Duo-Therm 39125, 39424, 59528.601, 59529.601, 59530.601 Service Manual

...

AIR CONDITIONER & HEAAIR CONDITIONER & HEA

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

AIR CONDITIONER & HEA

AIR CONDITIONER & HEAAIR CONDITIONER & HEA

T PUMPT PUMP

T PUMP

T PUMPT PUMP

SERVICE MANUSERVICE MANU

SERVICE MANU

SERVICE MANUSERVICE MANU

This Service Manual is the result of the dedication of The Dometic Corporation and its engineers to providing service people the necessary

instructions for making accurate analysis of certain conditions. Provided

is a comprehensive guide designed to lead a qualified mechanic through

the Service Manual to locate and solve symptoms that may occur.

Dometic continues their commitment to providing the most up to date

information about servicing Duo-Therm Air Conditioners and Heat Pumps.

ALAL

AL

ALAL

Form No. 3108892.013 10/00

©2000 The Dometic Corporation

LaGrange, IN 46761

Table of Contents

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Section Page

Installation ......................................................................... A.................................. 1

AC Power Requirements ............................................... A1 ................................ 1

DC Power Requirements .............................................. A2 ................................ 1

Field Wiring ................................................................... A3 ................................ 1

Breaker ......................................................................... A4 ................................ 2

Airbox ............................................................................ A5 ................................ 2

Ducting System ............................................................. A6 ................................ 2

Roof Top Units ........................................................ A6a .............................. 2

Basement Units ...................................................... A6b .............................. 9

Thermostat Location ..................................................... A7 .............................. 12

Operation ........................................................................... B ................................ 14

Air Conditioners ............................................................. B1 .............................. 14

Mechanical Controls ............................................... B1a ............................ 14

Bi-Metal Control System ......................................... B1b ............................ 14

Analog Control System ........................................... B1c ............................ 15

Comfort Control Center System .............................. B1d ............................ 16

Heat Pumps .................................................................. B2 .............................. 22

Mechanical Controls ............................................... B2a ............................ 24

Bi-Metal Control System ......................................... B2b ............................ 24

Analog Control System ........................................... B2c ............................ 25

Comfort Control Center System .............................. B2d ............................ 26

Components ...................................................................... C ................................ 27

Motors ........................................................................... C1.............................. 27

Capacitor, Fan/Run ....................................................... C2.............................. 28

Capacitor, Start .............................................................. C3 .............................. 28

PTCR Device or Start Relay .......................................... C4 .............................. 29

Compressor .................................................................. C5 .............................. 29

Overload Protector ........................................................ C6.............................. 30

Cold (Freeze) Control .................................................... C7.............................. 30

Electric Heat Strip.......................................................... C8.............................. 30

Selector Switch ............................................................. C9 .............................. 31

Changeover Thermostat ............................................... C10 ............................ 32

Remote Sensor ............................................................. C11 ............................ 32

Ambient Sensor ............................................................ C12 ............................ 33

Reversing Valve ............................................................ C13 ............................ 34

Transformer .................................................................. C14 ............................ 34

Fuse .............................................................................. C15............................ 34

Relay ............................................................................. C16............................ 35

Printed Circuit Board ..................................................... C17 ............................ 38

Thermostat .................................................................... C18 ............................ 42

Cable Assembly ............................................................ C19 ............................ 52

Sealed System .............................................................. C20 ............................ 55

Wiring ........................................................................... C21 ............................ 58

Other ............................................................................. C22 ............................ 59

Roof Gasket .................................................................. C23 ............................ 60

Configuration ..................................................................... D................................ 60

Symptom/Cause Chart ...................................................... E................................ 80

Roof Mounted Heat Pumps ........................................... E ................................ 80

Basement Heat Pumps ................................................. E ................................ 93

Roof Mounted Air Conditioners ..................................... E .............................. 102

Basement Air Conditioners ............................................ E............................... 116

Section A - Installation

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

A1. AC Voltage

The unit is a 115VAC, 60Hz appliance. The proper operating range is between 103 and 126.5 volts AC. The voltage

reading should be taken at the unit power supply leads.

One test should be performed when the unit is turned OFF

and another with it running under load. If the voltage is not

within the proper operating range, it must be corrected before operation of the unit.

This is an energized circuit. Shock can occur if not tested properly. Testing to be done

by a qualified service technician.

Check for proper AC volts at the connections at the units

electronic control box on roof mounted units and at the

connections at the electric box on basement units.

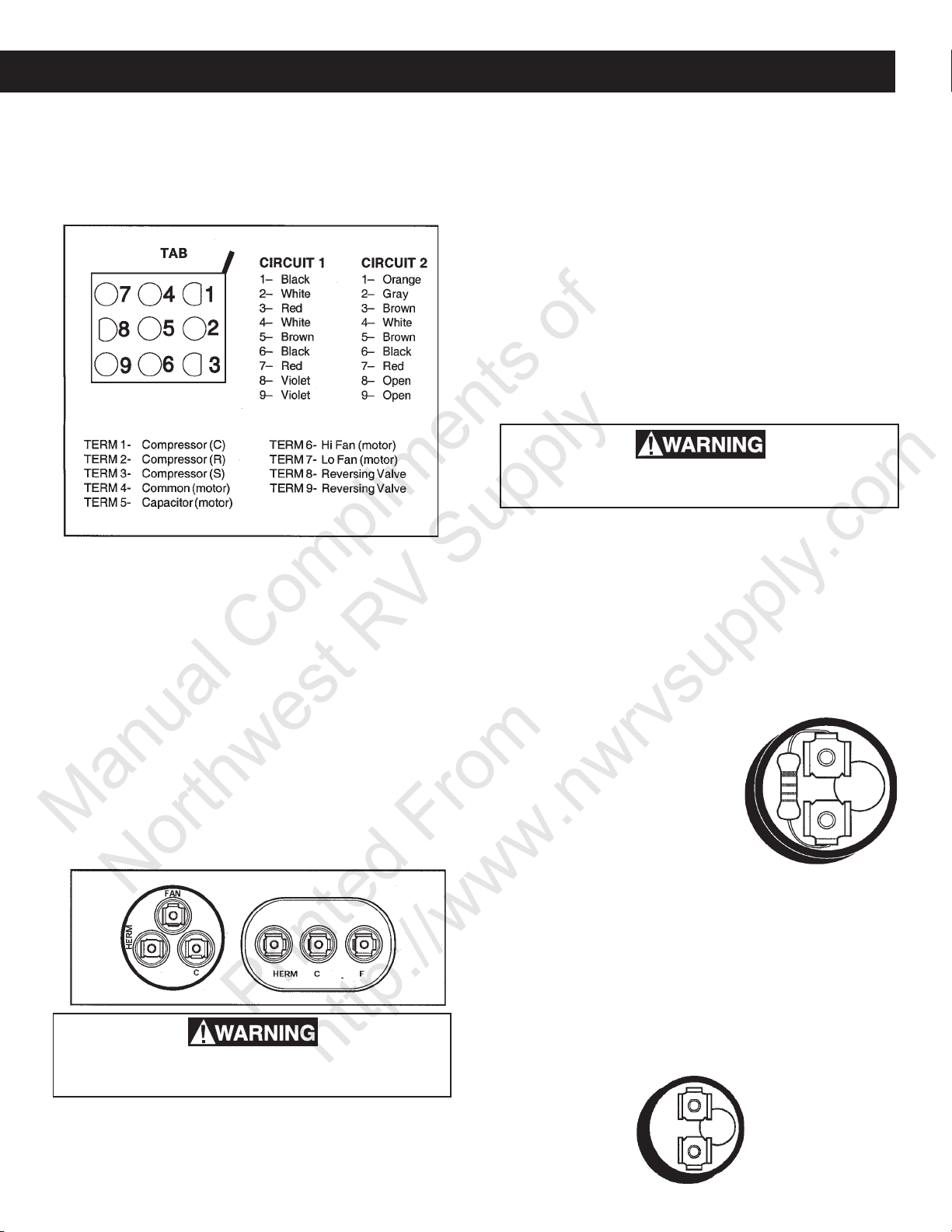

The dual units (Models 39224 and 39424) have two AC

volt circuits. Verify that Circuit 1 is wired into CIR 1 terminal block and Circuit 2 is wired into CIR 2 terminal block.

Check for proper AC volts at each terminal block.

A1a. AC Control Voltage

AC control voltage is supplied by the transformer for the

control circuits on the following units: 39025.XXX,

39035.XXX and 39045.XXX. Se Section C14- Transformers on page 34.

If a furnace is to be operated by the Analog Control System, the furnace thermostat leads are connected to the

blue/white striped wires out of the Analog Control Box. The

furnace wires can be connected to either wire as polarity is

not important. DC voltage is required by the Analog Control Board on one of the two wires for furnace operation.

A2b. Comfort Control Center System

A DC volt supply is required for the operation of the Comfort Control Center. The operational range is 10 to 30 volts

DC. If DC volts are outside of the operating range, you

could experience improper or erratic operation. To check

DC volts, first check the incoming DC volts between the

red (+) positive and black (-) negative, at the connections

on the Comfort Control Center control box on roof top units

or at the connections at the electric box of basement units.

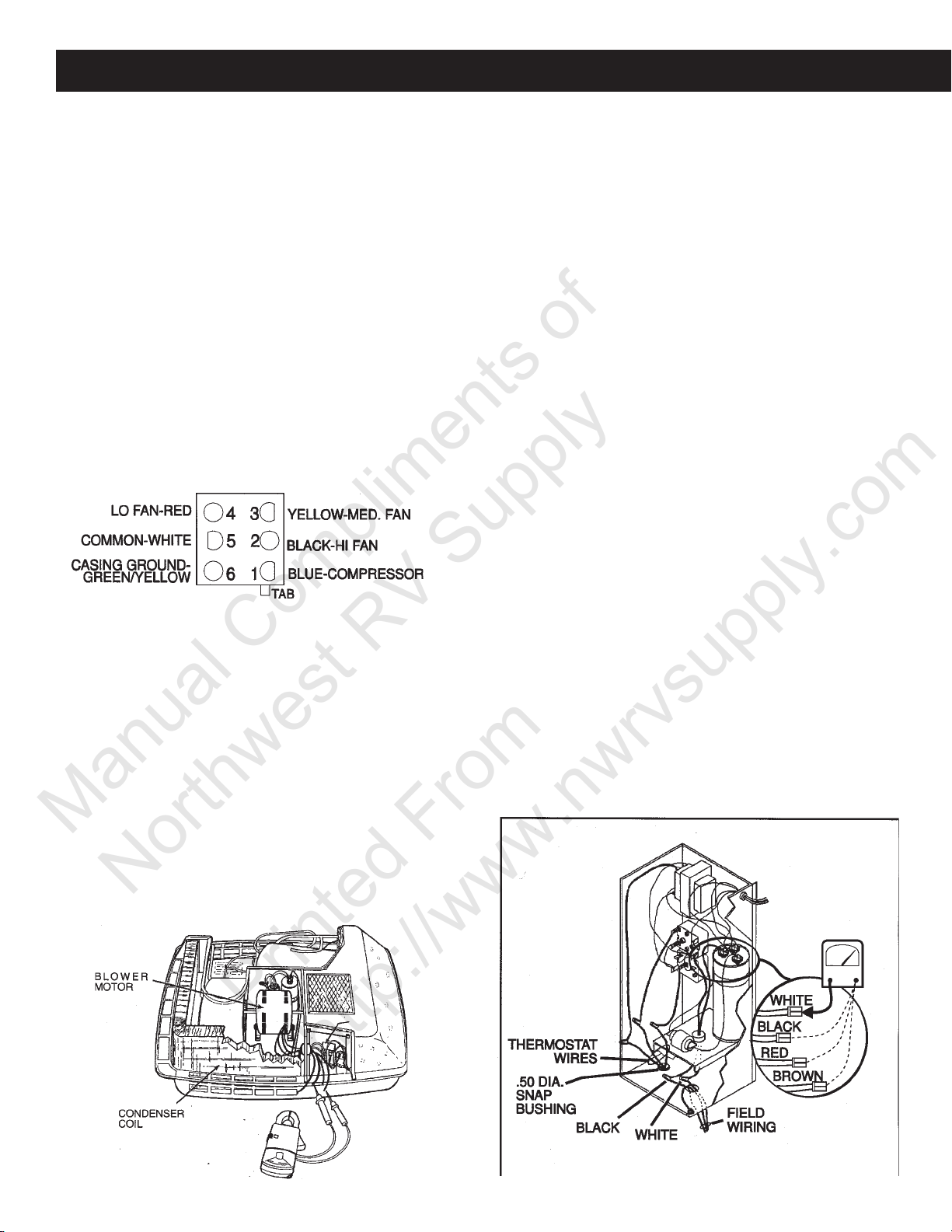

A3. Field Wiring

If the unit’s compressor or fan fails to operate, chances are

it is not receiving proper power. Be sure the power cord is

plugged in and fuses ore breakers are ope.

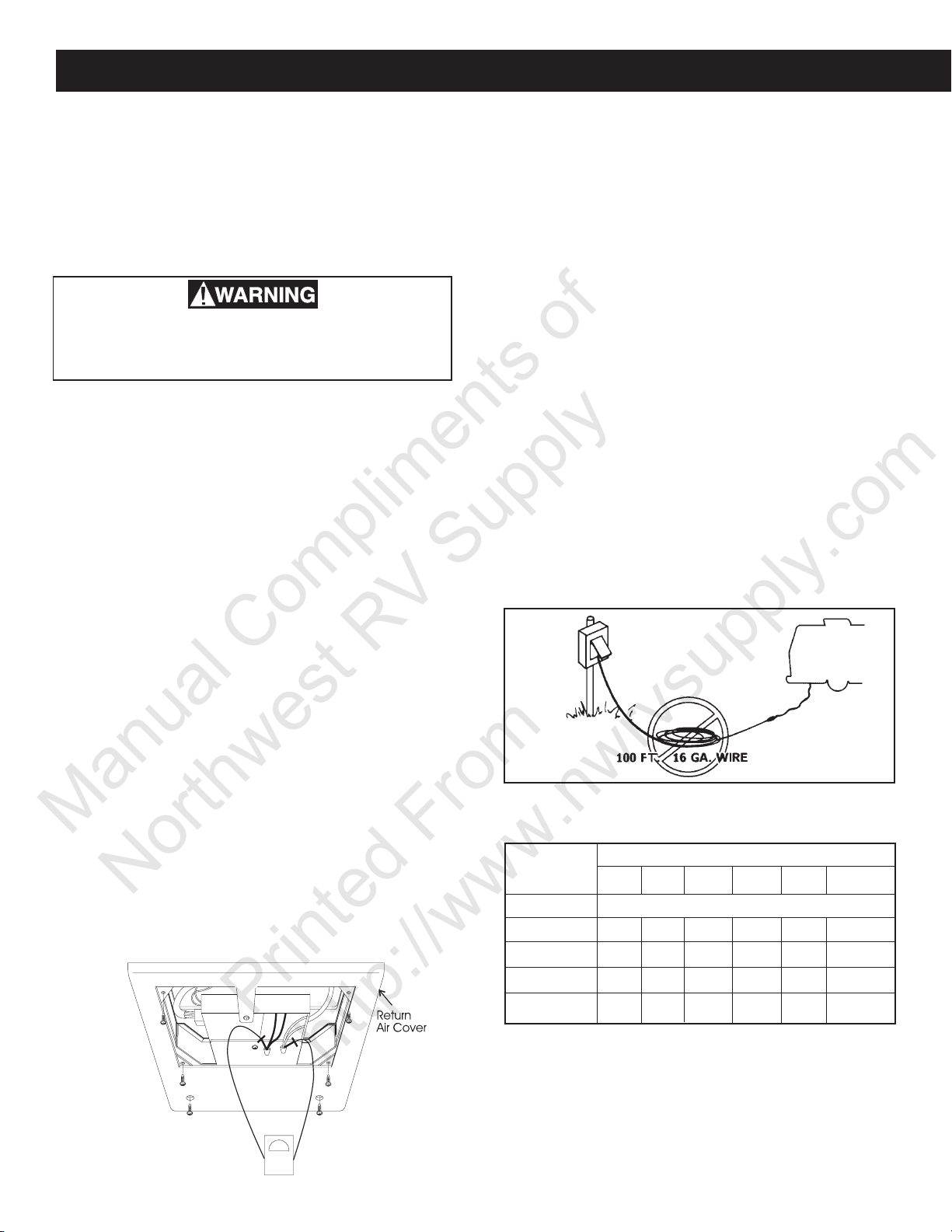

Note: Many customers use extremely long power cords

that are undersized. If possible, ask the owner to hook up

the RV just like it was when the problem occurred. See

FIG. A2

FIG. A2

A2. DC Volts

On certain models of electronic controlled air conditioners

and heat pumps, DC volts must be supplied to the control

board. The operational range is 10 to 16 VDC. If the DC

voltage is below 10 VDC, you could experience improper

operation of the components within the main board.

A2a. Analog Control System

A DC voltage supply is wired to the control board. The

operating range is 10-16 Volts DC, with a maximum current draw of 0.250 Amps.

To check DC volts, first check the voltage between the red

(+12) positive and black (-12) negative, at the connections

on the Analog Control Box on the roof top unit.

FIG. A1

Make note of the wire size and compare it to the chart for

wire sizing. See Section A1a - AC Control Voltage.

CURRENT WIRE SIZE

IN

AMPS 16 14 12 10 8 6

5 47 76 121 192 216 486

10 38 60 96 153 243

15 25 40 64 102 162

20 30 48 76 121

LENGTH IN FEET

1

Section A - Installation, cont’d.

