Page 1

Cleaning and

Clearing A Jam

For efficient use, this tool

should be cleaned

periodically. The Front Jaw

can be removed to give

access to the staple

Magazine for cleaning and

jam clearing. Damage to

parts and/or excessive

accumulation of dirt are the

principal causes of jams. If a

jam should occur, or if

cleaning is required,

disengage staple feeder

spring and remove all

staples. Unhook the Jaw and

release as shown (1). Swing

Trip Lever out of position by

lifting round head pin from

notch on top of Trip Lever

(2). Slip off Front Jaw by

pivoting it down and off from

back end (3). Then remove

any jammed staples and

carefully clean the tool.

Hammer Stapler

Operation and

Maintenance Manual

HT-550 (use only 5000 staples)

HT-755 (use only 7500 staples)

Limited Warranty

WHAT IS COVERED: This warranty covers any defects in material or

workmanship. HOW LONG: This warranty lasts one year from the date of

original purchase. WHAT DUO-FAST WILL DO: Duo-Fast will within one

year from date of original purchase replace or repair the tool without any

cost for parts or labor.

WHAT IS NOT COVERED: This warranty does not cover damage by

accident, misuse, unauthorized repair or modification. Also consequential

and incidental damages (including but not limited to lost profits, lost sales

and injury to property) are not recoverable under this warranty. Some

states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you. This

warranty is the exclusive express warranty and any representations or

promises inconsistent with or in addition to this warranty are unauthorized

and shall not be binding on Duo- Fast. Finally, the IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE LIMITED IN DURATION TO A PERIOD

OF ONE YEAR FROM THE DATE OF PURCHASE BY THE ORIGINAL

CONSUMER. Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you.

HOW TO GET SERVICE: To obtain repair or replacement under this

warranty, the tool must be returned to the nearest authorized Duo-Fast

service center, postage prepaid together with proof of original purchase

date (sales receipt or other). Consult your white pages for the authorized

Duo-Fast service center in your area or call, toll-free, 1-800-752-5207.

HOW STATE LAW APPLIES: This warranty gives you specific legal

rights, and you may also have other rights which vary from state to state.

To replace Front Jaw

- reverse the above procedure, making sure the

driver blade is fitted correctly in the slot provided in the front jaw.

Then pivot the jaw back end up and into place. If the tool continues to

jam, have it serviced by qualified service personnel or contact your

Duo-Fast Distributor for additional help.

HAMMER STAPLER TIPS

• The staple Feeder Bar should slide freely on the Channel.

• The staple Feeder Spring must have sufficient tension to feed the staples

properly.

• In addition to occasional cleaning, apply a light film of grease to the

driver plunger.

Parts—Parts listed below may be ordered from your nearest

authorized Duo-Fast Service Center. When ordering parts,

always give the following information: (1) part number; (2) part

description; (3) model number; (4) name of item—Hammer

Stapler.

Repair parts:

Part No. Description Model No.

766 Jaw Release Spring HT-755

7066 Jaw Release Spring HT-550

5556A Front Jaw HT-550

756A Front Jaw HT-755

5513 Feeder Bar HT-550

713 Feeder Bar HT-755

743 Plastic Handle HT-755

7043 Plastic Handle HT-550

744-A Handle Mount Screws All Models

Form HT-185 4/97

Duo-Fast Corporation

USA 1-888-DUO-FAST

Duo-Fast Corporation is the leading manufacturer of automatic

industrial stapling and nailing equipment. Consult White Pages

for the authorized Duo-Fast Distributor in your area.

READ BEFORE USING TOOL. IF WARRANTY TERMS ARE NOT

ACCEPTABLE, RETURN AT ONCE UNUSED FOR REFUND.

EMPLOYER’S RESPONSIBILITIES

Employer must provide the recommended safety eye protection

equipment, as required in the first paragraph of the SAFETY

INSTRUCTIONS, for use by the tool operator and everyone in

the vicinity of the tool. Employer must enforce compliance with

the SAFETY INSTRUCTIONS and all applicable OSHA

regulations. Employer must provide complete training in safe

tool operation for all tool operators as well as provide an

instruction manual for use by all tool operators.

1.

2.

3.

Always Wear

Safety Glasses

When Using

Power Tools

XA-1011 CLEAR

XA-1022 TINTED

Cleaning and

Clearing A Jam

For efficient use, this tool

should be cleaned

periodically. The Front Jaw

can be removed to give

access to the staple

Magazine for cleaning and

jam clearing. Damage to

parts and/or excessive

accumulation of dirt are the

principal causes of jams. If a

jam should occur, or if

cleaning is required,

disengage staple feeder

spring and remove all

staples. Unhook the Jaw and

release as shown (1). Swing

Trip Lever out of position by

lifting round head pin from

notch on top of Trip Lever

(2). Slip off Front Jaw by

pivoting it down and off from

back end (3). Then remove

any jammed staples and

carefully clean the tool.

