Page 1

SLITTER / CUTTER / CREASER

DC-616

Apr. 2014 Revision 0

DUPLO DC-616 S2-Y1540

Page 2

Page 3

Introduction

The cause of most accidents is failure to adhere to basic safety rules and observe

safety instructions. It is important to prevent potential causes of accidents from

occurring. In order to do so, read this manual carefully, and be sure to understand

all the safety instructions and correct inspection and servicing procedures that it

provides before beginning repair or servicing work.

Repairing or servicing the machine with insuffi cient knowledge about it could lead

to unforeseen accidents.

It is not possible to anticipate and describe in a manual such as this every possible

hazard that could arise in the course of repair and servicing. Therefore, besides

observing the safety instructions marked in this manual and on the machine’s

labels,

as necessary. When performing repair or service work not covered by this manual,

you should obtain safety guidance from an appropriately knowledgeable person.

Trademarks

• Microsoft, Windows, Windows NT, and Windows Vista are either registered trademarks or

trademarks of Microsoft Corporation in the United States and/or other countries.

All other company names and product names shown in this manual are trademarks or

registered trademarks of their respective companies.

service person should be safety-conscious and take other safety precautions

PLEASE NOTE

In the interests of upgrading our product, specifi cations and other data given in this manual are

subject to change without notice.

If the manual contains anything that you do not understand, contact the dealer for clarifi cation.

S2-Y1540

-0

1

Page 4

■ How to Use This Service Manual

• This service manual includes the structural and functional descriptions for the major areas

of DC-616, along with the descriptions of procedures for disassembly and assembly, design

standard and adjustment, maintenance and service requirements, and actions to be taken

in the case of malfunctions. These are the information as of April, 2014. The parts and

components used are subject to change for the quality and performance improvements, or

for safety reasons. In such cases, please note that certain part of the descriptions and/or

illustrations contained in this manual may differ from the actual product.

• The marking listed below accompanied by indicates the instruction of particular

importance for safety reasons. Never fail to comply with them.

●Safety instructions

WARNING

CAUTION

[Examples of Pictorial Symbols]

Indicates a high degree of potential danger. Failure to heed the warning

may lead to death or serious injury.

Indicates a medium degree of potential danger. Failure to heed the

caution may lead to injury or damage to property.

Δ symbol is to note that the instruction calls for close attention (including

danger and warning).

Specifi c hazard to be careful about is indicated in the drawing (e.g.

warning for electric shock in the case of illustration on the left).

A circle with a line through it indicates a prohibited action.

The particular act prohibited is indicated by a picture inside the circle.

(In the example shown here, the prohibited act is disassembly.)

● A black disc indicates an instruction, or sometimes a prohibited action.

The instruction itself is indicated by pictorial symbols drawn in white on

the disc. (In the example shown here, the instruction is “Remove the

plug from the outlet”.)

●For maintenance operation

IMPORTANT :

REFERENCE

S2-Y1540

2

-0

Introduces instructions for correct operation of the machine.

If these instructions are ignored, the machine may not be able to

operate at optimum performance or may break down.

Introduces information that is useful for operation and maintenance of

the machine, or information about the machine’s performance, etc.

Page 5

Safety Instructions

1. Cautions regarding the installation location

CAUTION

Installation environment

● Avoid installing the machine in places exposed to direct sunlight.

• Sunlight will cause the temperature in the machine’s interior to rise, possibly leading to

malfunction of the control system.

• Sunlight could cause misoperation of the sensors.

• The heat of direct sunlight could cause deformation of the machine’s plastic parts.

* Also avoid installation near to a ground glass window; light and heat penetrate such windows

although they are opaque.

Avoid installing the machine in places subject to high or low temperature or humidity.

●

• High or low temperature or humidity could cause the machine to operate abnormally.

Suitable temperature and humidity ranges are:

Ambient temperature : 10°C–30°C

Ambient humidity : 40%–70%

Optimum temperature and humidity : 20°C, 65%

If the machine is installed near to faucets, water heaters or humidifi ers, or in cool (sunless)

•

of a building or in the vicinity of water sources, the paper could absorb moisture and curl,

parts

leading

●

● Avoid installing the machine in poorly ventilated places.

● Avoid installing the machine in dusty places.

● The machine should not be tilting when it is used.

Install the machine so that it is level. (The machine should be level to within 5 mm in the front-rear

•

direction, and 5 mm in the lateral direction.)

● Do not install the machine on shaky, sloping or otherwise unstable surfaces.

• The machine could fall over on such surfaces, or fall off them, causing injury.

to misfeeds.

Avoid installing the machine in places with open fl ames, or where refl ected heat or other

hot air currents (from stoves, etc), or cold air currents from coolers, etc will strike

it directly.

S2-Y1540

-0

3

Page 6

2. Cautions for installation work

WARNING

● The machine’s power supply voltage and power consumption are given in the table

below. The machine's power supply voltage is indicated on the identifi cation plate on

machine; the machine must be connected to a power supply of the voltage indicated.

→ Otherwise, fi re or electric shock could result.

If the power supply voltage is unstable or if the power supply has insuffi cient capacity, the

machine may not operate normally. Make sure that the power supply has suffi cient capacity

for the system as whole, including optional equipment.

Power supply

Power consumption

Standby energy

● Use only the power cord that is provided with the accessories. Insert the power cord

plug fi rmly into the socket, so that proper electrical contact is made. Use of any other

power cord could result in imperfect grounding. If grounding is imperfect and

electrical leakage occurs, fi re or electric shock could result.

Install the machine close to its power supply. The outlet used should be exclusively for

●

the machine, and have no other equipment connected to it.

If an extension cord is necessary, it should have a ground terminal, and be of the following

ratings;

• For a 120 VAC model: 130 V, at least 15 A, length not exceeding 5 m

• For a 230 VAC model: 250 V, at least 8 A, length not exceeding 5 m

● Never tread on the power cord or pinch it between other objects, or accidents could

result.

115 VAC ±10%, 60Hz 230 VAC ±10%, 50/60 Hz

1.5 A,190 W 0.7 A,190 W

0.25 A, 26 W 0.22 A,26 W

CAUTION

● Install the machine in accordance with the Installation Manual supplied.

● Lock the casters after the machine is installed.

→ Otherwise, the machine could move or fall over, causing injury.

4

S2-Y1540

-0

Page 7

3. Cautions for maintenance, inspection and servicing

WARNING

● Always remove the power cord plug from the outlet before starting work.

→ Otherwise, your hands/fi ngers could get damaged beside electrical shock.

• However, the plug must be left connected to the outlet when performing function checks

individual motors, a given series of operations, or electrical circuits). When motors are

(of

operated

conditions and positions

or fi ngers into moving parts.

● The cutter unit, slitter unit, and perforation unit contain sharp tools (blades) which may

cause danger. Exercise great care when inspecting these units or replacing them or

their parts.

→ Otherwise, your hands/fi ngers could get caught and injured.

● Do not put your hands or fi ngers inside the machine while it is operating and while

you are pressing the JOG key.

→ Otherwise, your hands/fi ngers could get caught and injured.

In addition, when you remove paper clogged up or work on the machine, be very careful not

to roll up a tie and/or a necklace by the machine.

● Working clothes

• Wear clothing that enables you to work safely.

Work clothing should be close-fi tting.

alone in function checks, interlocks are deactivated, so be aware of the

of related equipment, and take great care not to put your hands

CAUTION

● Tools

• Use tools that are appropriate for the work.

S2-Y1540

-0

5

Page 8

■ Warning Labels

No. Part No. Name Q'ty

L1-T108*

1

L1-T111* (EU)

2

S2-T105* WARNING LABEL

M7-T303*

3

M7-T307* (EU)

4

S2-T115* WARNING LABEL

WARNING LABEL

WARNING LABEL

2

6

2

2

6

S2-Y1540

-0

Page 9

5

No. Part No. Name Q'ty

5

R7-T115* WARNING LABEL

1

S2-Y1540

-0

7

Page 10

No. Part No. Name Q'ty

L8-T109*

6

L8-T112* (EU)

WARNING LABEL

1

8

S2-Y1540

-0

Page 11

Introduction

Operation in General

Mechanism

Adjustment

Maintenance Checks

1

2

3

4

5

Troubleshooting

HELP Mode

Others

PC Controller

6

7

8

9

10

Page 12

Contents

Contents

Introduction

■ How to Use This Service Manual

Safety Instructions

■ Warning Labels

Chapter 1

1 Specifi cations

2 Part Names and Their Functions

3 Dimensions

Chapter 2

1 Paper Feed Section

2 Double Feed Detection Section (Option)

3 CCD Section

4 Margin Slitter Section

5 Center Slitter Section

6 Cutter Section

7 Creaser Section

8 Main Drive Section

9 Exit Tray

10

Exterior

11

Barcode

12

REG Mark

Chapter 3

1 Exterior of the Machine

2 Paper Feed Section

3 Double Feed Detection Section (Option)

4 CCD Section (Option)

5 Margin Slitter Section

6 Center Slitter Section

7 Cutter Section

8 Creaser Section

9 Main Drive Section

10

Electrical System Section

..........................................

