Duon System AUTROL Series, APT3500, AUTROL APT3200 SERIES Operation Manual

APT3500 Smart Pressure Transmitter Operation Manual M3500-E01A

* Information on this manual can be changed without an advance notice.

APT3500 Smart Pressure Transmitter

Operation Manual

DUON SYSTEM CO., LTD

Autrol

®

DUON SYSTEM Co., Ltd. http://www.autrol.com/

AUTROL Series Operation Manual : M3500-E01A

APT3500 Smart Pressure Transmitter Operation Manual M3500-E01A

ii

Duon System Co.,Ltd.

APT3500 Smart Pressure Transmitter Operation Manual M3500-E01A

APT3500 Smart Pressure Transmitter

This manual is made so that general user can help to install and operate

APT3500 Smart Pressure Transmitter efficiently.

Before handling APT3500 transmitter, all users have to be fully aware of it.

Information on this manual can be changed

Without an advance notice.

DUON SYSTEM CO., Ltd

60-31, Gasan-dong, Guemchon-gu, Seoul, Korea

Tel: +82-2-860-7900

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

2 DUON System Co., Ltd.

Table of Contents

Chapter 1 Introduction

1.1 Using This Manual

1.2 Overview of Transmitter

1.3 Software Compatibility

1.4 Transmitter Components

Chapter 2 Handling Cautions

2.1 Unpacking

2.2 Models and Specifications Check

2.3 Storage

2.4 Selecting the Installation Locations

2.5 Calibration on Spot after Installation

2.6 Pressure Connections

2.7 Waterproofing of Cable Conduit Connections

2.8 Restrictions on Use of Radio Transceiver

2.9 Insulation Resistance Test and Dielectric Strength Test

2.10 Installation of Explosion Protected Type Transmitters

2.11 EMC Conformity Standards

Chapter 3 Transmitter Functions

3.1 Overview

3.2 Safety Messages

3.3 Warning

3.4 Fail Mode Alarm

3.5 EEProm-Write Enable and Disable Mode Switch

3.6 Configuration of Alarm and Security Jumper Procedures

3.7 Configuration of Zero and Span Procedures

3.8 Shop Commissioning using HHT

Chapter 4 Installation

4.1 Overview

4.2 Safety Messages

4.3 Warning

4.4 Commissioning on the bench with Hand-Held Terminal

4.5 General Considerations

4.6 Electrical Considerations (Power Supply)

4.7 Wiring

4.8 Mechanical Considerations

4.9 Environmental considerations

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

3 DUON System Co., Ltd.

Chapter 5 On-line Operation

5.1 Overview

5.2 Safety Messages

5.3 Configuration Data Review

5.4 Check Output

5.5 Basic Setup

5.6 Detail Setup

5.7 Configuration of Information Variable

5.8 Configuration of Breakdown Diagnostics Function

5.9 Calibration

Chapter 6 Maintenance

6.1 Overview

6.2 Safety Messages

6.3 Hardware Diagnosis

6.4 Hardware Maintenance

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

4 DUON System Co., Ltd.

Appendix I

APT3500 Smart Pressure Transmitter

LCD Display Code

APPENDIX II

PRODUCT CERTIFICATION

APPENDIX III

Special Condition for Safe use

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

5 DUON System Co., Ltd.

Chapter 1 Introduction

The APT3500 Smart Pressure Transmitter are correctly calibrated at the factory before shipment. To

ensure correct and efficient use of the instrument, please read this manual thoroughly and fully

understand how to operate the instrument before operating it

① The contents of this manual are subject to change without prior notice.

② All rights reserved. No part of this manual may be reproduced in any form without DUON

System’s written permission.

③ If any question arises or errors are found, or if any information is missiong from this manual,

please inform the nearest DUON System sales office.

④ The specifications covered by this manual are limited to those for the standard type under the

specified model number break-down and do not cover custom-made instrument.

⑤ Please note that changes in the specifications, construction, or component parts of the

instrument may not immediatelty be reflected in this manual at the time of change, provided

that postponement of revisions will not cause difficulty to the user from a functional of

performance standpoint.

1-1 Using This Manual

The Chapters in this operating manual provide information on installing, operating, and maintaining

devices from the AUTROL Model APT3500 Samrt Pressure Transmitter. The Chapters are organized as

follows.

Chapter 2 Handling Cautions

Chapter 2 provides instructon on commissioning and operating Model APT3500 Smart

Pressure Transmitters. Informations on software functions, configuration parameters, and on-line

variables is also included.

Chapter 3 Transmitter Functions

Chapter 3 contains in consideration of handling Model APT3500 Smart Pressure Transmitters.

Chapter 4 Installation

Chapter 4 contains mechanical, environment consideration and electrical installation

instructions on the Model APT3500 Smart Pressure Transmitters.

Chapter 5 On-line Operation

Chapter 5 describes the configuration the parameter how to use variety of the Model

APT3500 Smart Pressure Transmitters' software fucntion and configuration. See the following list for

the details.

① Regulations of circuit's Input/Output characteristics; Sensor or Output Trim

② Changed of output characteristic; Range Configuration, Output Type, Damping,Unit

③ Changed of general data; Tag No.,Date,Message etc.

Chapter 6 Maintenance

Chapter 6 contains hardware diagnostics ,troubleshooting and maintenace task.

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

6 DUON System Co., Ltd.

1.2 Overview of Transmitter

Autrol® Smart Pressure Transmitter based in a microprocessor is the pressure transmitter, has a

designed capacitance sensor optimized for draft measurement. APT3500 has a true draft analog range

from 4 to 20mA offering that feature that a pressure range or after convert analog range to HART

(Communication) digital signal transmit for control systems like DCS, PLC. This Model has explosion

protected type and high precision, better reliabilty and is available on digital commuication for the use

remotes communication system.

This transmitter is enabled in HART commmunication with Host, HHT (HART Hand-Held Terminal) or

PC Configurator. Thus, transmitter various variables in host is enable to be changed, configured and

tested calibrated by users. For the HART Communication between DC Power Supply and Transmitter

has to terminate 250~ 550 Ohm.

1.3 Software Compatibility

Autrol® Smart Pressure Transmitter's software is implemented and complemented if necssary. Uses of

the transmitter will not be a compatibility software is contained in the host of the HHT(ACONF312 or

275/375/475 HART Communicator). In this case contact us for software DD(Device Descriptor) to be

able to use with the transmitter, you must to use loading in HHT, etc.