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

A6a. Roof Top Units

A4. Breaker

A6. Ducting

A6a. Rooftop Units

Make sure that the power supply to the unit

is disconnected before performing any work

on the unit to avoid the possibility of shock

injury or damage to the equipment.

The unit is to be protected by a time delay fuse or HACR

(heating, air conditioner, refrigerator) breaker. By taking

an amp reading at the unit AC voltage supply line, you can

determine if the breaker is tripping prematurely. Place a

clamp-on type ammeter around the black wire between the

unit and breaker. Turn ON the unit and record the amp

draw. If the breaker trips before the rated amperage, replace the breaker.

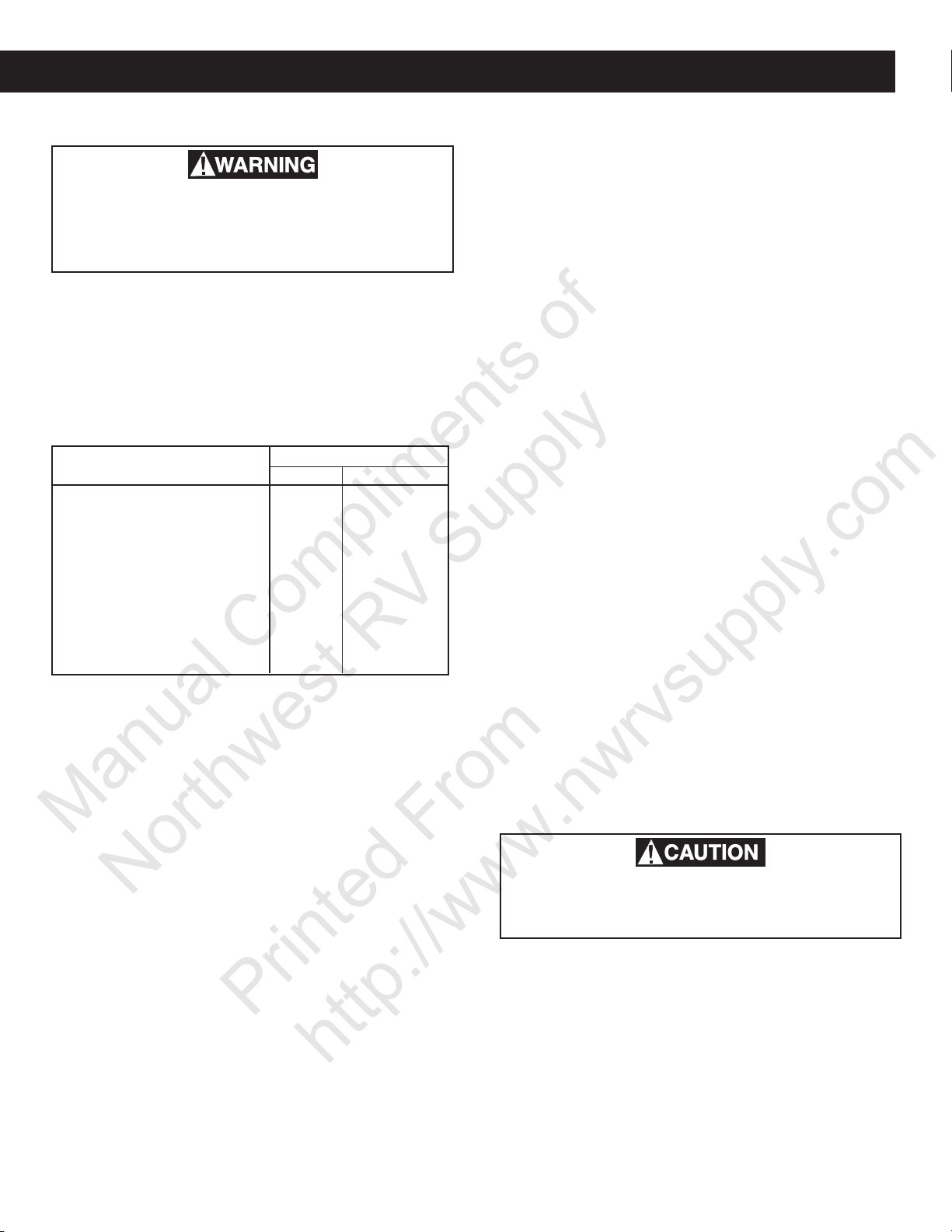

MODELS CIRCUIT PROTECTION

T.D. Fuse HACR Breaker

39125 (Basement) 15 amp 15 amp

39325 (Basement) 20 amp 20 amp

39224 (Basement)- Circuit 1 15 amp 15 amp

- Circuit 2 15 amp 15 amp

39424 (Basement)- Circuit 1 15 amp 15 amp

- Circuit 2 15 amp 15 amp

All Rooftop Units 20 amp 20 amp

59528.601 15 amp 15 amp

59529.601 15 amp 15 amp

59530.601 15 amp 15 amp

A5. Air Box

Improperly installed, the air box can be a source of cooling

problems. The air box must be sealed to the ceiling template to prevent the mixing of discharge and return air. This

will cause short cycling or frost formation on the inside coil

On heat pumps, recirculation can cause the high side pressure to build, tripping the overload and/or breaker. In some

instances, the ceiling template is bent when the anchor bolts

are overtightened, causing gaps between the air box and

the ceiling template. These gaps can be sealed with aluminum tape or a closed cell foam weather strip. The duct

connecting the air conditioner or heat pump must be air

tight. Use aluminum tape to seal the joints. The thermostat sensing bulb must be properly located to control temperature. If the sensing bulb is left curled against the side

of the electric box or used as a ground connection, improper operation will occur. Relocate the sensing bulb in

its proper place as indicated in the Installation and Operating Instructions. Check the air filters and clean.

Sizing and Design

The installer of this air conditioner system must design the

air distribution system for his particular application. Several requirements for this system MUST be met for the air

conditioner to operate properly. These requirements are

as follows:

Roof cavity thickness must be between 2.00" and 5.50".

This distance is measured between roof and ceiling surface.

The total cross-sectional discharge area of the outlet ducts

from the plenum area under the air conditioner must be as

follows:

1. 579 & 600 Series 17.5 sq. in.

2. 591, 595 & 630 Series 21.0 sq. in.

Duct Sizing Requirements as Follows:

Duct Depth (591/595/630 Series) 1-1/2" 2-1/4"

(579/600 Series) 1-1/4" 2-1/4"

Duct Width 7" — —

Total Duct Length 12 ft. 36 ft.

Duct Length (short run) 1/3 Total Length

Register Requirements as follows:

Distance from Duct End 5" 8"

Distance from End of Elbow 15" — —

Distance between Registers 24" — —

Total Number Required/AC 4 8

Number Required per Run/AC 2 — —

Free Area per Register 14 sq. in.— —

The duct material must meet or exceed any agency or RVIA

Standard that may be in existence at the time the RV is

produced.

It is the responsibility of the installer of this

system to ensure the ductwork will not collapse or bend during or after the installation.

All discharge air ducts must be properly insulated to prevent condensation from forming on their surfaces or adjacent surfaces during operation of the air conditioner or heat

pump. This insulation must be R-7 minimum.

Note: The Dometic Corporation will not be held liable for

roof, structural or ceiling damage due to improperly insulated or sealed ductwork.

Return air opening must have 40 sq. in. minimum free area

including the filter.

Min. Max.

Min. Max.

Return air to the air conditioner must be filtered to prevent

dirt accumulation on air conditioner cooling surface.

2

A6a. Roof Top Units

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Section A - Installation, cont’d.

Total System Pressure must be between the following:

0.55 to 0.90 in. W.C. for 579 Series

0.40 to 1.10 in. W.C. for 591, 595 & 630 Series

0.12 to 0.65 in. W. C. for 600 Series

This is determined with the air conditioner blower operation on high speed and return air filter and grille in place.

The Dometic Corporation recommends the basic configuration shown below for installing this Air Conditioner System. We have found by testing that this configuration works

best in most applications of the Air Conditioner/Heat Pump

System.

It is the responsibility of the installer of this system to review each RV floor plan and determine the following:

A. Duct Size

B. Duct Layout

C. Register Size

D. Register Locations

E. Thermostat Location

These items must be determined in conjunction with the

Air Distribution System Sizing and Design Requirements

listed.

Note: Alternate configurations and methods may be used

which still allow the air conditioner to operate properly.

However, these alternate configurations and methods must

be approved by The Dometic Corporation in writing.

The following instructions are based upon the use of

Dometic Return Air Kit. The electronic control kit has

mounting bolts supplied for use with this Kit. See FIG. A3.

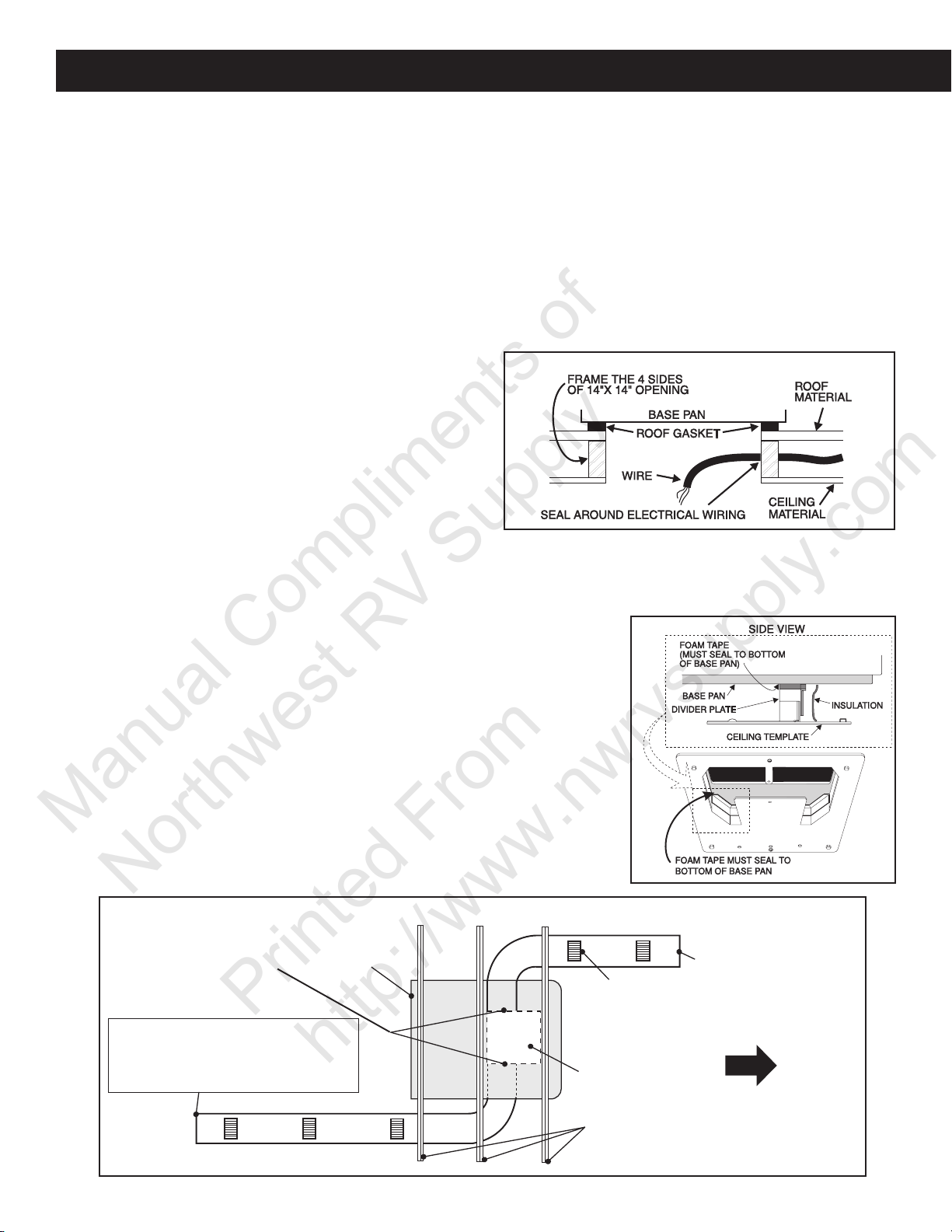

Before preparing the ceiling opening, the type of system

options must be decided upon. If a remote sensor is to be

used, provisions must be made for it. If the load shed option (Energy Management System feature) is to be used,

wires must be run from the load shed control to the Dometic

A/C. If a furnace is to be connected, wires must be run

from the furnace to the Air Conditioner.

The 14-1/4" x 14-1/4" (±1/8") opening must be framed to

seal off the roof cavity. Holes used to route electrical wiring should be sealed. The 14-1/4" x 14-1/4" (±1/8") open-

ing is part of the return air duct and must be finished in

accordance with NFPA Standard 501C, Standard for Recreational Vehicles, Section 2-7.

The most commonly found installation problem is the improper sealing of the 14-1/4" x 14-1/4" (±1/8") opening in

the roof cavity. The cooled discharge and warm return air

are mixed in the roof cavity and produce conditions that

are excellent for frost production.

