Dunsley Heat Wentworth User Instructions

USER'S INSTRUCTIONS

The Wentworth is controlled by a flame supervision

device control unit, which automatically shuts off the

gas supply should the flame be extinguished with or

without your knowledge. An oxygen depletion system

is also fitted for additional safety.

FIG.

t.

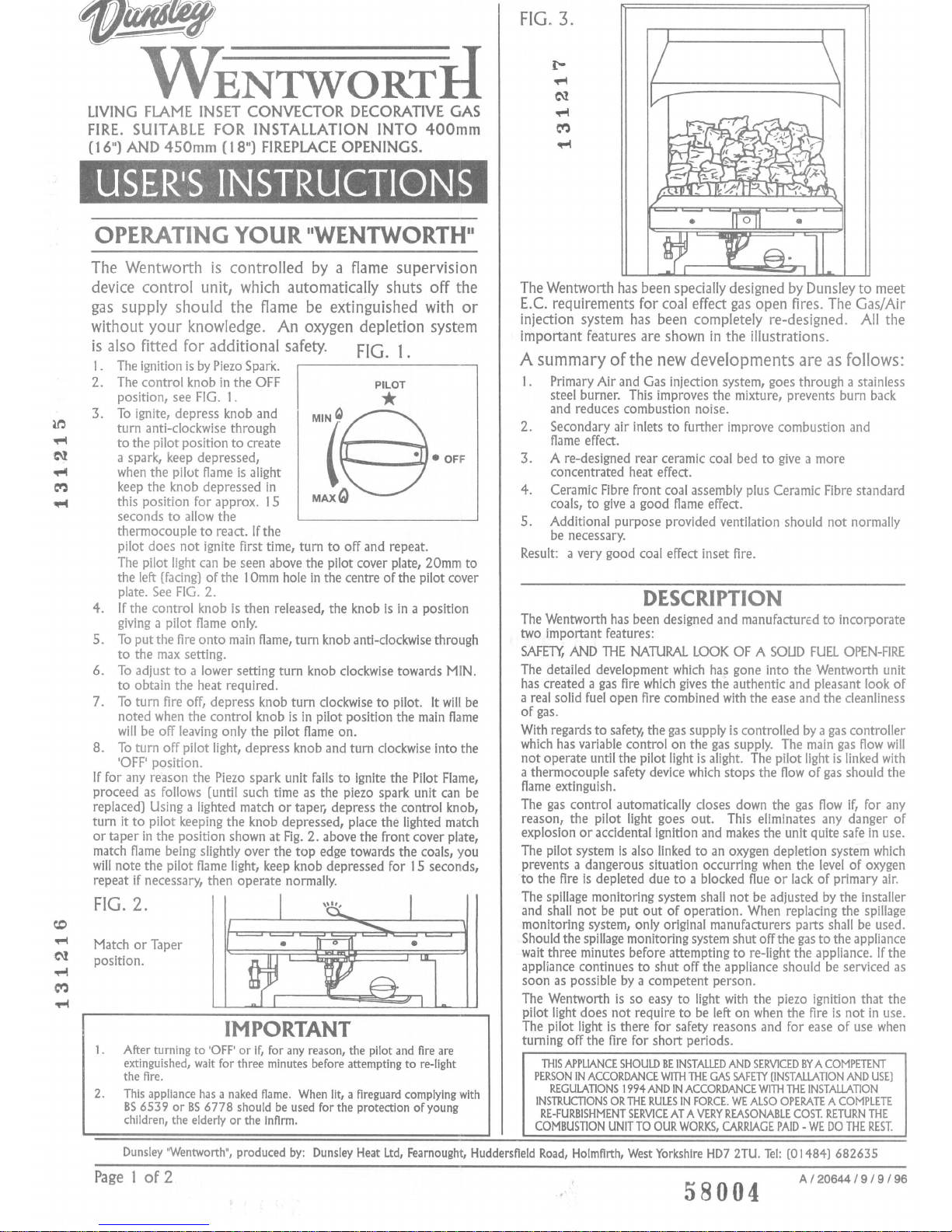

1. The ignition is by Piezo Spark.

2. The control knob in the OFF

position, see FIG. 1.