There may be some differences on supported fucntions as to Firmware Revision of transmiter. This

manual is based on Firmware Revision 10. Function deviations as to firmware Revision are same as

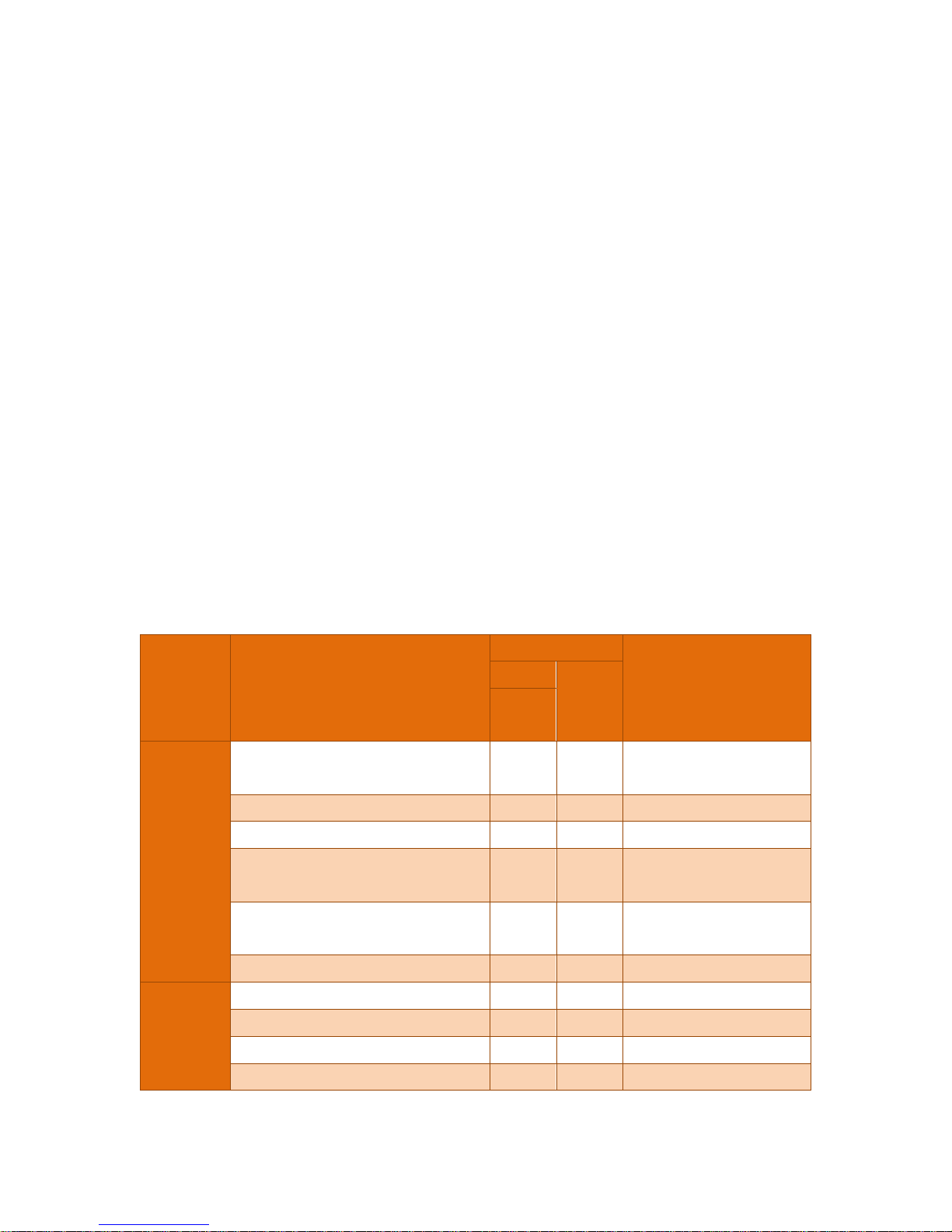

under box

Item Function

Function Supports

Output that is affected by

set-up change

Button HART

(HHT/

SST30)

Rev.10

Basic

Set-up

Range set ● ●

Whole output excluding PV

displayed on LCD

Units set ● ● PV displayed on LCD

Damping Seccond set ● ● Whole Output

Transfer Function set ● ●

Whole output excluding PV

displayed on LCD

Low-cut set ● ●

Whole output excluding PV

displayed on LCD

Loop Test ● ● 4~20mA

Calibration

Zero Trim ● ● Whole Output

Zero Adjustment ● ● Whole Output

Full Trim ⅹ ● Whole Output

D/A Trim ⅹ ● 4~20mA

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

7 DUON System Co., Ltd.

Transm itter

Information

Set-up

Polling Address set ● ● 4~20mA

Setting up transmitter basic information

(Tag, Date, Descriptor, Message)

ⅹ ● -

LCD

Display

LCD mode set ● ● Whole LCD Display

Decimal Place set ● ● Whole LCD Display

LCD Engineering Mode set

(Eng Range, Eng Unit, Eng Transfer

Function…)

● ● LCD Engineering Value

Other

Button Lock set ● △ -

Master Reset ● ● Whole Output

: Supported.

