Page 1

¡Store in a manner that permits use anytime.

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,

For the safe usage of the machine, correct operation and

periodic maintenance are essential. Read this manual

before using the machine.

WARNING

DC-535 Cutter

Ver.1

Page 2

- 1 -

Introduction

Thank you for purchasing the DC-535 Cutter.

This product is the result of our many years of experience in the field of office

equipment.

Be sure to read this manual before using the machine.

In order to use the machine safely and efficiently, read this manual thoroughly, and make

sure that you understand all of the instructions that it gives, so that you operate the

machine correctly.

Take good care of this manual. Keep it in a safe place where it can be consulted at any

time.

Symbols and pictures

Safety instructions

In this manual and on the stickers affixed to the machine, a variety of symbols and

pictures are used. These symbols and pictures provide warnings and instructions to

prevent danger to you or other people and damage to office property. The meanings

Indicates potential danger of death or serious injury if it is ignored.

Indicates potential danger of injury or damage to property if it is ignored.

Warning :

Caution :

Examples of pictorial symbols

Other nomenclature

A triangle indicates danger. The precise nature of the danger is indicated by a

pictorial symbol inside the triangle. The symbol shown here indicates danger of

electric shock.

A circle with a line diagonally across it indicates prohibition. The particular act

prohibited is indicated by a picture inside the circle. The symbol shown here indicates

a prohibition of disassembly.

A black disc indicates an instruction, or sometimes prohibition. The content is

indicated by pictorial symbols drawn in white in the disc. The symbol shown here

indicates an instruction to pull the plug out of the outlet.

IMPORTANT

:

NOTE

:

Introduces instructions for correct operation and maintenance of the

machine. A failure to follow them may cause insufficient performance or

breakdown.

Introduces useful information for the operation and maintenance of the

machine as well as information on the performance, etc. of the product.

PLEASE NOTE

In the interest of upgrading our products, specifications and other data given in this

manual are subject to change without notice. If the manual contains anything that

you do not understand, contact the manufacturer for clarification.

2

u

Page 3

- 2 -

TABLE OF CONTENTS

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.Names and functions of each part. . . . . . . . . . . . . . . . . . 7

s

Feed side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

s

Ejection side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.Names and function of the operation panel. . . . . . . . . . 9

s

Display unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

s

Operation unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. Procedures for using the machine . . . . . . . . . . . . . . . . 10

4. Basic operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

¡ About modes and mode displays . . . . . . . . . . . . . . . . . . . . . . . . . 15

1. Turning on the power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2. Selecting the cutting dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3. Performing test operation

to check the cutting dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4. Starting operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5. Registering cutting dimensions . . . . . . . . . . . . . . . . . . 19

1. Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2. Procedure for registering cutting dimensions . . . . . . . . . . . . . . . . . 19

6. Other functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

¡ Deleting registered data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

¡ To temporarily offset the cutting position . . . . . . . . . . . . . . . . . . . 21

7. Suggestions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

<<Message displayed on LCD when a jam occurs>> . . . . . . . . . . . . 22

<<Corrective action for paper jams>> . . . . . . . . . . . . . . . . . . . . . . . . 23

¡ Removing jammed paper from the feed unit . . . . . . . . . . . . . . . . . 23

¡ Removing jammed paper from the cutter

or ejection unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8. Specifications and accessories . . . . . . . . . . . . . . . . . . 25

s

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

s

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Page 4

- 3 -

Safety instructions

¡Be sure to follow these instructions. They are extremely important for safety.

WARNING

¡Do not modify the machine. Do not remove any of the covers from the machine.

¡Do not insert pins, wire or other foreign objects into the machine. Do not allow

any liquid to get into the machine through its openings or gaps in its structure.

Liquid inside the machine may result not only in breakdown, but also in electric

shock or fire.

¡Keep your hands off inside the margin trimmer. It contains cutting edges which

may hurt you.

¡Do not put your hands or fingers inside the front or rear safety cover during

operation, or they could be crushed or otherwise injured.

¡Use tweezers or a similar tool to remove jammed paper. Before removing

jammed paper, be sure to pull the power supply plug out from its outlet in order

to prevent electric shock.

To avoid electric shock:

To avoid injury to hands or fingers:

¡Do not use supply voltage other than the specified voltage.

Doing so may result in fire or electric shock.

¡Always pull the power supply plug out of its outlet before removing jammed

paper.

Do not insert or remove the plug with wet hands.

Page 5

- 4 -

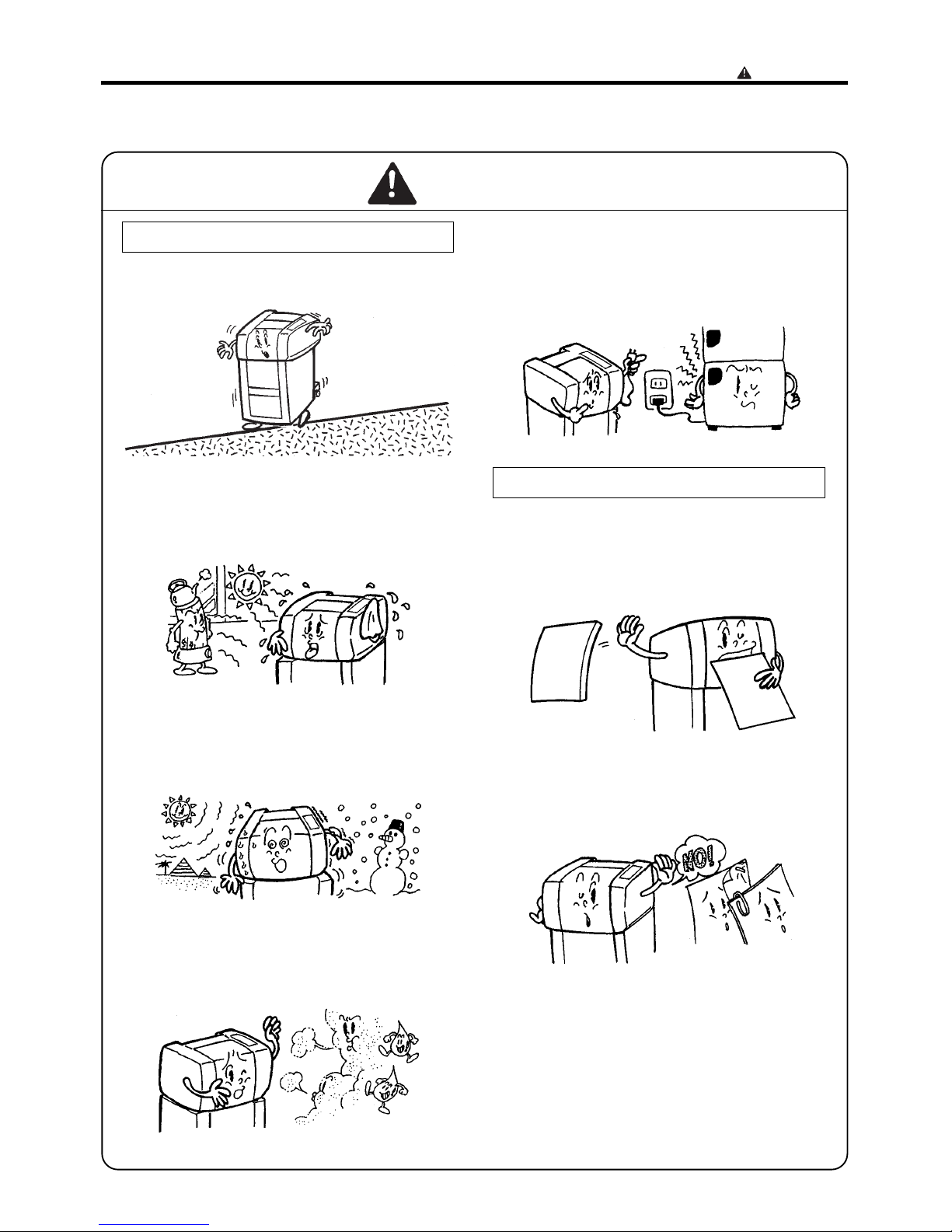

CAUTION

Installation location

General operation instructions

¡Install the machine in a level place.

¡Do not install the machine in a place subject

to direct sunlight or near heating equipment.

¡Do not install the machine in a place subject

to extreme temperatures (high or low), or in a

place subject to heavy vibration.

¡Avoid installing the machine in a place with

high humidity, or with large amount of oil,

iron filings, or dust.

¡Do not connect the cutter to a power outlet

that is also used for equipment that

generates noise, such as large-size office

equipment or refrigerators.

¡ Do not use the cutter to cut paper that

exceeds the specification paper thickness.

Doing so could result in breakdown.

¡ Do not attempt to cut paper with staples,

paper clips or any other pieces of metal

attached to it.

¡Use a dry cloth to remove paper cuttings

collected in the machine and to clean the

rubber rollers or other parts. Be sure to pull

the power supply plug out from its outlet

before cleaning.

Safety instructions

Page 6

- 5 -

q

Safety instructions

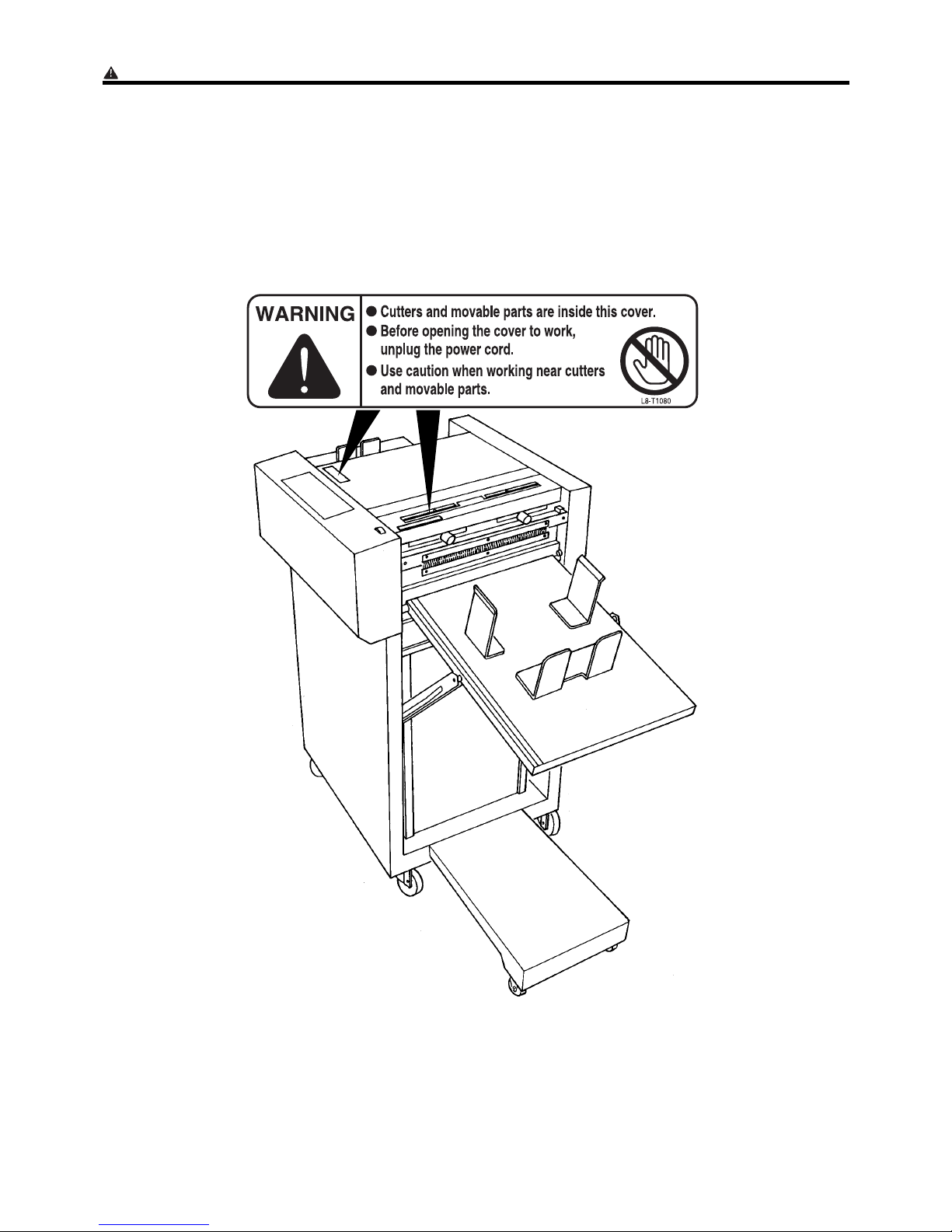

DLocations of warning stickers

The locations of the machine's warning stickers are shown below. To ensure safe work, read the stickers and

heed their instructions. Keep the stickers clean at all times. If they become damaged or peel off, replace them

with new ones.

Page 7

- 6 -

No. Part No. Name Q'ty

q

w

e

L8-T1080

L8-T1070

L8-T1100

Warning Sticker 1

Warning Sticker 2

Warning Sticker 3

2

1

1

w

e

Safety instructions

Page 8

- 7 -

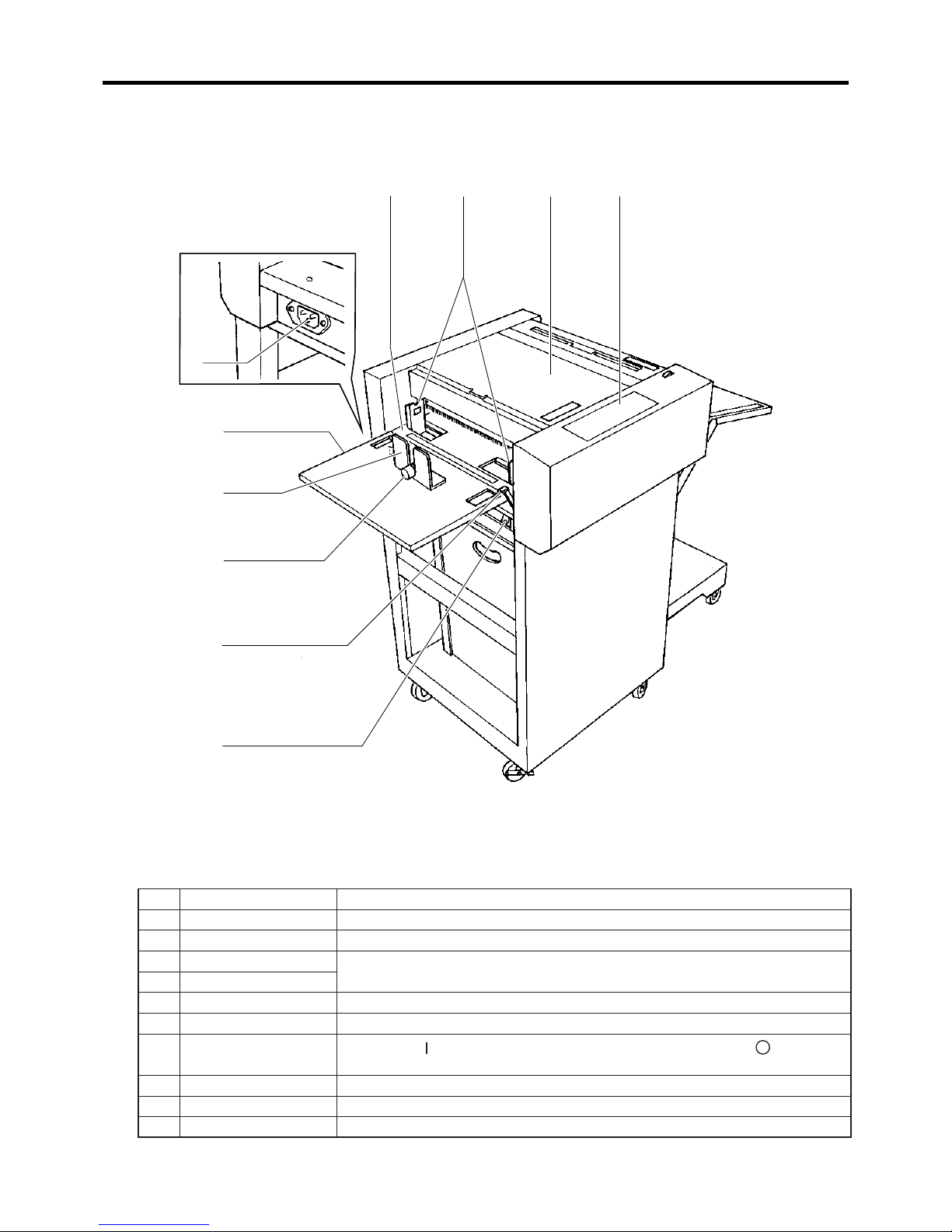

1. Names and functions of each part

s

Feed side

No. Name Function

q

Front safety cover Open this cover to adjust the paper thickness or to remove jammed paper.

w

Operation panel See "Names and functions of the operation panel" on p. 9.

e

Paper tray

Load the paper into these trays.

r

Auxiliary paper tray

t

Paper stopper Guides the trailing edge of the paper.

y

Guide Hold the trailing edge of the paper.

u

Power switch

Press the [ ] side of the switch to turn the power on, and the [ ] side to

turn it off.

i

Inlet The power cord (an accessory) is inserted into this.

o

Paper guides Set the position of these guides to match the width of the paper.

!0

Lock lever Pull this lever backward (toward you) to lock the paper guides.

qoe w

i

r

t

y

!0

u

Page 9

- 8 -

1. Names and functions of each part

s

Ejection side

No. Name Function

!1

Rear safety cover Open this cover to adjust the margin slitters or to remove jammed paper.

!2

Ejection tray Receives ejected paper.

!3

Ejection stopper Stops the leading edge of ejected paper sheets.

!4

Ejection guides Laterally positions the ejected paper.

!5

Knob Moves the margin slitter. Turn clockwise to lock.

!6

Pointers Indicate the margin cutting position.

!7

Scale Measures the paper dimensions for cutting.

!8

Aligner Moves the left and right margin slitters simultaneously.

!9

Trash box Cut-off margins are deposited into this box.

!7

!2

!9

!4

!5

!6

!1

!8

!3

Page 10

- 9 -

2.

Names and function of the operation panel

No. Name Function

q

Liquid crystal Display

Displays various messages.

w

COVER indicator Lights when a safety cover is open.

e

JAM indicator Lights when a paper jam occurs.

r

PAPER indicator Lights when there is no paper in the paper tray.

t

READY TO RUN

indicator

In the RUN mode, lights to indicate the machine is ready to run.

y

POWER indicator Lights when the power is on.

No. Name Function

q

F button

Function button - used in conjunction with other buttons to execute functions

such as cutting dimension registration.

w

MODE button Switches among the LCD's display modes.

e

SET button

In the RUN mode, pressing this button executes test cutting.

In the SET mode, pressing this button memorizes cutting dimensions.

r

3

button

When the machine is stopped in the RUN mode, or due to a jam, pressing

the + button will move the paper forward, and pressing the - button will

move it backward.

t

4

button

y

RESET button

A multifunction button that when pressed at the same time the STOP button

is pressed,the number of sheets fed and cut will be reset.

If pressed for three or more seconds in the Freesize Input Mode, the current

registered data will be erased.

u

START button

In the RUN mode, pressing this button starts cutting operation (except when

a paper jam has stopped operation).

i

STOP button

Press this button to stop the machine. Also press this button to restart the

machine after it has been stopped by a paper jam (but note that you must

first eliminate the cause of the jam before the machine can be restarted).

Display unit

q w t yer

tewq

y u i

r

Operation unit

Page 11

- 10 -

3. Procedures for using the machine

Setting the ejection tray in place1

1.2.Lift the ejection tray upward.

Hook the slots in the tray's struts onto the pins on both

sides of the machine body. Make sure that the tray is

securely set in place.

Note

¡ The ejection tray can be adjusted to two different

inclination angles. Select the angle appropriate for the

paper's size and quality.

Connecting the power2

1.

Fit the female plug of the power cord (one of the

accessories) into the inlet on the feed side of the

machine.

1.

Move the auxiliary paper tray in the direction indicated by

the arrow.

2.

Insert the power cord's male plug into power outlet.

Setting the auxiliary paper tray3

Power cord

Female plug

Ejection tray

Strut

Pin

Inlet

Auxiliary

paper tray

Page 12

- 11 -

Loading the paper4

1.2.Lift up the paper tray's lock lever, to unlock the paper

guides.

Align the paper guides with the marks for the size of

paper to be loaded.

3.

Take a stack of paper, flip through it to loosen up the

sheets, and straighten up the edges of the stack on a

level surface.

4.

Slightly curl up both sides of the paper stack, and load it

into the paper tray, so that it rests between the guides.

3. Procedures for using the machine

¡Be sure to loosen up the paper sheets before loading

the stack into the tray. Otherwise, paper feed errors or

jams will occur.

IMPORTANT

¡The sides of the paper stack must be curled up

slightly when it is loaded into the tray, or it will not be

loaded properly.

IMPORTANT

5.

Position the paper guides so that they match the width of

the paper, then push down the lock lever to lock them in

place.

¡The amount of paper loaded must not exceed the line

on the maximum load sticker.

¡ Position the paper guides so that they are just

touching the paper, not pressing on it.

IMPORTANT

Lock lever

Lock lever

Paper guides

Paper guides

Paper size marks

Line

Page 13

- 12 -

3. Procedures for using the machine

6.

Fit the paper stopper to the paper tray, so that it rests

against the trailing edge of the paper.

7.

Fit the No. 1 paper retainer into the gap between the

stopper's prongs, so that it holds down the paper.

1.

Fit the No. 2 paper retainers (accessories) into the gap

between the paper guides' prongs.

S If the paper is laminated, or curls to a large degree:

• Be sure to use the No. 2 paper retainer accessories if

the paper curls to a large degree. Otherwise the paper

will not be fed properly.

IMPORTANT

Paper

stopper

No.1

Paper

retainer

No.2 Paper retainer

Adjust the paper thickness5

1.

Open the front safety cover.

Front safety cover

Page 14

- 13 -

3. Procedures for using the machine

3.

Check the separator plate's degree of emergence. To do

so, remove the thumb screw indicated, and open out the

suction unit. This will render the separator plate visible.

1.

Press and hold down the F button, and press the MODE

button. The display will change in the way shown at

right.

2.

Use the MODE button to select "Normal" or "Heavy".

(Pressing the MODE button toggles the asterisk "1"

between the two items. The asterisked item is the one

selected.) Select "Heavy" for thick paper.

3.

Press the SET button. The item selected in 2. will be set,

and the RUN mode display will reappear.

*You can tell whether "Normal" or "Heavy" has been set

by the presence/absence of a "1" in the Run mode

display. See figure at right.

2.

Turn the adjuster knob to adjust the separator plate's

position to match the paper thickness.

The separator plate's standard position is the fullyemerged position.

¥ For thin paper: Turn the adjuster knob in the "L"

direction to make the separator plate emerge.

¥ For thick paper: Turn the adjuster knob in the "H"

direction to make the separator plate retract.

¥ Adjust the separator plate's position to suit the paper

feed situation.

Thumb screw

Adjuster knob

Suction unit

Separator plate

IMPORTANT

¥ If a jam occurs in the paper feed unit during operation,

carry out the following procedure to eliminate the jam.

IMPORTANT

[Run]

No.01: 3:T 307.0

[PaperWeight ]

1

No rma l Heavy

[PaperWeight ]

No rma l

1

Heavy

[Run] [Run]

1

¡When "Normal" is set: ¡When "Heavy" is set:

Asterisk displayed

Page 15

- 14 -

3. Procedures for using the machine

Adjusting the margin slitter6

1.

Place 1 sheet of the paper to be used against the scale on

the safety cover, and align the center of the paper with

the scale's central line.

2.

Loosen the left and right margin slitter knobs, and align

the pointers with the required slitting positions.

3.

Tighten the margin slitter knobs.

1.

Open the rear safety cover.

2.

Loosen the fixing knob.

The alignment dial is now ready for use.

¥ The alignment dial can be used to align the left and right

margin slitters simultaneously, as follows.

Note

Scale

Paper

Slitter knobs

Rear safety cover

Fixing knobAlignment dial

Align

Page 16

- 15 -

4. Basic operation

About modes and mode displays

The DocuCutter has 4 modes. After completing the "Procedures for using the machine" (p.10), turn on

the power, select a registration number (in the Select mode), and perform test cutting. Then use the

RUN mode to run the machine.

* No cutting dimensions are registered when the machine is shipped. After turning the power on for

the first time, register cutting dimension data (in the Freesize Input mode) before running the

machine.

1

(Operation)

[Run mode] Mode for operation

aP.18

Testing

Press

Press

aP.18

Operation

MODE

qTest cutting (executed by pressing SET

button)

wOperation start (executed by pressing

START button)

¥ Operation stops when counter reaches

set quantity, or when STOP button is

pressed

¥ Use the RESET button to reset the

counter

¥ Use the button to move the paper

forward

¥ Use the button to move the paper

backward

2

(Selection)

[Select mode]

For selecting

registration number

aP.17

Selection

MODE

qSelection of registration No.

¥ No. Cut(side-margins-only cut)

¥ No. 00

¥ No. 98

(Use and buttons to select

number. Use F button to view registered

data.)

wConfirmation of selection

Press the SET button to confirm the

selection. "#", indicating "selected" will

be displayed.

[Run]

No.01: 3:T 307.0

[Select ] #

No.01: 3:T 307.0

Page 17

- 16 -

4. Basic operation

Press

As necessary

[Offset Adjust]

To [Run mode]

For temporarily offsetting

cutting position

aP.21

Offsetting

MODE

qSetting of offset dimension

¥ Top 1.0mm

¥ Top 0.5mm

¥ Standard 0mm

¥ Bottom 0.5mm

¥ Bottom 1.0mm

(Use and buttons to select value.)

Press

3

(

Registration

)

[Freesize mode]

For registering / deleting

cutting dimensions

aP.19

Registration

aP.21

Deletion

MODE

qSetting of registration number (No. 00 -

98)

(Use and buttons to select

number. Press SET button to confirm.)

wSetting of number of pieces (2-15

pieces)

(Use and buttons to select

number. Press SET button to confirm.)

eSetting of leading edge cutting

dimension

(Use and buttons to select value.

Press SET button to confirm.)

rSetting of middle cutting dimension

(not used with 2 pieces)

(Use and buttons to select value.

Press SET button to confirm.)

tSetting of trailing edge cutting

dimension

(Use and buttons to select value.

Press SET button to confirm.)

¥ To delete registered data:

(Use and buttons to select

registration number, and press RESET

button for at least 3 seconds to delete.)

[Freesize Input]

No . ?

44

> No.00

[Of fset Adjust ]

0mm

Page 18

- 17 -

4. Basic operation

Turning on the power1

Selecting the cutting dimensions2

1.

Press the [ ] side of the power switch, to turn the power

on. When the power is turned on, the screen that was

displayed when the power was last turned off appears on

the LCD panel.

1.

Press the MODE button as many times as needed to

select the SELECT mode.

2.

Use the "+" and "-" buttons to select a pre-registered

number.

Pre-register cutting dimensions, and call them up as

required by selecting registration numbers.

Numbers 0 through 98 are available for registering

cutting dimensions.

* To turn off the power:

Press the [ ] side of the power switch.

Note

¥ No dimensions are registered when the machine is

shipped. For the registration procedure, see "Registering

the cutting dimensions" below.

Note

¥ To view the registered data:

Press and hold down the F button. The registered cutting

data will be displayed sequentially.

DocuCu t t er 535

Ver .

41.11

[Run]

No.01: 3:T 307.0

[Run]

No.01: 3:T 307.0

[Select ]

No.01: 3:T 307.0

[Select ]

No.01: 3:T 307.0

[Select ]

No.01: 1: 10.0mm

Power switch

ON

OFF

Registration No.

Sequential display

Number

of pieces

Total

Length

¡Screen displayed when power was last turned off

Page 19

- 18 -

4. Basic operation

Performing test operation to check the cutting dimensions

3

3.

Press the SET button. "#" will be displayed, and then the

RUN mode display will appear. The machine is now ready

to run using the cutting dimensions registered under the

number selected in 2. above.

1.

Press the SET button.

A single sheet of paper will be test-cut. Check that it is

cut correctly.

a

Press the START button. Operation will start.

Press the STOP button.

* To stop operation:

See the instructions in "Using the offset adjust mode"

below.

* To temporarily offset the cutting position:

* When the trash box becomes full:

Press the STOP button.

Pull out the trash box, and empty the accumulated paper

scraps from it.

Push the emptied trash box back into the machine, then

press the START button. Operation will restart.

2.

Position the ejection stopper and ejection guides so that

they are 3mm away from the edges of the cut paper.

Starting operation4

¥ Paper jams will occur if the trash box fills up

completely. Empty the trash box before it fills up

completely.

¥ When cutting long paper, do not use the trash box, or

paper jams will result.

IMPORTANT

[Run]

No.01: 3:T 307.0

[Select ] #

No.01: 3:T 307.0

Ejection guides

Ejection stopper

Trash box

Page 20

- 19 -

5. Registering cutting dimensions

Overview

Pre-register cutting dimensions, and call them up as

required by selecting registration numbers.

Numbers 0 through 98 are available for registering

cutting dimensions.

¥ Do not register the following dimensions. They will

result in paper jams in the machine's interior.

¥ Leading edge cut (CUT No.1) 3.2mm or less.

¥ Middle cut (CUT No.2) 90mm or less.

¥ Trailing edge cut (CUT No.3) 3.2mm or less.

IMPORTANT

Procedure for registering cutting dimensions2

1

1. Press the MODE button as many times as needed to

select "Freesize Input".

6.

Use the "3" and "4" keys to select the leading edge cut

(CUT No. 1) dimension.

7. Press the SET button. The leading edge cut (CUT No. 1)

dimension selected will be set.

4.

Use the "3" and "4" keys to select the number of

pieces.

5. Press the SET button. The number selected will be set. (2

through 15 can be set for the number of pieces.)

2.

Use the "3" and "4" keys to set a registration number.

3. Press the SET button. The registration number will be

set.

[Freesize Input]

No . ?

44

>No.00

[Freesize Input]

No . ?

44

>No.01

Pieces ? : 3

Length? T: 5.0

1: 5.0mm

Example : selecting No.1

¡Brackets( )indicate the case with 3 pieces

Leading edge cut

(CUT No.1)dimension

Middle cut

(CUT No.2)dimension

Trailing edge cut

(CUT No.3)dimension

Example : selecting 3 pieces

Example : inputting 5mm

for CUT No.1

Total length

CUT No. Cutting length

Page 21

- 20 -

5. Registering cutting dimensions

11.

a

a

Press the SET button. The trailing edge cut (CUT No. 3)

dimension selected will be set. Registration is now

complete.

The display in step 1 will reappear on the screen.

To register more dimensions, repeat the above

procedure.

To run the machine at this point:

¥ If you set only the leading edge cut (CUT No. 1)

dimension, to a value in the range 101.5-170mm, or

only the trailing edge cut (CUT No. 3) dimension, to a

value over 210mm:

The number of cuts will be automatically increased,

for smoother processing of the cut paper. Note also

that the set number of cuts will also increase, and the

number-of-sheets-cut-count will be decreased.

IMPORTANT

8.

Use the "3" and "4" keys to select the middle cut (CUT

No. 2) dimension.

9. Press the SET button. The middle cut (CUT No. 2)

dimension selected will be set.

10.

Use the "3" and "4" keys to select the trailing edge cut

(CUT No. 3) dimension.

Length? T: 105.0

2:100.0mm

Length? T: 110.0

3: 5.0mm

Press the MODE button as many times as needed to

select the SELECT mode. Then refer to "Selecting the

cutting dimensions" on p.17.

Example : inputting 100mm for CUT No.2

Example : inputting 5mm for CUT No.3

Page 22

- 21 -

6. Other functions

Deleting registered data

To temporarily offset the cutting position

1.

Press the MODE button as many times as needed to

select "Freesize Input".

1.

Press the MODE button as many times as needed to

select "Offset Adjust".

2.

Use the "3" and "4" keys to set the offset dimension.

3.

Press the MODE button as many times as needed to

select the RUN mode.

4.

Press the START button, to start operation. Cutting will

be executed with the offset that was set.

The offset adjust mode is used to temporarily offset the

cutting position. The offset can be set to 20mm, with

pitch 0.5mm.

3

4

2.

Use the "3" and "4" keys to select a pre-registered

registration number.

3.

Press the RESET button and hold it down for at least 3

seconds. The buzzer will sound, and the data registered

under the specified number will be deleted.

¥ When the CUT No. is changed, the offset dimension is

reset to 0mm.

IMPORTANT

[Freesize Input]

No . ?

44

>No.00

[Freesize Input]

No . ?

44

>No.02

[Offset Adjust]

0mm

[Offset Adjust]

Top 0.5mm

[Run]

No.01: 3:T 307.0

Example : selecting No.2

Example : selecting Top 0.5mm

¡Example : setting 5mm offset

With Bottom

5.0mm

With 0mm

(standard)

With Top

5.0mm

Page 23

- 22 -

7. Suggestions

Messages displayed on LCD when a jam occurs

When a paper jam occurs, the buzzer sounds and a message is displayed on the LCD panel. When this

happens, take the corrective action given below.

Message Cause and corrective action Page

Shut Cover !! Cause: Safety cover (front or rear) is open.

Corrective action: Close the cover.

4

Paper Jam !!

Feed jam 1

Cause: Paper feed error.

Corrective action: Adjust the paper separator.

13

Paper Jam !!

Center jam 2

Cause: Paper jammed just before the cutter.

Corrective action: • Check that cutting dimensions are appropriate.

• Remove the jammed paper and press the STOP button.

23

Paper Jam !!

Center jam 3

Cause: Paper jammed just before the cutter.

Corrective action: • Check that cutting dimensions are appropriate.

• Remove the jammed paper and press the STOP button.

23

Paper Jam !!

Cutter jam 4

Cause: Paper jammed inside the cutter.

Corrective action: • Check that cutting dimensions are appropriate.

• Remove the jammed paper and press the STOP button.

24

Cutter Lock !!

jam 5

Cause: Cutter does not cut properly.

Corrective action: • Check if the paper being cut is outside the specification

range.

• Remove the paper causing the problem and press the

• STOP button.

24

Paper Jam !!

Slitter jam 6

Cause: Paper jammed inside the slitter.

Corrective action: Remove the jammed paper and press the STOP button.

24

Elevator Error Cause: Feed elevator error.

Corrective action: Press the STOP button. If the elevator doesn't return to

normal, call the service representative.

4

Elevator Full

Error

Cause: Too much paper in the paper tray.

Corrective action: Reduce the amount of paper to below the line on the

maximum load sticker.

11

Page 24

- 23 -

7. Suggestions

Corrective action for paper jams

Removing jammed paper from the feed unit

1.

Turn off the power switch, and pull the power cord plug

out from the outlet.

¥ If you will have to put your hands near moving parts to

remove the jammed paper, first remove the power cord

plug from the outlet.

2.

Open the front safety cover.

3.

Remove the fixing thumb screw from the suction unit.

4.

Raise up the suction unit, and remove the jammed paper.

WARNING

¥ After removing the paper, don't forget to lock the

suction unit by screwing its fixing thumb nut back in

place.

IMPORTANT

Power switch

Front safety cover

Thumb screw

Jammed paper

Suction unit

OFF

Page 25

- 24 -

7. Suggestions

Removing jammed paper from the cutter or ejection unit

¥ If you will have to put your hands near moving parts to

remove the jammed paper, first remove the power cord

plug from the outlet.

¥ The cutter unit and slitter unit contain hazardous

cutting edges inside them. Keep your hands away from

these units' interiors.

¥ To remove jammed paper, use the tweezers included in

the accessories, or a similar tool.

WARNING

1.

It is sometimes possible to remove the paper by pressing

the "3" key to move it forward, and the "4" key to move

it backward.

* Using these keys may however make the paper jam

worse. Watch the condition of the jammed paper as you

operate the keys.

1.

Turn off the power switch, and pull the power cord plug

out from the outlet.

2.

Open the rear safety cover. If the paper is jammed in the

cutter unit, open the front safety cover.

3.

Remove the jammed paper.

4.

If the paper is jammed in the cutter unit, use the tweezers

included in the accessories to remove it.

Using the "3" and "4" keys to remove jammed paper.

1

If the jammed paper cannot be removed by the procedure described in "1"

2

Front safety cover

Rear safety cover

Page 26

- 25 -

8. Specifications and accessories

Model name DC-535 Cutter

Paper size

Minimum: 6" (width) 56" (length)

Maximum: 12.6" (width) 518" (length)

Cut paper size

Minimum: 6" (width) 54" (length) (postcard size)

Maximum: 11" (width) 517" (length)

Paper thickness

61-249g/m3(but depending on paper quality and lamination condition, certain

paper within this thickness range may not be cuttable)

Paper holding capacity 25" (0.8mm

)

Leading edge cut

dimension

Minimum: 0.125 (3.2mm)

Maximum: 0.63" (16mm)

Trailing edge cut

dimension

Minimum: 0.125" (3.2mm)

Maximum: 0.63" (16mm)

Side cut

Minimum: 0.125" (3.2mm)

Maximum: 5" (127mm)

Cutting precision 0.5mm (with paper cutting length not exceeding 17")

Cutting speed

35 sheets / minute (when cutting leading and trailing edges of 8.5" 511" paper)

55 sheets / minute (when cutting both sides of 8.5" 511" paper)

Feed method Air suction method

Stacker Drop type

Power supply

AC 120V Type

AC 120

V 10%

, 50/60Hz, 1.2A

Machine dimensions

(mm)

When out of use: 503 (W) 578 (D) 51040 (H)

When in use: 1160 (W) 5578 (D) 5954 (H)

Machine weight (kg) 64

AC 230V Type

AC 230V 10%, 50/60Hz, 0.6A

3

4

3

4

3

4

Name Q'ty Name Q'ty

Power cord 1 Trash box 1

Instruction Manual 1 Paper stopper 1

Tweezers 1 No. 1 paper retainer 1

Ejection stopper 1 No. 2 paper retainers 2

Ejection guides 2

Note : The specifications and other data above are subject to change without notice.

s

Specification

s

Accessories

Page 27

L8-Y1030 1998. 12

Printed in Japan

DUPLO SEIKO CORPORATION

353 KOUDAI KOKAWA-CHO NAGA-GUN

WAKAYAMA-KEN JAPAN

Loading...

Loading...