Page 1

MODEL DF350S

20° Round Head Framing Nailer

IMPORTANT!

DO NOT DESTROY

It is the customer’s responsibility to have all

operators and service personnel read and

understand this manual.

PRINTED IN U.S.A.

© 2008, Illinois Tool Works, Inc.

405669-3

OPERATING MANUAL AND

SCHEMATIC

1

Page 2

INTRODUCTION

The DUO-FAST® DF350S strip nailer is a quality-built tool designed for use in residential

framing applications. This tool will deliver efficient, dependable performance when used

according to the manufacturer’s guidelines. Please study this manual including the safety

instructions to fully understand the operation of this tool.

TABLE OF CONTENTS

TOOL AND FASTENER SPECIFICATIONS ................................................................. 3

SAFETY INSTRUCTIONS ............................................................................................. 4

TOOL INSTALLATION AND OPERATION ................................................................ 5-6

AIR SYSTEMS ............................................................................................................. 7-8

FEATURES AND BENEFITS .......................................................................................... 9

EXPLODED VIEW AND SPARE PARTS LIST ....................................................... 10-11

MAINTENANCE ....................................................................................................... 12-13

TROUBLESHOOTING .................................................................................................. 14

WARRANTY .................................................................................................................. 15

ACCESSORIES ........................................................................................................... 16

2

Page 3

TOOL AND FASTENER SPECIFICATIONS

TOOL SPECIFICATIONS

MODEL NO. DF350S (Part# 502200)

HEIGHT 13”

WIDTH 5"

LENGTH 21"

WEIGHT 8 lbs. 1oz.

OPERATING PRESSURE 80 to 120 p.s.i. (5.5 to 8.3 bars)

FASTENER SPECIFICATIONS

NAIL LENGTH 2" - 3-1/2"

SHANK DIAMETER .113 - .148

TOOL AIR FITTINGS:

This tool uses a 3/8” N.P.T. male plug. The fitting must be capable of discharging tool air

pressure when disconnected from the air supply.

OPERATING AIR PRESSURE:

80 to120 p.s.i. (5.5 to 8.3 bars). Select the operating air pressure within this range

for best tool performance.

DO NOT EXCEED THIS RECOMMENDED OPERATING PRESSURE.

3

Page 4

SAFETY INSTRUCTIONS

SAFETY FIRST

These safety instructions provide information necessary for safe operation of Duo-Fast® tools. DO NOT

ATTEMPT TO OPERATE THE TOOL UNTIL YOU READ

AND UNDERSTAND ALL SAFETY PRECAUTIONS

AND MANUAL INSTRUCTIONS.

WEAR EYE AND HEARING PROTECTION

Always wear hearing and eye protection devices, that

conform to ANSI Z87.1 requirements, when operating

or working in the vicinity of a tool. As an employer you

are responsible for enforcing the use of eye protection.

Wear hard hats in environments that require their use.

THE TOOL MUST BE USED ONLY FOR THE PURPOSE FOR WHICH IT WAS DESIGNED

Do not throw the tool on the floor, strike the housing in

any way or use the tool as a hammer to knock

material into place.

NEVER ENGAGE IN HORSEPLAY WITH THE TOOL

The tool is not a toy so do not use it like one. Never

engage in horseplay with the tool or point it at yourself

or any other person, even if you think it is not loaded.

NEVER ASSUME THE TOOL IS EMPTY

Check the magazine for fasteners that may be left in the

tool. Even if you think the tool is empty or disconnected,

never point it at anyone or yourself. Unseen fasteners

could fire from the tool.

NEVER CLAMP THE TRIGGER IN A LOCKED OR

OPERATING POSITION

The trigger of the tool must never be tampered with,

disabled or clamped in a locked or operating position

since this will cause the tool to drive a fastener any time

the work contacting element is depressed.

DO NOT LOAD FASTENERS WITH THE AIR LINE

CONNECTED, OR WITH THE TOOL TRIGGER OR

WORK CONTACTING ELEMENT DEPRESSED

When loading fasteners into the tool be sure you disconnect the air line and that you do not depress the trigger

or work contacting element.

OPERATE THE TOOL ONLY ON A WORKPIECE

The tool should be operated only when it is in contact

with the workpiece. Even then you should be careful

when fastening thin material or working near the edges

and corners of the workpiece since the fasteners may

drive through or away from the workpiece.

DO NOT DISABLE OR REMOVE THE WORK

CONTACTING ELEMENT

This tool is equipped with a safety mechanism, called

a work contacting element, to help prevent accidental

firing. Never tamper with, disable or remove the work

contacting element. Do not use the tool unless the work

contacting element is working properly. The tool could

fire unexpectedly.

DISCONNECT THE TOOL WHEN NOT IN USE

Always disconnect the tool from the air line when it

is not in use, when you leave the work area or when

moving the tool to a new location. The tool must

never be left unattended because people who are

not familiar with the tool might handle it and injure

themselves or others.

CARRY THE TOOL ONLY BY THE HANDLE

Always carry the tool by the handle only. Never carry

the tool by the air hose or with the trigger depressed

since you could drive a fastener unintentionally and

injure yourself or someone else.

DO NOT WEAKEN THE TOOL HOUSING

The tool housing is a pressure vessel and should never

be weakened by having your company’s name, area of

work or anything else stamped or engraved into its

surface.

DISCONNECT THE TOOL WHEN PERFORMING

REPAIRS AND CLEARING JAMS

Never attempt to clear a jam or repair a tool unless you

have disconnected the tool from the air line and

removed all remaining fasteners from the tool.

ALWAYS USE THE PROPER FITTING FOR THE

TOOL

Only MALE pneumatic type air connectors should be

fitted to the tool, so that high pressure air in the tool is

vented to atmosphere as soon as the air line is

disconnected.

NEVER install FEMALE quick disconnect couplings on

the tool. Female couplings will trap high pressure air in

the tool when the air line is disconnected, leaving the

tool charged and able to drive at least one fastener.

DO NOT EXCEED THE MAXIMUM RECOMMENDED

AIR PRESSURE

Operate the tool only at the recommended air pressure.

Do not exceed the maximum air pressure marked on

the tool. Be sure the air pressure gauge is

operating properly and check it at least twice a day.

Never use any bottled air or gases such as oxygen to

operate the tool since they could cause the tool to

explode.

INSPECT TOOL FOR PROPER OPERATION

Clean the tool at least daily and lubricate as required.

Never operate a dirty or malfunctioning tool.

USE ONLY DUO-FAST RECOMMENDED PARTS

AND FASTENERS

Use only parts and fasteners specifically designed and

recommended by Duo-Fast for use in the tool and for

work to be done. Using unauthorized parts and

fasteners or modifying the tool in any way creates

dangerous situations. Replace all missing warning

labels---refer to tool schematic for correct placement

and part number.

WARNING

Failure to follow any of the above instructions could result in severe personal

injury to tool user and bystanders or cause damage to tool and property.

Contact your local Duo-Fast Representative for presentation of Duo-Fast’s Safety Awareness Program

4

Page 5

TOOL INSTALLATION

Your Duo-Fast tool comes ready for immediate use

and can be installed by following these steps:

1. SAFETY - All tool operators and their immediate

supervisors must become familiar with the

operator safety instructions before operating the

tool. The instructions are on page 4 of this manual.

2. Included with each tool is the operating manual

and schematic. Keep these publications for future

reference. An ownership registration card is also

included. This card must be completed and

returned to Duo-Fast immediately to register your

ownership.

3. The plastic cap in the air inlet of the tool must

be removed before the male fitting is installed.

The fitting must be a male pneumatic type that

discharges the air from the tool when the air line is

disconnected.

TOOL OPERATION

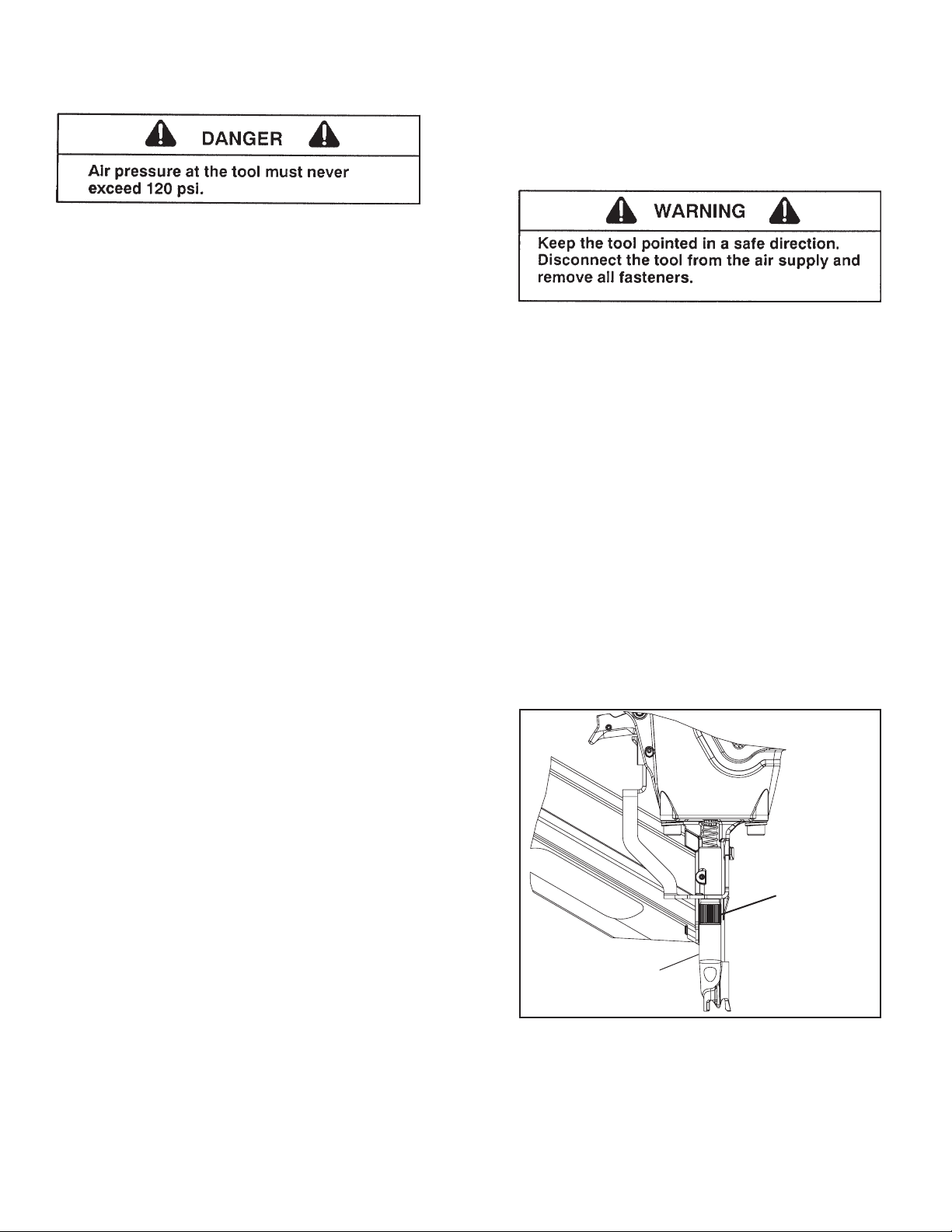

Depth of Drive Adjustment

The depth of drive adjustment is made by

turning the thumbwheel on the work contact

element.

