-1260zz 2

4 00C-000-1606

Collar, OD16, ID 6 1

5 883-190-050A

Block, Slitter Fine Tune Adjustment Holding 1

6 883-190-060A

Ball Steel, Pressure Holding 2

883-190-060B

Spring, Ball Screw Pressure Holding 2

00S-M04-006S

Screw, Set, M4x6 2

7

883-190-070A

Joint, Slitter Fine Tune 1

8 883-190-080A

Clamp, Slitter Joint Locking 1

9 883-190-090A

Knob, Slitter Left/Right Adj 1

10 00E-M06-000E

E-Ring, 6mm 1

Fig. 18

Page 50

- 49 -

Slitter Asm (Fig. 19)

NO P/N Name Q’TY

1 881-801-000A

Chassis, Slitter, 2 x 3.5” 1

881-801-010A

Chassis, Slitter, 5.47X 4.21” 1

2 881-803-000A

Side Plate, L, Slitter 1

881-802-000A

Side Plate, R, Slitter 1

3 881-805-000A

Shaft, Slitter, Lower 1

4 881-804-010A

Shaft, Slitter, Upper, 2x3.5” Slitter 1

881-804-020A

Shaft, Slitter, Upper, 5.47x4.21” Slitter 1

5 881-807-000A

Slitting Wheel, Center Gutter, 0.5” 1

881-807-010A

Slitting Wheel, Center Gutter, 6mm 1

881-807-020A

Slitting Wheel, Center Gutter, 0.25” 1

881-807-030A

Slitting Wheel, Center Gutter, 3mm 1

6 881-808-000A

Slitting Wheel, Side Trim 2

7 881-827-000A

O Ring, JASO 2027 3

PU

8 881-810-000A

Roller, Ejection Driving, Slitter 2

POM

9 881-115-000A

Belt, Transport, Slitter 2

PU

10 881-809-020A

Roller, Transport, Slitter 4

11 881-806-000A

Slitting Wheel, Upper, CC-228 4

12 00B-00F-6901

Ball Bearing, F6901ZZ 4

13 00E-M10-E000

E-Ring, 10mm 2

14

00G-M10-3112

Gear, M1.0, 31T, ID12 2

15

881-812-000A

Deflector, Side Waste, 0.5” 2

881-812-000A

Deflector, Center Gutter, 0.5” 1

881-812-010A

Deflector, Center Gutter, 0.25” 1

881-812-020A

Deflector, Center Gutter, 6mm 1

881-812-030A

Deflector, Center Gutter, 3mm 1

16 881-114-000A

Asm, Upper Ejection Roller 2

881-114-010A

Roller, Upper, Ejection 2

POM

881-114-020A

Spring, Upper Ejection Roller 2

881-114-030A

Pin, Upper Ejection Roller 2

00E-M03-E000

E-Ring, M3 4

17

881-113-000A

Roller, Lower, Ejection 2

POM

881-113-010A

Pin, Lower Ejection Roller 2

00E-M03-E000

E-Ring, M3 4

18 881-R17-000A

Handle 1

Page 51

- 50 -

Fig. 19

Page 52

- 51 -

883-021-000A Top, Safety Cover Asm (Fig. 18)

NO P/N Name Q’TY

1 883-021-010A

Top, Safety Cover 1

2 883-021-020A

Bracket, Top Cover 2

3 883-021-030A

Trigger, Top Cover 1

Fig. 18

Page 53

- 52 -

Rear, Safety Cover Asm 883-220-000A (Fig. 19)

NO P/N Name Q’TY

1 883-220-010A

Rear, Safety Cover , CC-229 1

2 883-220-020A

Catcher

1

3 881-109-1000

Asm, Divider 1

881-109-1000-0A

Plate, Divider 1

881-109-1000-0B

Flexible Magnets 75 * 18 1

Fig. 19

Page 54

- 53 -

Waste Bin Asm 883-250-000A (Fig. 20)

NO P/N Name Q’TY

1 883-250-010A

Waste Bin , CC-229 1

2 00A-000-220A

Index, Waste Bin 1

3 881-R17-000A

Handle 1

Fig. 20

Page 55

- 54 -

Recommended Spare Parts List

Part Number Name

00A-51G-FC12 Asm, Pulley/Clutch, 51G/FC12

00B-000-1209

Hardening Bushing, OD12, ID9(LRT-91216)

00B-0UF-L001 Pillow Block Ball Bearings, UFL-001

00B-MXL-099C Belt, 0.2P, 99 MXL, 8mm

00B-MXL-132C Belt, 0.2P, 132MXL, 8mm

00D-000-0304 Display, LCD, 4 Row x 20

00M-000-0401 Motor, CKM245-01AH

00M-000-0427

Motor, 103H7823-1760

00S-000-1604 Separator, CC-228

00S-000-5611 Spring, Rocker Tension, Outer {Folder Black}

00S-000-6105

Switch, Interlock,

02P-17G-0500 Pulley, 0 .2 P, 17G, ID 5

02P-17G-0800 Pulley, 0. 2 P, 17G, ID 8

02P-51G-080A

Pulley, 0 .2 P, 51G, ID 8

02P-51G-08WK Pulley, 0 .2 P, 51G, ID8-WK

881-403-000B

Spring, Feed Tray Tension, Outer

881-403-000C

Spring, Feed Tray Tension, Inner

881-403-000D

Spring, Lever Tension

881-405-070A Spring, Rocker Tension, Inner

881-704-000A

Knife, Upper. CC-228

881-705-000A Knife, Lower, CC-228

881-714-000A Asm, Middle, Upper Knife Holding Spring

881-715-000A Asm, Left, Upper Knife Holding Spring

881-716-000A Asm, Right, Upper Knife Holding Spring

881-H01-000A Roller, Transport, CC-228

881-L01-000B

Roller, Upper, Transport

881-M01-000B Roller, Transport

883-010-260A Case, R, CC-229

883-020-050A Main Board

883-020-051A Adaptor Board, Firmware Upgrade

883-020-160A Asm, Cutting Knife Home Position Sensor

883-020-200A

Asm, Die Home Position Sensor

883-020-250A

Asm, PCB, Control Panel

883-020-270A Key Pad, CC-229

883-020-280A Case, L, CC-229

Page 56

- 55 -

883-030-020A Power Supply, 24 V, RSP-320-24

883-030-040A Driver Board

883-050-100A

Asm, Feed Tray Sensor, CC-229

883-070-060A Asm, Paper Sensor

883-112-010A Asm, Dummy Die Module

883-120-040A Rocker Asm

883-150-000A Asm, Die Module

883-150-250A Die Plate, Crease, Lower

883-150-260A Die Plate, Crease, Upper

Loading...

Loading...