Page 1

153-164 Bridge Street

Northampton

NN1 1QG

United Kingdom

www.dunlopge.co.uk ⁄ E. export@dunlopge.co.uk ⁄ T. +44 (0) 1604 828 540

The specications stated in this manual are not binding, due to the process of continuous improvement and

development we reserve the right to change any specication without prior notication.

Model No. DTSL3 MKII - Scissor Lift - Low Rise

Instruction Manual

Maintenance Manual

Spare Parts

(Rev. 04 - 10.03.2015)

Page 2

DTSL3MKII USER’S MANUAL

2

MANUFACTURER AND SERVICE AGENT

HYDRAULIC

HYDRAULIC

HYDRAULIC

HYDRAULIC AUTOMOBILE

AUTOMOBILE

AUTOMOBILE

AUTOMOBILE LIFT

LIFT

LIFT

LIFT

Model:

Serial No:

Year of Manufacture:

Manufacturer

Name:

Name:

Name:

Name: Dunlop Garage Equipment

Address:

Address:

Address:

Address: 153-165Bridge Street Northampton NN11QG,UK

Tel

Tel

Tel

Tel.

.

.

.:

:

:

: +44

+44

+44

+44 (0)1604

(0)1604

(0)1604

(0)1604 828

828

828

828 557

557

557

557

F

F

F

Fax

ax

ax

ax:

:

:

: +44

+44

+44

+44 (0)1604

(0)1604

(0)1604

(0)1604 609667

609667

609667

609667

Http://www.dunlopge.co

.uk

Htt

p://www.dunlopge.co.uk

Http://www.dunlopge.co.uk

Http://www.dunlopge.co.uk

AUTHORI

AUTHORI

AUTHORI

AUTHORIS

S

S

SED

ED

ED

ED SERVICE

SERVICE

SERVICE

SERVICE CENTRE:

CENTRE:

CENTRE:

CENTRE:

Day Month

Year

DTSL3 MKII

Page 3

DTSL3 MKII USER’S MANUAL

3

Contents

Contents

Contents

Contents

Contents

Manufacturer and service

Packing, transport and storage

Introduction

Description of the machine

Technical specifications

Safety

Installation

Adjustment

Operation

Maintenance and care

Troubleshooting

Accessory

Page 4

DTSL3 MKII USER’S MANUAL

4

PACKING,

PACKING,

PACKING,

PACKING, TRANSPORT

TRANSPORT

TRANSPORT

TRANSPORT AND

AND

AND

AND STORAGE

STORAGE

STORAGE

STORAGE

PACKING

PACKING

PACKING

PACKING (Picture 1)

Transport

Transport

Transport

Transport (Picture 2)

Packing

Packing

Packing

Packing can

can

can

can be

be

be

be lifted

lifted

lifted

lifted or

or

or

or moved

moved

moved

moved by

by

by

by lift

lift

lift

lift trucks,

trucks,

trucks,

trucks, cranes

cranes

cranes

cranes or

or

or

or bridge

bridge

bridge

bridge cranes.

cranes.

cranes.

cranes. In

In

In

In case

case

case

case of

of

of

of sli

nging,

slinging,

slinging,

slinging, a

a

a

a second

second

second

second person

person

person

person must

must

must

must

always

always

always

always take

take

take

take care

care

care

care of

of

of

of the

the

the

the load,

load,

load,

load, in

in

in

in order

order

order

order to

to

to

to avoid

avoid

avoid

avoid dangerous

dangerous

dangerous

dangerous oscillations.

oscillations.

oscillations.

oscillations.

During loading and unloading operation, goods must be handled by vehicles or ships.

At the arr

ival of the goods, verify that all items specified in the delivery notes are included.

If finding missing parts, possible defects or damage due to transport, one should examine damaged cartons according to ‘Packing

List’ to verify the condition of damaged goods and missing parts, also the person in charge or the carrier must be immediately

informed.

The machine is heavy goods! Don’t take manpower load and unload and transporting way into consideration, the safety of working

is important.