If the tool is overdriving (the fastener head

is driven below the work surface), the work

contact element should be moved downward.

If the fasteners stand up (the head is not flush

with the surface), the work contact element

should be moved up.

Adjust the work contact element until the

fastener head depth meets job requirements.

4. Install a filter/regulator/lubricator unit, with a gauge

as close as practical to the tool, preferably within

ten feet. Refer to the Air Systems section of this

manual for air hose requirements and lengths. In

general, no other special installation is required.

5. If the operator is working at a bench or table, it is

usually best to run the air line underneath the

bench. A small tray under the benchtop can hold

the fastener supply and the tool when not in use.

6. If this tool does not work when it is first connected,

do not try to make repairs. Call your Duo-Fast

representative immediately.

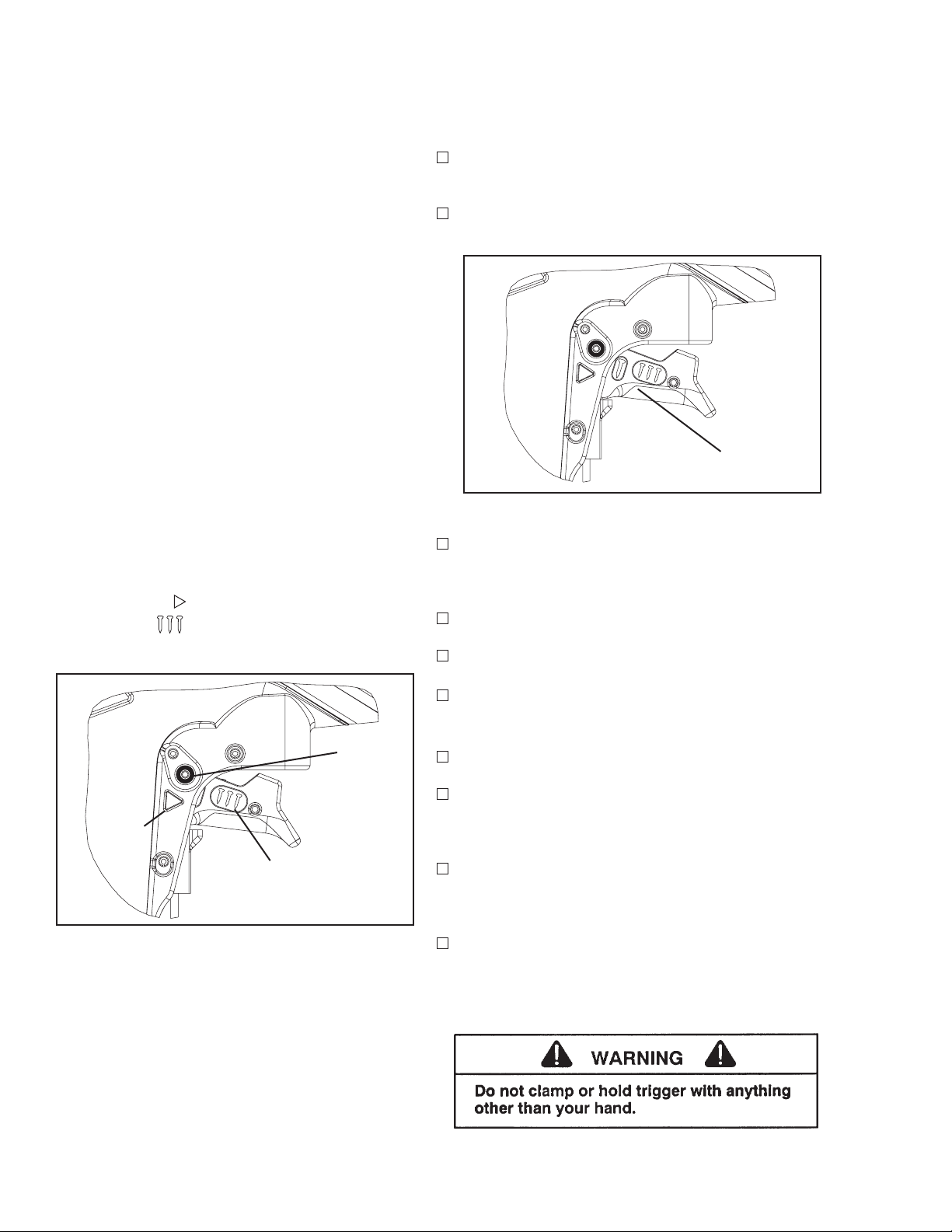

ROTATE

THUMBWHEEL

IN EITHER

DIRECTION

WORK

CONTACT

ELEMENT

5

Page 6

TOOL OPERATION continued

Loading of Nails

Step 1 - Grasp the handle firmly. Pull the follower

all the way to the rear of the magazine

until it is latched into its loading position

by the magazine latch.

Step 2 - Insert one or two strips of nails into the

top of the magazine.

Step 3 - Hold the follower firmly and press the

follower latch. Slide the follower forward

until it contacts the nails.

Switching the Trigger

The tool is manufactured with a trigger that

can be switched from sequential operation to a

bounce drive operation. The trigger is placed in

the sequential operating position when the tool

was manufactured. To switch the trigger to the

bounce operating position, remove the O-ring

and trigger pivot pin from the trigger assembly.

Move the trigger to the bounce operation position

and install the trigger pivot pin and O-ring. The

postion indicator on the tool should now be

pointing to the as shown in the illustration.

▼

Sequential Operation

The sequential operating kit prevents succesive or "bounce"

driving.

■ Depress the work contacting element and hold it against the

work surface before pulling the trigger.

■ After each fastener is driven, completely release the trigger

and lift the tool from the work surface.

Sequential

drive position

Precision Placement Driving

■ Grasp the tool handle firmly and place the bottom of the

work contacting element firmly against the workpiece until it

is completely depressed.

■ Squeeze the trigger to drive the fastener.

Position

indicator

Bounce drive

position

Pivot pin

and o-ring

■ Lift the tool from the workpiece.

■ Repeat the procedure for the next fastener.

Successive (Bounce) Driving

■ Grasp the handle firmly.

■ Squeeze the trigger and move the tool along the workpiece

with a bouncing motion, depressing the work contacting

element at the points where you want to insert a fastener.

■ Keep the trigger depressed and continue to bounce the work

contacing element against the workpiece, positioning the tool

above as carefully as possible.

■ When the desired number of fasteners have been driven,

release the tool trigger to avoid unintentional fastener

discharge.

6

Page 7

AIR SYSTEMS

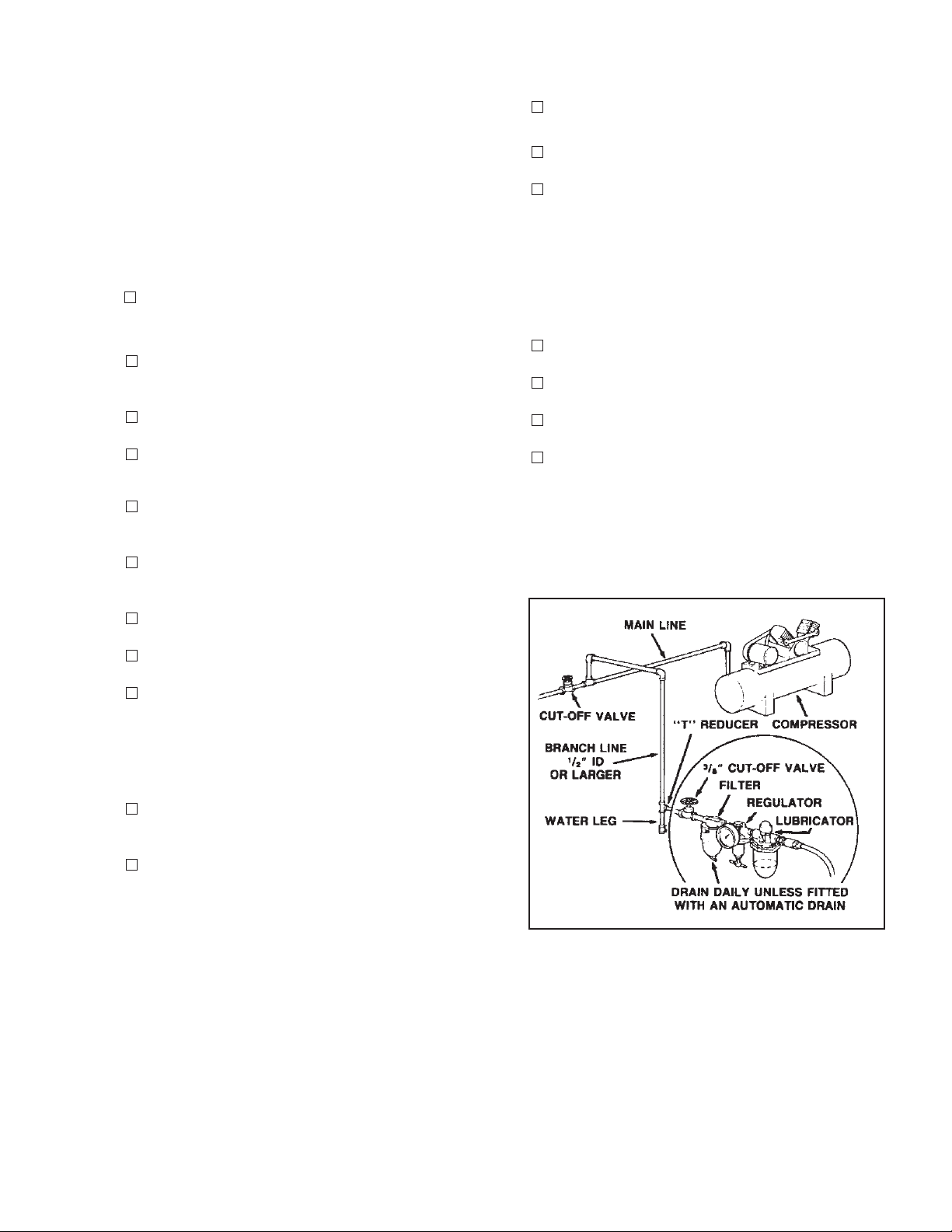

For air-powered tools to work their best, the air

supply system must be properly installed and

maintained regularly. A drawing in this section

shows a properly installed air supply system.

Handy checklists for installing and maintaining

air supply systems follow.

Indoor Air System Installation

-Be certain that:

■ All pipes supplying air have a large enough

inside diameter to ensure adequate air supply.

■ The main supply pipe slopes down, away from

the compressor (1/16 inch per foot).

■ Air storage is provided along lengthy air lines.

■ Pipe line branch outlets are at the top of the

main pipe line.

■ Cutoff valves are provided at each branch pipe

line throughout the system.

■ Air hoses are not longer than 150 feet.