ⅹ : Not Supported

: Supported but update required

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

8 DUON System Co., Ltd.

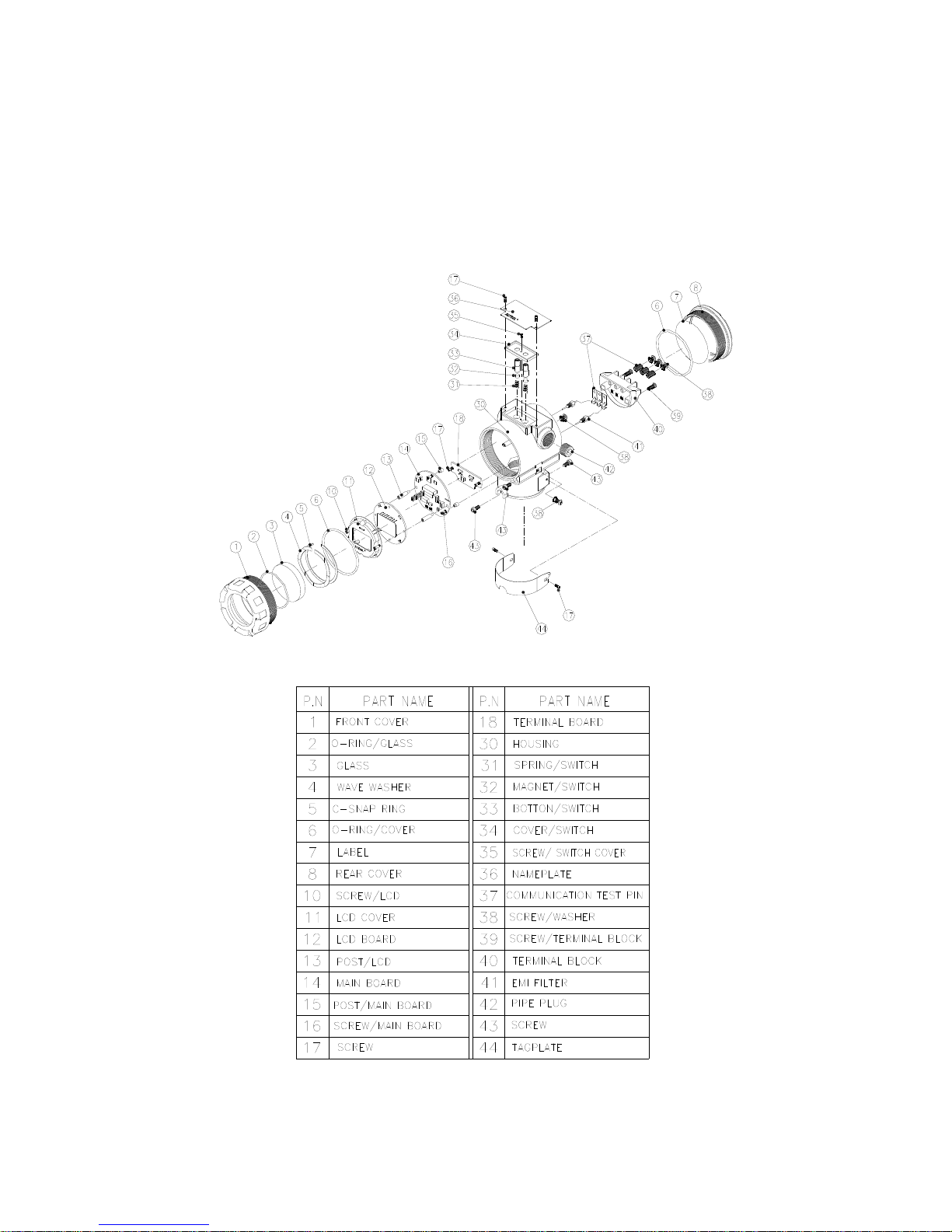

1.4 Transmitter Components

The components and figure of Autrol® Smart Pressure Transmitter is suggested on the next page.

Follow the precedure described on figure 1-1, 1-2, 1-3, 1-4, 1-5, 1-6.

Figure 1-1. Model APT3500 Transmitter Exposed View (Housing)

Figure 1-2. TRANSMITTER COMPONENTS

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

9 DUON System Co., Ltd.

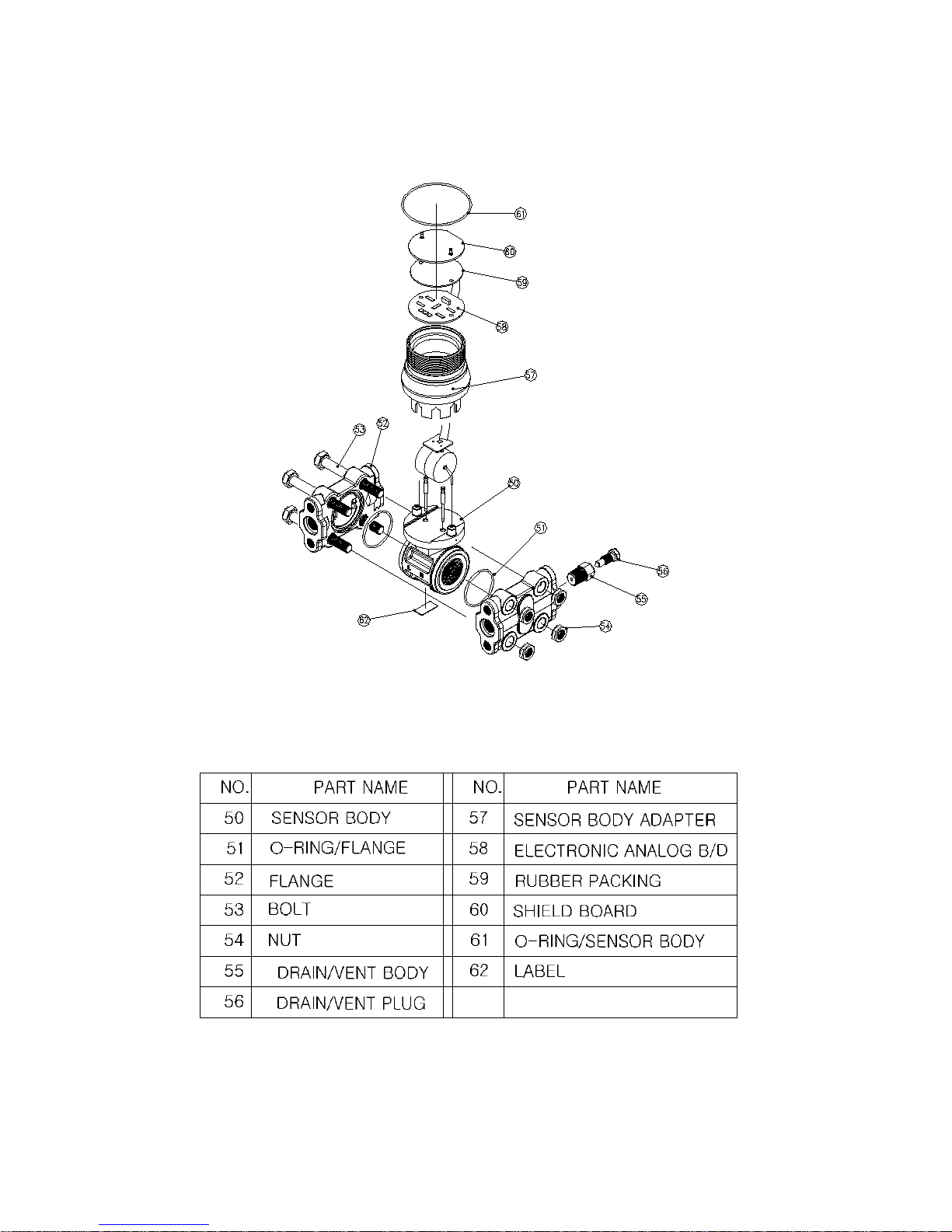

Figure 1-3. Model APT3500 Exploded View (Sensor Module-D,G,L)

Figure 1-4. TRANSMITTER COMPONENTS

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

10 DUON System Co., Ltd.

Chapter 2 Handling Cautions

This chapter consists of cautions for transmitter handling and storage, selection of installation

locations, insulation and explosion structure, etc.

[Quick Reference Manual]