Hammer Stapler

Operation and

Maintenance Manual

HT-550 (use only 5000 staples)

HT-755 (use only 7500 staples)

Limited Warranty

WHAT IS COVERED: This warranty covers any defects in material or

workmanship. HOW LONG: This warranty lasts one year from the date of

original purchase. WHAT DUO-FAST WILL DO: Duo-Fast will within one

year from date of original purchase replace or repair the tool without any

cost for parts or labor.

WHAT IS NOT COVERED: This warranty does not cover damage by

accident, misuse, unauthorized repair or modification. Also consequential

and incidental damages (including but not limited to lost profits, lost sales

and injury to property) are not recoverable under this warranty. Some

states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you. This

warranty is the exclusive express warranty and any representations or

promises inconsistent with or in addition to this warranty are unauthorized

and shall not be binding on Duo- Fast. Finally, the IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE LIMITED IN DURATION TO A PERIOD

OF ONE YEAR FROM THE DATE OF PURCHASE BY THE ORIGINAL

CONSUMER. Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you.

HOW TO GET SERVICE: To obtain repair or replacement under this

warranty, the tool must be returned to the nearest authorized Duo-Fast

service center, postage prepaid together with proof of original purchase

date (sales receipt or other). Consult your white pages for the authorized

Duo-Fast service center in your area or call, toll-free, 1-800-752-5207.

HOW STATE LAW APPLIES: This warranty gives you specific legal

rights, and you may also have other rights which vary from state to state.

To replace Front Jaw

- reverse the above procedure, making sure the

driver blade is fitted correctly in the slot provided in the front jaw.

Then pivot the jaw back end up and into place. If the tool continues to

jam, have it serviced by qualified service personnel or contact your

Duo-Fast Distributor for additional help.

HAMMER STAPLER TIPS

• The staple Feeder Bar should slide freely on the Channel.

• The staple Feeder Spring must have sufficient tension to feed the staples

properly.

• In addition to occasional cleaning, apply a light film of grease to the

driver plunger.

Parts—Parts listed below may be ordered from your nearest

authorized Duo-Fast Service Center. When ordering parts,

always give the following information: (1) part number; (2) part

description; (3) model number; (4) name of item—Hammer

Stapler.

Repair parts:

Part No. Description Model No.

766 Jaw Release Spring HT-755

7066 Jaw Release Spring HT-550

5556A Front Jaw HT-550

756A Front Jaw HT-755

5513 Feeder Bar HT-550

713 Feeder Bar HT-755

743 Plastic Handle HT-755

7043 Plastic Handle HT-550

744-A Handle Mount Screws All Models

Form HT-185 4/97

Duo-Fast Corporation

USA 1-888-DUO-FAST

Duo-Fast Corporation is the leading manufacturer of automatic

industrial stapling and nailing equipment. Consult White Pages

for the authorized Duo-Fast Distributor in your area.

READ BEFORE USING TOOL. IF WARRANTY TERMS ARE NOT

ACCEPTABLE, RETURN AT ONCE UNUSED FOR REFUND.

EMPLOYER’S RESPONSIBILITIES

Employer must provide the recommended safety eye protection

equipment, as required in the first paragraph of the SAFETY

INSTRUCTIONS, for use by the tool operator and everyone in

the vicinity of the tool. Employer must enforce compliance with

the SAFETY INSTRUCTIONS and all applicable OSHA

regulations. Employer must provide complete training in safe

tool operation for all tool operators as well as provide an

instruction manual for use by all tool operators.

1.

2.

3.

Always Wear

Safety Glasses

When Using

Power Tools

XA-1011 CLEAR

XA-1022 TINTED

Page 2

IMPORTANT SAFETY INSTRUCTIONS

For personal safety and proper operation of this tool read

all of these instructions carefully.

To avoid serious eye injury from fasteners, approved eye

protection must be worn by the tool operator and everyone in the vicinity of the tool. Use safety glasses with

side shields, goggles, or a wide-vision safety mask over

prescription glasses. Eye protection equipment must

conform to the requirements of the latest revision of the

American National Standards Institute (ANSI) Standard

Z87.1, Practice for Occupational and Educational Eye

and Face Protection. Eye protection which meets these

requirements also conforms to OSHA regulations.

