Duomo BX444-Mc Installation And User Manual

Installation and User Guide Rev.01.

BX444-Mc Gas Detector

Detection of Toxic, explosive gases & O2

3 Stages of Alarm - 1st & 2nd level and Main Alarm

Digital display - Colour change feature in Alarm

Microprocessor control

Wall or panel fascia mounted

For up to 4 Sensor

4 - 20mA signal input from each sensor

Measuring range 0 - 20% LEL / 0 -

NEW - Oxygen Depletion or excess monitoring

IP44 protective rating

CE Certified and approved to EN50194 for

gases and EN50291 for toxic gases

2 year Warranty - extendable to 3 years by registering

this product on-line www.duomo.co.uk

300ppm

explosive

Application

Duomo is recognised within the gas industry for

providing a comprehensive range of low cost, high

reliability gas detection for many applications. Duomo

Gas detectors are installed in locations such as boiler

rooms, kitchens, car parks, aircraft hangers,

factories and shopping centres. The BX444-M is the

command centre for the complete range of Duomo

gas sensors. All Duomo products are manufactured

to meet relevant European Normatives and proposals

for explosive and toxic gases. EN50194 EN50291

EN50270 EN 61010-1 and designed to be installed to

EN60079-29-2.

Operation

When any connected sensor detects the presence of

the targetgasa4-20mA signal is sent to the

detector, proportional to the level of gas. The

BX444-M then operates a pre-alarm relay - used for

remote sirens or visual indicators. If the level of gas

continues to rise then the second pre-alarm is

actuated. In the case of explosive gases, when the

level of gas reaches 20% LEL, the main alarm relay is

activated to break the electrical supply to the gas

safety shut-off valve (SSOV). The BX444-M also has a

separate volt-free sensor fault relay that actuates if the

correct return signal is not sensed by the detector. The

BX444-M can be configured to detect explosive or toxic

gases. The backlit colour display scrolls through each

sensor and reports their individual status.

Features

The BX444-M is a wall or panel mounted microprocessor

based gas detector control unit. It can be configured to

meet customer requirements. The following parameters

can be changed using on board DIP switches:

Number of sensors from 1 to 4

of gas to be sensed (explosive or toxic)

Type

Display type, either LEL or ppm

Intrinsic safety option (on or off)

Main alarm relay action (latching or auto-reset)

Oxygen Depletion or Excess monitoring

New BX444Mc has a TEST timer function for use by

The

service and commissioning engineers only. The

controller has a built in sensor test delay that permits the

main alarm relay - in a typical installation operates the

gas valve - to remain on during the alarm phase of a gas

test. This is a great feature in situations where shutting

down the gas supply to boiler plant and other

appliances is not desirable. For more information call the

Duomo technical department on 01905 797989.

i

CAUTION!

Carefully read the following instructions prior to

installation of this device. Always keep this pamphlet for

future reference. Ensure that the gas detection system is

wired correctly and is only used for the purpose for

which it is intended.

w: www.duomo.co.uk - e: sales@duomo.co.uk - t: 01905 797989 - f: 01905 774296 |

© Duomo (UK) Ltd. 2016

Technical Specification

Power Supply

Secondary Battery

Battery Charger max 2.2Ah

Power consumption

Power Consumption

Relay contact range

Pre-alarm No. 1

Pre-alarm No. 2

General alarm

Sensor fault

No. of remote sensors

Input signal

Device precision

Reaction time

Control Unit

Working temperature

Start-up self diagnostic delay

Suitable for use with sensor type

Maximum distance for sensor connection

Cable diameter for sensors

Dimensions

Protective rating

Electromagnetic compatibility CE Ref. Norms

Guarantee

230V AC 50Hz +/- 10%

12V

DC +/- 10% Max 2.2Ah

Controlled

9.3W maximum @ 230V supply voltage

5W maximum @ 12VDC.