Furthermore, during loading and unloading operation goods must be handled as shown in the picture. (Picture 2)

Storage:

Storage:

Storage:

Storage:

-The machine equipment should be stocked in the warehouse, if stocked outside should do the disposal well of waterproof.

-Use box truck in the process of transport, use container storage when shipping.

-The control box should be placed perpendicularly during the transport; and prevent other goods from extrusion.

-The temperature for machine storage: -25ºC-- 55ºC

Picture 1

Picture 2

Picture 1

Page 5

DTSL3/FRMKIIUSER’SMANUAL

5

Manual

M anual

Manual

ManualIntroduction

I ntroduction

Introduction

Introduction

Thismanualhasbeenpreparedforworkshoppersonnelexpertintheuseoftheliftoperatorandtechniciansresponsibleforroutine

maintenancefitter.

Workersshouldreadthe‘Maintenance&UserManual’carefullybeforecarryingoutanyoperationwiththelift.Thismanual

containsimportantinformationregarding:

-Thepersonalsafetyofoperatorsandmaintenanceworkers.

-Liftsafety,

-Thesafetyofliftedvehicles

CONSERVING

CONSERVING

CONSERVING

CONSERVINGTHE

T HE

THE

THEMANUAL

M ANUAL

MANUAL

MANUAL

Thismanualisanintegralpartofthelift.

Themanualmustbekeptinthevicinityofthelift,sothattheoperatorandmaintenancestaffmustbeabletolocateandconsultthe

manualquicklyandatanytime.

AttentivelyreadingChapter3,whichcontainsimportantinformationandsafetywarning,isparticularlyrecommended.

The

The

The

Thelift

l ift

lift

liftis

i s

is

isdesigned

d esigned

designed

designedand

a nd

and

andmanufactured

m anufactured

manufactured

manufacturedaccording

a ccording

according

accordingto

t o

to

toEuropean

E uropean

European

EuropeanStandard

S tandard

Standard

Standard

Thelifting,transport,unpacking,assembly,installation,startingup,initialadjustmentandtesting,extraordinarymaintenance,repair,

overhauls,transportanddismantlingoftheliftmustbeperformedbyspecializedpersonnelfromthelicenseddealerauthorisedby

themanufacturer.

Themanufacturerdeclinesallresponsibilityforinjurytopersonsordamagetovehiclesorobjectswhenanyoftheabovementioned

operationshasbeenperformedbyunauthorisedpersonnelorwhentherackhasbeensubjecttoimproperuse.

Thismanualindicates:theoperativeandsafetyaspectsthatmayproveusefultotheoperatorandmaintenanceworker.Forbetter

understandingthestructureandoperationoftheliftandforbestuseofthesame,workersmustreadthe‘Maintenance&Use

Manual’carefullybeforecarryingoutit.

Inordertounderstandtheterminologyusedinthismanual,themaintenanceandrepairactivities,theabilitytointerpretcorrectlythe

drawingsanddescriptionscontainedinthemanualandbethecountryinwhichthemachinehasbeeninstalled.

Thesameappliestothemaintenanceandthemaintenancefittermustalsopossessspecificandspecializedknowledgebothin

mechanicalandengineeringfield.

�OPERATOR:personauthorisedtousethelift

�MAINTENANCEFITTER:personauthorisedforroutinemaintenanceofthelift.

Manufacturerownstherighttomakelittlechangeforthemanualowingtotheimprovementoftechnology.

Page 6

DTSL3/FRMKIIUSER’SMANUAL

6

Chapter

C hapter

Chapter

Chapter1

1

1

1DESCRIPTION

D ESCRIPTION

DESCRIPTION

DESCRIPTIONOF

O F

OF

OFTHE

T HE

THE

THEMACHINE

M ACHINE

MACHINE

MACHINE

Machine

Machine

Machine

MachineApplication:

A pplication:

Application:

Application:

Thisliftcanlifteachkindofvehiclewhoseweightislessthan3000kg,andi ssuitableforuseinvehicletests,maintenance,and

caringforautomobiles,whichisparticularlysuitableforuseinthebasementoronthefloor,withoutconstructionandhole.