Duo-Fast Staples are manufactured to very exact and

critical specifications for safe and proper tool operation.

Do not use fasteners other than the type and lengths

specified for this tool. Using improper fasteners can

cause jamming, damage to the tool and serious injury to

yourself or others in the work area from fastener

fragments, a ricocheting fastener or flying debris from an

improperly driven fastener.

Do not use a tool that is not working properly. Have it

repaired by qualified service personnel.

Always assume that the tool contains fasteners.

Never point the tool toward yourself or anyone else,

whether it contains fasteners or not.

To avoid serious personal injury from discharged

fasteners, never operate/activate the Trip Lever with your

fingers, thumbs or palm of your hand.

Respect the tool. It is powerful and can be dangerous if

not handled properly. Do not engage in horseplay.

Do not modify a tool in any way unless the modification

is approved by Duo-Fast Corp.

To avoid personal injury to yourself and others, obtain

complete training in safe tool operation and read all of

this instruction manual before using the tool.

Refer to this instruction manual for detailed information

on the proper use and maintenance of the tool.

Repairs to a tool must be performed by qualified service

personnel only. Use only Duo-Fast authorized parts for

repair or replacement. Never remove the front jaw

without first disengaging the pusher assembly and

removing all staples from the tool.

If you have any questions about safe tool operation,

contact your local Duo-Fast office or Sales/Service

representative for help. If no one is immediately

available, or cannot answer your questions, please call

Duo-Fast at 1-888-DUO-FAST for assistance.

