Page 1

Duplo DF-755

Manual Setting Desktop

Paper Folder

Instruction Manual

Page 2

INSTRUCTION MANUAL

Be sure to read this manual prior to use.

Please leave this manual at the site of use for easy reference.

Duplo Folder

[120 V]

Page 3

“This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

–Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

–Consult the dealer or an experienced radio/TV technician for help.“

Page 4

3

Introduction

Thank you for purchasing a Duplo product.

Be sure to read this manual prior to using the product.

Af

ter reading, leave the manual at the site of use for easy reference whenever questions related to the

product arise in the future.

Symbols

In this manual, several symbols are used to indicate important warnings. Please make sure to read

instructions accompanied by these symbols. These symbols have the following

meanings.

Describes instructions which must be followed in use.

Be sure to read the instructions to avoid problems due to incorrect operations.

Indicates supplementary or useful information.

Describes names of related items and supplementary instructions.

Trademark

The product name and company name used in this manual are trademarks or registered trademarks

of the respective companies.

Page 5

i

Safety Precautions

In this manual, operations and handling of the unit which are hazardous are described using the

following marks to prevent personal injury or property damage to the user and others.

Ignoring this mark could result in the possibility of

serious injury or even death.

Ignoring this mark could result in the possibility of injury

or physical damage.

This mark indicates a “Warning” or “Caution”.

A graphic may be shown inside the mark to describe the warning or caution more specifically.

This mark indicates a forbidden action.

A graphic may be shown inside the mark to describe the forbidden action more specifically.

This mark indicates actions that must be performed.

A graphic may be shown inside the mark to describe the action to be performed more specifically.

Power Supply

● This unit shall be installed near the socket-outlet where the plug on the power supply cord is easily

accessible.

● Make sure the power supply used is always within the following range.

Power supply : 120 V AC, 60 Hz

● When you power other appliances from the same AC outlet, make sure that the combined power

consumption does not exceed the power supply capacity.

Rated current (Rated power) : 0.85 A

● The equipment must be reliably connected to an earthed main socket-outlet.

Use only the power supply voltage specified on the main nameplate.

Using other voltages could result in a fire or an electrical shock.

Make sure that the combined power consumption of the appliances to be

connected does not exceed the capacity rating of the power outlets or plug

receptacles.

Exceeding the capacity rating could cause the power outlets, plug receptacles, or power extension

cords to overheat and catch a fire.

Page 6

ii

Safety Precautions

Operating Environment

Operate this unit in the following environment.

● where the temperature range is between 41 and 95°F (14 to 122°F in storage)

● where the humidity range is between 20 and 85% RH (10 to 90% RH in storage, however no

condensation)

●

which is not subject to direct sunlight

● which is reasonably free from dust

● which is subject to little or no vibration

● which is free from air-borne salt

● where there are no harmful chemicals

● where the unit is not exposed to water

Keep this unit and the power cord away from heaters and heater vents.

Excessive heat could melt the cover or power cord covering, and result in a fire or an electrical shock.

Do not place metal objects or vessels containing liquids on top of the unit.

The entry of any metal object or liquid could result in a fire or an electrical shock.

Do not insert any metal or easily-combustible object inside this unit.

This could result in a fire or an electrical shock.

Do not use flammable sprays inside or near the unit (e.g. when cleaning the

unit).

Such flammable gas may ignite and cause a fire or combustion.

Do not install this unit in a location where there is excessive humidity or where

contact with water is possible.

Poor choice of location could result in deterioration of the insulation, a fire or an electrical shock.

Install this unit on a level, stable stand or floor, with sufficient space around it.

Failure to do so could result in the unit overturning and causing injury.

Disconnect the power plug from the power outlet before attempting to move

this unit.

Failure to do so could result in power cord damage, a fire or an electrical shock.

Always disconnect the power plug from the power outlet when the unit is not

to be used for an extended period.

Failure to do so could result in a fire due to leakage current if the insulation should deteriorate.

Page 7

iii

Safety Precautions

Maintenance / Other

Do not damage the power cord or power plug.

Do not scratch, alter, bend, twist, pull or place heavy objects on the power cord or power plug.

This could result in damage, a fire or an electrical shock.

Do not touch the power switch with wet hands.

Otherwise electric hazards may occur.

Do not remove the cover or back panel.

This unit contains high-voltage components that could cause an electrical shock.

Do not disassemble, modify or repair this unit.

There is a danger of fire, electrical shock or injury.

Contact your dealer when repairs are necessary.

If any foreign object such as metal or liquid should enter this unit, immediately

turn the unit off at the power switch and disconnect the power plug from the

power outlet.

Failure to do so could result in a fire or an electrical shock.

Contact your dealer immediately.

Before cleaning this unit, turn the unit off at the power switch and disconnect

the power plug from the power outlet.

Accidental operation of the unit during cleaning could result in injury.

Remove any dust that accumulates on the power plug prongs and the surface

of the plug from which the prongs extend.

Accumulated dust could result in a fire.

Always grip the plug when disconnecting the power plug from the power

outlet.

Forcibly pulling on the power cord could cause damage, resulting in a fire or an electrical shock.

Do not touch or insert foreign objects into any rotating part during operation.

This could result in injury.

Page 8

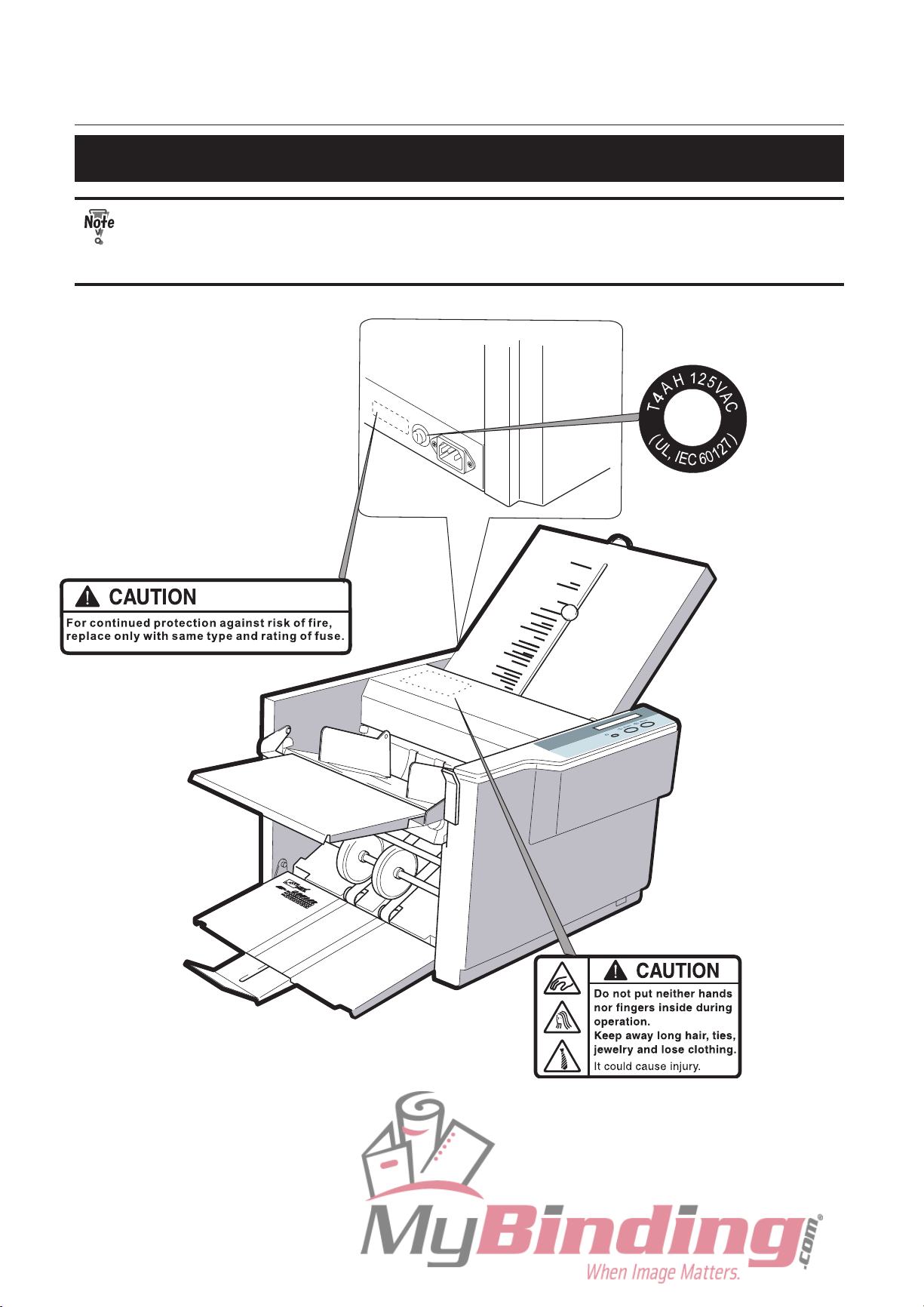

iv

Safety Precautions

WARNING / CAUTION Labels

"WARNING" and "CAUTION" labels are pasted on the machine to ensure user safety.

Do not remove or change them.

When the labels become dirty or are lost, be sure to contact your dealer for a new one.

When changing a huse, make

sure that the fuse rating is same

as that indicated on this label.

Page 9

v

Contents

Introduction ................................................3

Safety Precautions .....................................i

Power Supply ...................................................... i

Operating Environment .......................................

ii

Maintenance / Other ...........................................iii

WARNING / CAUTION Labels

...........................iv

Chapter 1

BEFORE OPERATION

1. Features .............................................1-2

2. Setting Up the Machine ....................

1-3

2-1. Components .......................................... 1-3

2-2. Removing the Press Release Lever ......

1-3

2-3. Locking the Bearing Support Levers .....

1-4

2-4. Attaching the Parts ................................ 1-5

3. Names and Functions ......................1-7

4. Describing Control Panel .................

1-9

5. Handling Paper ...............................

1-10

5-1. Paper Used ......................................... 1-10

5-2. Precautions on Stacking Paper ........... 1-10

6. Emergency Stop .............................1-12

Chapter 2

BASIC OPERATION

1. Standard Folding of Standard

Paper ..................................................2-2

1-1. Standard Paper ..................................... 2-2

1-2. Standard Folding ................................... 2-2

1-3.

Operation Procedures ........................... 2-3

Chapter 3

ADVANCED OPERATION

1. Single Folding of Standard Paper ...3-2

1-1. Single Folding Thick Paper ................... 3-2

1-2. Double Folding Thick Paper .................. 3-4

1-3. Double Folding Small

Thin Paper .........3-7

2. Custom Folding of Standard

Paper ................................................3-10

3. Standard Folding of

Non-Standard Size Paper ...............3-14

4. Cross Folding ..................................

3-18

4-1. Cross Folding Standard Size Paper .... 3-18

4-2. Cross Folding Non-Standard Size

Paper ................................................... 3-23

Chapter 4

TROUBLESHOOTING

GUIDE

1. Correcting Folding Misalignment ....4-2

1-1. Correcting Folding Misalignment along

Vertical Length of Paper ........................ 4-2

1-2. Correcting Folding Misalignment along

Sides of Paper .......................................

4-4

1.3 Correcting Deformed Folding ................ 4-5

2. Removing Jammed Paper ................4-6

2-1. When Paper Has Jammed Near

the Paper Feed Ring ............................. 4-6

2-2. When Paper Has Slipped at the Paper

Feed Section .........................................

4-6

2-3. When Paper Has Coiled Around the

Rubber Roll ...........................................

4-7

2-4. When Paper Has Jammed at the First

Folding Plate .........................................

4-8

2-5. When Paper Has Jammed at the

Second Folding Plate ............................

4-9

2-6. When Paper Has Jammed Near the

Stacker ................................................ 4-10

3. Error Messages ...............................4-11

4. Troubleshooting ..............................4-12

Chapter 5

CLEANING THE UNIT

1. Cleaning Each Section .....................5-2

1-1. Cleaning the Rubber Roll ...................... 5-2

1-2. Cleaning the Paper Feed Rings ............

5-3

1-3. Cleaning the Paper Separator ............... 5-4

1-4. Cleaning the Paper Sensor ................... 5-4

1-5. Cleaning the Ejection Gate Sensor ....... 5-5

1-6. Cleaning the Paper Ejection Belts

.........

5-5

Chapter 6 APPENDIX

1.

Specification .....................................6-2

Page 10

Chapter 1

BEFORE OPERATION

Page 11

1-2

1. Features

The DF-755 is designed to fold paper into six popular folding patterns and is capable of folding up to

135 sheets of paper per minute when

single folding 11 lb of fine quality LT paper

.