Even the best framing job will not stop frost from occurring

if the cold air discharge is allowed to enter into the return

air portion of the 14-1/4" x 14-1/4" (±1/8") opening. See

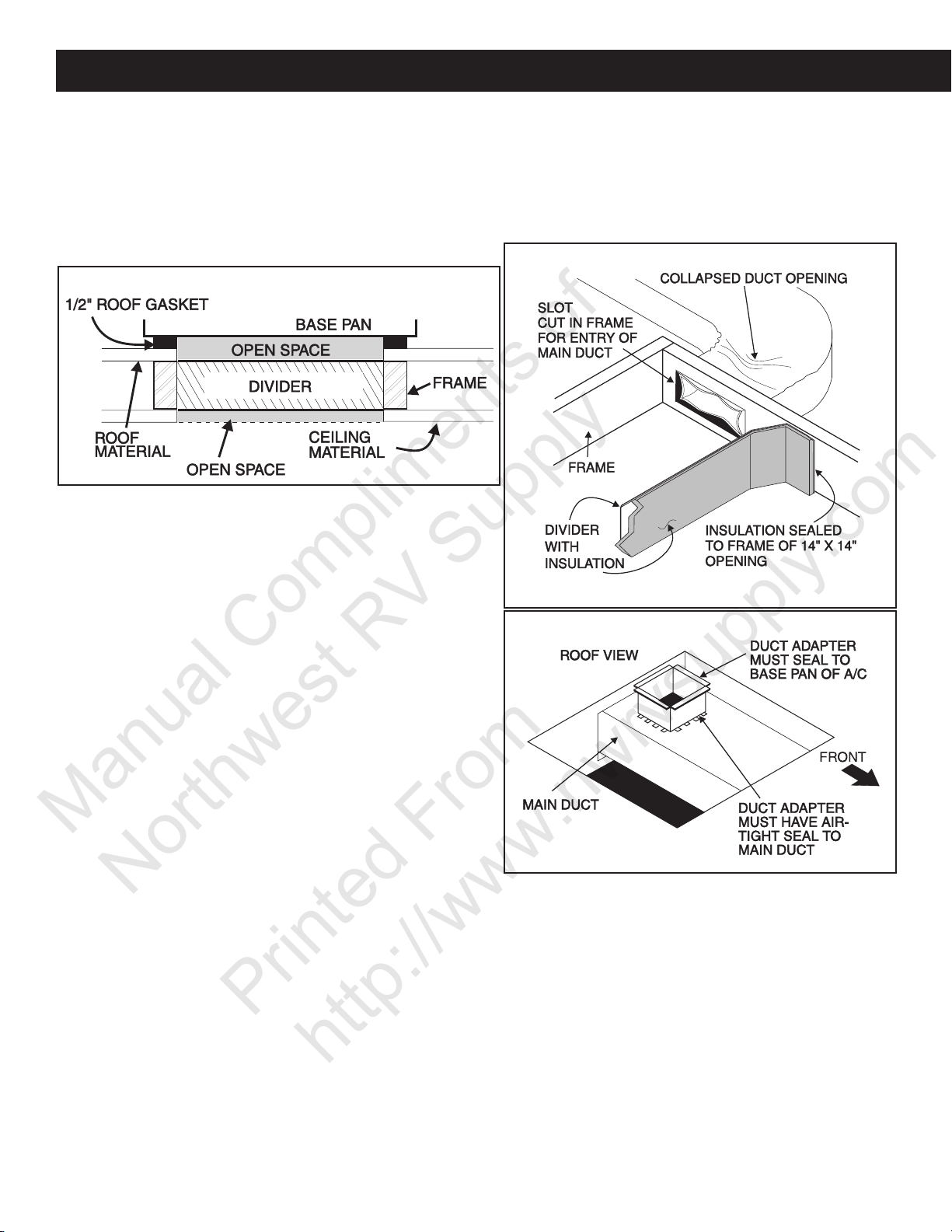

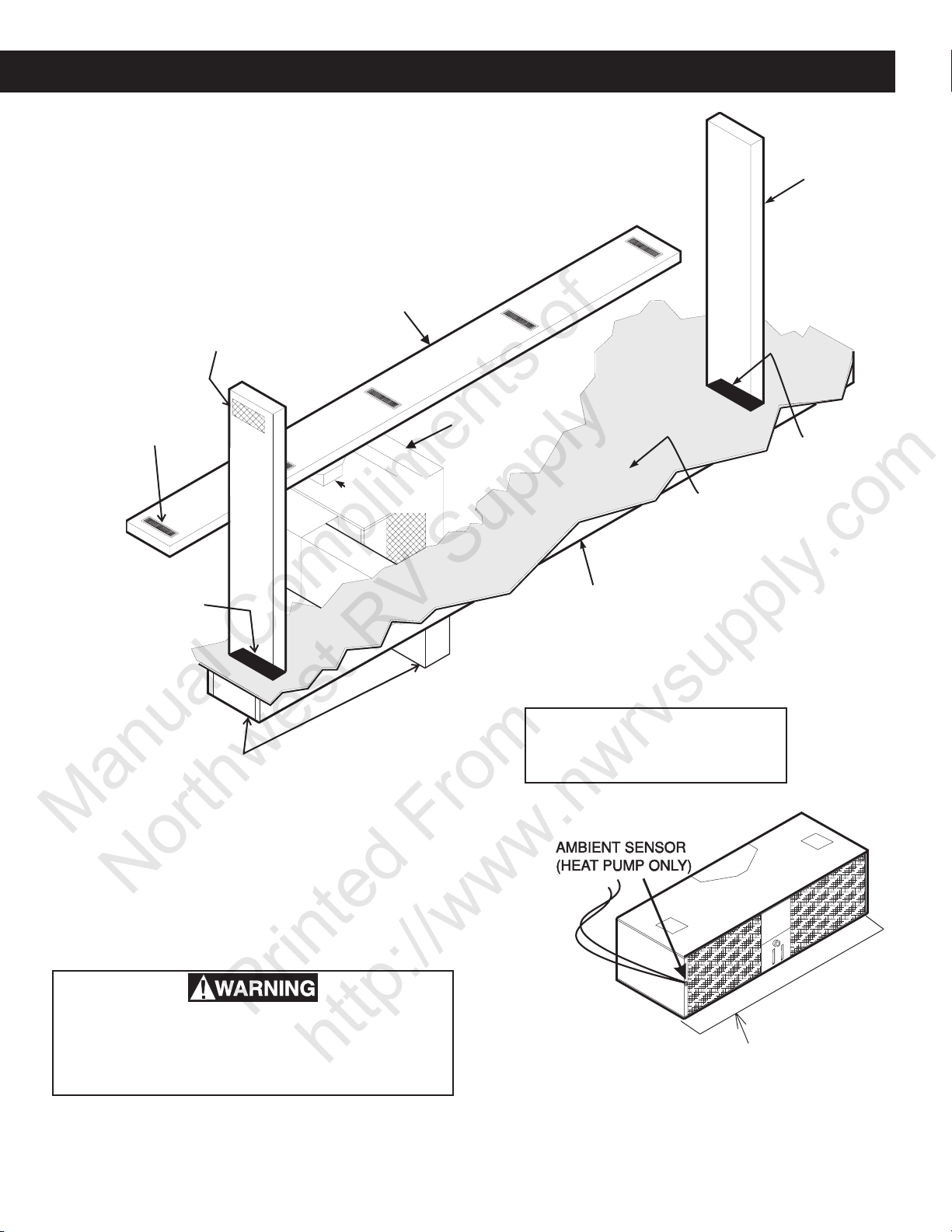

FIG. A4.

FIG. A4

Duo-Therm’s return air kits are designed to be installed

tightly to the bottom of the base pan and ceiling template.

Insulation supplied in the kit not only stops condensation

from forming on the divider plate, but prohibits air leaks as

well. The insulation

is purposely oversized to be attached to the sides

of the 14-1/4" x 141/4" (±1/8") opening and the base of

the air conditioner

and ceiling template. Make sure

the data plate does

not get covered

with insulation.

See FIG. A5.

FIG. A5

FIG. A3

TOTAL OUTLET

AIR AREA MINIMUM:

17.5 sq. in. - 579 & 600 Series

21.0 sq. in. - 590 & 595 Series

DUCTS MIN. MAX.

DEPTH (590 & 595 Series) 1-1/2" 2-1/4"

(579 & 600 Series) 1-1/4" 2-1/4"

WIDTH 7" — —

TOTAL LENGTH 12' 36'

AIR CONDITIONER

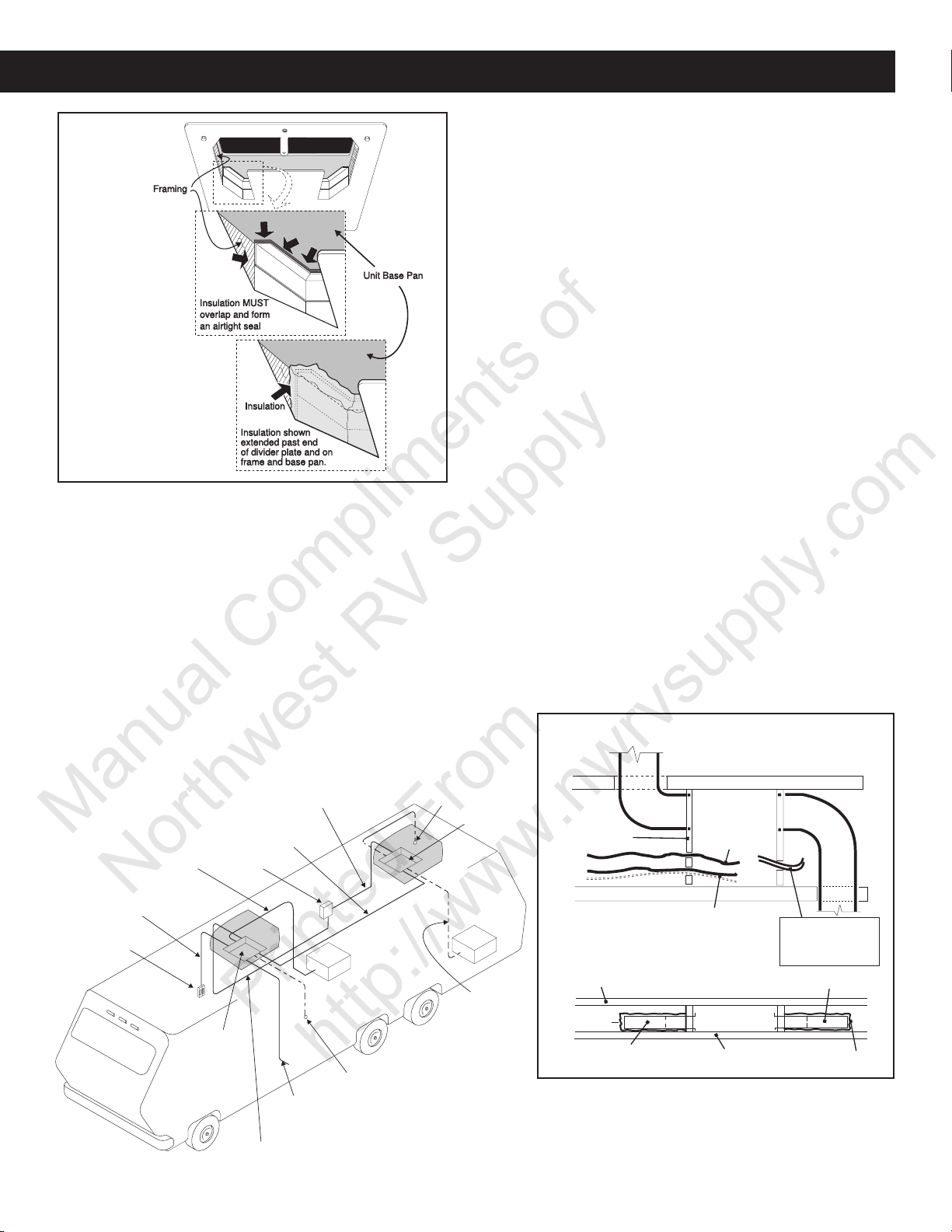

If a Remote Temperature Sensor is to be used, (Comfort

REGISTERS

4 MIN. — 8 MAX. (Per A/C)

14 SQ. IN. FREE AREA

PER REGISTER

14 INCH ROOF

OPENING

ROOF RAFTERS

3

THE MINIMUM SHORT DUCT

RUN MUST EQUAL 1/3 OF

TOTAL DUCT LENGTH

VEHICLE

FRONT

REAR REMOTE SENSOR

(Required with Second

Air Conditioner)

14-1/4" x 14-1/4"

(±1/8”) OPENING

14-1/4" x 14-1/4"

(±1/8”) OPENING

OPTIONAL

FURNACE

FURNACE

2 WIRES

OPTIONAL FRONT

REMOTE SENSOR

12V DC INPUT

2 WIRES

4-CONDUCTOR

CONTROL CABLE

BREAKER BOX

115V AC

REAR A/C

4-CONDUCTOR

CONTROL CABLE

115V AC

FRONT A/C

FURNACE

2 WIRES

DOMETIC COMFORT

CONTROL CENTER

Section A - Installation, cont’d.

FRAME

14-1/4" (±1/8”)

OPENING

AC POWER

SUPPLY WIRE

DUCT

FRAME

FRAME

CCC, CONTROL CABLE(S)

or 7-Wire Analog Cable

LOW VOLTAGE WIRES:

12VDC

Furnace

Load Shed

Sensors

DUCT

ROOF

INSULATION

DUCT TO REAR

CEILING

DUCT TO FRONT

14-1/4" (±1/8”)

OPENING

INSULATION

SIDE VIEW

(TOWARD BACK OF RV)

TOP VIEW

(BACK OF RV)

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

A6a. Roof Top Units

Control Center configuration, page 16) the connector end

must be routed to the roof opening of the system which it

will control. Make sure that at least 15" of the sensor cable

extends into the roof opening. If a furnace is to be controlled by the system, the two furnace thermostat leads must

be routed to the roof opening of the air conditioner that will

control it. Make sure at least 15" of the furnace thermostat

wires extend into the roof opening. If an Energy Management System - EMS (load shed) is to be used with the

control, two wires must be routed to the roof opening of the

zone to be managed. The signal required for this function

is a normally open relay contact. When the EMS calls for

the compressor to shut off, the relay contacts should close.

Make sure that at least 15" of the EMS wires extend into

the roof opening.

DOMETIC COMFORT

CONTROL CENTER

FIG. A6

Route a copper 12 AWG, with ground, 115 VAC supply line

from the fuse or circuit breaker box to the roof opening.

a. This supply line must be located in the front portion of

the 14-1/4" (±1/8") opening.

b. The power supply MUST be on a separate Time Delay

Fuse or HACR Circuit Breaker.

c. Make sure at least 15" of supply wire extends into the

roof opening. This ensures easy connection at the

Junction Box.

d. Wiring must comply with all National, State and Local

Wiring Codes.

e. Use a steel sleeve and a grommet or equivalent meth-

ods to protect the wire where it passes into the open-

ing.

Route a dedicated 12 VDC supply line (18-22 AWG) from

the RV’s Converter or Battery to the roof opening.

a. This supply line must be located in the front portion of

the 14-1/4" (±1/8") opening.

b. Make sure that at least 15" of supply wire extends into

the roof opening.

c. In a multiple zone installation, this wiring is required in

only one of the 14-1/4" (±1/8") openings.

Route a 4-conductor telephone cable from the Comfort

Control Center™ mounting position into the 14-1/4" (±1/

8") roof opening. Make sure that at least 15" of the wire

extends into the roof opening and 6" extend from the wall

at the mounting position of the Comfort Control Center™.

In the event that other A/C’s are to be installed (additional

zones) and additional 4-conductor telephone cable must

be routed to the other A/C’s. Make sure that at least 15" of

the wire extends into each of the roof openings. See FIG.

A8.

FIG. A8

REAR REMOTE SENSOR

115V AC

FIG. A7

4-CONDUCTOR

CONTROL CABLE

FURNACE

2 WIRES

4-CONDUCTOR

CONTROL CABLE

BREAKER BOX

14-1/4" x 14-1/4"

(±1/8”) OPENING

115V AC

FRONT A/C

REAR A/C

FURNACE

OPTIONAL FRONT

12V DC INPUT

2 WIRES

REMOTE SENSOR

(Required with Second

Air Conditioner)

14-1/4" x 14-1/4"

(±1/8”) OPENING

OPTIONAL

FURNACE

FURNACE

2 WIRES

A seven-conductor cable, 18-22 AWG is to be used for low

voltage connections for Analog Controls. Choose the shortest, direct route from the 14" opening to the thermostat

location selected. Consider where screws, nails or staples

might contact the cable. See FIG. A8.

4

A6a. Roof Top Units

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Leave approximately 6" of cable extending through the wall

for connection to thermostat. Leave approximately 10" of

cable extending into the 14-1/4" (±1/8") opening for connection at Relay Kit. See A7 Thermostat Location, page

12.

If System if to control a gas furnace:

Route two 18 AWG from the furnace to 14-1/4" (±1/8") opening at this time.

FIG. A9

Section A - Installation, cont’d.

FIG. A10

In some installations, the OEM supplies their own return

air kits. Sometimes both the return and the discharge air

are ducted to and from the 14-1/4" x 14-1/4" (±1/8") opening. In some cases the bottom of the 14-1/4" x 14-1/4" (±1/

8") opening is covered with ceiling material.

In this type of installation the 14-1/4" x 14-1/4" (±1/8") opening is divided. If the divider only fills to the thickness of the

ceiling cavity, an air gap may be created both on the top

and bottom of the thickness of the roof gasket, roof or ceiling material. A gasket, etc., must be used to fill up the

open space to reduce recirculation. See FIG. A9.

Another method of connecting the discharge air to the

coach’s main duct used Duo-Therm’s return air kit. It uses

half of the 14-1/4" x 14-1/4" (±1/8") opening as a discharge

plenum. If the duct opening is not clean, restriction of air

can cause the coil to freeze. The opening of the duct should

be as large as possible to make the air distribution better in

the coach and reduce freeze-up. See FIG. A10.

The final method of installation dumps the discharge air

directly into the RV’s main duct. The duct is routed through

the 14-1/4" x 14-1/4" (±1/8") opening. A duct adapter is used

to connect the air conditioner to the main duct. If this connection is not made properly, cold air can migrate back into

the return air path and make conditions right for freeze-up.

Be sure the duct adapter is sealed to the main duct and air

conditioner. See FIG. A11.

FIG. A11

5

Section A - Installation, cont’d.

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

A6a. Roof Top Units

Restrictions at the connection to the air conditioner is the

most common cause, but blockage in the main duct runs

can also cause freeze-up. Blockages commonly occur in

the areas where the duct changes direction. Other obstacles that can cause a change in the duct (air) path include rafters, vent pipes, wire bundles, etc. See FIG. A12.

A good way to check for duct blockage is with a flashlight

and a mirror. Remove ceiling register cover to allow a flashlight to be put in the duct and use a mirror to view the flashlight from the next register opening. A blockage will be

visible in the mirror. See FIG. A12.

Duo-Therm has available a quick cool return air kit that will

allow the cooled air to come directly out of the air conditioner. This will bypass any restrictions in the coach duct

system. (Part No. 3105958.007 Shell White, 3105958.015

Polar White).