■ The air system is lubricated regularly.

■ A regular maintenance program is followed.

Filter/Regulator/Lubricator Units

Filter/regulator/lubricator units that can supply

enough air and protection for Duo-Fast tools

must meet the following specifications:

■ Minimum 3/8 inch NPT port size .

■ 50 micron or fine filters.

■ Regulated pressure from zero to 120 psi.

■ Lubricators designed for low or changing

airflow.

■ Water legs extend from the bottom of each branch

line.

■ A refrigerant-type dryer is installed on the system.

■ Air hoses are kept as short as practical.

■ A regular maintenance program is followed.

Outdoor Air System Installation

-Be certain that:

■ A moisture trap and a filter/regulator/lubricator are

installed at the compressor.

■ Air hoses and fittings are large enough so that air

flow is not restricted. Minimum hose size is 3/8

inch ID with 1/2 inch ID hose used for any

application over 25 feet.

7

Page 8

AIR SYSTEMS - Continued

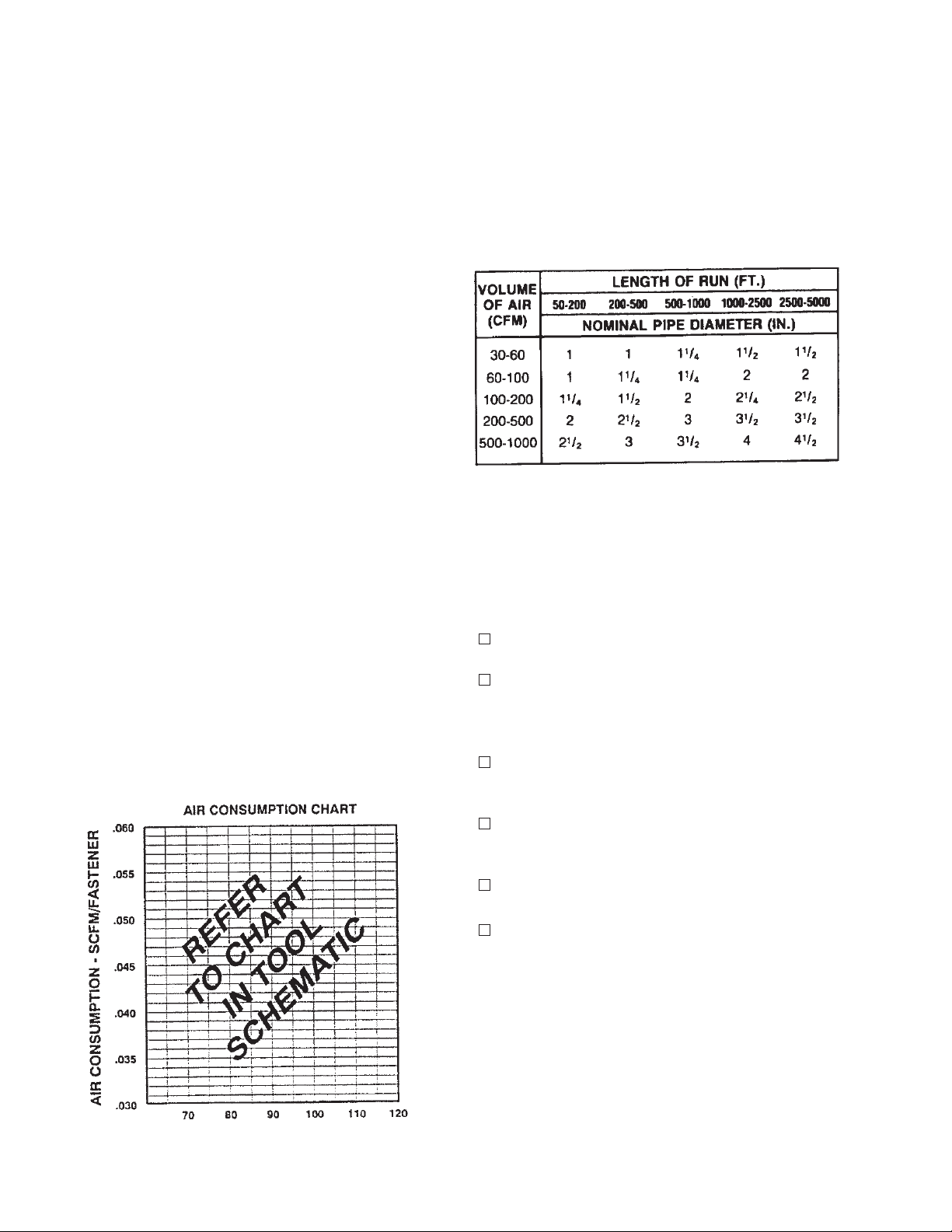

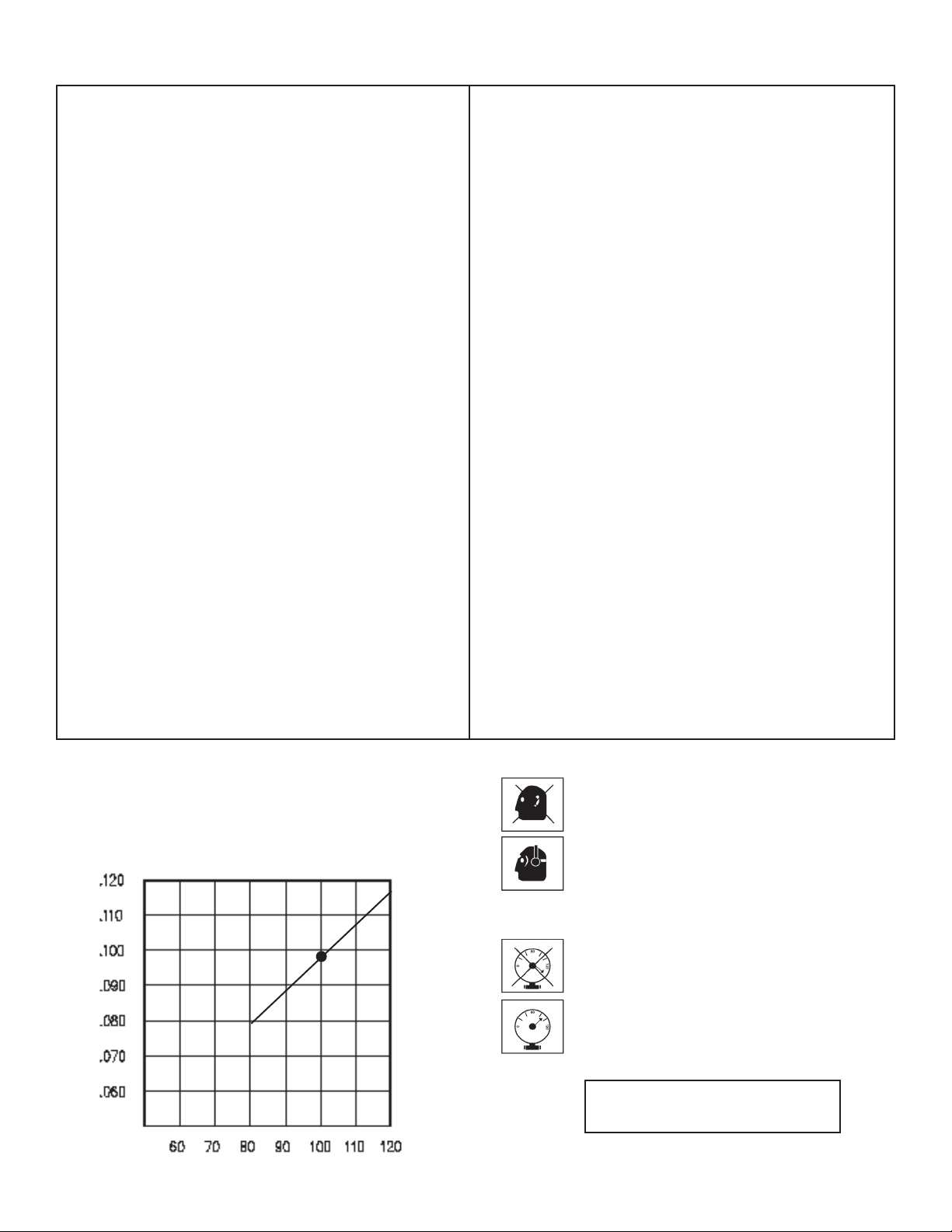

Calculating Compressor Size

Use the air consumption chart in the Tool

Schematic for each tool when calculating the

operating requirements for the tools. Duo-Fast

tools are designed to operate efficiently

between 80 and 120 psi and should never be

operated at pressure greater than 120 psi.

The air consumption chart will help you find the

correct compressor size for your application

that will quickly replenish tool air pressure.

To use the chart you will need to know how

many tools will be used and approximately

how many fasteners will be driven each minute

by each tool on the line. Using the equation:

Number of tools X average fasteners/minute/

tool X 1.2 (safety factor) X air consumption

(scfm) @ pressure* (psi) = scfm required.

We can use the following example:

10 tools X 30 fasteners/minute/tool X 1.2 X

0.051scfm* (@100psi) = 18.36 scfm.

*This number is found in the Air Consumption

Chart

Calculated Required Piping

For example, given a 20 hp electric compressor

supplying approximately 80 cfm of air at 120 psi

and a main supply pipe length of 350 feet, we

see by the table the minimum main pipe inside

diameter required for this application is 1-1/4 inch.

IMPORTANT: AIR PRESSURE (80-120psi)

Pneumatic System Maintenance

- Be certain that:

■ Pneumatic fittings are tight and do not leak.

In this example, using the air consumption

chart we find that a compressor providing at

least 19 scfm of air is required. Because in

compressors approximately 1 hp is required to

produce 4 scfm, a compressor of at least 5 hp

is required.

■ Water legs, filters and air lines are drained daily,

and ensure that automatic draining systems are

operating correctly.

■ Air lines are cleared to prevent freezing,

especially in winter.

■ Lubricator operation is checked regularly and

ensure it has an adequate supply of lubricant.

■ The filter element is cleaned every six months.

■ Only regulated air is being used and that each

regulator is operating properly.