Structure

Structure

Structure

StructureFeatures:

F eatures:

Features:

Features:

-Usehiddenandthinscissorstructure,dispensewithconstructionandgroundhole,theoccupationissmall.

-Independentcontrolbox,l ow-voltagecontrolling,goodsecurity.

-Hydrauliccubageandin-phasecylinder,thesynchronizationofplatform.

-Ownthesafetyequipmentofhydrauliclock.

-Ownprotectionofsafetyvalveandburst-proofequipmentforhydraulicfailureandoverloading.Sowhentheoilpipebursts,the

machinewillnotfallquickly.

-Ownmanualloweringoperationwhenthepoweriscut,andthemanualpumpispreparedbytheuser.

Equipment:

Equipment:

Equipment:

Equipment:

-Machinebasement(Thepositionandspaceofequipmentinstallation)

-Machineframe(Themainstructureofliftandinsuranceinstitution)

-Controlbox(Machine-controlledpart)

Basic

Basic

Basic

Basicstructure

s tructure

structure

structure

Themachinebasementismadeofcementandconcrete

Frame

Frame

Frame

Frame

Makeofsteelconnectingrod,mainliftingplatform,slidingboard,andhydraulicoiltank.

Control

Control

Control

Controlbox

b ox

box

box

Underthecontrolboxishydraulic

oil

tankandhydraulicpump,valveandothercontrolsystem.Onthecontrolboxiselectrical

system.

Scissorliftisdesignedandbuilttoliftallkindsofvehicles,allotheruseareunauthorised.Inparticular,theliftisnotsuitablefor

washingspraywork.Andnotliftthevehiclewhoseweightexceedsthemaximumweight.