10A resistive 250VAC, 5A 30VDC Resistive

8% LEL / 120ppm CO

13% LEL / 200ppm CO

Fixed at 20% LEL / 300ppm CO

Short circuit, interruption, sensor deterioration

1- 4 - Configurable by dip switch.

4 - 20mA on 220 ohm.

1% FS

<2"

Microprocessor

-10 °C to 6

0 °C

90 seconds

All Duomo Sensors e.g. SG500, SGM595, CO100A, CO200A, SG810

100m

1mm2 CSA (Screened and earthed one end if run with power cables).

144mm x 144mm x 110mm

IP44

EN 50270

2 years from date of manufacture extendable to 3 years by registering

this product online at www.duomo.co.uk

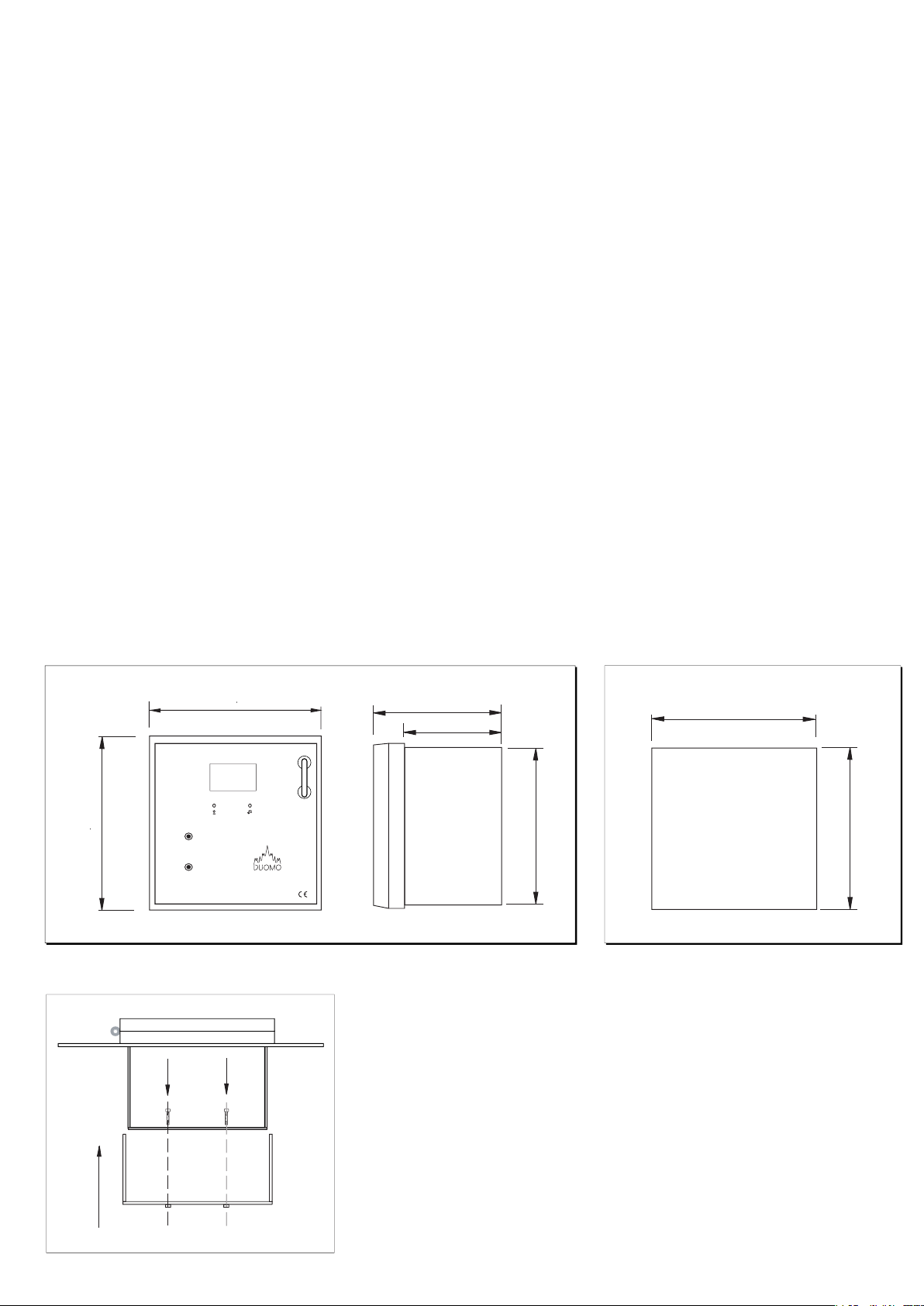

Overall Dimensions (mm)

14444

108

Cutout Dimensions (mm)

