Page 1

INSTRUCTION MANUAL

STITCHER FOLDER

DBM-600

TRIMMER

DBM-600T

Original instructions

Be sure to read this manual prior to use.

Please leave this manual at the site of use for easy reference.

Page 2

Introduction

Thank you for purchasing a Duplo product.

Be sure to read this manual and "Safety Guide A" supplied with this product before use. “Safety Guide”

contains information for correct and safe use of this product.

After reading, leave the manual and “Safety Guide” at the site of use for easy reference whenever questions

related to the product arise in the future.

Symbols

In this manual, several symbols are used to indicate important warnings. Please make sure to read

instructions accompanied by these symbols. These symbols have the following meanings.

Describes instructions which must be followed in use.

Be sure to read the instructions to avoid problems due to incorrect operations.

Indicates supplementary or useful information.

Describes names of related items and supplementary instructions.

Trademark

The product name and company name used in this manual are trademarks or registered trademarks of the

respective companies.

Statement of Photobiological Safety

This product not only employs LED lamps as an indicator but also as lighting.

The LED light is conrmed with a safety standard IEC62471 and classied into the risk group 1 (low risk). The

risk group 1 (low risk) LED light does not lead to injury required such as an access restriction. However the

risk depends upon a distance between eyes and the LED lamp.

Please see a part “Name and Function” in this instruction manual that points to a place for LED lamp in the

product.

Do not stare into the LED lamp. Do not come closer to the LED lamp intentionally. A decrease in distance

between eyes and the LED light causes an increase in the risk.

For North America

Note:

In a residential area this product may cause radio interference in which case the user may be required to take

adequate measures.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Page 3

Safety Precautions

Safety Precautions

Power supply

• Make sure the power supply used is always within the following range.

Power supply : 120 V AC, 60 Hz (North America)

220 to 240 V, 50/60 Hz (EU)

• When you power other appliances from the same AC outlet, make sure that the combined power

consumption does not exceed the power supply capacity.

Rated power: DBM-600

430 W (North America)

465 W (EU)

DBM-600T

625 W (North America)

645 W (EU)

Rated current: DBM-600

4.5 A (North America)

2.5 A (EU)

DBM-600T

6.5 A (North America)

3.4 A (EU)

Operating environment

Operate this unit in the following environment.

• where the temperature range is between 5 and 35°C/41 and 95°F (–10 to 50°C/14 to 122°F in storage)

• where the humidity range is between 20 and 85% RH (10 to 90% RH in storage, however no condensation)

• which is not subject to direct sunlight

• which is subject to little or no vibration

• which is free from air-borne salt

• where there are no harmful chemicals

• where the unit is not exposed to water

i

Page 4

Safety Precautions

WARNING/CAUTION labels

"WARNING" and "CAUTION" labels are pasted on the machine to ensure user safety.

Do not remove or change them.

When the labels become dirty or are lost, be sure to contact your dealer for a new one.

For EU

ii

Page 5

For North America

Safety Precautions

iii

Page 6

Safety Precautions

Safety devices

[3]

[2]

[4]

[1]

[1]

No. Name Function

[1] Emergency stop switch Press this switch to stop the machine in emergencies. Turn the pressed

switch to the right to release it. While pressed, the machine will not

start and its moving parts will also not move.

[2] Top cover interlock switch L The switch is associated with the cover and it activates the interlocking

[3] Top cover interlock switch R

[4] Top cover interlock switch

system which consists of the protective guards, the electrical circuit

and the actuators.

The hinged or sliding cover, which can be manually opened or closed,

works as an interlocking guard associated with the electrical drive

circuit so that the hazardous moving parts do not move while the

cover is opened.

iv

Page 7

[1]

Safety Precautions

[3]

[2]

[5]

[6] [8]

No. Name Function

[1]

Fixed cover The cover is xed by screws to prevent hazardous parts from being

to

[8]

exposed. Do not remove the cover. Doing so could cause serious

injury.

[4]

[7]

v

Page 8

Safety Precautions

Memo

vi

Page 9

Contents

Contents

Safety Precautions .............................................i

Power supply .................................................................................i

Operating environment ............................................................i

WARNING/CAUTION labels .....................................................ii

Safety devices .............................................................................iv

Chapter 1 Before Operation

1. Features ...................................................1-1

1-1. Features of the DBM-600 ......................................1-1

1-2. Features of the DBM-600T ...................................1-2

2. Names and Functions of

Components ............................................ 1-3

2-1. DBM-600 external parts ........................................1-3

2-2. DBM-600T external parts .....................................1-5

2-3. DBM-600 internal parts (stitching section) ... 1-6

2-4. DBM-600 internal parts (folding section) ......1-8

2-5. DBM-600T internal parts ....................................1-10

2-6. Stitcher head ...........................................................1-12

3. Accessories ............................................1-13

3-1. Accessories for the DBM-600 ............................1-13

3-2. Accessories for the DBM-600T .........................1-14

4. DBM-600 Control Panel .......................1-15

4-1. Names of control panel .......................................1-15

4-2. Screen descriptions ..............................................1-16

4-3. Colors of the keys on the setting screen ......1-16

4-4. [Main] screen ...........................................................1-17

4-5. [Adjust] screen ........................................................1-25

4-6. [Function] screen ...................................................1-26

4-7. [Options] screen .....................................................1-31

5. DBM-600T Control Panel .....................1-36

5-1. Names of control panel .......................................1-36

5-2. Screen menus .........................................................1-37

6. Stitching Width .....................................1-38

7. Options ..................................................1-40

7-1. DBM-SSW ..................................................................1-40

7-2. DBM-LSW ..................................................................1-41

7-3. DKT-K ..........................................................................1-41

8. Workflow ...............................................1-42

Chapter 2 Basic Operation

1. Turning On/Off the Power ..................... 2-1

1-1. Turning on the power ............................................2-1

1-2. Turning o the power ............................................2-2

2. Setting the Control Panel ......................2-3

2-1. Setting the standard size ......................................2-4

2-2. Setting the custom size .........................................2-7

3. Preparing the DBM-600 for

Operation ..............................................2-16

3-1. Using the paper guide .........................................2-16

3-2. Attaching the parts for page insertion .........2-16

3-3. Moving the stitch release levers (for corner

stitching) ...................................................................2-17

3-4. Adjusting the paper receiver stopper

(for side stitching, corner stitching) ...............2-17

3-5. Aligning the paper passage lines ....................2-18

4. Preparing the DBM-600T for

Operation ..............................................2-19

5. Making the Upstream Unit Ready ......2-20

6. Adjusting Each Section

(Step Mode) ...........................................2-20

6-1. Starting the step mode .......................................2-20

6-2. Adjusting the stitching section (when

“stitching on” has been selected) ....................2-21

6-3. Adjusting the folding section (when “folding

on” has been selected).........................................2-23

6-4. Adjusting the trimming section (when

“trimming on” has been selected) ..................2-25

7. Checking Finished Booklets ................2-25

7-1. When paper does not align ...............................2-25

7-2. When stitching and folding positions do not

align ............................................................................2-27

7-3. Adjusting stitching and folding positions

simultaneously .......................................................2-29

7-4. Adjusting the stitching width ...........................2-30

7-5. When fold is skewed ............................................2-31

7-6. When the stitching position is not at right

angle to paper ........................................................2-32

7-7. When paper does not align on the belt

stacker ........................................................................2-33

7-8. When there is a scratch on a booklet ...........2-34

7-9. Stripping occurs on the surface of a

booklet .......................................................................2-36

8. Adjusting Each Part (DBM-600) ..........2-37

8-1. Adjusting the infeed paper holder .................2-37

8-2. Adjusting the stitching paper holder ............2-37

8-3. Adjusting the height of the stitch ejection

roller R ........................................................................2-38

8-4. Adjusting the folding roller gap ......................2-38

8-5. Adjusting the height of the insertion

roller ............................................................................2-39

8-6. Adjusting the pressure adjustment lever ....2-39

8-7. Using the fold paper holder ..............................2-40

8-8. Adjusting the ejection pressure ......................2-40

8-9. Using the paper receiving guides F and B ...2-41

vii

Page 10

Contents

8-10. Using the paper guide bracket ........................2-41

8-11. Adjusting the height of the paper receiver

full loading sensor .................................................2-42

8-12. Removing booklets from the paper

receiver ......................................................................2-42

9. Adjusting Each Part (DBM-600T) ........2-42

9-1. Adjusting the infeed rollers ...............................2-42

9-2. Adjusting the stopper angle .............................2-43

9-3. Adjusting nished length ..................................2-43

9-4. Adjusting the press angle unit .........................2-44

9-5. Adjusting the infeed sensor height ...............2-45

9-6. Preparing for the loop stitching ......................2-45

10. Adjusting the Paper Guide Roller

Unit ........................................................2-46

10-1. Adjusting the position of the paper guide

roller unit ...................................................................2-46

