Page 1

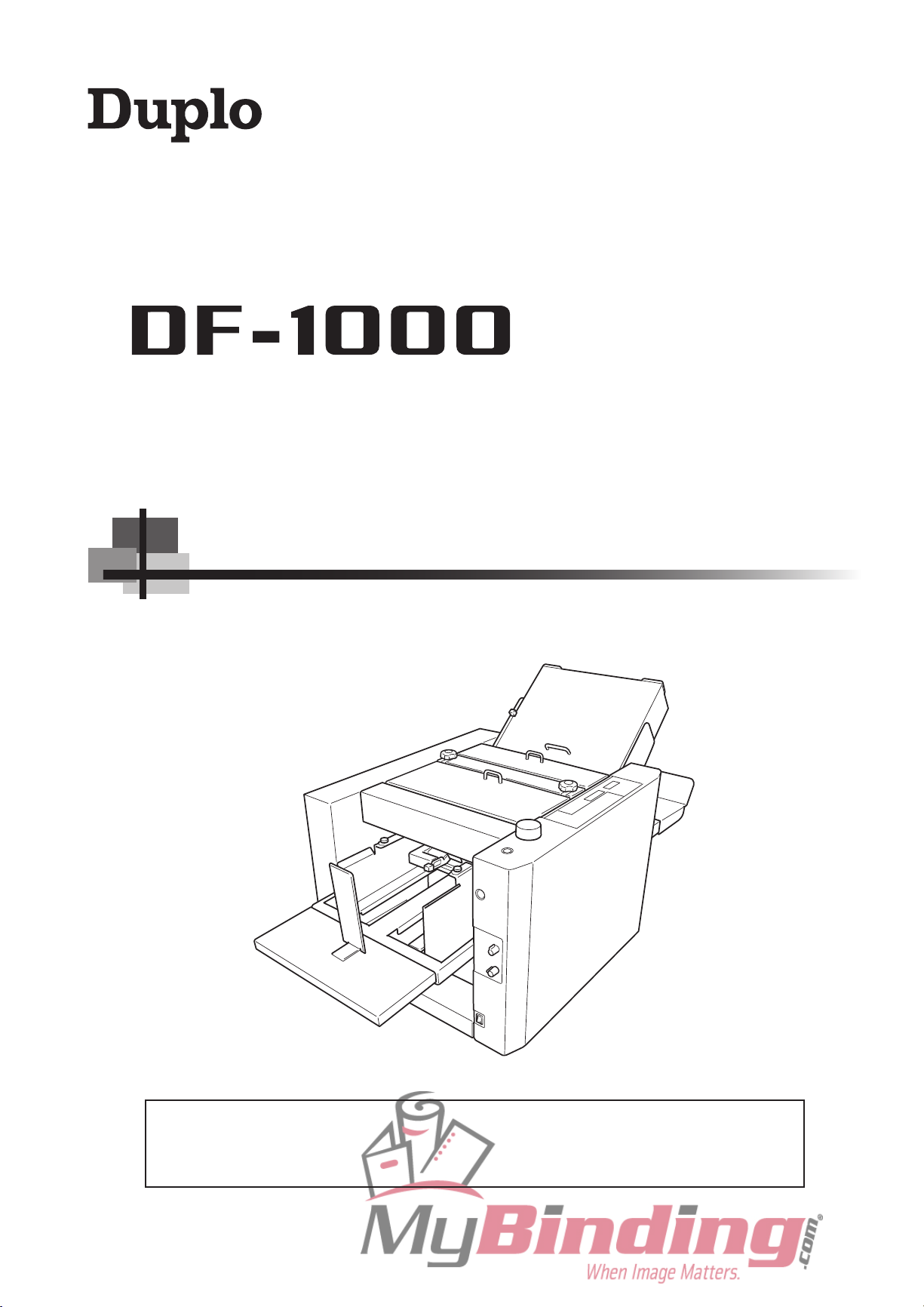

Duplo DF-1000 Air

Suction Paper Folder

Instruction Manual

Page 2

AIR SUCTION PAPER FOLDER

[220 to 240 V]

INSTRUCTION MANUAL

Be sure to read this manual prior to use.

Please leave this manual at the site of use for easy reference.

Page 3

DECLARATION OF CONFORMITY

DUPLO CORPORATION, located at 1-6, Oyama 4-chome, Sagamihara-shi, Kanagawa-ken 229-1180, Japan, declares

that the following product,

Name of product : Air Suction Paper Folder

Models : DF-1000

complies with the provisions defi

Regulation : Low Voltage Directive 73/23/EEC under IEC60950-1:2001 including EN60950-1:2001 deviations.

Electromagnetic Compatibility Directive 89/336/EEC under EN55011:1998 + A1:1999 + A2:2002,

EN55014-2:1997 + A1:2001, EN61000-3-2:2000, EN61000-3-3:1995 + A1:2001.

ned by the regulations listed below.

En

KONFORMITÄTSERKLÄRUNG

Die DUPLO CORPORATION mit Sitz in 1-6, Oyama

4-chome, Sagamihara-shi, Kanagawa-ken 229-1180,

Japan, erklärt hiermit, dass das folgende Produkt,

Bezeichnung des Produkts :

Luftsaugen Papierfaltmaschine

Modell :

DF-1000

den nachfolgend aufgelisteten Richtlinien entspricht :

Richtlinien :

N i e d e r s p a n n u n g s r i c h t l i n i e 7 3 / 2 3 / E W G un t e r

IEC60950-1:2001 und EN60950-1:2001 Abweichungen.

Richtlinie über die elektromagnetische Verträglichkeit

89/336/EWG unter EN55011:1998 + A1:1999 + A2:2002,

EN5 501 4-2 :199 7 + A 1:20 01, EN6 100 0-3- 2:2 000 ,

EN61000-3-3:1995 + A1:2001.

Ge

DECLARATION DE CONFORMITE

DUPLO CORPORATION, située à 1-6, Oyama 4-chome,

Sagamihara-shi, Kana gaw a-k en 2 29- 118 0, Japon,

déclare que le produit suivant ;

Nom du produit :

L’air sucent la plieuse de papier

Modèle :

DF-1000

DICHIARAZIONE DI CONFORMITÁ

DUPLO COPRORATION sita a 1-6, Oyama 4-chome,

Sagamihara-shi, Kanagawa-ken 229-1180 Japan, dichiara

che il seguente prodotto,

Nome del prodotto :

L’aria succhia il macchina piegantesi di carta

Modello :

DF-1000

è conforme ai requisiti definiti dalle norme sotto elencate.

Direttiva Bassa Tensione :

Direttiva relativa alle apparecchiature a bassa tensione

73/23 / C E E i n bas e a I E C 6 0 950-1: 2 0 0 1 inc l u s o

EN60950-1:2001 deviazioni.

Direttiva EMC 89/336/CEE in base a EN55011:1998

+ A1:1999 + A2:2002, EN55014-2:1997 + A1:2001,

EN61000-3-2:2000, EN61000-3-3:1995 + A1:2001.

It

DECLARACIÓN DE CONFORMIDAD

DUPLO CORPORATION, con domicilio en 1-6, Oyama

4-chome, Sagamihara-shi, Kanagawa-ken 229-1180

Japan, declara que el producto siguiente :

Nombre del producto :

Succión del aire máquina que dobla de papel

Modelos :

DF-1000

e s t c o n for m e a u x di s p osi t i o n s dé f i n i e s pa r l e s

réglementations suivantes ;

Réglementations :

Directive sur la basse tension 73/23/EEC en application

de IEC60950-1:2001 et EN60950-1:2001 derogations.

Directive de compatibilité électromagnétique 89/336/

EEC d’après EN55 011:1998 + A1:1999 + A2:2002,

EN5 501 4-2 :199 7 + A 1:20 01, EN6 100 0-3- 2:2 000 ,

EN61000-3-3:1995 + A1:2001.

Fr

Cumple las disposiciones definidas por las siguientes

reglamentaciones :

Reglamentaciones :

D i re c t i v a s o b r e ba j a t e n s i ó n 7 3 / 2 3 / C E E b a j o

IEC60 9 5 0 - 1:2001 inclu y e n d o la s d e r o gacion e s

EN60950-1:2001.

Directiva sobre CEM 89/336/CEE bajo EN55011:1998

+ A1:1999 + A2:2002, EN55014-2:1997 + A1:2001,

EN61000-3-2:2000, EN61000-3-3:1995 + A1:2001.

Sp

Page 4

INTRODUCTION

Thank you for purchasing a Duplo product.

Be sure to read this manual prior to using the product.

After reading, leave the manual at the site of use for easy reference whenever questions

related to the product arise in the future.

Symbols

In this manual, several symbols are used to indicate important warnings. Please make sure

to read instructions accompanied by these symbols. These symbols have the following

meanings.

Describes instructions which must be followed in use.

Be sure to read the instructions to avoid problems due to incorrect operations.

Describes restrictions in operations.

Be sure to read to make full use of the functions of this product.

Describes names of related items and supplementary instructions.

i

Page 5

SAFETY PRECAUTIONS

In this manual, operations and handling of the unit which are hazardous are described using

the following marks to prevent personal injury or property damage to the user and others.

Ignoring this mark could result in the possibility of

WARNING

serious injury or even death.

Ignoring

CAUTION

This mark indicates a “Warning” or “Caution”.

A graphic may be shown inside the mark to describe the warning or caution more specifically.

This mark indicates a forbidden action.

A graphic may be shown inside the mark to describe the forbidden action more specifically.

This mark indicates actions that must be performed.

A graphic may be shown inside the mark to describe the action to be performed more specifically.

or physical damage.

this mark could result in the possibility of injury

Power Supply

This unit shall be installed near the socket-outlet where the plug on the power supply cord is

easily accessible.

Make sure the power supply used is always within the following range.

Power supply : 100 to 240 V AC, 50/60 Hz

When you power other appliances from the same AC outlet, make sure that the combined

power consumption does not exceed the power supply capacity.

Rated current (Rated power) : 2 to 1 A (140 W)

WARNING

Use only the power supply voltage specified on the main nameplate.

Using other voltages could result in a fire or an electrical shock.

Make sure that the combined power consumption of the appliances to be

connected does not exceed the capacity rating of the power outlets or plug

receptacles.

Exceeding the capacity rating could cause the power outlets, plug receptacles, or power extension

cords to overheat and catch a fire.

ii

Page 6

SAFETY PRECAUTIONS

Operating Environment

Operate this unit in the following environment.

where the temperature range is between 5 and 35°C (–10 to +50°C in storage)

where the humidity range is between 20 and 80% RH (10 to 90% RH in storage, however

no condensation)

which is not subject to direct sunlight

which is reasonably free from dust

which is subject to little or no vibration

which is free from air-borne salt

where there are no harmful chemicals

where the unit is not exposed to water

WARNING

Keep this unit and the power cord away from heaters and heater vents.

Excessive heat could melt the cover or power cord covering, and result in a fire or an electrical

shock.

Do not place metal objects or vessels containing liquids on top of the unit.

The entry of any metal object or liquid could result in a fire or an electrical shock.

Do not insert any metal or easily-combustible object inside this unit.

This could result in a fire or an electrical shock.

Do not use flammable sprays inside or near the unit (e.g. when cleaning the

unit).

Such flammable gas may ignite and cause a fire or combustion.

CAUTION

Do not install this unit in a location where there is excessive humidity or

where contact with water is possible.

Poor choice of location could result in deterioration of the insulation, a fire or an electrical shock.

Install this unit on a level, stable stand or floor, with sufficient space around

it.

Failure to do so could result in the unit overturning and causing injury.

Disconnect the power plug from the power outlet before attempting to move

this unit.

Failure to do so could result in power cord damage, a fire or an electrical shock.

Always disconnect the power plug from the power outlet when the unit is not

to be used for an extended period.

Failure to do so could result in a fire due to leakage current if the insulation should deteriorate.

iii

Page 7

SAFETY PRECAUTIONS

Maintenance, etc.

Do not damage the power cord or power plug.

Do not scratch, alter, bend, twist, pull or place heavy objects on the power cord or power plug.

This could result in damage, a fire or an electrical shock.

Do not handle the power plug with wet hands.

This could result in an electrical shock.

Do not touch the power switch with wet hands.

Otherwise electric hazards may occur.

Do not remove the cover or back panel.

This unit contains high-voltage components that could cause an electrical shock.

WARNING

Do not disassemble, modify or repair this unit.

There is a danger of fire, electrical shock or injury. Contact your dealer when repairs are necessary.

If any foreign object such as metal or liquid should enter this unit,

immediately turn the unit off at the power switch and disconnect the power

plug from the power outlet.

Failure to do so could result in a fire or an electrical shock. Contact your dealer immediately.

Before cleaning this unit, turn the unit off at the power switch and

disconnect the power plug from the power outlet.

Accidental operation of the unit during cleaning could result in injury.

Remove any dust that accumulates on the power plug prongs and the

surface of the plug from which the prongs extend.

Accumulated dust could result in a fire.

Always grip the plug when disconnecting the power plug from the power

outlet.

Forcibly pulling on the power cord could cause damage, resulting in a fire or an electrical shock.

Do not touch or insert foreign objects into any rotating part during operation.

This could result in injury.

iv

CAUTION

Keep away long hair, ties, jewelry and loose clothing.

This could result in injury.

Do not put fingers inside during operation.

This could result in injury.