3. To ignite, depress knob and

turn anti-clockwise through

to the pilot position to create

a spark, keep depressed,

when the pilot flame is alight

keep the knob depressed in

this position for approx. 15

seconds to allow the

thermocouple to react. Ifthe

pilot does not ignite first time, turn to off and repeat.

The pilot light can be seen above the pilot cover plate, 20mm to

the left (facing) of the 10mm hole in the centre of the pilot cover

plate. See FIG. 2.

4. If the control knob is then released, the knob is in a position

giving a pilot flame only.

S. To put the fire onto main flame, turn knob anti-clockwise through

to the max setting.

6. To adjust to a lower setting turn knob clockwise towards MIN.

to obtain the heat required.

7. To turn fire off, depress knob turn clockwise to pilot. It will be

noted when the control knob is in pilot position the main flame

will be off leaving only the pilot flame on.

8. To turn off pilot light, depress knob and turn clockwise into the

'OFF' position.

If for any reason the Piezo spark unit fails to ignite the Pilot Flame,

proceed as follows (until such time as the piezo spark unit can be

replaced) Using a lighted match or taper, depress the control knob,

turn it to pilot keeping the knob depressed, place the lighted match

or taper in the position shown at Fig. 2. above the front cover plate,

match flame being slightly over the top edge towards the coals, you

will note the pilot flame light, keep knob depressed for I 5 seconds,

repeat if necessary, then operate normally.

Match or Taper

position.

1. After turning to 'OFF' or if, for any reason, the pilot and fire are

extinguished, wait for three minutes before attempting to re-light

the fire.

2. This appliance has a naked flame. When lit, a fireguard complying with

BS 6539 or BS 6778 should be used for the protection of young

children, the elderly or the Inflrm.

The Wentworth has been specially designed by Dunsley to meet

E.C. requirements for coal effect gas open fires. The Gas/Air

injection system has been completely re-designed. All the

important features are shown in the illustrations.

A summary of the new developments are as follows:

1. Primary Air and Gas injection system, goes through a stainless

steel burner. This improves the mixture, prevents burn back

and reduces combustion noise.

2. Secondary air inlets to further improve combustion and

flame effect.

3. A re-designed rear ceramic coal bed to give a more

concentrated heat effect.

4. Ceramic Fibre front coal assembly plus Ceramic Fibre standard

coals, to give a good flame effect.

5. Additional purpose prOVided ventilation should not normally

be necessary.

Result: a very good coal effect inset fire.

DESCRIPTION

The Wentworth has been designed and manufacturEd to incorporate

two important features:

SAFETY,AND THE NATURAL LOOK OF A SOUD FUEL OPEN-FIRE

The detailed development which has gone into the Wentworth unit

has created a gas fire which gives the authentic and pleasant look of

a real solid fuel open fire combined with the ease and the cleanliness

of gas.

With regards to safety, the gas supply is controlled by a gas controller

which has variable control on the gas supply. The main gas flow will

not operate until the pilot light is alight. The pilot light is linked with

a thermocouple safety device which stops the flow of gas should the

flame extinguish.

The gas control automatically closes down the gas flow if, for any

reason, the pilot light goes out. This eliminates any danger of

explosion or accidental ignition and makes the unit quite safe in use.

The pilot system is also linked to an oxygen depletion system which

prevents a dangerous situation occurring when the level of oxygen

to the fire is depleted due to a blocked flue or lack of primary air.

The spillage monitoring system shall not be adjusted by the installer

and shall not be put out of operation. When replacing the spillage

monitoring system, only original manufacturers parts shall be used.