10-2. Replacing with the paper guide roller unit

(small) .........................................................................2-47

11. Setting the Conveyance Belt

Timing ....................................................2-47

11-1. Adjusting conveyance stop timing ................2-47

11-2. Adjusting conveyance restart timing ............2-47

11-3. Adjusting start timing and operating time of

the stacker belt .......................................................2-47

12. Starting Binding Operations ...............2-48

Chapter 3 Advanced Operation

1. Sending Paper Manually ....................... 3-1

1-1. Using the DBM-600 HAND FEED KIT

(optional) ....................................................................3-1

1-2. Using the DSF-2200 HAND FEED KIT

(optional) ....................................................................3-1

2. Using the DBM-600 AIR KIT (Option) .... 3-2

3. 2-stitch Binding with 4 STITCH KIT

(option) Attached ................................... 3-2

1-3. Cleaning the sensor ................................................4-2

2. Emptying the Scrap Box ........................ 4-3

3. Stitcher Head ..........................................4-4

3-1. Information on wire we specify .........................4-4

3-2. Removing wire ..........................................................4-4

3-3. Wire threading ..........................................................4-5

3-4. Installing new wire ..................................................4-7

3-5. Lubricating the stitcher head .............................4-8

Chapter 5 Trouble Guide

1. DBM-600 Error Code ..............................5-1

1-1. Error related to emergency stop switch and

covers ...........................................................................5-1

1-2. Paper jam error .........................................................5-2

1-3. Downstream unit and motor error ...................5-2

1-4. Other errors ................................................................5-2

1-5. Errors requiring a service call ..............................5-3

2. DBM-600T Error Code ............................ 5-3

2-1. Error related to emergency stop switch,

covers, etc. ..................................................................5-3

2-2. Paper jam error .........................................................5-4

2-3. Downstream unit and motor error ...................5-4

2-4. Errors requiring a service call ..............................5-5

3. Paper Jam ................................................ 5-6

3-1. Paper jam in the DBM-600 ...................................5-6

3-2. Paper jam in the DBM-600T ................................5-8

3-3. Step ejection............................................................5-10

4. Troubleshooting ...................................5-10

4-1. Entire machine ........................................................5-10

4-2. DBM-600 stitching section ................................5-10

4-3. DBM-600 folding section ....................................5-12

4-4. DBM-600 paper receiver and the stacker ....5-14

4-5. DBM-600T trimming section ............................5-14

4-6. Problem with nished booklets ......................5-15

4. Using the CALENDAR KIT (Option) ....... 3-3

5. Using the DKT-K (Option)....................... 3-3

5-1. Attaching the kicker support wheel unit .......3-3

5-2. Adjusting the position of the kicker ................3-4

5-3. Attaching the stopper ...........................................3-4

5-4. Using the sorting function ...................................3-5

6. Adjusting the Stitcher Head .................. 3-5

Chapter 4 Cleaning the Unit

1. Cleaning Each Part .................................4-1

1-1. Cleaning the conveyance belt and rollers .....4-1

1-2. Cleaning the LCD .....................................................4-1

viii

Chapter 6 Appendix

1. Specifications ..........................................6-1

2. Limit on Stitching Width ........................ 6-7

Page 11

Chapter 1 Before Operation

Chapter 1 Before Operation

1. Features

1-1. Features of the DBM-600

• The DBM-600 is a stitcher folder that can make a booklet in the following binding methods.

[A] Saddle stitch

[B] Saddle stitch and fold

[C] Fold

[D] No stitch and no fold

[E] Side stitch

[F] Side stitch and fold

[G] Corner stitch

[H] Page insertion(*)

(*) Page insertion is a 6 to 22-page booklet consisting of a sheet of A3 (LGR) with a sheet of A4 (LTR).

[B][A] [C] [D]

[F] [G][E] [H]

1-1

Page 12

Chapter 1 Before Operation

• The DBM-600T (trimmer) can be connected to the DBM-600 as a downstream unit.

DBM-600

DBM-600T

• The DBM-600 can be used as a system by connecting it to other machines such as a collator.

• When the 4 STITCH KIT (option) is installed, four stitches can be applied to a booklet.

[A] Saddle stitch

[B] Saddle stitch and fold

[C] Side stitch

[D] Side stitch and fold

[B][A] [C] [D]

• When the CALENDAR KIT (option) is installed, a calendar as shown in the gure below can be made.

1-2. Features of the DBM-600T

• The DBM-600T is a fore-edge trimmer and is used as a downstream unit of the DBM-600.

The trimming width is 1 to 25 mm/0.04 to 0.98 inch. When the number of sheets is 12 or less, up to 75

mm/2.95 inches can be trimmed.

• A head and foot trimmer can be connected to the DBM-600T as a downstream unit.

1-2

Page 13

Chapter 1 Before Operation

2. Names and Functions of Components

2-1. DBM-600 external parts

[3]

[4]

[1]

[2]

[5]

[6]

parsparssparts

[7]

[8]

[15]

[14]

[9] [10] [11] [12] [13]

No. Name Function

[1] Power switch

[2] Inlet for D Link connector Insert the D Link cable of the machine equipped with a D Link unit into

[3] Top cover R Cover for ensuring user safety. This machine will not operate if open.

”1-2. Turning off the power” (p.2-2)

this connector.

1-3

Page 14

Chapter 1 Before Operation

No. Name Function

[4] Control panel Use this to operate the machine.

(p.1-15)

[5] Emergency stop switch Press this switch to stop the machine in emergencies. Turn the pressed

switch to the right to release it. While pressed, the machine will not

start and its moving parts will also not move.

[6] Top cover L Cover for ensuring user safety. This machine will not operate if open.

[7] Fold misalignment adjustment Adjusts the angle of the folding side guides.

[8] Fold misalignment adjustment knob

Secures the angle of the folding side guides.

(p.2-31)

(p.2-31)

screw

[9] Paper receiver knob screw Secures the position of the paper receiver.

(p.2-17)

[10] Paper receiver stopper Stops side-stitched or corner-stitched booklets on the paper receiver.

(p.2-17)

[11] Paper receiver Receives side-stitched or corner-stitched booklets.

(p.2-17)

[12] Paper receiver booklet holder Holds down the booklets ejected to the paper receiver.

[13] Handle Used to pull the paper receiver.

[14] Paper receiver full loading sensor

Secures the height of the paper receiver full loading sensor.

height adjustment

[15] Power inlet Connector for the power cord.

1-4

Page 15

2-2. DBM-600T external parts

[6]

Chapter 1 Before Operation

[7]

[4]

[5]

[1]

[2]

[3]

[8] [9]

No. Name Function

[1] Top cover Cover for ensuring user safety. This machine will not operate if open.

[2] Control panel Use this to operate the machine.

[3] Emergency stop switch Press this switch to stop the machine in emergencies. Turn the pressed

switch to the right to release it. While pressed, the machine will not

start and its moving parts will also not move.

[4] Paper guide roller unit Holds a booklet and supports the stacker.

[5] Damage prevention switch Prevents the paper guide roller unit from hitting the main unit.

[6] Kicker connector Connector for the kicker.

[7] Power inlet Connector for the power cord.

[8] Scrap box Ocuts are ejected to this box.

[9] Scrap box stopper Secures the position of the scrap box. When storing the scrap box,

push the box until it stops.

(p.1-36)

(p.2-46)

(p.2-46)

(p.4-3)

(p.4-3)

1-5

Page 16

Chapter 1 Before Operation

2-3. DBM-600 internal parts (stitching section)

[4]

[15]

[3]

[3]

[4]

[2]

[1]

[5]

[14]

[13]

[9]

[1]

[10]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12] [12]

No. Name Function

[1] Stitcher head Stitches paper with a wire.

(p.1-12) (p.4-4)

[2] Stitch release lever Used to release stitching operations of the stitcher head. Use this for

corner stitches.

(p.2-17)

[3] CALENDAR KIT stopper Used for CALENDAR KIT (option). When paper reaches here, the

stopper goes down.

[4] Stitching side guide knob screw Used to secure the angle of the stitching side guides.

[5] Stitching side guide adjustment Used to adjust the angle of the stitching side guides.

[6] Stitch ejection roller R height

Adjusts the height of the ejection roller R.

(p.2-38)

(p.2-32)

(p.2-32)

adjustment

[7] Stitch ejection roller R knob screw Secures the ejection roller height.

[8] Stitch ejection roller R Conveys stitched paper to the folding section.

[9] Stitching paper holder knob screw Secures the stitching paper holder.

