Page 1

INSTRUCTION MANUAL

FOLDER

AIR SUCTION FOLDER

DF-1200

Be sure to read this manual prior to use.

Please leave this manual at the site of use for easy reference.

Page 2

Introduction

Thank you for purchasing a Duplo product.

Be sure to read this manual prior to using the product.

After reading, leave the manual at the site of use for easy reference whenever questions related to the

product arise in the future.

Symbols

In this manual, several symbols are used to indicate important warnings. Please make sure to read

instructions accompanied by these symbols. These symbols have the following

meanings.

Describes instructions which must be followed in use.

Be sure to read the instructions to avoid problems due to incorrect operations.

Indicates supplementary or useful information.

Describes names of related items and supplementary instructions.

Trademark

The product name and company name used in this manual are trademarks or registered trademarks of the

respective companies.

Page 3

For EU

DECLARATION OF CONFORMITY

Duplo Corporation, located at 1-6, Oyama 4-chome, Chuo-ku, Sagamihara, Kanagawa 252-5280, Japan, declares that the product (or products)

complies with the provisions dened in the regulations. The reference table is mentioned below.

Name of product Model

Folder DF-1200 IEC60950-1: 2005 + A1: 2009 including EN60950-1:

Folder Accessories SIDE AIR KIT

Low Voltage Directive 2006/95/EC under

2006 + A11: 2009 + A1: 2010 + A12: 2011 deviations

KONFORMITÄTSERKLÄRUNG

Die Duplo Corporation mit Sitz in 1-6, Oyama 4 chome, Chuo-ku, Sagamihara, Kanagawa 252-5280 Japan, erklärt hiermit, dass das Produkt (oder die

Produkte) die in den Vorschriften denierten Bestimmungen erfüllt. Die Bezugstabelle ist unten aufgeführt.

Bezeichnung des

Produkts

Falzgerät DF-1200 IEC60950-1: 2005 + A1: 2009 including EN60950-1:

Zubehör der falzgerät SIDE AIR KIT

Modell

Niederspannungsrichtlinie 2006/95/EG unter

2006 + A11: 2009 + A1: 2010 + A12: 2011 deviations

DECLARATION DE CONFORMITE

Duplo Corporation, dont le siège est situé au 1-6, Oyama 4-chome, Chuo-ku, Sagamihara, Kanagawa 252-5280, Japon, déclare que le ou les produits

sont conformes aux dispositions dénies par la réglementation. Un tableau de référence est proposé ci-dessous.

Nom du produit Modèle

Plieuse DF-1200 IEC60950-1: 2005 + A1: 2009 including EN60950-1:

Accessoires de la plieuse SIDE AIR KIT

Directive Basse tension 2006/95/CE en application

de la

2006 + A11: 2009 + A1: 2010 + A12: 2011 deviations

Regulation

Electromagnetic Compatibility Directive

2004/108/EC under

EN55011: 2009 + A1: 2010

EN55014-2: 1997 + A2: 2008

EN61000-3-2: 2006 + A1: 2009 + A2: 2009

EN61000-3-3: 2008

Richtlinie

Richtlinie zur elektromagnetischen Verträglichkeit

2004/108/EG unter

EN55011: 2009 + A1: 2010

EN55014-2: 1997 + A2: 2008

EN61000-3-2: 2006 + A1: 2009 + A2: 2009

EN61000-3-3: 2008

Réglementation

Directive sur la compatibilité électromagnétique

2004/108/CE en application de

EN55011: 2009 + A1: 2010

EN55014-2: 1997 + A2: 2008

EN61000-3-2: 2006 + A1: 2009 + A2: 2009

EN61000-3-3: 2008

En

Ge

Fr

DICHIARAZIONE DI CONFORMITÁ

Duplo Corporation, sita a 1-6, Oyama 4-chome, Chuo-ku, Sagamihara, Kanagawa 252-5280, Giappone, dichiara che il prodotto (o i prodotti) è/sono

conforme/i ai requisiti deniti dalle norme sottoelencate. La tabella di riferimento è riportata qui di seguito.

Nome del prodotto Modello

Piegatrice DF-1200 IEC60950-1: 2005 + A1: 2009 including EN60950-1:

Accessorio del piegatrice SIDE AIR KIT

Direttiva 2006/95/CE relativa alle apparecchiature

a bassa tensione

2006 + A11: 2009 + A1: 2010 + A12: 2011 deviations

Direttiva Bassa Tensione

Direttiva di compatibilità elettromagnetica

2004/108/CE in base a

EN55011: 2009 + A1: 2010

EN55014-2: 1997 + A2: 2008

EN61000-3-2: 2006 + A1: 2009 + A2: 2009

EN61000-3-3: 2008

DECLARACIÓN DE CONFORMIDAD

Duplo Corporation, con domicilio en 1-6, Oyama 4-chome, Chuo-ku, Sagamihara, Kanagawa 252-5280, Japón, declara que el producto (o los

productos) cumple con las disposiciones previstas en los reglamentos. Seguidamente se indica la tabla de referencia.

Nombre del producto Modelos

Plegadora DF-1200 IEC60950-1: 2005 + A1: 2009 including EN60950-1:

Accesorios de la plegadora SIDE AIR KIT

Directiva sobre baja tensión 2006/95/CE, según

2006 + A11: 2009 + A1: 2010 + A12: 2011 deviations

Reglamentación - Reglamentaciones

Directiva sobre compatibilidad electromagnética

2004/108/CE, según

EN55011: 2009 + A1: 2010

EN55014-2: 1997 + A2: 2008

EN61000-3-2: 2006 + A1: 2009 + A2: 2009

EN61000-3-3: 2008

It

Sp

Page 4

For EU

Disposal of Old Electrical & Electronic Equipment

This symbol (the symbol of the crossed out wheeled

bin) indicates that in European countries this product

should not be disposed of as household waste.

Please recycle where facilities exist by checking with

your local authority or supplier for recycling advice.

By ensuring this product is disposed of correctly

through proper treatment, recovery and recycling,

you will help prevent potential negative eects on the

environment and human health.

Entsorgung von alten elektrischen und

elektronischen Ausrüstungsteilen

Dieses Symbol (das Symbol mit dem durchgekreuzten

fahrbaren Müllbehälter) zeigt an, dass dieses Produkt

in europäischen Länden nicht als Haushaltsmüll

entsorgt werden darf. Bitte informieren Sie sich bei

Ihren örtlichen Behörden oder bei Ihrem Händler

hinsichtlich einer Empfehlung für die Entsorgung

und führen Sie die betreenden Teile dort, wo solche

Einrichtungen vorhanden sind, einem RecyclingProzess zu.

Indem sie sicherstellen, dass das betreende Produkt

durch richtige Behandlung, Rückführung und Recycling

entsorgt wird, tragen Sie dazu bei, möglichen negativen

Auswirkungen auf die Umwelt und die menschliche

Gesundheit vorzubeugen.

En

Ge

Eliminación de residuos de aparatos eléctricos y

electrónicos

Este símbolo (un cubo de basura tachado) indica

que en los países europeos este producto no deberá

eliminarse como si se tratara de un residuo doméstico.

Solicite asesoramiento sobre reciclaje a las autoridades

locales o a su distribuidor, y siga la normativa en

materia de gestión medioambiental y reciclaje de este

tipo de residuos.

Si toma las medidas pertinentes para que este

producto se elimine mediante un tratamiento,

recuperación y reciclaje adecuados, contribuirá a evitar

posibles efectos negativos en el medio ambiente y la

salud humana.

Sp

Elimination du matériel électronique et électrique

usagé

Ce symbole (une poubelle marquée d’une croix)

indique que dans les pays européens, ce produit ne

doit pas être éliminé comme des ordures ménagères.

Recyclez-le dans les sites adaptés qui vous seront

indiqués par les autorités locales ou renseignez-vous

auprès de votre fournisseur.

En veillant à ce que ce produit soit éliminé

correctement avec un traitement, une collecte et un

recyclage adaptés, vous contribuez à éviter son action

nocive potentielle sur l’ environnement et la santé

humaine.

Smaltimento di attrezzature elettriche ed

elettroniche consumate

Questo simbolo (il simbolo della pattumiera con rotelle

barrata) indica che nei paesi europei questo prodotto

non deve essere buttato nei rifiuti domestici.

Per favore smaltire in luogo addetto al riciclo, dove

esistente, chiedendo informazioni alle autorità locali o

a chi fornisce consulenza a proposito.

Garantendo uno smaltimento adeguato di questo

prodotto (trattamento, recupero e riciclo corretto),

aiuterete a prevenire eetti negativi sull’ambiente e

sulla salute dell’uomo.

Fr

It

Page 5

For North America

Note:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment o and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit dierent from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Page 6

Memo

c6

Page 7

Safety Precautions

Safety Precautions

In this manual, operations and handling of the unit which are hazardous are described using the following

marks to prevent personal injury or property damage to the user and others.