Should the spillage monitoring system shut off the gas to the appliance

wait three minutes before attempting to re-light the appliance. If the

appliance continues to shut off the appliance should be serviced as

soon as possible by a competent person.

The Wentworth is so easy to light with the piezo ignition that the

pilot light does not require to be left on when the fire is not in use.

The pilot light is there for safety reasons and for ease of use when

turning off the fire for short periods.

THIS APPLIANCE SHOULD BE INSTALLED AND SERVICED BY A COMPETENT

PERSON IN ACCORDANCE WITH THE GAS SAFETY (INSTALLATION AND USE)

REGULATIONS 1994 AND IN ACCORDANCE WITH THE INSTALLATION

INSTRUCTIONS OR THE RULES IN FORCE. WE ALSO OPERATE A COMPLETE

RE-FURBISHMENT SERVICE AT A VERY REASONABLE COST. RETURN THE

COMBUSTION UNIT TO OUR WORKS, CARRIAGE PAID - WE DO THE REST.

58004

FIG. 4. FRONT

ELEVATION

FIG. 5. PLAN OF BURNER BAR

••

".e.".".0

••••••••

in position on burner bar. Push well back against fire bed retainer.

FIRE BED RETAINER

;

Q·······-ii··········cit····:····tl··········ci>··········Q

in position in front of the rear ceramic coai bed fitting inside the

Fire Bed Retainer.

NOTE: Tunnel at bottom running from front to rear to give

correct gas ignition

Required - 6 small coals,S medium coals, 7 angle coals. Coals vary a little

in size, but are easily selected.

Note coal position in FIG 6.C. and 6.D. See aiso letter chart below, which

gives positions of coals. Position coals on ceramic bed keeping the flame

holes reasonably clear.

Four small coals on back row

resting against convector back.

One small coal at each end of

third row.

M:- Five medium coals.

A:- SevenAngle coals.

S=Small Coals

M=Medium Coals

A=Angle Coals

) .'. ANGLE

, ~~. COAL

'\'

J

FRONT

The angle coals must

sit on the short base,

upright with the long

surface facing the

front.

1. The Wentworth should be serviced at least once per year by a

Corgi Registered gasengineer, to ensure many years of trouble

free operation.

2. The chimney or flue must· be swept before installation of t}";e

Wentworth.

3. The chimney or flue must be checked annually to ensure

continued clearance of combustion products and that there is

no excessive build up of soot. Any purpose-provided

ventilation should be checked periodically to ensure that it is

free from obstruction.

4. The Wentworth is designed such that it is very unlikely any

excessive soot will accumulate on any part of the fire.

S. If excessive deposits of soot are noted the fire should be left

to cool for three to four hours before any servicing work is

carried out. Any debris from the chimney or other sources

must be removed and any soot formed should be cleared.

Gloves should be worn. A soft brush should be used if it is

necessary to clean off any soot which may have formed on the

coals, front coal assembly, rear ceramic bed or burner. If any

large pieces of debris are found the chimney should be

inspected and the appliance fully serviced before further use,

to maintain good combustion. A vacuum cleaner may be used

after removal of the ceramic coals and supports. Ensure all gas

jet holes in the burner are clear. Do not change the layout or

alter the quantities of the coals used.

6. The rear ceramic bed is made of pure ceramic and will break if

dropped. If handled with reasonable care when placing in

position it will last indefi"itely. It will not break in use.

It is precision made and designed to be placed in the correct

position to givea good performance. It will not require replacing

unless it is broken. The black coat will not burn off, it can be

chipped off, if not handled with care when removing or replacing

for servicing. To meet this possibility we supply a small bottle

of black ceramic paint complete with touch up brush.

7. If for any reason any of the coals or fire bed are removed they

must be replaced carefully and correctly, see FIG 4, Sand

6A, B, C and D.

8. Rubbish or combustible material must not be thrown, or put,

onto the fuel bed. Do not disturb the fuel bed.

58004

Loading...

Loading...