[10] Stitching side guide Aligns the sides of paper conveyed to the stitching section.

Infeed conveyance unit Conveys paper to the stitching section.

[11]

Stitching back guide Aligns the leading and trailing edges of paper conveyed to the

[12]

stitching section.

Infeed paper holder Prevents paper conveyed to the stitching section from rising.

[13]

Infeed conveyance unit lock lever Locks and releases the infeed conveyance unit.

[14]

Side-stitching stopper Used during side-stitching operations. Stops paper conveyed from the

[15]

(p.2-21)(p.2-27)

(p.2-38)

(p.1-27)(p.2-38)

(p.2-37)

(p.2-14)(p.2-25) (p.2-27)

(p.2-35)

(p.2-37)

(p.2-35)(p.5-6)

infeed section.

1-6

Page 17

Chapter 1 Before Operation

[4]

[3]

[2]

[1]

[6][5]

[7]

No. Name Function

[1] Saddle-stitching stopper lock plate Secures the saddle-stitching stopper angle.

[2] Saddle-stitching stopper angle

Adjusts the angle of the saddle-stitching stopper.

(p.2-32)

(p.2-32)

adjustment

[3] Saddle-stitching stopper Used during saddle stitching operations. Stops paper conveyed from

the infeed section.

[4] Stitch ejection roller L Conveys stitched paper to the folding section.

[5] Stitching paper holder Prevents paper conveyed to the stitching section from rising.

[6] Stitching paper holder knob screw Secures the stitching paper holder.

(p.2-32)

(p.1-27)

(p.2-37)

(p.2-37)

[7] LED inner lamp LED lamp for partially lighting up inside the machine.

1-7

Page 18

Chapter 1 Before Operation

2-4. DBM-600 internal parts (folding section)

[12]

[18]

[19]

[11]

[10]

[14][15]

[13]

[4]

[2]

[1]

[2]

[3]

[17]

[16]

[10]

[13]

[5]

[6] [7] [8]

[9][9] [11]

[14]

[15]

[12]

1-8

Page 19

Chapter 1 Before Operation

No. Name Function

[1] Folding back guide unit Unit for aligning the leading and trailing edges of paper conveyed to

the folding section.

(p.5-7)

[2] Folding back guide Aligns the leading and trailing edges of paper conveyed to the folding

section.

[3] Folding side guide Aligns the sides of the paper conveyed to the folding section.

(p.2-23) (p.2-25)

(p.2-14)(p.2-23)

[4] Press roller Presses paper folded into two.

[5] Folding roller Folds paper into two.

[6] Fold paper holder Prevents paper conveyed to the folding section from rising.

[7] Folding stopper Stops booklets conveyed to the folding section.

[8] Fold paper holder height adjustment Adjusts the height of the fold paper holder.

(p.2-38)

(p.2-40)

(p.2-16)

(p.2-40)

[9] LED inner lamp LED lamp for partially lighting up inside the machine.

[10] Press roller gap adjustment lever Adjust the clearance (gap) between the press rollers. Use this when the

surface of a booklet is stripped.

Pressure adjustment lever Adjusts the pressure of the press roller.

[11]

Ejection pressure adjustment lever Adjusts the ejection pressure.

[12]

Press roller gap xing lever Secure the clearance (gap) between the press rollers.

[13]

Fold ejection roller gap knob screw Secures the fold ejection roller gap adjustment lever.

[14]

Fold ejection roller gap adjustment

[15]

lever

Fold paper holder knob screw Secures the height of the fold paper holder.

[16]

Ejection at belt Ejects paper folded into two.

[17]

Page insertion roller height

[18]

Adjust the clearance (gap) between the fold ejection rollers. Use this

when the surface of a booklet is stripped.

Adjusts the height of the insertion rollers.

(p.2-36)

(p.2-39)

(p.2-40)

(p.2-36)

(p.2-36)

(p.2-36)

(p.2-40)

(p.2-16)(p.2-39)

adjustment

Page insertion roller knob screw Secures the height of the insertion rollers.

[19]

(p.2-16)

1-9

Page 20

Chapter 1 Before Operation

2-5. DBM-600T internal parts

[10]

[12]

[9][8]

[11]

[7]

[6]

[5]

[16]

[1]

[4] [3]

[2]

[13]

[12]

[14]

[15]

1-10

[15]

[16]

Page 21

Chapter 1 Before Operation

No. Name Function

[1] Stopper angle xing knob Loosen when adjusting the stopper angle adjustment.

[2] Stopper angle adjustment Adjusts the angle of the stopper.

(p.2-43)

(p.2-43)

[3] Conveyance belt Conveys a booklet. The height is automatically adjusted according

to the number of sheets in the booklet.

[4] Press angle unit Weakens pressure of the press bar against a booklet. Use this when

a booklet is torn by a stitch.

(p.2-44)

[5] Press bar Holds a booklet when trimming a booklet.

[6] Stopper Stops a booklet at the trimming position.

[7] Infeed sensor height adjustment knob

Adjusts the height of the infeed sensor.

(p.2-25)

(p.2-45)

screw

[8] Ocut ejection air Ejects ocuts, which are left after booklets are trimmed, into the

scrap box.

[9] Duct unit Sends ocuts ejection air to the knife section. Remove the duct

unit when paper jams under the infeed roller unit.

[10] Knife section Trims the fore-edge of a booklet.

(p.5-8)

[11] Infeed roller unit Sends booklets conveyed from the upstream unit to the inside the

machine.

(p.5-9)

[12] Support roller knob screw Used to change the position of the support rollers. When the

infeed roller unit has been raised using the infeed roller unit knob

screw, short booklets may stop under the infeed roller unit. In that

case, move the support roller knob screw downward to lower the

support rollers.

(p.2-19)

[13] Infeed roller adjustment Adjusts holding pressure of the infeed roller unit against a booklet.

(p.2-42)

[14] Infeed roller unit knob screw Used to raise the infeed roller unit. When the trimming width is

25 mm/0.98 inch or more, raise the infeed roller unit so that the

support rollers do not touch a booklet.

(p.2-19)

[15] Infeed roller Sends a booklet conveyed from the upstream unit to the inside of

the machine.

[16] Ejection roller Ejects a booklet to the downstream unit.

1-11

Page 22

Chapter 1 Before Operation

2-6. Stitcher head

[2]

[19]

[18]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[17]

[11]

[15]

[13]

[8]

[9]

[10]

[11]

[12]

[2]

[1]

[3]

[4]

[5]

[6]

[7]

[15]

[16]

[14]

”3. Stitcher Head” (p.4-4)

No. Name Function

[1] Wire guide spring Feeds wire to the saddle stitching section.

[2] Wire guide When setting the wire, pass through the wire among the wire guides.

[3] Felt disks Cleans the wire surface and applies a small amount of oil.

[4] Wire return lock Prevents the wire supplied from returning.

[5] Release disk When lowered, releases the wire return lock.

[6] Fixing knob Fixes the wire guide spring to the wire tube.

[7] Wire tube upper Wire path

[8] Stitch length adjustment knob Wire is cut short when turned clockwise, and long when turned

counterclockwise.

[9] Triangular handle For switching whether to stitch or not

[10] Feed wheels Grip the wire when the triangular handle is set to the stitching

position. When rotated with the adjusting handle, wire is fed.

[11] Wire tube lower Wire path

[12] Mounting bolt Secures the stitcher head to the mounting block.

[13] Balance adjustment wheel When rotated, adjusts the left and right leg length of a stitch.

[14] Wire straightener Straightens the wire.

[15] Leaf spring Holds the former.

[16] Former Cuts the wire and bends it into C shape.

[17] Adjusting handle Used when feeding wire manually. (Accessory)

[18] Tenon block Secures the stitcher head to the mounting block.

[19] Clinching block Performs clinching operations.

[13]

[14]

[16]

1-12

Page 23

3. Accessories

3-1. Accessories for the DBM-600

Chapter 1 Before Operation

[1]

[6]

[11] [13][12] [14] [15]

[2] [3] [5]

[8][7]

[4]

[9] [10]

[16]

[20] [22] [23] [24]

No. Name QTY Use

[1] Star-shaped wrench L (*) 1 Used for adjusting the stitcher head. For information on how to use this,

[2] Star-shaped wrench M (*) 1

[3] Star-shaped wrench S (*) 1

[21]

refer to the stitcher head instruction manual.

[18][17] [19]

1-13

Page 24

Chapter 1 Before Operation

No. Name QTY Use

[4] Hexagonal wrench (*) 1 Used for removing the stitcher head. For information on how to use this,

refer to the stitcher head instruction manual.

[5] Positioning guide 1 Used for attaching the stitcher head. For information on how to use this,

refer to the stitcher head instruction manual.