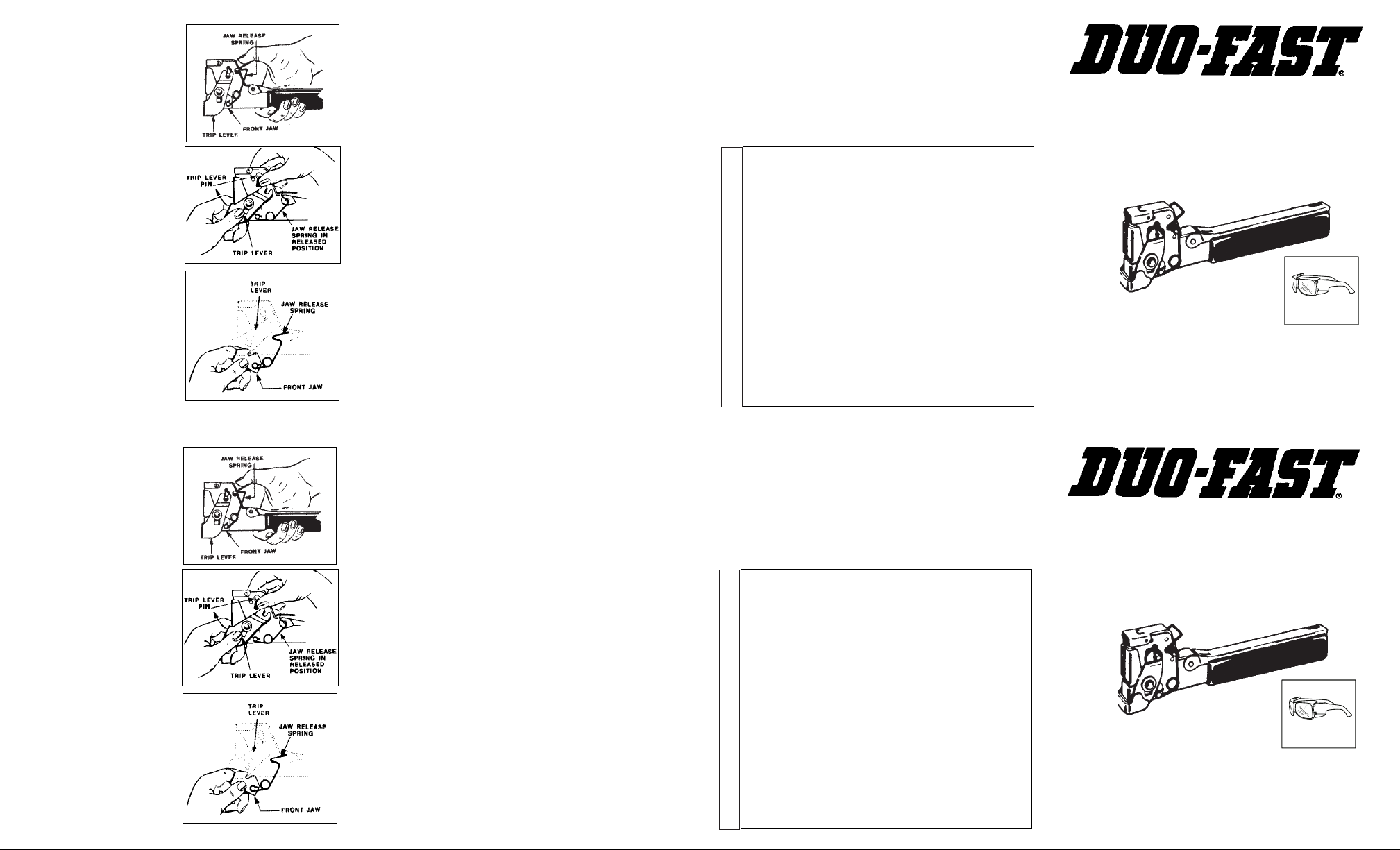

Loading Staples

Be sure you only use Duo-Fast Staples of the correct type

and size, as marked on the side of the tool. Using improper

staples can cause jamming, damage to the tool and

serious injury to yourself or others in the work area from

staple fragments, a ricocheting staple or flying debris

from an improperly driven staple.

1.) Lift Handle lid “A” up.

2.) Pull Feed Spring “B” to the back of the tool and

disengage it from the Feeder Bar “C”

3.) Slide 2 strips of the correct type and size Duo-Fast

Staples into the Magazine through the back end.

4.) Slide the Feeder Bar “C” behind the staples.

5.) Hook the Feeder Spring “B” onto the Feeder Bar and

allow it to move forward.

Driving Staples

Swing the tool like a hammer. The Trip Lever will drive a

staple as it contacts the surface you are hitting. Do not

hit the material being stapled any harder than necessary

to drive the staple. You will get a feeling for the amount of

force to use after a few trials.

CAUTION—Do not use the top surface of the tool to tap

down improperly driven staples. This could eject a staple

from the tool and cause injury to yourself or other

persons in the work area.

IMPORTANT SAFETY INSTRUCTIONS

For personal safety and proper operation of this tool read

all of these instructions carefully.

To avoid serious eye injury from fasteners, approved eye

protection must be worn by the tool operator and everyone in the vicinity of the tool. Use safety glasses with

side shields, goggles, or a wide-vision safety mask over

prescription glasses. Eye protection equipment must

conform to the requirements of the latest revision of the

American National Standards Institute (ANSI) Standard

Z87.1, Practice for Occupational and Educational Eye

and Face Protection. Eye protection which meets these

requirements also conforms to OSHA regulations.

Duo-Fast Staples are manufactured to very exact and

critical specifications for safe and proper tool operation.

Do not use fasteners other than the type and lengths

specified for this tool. Using improper fasteners can

cause jamming, damage to the tool and serious injury to

yourself or others in the work area from fastener

fragments, a ricocheting fastener or flying debris from an

improperly driven fastener.

Do not use a tool that is not working properly. Have it

repaired by qualified service personnel.

Always assume that the tool contains fasteners.

Never point the tool toward yourself or anyone else,

whether it contains fasteners or not.

To avoid serious personal injury from discharged

fasteners, never operate/activate the Trip Lever with your

fingers, thumbs or palm of your hand.

Respect the tool. It is powerful and can be dangerous if

not handled properly. Do not engage in horseplay.

Do not modify a tool in any way unless the modification

is approved by Duo-Fast Corp.

To avoid personal injury to yourself and others, obtain

complete training in safe tool operation and read all of

this instruction manual before using the tool.

Refer to this instruction manual for detailed information

on the proper use and maintenance of the tool.

Repairs to a tool must be performed by qualified service

personnel only. Use only Duo-Fast authorized parts for

repair or replacement. Never remove the front jaw

without first disengaging the pusher assembly and

removing all staples from the tool.

If you have any questions about safe tool operation,

contact your local Duo-Fast office or Sales/Service

representative for help. If no one is immediately

available, or cannot answer your questions, please call

Duo-Fast at 1-888-DUO-FAST for assistance.