Page 7

DTSL3/FRMKIIUSER’SMANUAL

7

Chapter

C hapter

Chapter

Chapter2

2

2

2SPECIFICATIO

S PECIFICATIO

SPECIFICATIO

SPECIFICATION

N

N

N

Main

Main

Main

Maintechnical

t echnical

technical

technicalparameter

p arameter

parameter

parameter

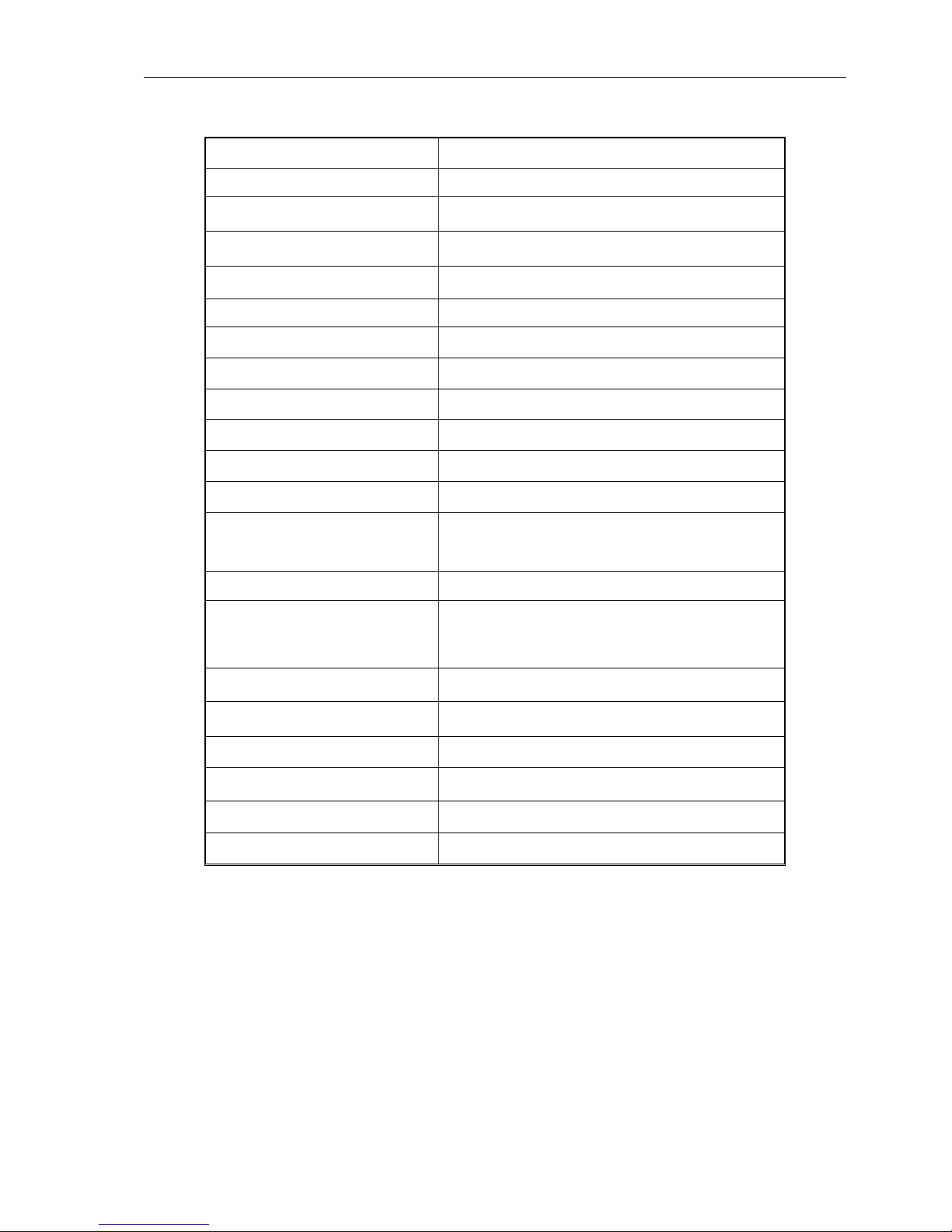

Item

I tem

Item

ItemParameter

P arameter

Parameter

Parameter

DriveElectricalhydraulic

Liftingweight3000kg

Liftingheight960mm

Platforminitialheight105mm

Platformlength1450mm

Platformwidth530mm

Liftingtime≤50s

Descenttime≤60s

Wholemachinelength2010mm

Wholemachinewidth1860mm

Weight600kg

Voltage

AC400Vor230V±5%50Hzor60HZ--specialordered)

Pleasecheckthenameplateoncontrolboxfordetail!

Motorpower2.2kw

Hydraulicoil12Lcorrespondstowearablehydraulicoil

(preparedbyuser)