[6] Longnose pliers (*) 1 Used for setting the wire on the stitcher head.

[7] Adjusting handle 1 Used for mounting and adjusting the wire.

[8] Oiler 1 Used for oiling the stitcher head.

[9] Guide 1 unit 2 Used when a booklet is damaged.

(p.4-8)

(p.2-43)

(p.4-5)

(p.3-5) (p.4-7)

[10] Guide 2 unit 2

[11] Guide 3 unit 2

[12] Angle F unit 1

[13] Angle B unit 1

[14] Paper guide 1 Used for side stitching.

(p.2-16)

[15] Paper receiving guide F 1 Used when paper is misaligned in the width direction on the paper

[16] Paper receiving guide B 1

receiver during side stitching. (magnet type)

(p.2-41)

[17] Paper guide bracket 1 Used when paper is not neatly stacked on the paper receiver during

side stitching. (magnet type)

(p.2-41)

[18] Page insertion rollers 1 Replace the ejection rollers with these rollers for page insertion

operations.

[19] Page insertion guide 1 Used for page insertion.

(p.2-41)

(p.2-16)

[20] Power cord 1 For North America

[21] Power cord 1 For EU

[22] Instruction manual 1 This manual

[23] Safety Guide A 1 Contains information for correct and safe use of this machine.

[24] Stitcher head instruction

1 CD-ROM manual for the stitcher head

manual

(*) Do not use these tools for purposes other than instructed in this manual or the stitcher head instruction

manual.

3-2. Accessories for the DBM-600T

[1] [3] [4][2]

No. Name QTY Use

[1] L-wrench (*) 1 Used to loosen or tighten the screw of the press angle unit.

[2] Scrap box 1 Ocuts are ejected to this box.

(p.4-3)

[3] Power cord 1 For North America

[4] Power cord 1 For EU

(p.2-44)(p.2-45)

(*) Do not use these tools for purposes other than instructed in this manual.

1-14

Page 25

Chapter 1 Before Operation

4. DBM-600 Control Panel

On all the screens shown in this manual, note that the values are displayed in “mm.”

Do not press the two or more keys on the control panel or two or more keys or boxes on the

touch panel at the same time. The machine will make an unexpected move and not operate

properly.

4-1. Names of control panel

The control panel consists of the touch panel and the three keys.

[1]

[2]

[3]

[4]

[5]

No. Name Function

[1] Touch panel Used to enter and display the settings related to the stitcher folder,

downstream unit and options.

[2] (paper ejection) key Ejects paper forcibly.

[3] Power lamp Lights up when turned on.

[4]

[5]

(start) key

(stop) key

Starts the system. Press for more than one second.

Stops the system including this machine.

(p.5-8)(p.5-10)

1-15

Page 26

Chapter 1 Before Operation

4-2. Screen descriptions

[1] [2] [3] [4]

No. Name Function

[1] [Main] tab Pressing the tab displays the main menu.

[2] [Adjust] tab Pressing the tab displays the adjustment menu.

[3] [Function] tab Pressing the tab displays the menu to set the stopper and guide

operations, the number of jogs and others.

[4] [Options] tab Pressing the tab displays the menu for options.

(p.1-17)

(p.1-25)

(p.1-26)

(p.1-31)

4-3. Colors of the keys on the setting screen

The key currently selected is displayed in green and the one not selected is displayed in grey on any of the

setting screen: [Main], [Adjust], [Function] and [Options] screen.

For the items you need to select one of two, the icon currently selected is displayed in green and the other

one in dark gray.

Example)

[a]

[b]

You will not be able to see the illustration or the character for the item displayed in dark gray as shown in the

gure above. However, note that in the gures used in this manual, the items in dark gray are also visible by

design.

1-16

Page 27

4-4. [Main] screen

The [Main] screen is a screen displayed rst when you turn on the power.

Chapter 1 Before Operation

[2]

[1]

[4]

[5]

[9]

No. Item Details

[1] Binding method Displays a binding method for the memory currently selected.

Saddle stitching

Side stitching

Corner stitching

No stitch

Calendar (*1)

Saddle stitching (4 stitches) (*2)

Side stitching (4 stitches) (*2)

(*1) Displayed when the CALENDAR KIT (option) is attached.

(*2) Displayed when the 4 STITCH KIT (option) is attached.

[2] Folding method Displays a folding method for the memory currently selected.

Fold

No fold

Page insertion

[3]

[6]

[7]

[8]

[11]

[10]

[12]

1-17

Page 28

Chapter 1 Before Operation

No. Item Details

[3] Trimming method and other

trimming(*)

Displays the trimming method for the memory currently selected.

Head/foot trimming on + fore-edge trimming on

Fore-edge trimming on

Trimming o

Head/foot trimming on + fore-edge trimming o

Head/foot trimming on + gutter cutting + fore-edge

trimming on(*3)

Head/foot trimming on + gutter cutting + fore-edge

trimming o(*3)

Head/foot trimming on + punch + fore-edge trimming

on(*3)

Head/foot trimming on + punch + fore-edge trimming

o(*3)

No downstream units

Oset trimming + punch + fore-edge trimming on(*3)

Oset trimming + gutter cutting + fore-edge trimming

on(*3)

Oset trimming(*3)

Oset trimming + fore-edge trimming on(*3)

Oset trimming + punch(*3)

Oset trimming + gutter cutting(*3)

(*3) Gutter cutting, punch and the oset trimming are displayed

when the DKT-G, DKT-2H and the OFFSET TRIM KIT (options) are

attached.

[4] Paper size Displays a paper size (length x width) for the memory currently

selected.

[5] Finished size Displays a nished size (length x width) for a booklet made.

[6] Memory number(*) Displays a memory currently selected.

[7] Memory number select key(*) Selects a memory number.

The number selected is displayed in No. [6] and its settings are

displayed from Nos. [1] to [5].

[8]

[9] The number of sets processed Displays the number of sets processed.

[10] C key Clears the “number of sets processed” to 0. Press for more than one

[11]

[12] Message display Displays a message.

(setting) key(*)

(size change) key(*)

Displays the menu to change the settings for the memory currently

selected. If changing the information is not available, the (lock)

icon will be displayed.

second.

Moves the guides and the base according to the settings of the

memory number selected.

Press for more than one second.

(*) These items are not displayed or deactivated when the PC CONTROLLER is connected to the system.

1-18

Page 29

4-4-1. Stitch and fold setting screen

This is displayed when the key is pressed.

Chapter 1 Before Operation

[1a][1d] [1e]

[1]

[2]

[3]

[3a]

[4] [5] [6] [7]

No. Item Details

[1] Stitch Displays stitching methods available. Select a desired stitching

method.

[1a] Saddle stitching

[1b] Side stitching

[1c] Corner stitching

[1d] No stitch

[1e] Calendar(*)

(*) This is displayed when the CALENDAR KIT (option) is attached.

[2] The number of stitches

*Displayed when the 4 STITCH KIT

(option) is attached.

[3] Fold Displays folding methods available.

[4] Job setting icon This icon means that you are currently setting a job.

[5] Memory No. Displays the memory No. for which you are currently making

[6] Return key Returns to the [Main] screen without saving the settings.

[7] Next page key Moves to the trimming setting screen.

Select the number of stitches you desire.

[3a] Fold on

[3b] Fold o

[3c] Page insertion

settings.

[1b] [1c]

[3c]

[3b]

1-19

Page 30

Chapter 1 Before Operation

4-4-2. Trimming setting screen

[1a][2a][2c] [2d][2b][1b]

[1]

[2]

[3]

[3a]

[3b]

[4] [5] [6] [8][7]

No. Item Details

[1] Fore-edge trimming Displays choices for fore-edge trimming. Select a desired trimming

method.

[1a] Fore-edge trimming on

[1b] Fore-edge trimming o

[2] Head/foot trimming

*Head/foot trimming is performed

using the DKT-200.

[3] Head/foot oset trimming

*Displayed when the OFFSET TRIM

KIT (option) has been attached

to the DKT-200 and changing the

settings by a user has been made

available by your dealer.

[4] Job setting icon This icon means that you are currently setting a job.

[5] Memory No. Displays the memory No. for which you are currently making

[6] Return key Returns to the [Main] screen without saving the settings.

[7] Previous page key Returns to the stitch and fold setting screen.

[8] Next page key Moves to the paper size entry screen.

Displays available choices for head/foot trimming. Select a desired

trimming method.

[2a]Head/foot trimming on

[2b] Head/foot trimming o

[2c] Head/foot trimming + gutter cutting (*1)

[2d] Head/foot trimming + punch (*2)

(*1) This is displayed when the DKT-G (option) is attached.