Ignoring this mark could result in the possibility of

serious injury or even death.

Ignoring this mark could result in the possibility of injury

or physical damage.

This mark indicates a “Warning” or “Caution”.

A graphic may be shown inside the mark to describe the warning or caution more specically.

This mark indicates a forbidden action.

A graphic may be shown inside the mark to describe the forbidden action more specically.

This mark indicates actions that must be performed.

A graphic may be shown inside the mark to describe the action to be performed more specically.

Power supply

• Make sure the power supply used is always within the following range.

Power supply : 100 to 240 V AC, 50/60 Hz

• When you power other appliances from the same AC outlet, make sure that the combined power

consumption does not exceed the power supply capacity.

Rated current (Rated power) : 1.8 to 0.7 A (175 W)

SIDE AIR KIT disconnected : 1.3 to 0.6 A (130 W)

Use only the power supply voltage specied on the main nameplate.

Using other voltages could result in a re or an electrical shock.

Make sure that the combined power consumption of the appliances to be

connected does not exceed the capacity rating of the power outlets or plug

receptacles.

Exceeding the capacity rating could cause the power outlets, plug receptacles, or power extension cords to

overheat and catch a re.

i

Page 8

Safety Precautions

Operating environment

Operate this unit in the following environment.

• where the temperature range is between 5 and 35°C/41 and 95°F (-10 to 50°C/14 to 122°F in storage)

• where the humidity range is between 20 and 80% RH (10 to 90% RH in storage, however no condensation)

• which is not subject to direct sunlight

• which is reasonably free from dust

• which is subject to little or no vibration

• which is free from air-borne salt

• where there are no harmful chemicals

• where the unit is not exposed to water

Keep this unit and the power cord away from heaters and heater vents.

Excessive heat could melt the cover or power cord covering, and result in a re or an electrical shock.

Do not place metal objects or vessels containing liquids on top of the unit.

The entry of any metal object or liquid could result in a re or an electrical shock.

Do not insert any metal or easily-combustible object inside this unit.

This could result in a re or an electrical shock.

Do not use ammable sprays inside or near the unit (e.g. when cleaning the

unit).

Such ammable gas may ignite and cause a re or combustion.

Do not install this unit in a location where there is excessive humidity or

where contact with water is possible.

Poor choice of location could result in deterioration of the insulation, a re or an electrical shock.

Install this unit on a level, stable stand or oor, with sucient space around it.

Failure to do so could result in the unit overturning and causing injury.

Disconnect the power plug from the power outlet before attempting to move

this unit.

Failure to do so could result in power cord damage, a re or an electrical shock.

Always disconnect the power plug from the power outlet when the unit is not

to be used for an extended period.

Failure to do so could result in a re due to leakage current if the insulation should deteriorate.

ii

Page 9

Maintenance / others

Safety Precautions

Do not damage the power cord or power plug.

Do not scratch, alter, bend, twist, pull or place heavy objects on the power cord or power plug.

This could result in damage, a re or an electrical shock.

Do not touch the power switch with wet hands.

Otherwise electric hazards may occur.

Do not remove the cover or back panel.

This unit contains high-voltage components that could cause an electrical shock.

Do not disassemble, modify or repair this unit.

There is a danger of re, electrical shock or injury.

Contact your dealer when repairs are necessary.

If any foreign object such as metal or liquid should enter this unit,

immediately turn the unit o at the power switch and disconnect the power

plug from the power outlet.

Failure to do so could result in a re or an electrical shock.

Contact your dealer immediately.

Before cleaning this unit, turn the unit o at the power switch and disconnect

the power plug from the power outlet.

Accidental operation of the unit during cleaning could result in injury.

If the unit emits smoke, unusual heat or unusual odors, immediately turn the

unit o at the power switch and disconnect the power plug from the power

outlet.

Failure to do so could result in a re or an electrical shock.

Contact your dealer immediately.

Remove any dust that accumulates on the power plug prongs and the surface

of the plug from which the prongs extend.

Accumulated dust could result in a re.

Always grip the plug when disconnecting the power plug from the power

outlet.

Forcibly pulling on the power cord could cause damage, resulting in a re or an electrical shock.

Because of its structure, there are tiny protruding objects inside the unit. Be

careful when putting your hand inside the unit.

This could result in injury.

Do not touch or insert foreign objects into any rotating part during operation.

This could result in injury.

iii

Page 10

Safety Precautions

WARNING / CAUTION labels

"WARNING" and "CAUTION" labels are pasted on the machine to ensure user safety.

Do not remove or change them.

When the labels become dirty or are lost, be sure to contact your dealer for a new one.

iv

Page 11

Contents

Contents

Safety Precautions .............................................i

Power supply .................................................................................i

Operating environment

Maintenance / others

WARNING / CAUTION labels

...........................................................ii

..............................................................iii

.................................................iv

Chapter 1

Before Operation

1. Features ...................................................1-1

2. Names and Functions of

Components ............................................ 1-2

2-1. External parts ............................................................1-2

2-2. Internal parts (paper feed section) ...................1-3

2-3. Internal parts (top cover section) ......................1-4

2-4. Internal parts (paper ejection section) ...........1-5

2-5. Accessories .................................................................1-6

3. Names of Control Panel .........................1-7

4. Screen Descriptions ............................... 1-8

4-1. Top screen ..................................................................1-8

4-2. Menu list ......................................................................1-9

4-3. Stopper adjust screen ..........................................1-11

4-4. Operation on the menu screen .......................1-11

4-5. Classication of buzzer sounds ........................1-12

5. Paper Types and Sizes ..........................1-12

Paper that cannot be used with this machine .........1-12

6. Handling Paper .....................................1-13

6-1. Paper used ................................................................1-13

6-2. Precautions on stacking paper ........................1-14

7. Workow ...............................................1-15

Chapter 2

Basic Operation

1. Turning On/O the Power .....................2-1

1-1. Turning on the power ............................................2-1

1-2. Turning o the power ............................................2-1

2. Stacking the Paper .................................2-2

2-1. Before stacking paper ............................................2-2

2-2. Stacking paper ..........................................................2-2

3. Standard Folding of Standard Paper .... 2-5

4. Storage of Machine .............................2-11

Chapter 3

Advanced Operation

1. Correcting Folding Misalignment .........3-1

1-1. Adjustment the folding misalignment in the

right and left direction ..........................................3-1

1-2. Adjustment the folding misalignment in the

up and down direction .........................................3-3

1-3. Deformed folding ....................................................3-6

2. Standard Folding of Non-Standard

Paper ........................................................3-7

3. Custom Folding ....................................... 3-8

3-1. Operation ....................................................................3-9

3-2. Using the registered data ...................................3-10

3-3. Locking the registered data ..............................3-11

3-4. Clearing the registered data .............................3-11

3-5. Registering the folding value directly while

processing ................................................................3-12

4. Cross Fold ..............................................3-12

4-1. Cross fold of standard paper .............................3-13

4-2. Cross fold of non-standard paper ...................3-16

4-3. Cross fold paper at the desired folding

position ......................................................................3-17

5. Changing the Stacker Roller Height ... 3-17

6. Stacking the Folded Paper ..................3-18

7. Function Setting ...................................3-18

7-1. Thin paper mode ...................................................3-18

7-2. Interval function ....................................................3-19

7-3. Double-feed detection setting ........................3-20

7-4. Paper feed interval time setting ......................3-22

7-5. Stacker roller adjustment ...................................3-23

7-6. Setting ejection conveyance amount ...........3-25

7-7. Operation mode settings ...................................3-26

7-8. Test feed setting .....................................................3-27

7-9. Power saving setting ............................................3-28

7-10. Alarm setting ...........................................................3-29

7-11. Detection OFF setting .........................................3-30

7-12. Default setting ........................................................3-31

7-13. Idling setting ...........................................................3-32

7-14. Tone setting .............................................................3-33

7-15. mm/inch setting ....................................................3-34

7-16. Paper feed tray descent distance setting ....3-35

v

Page 12

Contents

Chapter 4

Cleaning the Unit

1. Cleaning the folding roller and conveyance

roller ..............................................................................4-1

2. Cleaning the LCD .....................................................4-2

3. Cleaning the belt .....................................................4-3

4. Cleaning the sensor ................................................4-4

Chapter 5

Trouble Guide

1. Error Code ...............................................5-1

1-1. Warning error ............................................................5-1

1-2. Motor error .................................................................5-2

1-3. Paper jam error .........................................................5-2

1-4. Errors requiring a service call ..............................5-3

2. Paper Jam ................................................ 5-4

2-1. Paper feed section ...................................................5-4

2-2. Folding plate..............................................................5-5

2-3. Folding roller .............................................................5-8

2-4. Ejecting section ........................................................5-9

3. Troubleshooting ...................................5-10

Chapter 6

Appendix

Specications ................................................6-1

vi

Page 13

Chapter 1 Before Operation

Chapter1 Before Operation

1. Features

• This machine is a desktop paper folder. Standard folding of standard paper can be easily controlled and

operated from the control panel.