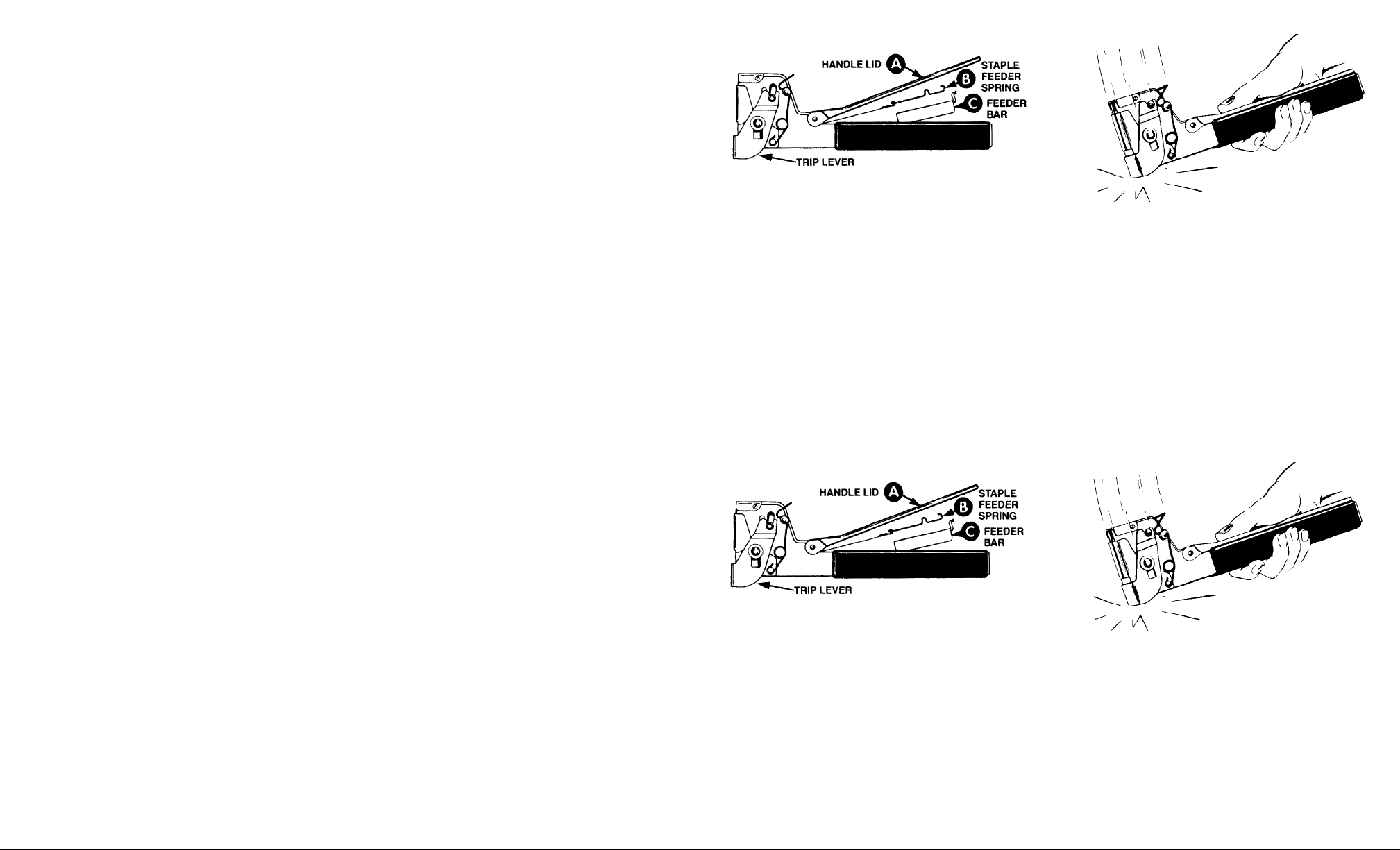

Loading Staples

Be sure you only use Duo-Fast Staples of the correct type

and size, as marked on the side of the tool. Using improper

staples can cause jamming, damage to the tool and

serious injury to yourself or others in the work area from

staple fragments, a ricocheting staple or flying debris

from an improperly driven staple.

1.) Lift Handle lid “A” up.

2.) Pull Feed Spring “B” to the back of the tool and

disengage it from the Feeder Bar “C”

3.) Slide 2 strips of the correct type and size Duo-Fast

Staples into the Magazine through the back end.

4.) Slide the Feeder Bar “C” behind the staples.

5.) Hook the Feeder Spring “B” onto the Feeder Bar and

allow it to move forward.

Driving Staples

Swing the tool like a hammer. The Trip Lever will drive a

staple as it contacts the surface you are hitting. Do not

hit the material being stapled any harder than necessary

to drive the staple. You will get a feeling for the amount of

force to use after a few trials.

CAUTION—Do not use the top surface of the tool to tap

down improperly driven staples. This could eject a staple

from the tool and cause injury to yourself or other

persons in the work area.

Loading...

Loading...