8

Page 9

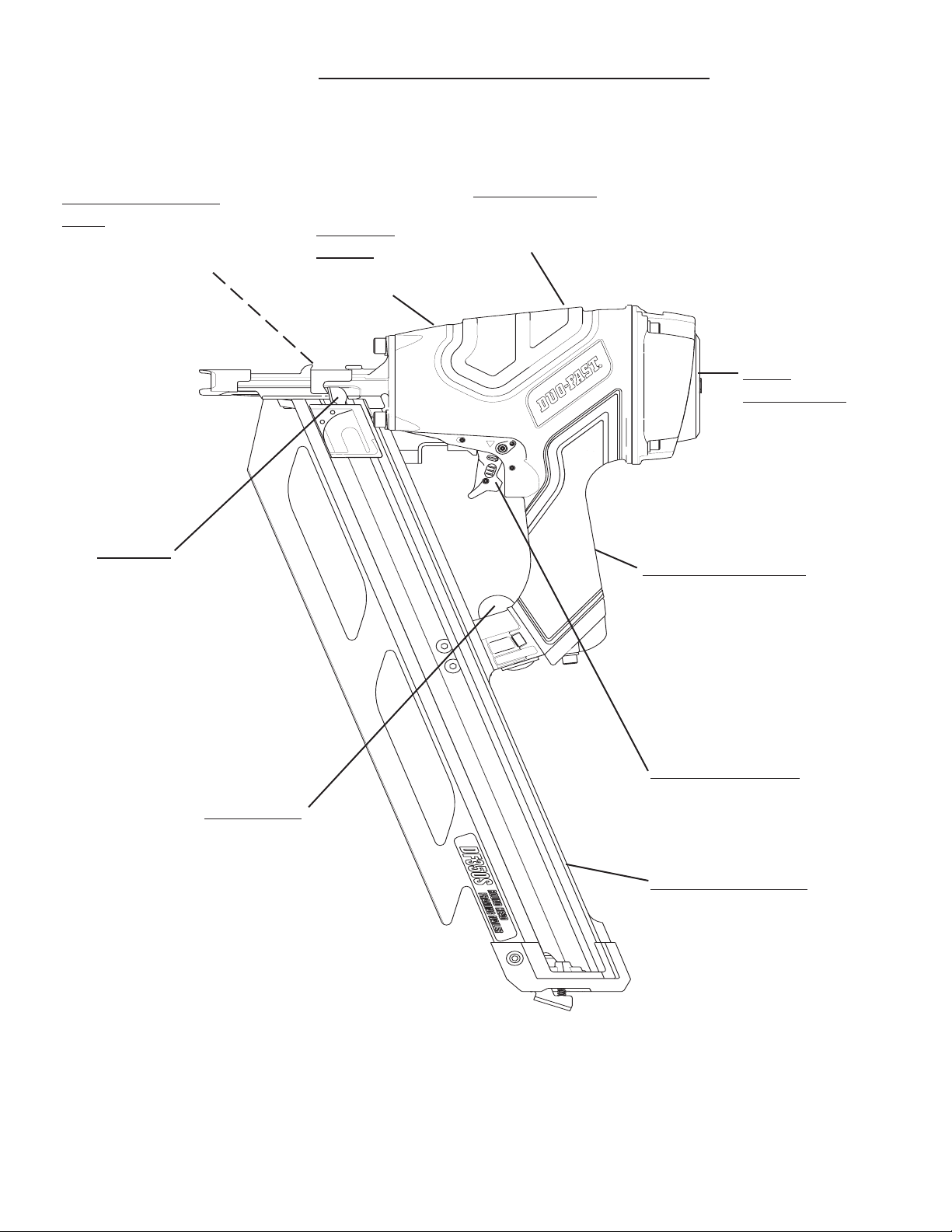

DF350S FEATURES & BENEFITS

Tool-Less Depth of

Drive

Provides precise control

of nail depth without adjusting

the compressor.

(on other side)

Lock Out

Eliminates blank

firing.

Compact

Design

Able to get into

tight spots

Powerful Motor

Consistently drives

into all engineered

lumber.

Metal

Exhaust Cap

For maximum

durability.

Light Weight Design

Easy to manuever with less arm

fatigue.

Rafter Hook

Conveniently stowes the

tool.

Switchable Trigger

Switches from sequential to

bounce fire.

Top Load Magazine

Holds 2 strips or 70 nails.

9

Page 10

PARTS LEGEND DF350S, 502200

1 502244 1 Air Deflector

2 502062 1 Air Deflector Gasket

*

3 501299 4 S.H.C.S. 1/4-20 x 1”

4 502235 1 Top Cap

5 502013 1 Top Cap Gasket

*

6 123984 1 Valve Spring

➔

7 502859 1 O-Ring

*

8 211664 1 O-Ring

*

9 1014052 1 Poppet Assembly

10 198028 1 O-Ring

*

11 502032 1 REMOVED

12 502056 1 Exhaust Seal

▲

13 502057 1 S.H.C.S.1/4-20 x 1-1/4” w/ patch

14 502011 1 Piston Seal

*

15 502012 1 Piston

16 502009 1 Sleeve

17 502010 1 Check Band

18 502261 1 Driver Blade

■

*

19 092235 1 O-Ring

*

20 502007 1 Bulkhead

21 401985 1 O-Ring

*

22 500866 1 Bumper

*

23 500729 1

24 502135 1 REMOVED

➔

25 502128 1 Magazine

26 502126 1 Follower

27 502147 1 Latch Bushing

28 502127 1 Follower Body

29 502258 2 P.P.H.S. #6 x 3/4”

30 502146 1 Follower Latch

31 502026 1 Negator Spring

*

32 502025 1 Drum Pin Assembly

33 403796 3 Roll Pin 1/8” x 1-1/4”

34 502017 2 B.H.C.S. 1/4-20 x 3/4”

35 502289 1 Model Label

36 502274 1 S.H.C.S. #8-32 x 1’

37 502188 2 Wear Rod

38 502129 1 Magazine End Cap

39 502237 1 Housing Label Left

40 404325 1 Locknut #8-32

41 502293 1 Lower W.C.E.

Driver Blade Seal

42 502046 1 Upper W.C.E.

43 502049 1 Detent Ball

44 502061 1 Detent Spring

45 404361 1 Roll Pin 1/8” x 1/2”

46 502050 1 Detent Body

47 502055 1 W.C.E. Spring

▲

48 009016 4 S.H.C.S. 5/16-18 x 1” with Patch

49 095417 4 Lock Washer 5/16

50 502125 1 Nose

51 502014 2 Magazine Isolator

*

*

52 502042 1 O-Ring

53 091866 1 Roll Pin 1/8” x 3/4”

54 502053 1 Dual Mode Trigger

55 502040 1 Trip Lever

56 502060 1 Trigger Spring

57 092747 1 O-Ring

*

58 502236 1 Housing Label Right

59 502043 1 Lower Valve Spool

60 502041 1 Trigger Pivot Pin

61 1015358 1 O-Ring

*

62 196345 1 O-Ring

*

63 502288 1 Name Plate/Warning Label

**

64 502033 1 W.C.E. Guide Block

65 502446 1 Valve Pin with O-Rings

➔

66 502059 1 Valve Pin Spring

67 502044 1 Upper Valve Spool

68 197913 1 O-Ring

*

69 502353 1 Housing with Grip

70 502294 1 Rafter Hook

71 502357 1 Rafter Hook Bolt

72 502351 1 Magazine Bridge

73 009041 2 S.H.C.S. 1/4-20 x 3/4”

■

74 442681 2 Locknut 1/4-20

75 417147 1 O-Ring

*

76 502005 1 Housing End Plug

77 501300 2 S.H.C.S. 1/4-20 x 1-1/4”

78 502193 1 Actuation Setting Label

79 502299 1 Thumb Wheel

80 502191 1 Latch spring

81 401955 1 #8 Flat Washer

* Denotes Normal Wear Items.

** Make sure Warning Label (502288) is properly affixed.

Replace if necessary.

Label available at no charge through the Service Parts Dept.

▲ Apply Loctite 242 (Blue) Part No. 093500

Apply Loctite (Green) Part No. 401491

■

Denotes New Change

➔

.098

scf

AIR CONSUMPTION - SCF/FASTENER

AIR PRESSURE - PSIG

10

SAFETY INSTRUCTIONS

WEAR EYE AND HEARING PROTECTION

Always wear hearing protection and eye protection devices, including side shields when operating or working

in the vicinity of a tool.

DO NOT EXCEED MAXIMUM

RECOMMENDED AIR PRESSURE

Operate the tool using only the recommended air

pressure. Do not exceed the maximum air pressure

marked on the tool. Be sure the air pressure gauge is

operating properly and check it at least twice a day.

Never use any bottled air or gases such as oxygen to operate the tool since they could cause the

tool to explode.

Page 11

DF

350

S

502200

❂

❂

250

❂

120

❂

120

❂

350

❂

350

120

❂

120

❂

120

❂

120

❂

160

*

Seal must be installed

❂

15

in this position.

❂Torque Values

IN/LBS

11

Page 12

MAINTENANCE

Duo-Fast® tools are built for ease of maintenance. A few

simple details will assure trouble-free operation and long

tool life. Anyone who uses or maintains the tool must read

the safety and maintenance instructions. Study the schematic drawing before starting any repairs on the tool.

Air-operated tools must be inspected periodically, and worn

or broken parts must be replaced to keep the tool operating

safely and efficiently. Also the items on the maintenance

chart must be checked often.

❑ Open the drain on the air compressor tank to drain any

moisture at least daily in extremely cold or humid

weather. A few ounces of anti-freeze in the tank will

keep the air free of frost.

Testing the Tool After Servicing

After replacing any part or parts, it is important to check

the tool for proper operation. This ensures that the tool

was put together correctly, is safe to use, and will perform

the job properly.

❑ Ensure that all hardware is tight.

Cold Weather Care

When temperatures are below freezing, tools should be

kept warm by any convenient, safe method. If this is not

possible, the following procedure should be used to warm

up the tools.

❑ Reduce the regulated air pressure to 30 psi.

❑ Remove all fasteners from the tool.

❑ Collect an air line and blank fire the tool. The reduced

air pressure will be enough to free-fire the tool. Slow

speed operation tends to warm up the moving parts.

Slowing up the piston helps the bumper and the O-rings

to become springy.

❑ Once the tool is warmed up, readjust the regulator to the

proper working pressure and reload the tool.

❑ Ensure that the work contacting element is installed

correctly in relation to the trigger, and that both parts

move freely.

❑ Ensure that the magazine is properly attached.

❑ Ensure that the required safety information on the tool

is legible.

❑ Use only Duo-Fast approved fasteners in the tool, and

ensure that they are correct for the application.

❑ Ensure that a male air fitting is securely connected to

the tool.

❑ Test the tool by driving fasteners into a workpiece

identical to the tool's application.

❑ Check the tool for air leaks during testing and for the

proper sequence of operation.

❑ Ensure that all fasteners are driven to the same depth

and that the crown of the fastener is flush with the

workpiece.

❑ Tool operators working outdoors or in unheated areas in

extremely cold temperatures should also:

Use pneumatic oil with antifreeze in the

lubricator, Part No. 219090 (8oz.)

Once a week, depending on the amount of tool

use, take the tool apart and wash away any sludge

with degreaser cleaner (Part No. 902330) to keep the

tool operating efficiently.

Cleaning the air-operated tools with solvents removes the

thin coating of grease applied to the cylinder wall and

O-rings at the factory. To replace this coating of grease,

use Chemplex grease (Part No. 403734).

Tool Lubrication

It is most important that the tool be properly lubricated by

keeping the air line lubricator filled and correctly adjusted.

Without proper lubrication the tool will not work properly

and parts will wear prematurely.

Use the proper lubricant in the air line lubricator. The lubricator should be of low air flow or changing air flow type,

and should be kept filled to the correct level. Use only

Duo-Fast recommended lubricants. Substitutes may harm

the rubber compounds in the tool’s O-rings and other rubber parts. Part No. 403720 is a pneumatic lubricating oil

specially made for pneumatic applications. If a filter/regulator/lubricator is not installed on the air system, air operated tools should be lubricated at least once a day with

6 to 20 drops of oil, depending on the work environment,

directly through the male fitting in the tool housing.