Workingtemperature5-40℃

Workinghumidity30-95%

Noisylevel<76db

InstallationheightHeightabovesealevel≤1000M

Storagetemperature-25℃~55

℃

InstallationplaceIndoor

Table1

Page 8

DTSL3/FRMKIIUSER’SMANUAL

8

Chapter

C hapter

Chapter

Chapter2

2

2

2SPECIFICATIO

S PECIFICATIO

SPECIFICATIO

SPECIFICATION

N

N

N

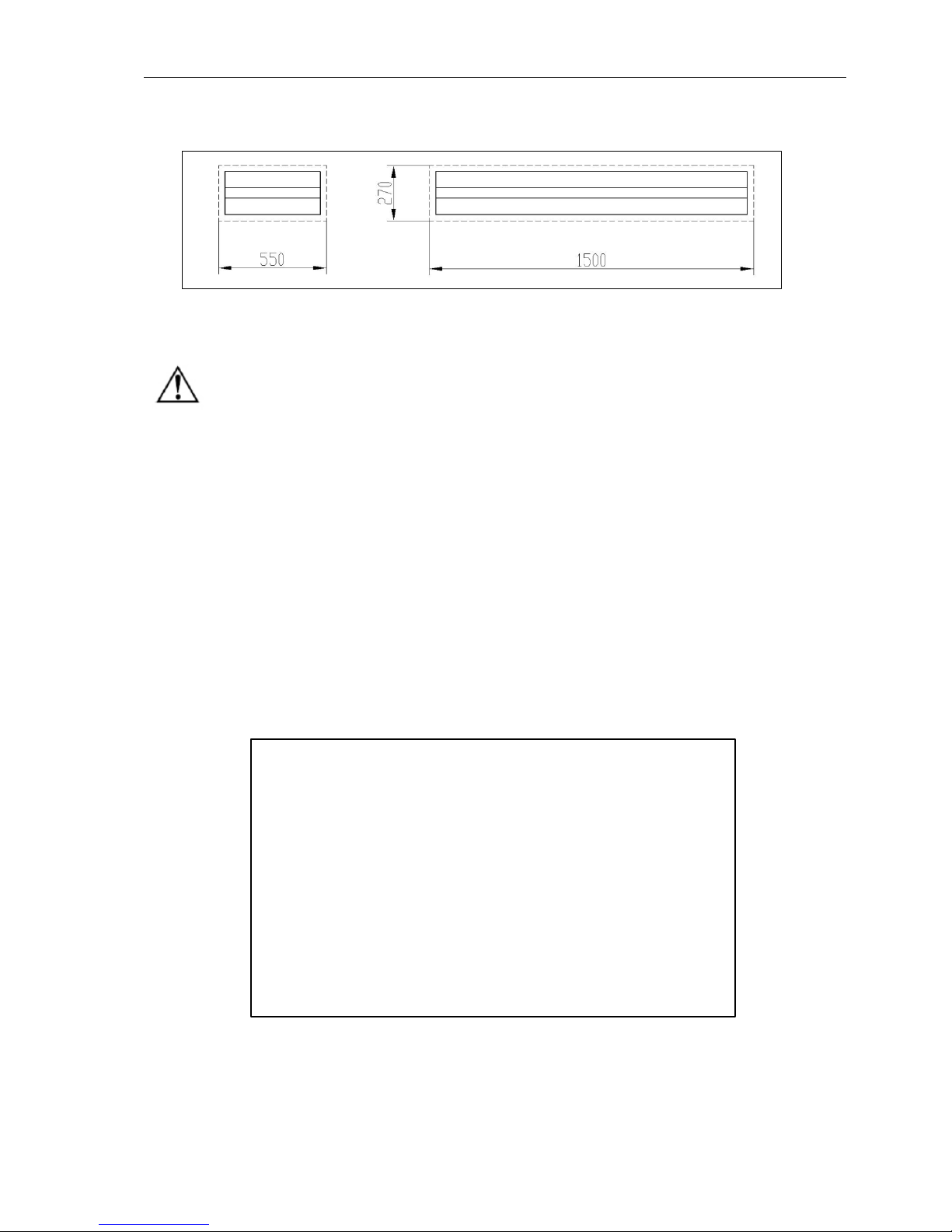

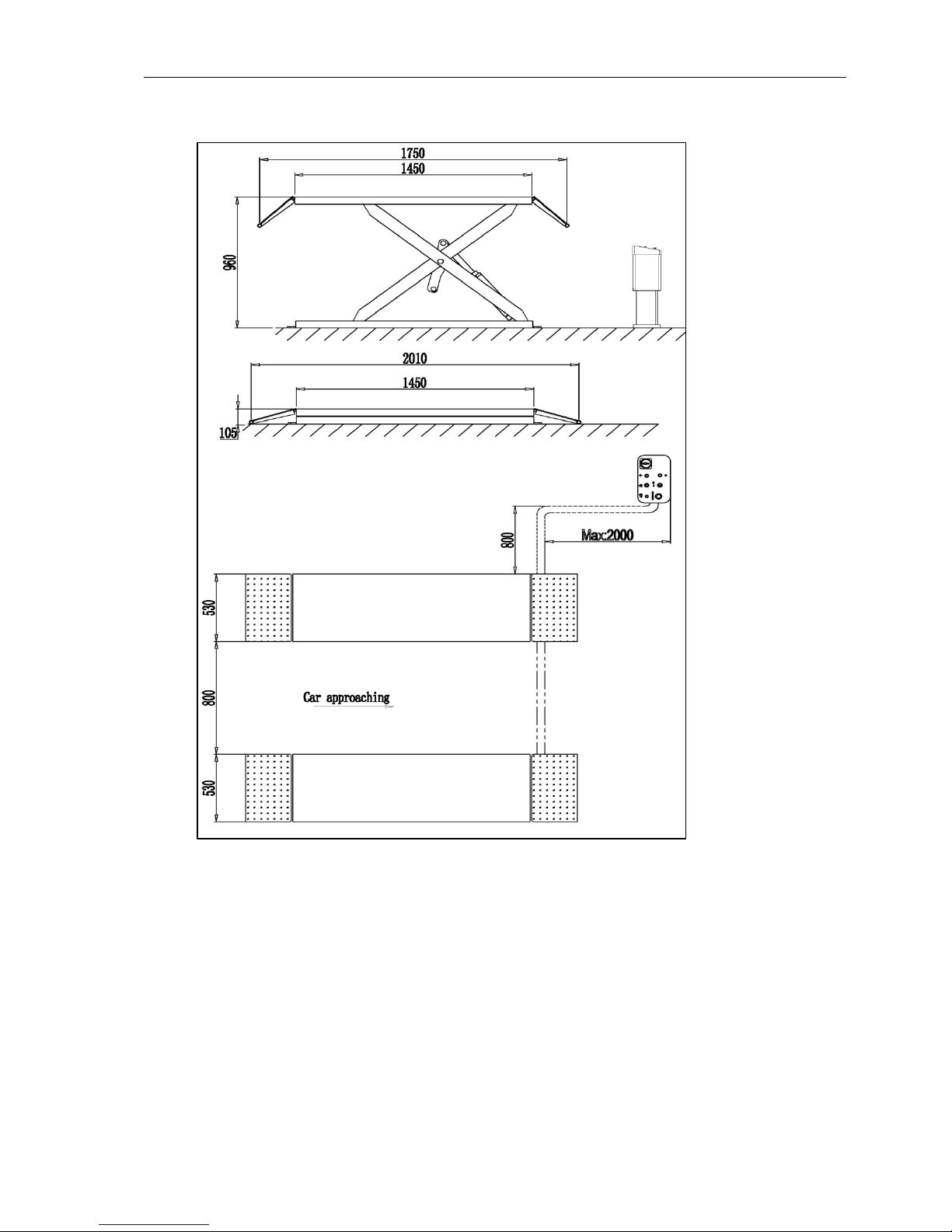

Lift

Lift

Lift

Liftdimension

d imension

dimension

dimensionpicture

p icture

picture

picture(Picture

P icture

Picture

Picture3)

3 )

3)

3):

:

:

:

Motor

Motor

Motor

MotorPump

P ump

Pump

Pump

Type……………………Y90L

Power……………2.2kw

V

oltage…………AC400or230V±5%

Current………400V:8A

…230V:15A

Frequency………50Hz(or60HZ----specialordered)