(*2) This is displayed when the DKT-2H (option) is attached.

Displays choices for head/foot trimming.

[3a] Oset trimming o

[3b] Oset trimming on

settings.

1-20

Page 31

Chapter 1 Before Operation

4-4-3. Paper size entry screen

This is a screen to enter a paper length and paper width.

Once you enter a length and width, the stitching position, folding position and the stitching width is

automatically displayed.

To change a value, press the box in which a value is displayed. The value will be [0] and the numeric entry

screen will be displayed. Enter a value using the numeric keypad.

”4-4-1. Stitch and fold setting screen” (p.1-19)

[1]

[2]

[5]

[6]

[8] [9] [10]

No. Item Details

[1] Paper conveyance direction Displays the paper conveyance direction.

[2] Unit Displays a unit for a value currently displayed.

[3] Paper length Enter a paper length.

[4] Paper width Enter a paper width.

[5] Stitching position Enter a stitching position. A distance from the lead edge of the paper

[3]

[7]

[4]

[13][12][11]

Setting range:

Saddle stitching, no stitch: 170 to 640 mm/6.70 to 25.19 inches

Side stitching, corner stitching: 170 to 364 mm/6.70 to 14.33 inches

Setting range:

Saddle stitching, no stitch: 105 to 364 mm/4.14 to 14.33 inches (for

2 stitches)

Saddle stitching: 193.5 to 364 mm/7.62 to 14.33 inches (for 4

stitches)

Side stitching: 210 to 364 mm/8.27 to 14.33 inches

Corner stitching: 210 to 356 mm/8.27 to 14.01 inches

to the stitching position is displayed. This is displayed when "saddle

stitching" has been selected.

Setting range:

Saddle stitching: (paper length/2) ±15 mm/0.59 inch

*The value must be between 85 and 320 mm/3.35 and 12.59 inches

and the dierence with the paper length must be between 85 and

320 mm/3.35 and 12.59 inches.

Default: paper length/2

*During calendar making operations, the default is +5 mm/0.20

inch.

1-21

Page 32

Chapter 1 Before Operation

No. Item Details

[6] Folding position Enter a folding position. A distance from the lead edge of paper to

the folding position is displayed.

Setting range: (paper length/2) ± 15 mm/0.59 inch

*The value must be between 85 and 320 mm/3.35 and 12.59 inches

and the dierence with the paper width must be between 85 and

320 mm/3.35 and 12.59 inches.

Default: paper length/2

[7] Stitching width Enter a length between the centers of two stitches.

Setting range:

58.5 mm/2.31 inches to (paper width - 30 mm/1.18 inches) (for 2

stitches)*

* The upper limit is 328 mm/12.91 inches

58.5 mm/2.31 inches to (paper width - 30 mm/1.18 inches) (for 2

stitches when the 4 STITCH KIT is attached)*

* The upper limit is 223 mm/8.77 inches.

Default: paper length/2

*It will be set at a position avoiding this area.

For side stitching, a length from the edge of the paper is displayed.

Default: 15 mm/0.59 inch

[8] Job setting icon This icon means that you are currently setting a job.

[9] Memory No. Displays the memory No. for which you are currently making

settings.

[10] Return key Returns to the [Main] screen without saving the settings.

[11] Previous page key Returns to the trimming setting screen.

[12] Next page key Moves to the nished size screen. This screen is displayed when “fore-

edge trimming on“ or “head/foot trimming on” has been selected.

[13] (return) key Pressing the key saves the setting in the memory and the {Main]

screen is displayed.

Numeric entry screen

[1]

[7]

No. Item Details

[1] Item icon An icon is displayed according to the item for which you are entering

values. In the gure above, the icon for paper size entry is displayed.

[2] Numerical display Displays a value entered.

[2]

[3]

[4][5][6]

1-22

Page 33

Chapter 1 Before Operation

No. Item Details

[3] Return key Returns to the paper size entry screen without saving the value.

[4] key Conrms the value entered. If the value entered is not within the

setting range, you will hear the beep sound twice. The value entered

will be invalid.

[5] Clear key Clears the value entered.

[6] Numeric keypad Use this to enter values.

[7] Message display Displays a setting range for the item currently selected.

4-4-4. Finished size entry screen

This is a screen to enter a nished size and is displayed when “fore-edge trimming on” or “had/foot trimming

on” has been selected.

[1]

[5]

[6]

[9] [10] [11]

No. Item Details

[1] Paper conveyance direction Displays the paper conveyance direction.

[2] Unit Displays a unit for a value currently displayed.

[3] Finished paper length Enter nished length.

Setting range: 75 to 304 mm/2.96 to 11.96 inches (trimming space is

Default: (nished length after trimming/2) - 3.0 mm/0.12 inch

[4] Finished paper width Enter a nished width.

For head/foot trimming on

For gutter cutting:

[3][2]

[7]

[4]

[8]

[13][12]

between 1 and 75 mm/0.04 and 2.96 inches)

Setting range:

paper width - (30.0 mm/1.18 inches x 2) to paper width -

(1.0 mm/0.04 inch x 2) mm

Default:

(paper width - (3.0 mm/0.12 inch x 2))

Setting range:

(paper width - 6.0 mm/0.24 inch - 30.0 mm/1.18 inches x 2)/2 to

(paper width - 6.0 mm/0.24 inch - 1.0 mm/0.04 inch x 2)/2

Default:

(paper width - 6.0 mm/0.24 inch - 30.0 mm/1.18 inches x 2)/2

1-23

Page 34

Chapter 1 Before Operation

No. Item Details

[5] Stitching width (outside)

*Displayed when the 4 STITCH KIT

(option) is attached.

[6] Stitching width (inside) Enter the stitching with for the middle 2 stitches.

[7] Head/foot trimming width 1 Displays the head trimming of a booklet.

[8] Head/foot trimming width 2 Displays the foot trimming of a booklet.

[9] Job setting icon This icon means that you are currently setting a job.

[10] Memory No. Displays the memory No. for which you are currently making

[11] Return key Returns to the [Main] screen without saving the settings.

[12] Previous page key Returns to the paper size entry screen.

[13] key Conrms the value entered. If the value entered is not within the

Out of 4 stitches, enter the stitching width for 2 stitches on the

operator's side and the other 2 on the non-operator's side.

For oset trimming o: When the nished width is entered, the

trimming width is automatically displayed.

For oset trimming on (option): Enter the head trimming width.

Default: 3 mm/0.12 inch

For oset trimming o: When the nished width is entered, the

trimming width is automatically displayed.

For oset trimming on (option): When the head/foot trimming width

1 is entered, the value is automatically displayed.

Default:3 mm/0.12 inch

settings.

setting range, you will hear the beep sound twice. The value entered

will be invalid.

Information on offset trimming

The default for the head/foot trimming width [3.0] is displayed in [7]. If you have selected “oset trimming

on,” you can change the value.

“Oset trim” means to widen trimming width either at the head or the foot.

In the normal head/foot trimming, the same amount is trimmed at both sides. When the OFFSET TRIM KIT

(option) is installed to the DKT-200, you can specify dierent trimming width between the head and the foot.

To specify the dierent width between the head and the foot, the following three conditions need to be

satised.

- The width of the booklet conveyed to the DKT-200 is 341 mm/13.42 inches or less.

- The respective width of the head and foot is between 1 mm and 30 mm/0.04 inch and 1.18 inches.

- The dierence of the trimming width between the head and foot is between 0 mm and 21 mm/0

inches and 0.83 inch.

Example)

When the trimming width at the head side is 1 mm/0.04 inch, the trimming width at the foot side varies

between 1 mm and 22 mm/0.04 inch and 0.87 inch depending on the nished size.

1-24

Page 35

Chapter 1 Before Operation

4-5. [Adjust] screen

The [Adjust] screen consists of the two sections: menu for the step mode, and the adjustment menu used for

purposes other than the step mode.

[4] [5] [6]

[2]

[1]

[3]

[8]

[9]

[13] [14] [15]

No. Item Details

[1] Step mode key Pressing this key displays the screen to perform the step mode.

[2] Trim setting key(*1) Select whether to trim a set bound in the step mode. When the DBM-

600 is not connected to the DBM-600T, this is not displayed.

[3] Stitching position adjustment key Pressing this key displays the stitching position adjustment screen.

[4] Folding position adjustment key Pressing this key displays the folding position adjustment screen.

[5] Stitching and folding position

adjustment key

[6] Stitching width adjustment key Pressing this key displays the stitching width adjustment screen.

[7] Base adjustment key Pressing this key displays the base adjustment screen.

[8] Stitching side guide adjustment key Pressing this key displays the stitching side guide adjustment screen.