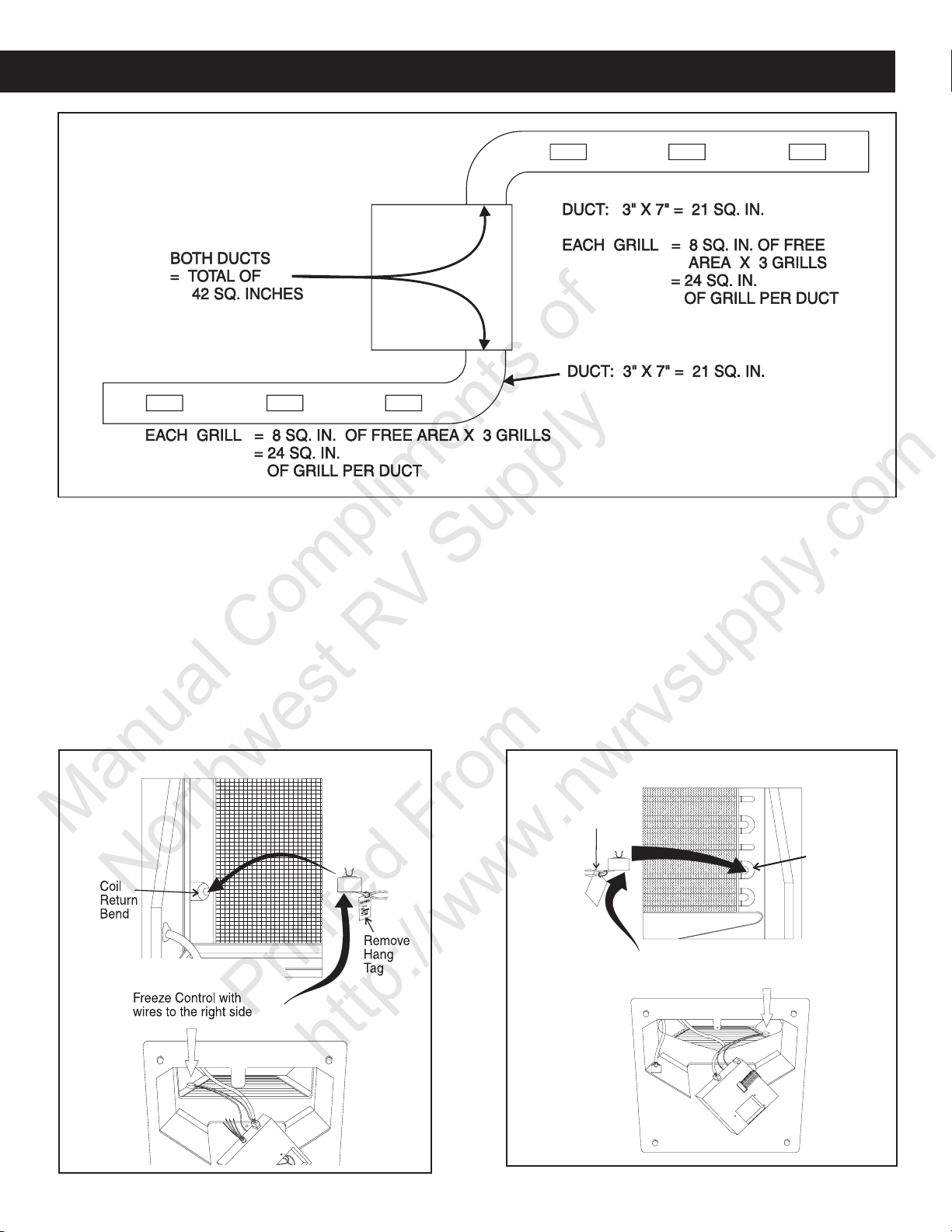

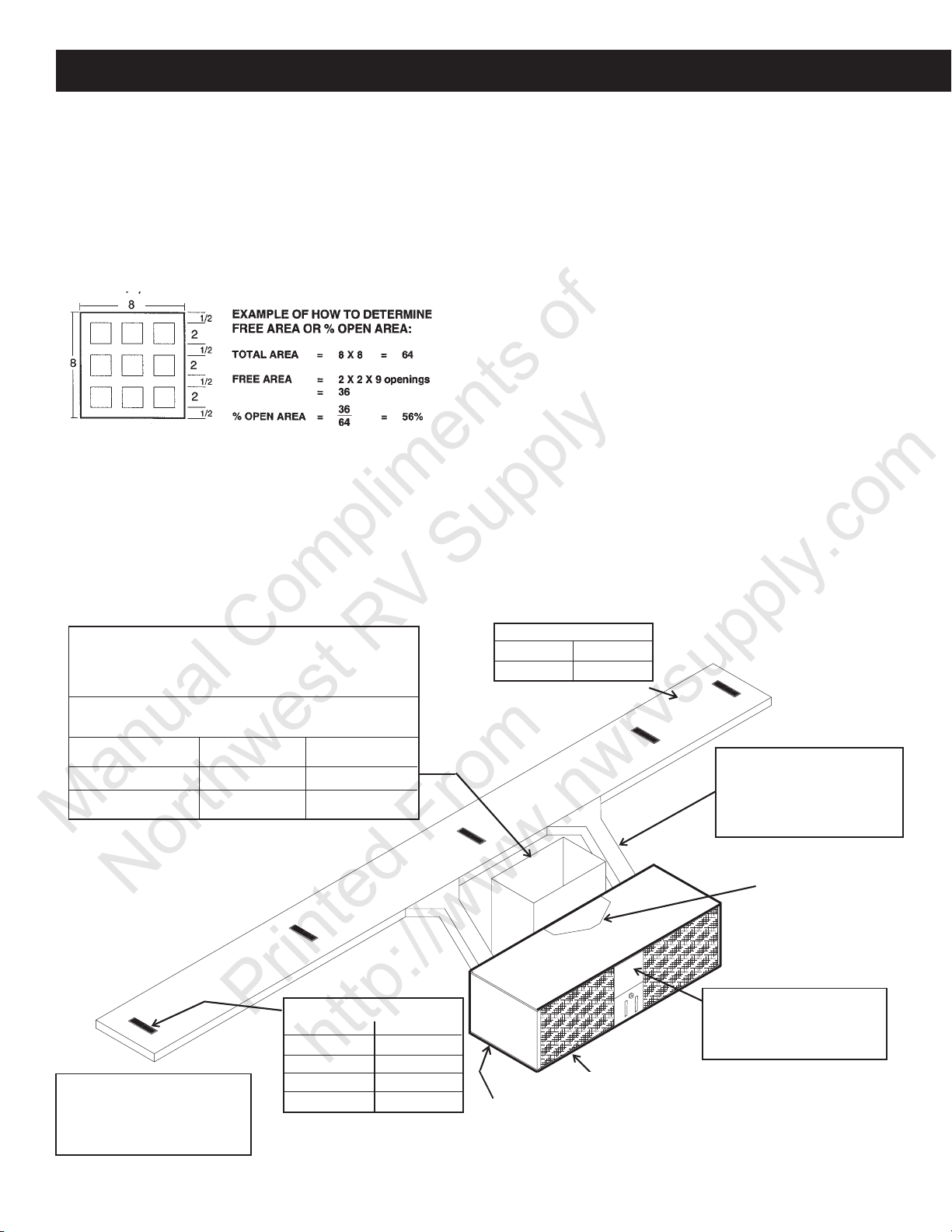

If the main duct in the vehicle is undersized, the volume of

air flowing through the ducts will decrease. The coil temperature will also drop because not enough air is moving

through it. The requirements for proper duct size are shown

in FIG. A13.

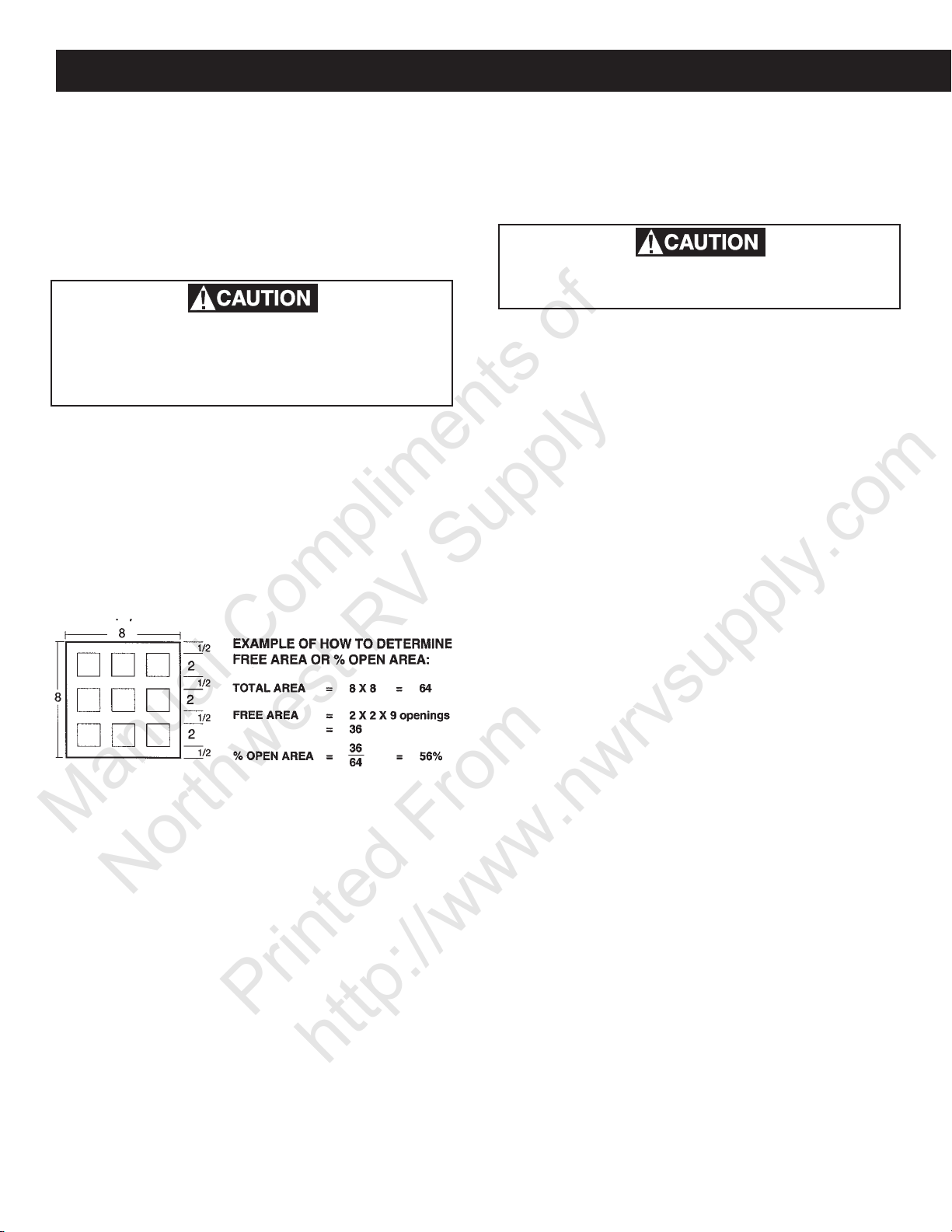

Up to this point we have mainly covered the discharge side;

however, restrictions of the return air can result in frost

buildup. The Duo-Therm air conditioner requires a minimum of 40 square inches of FREE AREA.

FREE AREA - is the opening that remains in a grill or louvered panel after the restrictions are taken away. For example, an opening of 10 x 20 inches has 200 square inches.

When this opening is covered with a grill that is 56 percent

open, the FREE AREA is (200 x .56), 112 square inches.

Dometic return air kits are designed to have the correct

free area; however some manufacturers use their own grills.

If a manufacturer’s grill is used, it must use the above formula to make sure the return air is sufficient to reduce the

chances for freeze-up. The filter material must also be considered as a restriction and subtracted from the FREE

AREA. See FIG. A14.

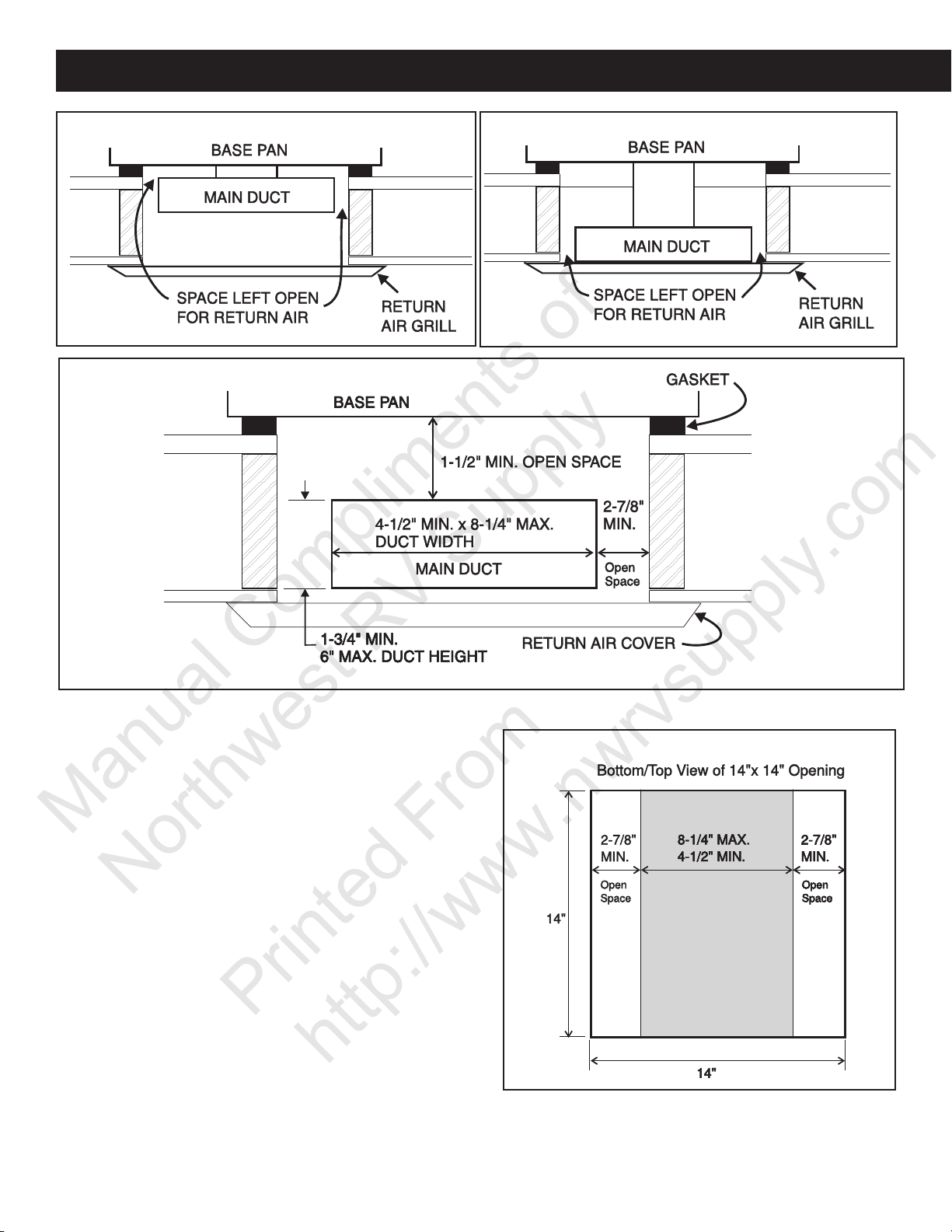

Main ducts running through the 14-1/4" x 14-1/4" (±1/8")

opening must leave space between the duct and return air

grill or duct and bottom of the air conditioner. See FIG.

A15, A16, A18.

FIG. A12

FIG. A13

TOTAL OUTLET

AIR AREA MINIMUM:

17.5 sq. in. - 579 & 600 Series

21.0 sq. in. - 590 & 595 Series

AIR CONDITIONER

"S" PATTERN DUCT SYSTEM

DUCTS MIN. MAX.

DEPTH (590 & 595 Series) 1-1/2" 2-1/4"

(579 & 600 Series) 1-1/4" 2-1/4"

WIDTH 7" — —

TOTAL LENGTH 12' 36'

FIG. A14

REGISTERS

4 MIN. — 8 MAX. (Per A/C)

14 SQ. IN. FREE AREA

PER REGISTER

14 INCH ROOF

OPENING

THE MINIMUM SHORT DUCT

RUN MUST EQUAL 1/3 OF

TOTAL DUCT LENGTH

ROOF RAFTERS

6

A6a. Roof Top Units

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Section A - Installation, cont’d.

FIG. A15

FIG. A17

FIG. A16

The gap between the top and the main duct to the bottom

of the air conditioner should be a minimum of 1-1/2". See

FIG. A17 & A18.

If the return air is ducted into the 14-1/4" X 14-1/4" (±1/8")

opening, the duct must be equal to the 40 sq. inches that

are needed by the air conditioner. Grill or registers used

ing this duct must be equal to or greater than the duct in

square inches.

The control system used by Duo-Therm Air Conditioner is

designed with a low temperature switch that will shut off

the compressor and allow air to flow through the coil to

melt the frost. A properly operating cold control may allow

a slight coating of frost to form on the evaporator coil before it turns off the compressor. If the cold control is not

installed in its intended mounting locations, frost buildup

can block all air flow through the evaporator coil and stop

cooling inside the RV. The cold control has clips that allow

it to be snapped onto the turn/bends of the evaporator coil.

See FIG. A20 & A21 for the correct location.

FIG. A18

7

Section A - Installation, cont’d.

Freeze Control with wires.

Coil

Return

Bend

Do

kdkd

mfmf

Remove

Hang

Tag

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

FIG. A19

A6a. Roof Top Units

Freeze Control Installation

579, 590 & 595 Series:

a. Snap freeze control into place on return bend located

at left side of evaporator coil as follows:

1) Locate “D” shaped notch in flange of evaporator

coil.

2) Place the horseshoe end of freeze control through

this notch and snap onto coil return bend. When

positioned correctly, control wires will be 90° to direction of coil fin surface. See FIG. A20

Note: Freeze control is not used on heat pump coils. Some

will have the “D” slot in the coil header.

579, 590 & 595 SERIES

FIG. A20

Mount the Freeze Control on left side

of coil, with wires to the right side

Freeze Control Installation

600 Series:

a. Snap the freeze control into place on return end lo-

cated at right side of evaporator coil as follows:

1) Locate vertical return bend at lower right of evaporator coil.

2) Place the horseshoe end of freeze control onto this

coil return bend and snap into place. When positioned correctly, control wires will be 90° to direction of coil fin surface. See FIG. A21.

Note: Freeze control is not used on heat pump coils, some

FIG. A21

600 SERIES

Install Freeze Control with wires as shown

8

A6b. Basement Units

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Section A - Installation, cont’d.

will have the “D” slot in the coil header.

A6b. Basement Units

Models 39335 and 39125

Outdoor Section:

The Condenser coil is designed to have a fresh supply of

air. If skirting is installed, allow a louvered grill with 330

square inches for supply air and a louvered grill on opposite side of coach (330 square inches) for discharge air.

Do not totally enclose the underside of the

unit. Air circulation prevents heat from building under unit and your system will perform

as designed.

The condenser section is a “blow-through” type. When the

face of the coil is positioned behind a louvered or other

type of restrictive opening, the FREE AREA of the opening

must be at least 260 square inches.

FREE AREA - is the opening that remains in a grill or louvered panel after the restrictions are taken away. For example, an opening of 10 x 20 inches has 200 square inches.

When this opening is covered with a grill that is 56 percent

open, the FREE AREA is (200 x .56), 112 square inches.

Expanded and perforated metal grills in general vary from

Indoor Section:

Clearances

The minimum clearances to the evaporator are zero inches

to the bottom, top, left and right sides. Access to the electrical connections and drain connection must be provided

when making the installation.

Be sure to allow sufficient room to service

the electrical components.

Inlet Air

The evaporator section must have free access to room air.

A minimum or 180 square inches of FREE AREA opening is required. Where the return air must be provided

through louvers or mesh scree, the FREE AREA percentage of the material used shall be taken into consideration

when making this determination. An example of how to

determine FREE AREA is included under “Outdoor Sec-

tion”.

Grills and Registers

Note: The return air grill must have the same square sur-

face as the coil face (15"H x 17"L).

For each air conditioning system, there must be a return

grill to bring cabin air back into the unit. There must also

be at least four discharge grills per unit.

Each return air grill must be filtered and accessible for cleaning and replacement.

Outlet Air

The central air conditioning unit is designed to use a discharge air duct with a static pressure of .10 to .25 inches

water column. Proper duct size is necessary to maintain

proper air flow without loss of static pressure and provide

30 percent to 60 percent open. Be certain that 260 square

inches of FREE AREA is available to the face of the condenser.