• This machine is designed to fold paper into six popular folding modes.

Single fold Double fold Irregular

accordion fold-out

• Single folded paper can be folded further into other folding modes. (Cross fold)

Letter fold

Accordion-fold

Gate fold

1-1

Page 14

Chapter1 Before Operation

2. Names and Functions of Components

2-1. External parts

[14]

[13]

[12]

[1]

(p.2-1)

[2]

(p.1-7)

.

.

[11]

[7]

[10]

[9]

[3]

[8]

[7]

No. Name Function

[1] Folding plate 1 Guide plate for deciding the paper folding position.

[2] Control panel Use this panel to enter information to operate the machine

[3] Separating air adjustment For adjusting the separating air amount.

[4] Separator adjustment For adjusting the height of the separator.

[5] Power switch Refer to Chapter 2 “1. Turning On/O the Power”

[6] Skew correction knob Use this knob to correct the folding misalignment in both directions.

[7]

Side guide unit

[8]

Plate unit

[9] Trail edge guide unit Holds the back edge of paper stacked on the paper feed tray.

[10] Auxiliary paper feed tray For stacking paper on the paper feed tray in a stable condition. Do

[11] Paper feed tray For stacking the paper to be folded. Do not lean on the paper feed

[12] Paper feed guide Holds both sides of paper when the paper is stacked on the paper

[13] Guide xing screw For securing the paper feed guide.

[14] Top cover Safety cover to prevent the user from touching the moving parts.

[6]

[5]

Use this guide to hold both sides of paper when stacking long size

paper.

Use this unit to send separating air toward the rear end of paper

when stacking long sheets of paper.

not lean on the auxiliary paper feed tray or hold on to it to lift up the

machine.

tray or hold on to it to lift up the machine.

feed tray.

[4]

1-2

Page 15

2-2. Internal parts (paper feed section)

Chapter1 Before Operation

[1][2]

[4][6]

[9]

[8]

[5]

[2]

[3]

[7]

No. Name Function

[1] Stack height sensor adjustment For adjusting the distance between the paper and suction belt.

[2] Suction belt Sucks and conveys paper.

[3] Separating-air duct Blows out air for separating paper stacked on the paper feed tray.

[4] Separator Prevents double-feed.

[5] Paper feed tray level sensor This is a sensor to decide the height of paper which is oating by

separating air.

[6] Shutter Adjusts the amount of separating air blown out. Use the separating

air adjusting knob to adjust the amount.

[7] Folding plate 2 Guide plate for deciding the paper folding position.

[8] Safety lever This lever prevents ngers from getting caught when the paper tray

is lowered.

[9]

Knob screw This screw secures the auxiliary paper feed tray in place.

1-3

Page 16

Chapter1 Before Operation

2-3. Internal parts (top cover section)

[2]

[1]

No. Name Function

[1] Jam correction knob For rotating the folding rollers when paper has jammed inside the

unit or when cleaning the unit.

[2] Folding roller These rollers are used to fold paper. This machine is equipped with

four rollers to make six types of folding.

1-4

Page 17

2-4. Internal parts (paper ejection section)

Chapter1 Before Operation

[7]

[6]

[5]

[4]

No. Name Function

[1] Stacker roller lever This is the lever that supports the stacker roller. The height of the

roller can be adjusted.

[2] Ejecting section For receiving folded paper ejected out.

[3] Power inlet Connector for the power cord.

[4] Paper receiving tray For stacking ejected paper.

[5] Stacker belt For ejecting folded paper.

[6] Auxiliary paper ejection guide Holds the ejected paper from the top and prevent the

mis-alignment of paper stacked on the paper feed tray.

[7] Stacker roller It holds down the ejected paper and supports conveyance of paper.

[1]

[2]

[3]

1-5

Page 18

Chapter1 Before Operation

2-5. Accessories

[1] [2] [3] [4]

[5] [6] [7] [8] [9] [10]

[11]

No. Name QTY Function

[1] Folding plate 1 1

[2] Folding plate 2 1

[3] Auxiliary paper ejection guide 1

[4] Auxiliary paper feed tray 1

[5] Trail edge guide unit 1

[6] Side guide unit 2

[7] Plate unit 1

[8] Scale label 1

[9] Instruction manual 1 This manual

[10] Power cord 1 Applicable for 220 to 240 V

[11] Power cord 1 Applicable for 120 V

1-6

Page 19

3. Names of Control Panel

Chapter1 Before Operation

[1] [2]

[15]

[14]

[13]

No. Name Function

[1] LCD display Displays the menus or error messages.

[2]

[3]

[4] Lamp When the machine is in the power saving mode, the lamp blinks slowly.

[5]

[6]

[7]

[8]

[9]

[10] Menu key Press to display the setting menu window.

[11] C (Clear) key Press to cancel the number of sheets to be processed, selected items or

[12] Keypad Use to input numeral value.

[13]

[14]

[15] Standard folding lamp Of the six standard folding modes, the lamp of the one selected will light up.

key Used to change a value.

(Stopper adjustment) key

Start key

Stop key

Test key

(Enter) key Press to enter the settings. Stopper adjustments can be stored by holding

(Cancel) key Use to cancel setting data.

(Custom folding) key

(Folding mode) key Press to select the folding mode from six standard folding modes. When the

[12]

On the top screen use the

or key to raise or lower the paper feed tray.

Press to open Stopper adjustment window of folding plates 1 and 2.

Press to start paper folding.

Press to stop paper folding.

Press to test fold.

Paper thickness can be stored by test folding while double-feed detection is

[ON].

down this key on the top screen.

Forces eject while cancel key and test key are pressed down at the same time.

Forces eject at folding plates while cancel key and clear key are pressed down

at the same time.

settings.

Press to select the registered settings of custom folding.

machine is switched on, the single folding mode lamp will light up.

Lighting up will shift to the right every time the key is pressed.

Single folding mode will be performed when custom folding is selected.

All the lamps will go out when the custom folding mode is selected.

[11]

[10]

or key to change processing speed and the

[9]

[3] [4]

[8]

[5]

[6]

[7]

1-7

Page 20

Chapter1 Before Operation

4. Screen Descriptions

4-1. Top screen

The top screen is a screen displayed rst when you turn on the power.

[1]

[2]

[3]

A4 +0.0/+0.0

Ready

0

No. Information displayed Details

[1] Paper size Displays the detected paper size.

[A3][A4][A5][B4][B5][B6]/

[LGR][LGL][LTR][INV][STMT]

The following will be displayed when custom folding is set.(*: Memory number)

[IR *]

Set values are displayed when paper size is manually set.

If paper size is not displayed, the paper size is not detected and folding cannot

be started.

[2] Machine status Displays the current status of the machine.

[3] Special function setting

display

Displays the settings of each special function.

Double-feed detection is set.

(State where the test folding is not performed)

Double-feed detection is set.

(State where the test folding is performed)

Double-feed detection is set.

(Double-feed detection is not performed because the paper length is 250

mm/9.84 inches or less.)

Interval function is set.

[4]

[5]

[6]

The refold mode is set.

The stopper xation mode is set.

Counting up.

Counting down.

Paper ejection amount: [Large] is selected.

[4] Stopper correction Displays the adjustments of the folding plates 1 and 2.

The stopper position will be displayed when custom folding is set.

[5] Process Speed The processing speed which is set is displayed with an icon.

[6] Number of processed

sheets

Displays the number of processed sheets.

1-8

Page 21

Chapter1 Before Operation

4-2. Menu list

The function menu is displayed if you press the menu key with the top screen displayed.

Press the menu key to change setting windows.

The function screen can be switched with the

Determine the selected item with the

The following menu items are provided with this machine.

Item Details

Air Adjust Sep. Air (Separating Air)

Pickup Air

Paper Size Set Set [Auto][Man] Default: [Auto]

P Length (Paper Legnth)

Irreg Set

(Registration for

irregular folding)

Interval Setting Set [ON][OFF] Default: [OFF]

D-Feed Detect

(Double Feed

Detection Setting)

Other Setting Feed Interval

P Length (Paper Legnth)

Fold1 * : Settings (42.0 to 325.0 mm/1.65 to 12.80 inches)

Fold2 * : Settings (0 or 47.0 to 217.0 mm/0 or 1.85 to 8.54 inches)

No of Sec

(The Number of

Seconds)

No of Sht

(The Number of Sheets)

Set [ON][OFF] Default: [OFF]

Thickness [Thin][Thick] Default: [Thin]

(Paper feed interval

setting)

Stack Roll Adj

(Stacker Roller

Adjustment)

Belt Convey Vol

(Ejecting Belt

Conveyance Volume)

key or key.

key.

Paper Size Set

Set

P Length

* : Settings (20 to 99

The side fan air amount is displayed only when attaching the

optional products.

Sets automatic detection of paper size or manual input of paper size.