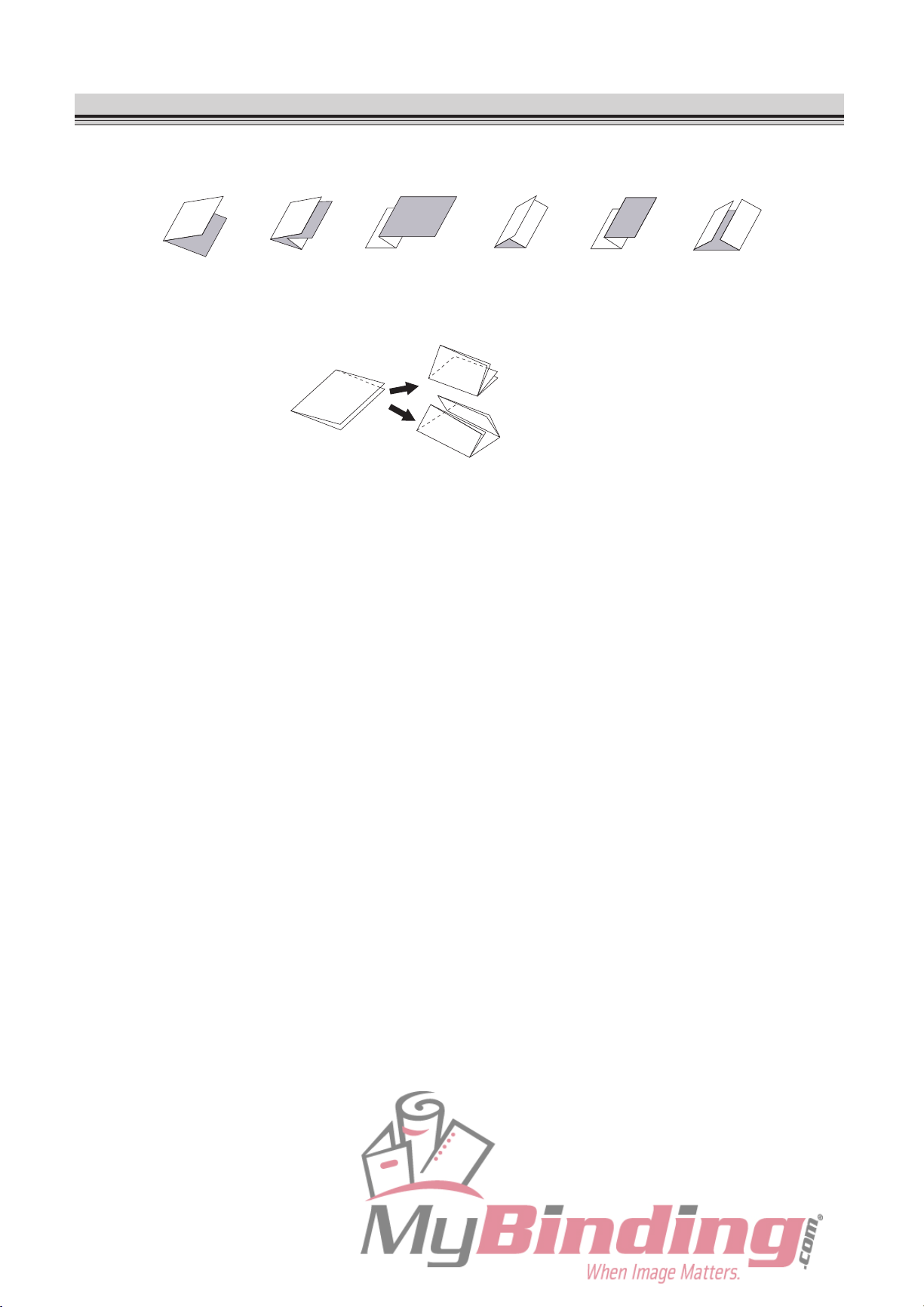

Single fold Double fold Irregular accordion fold Letter fold Accordion fold Gate fold

The DF-755 is also able to create cross single fold and cross letter fold as shown in the figure.

Cross fold

Cross single fold

Cross letter fold

Page 12

1-3

2. Setting Up the Machine

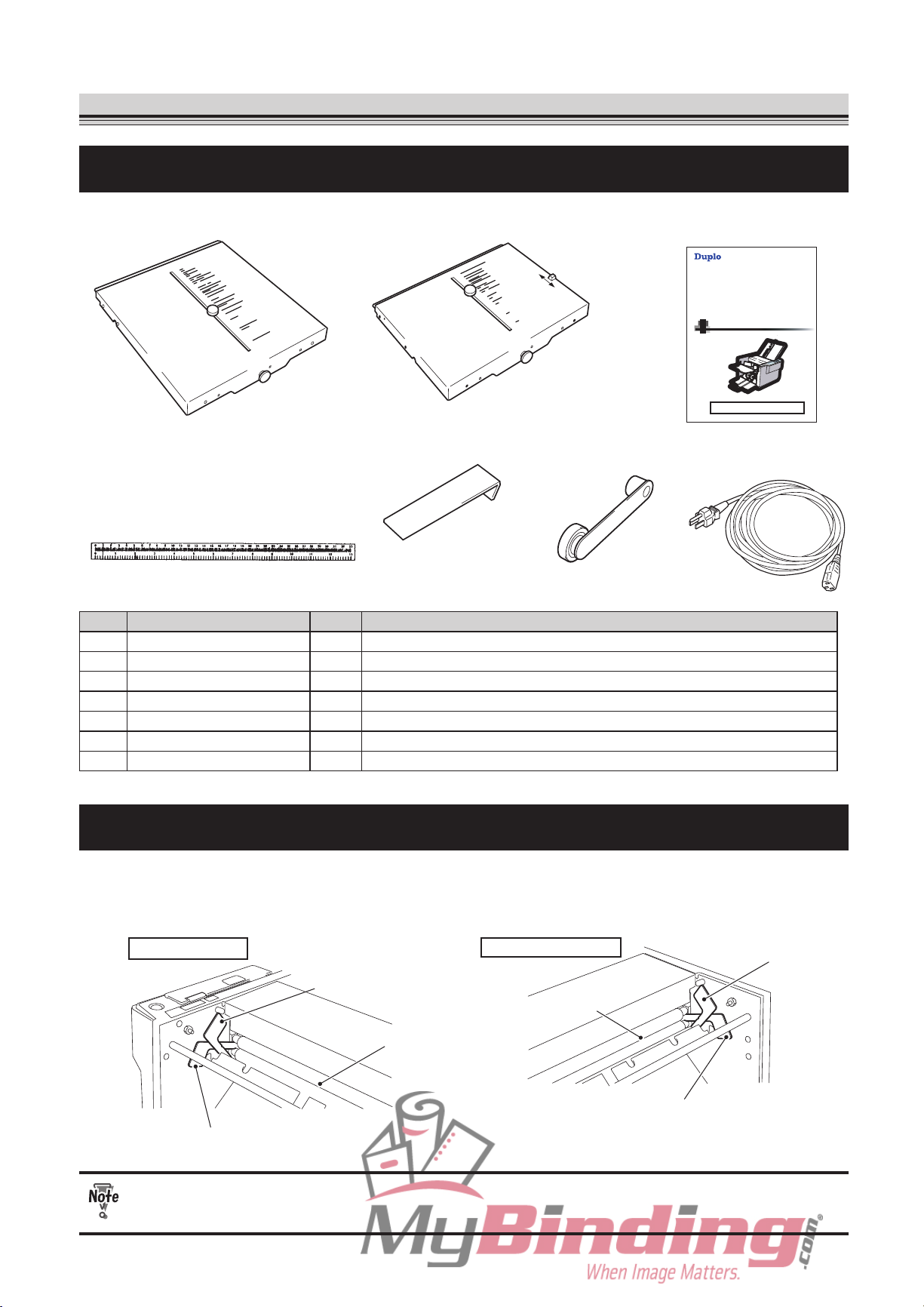

2-1. Components

[1] [2] [3]

[4] [5]

DF-755

[220 to 2 0 V]

INSTRUCTION MANUAL

Be su e to ead th s manua p o o use

ease eave th s manua at he s e o use o easy e e ence

Duplo Folder

[6]

[7]

No. Name Qty. Remark

[1] First folding plate 1 Attached to the right upper section on the operator's side.

[2] Second folding plate 1 Attached to the right lower section on the operator's side.

[3] Instruction manual 1 This manual

[4] Scale label 1 Used to measure non-standard size paper

.

Attach the scale.

[5] Guide plate unit 1 Used when folding small sized medium thickness paper into four.

[6]

Cross folding lever 1 Used when cross folding paper.

[7]

Power cord 1

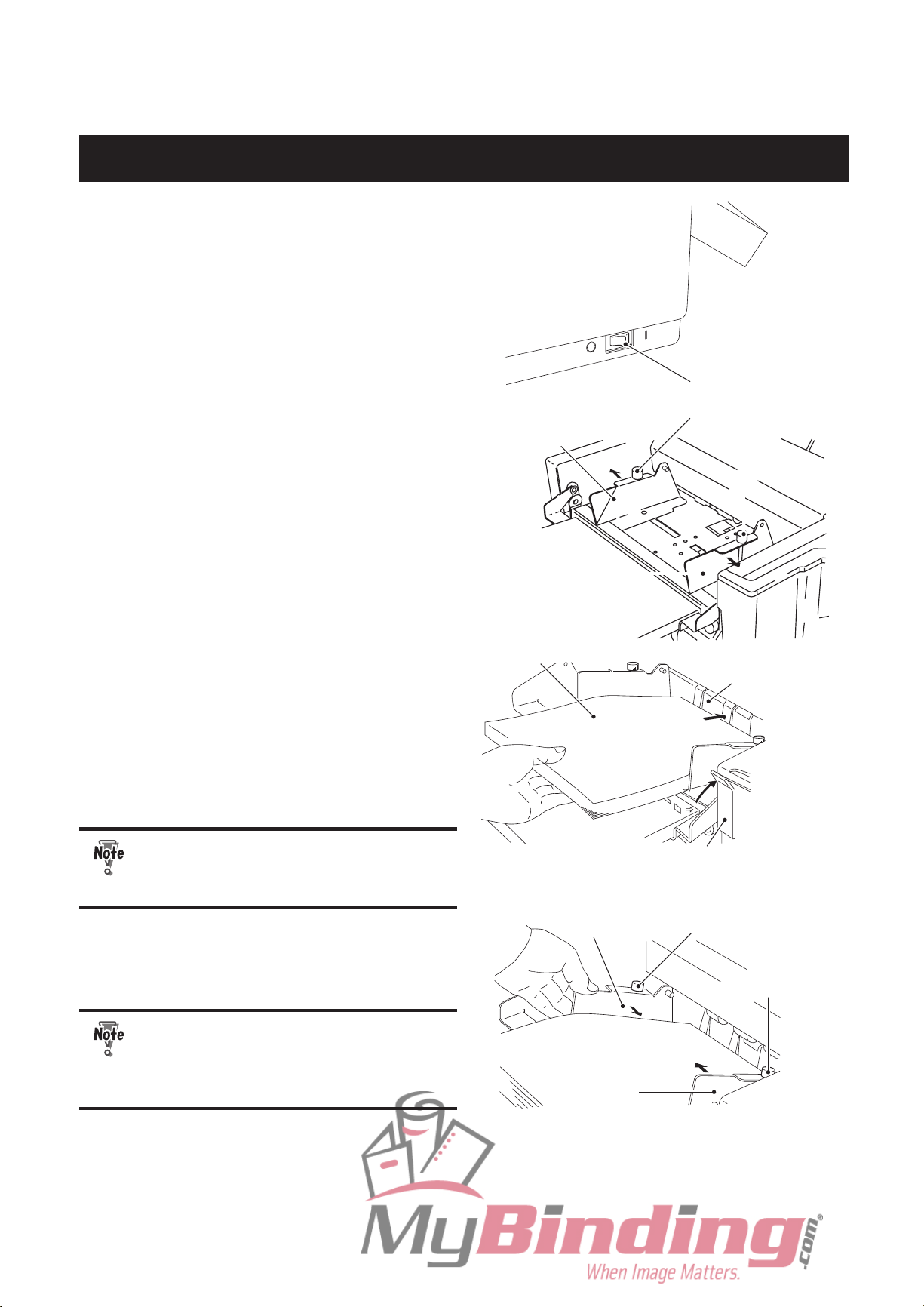

2-2. Removing the Press Release Lever

The press release levers are attached to the unit at shipment to prevent the rubber roll from becoming

distorted. Be sure to remove them when setting up the machine.

The two types of press levers are attached to either side of the rubber roll.

Press release lever (A)

Operator’s side

Rubber roll

Press release lever (B)

Press release lever (A)

Press release lever (B)

Rubber roll

Non-operator’s side

The machine will be damaged if it is used without removing the lever.