[9] Stitching back guide adjustment key Pressing this key displays the stitching back guide adjustment

[10] Folding side guide adjustment key Pressing this key displays the folding side guide adjustment screen.

[11] Folding back guide adjustment key Pressing this key displays the folding back guide adjustment screen.

[12] Folding roller gap adjustment key Pressing this key displays the folding roller gap adjustment screen.

[13] Stitching width (inside) adjustment

key(*2)

[14] Stitching width (outside) adjustment

key(*2)

[15] Stitching width (inside and outside)

adjustment key(*2)

Pressing this key displays the stitching position and the folding

position adjustment screen.

screen.

Pressing this key displays the stitching width adjustment screen. You

can change the stitching width between the two stitches inside. The

stitching width between the two stitches on the operator’s side and

the other two stitches on the non-operator’s side is xed.

Pressing this key displays the stitching width adjustment screen. You

can change the stitching width between the two stitches outside.

The stitching width between the two stitches located in the middle is

xed.

Pressing this key displays the stitching width adjustment screen.

You can change the stitching width between the two stitches on the

operator’s side and the other two stitches on the non-operator’s side.

The center positions of the two stitches on the operator’s side and

the other two on the non-operator’s side are xed.

[7]

[10]

[11]

[12]

1-25

Page 36

Chapter 1 Before Operation

(*1) This is not displayed when the PC CONTROLLER is connected.

(*2) This is displayed when the 4 STITCH KIT (option) is attached.

4-6. [Function] screen

The [Function] screen is used to displays the menu to set the stopper and guide operations, the number of

jogs and others for the DBM-600.

1/7 page

[1a] [1b]

[1]

[2]

[3]

[4] [5] [6]

No. Item Details

[1] Stitching side guide moving width Specify the moving width of the stitching side guides.

[1a] 5 mm/0.20 inch

[1b] 2 mm/0.08 inch

Default: 5 mm/0.20 inch

[2] Stitching side guide opening

timing(*)

[3] Stitching stopper ascending timing(*) Adjusts the ascending timing for the stitching stopper after saddle

[4] Page number Displays the current page number.

[5] Previous page key Returns to the previous page.

[6] Next page key Goes to the next page.

Adjusts the opening timing of the stitching side guides.

+: The value increases and they moves with slower timing.

-: The value decreases and they moves with faster timing.

Setting range: 0 to 10, default: 0

stitching is made.

+: The value increases and the stopper ascends with slower timing.

-: The value decreases and the stopper ascends with faster timing,

Setting range: -5 to 5, default: 0

(*) The larger the value, the slower the processing speed.

1-26

Page 37

2/7 page

Chapter 1 Before Operation

[1a] [1b]

[1]

[2]

[3]

[4]

No. Item Details

[1] Ejection roller Specify whether to move the stitch ejection rollers R and L. When set

to on, the ejection roller stops.

[1a] Stitch ejection roller L

[1b] Stitch ejection roller R (*1)

Default: o

[2] Folding conveyance belt Specify whether to use the folding conveyance belt. When set to on,

the conveyance belt keeps moving and presses a booklet against

the stopper. Set this to on to stabilize the folding position when

”stitching with no fold" has been selected.

Default: o

[3] Fold start timing(*2) Adjusts the start timing for folding operations.

+: The value increases and folding starts with slower timing.

-: The value decreases and folding starts with faster timing.

Setting range: 0 to 10, default: 1

[4] Page number Displays the current page number.

[5] Previous page key Returns to the previous page.

[6] Next page key Goes to the next page.

[5] [6]

(*1) During page insertion operations, the stitch ejection roller R stops regardless of this setting.

(*2) The larger the value, the slower the processing speed.

1-27

Page 38

Chapter 1 Before Operation

[1]

[2]

[3]

[4]

[5] [6]

3/7 page

No. Item Details

[1] Middle jog If a sheet feeder or a collator is connected to the DBM-600 as a

upstream unit, each time the number of the specied sheets reaches

the stitching section, one jogging motion is made. Specify the

number of sheets.

Setting range: 0, 2 to 9, default: 0

When set to “0,” a jogging motion is not made.

You can set this item when a sheet feeder or a collator is connected

to the DBM-600. If a collator is connected, you need to use the

intelligent function.

[2] The number of jogs(*1) Specify the number of jogs at the stitching section.

+: The number of jogs increases.

-: The number of jogs decreases.

Setting range: 1 to 9, default: 1

[3] The number of sheets to be

processed(*2)

[4] Page number Displays the current page number.

[5] Previous page key Returns to the previous page.

[6] Next page key Goes to the next page.

Specify the number of sheets for manual feed or merged collation

when a upstream unit is connected to the DBM-600.

Setting range: fold on 2 to 30, fold o 2 to 50

Default: 2

(*1) The processing speed is slower with more jogs.

(*2) This item is deactivated when the PC CONTROLLER is connected to the system.

1-28

Page 39

4/7 page

Chapter 1 Before Operation

[1]

[2]

[3]

[4]

No. Item Details

[1] The number of manual feeds(*1) Specify the number of sheets feeding manually.

Setting range: 1 to 9, default: 1

[2] Stitch test key(*2) Used to check the stitching conditions. Pressing this key displays the

stitch test screen.

[3] Home reset key Pressing the key for more than one second moves the guides to the

home position.

[4] Page number Displays the current page number.

[5] Previous page key Returns to the previous page.

[6] Next page key Goes to the next page.

(p.3-6)

[5] [6]

(*1) This item is deactivated when the PC CONTROLLER is connected to the system.

(*2) This is active when the stitching method has been set to “saddle stitching.”

5/7 page

[1]

[2]

[3] [4] [5]

No. Item Details

[1] Wire feed detection Set the wire feed detection for each stitcher to on or o.

B1 = non-operator’s side, B2 = non-operator’s side (*), F1 = operator’s

side, F2 =operator’s side (*)

Default: on (F1, B1), o (F2, B2)

(*)B2 and F2 are displayed when the 4 STITCH KIT (option) is attached.

1-29

Page 40

Chapter 1 Before Operation

No. Item Details

[2] Screen contrast Adjusts the screen brightness.

+: Makes the screen brighter.

-: Makes the screen darker.

Default: 7

[3] Page number Displays the current page number.

[4] Previous page key Returns to the previous page.

[5] Next page key Goes to the next page.

6/7 page, 7/7 page

These pages are not displayed when the PC CONTROLLER is connected to the system.

[1]

[2] [3] [4]

No. Item Details

[1] Memory No. Specify whether to allow to change registered information in each

memory.

Grey: changeable

Yellow: not changeable

[2] Page number Displays the current page number.

[3] Previous page key Returns to the previous page.

[4] Next page key Goes to the next page.

[1]

[2] [3] [4]

1-30

Page 41

Chapter 1 Before Operation

4-7. [Options] screen

The [Options] screen is used to adjust operations of the options that can be connected to this machine.

This screen is not displayed or deactivated when the PC CONTROLLER is connected to the system.

[1]

[3] [4]

No. Item Details

[1] Stacker setting Displays the stacker setting screen.

[2] Kicker setting Displays the kicker setting screen.

[3] Fore-edge trimming setting Displays the fore-edge trimming setting screen.

[4] Head/foot trimming setting Displays the head/foot trimming screen.

[2]

1-31

Page 42

Chapter 1 Before Operation

4-7-1. Stacker setting screen

[1]

[2]

[3]

No. Item Details

[1] Conveyance start timing Adjusts the start timing of the conveyance belt.

+: The value increases and it starts to move with slower timing.

-: The value decreases and it starts to move with faster timing.

Depending on a machine the stacker is connected to, the setting

range vary as follows;

DBM-600: 0 to 9

DBM-600T: -5 to 5

DKT-200: 0 to 3

Default: 0

[2] Stacker conveyance time Adjusts the conveyance time of the stacker.

+: The value increases and the conveyance time is longer.

-: The value decreases and the conveyance time is shorter.

Setting range: 1 to 11, default: 3

[3] Return key Returns to the [Options] screen.

1-32

Page 43

4-7-2. Kicker setting screen

[1]

Chapter 1 Before Operation

[2]

No. Item Details

[1] The number of booklets to be sorted Specify the number of booklets to be sorted.

Pressing the box displays the numeric entry screen.

Setting range: 0 to 999, default: 0

When set to “0,“ booklets are not sorted.

[2] Return key Returns to the [Options] screen.

1-33

Page 44

Chapter 1 Before Operation

4-7-3. Fore-edge trimming setting screen

[1]

[2]

[3]

No. Item Details

[1] Conveyance stop timing Specify the conveyance belt stop timing.

+: The value increases and it stop with slower timing.

-: The value decreases and it stops with faster timing.