Most minor problems can be resolved quickly and eaily

using the maintenance table that follows. If problems persist, contact your Duo-Fast dealer for assistance.

12

Page 13

MAINTENANCE - Continued

CAUTION

Disconnect the tool when performing

repairs or clearing jams.

MAINTENANCE TABLE

ACTION WHY HOW

Drain air line filter(daily).

Keep lubricator filled.

Clean filter element-then blow

air through filter in direction

opposite to normal flow.

Check that all screws on tool

are tight.

Keep work contacting elelment

working properly.

Prevent accumulation of

mositure and dirt.

Keep tool lubricated.

Prevent clogging of filter with

dirt.

Prevent air leakage and promote efficient operation.

Promote operator safety and

efficient tool operation.

Open manual petcock (most

air supply systems have such

a valve).

Fill with pneumatic tool lubricant. Part No. 403720.

Wash with soap and water or

follow manufacturers instructions.

Check screws daily.

Blow clean daily.

Keep magazine and feeder

mechanism clean.

Lubricate "O" rings that are

replaced.

Use only Duo-Fast replacement

parts.

Prevent jamming of fasteners.

Assure long life and proper

operation of tool.

Keep tool operating efficiently

and maintain Duo-Fast tool

warranty.

13

Blow clean daily.

Use Chemplex grease, Part

No. 403734.

Order any replacement parts

needed from a Duo-Fast

Dealer.

Page 14

OPERATOR TROUBLESHOOTING

CAUTION

Disconnect the tool when performing

repairs or clearing jams.

PROBLEM CORRECTIVE ACTION

Fasteners will not drive completely into wood.

Fasteners penetrate properly during normal

operation, but won't drive fully at faster speeds.

Fasteners drive too deeply into wood.

Tools skips during operation - no fasteners are

driven from time to time.

Adjust work contacting element (retract length).

Increase air pressure (do not exceed 120 psi).

Increase air flow to tool -- use larger air lines

(3/8 inch ID minimum).

Adjust work contacting element (extend length).

Reduce air pressure.

Check magazine for proper fasteners. Magazine follower should slide freely. Clean as needed to remove

debris.

Make sure correct fasteners are being used.

Use fasteners that meet Duo-Fast

only.

Increase air flow to tool -- use larger air lines

(3/8 ID minimum).

®

specifications

Tool operates, but no fasteners are driven.

Air leaks at cap when tool is connected to air.

Adjust work contacting element where available.

Check magazine for proper fasteners. Fasteners

should slide freely with no follower pressure.

Increase air pressure (do not exceed 120psi).

Tighten cap screws.

14

Page 15

TOOL WARRANTY

An Illinois Tool Works Company

955 National Parkway

Schaumburg, Illinois 60173-5172

TOOL WARRANTY AND LIMITATIONS

Duo-Fast warrants that newly purchased power

fastening tools, parts and accessories will be free

from defects in material and workmanship for the

period shown below, after the date of delivery to the

original user.

ONE-YEAR LIMITED WARRANTY

A one-year warranty will apply to all parts, except

those which are specifically covered by an extended

warranty.

FIVE-YEAR EXTENDED LIMITED WARRANTY

A five-year warranty will apply to all housing and cap

assembly castings.

WARRANTY STATEMENT

This warranty is limited to tools sold and service requested

in the United States. To obtain information on warranty

service in the United States, refer to the Service Center

listing that was provided with your tool.

Duo-Fast's sole liability hereunder will be to replace any part

or accessory which proves to be defective within the specific

time period. Any replacement part or accessory provided in

accordance with this warranty will carry a warranty for the

balance of the period of warranty applicable to the part it

replaces. This warranty does not apply to part replacement

required due to normal wear.

This warranty is void as to any tool which has been subjected

to misuse, abuse, accidental or intentional damage, use with

fasteners, fuel, batteries, or battery chargers not meeting DuoFast specification, size, or quality, improperly maintained,

repaired with other than genuine Duo-Fast replacement parts,

damaged in transit or handling, or which, in Duo-Fast's opinion,

has been altered or repaired in a way

from the performance of the tool.

DUO-FAST MAKES NO WARRANTY, EXPRESSED OR

IMPLIED, RELATING TO MERCHANTABILITY, FITNESS,

OR OTHERWISE, EXCEPT AS STATED ABOVE, and DUOFAST's liability AS STATED ABOVE AND AS ASSUMED

ABOVE is in lieu of all other warranties arising out of, or

in connection with, the use and performance of the tool,

except to the extent other wise provided by applicable law.

DUO-FAST SHALL IN NO EVENT BE LIABLE FOR ANY

DIRECT, INDIRECT, OR CONSEQUENTIAL DAMAGES,

INCLUDING, BUT NOT LIMITED TO, DAMAGES WHICH

MAY ARISE FROM LOSS OF ANTICIPATED PROFITS OR

PRODUCTION, SPOILAGE OF MATERIALS, INCREASED

COST OF OPERATION, OR OTHERWISE.

that affects or detracts

15

Page 16

For additional information on DUO-FAST products:

Visit our website at www.duo-fastconstruction.com.

For technical support call, 866-443-5754.

For customer service call, 888-631-2020.

ACCESSORIES

ubricants and Loctite

L

Loctite 242 (Blue) Part No. 093500

Lubricating Oil 16 oz. Part No. 403720

Lubricaing Oil with Anitfreeze 8 oz. Part No. 219090

Chemplex 710 Lubricant 1lb. Part No. 403734

Degreaser Cleaner

Ideal cleaner for all Duo-Fast tools. Part No. 902330

Safety Glasses

Clear Part No. 402510

Sequential Only Trigger

Tool Case

Heavy duty nylon carrying case with 16 pockets. Part No. 219246

No-Mar Work Contact Part No. 502234

Part No. 502253

An Illinois Tool Works Company

955 National Parkway

Schaumburg, Illinois 60173-5172

Page 17

Clavadora de Entramado para Clavos de 20˚con Cabeza Redonda

Modelo DF350S

¡IMPORTANTE!

NO DESTRUYA ESTE MANUAL

El cliente tiene la responsabilidad de que

todo el personal de operaciones y servicio lea

y entienda este manual.

Manual de Funcionamiento y

Esquema

17

Page 18

INTRODUCCIÓN

La herramienta Duo-Fast DF350S es una herramienta de calidad, diseñada para uso en aplicaciones

residenciales. Esta herramienta le provera un rendimiento fiable cuando sea usada en acorde con las

reglas del fabricante.

Lea cuidadosamente este manual y las instrucciones de seguridad para comprender como usar la

herramienta correctamente.

CONTENIDO

ESPECIFICACIONES DE LA HERRAMIENTA Y SUS SUJETADORES......................................3

INSTRUCCIONES DE SEGURIDAD.............................................................................................4

INSTALACIÓN Y OPERACIÓN DEL LA HERRAMIENTA.........................................................5-6

SISTEMAS DE AIRE..................................................................................................................7-8

BENEFICIOS DEL LA HERRAMIENTA........................................................................................9

VISTA EXPANDIDA CON LISTA DE PIEZAS........................................................................10-11

MANTENIMIENTO..................................................................................................................12-13

DETECCIÓN Y CORRECCIÓN DE FALLAS..............................................................................14

GARANTÍA..................................................................................................................................15

ACCESORIOS.............................................................................................................................16

18

2

Page 19

ESPECIFICACIONES DE LA HERRAMIENTA Y LOS SUJETADORES

ESPECIFICACIONES DE LA HERRAMIENTA

NO. de MODELO DF350S (Pieza# 502200)

ALTURA 13”

ANCHO 5"

LONGITUD 21"

PESO 8 lbs. 1oz.

PRESIÓN de OPERACIÓN 80 hasta 120 p.s.i. (5.5 hasta 8.3 bars)

ESPECIFICACIONES DE LOS SUJETADORES

LONGITUD DEL CLAVO 2" - 3-1/2"

DIAMETRO DEL TALLO .113 - .148

ACOPLAMIENTO DE AIRE:

Esta herramienta utiliza un tapón macho de 3/8" N.P.T. El acoplamiento debe ser capaz

de descargar la presión de aire en la herramienta cuando sea desconectada del

suministro de aire.

PRESIÓN DE AIRE:

80 hasta 120 p.s.i. (5.5 hasta 8.3 bars). Seleccione una presión de aire para operación

dentro de esta gama para obtener el mejor rendimiento.

NO EXCEDA LA PRESIÓN DE AIRE RECOMENDADA

19

3

Page 20

INSTRUCCIONES DE SEGURIDAD

LA SEGURIDAD ESTA PRIMERO

Estas instrucciones proporcionan la información necesaria para el

funcionamiento seguro de las herramientas Duo-Fast. NO TRATE

DE USAR SU HERRAMIENTA HASTA QUE NO HAYA LÉIDO Y

ENTENDIDO TODAS LAS PRECAUCIONES DE SEGURIDAD Y

LAS INSTRUCCIONES DE ESTE MANUAL.

PROTEJASE LOS OJOS Y LOS OÍDOS

Use siempre el equipo adecuado para protegerse los ojos y los oídos que sea conforme con ANSI Z87, meintras usa una herramienta o trabaja cerca de una herramienta en uso. Como empleador

usted es responsable de imponer el uso del la protección de ojos.

Lleve casco de seguridad en los ambientes que requieren su uso.

USE SU HERRAMIENTA SOLAMENTE PARA EL

PROPOSITO CON QUE FUE DISEÑADA

No arroje la herramienta al suelo; no golpee el armazón ni la use

como un martillo.

NUNCA JUEGE CON LA HERRAMIENTA

Esta herramienta no es un juguete; por lo tanto no la trate como

tal. Nunca juege con ella, ni se apunte a usted mismo ni a otra

persona, aun cuando crea que no está cargada.

NUNCA SUPONGA QUE LA HERRAMIENTA ESTA

VACIA

Verfique que no haya sujetadores en el cargador. Aun cuando crea

que está vacía o desconectada, nunca se apunte ni apunte a otra

persona con la herramienta, porque podría dispararse un sujetador

que no esté a la vista.

NUNCA SUJETE EL GATILLO EN LA POSICIÓN DE

CIERRE O DE FUNCIONAMIENTO

Nunca se debe manipular indebidamente o dejar inoperante el

gatillo, o sujetarlo en la posición de cierre o de funcionamiento,

porque se podría disparar un sujetador al oprimirse el elemento de

contacto.

NO CARGUE SUJETADORES CUANDO LA LINEA DE

AIRE ESTE CONECTADA, O CUANDO EL GATILLO O

EL ELEMENTO DE CONTACTO ESTE OPRIMIDO.

Antes de cargar sujetadores en la herramienta, verifique que la

línea de aire esté desconectada y que ni el gatillo ni el elemento de

contacto estén oprimidos.