Page 8

Caution Label Location

SAFETY PRECAUTIONS

v

Page 9

TABLE OF CONTENTS

Chapter 1

Before Operation

1. Names and Operation of Parts ........1-2

2. Names and Operation of Control

Panel ..................................................1-6

3. Description of LCD ...........................1-7

4. Handling of Paper

4-1. Paper Used ..................................... 1-8

4-2. Precautions on Stacking Paper

.............................1-8

...... 1-9

Chapter 2

Basic Operation

1. Standard Folding of Standard

Paper .................................................2-2

1-1. Standard Paper .............................. 2-2

1-2. Standard Folding Modes

1-3. Operation Procedure

................ 2-2

...................... 2-3

Chapter 4

Troubleshooting

1. Correcting Folding Misalignment ...4-2

1-1. Correcting Folding Misalignment

Along Sides of Paper

1-2. Correcting Folding Misalignment

Along Vertical Length of Paper

1-3. Correcting Deformed Folding

2. Adjusting the Stacker Roller ...........4-13

2-1. Changing the Stacker Roller

Position

2-2. Changing the Stacker Roller

Height

........................................... 4-13

............................................. 4-14

3. When Paper Jamming Occurs ........4-15

3-1. When Paper Jams at

Paper Feed Tray ............................. 4-15

3-2. When Paper Jams Inside Unit

3-3. When Paper Jams at

Stacker Unit .................................... 4-18

...................... 4-2

....... 4-5

......... 4-12

........ 4-15

Chapter 3

Applied Use

1. Standard Folding of

Non-standard Paper .........................3-2

1-1. Paper Size Restrictions .................. 3-2

1-2. Operation Procedure

2. Custom Folding ................................3-5

2-1. Paper Size Restrictions .................. 3-5

2-2. Operation Procedure

3. Using Special Paper .........................3-8

3-1. Art Paper, Coated Paper ................ 3-8

3-2. Recycled Paper

3-3. B6 Size Paper ................................. 3-10

4. Function Setting Mode .....................3-11

4-1. Non-standard Paper Length

Setting ............................................ 3-11

4-2. Operation Mode Setting

4-3. Interval Setting ................................ 3-15

4-4. Separating Air Strength Setting

4-5. Paper Feed Interval Setting

4-6. Stacking Amount Setting

4-7. Stacker Belt Setting ........................ 3-20

4-8. Thick Paper Stopper Correction

Setting ............................................ 3-21

...................... 3-2

...................... 3-5

.............................. 3-9

.................. 3-12

...... 3-17

............ 3-18

................ 3-19

4. Error Messages ................................4-19

4-1. Paper Jam Messages ..................... 4-19

4-2. Operation Error Messages

4-3. Key Input Error Messages .............. 4-21

4-4. Motor and Sensor Error

Messages

....................................... 4-21

............. 4-19

5. Troubleshooting ...............................4-24

Chapter 5

Maintenance

1. Cleaning the Unit ..............................5-2

1-1. Cleaning the Folding Rollers .......... 5-2

1-2. Cleaning the Suction Belts

1-3. Cleaning the Stacker Belts

1-4. Cleaning the Paper Sensor

1-5. Cleaning the Paper Feed Inlet

Sensor ............................................ 5-5

1-6. Cleaning the Paper Ejection Outlet

Upper Sensor

1-7. Cleaning the Paper Ejection Outlet

Lower Sensor

................................. 5-6

................................. 5-6

............. 5-4

............. 5-4

............ 5-5

Appendix

1. Specifications ...................................A-2

vi

Page 10

Chapter 1

BEFORE OPERATION

1-1

Page 11

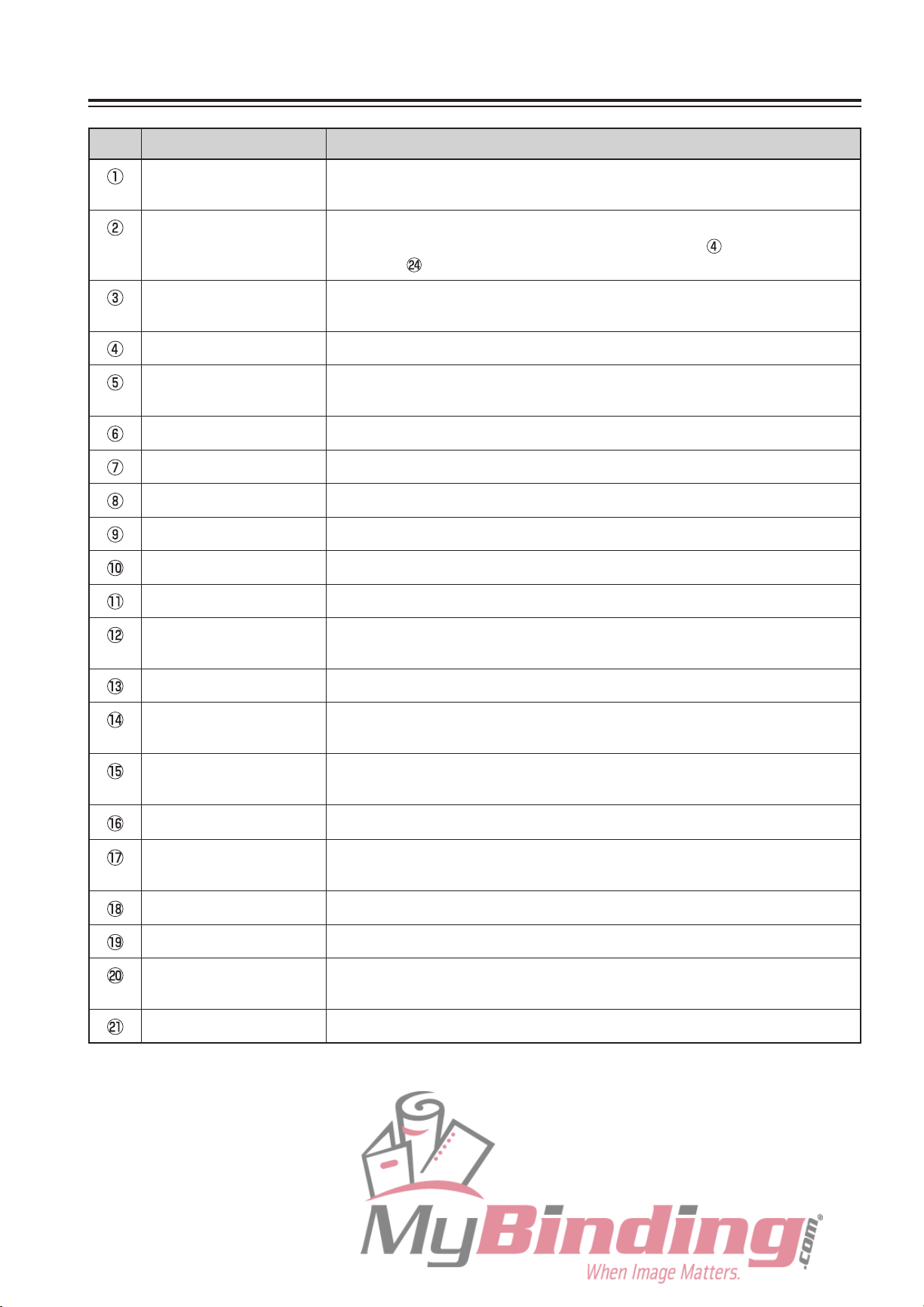

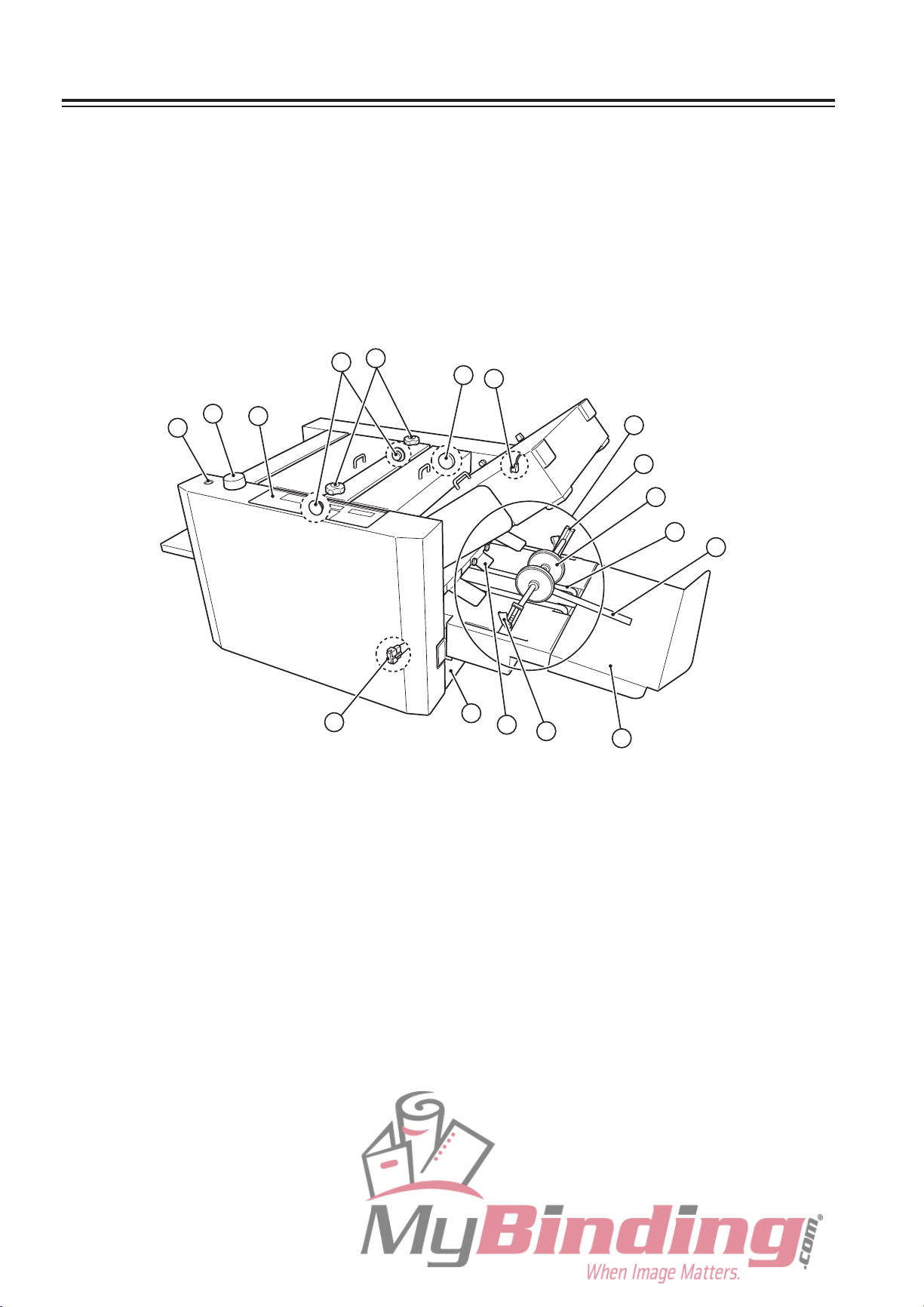

1. NAMES AND OPERATION OF PARTS

13

14

15

11

16

12

7

10

9

8

2

5

6

3

4

1

17

21

20

19

18

1-2

Page 12

1. NAMES AND OPERATION OF PARTS

No. Name Operation

Folding plate Guide plate for deciding the paper folding position. Composed of folding

plates 1 and 2.

Top cover L When paper is jammed at the paper feed section, open this cover to

remove the paper. Also open this cover to use the Skew correction

knob and Skew roller spring pressure adjusting knob.

Top cover R When paper is jammed at the folding roller section, open this cover to

remove the paper.

Skew correction knob For correcting skewed paper feed. Located inside the top cover L.

Side guide adjusting

knob

Side guide Holds the left and right of the paper stacked on the paper feed tray.

Paper feed tray For stacking paper

Auxiliary paper feed tray Supports the rear of the paper.

Rear guide Holds the trail edge of paper stacked on the paper feed tray.

Power cord inlet For connecting the power cord

Power switch For turning on/off the power

Level sensor adjusting

lever

Tray down button For lowering the paper feed tray

Separating air adjusting

knob

Separator adjusting

knob

For correcting the direction of the side guide (paper feed direction)

For adjusting the gap between the paper and suction belt

For adjusting the amount of separating air

For adjusting the height of the separator

Safety lever Prevents hand from getting caught when the paper feed tray is descending.

Separating-air duct Blows out air for separating paper stacked on the paper feed tray. (3

locations)

Separator Prevents double-feed.

Suction belt Sucks and conveys paper.

Shutter Adjusts the amount of separating air blown out. Linked to the separator

adjusting knob.

Level sensor Determines the height of the paper floated by separating air.

1-3

Page 13

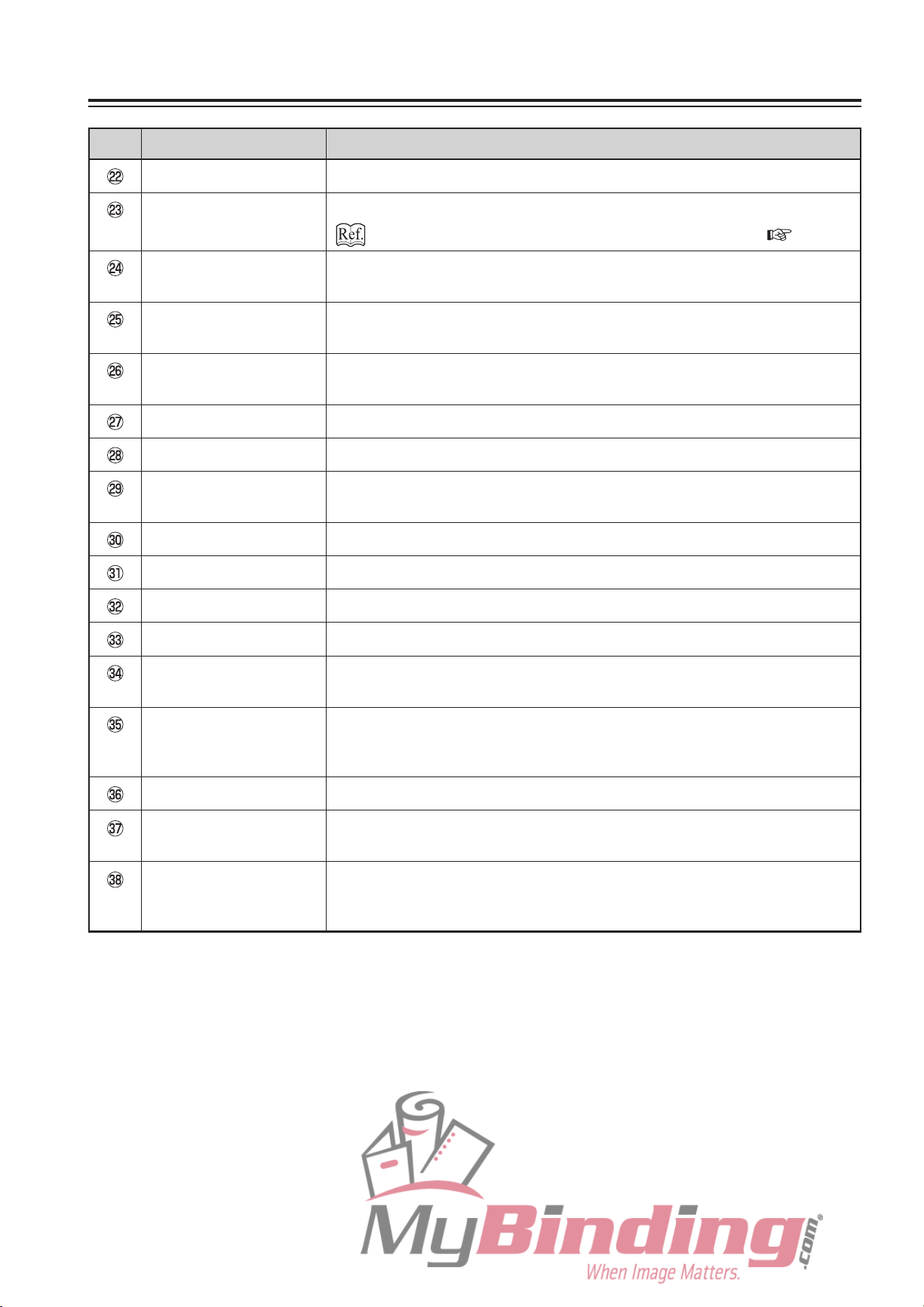

1. NAMES AND OPERATION OF PARTS

32

30

34

31

23

38

22

26

27

37

36

33

35

24

25

29

28

1-4

Page 14

1. NAMES AND OPERATION OF PARTS

No. Name Operation

Side guide dial Turn this dial to move the side guide.

Control panel For operating the unit

“2. NAMES AND OPERATION OF CONTROL PANEL” ( p.1-6)

Skew roller spring

pressure adjusting knob

Skew roller fixing knob Loosen this knob to use the skew correction knob. Be sure to tighten it after

Jam correction knob For rotating the folding rollers when paper has jammed inside the unit or

Folding plate connector For connecting the folding plate and the main body

Stacker unit connector For connecting the stacker unit and the main body

Stacker unit Composed of the stacker roller, stacker belt, and stacker support for

Stacker roller For receiving folded paper and aligning the paper

Stacker belt For ejecting folded paper to the paper receiving tray

Stacker support For supporting the stacker roller

Lever For changing the height of the stacker roller

Auxiliary paper ejection

guide

For switching the roller spring pressure when folding misalignment occurs.

Normally, use at the “bottom” position. Located inside the top cover L.

adjustments.

when cleaning the unit

ejecting folded paper to the paper receiving tray.

When alignment of the ejected paper is poor, hook to the shaft of the

stacker roller.

Paper ejection guide Helps guide folded paper onto the stacker unit. Remove if paper jams

frequently at the stacker roller, or when it is difficult to remove jammed

paper.

Paper receiving tray For receiving folded paper from the stacker unit

Side cover When paper jams during paper ejection, open this cover to remove the

paper.

Thin paper feed button Switch this button according to the paper thickness. Set to ON when using

fine quality paper less than 81.4 g/m2.

(Lamp lit: ON, lamp is off: OFF)

1-5

Page 15

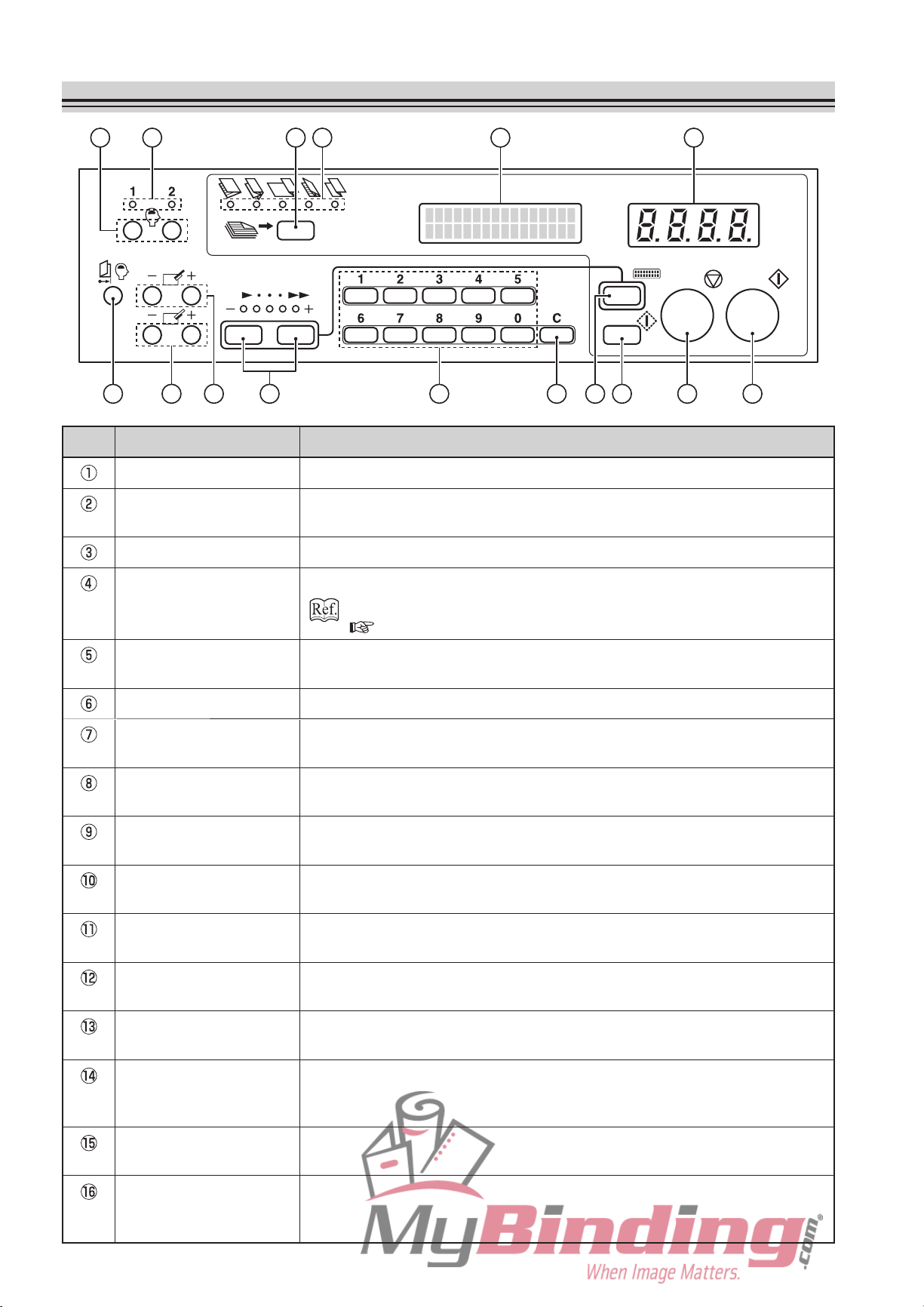

2. NAMES AND OPERATION OF CONTROL PANEL

11 13

10

12

14 15 16

7 35 2 1489 6

No. Name Operation

Start key Press to start paper folding.

Stop key Press to stop paper folding. Pressing this key at the function setting mode

screen registers that setting.

Test key Press to test fold two sheets of paper.

Mode key Press to switch the function setting mode.

Chapter 3 APPLIED USE “4. FUNCTION SETTING MOD E”

( p.3-11)

Clear key Press to change or erase the number of sheets to be processed or paper

length entered.

Numerical keys (0 to 9) Press to enter the number of sheets to be processed or paper length.

Speed key Press to select the processing speed from five levels (Speed 1 to 5).

When the power is turned on, the speed used the last time is displayed.

Folding plate 1 folding

stopper adjusting key

Folding plate 2 folding

stopper adjusting key

Adjustment registration

key

Custom folding

registration key

Custom folding

registration lamp

Press to adjust the position (folding position) of the folding stopper of

folding plate 1.

Press to adjust the position (folding position) of the folding stopper of

folding plate 2.

If the position of the folding stopper has been finely adjusted in standard

folding operations, the adjustment value can be registered with this key.

Press to register the position of the folding stopper and stacker roller which

have been moved when using custom folding modes.

When this lamp is lit, it means that the custom folding mode is registered.

Folding mode key Press to select the folding mode from five standard folding modes. If the

Standard folding lamp Displays the folding mode selected from five standard folding modes.

Liquid crystal display

(LCD)

Numerical display

(Counter)

1-6

custom folding mode is registered, use this key to select it.

When a f old ing mode reg ist ered wit h the fol din g sto ppe r pos iti on

adjustment value is selected, the corresponding lamp blinks.

Displays the size of standard paper stacked on the paper feed tray (A3 to

B6), paper length registered, and error messages.

When using the add count mode, displays the number of sheets processed.

When using the subtract count mode, displays the number of sheets left to

be processed.

Page 16

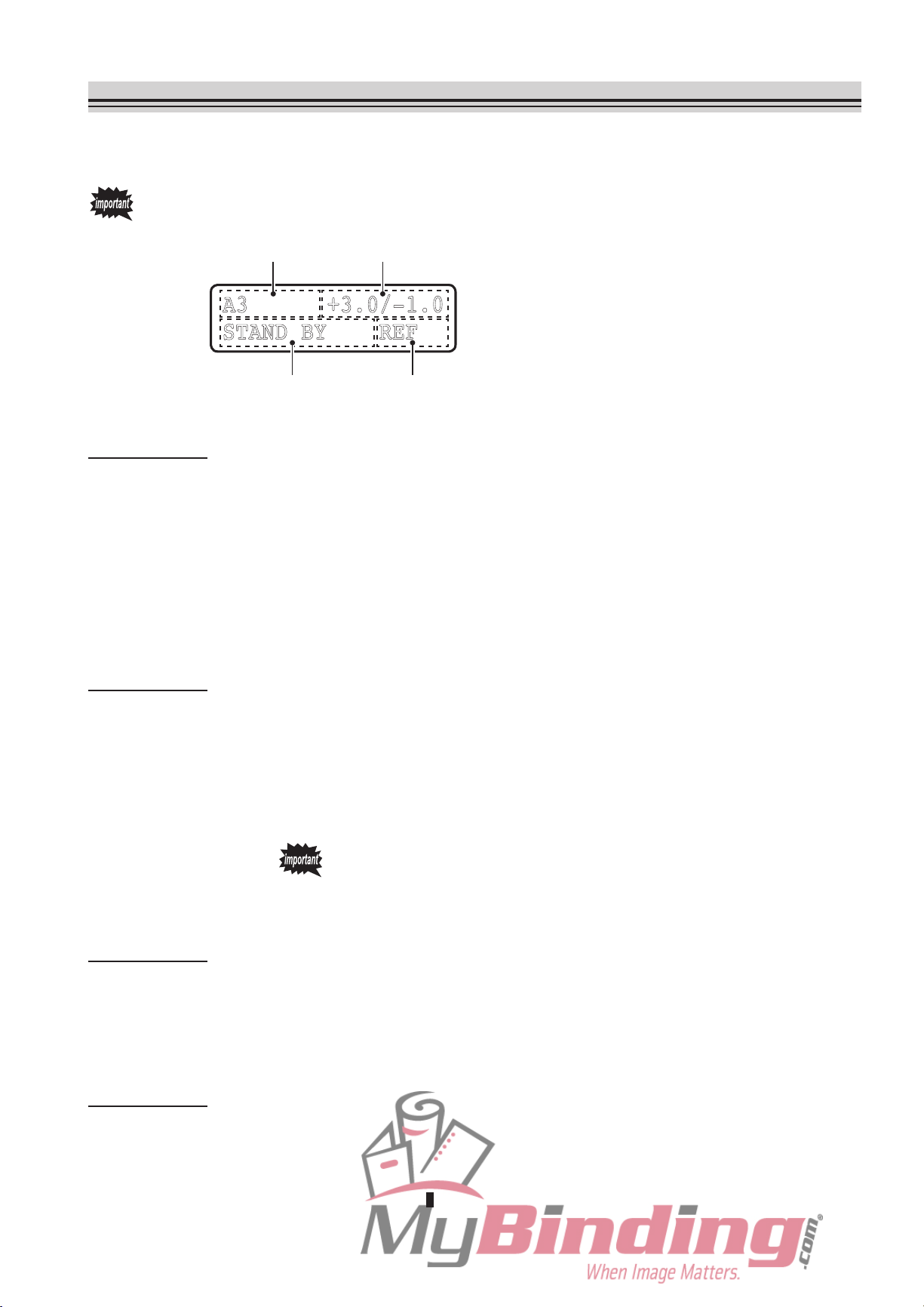

3. DESCRIPTION OF LCD

The LCD displays standard paper size, various registration data, operation modes, operation

states, and error messages, etc.

The backlight of the LCD will go off automatically if the unit is not used for a certain

period of time.

A area B area

A .0/- .0

AN Y

C area D area

This LCD example shows the standard folding of

standard paper when set to the last time fold mode.

(1) A area

Standard paper size : Six types: A3, B4, A4, B5, A5, and B6

Registration data : When the length of non-standard paper is registered, the length will be

displayed (182 to 432 mm).

Operation mode

Folding mode :

When set to the folding stopper fixed mode, “FIX” will be displayed.

:

When set to the custom folding mode, “CF-1” or “CF-2” will be

displayed.

(2) B area

Registration data : The correction value of the folding stopper position of folding plates 1

and 2 will be displayed as “±∗.∗ / ±∗.∗” (unit: mm). As folding plate 2 is

not used in single folding, “±∗.∗ / ...” (unit: mm) will be displayed.

In custom folding, the folding stopper position of folding plates 1 and 2

will be displayed as “

When the operation mode is set to folding stopper fixed mode,

the folding stopper position displayed will be the same as custom

folding.

∗∗∗.∗

∗∗∗.∗

/

” (unit: mm).

(3) C area

Operation status : “WAIT”, “STAND BY”, “PROCESSING”, “TEST RUN”

Error message :

The place of paper jam or malfunction, and details of operation error,

etc. will be displayed.

(4) D area

Operation mode : When set to the last time fold mode, “REF” will be displayed.

When set to the interval function, “I” will be displayed.