.............

..............................

..................................

Introduction

....................................

.............

......................................

Operation in General

............................

.....................................

..........................

..........................

...................................

.................................

.............................

..........................................

..........................................

..........................................

.......................................

Mechanism

........................

............................

..........................

..........................

..........................

...................................

.................................

.............................

....................

...

...

12

14

20

22

26

27

28

30

33

35

39

40

41

43

46

51

56

67

68

70

76

83

85

90

96

1

2

3

6

Chapter 5

1 Guaranteeing Maintenance Cycle

2 Cleaning and Oiling

3 Periodic Maintenance Check List

4 Recommended Parts List

Chapter 6

1 Troubleshooting

2 Conditions for the Error Detection

3

Major Cause and Preventive Action for the Paper Jam

4 Slitter Blade Intersection Correction

Chapter 7

1 HELP Mode List

2 Accessing the HELP Mode

3 Finishing the HELP Mode

4 Setting the Other HELP Mode No.

5 Accessing the Service Person JOB

6 HELP Mode Description

Chapter 8

1

Position and Function of Electronic Parts

2 Service Person JOBs

3 Overall Wiring Layout

Chapter 9

1 Main Menu of PC Controller

2 Maintenance Menu

3 Data Folder

4 Maintenance

5 Confi rming the Version

Maintenance Checks

...........................

Troubleshooting

................................

HELP Mode

...............................

Others

........................

........................

PC Controller

...........................

....................................

...................................

..........

...........

....................

.........

.......

..................

...................

.........

.......

.....................

..

................

.......................

110

110

111

112

116

122

.

124

125

128

129

129

129

129

130

168

178

182

186

188

191

192

202

Chapter 4

1 Exterior of the Machine

2 Paper Feed Section

3 CCD Section

4 Margin Slitter Section

5 Center Slitter Section

6 Cutter Section

7 Creaser Section

8 Main Drive Section

10

Adjustment

W5-Y1030

..........................

...................................

........................

........................

.................................

...............................

...........................

-0

......................

100

101

102

103

104

105

106

108

Page 13

1

Chapter 1

Introduction

1 Specifi cations

2 Part Names and Their Functions

1. Appearance

2. Ejection Side

3. Appearance (Ejection side)

4. Inside

5. Control Panel

6. LCD Panel

3 Dimensions

..................................

.................................

................................

........................................

...............................

..................................

.....................................

...........

..............

12

14

14

15

16

17

18

19

20

Page 14

Chapter 1 1 Specifi cations

1 Specifi cations

Model name DC-616

Product type Slitter/Cutter/Creaser Floor stand model

Feeding method Belt suction

Infeed document size Width: 210–320 mm

Length: 210–670 mm*

* The standard feed tray takes up to 460 mm. For longer sheet, the

optional long paper tray is available.

Minimum fi nishing size Width: 48 mm (1.89 in)

Length: 50 mm (1.97 in)*

The distance between the lead edge of the last card and the trail edge

of the parent sheet should be 67 mm or more.

Document type Uncoated, coated, laminated*

* Laminated document is not included in the specifi cations of the

perforation unit.)

Document weight 110 gsm–350 gsm

Paper curl Within 5 mm

Feeder capacity 100 mm

Speed 10 ppm (A4 SEF, 2 cuts, 1 crease)

Number of slits Max 6 slits per document (2 margin slitters and 4 center slitters)

Margin slit spec 3.2–55.0 mm from document side edges

Gutter slit width 5.0–15.0 mm

Gutter slits wider than above are exited onto the exit tray.

Gutter defl ector Max 2 gutter slits can be defl ected.

Number of cuts

Cut position spec Lead edge: min. 3.0 mm

Number of creases Max 20 per document

Crease depth adjustment 3 steps (from control panel)

Tolerance +/-0.3 mm from programmed positions

Stacker capacity 100 mm (with card stacker: 40 mm)

Control panel 64×128 dots LCD

LCD languages Japanese, English, French, German, Italian, Spanish, Polish, Russian

Software update DDL-01, DDL-02

Perforation unit Operator replaceable unit

Perforation position Minimum distance from the card side edge: 5 mm

Perforation tool spec Cut: 0.84 mm Tie: 0.84 mm

Max 25 per document

Gutter cut: min. 3.0 mm

Trail edge: min. 5.0 mm

(+/-0.4 mm with business cards)

When creasing, it may fl uctuate depending on the number of creases

and their depths.

Max 2 perforations parallel to the feeding direction

Manual positioning

Minimum distance between 2 perforations: 48 mm

12

S2-Y1540

-0

Page 15

Chapter 1 1 Specifi cations

Model name DC-616

Functions 80 job memory

Test feed

Skew adjustment

Slitter guide

Auto cut

Apply shrinkage

Adjust all

Cleaning mode

Automatic job setup by reading barcode (CCD is optional on “115V”

and “230V Asia Oceania” models.)

Image shift compensation by reading REG mark (CCD is optional on

“115V” and “230V Asia Oceania” models.)

Options Air knife (optional on “230V Asia Oceania” model)

Double feed detection (optional on “115V” and “230V Asia Oceania”

models)

CCD (standard on “115V PRO” and “230V EMEA” models)

Card stacker (optional on “230V Asia Oceania” model)

Perforation unit (optional on “115V” and “230V Asia Oceania” models)

Long paper tray

PC am mount (standard on “115V PRO” model)

PC controller software (standard on “115V PRO” model)

USB (B TYPE CONNECTOR)

Compatible OS:

Windows XP Professional/Home edition (x86 32bit only)

Windows Vista Ultimate/Business/Home basic/Home premium

Windows 7 Ultimate/Professional/Home premium

Windows 8 Professional/Enterprise

Power supply 115 VAC, 60 Hz 230 VAC, 50/60 Hz

Power consumption 115 V: current consumption 1.5 A (standby: 0.25 A)

power consumption 190 W (standby: 26 W)

230 V: current consumption 0.7 A (standby: 0.22 A)

power consumption 190 W (standby: 26 W)

Dimensions In use: 1610 (W) × 625 (D) × 1060 (H) mm

In use with max paper: 2025 (W) × 625 (D) × 1060 (H) mm

Stored: 975 (W) × 625 (D) × 1060 (H) mm

Packed: 1140 (W) × 770 (D) × 1360 (H) mm

Machine weight 115 V: 145 kg (Gross weight: 178 kg)

115 V PRO: 155 kg (Gross weight: 188 kg)

230 V EMEA: 150 kg (Gross weight: 183 kg)

230 V Asia Oceania: 140 kg (Gross weight: 173 kg)

Operating temperature 10–30 degrees (Celsius) (50-80 degrees (F))

Operating humidity 40%–70% RH (No condensation)

Storing temperature 5–35 degrees (Celsius)

Storing humidity 20%–70% RH (No condensation, No exposure to salt)

Operating altitude Max 1000 m ALT

Safety standard UL, CE, VCCI

1

The specifi cations are subject to change without prior notice.

Paper Curl

Due to the automated slitter function, the paper path of the DC-616 is sensitive to paper curl.

If paper curl is causing paper jams, the following are suggestions for remedying the problem:

1. Adjust the printing devices de-curler (if available).

2. Manually de-curl the stock before loading in the fe tray.

3. Turn the paper over (reprogramming the job may be necessary).

4. Use different paper stock.

S2-Y1540

-0

13

Page 16

Chapter 1 2 Part Names and Their Functions

2 Part Names and Their Functions

1. Appearance

1

7

6

2

5

3

4

No. Name Function

1

Control panel Displays operations and status.