USE LA HERRAMIENTA SOLAMENTE SOBRE UN

MATERIAL DE TRABAJO

La herramienta debe funcionar sólo cuando esté en contacto con

el material de trabajo. Debe tener mucho cuidado cuando el material sea delgado o cuando trabaje cerca de las aristas del mismo,

porque los sujetadores podrían atravesar o salirse del material.

NO INUTILIZE NI QUITE EL ELEMENTO DE CONTACTO

Esta herramienta está equipada con un mecanismo de seguridad,

llamado elemento de contacto, para prevenir cualquier disparo accidental. Nunca interfiera con, inutilize, ni quite el elemento de contacto. No use la herramienta a menos que dicho elemento funcione

correctamente, porque podría producirse un disparo imprevisto.

TOME LA HERRAMIENTA SOLAMENTE POR EL

MANGO

Siempre tome la herramienta sólo por el mango. Nunca la

tome por la manguera o con el gatillo oprimido, porque se

podría disparar un sujetador y herirlo o herir a otra persona.

NO ALTERE EL ARMAZON DE LA HERRAMIENTA

El armazón de la herramienta es un recipiente a presión y

nunca se debe grabar en su superficie el nombre de su com-

pañia, el área de trabajo, ni ningún otro detalle.

DESCONECTE LA HERRAMIENTA PARA HACER

REPARACIONES O ELIMINAR OBSTRUCCIONES

Nunca trate de eliminar obstrucciones o reparar una herramienta sin haberla desconectado de la línea de aire y quitado

todos los sujetadores.

USE SIEMPRE LOS ADAPTADORES APROPIADOS

PARA SU HERRAMIENTA

Se debe conectar a la herramienta solamente conectores

neumáticos MACHOS, para permitir que el aire de alta presíon

salga tan pronto como se desconecte la línea de aire.

NUNCA coloque enlaces HEMBRAS de desconexíon rápida

en la herramienta, porque atrapan el aire a alta presión al

desconectar la línea de aire, dejándola cargada y lista para

disparar por lo menos un sujetador.

NO EXCEDA LA PRESIÓN NEUMATICA MAXIMA

RECOMENDADA

La herramienta debe funcionar sólo con la presión neumática

recomendada. No exceda la presión neumática máxima

marcada en la herramienta. Verifique por lo menos dos veces

al día que el calibre de la presión neumática funcione correctamente.

Nunca use aire o gases envasados, como el oxígeno, para

hacer funcionar la herramienta porque podrían hacerla explotar.

INSPECCIONE LA HERRAMIENTA PARA LA

OPERACIÓN APROPIADA

Limpie diariamente la herramienta y lubríquela como se recomienda. Nunca trate de hacer funcionar una herramienta

sucia o defectuosa.

USE SOLAMENTE PIEZAS Y SUJETADORES

RECOMENDADOS POR DUO-FAST

Use sólo piezas y sujetadores específicamente diseñados y

recomendados por Duo-Fast para usar con esta herramienta

y para la tarea requerida. Si se usan piezas o sujetadores no

autorizados o se modifica de alguna forma la herramienta, se

pueden crear situaciones peligrosas. Vuelva a colocar todas

las etiquetas de precaucíon que falten. Consulte el esquema

de la herramienta sobre el número de cada parte y su ubicación correcta.

DESCONECTE LA HERRAMIENTA CUANDO NO LA

ESTE USANDO

Siempre desconecte la herramienta de la línea de aire cuando no

la esté usando o al dejar su lugar de trabajo. Nunca la descuide,

porque cualquier persona que no esté familiarizada con ella podría

lastimarse o lastimar a otros.

ADVERTENCIA

La falta de observación de cualquiera de estas instrucciones puede causar graves

lesiones personales, tanto al operador de la herramienta como a quienes estén cerca

de ella o puede causar daños a la herramienta o la propiedad.

Comuníquese con el representante de Duo-Fast sobre la presentación de Programa de Alerta sobre

Seguridad.

20

4215

Page 21

INSTALACIÓN DE LA

FUNCIONAMIENTO DE LA

HERRAMIENTA

PELIGRO

La presión de aire en la herramienta nunca

debe exceder 120 psi.

Su herramienta Duo-Fast está lista para usarse y

se puede instalar siguiendo estos pasos:

1. SEGURIDAD: Antes de usar la herramienta, todos

los operadores y sus supervisores inmediatos deben

familiarizarse con las instrucciones de seguridad de

la página 4 de este manual.

2. Con cada herramienta se entrega una copia de este

manual. Conserve este manual para cualquiera

consulta futura. Además, se incluye una targeta

de registro, que debe llenarse y devolverse

inmediatamente a Duo-Fast para que su herramienta

quede registrada.

3. Quite la cubierta plástica en la entrada del aire de

la herrmienta antes de instalar el adaptador

macho. Se requiere un adaptador neumático tipo

macho, que descargue el aire de la herramienta

cuando se desconecte la línea de aire.

HERRAMIENTA

Ajuste de Profundida

ADVERTENCIA

Apunte la herramienta en alguna dirección en

que no haya peligro. Desconectela de la

fuente de aire y quítele todos los sujetadores.

El adjuste de profundidad se acomoda al darle vueltas

a la tuerca de ajuste sobre el elemento de contacto.

Si la herramienta excede la profundidad deseada (la

cabeza del sujetador es impulsada por debajo de la

superfice de trabajo), baje el elemento de contacto. Si

los sujetadores sobresalen (la cabeza del sujetador no

está al mismo nivel que la superficie de trabajo), suba

el elemento de contacto.

Mueva el elemento de contacto hasta que la cabeza del

sujetador quede a la profundidad deseada.

4. Instale una unidad de filtro/regulador/lubricador con

un calibre, tan cercano al de la herramienta como sea

posible, de preferencia a menos de tres metros.

Consulte la sección de Sistemas Neumáticos de

este manual sobre la longitud y los requisitos de las

mangueras de aire. En general, no se requiere

ninguna otra instalación especial.

5. Si el operador usa una mesa para trabajar, se

aconseja colocar la línea de aire debajo de la misma.

Se puede colocar una pequeña bandeja en la parte

inferior de la mesa para guardar los sujetadores y la

herramienta cuando no están en uso.

6. Si la herramienta no funciona cuando se conecta por

primera vez, no trate de repararla; llame de inmediato

al representate de Duo-Fast.

Tuerca de

ajuste

Elemento de

contacto

Page 22

FUNCIONAMIENTO DE LA

HERRAMIENTA (continuación)

Carga de Sujetadores

Funcionamiento en Secuencia

El juego de funcionamiento en secuencia evita los

impulsos sucesivos o "de rebote".

Paso 1 Agarre el mango firmemente. Mueva el seguidor

de clavos hacia la parte de atrás del cargador

hasta que se cierre en la posición de carga.

Paso 2 Meta una o dos tiras de clavos en la parte de

arriba del cargador.

Paso 3 Agarre el mango firmemente. Mueva el seguidor

de clavos hacia atrás ligeramente y apriete el

cierre del seguidor para soltarlo de la posición

de carga. Deslize el seguidor hacia delante

hasta que se reúna con los clavos.

Cambio de Gatillo

La herramienta ha sido fabricada con un gatillo que

se puede cambiar de funcionamiento en secuencia a

funcionamiento en rebote (bounce drive). El gatillo fue

colocado en posición de funcionamiento en secuencia

cuando la herramienta fue fabricada. Para cambiar el

gatillo a posición de funcionamiento en rebote, quite

el anillo-o y la clavija giratoria del sistema de ensamblado del gatillo. Mueva el gatillo a posición de robote

y instale la clavija giratoria y el anillo-o. El indicador de

posición sobre la herramienta debe indicar como

se muestra en la ilustración.

▼

■ Oprima el elemento de contacto y

manténgalo apoyado contra el material de

trabajo antes de apretar el gatillo.

■ Después de haber impulsado cada

sujetador, suelte completamente el gatillo y

levante la herramienta del material de trabajo.

Posición de

disparo secuencial

Colocación Precisa

■ Tome firmamente la herramienta por el mango y

sosténgala de modo que el base del elemento de

contacto quede bien apoyada en el material de

trabajo.

■ Apriete el gatillo para disparar el sujetador.

■ Separe la herramienta del material de trabajo.

■ Repita el mismo procedimiento con el próximo

sujetador.

Clavija giratoria

y anillo-o

Indicador

de posición

Posición de disparos

de rebote

ADVERTENCIA

No sujete ni sostenga el gatillo con ninguna

otra cosa que no sea la mano.

Impulsos Sucesivos (de Rebote)

■ Tome la herramienta firmemente por el mango.

■ Apriete el gatillo y mueva la herramienta a lo

largo del material de trabajo con un movimiento

de rebote, oprimiendo el elemento de contacto

en los lugares donde quiera colocar un

sujetador.

■ Manteniendo apretado el gatillo continúe

haciendo rebotar el elemento de contacto contra

el material de trabajo, colocando cuidadosamente

la herramienta.

■ Una vez que haya colocado todos los

sujetadores necesarios, deje de oprimir el gatillo

para evitar que salgan más.

22

6

Page 23

Duo-Fast

SISTEMAS NEUMÁTICOS

■ Las mangueras de aire no midan más de 45.70 m

de longitud.

El sistema neumático debe estar correctamente

instalado y recibir mantenimiento periódicamente para

que todas las herramientas de potencia neumática

funcionen bien. El diagrama de más abajo muestra

un sistema neumático correctamente instalado. A

continuación se detallan las revisiones necesarias

para la instalación y el mantenimiento de los sistemas

neumáticos.

Instalación de Un Sistema Neumático

para Interiores

- Asegure Que:

■ El diámetro interior de todas las líneas que

suministran aire sea bastante grande como para

garantizar un suministro de aire adecuado.

■ La línea principal tenga una inclinación de (1/16

de pulgada por pie) a partir del compressor.

■ Existen almacenamientos de aire a lo largo de las

líneas muy largas.

■ Las salidas de aire en las líneas secundarias

estén en la parte superior de la línea principal.

■ El sistema neumático sea lubricado

periódicamente.

■ Se siga un programa regular de mantenimiento.

Unidades de Filtro/Regulador/Lubricador

Las unidades de filtro/regulador/lubricador capaces

de proporcionar aire y proetección suficientes a las

herramientas Duo-Fast deben tener las siguientes

características:

■ Tamaño mínimo del orificio a presión y tempera

tura normales de 3/8 de pulgada

■ Filtros de 50 micrones o más finos

■ Presión regulada de 0 a 120 psi

■ Lubricadores diseñados para corriente de aire

baja o variable

■ Existen válvulas de cierre en cada una de las

líneas secundarias de todo el sistema.

■ Las columnas de agua se extiendan desde el

extremo inferior de cada línea secundaria.

■ Se haya instalado en el sistema un secador tipo

refrigerante.

■ Las mangueras de aire sean tan cortas como sea

posible.

■ Se siga un programa regular de mantenimiento.

Instalación de Un Sistema Neumático

para Exteriores

- Asegure Que:

■ Se hayan instalado en el compresor un colector

de humedad y un filtro/regulador/lubricador.

■ Las mangueras de aire y los adaptadores tengan

la longitud suficiente para que el aire circule sin

problemas. El diámetro mínimo de una manguera

de aire es de 3/8 de pulgada y de 1/2 pulgada

para cualquier apalicación de más de 7.60 m.

23

7

Page 24

SISTEMAS NEUMÁTICOS (continuación)

Duo-Fast®

).

Cómo Calcular el Tamaño del Compresor

Use la tabla de consumo de aire en el esquema de

cada herramienta para calcular los requisitos de

funcionamiento de las herramientas. Las herramientas Duo-Fast® han sido diseñadas para funcionar

eficientemente entre 80 y 120 psi, y nunca se deben

usar a presiones superiores a 120 psi. La tabla de

consumo de aire le permitirá encontrar el tamaño

correcto del compresor para reponer rápidamente la

presión del aire en su herramienta.

Para usar la tabla necesita saber cuántas herramientas se usarán y aproximadamente cuántos sujetadores aplicará, por minuto, cada herramienta de la línea.

Use esta ecuación:

Número de herramientas X promedio de

sujetadores/minuto/herramienta X 1.2 (factor

de seguridad) X consumo de aire (pies³/min./

estándar) @ presión* (psi) = pies³/min./

estándar requeridos

Por ejemplo:

10 herramientas X 30 sujetadores/minuto/

herramienta X 1.2 X 0.051 pies³/min./

estándar* (@ 100 psi) = 18.36 pies³/min./

estándar.

* Esta cifra aparece en la tabla de Consumo de Aire.

Usando la tabla de consumo de aire, este ejemplo

demuestra que se necesita un compresor que proporcione 19 pies³/min./estándar de aire, por lo menos.

Como en compresores se necesita aproximadamente

1 hp para proporcionar 4 pies³/min./estándar, se requiere, por lo menos, un compresor de 5 hp.

Cómo Calcular la Tubería Necesaria

Por ejemplo, si un compresor eléctrico de 20 hp

proporciona aproximadamente 80 pies³/min. de aire a

120 psi y la longitud de la línea principal es de 106.70

m, la tabla indica que el diámetro interior de la línea

principal necesario para esta aplicación debe ser de

1-1/4 pulgadas como mínimo.

Importante: Presión de Aire (80-100 psi)

Mantenimiento del Sistema Neumático

- Asegure Que:

■ Los adaptadores neumáticos estén apretados y

no haya pérdidas.

■ Las columnas de agua, o los filtros y las líneas

de aire se drenen diariamente, y que los

sistemas de drenaje automáticos funcionen

correctamente.

■ Las líneas de aire estén limpias para evitar que

se congelen, especialmente en invierno.

■ El funcionamineto del lubricador se examine

periódicamente y que el suministro de lubricante

sea adecuado (Pieza N° 403720).

24

■ Se limpie el filtro cada seis meses.

■ Sólo se use aire regulado y que cada regulador

funcione correctamente.

8

Page 25

CARACTERÍSTICAS Y BENEFICIOS DE LA DF350S

Ajuste de Profundidad Sin

Uso de Herramienta

Proporciona control preciso

de la profundidad de clavo sin

ajustar el compresor

(sobre lado opuesto)

Cierre de Disparo

Elimina disparos en

blanco

Diseño Compacto

Puede entrar en

lugares apretados

Motor Potente

Impulsa consistentemente

en toda madera

procesada

Tapa de Escape

Hecha de Metal

Para máxima durabilidad

Diseño Ligero

Fácil de manejar con menos cansancio del brazo

Gancho de Vigas

Sitúa la herramienta a

mano

25

Gatillo de Intercambió

Cambia de disparos en

secuencia a disparos en

rebote

Cargador de Carga por Arriba

Sostiene dos tiras o 70 clavos

9

Page 26

LISTA DE PIEZAS DF350S, 502200

1 502244 1 Air Deflector

*

2 502062 1 Air Deflector Gasket

3 501299 4 S.H.C.S. 1/4-20 x 1”

4 502235 1 Top Cap

5 502013 1 Top Cap Gasket

*

6 123984 1 Valve Spring

➔

7 502859 1 O-Ring

*

*

8 211664 1 O-Ring

9 1014052 1 Poppet Assembly

10 198028 1 O-Ring

*

11 502032 1 REMOVED

12 502056 1 Exhaust Seal

13 502057 1 S.H.C.S.1/4-20 x 1-1/4” w/ patch

▲

14 502011

*

15 502012 1 Piston

16 502009 1 Sleeve

17 502010 1 Check Band

18 502261 1 Driver Blade

*

■

19 092235 1 O-Ring

*

20 502007 1 Bulkhead

21 401985 1 O-Ring

*

22 500866 1 Bumper

*

23 500729 1

24 502135 1 REMOVED

➔

25 502128 1 Magazine

26 502126 1 Follower

27 502147 1 Latch Bushing

28 502127 1 Follower Body

29 502258 2 B.H.C.S. #6 x 3/4”

30 502146 1 Follower Latch

31 502226 1 Negator Spring

*

32 502025 1 Drum Pin Assembly

33 403796 3 Roll Pin 1/8” x 1-1/4”

34 502017 2 B.H.C.S. 1/4-20 x 3/4”

35 502289 1 Model Label

36 502274 1 S.H.C.S. #8-32 x 1’

37 502188 2 Wear Rod

38 502129 1 Magazine End Cap

39 502237 1 Housing Label Left

40 404325 2 Locknut #8-32

41 502293 1 Lower W.C.E.

1 Piston Seal

Driver Blade Seal

42 502046 1 Upper W.C.E.

43 502049 1 Detent Ball

44 502061 1 Detent Spring

45 404361 1 Roll Pin 1/8” x 1/2”

46 502050 1 Detent Body

47 502055 1 W.C.E. Spring

48 009016 4 S.H.C.S. 5/16-18 x 1” with Patch

▲

49 095417 4 Lock Washer 5/16

50 502125 1 Nose

51 502014 2 Magazine Isolator

*

52 502042 1 O-Ring

*

53 091866 1 Roll Pin 1/8” x 3/4”

54 502053 1 Dual Mode Trigger

55 502040 1 Trip Lever

56 502060 1 Trigger Spring

57 092747 1 O-Ring

*

58 502236 1 Housing Label Right

59 502043 1 Lower Valve Spool

60 502041 1 Trigger Pivot Pin

61 1015358 1 O-Ring

*

62 196345 1 O-Ring

*

63 502288 1 Name Plate/Warning Label

**

64 502033 1 W.C.E. Guide Block

➔

65 502446 1 Valve Pin with O-Rings

66 502059 1 Valve Pin Spring

67 502044 1 Upper Valve Spool

68 197913 1 O-Ring

*

69 502353 1 Housing with Grip

70 502294 1 Rafter Hook

71 502357 1 Rafter Hook Bolt

72 502351 1 Magazine Bridge

73 009041 2 S.H.C.S. 1/4-20 x 3/4”

■

74 442681 2 Locknut 1/4-20

*

75 417147 1 O-Ring

76 502005 1 Housing End Plug

77 501300 2 S.H.C.S. 1/4-20 x 1-1/4”

78 502193 1 Actuation Setting Label

79 502299 1 Thumb Wheel

80 502191 1 Latch spring

81 401955 1 #8 Flat Washer

* Indica piezas de desgaste normal

** Asegure que la Etiqueta de Advertencia (502288) este bien

pegada. Reemplaze si es necesario. La etiqueta esta disponible

sin costo adicional a traves del Departamento de Servicio.

▲ Aplique Loctite 242 (Azul) No. de Pieza 093500

Aplique Loctite (Verde) No. de Pieza 401491

■

Indica un cambio nuevo

➔

.098

scf

CONSUMO DE AIRE - SCF/SUJETADOR

PRESIÓN DE AIRE - PSI

26

10

INSTRUCCIONES DE SEGURIDAD

USE PROTECCIÓN PARA OJOS Y OÍDOS.

Siempre use protección para oídos y equipo de seguridad para los ojos, incluyendo protectores laterales

cuando este manejando o trabajando en los alred-

edores de una herramienta.

NO SOBRE PASE LA MAXIMA PRESIÓN DE

AIRE RECOMEND

Solo opere la herramienta usando la presión de aire

recomendada. No sobre pase la maxima presión de

aire marcada sobre la herramienta. Asegure que el

indicador de presión de aire este trabajando bien y

reviselo por lo menos dos veces al día.

Nunca use algún aire o gas embotellado tal como el

oxígeno para funcionar la herramienta ya que pueden

causar que la herramienta explote.

ADA

Page 27

DF

350

S

502200

MONTAJE DEL PISTÓN

#502358

❂

❂

250

❂

120

❂

120

❂

350

MONTAJE DE

❂

350

LA

VÁLVUA

DEL GATILLO

#502446

120

❂

120

❂

120

MONTAJE DEL

ELEMENTO DE

CONTACTO

SUPERIOR

#502734

❂

120

❂

15

MONTAJE

DEL GATILLO

DE OPERACIÓN

DUAL

#502435

MONTAJE DEL CARGADOR

❂

160

MONTAJE DEL CARGADOR

#502437

❂Torsión Valora

IN/LBS

11

El sello tiene que ser

*

instalada en esta posición.

Page 28

MANTENIMIENTO

El mantenimiento de cualquier herramienta Duo-Fast es

simple. Su funcionamiento sin problemas y la prolongación de la vida de la herramienta se logran siguiendo un

sencillo procedimiento. Las personas encargadas de usar

y mantener la herramienta deben leer las instrucciones de

seguridad y mantenemiento. Estudie los diagramas antes

de hacer cualquier reparación.

Las herramientas neumáticas deben revisarse periódicamente, y se deben cambiar las piezas gastadas o deterioradas para que la herramienta siga funcionando con

eficiencia y sin peligro. Además, se debe revisar la tabla

de mantenimiento frecuentemente.

Cuando Hace Mucho Frio

Cuando la temperatura es inferior a la de congelamiento,

las herramientas deben mantenerse a la temperatura

ambiente por el método más seguro y conveniente. De lo

contrario, aconsejamos seguir el siguiente procedimiento

para calentar las piezas de la herramienta.

■ Disminuya la presión regulada del aire a 30 psi

■ Quite todos los sujetadores de la herramienta.

■ Conecte una línea de aire y dispare la herramienta

sin clavos. La presión reducida del aire será suficiente

para lograrlo. El funionamiento a poca velocidad tiene

la tendencia de calentar las partes movibles.

Disminuyendo la velocidad del pistón le da cierta

elasticidad al amortiguador y los anillos-o.

PRECAUCIÓN

Nunca dispare la herramienta sin clavos a

alta presión.

■ Una vez que la herramienta se haya calentado, ajuste

nuevamente el regulador a la presión apropiada para

trabajar y cargue de nuevo la herramienta.

■ Los operadores que trabajen al aire libre o en áreas

sin calefacción con temperaturas extremadamente

frías también tienen que usar en el lubricador el

aceite neumático con anticongelante N° 219090

(8 oz.).

■ Una vez por semana, según el uso que le dé a su

herramienta, desármela y lávela con el solvente N°

902330, para eliminar cualquier suciedad y asegurar

que la herramienta siga funcionando bien.