W h e n t h e t h i c k p a p e r s t o p pe r c o rr ec t i o n s e t t in g i s s e t to

“CORRECTED”, “ ” will be displayed.

1-7

Page 17

4. HANDLING OF PAPER

4-1. Paper Used

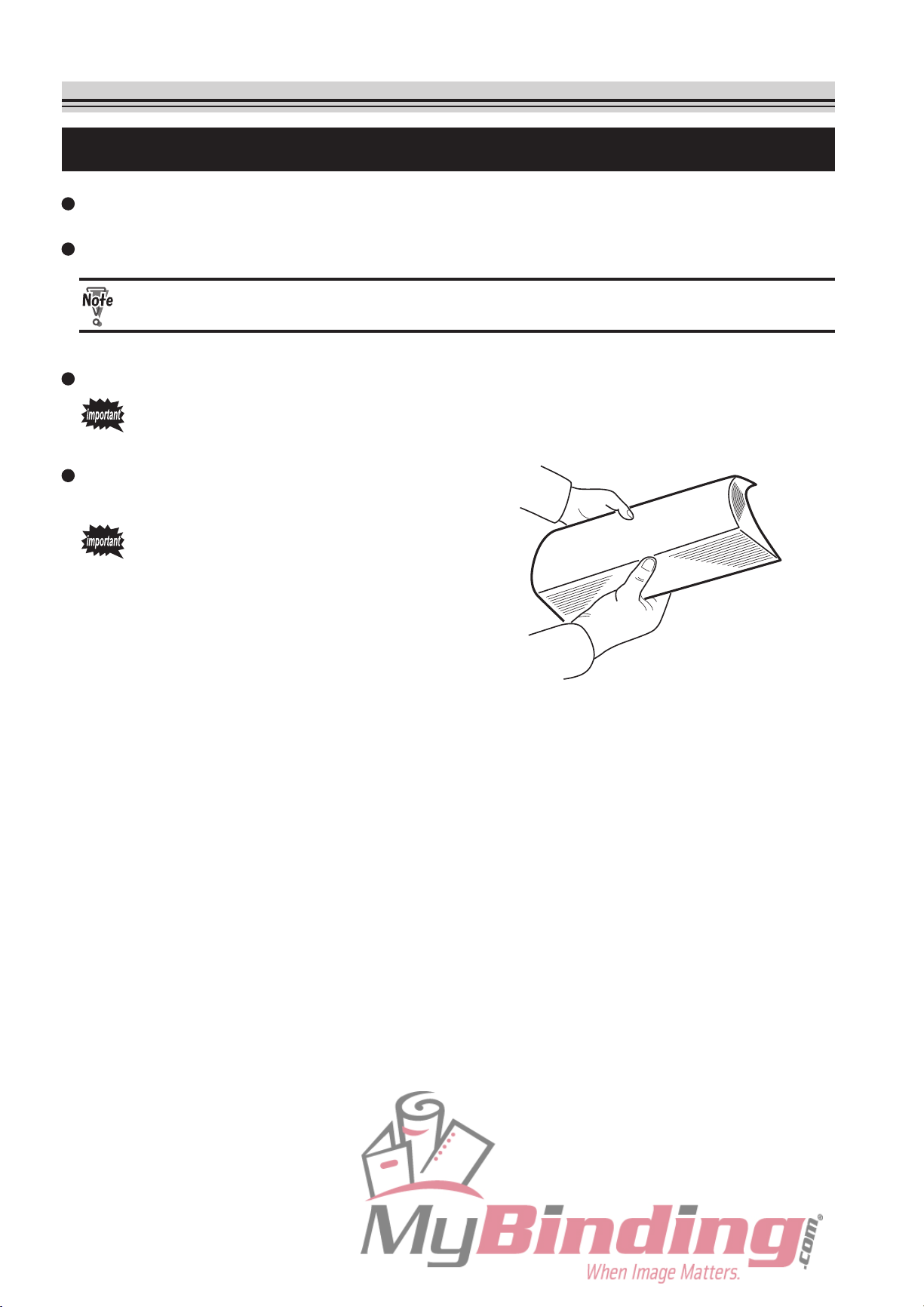

If using folded or curled paper, flatten first prior to use.

Make sure that the printing ink on the paper has dried completely prior to use.

If used without the ink completely dried, the folding roller or paper may become dirty.

Use paper that has been cut at right angles.

If not cut at right angles, problems such as folding misalignment may occur.

Fan paper just copied or printed well prior

to use.

Paper just copied or printed contains

considerable static electricity, and

if not fanned well, problems such as

double-feed will result.

1-8

Page 18

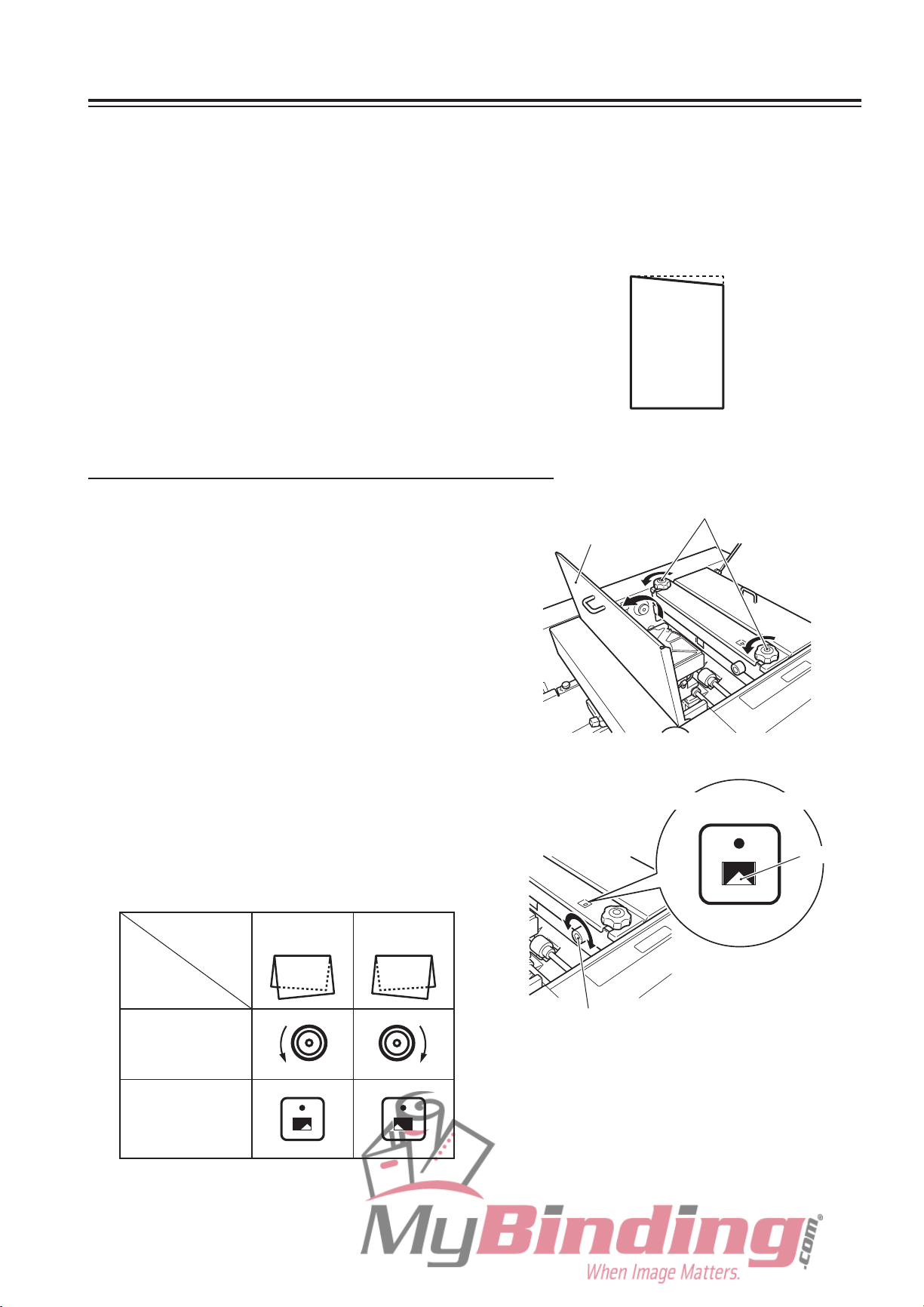

4-2. Precautions on Stacking Paper

4. HANDLING OF PAPER

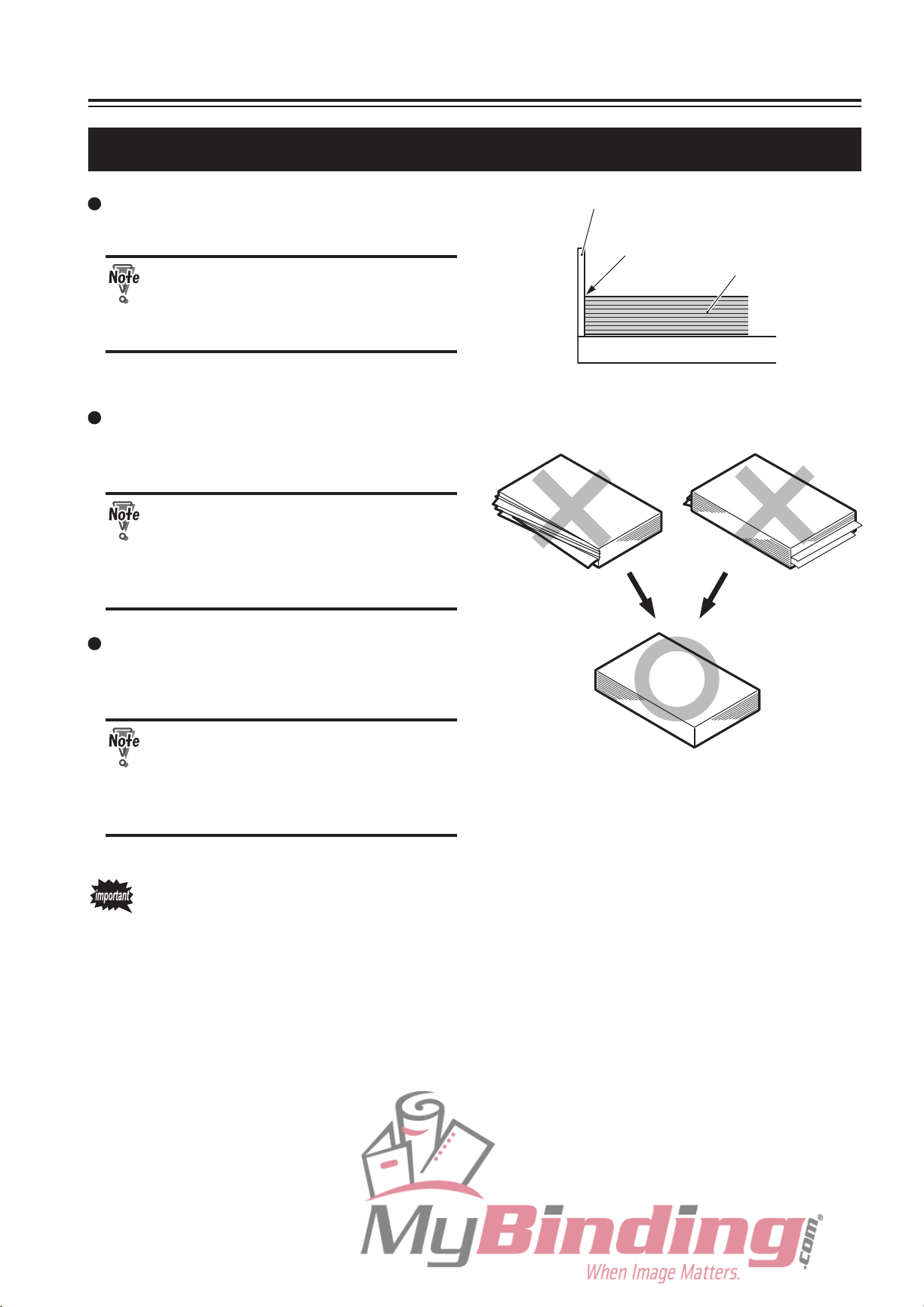

Stack the paper so that the lead edge

touches the shutter gently.

I f th e r e is a ga p b e t w e en th e

lead edge and shutter, the paper

detection sensor will not function

properly.

Do not stack paper on the paper feed tray

with the left and right sides of the paper

unaligned or some sheets protruding out.

If the paper is protruding on the

left or right side, the paper size

detection sensor will not function

normally and detect the paper size

accurately.

Shutter

Stack so that

there is no gap.

Paper feed tray

<Paper protruding on

the left and right sides>

Paper

<Paper protruding at

the lead and trail edges>

Do not stack paper on the paper feed tray

with the lead and trail edges unaligned or

some sheets protruding out.

If the paper is protruding at the lead

or trail edge, paper will not be fed

stably, resulting in problems such

as paper feed e rror and folding

misalignment.

In some cases, paper may not be fed smoothly into the folding plate due to the

environment (temperature, humidity), paper thickness, paper type, paper states, and

processing speed, etc., and as a result, the paper may not be folded properly.

In such cases, lower the processing speed, or improve the paper states before use.