Note: Service access must always be supplied either as

clearance or as a defined access panel.

Mounting

Vibration eliminators are supplied to prevent the transmittance of vibration into the living area.

The air conditioning unit may be attached to rails beneath

the vehicle, attached to the frame, or mounted directly to

the floor of some vehicles.

Unit should be mounted with a tilt toward the rear (condenser) a half-bubble using a level. Unit rear should be 1/

4" lower than the front.

Service Access

Be sure NOT to block the inlet or discharge air, or service

access, when mounting.

good air circulation.

All air handling ducts must be properly insulated to prevent

condensation forming on their surface during operating. A

vapor barrier must also be supplied on the outer surface of

the insulation to prevent moisture from traveling through

the insulation and condensing on the cold ductwork.

Note: If the air conditioning unit is attached to the central

furnace, a damper must be installed at the furnace outlet

to prevent cold air from circulating through the furnace heat

exchanger, unless furnace is so equipped to utilize the builtin furnace relay.

9

Section A - Installation, cont’d.

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

FIG. A22

2" X 12" INSULATED

90 SQ. IN.

FILTERED

(MIN. X 2)

DUCT (MIN.)

A6b. Basement Units

RETURN

RISER X 2

2" X 10" CLOSEABLE

GRILL (MIN. X 4))

SUPPLY AIR

INSULATED

FLOOR CUTOUT

90 SQ. IN. MINIMUM

MIN. 180 SQ. IN.

REQUIRED OPENING

Models 39224 and 39424

Condenser Section:

Supply Air

The inlet of the condenser coil should be positioned so that

it draws air from outside the vehicle. Special care must

be taken to prevent the discharge air from recirculating to the inlet of the condenser coil. Shields should be

added to ensure fresh air supply.

DISCHARGE

CONDENSER

AIR

ENCLOSED

FLOOR JOIST

RETURN SYSTEM

-Risers use interior wall structure

-Using floor joists area for return to unit

-Each return grill is filtered

FIG. A23

FLOORING

FLOOR CUTOUT

90 SQ. IN. MINIMUM

Do not install the condenser where the fan

will draw air from the exhaust of the vehicle,

a motor generator set, transmission, road

heat or ANY other heat producing source.

FIELD INSTALLED SHIELD THAT WILL PREVENT

RECIRCULATION OF CONDENSER AIR.

The condenser section is a “draw-through” type. When the

face of the coil is positioned behind a louvered or other

type of restrictive opening, the FREE AREA of the opening

must be at least 460 square inches.

10

A6b. Basement Units

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Section A - Installation, cont’d.

FREE AREA - is the opening that remains in a grill or lou-

vered panel after the restrictions are taken away. For example, an opening of 10 x 20 inches has 200 square inches.

When this opening is covered with a grill that is 56 percent

open, the FREE AREA is (200 x .56), 112 square inches.

Expanded and perforated metal grills in general vary from

30 percent to 60 percent open. Be certain that 460 square

inches of FREE AREA is available to the face of the condenser.

Note: Service access must always be supplied either as

clearance or as a defined access panel.

Clearances

The air conditioning unit clearances depend on:

1. Inlet air access used

2. Discharge air duct arrangement

3. Return air duct

4. Storage compartment location and design

A one (1) inch clearance is required on three (3) sides of

the air conditioner if the top return is used. When using the

side access for return, please allow a minimum of eight (8)

inches for the return air duct. Access to the electrical connections must be provided when making the installation.

Evaporation Section:

Inlet Air

The evaporation section must have free access to room

air. A minimum of 128 square inches of FREE AREA opening is required. Where the return air must be provided

through louvers or mesh screen, the FREE AREA percentage of the material used shall be taken into consideration

when making this determination. An example of how to

determine FREE AREA is included under Condenser Sec-

tion. See FIG. A24.

FIG. A24

RETURN SYSTEM

Return to be 6 ft. minimum from floor.

Use wall structure for delivery to basement area.

Return grille must be filtered.

Minimum return required per duct sizing for unit to

perform within Engineering specifications. See Chart below:

DUCT SIZE MINIMUM MAX.

40 IN.

60 IN.

2

2

128 IN.

128 IN.

2

2

189 IN.

189 IN.

2

2

INSULATED DUCT

Minimum Maximum

2

40 IN.

(3 " depth Min.)

60 IN.

REGISTER REQUIREMENTS

ADDITIONAL REQUIREMENTS:

Damper required in furnace.

Vibration isolators should be

used at each mounting point.

12 VDC required for Comfort

Control operation.

REQ. SIZE MIN. QTY.

4 X 6 4

4 X 8 4

4 X 10 4

4 X 12 4

Condenser air outlet ( X2 in bottom)

Must be isolated from condenser inlet air.

Condenser inlet air 2 places.

2

Supply Duct must be insulated.

Supply Duct from air conditioner

must be equal to or greater

in IN.2 as the floor ductwork.

Use 45 degree angle on inlets

& outlets

Optional return area.

May be used in

conjunction with side

return.

Electrical box access required.

Each circuit, 15 AMP HACR

breaker

11

Section A - Installation, cont’d.

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Grills

Note: The Return air grill must have the same square sur-

face as the return air duct.

1. For each air conditioning system, there must be a return grill to bring cabin air back into the unit. There

must also be at least four discharge grills per unit.

2. Return grills must be mounted in front of the evaporator. If this is not possible, make sure there is nothing

blocking the air flow from the grill to the evaporator.

3. The unit must have a return filter between the grill and

the unit. This filter must be accessible for periodic cleaning.

Outlet Air

The air diffusion system, supplied by the installer, must be

sized to maintain a static pressure at the blower outlet between .4 and 1.2 inches water column.

All air handling ducts must be properly insulated to prevent

condensation forming on their surface during operation. A

vapor barrier must also be supplied on the outer surface of

the insulation to prevent moisture from traveling through

the insulation and condensing on the cold ductwork. See

section A6a - Rooftop Units.

A7. Thermostat Location

The thermostat location is very important for balanced

temperature control in any RV.

Today’s interior design has become both cosmetically more

appealing and more efficient in its use of storage space.

These improvements have generated complex interior

space requirements which, in turn, have caused many RV’s

to become a maze for heating and air conditioning circulation.

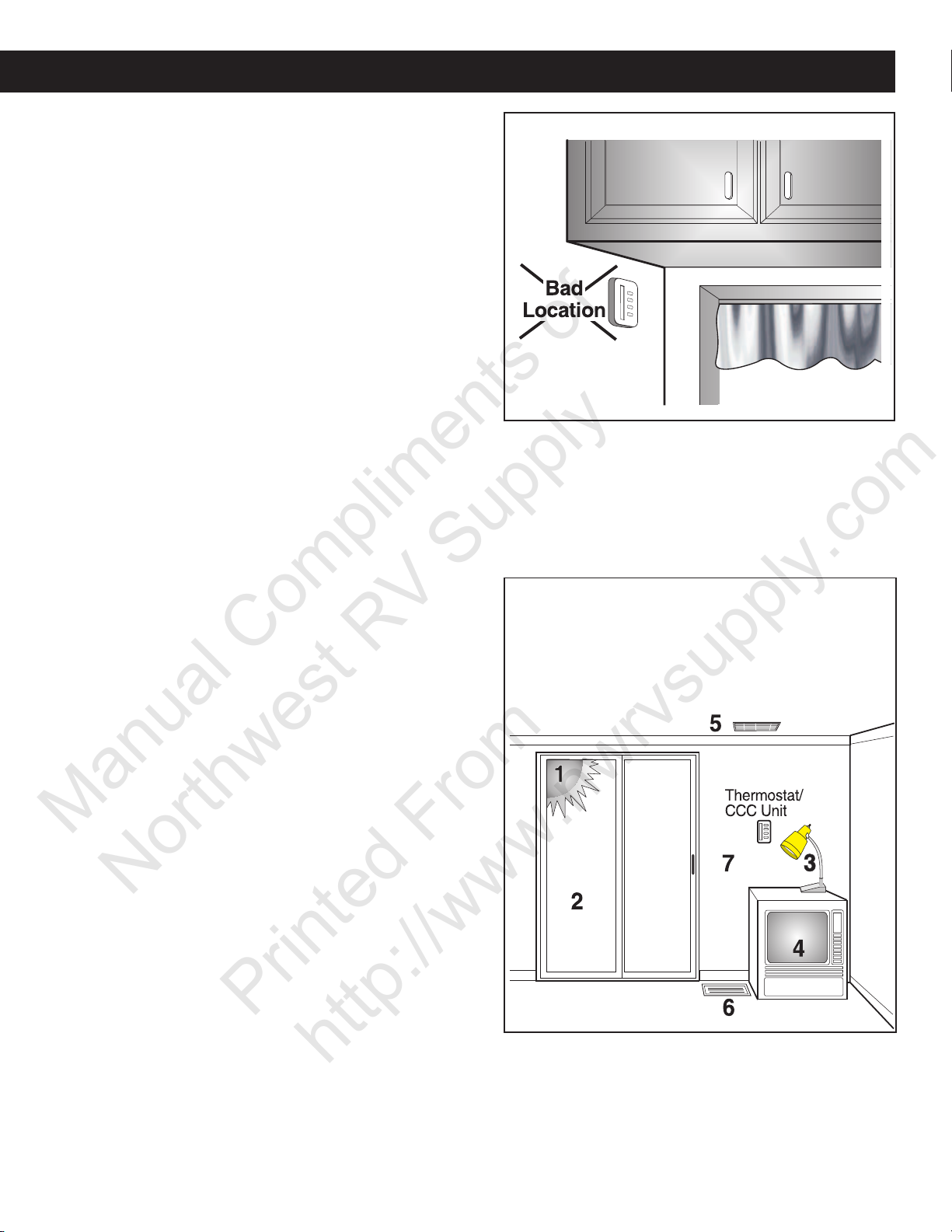

FIG. A25

The proper location for the thermostat or remote sensor is

54" from the floor and on an inside wall. It should be located where it cannot be affected by heat from the sun,

lamps, oven, etc., or other sources of draft. Locations close

to entry doors and windows should be avoided. The discharge from registers blowing directly on the thermostat or

remote sensor can cause the system to short-cycle and

should be avoided. See FIG. A26.

FIG. A26

Examples of Bad Thermostat Locations

1, 3, 4 Near Heat Sources

2 Near Drafts or Heat source

5, 6 Near Drafts

7 On an Outside Wall

The heating system is usually mounted close to floor level

and consists of one or more furnaces. The air conditioner(s)

is mounted on the roof with a different air distribution system. It is very important to locate the thermostat and remote sensors in areas that have good air movement. This

may be difficult because what works well for heating may

not work well for air conditioning.

The thermostat or remote sensors must be placed in a location with good air movement. Placing a thermostat or

sensor under a cabinet or in a corner will result in a large

fluctuation in the temperature. See FIG. A25.

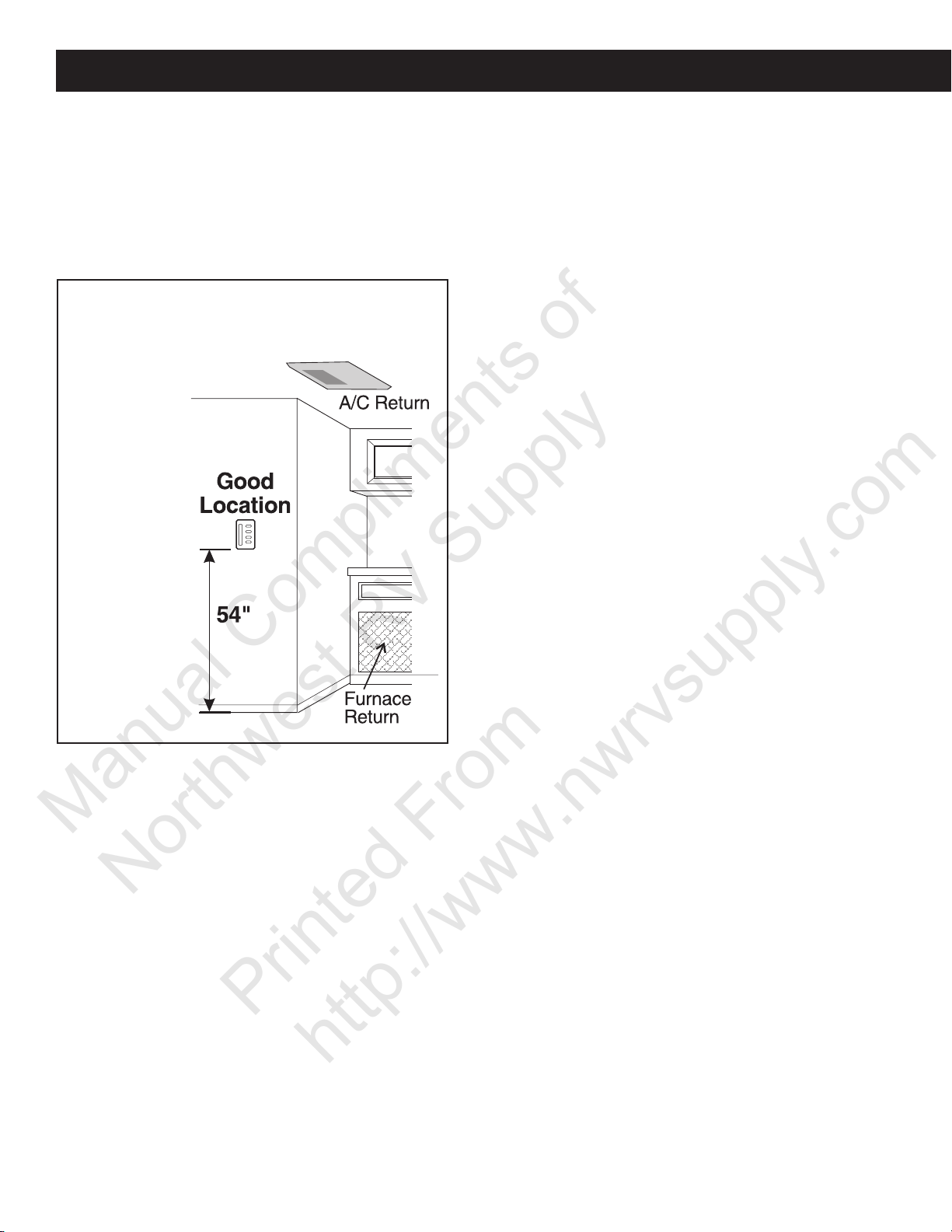

12

When the floor plan or interior design of an RV changes,

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Dometic suggests trying several locations for the thermostat or remote sensor to determine the best location for

mounting. Both heating and air conditioning should be

tested, especially when using different duct systems and

the same thermostat. When the proper thermostat or remote sensor location is determined, this location can be

used on other RV’s with the same basic plan. See FIG.

A27.

FIG. A27

Example of

Good Thermostat Location

(Interior Hallway Wall)

Section A - Installation, cont’d.

13

Section B - Operation

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

B. Operation

The recreational vehicle manufacturer has equipped the

vehicle with Duo-Therm’s Air Conditioner. The ability of

the unit to maintain the desired inside temperature depends

on the heat gain of the RV. Some preventative measures

can be taken by the occupants of the RV to reduce the

heat gain and improve the performance of the unit. During

extremely high outdoor temperatures, the heat gain of the

vehicle may be reduced by:

1. Parking the RV in a shaded area.

2. Using window shades (blinds and/or curtains).

3. Keeping windows and doors shut or minimizing usage.

4. Avoid use of heat producing appliances.

5. Starting the unit early in the morning and giving it a

“head start” on the expected high outdoor temperatures will greatly improve its ability to maintain the desired indoor temperature.

The operating instructions can change from one model to

another.

Be sure you are familiar with the proper operating instructions for the specific model of air conditioner you are diagnosing. An installation and operating manual is packaged

with each air conditioner system.

B1. Air Conditioners

Mechanical Cooling Operation

Set the thermostat at the desired temperature level. Select the fan speed that best satisfies your needs. See FIG.

B1.

a. HIGH COOL - Selected when maximum cooling

and dehumidification is required.

b. MED. COOL - Selected when normal or average

cooling is required.

c. LOW COOL - Selected when room is at desired

comfort level and needs to be maintained. Normally this speed is used for nighttime operation.

Note: The blower runs continuously to circulate air and

maintain an even temperature. The compressor will come

on as cooling is required to maintain the selected temperature level.

After shutting the air conditioner down with

either selector switch or thermostat, wait at

least two (2) minutes before restarting. This

allows the refrigerant pressure to equalize

and compressor to restart easily.

Fan Operation

This will circulate the air in your RV without cooling or heating. There are three positions: HIGH FAN, MED. FAN or

LOW FAN to select from, depending upon personal choice.