2 Exit tray Receives the fi nished products.

3 Waste box Receives pieces of waste paper.

4 Front cover Open this to remove the waste box.

5 Feed tray Original document is placed here.

6 Scale Measures the cut and slit position, and the fi nished product.

7

Top cover Open this to remove paper jam from inside of the machine.

14

S2-Y1540

-0

Page 17

2. Appearance (Feed Side)

1

2

Chapter 1 2 Part Names and Their Functions

1

4

3

No. Name Function

1 Airfl ow adjustment knob Adjusts airfl ow level.

2 Separator adjustment

knob

3 Skew adjustment knob Adjusts the document skew.

4 Level adjustment knob Adjusts the elevator height.

Adjusts the distance between the separator and conveyance

belt.

S2-Y1540

-0

15

Page 18

Chapter 1 2 Part Names and Their Functions

3. Appearance (Ejection side)

2

1

3

6

4

5

No. Name Function

1 Perforation unit Perforates parallel to the document feed direction.

2 Side guide Receives the processed documents.

3 Back guide Receives the processed documents.

4 USB terminal Used for the connection to your computer on PC Controller using.

5 AC inlet Connect the power cord here.

6 Power switch Press to switch the power on and off.

16

S2-Y1540

-0

Page 19

4. Inside

Chapter 1 2 Part Names and Their Functions

8

7

6

5

4

3

2

1

1

5

No. Name Function

1 Double feed detection

section

2 CCD section Reads out REG Mark/Barcode. (Option)

3 Slitter module 1,2 Cuts side margins parallel to the document feed direction

4 Slitter module 3,4

5 Slitter module 5,6

6 Gutter defl ector Drops the margin cut off by the slitters into the waste box.

7 Cutter module Cuts perpendicularly to the document feed direction.

8 Creaser module Creases perpendicularly to the document feed direction.

Detects double feed by the ultrasonic sensor. (Option)

Cuts parallel to the document feed direction

4

3

.

.

S2-Y1540

-0

17

Page 20

Chapter 1 2 Part Names and Their Functions

5. Control Panel

1

32

No. Name Function

1 LCD panel

2 F key Switches to function selecting screen.

3 RETURN key Switches to the previous screen.

CURSOR (Left/

4

Right) key

CURSOR (Up/

5

Down) key

6 SET key Press to set selection/entry.

JOG (Forward/

7

Backward) key

8 TEST key

9 START key

10 STOP key

4

5

Displays the status of the machine.

Displays the message when an error or paper jam occurs.

Press to move the cursor to the left or right.

Press to the cursor in a lower or an upper direction.

Press to eject the document from the machine when paper jam

occurred.

One (sheet) document is processed to test to the current JOB

details. When the card stacker is installed, if you press and hold the

TEST key for guide adjustment, the processed document temporarily

stops. Then, when you press the START key or the TEST key, the

processed document is ejected.

Press to start processing documents. The START key light turns

green when when the machine is ready to process the document in

this machine. The machine is inactive when the light is red. In this

case, the machine may be running or having an error.

Press to return the current screen to the main screen or to stop

processing

6

7

9

8

10

1

1

3

No. Name Function

1 NUMERIC key Press to enter JOB/values during manual programming.

2 SET key Press to set selection/entry.

3 CLEAR key Press to clear the count. Press to cancel manual programming.

18

S2-Y1540

-0

2

Page 21

6. LCD Panel

Chapter 1 2 Part Names and Their Functions

● Standby screen

2

1

3

4

No. Name Function

1 JOB No. Displays the JOB number currently selected.

2 JOB Name Displays the JOB name currently selected.

3 Counter

Function setting

AC: Auto cut

REG: REG mark

4

BC: BARCODE

%

Displays the number of document sheets processed with the JOB

currently set.

AC is displayed when “Auto cut” is enabled.

REG is displayed when “REG mark reading” is enabled.

BC is displayed when “Barcode reading” is enabled.

% is displayed when “Apply shrinkage” is enabled.

is displayed when “Adjust all” is enabled.

1

is displayed when the PC Controller is online.

● “Select menu” screen

Select menu Select menu

1

2

3

No. Name Function

1 Retrieve JOB Retrieves saved JOB.

2 Enter JOB Enters and changes JOB.

3 Setting Changes functions of the machine.

4 Cleaning mode Retrieves Cleaning mode to clean conveyance belt / conveyance

5 Return Returns to standby screen.

Retrieve JOB

Enter JOB

Setting

roller.

3

Setting

4

Cleaning mode

5

Return

S2-Y1540

-0

19

Page 22

Chapter 1 3 Dimensions

3 Dimensions

Unit: mm

20

S2-Y1540

-0

Page 23

Chapter 2

Operation in General

2

1 Paper Feed Section

1. Description

2. Operation

3. Operation of Each Part

2 Double Feed Detection Section (Option)

1. Description

2. Operation

3. Operation of Each Part

3 CCD Section

1. Description

2. Operation

3. Operation of Each Part

4 Margin Slitter Section

1. Description

2. Operation

3. Slitter Blade

4. Operation of Each Part

5 Center Slitter Section

1. Description

2. Operation

3. Slitter Blade

4. Operation of Each Part

6 Cutter Section

1. Description

2. Operation

3. Operation of Each Part

7 Creaser Section

1. Description

2. Operation

3. Operation of Each Part

8 Main Drive Section

1. Description

9 Exit Tray

1. Description

10

Exterior

1. Description

2. Operation

3. Operation of Each Part

11

Barcode

1. Description

12

REG Mark

1. Description

....................................

....................................

...................................

....................................

....................................

....................................

....................................

....................................

.........................................

.........................................

....................................

........................................

.....................................

...........................

..................................

...................

..................................

...................

..................................

...................

.........................

..................................

.................................

...................

.........................

..................................

.................................

...................

..................................

..................................

...................

...............................

..................................

...................

............................

..................................

..................................

..................................

...................

..................................

..................................

22

22

22

22

..

26

26

26

26

27

27

27

27

28

28

28

28

28

30

30

30

30

30

33

33

33

33

35

35

35

36

39

39

40

40

41

41

41

41

43

43

46

46

Page 24

Chapter 2 1 Paper Feed Section

1 Paper Feed Section

1. Description

Paper feed section feeds the paper into the machine

after separating each sheet of paper by air knife.

This is done through the operation of the air suction

mechanism and the air blow duct mechanism.

2. Operation

Air blow duct mechanism blows the compressed

air to the paper from the front side to create some

gap between the papers. The separated paper is

transferred when the shutter solenoid and the feed

motor provided in the air suction mechanism are

turned ON.

3. Operation of Each Part

1. Level Sensor

<Operation>

• Detect the top of the paper on the feed tray

When the feed tray rises to the extent that the

actuator is lifted up by the paper, the sensor comes

to the “light blocked” state.

Once the topmost sheet of paper is detected, the

rising motion of the feed tray is stopped.

• Detect the low level of paper

The actuator comes down as the paper level gets

low until the sensor comes to the “light through”

state. Once the sensor comes to the “light through”

state, the feed tray rises until the sensor comes

to the “light blocked” state. “E02” (elevator error)

appears on the display if the topmost paper sensor

does not switch to the “light blocked” state within 10

seconds after the transmission of feed tray go-up

command.

22

S2-Y1540

-0

Page 25

<Circuit diagram>

Chapter 2 1 Paper Feed Section

Level sensor

Red Red

1

2

3

Yellow

Blue

6

7

8

Yellow

Blue

2. Elevator Upper Limit Switch

<Operation>

If the topmost sheet of paper cannot be detected, and

the feed tray continues to go up, the air suction unit

is pulled away from the elevator upper limit switch to

come to the “OFF” state.

The elevator upper limit switch stops the machine

operation immediately once it comes to the “OFF”

state.

CN2-10

11

12

Main PCB unit

5V

5V

2

Light not transmitted: 5V

Light transmitted: 0V

3. Elevator Motor

<Operation>

Elevator motor rotation lets the feed tray move up and

down.

<Circuit diagram>

Elevator upper limit switch

Brown

Brown

2

1

Elevator motor

BrownBrown

1

M

Black

2

Brown

Black

Drive PCB unit

CN5-2

1

S2-Y1540

-0

23

Page 26

Chapter 2 1 Paper Feed Section

4. Elevator Lower Switch

<Operation>

As the feed tray goes up, the angle is pulled away

from the elevator lower limit switch to come to the

“OFF” state. As the feed tray goes down to reach the

lower limit, the angle pushes the switch actuator to

trigger the “ON” state. “E02” (elevator error) appears

on the display if the angle does not push the elevator

lower limit switch actuator within 30 seconds after the

transmission of the feed tray go-down command.