<Paper properly aligned>

1-9

Page 19

Memo

1-10

Page 20

Chapter 2

BASIC OPERATION

2-1

Page 21

3

2

1

3

2

1

3

2

1

3

2

1

3

2

1

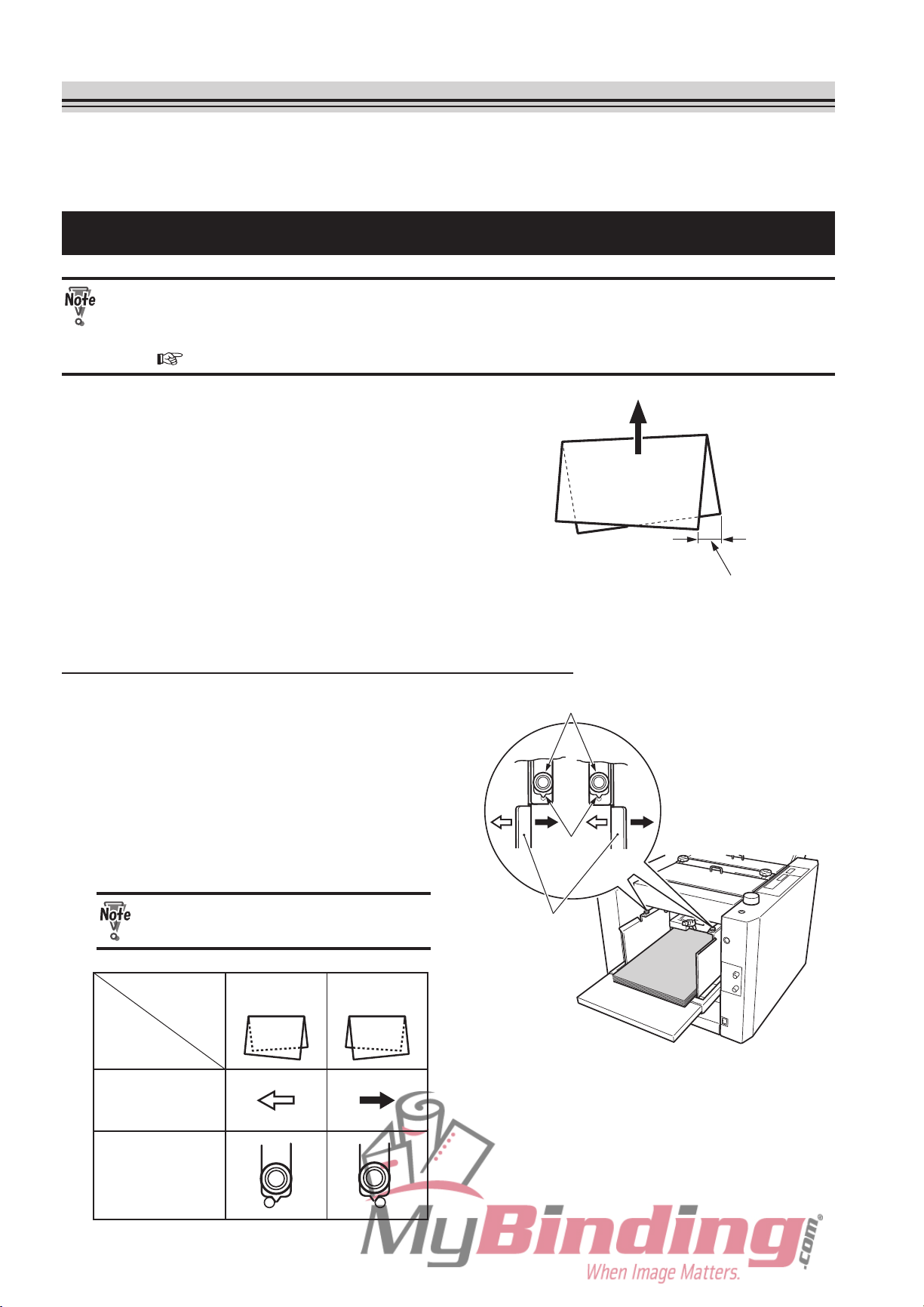

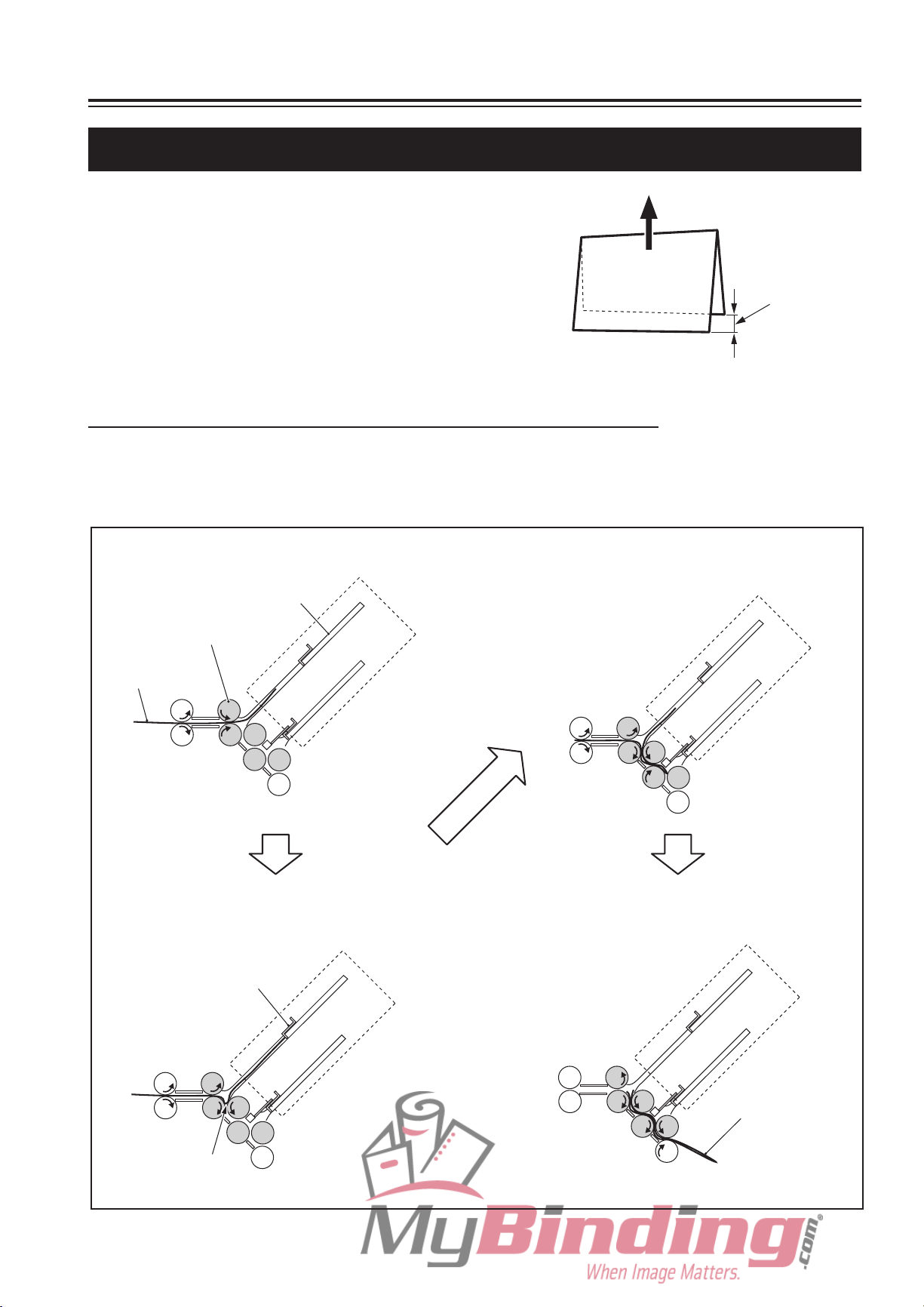

1. STANDARD FOLDING OF STANDARD PAPER

1-1. Standard Paper

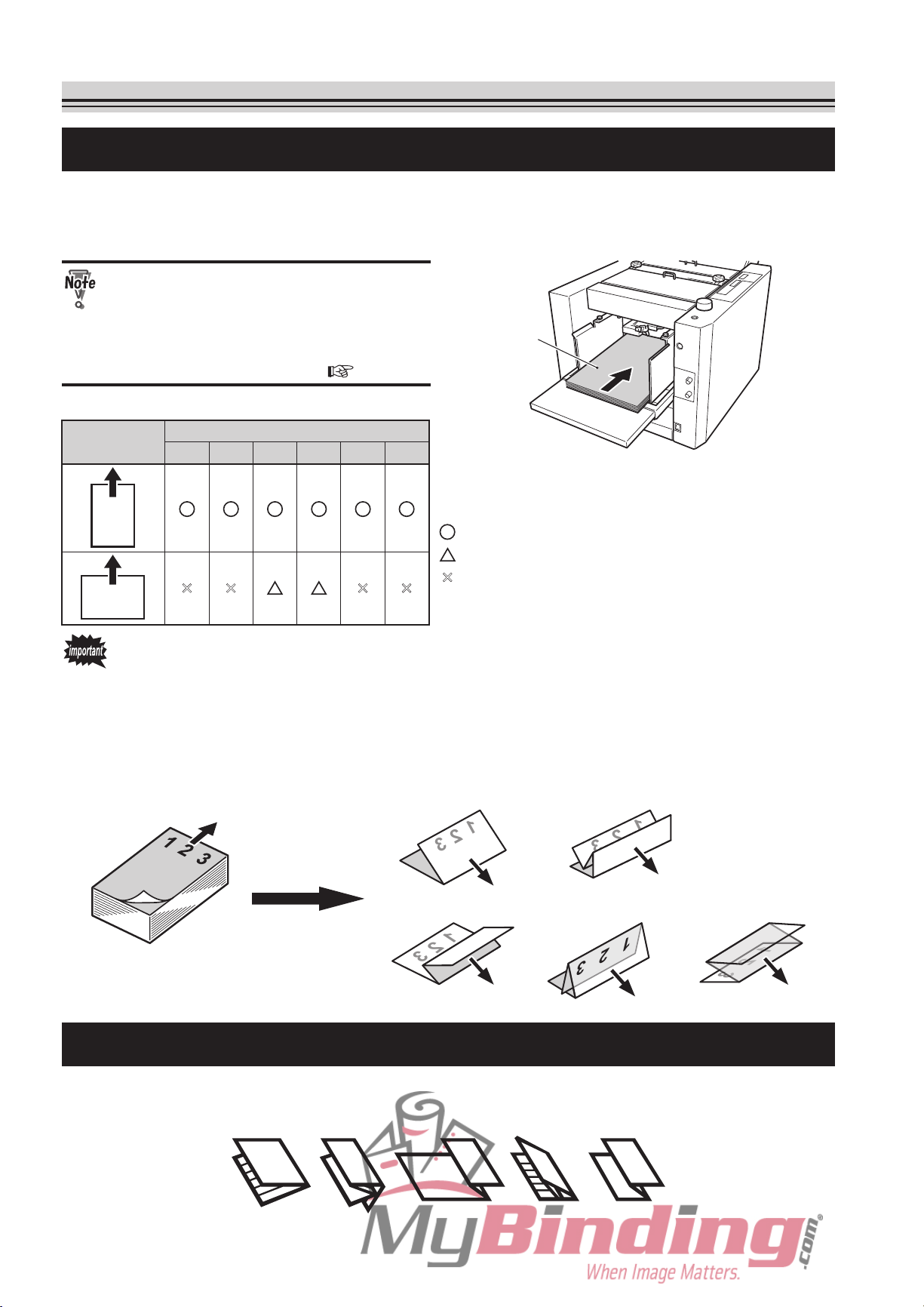

There are six types of standard paper sizes; A3, B4, A4, B5, A5, and B6. All these sizes are

detected as standard paper only when stacked in the short edge feeding direction (direction

shown in the figure).

For A4 and B5 sizes, these can be

used as non-sta ndard paper e ven

when stacked in the long edge feeding

direction. (Refer to Chapter 3 APPLIED

E “ 1 . STANDARD FOLDING OF

US

NON-STANDARD PAPER” (

Table of paper stacking direction

Stacking

direction

A3 B4

Paper size

A4

B5 A5 B6

p.3-2).)

Paper

: Can be used as standard paper

: Can be used as non-standard paper

: Cannot be used

×

× × ×

When stacking paper on the paper feed tray, take note of the front/back, top/end of the

paper.

cause the relations between the folding misalignment state and the front/back, top/

Be

end of the paper must also be taken into consideration when checking the finish by test

folding.

<Example> When paper

shown and finished in the following standard folding modes

Paper feed direction

Paper stacked on

paper feed tray

(front is gray and back is white) is stacked on the paper feed tray as

<Irregular accordion fold> <Letter fold> <Accordion fold>

<Single fold> <Double fold>

Ejection

direction

1-2. Standard Folding Modes

There are five types of standard folding modes; single fold, double fold, irregular accordion

fold, letter fold, and accordion fold.

Letter

fold

Accordion

fold

2-2

Single

fold

Double

fold

Irregular

accordion fold

Page 22

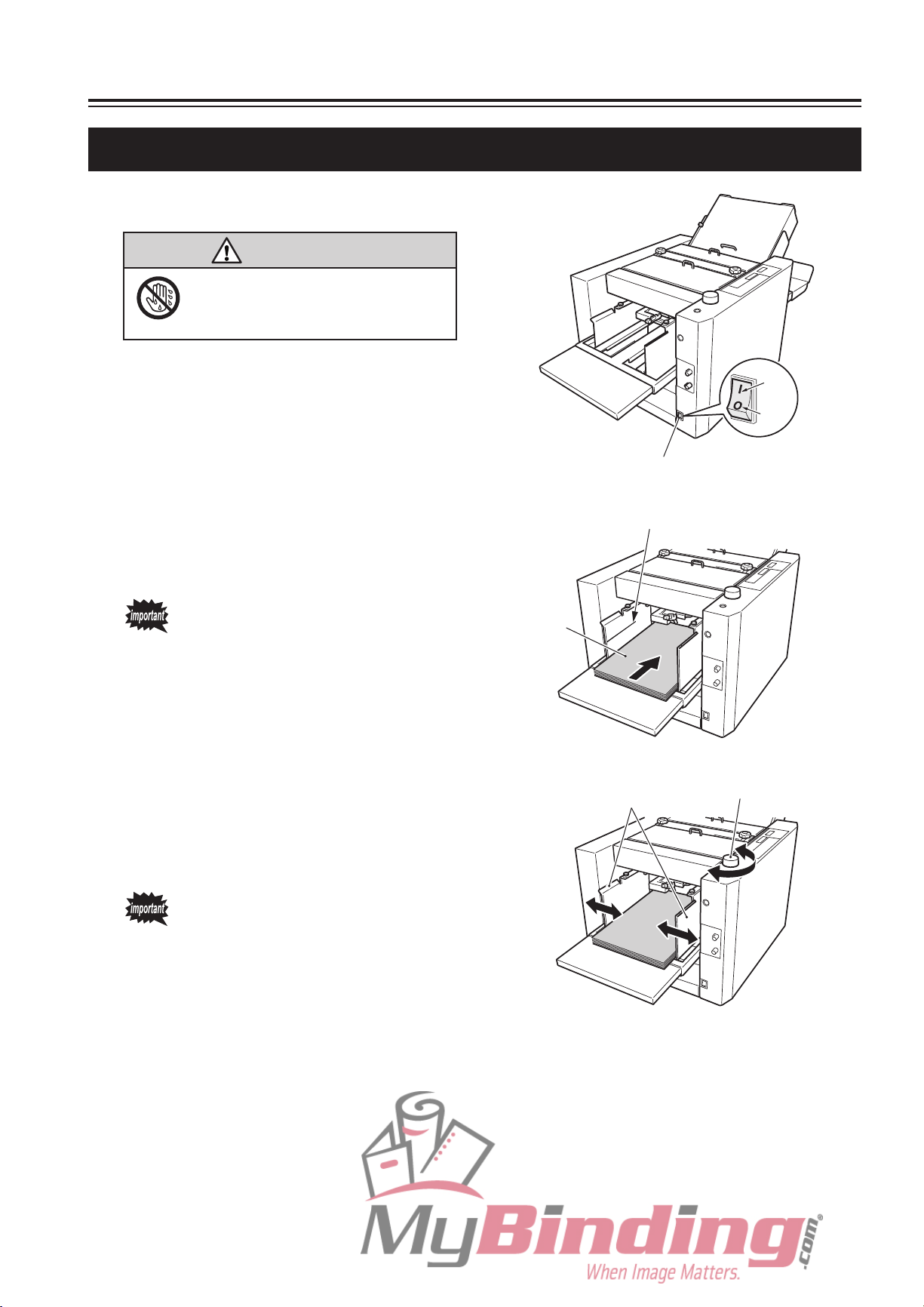

ON

OFF

1. STANDARD FOLDING OF STANDARD PAPER

MAX

1-3. Operation Procedure

Turn on the power switch.

1

WARNING

Do not touch the power switch

with wet hands.

Otherwise electric hazards may occur.

Power switch

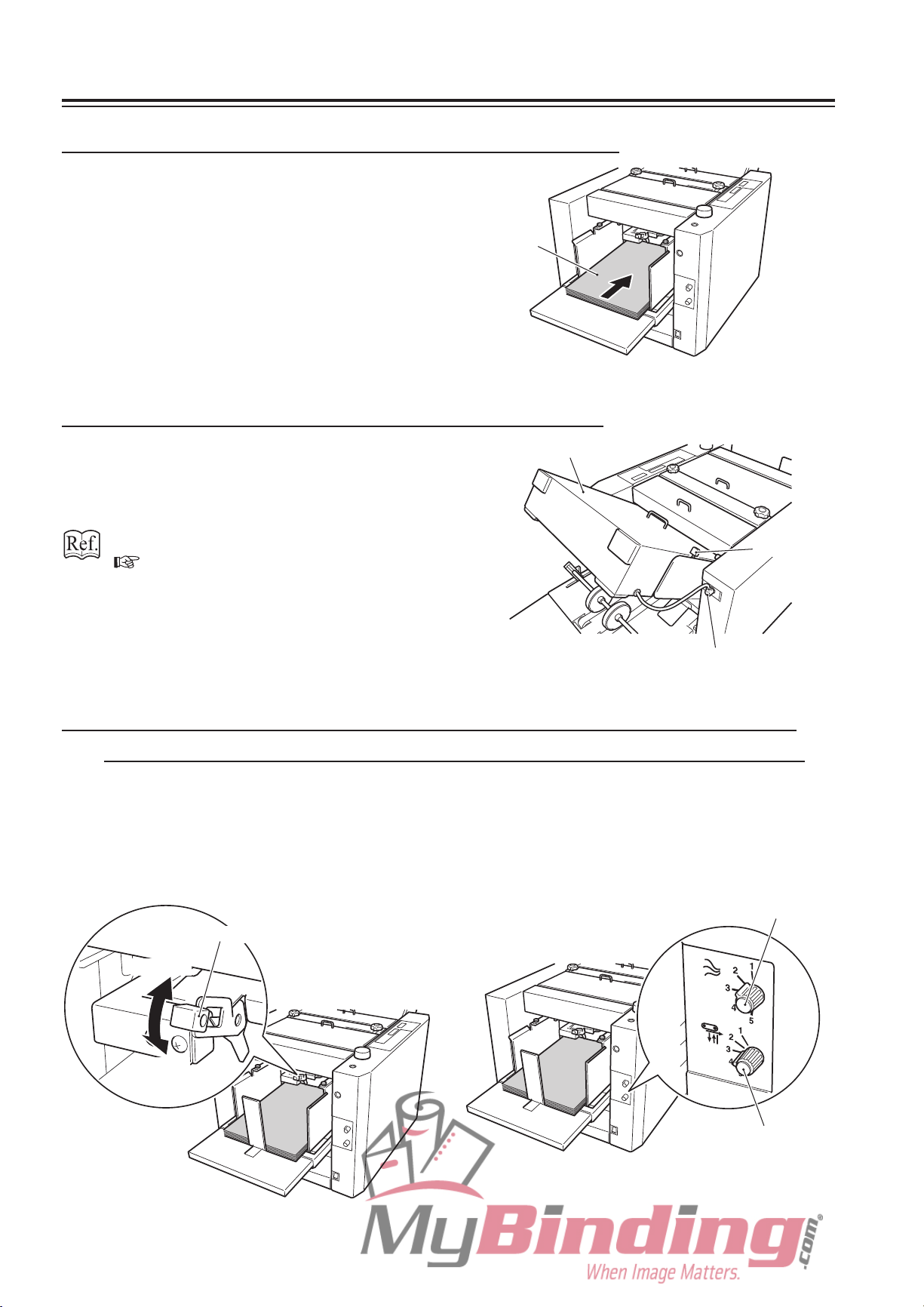

Stack paper on the paper feed tray.

2

Push in the paper until the lead edge touches

the shutter below the paper feed inlet slightly.

Do not overstack paper. Paper can

be stacked up to the mark “MAX”

on the side guide (about 100 mm

high).

Move the side guides according to

3

the paper width.

Move the side guides to the left and right by

rotating the side guide dial.

Be sure to adjust the side guides

accor ding to the paper width,

otherwise the unit may not operate

normally or problems such as

folding misalignment may result.

Maximum stacking height

Paper

Side guides

Side guide dial

2-3

Page 23

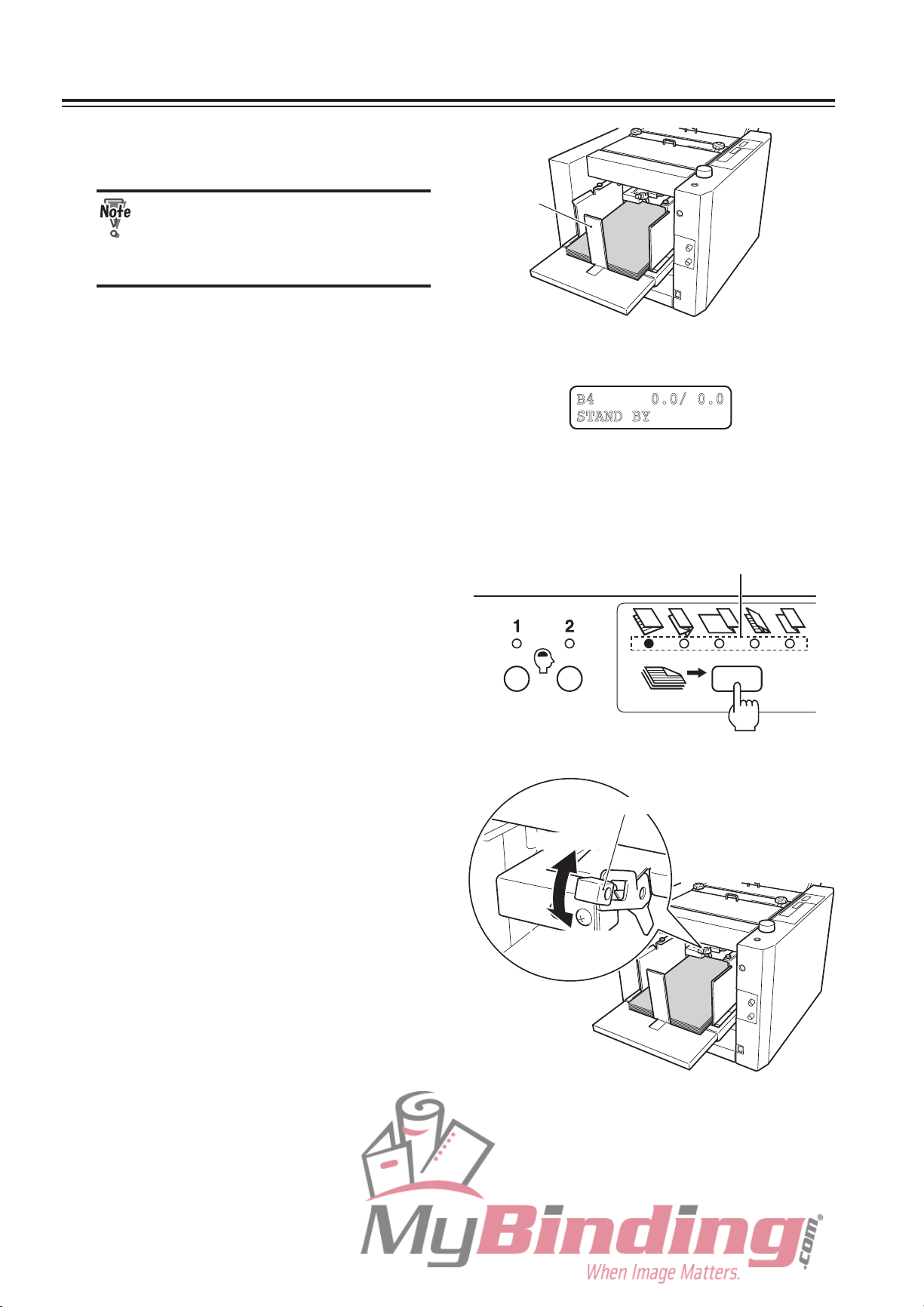

1. STANDARD FOLDING OF STANDARD PAPER

Standard folding lamp

Set the rear guide at the trail edge of

4

the paper.

Be sure to set the rear guide.

Starting the unit without setting

it will cause the separating air to

blow away the paper.

Check the paper size displayed at the

5

top left of the LCD.

If the side guides are not set at the designated

position, the paper size will not be displayed

even when using standard size paper. Make

sure t he side gui des are set to the cor rec t

position.

Press the folding mode key to select

6

the desired fold.

Each time the folding mode key is pressed, the

standard folding lamp will light up in order from

left to right, starting from single fold.

Rear guide

<LCD message in standard paper/standard folding>

. /

T

Adjust the level sensor height using

7

the level sensor adjusting lever.

The stan dard heig ht of the leve l sen sor is

between “1” and “2”.

Moving the adjusting lever to “1” raise s the

paper feed position and moving it to “2” lowers it.

If mis-feed occurs with thick paper, adjust to “1”.

If double-feed occurs with thin paper, adjust to

“2”.

Level sensor adjusting lever

To “2” side

To “1” side

2-4

Page 24

1. STANDARD FOLDING OF STANDARD PAPER

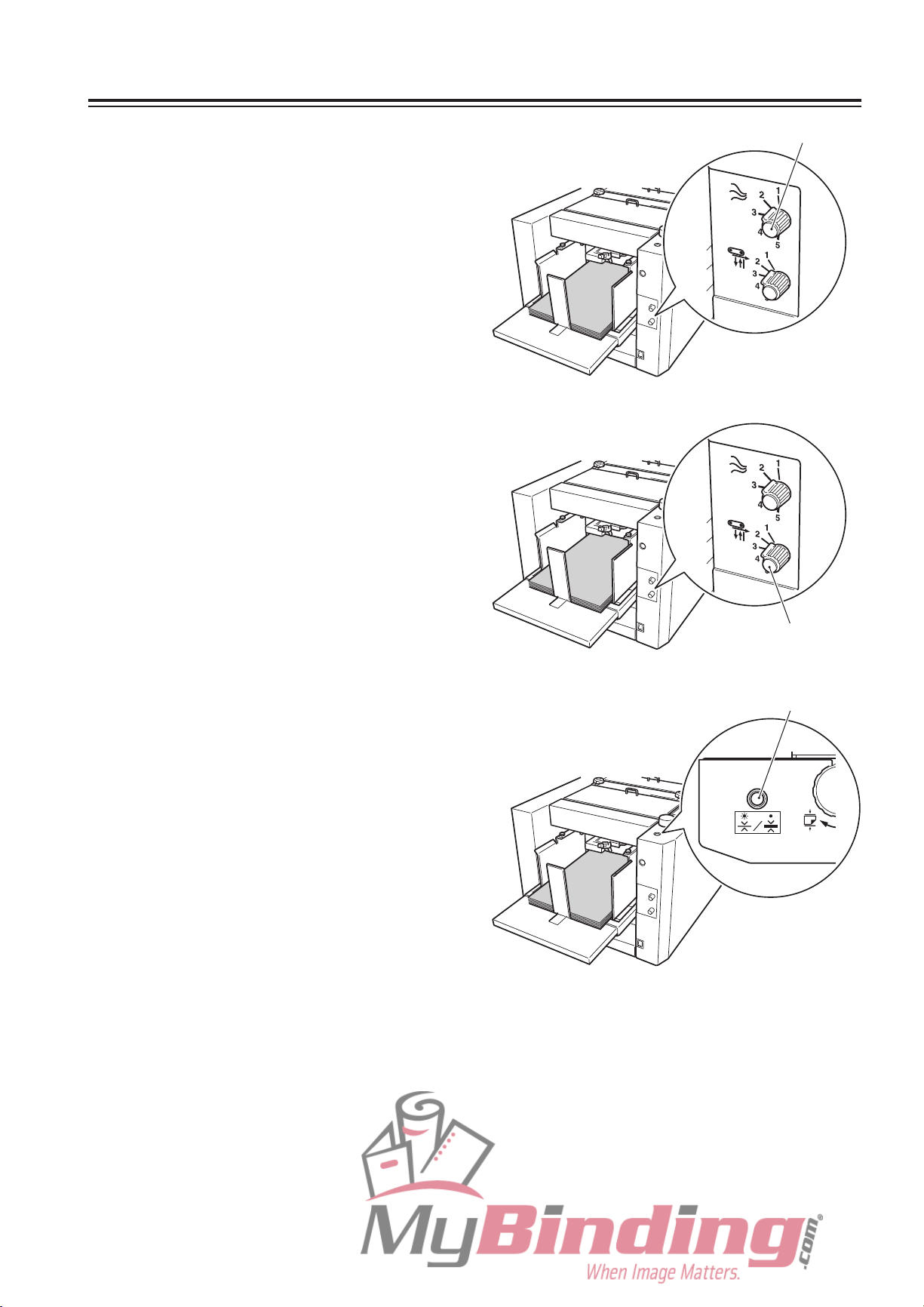

Adjust the separating air amount

8

using the separating air adjusting

knob.

The standard amount of the separating air is “2”.

The larger the figure, the stronger the separating

air blown will be. When using large art paper or

coated paper, adjust the knob to a large value.

Adjust to a small value for small and thin paper.

Adjust the separator height using the

9

separator adjusting knob.

The standard height of the separator is one

where the separator is touching the suction belt

lightly. Normally, set the knob to “2”.

If mis-feed occurs, adjust the knob to a large

value. If double-feed occurs, adjust to a small

value.

Separating air adjusting knob

Set the thin paper feed button to

10

ON or OFF according to the paper

thickness.

Press the button to select ON or OFF. When the

lamp is lit, the thin paper function is ON. When

the lamp is off, the thin paper function is OFF.

Set to ON if the paper thickness is less than 81.4

g/m2.

Separator adjusting knob

Thin paper feed button

2-5

Page 25

1. STANDARD FOLDING OF STANDARD PAPER

Speed 1 Speed 5

Speed 1 lamp blinks

(When set slower than

speed 1)

Speed 5 lamp blinks

(When set faster than

speed 5)

P re ss th e s p ee d k ey to s et th e

11

processing speed.

Five speed can be selected (Speed 1 to 5).

Every time the “+” key is pressed, the speed

lamp lights up towards the right and the speed

increases. Every time the “–” key is pressed, the

speed lamp lights up towards the left and the

speed decreases.

When the power is turned on, the speed used

the last time is displayed.

When using thin and flimsy paper, setting the speed to 5 may cause problems

such as paper jam and deformed folding. Set to lower speeds.

The speed can be set faster than 5 or slower than 1. (This setting becomes invalid

when the power is turned OFF, and when the power is turned ON again, it will be

set to speed 5 or 1.)

<To set faster than speed 5>

1) Press the “+” key until the speed 5 lamp lights up.

2) Press and hold the “+” key for more than three seconds. The lamp will stop lighting and start

blinking.

To return to speed 5, press the “–” key once. The lamp will start lighting.

<To set slower than speed 1>

1) Press the “–” key until the speed 1 lamp lights up.

2) Press and hold the “–” key for more than three seconds. The lamp will stop lighting and start

blinking.

To return to speed 1, press the “+” key once. The lamp will start lighting.

2-6

Page 26

1. STANDARD FOLDING OF STANDARD PAPER

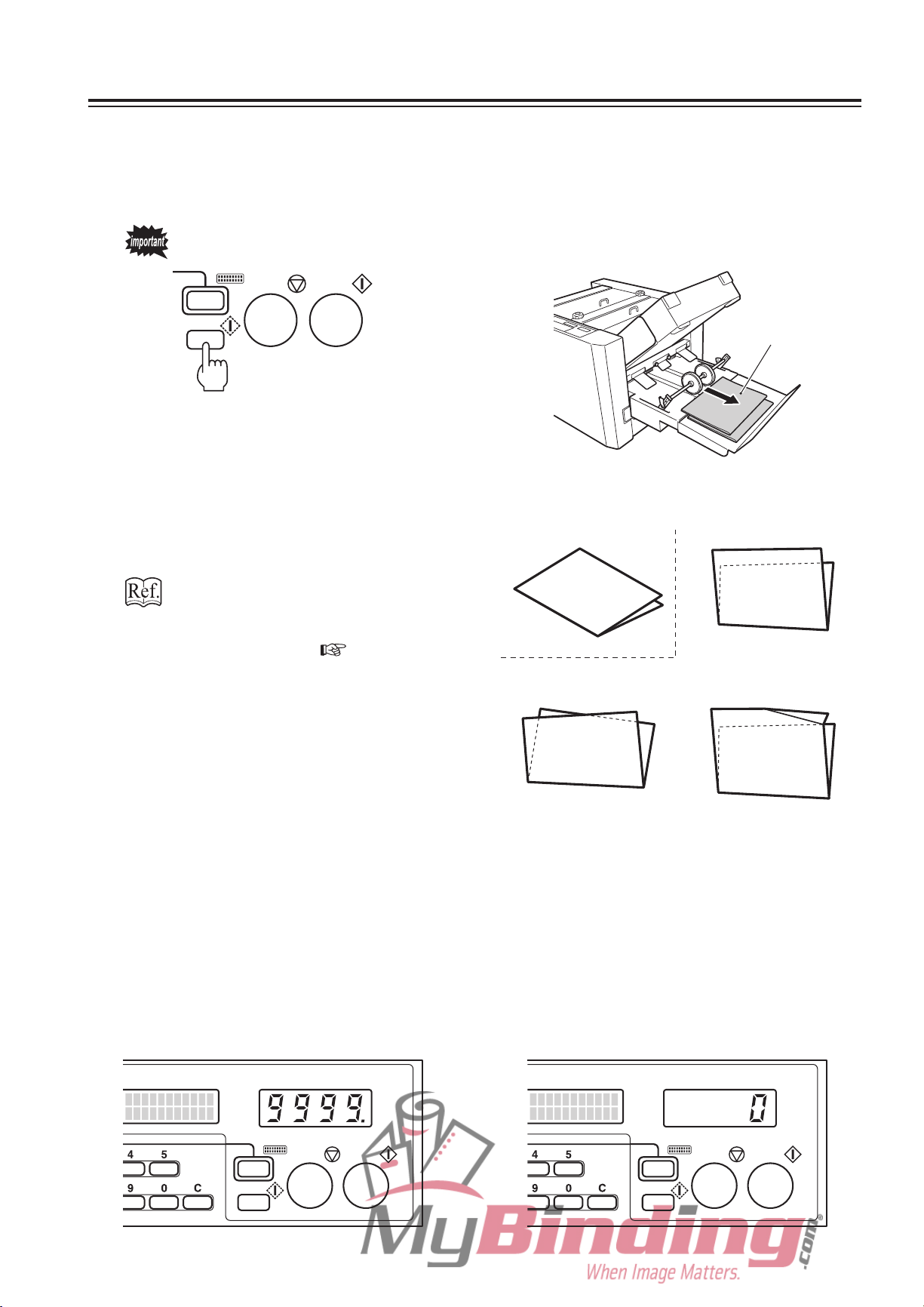

Press the test key to perform test folding.

12

Test folding feeds two sheets of paper and allows the finish to be checked.

When the test key is pressed, the LCD displays “WAIT” and the folding stopper starts moving to the set

position. When it completes moving, the message changes to “TEST RUN” and test folding starts.

Test folded paper are not counted in the number of sheets processed.

Folded paper

Check the finish of test folding.

13

Check for folding misalignment using the second

test folded sample.

If folding misalignments occur, refer

to Chapter 4 TROUBLESHOOTING

“ 1 . C O R RE C T IN G F O LD I NG

MISALIGNMENT” (

Select the method of using the counter.

14

The counter can be used in two ways: subtract count and add count.

Enter the number of sheets to be processed using the numerical keys first before beginning operations.

In this case, the counter will be set to the subtract count method. (A period is displayed at the bottom right

where the count is displayed.)

If the clear key is pressed to clear the counter to “0” before beginning operations, the counter will be set to

the add count method.

Up to four digits (9999) can be displayed.

p.4-2).

<Normal folding>

<Folding misalignment

along sides of paper>

<Folding misalignment along

vertical length of paper>

<Deformed folding>

<Counter display for “Subtract count method”> <Counter display for “Add count method”>

2-7

Page 27

1. STANDARD FOLDING OF STANDARD PAPER

The following description is based on the subtract count method.

Press the numerical keys to enter the

15

number of sheets to be processed.

Press the start key to start folding.

16

To cancel operations halfway through, press the

stop key. Pressing the start key another time

resumes operations.

When the number entered is reached in folding

operations, the buzzer sounds “pi...pi...”, and

paper feed will stop automatically.

If the paper feed tray runs out of paper, the

buzzer sounds “pi.pi.pi”, and the unit will stop

automatically.

After stopping, the paper feed tray moves down

automatically.

If double-feed, continuous-feed, or mis-feed occurs during folding operations, refer to the

following table and re-adjust the adjusting knobs and adjusting lever.

Adjusting knobs and

lever used

Separating air adjusting

knob

Level sensor adjusting

lever

Separator adjusting

knob

Double-feed/Continuous-feed Mis-feed

<When using thin paper>

Adjust

weaken the separating air.

<When using thick paper>

A

increase the separating air amount.

Move

sensor.

Adjust

raise the separator.

the knob to a smaller value and

djust the knob to a larger value and

the lever to “2” and lower the level

the knob to a smaller value and

Error state and adjustment method

Adjust the knob to a larger value and

increase the separating air amount.

Move the lever to “1” and raise the level

sensor.

Adjust the knob to a larger value and

lower the separator.

2-8

Page 28

Chapter 3

APPLIED USE

3-1

Page 29

1. STANDARD FOLDING OF NON-STANDARD PAPER

Paper that is not A3, B4, A4, B5, A5, or B6 are considered non-standard paper. Standard

paper that is fed in the long edge feeding direction is also considered as non-standard paper.

When using non-standard paper, the length must be entered and registered before beginning

folding operation.

Starting operations without registering the paper length will display the error message

“INPUT LENGTH” on the LCD.

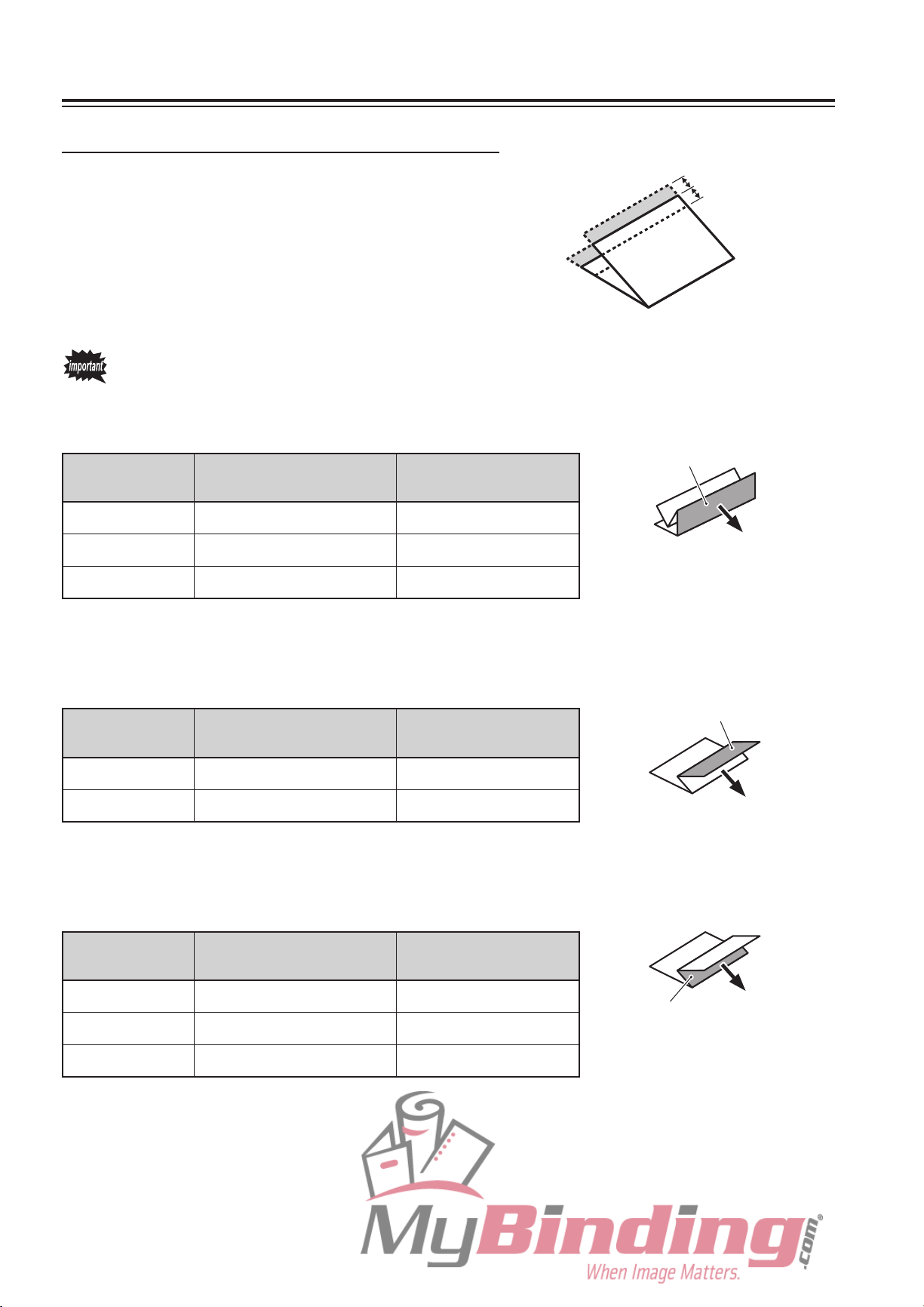

1-1. Paper Size Restrictions

Paper sizes which can be used are the sizes

within the range shown on the right.

To insu r e t h e quality of the fo l d

when paper width is 120 mm, it is

recommend not to exceed 240 mm in

length.

Width: 120 to 297 mm

1-2. Operation Procedure

Measure the length of the paper to be used.

1

The length is the side parallel to the paper feed direction (see top figure).

Turn on the power switch.

2

Paper feed direction

Paper

Length: 182 to 432 mm

Stack paper on the paper feed tray.

3

Move the side guides according to the paper width.

4

Set the rear guide at the trail edge of the paper.

5

For details of steps 2 to 5, refer to “1-3. Operation Procedure” in Chapter 2 BASIC

OPERATION “1. STANDARD FOLDING OF STANDARD PAPER” (

3-2

p.2-3).

Page 30

1. STANDARD FOLDING OF NON-STANDARD PAPER

�

Pr es s t h e m od e k ey to d is pl ay

6

“LENGTH” on the LCD.

Using the numerical keys, enter the

7

length of the paper.

The paper length which can be entered ranges

from 182 to 432 mm.

If the value enter ed exc eeds t he all owable

range, the buzzer sounds and the LCD shows

“TOO LONG” or “TOO SHORT”.

If a paper length has already been

registered, press the clear key to

clear this value before entering the

length with the numerical keys.

Press the stop key.

8

The entered paper length is registered, and the

value is displayed at the top left of the LCD.

The paper length data registered is

erased when the power is turned

off. To save the registered data,

set the last time fold mode at the

function setting mode screen.

R

efer to “4-2. Operation Mode

(

Setting” (

p.3-12).)

<Canceling non-standard paper length setting>

1) Press the mode key to display “LENGTH” on

the LCD.

2) Press the clear key to display “OFF”.

3) Press the stop key.

The unit returns to the automatic paper size

detection mode.

3-3

Page 31

1. STANDARD FOLDING OF NON-STANDARD PAPER

Press the folding mode key to select the desired fold.

9

Adjust the level sensor height.

10

Adjust the separating air amount.

11

Adjust the separator height.

12

Set the thin paper feed button to ON or OFF according to the paper thickness.

13

Press the speed key to set the processing speed.

14

Press the test key to perform test folding.

15

Check the finish of test folding.

16

Press the numerical keys to enter the number of sheets to be processed.

17

(Skip this step if using the add-count counter.)

Press the start key to start folding.

18

For details of steps 9 to 18, refer to “1-3. Operation Procedure” in Chapter 2 BASIC

OPERATION “1. STANDARD FOLDING OF STANDARD PAPER” (

p.2-4).

3-4

Page 32

2. CUSTOM FOLDING

Custom folding is the method of folding paper by specifying and registering the positions (folding

positions) of the folding stoppers of folding plates 1 and 2.

2-1. Paper Size Restrictions

Paper sizes which can be used are the sizes

within the range shown on the right.

To insu r e t h e quality of the fo l d

when paper width is 120 mm, it is

recommend not to exceed 240 mm in

length.

However, the length of the folded plane (see

right figure) which can be folded by folding

plates 1 and 2 is restricted.

Do not set the folded paper length to above

250 mm.

Folding plate 1 : 42 to 325 mm

Folding plate 2 : 0 mm*/47 to 217 mm

As folding plate 2 is not used in single folding, it is 0

∗

mm.

Paper feed direction

Paper

Width: 120 to 297 mm

Length: 182 to 432 mm

Length of

folded plane

2-2. Operation Procedure

The following describes the custom folding procedure taking accordion fold as an example.

C r e a t e th e f o l d i n g sa m p l e o f

1

accordion fold with the paper to be

used.

Measure the size of each folded plane

2

(A and B) of the sample, and the

folded paper length C.

Turn on the power switch.

3

Stack paper on the paper feed tray.

4

Move the side guides according to the paper width.

5

A (200 mm)

B (95 mm)

Paper feed

direction

C (105 mm)

Ejection

direction

3-5

Page 33

2. CUSTOM FOLDING

Set the rear guide at the trail edge of the paper.

6

For details of steps 3 to 6, refer to “1-3. Operation Procedure” in Chapter 2 BASIC

OPERATION “1. STANDARD FOLDING OF STANDARD PAPER” (

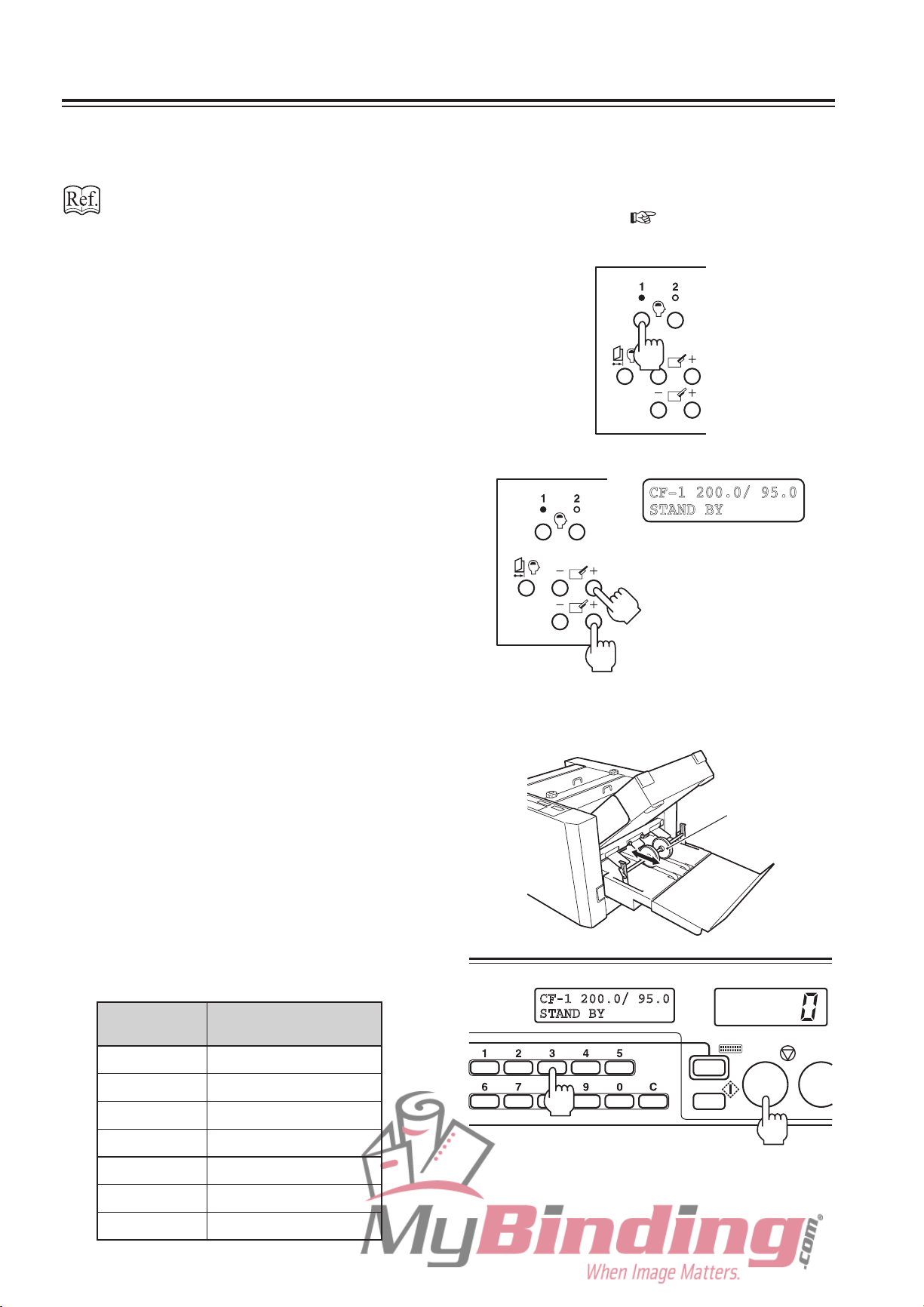

Press the custom folding registration

7

key 1 or 2 until the buzzer sounds

“pi.pi...” to switch to the custom

folding mode.

p.2-3).

Set the folding stopper positions.

8

Press the “+” key of the folding plate 1 folding

stopper a djusting key and move the folding

stopper to the measured dimensions A (200

mm) of the sample.

Press the “+” key of the folding plate 2 folding

stopper a djusting key and move the folding

stopper to the measured dimensions B (95 mm)

of the sample.

The position moved to by the folding stopper is

displayed in mm on the LCD.

Set the position of the stacker roller.

9

The position of the stacker roller needs to be

changed according to the folded paper length.

Selecting and pressing a numerical key (1 to 7)

while pressing the stop key moves the stacker

roller to the position set. Refer to the following

table for approximate set positions.

In this example, the folded paper length C is 105

mm. Therefore press the numerical key 3 while

pressing the stop key.

. /

T

Stacker roller

Approximate stacker roller set position

Numerical

key setting

1

2 To 80

3 81 to 110

4 111 to 140

5 141 to 170

6 171 to 210

7 211 to 250

Folded paper

length (mm)

∗

3-6

∗

Use numerical key “1” if paper jams at the “2” position.

Page 34

2. CUSTOM FOLDING

Adjust the level sensor height.

10

Adjust the separating air amount.

11

Adjust the separator height.

12

Set the thin paper feed button to ON or OFF according to the paper thickness.

13

Press the speed key to set the processing speed.

14

Press the test key to perform test folding.

15

Check the finish of test folding.

16

For details of steps 10 to 16, refer to “1-3. Operation Procedure” in Chapter 2 BASIC

OPERATION “1. STANDARD FOLDING OF STANDARD PAPER” (

After completing all settings, register

17

the custom folding setting.

Press the custom folding registration key 1 or 2

until the buzzer sounds “pi.pi...”.

The registered data is preserved

even after the power is turned off.

<Changing/erasing custom folding registration data>

1) Press the folding mode key so that the registration lamp (1 or 2) of the custom folding mode registering

the data to be changed or erased lights up.

2) To change the registered data, perform steps 8 to 17 of the above registration procedure. The data will

be rewritten.

To erase the data, proceed to step 3).

3) Press the custom folding registration key (1 or 2) registering the data to be erased until the buzzer

sounds “pi.pi...” (press for about two seconds), and then continue pressing for another two seconds until

the buzzer sounds “pi...”. (Total four seconds)

When the registered data is erased, the single folding lamp will light up.

p.2-4).

Press the numerical keys to enter the number of sheets to be processed.

18

(Skip this step if using the add-count counter.)

Press the start key to start folding.

19

For details of steps 18 and 19, refer to “1-3. Operation Procedure” in Chapter 2 BASIC

OPERATION “1. STANDARD FOLDING OF STANDARD PAPER” (

p.2-8).

3-7

Page 35

3. USING SPECIAL PAPER

3-1. Art Paper, Coated Paper

Fan the paper well before stacking.

Set the separating air adjusting knob to a

larger value.

Set the separato r adjusting knob to a

smaller value.

If the paper is folded abnormally, lower the

processing speed.

If paper feed error occurs and it cannot be

correct by the above two adjusting knobs

and level sensor adjusting lever, lower the

processing speed.

Separating air adjusting knob

Separator adjusting knob

3-8

Page 36

3-2. Recycled Paper

Speed 1 lamp blinks

(When set slower than speed 1)

Fan the paper well before stacking.

3. USING SPECIAL PAPER

Set the separating air adjusting knob to a

smaller value.

Set the separato r adjusting knob to a

larger value.

Set the processing speed to a low speed.

If paper feed error occurs frequently,

set the processing speed slower

than speed 1. Press and hold the

“–” speed key for more than three

seconds with the speed 1 lamp lit.

This lamp will start blinking.

Separating air adjusting knob

Separator adjusting knob

3-9

Page 37

3. USING SPECIAL PAPER

3-3. B6 Size Paper

Paper may jam more easily at the stacker roller according to the paper thickness, type, and

folding mode. Perform the following procedure if paper jams frequently.

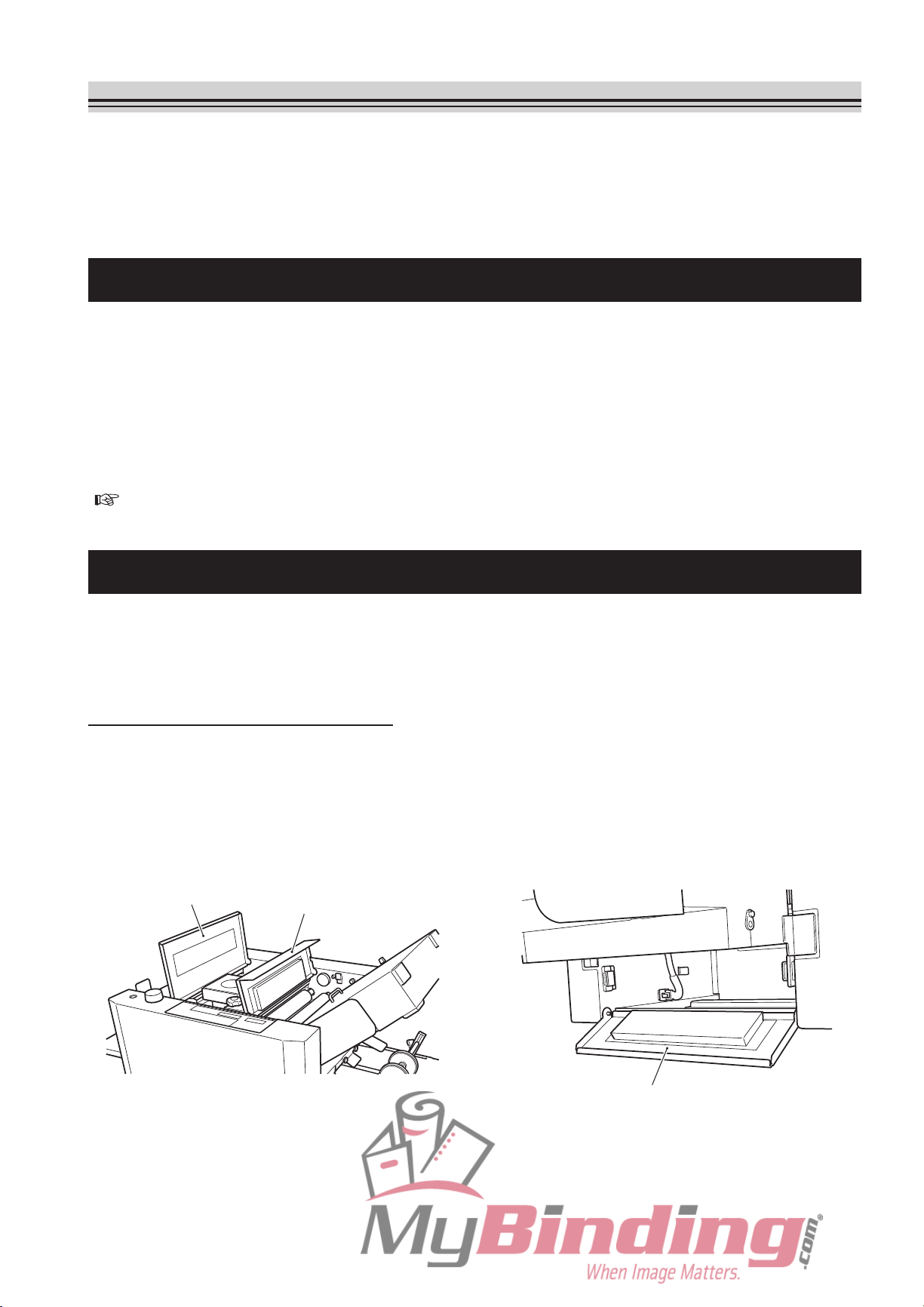

Loosen the two knob screws and

1

remove the paper ejection guide.

Change the stacker roller height.

2

Chapter 4 TROUBLESHOOTING

“2-2. Changing the Stacker Roller

Height” (

p.4-14)

Lever

Stacker belt

Paper ejection guide

Stacker roller

Set the operations of the stacker belt

3

to “CONTINUOUS” at the function

setting mode screen.

“ 4 - 7 . S t ac k e r B e l t S e t t i n g ”

p.3-20)

(

After completing folding operations, be sure to return the places changed in steps

4

1 to 3 to their original state.

Depending on the paper thickness, type, and folding mode, the ejected paper may not be

aligned and stacked neatly on the paper receiving tray.

If paper alignment is poor, hook the auxiliary paper ejection guide to the stacker roller shaft.

<Example of paper stacked neatly>

< T CK L

CO

Auxiliary paper ejection guide

To remove the paper ejected with the auxiliary paper ejection guide mounted, lift the

guide edge or remove the guide first.

3-10

Page 38

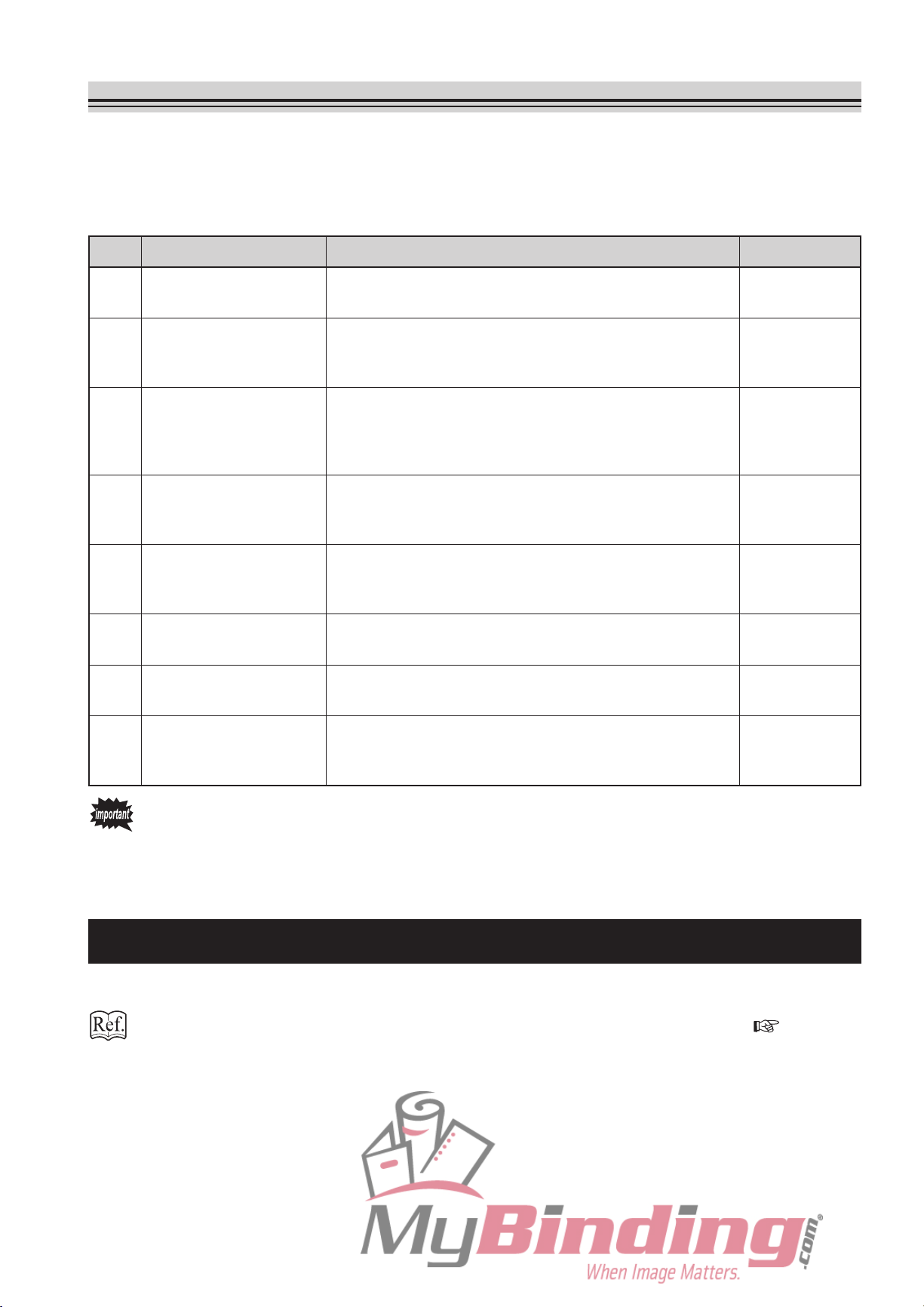

4. FUNCTION SETTING MODE

The function setting mode is a function for shortening the operation procedure or adjusting

according to the paper used based on the purpose of the user.

The function setting mode consists of the following eight types.

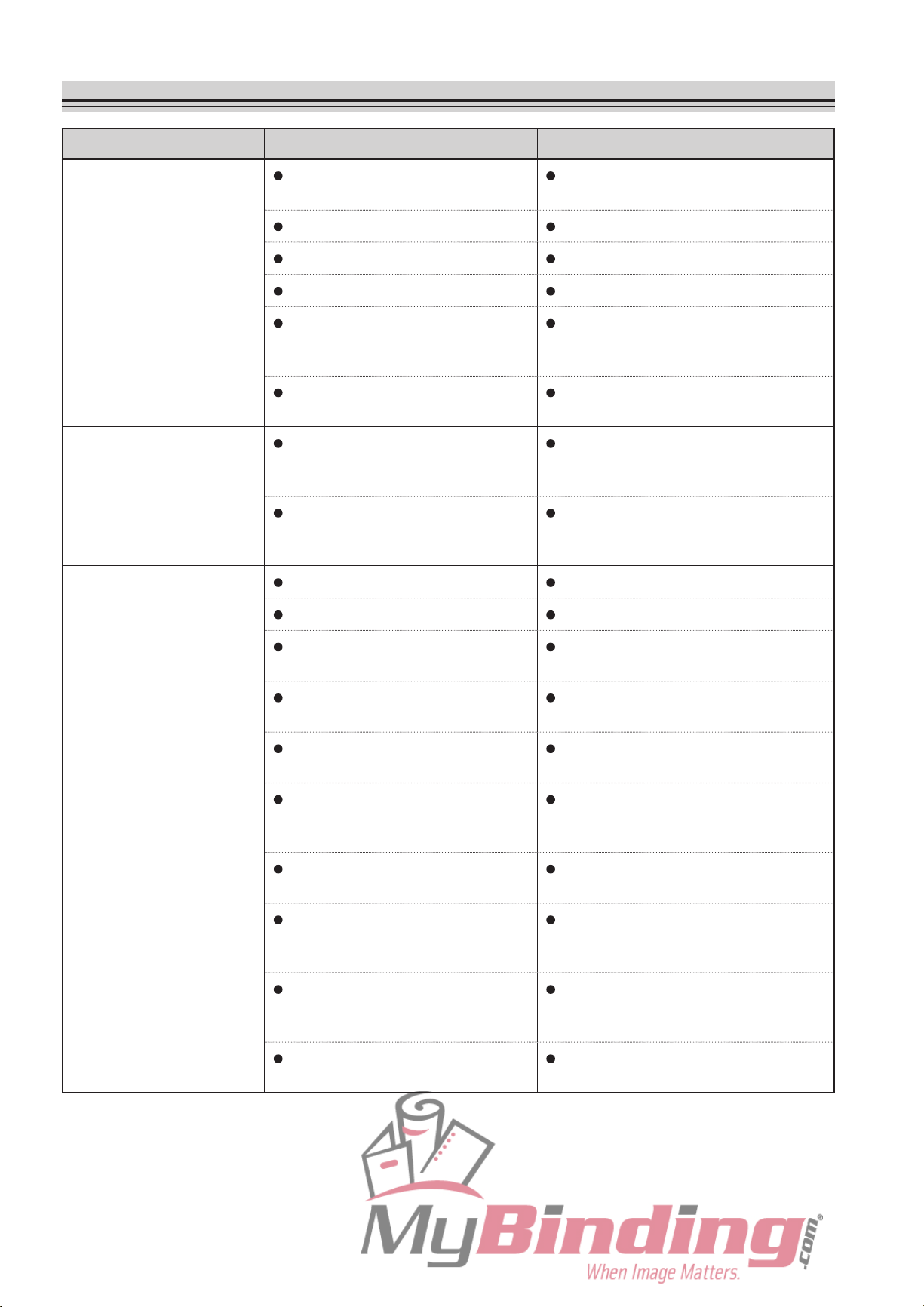

No. Mode Purpose Default setting

1 Non-standard paper

length setting

2 Operation mode setting S

3 Interval setting S

4 Separating air strength

setting

5 Paper feed interval

setting

6 Stacking amount setting The

7 Stacker belt setting Select

Set

and register the paper length when standard folding

non-standard paper.

etting for shortening the operation procedure. Select

from three modes “NORMAL”, “LAST TIME FOLD”, and

“STOPPER FIXED”.

etting this setting to ON repeatedly pauses operations

for ever y specifi ed n umber of shee ts a nd re star ts

operations after several seconds. The pause time can be

selected from “3 SEC”, “5 SEC”, and “10 SEC”.

T

he separ a t ing air volume c a n be s e lected f r o m

“NORMAL” a nd “L I G H T ” a c c o r d i n g t o t h e paper

thickness.

T

he processing speed for single fold, double fold, and

letter fold of standard paper can be selected from “FAST”,

“NORMAL”, and “SLOW”.

volume of paper stacked on the paper feed tray can

be selected from “HIGH”, “NORMAL”, “LOW”.

“NORMAL” and “CONTINUOUS”.

the operations of the stacker belt from two modes

OFF

NORMAL

OFF

NORMAL

NORMAL

HIGH

NORMAL

8 Thick paper stopper

correction setting

T

he correction value of the folding stopper positions of

the folding plates can be changed for thick paper. Select

“NOT CORRECTED” or “CORRECTED”.

The No. 1 registered data of paper length will be preserved even after the power is turned

off when the No. 2 operation mode setting is set to last time fold mode.

The No. 2, 4 to 8 settings will be preserved even after the power is turned off.

The No. 3 setting will be erased when the power is turned off.

4-1. Non-standard Paper Length Setting

Set and register paper length in this mode when using non-standard paper.

For details, refer to “1. STANDARD FOLDING OF NON-STANDARD PAPER” ( p.3-2).

NOT

CORRECTED

3-11

Page 39

4. FUNCTION SETTING MODE

4-2. Operation Mode Setting

Setting to the last time fold mode or folding stopper fixed mode enables setting operations

after power ON to be omitted, thus shortening the time to the start of work. At shipment, this is

set to the normal mode.

(1) Last time fold mode

Function which starts the unit at the settings used the last time when the power is turned ON.

When set to this mode, the following will be set automatically at power ON.

To correct the folding stopper position and save the data, be sure to register the

corrected data. Otherwise, the corrected data will be erased when the power is turned

OFF.

Setting Last time fold mode Normal mode

Paper size

Folding mode S

Stacker roller position S

Processing speed Set

Sta ndard pap er is auto mati cal ly

detected.

When non-standard paper length is

registered, the registered data is set.

et t o the f oldi ng mod e when the

power was turned OFF.

et to the position when the power

was turned OFF.

to the speed when the power was

turned OFF.

Standa rd p ape r is auto mat ica lly

detected.

When using non-standard paper, the

paper length must be registered.

Single folding

Default setting

Set to the speed when the power was

turned OFF.

(2) Folding stopper fixed mode

Mode for omitting settings of the control panel when folding paper under the same conditions

at all times. When set to this mode, the folding stopper position, stacker roller position, and

processing speed will be fixed. Therefore initial settings of the unit will be omitted when the

power is turned ON, enabling folding to be started immediately.

3-12

When set to this mode, the folding mode, processing speed, stacker roller position

cannot be selected. Before setting this mode, perform test folding in the “normal

mode” and fix the folding stopper position, processing speed, and stacker roller

position.

To correct the folding stopper position and save the data, be sure to register the

corrected data. Otherwise, the corrected data will be erased when the power is turned

OFF.

When set to this mode, the standard folding lamp and custom folding registration lamp

will not be lit.

Page 40

4. FUNCTION SETTING MODE

The following shows the recommended operation modes by purpose. Change the operation

mode according to purpose.

<Example of purpose> <Recommended operation mode>

When the paper size and folding mode differs

each time

When various people use the machine

When the paper size and folding mode are

always more or less the same, but want to

change it occasionally

When the paper size and folding mode are the

same every time, and want to start operations

immediately after power ON

Normal mode (Default setting)

Last time fold mode

Folding stopper fixed mode

The following shows how to set the last time fold mode and folding stopper fixed mode.