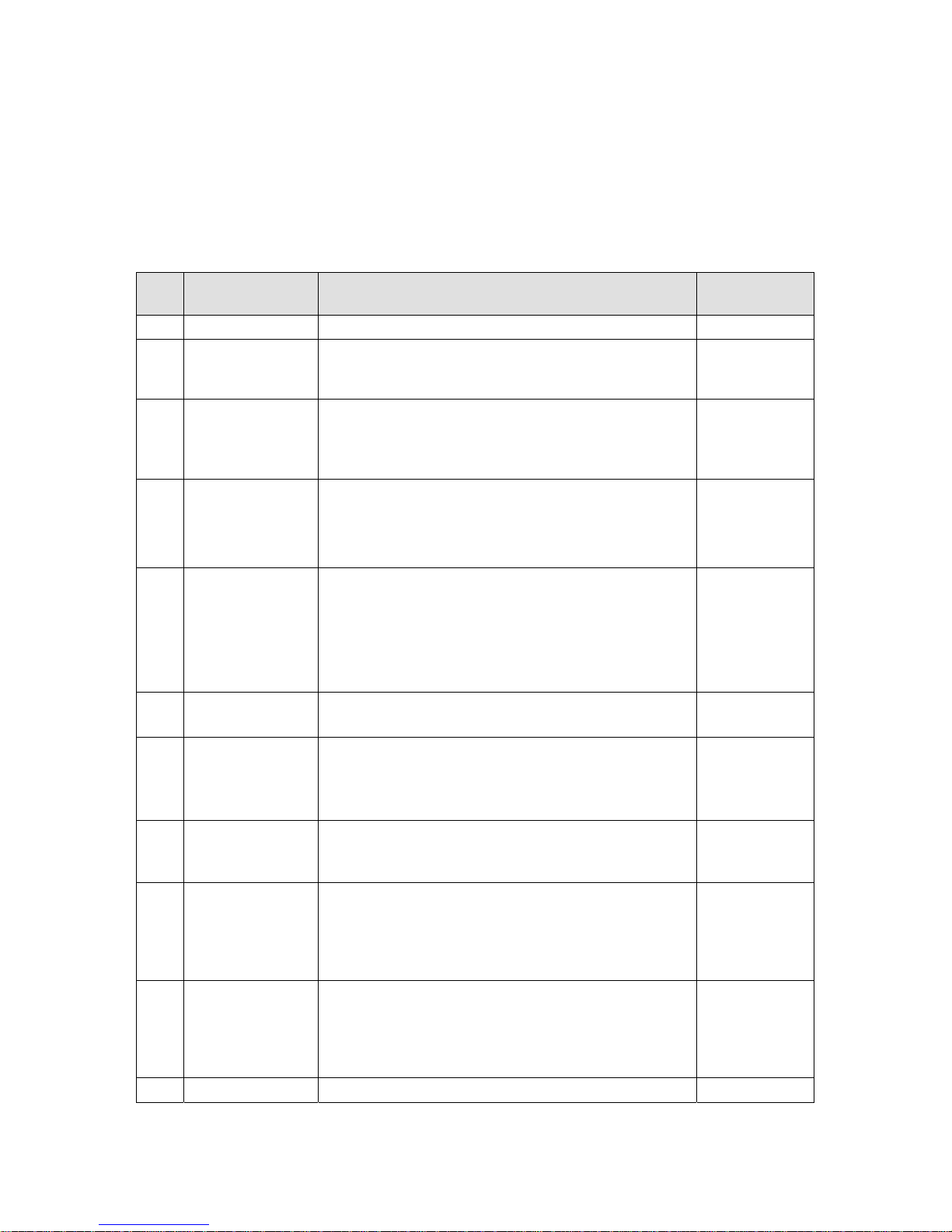

Step Job Job Details Instrument

1 Unpacking - Unpack transmitter packing

2

Model and

Specifications

Check

- Make sure whether the delivered transmitter is same

as options attached on its nameplate

3 Storage

- Places not exposed to water, non-vibration and non-

impact area

- Ambient temperature 25 deg C and relative humidity

65% RH

4

Calibration on a

Calibration Room

- Configuration of Range, Zero/Span, Unit, Tag,

Damping Time, Transfer Function, DA Trim and other

parameters

- HHT

- Pressure

Source

(requested)

- Galvanometer

5

Installation

Locations

- Where ambient temperature is not fluctuated

- Where corrosion happens by chemical materials, etc.

- Where vibration and impact is not severe

- Where non-explosion area is matched on

explosionproof regulations

- Where maintenance is very easy

(Engineering)

6

Mechanical

Considerations

- Where transmitter can be handled easily

- Be cautious not leaking the pressure.

(Engineering)

7

Electrical

Considerations

- Connect 24 Vdc

(Power Supply is 12 Vdc – 45 Vdc)

- For HART communication, total resistance on

transmitter terminal loop should be 250 – 550 Ohm.

(Engineering)

8

Mounting and

Installation

- For mounting transmitter, an appropriate bracket

should be used.

- Transmitter should be fixed well against swing.

(Mounting and

Installation)

9

Calibration on

Spot

- Sensor Zero Trim has to be done after ten seconds,

namely, differential pressure become zero and

stabilized.

- Make sure that PV value of transmitter is zero and

current is 4 mA.

HHT or

Zero/Span

button

10 Pressure

- Do not apply the regulated differential and line

pressure.

- Close equalizing valve of 3 valve manifold, Then,

open stop valve on high and low side slowly and

simultaneously.

(Applying

pressure)

11 Operation - Make sure whether transmitter operates well or not Eye or HHT

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

11 DUON System Co., Ltd.

2.1 Unpacking

When moving the transmitter to the installation site, keep it in its original packaging. Then, unpack

the transmitter there to avoid damage on the way.

2.2 Models and Specifications Check

The model name and specifications are indicated on the nameplate to the case. Please check your

specification and wanted model.

2.3 Storage

The following precautions must be observed when storing the instrument, especially for a long period.

(1) Select a storage area that meets the following conditions:

(a) It is not exposed to rain or water.

(b) It suffers minimum vibration and shock.

(c) If possible, it is preferable at normal temperature and humidity (approx. 25°C, 65% RH).

However, it has an ambient temperature and relative humidity within the following ranges.

● Ambient Temperature: -40 ~ 85°C (without LCD module)

-30 ~ 80°C (with LCD module)

* General Use -20 ~ 60°C (CSA Explosionproof)

● Relative Humidity: 5% ~ 98% RH (at 40°C)

(2) When storing the transmitter, repack it as nearly as possible to the way it was packed when

delivered from the factory.

(3) If storing a transmitter that has been used, thoroughly clean diaphragm surfaces (the pressure-

detector sections) of the diaphragm seals, so that no measured fluid remains on them. In addition,

make sure before storing that the pressure-detector and transmitter assemblies are securely

mounted.

2.4 Selecting the Installation Locations

The transmitter is designed to withstand severe environmental conditions. However, to ensure stable

and accurate operation for many years, the following precautions must be observed when selecting an

installation location.

(1) Ambient Temperature

Avoid locations subject to wide temperature variations or a significant temperature gradient. If the

location is exposed to radiant heat from plant equipment, provide adequate insulation or

ventilation.

(2) Ambient Atmosphere

Avoid installing the transmitter in a corrosive atmosphere. If the transmitter must be installed in a

corrosive atmosphere, there must be adequate ventilation as well as measures to prevent intrusion

or stagnation of rainwater in conduits. Moreover, there should be appropriate ventilation

preventing corrosion by rain gathered on conduit.

(3) Shock and Vibration

Select an installation site suffering minimum shock and vibration (although the transmitter is

designed to be relatively resistant to shock and vibration)

(4) Installation of Explosion-protected Transmitters

Explosion-protected transmitters can be installed in hazardous areas according to the gas types

for which they are certified.

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

12 DUON System Co., Ltd.

(5) Select a place that transmitter maintenance is very easy.

2.5 Calibration on Spot after Installation

(1) Sensor Zero Trim should be done after transmitter is installed on spot, because zero point is not

accurate as to mounting status.

(2) For Sensor Zero Trim, make differential pressure of transmitter for zero in advance. Then, make

Sensor Zero Trim after pressure is sufficiently stabilized (after approximately 10 seconds).

(3) There are two ways for making differential pressure for zero. One is to apply zero differential

pressure (making same pressure both high and low side pressure). The other is to close Hign and

Low side of stop valve of 3 valve manifold and to open its equalizing valve.

(4) Sensor Zero Trimming is to use HHT (ACONF312 or 275/375/475 HART Communicator), PC or PDA

configurator, and to use Zero/Span button. Make sure all details on this manual.

(5) Refer to On-line Operation for configuring another parameters except Sensor Zero Trim

2.6 Pressure Connections

The following precautions must be observed in order to safely operate the transmitter under pressure.

