Page 1

Duplo DF-920

Automatic Tabletop

Paper Folder

Instruction Manual

Page 2

PAPER FOLDER

DF-920

INSTRUCTION MANUAL

[120 V]

Page 3

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

Page 4

INTRODUCTION

Thank you for purchasing this Duplo equipment.

To ensure correct usage, please read this instruction manual thoroughly, especially the section

Safety Precautions.

The aim of this instruction manual is safe and proper use. For this reason, users of this equipment

for purposes or by methods other than those described in this manual and users who remodel this

equipment for their own reasons are asked to ensure safety in use at their own responsibility.

After reading, please keep this instruction manual handy for future reference.

ABOUT THIS INSTRUCTION MANUAL

This instruction manual describes the functions of the equipment. It is composed of the following

chapters.

It can be read from the required pages in use of this equipment.

Safety (p.3 to 6)

◆

This chapter describes user safety, such as precautions in use of this equipment, etc.

Outline (p.7 to 17)

◆

This chapter describes what users need to know about this equipment before using it.

Basic Operations (p.18 to 25)

◆

This chapter describes the most basic paper folding operation.

Correcting Folding Misalignment (p.26 to 31)

◆

This chapter describes how to correct folding misalignment of folded paper.

Applied Use (p.32 to 44)

◆

This chapter outlines applied paper folding operations such as standard folding of non-standard

paper, custom folding, and cross folding, etc.

Others (p.45 to 59)

◆

This chapter describes additional functions, error messages, troubleshooting guide, etc.

1

Page 5

TABLE OF CONTENTS

Safety

◆

1. Safety Precautions.............................................3

Caution Label Location ........................................5

2. Installation Precautions ....................................5

2-1. Installation Location ...................................5

2-2. Precautions in Moving the Unit ..................5

3. Usage Precautions.............................................6

3-1. Power Supply.............................................6

3-2. Operating Environment.............................. 6

3-3. Storage Conditions .................................... 6

3-4. Maintenance .............................................. 6

Outline

◆

4. Installation ..........................................................7

4-1. Standard Accessories................................ 7

4-2. Installation Procedure ................................8

5. Names and Operation of Parts .........................11

5-1. External Parts ............................................ 11

5-2. Internal Parts .............................................12

6. Control Panel......................................................14

6-1. Names and Operation of Control Panel..... 14

6-2. Description of LCD.....................................16

6-3. Energy Saving Mode Function...................17

6-4. Types of Buzzer Sounds............................17

Applied Use

◆

11. Standard Folding of Non-standard Paper........32

11-1. Paper Size Restrictions .............................32

11-2. Operation Procedure .................................32

12. Custom Folding..................................................35

12-1. Paper Size Restrictions .............................35

12-2. Operation Procedure .................................35

13. Cross Folding..................................................... 38

13-1. Cross Folding Methods..............................38

13-2. Precautions on Cross Folding....................38

13-3. Cross Folding of Standard Paper ..............39

13-4. Cross Folding of Non-standard Paper ....... 40

13-5. Cross Folding Paper at the Desired

Folding Position ......................................... 40

14. Using Art Paper and Coated Paper .................. 41

14-1. Characteristics of Art Paper and Coated

Paper ......................................................... 41

14-2. Operation Procedure .................................41

15. Using Special Paper ..........................................42

15-1. Double Folding Thick Paper ......................42

15-2. Using Recycled Paper ............................... 42

15-3. Folding Small Size Paper ..........................43

16. Stacker Roller..................................................... 44

16-1. Changing the Stacker Roller Position ........44

16-2. Changing the Stacker Roller Height ..........44

Basic Operations

◆

7. Precautions Prior to Use ...................................18

7-1. Paper Used................................................ 18

7-2. Precautions on Stacking Paper .................19

7-3. Automatic Detection of Paper Size ............19

7-4. Automatic Rise/Descent of the Paper

Feed Tray ..................................................20

7-5. Checking the Front/Back, Top/End of

Paper ......................................................... 20

7-6. Using the “QUICK START” ........................21

8. Paper Folding Methods ..................................... 21

9. Standard Folding of Standard Paper ...............22

9-1. Standard Paper..........................................22

9-2. Standard Folding Modes............................22

9-3. Operation Procedure .................................22

Correcting Folding Misalignment

◆

10. Folding Misalignment ........................................26

10-1. Correcting Folding Misalignment Along

Sides of Paper ........................................... 26

10-2. Correcting Folding Misalignment Along

Vertical Length of Paper ............................ 27

10-3. Correcting Deformed Folding.....................31

Others

◆

17. Additional Functions ......................................... 45

17-1. Interval Function ........................................ 45

17-2. Folding Stopper Operation Mode Setting

Function .....................................................46

18. When Paper Jamming Occurs ..........................48

18-1.

When Paper Jams at Paper Feed Section...

18-2.

When Paper Jams Near Paper Feed Ring ...

18-3. When Paper Jams Inside Folding Plate.....49

18-4.

When Paper Winds Around Folding Roller ...

18-5. When Paper Jams Near Folding Plate 1 ...50

18-6. When Paper Jams Near Folding Plate 2 ...51

18-7. When Paper Jams at Paper Ejection

Section.......................................................52

19. Error Messages..................................................53

20. Troubleshooting.................................................54

21. Cleaning the Unit ...............................................56

21-1. Cleaning the Folding Rollers......................56

21-2. Cleaning the Paper Feed Rings.................57

21-3. Cleaning the Paper Separator ................... 57

21-4. Cleaning the Paper Feed Inlet Sensor.......57

21-5.

Cleaning the Paper Ejection Outlet Sensor ...

22. Specifications.....................................................59

48

48

49

58

2

Page 6

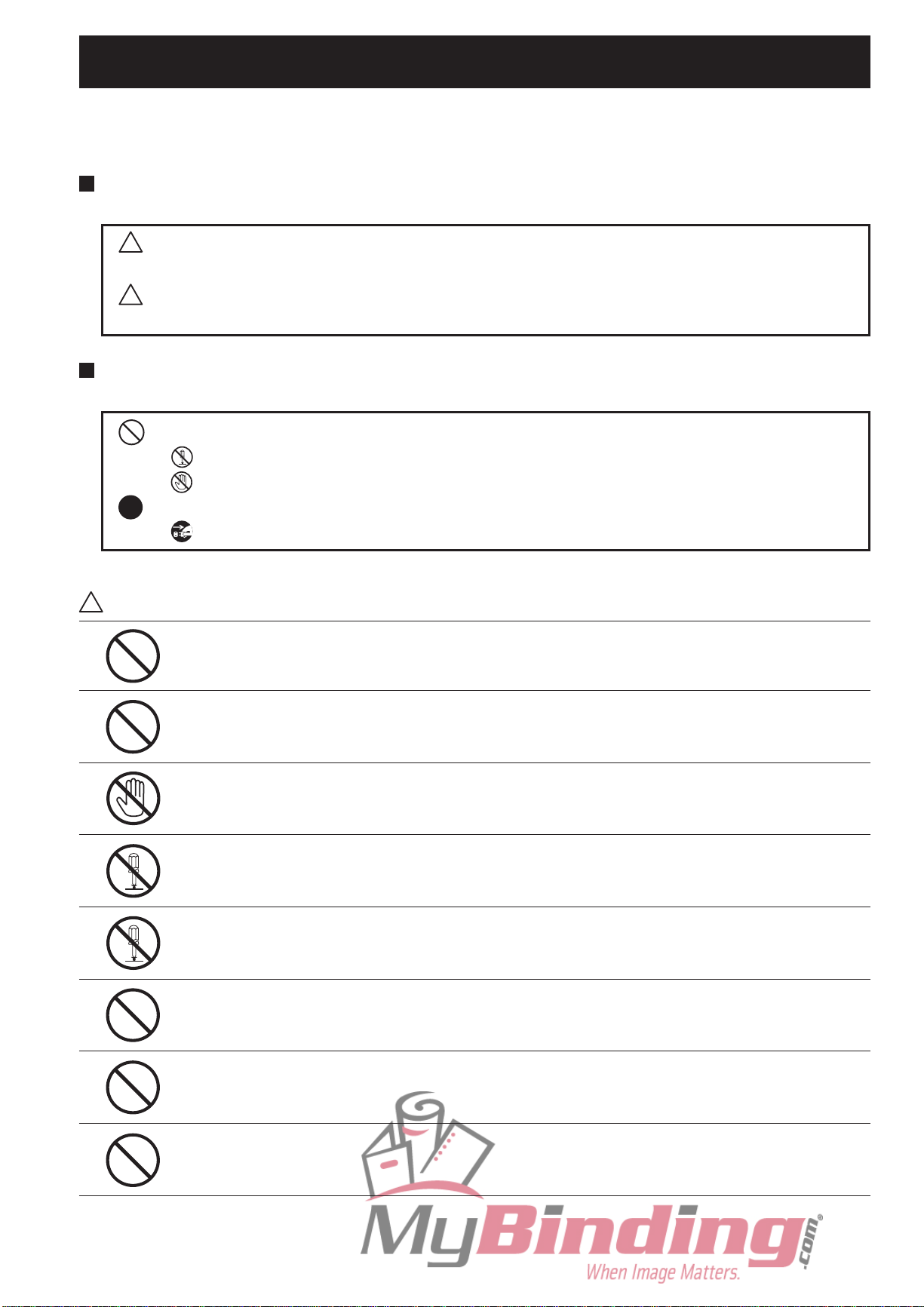

1. SAFETY PRECAUTIONS

Always observe the cautions and warnings given below to prevent personal injury or property

damage.

The degree of danger and damage that could occur is indicated on two levels by the

following marks.

WARNING : Ignoring this mark could result in the possibility of serious injury or

!

even death.

CAUTION : Ignoring this mark could result in the possibility of injury or physical

!

damage.

The following graphic symbols indicate the various types of action to be performed or

avoided.

This graphic symbol indicates a forbidden action.

means “Do not disassemble.”

means “Do not touch.”

This graphic symbol indicates actions that must be performed.

means “Disconnect the power plug.”

!

WARNING:

Do not place metal objects or vessels containing liquids on top of the unit. The entry of any

metal object or liquid could result in a fire or an electrical shock.

Do not insert any metal or easily-combustible object inside this unit. This could result in a fire

or an electrical shock.

Do not touch or insert foreign objects into any rotating part during operation. This could

result in injury.

Do not remove the cover or back panel. This unit contains high-voltage components that

could cause an electrical shock.

Do not disassemble, modify or repair this unit. There is a danger of fire, electrical shock or

injury. Contact your dealer when repairs are necessary.

Use only the power supply voltage specified on the main nameplate. Using other voltages

could result in a fire or an electrical shock.

Keep this unit and the power cord away from heaters and heater vents. Excessive heat could

melt the cover or power cord covering, and result in a fire or an electrical shock.

Do not use solvent inside or near the unit (e.g. when cleaning the unit). Such solvents may

damage the rubber rollers and resin inside the unit, resulting in malfunctions.

(Continued on the next page)

3

Page 7

SAFETY PRECAUTIONS (continued)

Make sure that the combined power consumption of the appliances to be connected does not

exceed the capacity rating of the power outlets or plug receptacles. Exceeding the capacity

rating could cause the power outlets, plug receptacles, or power extension cords to overheat

and catch a fire.

Remove any dust that accumulates on the power plug prongs and the surface of the plug from

which the prongs extend. Accumulated dust could result in a fire.

If any foreign object such as metal or liquid should enter this unit, immediately turn the unit

off at the power switch and disconnect the power plug from the power outlet. Failure to do

so could result in a fire or an electrical shock. Contact your dealer immediately.

Do not damage the power cord or power plug. (Do not scratch, alter, bend, twist, pull or place

heavy objects on the power cord or power plug.)

This could result in damage, a fire or an electrical shock.

Always grip the plug when disconnecting the power plug from the power outlet. Forcibly

pulling on the power cord could cause damage, resulting in a fire or an electrical shock.

!

CAUTION:

Do not handle the power plug with wet hands. This could result in an electrical shock.

Before cleaning this unit, turn the unit off at the power switch and disconnect the power plug

from the power outlet. Accidental operation of the unit during cleaning could result in injury.

Do not touch the power switch with wet hands. Otherwise electric hazards may occur.

Do not use flammable sprays inside or near the unit (e.g. when cleaning the unit). Such

flammable gas may ignite and cause a fire or combustion.

Keep away long hair, ties, jewelry and loose clothing. This could result in injury.

Do not put fingers inside during operation. This could result in injury.

Always disconnect the power plug from the power outlet when the unit is not to be used for

an extended period. Failure to do so could result in a fire due to leakage current if the

insulation should deteriorate.

Install this unit on a level, stable stand or floor, with sufficient space around it. Failure to do

so could result in the unit overturning and causing injury.

Do not install this unit in a location where there is excessive humidity or where contact with

water is possible. Poor choice of location could result in deterioration of the insulation, a fire

or an electrical shock.

Disconnect the power plug from the power outlet before attempting to move this unit. Failure

to do so could result in power cord damage, a fire or an electrical shock.

4

Page 8

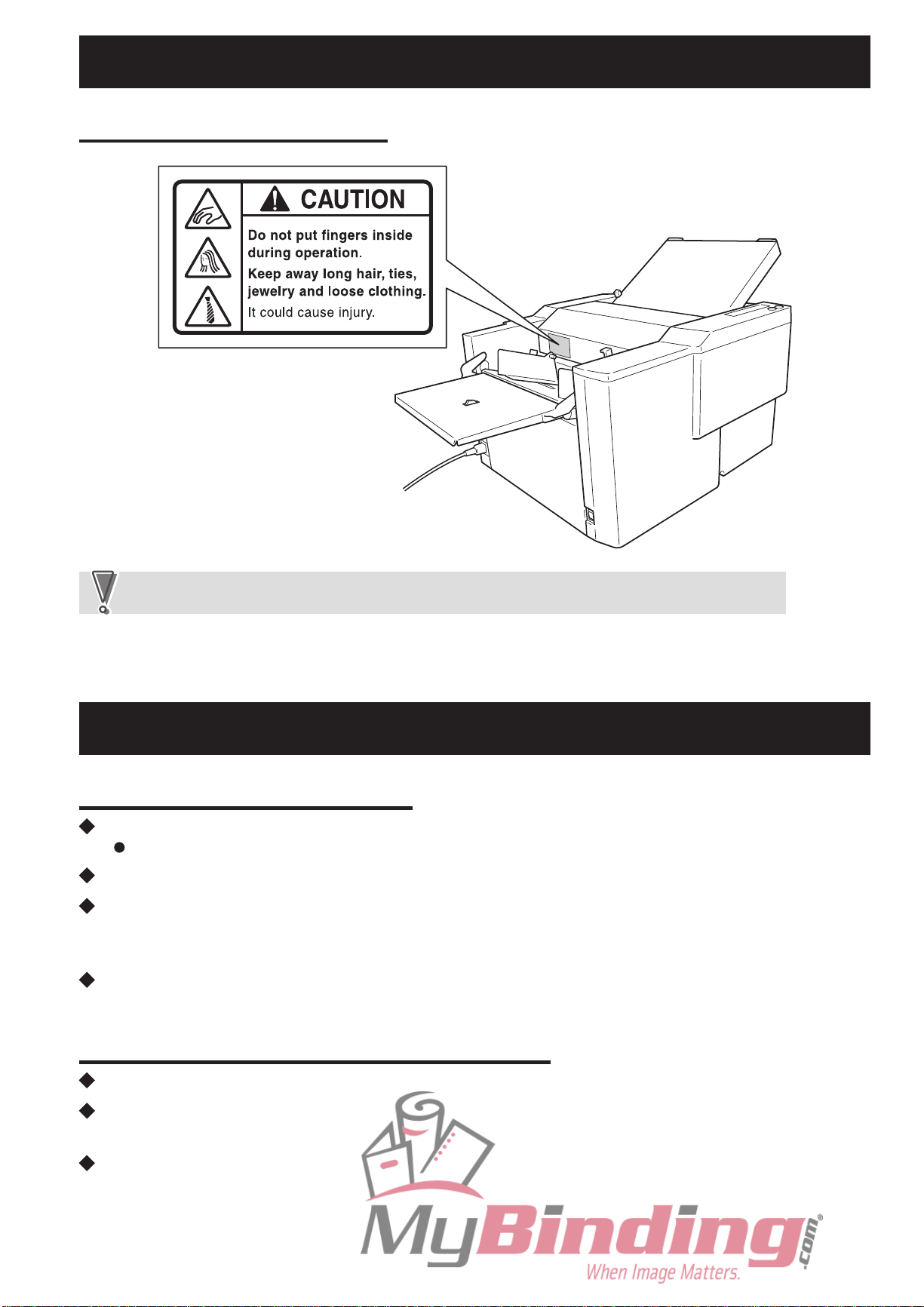

Caution Label Location

The caution label is pasted on the unit to ensure the safety of users. Do not remove nor change it.

NoteNote

If the label becomes dirty, damaged, or lost, be sure to contact your nearest dealer for a new one.

2. INSTALLATION PRECAUTIONS

2-1. Installation Location

Install the unit on a table which can tolerate its weight. The mass of the unit is as follows.

96 lb

Install the unit close to a power outlet.

The unit may make loud sounds while operating according to the processing speed and paper

used due to its paper-folding mechanism. Therefore install it where it will not disturb the office

environment.

Refer to “1. SAFETY PRECAUTIONS” (

☞

p.3, 4).

2-2. Precautions in Moving the Unit

As the unit weights 96 lb, when moving it, it should be held at the base by two persons.

When moving the unit with folding plates 1 and 2 removed, make sure the folding plates are not

subject to shock. Otherwise, the folding plates may damage, resulting in poor folding accuracy.

Arrange the power cord carefully so that it does not get stepped on, and damage as a result.

5

Page 9

3. USAGE PRECAUTIONS

3-1. Power Supply

This equipment shall be installed near the socket-outlet where the plug on the power supply

cord is easily accessible.

Make sure the power supply used is always within the following range.

100 to 240 V AC, 50/60 Hz

When you power other appliances from the same AC outlet, make sure that the combined

power consumption does not exceed the power supply capacity.

Rated power of this equipment: 1.4 to 0.7 A (95 W)

3-2. Operating Environment

Operate this unit in the following environment:

– where the temperature range is between 41 and

95°F,

– where the humidity range is between 20 and

80% RH (no dew condensation),

– which is not subject to direct sunlight,

– which is subject to little or no vibration,

– where there are no harmful chemicals,

– which is reasonably free from dust,

– which is free from air-borne salt, and

– where the equipment is not exposed to water.

3-3. Storage Conditions

Store this unit in the following environment:

– where the temperature range is between 14 and

122°F,

– where the humidity range is between 10 and

85% RH (no dew condensation),

– which is not subject to direct sunlight,

– which is subject to little or no vibration,

– where there are no harmful chemicals,

– which is reasonably free from dust,

– which is free from air-borne salt, and

– where the equipment is not exposed to water.

3-4. Maintenance

To protect the special features of this unit, the customer should never apply oil or grease to the

parts. Please contact your dealer in case of any problem.

!

WARNING

Do not use flammable sprays or solvent inside or near the unit (e.g. when cleaning the

unit). Such flammable gas may ignite and cause a fire or combustion. Such solvents may

damage the rubber rollers and resin inside the unit, resulting in malfunctions.

6

Page 10

4. INSTALLATION

4-1. Standard Accessories

Confirm that the following parts are provided.

qw e

No.

q

w

e

r

r

t

PAPER FOLDER

INSTRUCTION MANUAL

Name Qty. Remarks

Folding plate 1 1

Folding plate 2 1

Cross folding guide 1

Power cord 1

DF-920

[120 V]

Auxiliary part for cross folding

t

Instruction manual 1

This manual

7

Page 11

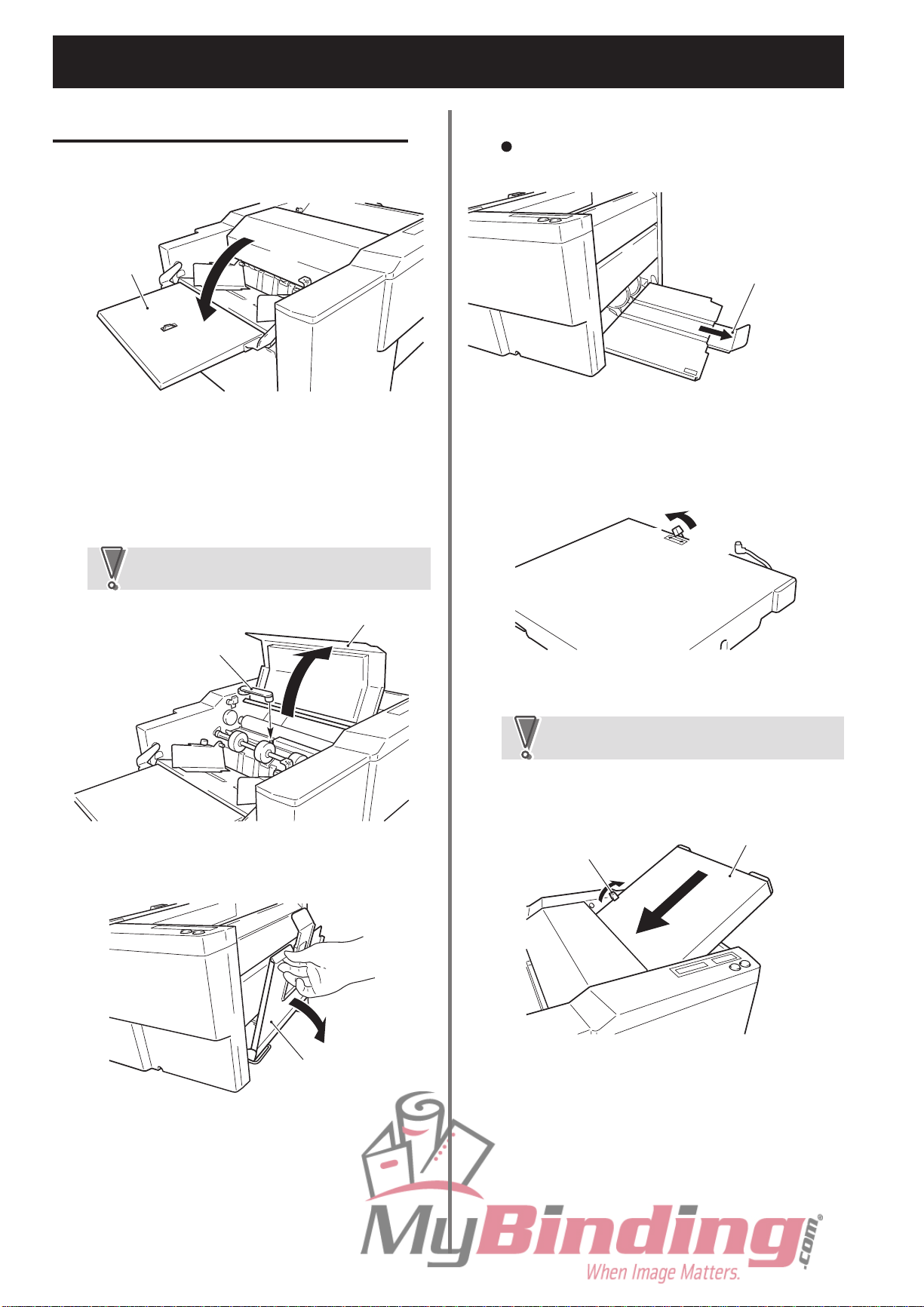

4. INSTALLATION

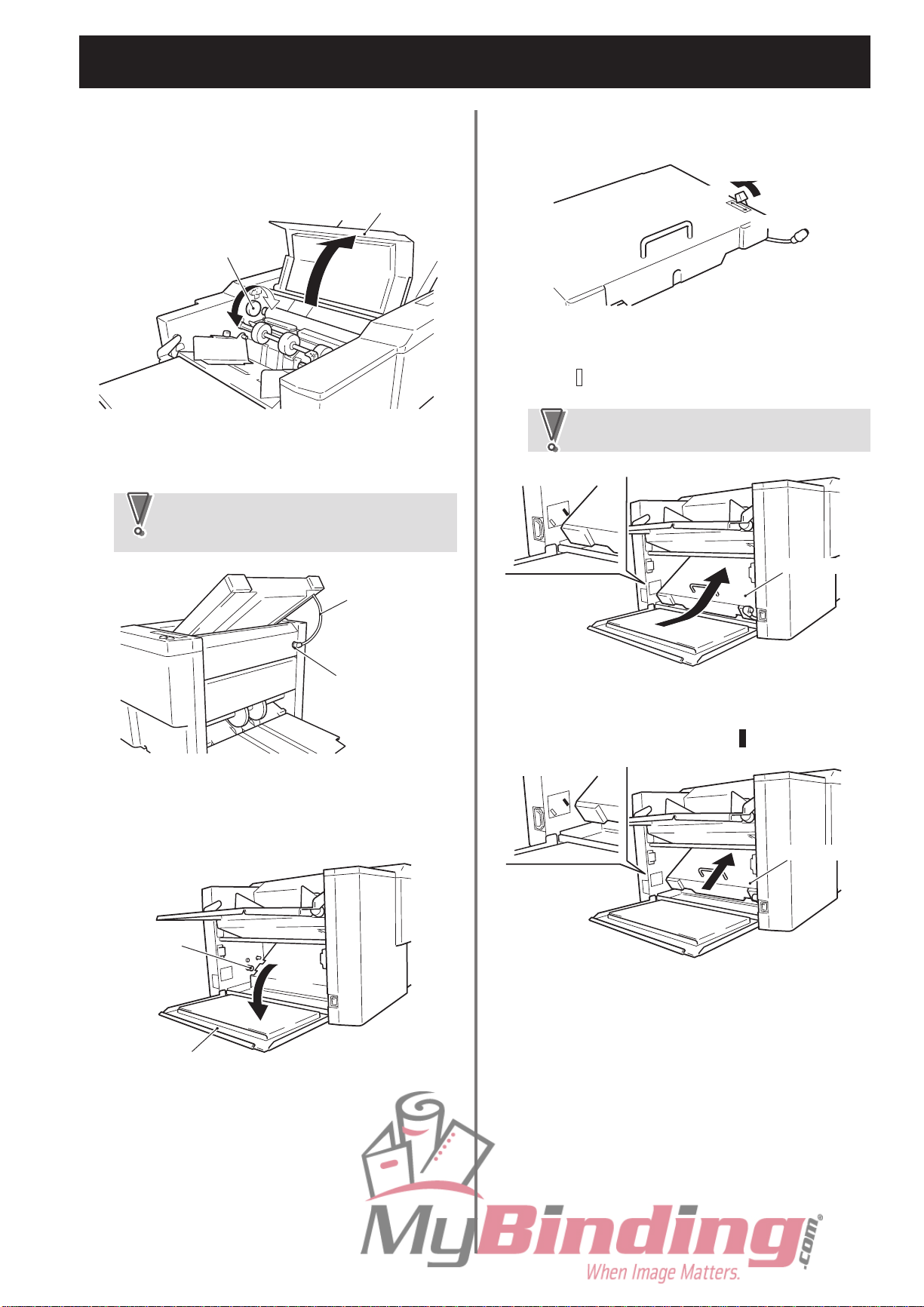

4-2. Installation Procedure

Open the auxiliary paper feed tray.

1

Extend the paper receiving stopper.

4

Adjust the stopper according to the paper size and

folded shape.

Auxiliary paper

feed tray

Open the top cover, and place the

2

cross folding guide as shown in the

figure.

After setting, close the top cover

properly.

If the top cover is open, the unit will not

NoteNote

operate.

Top cover

Cross folding guide

Paper receiving stopper

Attach folding plate 1.

5

q Push the lock lever on folding plate 1 towards

“UNLOCK”.

UNLOCK

LOCK

Open the paper receiving tray.

3

Paper receiving tray

w Insert folding plate 1 into the unit.

When inserting the folding plate, be sure to

NoteNote

hold it with both hands.

e Push the lock lever towards “LOCK”, and

secure folding plate 1.

Lock lever

Folding plate 1

8

Page 12

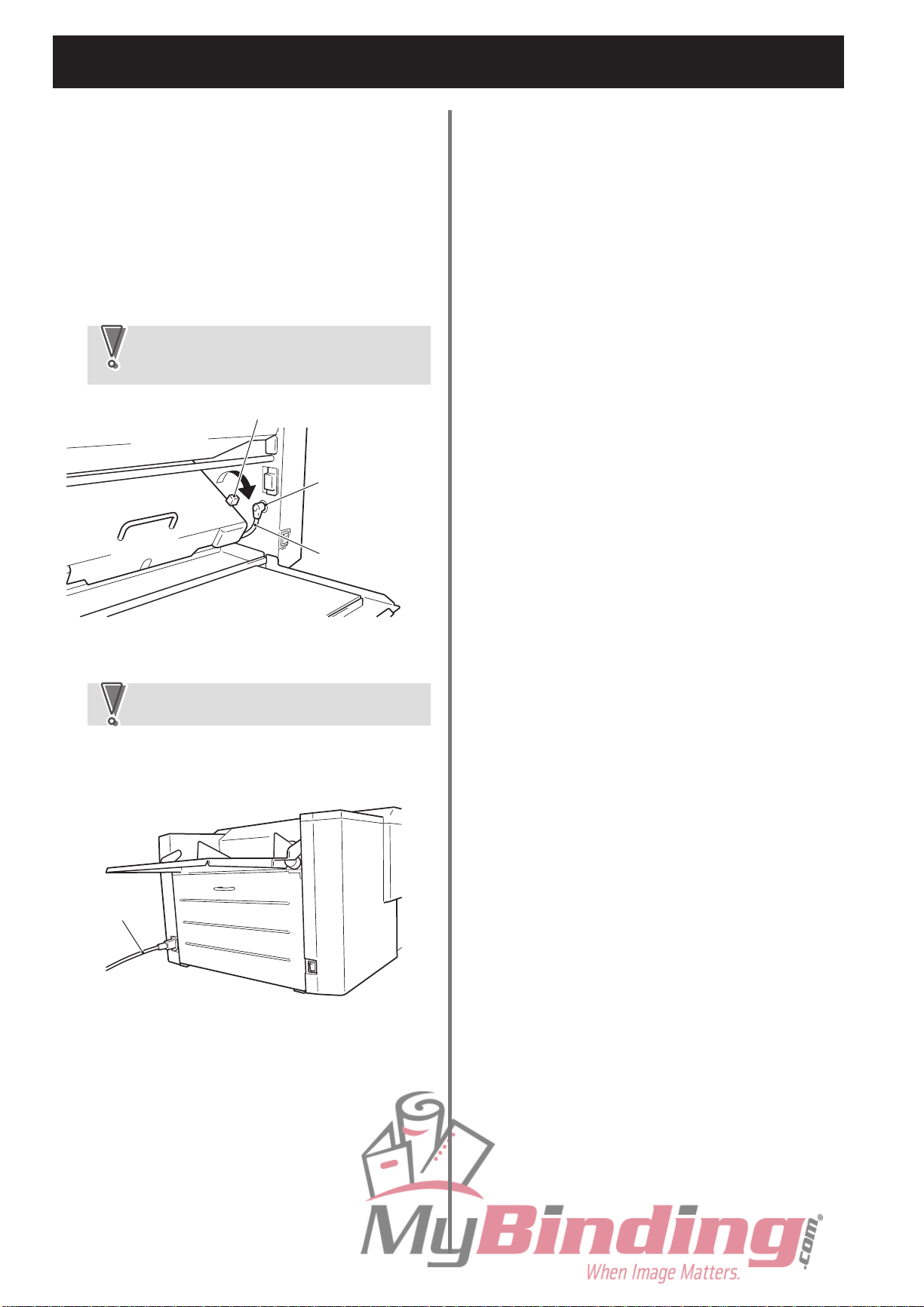

4. INSTALLATION

r Open the top cover, rotate the jam correction

knob to check that folding plate 1 is properly

secured. If the knob rotates smoothly, it means

that folding plate 1 is secured.

Top cover

Jam correction knob

t Connect control cord 1 of folding plate 1 to the

No.1 connector.

Be sure to turn off the power before

NoteNote

connecting or disconnecting the control

cord. Otherwise the unit will malfunction.

w Push the lock lever on folding plate 2 towards

“UNLOCK”.

UNLOCK

LOCK

e Push in folding plate 2 along the set guide to the

“2 ( )” mark. The safety stopper locks at this

position.

Be sure to insert the folding plate holding

NoteNote

the handle with both hands.

1

2

Folding plate 2

Attach folding plate 2.

6

q Open the side cover.

Set guide

Control cord 1

No.1 connector

r While slightly lifting folding plate 2 with the

handle, push in it to the “1 ( )” mark.

1

2

Folding plate 2

Side cover

9

Page 13

4. INSTALLATION

t Push the lock lever towards “LOCK”, and

secure folding plate 2.

y Move folding plate 2 up and down with the

handle to check that it is secured.

u Open the top cover, rotate the jam correction

knob to check that folding plate 2 is properly

secured again. If the knob rotates smoothly, it

means that folding plate 2 is secured.

i Connect control cord 2 of folding plate 2 to the

No.2 connector.

Be sure to turn off the power before

NoteNote

connecting or disconnecting the control

cord. Otherwise the unit will malfunction.

Lock lever

No.2 connector

o Close the side cover properly.

If the side cover is open, the unit will not

NoteNote

operate.

Connect the power cord to the unit.

7

Power cord

Control cord 2

Insert the power plug into the outlet.

8

10

Page 14

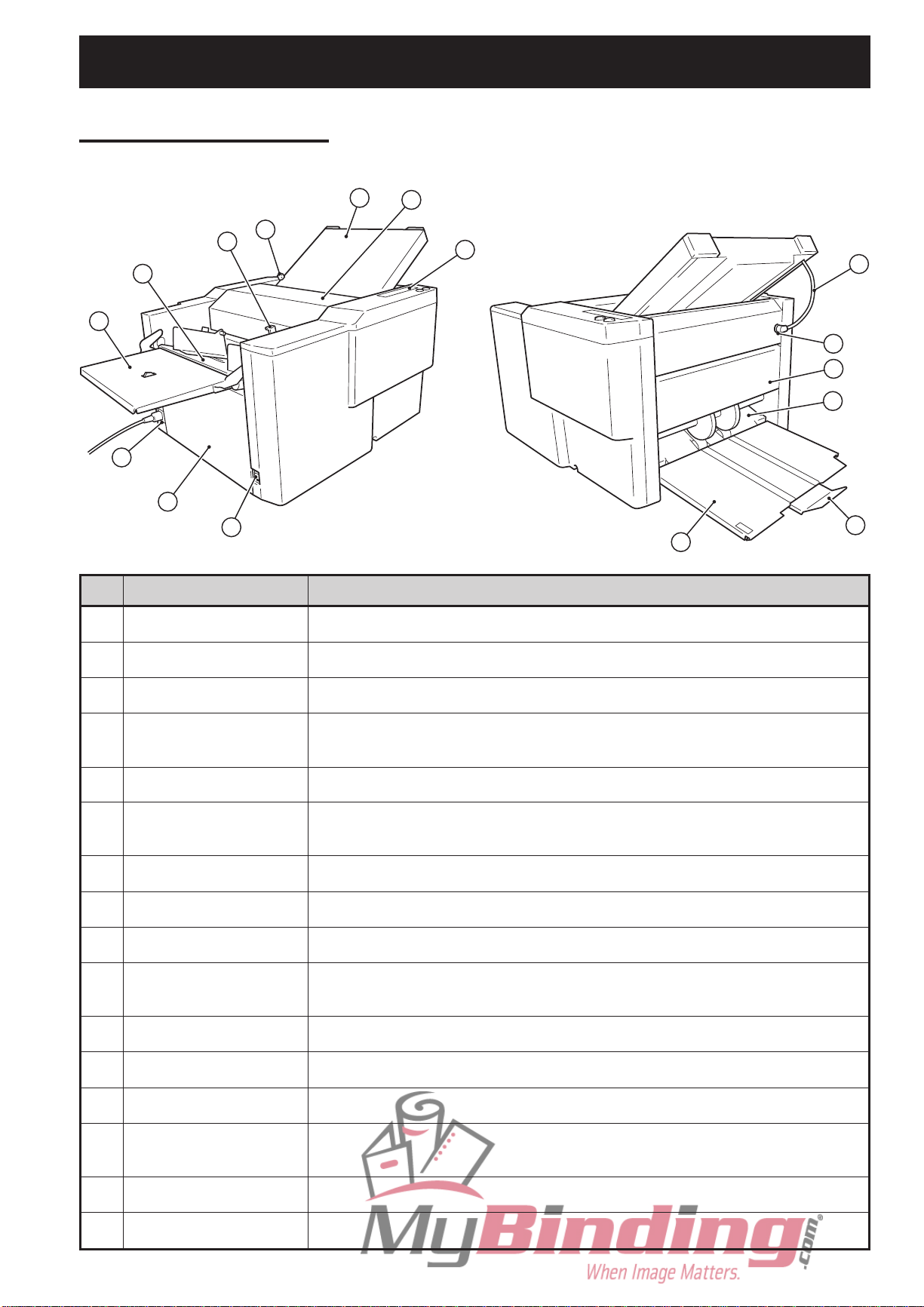

5. NAMES AND OPERATION OF PARTS

5-1. External Parts

<Paper feed side>

1

10

4

5

6

9

8

7

2

<Paper ejection side>

3

16

11

12

14

13

15

No.

q

Folding plate 1

Top cover

w

Control panel

e

Paper feed pressure

r

adjusting lever

Paper feed tray

t

Auxiliary paper feed

y

tray

Power switch

u

Side cover

i

Power inlet

o

Folding plate 1 lock

!0

lever

Name

Operation

Guide plate for deciding the paper folding position

Safety cover to prevent the user from touching the moving parts

For operating the unit

For adjusting the paper feed pressure

For stacking the paper to be folded

For ensuring paper are stacked on the paper feed tray properly

For turning on/off the power

For reducing operating sounds

For connecting external power

For securing folding plate 1

Control cord 1

!1

No.1 connector

!2

Paper ejection section

!3

Paper ejection section

!4

cover

Paper receiving stopper

!5

Paper receiving tray

!6

For controlling folding plate 1

For inserting control cord 1

Section which ejects folded paper from the unit

For reducing operating sounds from the paper ejection section

For aligning ejected paper

For receiving folded paper ejected out

11

Page 15

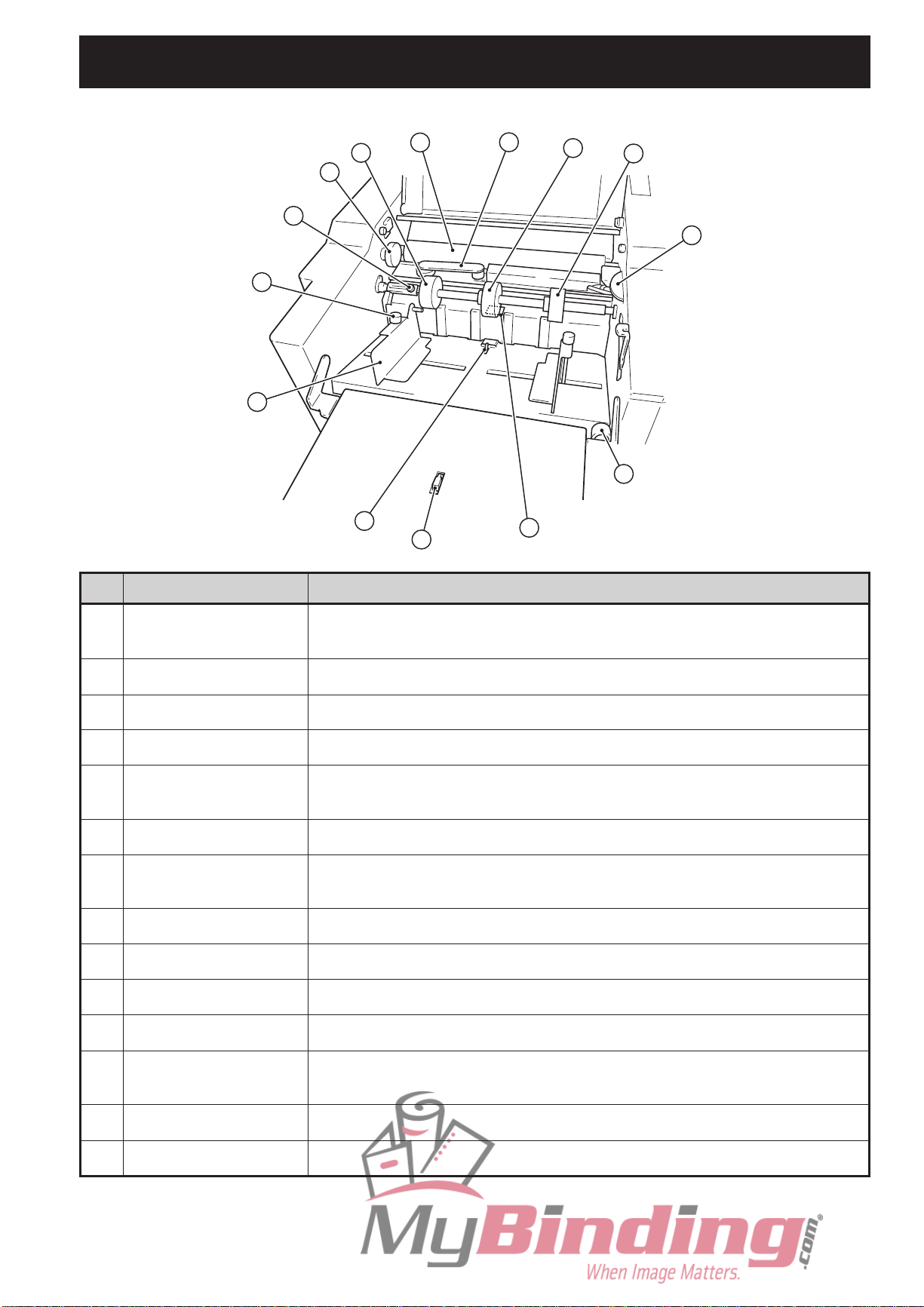

5. NAMES AND OPERATION OF PARTS

23

22

24

5-2. Internal Parts

<Inside side cover>

18

19

21

17

<Inside paper ejection section cover>

20

No. Name Operation

!7

Folding plate 2

!8

Folding plate 2 handle

Guide plate for deciding the paper folding position

For attaching/removing folding plate 2

Folding plate 2 lock

!9

lever

Control cord 2

@0

No.2 connector

@1

Stacker roller

@2

Stacker support

@3

Stacker belt

@4

For securing folding plate 2

For controlling folding plate 2

For inserting control cord 2

Functions together with the stacker belt to eject folded paper from the unit.

For supporting the stacker roller. The height of the roller can be adjusted.

For ejecting folded paper from the unit

12

Page 16

<Inside top cover>

31

25

27

34

35

28

5. NAMES AND OPERATION OF PARTS

26

30

29

36

37

No.

@5

Jam correction knob

Cross folding guide

@6

Set knob

@7

Folding roller

@8

Auxiliary paper feed

@9

ring

Paper feed ring

#0

Auxiliary paper feed

#1

ring (movable)

Paper switch 1

#2

Name

32

33

38

Operation

For rotating the folding rollers when paper has jammed inside the unit or when

cleaning the unit

For holding down the folded paper when cross folding

Screw for securing the auxiliary paper feed ring (movable)

For folding paper

For holding down curled paper for reliable paper feed

For feeding paper

Movable according to the paper size in cross folding

For detecting the presence of paper

Paper switch 2

#3

Guide fixing screw

#4

Paper feed guide

#5

Separating pressure

#6

adjusting dial

Skew correction knob

#7

Paper separator

#8

For detecting the presence of legal size paper

For securing the paper feed guide

For holding paper stacked on the paper feed tray firmly

For adjusting the paper separating pressure

For correcting skewed paper feed

For separating paper

13

Page 17

6. CONTROL PANEL

6-1. Names and Operation of Control Panel

13

14 15 16

12

11

10

8

9

No. Name Operation

7 6 5

3 2 1

4

Start key

q

Stop key

w

Test key

e

No. of sheets/Paper

r

length key

Clear key

t

Numerical keys (0 to 9)

y

Speed key

u

Folding plate 1 folding

i

stopper adjusting key

Press to start paper folding.

Press to stop paper folding.

Press to test fold two sheets of paper.

Press to switch between the mode for entering the number of sheets to be

processed and that for entering the paper length.

When entering the paper length, register the value entered with this key.

Press to change or erase the number of sheets to be processed or paper length

entered.

Press to enter the number of sheets to be processed or paper length.

Press to select the processing speed from five levels.

The processing speed needs to be changed according to the size and thickness

of the paper used.

Pressing the “+” key increases the speed. Pressing the “–” key decreases the

speed.

Press to adjust the position (folding position) of the folding stopper of folding

plate 1.

Every time the “+” key on the right is pressed, the folding stopper moves in

direction A shown in the figure on the next page. Every time the “–” key on the

left is pressed, the folding stopper moves in direction B shown in the figure on

the next page.

The folding stopper moves by 0.005" every time the key is pressed. Pressing this

key continuously moves the folding stopper continuously within the range set.

If the paper is more than ±0.2" of standard paper size, take it to be non-standard

size paper instead of adjusting the folding position with this key.

eSee

“ Correction range” (☞p.27)

14

Folding plate 2 folding

o

stopper adjusting key

Press to adjust the position (folding position) of the folding stopper of folding

plate 2.

Every time the “+” key on the left is pressed, the folding stopper moves in

direction A shown in the figure on the next page. Every time the “–” key on the

right is pressed, the folding stopper moves in direction B shown in the figure on

the next page.

The other functions are the same as the i Folding plate 1 folding stopper

adjusting key.

Page 18

No. Name Operation

6. CONTROL PANEL

!0

Adjustment registration

key

!1

Custom folding

registration key

!2

Custom folding

registration lamp

!3

Folding mode key

If the position of the folding stopper has been finely adjusted in standard folding

operations, the adjustment value can be registered with this key.

A total of 30 different adjustment values can be registered (6 standard folding

modes × 5 standard paper sizes). The registered data is preserved even after the

power is turned off.

To erase the registered data, select the paper size and folding mode to be

erased. Next press this key until the buzzer sounds “pi.pi...” for about two

seconds, and then press it continuously for another two seconds until the buzzer

sounds “pi...”. (Four seconds in total)

Press to register the position of the folding stopper and stacker roller which have

been moved when using custom folding modes.

Up to two individual paper folding modes can be registered for custom folding.

The registered data is preserved even after the power is turned off.

To erase the registered data, continue pressing the custom folding registration

key “1” or “2” registering the data to be erased until the buzzer sounds “pi...”.

When this lamp is lit, it means that the custom folding mode is registered.

The custom folding mode cannot be selected if it has not been registered with the

!1 Custom folding registration key.

Press to select the folding mode from six standard folding modes.

When the power is turned on, the lamp of the single-folding mode lights up. Each

time this key is pressed, the folding mode lamp lights up in order towards the

right.

If a custom folding mode is registered with the !1 Custom folding registration

key, the custom folding mode can be selected.

!4

Standard folding lamp

!5

Liquid crystal display

(LCD)

!6

Numerical display

(Counter)

Paper feed ring

Paper feed tray

Folding stopper

Displays the folding mode selected from six standard folding modes.

When a folding mode registered with the folding stopper position adjustment

value is selected, the corresponding lamp blinks.

Displays the size of standard paper stacked on the paper feed tray (LGR to INV),

paper length registered, and error messages.

Displays the paper length or number of sheets to be processed entered with the

numerical keys.

<Outline of paper folder>

Folding stopper

Folding rollers 1 to 4

B

A

Folding plate 1

1

Stacker roller

2

B

3

4

A

Folding plate 2

Flow of paper

15

Page 19

6. CONTROL PANEL

6-2. Description of LCD

(1) Example of LCD message in standard paper/standard folding

LTR +.O3O/-.O4O

STAND BY I

The “LTR” displayed at the top left of the screen indicates the paper size.

“+.030” indicates that the folding stopper of folding plate 1 is set 0.03" from the

automatically set position in direction A shown in the figure on the previous

page.

“–.040” indicates that the folding stopper of folding plate 2 is set 0.04" from the

automatically set position in direction B shown in the figure on the previous

page.

The “STAND BY” displayed at the bottom is the area where messages are

displayed.

When “I” or “REF” is displayed at the bottom right and “FIX” is displayed at the top

left, it means that these additional functions are currently being used.

“17. ADDITIONAL FUNCTIONS” (☞p.45)

eSee

(2) Example of LCD message in standard paper/standard folding (single folding)

LTR .OOO/ ···

STAND BY

As folding plate 2 is not used in single folding, the display area of the folding

stopper of folding plate 2 shows “· · ·”.

This indicates that the folding stopper of folding plate 2 is at the home position*.

* Home position means the starting position of the folding stoppers of folding plates 1 and 2.

(3) Example of LCD message in non-standard paper/standard folding

12.O +.O4O/-.O5O

STAND BY

“12.0” displayed at the top left of the screen indicates the paper length (unit:

inch).

“+.040” indicates that the folding stopper of folding plate 1 is set 0.04" from the

automatically set position in direction A shown in the figure on the previous

page.

“–.050” indicates that the folding stopper of folding plate 2 is set 0.05" from the

automatically set position in direction B shown in the figure on the previous

page.

(4) Example of LCD message in custom folding

CF-1 5.5O/2.75

STAND BY

Length of

folded plane

The “CF-1” displayed at the top left of the screen indicates that custom folding

mode 1 is selected.

“5.50” indicates that the length of the folded plane by folding plate 1 (see left

figure) will be about 5.5".

“2.75” indicates that the length of the folded plane by folding plate 2 will be about

2.75".

The value displayed by the LCD is an approximate, and the actual folded size

NoteNote

may differ according to the thickness and characteristics of the paper used.

16

Page 20

6. CONTROL PANEL

6-3. Energy Saving Mode Function

This unit has the following two functions for saving energy.

(1) Backlight automatic OFF function of LCD

The backlight of the LCD will go off automatically if the unit is not used for a certain period of time.

At shipment, the backlight is set to go off in 30 seconds.

(2) Power still ON alert function

If the unit is not used for a certain period of time, the buzzer will sound to indicate that the unit power is on.

NoteNote

At shipment, this function is set to OFF. To set it ON (enabled), contact your nearest dealer.

6-4. Types of Buzzer Sounds

This unit sounds the verification buzzer when keys on the control panel are pressed or when paper

has run out on the paper feed tray. The different types of buzzer are as follows.

“Pi”

Normal operating sound when the numerical key is entered, etc.

“Pi.Pi.Pi”

Warning buzzer to indicate operation error or that paper has run out.

“Pi...Pi...”

Indicates that the stop key has been pressed or the entered number of sheets to be processed has been reached.

“Pi.Pi...”

Indicates that a registration procedure (paper length registration, standard folding correction registration, custom

folding registration, etc.) has been completed.

“Pi...Pi...Pi...”

Indicates that problems such as paper jamming have occurred.

“Pi...”

Indicates that a registered value has been cleared.

17

Page 21

7. PRECAUTIONS PRIOR TO USE

The following explains precautions to be understood prior to using this unit.

7-1. Paper Used

If using folded or curled paper, flatten first prior to use.

NoteNote

Always pile up paper when storing. Also do not store paper in humid places.

Make sure that the printing ink on the paper has dried completely prior to use.

Otherwise, the ink will dirty the paper feed ring and folding roller, and this will not only lead to reduced folding

performance, but the ink will also adhere to and dirty the folded paper.

Use paper that has been cut at right angles.

Otherwise, problems such as folding misalignment will result.

Fan paper just copied or printed well

prior to use.

Paper just copied or printed contains considerable

static electricity, and if not fanned well, problems

such as double-feed will result.

In some cases, paper may not be fed smoothly into the folding plate due to the environment (temperature,

NoteNote

humidity), paper thickness, paper type, paper grain direction, paper states (curled, etc.), and processing speed,

etc., and as a result, the paper may not be folded properly.

In such cases, lower the processing speed, or improve the paper states (curled, etc.) before use.

18

Page 22

7-2. Precautions on Stacking Paper

7. PRECAUTIONS PRIOR TO USE

Do not stack paper on the paper feed tray

with the left and right sides of the paper

unaligned or some sheets protruding

out.

This unit has an automatic standard paper size

detection function. It automatically detects paper size

at the paper feed guides.

Therefore, if paper is protruding out from the left or

right side, it is unable to detect paper size accurately

and may determine standard paper as non-standard.

It may also result in problems such as paper feed

errors and folding misalignment, etc.

Be sure to align paper neatly when stacking.

Do not stack paper on the paper feed tray

with the lead and trail edges unaligned or

some sheets protruding out.

This will result in unstable paper feed, and result in

problems such as paper feed errors and folding

misalignment, etc.

Be sure to align paper neatly when stacking.

<Paper unaligned on

the left and right sides>

<Paper properly aligned>

<Paper unaligned at

the lead and trail edges>

7-3. Automatic Detection of Paper Size

Five standard paper sizes can automatically be detected by this unit: LGR, LGL, LTR, STMT,

and INV.

For paper to be automatically detected, paper must be set in the short edge feeding direction.

For some paper, stacking paper on the paper feed tray in the long edge feeding direction will result in paper

NoteNote

size detection error.

(For example, if LTR paper is stacked in the long edge feeding direction on the paper feed tray, it will be

detected as LGR size.)

When paper is stacked on the paper feed tray according to the corresponding paper size on the

tray scale, and the paper feed guides are secured at the scale position, the paper size is

automatically detected. The detectable range is within ±0.28".

When paper size is detected, it will be displayed at the top left of the LCD.

Fixing screw

Paper feed guides

Example of

LTR paper

Paper size

LTR .OOO/ .OOO

STAND BY

19

Page 23

7. PRECAUTIONS PRIOR TO USE

7-4. Automatic Rise/Descent of the Paper Feed Tray

When paper is stacked on the paper feed tray, the paper feed guides are set, and the start or

test key is pressed, the paper feed tray rises automatically.

When using large or heavy paper, the paper feed tray may not be able to rise due to the weight of the paper. In

NoteNote

such cases, stack less paper.

Paper feed guides

The paper feed tray descends automatically when paper is removed from the paper feed tray.

It will also descends automatically when paper runs out on the paper feed tray during a folding

operation.

Raising/lowering paper feed tray manually

To raise the paper feed tray, press the “+” key of the folding

plate 1 folding stopper adjusting key while pressing the stop

key. To lower, press the “–” key.

7-5. Checking the Front/Back, Top/End of Paper

Check how the paper was placed on the paper feed tray (front/back, top/end), because this will

affect the folding misalignment which may occur.

<Example> When paper with a white front and black back is finished in the following folding

modes

A

Lead edge of paper: A

Paper feed

direction

Single folding

B

Single-folded paper

Trail edge of paper: B

20

Paper stacked on

paper feed tray

Letter folding

A

B

Letter-folded paper

Page 24

7. PRECAUTIONS PRIOR TO USE

7-6. Using the “QUICK START”

The QUICK START at the end of this manual outlines the most common paper folding procedure

standard folding of standard paper to facilitate use of this unit, after having read this instruction

manual once.

Use it as follows.

Enlarge pages 1/2 and 2/2 of the QUICK START on a copy machine, and paste them on the wall

in front of the unit for reference when operating this unit.

Copy pages 1/2 and 2/2 in the same size, and place them in a plastic file for reference when

operating this unit.

NoteNote

When adding comments or changing the contents of the QUICK START, give consideration to safety.

8. PAPER FOLDING METHODS

The paper folding methods of this unit can broadly be divided into the following three types.

(1) Standard folding of standard paper

This is the basic paper folding operation of this unit. With this method, the “standard paper” designated by this

unit is set to the standard folding mode displayed on the control panel and paper folding is performed.

(2) Standard folding of non-standard paper (folding by entering paper length)

With this method, the length of paper other than the standard paper designated by this unit (this is called “nonstandard paper”) is registered, this paper is set to the standard folding mode displayed on the control panel, and

paper folding is performed. The length of the paper registered is calculated to match the standard folding mode,

and the positions (folding positions) of the folding stoppers of the folding plates are automatically set.

(3) Custom folding

Set the positions (folding positions) of the folding stoppers of folding plates 1 and 2 manually. As the stopper

position (folding position) can be specified, it allows non-standard folding to be performed freely.

There are certain restrictions (unfoldable areas) according to the paper length, folding plate length, etc. for the

NoteNote

above methods. For specific details of folding methods and restrictions, refer to the following chapters on

folding methods.

“9. STANDARD FOLDING OF STANDARD PAPER” (

“11. STANDARD FOLDING OF NON-STANDARD PAPER” (

“12. CUSTOM FOLDING” (

☞

☞

☞

p.22)

p.32)

p.35)

21

Page 25

9. STANDARD FOLDING OF STANDARD PAPER

Standard folding of standard paper is the basic operation of this unit.

9-1. Standard Paper

The standard paper designated by this unit

consists of the following five types: LGR, LGL,

LTR, STMT, and INV.

All of these sizes are valid only when stacked

on the paper feed tray in the short edge

feeding direction.

The above standard paper may not be usable for

NoteNote

certain paper thickness in some cases.

(Refer to “22. SPECIFICATIONS” (☞p.59).)

9-2. Standard Folding Modes

Six standard folding modes are available as shown below.

Single fold Double fold Irregular

accordion fold

Letter fold

Paper size L × W

Ledger (LGR) 17" × 11"

Legal (LGL) 14" × 8.5"

Letter (LTR) 11" × 8.5"

Statement (STMT) 8.5" × 7"

Invoice (INV) 8.5" × 5.5"

Accordion

fold

Brochure

fold

9-3. Operation Procedure

Turn on the power switch.

1

!

WARNING

Do not touch the power switch with

wet hands. Otherwise electric

hazards may occur.

Stack paper on the paper feed tray.

2

Do not overstack paper. Paper can be stacked up to a

height of approx. 1.8".

Push in the paper until the lead edge touches the

paper feed inlet lightly.

Power switch

ON

OFF

Max. stacking amount: Approx. 1.8"

22

Page 26

Move the paper feed guides to the

3

corresponding paper size on the paper

feed tray scale. Tighten the fixing

screws to secure.

The left and right paper feed guides move together.

Be sure to tighten the fixing screws of the left and right

paper feed guides. Otherwise, the guides will move

while the unit is operating, causing folding

misalignment along the sides of the paper.

Be sure to adjust the paper feed guides to the paper

feed tray scales. If the guides are positioned

incorrectly, the automatic paper size detection

function will not work, and the test key and start key,

etc. will not operate.

Do not press the paper with the paper feed

NoteNote

guides too strongly. Otherwise, paper feed

errors such as mis-feed will occur.

9. STANDARD FOLDING OF STANDARD PAPER

Fixing screw

Paper feed

guides

Example of

LTR paper

Check the paper size displayed at the

4

top left of the LCD.

Paper size will not be displayed even if standard paper

size is used if the paper feed guides are not set at the

designated positions.

Set the paper feed guides at the correct positions.

When set to the standard folding of non-standard

paper, the top left of the LCD will show values in inch.

For details on standard folding of non-

eSee

standard paper, refer to “11. STANDARD

FOLDING OF NON-STANDARD PAPER”

p.32).

(

☞

When set to the custom folding, the automatic paper

size detection function will not work and the paper size

will not be displayed.

“CF-1” or “CF-2” is displayed on the top left of the

LCD.

For details on custom folding, refer to “12.

eSee

CUSTOM FOLDING” (

Press the folding mode key to select

5

☞

p.35).

the folding mode.

<LCD message in standard paper/standard folding>

LTR .OOO/ .OOO

STAND BY

<LCD message in non-standard paper/standard folding>

12.O .OOO/ .OOO

STAND BY

<LCD message in custom folding>

CF-1 5.5O/2.75

STAND BY

For details of LCD messages, refer to “6-2.

eSee

Description of LCD” (

Custom folding

registration lamp

p.16).

☞

Standard folding lamp

Each time the folding mode key is pressed, the

standard folding lamp lights up in order from the

leftmost single folding lamp towards the right.

If custom folding data is registered, the custom folding

registration lamp will automatically light up after the

standard folding lamp.

If not registered, it will not light up.

23

Page 27

9. STANDARD FOLDING OF STANDARD PAPER

Set the paper feed pressure adjusting

6

lever to “0”.

Move the adjusting lever to the left and right while

pulling upwards.

If paper slips and mis-feed occurs, increase the paper

feed pressure by one from “0” to “1”.

Paper feed pressure increases as the scale value

increases.

If several sheets of paper are fed at the same time

(double-feed), decrease the paper feed pressure by

one from “0” to “–1”.

Open the top cover, and set the

7

separating pressure adjusting dial to

“0”.

After setting, close the top cover.

If several sheets of paper are fed at the same time

(double-feed), increase the paper separating pressure

gradually in steps of 0.5.

Paper separating pressure increases as the scale

value increases.

Top cover

Paper feed pressure adjusting lever

-1 1 2 3 4 5 6

0

3

4

2

5

1

6

0

Separating pressure adjusting dial

6

Press the speed key to set the

8

processing speed.

When using thin and flimsy paper, setting the

maximum processing speed causes problems such as

paper jam and deformed folding. Set a lower

processing speed.

When the power is turned on, the last processing

speed used is displayed.

Press the test key to perform test folding.

9

When the test key is pressed, “WAIT” is displayed on the LCD, and the folding stopper starts moving to the set position.

When it completes moving, the message changes to “TEST RUN”, and test folding starts.

Test folding feeds two sheets of paper and allows the finish to be checked.

Test folded paper are not counted in the number of sheets processed.

If the unit does not start even if the test key is pressed, the automatic paper size detection function may not

NoteNote

be working. Check if the paper feed guides are at the appropriate paper size on the scale.

When the automatic paper size detection function starts working, the paper size will be displayed on the

LCD.

(Refer to “7-3. Automatic Detection of Paper Size” (☞p.19).)

24

Folded paper

Page 28

9. STANDARD FOLDING OF STANDARD PAPER

Check the finish of test folding.

10

Check for folding misalignment using the second test

folded sample.

If folding problems occur, refer to the following pages

according to the folded state.

Folding misalignment along the vertical

length of the paper................................... (

Folding misalignment along the sides of

the paper ................................................. (

Deformed folding ..................................... (

Select the method of using the counter.

11

The counter can be used in two ways: subtract count and add count.

Enter the number of sheets to be processed using the numerical keys first before beginning operations. In this case, the

counter will be set to the subtract count method. (A period is displayed at the bottom right where the count is displayed.)

If the clear key is pressed to clear the counter to “0” before beginning operations, the counter will be set to the add count

method.

Up to four digits (9999) can be displayed.

☞

☞

☞

p.27)

p.26)

p.31)

<Normal folding>

<Folding misalignment along

vertical length of paper>

<Deformed folding>

<Folding misalignment

along sides of paper>

<Counter display for “Subtract count method”> <Counter display for “Add count method”>

Period

The following description is based on the subtract count method.

Press the numerical keys to enter the

12

number of sheets to be processed.

Press the start key to start folding.

13

To cancel operations halfway through, press the stop

key. Pressing the start key another time resumes

operations.

When the number entered is reached in folding

operations, the buzzer sounds “pi...pi...”, and paper

feed will stop automatically.

If the paper feed tray runs out of paper, the buzzer

sounds “pi.pi.pi”, and the unit will stop automatically.

25

Page 29

10. FOLDING MISALIGNMENT

Depending on the paper type, thickness, printing state, processing speed, etc., paper of the same

size may be folded differently and folding misalignment may occur.

Folding misalignment consists of two types; “folding misalignment along the sides of the paper”

and “folding misalignment along the vertical length of the paper”. Other than this, “deformed

folding” may also occur due to paper characteristics, etc.

The following describes how to correct folding misalignments and deformed folding.

Rotate the skew correction knob and

10-1. Correcting Folding Misalignment

Along Sides of Paper

When the folded paper is misaligned along

the sides as shown in the figure due to slight

misalignment when the paper was trimmed,

paper printing state, dirty folding roller, etc.,

correct using the skew correction knob of the

paper feed tray.

1

adjust.

When the folding misalignment is as shown in Figure

A, rotate the knob to the right (clockwise).

<Folding

misalignment A>

<Example of folding misalignment along sides of paper>

Folding misalignment at this part

Paper ejection direction

Before adjusting with the skew correction

knob, check that the paper feed guides are

set correctly. Gaps between the paper and

paper feed guides will cause folding

misalignment along the sides to occur

easily.

Fixing screw

Paper feed guides

Paper ejection

direction

Skew correction knob

When the folding misalignment is as shown in Figure

B, rotate the knob to the left (counter-clockwise).

<Folding

misalignment B>

Paper ejection

direction

After completing folding operations,

2

Skew correction knob

return the skew correction knob to the

standard position.

26

The position at which the round hole of the paper feed

tray and pin match is the standard position.

<Standard

position>

Round hole

Pin

Skew correction knob

Page 30

10. FOLDING MISALIGNMENT

10-2. Correcting Folding Misalignment Along Vertical Length of Paper

When the folded paper is misaligned along

the vertical length as shown in the figure due

to the paper thickness, type, printing state,

<Example of folding misalignment along

vertical length of paper>

Folding misalignment

at this part

etc., adjust the positions of the folding

stoppers of folding plates 1 and 2 to correct

the misalignment.

Paper ejection direction

Adjust the positions of the folding stoppers using the folding stopper adjusting keys of folding

plates 1 and 2 on the control panel.

Pressing the “+” key moves the folding stoppers of folding plates 1 and 2 in the A direction of the

figure. Pressing the “–” key moves in the B direction of the figure.

Each press moves the folding stopper by 0.005".

(One folding stopper is provided inside folding plates 1 and 2 respectively. Folding stoppers

cannot be seen from outside.)

Values corrected by the folding stopper adjusting keys are displayed at the top of the LCD.

Folding stopper

Folding plate 1

folding stopper adjusting key

Folding plate 2

folding stopper adjusting key

Paper feed ring

Paper feed tray

Folding stopper

Folding rollers 1 to 4

1

2

B

LTR +.O3O/-.O4O

STAND BY

A

Folding plate 2

Corrected values can be registered using the adjustment registration key.

eSee

“ Adjustment registration procedure” (☞p.30)

Corrected values cannot be registered in the standard folding of non-standard paper. To register the folding

NoteNote

stopper position, use the custom folding registration function.

Correction range

A

B

Folding plate 1

Stacker roller

3

4

Flow of paper

For standard folding, the adjustable range

using the folding stopper adjusting key is

within ±0.2" from the center of the paper.

If set exceeding ±0.2", the LCD shows “OUT

OF CORRECT”, and the folding stoppers

will stop at the ±0.2" position of the

adjustable range.

Correction by the “+” key

Within +0.2"

Paper

Center

Correction by the “–” key

Within –0.2"

Conveyance direction

27

Page 31

10. FOLDING MISALIGNMENT

Correction restrictions

The positions of the folding stoppers of folding plates 1 and 2 may not be adjustable to ±0.2"

according to the length of the paper used. This restriction is due to the length of the paper and

length of folding plates 1 and 2.

The restricted folding plate and correction details differ according to the folding mode and paper

length. Refer to the following table.

Folding

mode

Double fold

Irregular

accordion fold

Letter fold

Accordion

fold

Brochure fold

*Range of paper length which cannot be corrected to ±0.2". The correction value differs according to the paper length.

If the correction value is within the restricted

range when this correction value is set using

Minimum paper length

that can be used

7.2"

7.2"

5.6"

5.6"

5.1"

Restricted range of

paper length*

7.2" to 8.1"

7.2" to 7.4"

7.2" to 8.1"

5.6" to 6.0"

5.6" to 6.1"

16.8" to 17.0"

16.7" to 17.0"

Restricted folding plate and

correction details

Correction by “–” key of folding plate 2

Correction by “–” key of folding plate 1

Correction by “–” key of folding plate 2

Correction by “–” key of folding plate 2

Correction by “–” key of folding plate 2

Correction by “+” key of folding plate 1

Correction by “+” key of folding plate 2

LTR +.O3O/ ···

OUT OF CORRECT

the folding stopper adjusting key, the buzzer

sounds “pi.pi.pi” and the LCD displays “OUT

OF CORRECT”.

The message then changes to “STAND BY”.

Set a valid correction value using the folding

stopper adjusting key.

28

Page 32

10. FOLDING MISALIGNMENT

Example of correcting folding misalignment along vertical length of paper by folding mode

Correct folding misalignment along the vertical

length of the paper in standard folding using

the folding stopper adjusting keys of folding

Folding plate 1

folding stopper adjusting key

plates 1 and 2, referring to the following

example.

The positions of the “+” and “–” folding stopper

NoteNote

adjusting keys of folding plates 1 and 2 are

located opposite to each other.

Folding plate 2

folding stopper adjusting key

Adjusting key of folding plate 1

Folding mode Correction method

A

Single foldDouble fold

Ejection direction

A

Ejection direction

A

Irregular

Ejection direction

accordion fold

A

Letter foldAccordion foldBrochure fold

Ejection direction

State of

folded plane A

A is long

A is short

A is long

A is short

A is long

A is short

A is long

A is short

A is long

Press the “+” key.

Press the “–” key.

Press the “+” key.

Press the “–” key.

Press the “–” key.

Press the “+” key.

Press the “+” key.

Press the “–” key.

Press the “–” key.

Adjusting key of folding plate 2

Folding mode Correction method

∗ Folding plate 2 is not used in single folding.

Single foldDouble fold

B

Ejection direction

B

Irregular

Ejection direction

accordion fold

B

Letter foldAccordion foldBrochure fold

Ejection direction

B

State of

folded plane B

B is long

B is short

B is long

B is short

B is long

B is short

B is long

Press the “–” key.

Press the “+” key.

Press the “–” key.

Press the “+” key.

Press the “+” key.

Press the “–” key.

Press the “+” key.

A

Ejection direction

A

Ejection direction

A is short

A is long

A is short

Press the “+” key.

Press the “+” key.

Press the “–” key.

Ejection direction

B

Ejection direction

B is short

B is long

B is short

Press the “–” key.

Press the “+” key.

Press the “–” key.

The folding stopper moves by 0.005" every time the folding stopper adjusting key is pressed.

Pressing the adjusting key continuously moves the folding stopper continuously within the

range set.

The standard adjustable range is within ±0.2". Some paper may not be correctable in this range

due to restrictions.

eSee

“ Correction restrictions” (☞p.28)

When correction of more than ±0.2" from the standard paper size is required, consider such

paper as non-standard paper.

eSee

“11. STANDARD FOLDING OF NON-STANDARD PAPER” (☞p.32)

29

Page 33

10. FOLDING MISALIGNMENT

Adjustment registration procedure

The adjustment value of folding misalignment along the vertical length of the paper can be

registered using the adjustment registration key.

A total of 30 different adjustment values can be registered (6 standard folding modes × 5

standard paper sizes (LGR, LGL, LTR, STMT, and INV)).

By registering adjustment, no adjustments need to be performed when performing folding

operations under the same conditions (paper, folding mode, processing speed, etc.) as those at

registration.

The adjustment registration function cannot be used for standard folding of non-standard paper and custom

NoteNote

folding. Use the custom folding registration function.

Stack paper on the paper feed tray, and

1

set the paper feed guides.

Fixing screw

Paper feed guides

Press the folding mode key to select

2

the folding mode.

Each time the folding mode key is pressed, the

standard folding lamp lights up in order towards the

right. Folding modes whose lamps are blinking

indicate that adjustment registration has been

performed.

Standard folding lamp

Check for folding misalignment along

4

the vertical length of the paper from the

test folding results.

Check for folding misalignment using the second test

folded sample.

Folded paper

Correct folding misalignment along the

5

vertical length of the paper using the

folding stopper adjusting keys of

folding plates 1 and 2. (

☞

p.27)

Press the test key to perform test

3

folding.

Test folded paper are not counted in the number of

sheets processed.

30

After adjusting the folding

6

misalignment, press the adjustment

registration key until the buzzer

sounds “pi.pi...” (about two seconds).

When adjustment registration completes, the lamp of

the folding mode selected stops lighting and starts to

blink.

The adjustment value data registered is preserved

even after the power is turned off.

Blinking (End of adjustment registration)

Page 34

10. FOLDING MISALIGNMENT

Correcting adjustment registration data

When the registration data of the paper size and folding mode

to be corrected is set again and registered according to the

above steps 1 to 6, the previous data will be rewritten.

Erasing adjustment registration data

Display the registration data of the paper size and folding

mode to be erased, and press the adjustment registration

key until the buzzer sounds “pi.pi...” for about two seconds,

and continue pressing for another two seconds until the

buzzer sounds “pi...” (total four seconds).

When the registration data is erased, the lamp of the folding

mode selected stops blinking and lights up.

The adjustment registration data must be erased

NoteNote

by registered paper size and folding mode. The

data cannot be erased for all sizes and modes

together.

Lit (When adjustment registration is erased)

(1) Is appropriate paper within the

specifications used?

Do not use paper outside the specifications.

Particularly, deformed folding occurs frequently in

the use of thin, flimsy paper not appropriate for the

paper folder.

“22. SPECIFICATIONS” (☞p.59)

eSee

(2) Is the processing speed too fast?

Lower the processing speed when deformed

folding occurs for thin and flimsy paper.

(3) Was the paper fanned appropriately

prior to stacking on the paper feed

tray?

Fan paper well prior to stacking.

10-3. Correcting Deformed

Folding

The paper fed to the folding plates may be

folded without reaching the folding stoppers

inside the folding plates due to the using

environment (temperature, humidity), paper

thickness, paper type, paper grain direction,

paper state such as curling, processing speed,

etc., resulting in deformed folding.

If this occurs, check the following.

<Example of deformed folding>

(4) Is the paper stacked correctly on the

paper feed tray?

Stack paper on the paper feed tray after aligning

well, and set the paper feed guides at the correct

positions. Also tighten the fixing screws of the

paper feed guides firmly.

Fixing screw

Paper feed guides

31

Page 35

11. STANDARD FOLDING OF NON-STANDARD PAPER

Standard folding of non-standard paper is the process of registering the length of non-standard

paper, setting the paper to a standard folding mode (six types) displayed on the control panel.

Non-standard paper

Paper other than the five standard paper specified by this unit LGR, LGL, LTR, STMT, and INV are called non-standard paper.

Standard paper size is the size of the paper stacked on the paper feed tray in the short edge feeding direction.

NoteNote

Standard paper which is stacked on the paper feed tray in the long edge feeding direction is considered nonstandard paper.

Standard folding

Six standard folding modes are available as shown below.

Single fold Double fold Irregular

accordion fold

11-1. Paper Size Restrictions

Paper sizes which can be used are the sizes

within the range shown on the right.

( ) shows the minimum foldable size under

conditions given.

“15-3. Folding Small Size Paper” (☞p.43)

eSee

The paper sizes which can be used may vary

NoteNote

with the paper type, thickness, and printing

state.

11-2. Operation Procedure

Stack paper on the paper feed tray, and

1

set the paper feed guides.

Letter fold Accordion

fold

Paper feed direction

Paper

Width: 5.1" (3.0") to 11.7"

Fixing screw

Brochure

fold

Length: 7.2" (5.1") to 17.0"

Paper feed guides

32

Page 36

11. STANDARD FOLDING OF NON-STANDARD PAPER

Press the No. of sheets/Paper length

2

key to switch from the mode for

entering the number of sheets to be

processed to the mode for entering the

paper length.

When switched to the mode for entering the paper

length, the LCD shows “REGISTER LENGTH” and the

numerical display shows “L. 0”.

Using non-standard paper in settings for

NoteNote

standard paper will result in detection

errors due to the priority functioning of the

automatic paper size detection, and the

unit will not operate.

Measure the length of the non-standard

3

paper used, and enter the length using

the numerical keys.

The paper length which can be entered ranges from

5.1" to 17.0".

If the value entered exceeds the allowable range, the

buzzer sounds “pi.pi.pi”, and the LCD shows “TOO

LONG” or “TOO SHORT”.

.OOO/ .OOO

REGISTER LENGTH

.OOO/ .OOO

TOO LONG

If the paper length has already been

NoteNote

entered, press the clear key to clear this

value before entering the length with the

numerical keys.

Register the entered paper length.

4

After entering the paper length, continue pressing the

No. of sheets/Paper length key until the buzzer

sounds “pi.pi...” (about two seconds).

When registration completes, the value entered is

shown on the LCD in inch. The numerical display

switches to number of sheets to be processed.

The paper length data registered is erased

NoteNote

when the power is turned off.

To save the registered data, set the refold

mode or folding stopper fixed mode.

(Refer to “17-2. Folding Stopper Operation

Mode Setting Function” (

☞

.OOO/ .OOO

REGISTER LENGTH

p.46).)

12.O .OOO/ .OOO

STAND BY

33

Page 37

11. STANDARD FOLDING OF NON-STANDARD PAPER

Press the folding mode key to select

5

the folding mode.

The registered paper length is calculated to match the

selected standard folding mode, and the positions

(folding positions) of the folding stoppers of folding

plates 1 and 2 are calculated.

Press the test key to perform test

6

folding.

The folding stoppers of folding plates 1 and 2 move to

the folding positions calculated in step 5, and test

folding starts.

Test folded paper are not counted in the number of

sheets processed.

Check the finish of test folding.

7

Check the finish using the second test folded sample.

When folding misalignment occurs, refer to “10.

FOLDING MISALIGNMENT” (

In the standard folding of non-standard

NoteNote

paper, the positions of the folding stoppers

can be adjusted, but the adjustment values

cannot be registered. To register the

positions of the folding stoppers, use the

custom folding registration function.

(Refer to “12. CUSTOM FOLDING”

p.35).)

(

☞

☞

p.26).

Folded paper

Other steps are the same as standard folding of standard paper.

“9. STANDARD FOLDING OF STANDARD PAPER” (☞p.22)

eSee

To return to standard paper standard folding

settings

Press the No. of sheets/Paper length key.

The paper size displayed in inch at the top left of the LCD

disappears.

STAND BY

.OOO/ .OOO

34

Page 38

12. CUSTOM FOLDING

Custom folding is the method of folding paper

by setting the positions (folding positions) of

the folding stoppers of folding plates 1 and 2

manually. As the folding position can be

specified, folding methods not available with

standard folding can be performed freely.

<Standard single folding> <Example of

custom single folding>

12-1. Paper Size Restrictions

Paper sizes which can be used are the sizes

within the range shown below.

( ) shows the minimum foldable size under

conditions given.

The paper sizes which can be used may vary

NoteNote

with the paper type, thickness, and printing

state.

Paper feed direction

12-2. Operation Procedure

The following describes the custom folding

procedure taking accordion fold as an

example.

Prepare a sample of the required

1

accordion fold manually with the paper

used.

Measure the dimensions of the folded

2

planes A and B of the sample, and

folded paper length C.

C (4.33")

B

(3.74")

Press the custom folding registration

3

key 1 or 2 until the buzzer sounds

“pi.pi...” (about two seconds) to switch

to the custom folding mode.

A

(3.35")

Paper feed

direction

Paper

Width: 5.1" (3.0") to 11.7"

Length: 7.2" (5.1") to 17.0"

However, the length of the folded plane (see

figure below) which can be folded by folding

plates 1 and 2 is restricted.

Folding plate 1: 1.65" to 12.79"

Folding plate 2: 0"*/1.85" to 8.54"

* As folding plate 2 is not used in single folding, it is 0".

Length of

folded plane

Be sure to press the custom folding

NoteNote

registration key before starting custom

folding settings.

Stack paper on the paper feed tray, and

4

set the paper feed guides.

Fixing screw

Paper feed guides

Incorrectly measuring the paper length or

NoteNote

setting the folding stopper position can cause

paper jamming inside the folding plate. If paper

jams, refer to “18-3. When Paper Jams Inside

Folding Plate” (

☞

p.49).

35

Page 39

12. CUSTOM FOLDING

Set the folding stopper positions of

5

folding plates 1 and 2.

Press the “+” key of the folding plate 1 folding stopper

adjusting key and move the folding stopper to the

measured dimensions A (3.35") of the sample.

Press the “+” key of the folding plate 2 folding stopper

adjusting key and move the folding stopper to the

measured dimensions B (3.74") of the sample.

The position moved to by the folding stopper is

displayed in inch on the LCD.

Set the position of the stacker roller.

6

The position of the stacker roller needs to be changed

according to the folded paper length.

Selecting and pressing a numerical key (1 to 6) while

pressing the stop key moves the stacker roller to the

position set.

Refer to the following table for approximate set

positions.

In this example, the folded paper length C is 4.33".

Therefore press the numerical key 3 while pressing

the stop key.

CF-1 3.35/3.74

STAND BY

Paper ejection section cover

Stacker roller

Approximate stacker roller set position

Numerical

key setting

1

2

3

4

5

6

Checking the stacker roller position

Press the No. of sheets/Paper length key while pressing

the stop key. The LCD shows the position of the stacker

roller in the value set using the numerical key.

Folded paper

length

To 3.35"

3.36" to 4.13"

4.14" to 4.72"

4.73" to 5.31"

5.32" to 5.91"

From 5.92"

CF-1 3.35/3.74

STAND BY

CF-1 3.35/3.74

STACKER ROLLER:3

Opening/closing the paper ejection section cover

Set the position of the stacker roller by opening the paper ejection section cover, and checking the movement of the stacker

roller visually.

After setting, be sure to close the paper ejection section cover. If not closed, operating the test key or start key shows

“DELIVERY COVER” on the LCD, and this unit will not operate.

36

Page 40

Press the test key to perform test

7

folding.

Test folded paper are not counted in the number of

sheets processed.

Check the finish of test folding.

8

Check the finish using the second test folded sample.

If the folding position needs to be adjusted, set the

position of the folding stopper again using the folding

stopper adjusting keys of folding plates 1 and 2.

If paper is not ejected smoothly, change the position of

the stacker roller.

12. CUSTOM FOLDING

Folded paper

After completing all settings, register

9

the custom folding setting.

Continue pressing the custom folding registration key

1 or 2 until the buzzer sounds “pi.pi...” (about two

seconds).

The registered data is preserved even after the power

is turned off.

Other steps are the same as standard folding of standard paper.

“9. STANDARD FOLDING OF STANDARD PAPER” (☞p.22)

eSee

37

Page 41

13. CROSS FOLDING

Cross folding is folding single-folded paper

another time as shown in the figure. Many

cross folding styles are available according to

settings.

<Cross single folding>

<Single folding>

<Cross brochure folding>

13-1. Cross Folding Methods

The following three cross folding methods are

available on this unit.

13-2. Precautions on Cross

Folding

Pay attention to the following in cross folding.

The maximum thickness of paper used is

28 lb.

The maximum thickness depends on conditions such

as using environment (temperature, humidity), paper

size, paper type, paper grain direction, paper printing

state, etc.

Press along the folded line of singlefolded paper with the fingers.

If the folded line is not folded properly, paper feed will

be unstable.

(1) Cross folding of standard paper

Standard paper consists of five types LGR, LGL,

LTR, STMT, and INV (short edge feeding of paper)

and is paper whose size can be automatically

detected.

(2) Cross folding of non-standard paper

Non-standard paper is paper other than standard

paper specified by this unit. It is paper within the

following size range.

( ) shows the minimum foldable size under

conditions given.

Paper feed direction

Paper

Width: 5.1" (3.0") to 11.7"

Length: 7.2" (5.1") to 17.0"

Paper ∑ dent and folding misalignment along the

NoteNote

sides of the paper may occur if the folded line of

single-folded paper is not folded properly or

according to the using environment

(temperature, humidity), paper thickness, paper

size, paper type, paper grain direction, etc. This

is not a malfunction of the unit.

∑ dent

(3) Cross folding of paper at desired

folding position

This is the cross folding of standard and nonstandard paper at the desired folding position.

Both standard and non-standard paper are

processed in the same way, and the folding

position is registered in the custom folding mode.

38

Page 42

13-3. Cross Folding of

Standard Paper

13. CROSS FOLDING

Open the top cover, move the auxiliary

4

paper feed ring (movable) to the folded

line of the paper, and secure it.

The following describes the cross folding of

standard paper, taking cross single folding

shown in the figure as an example.

Cross folding

Single fold standard paper according

1

to the procedure of “9. STANDARD

FOLDING OF STANDARD PAPER”

(

p.22).

☞

To prevent folding misalignment along

2

the sides of the paper and feed paper

smoothly, fold the folded line of the

single-folded paper firmly with the

fingers.

Move the auxiliary paper feed ring by loosening the set

knob. After moving, tighten the set knob to secure.

Auxiliary paper feed ring

Set knob

Set the separating pressure adjusting

5

dial to “0”.

Set the paper separating pressure as low as possible.

Setting it high will cause the single-folded paper to

open during paper feed, resulting in paper feed error.

Paper separating pressure decreases as the scale

value decreases.

(movable)

Top cover

Stack the single-folded paper on the

3

paper feed tray with the folded line