* : Settings (182 to 457.2 mm/7.17 to 18 inches)

* : Settings (182 to 457.2 mm/7.17 to 18 inches)

Adjusts the stopper position of the folding plate 1. There is a limit to

the settings according to the length of paper used.

Adjusts the stopper position of the folding plate 2. There is a limit to

the settings according to the length of paper used and the position

of folding plate 1 stopper.

Select ON to use interval function.

[3][5][10] Default: [5]

Sets the number of seconds to be interrupted during folding

operation.

* : Settings (1 to 999) Default: [1]

Sets the number of sheets to be suspended during folding operation.

Select ON to detect double-feed.

Select the thickness of paper for which double-feed is detected.

[Slow][Normal][Fast] Default: [Normal]

Sets the paper feed timing.

* : Settings (1 to 16)

Adjusts the position of the stacker roller.

[Large][Normal] Default: [Normal]

Sets the paper ejection conveyance amount.

)

Auto

457.0

1-9

Page 22

Chapter1 Before Operation

Item Details

Other Setting Oper Mode

(Operation Mode

Settings)

Test Feed Set * : Settings (1 to 3) Default: [2]

Power Save

Set

Alarm

Setting

Detect OFF

(Detection

OFF Setting)

Default

setting

Idling [ON][OFF] Default: [OFF]

Tone [ON][OFF] Default: [ON]

mm/inch Setting [mm][inch] Default: [mm]

Tray Desc Amt

(Paper Feed Tray

Descending Amount)

[Normal] [Last Fold][Stopper Fixed] Default: [Normal]

Sets operations of folding stopper on the folding plates 1 and 2,

when the power is turned on.

[Normal] : Start up the machine in the normal setting state, when the

power is turned on.

[Last Fold] : Start up the machine with the same settings as the last

time it was used.

[Stopper Fixed] : Start up in the same conditions at all times.

Sets the number of sheets to perform test feeding.

Set [ON][OFF] Default: [ON]

Sets the power saving mode to ON or OFF.

Time * : Settings (15 to 60) Sec Default: [30]

Set [ON][OFF] Default: [OFF]

Sets to the alarm (buzzer sound) setting when leaving the machine

unused.

Time * : Settings (5 to 120) Min Default: [60]

Load

(Load

Paper)

Speed * : Settings (0 to 6) Default: [5]

D-Feed

(Doublefeed)

[ON][OFF] Default: [ON]

Sets the detection of paper stacked.

Sets the value to be used when the power is turned on. Set to [0] for

folding thin paper mode.

[ON][OFF] Default: [OFF]

Sets to the idling setting depending on whether to use at the time of

occurrence of mis-feed or double-feed.

Sets the buzzer to ON or OFF.

Sets the unit to be displayed to [mm] or [inch].

[Not Descend][Small][Normal][Large] Default: [Large]

Sets how far the paper feed tray is lowered.

1-10

Page 23

4-3. Stopper adjust screen

[A] [B]

Chapter1 Before Operation

A4 +0.0/

- +

Screen Item Display Details

[A] Folding plate 1 stopper correction ** * : Settings (-5.0 to 5.0/-0.20 to 0.20)

[B] Folding plate 2 stopper correction

A4 +0.0/+0.0

+ -

4-4. Operation on the menu screen

The basic operation on the menu screen is as follows. Here how to open [Air Adjust] window is explained as

an example.

1

Press Menu while the top screen is

displayed.

A setting window will be displayed.

Air Adjust

Sep. Air

Pickup Air 40

45

2

3

4

5

6

Press the key or key to select [Sep.

Air].

Press the key.

At this stage numerical values can be changed.

Input numerical values on the keypad

or with the

The numerical values can be changed by [5]

using the

Press the key.

The gures are set.

Press the key.

Returns to the top screen.

or key.

or key.

Air Adjust

Sep. Air 45

Pickup Air 40

Air Adjust

Sep. Air

Pickup Air 40

A4 +0.0/

Ready

50

0

1-11

Page 24

Chapter1 Before Operation

4-5. Classication of buzzer sounds

In this machine the buzzer sounds in conrmation when setting on the control panel or paper runs out on

the paper feed tray, etc. Classication of the sounds is as follows.

“pi” : Operational sound at the time of normal key operation

“pipi” : Warning alarm at the time of mis-operation, mis-feed of paper, or paper empty

“pii” : At the start of folding operation or end of normal folding operation

In conrmation of change of various settings

“piipii” : At the occurrence of an error such as paper jam

“piipiipii” : At the occurrence of an error to be asked for Duplo dealer’s assistance

5. Paper Types and Sizes

Paper type

Fine quality paper, Rough paper, Stencil paper, Recycle paper : 52.3 to 157 g/m2/14 to 40 lb

2

Art paper, Coated paper : 73.3 to 157 g/m

/19 to 40 lb

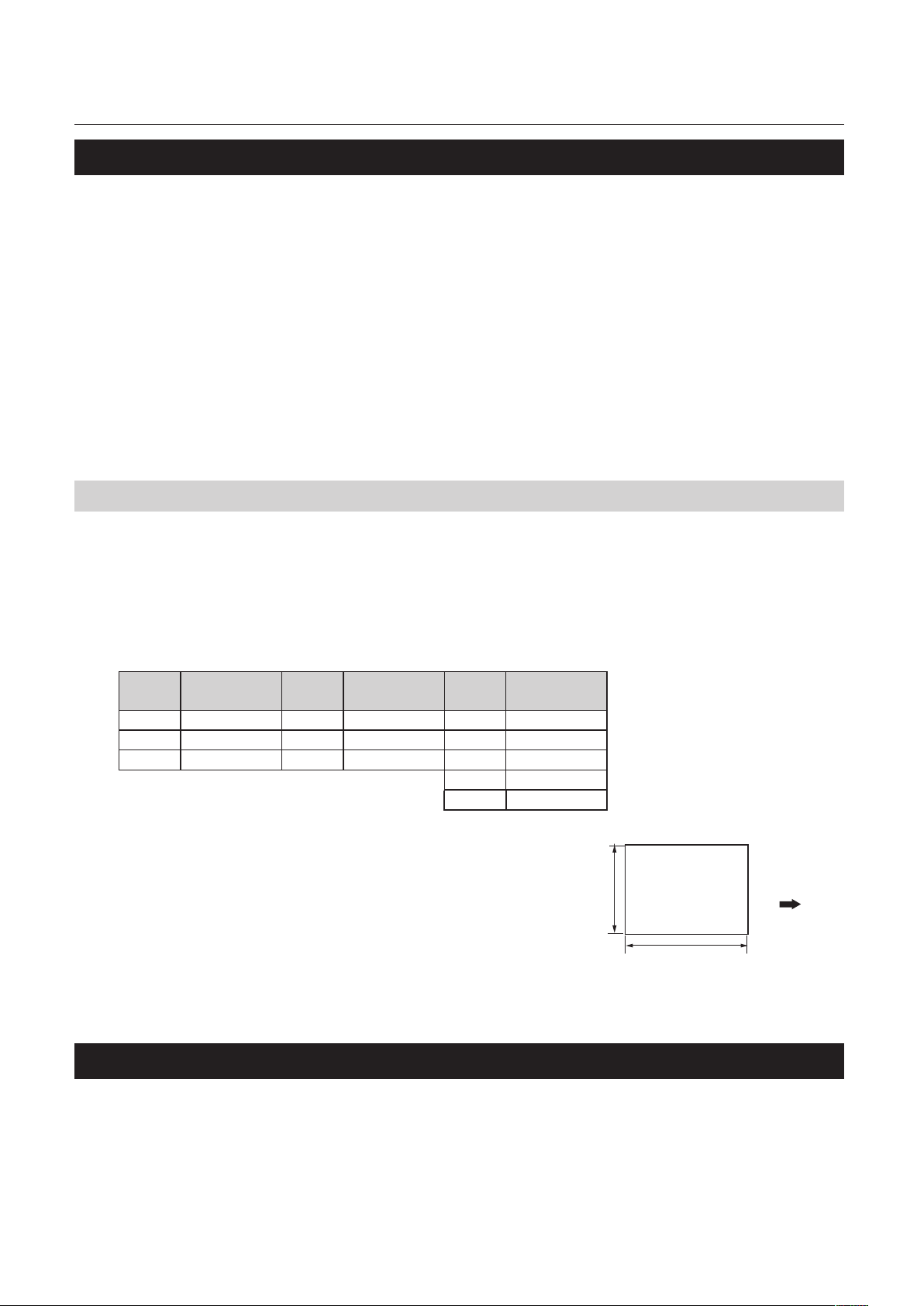

Paper size

Standard paper (The standard paper can be used only when it is stacked in the machine direction.)

Paper

size

A3 297 x420 B4 257 x 364 LGR 11 x 17

A4 210 x 297 B5 182 x 257 LGL 8.5 x 14.0

A5 148 x 210 B6 128 x 182 LTR 8.5 x 11.0

Non-standard paper

Width : 120 to 311 mm/4.73 to 12.24 inches

Length : 182 to 457.2 mm/7.17 to 18.00 inches

* The aspect ratio for non-standard paper is

1:1 to 2.2:1.

Some limitations in setting and paper quality

may be applied depending on paper size.

W × L

(mm)

Paper

size

W × L

(mm)

Paper

size

INV 7 x 8.5

STMT 5.5 x 8.5

Width : 120 to 311/

Unit : mm/inches

W × L

(inches)

4.73 to 12.24

Paper

Length : 182 to 457.2/

7.17 to 18.00

Paper feed

direction

Paper that cannot be used with this machine

• Paper out of specications

• Curled paper

• Wavy paper

1-12

Page 25

Chapter1 Before Operation

6. Handling Paper

6-1. Paper used

• Make sure that the printing ink on the paper has dried completely prior to use.

• Wet ink or ink that is not completely dried may stain the folding roller causing trouble such

as smearing on paper.

• Use of paper printed with special types of ink may cause the folding roller to swell or deform,

and folding misalignment may occur.

• Paper may not be fed smoothly into the folding plate or deformed folding may occur depending on

dierent environmental factors (temperature, humidity), paper ream weight, paper type, paper grain

direction if curled paper is used. Make sure to atten curled paper or paper with folded lines before

use.

• Separate the sheets of paper well before

stacking them.

1-13

Page 26

Chapter1 Before Operation

6-2. Precautions on stacking paper

• Stack paper striking the leading edge of paper

lightly at the shutter.

If there is some clearance between the

leading edge of paper and shutter, the

paper detecting sensor does not function

properly.

• Do not stack the sheets of paper on the paper

feed tray with the sides of sheets unaligned or

some sheets protruding from the stack.

Processing with sheets unaligned on the

right or left side may cause such trouble as

folding misalignment and jamming.

Paper

Shutter

Striking

Paper feed tray

paper

detecting

sensor

• Do not stack paper on the paper feed tray with

the lead and trail edges unaligned or some

sheets protruding out.

Processing with sheets unaligned on the

lead and trail edges may lead to unstable

feed causing such trouble as mis-feed and

double-feed.

1-14

Page 27

Chapter1 Before Operation

7. Workflow

The owchart below illustrates the ow of basic operation. For details, refer to the text and relevant pages.

Turning on the power

Stacking paper

Selecting folding mode

Adjusting air

Checking the separating air adjustment knob

Checking the separator adjustment knob

(p.2-1)

(p.2-2)

(p.2-6)

(p.2-6)

(p.2-8)

(p.2-8)

Checking the level sensor adjustment knob

Setting processing speed

Test feed

Starting paper folding

Ending paper folding

Removing processed paper

(p.2-8)

(p.2-9)

(p.2-9)

(p.2-10)

Turning o the power

(p.2-1)

1-15

Page 28

Chapter1 Before Operation

Memo

1-16

Page 29

Chapter 2 Basic Operation

1. Turning On/Off the Power

Chapter 2 Basic Operation

• Be sure to use the attached power cord.

• Make sure that the power plug is connected to the wall socket.

1-1. Turning on the power

Set the power switch to the “ I ” side.

Do not touch the power switch

with wet hands.

Otherwise electric hazards may occur.

1-2. Turning o the power

Set the power switch to the “ ” side.

2-1

Page 30

Chapter 2 Basic Operation

2. Stacking the Paper

2-1. Before stacking paper

Checking the front/back,top/end of paper

Check the “front/back” and “top/end” of paper when stacking paper on the paper feed tray.

Check for folding misalignment, and check “front/back” and “top/end” of paper when checking the nished

fold after test folding.

When paper is stacked with the gray surface on the obverse side and white surface on the reverse side on

the paper feed tray, and processing is completed in the standard folding mode, the folded paper is as shown

in the gure.

Paper feed direction

Single

fold

Double

fold

Irregular

accordion fold-out

2-2. Stacking paper

Do not put ngers inside during operation.

Keep away long hair, ties, jewelry and loose clothing.

It could cause injury.

Loosen the guide xing screw.

1

Stack paper on the paper feed tray.

2

Push in the paper until the lead edge touches

the shutter below the paper feed inlet slightly.

Letter

fold

Accordionfold

Gate fold

Ejection

direction

The round hole (upper side) on the paper feed

guide indicates the maximum paper stacking

height (50 mm/1.97 inches).

2-2

50 mm/

1.97 inches

Maximum paper

stacking height: 50 mm/1.97 inches

Page 31

Adjust the paper feed guide to match

3

the paper size.

Set the paper feed guide in such a way that it

touches the paper lightly.

• Do not press the paper with the paper

feed guides too strongly. Otherwise,

paper feed errors such as mis-feed will

occur.

• If the guides are positioned incorrectly,

the automatic paper size detection

function will not work, and the test key

and start key,etc. will not operate.

Tighten the guide xing screws.

4

Chapter 2 Basic Operation

(p.2-5)

Make sure to tighten the guide xing screws on both right and left sides. If the screws are not

xed, the paper feed guide moves during operation, and folding misalignment may occur in the

right and left direction.

Set the trail edge guide unit to the rear

5

end of paper.

Set the trail edge guide unit so that it will be in

contact with the paper lightly.

The trail edge guide unit must be set

in place without fail. When starting the

machine without setting the back edge

stack guide, the paper will be blown by

separating air.

2-3

Page 32

Chapter 2 Basic Operation

When processing long paper, use the plate unit and side guide unit.

Range of paper length: A3 (LGR) or more, or back edge of paper is positioned at more than two-third of

auxiliary paper feed tray.

Set the plate unit onto the auxiliary

6

paper feed tray.

Be sure to set the plate unit so that it does not

extend beyond the rear end of paper.

Attach the side guide unit on each side

7

of paper.

Attach the side guide unit leaving some

clearance between the side guide unit and

paper. However, if the side guide unit is set

leaving too much clearance between the

side guide and paper, accuracy of feeding

may be lowered, and folding misalignment

may be apt to occur. If the side guide unit

is set striking at the paper, double-feed or

mis-feed may be caused.

Automatic rise/descent of the paper feed tray

• When paper is stacked on the paper feed tray, the paper feed guides are set, and the start or test key is

pressed, the paper feed tray rises automatically.

When using large or heavy paper, the paper feed tray may become over stacked and may not be

able to rise due to paper weight. In such cases, stack less paper.

• The paper feed tray will descend under the following conditions or after the following operations.

Paper is removed from the paper feed tray.

Paper runs out during folding operation.

The stop key is pressed during folding operation to stop processing.

key is pressed in the stand-by state. (The paper feed tray descends while the key is being

The

pressed.)

2-4

Page 33

Chapter 2 Basic Operation

3. Standard Folding of Standard Paper

Method to fold standard paper by setting a mode among standard folding modes displayed on the control

panel.

For the standard paper sizes, refer to Chapter 1 “5. Paper Types and Sizes” (p.1-12).

Six standard folding modes are available as shown below.

Paper feed direction

Ejection

Single

fold

Depending on the thickness of paper, this machine may not be able to process some standard sheets of

paper.

Double

fold

Irregular

accordion fold-out

Letter

fold

Accordionfold

Gate fold

direction

Do not put ngers inside during operation.

Keep away long hair, ties, jewelry and loose clothing.

It could cause injury.

Automatic detection of standard paper size

When paper for all paper sizes is stacked in the

machine direction shown in the gure, paper

is detected as standard paper.

When paper of standard paper size is

stacked on the paper feed tray in the

sideways, the paper size is detected as

wrong paper size. Use paper as nonstandard paper when stacking paper in the

sideways.

For the use of non-standard paper, refer

to Chapter 3 “2. Standard Folding of NonStandard Paper” (p.3-7).

2-5

Page 34

Chapter 2 Basic Operation

Check the paper size display.

1

The paper size is not displayed if the paper

feed guide is not positioned as specied even

though the size of standard paper is used. If

not, reset the paper feed guide to a correct

position.

Press the folding mode key to select the

2

folding mode.

Press the menu key to display [Air

3

Adjust] window.

Select [Sep. Air] using the or key.

4

A4 +0.0/

Ready

Air Adjust

Sep. Air

Pickup Air

0

45

40

Press the key.

5

At this stage numerical values can be changed.

Input numerical values on the keypad

6

or with the

The numerical values can be changed by [5] using the or key.

Setting range: 20 to 99

Refer to “Air Adjustment Table” for appropriate volume of [Sep. Air].

Press the key.

7

The gures are set.

• The volume of [Sep. Air] can be checked by

pressing the test key or start key while [Air

Adjust] window is displayed.

• Press either of the stop key, key, or

menu key to stop separating air.

• When the air volume is appropriate, the

paper does not ap but it oats as air

reaches the rear end of paper as shown in

the right gure.

or key.

Air Adjust

Sep. Air

Pickup Air

50

40

2-6

Page 35

Chapter 2 Basic Operation

8

Set [Pickup Air] by following the same procedures as step 4 to 7.

Setting range: 20 to 99

Refer to “Air Adjustment Table” for appropriate volume of [Pickup Air].

9

Press the key.

Returns to the top screen.

Also use the menu key to return to the top screen when [Air Adjust] is set in the idling state.

Air Adjustment Table

The air adjustment table is a guide to set numerical values. The setting range of each setting is the following

numerical value ±5. The numerical values in ( ) in the table refer to the setting range for the paper.

Set each air volume to a smaller value than that of the table, when handling thin and imsy paper such as

rough paper and recycled paper. The larger the air volume, the more folding misalignment may occur.

Change the numerical value when double-feed or mis-feed occurs even though the values are set according

to the air adjustment table.

A3 / LGR A4 / LGL,LTR A5 / INV, STMT

Paper

quality

Fine

quality

paper

Coated

paper

Paper ream

weight

(g/m2 / lb)

52.3/14 35 30 (25 to 40) 35 30 40 30

64/16 40 35 40 35 45 30

81.4/22 50 45 45 40 50 35

104.7/28 60 45 50 45 50 40

127.9/34 65 50 55 45 50 40

157/40 75 50 60 50 50 45

73.3/19 45 (40 to 55) 40 (35 to 50) 40 35 45 30

79.1/21 50 40 (35 to 50) 45 40 45 35

84.9/22 55 45 45 40 45 35

104.7/28 65 50 55 45 50 40

127.9/34 75 50 60 50 50 40

157/40 85 55 75 50 70 45

[Sep. Air] [Pickup Air] [Sep. Air] [Pickup Air] [Sep. Air] [Pickup Air]

Paper

quality

Fine

quality

paper

Coated

paper

B4 B5 B6

Paper ream

weight

(g/m2 / lb)

52.3/14 40 35 40 30 40 30

64/16 40 35 45 35 45 30

81.4/22 45 40 50 40 50 35

104.7/28 55 45 55 45 50 40

127.9/34 60 45 60 50 60 40

157/40 65 50 60 50 65 40

73.3/19 45 35 40 30 45 35

79.1/21 45 40 45 35 45 35

84.9/22 50 40 50 40 50 40

104.7/28 60 45 55 45 50 40

127.9/34 70 50 60 45 50 40

157/40 80 50 60 50 70 40

[Sep. Air] [Pickup Air] [Sep. Air] [Pickup Air] [Sep. Air] [Pickup Air]

2-7

Page 36

Chapter 2 Basic Operation

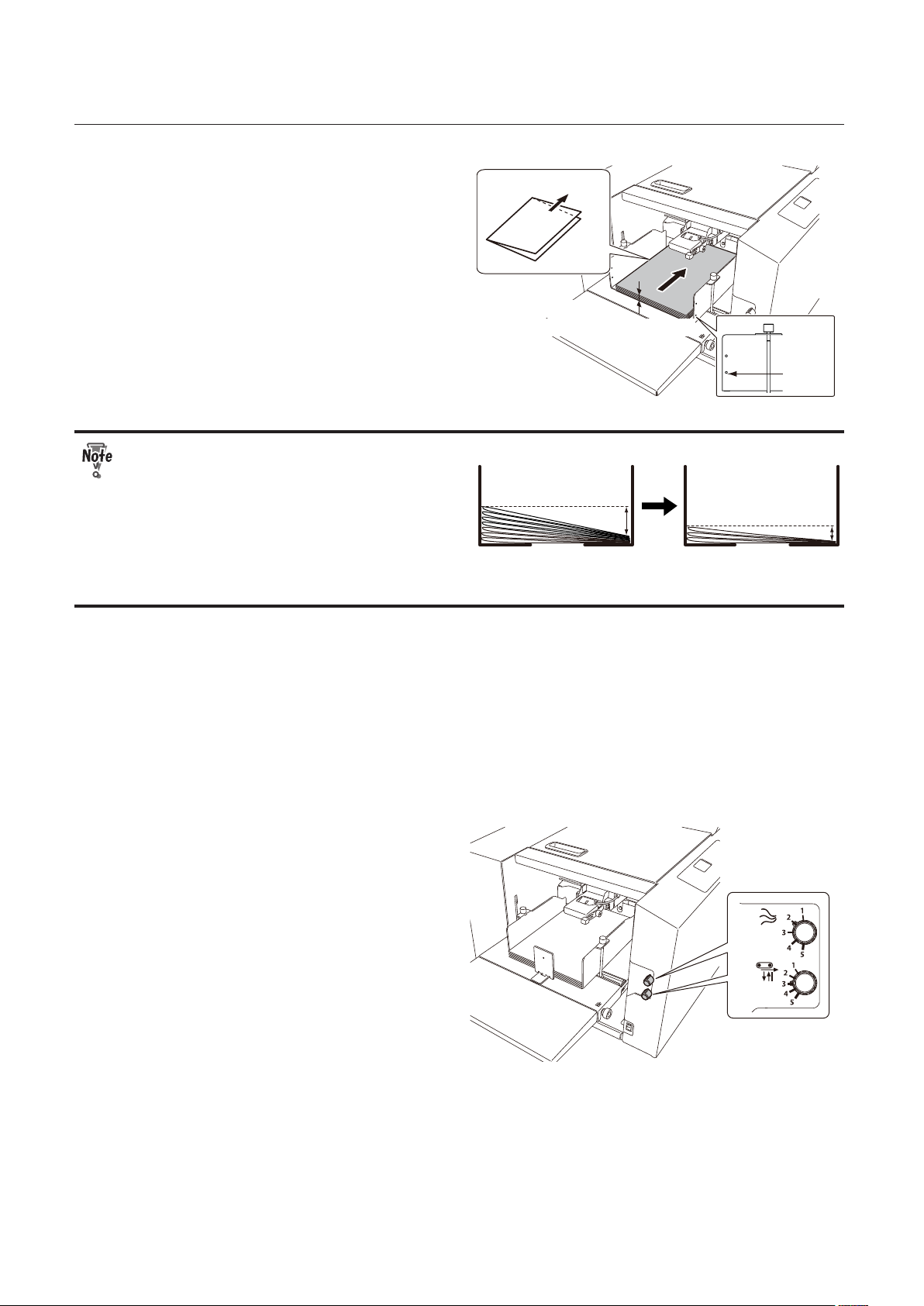

Check that the separating air

10

adjustment knob is set to [2].

• Larger settings increase and smaller settings

decrease the amount of air.

• Set the air volume to [4] to [5] as paper is

heavy when handling large size paper.

• Set the knob to [1] when using small size thin

paper.

Check that the separator adjustment

11

knob is set to [2]. (The separator should

be lightly in contact with the suction

belt.)

• The larger the setting, the wider the space

between the separator and the suction belt.

• Turn the knob towards [3] if mis-feed occurs.

• Turn the knob towards [1] if double-feed

occurs.

Check that the stack height sensor

12

adjustment knob is set to the standard

position (the second scale from the

bottom).

• Setting the knob to the upper scales (round

hole) lowers feeding position, and setting

the knob to the lower scales raises feeding

position.

• Lower the sensor knob by one scale if mis-feed

occurs.

• Raise the sensor knob by one scale if doublefeed occurs.

A feeding error may occur when stopping

feeding paper with the scale of stack height

sensor adjustment knob set to the rst

scale, and restarting feeding paper with

smaller amount of paper on the paper feed

tray. If so, match the stack height sensor

adjustment knob with paper and set it to

the following position.

• Thin paper: between the second scale and third scale from the bottom

• Thick paper: between the rst scale and second scale from the bottom

Thin paper

Thick paper

2-8

Page 37

Press the or key to set the

13

processing speed.

The default of processing speed is [5]. Folding

misalignment, etc. May occur depending on

the paper used and folding mode. If so, lower

the processing speed.

When paper jam or abnormal folding occurs by using thin and imsy paper, adjust the processing

speed referring to “Thin paper mode”.

The processing speed can be changed during folding process or in the idling state.

folding misalignment may be caused by changing the processing speed largely.

When setting the folding mode of B6 size paper to double fold, the operable processing speed is

[4] or more. Even if the processing speed is set to [0] to [3], the processing speed will be changed

automatically to [4] when the test key or start key is pressed.

Adjust the position of the paper

14

receiving tray.

Set to [A] to stack ejected paper diagonally.

Set to [B] to stack ejected paper straight.

Refer to Chapter 3 “6. Stacking the Folded

Paper” (p.3-18).

(p.3-18)

A4 +0.0/+0.0

Ready

0

Chapter 2 Basic Operation

(p.3-32)

However,

[A]

[B]

Press the test key.

15

Perform test folding.

Test folded paper are not counted in the

number of sheets processed.

If this machine does not start by pressing the test key, automatic detection of paper size may

not function. Check the paper feed guide is set appropriately to the scale of paper size.

Check the nish of test folding.

16

Check the last sheet of test folded paper for

folding misalignment.

When folding misalignment occurs, refer to

Chapter 3 “1. Correcting Folding Misalignment”

(p.3-1)

<along vertical

length of paper>

<Normal folding>

<along sides of paper>

<Deformed folding>

2-9

Page 38

Chapter 2 Basic Operation

Select the method of using the counter.

17

• The counter can be used in two ways “Count

Down” and “Count Up”.

Count up : Press the clear key and set

the counter to “0” to start

operation.

Count down : Enter the number of sheets

to be processed on the

keypad to start operation.

• Up to four digits (9999) can be displayed.

• An icon will be displayed by pressing the start key.

A4 +0.0/ A4 +0.0/

Ready Ready

0

Count up Count down

Count up

When pressing the clear key, the buzzer sounds “pi”, and the count display will return to [0].

When pressing the start key without pressing the clear key, paper folding operation will restart and the

number of sheets processed will be counted up.

The machine will stop operations when the count display shows [9999]. Press the clear key to return

the count display to [0] and press the start key when processing paper folding continuously.

100

Count down

The machine will stop when the number of sheets set for processing is processed, and the count

display will return to the number of sheets set for processing.

When pressing the clear key, the buzzer sounds “pi”, and the use of the counter will return to “Count

up” instead of “Count down”.

The count display will return to [0].

When pressing the start key without pressing the clear key, paper folding operation will restart and the

number of sheets processed will be counted down.

After that, the procedures vary depending on the use of the counter.

For counting down, refer to procedure 18.

For counting up, refer to procedure 19.

Press the keypad to enter the number

18

of sheets to be processed.

Press the start key to start folding.

19

• Press the stop key to interrupt or stop

operation. Press the start key again to

restart operation.

• When paper stacked on the paper feed tray runs out,

the machine will stop automatically, and [No Paper]

will be displayed on the LCD display. When paper is

stacked on the paper feed tray, the display of [No Paper]

will disappear, and the machine will be in the stand-by

state.

• When double-feed or paper size error occurs during folding operation, the fed paper is processed

and ejected, but the number of processed sheets will not be counted.

• When paper jams at the paper ejection section, paper may be fed after detecting paper jam at the

paper ejection section, but the number of sheets processed will not be counted.

2-10

Page 39

4. Storage of Machine

Store the machine as follows, when it is not used.

Chapter 2 Basic Operation

1

2

3

4

Turn o the power switch.

Disconnect the power plug from the

outlet.

Remove the power cord from this

machine.

Remove the auxiliary paper ejection

guide.

Do not touch the power switch

with wet hands.

Otherwise electric hazards may occur.

Do not touch the power

plug with wet hands.

Otherwise electric hazards

may occur.

5

6

Hang the hook section of the paper

receiving tray.

Hang the auxiliary paper ejection guide

on the paper receiving tray.

2-11

Page 40

Chapter 2 Basic Operation

Loosen the setting screws.

7

Remove the auxiliary paper feed tray.

8

2-12

Page 41

Chapter 3 Advanced Operation

Chapter 3 Advanced Operation

1. Correcting Folding Misalignment

Folding misalignment consists of “folding misalignment along the sides of the paper” and “folding

misalignment along the vertical length of the paper”. Other than this, “deformed folding” may also occur due

to paper characteristics, etc.

Depending on the usage environment (temperature and humidity), paper type, thickness, paper grain

direction, trimming accuracy, and printing states folding misalignment may occur.

Do not put ngers inside during operation.

Keep away long hair, ties, jewelry and loose clothing.

It could cause injury.

1-1. Adjustment the folding misalignment in the right and left direction

1

When the folded paper is misaligned along

the sides, correct using the skew correction

knob of the paper feed tray.

Ejection

direction

Check that the paper feed guides are

set correctly.

Gaps between the paper and paper feed

guides will cause folding misalignment along

the sides to occur easily.

Proceed to step 2 if the paper feed guides are

set properly.

Perform test folding after resetting the paper

feed guides. Proceed to step 2 if folding

misalignment occurs after setting the paper

feed guides properly.

3-1

Page 42

Chapter 3 Advanced Operation

Remove the paper stacked on the paper feed tray.

2

Adjustments cannot be made eectively by adjusting folding misalignment with skew correction knob

when the leading edge of paper is in contact with the shutter.

Rotate the skew correction knob and adjust.

3

Rotate the skew correction knob by a quarter to half turn to adjust. Check the skew correction eect (test

fold) and adjust.

Folding misalignment A

Rotate the knob in the clockwise direction.

The leading edge of paper on the right side (on

the control panel side) will be fed earlier.

Folding

misalignment A

Ejection direction

Folding misalignment B

Rotate the knob in the counterclockwise

direction. The leading edge of paper on the

left side (on the non-operator’s side) will be

fed earlier.

Stack paper on the paper feed tray.

4

Push in paper so that the edge of paper comes

lightly in contact with the shutter.

Perform test folding.

5

After completing folding

6

operations,return the skew correction

knob to the standard position.

Folding

misalignment B

Ejection direction

<Standard position>

Round

hole

3-2

Plate

Page 43

Chapter 3 Advanced Operation

1-2. Adjustment the folding misalignment in the up and down direction

When the folded paper is misaligned along

the vertical length, adjust the positions of the

folding stopper of folding plates 1 and 2 to

correct the misalignment.

Adjustable range and correction restrictions

• For standard folding, the adjustable range

using the stopper adjustment key is within ± 5

mm/0.20 inch from the center of the paper.

• The positions of the folding stoppers of

folding plates 1 and 2 may not be adjustable

to ± 5 mm/0.20 inch according to the length

of the paper used.

• For [Special folding] and [Stopper xing

mode], the folding positions are set directly

according to the paper length, and the

adjustable range of ± 5 mm/0.20 inch is not

restricted.

Adjustment by

using the key.

-5.0 mm/0.20 inch

or less

Center

Paper

Adjustment by

using the key.

+5.0 mm/0.20 inch

or less

Ejection

direction

Ejection

direction

The restricted folding plate and adjustment details dier according to the folding mode and paper length.

For EU

Folding mode Restricted range of

paper length*

Double fold 182 to 203.9 mm Correction by

Irregular accordion fold-out 182 to 182.7 mm Correction by

182 to 199.9 mm Correction by

Gate fold 424.4 to 432 mm Correction by

421.8 to 432 mm Correction by

Restricted folding plate and

adjustment key

key of folding plate 2

key of folding plate 1

key of folding plate 2

key of folding plate 1

key of folding plate 2

For Noth America

Folding mode Restricted range of

paper length*

Double fold 7.17 to 8.02 inches Correction by

Irregular accordion fold-out 7.17 to 7.90 inches Correction by

Gate fold 16.69 to 17.00 inches Correction by

16.56 to 17.00 inches Correction by

Restricted folding plate and

adjustment key

key of folding plate 2

key of folding plate 2

key of folding plate 1

key of folding plate 2

* Range of paper length which cannot be corrected to ± 5 mm/0.20 inch. The adjustment value diers

according to the paper length.

3-3

Page 44

Chapter 3 Advanced Operation

Adjustment folding misalignment along vertical length of paper by folding mode

Adjust folding misalignment along the vertical length of the paper in standard folding using the folding

stopper Adjustment keys of folding plates 1 and 2.

Folding plate 1 Folding plate 2

Folding mode State of

Single

fold

A

folded plane

A

A is long key Single

A is short

Adjustment

key

key

Folding mode State of

fold

* Folding plate 2 is not used in single

folding.

folded plane

B

Adjustment

key

Double

fold

Irregular

accordion

fold-out

Letter

fold

Accordion

fold

Gate

fold

A

A

A

A

A

A is long key Double

fold

A is short

key B is short key

A is long key Irregular

accordion

A is short

key B is short key

fold-out

A is long key Letter

fold

A is short

key B is short key

A is long key Accordion

fold

A is short

key B is short key

A is long key Gate

fold

A is short

key B is short key

B is long key

B

B

B

B

B is long key

B is long key

B is long key

B is long key

B

Adjustment method

Adjust the positions of the folding stopper using the stopper adjustment keys of folding plates 1 and 2 on

the control panel.

Folding plate 1 :The folding stopper of the folding plate 1 moves in the direction of A shown in the gure by

pressing the key, and moves in the direction of B shown in the gure by pressing the key.

Folding plate 2 :The folding stopper of the folding plate 2 moves in the direction of A shown in the gure by

pressing the key, and moves in the direction of B shown in the gure by pressing the key.

3-4

A

Folding plate 1

B

B

Folding plate 2

A

Page 45

Chapter 3 Advanced Operation

The folding stopper moves by 0.1 mm/0.004 inch every time the stopper adjustment key is pressed. While

holding down the stopper adjustment key, the value will continue to increase/decrease within the setting

range.

The value adjusted with the stopper

adjustment key will be displayed on the top

right section of the LCD display.

Folding plate 1

A4 +0.0/

Folding plate 2

A4 +0.0/+0.0

Example of operation procedures of single folding with

folded plane A longer by 1 mm/0.03 inch shown in the gure.

Press the stopper adjustment key of the

1

folding plate 1.

The numerical value can be changed at this

stage.

2

3

Press the key to set the value to [+0.5].

Press the key.

The changed value is set.

- +

+ -

A

Ejection direction

+0.0/

- +

+0.5/

- +

The changed value will be cleared by turning o the power switch. For registration of the changed

value, refer to “Registering the adjusted value” (p.3-6).

The numerical value of the folding plate can be changed by inputting the numerical value on the

keypad.

Inputting plus numerical value : Input the numerical value to be changed on the keypad.

Inputting minus numerical value : Change the display to minus with the key and input

the numerical value to be changed on the keypad.

3-5

Page 46

Chapter 3 Advanced Operation

Registering the adjusted value

Adjustment values of folding misalignment in the vertical direction of thirty-six registration types including

six standard folding modes x six types of standard paper sizes can be registered. (Thirty registration types in

total including ve types of standard paper sizes for North America) Once adjustment values are registered,

folding operation can be performed in the same condition as the registration is made without registering the

same adjustment.

Register the values by press and hold the

key after adjustment the folding plates 1 and 2. The buzzer

sounds “pii” once and the adjustment value is registered.

To cancel the adjustment value already registered, set the adjustment value to [0] using the keypad,

or key and press and hold the

Adjusted folding stopper position can be registered to special folding.

key. The buzzer sounds “pii” once and the adjustment value is registered.

(p.3-8)

or

The adjustment values cannot be registered for standard folding of non-standard paper.

1-3. Deformed folding

The paper may not be folded properly due to the characteristics of paper. In such cases, check the following

points.

• Do not use paper outside the specications.

Particularly, deformed folding occurs

frequently in the use of thin and imsy paper.

• Lower the processing speed when deformed

folding occurs for thin and imsy paper.

• Separate paper well prior to stacking.

• Stack paper on the paper feed tray after

aligning well, and set the paper feed guides at

the correct positions. Also tighten the xing

screws of the paper feed guides rmly.

(p.3-18)

(p.1-13)

(p.2-2)

3-6

Page 47

Chapter 3 Advanced Operation

2. Standard Folding of Non-Standard Paper

Standard folding of non-standard paper is a method to register the paper length of paper other than

standard paper, select the standard folding mode, and fold paper.

Paper other than the six standard paper is called non-standard paper. (Five standard paper sizes for North

America)

The foldable sizes are as follows. (Width x Length)

Maximum : 311 x 457.2 mm/12.24 x 18.00 inches

Minimum :120 x 182 mm/4.73 x 7.17 inches

When performing gate fold, the maximum

paper length is 432.0 mm/17.00 inches.

• Standard paper which is stacked on the paper feed tray in the long edge feeding direction is

considered non-standard paper.

• The paper sizes which can be used may vary with the paper type, thickness, and printing

state.

Width : 120 to 311/

4.73 to 12.24

Unit : mm/inches

Paper

Length : 182 to 457.2/

7.17 to 18.00

Paper feed

direction

1

2

3

4

5

6

For standard folding, refer to Chapter 2 “3. Standard Folding of Standard Paper” (p.2-5).

Press the menu key to display [Paper Size Set].

Paper Size Set

Set

P Length

Press the key.

Setting can be changed at this stage.

Press the key or key to select [Man].

Press the key.

The selected details are set.

Press the key to select [P Length].

Press the key.

Setting can be changed at this stage.

Paper Size Set

Set

P Length

Paper Size Set

Set

P Length

Auto

457.0

Man

457.0

Man

457.0

3-7

Page 48

Chapter 3 Advanced Operation

Input the paper length on the keypad.

7

Setting range :182.0 to 457.2 mm/7.17 to 18.00

inches

When the numerical value has been inputted,

press the clear key to clear the value before

inputting.

Example of inputting a value: Input [2500] when the paper length is 250 mm.

Press the key.

8

The inputted value will be set.

Press the key.

9

Paper Size Set

Set

P Length

250.0

250 +0.0/

Ready

Man

0

The procedures taken after that will be the same as the Chapter 2 “3. Standard Folding of Standard Paper”

(p.2-5).

3. Custom Folding

Custom folding is an operation method to fold

paper at any position by specifying the folding

stopper positions (folding position) of the

folding plates 1 and 2.

The foldable sizes are as follows. (Width x Length)

Maximum : 311 x 457.2 mm/12.24 x 18.00 inches

Minimum : 120 x 182 mm/4.73 x 7.17 inches

<Standard single fold> <Example of custom single fold>

Width : 120 to 311/

4.73 to 12.24

Paper

Paper feed

direction

The paper sizes which can be used may vary

with the paper type, thickness, and printing

state.

3-8

Unit : mm/inches

Length : 182 to 457.2/

7.17 to 18.00

Page 49

Chapter 3 Advanced Operation

The length of the folded plane (see gure on the right) which

can be folded by folding plates 1 and 2 is restricted.

Folding plate 1 : 42 to 325 mm/1.65 to 12.80 inches

Folding plate 2 : 0 * or 47 to 217 mm/0 * or 1.85 to 8.54 inches

* As folding plate 2 is not used in single folding, it is 0 mm/0 inch.

Incorrectly measuring the paper length or setting the folding stopper position can cause paper

jamming inside the folding plate.

Length of

folded plane

3-1. Operation

As an example of accordion-fold, operation procedures for custom folding are described with the following

setting.

Paper size : A4 (210 x 297 mm/8.26 x 11.69 inches)

Fold1 : 85 mm/3.34 inches (length A)

Fold2 : 95 mm/3.74 inches (length B)

1

2

3

4

Prepare a folding sample manually

using the paper to be folded.

Measure the length of the folding

position of the sample.

Press the menu key to display [Irreg Set]

display.

Input the registration number using the

numerical keypad or the

[00] cannot be used to input as a registration number.

For the registration number, refer to Chapter 6 “Specications” (p.6-1).

keys.

B

A

Irreg Set

P Length

Fold1

Fold2

Irreg Set

P Length

Fold1

Fold2

Paper feed

direction

00

250.0

01

250.0

5

6

Press the key.

The inputted registration number is set and [P

Length] can be changed at this stage.

Input [P Length] using the numerical

keypad.

Input [2970].

Irreg Set

01

P Length 0.0

Fold1 0.0

Fold2 0.0

3-9

Page 50

Chapter 3 Advanced Operation

Press the key.

7

Inputted numerical value is set, and [Fold1]

can be changed.

Input [Fold1] using the numerical

8

keypad.

Input [850].

Press the key.

9

Inputted numerical value is set, and [Fold2]

can be changed.

Input [Fold2] using the numerical

10

keypad.

Input [950].

Irreg Set

01

P Length 297.0

Fold1 0.0

Fold2 0.0

Irreg Set

01

P Length 297.0

Fold1 85.0

Fold2 0.0

Press the key.

11

The inputted numerical value is set, and the

display will return to the top screen.

Irreg Set

P Length 297.0

Fold1 85.0

01

Fold2 95.0

The procedures taken after that will be the same as the

(p.2-5)

The value of air volume of each fan, paper ejection conveyance amount, and stacker roller position that are

changed during special folding will be registered automatically.

Chapter 2 “3. Standard Folding of Standard Paper”

When the registered numerical value has been ne-adjusted

• Press and hold the key to register the numerical value after ne-adjusting the registered value using

the stopper adjustment key. The buzzer sounds “pii” and the numerical value that has been ne-adjusted

is registered.

• When turning o the power without registering the value, the ne-adjusted numerical value will be

cleared.

• Air volume of each fan, paper ejection conveyance amount, and stacker roller position that are changed

during special folding will be registered automatically.

3-2. Using the registered data

Press the custom folding key to select the

registered data.

3-10

Page 51

Chapter 3 Advanced Operation

3-3. Locking the registered data

Lock the registered data to keep the value unchanged so that the registered data will be saved without

being deleted mistakenly.

1

2

3

4

Press the menu key to display the [Irreg Set] screen.

Select the registration number to be locked on the keypad or with the or key.

Press the stop key.

The lock icon will be displayed to the right of

the registration number.

Irreg Set

Press the stop key again to release the lock.

Press the key.

Returns to the top screen.

Even if paper folding is being processed using the locked data, the folding position can be neadjusted.

Press and hold the key to register the ne-adjusted numerical value.

If there is no need to register the ne-adjusted numerical value, turn o the power to clear the value.

(p.3-5)

P Length 297.0

Fold1 85.0

Fold2 95.0

01

Locked

3-4. Clearing the registered data

1

2

3

4

5

Press the menu key to display the [Irreg Set] screen.

Select the registration number to be cleared on the keypad or with the key.

Press the key.

[P Length] can be changed.

Press and hold the clear key.

A buzzer sounds “pii” and the registered data

will be cleared.

Press the key.

Returns to the top screen.

Irreg Set

P Length

Fold1

Fold2

01

3-11

Page 52