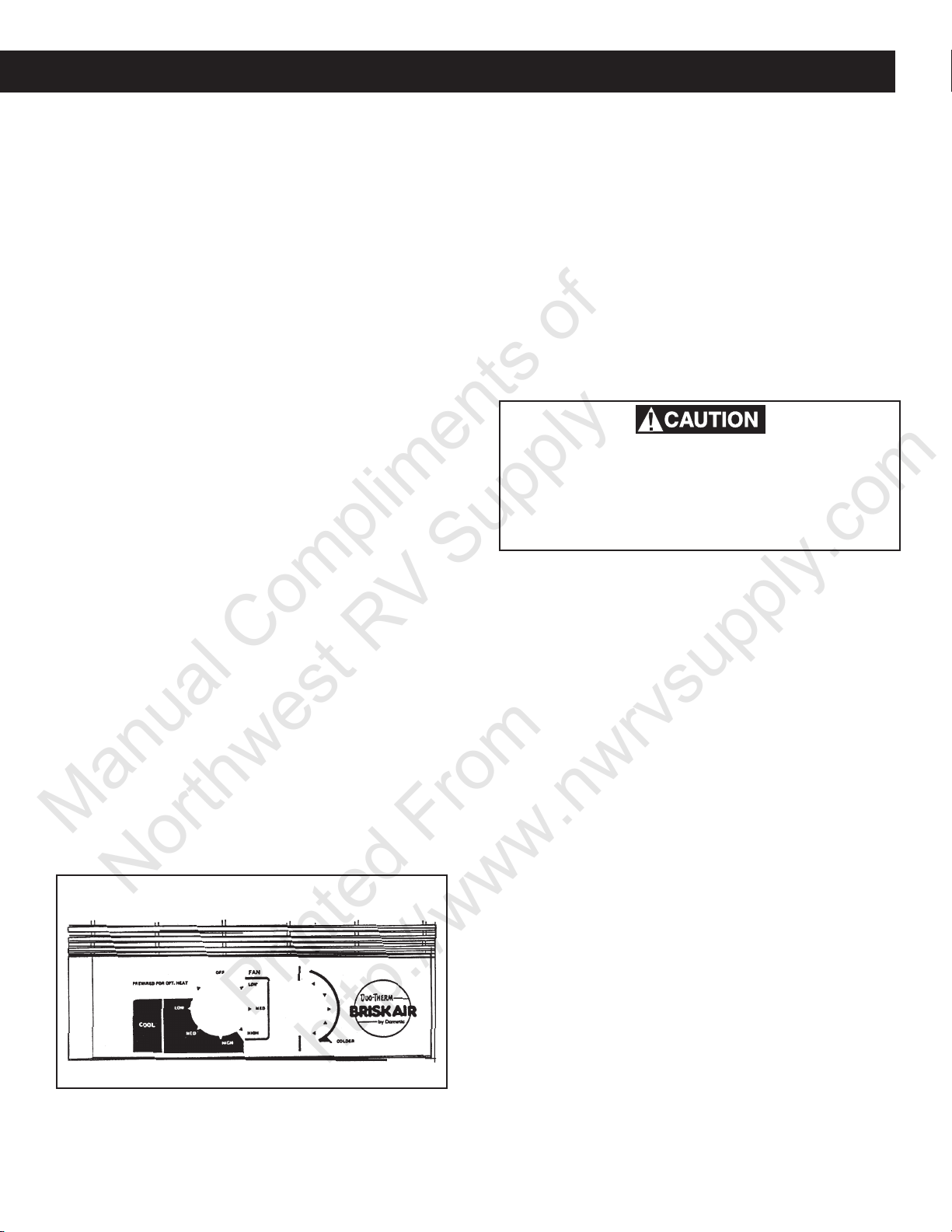

B1a. Mechanical Controls

This type of air conditioner has an air distribution box that

has a mechanical selector switch and thermostat installed

in it.

Controls

The Selector Switch has eight positions including “OFF”.

This controls fan speed, heating mode and cooling modes.

The Thermostat controls the temperature range from 65°F

on the coldest side to 90°F on the warmest side. In the

cooling mode, the compressor ON/OFF is controlled by

the thermostat setting. See FIG. B1.

Heating Operation

(With Optional Heat Kit Installed)

Note: This electric heater will not replace a furnace for

heating your RV in cold weather. The intent is to remove

the chill on cool days or mornings.

1. Turn the selector switch to “OPT. HEAT”.

2. The heater will come on and begin heating.

3. When desired temperature level in RV is reached, move

the selector switch to off position or fan position.

Note: Thermostat does not control heater ON/OFF cycle.

“OFF” Position turns unit off. See FIG. B1.

B1b. Bimetal Relay Controls

FIG. B1

This type of air conditioner has a wall mounted bimetal thermostat and a relay board that replaces the mechanical

switch and thermostat on the mechanical units and replaces

the main board and control board on the electronic units.

Note: Remember to check the installation and operating

instructions for the specific model of air conditioner you

are diagnosing.

14

B1b. Bimetal Relay Controls

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Section B - Operation, cont’d.

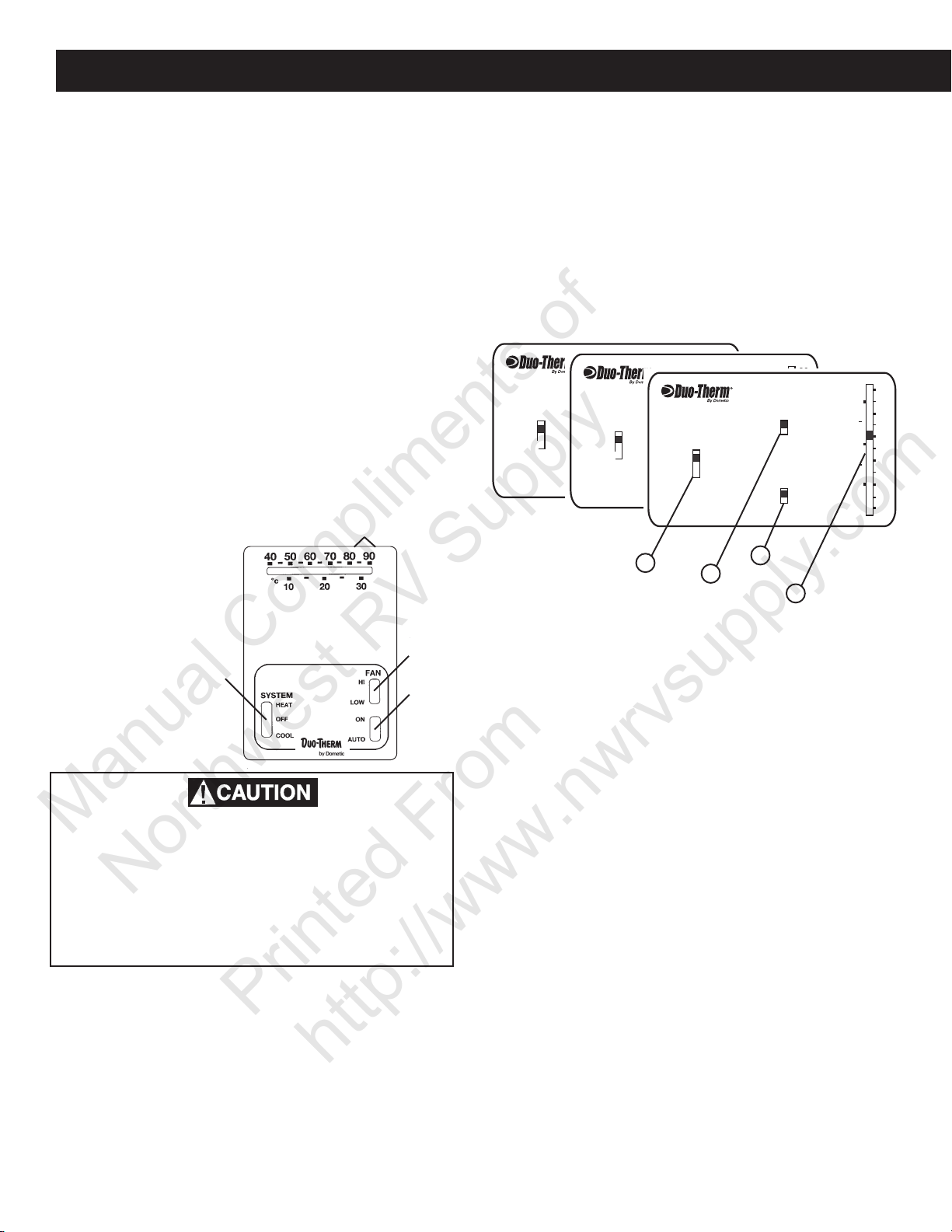

Cooling Operation

Place the Temperature Set Lever to desired temperature

level (located at top of thermostat). Select fan speed that

best satisfies your needs: (upper right switch at bottom of

thermostat). See FIG. B2.

a. High Speed: Selected when maximum cooling and

dehumidification are required.

b. Low Speed: Selected when RV reaches desired com-

fort level and needs to be maintained. Normally this

speed is used for nighttime operation.

Select Auto/ON Switch operation as follows:

(Lower right switch at bottom of thermostat)

a. Auto Position: Air conditioner fan runs whenever cool-

ing is required and stops whenever cooling is not re-

quired.

b. On Position: Air conditioner fan runs continuously to

circulate air in RV.

Set the Heat/OFF/Cool Switch to cool position

(Located at lower left side of thermostat)

The air conditioner will now come on when cooling is required and cycle off when the temperature level selected is

reached.

1

FIG. B2

1 = Temp Set Lever

2 = Auto/ON Switch

3 = System Switch

4 = Fan Speed

4

Special Feature

When thermostat:

Heat/Off/Cool Switch is in the OFF or HEAT position

and Auto/On Switch is in the ON position, the air con-

ditioner fan will run continuously to circulate the air inside the RV. See FIG. B2.

B1c. Analog Control System

In order to familiarize yourself with the operation of the

Analog Control System, the following diagrams along with

the accompanying text will explain all the functional characteristics of the system.

FAN

ON

SYSTEM

COOL

OFF

FURNACE

HEAT PUMP

SYSTEM

COOL

OFF

FURNACE

HEAT PUMP

HEAT STRIP

AUTO

HI

FURNACE

LO

HEAT PUMP

FIG. B3

3

1. Temperature Set Lever

2. Fan Auto/On Switch

3. System Switch

4. Fan High/Low Switch

ON

AUTO

SYSTEM

COOL

OFF

HI

LO

30

20

10

°C

FAN

2

90

80

70

60

50

40

4

AUTO

90

30

80

FAN

70

ON

20

60

50

10

°C

40

HI

LO

30

20

10

°C

1

90

80

70

60

50

40

3

2

Analog Control Cooling Operation

1. Place the Temperature Set Lever (1) to desired tem-

perature level. See FIG. B3.

2. Select desired fan speed by moving the Fan Speed

Switch (4) to :

a. High speed: Selected when maximum cooling and

dehumidification are required.

Wait at least two (2) minutes before restarting the air conditioner after shutting off with

either the Heat/OFF/Cooling Switch of the

Temperature Set Lever. This allows the refrigerant pressure in the air conditioner to equalize and will allow the compressor to restart

easily.

Heating Operation

(If furnace is connected to Thermostat)

Set Temperature Set Lever to desired temperature level

(located at top of thermostat). See FIG. B2.

Set the Heat/Off/Cool Switch to heat position (located at

lower left side of thermostat). See FIG. B2.

The furnace will now come on when heat is required and

cycle off when temperature level selected is reached.

b. Low speed: Selected when RV reaches desired

comfort level and needs to be maintained. Normally this speed is used for night time operation.

3. Move the FAN Auto/On Switch (2): See FIG. B3

a. Auto Position: Unit fan runs whenever cooling is

required and stops whenever cooling is not required.

b. ON Position: Unit fan runs continuously to circu-

late air in RV. See FIG. B3.

4. Set the System Switch to cool position. The unit compressor will now come ON and cycle OFF when the

temperature level selected is reached.

Furnace Operation

(If furnace is connected to relay box.)

1. Set the Temperature Set Lever (1) to desired tem-

perature setting. See FIG. B3

2. Set the System Switch (3) to furnace position. The

furnace will now come ON when heat is required and cycle

OFF when the temperature setting selected is reached.

15

Section B - Operation, cont’d.

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

B1d. Comfort Control Center

Analog Control Electric Heat Strip Operation

(If unit is equipped with optional electric heat strip.)

1. Set the Temperature Set Lever (1) to desired tem-

perature level. See FIG. B3.

2. Set the System Switch (3) to heat strip position.

3. Move the FAN Auto/On Switch (2):

a. Auto Position: Unit fan runs whenever heat is

required and stops whenever heating is not required. See FIG. B3.

b. ON Position: Unit fan runs continuously to circu-

late air in RV. See FIG. B3.

4. Select desired fan speed by moving the Fan Speed

Switch (4) to:

a. High Speed: Selected when maximum air flow is

required. The discharge air will feel cool due to the

maximum air flow. It is normally not used for heat

strip operation. See FIG. B3.

b. Low Speed: Normally selected for heat strip op-

eration, because less air movement is needed for

heat and discharge air is warmer. See FIG. B3.

5. Set System Switch (3) to the heat strip position. The

unit’s heat strip will now come “ON” and cycle “OFF”

when the temperature level selected is reached.

Continuous Blower Operation

1. Set the System Switch (3) to any position (including

“OFF”). See FIG. B3.

2. Move the FAN Auto/On Switch (2) to the ON position,

the unit fan will operate continuously at the fan speed

selected by the Fan Speed Switch (4). See FIG. B3.

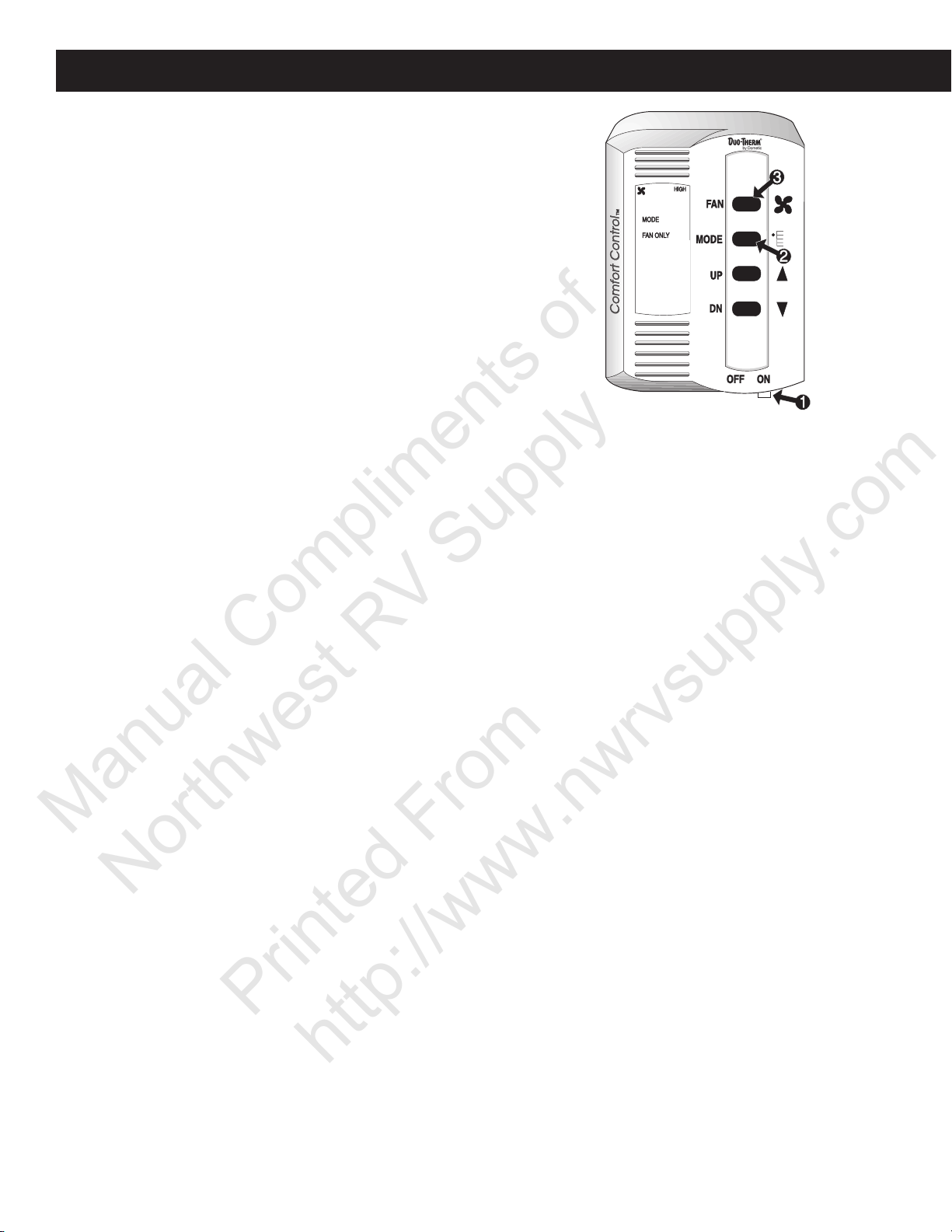

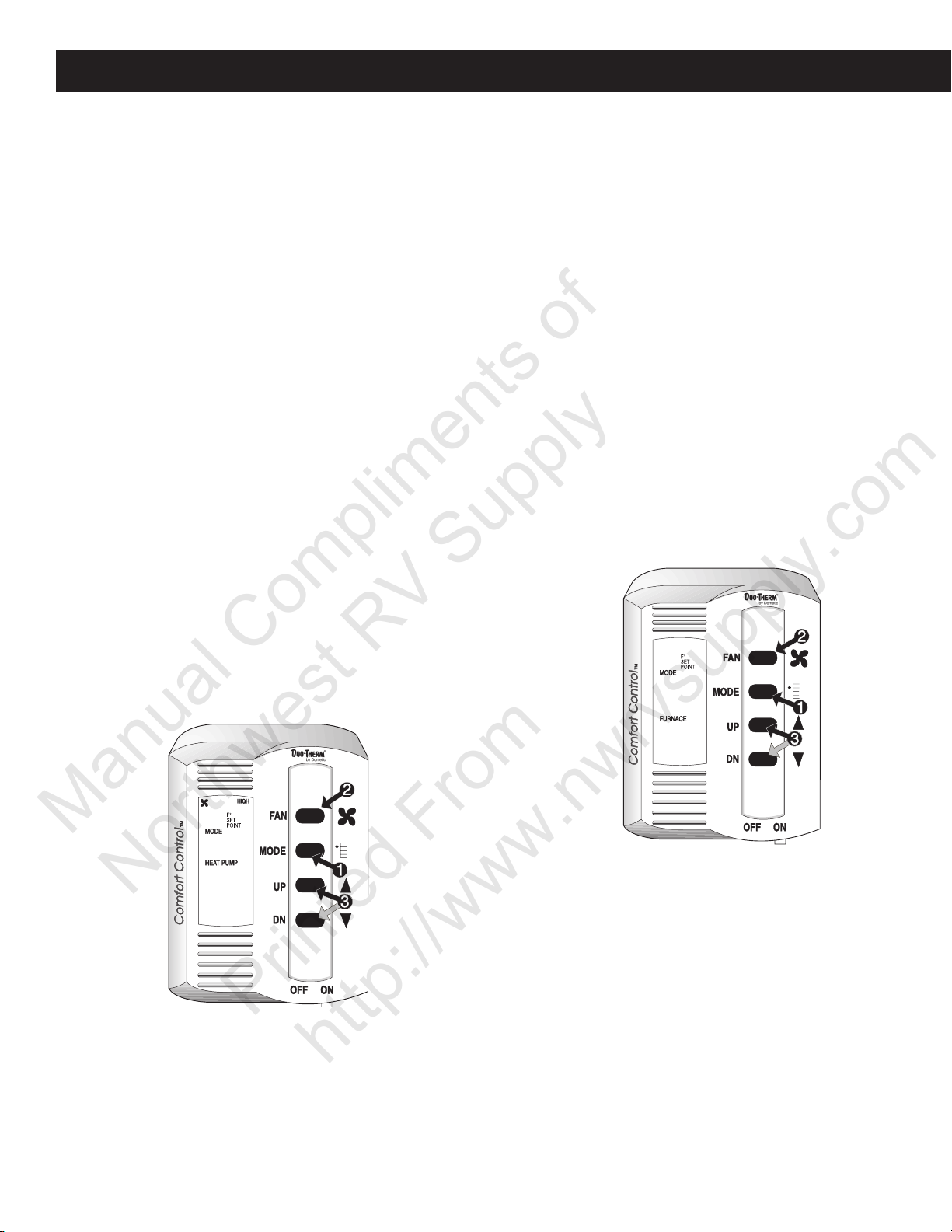

B1d. Comfort Control Center

The Comfort Control Center has been designed for you to

easily operate all the air conditioning and gas heating appliances found in your vehicle from one location.