(1) Never apply a pressure higher than the specified maximum working pressure.

(2) Confirm the option of pressure connection of transmitter. Necessarily use standardized and quality-

approved parts.

(3) In case of being needed by hard circumstances and regulations, there should be seal equipment

for leakage.

2.7 Waterproofing of Cable Conduit Connections

Apply a non-hardening sealant (silicone or tape, etc.) to the threads to waterproof the transmitter

cable conduit connections.

2.8 Restrictions on Use of Radio Transceivers

▲ Warning

◈ Instrument installed in the process is under presure. Never loosen or tighten the flange bolts as it may

cause dangerous spouting of process fluid.

◈ If the accumulated process fluid may be toxic or otherwise harmful, take approriate care to avoid contack

with the body of inhalation of vapors even after dismounting the instrument from process line for

maintenance.

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

13 DUON System Co., Ltd.

2.9 Insulation Resistance Test and Dielectric Strength Test

Since the transmitter has undergone insulation resistance and dielectric strength tests at the factory

before shipment, normally these tests are not required. However, if required, observe the following

precautions in the test procedures.

(1) Do not perform such tests more frequently than is absolutely necessary. Even test voltages that

do not cause visible damage to the insulation may degrade the insulation and reduce safety margins.

(2) Never apply a voltage exceeding 500 Vdc (100 Vdc with an internal lightening protector) for

the insulation resistance test, nor a voltage exceeding 500V AC (100V AC with an internal lighting

protector) for the dielectric strength test.

(3) Before conducting these tests, disconnect all signal lines from the transmitter terminals.

Perform the tests in the following procedure.

(4) Insulation Resistance test

(a) Short-circuit the + and - SUPPLY terminals in the terminal box.

(b) Turn OFF the insulation tester. Then connect the insulation tester plus (+) lead wire to the

shorted SUPPLY terminals and the minus (-) lead wire to the grounding terminal.

(c) Turn ON the insulation tester power and measure the insulation resistance. The voltage

should be applied short as possible to verify that insulation resistance is at least 20M.

(d) After completing the test and being very careful not to touch exposed conductors disconnect

the insulation tester and connect a 100k resister between the grounding terminal and the short-

circuiting SUPPLY terminals. Leave this resistor connected at least three second to discharge any static

potential. Do not touch the terminal while it is discharging.

(5) Dielectric Strength Test

(a) Short-circuit the + and - SUPPLY terminals in the terminal box.

(b) Turn OFF the dielectric strength tester. Then connect the tester between the shorted SUPPLY

terminal and the grounding terminal. Be sure to connect the grounding lead of the dielectric strength

tester to the ground terminal.

▲ Warning

◈ Although the transmitter has been designed to resist high frequency electrical noise, if a radio transeiver is

used near the transmitter of its external wiring, the transmitter may be affected by high frequency noise

pickup. To test for such effects, bring the transceiver in use slowly from a distance of several meters from

the transmitter, and observe the measurement loop for noise effects. Thereafter, always use the

transceiver outside the area affected by noise.

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

14 DUON System Co., Ltd.

(c) Set the current limit on the dielectric strength tester to 10mA, then turn ON the power and

gradually increase the tester voltage from '0' to the specified voltage.

(d) When the specified voltage is reached, hold it for one minute.

(e) After completing this test, slowly decrease the voltage to avoid any voltage surges.

2.10 Installation of Explosion Protected Type Tra ns mi tters

2.10.1 KOSHA Certification

Caution for KOSHA Flameproof is following type.

[Note1] Model APT3500 diaphragm sealed for potentially explosive atmosphere:

Type of Protection and Marking Code: Ex d ⅡC T6

Temperature Class: T6

Ambient Temperature: -20 ~ 60'C

Process Temperature: Max. 80'C

[Note2] Electrical Data

Supply Voltage: Maximum 45 Vdc

Output signal: 4 ~ 20mA, maximum 22mA

[Note3] Installation

All wiring shall comply with local installation requirement.

The cable entry devices shall be of a certified flameproof type, suitable for conditions of

use.

[Note4] Operation

Wait one minute after power -disconnection, before opening the enclosure.

Take care not to generate mechanical spark when access to the instrument and

peripheral devices in hazardous location.

[Note5] Maintenance and Repair

The instrument modification or parts replacement by other than authorized

representative of DUON System is prohibited and will void KOSHA Flameproof.

2.11 EMC Conformity Standards

EMC Standaed : IEC 61000-4 series

DUON System recommends customer to apply the Metal Conduit Wiring or to upset he twisted pair

Shield Cable for signal wiring to conform the requirement of EMC Regulation, when customer installs

AUTROL Series Transmitters to the plant.

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

15 DUON System Co., Ltd.

Chapter 3 Transmitter Functions

3.1 Overview

This Chapter contains information on operating Model APT3500. Tasks that should be performed on

the bench priori to installation are explained in this chapter.

3.2 Safety Message

Procedures and instructions in this chapter may require special precautions to ensure the safety of the

personal performing the operations. Information that raises potential safety issues is indicated by

warning symbol(▲). Refer to the following safety messages before performing an operation preceded

by this symbol.

3.3 Warning

▲ Warning

Explosion can result in death or serious injury:

◈ Do not remove the transmitter covers in explosion environments when the circuit is alive.

◈ Transmitter covers must be fully engaged to meet explosionproof requirements.

▲ Warning

Electrical can result in death serious injury:

◈ The qualif ication which is educated only the person whom it prepares will be able to establish the

transmitter.

▲ Warning

Electrical can result in death serious injury:

◈ Avoid contact with the leads and terminals. High voltage that may be present on leads can cause electrical

shock.