Setting range: -20 to 10, default: 0

[2] Conveyance start timing Specify the timing for the trimmer to resume conveyance.

+: The value increases and it starts to move with slower timing.

-: The value decreases and it starts to move with faster timing.

Setting range: 0 to 5, default: 0

[3] Return key Returns to the [Options] screen.

4-7-4. Head/foot trimming setting screen (first page)

[1]

[2]

[3]

[4] [5]

No. Item Details

[1] Knife start timing Specify the knife start timing.

+: The value increases and it starts to move with faster timing.

-: The value decreases and it starts to move with slower timing.

Setting range: -15 to 15, default: 0

1-34

Page 45

No. Item Details

[2] Conveyance stop timing Specify the conveyance belt stop timing.

+: The value increases and it stops with faster timing.

-: The value decreases and it stops with slower timing.

Setting range: -15 to 15, default: 0

[3] Conveyance restart timing Specify the conveyance restart timing.

+: The value increases and it restarts with faster timing.

-: The value decreases and it restarts with slower timing.

Setting range: -15 to 15, default: 0

[4] Return key Returns to the [Options] screen.

[5] Next page key Goes to the next page.

4-7-5. Head/foot trimming setting screen (second page)

[1] [2]

Chapter 1 Before Operation

[3] [4]

No. Item Details

[1] Head/foot trimming conveyance belt

stop setting

[2] On/o setting key On: The head/foot trimming belt stops during head/foot trimming.

[3] Return key Returns to the [Options] screen.

[4] Previous page key Returns to the previous page.

Specify whether to stop the head/foot trimming conveyance belt of

the DKT-200 during head/foot trimming. If the head/foot trimming

conveyance belt is stopped, the processing speed of the system may

decrease. If you do not want to decrease the speed, set it to o.

Binding operations will be made at the speed at which the

conveyance belt stops during head/foot trimming.

O: The head/foot trimming belt does not stop during head/foot

trimming. Binding operations can be made at the maximum speed.

Default: o

1-35

Page 46

Chapter 1 Before Operation

5. DBM-600T Control Panel

5-1. Names of control panel

[1] [2]

[7][8][9]

[3]

[4]

[5]

[6]

No. Name Function

LCD display Displays the menus or error messages.

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

key Used to change a value.

(nished length adjustment) key

(roller gap adjustment) key

(step) key

(knife reverse) key

(paper ejection) key Ejects the paper jammed in the machine forcibly. Pressing the key

(clear/cancel) key Holding down the key clears the counter.

Lamp When the power of the machine is on, the lamp lights up.

Opens the nished length adjustment screen. This key is available

after a size change. If you start the step mode while the adjustment

screen is displayed, the machine will be set to the separate step

mode.(*)

Holding down the key for more than three seconds returns the

stopper to the home position (default position).

Opens the roller gap adjustment screen. This key is available after

a size change. If you start the step mode while the adjustment

screen is displayed, the machine will be set to the separate step

mode.(*)

With the system set to the step mode, when a booklet reaches

the stopper, pressing this key trims the booklet. When trimming is

set to o in the step mode, a booklet goes to the ejecting section

without being trimmed.

Holding down the key moves the knife counterclockwise to its

home position. Use this key when the paper jams under the knife.

during operations will move the conveyance belt of the stacker.

While holding down the key, the conveyance belt of the stacker

will continue turning.

(*) In the normal step mode, a step-by-step operation is performed for all the machines connected.

Meanwhile in the separate step mode, a step-by-step operation is performed only for the machine

selected.

1-36

Page 47

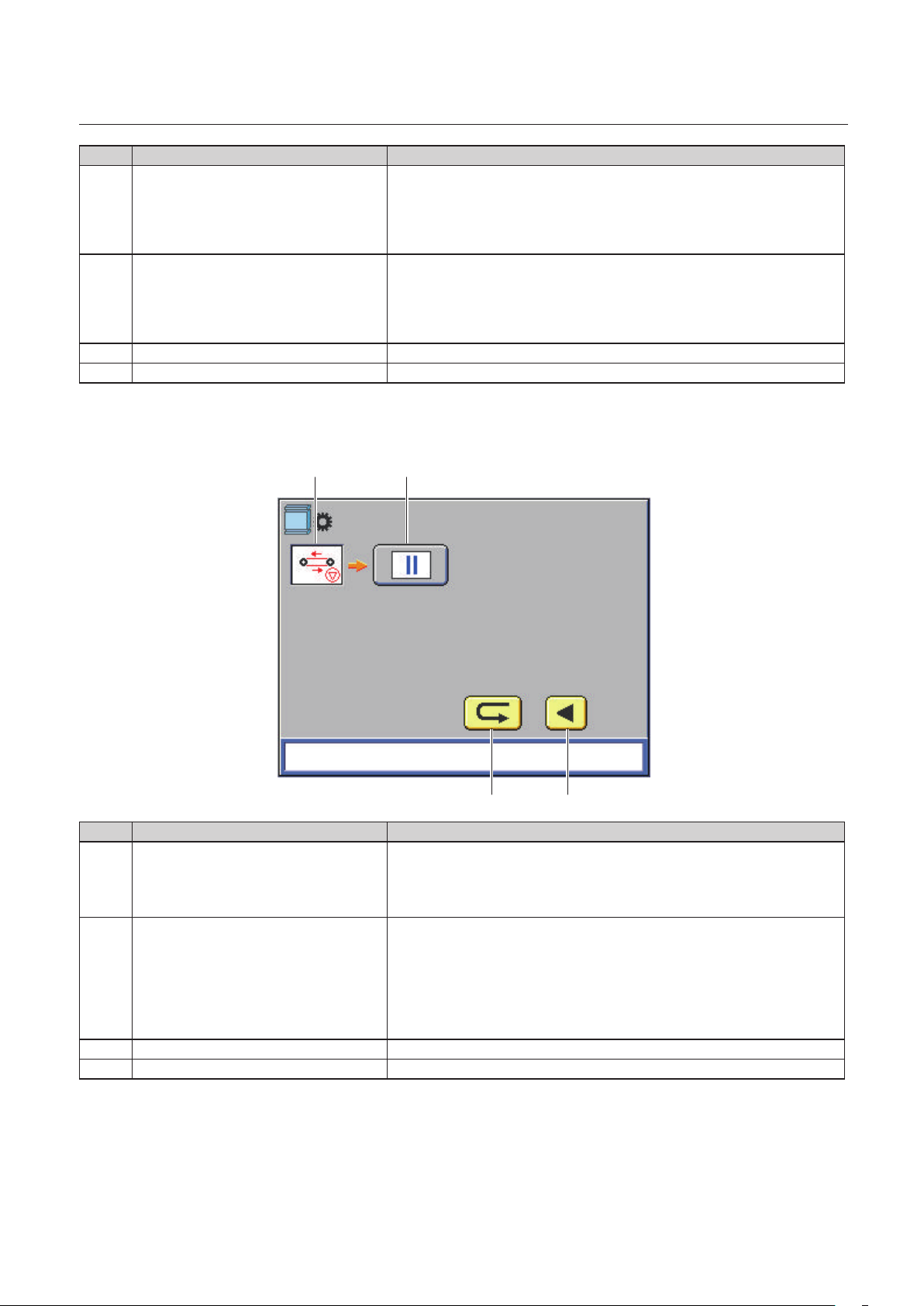

5-2. Screen menus

5-2-1. Top screen

The top screen is a screen displayed rst when you turn on the power.

Chapter 1 Before Operation

[1]

[2]

[3]

[4]

No. Name Function

Machine status Displays a current machine status. While the machine is in

[1]

Trimming mode Displays whether to perform trimming.

[2]

Finished length Displays a length of the fore-edge trimmed booklet.

[3]

Square spine display

[4]

*This is displayed when the ASM is

connected to the DBM-600T as a

downstream unit.

Processed number display Displays the number of booklets processed by the machine.

[5]

Ready

Trimming On

Fin Length

:2

operation, any of the following messages is displayed.

[Ejecting Paper] [Home Resetting] [Size Changing] [Processing] [In

Step Mode]

Displays how the Automatic SpineMaster (ASM) has been set.

: OFF: Bypass Mode

: 1: Single Pass

: 2: Double Pass (default)

To change the setting, when [Ready] is displayed as a machine

status, press the or key. When the power is turned o, the

display returns to [ : 2].

*The setting must be the same as that you made on the ASM. If the

setting is dierent between the DBM-600T and the ASM, a paper

jam or mechanical malfunction may occur.

Pressing the key for more than one second returns the count

to [0]. Once you turn o the power, the count returns to [0].

123.0

0

[5]

5-2-2. Menu list

The following menu items are provided with this machine.