In order to familiarize yourself with the operation of the

Comfort Control Center, the following diagram along with

FIG. B4

A. Liquid Crystal Display

the accompanying text will explain all the functional characteristics of the system.

Liquid Crystal Display - The Comfort Control Center is

equipped with a liquid crystal display (LCD) that identifies

the mode of operation, the temperature set-point, the zone

identification and the fan speed. The Comfort Control Center is designed to accept and control many varied air con-

B. Fan Speed Selector Button

C. Mode Selector Button

D. Temperature Selector Buttons

E. Zone and Stage Selector

F. On/Off Switch

ditioning and gas heating appliances. When you begin to

first operate the Comfort Control Center, you will see that

the LCD readout will only show the options available based

on the appliances installed on your vehicle. An incandescent light will illuminate the LCD area when a selector button is pushed for easy reading at all times. See FIG. B4.

Fan Speeds - Possible available fan speeds are: LOW,

MEDIUM, HIGH and AUTO. To select the desired fan speed,

momentarily depress the FAN push button. You will need

to continue to depress and release the FAN button until the

desired fan speed is shown in the LCD readout area of the

Comfort Control Center. See FIG. B4.

Mode Selector Button - Modes of operation available are:

OFF, FAN ONLY, COOL, HEAT PUMP, FURNACE, STAGE

and HEAT STRIP. Remember, the LCD readout will only

show the options available based on the appliances installed

on your vehicle. To select the mode of operation, momentarily depress the MODE push-button. You will need to

continue to depress and release the button until the desired mode is shown in the LCD readout area on the Comfort Control Center. See FIG. B4

To determine the Comfort Control Center options available

to you, depress and release the MODE push-button until it

goes through all selections. See FIG. B4

Temperature Selector Buttons - The temperature setpoint range is from 40° to 99° Fahrenheit. Determination

of Fahrenheit or Celsius standard is done at the time of

your manufacturer’s installation of the Comfort Control

Center. To set the temperature at your comfort level, simply depress and release the UP or DN push-button until the

desired temperature is shown in the LCD readout area of

the Comfort Control Center. See FIG. B4

Zone and Stage Selector Buttons - A ZONE is also es-

tablished at the time of installation of the Comfort Control

Center. If you have one air conditioner, you will have one

ZONE. If the vehicle has more than one cooling system,

depending on the manufacturing installation, you may have

2, 3 or 4 ZONES. Zones are defined and preset by the

manufacturer. A zone is an area of cooling/heating which

is controlled independently within that area, and regulated

at the Comfort Control Center. A typical example of a two

zone application would be a vehicle with two air conditioning systems, one in the front area (living room, kitchen)

and one in the back section (bedroom and bath). The front

area could be established as ZONE 1 and the back section

ZONE 2. You can select the desired temperature and fan

speeds for each zone independently, thereby keeping your

bedroom cooler than the front portion of the vehicle. To

determine the number of established zones in the vehicle,

simultaneously depress the FAN and MODE push-buttons.

ZONE 1 will be the first Zone to appear in the LCD readout.

Continue to depress and release these buttons until you

see ZONE 1 reappear. See FIG. B4.

16

B1d. Comfort Control Center

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Section B - Operation, cont’d.

ON/OFF Switch - The ON/OFF switch is located on the

lower right hand edge of the Comfort Control Center. Move

the lever from side to side to change status. See FIG. B5.

General Information

The ability of the air conditioner to maintain the desired

inside temperature depends on the heat gain of the RV.

Some preventative measures taken by the occupants of

the RV can reduce heat gain and improve the performance

of the air conditioner. During extremely high outdoor temperatures, the heat gain of the vehicle may be reduced by:

1. Parking the RV in a shaded area.

2. Using window shades (blinds and/or curtains).

3. Keeping windows and doors shut or minimizing usage.

4. Avoiding the use of heat producing appliances.

Starting the air conditioner early in the morning and giving

it a “head start” on the expected high outdoor ambient will

greatly improve its ability to maintain the desired indoor

temperature.

The manufacturer of this air conditioner will not be responsible for damage caused by condensed moisture on ceilings or other surfaces. Air contains moisture and this moisture tends to condense on cold surfaces. When air enters

the RV, condensed moisture may appear on the ceiling,

windows, metal parts, etc. The air conditioner removes

this moisture from the air during normal operation. Keeping doors and windows closed when the air conditioner is

in operation will minimize condensed moisture on cold surfaces.

This equipment must be serviced by qualified personnel

and some states require these people to be licensed.

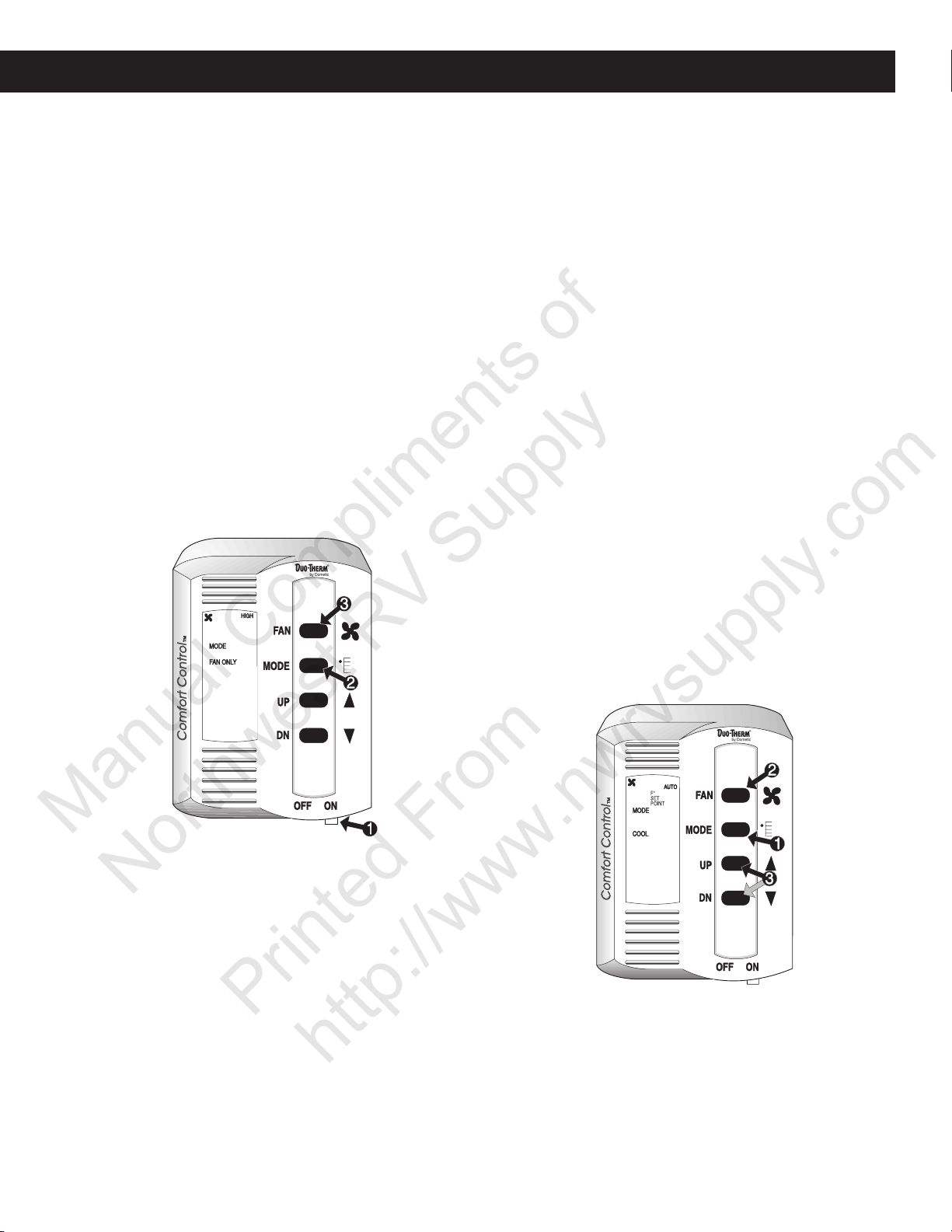

Fan Only Mode of Operation - See FIG. B4 & B5

1. Begin by placing the power switch on the lower right

hand edge of the Control Center in the ON position.

To do this, simply move the lever to the right.

2. Momentarily depress and release the MODE push-

button until the FAN ONLY indicator on the Liquid

Crystal Display (LCD) is illuminated.

3. Momentarily depress and release the FAN push-

button until the desired fan speed indicator (LOW, MED,

HIGH, AUTO) is illuminated. If your vehicle is equipped

with a heat pump or a dual basement air conditioning

system, your selection choice will be LOW, HIGH or

AUTO.

4. After approximately 5 seconds, the selected fan speed

will come on. The MODE and FAN speed you have

selected will remain shown in the LCD area of the Control Center until you change your selection.

5. If the vehicle contains more than one ZONE, depress

the FAN and MODE push-buttons simultaneously to

select ZONE 2, and repeat procedures from step two

above. Repeat entire procedure for each additional

zone.

FIG. B5

Cooling Mode Operation - See FIG. B4 & B5

(To set cooling temperatures and fan speeds on Duo-Therm

Air Conditioners and the cooling mode of Duo-Therm Heat

Pumps.)

1. Momentarily depress and release the MODE

push-button until the COOL indicator on the LCD is

illuminated.

2. Depress and release the FAN push-button to select

your desired fan speed.

3. Depress and release the UP push-button to increase

the temperature or the DN push-button to decrease

the desired temperature. The final selected SETPOINT

will be displayed in the LCD area of the Comfort Control Center.

4. After a delay of approximately 2 minutes the air

conditioner’s compressor will come on and the cooling

process will begin. Once the room temperature

reaches the selected SETPOINT, the compressor will

cycle off. Once the Comfort Control Center senses the

need for cooling, the compressor will restart in approximately two minutes. At this point, the fan will either:

a. continue to operate in the single selected fan speed

or,

b. cycle OFF and ON with the compressor if the AUTO

fan speed has been selected.

If the vehicle has a dual basement air conditioner or

dual heat pump system, the word STAGE (see stage

operation, page 20) will be illuminated. Both of these

units operate in two different stages, and the word

STAGE will show when the second stage operation has

been selected. To select the second stage, simultaneously depress the FAN and MODE push-buttons.

See FIG. B4 & B5.

17

Section B - Operation, cont’d.

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

B1d. Comfort Control Center

Fan Only Mode of Operation - See FIG. B4 & B6

1. Begin by placing the power switch on the lower right

hand edge of the Control Center in the ON position.

To do this, simply move the lever to the right.

2. Momentarily depress and release the MODE

push-button until the FAN ONLY indicator on the Liq-

uid Crystal Display (LCD) is illuminated.

3. Momentarily depress and release the FAN pushbutton until the desired fan speed indicator (LOW, MED,

HIGH, AUTO) is illuminated. If your vehicle is equipped

with a heat pump or a dual basement air conditioning

system, your selection choice will be LOW, HIGH or

AUTO.

4. After approximately 5 seconds, the selected fan speed

will come on. The MODE and FAN speed you have

selected will remain shown in the LCD area of the Control Center until you change your selection.

5. If the vehicle contains more than one ZONE, depress

the FAN and MODE push-buttons simultaneously to

select ZONE 2, and repeat procedures from step two

above. Repeat entire procedure for each additional

zone.

FIG. B6

Cooling Mode Operation

(To set cooling temperatures and fan speeds on Duo-Therm

Air Conditioners and the cooling mode of Duo-Therm Heat

Pumps.) See FIG. B7.

1. Momentarily depress and release the MODE

push-button until the COOL indicator on the LCD is

illuminated.

2. Depress and release the FAN push-button to select

your desired fan speed.

3. Depress and release the UP push-button to increase

the temperature or the DN push-button to decrease

the desired temperature. The final selected SETPOINT

will be displayed in the LCD area of the Comfort Control Center.

4. After a delay of approximately 2 minutes the air

conditioner’s compressor will come on and the cooling process will begin. Once the room temperature

reaches the selected SETPOINT, the compressor will

cycle off. Once the Comfort Control Center senses the

need for cooling, the compressor will restart in approximately two minutes. At this point, the fan will either:

a. continue to operate in the singe selected fan speed

or,

b. cycle OFF and ON with the compressor if the

AUTO fan speed has been selected.

5. If the vehicle contains more than one ZONE, depress

the FAN and MODE push-buttons simultaneously to

select ZONE 2, and repeat procedures from Step 1.

Repeat entire procedure for each additional zone.

Note: If set point is too low, the inside could freeze up.

FIG. B7

72

18

B1d. Comfort Control Center

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Section B - Operation, cont’d.

Heat Pump Operation

(To set heating temperatures for vehicles equipped with a

Duo-Therm rooftop or basement heat pump, see “Cooling

Mode Operation”.) See FIG. B8.

1. Momentarily depress and release the MODE

push-button until the HEAT PUMP indicator on the LCD

is illuminated.

2. If you have not previously set your fan speed, you may

do so by depressing and releasing the FAN pushbutton to select.

3. Depress and release the UP push-button to increase

the temperature or the DN push-button to decrease

the desired temperature. The final selected SETPOINT

will be displayed in the LCD area of the Comfort Control Center.

4. After a delay of approximately 2 minutes the heat

pump’s compressor will come on and the heating process will begin. Once the room temperature reaches

the selected SETPOINT, the compressor will cycle off.

Once the Comfort Control Center senses the need for

heating, the compressor will restart in approximately

two minutes. At this point, the fan will either:

a. continue to operate in the single selected fan speed

or,

b. cycle OFF and ON with the compressor if the AUTO

fan speed has been selected.

5. If the vehicle contains more than one ZONE, depress

the FAN and MODE push-buttons simultaneously to

select ZONE 2, and repeat procedures from Step 1

above. Repeat entire procedure for each additional

zone.

Furnace Mode Operation

(If the vehicle is equipped with a gas furnace connected to

the Comfort Control Center.) See FIG. B9

1. Momentarily depress and release the MODE

push-button until the FURNACE indicator on the LCD

is illuminated.

2. The Heat Pump fan does not operate in the FURNACE

mode.

3. Depress and release the UP push-button to increase

the temperature or the DN push-button to decrease

the desired temperature. The final selected SETPOINT

will be displayed in the LCD area of the Comfort Control Center.

4. The Duo-Therm heat pump system will not operate

when the Comfort Control System is in the FURNACE

mode. For cooling, change MODE to COOL.

5. If the vehicle contains more than one ZONE, depress

the FAN and MODE push-buttons simultaneously to

select ZONE 2, and repeat procedures from Step 1

above. Repeat entire procedure for each additional

zone.

Note: When furnace mode is selected in any Zone, all heat

pump units will terminate operation.

FIG. B9

68

FIG. B8

68

19

Section B - Operation, cont’d.