PRECAUCIÓN

Nunca use queroseno ni ningún solvente

inflamable par limpiar la herramienta.

Al usar solventes para limpiar herramientas neumáticas se

destruye la delgada capa de grasa lubricante, que se aplica en la fábrica, de la pared del cilindro y de los anillos-o.

Use grasa Chemplex N° 403734 para reemplazar la capa

de grasa lubricante.

■ Abra, por lo menos diariamente, el drenaje del tanque

del compresor del aire para eliminar cualquier

humedad, cuando haga mucho frío o el grado de

humedad sea muy alto. Poniendo una pequeña

cantidad de descongelante en el tanque evitará que

la humedad se congele.

Probar la Herramienta Después de Darle

Servicio

Después de reemplazar una o más piezas, es importante

comprobar si la herramienta funciona como es debido.

Esto asegura que todas las piezas estén puestas correctamente, que la herramienta esté segura y que funcione correctamente.

■ Verifique que ninguna pieza esté floja.

■ Compruebe que el elemento de contacto haya sido

correctamente instalado en relación con el gatillo y

que ambas piezas se muevan libremente.

■ Verifique que el cargador esté colocado

correctamente.

■ Verifique que la información sobre seguridad, que

está en la herramienta, sea legible.

■ Use solamente sujetadores aprobados por Duo-Fast

y compruebe que sean los apropiados para su

aplicación.

■ Verifique que se haya conectado firmemente un

adaptador macho a la herramienta.

■ Pruebe la herramienta impulsando sujetadores en un

material de trabajo idéntico al de la aplicación.

■ Verifique que no haya pérdidas de aire en la

herramienta durante las pruebas y revise la

secuencia apropiada de funcionamiento.

■ Asegure que todos los sujetadores sean impulsados

a la misma profundidad y que la cabeza del

sujetador esté al ras con el material de trabajo.

Lubricación de la Herramienta

Es muy importante lubricar la herramienta correctamente,

manteniendo lleno el lubricador de la línea de aire y

correctamente regulado. Sin la lubricación apropiada, la

herramienta no funcionará como es debido y sus piezas

se gastarán prematuramente.

Use el lubricante apropiado en el lubricador de la línea de

aire. El lubricador debe ser para corriente de aire baja o

variable, y tiene que estar lleno hasta el nivel apropiado

por Duo-Fast porque otros lubricantes podrian dañar el

caucho de los anillos-o y otras piezas de caucho. El lubricante N° 403720 (474 ml) es un aceite lubricante especialmente diseñado para aplicaciones neumáticas.

Si no se instala un filtro/regulador/lubricador en el sistema

neumático, las herramientas neumáticas deben ser

lubricadas, por lo menos, diariamente, poniendo entre 6

y 20 gotas de aceite, según sea el tipo de trabajo que se

realice, directamente a través del adaptador macho.

Usando la siguiente tabla de mantenimiento es posible resolver rápidamente y fácilmente la mayoría de los pequeños problemas. Si un determinado problema persiste,

28

comuniquese con el representante de Duo-Fast.

12

Page 29

MANTENIMIENTO (continuación)

Desconecte la herramienta al hacer cualquier

reparación o eliminar cualquier obstrucción.

PRECAUCIÓN

TABLA DE MANTENIMIENTO

ACTIVIDAD POR QUE COMO

Drene el filtro de la línea de aire a

diario.

Mantenga lleno el lubricador.

Limpie el elemento del filtro;

luego, sople aire a través del filtro

en la dirección opuesta a la corriente normal.

Verifique que todos los tornillos de

la herramienta estén apretados.

Revise si el elemento de contacto

funciona correctamente.

Para evitar que se acumulen la

humedad y la suciedad.

Para mantener lubricada la herramienta.

Para evitar que la suciedad obstruya el filtro.

Para evitar pérdidas de aire y asegurar el buen funcionamiento de la

herramienta.

Para promover la seguridad del

operador y el buen funcionamiento

de la herramienta.

Abra la llave de escape. (La mayoría de los sistemas neumáticos

la tienen.)

Llene con lubricante neumático

N° 403720 (474 ml).

Lave con agua y jabón, o siga las

instrucciones del fabricante.

Revise los tornillos a diario.

Límpielo con aire a diario.

Mantenga limpios los mecanismos

del cargador y del alimentador.

Lubrique los anillos-o que se

hayan reemplazado.

Use solamente piezas de repuesto

Duo-Fast.

Par prevenir que se obstruyan los

sujetadores.

Para prolongar la vida de la herramienta y su funcionamiento adecuado.

Para que la herramienta continúe

funcionando eficientemente y

mantener vigente la garantía de

Duo-Fast.

29

13

Límpielos con aire a diario.

Use grasa lubricante Chemplex

N° 403734.

Solicite al representante de DuoFast cualquier pieza de repuesto

que necesite.

Page 30

DETECCIÓN Y CORRECCIÓN DE FALLAS

PRECAUCIÓN

Desconecte la herramienta al hacer cualquier

reparación o eliminar cualquier obstrucción.

PROBLEMA SOLUCIÓN

Los sujetadores no penetran completamente en la

madera.

Los sujetadores penetran bien durante las operaciones

normales, pero fallan a velocidades más altas.

Los sujetadores penetran demasiado en la madera.

Los sujetadores se acumulan en la punta de la herramienta.

La herramienta “salta” mientras está funcionando; de

vez en cuando no impulsa sujetadores.

Cambie la posición del elemento de contacto (Retraiga

la longitud).

Aumente la presión de aire (no debe exceder 120 psi).

Aumente el flujo de aire a la herramienta; use líneas

de aire más grandes (3/8” de diámetro como mínimo).

Cambie la posición del elemento de contacto (Extienda la longitud).

Reduzca la presión de aire.

Abra el seguro delantero, quite el sujetador obstruido y

cierre bien el segurro.

Compruebe si el cargador tiene los sujetadores apropiados. El transportador debe deslizarse sin dificultad.

Límpielo para quitar cualquier suciedad.

Verifique que se usen los sujetadores apropiados.

Use solamente sujetadores que reúnan las especificaciones de Duo-Fast.

La herramienta funciona, pero no dispara sujetadores.

Hay pérdidas de aire en la cubierta cuando la herramienta está conectada a la línea de aire.

Aumente el flujo de aire a la herramienta; use líneas

de aire más grandes (3/8” de diámetro como mínimo).

Ajuste el elemento de contacto donde sea posible.

Compruebe si el cargador tiene los sujetadores apropiados. Los sujetadores deben deslizarse libremente

sin presión del transportador.

Abra el seguro delantero o afloje el botón del cargador

y revise si hay suciedad o alguna obstrucción en el

área de la punta. Límpiela si es necesario.

Aumente la presión de aire (no debe exceder 120 psi).

Apriete los tornillos.

30

14

Page 31

GARANTÍA

Una Compañia de Illinois Tool Works

955 National Parkway

Schaumburg, Illinois 60173-5172

TERMINOS DE LA GARANTÍA

Duo-Fast garantiza que sus herramientas mecánicas,

sus piezas y accesorios, que hayan sido comprados

nuevos, están libres de defectos de material y

fabricación por el período indicado más abajo, a partir

de la fecha de compra del comprador original.

GARANTÍA LIMITADA DE UN AÑO

La garantía limitada de un año cubre todas las piezas,

con excepción de aquellas cubiertas por la extención

de garantía.

GARANTÍA LIMITADA ADICIONAL DE CINCO AÑOS

La garantía de cinco años cubre todos los armazones

y ensambles de las tapas.

DECLARACIÓN DE LA GARANTÍA

Esta garantía esta limitada a las herramientas vendidas y revisadas en los Estados Unidos. Para obtener

más información sobre el servicio de garantía en los

Estados Unidos, véa la lista de Centros de Servicio

que fue proporcionada con su herramienta.

Duo-Fast asume únicamente la responsabilidad de reponer

cualquier pieza o accesorio que se compruebe como defectuoso dentro del período especificado. Cualquier pieza o

accesorio de repuesto, entregado de conformidad con esta

garantía, gozará de la garantía por el período restante de la

garantía que cubría a la pieza o al accesorio original. Esta

garantía no cubre las piezas que necesitan ser repuestas

como consecuencia de su desgaste normal.

Se cancelará esta garantía a cualquier herramienta que haya

sido usada incorrectamente, dañada accidental o intencionalmente, usada con sujetadores, combustible, baterías o

cargadores de batería que no reúnan las especificaciones,

el tamaño o la calidad de Duo-Fast, o a la que no se le haya

dado el mantenimiento o el uso adecuado, o que haya sido

reparada con piezas que no sean marca Duo-Fast, o que

en opinión de Duo-Fast hayan sido modificadas o reparadas

de manera que afecte o sea contraria al funcionamiento de

la herramienta.

DUO-FAST NO OTORGA NINGUNA GARANTÍA EXPLÍCITA O IMPLÍCITA CON RESPECTO A LA COMERCIALIZACIÓN O ADAPTACIÓN AL USO PREVISTO, O DE

CUALQUIER OTRA NATURALEZA, CON EXCEPCIÓN DE

LO DECLARADO ANTERIORMENTE, y la responsabilidad

de Duo-Fast TAL COMO SE INDICA Y SE ASUME MÁS

ARRIBA reemplaza a todas las otras garantías que resulten

o estén relacionadas con el uso y funcionamiento de la

herramienta, excepto según lo estipulen las leyes pertinentes. DUO-FAST NO SERÁ RESPONSABLE EN NINGÚN

CASO POR NINGÚN DAÑO DIRECTO, INDIRECTO O

CONSECUENTE INCLUYENDO, PERO SIN LIMITARSE,

CUALQUIER DAÑO RESULTADO DE LA PÉRDIDA DE

PRODUCCIÓN O GANANCIAS ANTICIPADAS, EL DETERIORO DE MATERIALES, AUMENTOS EN EL COSTO DE

OPERACIÓN O CUALQUIER OTRO.

31

15

Page 32

ACESORIOS

ubricantes Y Loctite

L

Loctite 242 (Azul) Pieza No. 093500

Aceite Lubricante 16 oz. Pieza No. 403720

Aceite Lubricante con Anticongelante 8 oz. Pieza No. 219090

Lubricante Chemplex 710 1lb. Pieza No. 403734

Desengrasador

El limpiador ideal para todas las herramientas Duo-Fast. Pieza No. 902330

Lentes de Seguridad

Claros Pieza No. 402510

Gatillo de Secuencia Pieza No. 502253

Contacto de Elemento de No-Estropear Pieza No. 502234

Maletin

Maletin de nylon resistente con 16 bolsillos. Pieza No. 219246

Para la información adicional en los productos DUO-FAST:

Visitan nuestro sitio web en www.duo-fastconstruction.com.

Para llamada técnica de apoyo, 866-443-5754.

Para llamar a servicio al cliente, 888-631-2020

PUBLICADO EN EE.UU.

© 2008, Illinois Tool Works, Inc.

Una Compañia de Illinois Tool Works

955 National Parkway

Schaumburg, Illinois 60173-5172

32

Loading...

Loading...