Page 13

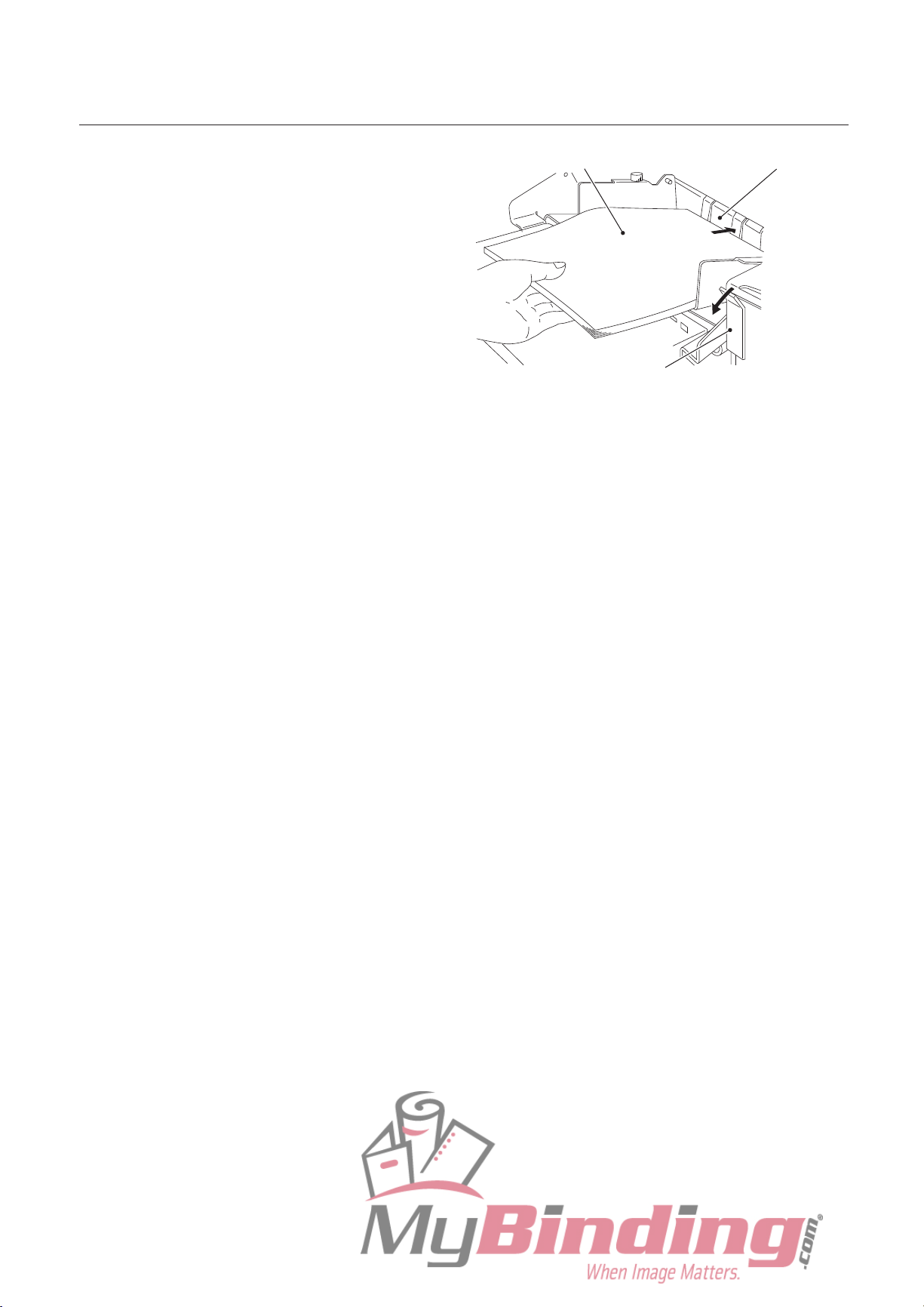

1-4

Chapter 1 BEFORE OPERATION

1

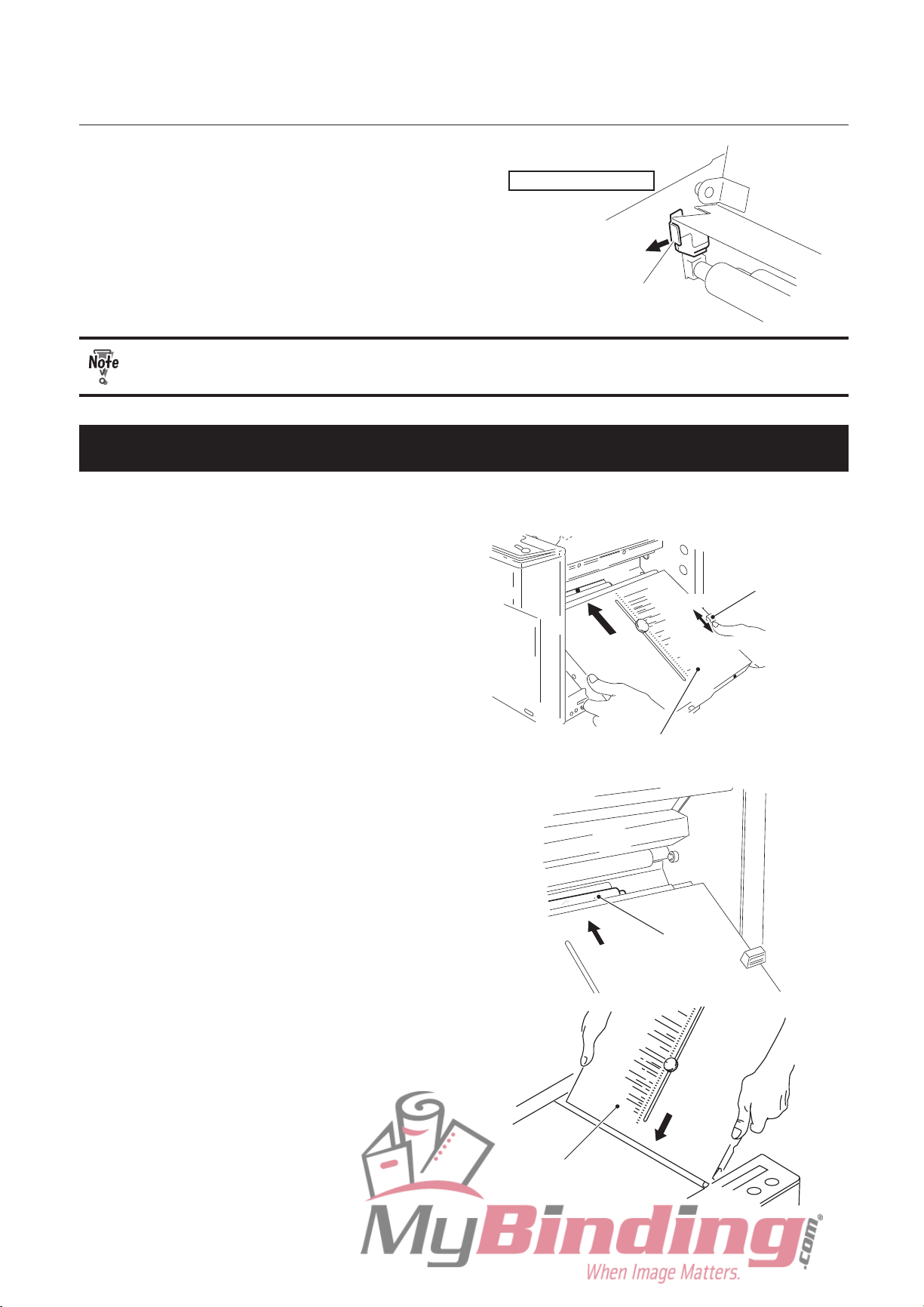

To remove the press release lever (A) on the non-operator's side, push it inwards

and pull it out.

Press release lever (A)

Press release lever (A)

2

To remove the press release lever (A) on the operator's side, push it inwards and

pull it out.

3

To remove the press release lever (B) on the non-operator's side, push it inwards

and pull it out.

Press release lever (B)

Press release lever (B)

4

To remove the press release lever (B) on the operator's side, push it inwards and

pull it out.

2-3. Locking the Bearing Support Levers

The bearing support levers are released at shipment to prevent the rubber roll from becoming

distorted. After removing the press release levers, be sure to lock the bearing.

Bearing support lever

Operator’s side

1

Turn the bearing support lever on the

operator's side in the direction of the

arrow

.

The bearing will be locked.

Page 14

1-5

Chapter 1 BEFORE OPERATION

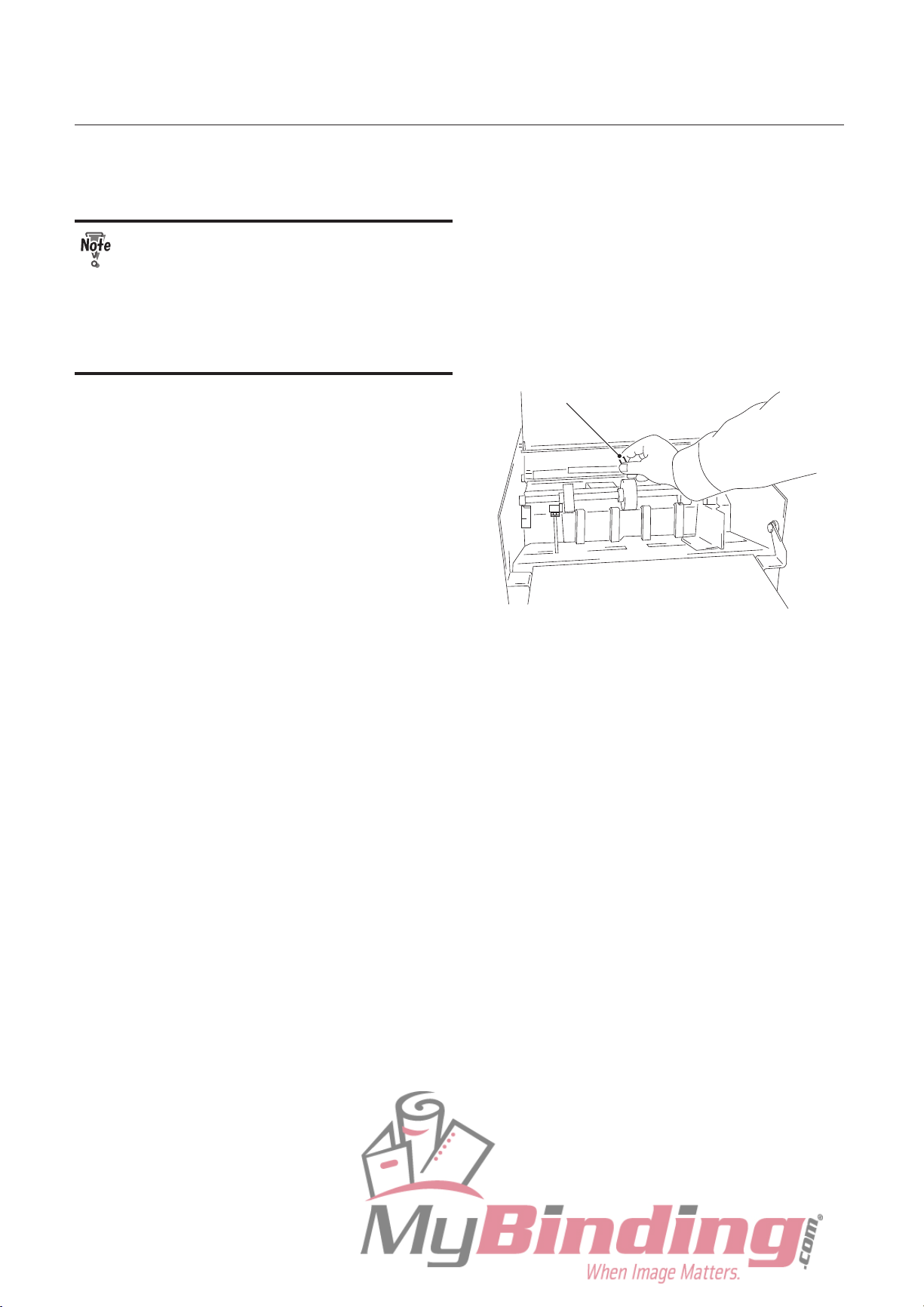

Bearing support lever

Non-operator’s side

2

Turn the bearing support lever on the

non-operator's side in the direction

of the arrow

.

The bearing will be locked.

Because the bearing support lever presses down the rubber roll, if it is not locked, thick

paper may not be folded properly.

2-4. Attaching the Parts

1

Attach the second folding plate.

Second folding plate

Lock lever

UNLOCK

LOCK

1) Move the lock lever of the second folding

plate to the position of "UNLOCK."

Slider

2) Insert the folding plate to the machine

along the slider.

3) Move the lock lever to the position of

"LOCK."

First folding plate

2

Attach the first folding plate.

It only needs to be inserted because the

first folding plate is not provided with a lock

lever.

Page 15

1-6

Chapter 1 BEFORE OPERATION

3

Make a ground connection using

the earth wire attached to the power

plug.

● Make sure that you make a ground

connection before connecting the

power plug to the wall socket.

● If earth leakage occurs without a

ground connection, a short circuit

may cause fire and electric shock.

Guide plate unit

4

Place the cross folding lever on the

magnet under the top cover.