77

1st

Alarm

2nd

Alarm

MAIN

ALARM

LEL

FAULT

140

14444

SERVICE

REQUIRED

SENSORS

OVER LOAD

BATTERY

OVER LOAD

ON

ppm

TEST

RESET

444MC

BX

Fascia mounting the BX444-Mc in a control panel

141

141

Mounting Bracket

w: www.duomo.co.uk - e: sales@duomo.co.uk - t: 01905 797989 - f: 01905 774296 |

© Duomo (UK) Ltd. 2016

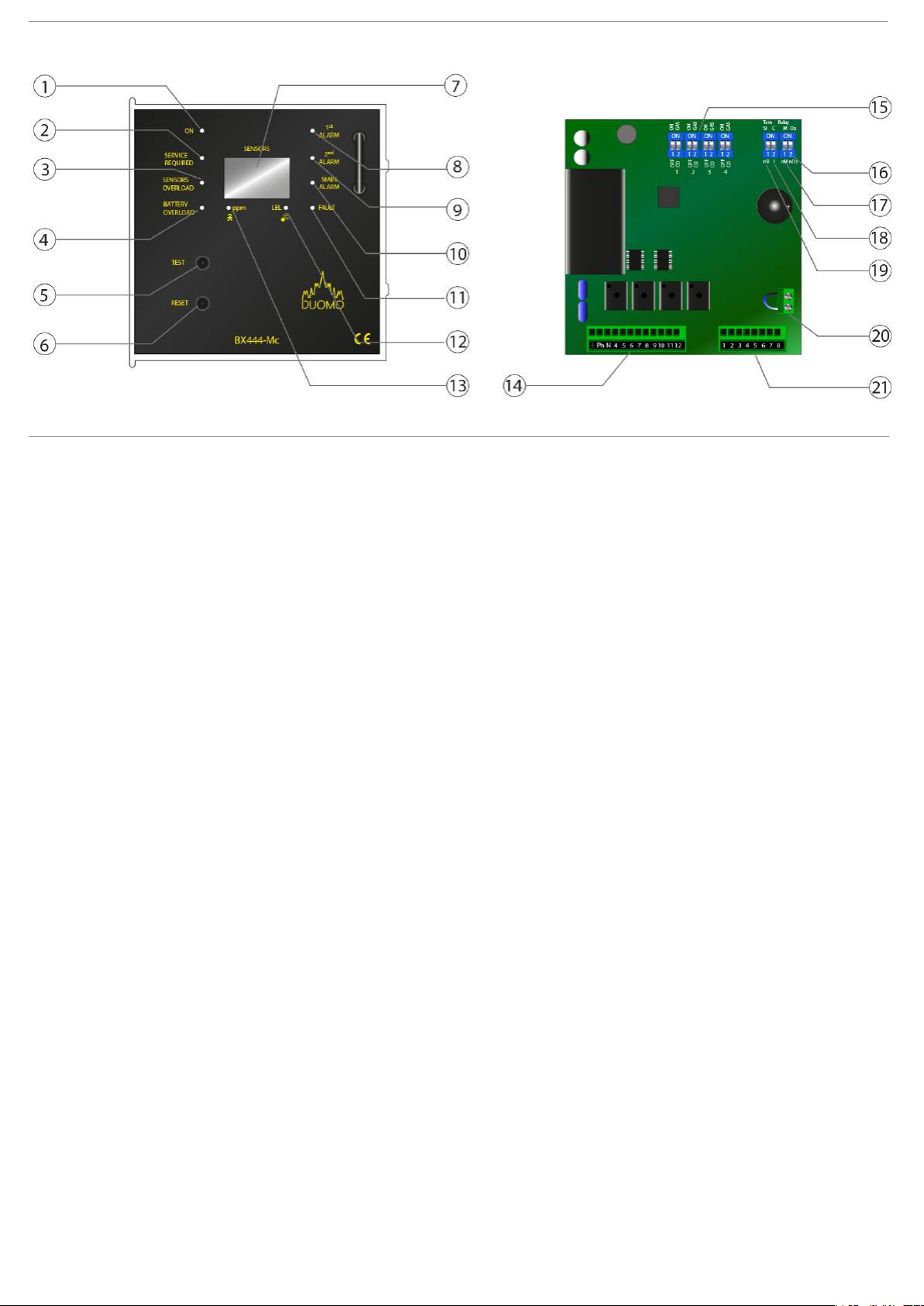

BX444-Mc Fascia & PCB Layout

Key

1. Power On - Lights when supply voltage is applied. This light flashes during self-diagnostics start up.

2. Service Required - This light flashes when the the scheduled service is required. This can period be set to

either 6 months or 1 year and is determined by risk assessment.

3. Sensors Overload - When lit indicates a short circuit or overload on the sensor circuitry.

4. Battery Overload - When lit indicates incorrect batter connection or high consumption during charging phase.

5. Test - When pressed checks the sequence and function of the BX444-Mc (See also sensor test timer)

6. Reset - Press this to reset the detector after an alarm or sensor fault condition.(See also sensor test timer)

7. LCD Display - Represents the connected sensors. Each connected sensor reading scrolls automatically. Also

displays the alarm condition and status of each sensor and the BX444mC status; e.g. Test or Fault.

8. 1st Pre-Alarm - At 8% LEL concentration of gas detected. this light is lit and Pre-alarm relay 1 actuated. This relay

output de-energises as the level of detected gas exceeds 13% LEL (Natural Gas) or 200ppm (CO).

9. 2nd Pre-Alarm - At 13% LEL or 200ppm CO detected. Pre-alarm relay 2 actuated.

10. Main Alarm - 20% LEL concentration of gas detected. Main alarm relay actuated.

11. Fault - Indicates a short circuit, sensor fault, loss of signal or incorrect connection of the sensor.In case of a sensor

failure the LED will flash when the relevant sensor is scanned.

12. LEL Explosive - lights when the internal DIP switch (CO/GAS) for a sensor is moved to the GAS position . As the

sensor value is displayed the corresponding light for that sensor is lit.

13. Toxic Gas - This lights when the internal DIP switch (CO/GAS) for a sensor is moved to the CO position. As the

sensor value is displayed the corresponding light for that sensor is lit.

14. Electrical Supply and relay connection terminal plug.

15. Sensor Switches

16. Select or deselect Oxygen mode

17. Switch for setting latching or non latching in Main alarm condition

18. Continuous or a single pulse alarm relay actuation

19. Positive safety switch.

20. Emergency Stop connection terminal. (remove link when E.Stop is fitted).

21. Sensor and battery (if fitted) connection terminal.

- These are used to turn the sensor on/off, determine the type of gas to be sensed,

w: www.duomo.co.uk - e: sales@duomo.co.uk - t: 01905 797989 - f: 01905 774296

© Duomo (UK) Ltd. 2016

Loading...

Loading...