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

16 DUON System Co., Ltd.

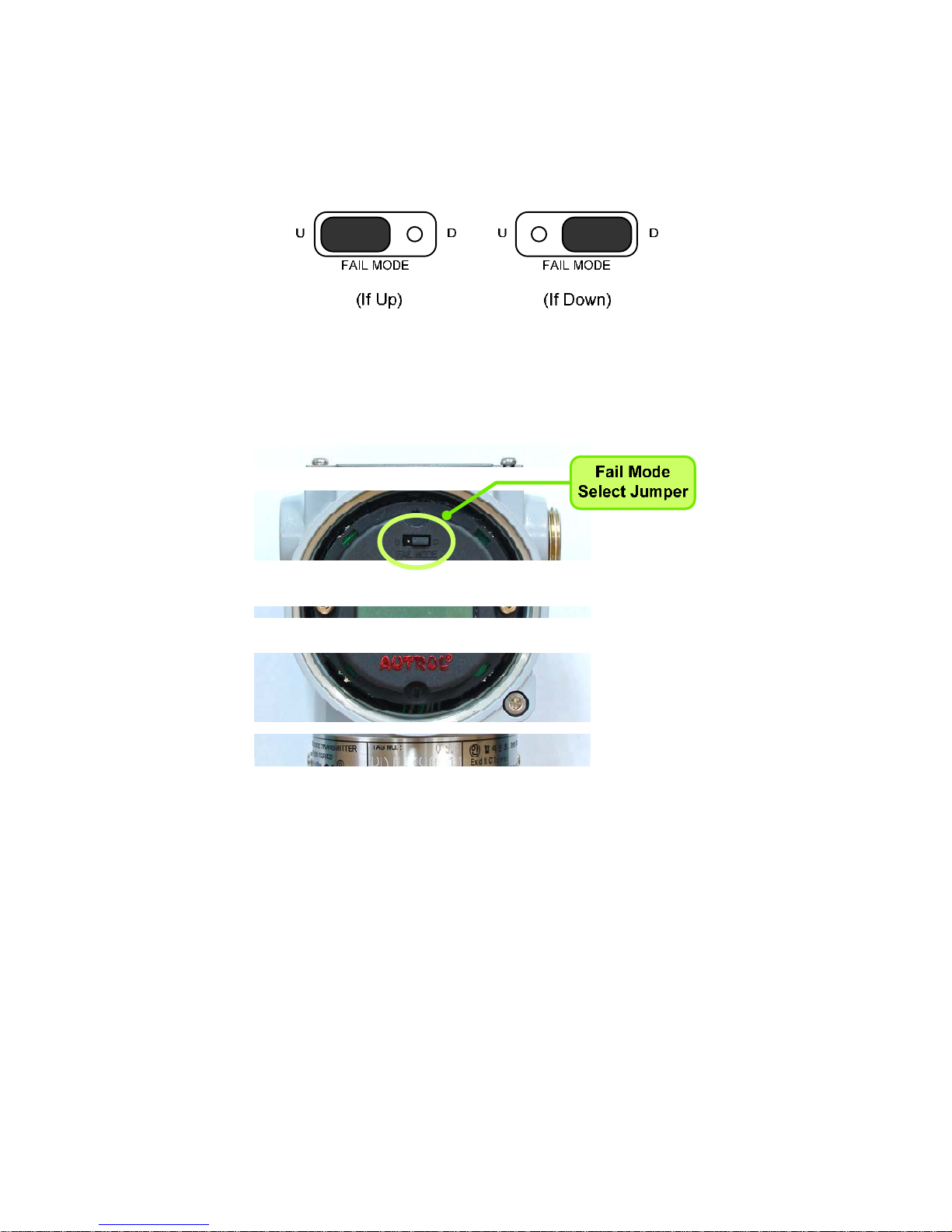

3-4. Fail Mode Alarm

AUTROL® Smart Pressure Transmitter automatically and continuously performs self-diagnostic

routines. If the self-diagnostic routines detect a failure, the transmitter drives its output outside of the

normal saturation values. The transmitter will drive its output low(down) or high(up) based on the

position of the failure mode alarm jumper . See Table 3.1 for Output values.

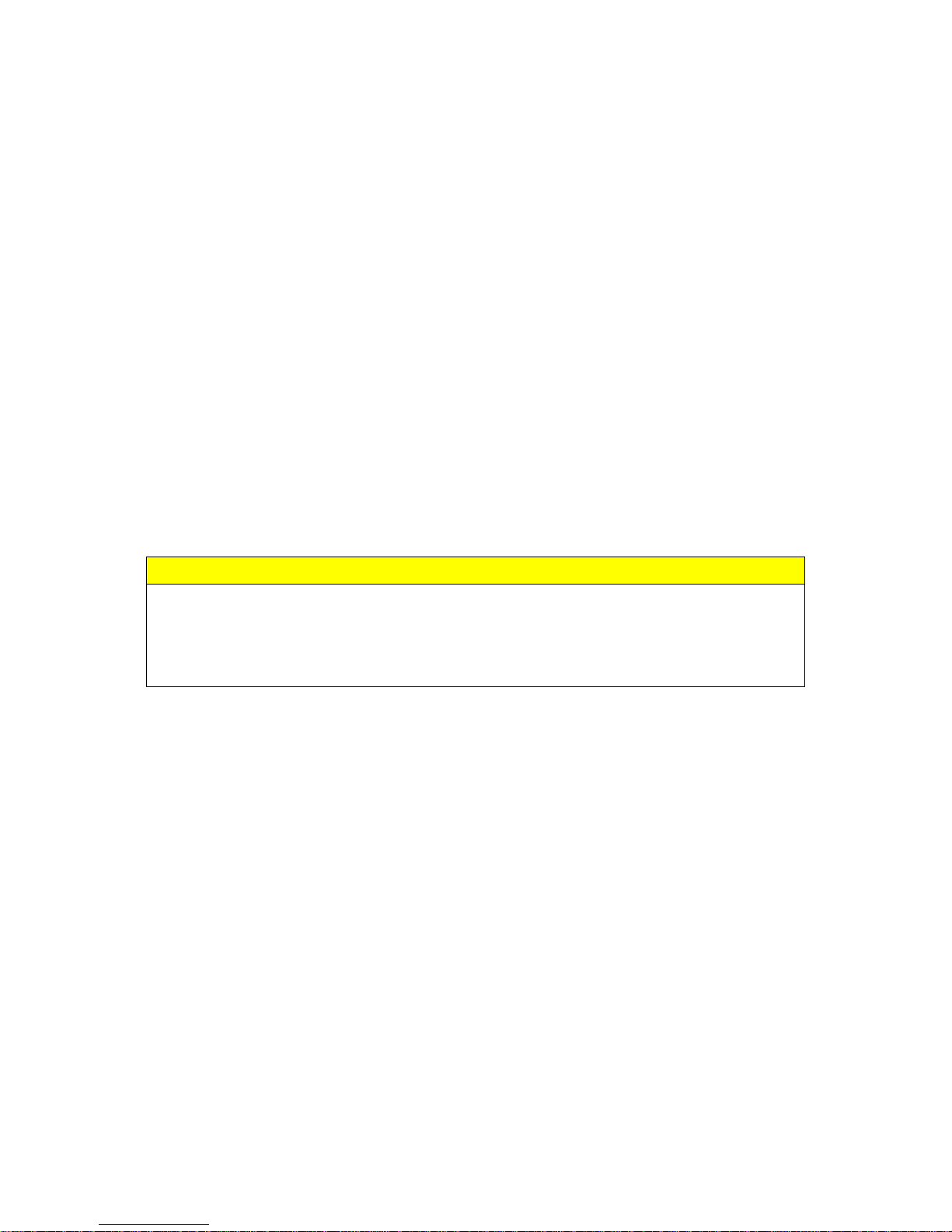

[Table 3-1 Standard Alarm and Saturation Value]