Item Adjustable

range

Roller Gap -12 to +28 Adjusts roller gap by 0.5 mm/0.020 inch. You can adjust this during

operations.

*If the roller gap after adjustment is 0 mm/0 inches or less, adjustment is

not possible.

Fin Lengh -25 to +25 Adjusts nished length by 0.2 mm/0.008 inch. You can adjust this during

operations.

*If nished length is other than 75 to 307 mm/2.96 to 12.09 inches,

adjustment is not possible.

Details

1-37

Page 48

Chapter 1 Before Operation

5-2-3. How to use the menu screen

The basic operation on the menu screen is as follows.

The following steps shows how to adjust a nished length as an example.

1

Press the key when the top screen is

displayed or [Ready] or [Processing] is

displayed as a machine status.

The screen for adjusting a nished length will

be displayed.

2

Adjust a finished length using the or

key.

3

When the adjustment is complete, press

the key.

The screen returns to the top.

When other adjustment key is pressed in step

3, the adjustment screen of the pressed key is

displayed.

6. Stitching Width

Ready

Trimming On

Fin Length

Processing

Trimming On

or

123.0

0 0

Fin Length

Value

Fin Length

+0

123.0

Stitching width is the center to center distance between the two stitches. Although the stitching width has

been set to the standard position, you can change the setting if the stitch and print overlaps.

If the value you entered falls on the stitch prohibited area, the folding knife and a stitch coincide

and the folding position may slightly change. We recommend that you do not fine adjust a

stitching position and leave it as it is.

[a] Paper conveyance direction

[b] Stitching width

[c] Paper width

[a]

[b] [c]

1-38

Page 49

Chapter 1 Before Operation

• Saddle stitching and folding, saddle stitching, side stitching and folding, side stitching

Standard position = paper width/2

Example: When the paper width is 210

mm/8.27 inches

210/2 = 105 mm/4.13 inches

The available input range: 58.5 mm/2.31

inches to (paper width - 30 mm/1.18 inches)

The upper limit is 328 mm/12.91 inches.

The available input range for 2 stitches with

the 4 STITCH KIT attached: 58.5 mm/2.31

inches to (paper width - 30 mm/1.18 inches)

The upper limit is 223 mm/8.77 inches.

• Corner stitching

Standard position = 15 mm/0.59 inch (from

the lead edge of the paper to the center of the

stitch)

Example: When the paper width is 210

mm/8.27 inches

210 - 30 mm = 180 mm

/8.27 - 1.18 inches = 7.09 inches

The available input range varies depending on

the number of stitches.

4 head 4 stitches:

15 mm/0.59 inch to (paper width - 163.5

mm/6.44 inches)/2

[a] [b]

105 mm

/4.13 inches

15 mm

/0.59 inch

[a] [b]

180 mm

/7.09 inches

[c]

[c]

2 head 2 stitches:

15 mm/0.59 inch to (paper width - 58.5

mm/2.31 inches)/2

4 head 2 stitches:

If the paper width is long, stitching at 15

mm/0.59 inch from the edge of paper may

not be available. Depending on a paper

size, the minimum value changes.

1-39

Page 50

Chapter 1 Before Operation

Stitch prohibited area

The position at which the folding knife and a stitch coincide is called the stitch prohibited area. When ne

adjusting the stitching width, avoid the stitch prohibited area.

Stitch prohibited area

250 to 286 mm/9.84 to 11.26 inches

192 to 202 mm/7.56 to 7.95 inches

118 to 144 mm/4.65 to 5.67 inches

61 to 80 mm

/2.40 to 3.15 inches

Folding knife

Paper center line

Stitch prohibited area

7. Options

The items listed below are the parts for options, which a user need to attach or remove.

7-1. DBM-SSW

The DBM-SSW can be connected to both the DBM-600 and the DBM-600T.

[1] [2]

No. Name QTY Function

[1] Paper guide roller unit

(large)

[2] Paper guide roller unit

(small)

1 Holds paper conveyed to the stacker.

1 Holds paper conveyed to the stacker. Use this when a nished size of

the booklet is 121 mm/4.76 inches or less.

1-40

Page 51

Chapter 1 Before Operation

7-2. DBM-LSW

The DBM-LSW can be connected to the DBM-600T.

[1] [3][2]

No. Name QTY Function

[1] Paper guide roller unit

(large)

[2] Paper guide roller unit

(small)

[3] Paper receiving angle 2 Attach the angle to the both sides of the paper receiving tray. (magnet

1 Holds paper conveyed to the stacker.

1 Holds paper conveyed to the stacker. Use this when a nished size of

the booklet is 121 mm/4.76 inches or less.

type)

7-3. DKT-K

The DKT-K can be attached to the DBM-LSW. The DKT-K cannot be attached to the DBM-SSW.

[1] [2]

No. Name QTY Function

[1] Kicker support wheel unit 1 Attach this to the stacker.

[2] Stopper 1 Prevents the sorted booklet from being kicked too much.

(p.3-3)

(p.3-4)

1-41

Page 52

Chapter 1 Before Operation

8. Workflow

The owchart below illustrates the ow of basic operation. For details, refer to the text and relevant pages.

Turning on the power

Setting the control panel(*)

Preparing the DBM-600 and the DBM-

Preparing the upstream unit

Step mode(*)

Checking the nished booklet

Starting binding operations(*)

600T

(p.2-1)

(p.2-3)

(p.2-16)(p.2-19)

(p.2-20)

(p.2-20)

Adjusting each section

DBM-600

(p.2-25)

(p.2-48)

DBM-600T

(p.2-37)

(p.2-42)

Turning o the power

(p.2-2)

Step mode

(*) When using the PC CONTROLLER, refer to the PC CONTROLLER operation manual.

(p.2-20)

1-42

Page 53

Chapter 2 Basic Operation

1. Turning On/Off the Power

Make sure that the power plug is connected to the wall socket.

Do not touch the power switch

with wet hands.

Otherwise electric hazards may occur.

Chapter 2 Basic Operation

• When a upstream unit is connected to the DBM-600, you cannot touch the power switch. To

prevent a user from touching it, the power switch cover has been attached.

• You cannot touch the power switch of the DBM-600T. To prevent a user from touching it, the power

switch cover has been attached.

1-1. Turning on the power

Normally set the power switch to “ .”

When the power switch of the paper feeding machine (a collator or a sheet feeder) is set to “l,” the remote

function will work and turn on the power of the connected machines including this machine.

When the upstream unit is not connected to the DBM-600

1

Set the power switch of the DBM-600 to

“l.”

2-1

Page 54

Chapter 2 Basic Operation

When the upstream unit is connected to the DBM-600

1

2

Set the main power switch of the paper feeding machine to “l.”

Set the power switch of the paper feeding machine to “l.”

The remote function will work and turn on the powers of the connected machines including this

machine.

When connected to a collator, set only the power switch of the tower A to “l” and leave the power

switches of other towers “ .”

1-2. Turning off the power

When the upstream unit is not connected to the DBM-600

1

Set the power switch of the DBM-600 to

“ .”

When the upstream unit is connected to the DBM-600

1

2

Make sure that all the operations in the system are complete.

Set the power switch of the paper feeding machine to “ .”

The powers of the all the machines connected to the DBM-600 will be turned o.

Before turning on the power, wait for two seconds or more.

When connected to the collator, set the power switch of only the tower A to “ .”

When the upstream unit is connected to this machine, do not turn on/off the power using the

power switch of this machine. This may cause a malfunction. Make sure that you use the power

switch of the paper feeding machine.

2-2

Page 55

Chapter 2 Basic Operation

2. Setting the Control Panel

Make settings for a binding mode, paper size, trimming and others on the control panel. If you do not use

the default memory, select a memory number and make settings following the procedures below. All the

memories can be overwritten. It would be useful to register 20 types of settings you regularly use.

The default setting is as shown in the table below.

• When the machine is connected to the PC CONTROLLER, use the PC CONTROLLER to make settings.

You cannot make settings using this machine.

• You can make settings to prevent you from overwriting data.

• Information on memory No. 0

If you do not want to overwrite the default memory, you can save the setting you made in the

memory No. 0. The information saved in No. 0 is cleared once you turn o the power.

How to use No. 0

1) Select either one from the memories No. 1 to 20 and press the key.

2) Select the memory No. 0.

3) The detailed information on the memory you have selected in step 1) is displayed on the touch

panel.

4) Press the key.

5) Change the binding method.

6) Press the key again.

Memory

No.

1 420 x 297 16.54 x 11.69 A3 Saddle stitch Fold on

2 297 x 210 11.69 x 8.27 A4 Saddle stitch Fold on

3 210 x 297 8.27 x 11.69 A4 LEF Side stitch Fold o