Page 16

1-7

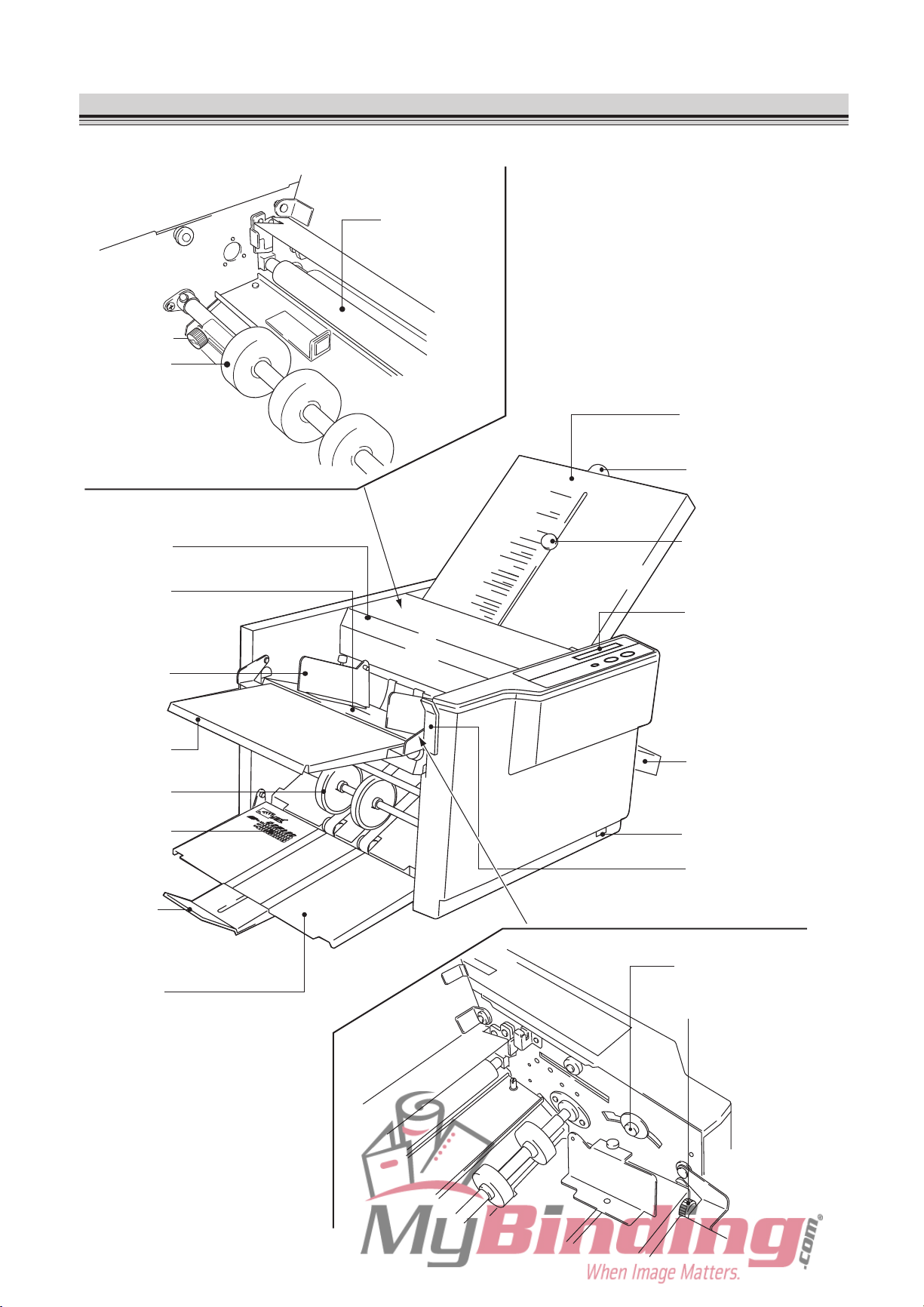

3. Names and Functions

[1]

[4]

[5]

[6]

[7]

[8]

[9]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[2]

[3]

[19]

Under the main cover

Paper feed table (operator’s side)

[10]

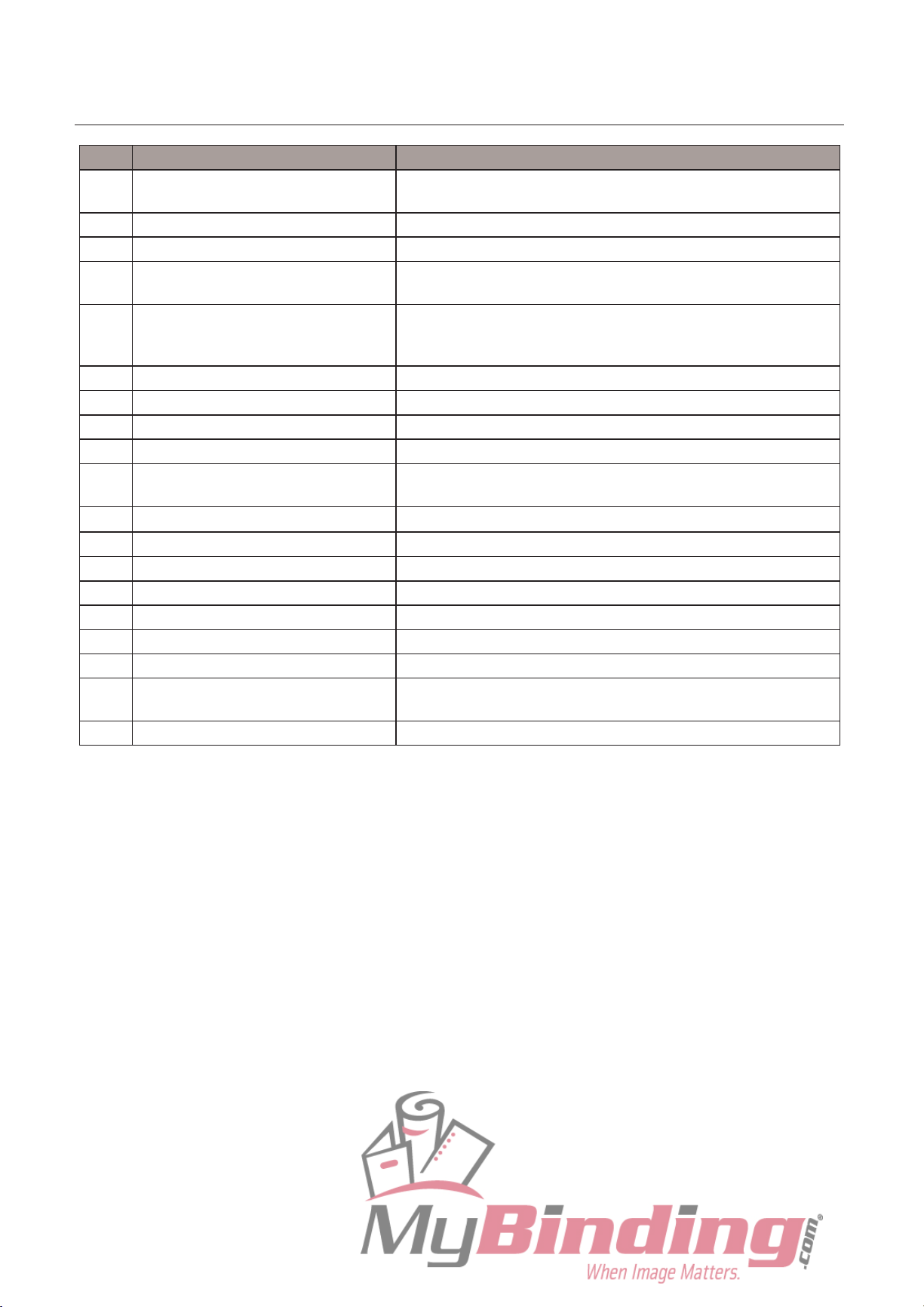

Page 17

1-8

Chapter 1 BEFORE OPERATION

No. Name Function

[1] First folding plate Guide plate for deciding a paper folding position. First folding

is made using this plate.

[2] Fine adjustment knob Used when adjusting a paper folding position.

[3] Rough adjustment knob Used when deciding a paper folding position.

[4] Control panel Used when operating the machine. Error messages are also

displayed on the LCD display

.

[5] Second folding plate Guide plate for deciding a paper folding position. Second

folding is made using this plate.

This plate is not used when

folding paper into two.

[6] Power switch T

urns on and off the power.

[7] Paper set lever When lowered, the paper feed table is raised.

[8] Paper receiving tray Receives folded paper ejected out.

[9] Paper receiving stopper Stops paper ejected out from the machine.

[10] T

able of stacker rollers position Used to check an appropriate position of the stacker rollers

depending on a paper size and folding pattern.

[11] Stacker rollers Ejects folded paper from the machine.

[12] Support paper feed plate Supports paper stacked on the paper feed table.

[13] Side guide Holds paper stacked on the paper feed table.

[14] Paper feed table Used to stack paper to be folded.

[15] T

op cover Prevents the user from touching the moving parts.

[16] Paper feed ring Feeds paper into the machine.

[17] Rubber roll Sends paper to the first folding plate.

[18] Paper feed pressure adjustment

knob

Adjusts paper feed pressure.

[19] Slant correction paper feed knob Corrects misalignment along sides of paper

.

Page 18

1-9

4. Describing Control Panel

[4]

[1]

[3] [2]

No. Name Function

[1] Counter/LCD display Counts up the number of folded paper or displays the status of

the machine. Up to four digit number is displayed.

[2] Stop button When pressed, the machine stops.

[3] Start button When pressed, the machine starts folding operations.

[4] C (clear) button When pressed for two seconds or longer, the number counted

up returns to "0."

When a paper jam has occurred, pressing this button clears

the message.

Page 19

1-10

5. Handling Paper

5-1. Paper Used

●

Make sure that the printing ink on the paper has dried completely prior to use.

If used without the ink completely dried, the folding roller or paper may become dirty.

●

If curled paper is used, depending on the environmental condition (temperature,

humidity), paper quantity, paper type, and paper fiber, it may not flow smoothly

into the folding plate or may not be folded properly. Flatten the paper prior to use.

●

Fan paper well prior to use.

5-2. Precautions on Stacking Paper

●

Do not stack paper on the paper feed

table with the left and right sides of

the paper unaligned or some sheets

protruding out.

●

Do not stack paper on the paper feed

table with the lead and tail edges

unaligned or some sheets protruding

out.

If the paper is protruding at the lead

or tail edge, paper will not be fed

stably, resulting in problems such

as paper feed error and folding

misalignment.

Page 20

1-11

Chapter 1 BEFORE OPERATION

Paper

Guide plate

Paper set lever

●

When stacking just a few sheets of

paper on the paper feed table, lower

the paper set lever while pressing

the lead edge of the paper against

the guide plate.

Page 21

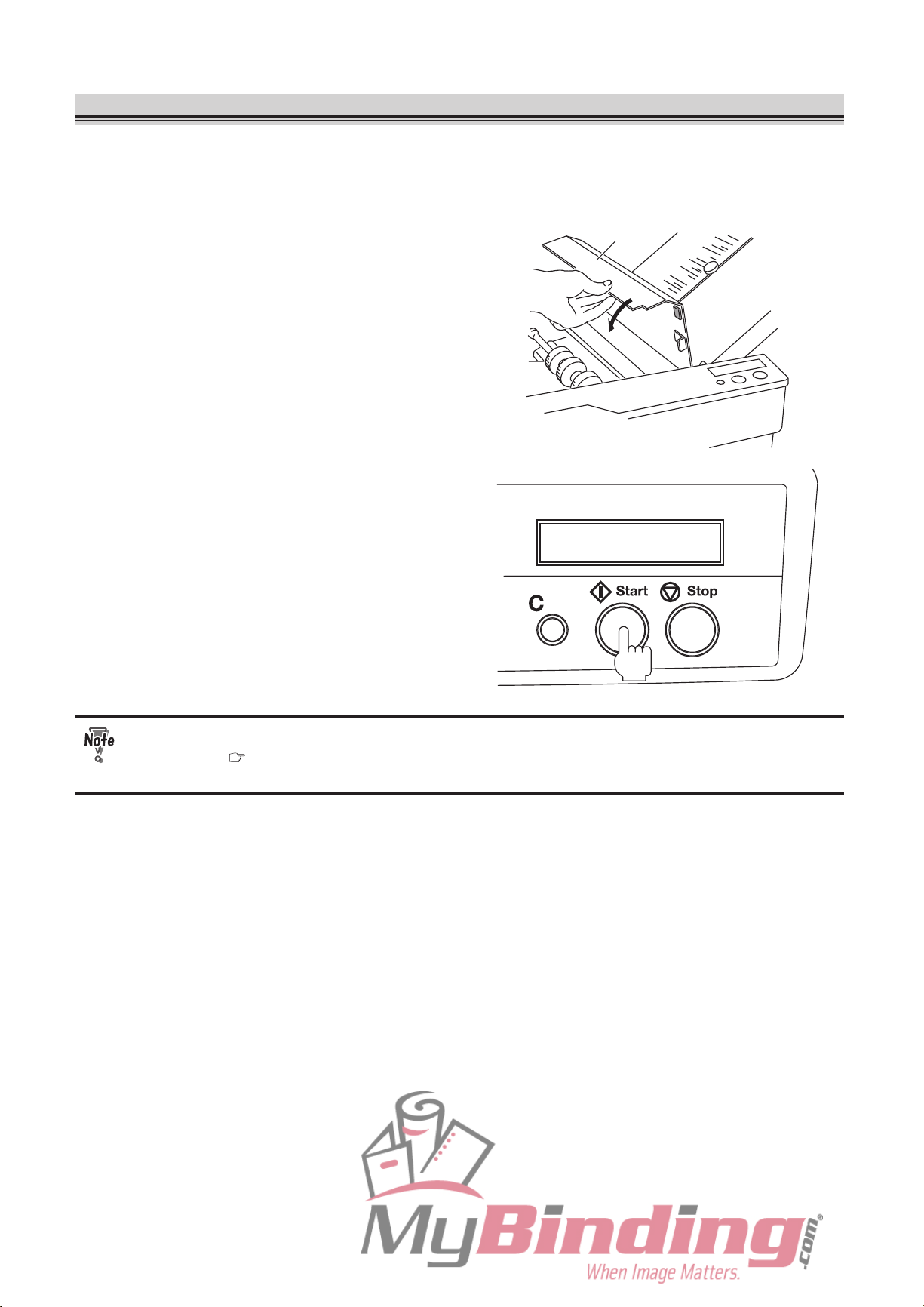

1-12

6. Emergency Stop

An emergency stop device to ensure safety has been installed to the top cover. Opening the cover

during operations will stop the machine.