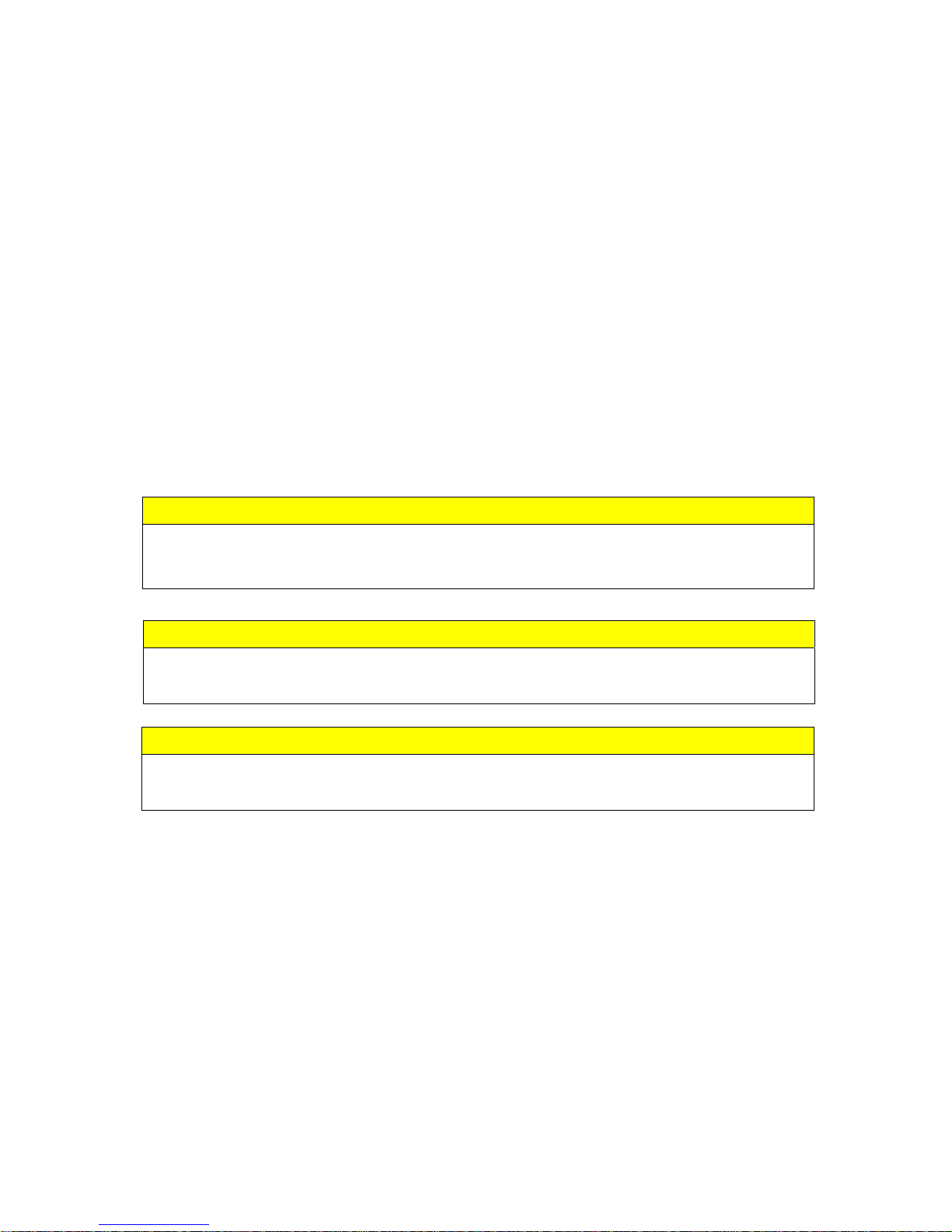

Fail Mode Select Jumper Switch has in LCD Module and Main CPU Module and Jumper Switch Line is

connected circuital. In case of Not LCD Module, we can use CPU Module's Fail Mode Select Jumper

Switch and In case of LCD Module we can use LCD Module's Jumper Switch. In this case, CPU Module

is selected "Down" side. No selected we can select "Down" side.

(Jumper Select Switch is followed in Figure 3-2, 3-3)

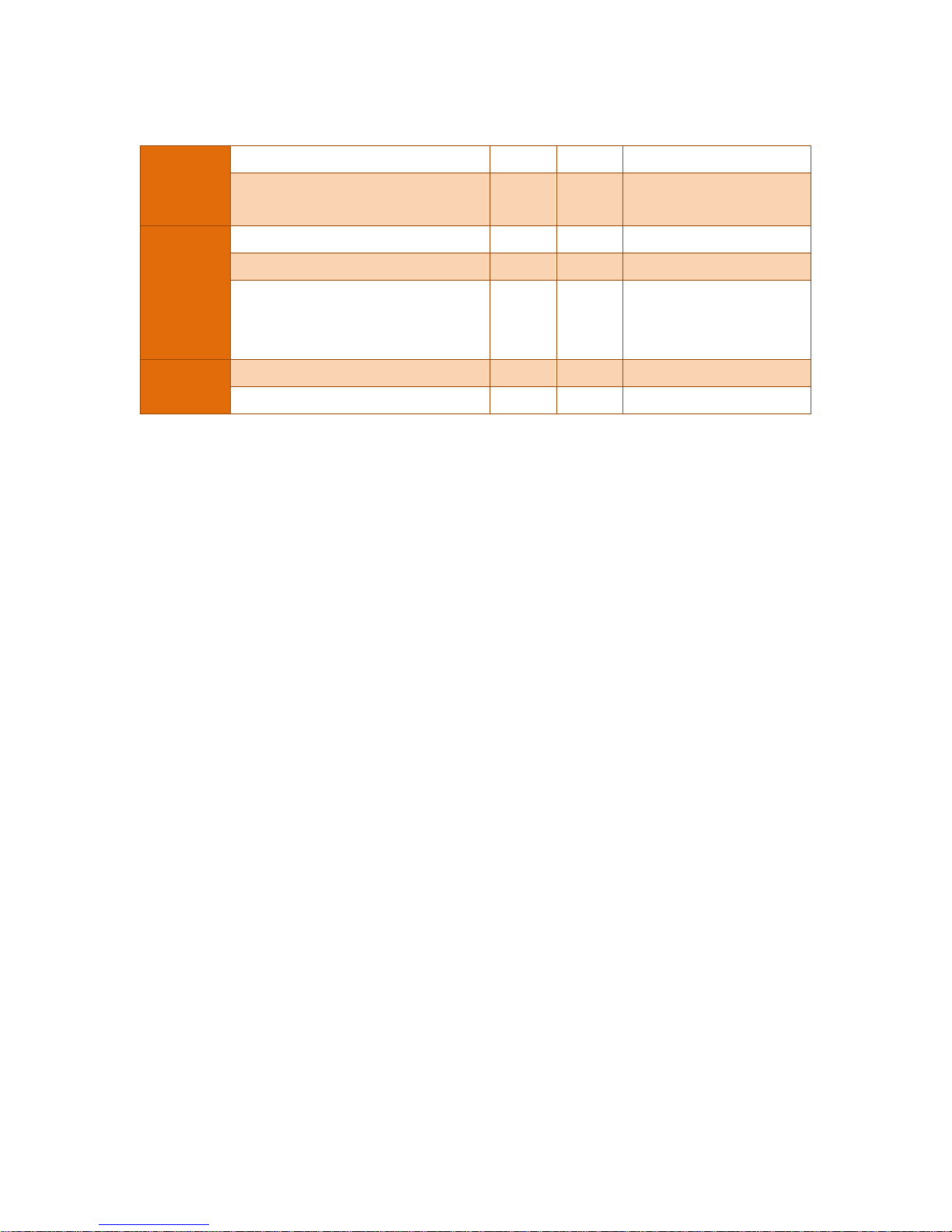

Select Fail Mode

Both LCD Module and CPU Module

Only CPU

Module

CPU Module LCD Module CPU Module

Fail Down Down D D

Fail Up

Down U

U

Up U or D

< Fail Mode Selection DIP Switch of CPU Module >

Level 4~20mA Saturation 4~20mA Alarm

Low/Down 3.9 mA

≤ 3.78 mA

High/Up 20.8 mA

≥ 21.1 mA

1

2

ON

Up

Down

1. WR_EN (EEPROM Write Enable)

DOWN : Enable

UP : Protected

2. Fail Mode Alarm

DOWN : Low

UP : High

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

17 DUON System Co., Ltd.

< Fail Mode Selection Jumper Switch of LCD Module >

Figure 3-1. Fail Mode and EEPROM-Write Selection Jumper Switch

Figure 3-2 Fail Mode Selection Jumper Switch of LCD Module

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

18 DUON System Co., Ltd.

Figure 3-3. CPU Module Fail Mode, EEPROM-Write Selection Jumper Switch

3-5. EEProm-Write Enable / Disable Mode Switch

There is the EEPROM (Electrically Erasable Programmable ROM) restoring various configuration