<Circuit diagram>

Elevator lower switch

Purple

1

Purple

2

Purple

4

Purple

5

5. Perforation unit Sensor

<Operation>

Normally the feed tray goes up and down

automatically. However, it may be lowered by the

elevator down switch as required, including the case

of paper jam.

Main PCB unit

5V

CN3-19

02

ON : 0V

OFF : 5V

<Circuit diagram>

Elevator down switch

24

S2-Y1540

-0

Light green Light green

Light greenLight green

Main PCB unit

5V

CN2-25

26

ON : 0V

OFF : 5V

Page 27

6. Shutter Solenoid

<Operation>

The suction solenoid is turned ON as the level sensor

is turned ON and the paper feed is ready.

Then, the valve opens to suck up the paper.

The valve is closed by the timer after the transferred

paper passes through the PPS2.

<Circuit diagram>

Chapter 2 1 Paper Feed Section

2

Shutter solenoid

Red

1

Yellow

2

Red

Yellow

7. PPS1

<Operation>

While the light goes through at PPS1, LED on the

control panel lights up in red. “NO PAPER” appears

on the display as the start key is pressed. While the

light is blocked at the PPS1, the start key lights up in

green.

* Wipe off the dirt or contamination, if any, on the

PPS sensor with a rag.

Drive PCB unit

24V

CN2-7

8

<Circuit diagram>

Paper sensor

Emitting

Receiving

Main PCB unit

1

3

1

2

3

Red Red

1

Orange Orange

2

Red Red

Gray

Blue

1

2

3

Gray

Blue

CN4-1

5V

2

5V

3

5V

4

5

Light not transmitted: 5V

Light transmitted: 0V

S2-Y1540

-0

25

Page 28

Chapter 2 2 Double-Feed Detection Section (Option)

2 Double Feed Detection Section (Option)

1. Description

The double feed detection sensor is provided at the

ejection side of feed belt.

An ultrasonic sensor is used, and no adjustment for

fi tting it to the particular type of paper, and no input of

the paper thickness are required.

2. Operation

Whenever the ultrasonic sensor detects double feed,

the machine stops the operation.

3. Operation of Each Part

1. Double Feed Sensor

<Operation>

Whenever the ultrasonic sensor detects double feed,

the machine stops the operation. The double feed is

detected not by the paper thickness, but by the number

of sheets.

Receiving

Receiving

<Circuit diagram>

Double feed sensor

Receiving

Main PCB unit

Red

White

CN9-2 4

White Blue

12

Receive PCB

TransmittingTransmitting

24V Power supply unit

21

42

Brown

Blue

V +

V -

26

Transmitting

S2-Y1540

-0

Red

Yellow

21

42

Transmit PCB

Page 29

3 CCD Section

1. Description

This section reads the barcode and REG mark by

CCD.

2. Operation

On the JOB using REG mark or barcode, PPS2 works

to assure the correct CCD reading by temporarily

stopping the paper run at the place of PPS2 and slows

it. The paper conveyance speed will be accelerated

after the CCD reading.

Chapter 2 3 CCD Section

2

3. Operation of Each Part

1. PPS2

<Operation>

•

PPS detects the presence or non-presence of paper

by the “light-through” or the “light-bloced” state of the

PPS photo-receiving sensor by means of

from the PPS photo-emitting sensor.

• In the operation without REG mark or barcode,

PPS2 detects the timing of passing paper.

<Circuit diagram>

PPS2

Red

Orange

Red Red

Gray

Blue Blue

Emitting

Receiving

1

3

1

2

3

receiving

1

2

1

2

3

Red

Orange

Gray

CN4-6

7

8

9

10

5V

5V

Main PCB unit

5V

Light not transmitted: 5V

Light transmitted: 0V

S2-Y1540

-0

27

Page 30

Chapter 2 4 Margin Slitter Section

4 Margin Slitter Section

1. Description

The margin slitter is provided (slitter 1, 2) on both

sides to cut the paper along the traveling direction

by means of the rotary blades. The cut-off margin is

dropped into the waste box.

2. Operation

The lead screw is turned by means of the stepping

motor to cause the margin slitter to move from the

home position by the specifi ed amount of pulse.

3. Slitter Blade

The slitter blades are constructed so that the lower

blade of the slitter is tilted relative to the paper feed

direction. This makes the upper and lower slitter

blades contact at only one point to maintain the clean

cut even after the slitter blade has worn out.

4. Operation of Each Part

1. Margin Slitter Home Position Sensor

<Operation>

Margin slitter HP sensor detects the home position

of the margin slitter by the photo-micro sensor, and

controls the margin slitter position based on the

amount of pulse from the home position.

28

S2-Y1540

-0

Page 31

<Circuit diagram>

Slitter HP1 sensor

Chapter 2 4 Margin Slitter Section

Main PCB unit

Blue

1

White

2

Red

3

2

3

1

Slitter HP2 sensor

Blue

1

Pink

2

Red

3

2

3

1

2. Margin Jam Sensor

<Operation>

The system stops the machine when a sensor cannot

detect light for more than fi xed period of time during

machine runs.

CN2-3

CN3-3

5V

2

1

5V

2

5V

2

1

5V

Light not transmitted: 5V

Light transmitted: 0V

<Circuit diagram>

Margin jam sensor

Receiving

Emitting

Main PCB unit

1

2

3

4

1

3

Black

White

Orange

Red

Black

Orange

4

3

2

1

2

1

CN4-27

26

25

24

23

22

5V

5V

Light not transmitted: 5V

Light transmitted: 0V

S2-Y1540

-0

29

Page 32

Chapter 2 5 Center Slitter Section

5 Center Slitter Section

1. Description

Two pairs of center slitters (slitter 3–6) are provided to

cut the paper in the traveling direction by mean of the

rotary blades arranged vertically side by side.

2. Operation

The lead screw is turned by means of the stepping

motor to cause the center slitters to move from the home

position by the specifi ed amount of pulse.

3. Slitter Blade

The slitter blades are constructed so that the lower blade

of the slitter is tilted relative to the paper feed direction.

This makes the upper and lower slitter blades contact at

only one point to maintain the clean cut even after the

slitter blade has worn out.

4. Operation of Each Part

1. Center Slitter Home Position Sensor

<Operation>

Center slitter HP sensor detects the home position

of the center slitter by the photo-micro sensor, and

controls the center slitter position based on the

amount of pulse from the home position.

30

S2-Y1540

-0

Page 33

<Circuit diagram>

Chapter 2 5 Center Slitter Section

Main PCB unit

Slitter HP3 sensor

1

2

3

Slitter HP4 sensor

1

2

3

Slitter HP5 sensor

1

2

3

Purple

Blue

Red

Gray

Blue

Red

Yellow

Blue

Red

CN2-5

6

4

CN3-5

6

4

CN2-8

9

7

5V

2

5V

Light not transmitted: 5V

Light transmitted: 0V

5V

5V

Light not transmitted: 5V

Light transmitted: 0V

5V

5V

Light not transmitted: 5V

Light transmitted: 0V

Slitter HP6 sensor

1

2

3

Yellow

Blue

Red

CN3-8

9

7

5V

5V

Light not transmitted: 5V

Light transmitted: 0V

S2-Y1540

-0

31

Page 34

Chapter 2 5 Center Slitter Section

2. PPS3

<Operation>

•

PPS detects the presence or non-presence of paper

by the “light-through” or the “light-bloced” state of the

PPS photo-receiving sensor by means of

from the PPS photo-emitting sensor.

receiving

• PPS3 detects the passing paper and paper jam in

the slitter area.

<Circuit diagram>

PPS3

Receiving

Emitting

Red

1

Orange

3

Red

1

Gray

2

Blue

3

1

2

1

2

3

Red

Orange

Red

Gray

Blue

3. Gutter ON/OFF Sensor

<Operation>

The gutter ON/OFF sensor

detects the gutter guide

position by the photo sensor, and in case the gutter is

not needed, “Gutter Released” is displayed.

CN4-11

12

13

14

15

Main PCB unit

5V

5V

5V

Light not transmitted: 5V

Light transmitted: 0V

<Circuit diagram>

Gutter ON/OFF sensor

32

S2-Y1540

-0

Receiving

Emitting

Main PCB unit

Black

1

White

2

Orange

3

Red

4

Black

1

Orange

3

4

3

2

1

2

1

CN4-21

20

19

18

17

16

5V

5V

Light not transmitted: 5V

Light transmitted: 0V

Page 35

6 Cutter Section

1. Description

The “Guillotine type” cutter module is provided in

which the lower blade is fi xed while the upper blade

moves up and down to cut the paper perpendicularly

to the traveling direction.

2. Operation

The rotating motion of the DC motor is transformed

into the reciprocating motion of the upper blade by

means of the eccentric shaft.

A sensor is provided at the top dead center of the

blade stroke, which works to apply the brake on the

blade movement at every reciprocating cycle to make

it stop.

Chapter 2 6 Cutter Section

2

3. Operation of Each Part

1. Cutter Home Position Sensor

<Operation>

Cutter HP sensor detects the blade positions

by sensing the light-blocking plate linked to the

movement of rotary blade by means of the photomicro sensor.

<Circuit diagram>

Cutter HP sensor

Blue Blue

1

Yellow Yellow

2

Red

3

3

2

1

Red

CN2-18

17

16

Main PCB unit

5V

5V

Light not transmitted: 5V

Light transmitted: 0V

S2-Y1540

-0

33

Page 36

Chapter 2 6 Cutter Section

2. Cutter Motor

<Operation>

Cutter motor controls the upper blade up and down

operation.

<Circuit diagram>

Cutter motor

M

Red

Black

Red

1

Black

2

CN6-3

Drive PCB unit

4

34

S2-Y1540

-0

Page 37

7 Creaser Section

1. Description

Creaser module contains the lower blade having

a concave (recessed) section and the upper blade

having a convex (projected) section. The creaser

unit works to crease the paper perpendicularly to its

traveling direction.

2. Operation

The sensor plate provided coaxially with the cam

detects the top dead center of the upper blade to

control the DC motor. The lower blade also can

move up and down by a cam. The height of the

lower blade is set by the DC motor with an encoder,

and is specifi ed relative to the lower blade’s bottom

dead center at which the sensor plate is provided.

The crease depth is determined in this way.

Chapter 2 7 Creaser Section

2

S2-Y1540

-0

35

Page 38

Chapter 2 7 Creaser Section

3. Operation of Each Part

1. Crease Lower Blade Home Position Sensor

<Operation>

This sensor detects the crease home position by

sensing the sensor plate attached to the eccentric

shaft by means of the photo-micro sensor.

<Circuit diagram>

CREASE LOW HP sensor

1

2

3

Red

Light green

Blue

4

5

6

2. Crease Home Position Sensor

<Operation>

This sensor detects the crease home position by

sensing the sensor plate attached to the eccentric

shaft by means of the photo-micro sensor.

<Circuit diagram>

CN3-13

14

15

Main PCB unit

5V

5V

Light not transmitted: 5V

Light transmitted: 0V

CREASE HP sensor

Main PCB unit

5V

Red

1

White

2

Blue

3

1

2

3

CN3-10

11

12

Light not transmitted: 5V

Light transmitted: 0V

5V

36

S2-Y1540

-0

Page 39

3. Creaser Lower Blade Encoder Sensor

<Operation>

Creaser lower blade encoder sensor adjusts the crease

depth in three levels from the lower limit position by

reading out the encoder attached to the crease depth

adjustment motor by means of the photo-micro sensor.

<Circuit diagram>

Chapter 2 7 Creaser Section

2

CREASE ENCODER

1

2

3

Red

Purple

Blue

7

8

9

4. PPS4

<Operation>

The

light from the PPS photo-emitting PCB is

received by the PPS photo-detecting PCB. The

presence or non-presence of the paper is determined

by the

receiving amount.

PPS4 detects the passing paper and paper jam in the

cutter and crease areas.

CN3-16

17

18

Main PCB unit

5V

5V

Light not transmitted: 5V

Light transmitted: 0V

<Circuit diagram>

PPS4

1

2

3

1

3

Red

Gray

Blue

Red

Orange

Main PCB unit

1

2

3

1

2

CN4-13

14

15

11

12

5V

5V

5V

Light not transmitted: 5V

Light transmitted: 0V

S2-Y1540

-0

37

Page 40

Chapter 2 7 Creaser Section

5. Crease Motor

<Operation>

Crease motor controls the crease upper blade up and

down operation.

<Circuit diagram>

CREASE MOTOR

Red

Red

1

M

Black

6. Crease Low Motor

<Operation>

Crease low motor rotates the encoder attached in the

crease lower motor to adjust the crease depth in three

steps.

<Circuit diagram>

CREASE LOW MOTOR

Brown Brown

Black

2

1

M

Black Black

2

CN6-1

CN5-4

Drive PCB unit

2

Drive PCB unit

5

7. Perforation Unit Sensor

<Operation>

Perforation unit sensor detects whether the perforation unit is installed or not.

<Circuit diagram>

Perforation Unit Sensor

5V

CN2-19

23

24

38

S2-Y1540

-0

1

2

3

Red

White

Blue

1

2

3

Main PCB unit

5V

Light not transmitted: 5V

Light transmitted: 0V

Page 41

8 Main Drive Section

1. Description

Stepping motors are used for activating components

related to the paper cutting dimensions, paper

transfer, each slitter, transversal position of the gutter.

The movement of other DC motors are also controlled

by the encoder attached to the motor as required.

Chapter 2 8 Main Drive Section

2

S2-Y1540

-0

39

Page 42

Chapter 2 9 Exit Tray

9 Exit Tray

1. Description

Exit tray is for receiving the fi nished paper discharged

from the machine.

The exit tray can be set at four different heights.

Normally the tray is set at the middle height position.

Upper position is to install the

Lower position is for the papers with strong static

electricity.

Card Stacker.

40

S2-Y1540

-0

Page 43

10

Exterior

1. Description

Exterior section detects the opening and closing of

each cover. The machine stops immediately when the

cover is opened during operations.

2. Operation

The machine stops immediately when opening of the

cover is detected during operations.

3. Operation of Each Part

1. Top Cover Interlock Switch

<Operation>

Top cover interlock switch detects the opening

and closing of the top cover. The machine stops

immediately when the cover is opened during

operations.

When the cover is closed, the cover presses the

switch.

When the cover is opened, the cover is off the switch.

Chapter 2 10 Exterior

2

2. Front Cover Interlock Switch

<Operation>

Front cover interlock switch detects the opening

and closing of the front cover. The machine stops

immediately when the cover is opened during

operations.

When the cover is closed, the cover presses the

switch.

When the cover is opened, the cover is off the switch.

S2-Y1540

-0

41

Page 44

Chapter 2 10 Exterior

<Circuit diagram>

Front cover interlock switch

Brown

Brown Brown

Rear cover interlock switch

Top cover interlock switch

Brown

Brown

Brown

Brown

Brown

CN7-2

3

1

2

CN14-1

2

Main PCB unit

Relay

Drive PCB unit

42

S2-Y1540

-0

Page 45

11

Barcode

1. Description

By adding barcode which indicates job number on

each document, DC-616 automatically set up the

machine and start the job. Operator can press the

START key and leave. Even if multiple types of jobs

are loaded on the feed tray at one time, DC-616

recognizes barcode on documents also with the builtin CCD reading and automatically switch setup and

fi nish the jobs.

To use this function, each documents must have

BARCODE printed on them. Please refer to following

instructions for specifi cations and position of

BARCODE.

1. Specifi cations

Barcode type : CODE-39

Start and Stop code : Required

Minimum resolving power : 0.254 mm

Thin bar: Thick bar : 1: 2.5

Bar height : 4 mm or more

Chapter 2 11 Barcode

Paper feed direction

2

Use barcode generator function equipped on your

software application or use barcode generator

software.

REFERENCE

Barcode may not be read even it is within the

specifi cations depending on the print quality of printer

and document type. If this is the case, enlarging the

barcode may enable it to be read.

S2-Y1540

-0

43

Page 46

Chapter 2 11 Barcode

2. Position of barcode

Paper feed direction: The whole BARCODE should be within

3 to 20 mm from the lead edge.

Paper width direction: The whole BARCODE should be

within 25 to 60 mm from the right edge.

* Here is the example barcode: CODE39 (*21*).