To resume operations, follow the procedures below.

Top cover

1

Close the top cover.

2

Press the Start button.

Operations will start.

If an error occurs when opening the top cover, an error message will be displayed on the

LCD display ( p.4-11) after closing the cover. Fix the error and press the start button to

resume operations.

Page 22

Chapter 2

BASIC OPERATION

Page 23

2-2

1. Standard Folding of Standard Paper

1-1. Standard Paper

There are six types of standard paper sizes; LD, LG and LT.

Paper Size Long×WIde (inch)

LD 11x17

LG 8.5x14

LT 8.5x1

1

LD and LG are detected as standard paper only when stacked with short edge feed.

Stacking

Direction

Paper Size

LD LG L

T

Short edge feed

O O O

Long edge feed

X X O

Can be used as standard paper : O

Cannot be used as standard paper : X

1-2. Standard Folding

There are six types of standard folding modes: single fold, double fold, irregular accordion fold, letter

fold, accordion fold and gate fold. Paper is folded as shown below when the paper is placed on the

paper feed table with its print side facing upward.

Single fold Double fold Irregular

accordion fold

Letter fold Accordion fold Gate fold

Paper feed direction

Paper ejection direction

Page 24

2-3

Chapter 2 BASIC OPERATION

1-3. Operation Procedures

Power switch

1

Insert the power cord in the wall

socket and turn on the power.

Press “ I ” to turn on the power.

Press “O" to turn off the power.

Side guide

Fixing screw

Side guide

Fixing screw

2

Loosen the fixing screws of the side

guides, and move the side guides to

fit the paper width.

Paper

Paper set lever

Guide plate

3

Raise the paper set lever and place

some paper on the paper feed table.

Push in the paper until its lead edge

touches the guide plate.

The message "NO PAPER" displayed on

the LCD disappears and "COUNT 0" is

displayed instead.

Fan the paper well and stack them

neatly at the center of the paper feed

table.

Side guide

Side guide

Fixing screw

Fixing screw

4

After pressing the side guide to each

side of the paper lightly, tighten the

screws to secure the side guides.

Paper can be stacked to a height of

approximately 2.0 inches at one time.

Do not stack too many sheets of

paper.

Page 25

2-4

Chapter 2 BASIC OPERATION

Paper set lever

5

Lower the paper set lever.

The paper feed table will be raised.

Make sure that you lower the paper

set lever. If you start operations

without the paper set lever lowered,

the paper feed rings will run idle,

causing the machine to stop.

Rough adjustment knob

First folding plateSecond folding plate

Rough adjustment knob

6

Move the rough adjustment knob of

the first and second folding plates

to the mark of a folding pattern you

desire.

Because the second folding plate is not

used for a single fold, move the rough

adjustment knob of the second folding plate

to the upper end to prevent the paper from

being sent to the second folding plate.

"Folding paper into two" ( p.2-7)

Rough adjustment knob

Rough adjustment knob

1) Slide the rough adjustment knob while

pulling it up.

The rough adjustment knob cannot

be turned either clockwise or

counterclockwise. Make sure that you

pull up the knob when you want to

move it.

Fine adjustment knob

Fine adjustment knob

First folding plateSecond folding plate

2) Turn the fine adjustment knob to the

right and left a few times and check that

it moves slightly.

Page 26

2-5

Chapter 2 BASIC OPERATION

Paper feed pressure

adjustment knob

7

Set the paper feed pressure

adjustment knob to “Thin paper.”

If the paper slips and no paper is conveyed,

change the paper feed pressure from “Thin

paper” to “Thick paper”.

Stacker roller

8

Move the stacker rollers to the

appropriate position referring to

the table of stacker rollers position

attached to the paper receiving tray

.

9

Press the Start button for test

folding.

10

Press the Stop button after a couple

of folded sheets are ejected.

Test folded sample

11

Check the finish of test folding.

Check for folding misalignment using the

second test folded sample.

If folding misalignments occur, refer

to Chapter 4 "TROUBLESHOOTING"

“1.Correcting Folding Misalignment”

(

p.4-2).

Page 27

2-6

Chapter 2 BASIC OPERATION

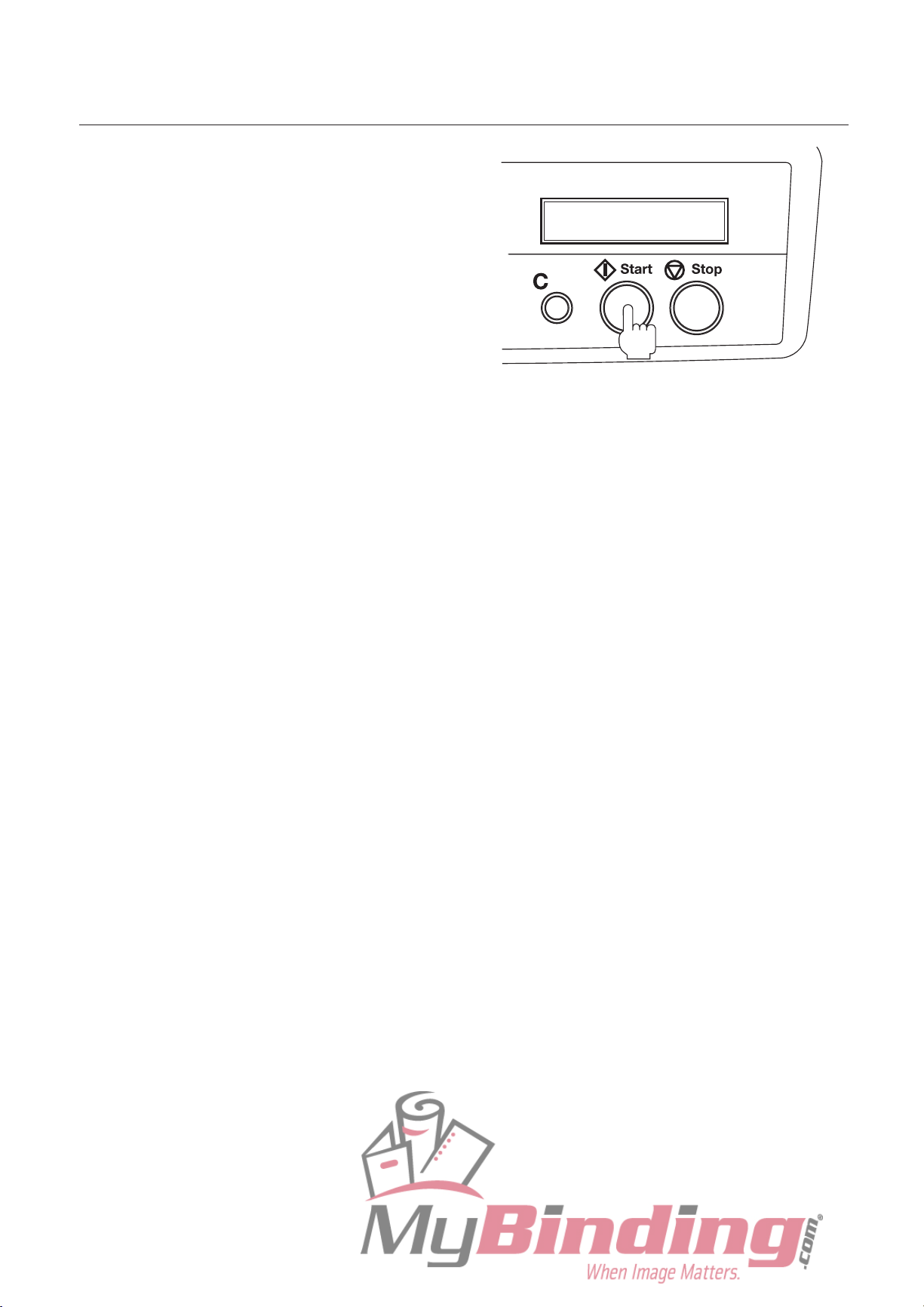

Clear button

12

After completing adjustments, press

the C (clear) button for two seconds

to clear the counter to "0."

13

Press the Start button to start folding

operations.

Press the Stop button to interrupt or stop

the operations. Pressing the Start button

again will resume operations.

When there is no paper on the paper feed

table, the machine will stop automatically

.

Page 28

2-7

Chapter 2 BASIC OPERATION

Folding paper into two

Because the second folding plate is not used for a single fold, move the rough adjustment knob of

the second folding plate to the upper end in the following methos.

Rough

adjustment knob

1) Slide the rough adjustment knob of the

second folding plate up to the upper end

while lifting it up.

Fine adjustment knob

2) Turn the fine adjustment knob to the left

until the rough adjustment knob reaches

the upper end.

0.59 inch

● When the rough adjustment knob has

not reached the upper end, thin paper

may get a crease at around 0.59 inch

from the folded line.

● Rotating the fine adjustment knob

excessively will result in paper

jamming, improper folding, and other

mechanical malfunctions.

Page 29

2-8

Memo

Page 30

Chapter 3

ADVANCED OPERATION

Page 31

3-2

1. Single Folding of Standard Paper

1-1. Single Folding Thick Paper

When folding drawing paper or fine quality thick paper 34 lb into two, the edge of the folding line of the

paper or a part near the center may bend due to environmental conditions (temperature, humidity),

paper size, paper fiber direction, etc. When this occurrs, follow the procedures below.

Bent corner

Bend near the center

Fine adjustment knob

1

Turn the fine adjustment knob of the

second folding plate to the right by

1/4 turn.

The rough adjustment knob will be slightly

apart from the upper end.

2

Press the Start button for test

folding.

3

Press the Stop button after a couple

of folded sheets are ejected.

Test folded sample

4

Check the finish of test folding.

Check for folding misalignment using the

second test folded sample.

If folding misalignments occur, refer to

"TROUBLESHOOTING" “1. Correcting

Folding Misalignment” (

p.4-2).

Page 32

3-3

Chapter 3 ADVANCED OPERATION

Clear button

5

After completing adjustments, press

the C (clear) button for two seconds

to clear the counter to "0."

6

Press the Start button to start folding

operations.

Press the Stop button to interrupt or stop

the operations. Pressing the Start button

again will resume operations.

When there is no paper on the paper feed

table, the machine will stop automatically

.

Fine adjustment knob

7

After completing the operations,

turn the fine adjustment knob to the

left until the rough adjustment knob

reaches the upper end.

After completing single-folding

operations for thick paper, make sure

that you move the fine adjustment

knob back to its normal position. If

thin paper is single-folded with the

stopper of the second folding plate

moved to the position for thick paper,

the thin paper will not be folded

neatly.

Page 33

3-4

Chapter 3 ADVANCED OPERATION

1-2. Double Folding Thick Paper

When folding fine quality thick paper 28 lb into four, its folding section may open when ejected to the

stacker because of the paper thickness and consequently the folded paper may not be able to pass

through the stacker rollers, resulting in paper jam. To prevent this, follow the procedures below.

Do not fold fine quality thick paper 34 lb into four because paper ejection problem may

occur.

Side guide

Fixing screw

Side guide

Fixing screw

1

Loosen the fixing screws of the side

guides, and move the side guides to

fit the paper width.

Paper

Paper set lever

Guide plate

2

Raise the paper set lever and place

some paper on the paper feed table.

Push in the paper until its lead edge

touches the guide plate.

Side guide

Side guide

Fixing screw

Fixing screw

3

After pressing the side guide to each

side of the paper lightly, tighten the

screws to secure the side guides.

Paper set lever

4

Lower the paper set lever.

The paper feed table will be raised.

Make sure that you lower the paper

set lever. If you start operations

without the paper set lever lowered,

the paper feed rings will run idle,

causing the machine to stop.

Page 34

3-5

Chapter 3 ADVANCED OPERATION

Stacker roller

5

Move the stacker rollers to "5."

Stacker roller

Lever

Belt

Stacker lever

6

While lifting up the stacker rollers

with your hand, pull the levers (left

and right) attached to the stacker

lever in the direction of the arrow so

that the stacker rollers are lifted up.

7

Press the Start button for test folding

and check if the paper is ejected

smoothly

.

8

Press the Stop button after a couple

of folded sheets are ejected.

Stacker roller

9

If the paper is not ejected smoothly,

change the position of the stacker

rollers to "3" or "4."

If folding misalignments occur, refer to

Chapter 4 "TROUBLESHOOTING" “1.

Correcting Folding Misalignment”

(

p.4-2).

Page 35

3-6

Chapter 3 ADVANCED OPERATION

Test folded sample

10

Check the finish of test folding.

Check for folding misalignment using the

second test folded sample.

If folding misalignments occur, refer to

Chapter 4 "TROUBLESHOOTING" “1.

Correcting Folding Misalignment”

(

p.4-2).

Clear button

11

After completing adjustments, press

the C (clear) button for two seconds

to clear the counter to "0."

12

Press the Start button to start folding

operations.

Press the Stop button to interrupt or stop

the operations. Pressing the Start button

again will resume operations.

When there is no paper on the paper feed

table, the machine will stop automatically

.