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

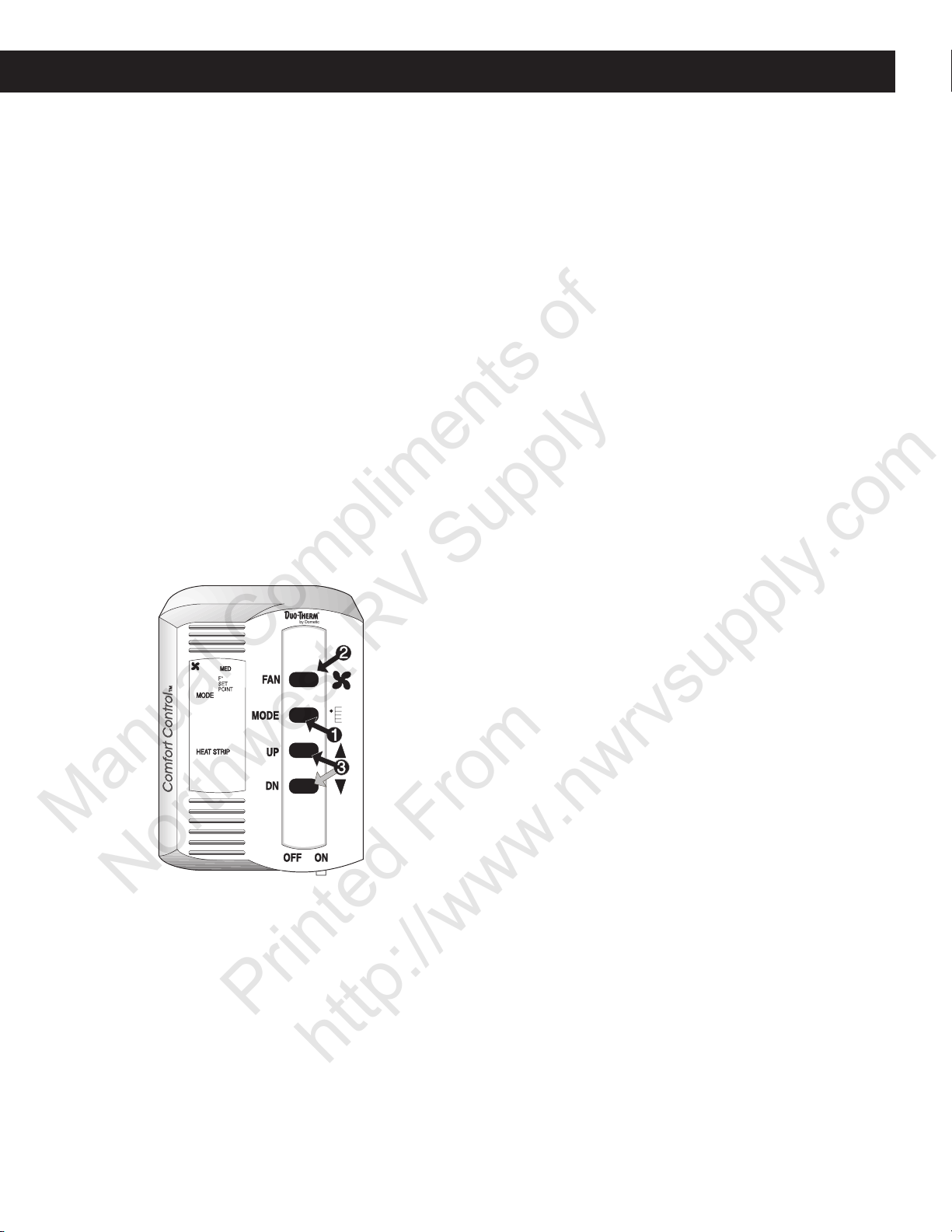

B1d. Comfort Control Center

Heat Strip Mode Operation - See FIB. B10

(For Duo-Therm air conditioners with an electric heat strip.)

1. Momentarily depress and release the MODE

push-button until the HEAT STRIP indicator on the LCD

is illuminated.

2. The fan will operate in LOW, MED or AUTO. You will

not be able to select HIGH speed when in the HEAT

STRIP mode. Depress and release the FAN pushbutton to select desired speed.

3. Depress and release the UP push-button to increase

the temperature or the DN push-button to decrease

the temperature. The final selected SETPOINT will be

displayed in the LCD area of the Comfort Control Center.

4. The electric heat strip will cycle ON and OFF per the

temperature SETPOINT displayed. The fan will either:

a. continue to operate in the selected fan speed or,

b. cycle OFF and ON with the heat strip if the AUTO

fan speed has been selected.

5. If the vehicle contains more than one ZONE, depress

the FAN and MODE push-buttons simultaneously to

select ZONE 2, and repeat procedures from Step 1

above. Repeat entire procedure for each additional

zone.

FIG. B10

HEAT PUMP MODE - When HEAT PUMP mode is

selected, the fan will automatically run in the LOW

speed.

HEAT STRIP MODE - When HEAT STRIP mode is

selected, the fan will automatically run in the LOW

speed.

FAN ONLY MODE - In the FAN ONLY mode, the fan

automatically runs in the LOW speed.

Refrigerant Compressor Time Delay

A time delay of approximately two minutes occurs any time

the compressor is required to begin the cooling or heat

pump cycle.

Power Interruption

In the event that power to the air conditioner or control is

interrupted, the system will restart with the same settings

you have previously set.

Zone Control

The Duo-Therm Comfort Control Center will operate cooling and heating appliances which the vehicle manufacturer

has designed to heat or cool different areas (ZONES) of

your RV. The Comfort Control Center will advise you if the

vehicle has multiple ZONES, by showing ZONE 1, 2, 3 or

4 in the LCD readout.

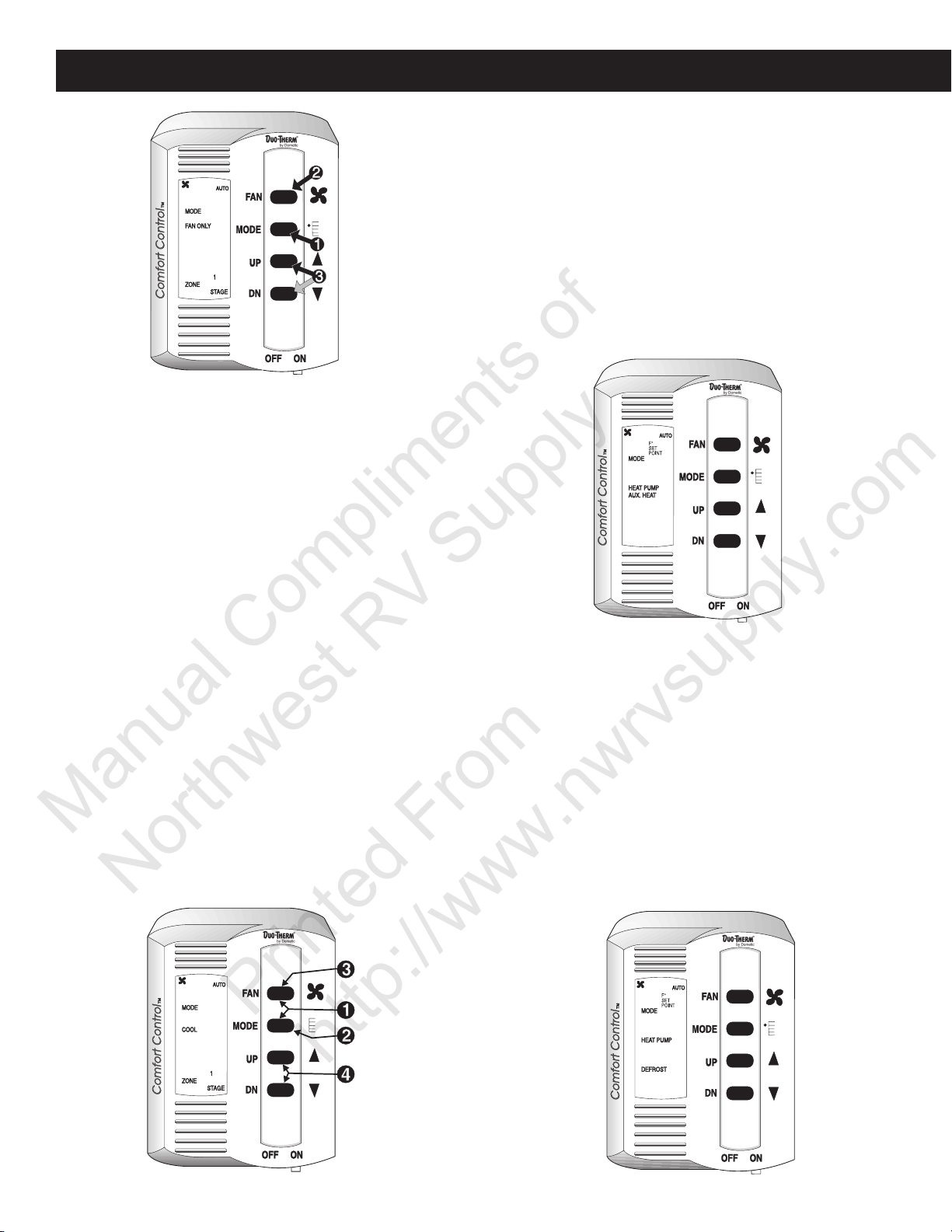

Stage Control Operation

If the vehicle is equipped with a Duo-Therm Dual Base-

72

Auto Fan

When AUTO FAN is selected, the fan speed will be deter-

mined by the mode you are in.

COOL MODE - In the COOL mode, which is the air

conditioning mode, the fan will automatically select the

speed depending upon the difference between the temperature SETPOINT and the room temperature. When

that difference is:

8° or more The fan will operate on HIGH

4° to 8° The fan will operate on MED

4° or below The fan will operate on LOW

ment Air Conditioner or a Dual Basement Heat Pump, you

have an air conditioning system that is designed to optimize comfort and running efficiencies. This is accomplished

by providing an on-demand secondary stage of operation.

Note: The primary stage will continue to operate even if

there isn’t electrical power available to run the second stage.

The Comfort Control Center simplifies this operation by

allowing you to set the primary temperature set-point and

the differential temperature set-point which activates the

secondary stage. After turning on your Comfort Control

Center, perform the following steps to set and activate the

stage control operation. See FIG. B11.

1. Momentarily depress the MODE push-button until the

desired mode of operation is selected. (FAN ONLY,

COOL, HEAT PUMP)

2. Momentarily depress the FAN push-button until the desired fan speed indicator is illuminated (LOW, HIGH,

AUTO)

20

B1d. Comfort Control Center

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Section B - Operation, cont’d.

FIG. B11

3. Momentarily depress the UP and DN push-button until

the desired room temperature set-point is displayed.

This completes the setup for the primary stage of the Dual

Basement Air Conditioner or Dual Basement Heat Pump.

Next, you will set up the secondary stage.

To Set Up the Secondary Stage

1. Simultaneously depress and release the FAN and

MODE push-buttons until the STAGE indicator on the

LCD is illuminated. See FIG. B12.

2. Momentarily depress the MODE push-button until the

desired mode of operation for the second stage is selected (FAN ONLY, COOL, HEAT PUMP). Normally,

the mode of operation is the same as the primary stage.

3. Momentarily depress the FAN push-button until the desired fan speed indicator is illuminated (LOW, HIGH,

AUTO).

4. Momentarily depress the UP or DN push-button to set

the desired differential temperature setpoint (0°F to

10°F). The secondary stage will run once the actual

room temperature reaches the differential temperature

setpoint. Example: Desired room temperature setpoint

for the primary stage in the COOL MODE is set at 72°F;

differential temperature setpoint is set at 5°F. The secondary stage will activate when the actual room temperature reaches 77°F (72°F + 5°F), and will continue

to operate until the room once again becomes 72°F.

Aux. Heat - See FIG. B13

When in the HEAT PUMP mode, if the outside ambient

temperature is measured to be below 24°F, the control will

automatically select the FURNACE operation. When this

happens, the AUX. HEAT and the HEAT PUMP indicators

on the LCD will illuminate. Once the outside ambient temperature is measured above 34°F, the control will return to

the HEAT PUMP operation. If your vehicle does not contain a furnace, and you have a Duo-Therm Heat Pump,

once the outside ambient temperature goes below 24°F,

the system will shut down until the outside temperature

reaches 34°F, at which time the Heat Pump will resume

operation.

FIG. B13

72

Defrost Cycle - See FIG. B14

This cycle is active during HEAT PUMP operation and al-

lows the heat pump to operate down to 24°F. When the

outside ambient temperature is less than 42°F and greater

than 24°F, a defrost timing cycle will begin. The defrost

timing cycle will allow operation of the heat pump for 40

minutes. The fan will the be shut off, the refrigerant flow

reversed and run for 4-1/2 minutes, this is the DEFROST

cycle. The refrigerant flow will then be returned to normal

and after a 30 second delay, will continue until the temperature is greater than 42°F or until the temperature becomes less than 24°F, at which time the furnace will activate. (See Aux. Heat). During the defrost cycle, the DE-

FROST indicator on the LCD shall be illuminated.

FIG. B12

FIG. B14

05

21

72

Section B - Operation, cont’d.

Manual Compliments of

Northwest RV Supply

Printed From

http://www.nwrvsupply.com

Reset

If the Comfort Control Center is not operational, inadequate

data or no functions occur, reset the Comfort Control Center to factory settings. When a reset procedure is done, all

previous program memory is removed. The factory setting

of 72°F for cooling mode and 68°F for heating modes are

entered.

To initiate a RESET, do the following in the order listed:

1. Turn control on to ensure annunciator data and light

are present. If data and light are present, continue to

next step.

2. Depress MODE switch to activate annunciator light.

3. Simultaneously depress the bottom two buttons (temperature UP and DOWN) and hold.

4. While holding these buttons down, depress the MODE

button once and release.

5. Release the two buttons previously held down.

6. Depress the MODE button once again.

7. At this time the light should extinguish, and the mode

should register “OFF”. If not, repeat Steps 2 through 6.

8. Retest system ensuring that all functions are present

and operational.

FIG. B15

72

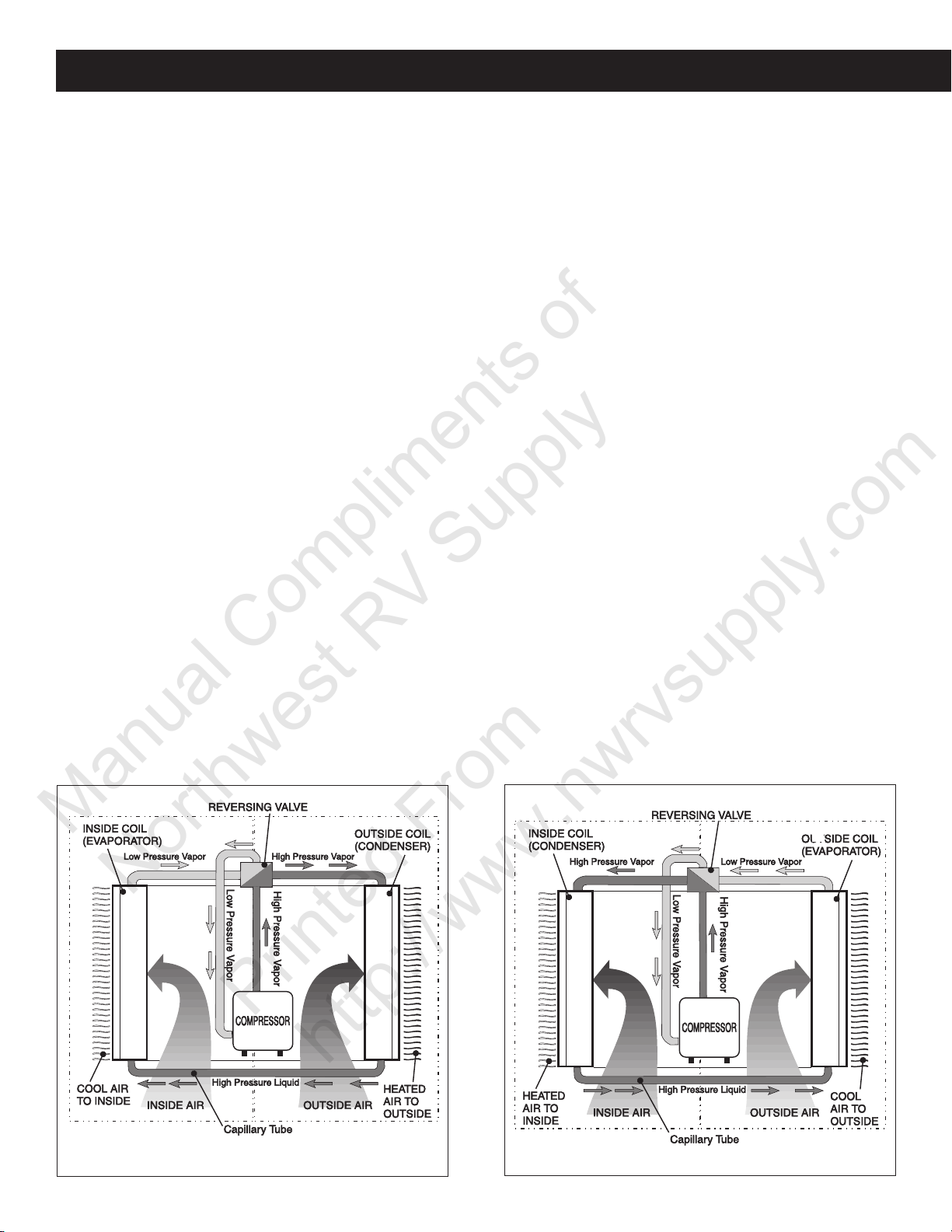

B2. Heat Pump

General Information

The roof-top heat pump was designed to operate in a MILD

GEOGRAPHICAL AREA for heating where the heat loss is

minimal. The heat pump was designed to operate down to

an outside ambient temperature of 40°F. As long as the

temperature remains below 40 degrees, the main furnace

will heat your home. As the outside temperature increases

to 45°F., the outdoor thermostat switches back to the heat

pump circuit.

Note: Model 59126.501 does not have an outdoor thermostat. When outdoor temperature is at or below 40°F., use

the main furnace to heat your home.

The advantages of the heat pump are: