Page 1

Instruction Manual

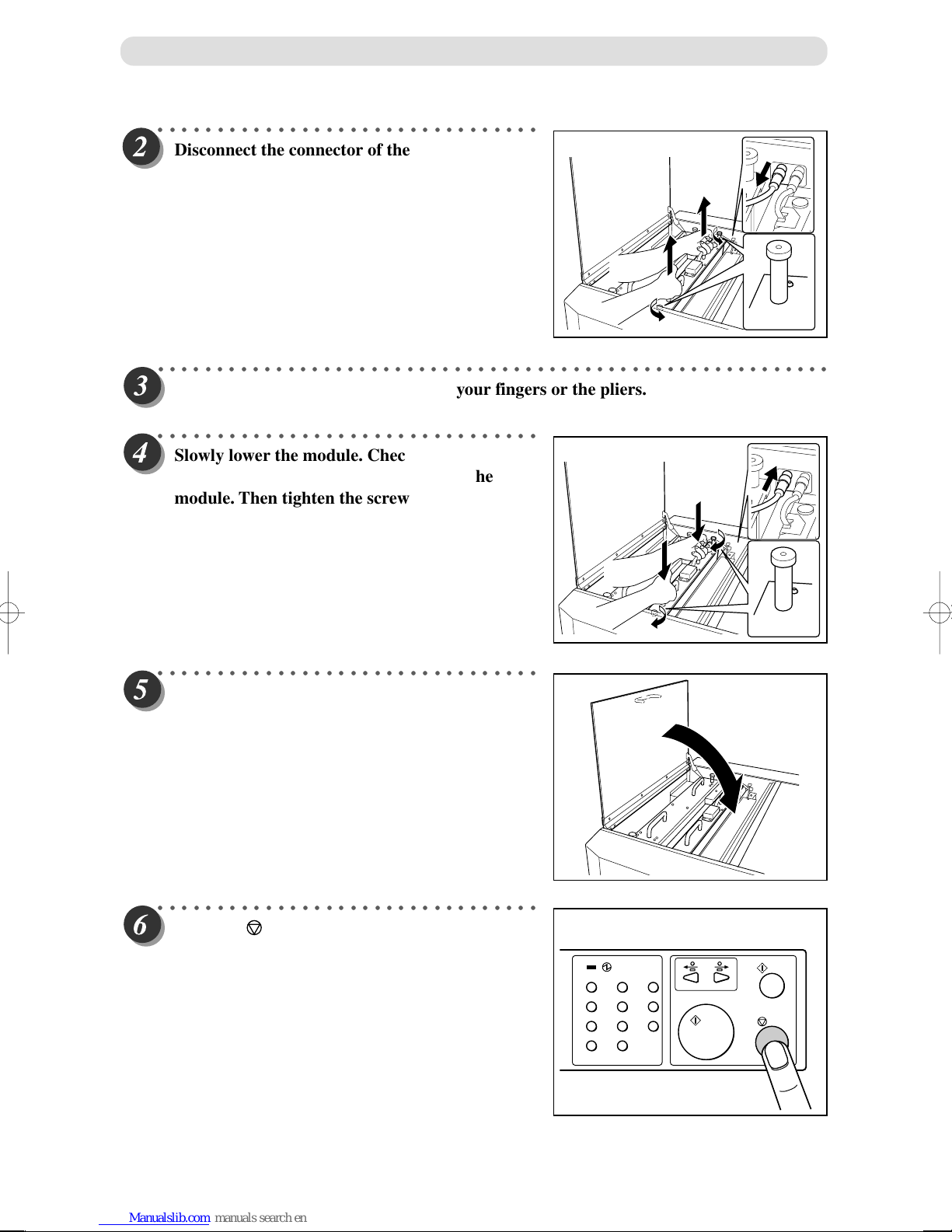

Duplo DC-645

(Slitter / Cutter / Creaser)

Version. 2 / March 2005

Correct operation and periodic maintenance are

essential for ensuring safe use of this machine.

Thoroughly read this manual before using this

machine.

Page 2

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Introduction

DC-645

Thank you for your purchase of the Duplo DC-645 (Slitter / Cutter / Creaser).

To ensure safe and efficient prolonged use of this machine, read and thoroughly understand this manual before

using this machine. After using this manual, be sure to keep it in a handy place to reference.

1

2

OVERVIEW

The DC-645 was created to produce high-quality, customized products; greeting cards, postcards, brochures,

business cards, and resized photographs. It does this by combining a number of devices that set up automatically to slit, cut, and crease a sheet of paper into the desired format with no operator intervention.

Initially, the DC-645 is manually programmed with the required positions of the slits, cuts and creases and the

values are stored in a memory for future recall. A CCD sensor reads the job number encoded in a barcode on

the unfinished sheet. Then, the DC-645 recalls the values from memory, sets up the slitter positions, activates

the cutter for lead, trail, and any intermediate cuts and any required creases.

In addition, when a small 90-degree angle register mark has been printed adjacent to the barcode, the position

is measured against the intended position stored in the job memory. As this mark is part of the original image,

any error in its location can be compared with the stored value and used to correct the setup positions of the

devices by applying a horizontal offset to the cut and crease positions, and a vertical offset to the slit positions

to maintain precise finishing every time.

PLEASE NOTE

In the interest of upgrading our products, specifications and other data given in this manual are subject to

change without notice. If the manual contains anything that you do not understand, contact the dealer for

clarification.

Trademarks

• Apple and Macintosh are trademarks of Apple Computer, Inc., registered in the U.S. and other countries.

• Windows is the registered trademark of Microsoft® Corporation.

All other trademarks are the property of their respective holders.

1

Page 3

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Contents

Introduction ......................................................................................................................... 1

DC-645 ....................................................................................................................... 1

Notes on Safety (Please Read and Observe) ................................................................... 4

Safety Precautions ............................................................................................... 4

Warning Sticker .......................................................................................................... 7

Positioning the Machine ............................................................................................. 8

Maintenance ............................................................................................................... 9

Conventions Used in This Manual ............................................................................ 10

Chapter 1 Before Using This Machine

Part Names and Their Functions ..................................................................................... 11

Appearance .............................................................................................................. 11

Modules .................................................................................................................... 13

Control Panel ............................................................................................................ 14

LCD Panel ................................................................................................................ 15

Turning Power ON/OFF .................................................................................................... 16

Turning ON the Power .............................................................................................. 16

Turning OFF the Power ............................................................................................ 17

How to Connect the DC-645 to your Computer ............................................................. 18

Before Preparing Document ............................................................................................ 19

Definition of Programming Terms ............................................................................. 20

Chapter 2 Program JOB for DC-645 Via Computer (JOB Creator)

What is JOB Creator? ...................................................................................................... 29

Installing JOB Creator ...................................................................................................... 29

Before Installation ..................................................................................................... 29

Installing Procedures (Windows) .............................................................................. 30

Installing Procedures (Macintosh) ............................................................................ 32

Uninstall and Update JOB Creator .................................................................................. 33

Uninstalling Procedures (Windows) ......................................................................... 33

Uninstalling Procedures (Macintosh)........................................................................ 34

Updating Drivers....................................................................................................... 34

JOB Creator Settings ....................................................................................................... 35

Main Menu ................................................................................................................ 35

Creating JOB with Preview Display (“Using Program Entry Wizard”) ....................... 36

Creating a JOB By Direct Number Input (“Direct Program”) .................................... 43

Reading JOB from DC-645 (“Upload Job Data from DC-645”) ................................ 45

JOB Saved on Computer Registered On DC-645

(“Download Job Data to DC-645”) ............................................................................ 47

Setting Frequent Functions From Computer (“Function Setting”)............................. 49

Create a File Recording the DC-645 Maintenance Information

(“Upload Maintenance Data from DC-645”) ............................................................. 51

List of Messages ............................................................................................................... 52

2

Page 4

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Contents

Chapter 3 Programing JOB for DC-645 on Control Panel

Prior to Programming a Job ............................................................................................ 54

Customer Programmed Jobs .......................................................................................... 56

How to Program Job on Control Panel ........................................................................... 57

Chapter 4 Basic Operations

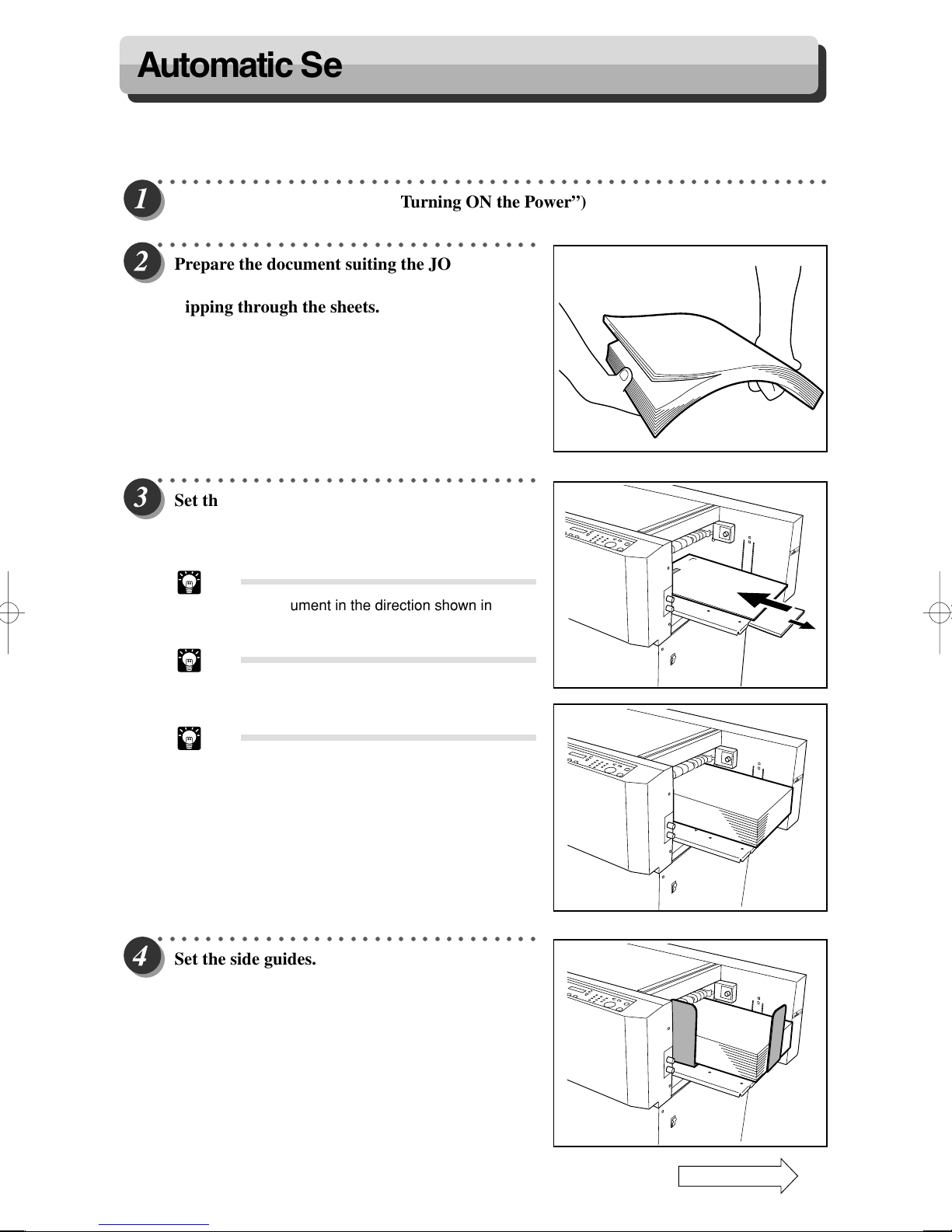

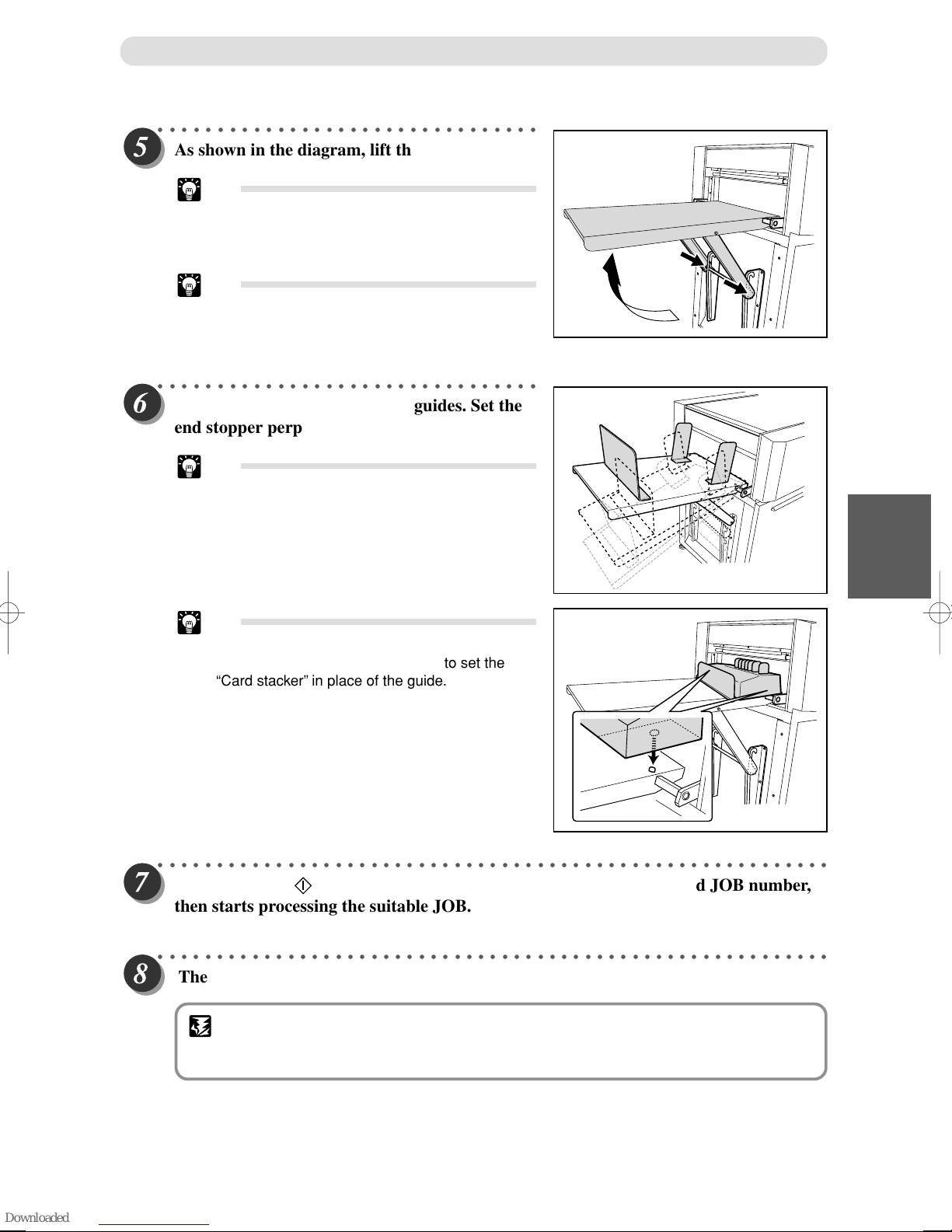

Process Documents by Selecting JOB........................................................................... 64

Automatic Set Up Using Barcodes ................................................................................. 68

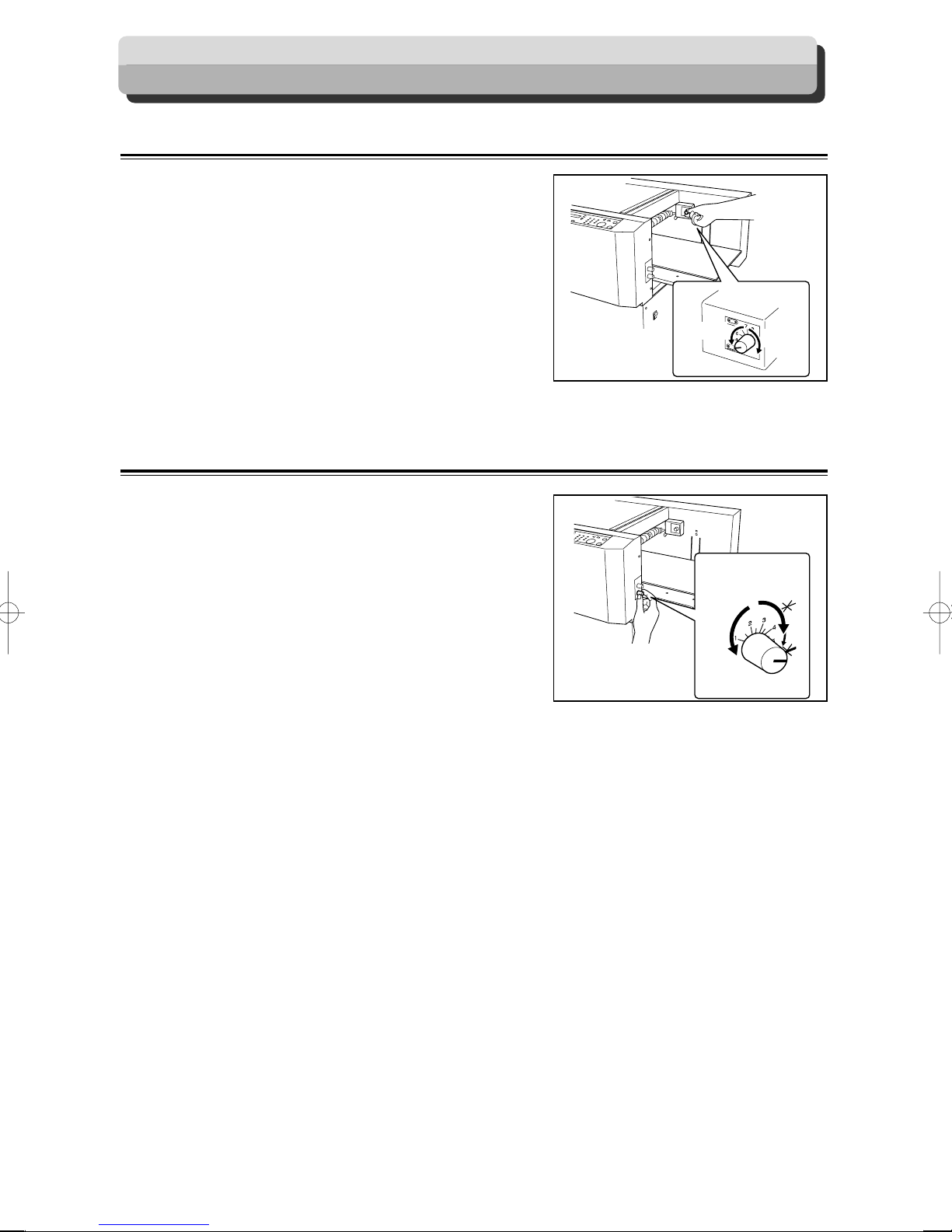

Adjust Feeder .................................................................................................................... 70

Elevator level (Feed tray) .......................................................................................... 70

Separator .................................................................................................................. 70

Airflow ....................................................................................................................... 71

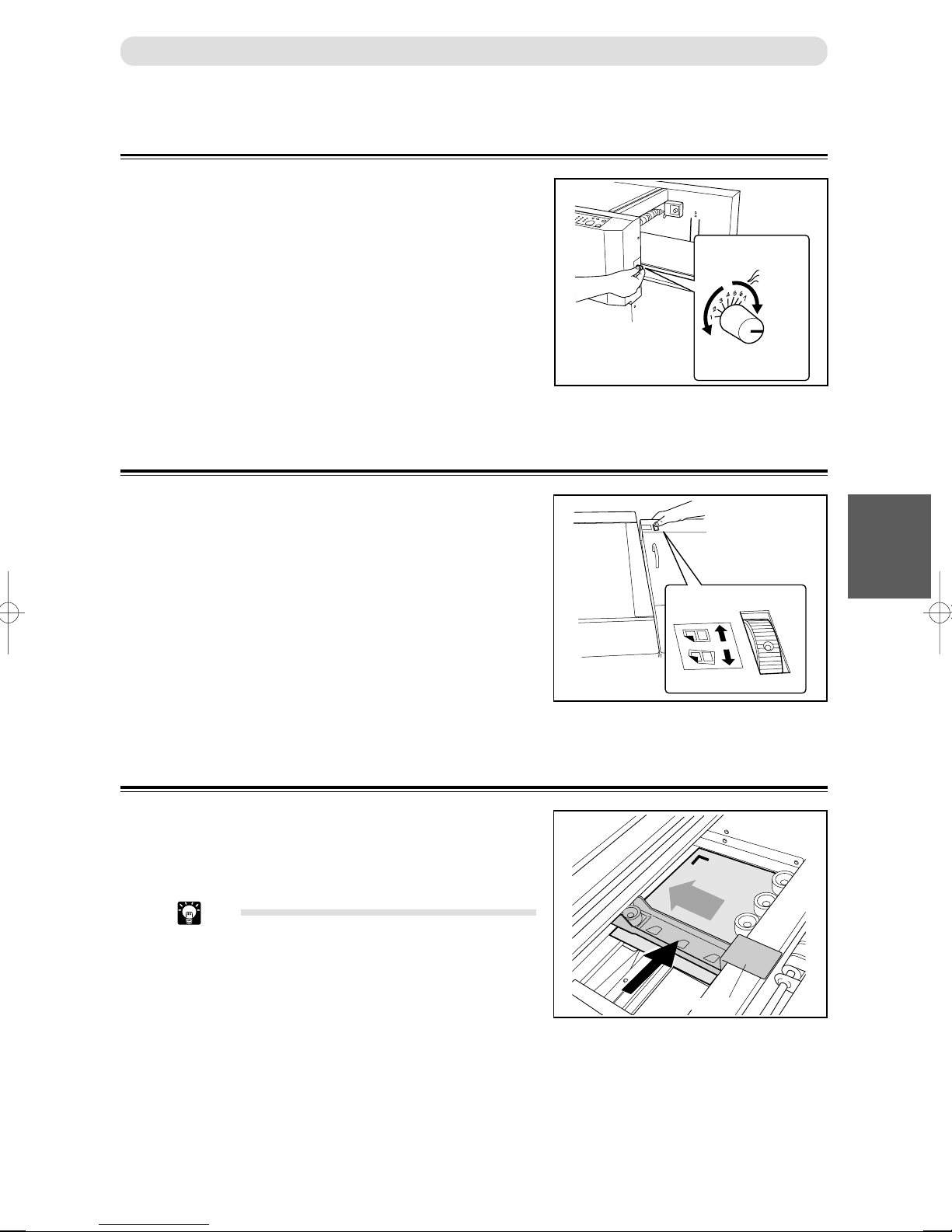

Print Image Skew ..................................................................................................... 71

Curled Document / Light Weight Document ............................................................. 71

FUNCTION Mode ............................................................................................................... 72

About the Waste Box ........................................................................................................ 74

Clean Feed Rollers ........................................................................................................... 75

Chapter 5 Troubleshooting

Troubleshooting Flow Chart ............................................................................................ 76

Power Does Not Turn ON ......................................................................................... 76

Cutting is Not Possible ............................................................................................. 77

OK Monitor Display and Jam Display ............................................................................. 78

Error Display ..................................................................................................................... 80

Warning Display................................................................................................................ 82

When a Paper Jam Has Occurred ................................................................................... 83

When “REJECT PAPER” is Displayed ...................................................................... 83

When “FEED JAM” is Displayed ............................................................................... 85

When “CENTER JAM” is Displayed.......................................................................... 87

When “CUTTER OR CREASE” is Displayed ............................................................ 89

When “OPTION AREA JAM” is Displayed ................................................................ 93

When “STACKER JAM” is Displayed ........................................................................ 95

When “OVER CAPACITY” is Displayed .................................................................... 97

When “REJECT AREA JAM” is Displayed................................................................ 98

1

2

Appendix

Specifications ................................................................................................................. 100

DC-645 Specifications ............................................................................................ 100

Index ................................................................................................................................ 102

3

Page 5

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Notes on Safety (Please Read and Observe)

Safety Precautions

Various symbols and pictures are used in this manual and on the stickers affixed to the machine. These symbols and

pictures provide warnings and instructions to prevent danger to you or other personnel, and to prevent damage to office

property. The meanings of these symbols and pictures are explained below.

WARNING

CAUTION

[Examples of Pictorial Symbols]

• These are particularly important safety points and should always be observed.

Indicates a high degree of potential danger. If the warning is ignored, death or serious

injury may result.

Indicates a medium degree of potential danger. If the caution is ignored, medium injury or

damage to property may result.

A circle with a line through it indicates a prohibited action. The particular act prohibited is indicated by a picture inside the circle. (In the example shown here, the prohibited

act is disassembly.)

A black disc indicates an instruction, or sometimes a prohibited action. The

instruction itself is indicated by pictorial symbols drawn in white on the disc. (In the

example shown here, the instruction is “Remove the plug from the outlet.”)

Precautions for Use

WARNING

If the machine is used after foreign matter (metal fragments, water, or liquid) has entered the

machine, this may result in fire or electric shock.

• Turn the main unit’s power switch OFF, and then remove the power plug from the outlet.

Contact the sales distributor.

If the machine is used after heat, smoke, strange smell, or other abnormality is detected, this may

result in fire or electric shock.

• Turn the main unit’s power switch OFF, and then remove the power plug from the outlet.

Contact the sales distributor.

Do not insert or drop metal, flammable material, or other matter through the ventilation holes into

the machine interior.

• Doing so may result in fire or electric shock.

Do not place flower vases, flowerpots, cups, or water containers (including metal containers) on top

of the machine.

• Fire or electric shock may result if liquid spills inside the machine.

4

Page 6

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Notes on Safety (Please Read and Observe)

Caution for Grounding (Be sure to use the supplied power cord)

WARNING

Use only the power cord that is provided among the accessories.

Insert the power cord plug firmly into the socket, so that proper electrical contact is effected.

• Use of any other power cord could result in imperfect grounding.

If grounding is imperfect and electrical leakage occurs, fire or electric shock could result.

Caution for Power Supply and Power Cord

WARNING

Do not use a source voltage other than that specified. Do not connect two or more loads to a single

outlet.

• Doing so may result in fire or electric shock.

Do not remove or insert the power plug with wet hands.

• Doing so may result in electric shock.

1

2

Do not damage, break, or modify the power cord.

Do not place heavy objects on, tug, or unnecessarily bend the power cord.

• Doing so may result in fire or electric shock.

CAUTION

Remove the power plug itself, not the cord.

• Tugging the cord may damage it (expose conductors, or cause disconnections, etc.), resulting in

fire or electric shock.

5

Page 7

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Notes on Safety (Please Read and Observe)

Prohibition of Disassembly or Modification

WARNING

Do not modify the machine.

• Doing so may result in fire or electric shock.

Do not remove the rear lid, cabinet, or covers from the machine.

• The inside of the machine contains high-voltage parts, which may cause electric shock.

Caution for Location

Do not move this machine by yourself.

• Please contact your service person when you wish to move the machine.

(Fine adjustment is required.)

Do not place the machine in a place subject to direct sunlight or heating equipment such as a stove.

• It may degrade ink quality and affect printing.

The machine also may malfunction.

Avoid placing the machine in a place subject to high or low temperature or high humidity.

• The paper absorbs moisture and it may cause paper jam or wrinkles.

WARNING

CAUTION

6

Page 8

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Notes on Safety (Please Read and Observe)

Warning Sticker

Keep the WARNING stickers clean at all times. If stickers become damaged or come off, replace them with new ones.

1

2

1

1

WARNING

1

Cutters and movable parts are inside this cover.

Before opening the cover to work,

unplug the power cord.

Use caution when working near cutters

and movable parts.

L8-T1080

2

2

2

WARNING

DO NOT put hands inside machine

while it is operating.

Hands could get caught up

or crushed.

No. Parts No. Name Q’ty

1 L8-T1080 Warning Sticker 1 2

2 M7-T3030 Warning Sticker 2 2

M7-T3030

7

Page 9

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Notes on Safety (Please Read and Observe)

Positioning the Machine

Installing the machine on a flat, stable surface.

Avoid installing the machine in a dusty area.

Avoid installing the machine in the direct sunlight or heat,

such as near a stove. The machine may indicate errors due

to overheating caused by sunlight. Also avoid hot, cold, or

humid areas since paper may absorb moisture, causing

paper jams or wrinkles.

8

Page 10

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Notes on Safety (Please Read and Observe)

Maintenance

Clean the exterior of the machine as described below.

Tightly wring a soft cloth that has been moistened with

water or neutral detergent, and wipe dirt from the machine’s surface.

Never use alcohol or organic solvents. Doing so may

discolor or damage the machine exterior.

Dust and clean the machine at least once a week to avoid

breakdowns.

Before cleaning, turn the power switch OFF, and then

remove the power plug from the outlet.

1

2

WARNING

• Before cleaning, remove the power plug from the outlet.

Failure to do so may result in an electrical shock or a fire hazard.

• Prevent water and neutral cleansers from getting inside the machine. If liquids spill inside the machine,

contact your agent immediately. Using the machine with water spilled inside may result in an electrical

shock or a fire hazard.

9

Page 11

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

[

SELECT

]

05:DUPLO

06:DUPLO 1

BC REG AC

∗ ∗ ∗

Notes on Safety (Please Read and Observe)

Conventions Used in This Manual

Each page of descriptions in this manual of how to operate the DC-645 is set up as follows.

Chapter

Title

Description of operational steps

Each step is described in detail.

Illustrations

The illustrations provide a visual

reference to which keys to operate

and other related conditions.

Chapter

4

Basic Operations

This chapter describes the operating sequence from turning ON the power switch until completing

finishing process.

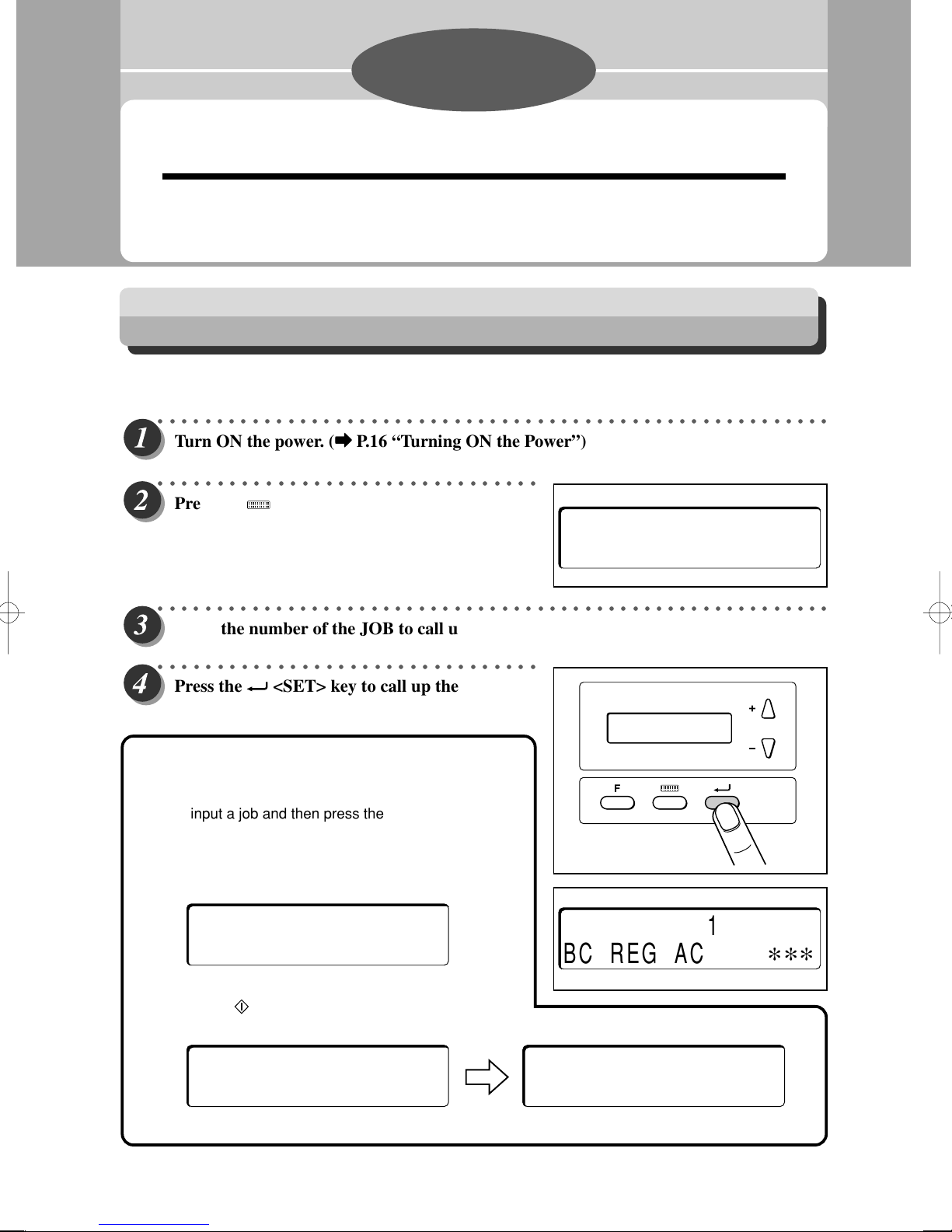

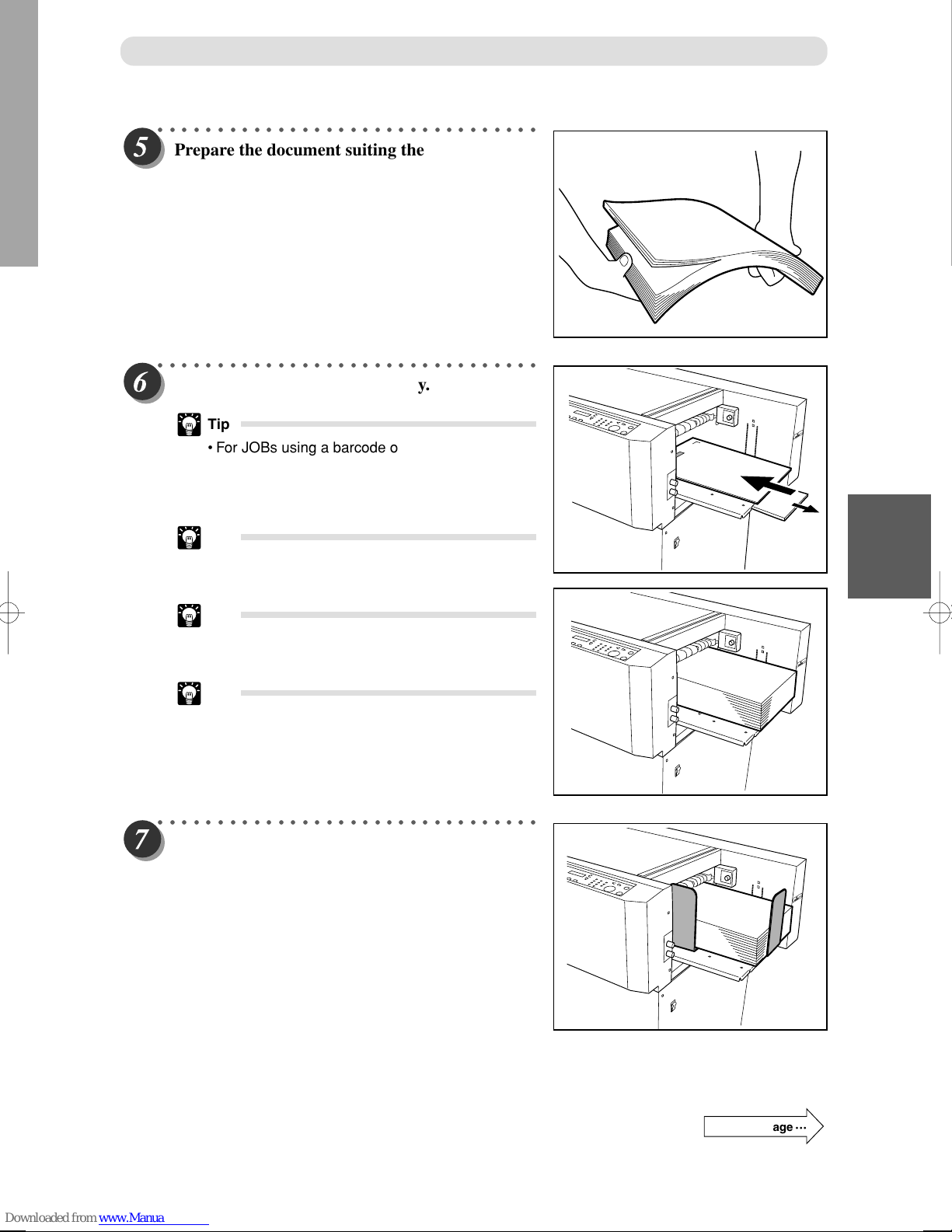

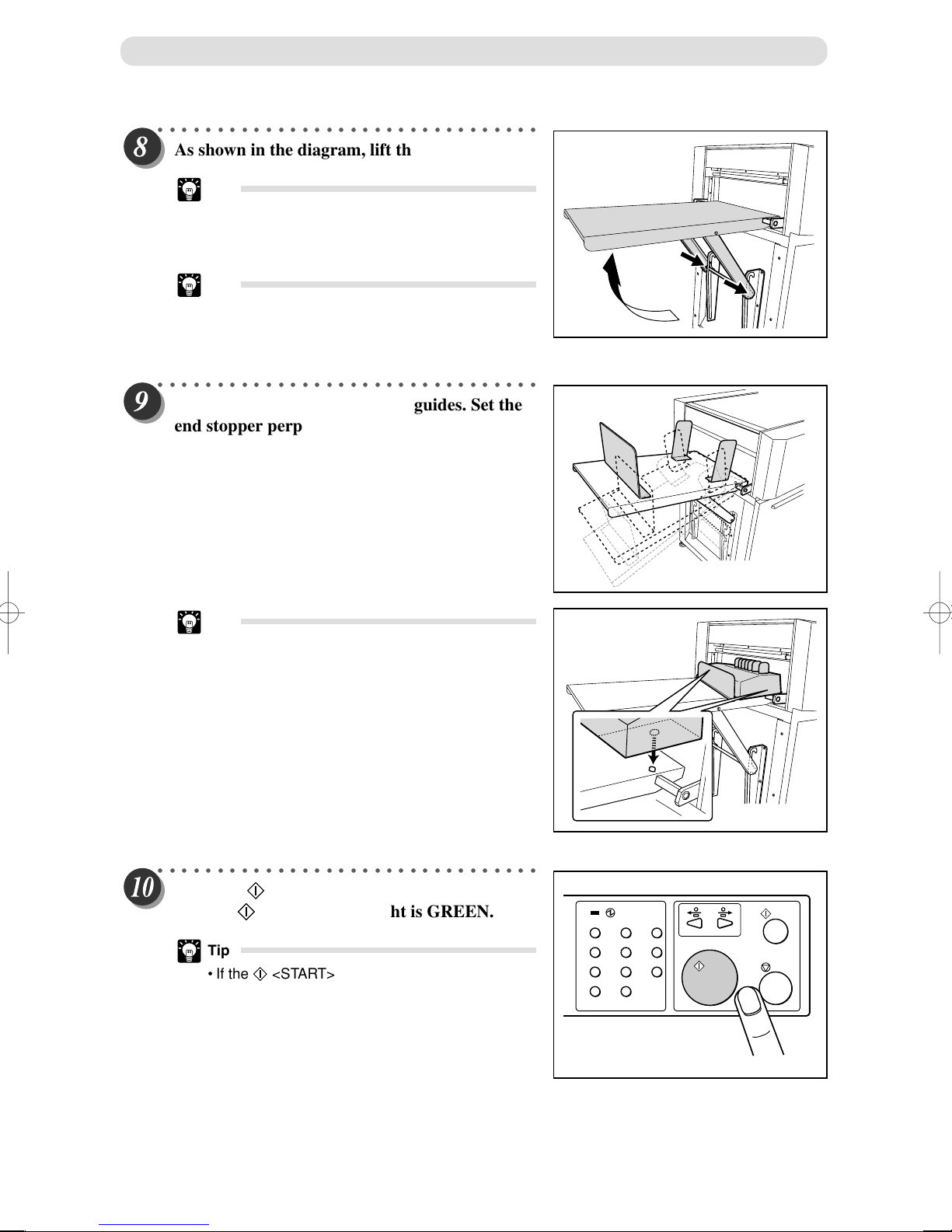

Process Documents by Selecting JOB

This section describes the procedures to process documents by selecting each JOB manually.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Turn ON the power. (

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

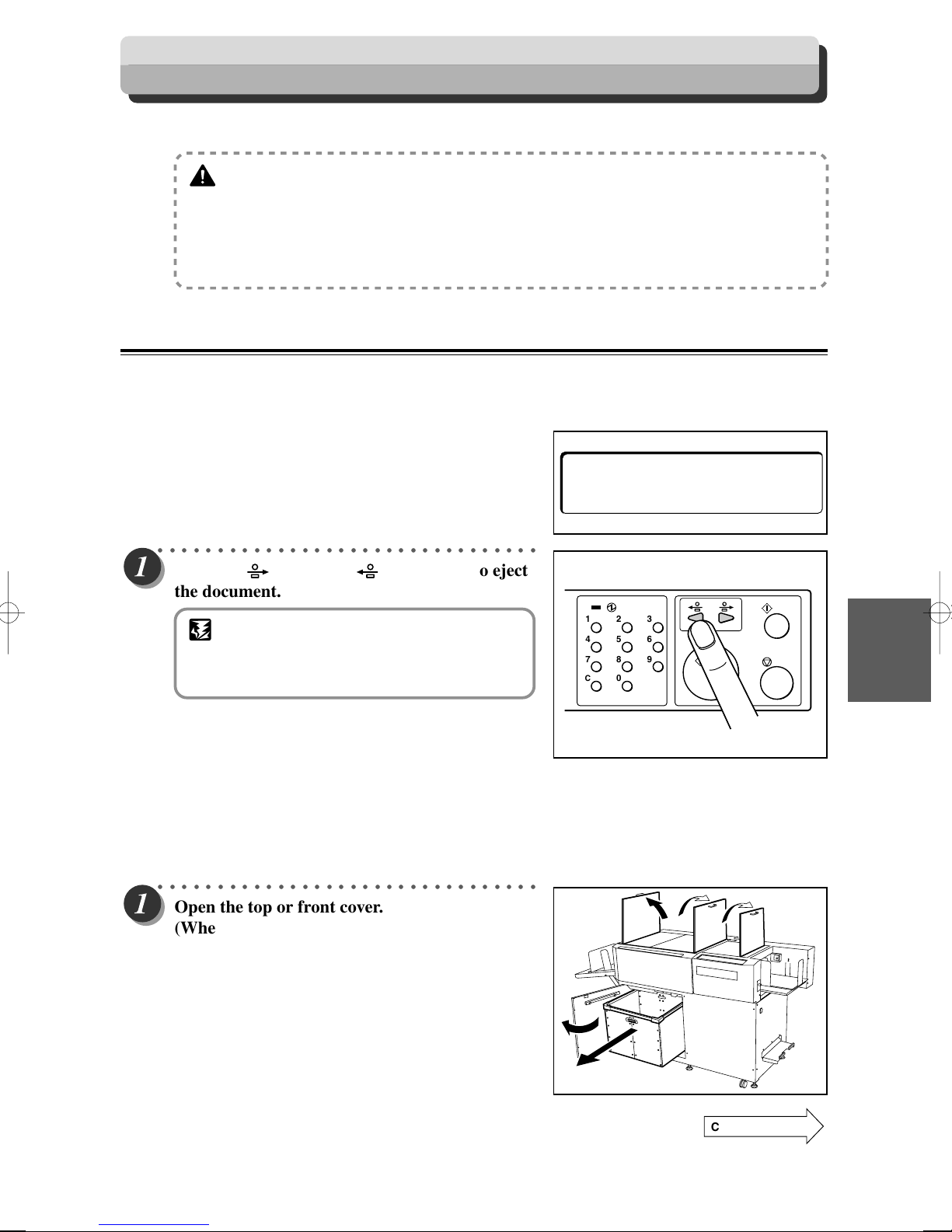

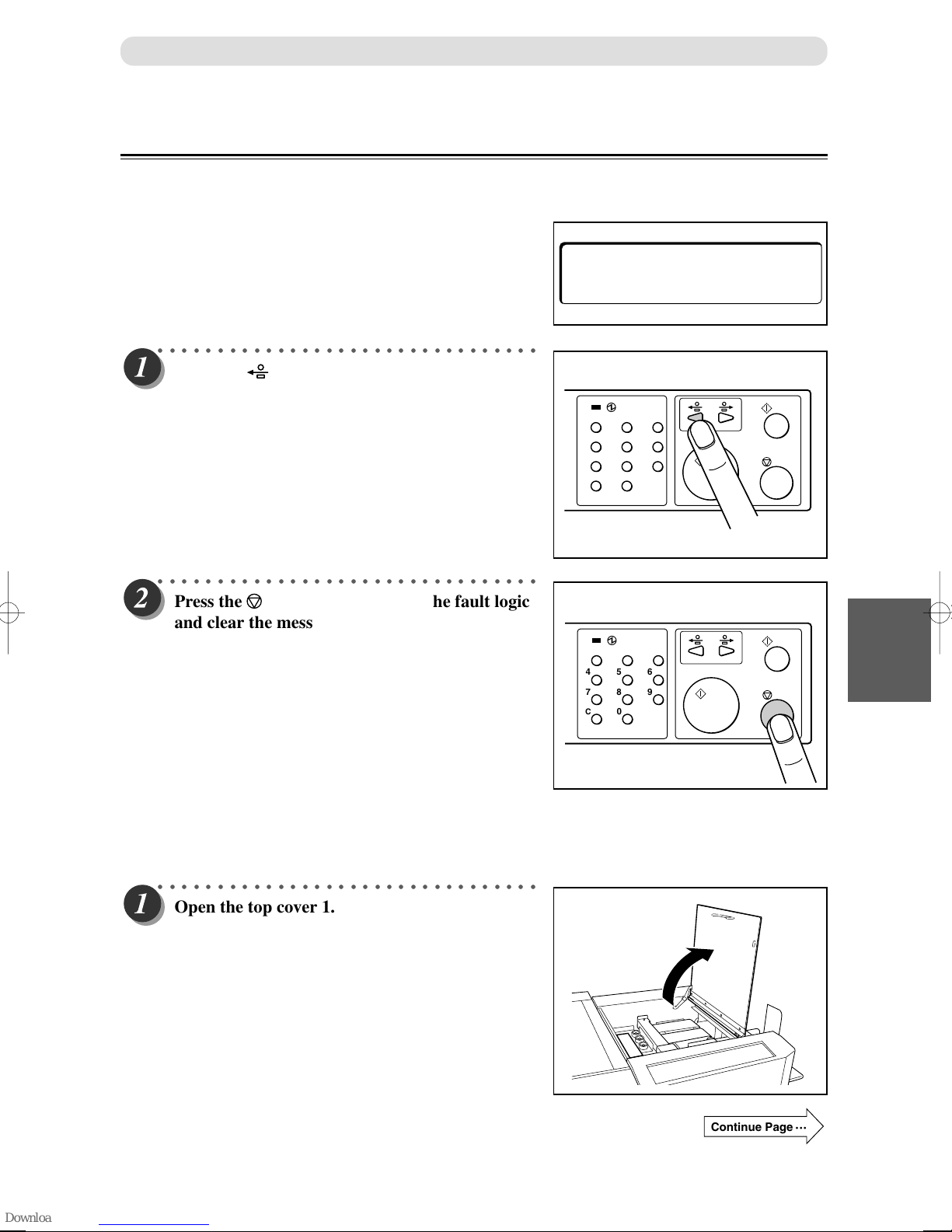

Press the <MODE> key and go to the

[SELECT] display.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Input the number of the JOB to call up, using the <Number> key.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the <SET> key to call up the JOB of

the number input.

How to execute batch counting

• The specified number of document are processed.

Select or input a job and then press the <Number> key in

standby state (excluding SELECT/INPUT display) to input the

number of document for batch counting. (The specified

number of document is displayed in the lower right portion of

the control panel.)

∗ ∗

100/100

(Ex.: When 100 documents are set, the above display appears.)

By pressing the <START> key, processed number of the

document is subtracted from the specified number as below.

∗ ∗

99/100

* If an error has occurred during processing, batch counting can not be executed.

aa

a P.16 “Turning ON the Power”)

aa

∗ ∗

98/100

F

■ Pictorial Symbols and Other Notations Used in This Manual

IMPORTANT : Introduces instructions for correct operation of the machine. If these instructions are ignored,

the machine may not be able to operate at optimum performance or may break down.

Tip : Introduces information that is useful for operation and maintenance of the machine, or

information about the machine’s performance, etc.

Continue Page

•••

: Indicates that the description of the operating sequence is continued on the next page.

(a P.00 “xxxx”) : Indicates the page number and item containing related information.

10

64

Page 12

Chapter 1

Before Using This Machine

This chapter contains essential information you should understand such as how to set up the system, the

names of the machine parts, etc.

Part Names and Their Functions

Appearance

11

11

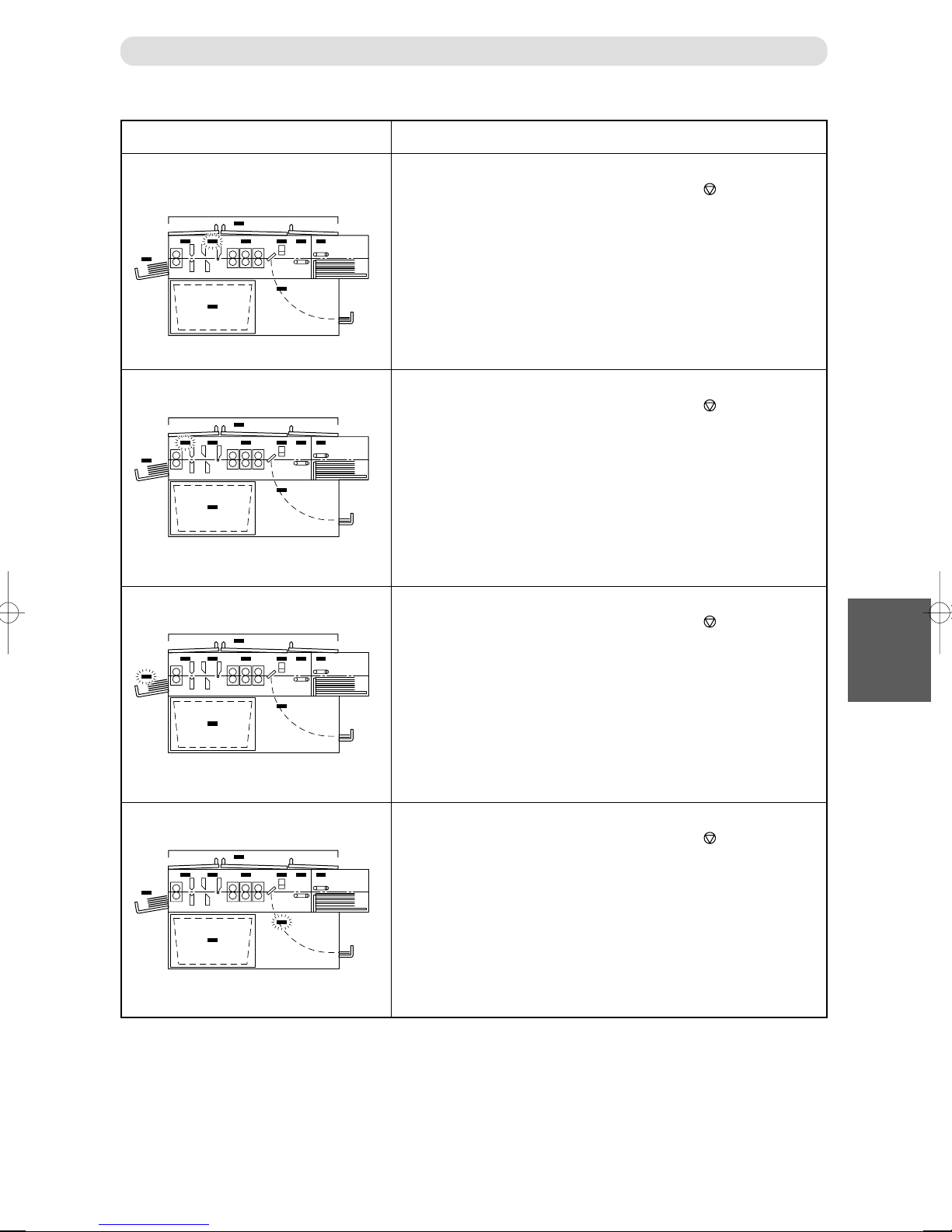

Before Using This Machine

5

6

7

8

9

4

10

11

3

No. Name Function

1 Control panel Displays operations and statuses.

2 Waste box Receives pieces of waste paper.

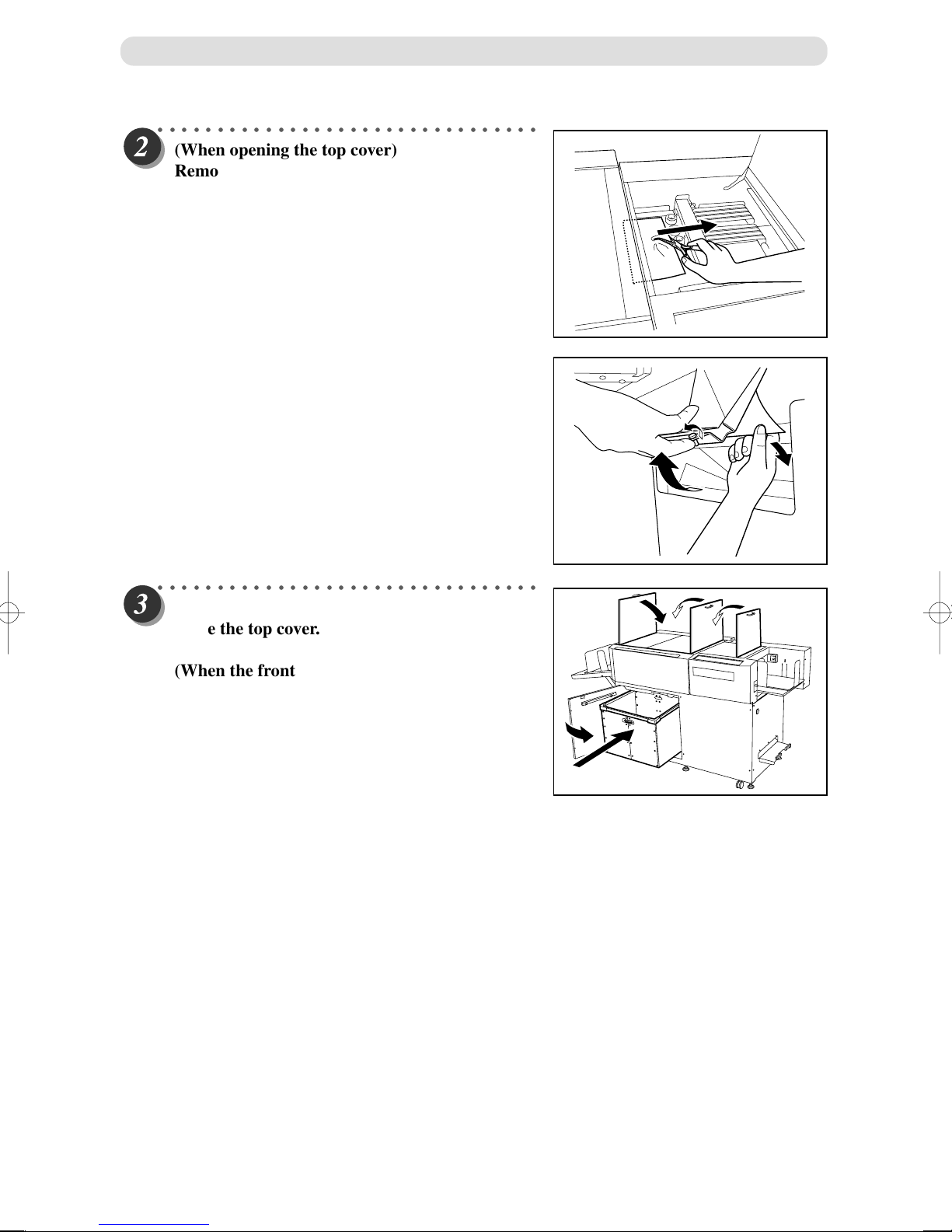

3 Front cover Open to remove pieces of paper in the waste box.

4 Stacker tray Receives the finished document.

5 Scale This measures the cut and slit position, and the finish of the document.

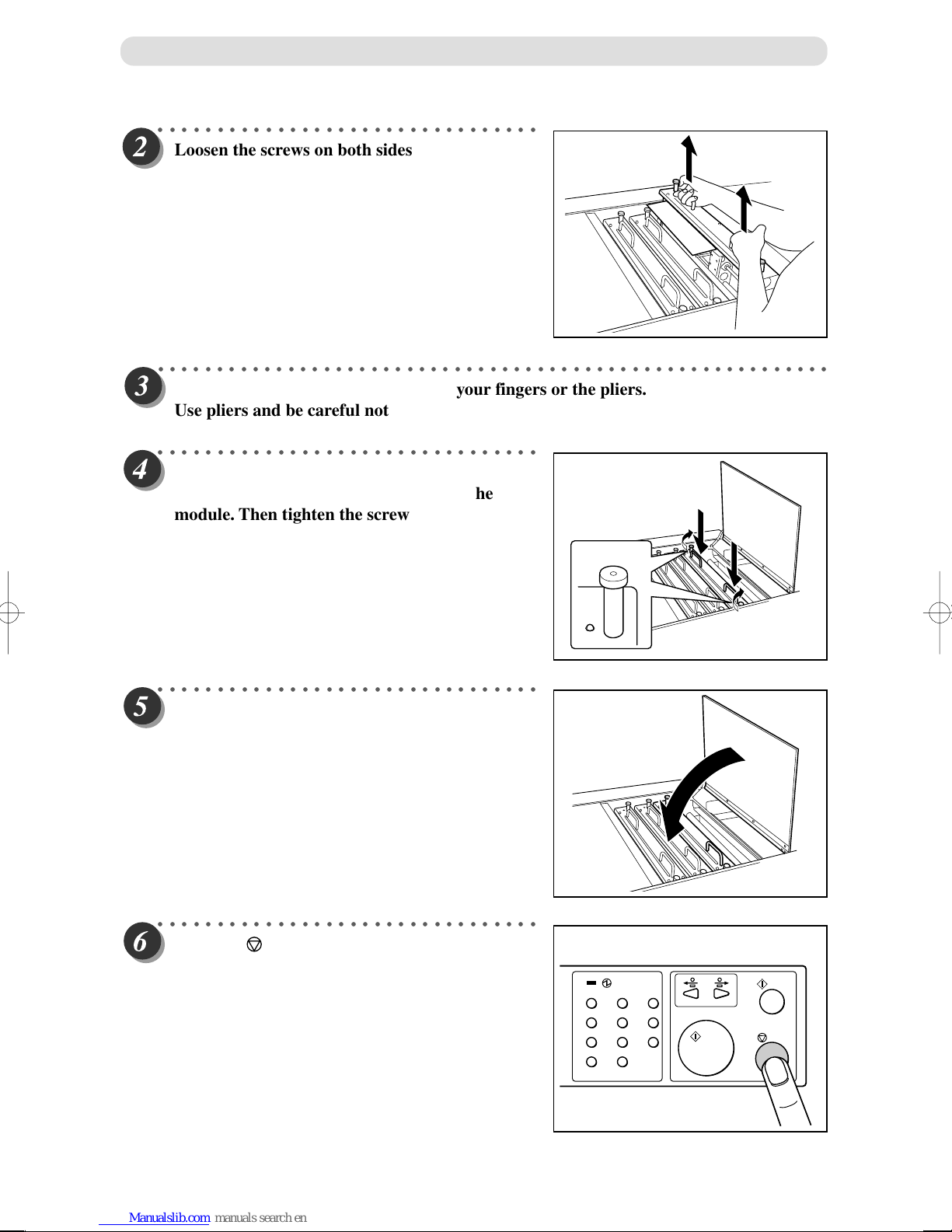

6 Top cover 3 Open this to remove the paper jam from the cutter/crease/optional module or

7 Top cover 2 Open this to remove the paper jam from the slitter module.

8 Top cover 1 Open this to move the upper guide or to remove the paper jam from the feed

9 Feed tray The original document is placed here.

10 USB terminal Insert a USB cable here to connect the computer and this machine.

11 AC inlet Connect the power cord.

12 Reject tray This is where the document comes when it is rejected due to double feed,

13 Power switch Press to switch the power on and off.

2

to replace the optional module.

unit.

barcode error, REG. Mark error, etc.

1

13

12

Reference

page

14

74

78,82

66,69

—

89 – 94

87,88

75,

85 – 86

70,97

18,31

16

81,99

16,17

11

Page 13

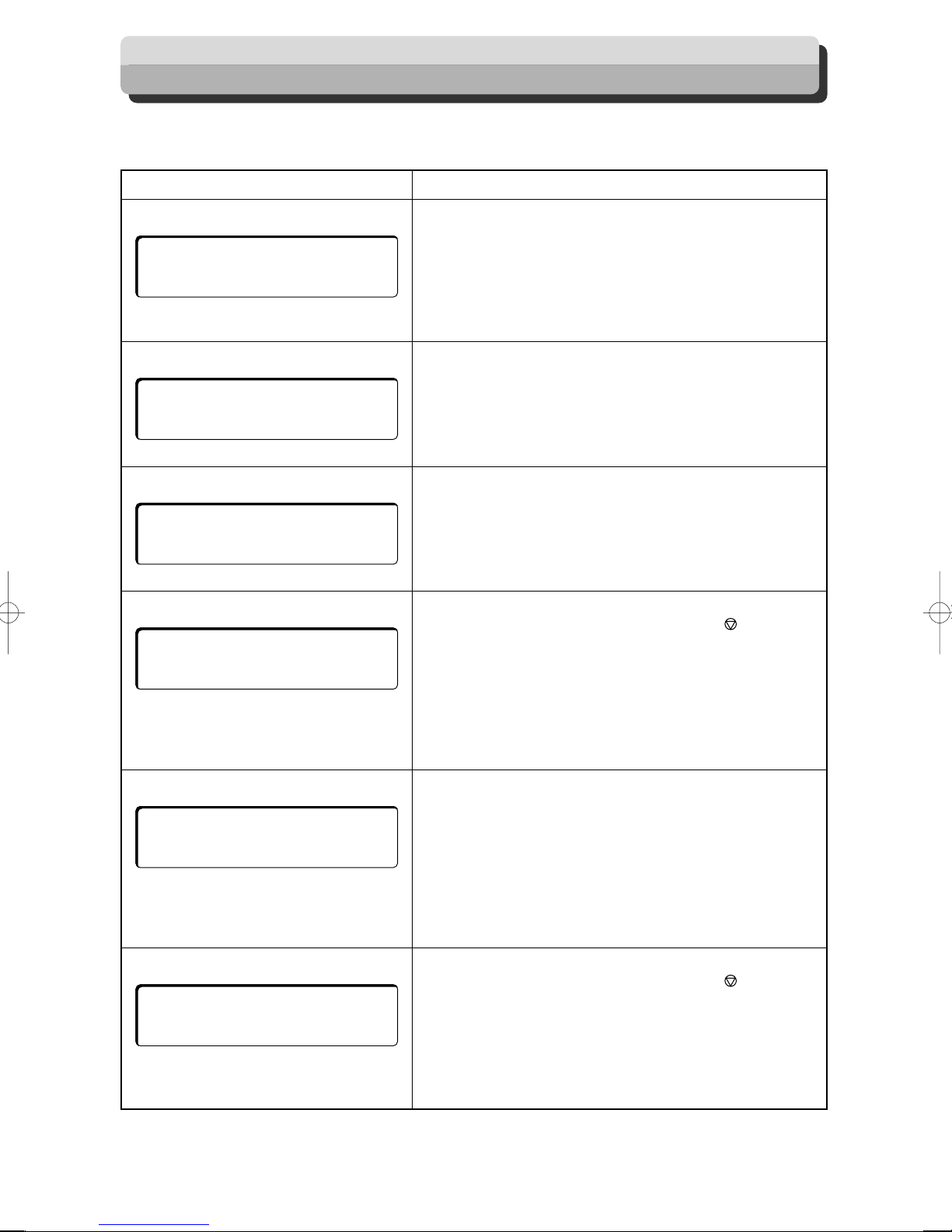

Part Names and Their Functions

17

16

1514

No. Name Function

14

12

Airflow adjustment knob

15

Separator adjustment knob

16

Level adjustment knob

17

Skew adjustment wheel

This adjusts the airflow level.

This adjusts the distance between the separator and document.

This adjusts the elevator height.

This adjusts the feed angle of the document.

Reference

page

71

70

70

71

Page 14

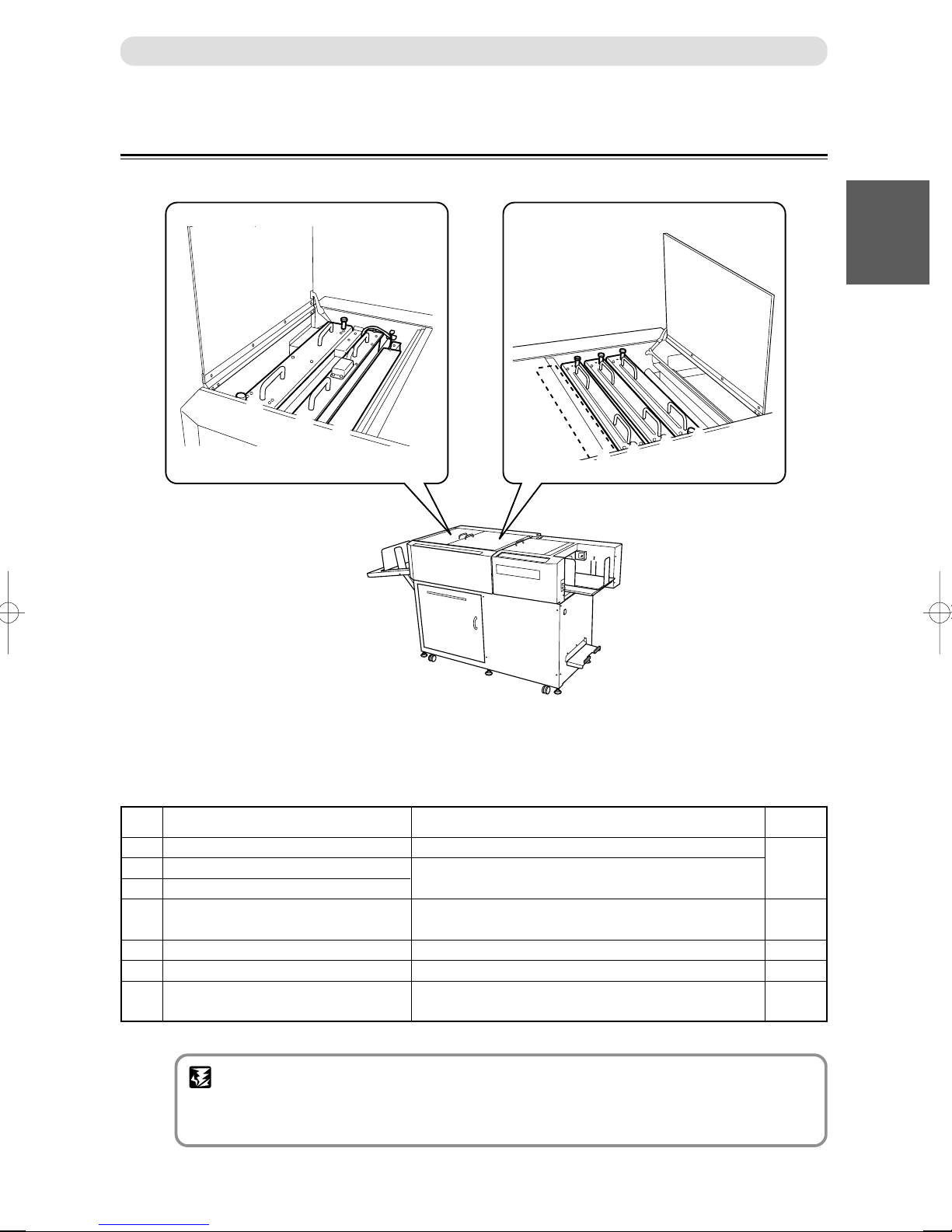

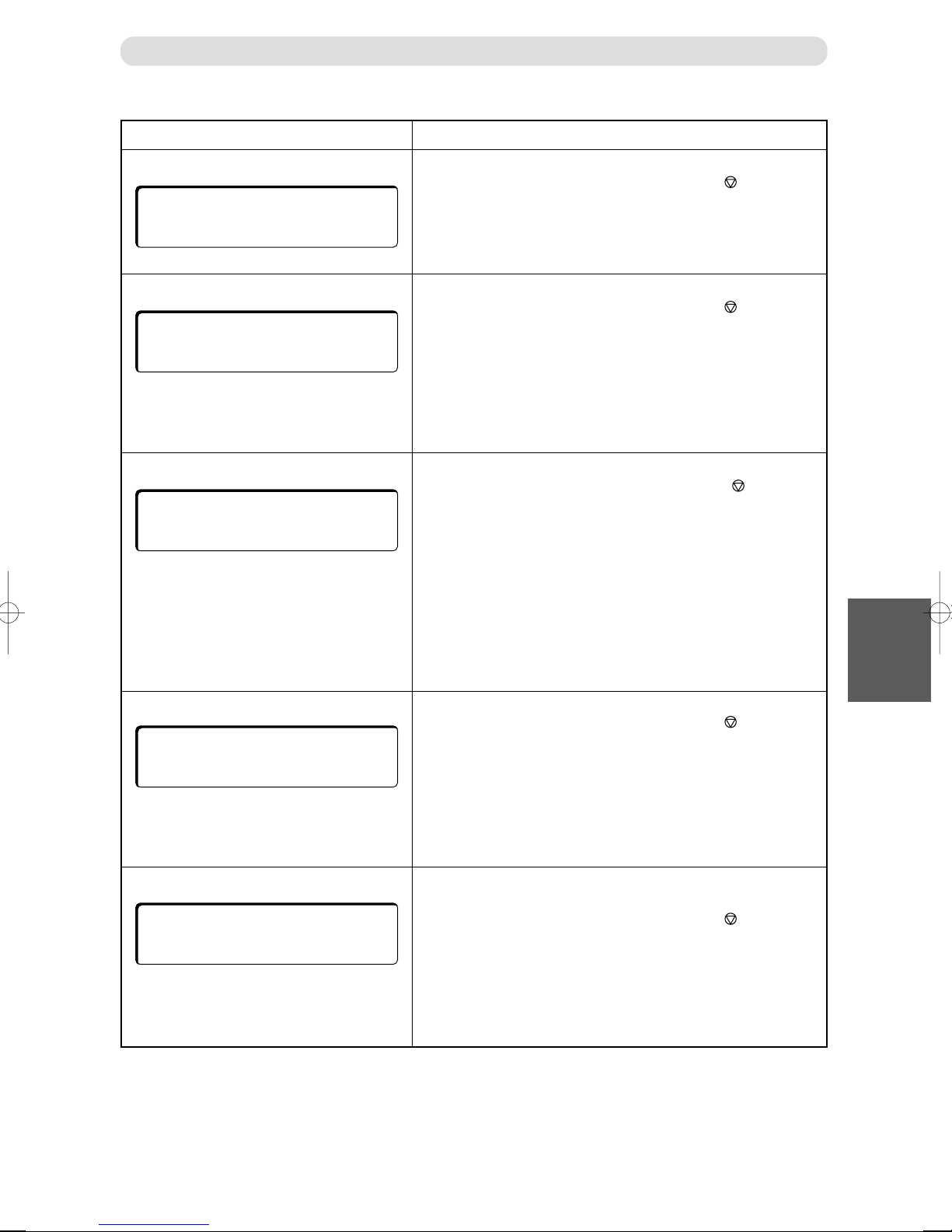

Modules

Part Names and Their Functions

11

Before Using This Machine

7

No. Name

1 Slitter Module A

2 Slitter Module B

3 Slitter Module C

4 Gutter Deflector

5 Cutter Module

6 Creaser Module

7 Transport Module

(or Optional Module)

6

5

1

2

3

4

Function

Cuts off the blank-area of the further-side and front-side.

Cuts parallel in the paper feed direction.

The blank-area cut off by the slitter is dropped in the

waste box.

Cuts in a right angle in the paper feed direction.

Creases parallely in the paper feed direction.

Transports the paper to the stacker tray.

Reference

page

19,54,

80,82

36,37,

72,81

54,79,80,89

54,79,81,89

36,57

IMPORTANT

• When removing various modules of this device, always re-set the module in the sequential

order indicated in the illustration above. It is especially that the slitter module is properly

assembled, when setting slitter module A, B and C again.

13

Page 15

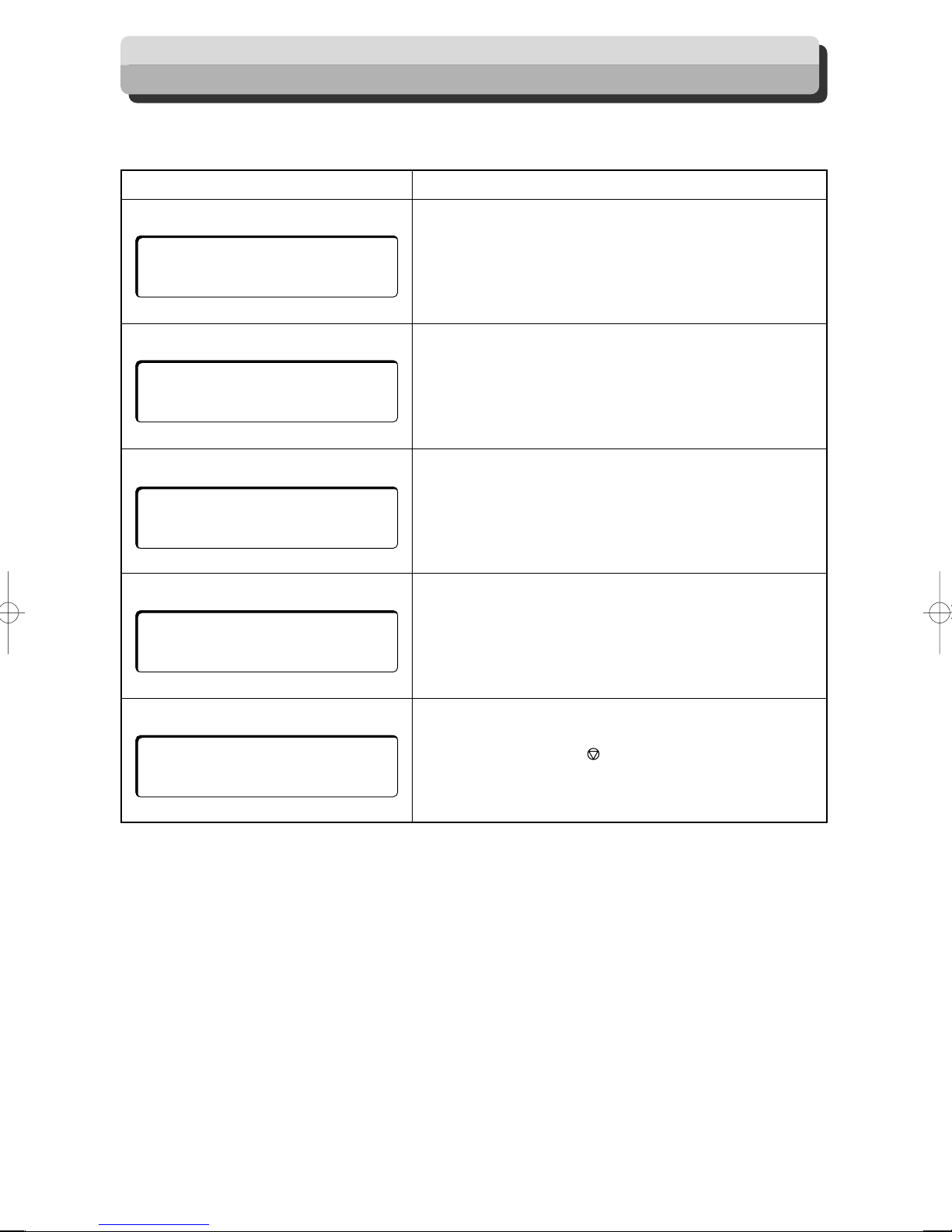

Part Names and Their Functions

Control Panel

123

71011456

8 9 12 13

No. Name Function

1 OK Monitor The LED of the Error area flashes when detecting an Error.

2 LCD panel Displays the status of the machine.

Displays the message when an error or paper jam occurs.

3 < + / – > key Select setting of function.

4 <F> key Switches to function selecting display.

5 <MODE> key Switches modes. (operating mode, JOB selectiong mode, JOB inputing mode)

6 <SET> key Press to confirm selection / entry.

7 POWER lamp Lights up when the power is switched on.

8 <CLEAR> key Press to clear the count. Press to cancel manual programming.

9 <Number> key Press to enter print numbers and enter values during manual programming.

10 •

11 <TEST> key One (sheet) document is processed to test the current JOB details.

12 <START> key Press this to start processing the document. The <START> key light

13 <STOP> key Press to stop automatic feeding after the current sheet is processed.

<JOG> keys

Press to eject the document from the machine when paper jam occured.

turns green when the machine is ready to process the document in this

machine. The <START> key can be activated when the LED on the key

is green. The <START> key is inactive when the light is red. In this

case DC-645 may be running or having an error.

Reference

page

78,79

15,

80 – 82

58 – 63,72,73

73

58,64,75

58 – 63,73

—

—

58,59,64

58,59,83 – 98

—

64,66,69

67,78 – 82,

85 – 99

14

Page 16

LCD Panel

Part Names and Their Functions

12

∗ ∗ :

BC REG AC

∗∗ ∗ ∗ ∗ ∗ ∗ ∗ ∗ ∗ ∗ ∗ ∗

∗ ∗ ∗

345 6

No. Name Function

1 JOB No. Displays the JOB No. currently selected.

2 JOB name Displays name of the JOB currently selected.

3 BARCODE BC is displayed when barcode reading is ON.

4

REGISTER MARK

5 AUTO CUT AC is displayed when AUTO CUT is ON.

6 COUNTER The number of document sheets processed with the JOB currently set, is

REG is diaplayed when REG. Mark reading is ON.

displayed.

Reference

page

36,58,64

36,58

37,72

37,72

37,55,72

64

11

Before Using This Machine

15

Page 17

Turning Power ON/OFF

This section describes the operating sequence from turning ON the power switch until the machine is ready to operate,

and how to turn OFF the power.

Turning ON the Power

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Connect the “female plug” of the power cord to

the “inlet”.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Connect the “male plug” of the power cord to

the “outlet”.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the “ | ” side of the power switch.

The power turns ON.

The illustration on the right shows what is displayed on the

LCD panel.

The illustration on the right shows that paper remains in the

machine. If this screen is displayed, remove them.

(a P.83, “When “REJECT PAPER” is Displayed”)

∗ ∗:∗∗∗∗∗∗∗∗∗∗

BC REG AC

∗∗∗

––– J 1 –––

REJECT PAPER

16

Page 18

Turning OFF the Power

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Press the “

The power turns OFF.

KK

K ” side of the power switch.

KK

Turning Power ON/OFF

11

Before Using This Machine

17

Page 19

How to Connect the DC-645 to your Computer

Prepare USB 2.0 Cable (A/B 4-pin).

Plug the type B connector into the DC-645 and the type A connector into the USB slot on your computer.

Computer

USB 2.0 Cable

18

Page 20

Before Preparing Document

Familialize your self with the following illustrations and instructions to make your documents appropriately.

DC-645 has six slitters. Two slitters are for the margins and the remaining four slitters are for the center of the

document.

There is a guillotine cutter that performs cuts perpendicular to the paper feeding direction. DC-645 can cut up to 15

cuts on 1 document.

There is a creaser that performs creases perpendicular to the paper feeding direction. DC-645 can crease up to 10

creasing on 1 document.

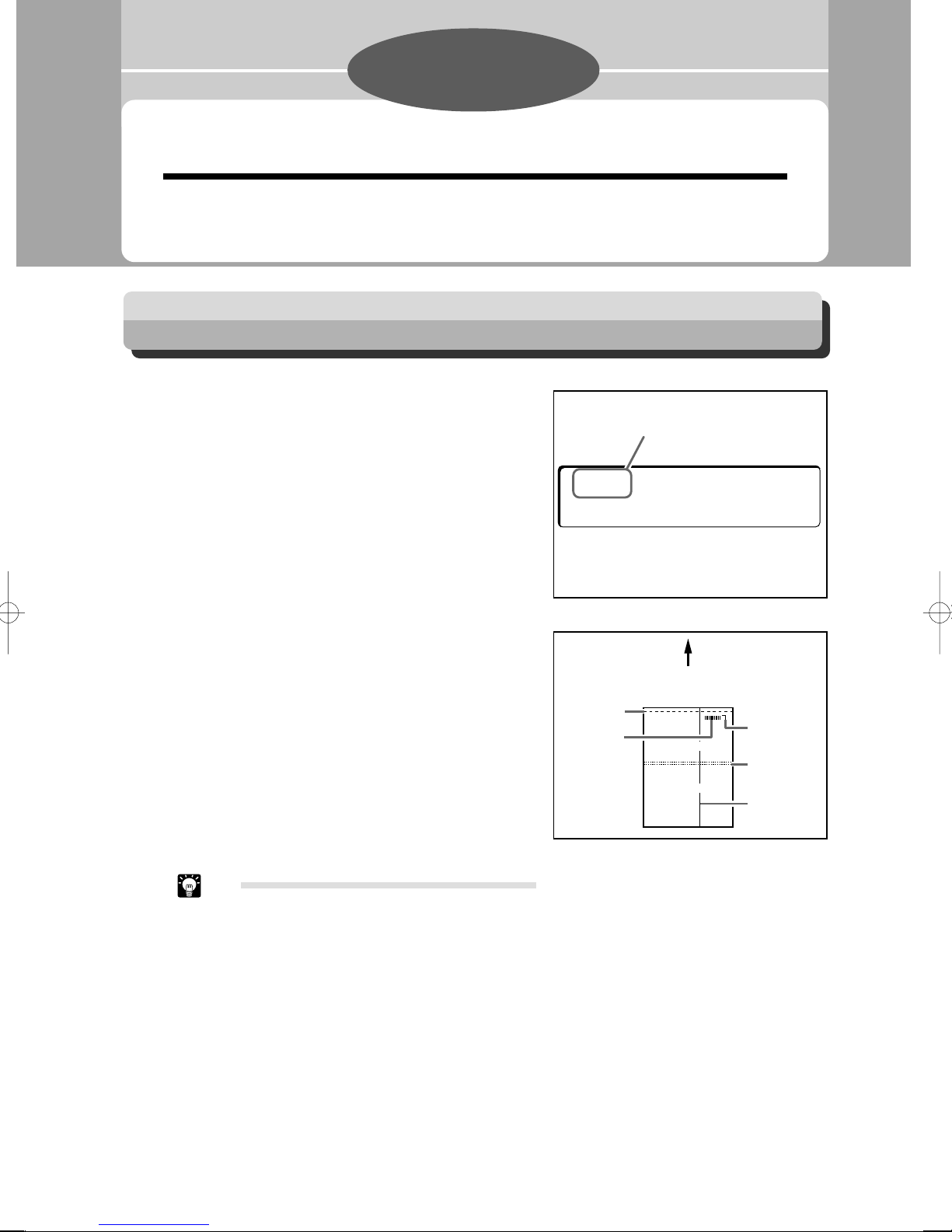

Paper and Processing Position

9

...CREASE

1

1

35

7C B A8910

...SLIT1

3

...SLIT3

5

...SLIT5

6

...SLIT6

11

Before Using This Machine

No. Name

1 Slitter 1 (in Slitter Module A)

2 Slitter 2 (in Slitter Module A)

3 Slitter 3 (in Slitter Module B)

4 Slitter 4 (in Slitter Module B)

5 Slitter 5 (in Slitter Module C)

6 Slitter 6 (in Slitter Module C)

7 Gutter Deflector

8 Cutter Module

9 Creaser Module

10 Transport Module

(or Optional Module)

Feed

direction

246

8

...CUT

Function

Cuts off the blank-area of the further-side and front-side.

Cuts off the blank-area of the front-side.

Cuts parallel in the paper feed direction.

Cuts parallel in the paper feed direction.

Cuts parallel in the paper feed direction.

Cuts parallel in the paper feed direction.

The gutter strips cut off by slitters are dropped into the

waste box.

Cuts in a perpendicular to the paper feed direction.

Creases parallely in the paper feed direction.

Transports the paper to the stacker tray.

4

...SLIT4

2

...SLIT2

Reference

page

60,80,82

61,80,82

40,81

54,79,80,89

54,79,81,89

36,57

IMPORTANT

• When removing various modules of this device, always re-set the module in the sequential

order indicated in the illustration above. It is especially that the slitter module is properly

assembled, when setting slitter module A, B and C again.

19

Page 21

Before Preparing Document

Definition of Programming Terms

PAPER FEEDING DIRECTION

Barcode

(Optional)

SLIT 2

SLIT 4

SLIT 6 SLIT 5

PAPER FEEDING DIRECTION

REG. Mark

(Optional)

SLIT 1

SLIT 3

First Cut

Last cut

20

REG. Mark

(Optional)

Barcode

(Optional)

Crease

(CRE. 01)

Page 22

Slit / Cut / Crease Limitations

There arer limitations for slit / cut / crease process on DC-645.

Before Preparing Document

CUT1

CREASE1

Paper feed direction

Slit: Up to 6 slits are possible on 1 document.

Cut: Up to 15 cuts are possible on 1 document.

Crease: Up to 10 creases are possible on 1 document.

SLIT2

SLIT4 SLIT6 SLIT5 SLIT3 SLIT1

11

Before Using This Machine

Lead margin:

3.2mm ~

Card length:

85mm ~

CUT2

CUT3

CREASE2

CUT4

Left margin:

3.2mm~40mm

from left edge

Card width:

48mm~

Gutter slit :

5-15mm

Trail margin:

5mm ~

Right margin:

3.2mm~40mm

from right edge

21

Page 23

Before Preparing Document

REG. Mark (Registration mark)

DC-645 automatically compensate for image drift, one of the common problems on digital printers. It detects

the image drift caused on each page by reading REG. mark with built-in CCD and adjust the cut / slit / crease

position accordingly.

To use this function, each documents must have REG, mark printed on them. Please refer to following

instructions for specifications and position of REG. mark.

1) Specifications

REG. mark consists of 2 straight & perpendicular lines.

line length : 5 mm or more / each

line thickness : 0.4 mm or more / each

Paper feed direction

Lead mark

Correct for image drift

in this direction

Correct for image drift

Side mark

in this direction

Use pen tool etc. of your software application to draw 2 straight & perpendicular lines.

2) Position

Paper feed direction : The whole REG. mark should be within 3 mm ~ 20 mm from the lead edge.

Paper width direction : The whole REG. mark should be within 3 mm ~ 20 mm from the right edge.

3mm

3mm

5mm or more

5mm

or more

20mm

22

0.4mm or more

REG. Mark

Position Range

REG. Mark

Page 24

BARCODE

By adding barcode which indicates job number on each document, DC-645 automatically set up the machine

and start the job. Operator can press the START key and leave. Even if multiple types of jobs are loaded on the

feed tray at one time, DC-645 recognizes barcode on documents also with the built-in CCD and automatically

switch setup and finish the jobs.

Before Preparing Document

To use this function, each documents must have BARCODE printed on them. Please refer to following

instructions for specifications and position of BARCODE.

1) Specifications

Barcode type : CODE-39

Start and Stop code : Required

Check digit : Optional

Minimum resolving power : 0.254 mm

Thin bar : Thick bar : 1 : 2.5

Bar height : 4 mm or more

Use barcode generator function equipped on your software application or use barcode generator software.

2) Position

Paper feed direction : The whole BARCODE should be within 3 mm~ 20 mm from the lead edge.

Paper width direction : The whole BARCODE should be within 25 mm~60 mm from the right edge

(See below)

q is the start code designator for CODE-39.

w is the 10’s digit data of the JOB number.

(Example: When the

JOB

number is 21, the data is “2”.)

Paper feed direction

11

Before Using This Machine

e is the 1’s digit data of the JOB number.

(Example: When the

r is the check digit.

t is stop code of CODE-39.

POSITIONING THE BARCODE

5 mm

JOB

number is 21, the data is “1”.)

60 mm

10 mm

NON PRINTING AREA

*24*

2

1

3

5

4

23

Page 25

Before Preparing Document

How to Make a Barcode for Use DC-645

The easiest way to create the code is with a TrueType Font. Fonts are readily available from many companies on the

internet. Here are two companies which have fonts suitable for use with the DC-645 (there are many companies offering

fonts).

www.barcodetrader.com/bct_scan_barcode.asp

http://www.squaregear.net/fonts/

Free download of Barcode creating software.

http://www.datascan.co.uk

Samples - standard font Price £149 for a single user; £298 for 2 – 5

*The above is only an example of a homepage.

*The above is a general homepage. Note that it may be ended or the URL may be relocated.

24

Page 26

Before Preparing Document

Basic Font Installation Instructions

The following briefly describes what is required to install a font on a Windows or Macintosh system. The font provider

will supply more detailed information, these guidelines are only intended to illustrate the basics and scope of the

installation process.

On a Windows computer the font is installed through the Control Panel’s “Fonts” folder.

On a Macintosh system select the font suitcases (for TrueType 1 fonts also select the printer outline files) and drag the

fonts onto the closed System Folder icon. For OS X drag the fonts onto the Fonts folder in the Library folder.

How to use a TrueType font

Once installed, the font will appear in the word processing or desktop publishing application in the font selection area.

Please note in MS Word, typing text surrounded by the characters * and *, automatically turns on auto format to bold

text. Since this is not the intended, or useful, turn off the auto formatting by following the steps below or use the 'undo

last action' after typing.

11

Before Using This Machine

25

Page 27

Before Preparing Document

Select Options

Delete *Bold* and _underline_with real formatting

26

Page 28

Before Preparing Document

Creating the Barcode

Making the barcode appear on the page is extremely easy with a TrueType font. In this case we will use the example job

“01.” The application designer simply does the following:

1. Place a text box in the predefined area. Make sure the text box is large enough to hold the entire barcode. It

may be necessary to increase the size of the text box after the font is created.

2. Type the desired job (program) number surrounded by a stop and start bit. Remember the stop and start bit

are recognized in Code 39 as an * or asterisk.

3. Select the text, in this case the text will appear as: *01*

4. Change the font type in the font selection window to the name of the code 39 font.

The text will appear as: *01*

5. Print a sample and make sure the font is at least 4 mm tall. If not, increase the size of the code 39 font by

reselecting the barcode and increasing the font size with through the Font size selection window.

Font

selection

window

Duplo Code 39

11

Before Using This Machine

Font size

selection

window

27

Page 29

Before Preparing Document

When both REG.Mark and Barcode are Printed

60mm or less

5mm

3mm

Barcode

Position Range

Barcode

20mm35mm

5mm or more

0.4mm or more

REG. Mark

Position Range

REG. Mark

5mm

or more

3mm

3mm

20mm

Feed Direction

Ifthereisanystainorscratchthatis0.3mmorlessintheslasharea,themarginoferrorinthefinishmay

slightlyincrease.

WhenREG.MARKand/orBARCODEareprintedoutsidethespecifiedarea,DC-645cannotdetectthem

properly.WhenpositioningtheREGmarkandBARCODEonthedocument,takethepossibilityofimage

shiftintoconsideration.

Non-Printing Area

3mm

or more

Theprintimageshouldnotinterferethered-coloredarea.

3mm

or more

Barcode

5mm

Non Printing Area

Feed Direction

20mm35mm

REG. Mark

3mm

or more

20mm

28

Page 30

Chapter 2

Program JOB for DC-645 Via Computer (JOB Creator)

DC-645 can save 80 patterns of JOBs. JOB contents can be programmed either via computer or on the

control panel. This chapter describes how to install the JOB Creator (attached to DC-645) in your

computer and set up a JOB for DC-645.

What is JOB Creator?

1

2

JOB creator is a software used to setup a JOB for DC645 on computer.

Installation of this software allows the user to create and

edit JOBs for DC-645, with preview image of the

document, as well as save JOB data and edit DC-645

settings from the computer.

Installing JOB Creator

This describes the procedures to install JOB Creator on computer.

Before Installation

Check the following before installing JOB Creator on computer.

System Requirements

The following computer specifications are necessary to run JOB Creator.

Program JOB for DC-645 Via Computer (JOB Creator)

English OS:

Windows: Windows XP Professional, Windows XP Home Edition, Windows 2000

Macintosh: Mac OS9.1 or later, OS10.1 or later (Do not run the classic environment with OSX)

29

Page 31

Installing JOB Creator

Installing Procedures (Windows)

○○○○○○○○○○○○○○○○○○○○○○○○○

Load the CD-ROM coming with DC645 in the CD-ROM drive of the

computer.

○○○○○○○○○○○○○○○○○○○○○○○○○

The display to specify a folder to

install file appears. If you want to

install the JOB Creator in a certain

place, click [Browse], then specify the

folder to install JOB Creator.

○○○○○○○○○○○○○○○○○○○○○○○○○

The display to specify the folder to

install JOB Creator in, appears.

A new folder is created at the top of

the list displayed. The file is then

installed in that folder.

To rename the folder, input the folder

name from the top list.

To install the JOB Creator file in an

existing folder, select a voluntary

folder from the bottom list.

○○○○○○○○○○○○○○○○○○○○○○○○○

After specification click [Next].

○○○○○○○○○○○○○○○○○○○○○○○○○

After completing the specification,

click [Next].

JOB Creator installation starts.

○○○○○○○○○○○○○○○○○○○○○○○○○

When installation is completed, the

screen shown below appears. A JOB

Creator shortcut is created on the

desktop.

Click [Finish] to close the installation

menu.

30

Page 32

Installing JOB Creator

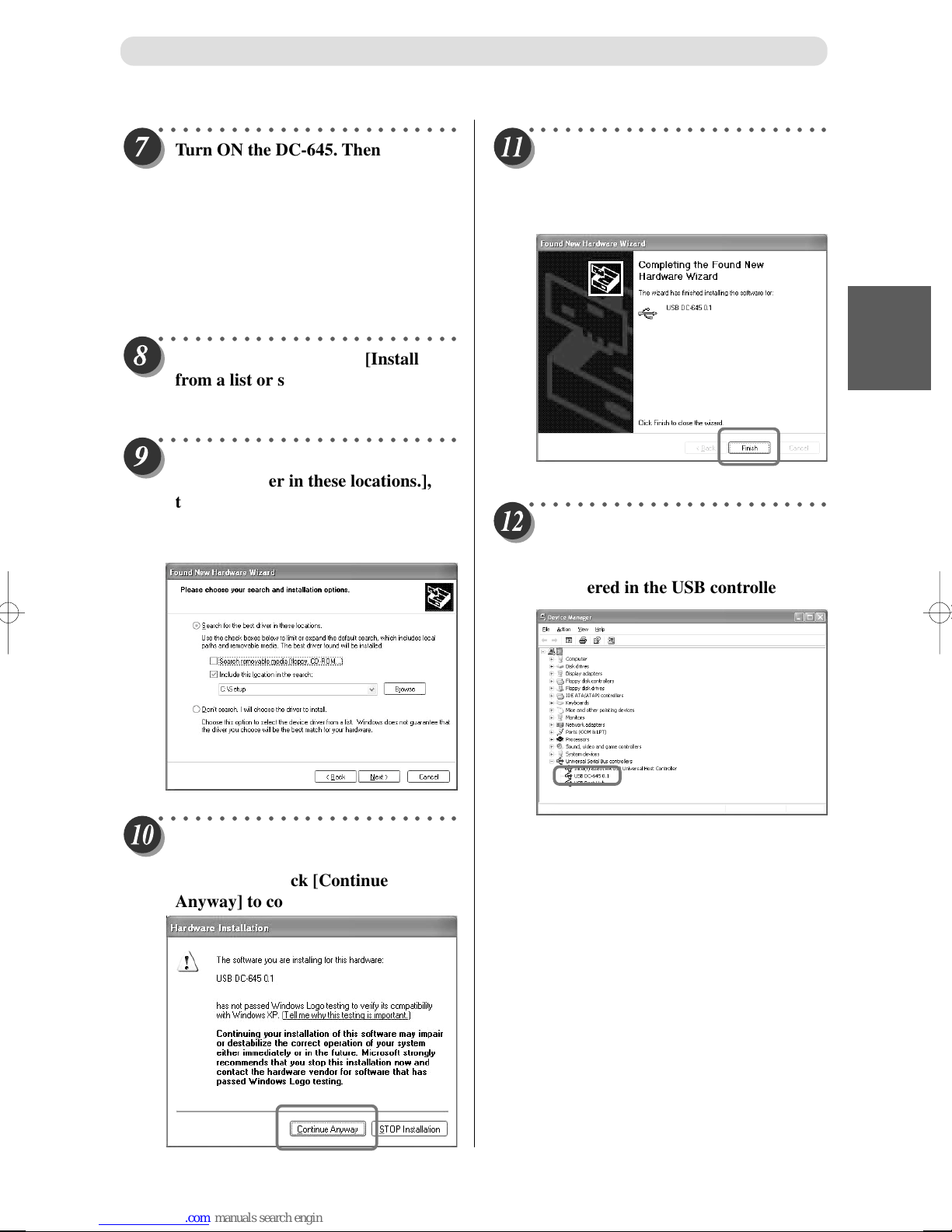

○○○○○○○○○○○○○○○○○○○○○○○○○

Turn ON the DC-645. Then connect

the computer and DC-645 using a

USB cable. (Computer USB Terminal

- DC-645 USB Terminal) (USB cable

(A to B type): The cable length must

be within 3 m.)

“Found New Hardware Wizard” menu appears

on the computer.

○○○○○○○○○○○○○○○○○○○○○○○○○

Click the radio button of [Install

from a list or specific location

(Advanced)], then click [Next].

○○○○○○○○○○○○○○○○○○○○○○○○○

Click the radio button of [Search for

the best driver in these locations.],

then click and select [Search

removable media].

Click [Browse], then click [Next].

○○○○○○○○○○○○○○○○○○○○○○○○○

When installation is completed, the

screen shown below appears. Click

[Finish] to end the Wizard.

○○○○○○○○○○○○○○○○○○○○○○○○○

Installation is successful if the

[Device Manager] dialog indicates

that the [USB DC-645 *.*] is

registered in the USB controller.

1

2

Program JOB for DC-645 Via Computer (JOB Creator)

○○○○○○○○○○○○○○○○○○○○○○○○○

Driver installation starts.

A warning dialog appears during

installation. Click [Continue

Anyway] to continue installation.

This completes the preparation and installing procedures.

31

Page 33

Installing JOB Creator

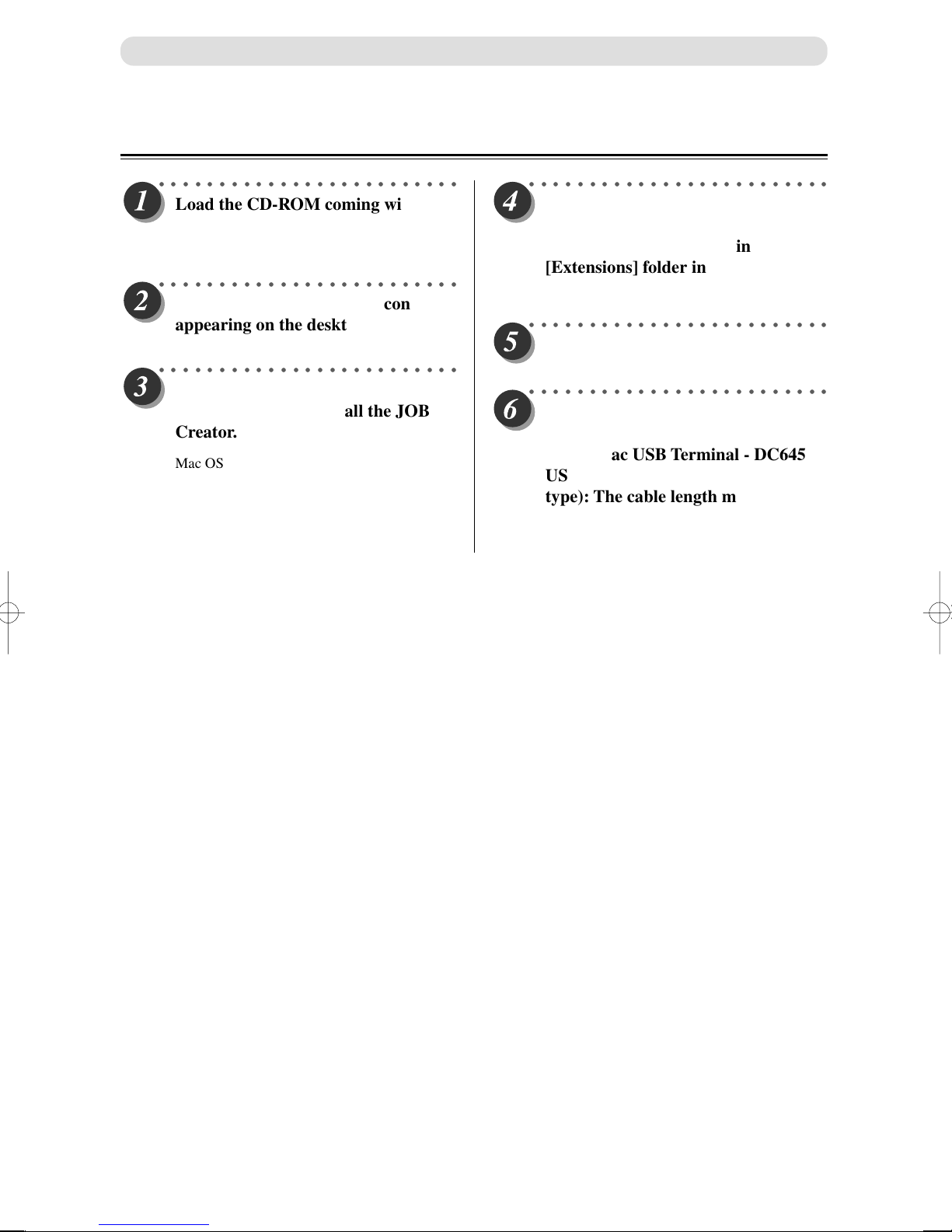

Installing Procedures (Macintosh)

○○○○○○○○○○○○○○○○○○○○○○○○○

Load the CD-ROM coming with this

machine in the CD-ROM drive of

your Macintosh.

○○○○○○○○○○○○○○○○○○○○○○○○○

Double click the CD-ROM icon

appearing on the desktop.

○○○○○○○○○○○○○○○○○○○○○○○○○

Copy [DC-645 JOB Creator] to

where you want to install the JOB

Creator.

Mac OS9 Users → Go to “Step 4”.

Mac OSX Users → Go to “Step 5”.

○○○○○○○○○○○○○○○○○○○○○○○○○

ONLY for Mac OS 9: Copy the

[USBDC645] on the CD-ROM

coming with the package in

[Extensions] folder in the [System]

folder.

○○○○○○○○○○○○○○○○○○○○○○○○○

Restart (reboot) the Macintosh.

○○○○○○○○○○○○○○○○○○○○○○○○○

Turn ON the DC-645. Then connect

the Mac and DC-645 with a USB

cable (Mac USB Terminal - DC645

USB Terminal). (USB cable (A to B

type): The cable length must be

within 3 m.)

This completes the preparation and installing procedures.

32

Page 34

Uninstall and Update JOB Creator

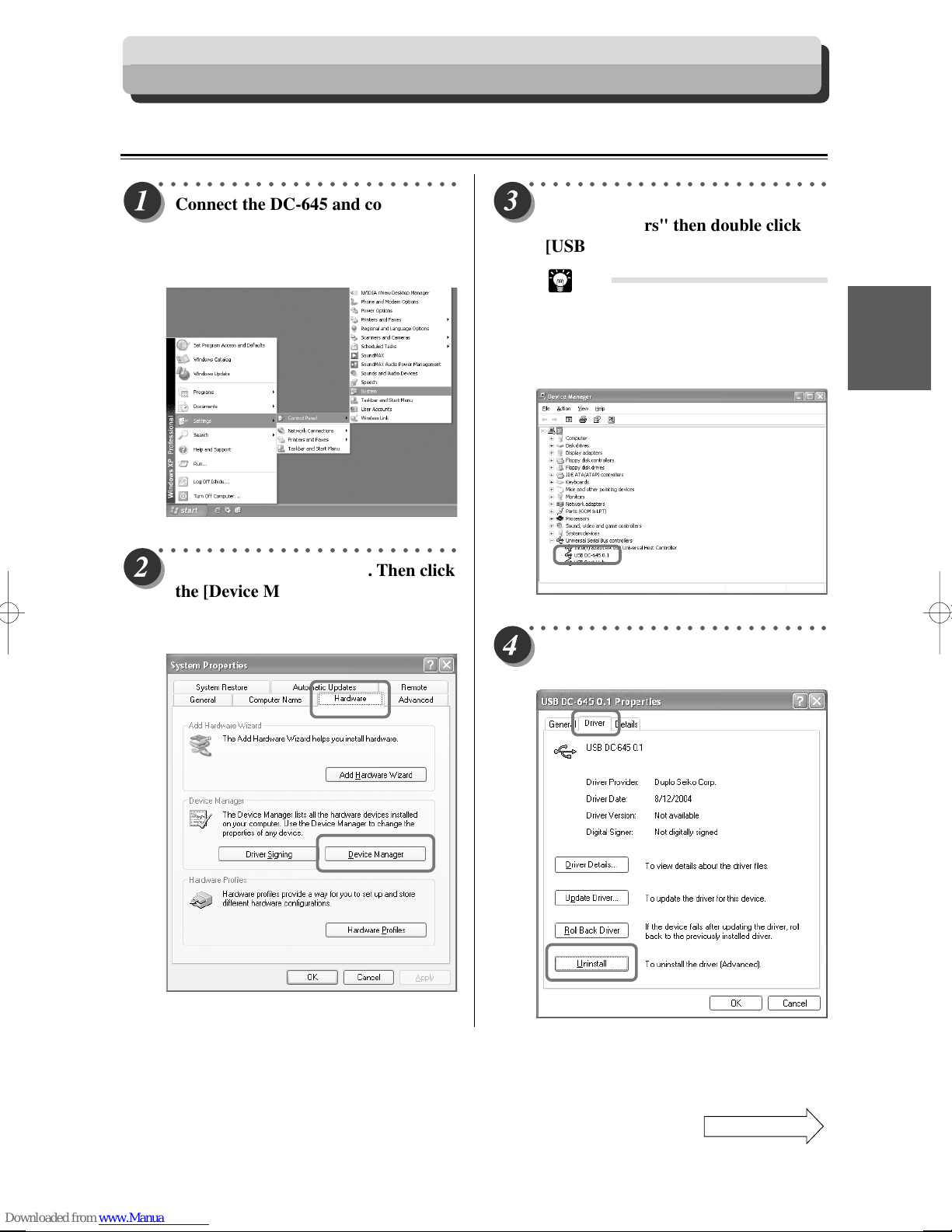

Uninstalling Procedures (Windows)

○○○○○○○○○○○○○○○○○○○○○○○○○

Connect the DC-645 and computer.

Select [Start] – [Settings] – [Control

Panel] – [System], then open the

[System Properties] dialog.

○○○○○○○○○○○○○○○○○○○○○○○○○

Select the [Hardware] tab. Then click

the [Device Manager] button.

The [Device Manager] dialog

appears.

○○○○○○○○○○○○○○○○○○○○○○○○○

Go to list and find "Universal Serial

Bus controllers" then double click

[USB DC-645 *.*].

Tip

• Note that the [USB DC-645 *.*] will

not appear in the “Universal Serial

Bus controllers” list unless the DC645 is connected to the computer

with a USB cable.

○○○○○○○○○○○○○○○○○○○○○○○○○

Select the [Driver] tab. Then click the

[Uninstall] button.

1

2

Program JOB for DC-645 Via Computer (JOB Creator)

Continue Page

•••

33

Page 35

Uninstall and Update JOB Creator

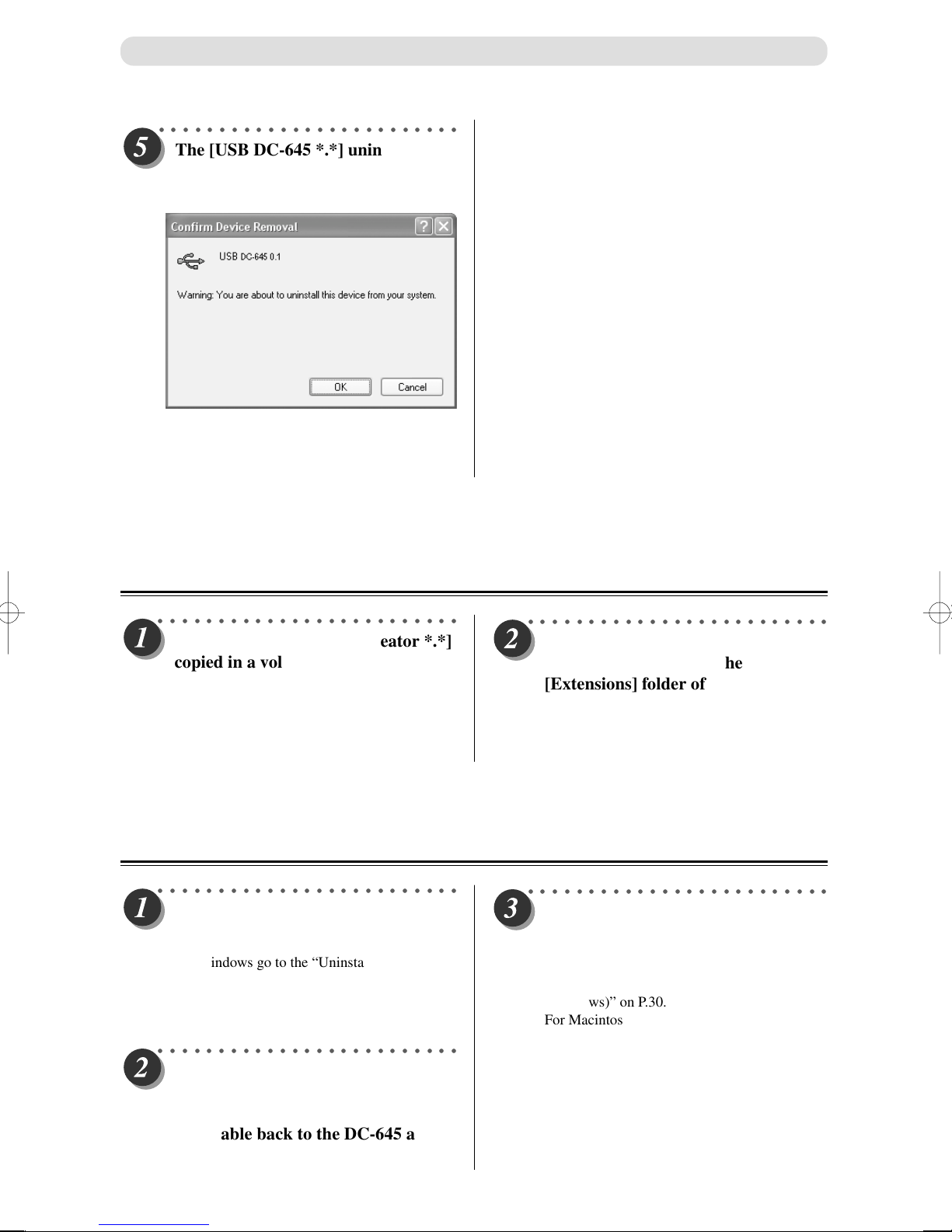

○○○○○○○○○○○○○○○○○○○○○○○○○

The [USB DC-645 *.*] uninstall

confirmation dialog appears. Click

[Uninstall] then click [OK].

The driver has been successfully removed if [USB DC645 *.*] no longer appears in the list of "Universal Serial

Bus controllers" in the [Device Manager] dialog.

Uninstalling Procedures (Macintosh)

○○○○○○○○○○○○○○○○○○○○○○○○○

Delete the [DC-645 JOB Creator *.*]

copied in a voluntary folder of the

Macintosh.

Mac OS9 Users → Go to “Step 2”.

Mac OSX Users → This completes the driver

removal procedures.

○○○○○○○○○○○○○○○○○○○○○○○○○

ONLY for Mac OS9: Remove the

[USBDC645] copied in the

[Extensions] folder of the [System]

folder on the Macintosh.

This completes the driver removal procedures.

Updating Drivers

○○○○○○○○○○○○○○○○○○○○○○○○○

Uninstall the previous driver using

the driver uninstalling procedures.

For Windows go to the “Uninstalling

Procedures (Windows)” on P.33.

For Macintosh go to the “Uninstalling

Procedures (Macintosh)” above.

○○○○○○○○○○○○○○○○○○○○○○○○○

FOR WINDOWS ONLY: Disconnect

the USB cable connecting the DC-645

and computer. Then reconnect the

USB cable back to the DC-645 and

computer.

○○○○○○○○○○○○○○○○○○○○○○○○○

Install a new driver according to the

Driver Install Procedures on P.31 –

32.

For Windows go to the “Installing Procedures

(Windows)” on P.30.

For Macintosh go to the “Installing Procedures

(Macintosh)” on P.32.

34

Page 36

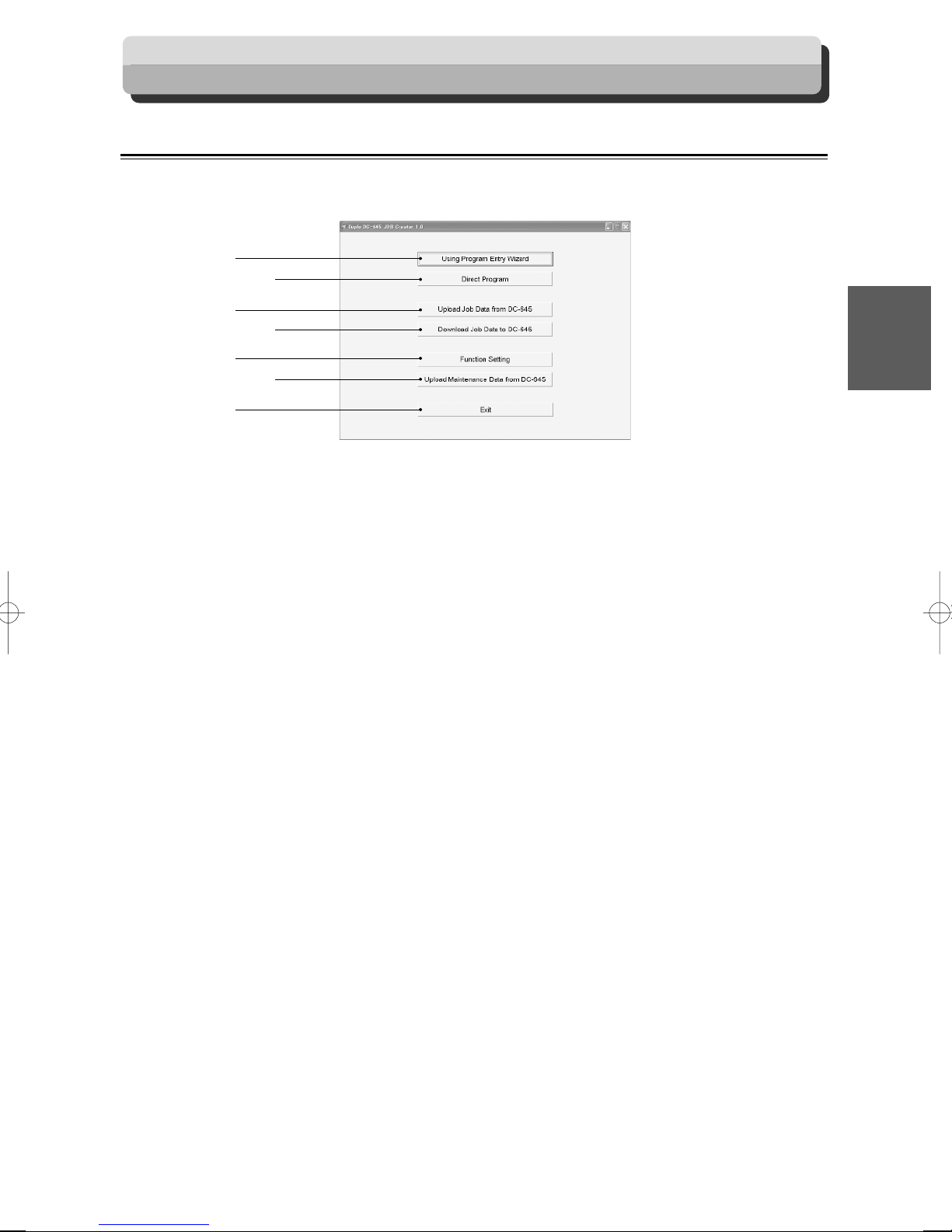

JOB Creator Settings

Main Menu

This menu appears when the JOB Creator is launched.

Select the sub menu to set from this main menu, for actual settings.

1

2

3

4

5

6

7

1 Using Program Entry Wizard

Create a JOB in Wizard format.

A preview of the JOB being created is displayed. Create the JOB while checking the input details.

1

2

Program JOB for DC-645 Via Computer (JOB Creator)

2 Direct Program

Directly input the number value to create a JOB.

Use this to create a JOB when the dimensions are already finalized.

3 Upload Job Data from DC-645

Read JOB from DC-645 and save in computer.

4 Download Job Data to DC-645

This sends the JOB saved on the computer to DC-645.

5 Function Setting

This is used to make settings in Function menu.

6 Upload Maintenance Data from DC-645

This creates the file that records the DC-645 status.

This may be used to report the status to the service personnel.

7 Exit

This is used to quit the JOB Creator.

This is the same function as the X button at the top right of the main menu.

35

Page 37

JOB Creator Settings

Creating JOB with Preview Display

This describes the procedures to set up a JOB in Wizard format. Following items should be entered to create a

JOB.

Optional Module ............................ Standard Module

Select an optional module for the job when necessary.

In following JOB, standard module is selected.

JOB Number .................................. 01

Select a JOB No. in which the JOB currently being programmed is saved.

In following JOB, 01 selected.

JOB Name ...................................... DUPLO1

Put a name to the JOB with your keyboard for easy reference.

Following job is named “DUPLO1.”

Paper Size ....................................... 12” x 18” (304.8 mm x 457.2 mm) (Standard Size)

Enter size of the document.

Standard paper size can be selected from “Standard size,” or custom size can be entered in

“Custom size.”

In following JOB, standard 12” x 18” is selected.

REG. Mark .................................... SIDE MARK10 mm (From right edge of document) /

LEAD MARK 10 mm (from top end of document)

Select whether to use REG MARK function or not.

When using this function, enter the position of REG. Mark.

In following JOB the REG. Mark is enabled and the position is 10 mm from the right edge of

document and 10 mm from the lead edge of the document.

(“Using Program Entry Wizard”)

Finished Size .................................. 100mm (W) x 130mm (L)

The size of cards after processing the documents.

Cards per Document ..................... 2 (Crosswise) x 3 (Lengthwise)

Specify how many cards are to be aligned in crosswise and in lengthwise direction.

In following JOB, 2 (crosswise) x 3 (lengthwise) cards are aligned.

Trim ................................................ 23.6 mm (Lead margin), 30 mm (Right margin)

Specify the position of first cut and right margin slit.

In following JOB, first cut is at 23.6 mm from the lead edge, and the right margin slit is at 30 mm

from the right edge of document.

Gutter Slits ..................................... 10mm (Distance between finished documents (left /

right))

When aligning 2 or 3 cards in crosswise direction, it is possible to have a gutter slit between each

cards. Specify the distance between each cards. (The distance should be between 5 mm and 15

mm.)

IN following job, Gutter slits are 10 mm.

36

Page 38

JOB Creator Settings

Gutter Cuts .................................... 10 mm / 10 mm (Distance between finished documents

(top / bottom))

When aligning 2 or more cards in lengthwise direction, it is possible to have a gutter cut between

each cards. The distance should be 4 mm or more.

IN following job, gutter cuts are 10 mm in length.

Crease ............................................. 65 mm

Specify the position of the crease on the cards.

Barcode Reading............................ ON

Auto Cut ......................................... ON

AIR KNIFE .................................... Compressed air is blown out to loosen the document.

This is to prevent double-feed.

FAN REGISTER ........................... Document skewing in feeding area is corrected. When

processing light weight document, turn this function

OFF as it may cause a paper jam in feed area.

SLIT GUIDE .................................. When any slitters are not used, these slitters act as

paper guide to stabilize the paper conveyance.

Recommended for light weight document.

AUTO CUT .................................... Lead margin, trail margin, and any gutter cuts (shorter

than 85 mm) are finely cut and dropped into the waste

box. When documents do not have lead margins or trail

margin, this must be turned off.

CREASE DEPTH .......................... This sets the depth of the crease when creasing a

document. Set to MAX for heavy paper and MIN for

light paper.

1

2

Program JOB for DC-645 Via Computer (JOB Creator)

SPEED ............................................ This is used to select HIGH / LOW processing speed.

Set to LOW for better processing precision.

Continue Page

•••

37

Page 39

JOB Creator Settings

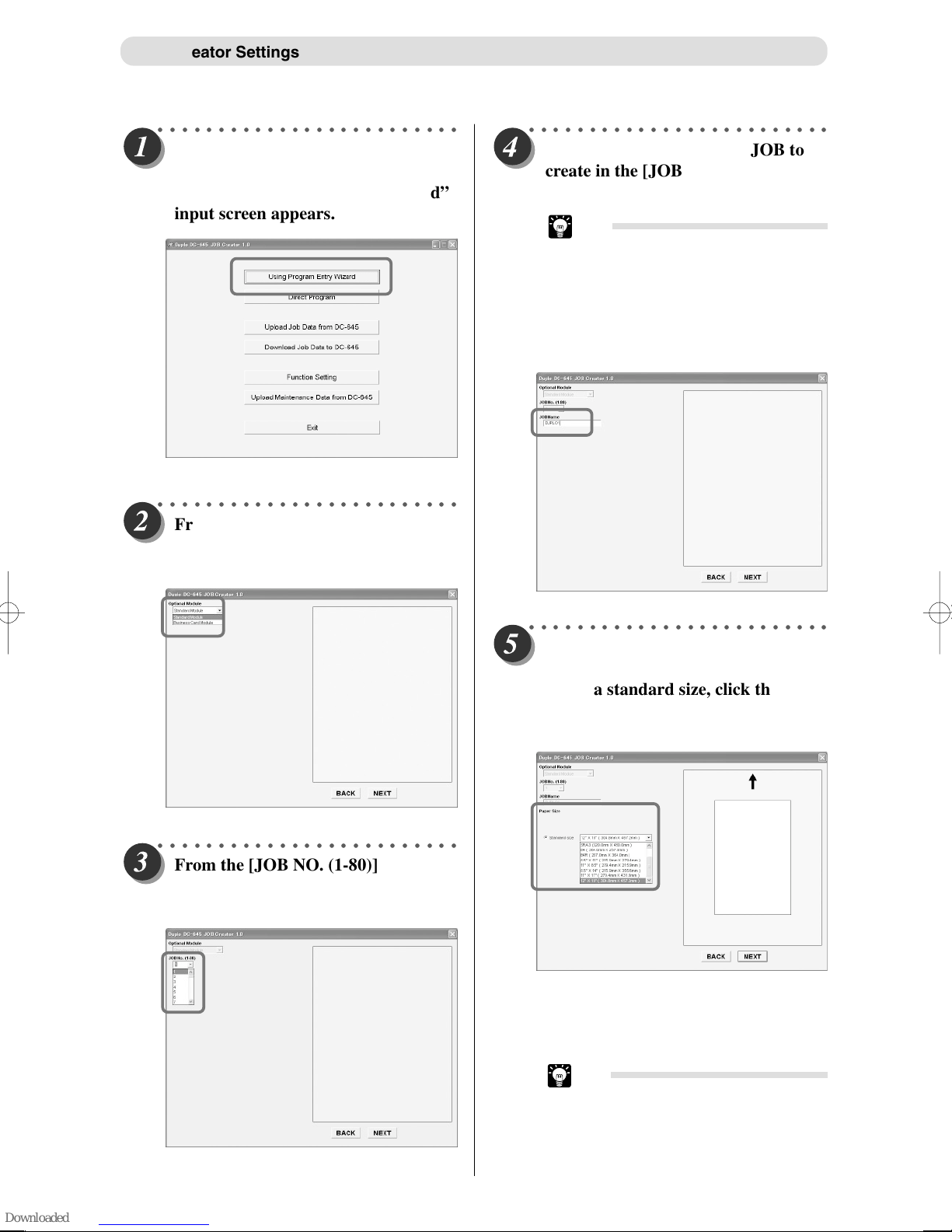

○○○○○○○○○○○○○○○○○○○○○○○○○

Click the [Using Program Entry

Wizard] button.

The “Using Program Entry Wizard”

input screen appears.

○○○○○○○○○○○○○○○○○○○○○○○○○

From the [Optional Module] list,

select the optional module to finish

the JOB then click [NEXT].

○○○○○○○○○○○○○○○○○○○○○○○○○

Input the JOB name of the JOB to

create in the [JOB Name] list, then

click [NEXT].

Tip

• The JOB name can be input with a

maximum of 13 characters.

• Usable Characters

Alphabets: A to Z, a to z

Numbers: 0 to 9

Symbols: ! " # $ % & ' ( ) - @ [ ] ; : ,

. / + * < > ? _ and space.

○○○○○○○○○○○○○○○○○○○○○○○○○

From the [JOB NO. (1-80)] list, select

the JOB Number of the JOB to

create, then click [NEXT].

○○○○○○○○○○○○○○○○○○○○○○○○○

Select the document size before

finishing.

If it is a standard size, click the

[Standard Size] radio button, then

select the size from the list.

If it is a nonstandard size, click the [Custom

Size] radio button, then input the number values

of the [Width] and [Length] on the right.

Click [NEXT] when the numbers are set.

38

Tip

• The range of number values that can

be input is displayed by each input

item of the JOB Creator. Use this as

a guideline (reference) to create a

JOB.

Page 40

JOB Creator Settings

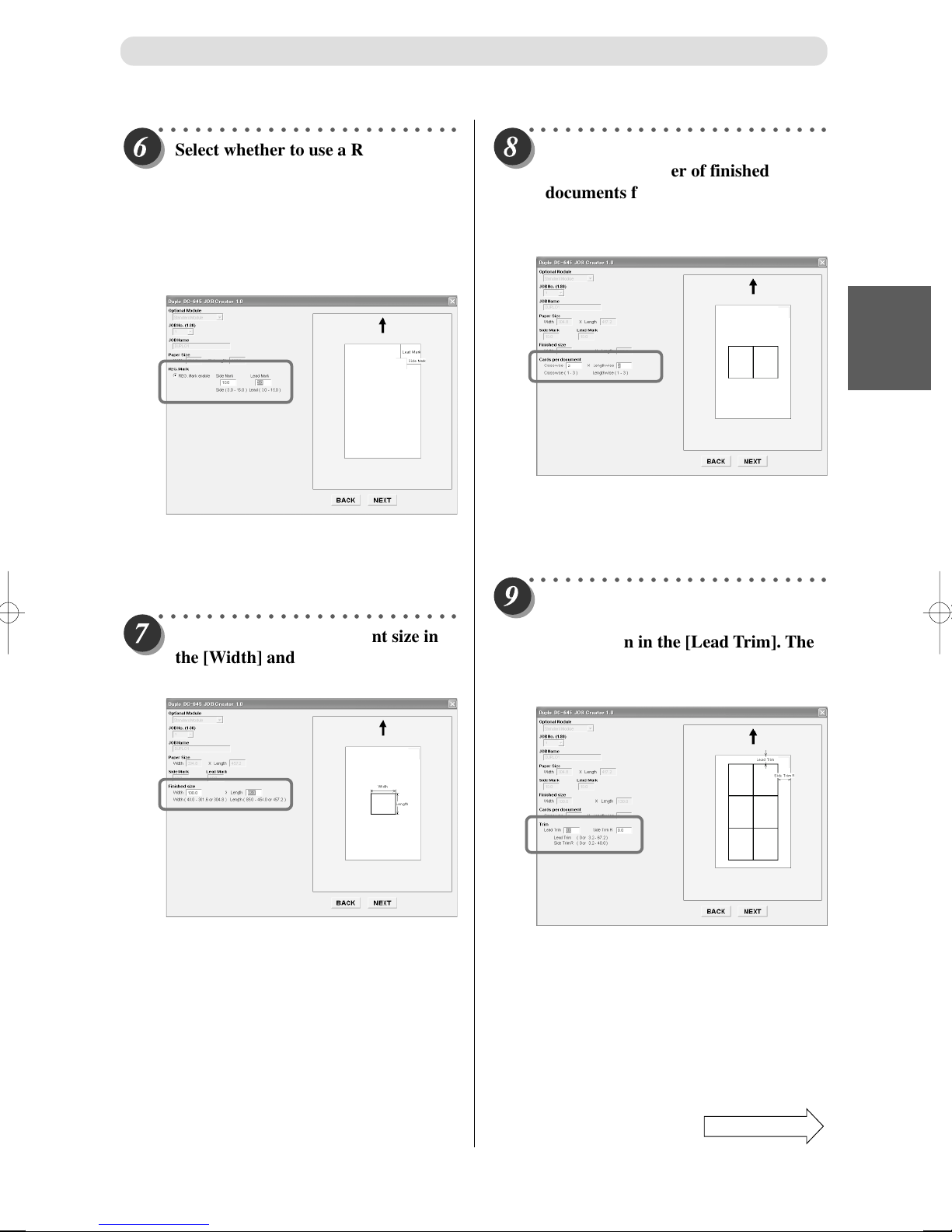

○○○○○○○○○○○○○○○○○○○○○○○○○

Select whether to use a REG. Mark

reading.

When using a REG. Mark, then click

the [REG. Mark enable] radio

button. Then input the number value

for [REG. Mark 1] and [REG. Mark

2] on the right.

When not using a REG. Mark, then click the

[REG. Mark disable] radio button. Click

[NEXT] once it is set.

○○○○○○○○○○○○○○○○○○○○○○○○○

Input the finished document size in

the [Width] and [Length], then click

[NEXT].

○○○○○○○○○○○○○○○○○○○○○○○○○

Respectively input the vertical and

horizontal number of finished

documents for the documents before

they are cut, in the [Crosswise] and

[Lengthwise] area.

Set [Crosswise] then click [NEXT] and go to

[Lengthwise]. Set [Lengthwise] then click

[NEXT] again to go to the next setting.

○○○○○○○○○○○○○○○○○○○○○○○○○

Set the margin of the document.

Input the number value of the topside margin in the [Lead Trim]. Then

input the number value of the rightside margin in the [Side Trim R].

1

2

Program JOB for DC-645 Via Computer (JOB Creator)

Set [Lead Trim] then click [NEXT] and go to

[Side Trim R]. Set [Side Trim R] then click

[NEXT] again to go to the next setting.

Continue Page

•••

39

Page 41

JOB Creator Settings

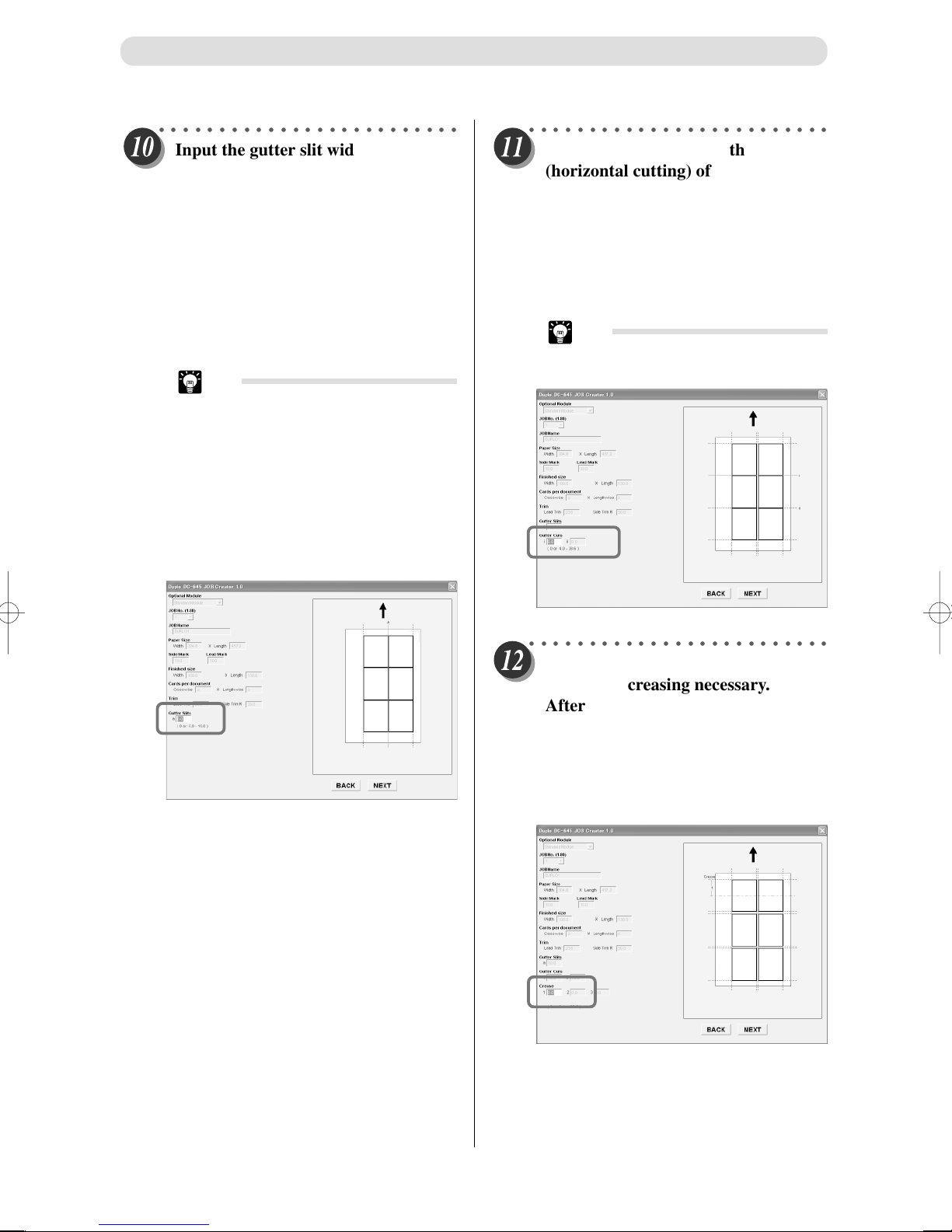

○○○○○○○○○○○○○○○○○○○○○○○○○

Input the gutter slit width (width

between each cards) (vertical cutting)

of the size determined document.

Input 0 if there is no gutter between

cards.

After inputting one number value,

click [NEXT]. Then input the next

number value. Set the all gutter slit

widths.

When all settings are complete, click [NEXT].

Tip

• If in Step 8, Crosswise = 1, then the

gutter slit width cannot be input.

• Only one gutter slit can be set if

crosswise is set to 3.

• No gutter slit can be set if crosswise

is set to 5 or more.

• The gutter slit cannot be changed if

the “Business Card Module” is

selected for the Optional Module.

(Fixed value: 5 mm)

○○○○○○○○○○○○○○○○○○○○○○○○○

Input the gutter cut length

(horizontal cutting) of the size

determined document.

Input 0 if there is no distancing.

After inputting one number value,

click [NEXT]. Then input the next

number value. Set the all gutter cut

lengths.

Tip

• If in Step 8, Lengthwise = 1, then the

gutter cut length cannot be input.

○○○○○○○○○○○○○○○○○○○○○○○○○

Input the creasing position. Input 0 if

there is no creasing necessary.

After inputting one number value,

click [NEXT]. Then input the next

number value. Set the distance of all

creasing positions.

When all settings are complete, click [NEXT].

40

Page 42

JOB Creator Settings

○○○○○○○○○○○○○○○○○○○○○○○○○

Set functions for this job by clicking

the [FUNCTION] button, then open

the “Function Settings” dialog.

When the settings are completed,

click [OK] and close the dialog. Then

click [NEXT].

○○○○○○○○○○○○○○○○○○○○○○○○○

The details of all the settings will

appear in a list. Check to see if the

JOB details are correct. If there are

any numbers to modify, re-input the

values at this time.

Tip

• For the “Function Settings” click the

[Function] button, open the “Function

Settings” dialog, then Confirm/

Modify.

Tip

• When the “Business Card Module” is

selected, it is possible to adjust the

business card processing position

with “Option 1” of this display item.

○○○○○○○○○○○○○○○○○○○○○○○○○

To register the JOB created with the

DC-645 immediately, click the

[DOWNLOAD] button.

Tip

• To save the JOB created on the

computer as a file, click [SAVE].

Determine the file name and where to save the

file. Then click [OK] to save the file.

The JOB file created can be registered on the

DC-645 again with “Download Job Data to DC645” of the main menu.

(a P.47 to “JOB Saved on computer Registered

on DC-645 [Download Job Data to DC-645]”)

1

2

Program JOB for DC-645 Via Computer (JOB Creator)

Tip

• When inputting the settings from

your computer, the machine

automatically judges positions of

slitters and the positions sometimes

differs from the description on page

19.

Tip

• The [Optional Module] cannot be

modified.

Continue Page

•••

41

Page 43

JOB Creator Settings

○○○○○○○○○○○○○○○○○○○○○○○○○

A registration confirmation dialog

appears. Click [YES].

Tip

• When downloading JOB data to the

DC-645, the JOB data is generally

registered in the DC-645 memory. To

update the JOB data without

registering it in memory, check the

“Temporary job data” check box at

the bottom of this dialog.

The JOB data downloaded as

“Temporary job data” will be deleted

when the DC-645 is turned OFF or

when another JOB is selected. To

download (save) the JOB data,

always download the “Job data”

without “Temporary job data” check

marked, or save the JOB data on the

computer with the JOB Creator

before downloading it.

Tip

• If there is already a JOB registered

in selected job number in the DC645 memory, a display appears

whether to overwrite file or not.

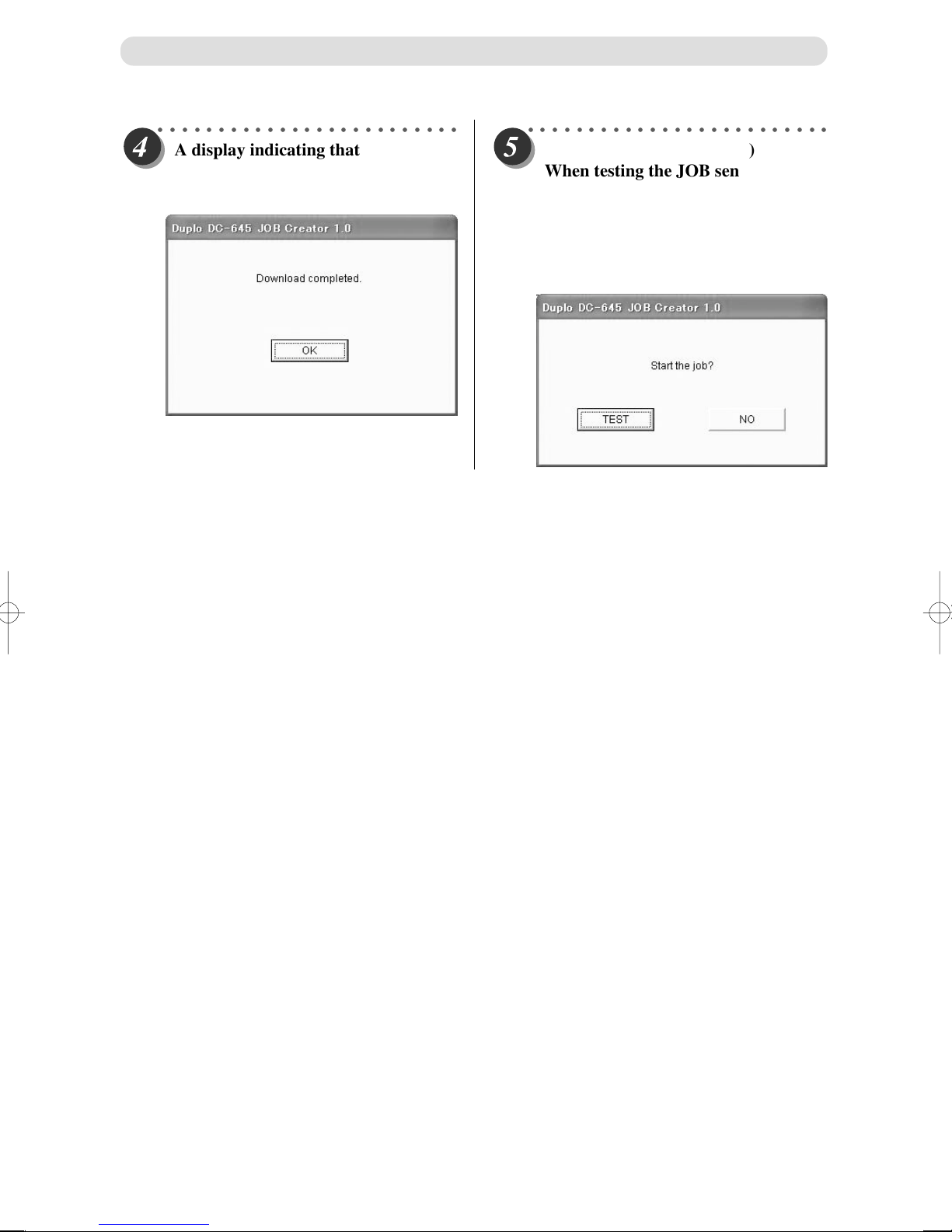

○○○○○○○○○○○○○○○○○○○○○○○○○

Click [OK] and a display indicating

that the data was successfully sent,

appears in approximately one second.

○○○○○○○○○○○○○○○○○○○○○○○○○

The dialog appears to ask whether to

test the program.

To test the created job by running 1

document, set the document on the

DC-645 then click [TEST]. If a test is

not intended, then click [NO].

42

ThiscompletestheJOBcreationprocedures.

Page 44

JOB Creator Settings

Creating a JOB By Direct Number Input (“Direct Program”)

With Direction program, the JOB is created by directly inputting the number value of each item, in the same

manner as the JOB program of the DC-645 main unit.

This describes the procedures to create a JOB with Direct Program.

○○○○○○○○○○○○○○○○○○○○○○○○○

Click the [Direct Program] button.

The Direct Program input menu

appears.

○○○○○○○○○○○○○○○○○○○○○○○○○

Input the JOB number of the JOB to

create in the [JOB No. (1-80)] list.

○○○○○○○○○○○○○○○○○○○○○○○○○

Input the JOB name of the JOB to

create in the [JOB Name] list.

Tip

• The JOB name can be input with a

maximum of 13 characters.

• Usable Characters

Alphabets: A to Z, a to z

Numbers: 0 to 9

Symbols: ! " # $ % & ' ( ) - @ [ ] ; : ,

. / + * < > ? _ and space.

1

2

Program JOB for DC-645 Via Computer (JOB Creator)

○○○○○○○○○○○○○○○○○○○○○○○○○

From the [Optional Module] list,

select the optional module to finish

the JOB.

Continue Page

•••

43

Page 45

JOB Creator Settings

○○○○○○○○○○○○○○○○○○○○○○○○○

Input the number value of each item

to create a JOB according to the

details intended.

Tip

• Slitter values cannot be changed if

the “Business Card Module” is

selected for the Optional Module.

Tip

• Option value cannot be set if the

“Standard Module” is selected for the

Optional Module.

○○○○○○○○○○○○○○○○○○○○○○○○○

Set the functions for this JOB by

clicking the [FUNCTION] button,

then open the “Function Settings”

dialog.

When the settings are completed,

click [OK] and close the dialog.

This completes the JOB programming procedures.

JOB registration and save can be done with the same

procedures as the Wizard system.

Run according to Steps 15 – 18 on page 41.

44

Page 46

JOB Creator Settings

Reading JOB from DC-645 (“Upload Job Data from DC-645”)

This describes the procedures to read a JOB from the DC-645 memory to the JOB Creator.

○○○○○○○○○○○○○○○○○○○○○○○○○

Click the [Upload Job Data from DC645] button.

The display to select the JOB to read

appears.

○○○○○○○○○○○○○○○○○○○○○○○○○

(To upload all JOB (#1 – #80) from

the DC-645 memory)

Click the [ALL JOB] radio button,

then click the [UPLOAD] button.

Tip

• With the above operations, JOB No.

1 – 80 is saved as 1 file.

(To select and upload only one JOB)

Click the [JOB No.] radio button.

Then select the JOB number to

upload from the following list.

1

2

Program JOB for DC-645 Via Computer (JOB Creator)

After selecting the JOB number, click the

[UPLOAD] button.

Continue Page

•••

45

Page 47

JOB Creator Settings

○○○○○○○○○○○○○○○○○○○○○○○○○

A display confirming whether to start

uploading the JOB will appear. Click

the [YES] button.

○○○○○○○○○○○○○○○○○○○○○○○○○

(To read all JOB from the DC-645

memory)

A JOB successfully read display will

appear. Click the [SAVE] button to

save the JOB on the computer or

click [END] to quit uploading the

JOB.

(When selecting and uploading only

ONE JOB)

The details of the JOB will appear in

a list.

If there are any number values to edit, input the

changes at this time.

To register the JOB edited with DC-645, click

the [DOWNLOAD] button.

To save the edited JOB on the computer, click

[SAVE]. Then, designate the file name and

place to save the file and then click [OK] to

save.

Click [BACK] to read the JOB data once again.

Tip

• The [Optional Module] cannot be

modified.

Tip

• Slitter values cannot be changed if

the “Business Card Module” is

selected for the Optional Module.

Tip

• Option value cannot be set if the

“Standard Module” is selected for the

Optional Module.

If [END] is clicked, then a display will appear

confirming whether to quit reading the JOB.

Click [YES].

46

Page 48

JOB Creator Settings

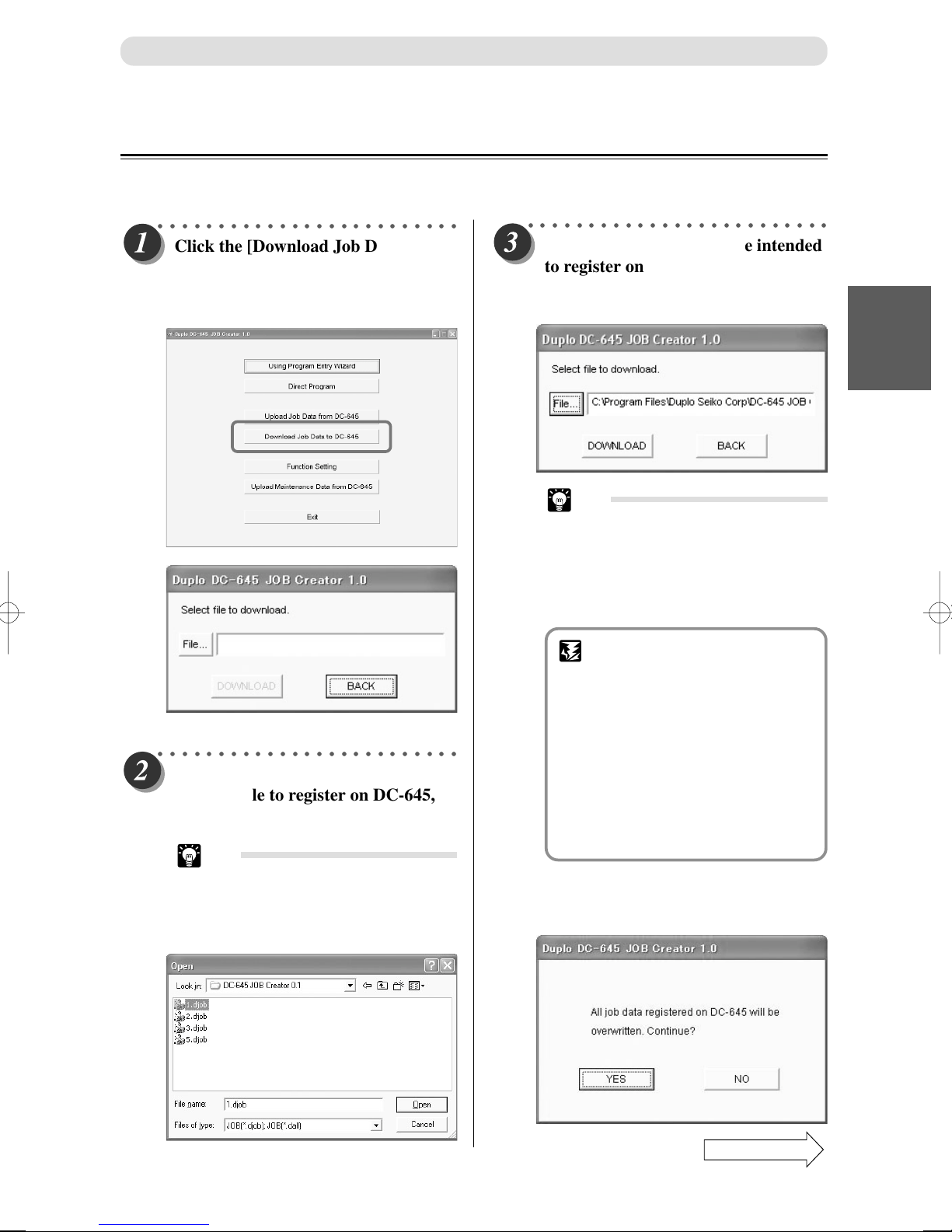

JOB Saved on Computer Registered On DC-645 (“Download Job Data to DC-645”)

This section describes the procedures to register on the DC-645 a JOB saved on the computer.

○○○○○○○○○○○○○○○○○○○○○○○○○

Click the [Download Job Data to DC645] button.

A display appears to select a JOB file

to send to the DC-645.

○○○○○○○○○○○○○○○○○○○○○○○○○

Click the [File...] button. Select and

click the file to register on DC-645,

then click the [Open] button.

Tip

• Extension of a file saved with ONE

JOB data: .djob

Extension of a file saved with ALL

JOB data: .dall

○○○○○○○○○○○○○○○○○○○○○○○○○

Check whether the JOB file intended

to register on the DC-645 is selected.

Then click the [DOWNLOAD]

button.

Tip

• When sending ONE JOB (with .djob

extension), if that JOB number

already exists in the DC-645

memory, then a display will appear

whether to overwrite the existing

JOB with this JOB.

IMPORTANT

• If the document file has a

extension, then the maximum

JOBs that can be registered on

the DC-645 are all saved.

When registering a file with a

“.dall”

extension on the DC-645,

all JOBs registered on the DC-645

at that time will be overwritten.

A display will appear to check

whether to overwrite all JOBs

when sending the data.

Confirm whether it is okay to overwrite the data

and if so click the [YES] button and send the

data.

“.dall”

1

2

Program JOB for DC-645 Via Computer (JOB Creator)

Continue Page

•••

47

Page 49

JOB Creator Settings

○○○○○○○○○○○○○○○○○○○○○○○○○

A display indicating that the JOB

was successfully transmitted appears.

Click the [OK] button to quit.

○○○○○○○○○○○○○○○○○○○○○○○○○

(To register only ONE JOB)

When testing the JOB sent

(processing one), a confirmation

screen will appear. To run the test, set

the document on the DC-645 then

click [TEST]. If a test is not intended,

then click [NO].

48

Page 50

JOB Creator Settings

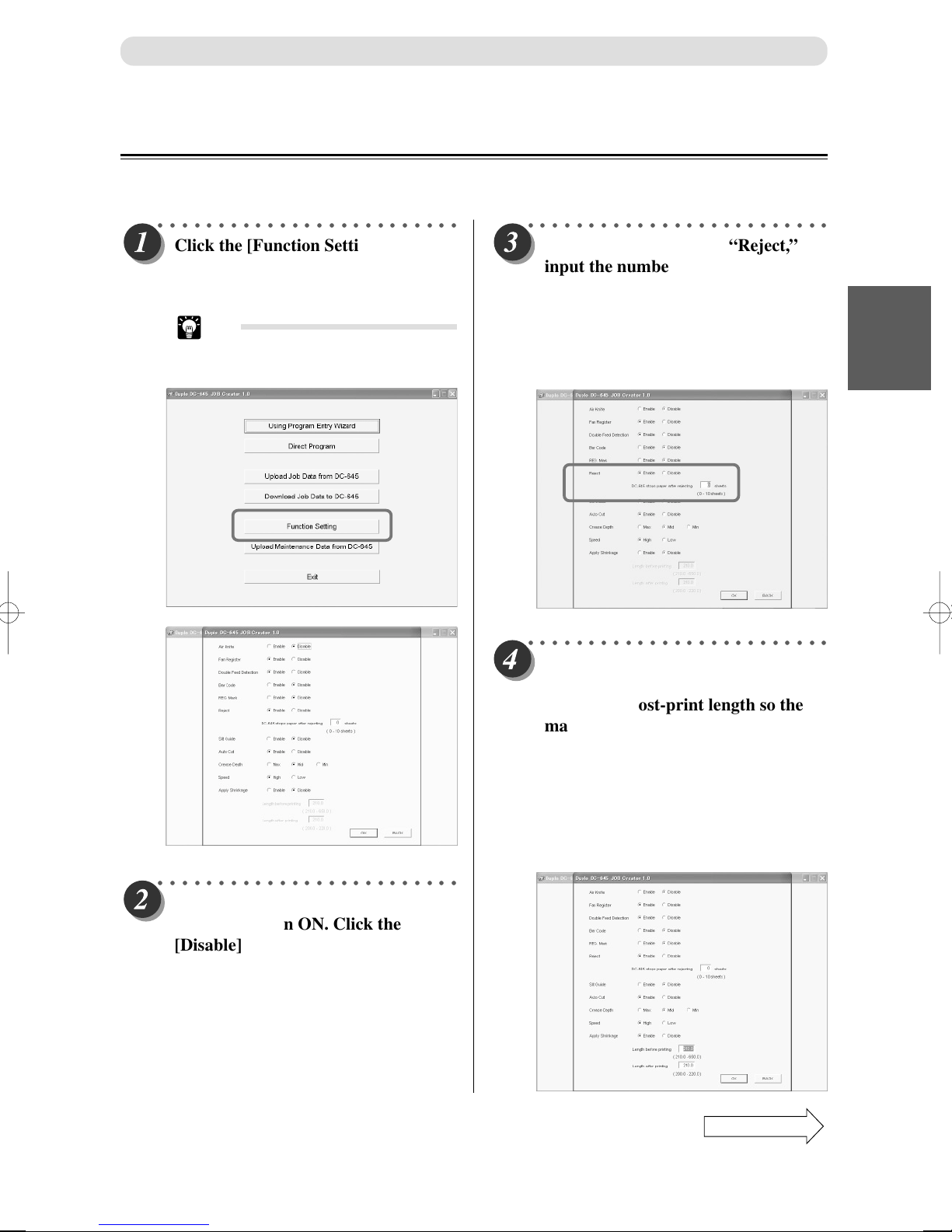

Setting Frequent Functions From Computer (“Function Setting”)

This describes the procedures to turn ON/OFF the barcode function, REG. Mark function and other functions.

○○○○○○○○○○○○○○○○○○○○○○○○○

Click the [Function Setting] button.

The display to turn ON/OFF the

function appears.

Tip

• The current DC-645 settings will

appear at this time.

○○○○○○○○○○○○○○○○○○○○○○○○○

Click the [Enable] radio button for

function to turn ON. Click the

[Disable] radio button for functions

to turn OFF.

○○○○○○○○○○○○○○○○○○○○○○○○○

If you set to [Enable] on “Reject,”

input the number of rejected

documents to stop the JOB.

Input “0” or click the [Disable] radio

button if DC-645 is not to be stopped

regardless of number of rejected

documents.

○○○○○○○○○○○○○○○○○○○○○○○○○

If you set to [Enable] on “Apply

Shrinkage,” input the pri-print

length and post-print length so the

machine can automatically calculate

the shrinkage rate and improve the

JOB processing precision.

Use the <Number> key to first input

the document length before printing.

Next, input the length of the

document after printing.

1

2

Program JOB for DC-645 Via Computer (JOB Creator)

Continue Page

•••

49

Page 51

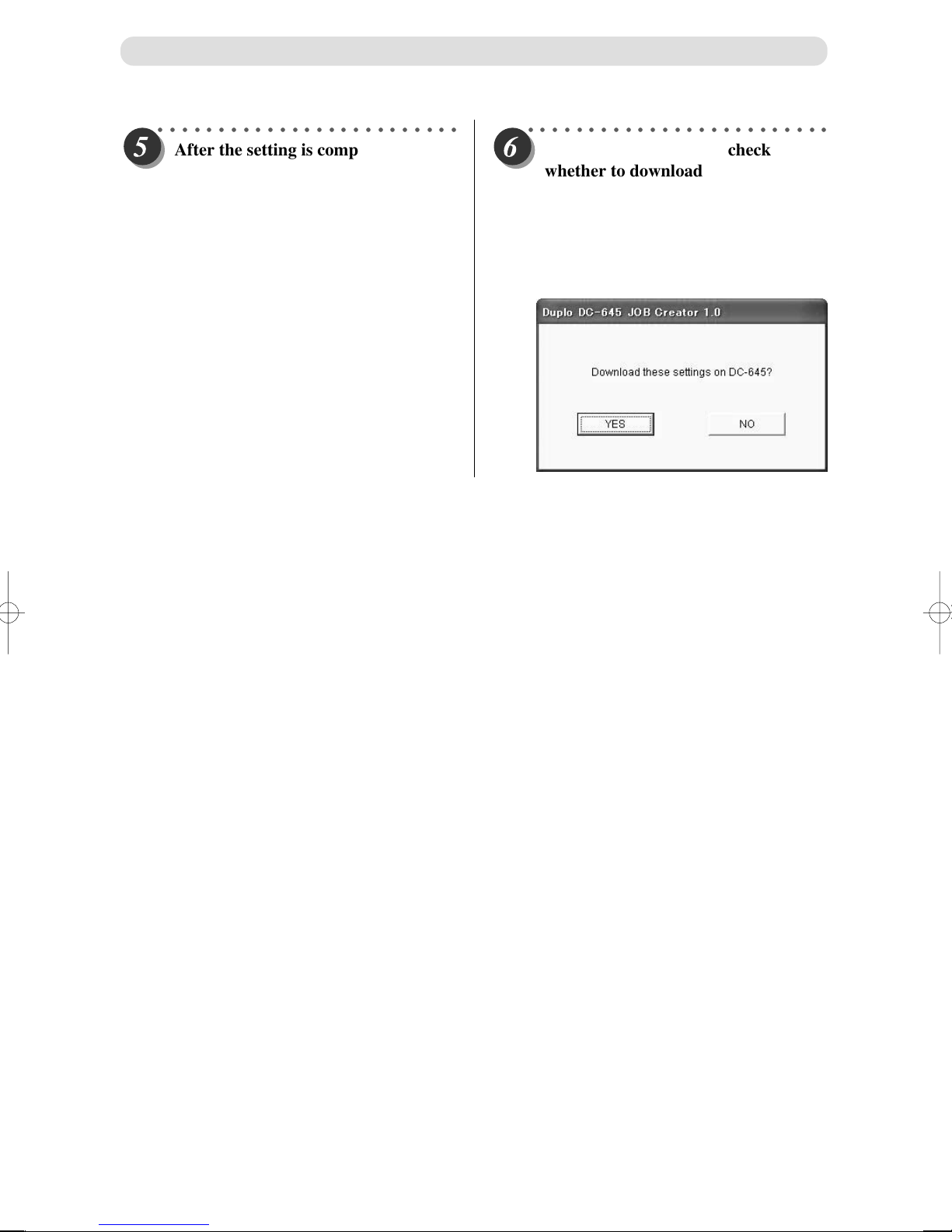

JOB Creator Settings

○○○○○○○○○○○○○○○○○○○○○○○○○

After the setting is completed, click

the [OK] button.

○○○○○○○○○○○○○○○○○○○○○○○○○

A display will appear to check

whether to download the Function

Setting Displayed contents on the

DC-645.

If it is okay, then click [OK].

If it is not okay, then click [NO]. The screen

will return to the [Function Setting] display.

50

Page 52

JOB Creator Settings

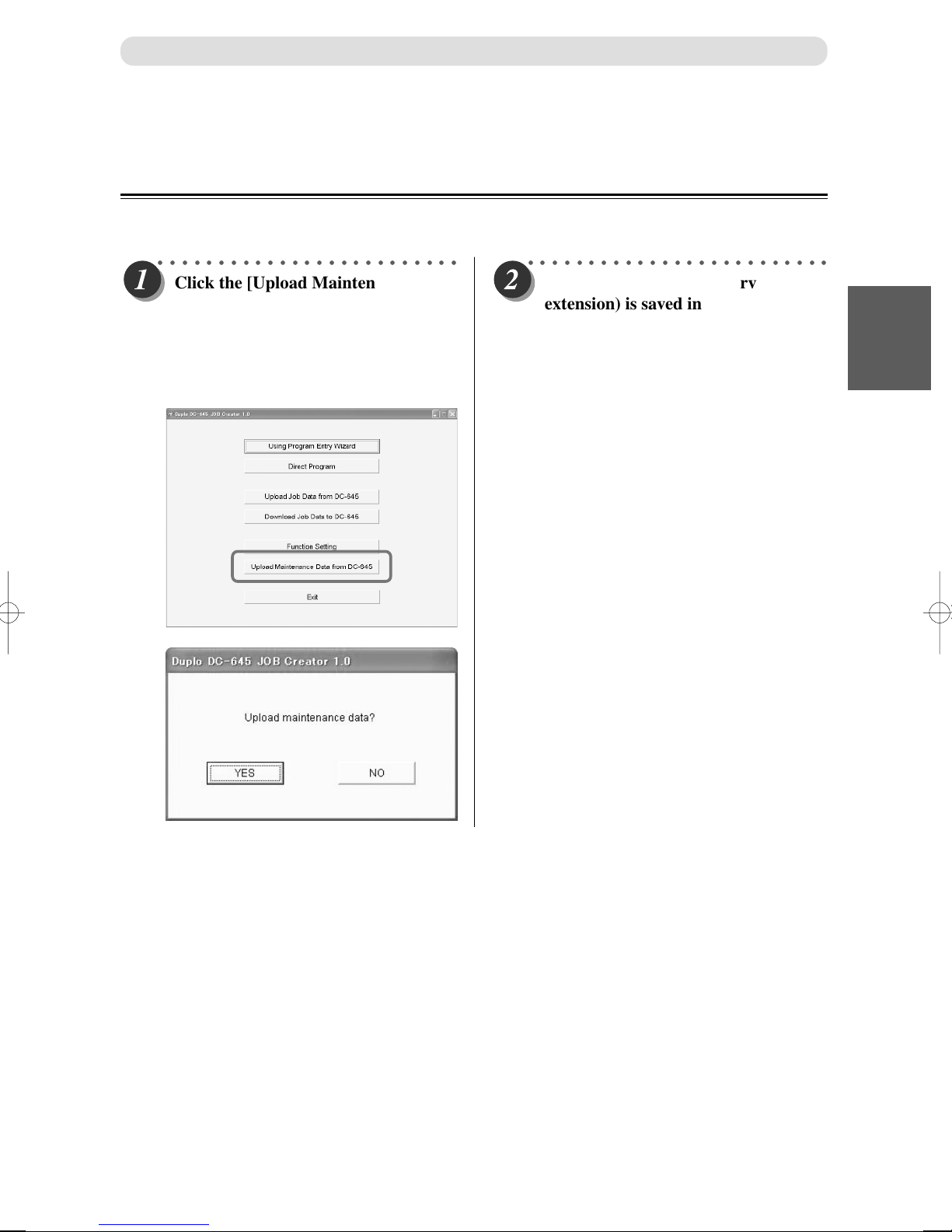

Create a File Recording the DC-645 Maintenance Information

(“Upload Maintenance Data from DC-645”)

This describes the procedures to create a file recording the DC-645 Maintenance Information.

○○○○○○○○○○○○○○○○○○○○○○○○○

Click the [Upload Maintenance Data

from DC-645] button.

A display appears to confirm

whether to start reading the DC-645

Maintenance Information.

Click the [YES] button.

○○○○○○○○○○○○○○○○○○○○○○○○○

The Maintenance File (.dsrv

extension) is saved in the same

direction as the DC-645 application

software.

1

2

Program JOB for DC-645 Via Computer (JOB Creator)

51

Page 53

List of Messages

Message

Cannot enter Gutter Slits.

Cannot enter Gutter Cuts.

The above job name is invalid.

Communication Error (001) – (***)

Countermeasure

Cannot input gutter slit since the number of page layout in the horizontal-

direction is either 1 or more than 4.

Cannot input gutter cut since the number of page layout in the vertical-

direction is 1.

The JOB name contains a character that cannot be used.

The JOB Creator cannot recognize the DC-645.

Check the following.

1. Is the USB cable securely connecting the computer and DC-645?

(a P.18 “How to Connect the DC-645 to your Computer”)

2. Is the DC-645 turned ON?

3. (Macintosh OS9): Is the USB driver copied in the [Extensions] folder in

the [System] folder? Check to see if its use has been turned OFF?

(a P.32 “Installing Procedures” (Macintosh)].

4. (Macintosh OSX): Is a Classic environment launched?

5. (Windows): Is [USB DC-645 Ver*.*] registered as a USB controller in

the [Device Manager] dialog?

(a P.30 “Installing Procedures (Windows)”)

6. Is the USB cable shorter than 3 meters?

Communication Error (002) – (003)

Communication Error (004)

File I/O ERROR

Communication Error occurred.

1. Restart the DC-645 and computer.

2. Is the USB cable shorter than 3 meters?

Communication error occurred with DC-645 while the DC-645 and the

computer was communication, showing a “Busy / Error / Jam Warming”.

Check the LCD panel for the Error display. Correct the Error, JAM and/or

Warning according to the procedures described in “Error Display” (P.80),

“Warming Display” (P.82), and “When a Paper Jam Has Occurred” (P.83 –

99).

Retry communications after that.

(Windows) Illegal file path. Check the correct file path.

52

Page 54

Message Countermeasure

DC-645 is busy.

ERROR on DC-645

List of Message

The DC-645 is in operation.

1. Either wait for the JOB to quit or press the <STOP> key on the DC-

645 to abort the JOB.

2. DC-645 is not ready to operate.

End the function setting, input, and JOB select mode, and go to the

Operation Mode (regular state).

3. An error has occurred with the DC-645.

Check the message displayed on the LCD panel and correct the error

according to the Troubleshooting Instructions described in this

Instruction Manual.

(a P.78 “OK Monitor Display and Jam Display”)

(a P.80 “Error Display”)

(a P.82 “Warning Display”)

Error is detected on DC-645.

Check the LCD panel for the Error display. Correct the Error, JAM and/or

Warning according to the procedures described in “Error Display” (P.80),

“Warming Display” (P.82), and “When a Paper Jam Has Occurred” (P.83 –

99).

1

2

Program JOB for DC-645 Via Computer (JOB Creator)

Load Paper

Install the Slitter Module.

Install the Standard Module.

Install the Business Card Module.

There is no document set in the 645 feed tray.

Install the Slitter Module on DC-645.

Install the Standard Module on DC-645.

Install the Business Card Module on DC-645.

Iftheproblemisnotsolvedwiththeaboveremedies,contacttheservicepersonnel.

53

Page 55

Chapter 3

Programing JOB for DC-645 on Control Panel

DC-645 can save 80 patterns of JOBs. Job contents can be programmed either via computer or on the

control panel. This chapter describes how to program a JOB on control panel of DC-645. Following items

should be entered to program a JOB.

Prior to Programming a Job

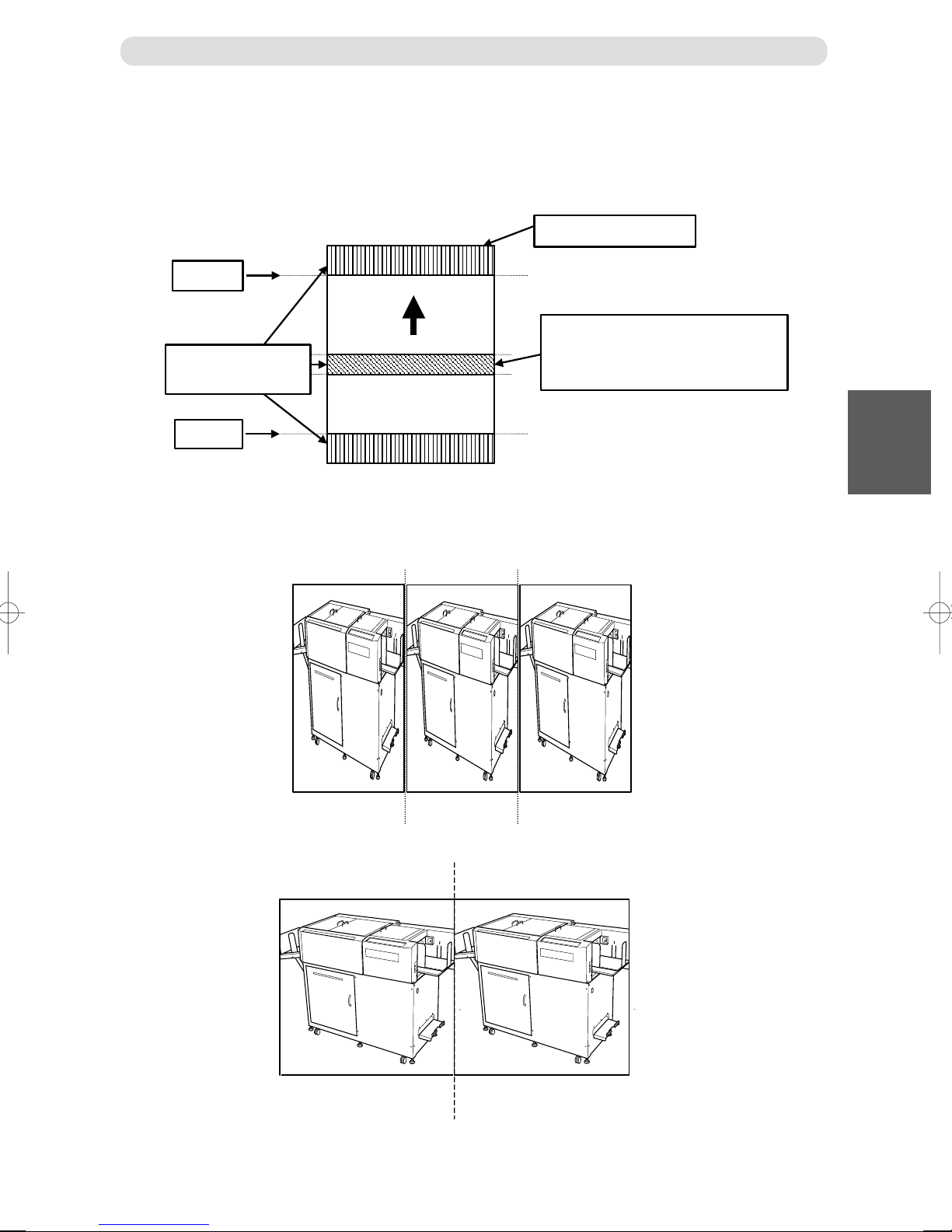

Before programming a job carefully measure, in

mm, the required slits, cuts and creases. See the

Figure 1 for reference and Figure 2 for a

detailed description of each function.

Familiarize yourself with the following illustrations and instructions to make the programming process easy and trouble free.

IMPORTANT NOTE

There are a total of six slitters. Two slitters are

for the margins and the remaining four slitters

are for the center of the document.

There is a guillotine cutter that performs cuts

perpendicular to the paper feeding direction.

DC-645 can cut up to 15 cuts on 1 document.

There is a creaser that performs creases

perpendicular to the paper feeding direction.

DC-645 can crease up to 10 creasing on 1

document.

Program

Number

01? (01––80

OK?––>SET

Figure 1

PAPER FEEDING DIRECTION

Cut

Barcode

(Optional)

Figure 2

)

REG. Mark

(Optional)

Crease

Slit

Tip

• Record the contents of each job in “Customer

Programmed Jobs” list for your easy reference.

54

Page 56

Definition of Programming Terms

AUTO CUT

Paper area before first cut and after last cut, and area between 2 cuts which is 20 – 84.99 mm long, are considered to be

waste and will be chopped up for disposal in waste box when AUTO CUT is enabled.

Leading edge of the paper

First Cut

When the distance between two cuts

arre 20 – 84.99 mm long, they will be

Area where automatic

cutting can be done

Last Cut

When documents do not have lead or trail margin, (as in the example 1 and 2 below), make certain to turn OFF the

AUTO CUT feature.

chopped up for smooth disposal into the

waste box.

1

3

Programing JOB for DC-645 on Control Panel

Example 1 - When AUTO CUT must be OFF

Example 2 - When AUTO CUT must be OFF

55

Page 57

Customer Programmed Jobs

ALL DIMENSIONS MUST BE IN MILLIMETERS

JOB Name

JOB No.

TOTAL LENGTH

PAPER WIDTH

OPTION

Side Mark

Lead Mark

SLIT1

SLIT2

SLIT3

SLIT4

SLIT5

SLIT6

CUT1

CUT2*

CUT3*

CUT4*

CUT5*

CUT6*

CUT7*

CUT8*

CUT9*

CUT10*

CUT11*

CUT12*

CUT13*

CUT14*

CUT15*

CRE.01*

CRE.02*

CRE.03*

CRE.04*

CRE.05*

CRE.06*

CRE.07*

CRE.08*

CRE.09*

CRE.10*

OPTION1

OPTION2

AIR KNIFE

FAN REG.

REG. MARK

SLIT GUIDE

AUTO CUT

CREASE DEPTH

SPEED

THERE IS A MAXIMUM OF 15 CUTS AND 10 CREASES

CONVERSION TABLE

Inches Millimeters

1.0 225.4

8.5 215.9

CONVERSION TABLE

Inches Millimeters

11 279.4

17 431.8

56

Page 58

How to Program Job on Control Panel

Optional module ............................ Select an optional module for the job when necessary.

JOB number................................... Select a JOB no. in which the JOB currently being

programmed is saved.

JOB name ....................................... Put a name to the JOB with number keys for easy

reference.

Paper length ................................... length of document

Paper width .................................... width of document

REG MARK position .................... When using REG. mark reading:

The distance between lead edge and leadmark, and the

distance between right edge and side mark.

Slit positions ................................... Distances between right edge and each slit position.

DC-645 can slit up to 6 positions on 1 document.

Cut positions .................................. Distances between lead edge and each cut positions.

DC-645 can cut up to 15 positions on 1 document.

Crease position............................... Distances between lead edge and each crease positions.

DC-645 can crease up to 10 creases on 1 document.

Option positions ............................. Distances between right edge and each option positions.

AIR KNIFE .................................... Compressed air is blown out to loosen the document.

This is to prevent double-feed.

FAN REGISTER ........................... Document skewing in feeding area is corrected. When

processing light weight document, turn this function

OFF as it may cause a paper jam in feed area.

1

3

Programing JOB for DC-645 on Control Panel

SLIT GUIDE .................................. When any slitters are not used, these slitters act as

AUTO CUT .................................... Lead margin, trail margin, and any gutter cuts (shorter

CREASE DEPTH .......................... This sets the depth of the crease when creasing a

SPEED ............................................ This is used to select HIGH/LOW processing speed.

paper guide to stabilize the paper conveyance.

Recommended for light weight document.

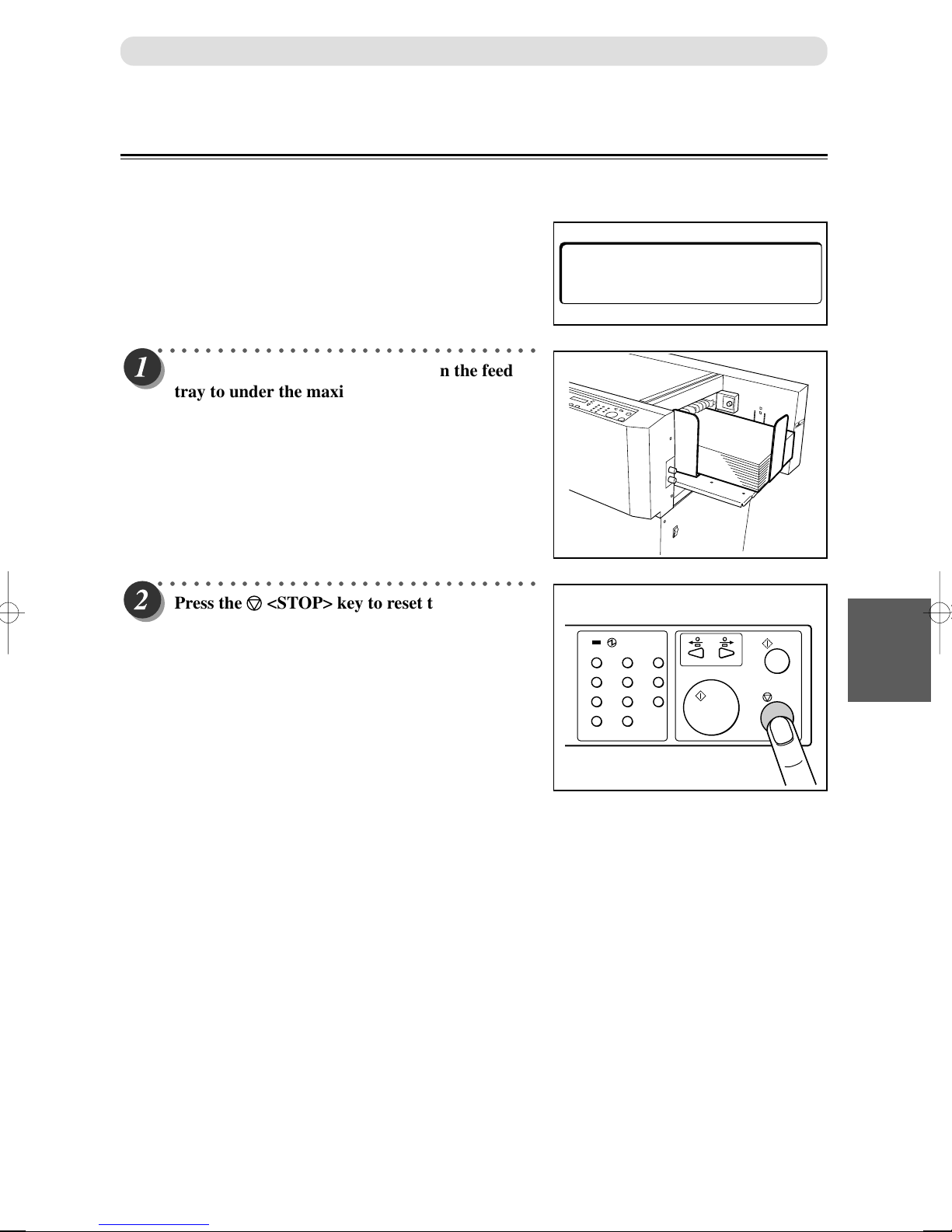

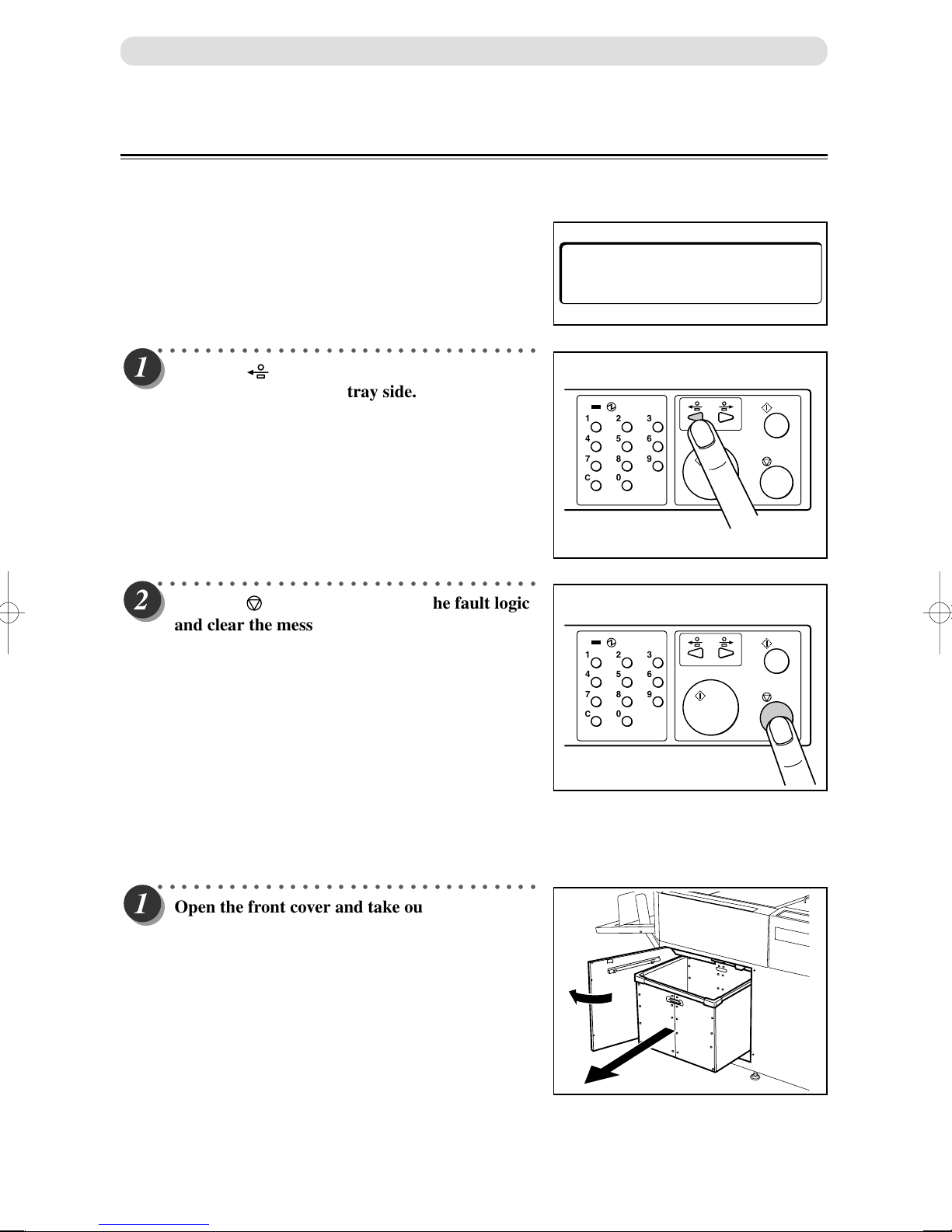

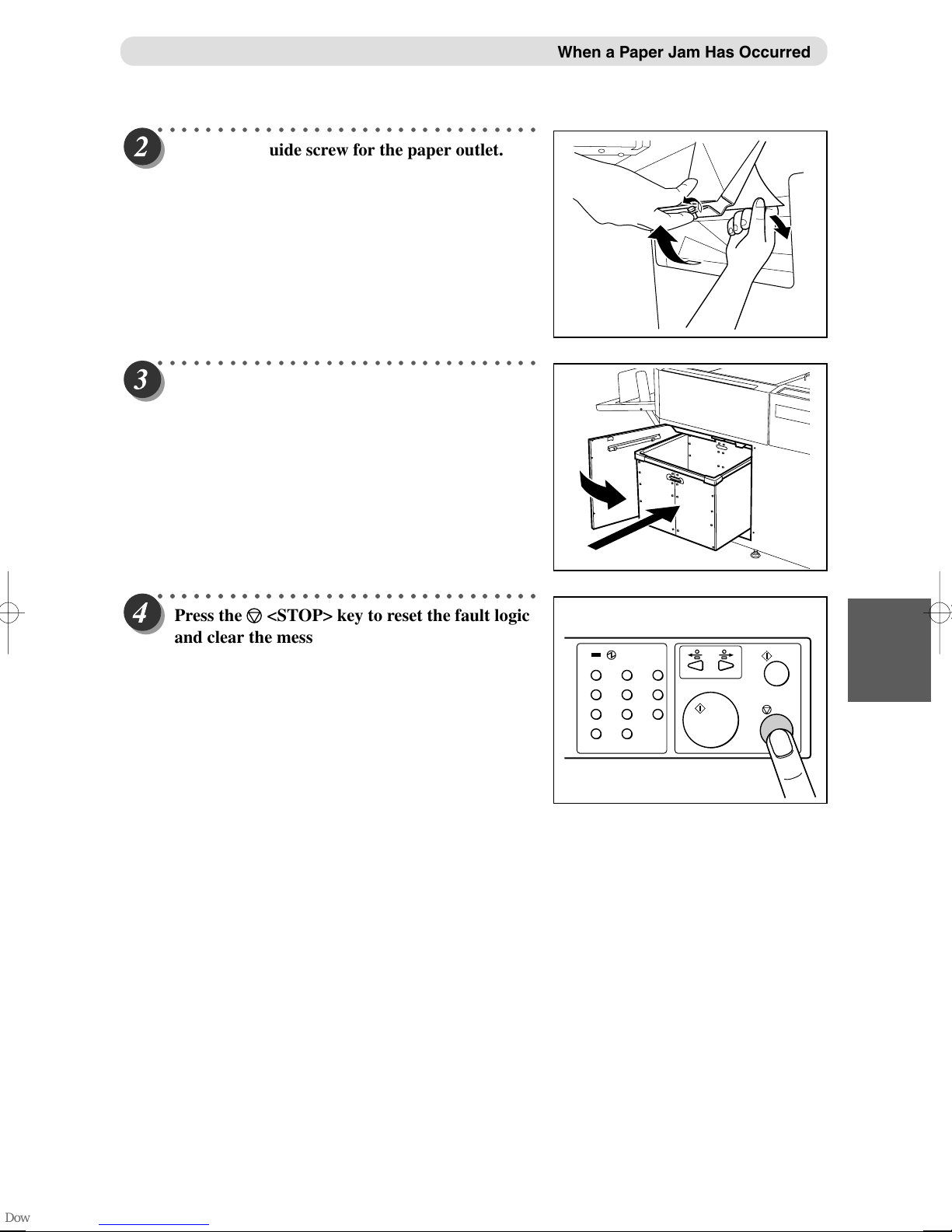

than 85mm) are finely cut and dropped into the waste