Stacker roller

Lever

Belt

Stacker lever

13

After the operations have completed,

move the left and right levers

attached to the stacker lever in the

direction of the arrow

.

If the stacker rollers are left lifted up,

problems will occur when the normal

paper size is used.

Page 36

3-7

Chapter 3 ADVANCED OPERATION

1-3. Double Folding Small Thin Paper

Paper jam may occur when folding 5.00 (W) x 7.00 (L) inch size fine quality paper of 22 lb or thinner

into four. Using the supplied guide plate unit will prevent paper jam.

Guide plate unit

1

Remove the guide plate unit stored

inside the top cover.

Paper ejection belt

Guide plate unit

2

Attach the guide plate unit to the

innermost center between the two

paper ejection belts.

Guide plate unit

Stacker roller

3

Move the stacker rollers to "4."

Page 37

3-8

Chapter 3 ADVANCED OPERATION

4

Press the Start button for test folding

and check if the paper is ejected

smoothly

.

5

Press the Stop button after a couple

of folded sheets are ejected.

Stacker roller

6

If the paper is not ejected smoothly,

change the position of the stacker

rollers.

Test folded sample

7

Check the finish of test folding.

Check for folding misalignment using the

second test folded sample.

If folding misalignments occur, refer to

Chapter 4 "TROUBLESHOOTING" “1.

Correcting Folding Misalignment”

(

p.4-2).

Clear button

8

After completing adjustments, press

the C (clear) button for two seconds

to clear the counter to "0."

Page 38

3-9

Chapter 3 ADVANCED OPERATION

9

Press the Start button to start folding

operations.

Press the Stop button to interrupt or stop

the operations. Pressing the Start button

again will resume operations.

When there is no paper on the paper feed

table, the machine will stop automatically

.

10

After completing the work, remove

the guide plate unit.

● Leaving the guide plate unit attached

may result in problems when other

types of paper are used.

● When folding fine quality paper 14 lb

into four, do not use the guide plate

unit.

11

Store the removed guide plate unit

inside the top cover.

Page 39

3-10

2. Custom Folding of Standard Paper

Custom folding is the method of folding paper where you specify the folding stoppers of the first and

second folding plates. The following describes the custom folding procedures taking accordion fold as

an example.

Side guide

Fixing screw

Side guide

Fixing screw

1

Loosen the fixing screws of the side

guides, and move the side guides to

fit the paper width.

Paper

Paper set lever

Guide plate

2

Raise the paper set lever and place

some paper on the paper feed table.

Push in the paper until its lead edge

touches the guide plate.

Side guide

Side guide

Fixing screw

Fixing screw

3

After pressing the side guide to each

side of the paper lightly, tighten the

screws to secure the side guides.

Paper set lever

4

Lower the paper set lever.

The paper feed table will be raised.

Make sure that you lower the paper

set lever. If you start operations

without the paper set lever lowered,

the paper feed rings will run idle,

causing the machine to stop.

Page 40

3-11

Chapter 3 ADVANCED OPERATION

Accordion fold

5

Fold a piece of paper as desired and

measure the dimensions of the A, B

and C.

The folding sizes should be within the

following ranges.

A: 1.60 to 12.80 inches

B: 1.60 to 8.50 inches

C: 8.50 inches or shorter

Rough adjustment knob

6

Adjust the rough adjustment knob

of the first folding plate to the mark

corresponding to measurement A.

7

Adjust the rough adjustment knob

of the first folding plate to the mark

corresponding to measurement B.

● The rough adjustment knob cannot

be turned either clockwise or

counterclockwise. Make sure that you

pull up the knob when you want to

move it.

● After moving the rough adjustment

knob, turn the fi

ne adjustment knob

to the right and left a few times to

check that it moves slightly.

Stacker roller

8

Move the stacker rollers to the

appropriate position referring to

T

able of Stacker Rollers Position on

the next page.

Page 41

3-12

Chapter 3 ADVANCED OPERATION

Table of Stacker Rollers Position

Stacker

Rollers

Position

Length of Folded Paper Folding Pattern

1 7.0 to 8.5 inches LD: single fold, irregular accordion fold, gate fold

Single folded paper larger than LD

2 6.0 to 7.0 inches LG: Irregular accordion, gate fold

3 5.0 to 6.0 inches L

T: single fold, irregular accordion fold, gate fold

LD: letter fold, accordion fold

4 4.0 to 5.0 inches LG: letter fold, accordion fold

LD: double fold

5 1.6 to 4.0 inches L

T: double fold, letter fold, accordion fold

LG: double fold

9

Press the Start button for test

folding.

10

Press the Stop button after a couple

of folded sheets are ejected.

Test folded sample

11

Check the finish of test folding.

Check for folding misalignment using the

second test folded sample.

If folding misalignments occur, refer to

Chapter 4 "TROUBLESHOOTING" “1.

Correcting Folding Misalignment”

(

p.4-2).

Clear button

12

After completing adjustments, press

the C (clear) button for two seconds

to clear the counter to "0."

Page 42

3-13

Chapter 3 ADVANCED OPERATION

13

Press the Start button to start folding

operations.

Press the Stop button to interrupt or stop

the operations. Pressing the Start button

again will resume operations.

When there is no paper on the paper feed

table, the machine will stop automatically

.

Page 43

3-14

3.

Standard Folding of Non-Standard Size Paper

Paper other than the six standard size paper are called non-standard size paper. The paper size that

can be used as non-standard size paper is as follows.

Length(L):

7.00 to 17.00 inches

Paper feed

direction

Width:5.00 to 11.00 inch

Maximum: 11.00 (W) x 17.00 (L) inches

Minimum: 5.00 (W) x 7.00 (L) inches

The following describes the single folding procedures

of 12.00 inch long paper as an example.

1

Measure the length (L).

2

Refer to Table of Rough Adjustment

Knob Positions to check the the

appropriate positions of first and

second folding plates.

Table of Rough Adjustment Knob Positions

L=Paper length

Folding

Pattern

Single Fold Double Fold Irregular

Accordion

Fold

Letter Fold Accordion

Fold

Gate Fold

First Folding

Plate

L/2 L/2 3L//4 L/3 2L/3 L/4

Second

Folding Plate

Upper End L/4 L/4 L/3 L/3 L/2

Rough adjustment knob

1) According to the table above, move the

rough adjustment knob to 6.00 inches

(12.00÷2).

● The rough adjustment knob cannot

be turned either clockwise or

counterclockwise. Make sure that you

pull up the knob when you want to

move it. ( p.2-4)

● After moving the rough adjustment

knob, turn the fine adjustment knob

to the right and left a few times to

check that it moves slightly. (

p.2-4)

Rough

adjustment knob

2) Move the rough adjustment knob of the

second folding plate to the upper end.

( p.2-7)

Page 44

3-15

Chapter 3 ADVANCED OPERATION

Stacker roller

3

Move the stacker rollers to the

appropriate position.

Refer to Table of Stacker Rollers Position

for their appropriate position ( p.3-12).

For this example, move the stacker rollers

to "2" for the finished size 6.00 inches.

Side guide

Fixing screw

Side guide

Fixing screw

4

Loosen the fixing screws of the side

guides, and move the side guides to

fit the paper width.

Paper

Paper set lever

Guide plate

5

Raise the paper set lever and place

some paper on the paper feed table.

Push in the paper until its lead edge

touches the guide plate.

Side guide

Side guide

Fixing screw

Fixing screw

6

After pressing the side guide to each

side of the paper lightly, tighten the

screws to secure the side guides.

Page 45

3-16

Chapter 3 ADVANCED OPERATION

Paper set lever

7

Lower the paper set lever.

The paper feed table will be raised.

Make sure that you lower the paper

set lever. If you start operations

without the paper set lever lowered,

the paper feed rings will run idle,

causing the machine to stop.

8

Press the Start button for test

folding.

9

Press the Stop button after a couple

of folded sheets are ejected.

Test folded sample

10

Check the finish of test folding.

Check for folding misalignment using the

second test folded sample.

If folding misalignments occur, refer to

Chapter 4 "TROUBLESHOOTING" “1.

Correcting Folding Misalignment”

(

p.4-2).

Clear button

11

After completing adjustments, press

the C (clear) button for two seconds

to clear the counter to "0."

Page 46

3-17

Chapter 3 ADVANCED OPERATION

12

Press the Start button to start folding

operations.

Press the Stop button to interrupt or stop

the operations. Pressing the Start button

again will resume operations.

When there is no paper on the paper feed

table, the machine will stop automatically

.

For custom folding of non-standard size paper, refer to "2.Custom Folding of Standard

Paper" (

p.3-10).

Page 47

3-18

4. Cross Folding

Cross folding is to fold single-folded paper another time into two or three.

Cross fold

Cross single fold

Cross letter fold

● The maximum paper thickness is 28 lb. However, this thickness may differ slightly

according to various conditions such as environmental conditions (temperature,

humidity), paper size, and paper fiber direction.

● When the paper is cross folded, Σ folding (folding slippage in the horizontal) and

folding misalignment along sides of paper may occur due to conditions such as

en

vironmental conditions (temperature, humidity), paper size and paper fiber direction.

This is not a malfunction of the machine.

folding

4-1. Cross Folding Standard Size Paper

The paper size that can be cross folded is LD, LG and LT.

The following describes the cross single folding procedures of LD size paper.

s

Only short edge feed is available for

cross folding.

1

Fold LD size paper into two

according to Chapter 2 "BASIC

OPERATION" "1.Standard Folding of

Standard Paper" (

p.2-2).

2

Press along the folded line of the

single-folded paper firmly with

your fingers to prevent the paper

from slipping and buckling in the

horizontal direction when folded.

Page 48

3-19

Chapter 3 ADVANCED OPERATION

Paper

36 mm

Side guide

Paper set lever

3

Raise the paper set lever and stack

the single-folded paper on the paper

feed table with the folded line facing

the non-operator's side.

The amount of paper stacked on

the paper feed table should be

approximately 2/3 (approx.1-1/2

inches) of the height of the side

guide.

4

Loosen the fixing screws of the side

guides.

Side guide

Side guide

Fixing screw

Fixing screw

5

After pressing the side guide to each

side of the paper lightly, tighten the

screws to secure the side guides.

Paper set lever

6

Lower the paper set lever.

The paper feed table will be raised.

Make sure that you lower the paper

set lever. If you start operations

without the paper set lever lowered,

the paper feed rings will run idle,

causing the machine to stop.

Rough adjustment knob

7

Move the rough adjustment knob of

the first folding plate to the position

for single-fold LT paper.

Page 49

3-20

Chapter 3 ADVANCED OPERATION

Rough

adjustment knob

8

Move the rough adjustment knob of

the second folding plate to the upper

end.

● The rough adjustment knob cannot

be turned either clockwise or

counterclockwise. Make sure that you

pull up the knob when you want to

move it.

● After moving the rough adjustment

knob, turn the fi

ne adjustment knob

to the right and left a few times to

check that it moves slightly.

Stacker roller

9

Move the stacker rollers to the

appropriate position.

Refer to the table of stacker rollers position

attached to the paper receiving tray for their

appropriate position ( p.3-12).

For this example (LT size, single fold),

move the stacker rollers to "3."

Top cover

10

Open the top cover.

Set screw

Paper feed ring

11

Loosen the set screw of the paper

feed ring.

12

Move the paper feed ring at the far

end to the folded line of the paper.

13

Tighten the set screw of the paper

feed ring.

Page 50

3-21

Chapter 3 ADVANCED OPERATION

Cross folding lever

14

Take out the cross folding lever

stored inside the top cover.

15

Close the top cover.

Cross folding lever

Weight roller

Side guide

16

Attach the cross folding lever to the

side guide of the non-operator' side.

Place the weight roller on the folding line.

Cross folding lever

To replenish paper, lift the cross folding

guide.

Paper feed pressure

adjustment knob

17

Set the paper feed pressure

adjustment knob to “Thin paper.”

If the paper slips and no paper is conveyed,

change the paper feed pressure from “Thin

paper” to “Thick paper

.”

Page 51

3-22

Chapter 3 ADVANCED OPERATION

18

Press the Start button for test

folding.

19

Press the Stop button after a couple

of folded sheets are ejected.

20

Check the finish of test folding.

Check for folding misalignment using the

second test folded sample.

If folding misalignments occur, refer to

Chapter 4 "TROUBLESHOOTING" “1.

Correcting Folding Misalignment”

(

p.4-2).

Clear button

21

After completing adjustments, press

the C (clear) button for two seconds

to clear the counter to "0."

22

Press the Start button to start folding

operations.

Press the Stop button to interrupt or stop

the operations. Pressing the Start button

again will resume operations.

When there is no paper on the paper feed

table, the machine will stop automatically

.

23

Store the cross folding lever.

Page 52

3-23

Chapter 3 ADVANCED OPERATION

4-2. Cross Folding Non-Standard Size Paper

Paper other than the six standard size paper are called non-standard size paper. The paper size that

can be cross folded is as follows.

Length: 7.00 to 17.00 inches

Width: 5.00 to 11.00 inches

Paper feeding direction

Maximum: 11.00 (W) x 17.00 (L) inches

Minimum: 5.00 (W) x 7.00 (L) inches

The following describes the cross single folding

procedures of 12.00 inch long paper as an example.

1

Fold the paper into two according to

Chapter 3 "ADVANCED OPERATION"

"3.Standard Folding of Non-Standard

Size Paper" (

p.3-14).