variables in Transmitter. For protect to change configuration variable data in software, hardware side

there is Write-Protect Mode and Jumper Switch selected it segmented "EEP-Write DIS / EN " in Main

CPU Module. Thus if you connect Jumper to DIS you can't change configuration data in EEPROM,

when you connect Jumper to EN you can change configuration data in EEPROM. No connected Jumper,

it is classified EN. At the factory before shipment, it is configured "EN". (Following figure 3-3)

CPU Modue DIP Switch

1 : Fail Mode Selection

2 : EEPROM Write Selection

There are two security methods in APT3500. Following this.

(1) Security Jumper: protect to writing configuration parameters of transmitter.

(2) Physical removing Zero and Span Magnetic Buttons of Transmitter: you are not able to regulate

Zero and Span in Local.

[Notification] If EEP-Write is not connected, it is classified Security Off state.

3.5.1 Security Jumper (EEPROM Write Protect)

Protect to change Configuration Parameter of transmitter to Write Protect Jumper.

3.5.2 Zero and Span Magnetic Button

To remove Magnetic Button, you can't configure Zero and Span in Local.

.

APT3500 Smart Pressure Transmitter Operation Manual M3500-EO1G

19 DUON System Co., Ltd.

3.6 Configuration of Alarm and Security Jumper Procedures

To change Jumper's position, follow this.

(1) If install the transmitter, cutoff power.

(2) Open the housing front side covers. In case Power Supply, don't open the covers of

transmitter

(3) After turn off Jumper, turn on at wanted position.

(4) Close the housing covers. You must fully engage to meet explosion proof requirements

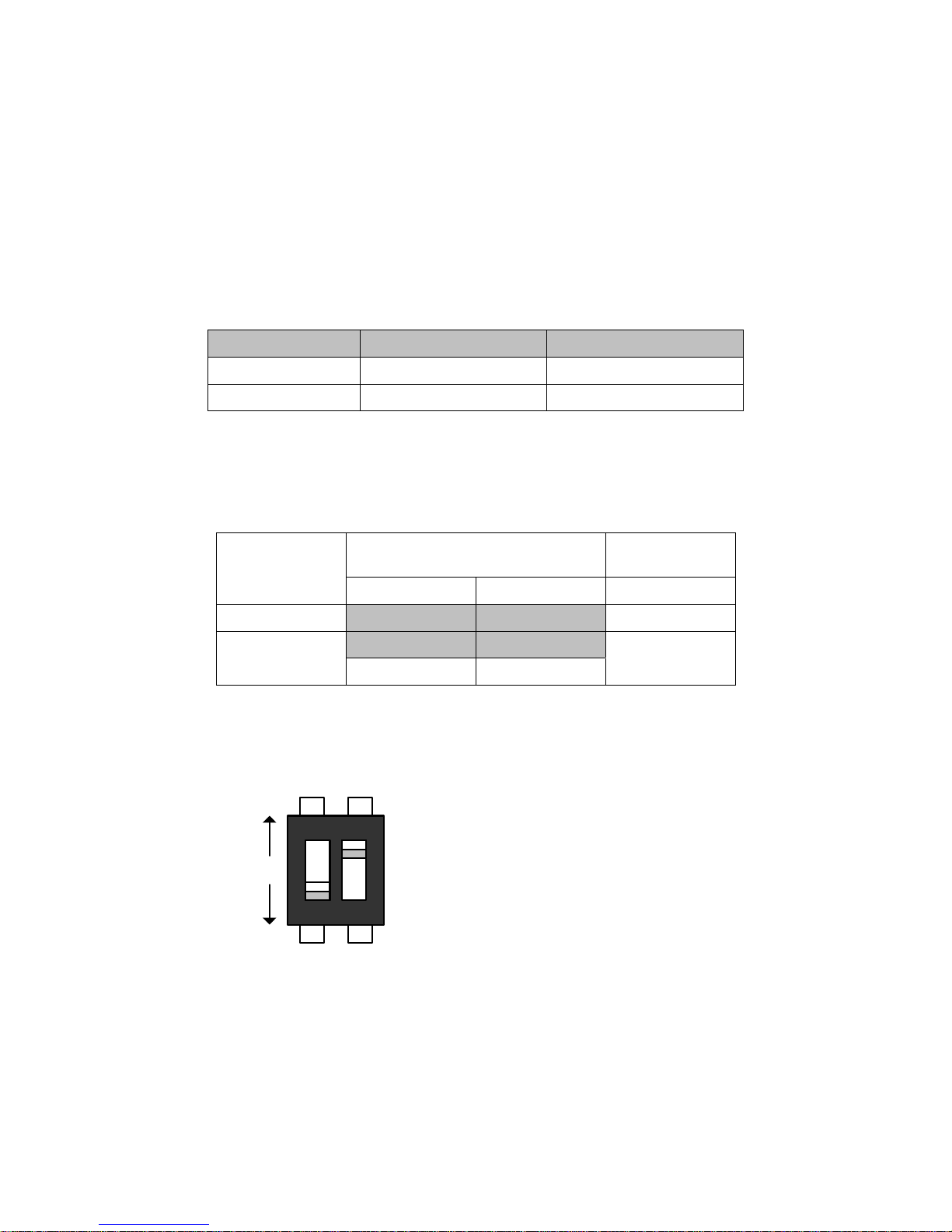

3.7 Configuration of Zero and Span Procedures

This product is designed to enable basic set-up only by Transmitter own buttons without additional

devices. Because progression of button manipulation is displayed on LCD, button manipulation can be

used only in products containing LCD module. Opening the Name Plate cover in the housing top, you

can see ZERO and SPAN buttons. This product uses contactless magnetic buttons, which are

completely separated from the Transmitter interior. Hence, this is suitable for the case, such as

flameproof environment, that Transmitter interior should be sealed.

ZERO & SPAN Button

[Note1] ZERO and SPAN button are designed to be active by finger push but, depending on use

environment, tools such as pen or screw driver should be used to push deep for accurate

action.

[Note2] If magnetic screw driver is used, button may not be active. Hence, non-magnetic screw

[Figure 3-4 Transmitter’s Zero/Span configuration Button]

Loading...

Loading...