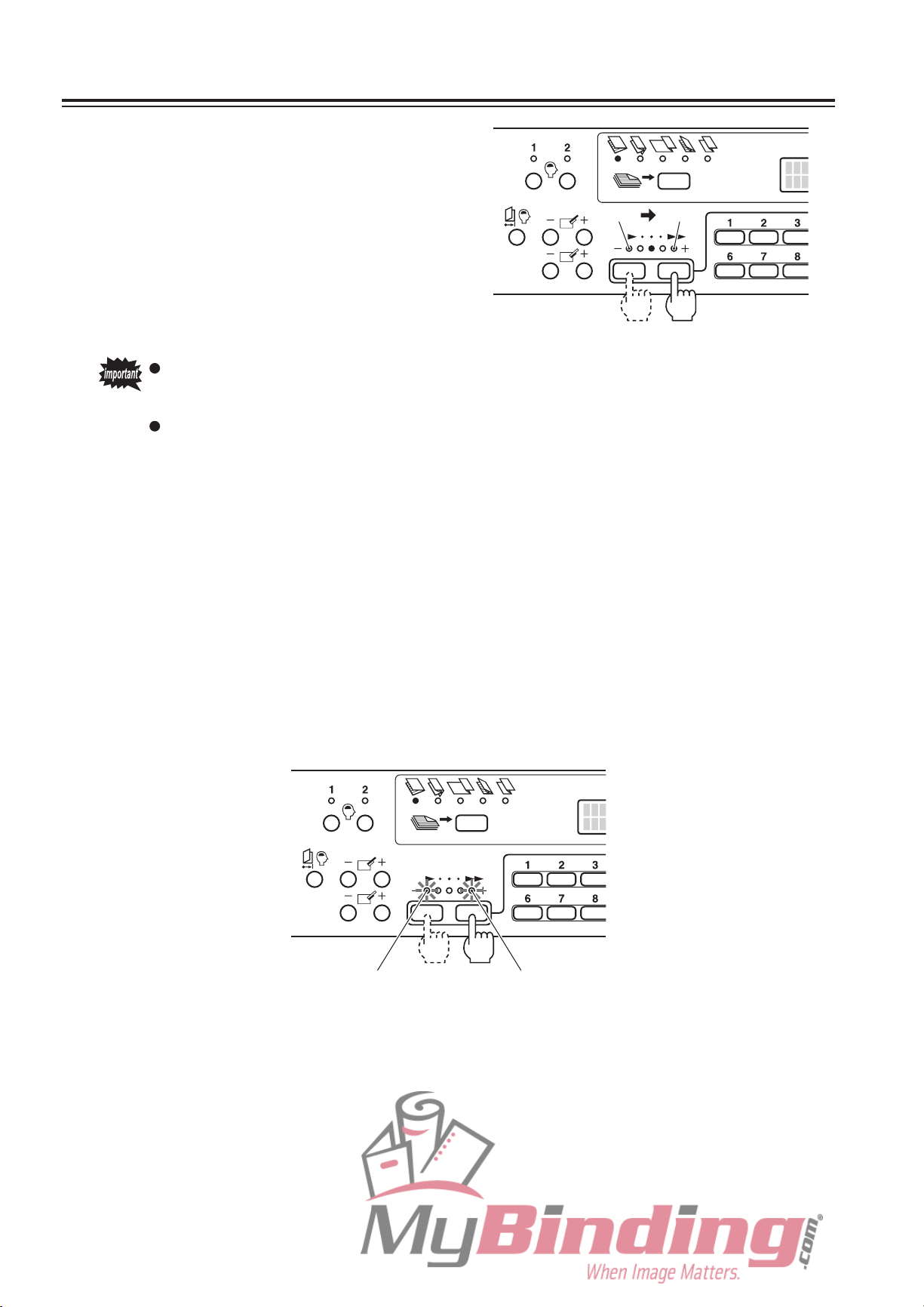

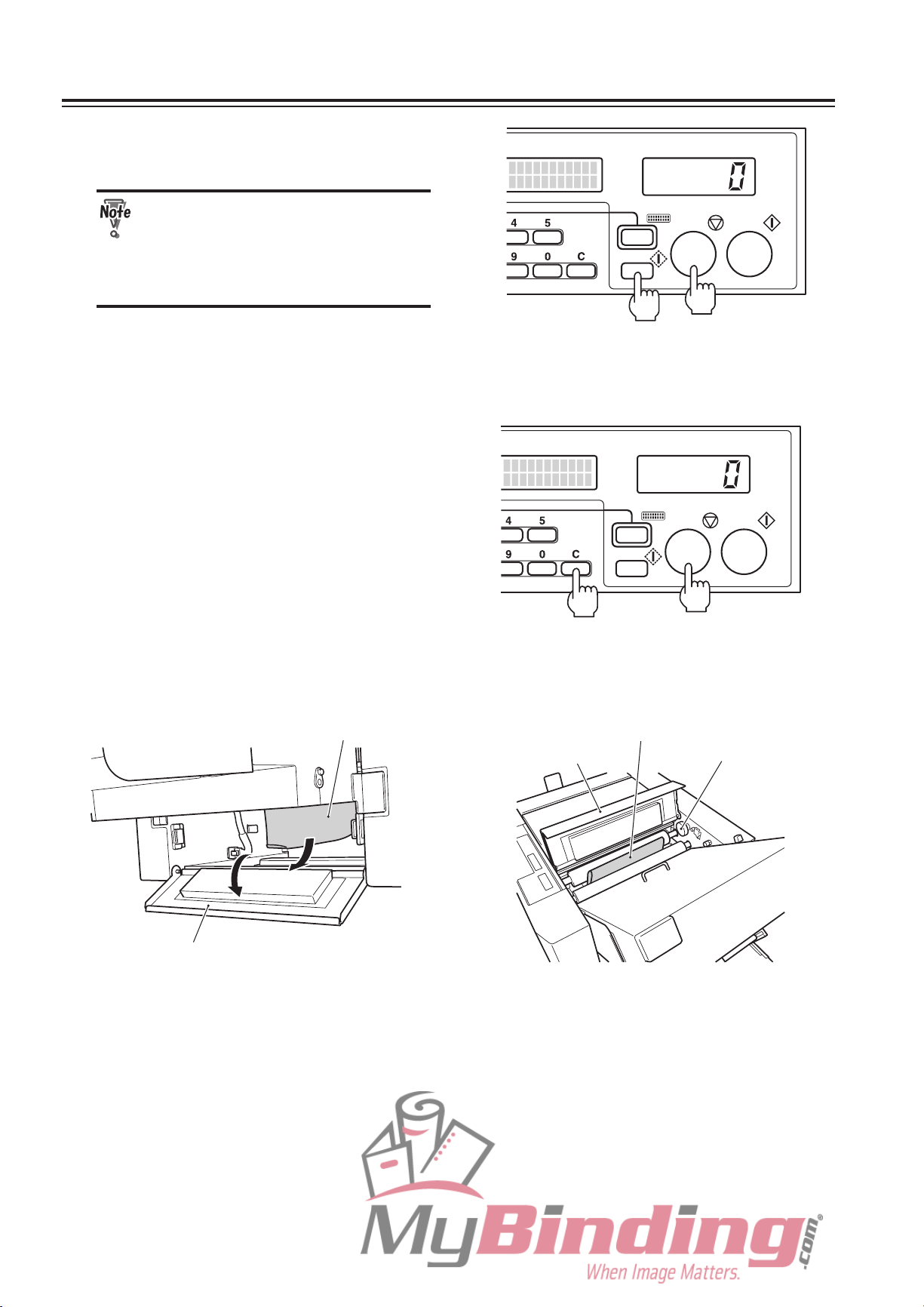

Pr ess th e mo de k ey an d se le c t

1

“MODE”.

Press the speed key and select “LAST

2

TIME FOLD” or “STOPPER FIXED”.

<When last time fold <When folding stopper

mode> fixed mode>

<

IX

Press the stop key and register the

3

setting.

Wh en se t to the last time fold mode, “REF”

appears at the bottom of the LCD.

When set to the folding stopper fixed mode, “FIX”

appears at the top of the LCD.

<When last time fold <When folding stopper

mode> fixed mode>

/ .

/

3-13

Page 41

4. FUNCTION SETTING MODE

<Returning to the normal mode>

1) Press the mode key and select “MODE”, and then

select “NORMAL” using the speed key.

2) Pressing the stop key switches to the normal

mode, and “REF” or “FIX” on the LCD disappears.

3-14

Page 42

4. FUNCTION SETTING MODE

4-3. Interval Setting

When this setting is set to ON, the unit will automatically repeat pause and restart at the

specified number of sheets as shown in the figure below. At shipment, this is set to “OFF”.

<Example> To remove ejected paper from the paper receiving tray or changing the direction

of the paper placed during pause

Start

Pause (Select the pause time from 3 seconds, 5 seconds, and 10 seconds.)

Restart

Stops when paper runs out or the subtract-count counter becomes “0”.

Press the mode key and select “SET

1

INTERVAL”.

Press the speed key and select the

2

pause time from “3 SEC”, “5 SEC”, or

“10 SEC”.

Enter the number of sheets to be

3

processed until the unit pauses using

the numerical keys.

< N

/ T

The number of sheets is shown on the LCD.

The number of sheets which can be entered

ranges from 1 to 999.

T V L

/

3-15

Page 43

4. FUNCTION SETTING MODE

Press the stop key and register the

4

setting.

“I” is displayed at the bottom of the LCD.

The setting is erased when the

power is turned OFF.

<Returning setting to “OFF”>

1) Press the mode key and select “SET INTERVAL”,

and then select “OFF” using the speed key.

2) Pressing the stop key clears the setting and “I” on

the LCD disappears.

/

N I

V

3-16

Page 44

4. FUNCTION SETTING MODE

4-4. Separating Air Strength Setting

Function for adjusting the air amount for separating paper. At shipment, this is set to

“NORMAL”.

<Example> To weaken the air as paper feed error occurs frequently when thin paper or small

paper is used

Press the mode key and select “AIR

1

POWER”.

Pres s the sp eed ke y and se lec t

2

“LIGHT”.

Press the stop key and register the

3

setting.

<Returning setting to “NORMAL”>

1) Press the mode key and select “AIR POWER”,

and then select “NORMAL” using the speed key.

R >

I T

>

2) Press the sto p ke y and switch the set tin g to

“NORMAL”.

3-17

Page 45

4. FUNCTION SETTING MODE

4-5. Paper Feed Interval Setting

Function for changing the processing speed when single folding, double folding, or letter

folding standard paper. At shipment, this is set to “NORMAL”.

<Example>

Press the mode key and select “FEED

1

SPEED”.

Pres s the sp eed ke y and se lec t

2

“FAST” or “SLOW”.

To raise the processing speed when the paper used and folding mode are

restricted to the above three types (This setting is valid only when the speed

5 lamp is blinking. Refer to “1-3. Operation Procedure” in Chapter 2

BASIC OPERATION “1. STANDARD FOLDING OF STANDARD PAPER”

p.2-6).)

(

To lower the processing speed to prevent paper jamming and paper feed

errors

Th e “ FA S T ” s e t t i n g i s v a l id

only when the speed 5 lamp is

blinking. (Refer to “1-3. Operation

Procedure” in Chapter 2 BASIC

O P E RA T IO N “1 . ST A N D A R D

FOLDING OF STANDARD PAPER”

p.2-6).)

(

T

Press the stop key and register the

3

setting.

<Returning setting to “NORMAL”>

1) Press the mode key and select “FEED SPEED”,

and then select “NORMAL” using the speed key.

2) Press the sto p ke y and switch the set tin g to

“NORMAL”.

3-18

< >

Page 46

4. FUNCTION SETTING MODE

4-6. Stacking Amount Setting

Function which changes the amount of paper stacked on the paper feed tray in three levels.

The distance descended by the paper feed tray when paper runs out changes according to

the setting. At shipment, this is set to “HIGH”.

The number of sheets stacked for each setting is as follows for fine quality paper 81.4 g/m2 or

equivalent.

“HIGH” : 1000 sheets

“NORMAL” : 600 sheets

“LOW” : 300 sheets

<Example> To decrease the amount stacked when the number of sheets used for one folding

operation is little and folding is to be carried out while changing the paper type

Pr ess th e mo de k ey an d se le c t

1

“QUANTITY”.

Pres s the sp eed ke y and se lec t

2

“NORMAL” or “LOW”.

Press the stop key and register the

3

setting.

<Returning setting to “HIGH”>

1) Press the mode key and select “QUANTITY”, and

then select “HIGH” using the speed key.

N >

N >

I

2) Press the stop key and switch the setting to “HIGH”.

3-19

Page 47

4. FUNCTION SETTING MODE

4-7. Stacker Belt Setting

Function for changing the operation mode of the stacker belt. At shipment, this is set to

“NORMAL”. At this time, the stacker belt operates according to the paper ejection timing.

The mode

and folding mode.

<Example> If paper is not ejected neatly or paper jams frequently at the stacker roller

When switching to “CONTINUOUS”, change the stacker roller height to the top and

remove the paper ejection guide. If the setting has been returned to “NORMAL”, return

the stacker roller and paper ejection guide to their original positions. (Refer to “3-3. B6

Size Paper” (

Pr ess th e mo de k ey an d se le c t

1

“STACKER BELT”.

can be changed so the stacker belt operates continuously, according to the paper

hen double folding B6 size paper, etc., set so that the stacker belt operates

w

continuously.

p.3-10).)

Pres s the sp eed ke y and se lec t

2

“CONTINUOUS”.

Press the stop key and register the

3

setting.

<Returning setting to “NORMAL”>

1) Press the mode key and select “STACKER BELT”,

and then select “NORMAL” using the speed key.

2) Press the sto p ke y and switch the set tin g to

“NORMAL”.

I

< >

3-20

Page 48

4. FUNCTION SETTING MODE

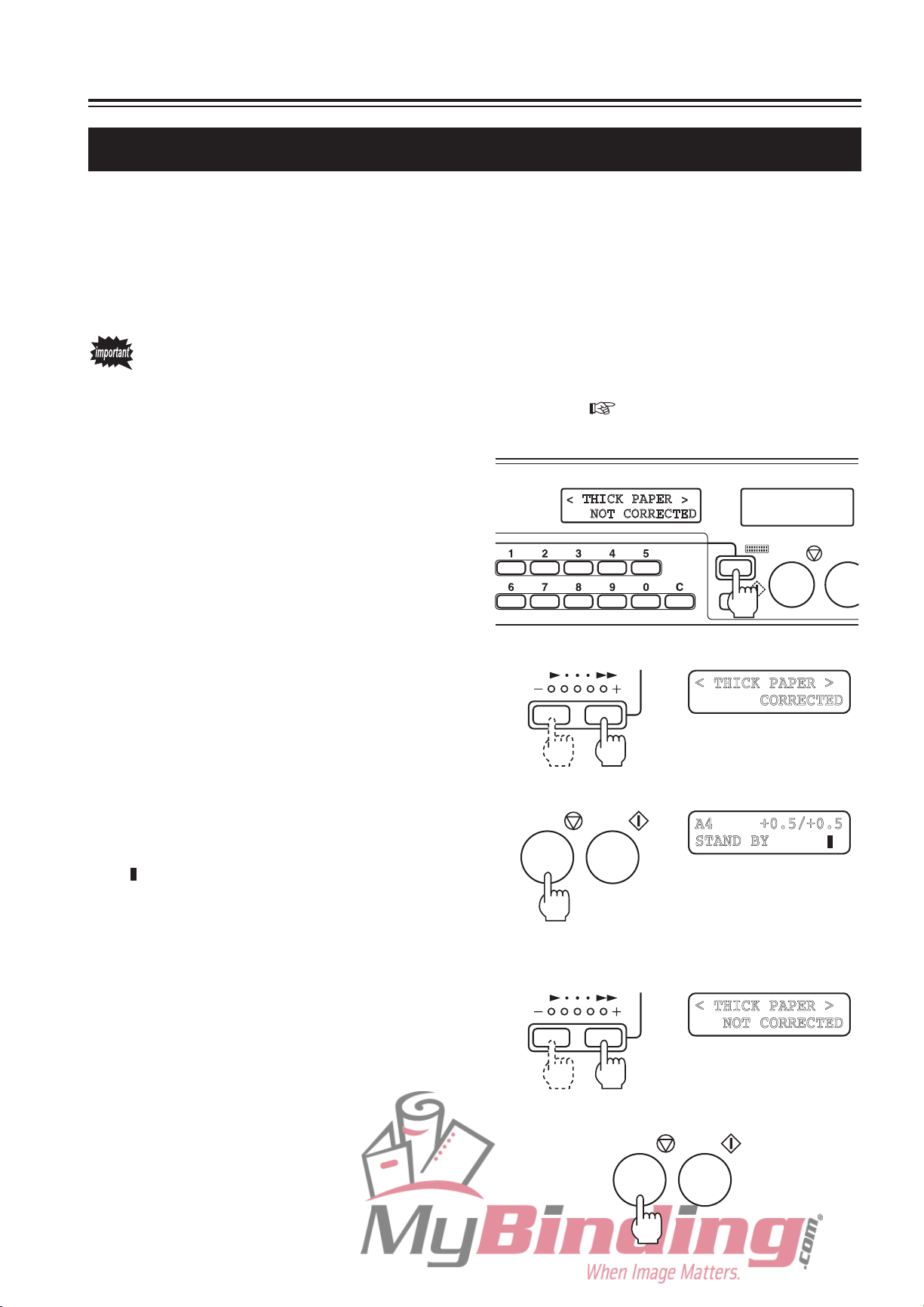

4-8. Thick Paper Stopper Correction Setting

Setting this setting to “CORRECTED” correct the folding stopper positions of both folding

plates 1 and 2 by +0.5 mm. At shipment, this is set to “NOT CORRECTED”.

<Example> When using thick paper, it is often necessary to correct the folding stopper

position to

without using the folding stopper adjusting key.

Even if set to “CORRECTED”, folding misalignment may occur due to such conditions as

using environment (temperature, humidity), paper thickness, paper type, paper state, and

processing speed. In this case, refer to Chapter 4 TROUBLESHOOTING “1-2. Correcting

Folding Misalignment Along Vertical Length of Paper” (

Press the mode key and select “THICK

1

PAPER”.

the + direction. In such cases, correction of +0.5 mm may be possible

p.4-5).

Pres s the sp eed ke y and se lec t

2

“CORRECTED”.

Press the stop key and register the

3

setting.

“ ” mark is displayed at the bottom of the LCD.

<Returning setting to “NOT CORRECTED”>

1) Press the mode key and select “THICK PAPER”,

and then select “NOT CORRECTED” using the

speed key.

/

N

2) Press the stop key and switch the setting to “NOT

CORRECTED”.

3-21

Page 49

Memo

3-22

Page 50

Chapter 4

TROUBLESHOOTING

4-1

Page 51

1. CORRECTING FOLDING MISALIGNMENT

Moving direction

of side guide

Example of

adjusting knob

needle position

Folding

misalignment A

Folding

misalignment B

Folding misalignment consists of “folding misalignment along the sides of the paper” and

“folding misalignment along the vertical length of the paper”.

Other than this, “deformed folding” may also occur due to paper characteristics, etc.

1-1. Correcting Folding Misalignment Along Sides of Paper

Before correcting, check that the skew roller spring pressure adjusting knobs are

set at the same position for the left and right sides. If their positions differ, folding

misalignment may occur. (Refer to (3) Using the skew roller spring pressure adjusting

knob (

p.4-4).)

When the folded paper is misaligned along

the sides as shown in the figure, correct the

folding misalignment using the side guide

adjusting knob and skew correction knob.

Ejection direction

(1) Adjusting the side guide adjusting knob

Loosen the side guide adjusting

1

knobs.

Mo v e th e sid e gu i d es by ha n d

2

according to the folding misalignment

direction.

Refer to the pos ition of t he adjust ing knob

needle for the adjusting amount.

Side guide adjusting knobs

Needles

Folding misalignment

at this part

4-2

Always move the left and right

side guides in the same direction.

Side guides

Page 52

1. CORRECTING FOLDING MISALIGNMENT

Rotating

direction of knob

Example of

check window

needle position

Folding

misalignment C

Folding

misalignment D

Tighten the side guide adjusting knobs and secure the side guides.

3

Perform test folding and check that the folding misalignment has improved.

4

If fol ding mis align ment is not improved

due to trimming misalignment, perform (2)

Adjusting the skew correction knob.

(2) Adjusting the skew correction knob

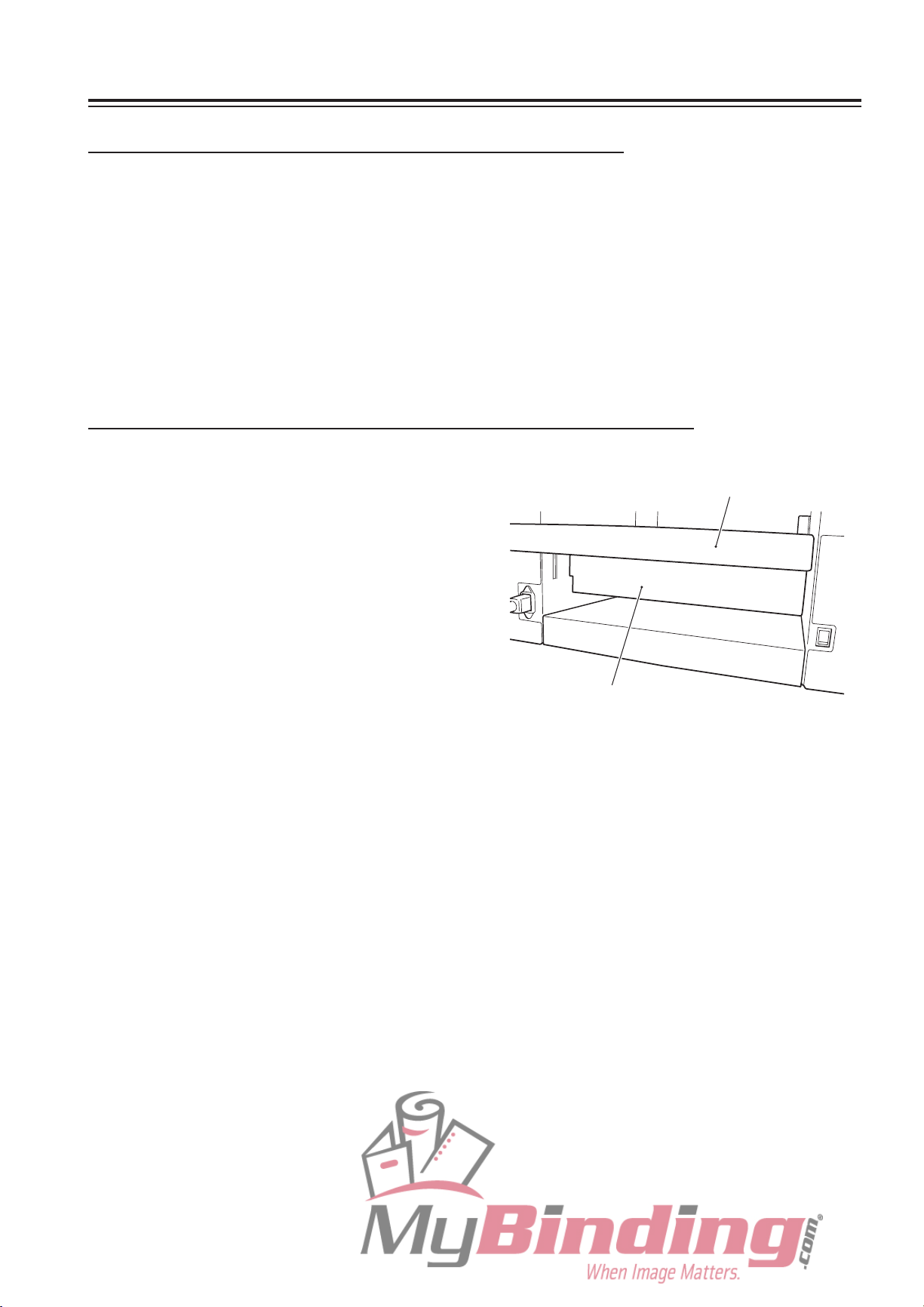

Loosen the skew roller fixing knobs.

1

Open the top cover L.

2

<Trimming misalignment of paper>

Skew roller fixing knobs

Top cover L

Rotate the skew correction knob

3

according to the folding misalignment

direction.

Refer to the position of the check window needle

shown in the figure for the adjusting amount.

<Adjusting amount check window>

Needle

Standard position

Skew correction knob

4-3

Page 53

1. CORRECTING FOLDING MISALIGNMENT

Close the top cover L.

4

Tighten the skew roller fixing knobs.

5

Perform test folding and check that the folding misalignment has improved.

6

After completing folding operations, be sure to return the needle back to the standard

position.

(3) Using the skew roller spring pressure adjusting knob

Open the top cover L.

1

Switch the position of the adjusting

2

k n o b a c c o r d i n g t o t h e pa p e r

thickness.

Skew roller spring

pressure adjusting knobs

Above 127.9 g/m

2

Set to the “top” position when using fine quality

paper above 127.9 g/m2 and to “bottom” position

when using paper thinner than this. However

switch while checking the folding misalignment.

Be sure to set the left and right

knobs at the same position.

Close the top cover L.

3

Less than 127.9 g/m

2

4-4

Page 54

1. CORRECTING FOLDING MISALIGNMENT

1

2

3

4

5

1

2

3

4

5

1

2 3

4

5

1

2

3

4

5

1) Paper enters folding plate 1. 3) Folding rollers 2 and 3 sandwich slackened

paper and send to folding rollers 4 and 5.

2) Paper contacts folding stopper and slacks

near folding rollers 2 and 3.

4) Single-folded paper is ejected out.

Folding plate 1

Paper

Folding rollers 1 to 5

Slacks near here.

Folding stopper

Paper

1-2. Correcting Folding Misalignment Along Vertical Length of Paper

When the folded paper is misaligned along

Ejection direction

the vertical length as shown in the figure,

adjust the positions of the folding stoppers

of fold ing plates 1 and 2 to c orrect the

misalignment.

Folding

misalignment

at this part

(1) Folding misalignment correction mechanism

This following describes single folding as an example.

The flow of paper and movements of the folding section when single folding is shown below.

In single folding, folding plate 2 is not used.

4-5

Page 55

1. CORRECTING FOLDING MISALIGNMENT

Folding plate 1 folding

stopper adjusting key

Length A of the folded plane is the length from the trail edge of the paper to the center of

paper slack.

Length B of the folded plane is the length from the center of paper slack to the folding stopper.

Therefore

by changing the position of the folding stopper, length B of the folded plane can be

adjusted.

Folded plane length B

Folded plane length A

Ejection direction

Folded plane

length A

Folded plane

length B

(2) Correcting single fold

Adjust the length of single folded plane using the “+” or “–” key of the folding plate 1 folding

stopper adjusting key.

<Example 1>

When folded

shorter than folded plane length A

plane length B is 6 mm

6 mm

In this example, by increasing the folded plane length B by 3 mm, A will become 3 mm

shorter, and as a result, folding misalignment of 6 mm in total can be improved.

To increase B, press the “+” key and move the folding stopper in the direction shown

below. To increase B by 3 mm, press the “+” key until “+3.0/ ...” appears on the LCD.

direction

+3.0 mm

+3.0 mm

–3.0 mm

+ /

4-6

Page 56

1. CORRECTING FOLDING MISALIGNMENT

Folding plate 1 folding

stopper adjusting key

<Example 2>

When folded plane length B is 3 mm

longer than folded plane length A

3 mm

In this example, by shortening the folded plane length B by 1.5 mm, A will become 1.5

mm longer, and as a result, folding misalignment of 3 mm in total can be improved.

To shorten B, press the “–” key and move the folding stopper in the direction shown

below. To shorten B by 1.5 mm, press the “–” key until “–1.5/ …” appears on the LCD.

direction

–1.5 mm

–1.5 mm

+1.5 mm

/

For details on the correction methods of other folding modes, refer to “(4) Correction

method by folding mode” (

p.4-9).

The corrected value can be registered for standard folding of standard paper. (Refer to “(5)

Registering folding misalignment correction values” (

p.4-10).)

4-7

Page 57

1. CORRECTING FOLDING MISALIGNMENT

(3) Correction range and restrictions

The correction range of standard folding is

within ±5 mm (to folding misalignment of 10

mm).

For double fold and irregular accordion fold, the correction range may be restricted

and cannot be corrected for some paper lengths. For details, refer to the following

description.

<Correction of folded plane B for double fold>

Paper length

[mm]

182 to 187 “–” key of folding plate 2 Cannot correct

188 to 207 “–” key of folding plate 2

208 to 432 No restriction ±5

Adjusting key restricted

Correction range

[mm]

∗

1

+5.0 mm

–5.0 mm

B

Ejection direction

∗

1:

The values which can be corrected vary in the –0.1 to –4.8 mm range

according to the paper length.

<Correction of folded plane A for irregular accordion fold>

Paper length

[mm]

427 to 432 “+” key of folding plate 1

182 to 426 No restriction ±5

∗

The values which can be corrected vary in the +0.6 to +4.3 mm range

2:

according to the paper length.

Adjusting key restricted

Correction range

[mm]

∗

2

<Correction of folded plane B for irregular accordion fold>

Paper length

[mm]

182 to 189 “–” key of folding plate 2 Cannot correct

190 to 208 “–” key of folding plate 2

Adjusting key restricted

Correction range

[mm]

∗

3

A

Ejection direction

Ejection direction

B

209 to 432 No restriction ±5

∗

3:

The values which can be corrected vary in the –0.2 to –4.7 mm range

according to the paper length.

4-8

Page 58

1. CORRECTING FOLDING MISALIGNMENT

Adjusting key of folding plate 1

Folding mode Correction method

State of

folded plane A

State of

folded plane B

A is long

A is short

Press the “–” key.

Press the “+” key.

A is long

A is short

Press the “–” key.

Press the “+” key.

A is long

A is short

Press the “+” key.

Press the “–” key.

A is long

A is short

Press the “–” key.

Press the “+” key.

A is long

A is short

Press the “+” key.

Press the “–” key.

Adjusting key of folding plate 2

Folding mode Correction method

B is long

B is short

Press the “–” key.

Press the “+” key.

B is long

B is short

Press the “–” key.

Press the “+” key.

B is long

B is short

Press the “–” key.

Press the “+” key.

B is long

B is short

Press the “–” key.

Press the “+” key.

� Folding plate 2 is not used in single folding.

Single foldDouble fold

Irregular

accordion fold

Letter fold

Accordion fold

Single foldDouble fold

Irregular

accordion fold

Letter fold

Accordion fold

A

Ejection direction

Ejection direction

A

A

Ejection direction

Ejection direction

A

B

Ejection direction

B

Ejection direction

Ejection direction

Ejection direction

Ejection direction

B

B

A

Folding plate 1 folding

stopper adjusting key

Folding plate 2 folding

stopper adjusting key

(4) Correction method by folding mode

Corr ect foldi ng m isalig nment usi ng t he

folding stopper adjusting keys of folding

plates 1 and 2 referring to the following table.

4-9

Page 59

1. CORRECTING FOLDING MISALIGNMENT

Folding plate 1 folding

stopper adjusting key

Folding plate 2 folding

stopper adjusting key

(5) Registering folding misalignment correction values

The adjustment value of folding misalignment along the vertical length of the paper can be

registered using the adjustment registration key for each standard paper size and standard

folding mode.

(6 standard paper sizes × 5 standard folding modes = 30 types of registrations are possible)

The corrected value cannot be registered for standard folding of non-standard paper

and custom folding.

The registered correction data will be preserved even after the power is turned off.

Stack standard paper on the paper feed tray, select the standard folding mode,

1

press the test key and start test folding.

Remove the second folded sample,

2

and check for folding misalignment

along the vertical length.

Using the folding stopper adjusting

3

keys of folding plates 1 and 2, adjust

the folded plane length.

Folded paper

Ejection direction

Folding

misalignment

at this part

Perform test folding again and check that folding misalignment has improved.

4

4-10

Page 60

1. CORRECTING FOLDING MISALIGNMENT

Blinking (End of adjustment registration)

Lit (When adjustment registration is erased)

After adjusting folding misalignment,

5

press the adjustment registration key

until the buzzer sounds “pi.pi...”.

When adjustment registration completes, the

lamp of the folding mode selected stops lighting

and starts to blink.

<Changing/erasing adjustment registration data>

1) Set the paper size whose adjustment registration data is to be changed or erased.

The paper need not be actually stacked on the paper feed tray, just move the side guides to this paper size

using the side guide dial.

2) Use the folding mode key to select the folding mode whose adjustment registration data is to be changed or

erased.

3) To

To erase the data, proceed to step 4)

4) Press the adjustment registration key until the

When

change the registered data, perform steps 3 to 5 of the above registration procedure. The data will be

rewritten.

.

buzze r sound s “pi.p i.. .” (pr ess for about two

seconds), and then continue pressing for another

two seconds until the buzzer sounds “pi...”. (Total

four seconds)

the registered data is erased, the selected

folding mode lamp stops blinking and lights up,

and the adjustment value displayed on the LCD

changes to “0.0/0.0”.

. / .

T

4-11

Page 61

1. CORRECTING FOLDING MISALIGNMENT

1-3. Correcting Deformed Folding

Check the following when deformed folding

occurs.

Set the processing speed to a low speed.

If paper feed error occurs frequently,

set the processing speed slower

than speed 1. Press and hold the

“–” speed key for more than three

seconds with the speed 1 lamp lit.

This lamp will start blinking.

Fan the paper well before stacking.

<Example of deformed folding>

Check that the side guides fit the paper

Side guides

Side guide dial

width.

Do not use paper sizes other than those specified. This will cause not only deformed

folding but the unit will also malfunction.

4-12

Page 62

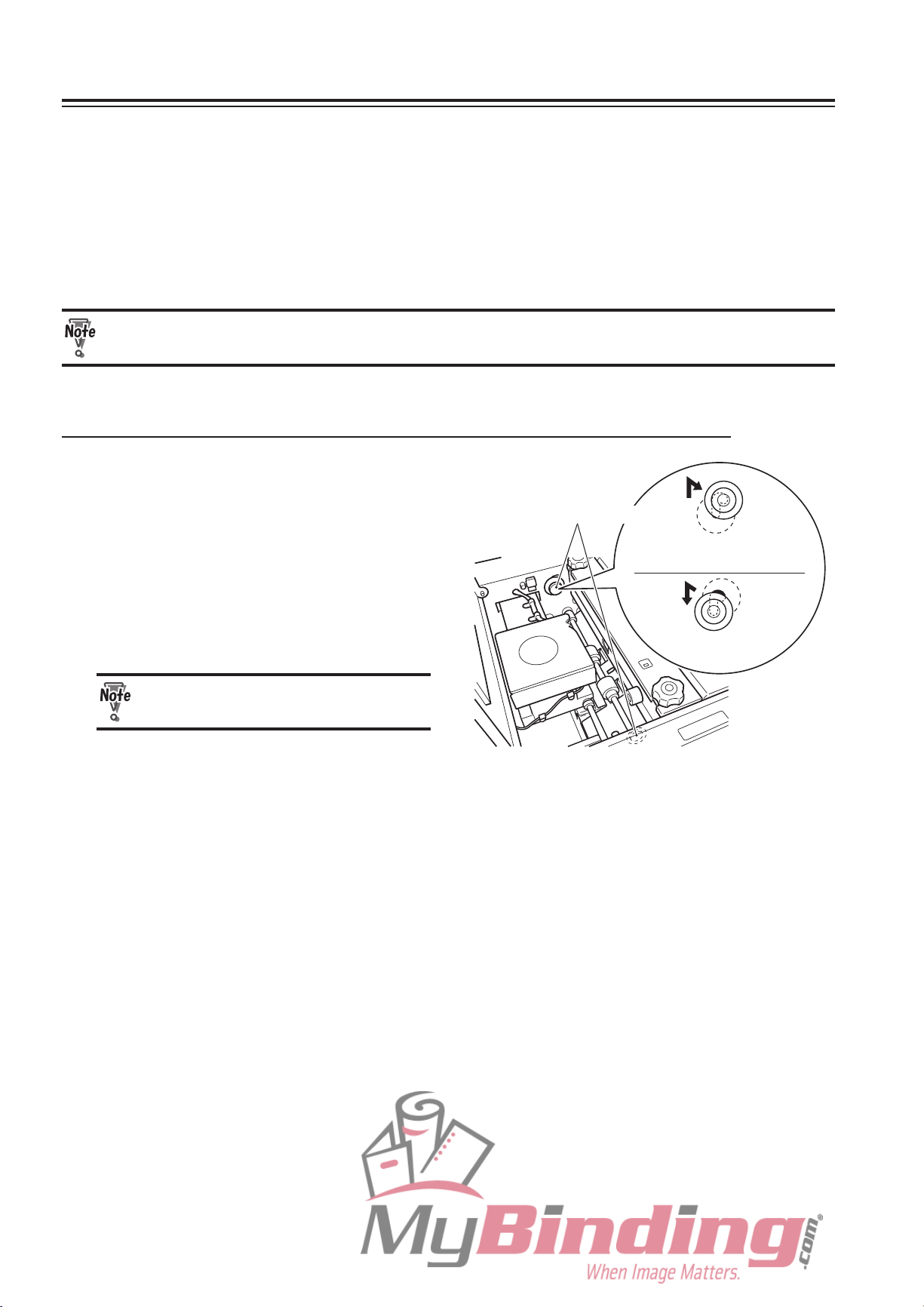

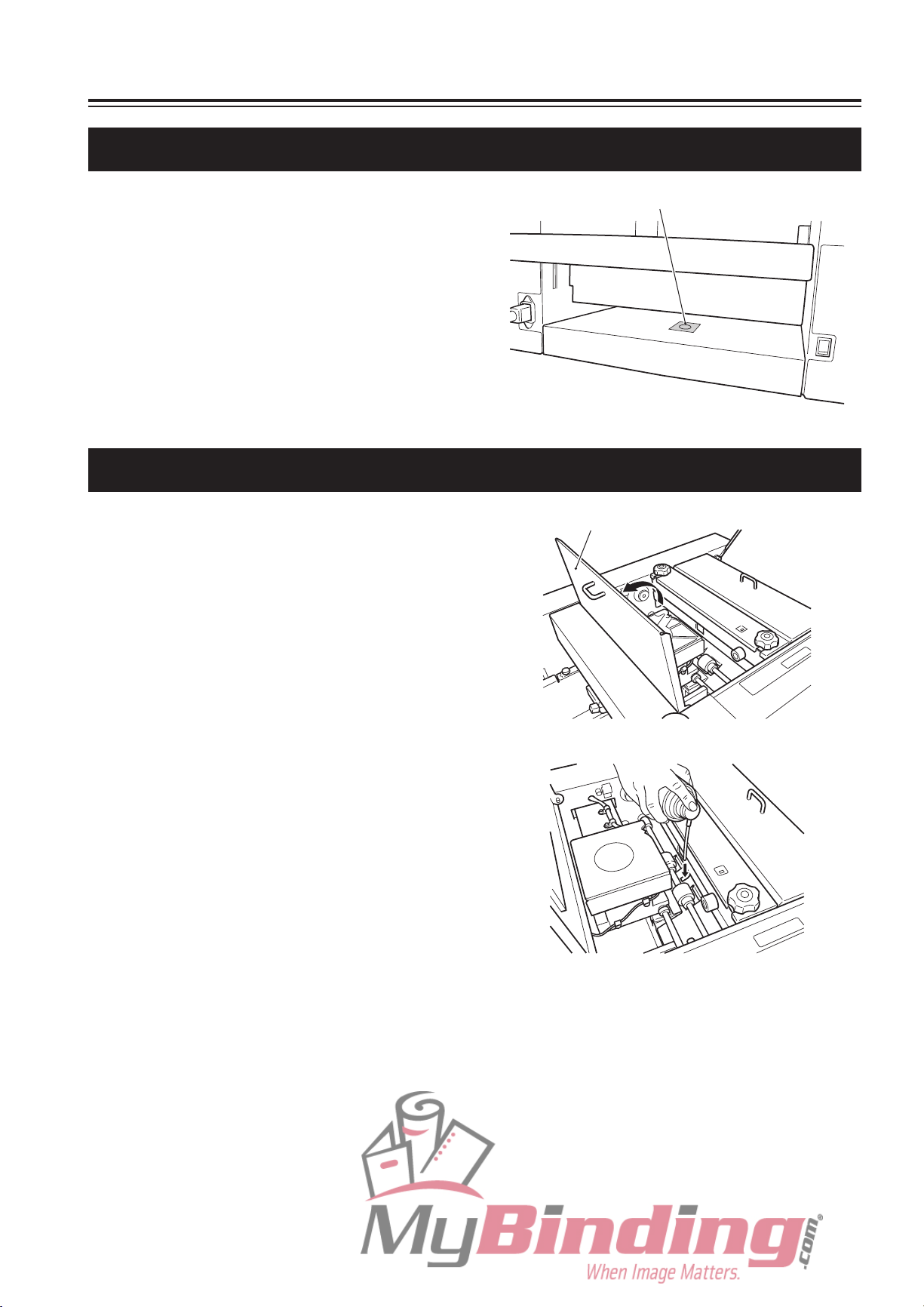

2. ADJUSTING THE STACKER ROLLER

� � �

2-1. Changing the Stacker Roller Position

The position of the stacker roller is automatically set in standard folding. However, if the

alignment of paper ejected to the paper receiving tray is poor, change the position.

While pressing the stop key, press a numerical key between 1 and 7.

Stacker roller

Refer to the following table for the position for setting the stacker roller according to the folded paper length.

Numerical

key setting

1

2 To 80 B4 ........... Letter fold

3 81 to 110 A3 ........... Double fold

4 111 to 140 A4 ........... Single fold

5 141 to 170 A3 ........... Letter fold, accordion fold

6 171 to 210 A3 ........... Single fold, irregular accordion fold

Folded paper

length (mm)

Applicable standard paper size and folding mode

∗

A4 ........... Double fold

B5 ........... Irregular accordion fold

A5 ........... Irregular accordion fold

B6 ........... Double fold, letter fold, accordion fold

B4 ........... Double fold, irregular accordion fold, accordion fold

A4 ........... Irregular accordion fold, letter fold, accordion fold

B5 ........... Double fold, letter fold

A5 ........... Single fold, double fold, letter fold, accordion fold

B6 ........... Single fold, irregular accordion fold

B5 ........... Single fold, accordion fold

B4 ........... Single fold