L

Paper feeding direction

2

Measure the length (L) of the singlefolded paper.

3

Press along the folded line of the

single-folded paper firmly with

your fingers to prevent the paper

from slipping and buckling in the

horizontal direction when folded.

Paper

36 mm

Side guide

Paper set lever

4

Raise the paper set lever and stack

the single-folded paper on the paper

feed table with the folded line facing

the non-operator's side.

The amount of paper stacked on

the paper feed table should be

approximately 2/3 (approx. 1-1/2

inches) of the height of the side

guide.

5

Loosen the fixing screws of the side

guides.

Page 53

3-24

Chapter 3 ADVANCED OPERATION

Side guide

Side guide

Fixing screw

Fixing screw

6

After pressing the side guide to each

side of the paper lightly, tighten the

screws to secure the side guides.

Paper set lever

7

Lower the paper set lever.

The paper feed table will be raised.

Make sure that you lower the paper

set lever. If you start operations

without the paper set lever lowered,

the paper feed rings will run idle,

causing the machine to stop.

8

Refer to Table of Rough Adjustment

Knob Positions to check the

appropriate positions of fi

rst and

second folding plates.

Table of Rough Adjustment Knob Positions

L=Paper length

Folding

Pattern

Single Fold Double Fold Irregular

Accordion

Fold

Letter Fold Accordion

Fold

Gate Fold

First Folding

Plate

L/2 L/2 3L//4 L/3 2L/3 L/4

Second

Folding Plate

Upper End L/4 L/4 L/3 L/3 L/2

Rough adjustment knob

1) According to the table of rough

adjustment knob positions, move the

knob of the first folding plate to 6.00

inches (12.00÷2).

Page 54

3-25

Chapter 3 ADVANCED OPERATION

Rough

adjustment knob

2) Move the rough adjustment knob of the

second folding plate to the upper end.

● The be turned either clockwise or

counterclockwise. Make sure that you

pull up the knob when you want to

move it.

● After moving the rough adjustment

knob, turn the fi

ne adjustment knob

to the right and left a few times to

check that it moves slightly.

Stacker roller

9

Move the stacker rollers to the

appropriate position.

Refer to Table of Stacker Rollers Position

for their appropriate position ( p.3-12).

For this example, move the stacker rollers

to "2."

Refer to procedures between step 10

of p.3-20 and step 23 of p.3-22 for rest

procedures.

Page 55

3-26

Memo

Page 56

Chapter 4

TROUBLESHOOTING

GUIDE

Page 57

4-2

1.

Correcting Folding Misalignment

Folding misalignment consists of two types; “folding misalignment along the vertical length of the

paper” and “folding misalignment along the sides of the paper.”

Other than this, “deformed folding” may also occur due to paper characteristics.

1-1. Correcting Folding Misalignment along Vertical Length of Paper

Paper feeding direction

Misalignment to

be corrected

When folded paper is misaligned along the vertical

length as shown in the figure, turn the fine adjustment

knob to correct the misalignment.

Adjusting Fine Adjustment Knob of the First Folding Plate

Folding Style Fold Surface A Adjustment

First folding plate

Fine adjustment knob

Single fold

Feeding direction

When A is longer

Turn the fine adjustment knob

counterclockwise.

When A is

shorter

Turn the fine adjustment knob

clockwise.

Double fold

Feeding direction

When A is longer

Turn the fine adjustment knob

counterclockwise.

When A is

shorter

Turn the fine adjustment knob

clockwise.

Irregular

accordion

fold

Feeding direction

When A is longer

Turn the fine adjustment knob

counterclockwise.

When A is

shorter

Turn the fine adjustment knob

clockwise.

Letter fold

Feeding direction

When A is longer

Turn the fine adjustment knob

counterclockwise.

When A is

shorter

Turn the fine adjustment knob

clockwise.

Accordion

fold

Feeding direction

When A is longer

Turn the fine adjustment knob

counterclockwise.

When A is

shorter

Turn the fine adjustment knob

clockwise.

Page 58

4-3

Chapter 4 TROUBLESHOOTING GUIDE

Folding Style Fold Surface A Adjustment

First folding plate

Fine adjustment knob

Gate fold

Feeding direction

When A is longer

Turn the fine adjustment knob

counterclockwise.

When A is

shorter

Turn the fine adjustment knob

clockwise.

Adjusting Fine Adjustment Knob of the Second Folding Plate

Folding Style Fold Surface A Adjustment

First folding plate

Fine adjustment knob

Single fold The second folding plate is not used in single folding.

Double fold

Feeding direction

When B is

longer.

Turn the fine adjustment knob

counterclockwise.

When B is

shorter.

Turn the fine adjustment knob

clockwise.

Irregular

accordion

fold

Feeding direction

When B is

longer.

Turn the fine adjustment knob

counterclockwise.

When B is

shorter.

Turn the fine adjustment knob

clockwise.

Letter fold

Feeding direction

When B is

longer.

Turn the fine adjustment knob

counterclockwise.

When B is

shorter.

Turn the fine adjustment knob

clockwise.

Accordion

fold

Feeding direction

When B is

longer.

Turn the fine adjustment knob

counterclockwise.

When B is

shorter.

Turn the fine adjustment knob

clockwise.

Gate fold

Feeding direction

When B is

longer.

Turn the fine adjustment knob

counterclockwise.

When B is

shorter.

Turn the fine adjustment knob

clockwise.

Page 59

4-4

Chapter 4 TROUBLESHOOTING GUIDE

1-2.

Correcting Folding Misalignment along Sides of Paper

Paper feeding

direction

When folded paper is misaligned along the sides

of paper as shown in the figure, turn the slant correction

knob to correct the misalignment.

Slant correction knob

1

Turn the slant correction knob to

adjust the folding slippage.

Slant correction knob

If folding slippage is as shown in Figure A,

turn the knob in the direction of the arrow.

Slant correction knob

If folding slippage is as shown in Figure B,

turn the knob in the direction of the arrow.

Pin

Round hole

Slant correction knob

2

After finishing operations, be sure

to turn the slant correction knob to

align the round holes of the paper

feed table with the pin.

The position at which the round hole meets

the pin is the standard position.

Page 60

4-5

Chapter 4 TROUBLESHOOTING GUIDE

1.3 Correcting Deformed Folding

Check the following when deformed folding occurs.

Deformed folding

●

Fan the paper well before stacking.

●

Check if the folding plates have been

installed properly. (

p.1-5)

●

Spray a commercially-available air

duster on the rubber roll because the

stati

c electricity may have resulted in

deformed folding.

Do not use paper other than those specified. This will cause not only deformed

folding but also malfunction of the machine.

Page 61

4-6

2. Removing Jammed Paper

When paper jam has occurred, "PAPER ERR" will be displayed on the LCD display. Check the

machine to find out where the jam has occurred and remove the jammed paper following the

procedures below.

2-1. When Paper Has Jammed Near the Paper Feed Ring

Paper feed tray

Paper

Paper set lever

1

Raise the paper set lever to lower the

paper feed table downwards.

2

Pull the jammed paper towards you.

2-2. When Paper Has Slipped at the Paper Feed Section

Paper feed pressure adjustment knob

●

If mis-feed frequently occurs using

thick paper (34 lb), set the paper feed

pressure adjustment knob to “Thick

paper

.”

●

Fan the paper well before stacking.

●

Decrease the stacking amount of

paper.

Page 62

4-7

Chapter 4 TROUBLESHOOTING GUIDE

2-3. When Paper Has Coiled Around the Rubber Roll

Turn off the machine before following the procedures below.

Top cover

1

Open the top cover.

Bearing support lever

Rubber roll

Paper

Bearing support lever

Non-operator’s side

Operator’s side

2

Turn the two bearing support levers

in the direction of the arrow to relase

them.

3

Pull the coiled paper towards you to

remove it.

If you cannot remove the paper easily, turn

the roll towards you with both hands and

pull the paper.

4

Return the bearing supprt levers.

Page 63

4-8

Chapter 4 TROUBLESHOOTING GUIDE

2-4. When Paper Has Jammed at the First Folding Plate

First folding plate

1

Remove the first folding plate from

the machine.

Top cover

2

Open the top cover.

3

Pull the jammed paper towards you.

4

Close the top cover.

5

Return the first folding plate.

● Check that the first folding plate has

been installed properly.

● When you remove and return the

folding plate, make sure that you use

both hands.

Page 64

4-9

Chapter 4 TROUBLESHOOTING GUIDE

2-5. When Paper Has Jammed at the Second Folding Plate

Turn off the machine before following the procedures below.

Second folding plate

Lock lever

UNLOCK

LOCK

1

Move the lock lever to the position of

"UNLOCK."

Second folding plate

2

Remove the second folding plate

from the machine.

3

Pull the jammed paper towards you.

Slider

4

Insert the second folding plate to the

machine along the slider.

5

Move the lock lever to the position of

"LOCK."

● Check that the first folding plate has

been installed properly.

● When you remove and return the

folding plate, make sure that you use

both hands.

Page 65

4-10

Chapter 4 TROUBLESHOOTING GUIDE

2-6. When Paper Has Jammed Near the Stacker

Paper

Remove the paper stuck in the

stacker section towards you.

Page 66

4-11

3. Error Messages

When a paper jam has occurred or the top cover is open, an error message is displayed on the LCD

display.

Follow the procedures below to fix the error.

Message Cause Solution

NO PAPER When the power is turned on, there

is no paper on the paper feed

table.

Stack paper on the paper feed

table.

NO PAPER/****(the number of

folded paper)

After paper is fed and folded, there

is no paper left on the paper feed

table.

Stack paper on the paper feed

table. The number of folded paper

will be displayed again.

COVER OPEN The top cover is open. Close the top cover.

P

APER ERR A paper jam has occurred. Remove the jammed paper and

pr

ess the C (clear) button. ( p.4-6)

A mis-feed has occurred. Stack paper properly on the paper

feed table and press the C (clear)

button. (

p.1-10, 4-6)

PRAT-1 SET ERR The first folding plate has not been

installed properly.

Install the first folding plate

properly. (

p.1-5)

PRAT-2 SET ERR The second folding plate has not

been installed properly.

Install the second folding plate

properly. (

p.1-5)

OVER LOAD The motor is overloaded. Turn of

f and on the power.

Page 67

4-12

4. Troubleshooting

When trouble has occurred, find the symptom from the table below and solve the trouble according to

the solution. If you cannot solve the trouble, contact your dealer.

Symptom Cause Solution

The machine does not start

even when the Start button is

pressed.

The power cord is not inserted to

the wall socket.

Insert the power cord to the wall

socket.

The power is not on. T

urn on the power switch.

( p.2-3)

There is no paper on the paper

feed table.

Stack paper on the paper feed

table. (

p.2-3)

Paper has not reached the guide

plate of the paper feed table.

Push in the paper until its lead

edge touches the guide plate.

(

p.2-3)

A paper jam has occurred. Remove the jammed paper.

(

p.4-6)

The top cover is open. Close the top cover.

A

trouble has occurred inside the

machine.

Call your dealer.

When the Start button is pressed,

the paper feed rings rotate but no

paper is fed.

The paper feed table has been

lowered.

Lower the paper set lever to raise

the paper feed table.

(

p.2-3)

The paper has not been fanned

well.

Fan the paper well. (

p.1-10)

The paper is curled. Straighten the paper curl.

The paper is thick. Set the paper feed pressure

adjustment knob to “Thick paper

.”

(

p.1-7)

The paper is outside the

specifications.

Use paper that meets

specifications. (

p.6-2)

The paper is not folded at the

proper folding position.

The paper folding plate is not

installed properly.

Install the paper folding plate

properly. (

p.1-5)

Static electricity has occurred in the

paper.

Fan the paper well. (

p.1-10)

Spray a commercially-available air

duster on the rubber roll.

Use thicker paper.

Paper is double-fed frequently

. The paper feed pressure

adjustment knob is set to “Thick

paper

.”

Set the paper feed pressure

adjustment knob to “Thin paper.”

(

p.1-7)

The paper separator is dirty. Clean it with alcohol. (

p.5-4)

The sheets of paper are sticking

to each other and cannot be

separated.

Fan the paper well. (

p.1-10)

The paper is outside the

specifications.

Use paper that meets

specifications. (

p.6-2)

A trouble has occurred inside the

machine.

Call your dealer.

Page 68

4-13

Chapter 4 TROUBLESHOOTING GUIDE

Symptom Cause Solution

Paper slips at the paper feed

section frequently

.

The paper feed pressure

adjustment knob is set to “Thin

paper.”

Set the paper feed pressure

adjustment knob to “Thick paper.”

( p.1-7)

The paper feed ring is dirty. Clean it with alcohol. (

p.5-3)

The sheets of paper are sticking

to each other and cannot be

separated.

Fan the paper well. (

p.1-10)

The paper is outside the

specifications.

Use paper that meets

specifications. (

p.6-2)

The side guides press

against the paper too tightly

.

Set the side guides so that they

push against the paper lightly.

( p.2-3)

A trouble has occurred inside the

machine.

Call your dealer

.

Paper jams frequently. The rubber roll is dirty. Clean it with alcohol. (

p.5-2)

Paper shreds are stuck inside the

paper conveyance passage.

Check inside the machine and

remove any paper shreds.

The stacker rollers position is not

correct.