(See below)

60 mm or less

35 mm

3 mm

Barcode

Position Range

Barcode

1. is the start code designator for CODE-39. (*)

2. is the 10’s digit data of the JOB number.

(Example: When the JOB number is 21, the data is “2”.)

3. is the 1’s digit data of the JOB number.

(Example: When the JOB number is 21, the data is “1”.)

4. is stop code of CODE-39. (*)

25 mm

20 mm

Paper feed direction

1 2 3 4

44

S2-Y1540

-0

Page 47

3. Position of check digit

Modulus43 is the calculational procedure of check

digit specifi ed for CODE39. Each of 43 character types

available to CODE39 are allocated each Numeric

Number to be calculated after converting them to the

numeric number. Here is the example calculation of

check digit (*21*) in CODE39.

1. is the start code designator for CODE-39. (*)

2. is the 10’s digit data of the JOB number.

(Example: When the JOB number is 21, the data is 2”.)

3. is the 1’s digit data of the JOB number.

(Example: When the JOB number is 21, the data is 1”.)

4. is stop code of CODE-39. (*)

4. Calculation procedure of check digit

1. Convert all the data characters to the numeric number

referring the table 1.

(Except start '*' and stop '*' code.) 21→2,1

Chapter 2 11 Barcode

1 2 3 4 5

2

2. Add the each converted number.

2 + 1 = 3

3. Divide the number of calculated in step 2 by 43, and

fi nd out the remainder.

3÷43 = Remainder 3

4. Convert the remainder 3 calculated in step 3 to the

character referring the table 1.

3→3

Therefore, the check digit is 3, and the data will be 213*'.

Table 1 Modulus43 Check Digit Calculation List

Character 0 1 2 3 456789ABCDE

Value 0 1 2 3 4567891011121314

Character F G H I J K L M N O P Q R S T

Value 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29

Character U V W X Y Z -

Value 30 31 32 33 34 35 36 37 38 39 40 41 42

•

$/+%

S2-Y1540

-0

45

Page 48

Chapter 2 12 REG Mark

12

REG Mark

1. Description

DC-616 automatically compensate for image drift, one

of the common problems on digital printers. It detects

the image drift caused on each page by reading REG

mark with built-in CCD and adjust the cut/slit/crease

position accordingly.

To use this function, each documents must have

REG mark printed on them. Please refer to following

instructions for specifi cations and position of REG

mark.

Lead mark

Correct for

image drift

in this direction

Paper feed direction

Side mark

Correct for image drift

in this direction

1. Specifi cations

REG mark consists of two straight and perpendicular

lines.

Line length: 5 mm or more / each

Line thickness: 0.4 mm or more / each

Use pen tool etc. of your software application to draw

2 straight and perpendicular lines.

2. Position

Paper feed direction: The whole REG mark should be

within 3 to 20 mm from the lead

edge.

Paper width direction: The whole REG mark should be

within 3 to 20 mm from the right

edge.

REFERENCE

Right fi gure shows optimum position of REG mark.

20 mm

5 mm or more

0.4 mm or more

REG Mark

Position Range

REG Mark

20 mm

6 mm

5 mm

or more

3 mm

3 mm

20 mm

3 mm

3 mm

6 mm

IMPORTANT

When there are scratches or stains in the printing range of the REG mark, the position may

not be corrected.

When the read side of the document is rough and glossy, the CCD scanner may not be able

to read REG mark and barcode. (The document may diffusely refl ect light.)

46

S2-Y1540

-0

20 mm

Page 49

3. Printing both REG mark and barcode

60 mm or shorter

Chapter 2 12 REG Mark

20 mm35 mm 5 mm

3 mm

3mm

5 mm or more

0.4 mm or more

5 mm

or more

3 mm

20 mm

REG MarkBarcode

Paper feed direction

IMPORTANT

REG marks or barcodes located out of the specifi ed printing area cannot be detected

properly by DC-616.

Take account of the possible variation in the printed position of REG marks and barcodes

when they are arranged on the paper.

2

S2-Y1540

-0

47

Page 50

Chapter 2 12 REG Mark

4. Non-printable area for REG marks and barcodes

3 mm

or

more

35 mm

3 mm or more

Barcode

5 mm

Non-Printing Area

Paper feed direction

20 mm

20 mm

3 mm

or

more

REG Mark

IMPORTANT

• Any part of the image to be printed shall not enter into the gray-colored area.

• No other printings than REG mark and barcode shall enter into the gray-colored area.

48

S2-Y1540

-0

Page 51

Chapter 3

Mechanism

1 Exterior of the Machine

(1)

Removing the Cover F (on control panel side)

(2)

Removing the Cover F2 Unit (on control panel side)

(3) Removing the Cover R2

(4) Removing the Cover

(5) Removing the Cover R

(6) Removing the Plate

(7) Removing the Top Cover

(8) Removing the Cover (Power supply)

(9)

Removing the Top Cover Interlock Switch

(10)

Removing the Front Cover Interlock Switch

(11) Removing the Exit Interlock Switch

2 Paper Feed Section

(1) Removing the Paper Separation Plate

(2) Removing the Belt Suction Unit

(3) Removing the Feed Motor

(4) Removing the Suction Fan

(5) Removing the Compressor

(6) Removing the Compressor Fuse

(7) Removing the Paper Level Sensor

(8)

Removing the Elevator Upper Limit Switch

(9)

Removing the Elevator Lower Limit Switch

(10) Removing the Elevator Motor

(11) Removing the PPS1

(12)

Removing the Elevator Down Switch

(13) Removing the Paper Feed Unit

(14) Removing the Blow Fan

.......................

.................

.....................

..................

......................

................

...........................

........

..............

..............

.............

.........

....................

...............

..

..

..

......

....

..

..

.......

51

52

.

52

52

53

53

53

53

.

54

54

.

55

55

56

56

56

58

58

59

60

61

62

62

63

64

.

65

65

66

..

..

....

..

..

67

.

67

68

3

68

69

70

70

.

73

.

74

75

76

76

.

79

.

80

81

82

83

83

84

85

..

85

.

85

86

.

87

.

87

.

88

89

3 Double Feed Detection Section (Option)

(1) Removing the Ultrasonic Sensor Unit

4 CCD Section (Option)

(1) Removing the CCD

(2) Removing the PPS2

5 Margin Slitter Section

(1) Removing the Margin Slitter Module

(2)

Removing the Margin Slitter Position Motor/Belt

(3)

Removing the Margin Slitter Home Position Sensor

(4) Removing the Margin Jam Sensor

6 Center Slitter Section

(1) Removing the Center Slitter Module

(2)

Removing the Center Slitter Position Motor

(3)

Removing the Center Slitter Home Position Sensor

(4) Removing the PPS3

(5) Removing the Gutter ON/OFF Sensor

7 Cutter Section

(1) Removing the Cutter Module

(2)

Removing the Cutter Home Position Sensor

8 Creaser Section

(1)

Removing the Creaser Motor and the Belt

(2)

Removing the Creaser Home Position Sensor

(3) Removing the Crease Blade

(4)

Removing the Crease Lower Blade Home Position Sensor

(5)

Removing the Crease Lower Blade Motor

(6)

Removing the Creaser Lower Blade Encoder Sensor

(7) Removing the PPS4

..................................

........................

.......................

.....................

.........................

.........................

.....................

...........

...............................

............

.....................

CAUTION

•Always remove the power cord plug from the outlet before starting work.

•Cautions Regarding Disassembly and Assembly

•In principle, do not operate this machine with parts removed.

•When assembling:

•Unless specifi ed otherwise, perform the disassembly procedure in reverse.

•Make sure that screw types (radius, length) and locations are correct.

•Be sure to use rosette washers when they are specifi ed.

(Rosette washers are used with installation screws to prevent static electricity.)

•To ensure electrical current, a rosette washer is used with the installation screw on

the ground wire. Be sure to use the rosette washer during assembly.

Page 52

9 Main Drive Section

(1)

Removing the Main Motor and the Drive Belt

(2) Removing the Driving Roller (Upper)

(3) Removing the Driving Roller (Lower)

(4) Removing the Perforation Tool

10 Electrical System Section

(1) Removing the Control Panel

(2) Removing the Power Supply Unit

(3) Removing the Main PCB Unit

(4) Removing the Drive PCB Unit

(5) Removing the Main Drive PCB Unit

(6)

Removing the Double Feed Detection PCB Unit

(7) Removing the USB PCB Unit

............................

.........

..................

............

.....

..........

..........

..........

...

..

90

.

90

.

91

.

92

92

96

96

96

97

97

98

98

98

50

S2-Y1540

-0

Page 53

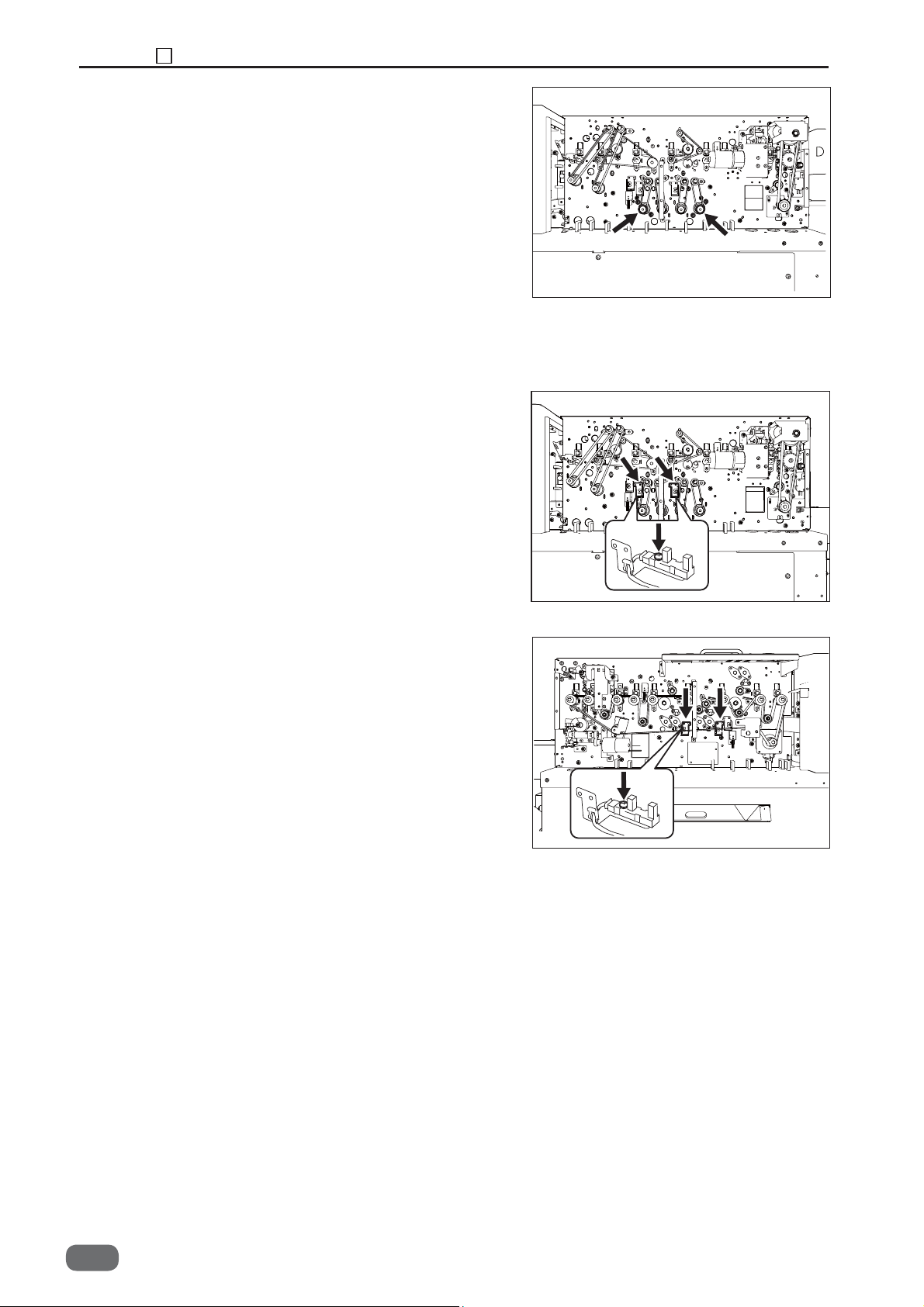

1 Exterior of the Machine

(9) Top cover interlock switch

Chapter 3 1 Exterior

(7) Top cover

(1) Cover F

(2) Cover F2 unit

(10) Front cover

interlock switch

(3) Cover R2

(5) Cover R

3

(11) Exit interlock switch

(4) Cover

(6) Plate

(8) Cover

(Power supply)

S2-Y1540

-0

51

Page 54

Chapter 3 1 Exterior

(1) Removing the Cover F (on control panel side)

1. Open the top cover.

Screw

2. Take out the three screws, and remove the cover F.

Screw

Screw

(2) Removing the Cover F2 Unit (on control panel side)

1. Open the top cover.

2. Remove the cover F.

3. Take out the three screws, and remove the cover

F2 unit.

Screw

Screw

Screw

(3) Removing the Cover R2

1. Open the top cover.

2. Take out the three screws, and remove the cover R2

unit.

Screw

Screw

Screw

52

S2-Y1540

-0

Page 55

(4) Removing the Cover

1. Loosen the thumbscrew, and remove the cover.

(5) Removing the Cover R

1. Open the top cover.

2. Take out the three screws, and remove the cover R.

Chapter 3 1 Exterior

Thumbscrew

3

(6) Removing the Plate

1. Take out the seven screws, and remove the plate.

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

(7) Removing the Top Cover

1. Open the top cover.

2. Take out the two screws and the screw plate, and

remove the hinge.

3. Take out the two screws (each), and remove the

top cover with the hinges (two places).

Screw

Screw

S2-Y1540

Screw

-0

53

Page 56

Chapter 3 1 Exterior

(8) Removing the Cover (Power supply)

1. Take out the six screws, and pull out the cover.

* Be sure to work with thepower cord removed.

(9) Removing the Top Cover Interlock Switch

1. Open the top cover.

2. Take out the two screws, and remove the micro

switch with the bracket.

Screw

Screw

Screw

Screw

Screw

Screw

3. Disconnect the connector.

4. Take out the two screws, and remove the micro

switch.

* After the installation, adjust the interlock switch.

(See→P.103)

Screw

Screw

Screw

Screw

54

S2-Y1540

-0

Page 57

(10) Removing the Front Cover Interlock Switch

1. Open the front cover.

2. Take out the two screws, and remove the front

cover interlock switch with the bracket.

Chapter 3 1 Exterior

Screw

Screw

3. Remove the two faston terminals.

4. Take out the two screws, and remove the switch.

* After the installation, adjust the interlock switch.

(See→P.100)

(11) Removing the Exit Interlock Switch

1. Open the Top cover.

2. Take out the three screws, and remove the cover R.

3. Take out the two screws, and remove the exit

interlock switch with the bracket.

Screw

3

Screw

Faston terminal

Screw

4. Remove the two faston terminals.

5. Take out the two screws, and remove the switch.

* After the installation, adjust the interlock switch.

(See→P.100)

Screw

Screw

Faston terminal

S2-Y1540

-0

55

Page 58

Chapter 3 2 Paper Feed Section

2 Paper Feed Section

(1) Removing the Paper Separation Plate

1. Take out the two screws, and remove the paper

separation plate with the unit.

(2) Removing the Belt Suction Unit

1. Open the top cover.

2. Remove the cover F2 unit.

3. Remove the feed motor connector and the suction

fan connector.

4. Take out the three screws, and remove the shutter

solenoid cover.

(See→P.52)

(See→P.58)

Screw

Screw

Screw

Screw

Screw

5. Disconnect the shutter solenoid connector.

6. Take out the two nuts and one screw, and remove

the belt suction unit.

* After the installation, perform the unit operation

check in HELP Mode: 19.

(HELP Mode : 19→P.143)

Connector

56

S2-Y1540

-0

Page 59

● Removing the Shutter Solenoid

1. Disconnect the connector.

2. Take out the two screws, and remove the shutter

solenoid with the bracket.

3. Take out the two screws, and remove the shutter

solenoid.

Chapter 3 2 Paper Feed Section

Connector

Screw

Screw

3

Screw

S2-Y1540

-0

57

Page 60

Chapter 3 2 Paper Feed Section

(3) Removing the Feed Motor

1. Open the top cover.

2. Remove the cover F2 unit.

3. Disconnect the connector from the motor.

4. Remove the belt suction unit.

5. Take out the two screws, and remove the feed

motor.

* After the installation, perform the motor operation

check in HELP Mode: 19.

(HELP Mode : 19→P.143)

(See→P.52)

(See→P.56)

Connector

Screw

(4) Removing the Suction Fan

1. Remove the cover F2 unit.

2. Disconnect the fan motor connector.

3. Take out the two screws, and remove the suction

fan.

* After the installation, perform the fan motor

operation check in HELP Mode: 18.

(HELP Mode : 18→P.142)

(See→P.52)

Screw

Screw

Screw

Connector

58

S2-Y1540

-0

Page 61

(5) Removing the Compressor

1. Remove the power cord plug.

2. Take out the three screws, and remove the cover R2.

(See→P.52)

3. Remove the plate.

4. Take out the four screws securing the compressor.

(Secured from the backside.)

(See→P.53)

Chapter 3 2 Paper Feed Section

5. Draw the compressor toward you, and remove the

wiring and air tube.

* After the installation, perform the compressor

operation check in HELP Mode: 20.

(HELP Mode : 20→P.144)

● Removing the SSR

1. Remove the power cord plug.

2. Remove the plate.

3. Take out the four screws, and remove the wirings.

4. Take out the two screws, and remove the SSR.

(See→P.53)

Screw Screw Screw

Screw

Screw

Screw

3

S2-Y1540

-0

59

Page 62

Chapter 3 2 Paper Feed Section

(6) Removing the Compressor Fuse

CAUTION

● Be sure to remove the power cord plug from the outlet before starting the work.

● Replace the compressor fuse for exclusive use of the rating that showed in the label.

Otherwise, fi re could result.

1. Remove the power cord plug.

2. Remove the plate.

3. Open the cover, and remove the fuse.

* Be sure to work with the power cord removed.

* Rating of compressor fuse: 250 V, 2 A

(See→P.53)

9

$+

60

S2-Y1540

-0

Page 63

(7) Removing the Paper Level Sensor

Chapter 3 2 Paper Feed Section

1. Remove the cover R2.

2. Disconnect the sensor connector.

3. Take out the two screws, and remove the paper

level sensor.

(See→P.52)

Connector

3

Screw

Screw

4. Take out one screw, and remove the shaft ASSY.

5. Take out the two screws, and remove the sensor

with the bracket.

* Install the sensor bracket at the lowest point

aligned with volume 1.

6. Remove the sensor from the bracket.

* After the installation, perform the sensor

operation check in HELP Mode: 11.

(HELP Mode : 11→P.137)

* Make sure that the pinion shaft and the cable

tube do not interfere with other at the time of

installation.

Screw

Screw

Screw

S2-Y1540

-0

61

Page 64

Chapter 3 2 Paper Feed Section

(8) Removing the Elevator Upper Limit Switch

1. Remove the cover R2.

(See→P.52)

2. Disconnect the connector.

3. Take out the nut, and remove the elevator upper

limit switch with the bracket.

4. Take out the two screws, and remove the elevator

upper limit switch.

* Adjustment required at the time of installation

(See→P.100)

Nut

Screw

Screw

(9) Removing the Elevator Lower Limit Switch

1. Remove the cover F2 unit.

2. Disconnect the two faston terminals.

3. Take out the two screws, and remove the elevator

lower limit switch.

* Adjustment required at the time of installation

(See→P.52)

(See→P.100)

Screw

Screw

62

S2-Y1540

-0

Page 65

(10) Removing the Elevator Motor

1. Move the elevator to the upper limit, and turn off the

power.

2. Remove the cover R2.

3. Disconnect the motor connector.

4. Remove the banding band.

(See→P.52)

Chapter 3 2 Paper Feed Section

Banding band

Screw

Connector

5. Take out the two screws and nut, and remove the

motor with the bracket.

6. Loosen the hexagon socket set screw, and remove

the gear.

7. Take out the three screws, and remove the motor.

* After the installation, perform the paper feed

elevator operation check in HELP Mode: 17.

(HELP Mode : 17→P.141)

Screw

Screw

Screw

Hexagon

socket set

screw

Screw

Nut

3

S2-Y1540

-0

63

Page 66

Chapter 3 2 Paper Feed Section

(11) Removing the PPS1

1. Move the elevator to the upper limit (HELP Mode:

17), and turn off the power.

2. Take out one screw, and remove the sensor with

the bracket.

Screw

3. Take out one screw, and remove the sensor.

* After the installation, perform the sensor operation

check in HELP Mode: 11.

(HELP Mode : 11→P.137)

Screw

64

S2-Y1540

-0

Page 67

(12) Removing the Elevator Down Switch

Chapter 3 2 Paper Feed Section

1. Remove the cover F2 unit.

2. Disconnect the switch connector.

3. Take out the two screws, and remove the elevator

down switch with the angle.

4. Push the part indicated by the arrow, and remove

the elevator down switch.

(See→P.52)

Screw

Screw

Connector

3

(13) Removing the Paper Feed Unit

1. Open the top cover.

2. Remove the cover F2 unit and cover R2.

(See→P.52)

3. Disconnect the following connectors.

• Elevator down switch

• Elevator lower limit switch

• Suction fan

• Feed motor

• Shutter solenoid

• Blow fan

• Paper level sensor

• Elevator motor

• Optional ultrasonic sensor

* After the installation, perform the sensor and motor

operation check in HELP Mode: 11, 15, 17, 18, 19.

(HELP Mode : 11→P.137)

(HELP Mode : 15→P.139)

(HELP Mode : 17→P.141)

(HELP Mode : 18→P.142)

(HELP Mode : 19→P.143)

(See→P.65)

(See→P.62)

(See→P.58)

(See→P.58)

(See→P.57)

(See→P.66)

(See→P.61)

(See→P.63)

(See→P.67)

S2-Y1540

-0

65

Page 68

Chapter 3 2 Paper Feed Section

4. Take out the four screws securing the paper feed

unit.

* Do not loose the collars and washers.

Screw

Screw

5. Disconnect the PPS1 connector, and remove the

paper feed unit.

* Adjust the indicator to "0" at the time of installation

(See→P.101)

(14) Removing the Blow Fan

1. Remove the paper feed unit.

* Be sure to work with the power cord removed.

2. Take out the three screws, and remove the fan

motor.

(See→P.65)

Screw

Screw

Connector

Screw

* After the installation, perform the fan motor

operation check in HELP Mode: 18.

(HELP Mode : 18→P.142)

Screw

Screw

66

S2-Y1540

-0

Page 69

Chapter 3 3 Double Feed Detection Section

3 Double Feed Detection Section (Option)

(1) Removing the Ultrasonic Sensor Unit

* The ultrasonic sensor unit cannot be disassembled.

(Sensor installation angle is a factory setting.)

Screw

Screw

1. Remove the cover R2.

2. Disconnect the fi ve connectors and remove the two

ground wires.

3. Take out the three screws, and remove the

ultrasonic sensor unit.

4. Take out the two screws, and remove the ultrasonic

sensor.

* After the installation, perform the sensor operation

check in HELP Mode: 15.

(HELP Mode : 15→P.139)

(See→P.52)

Connector

3

Connector

Screw

Screw

Screw

S2-Y1540

-0

67

Page 70

Chapter 3 4 CCD Section

4 CCD Section (Option)

(1) Removing the CCD

1. Remove the cover (power supply) and cover R.

(See→P.53)

* Be sure to work with the power cord removed.

2. Disconnect the connector (CN8).

* Make sure that the terminals do not interfere each

other at the time of installation.

3. Open the top cover.

4. Take out the three screws, and remove the hinge of

the top cover.

CN8

5. Take out the two screws, and remove the CCD unit.

* Adjustment required at the time of installation

(See→P.102)

Screw

Screw

Screw

Screw

Screw

68

S2-Y1540

-0

Page 71

(2) Removing the PPS2

● Photo-emission sensor

1. Open the top cover.

2. Take out the three screws, and remove the hinge of

the top cover.

Chapter 3 4 CCD Section

Screw

Screw

Screw

3. Take out the two screws, and remove the sensor

with the bracket.

4. Take out one screw, and remove the sensor.

* Adjustment required at the time of installation

(See→P.102)

3

Screw

Screw

Screw

● Photo-detecting sensor

1. Open the front cover.

2. Remove the shutter.

3. Take out the screw, and remove the sensor.