Adjust the position of the stacker

rollers.(

p.2-5)

The paper is curled. Straighten the paper curl.

The guide plate unit is left attached

to the paper ejection plate.

Remove the guide plate unit.

(

p.3-7)

Static electricity has occurred in the

paper.

Spray a commercially-available air

duster on the rubber roll.

Paper slips in the vertical direction. After a paper type was changed,

a folding position has not been

adjusted.

Check that the rough adjustment

knob position is correct.

(

p2-4)

Paper slips in the horizontal

direction.

The paper is stacked unevenly

. Stack the paper neatly on the

paper feed table.

(

p.1-10)

There is space between the paper

and side guide.

Set the side guides so that they

push against the paper lightly

.

( p.2-3)

Paper jam at the rubber roll when

thick paper or cross folded thick

paper is folded into two.

The paper is outside the

specifications.

Use paper that meets

specifications. (

p.6-2)

The space inside the internal paper

conveyance passage is narrow

.

Widen the space using the fine

adjustment knob of the second

folding plate. ( p.3-2)

Small paper is fed continuously

(stream-fed).

The paper is outside the

specifications.

Use paper that meets

specifications. (

p.6-2)

The paper feed pressure

adjustment knob is set to “Thick

paper

.”

Set the paper feed pressure

adjustment knob to “Thin paper.”

( p.1-7)

Page 69

4-14

Memo

Page 70

Chapter 5

CLEANING THE UNIT

Page 71

5-2

1. Cleaning Each Section

The adherence of paper dust and printing ink on the rubber rolls and paper feed rings may cause

problems such as paper feed errors and folding misalignment. Adherence of paper dust near sensors

will also cause misdetection. Clean the machine once a week. We recommend that you use a

commercially-available air duster for office equipment to clean sensors.

● Prior to cleaning, be sure to disconnect the power cord from the outlet.

● After cleaning, make sure that the areas that were cleaned are completely dry before

resuming paper folding operations.

Do not use flammable sprays or solvent inside or near the unit (e.g.

when cleaning the unit).

Such flammable gas may ignite and cause a fire or combustion.

Take precautions against fire and ensure ventilation when using alcohol, and store the

alcohol in a safe place after use. Also note that use of other solvents can damage the

rubber rollers and resin inside the unit, resulting in malfunctions.

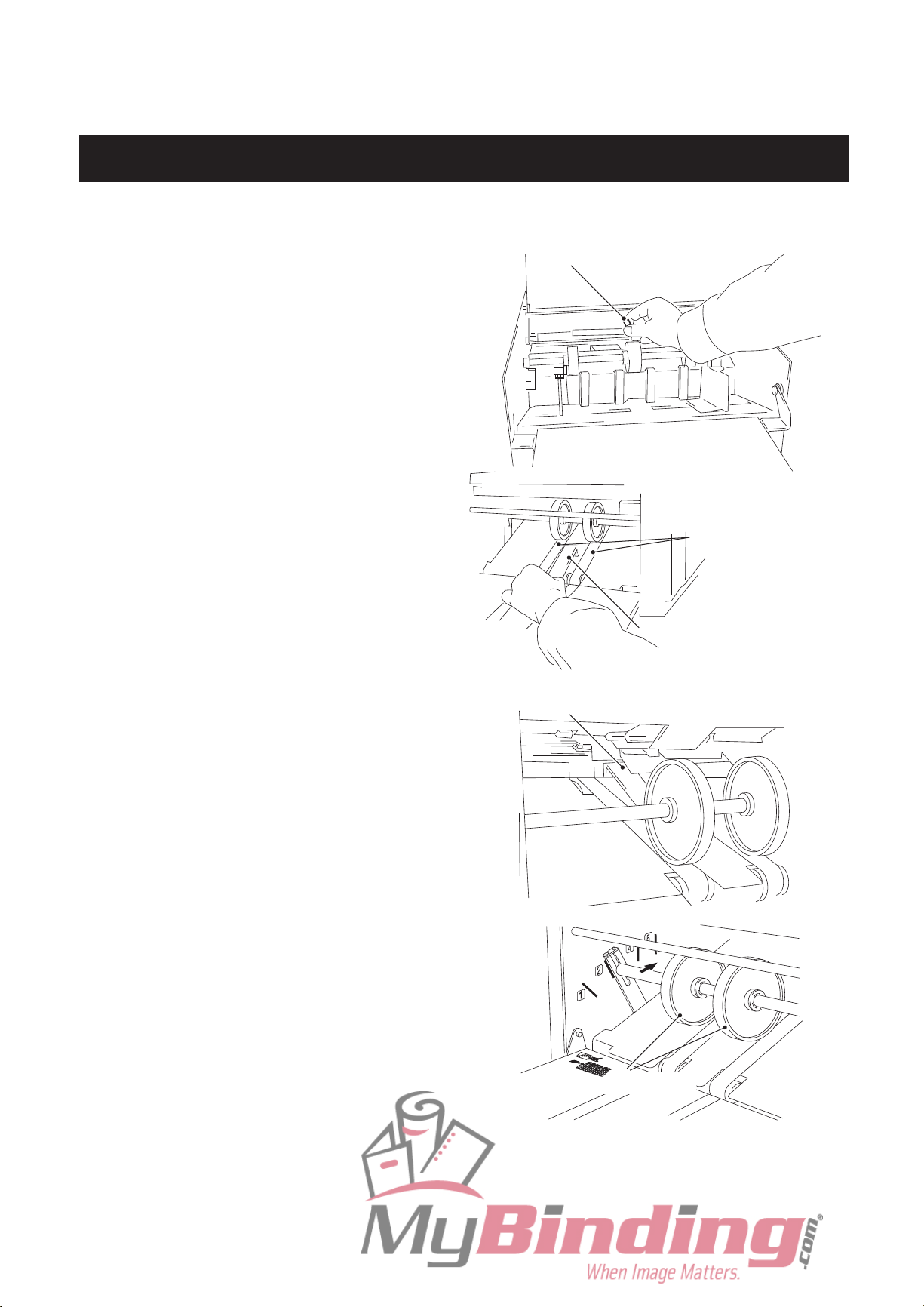

1-1. Cleaning the Rubber Roll

Top cover

1

Open the top cover.

Second folding plate

First folding plate

2

Remove the first folding plate

and second folding plate from the

machine.

Page 72

5-3

Chapter 5 CLEANING THE UNIT

Rubber roll

3

While rotating the rubber roll, clean

off the dirt with a cloth moistened

with alcohol.

1-2. Cleaning the Paper Feed Rings

Top cover

1

Open the top cover.

Paper feed ring

2

Rotate the rubber roll, and clean off

the dirt with a cloth moistened with

alcohol.

Page 73

5-4

Chapter 5 CLEANING THE UNIT

1-3. Cleaning the Paper Separator

Top cover

1

Open the top cover.

Paper separator

Cloth

Paper feed ring

(middle)

2

Insert a cloth moistened with alcohol

between the paper feed ring (middle)

and the paper separator

.

3

Turn the paper feed rings in the

direction of the arrow.

1-4. Cleaning the Paper Sensor

Paper sensor

Clean the paper sensor using an air

duster or a cotton bud.

Page 74

5-5

Chapter 5 CLEANING THE UNIT

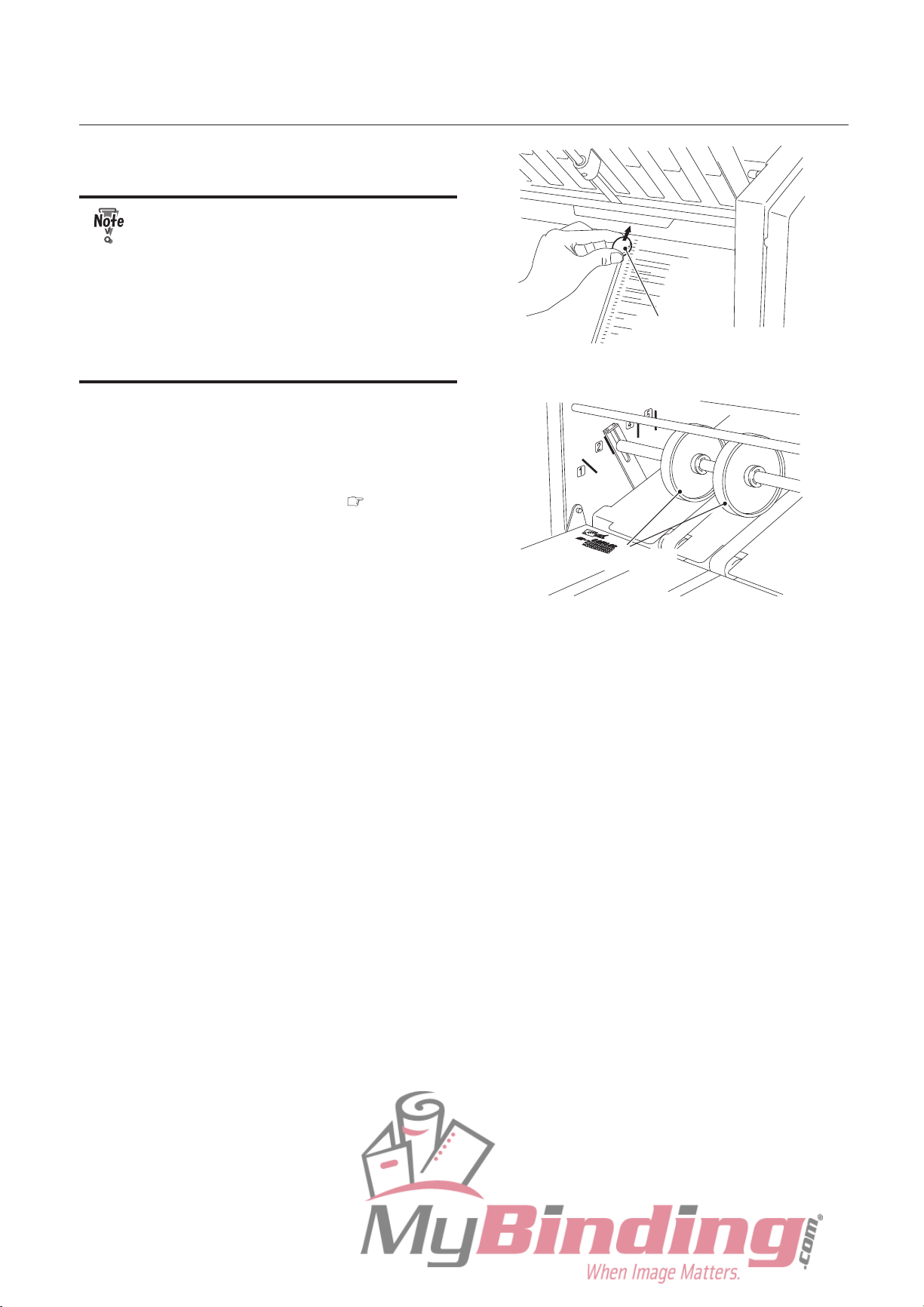

1-5. Cleaning the Ejection Gate Sensor

Ejection gate

sensor

Stacker rollers

Clean the ejection gate sensor,

located on the back of the stacker

rollers using an air duster.

1-6. Cleaning the Paper Ejection Belts

Stacker roller

Paper ejection belt

1

Move the stacker rollers to “5.”

Stacker roller

Lever

Belt

Stacker lever

2

While lifting up the stacker rollers

with your hand, pull the levers (left

and right) attached to the stacker

lever in the direction of the arrow so

that the stacker rollers are lifted up.

3

Rotate the stacker roller, and clean

off the dirt with a cloth moistened

with alcohol.

Page 75

5-6

Memo

Page 76

Chapter 6

APPENDIX

Page 77

6-2

1. Specification

Model DF-755

Type Office use, desktop

Paper size

that can

be folded

Min. 5.00 (W) x 7.00 (L) inches

Max. 1

1.00 (W) x 17.00 (L) inches

Paper quality Rough paper, fine quality paper

, stencil paper, recycled paper

Folding mode Single fold, double fold, ireegular accordion fold, letter fold, accordion fold, gate

fold, custom fold, special cross fold (paper thickness 14 lb to 28 lb)

Paper thickness 14 lb to 34 lb.

34 lb paper cannot be folded into four

.

Loading capacity of paper

feed table

500 sheets (fine quality paper 17 lb.)

Procesing speed 135 sheets/min. (For single folding 1

1 lb of fine quality L

T paper)

Paper feed method 3 rings automatic paper separation method, slant correction device

Counter 4-digit digital display

Folding stopper Manual setting

Stacker roller Manual setting 5 steps

Detection function Opening/closing of top cover

, no paper

, mis-feed, paper jam, first and second

folding plates improper setting, motor overload

Power supply 120 V 60 Hz

Power consumption 0.85

A

Dimensions In use 36.61 (W) x 18.90 (D) x 21.06 (H) inches

In storage 24.41 (W) x 18.90 (D) x 21.06 (H) inches

W

eight 70.4 lb.

Design and specifications are subject to change without notice.

Page 78

6-3

Memo

Page 79

Duplo building, 1-6, Oyama 4 chome, Sagamihara,

Kanagawa 229-1180, Japan

TEL: +81-42-775-3602

F

AX: +81-42-775-3606

E-mail: info@duplo.com

http://www.duplo.com

86V-74020-0

Loading...

Loading...