Poles…………………4

Speed………………1450rpm/min

Buildingshape…………B14

Insulationclass…………F

Type…………………………gearpump

Model…………………………P4.3

Flux…………………4.3cc/r

Jointtype………………………directjoint

Overfullvalve

Settingpressure………………220bar

Adjustableworkingpressure…………150~300bar

Picture3

Page 9

DTSL3/FRMKIIUSER’SMANUAL

9

Chapter

C hapter

Chapter

Chapter2

2

2

2SPECIFICATIO

S PECIFICATIO

SPECIFICATIO

SPECIFICATION

N

N

N

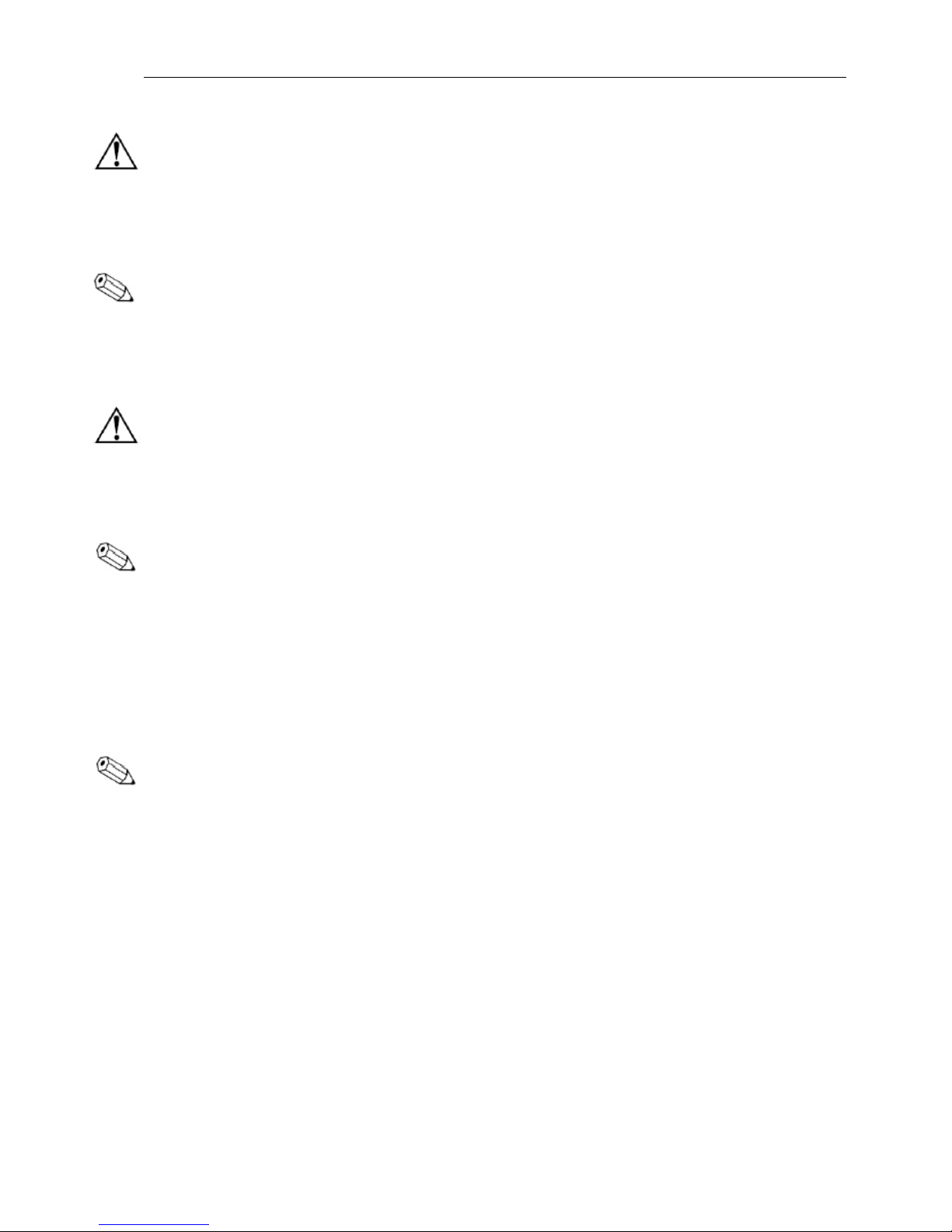

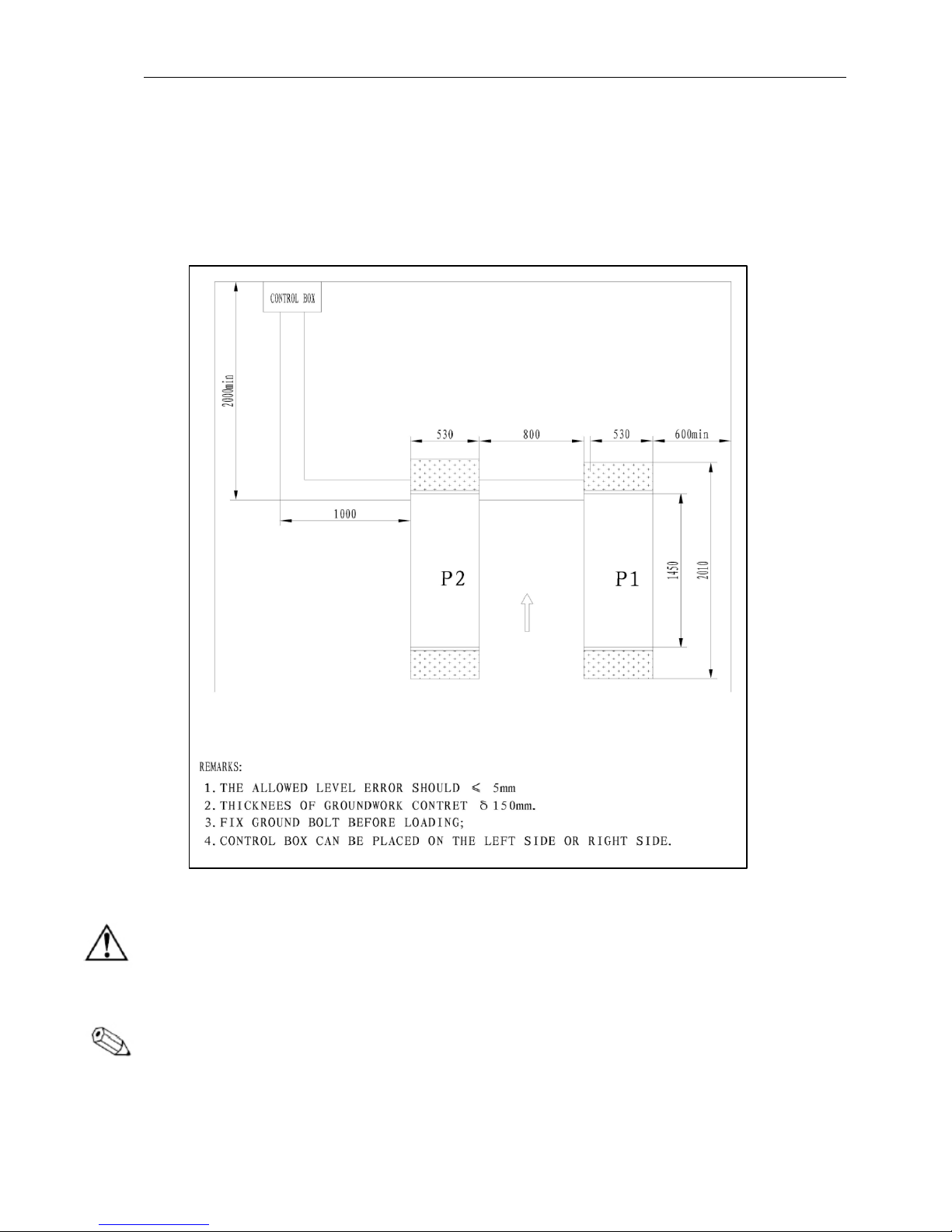

INSTALLATIONSCHEMEFORSCISSORLIFT

Note:ThefoundationoftheendoftheliftplatformP1,P2isthestructureofconcrete.Whenthethicknessofinsidelevelgroundis

lessthan150mm,theendofP1,P2shouldbeirrigatedtheacreage:2500×2500mmandthicknessofconcrete≥150mm。

Thebasicthicknessofconcreteandlevelingarekeys,shouldn’tegregiouslyexpecttheabilityofleveladjustmentofmachine-self.

TYPESOFVEHICLESSUITABLEFOR:

THELOWERPART SOFTHEVEHICLESU NDERBODYCOULDINTERFEREWITHSTRUCTURALPART SOFTHELIFT,

TAKEPARTICULARPARTSOFTHESPORTS-CAR.

Theliftwillalsohandlecustomizedornon-standardvehiclesprovidedtheyarewithinthemaximumspecifiedcarryingcapacity.

Alsothepersonnelsafetyzonemustbedefinedinrelationtovehiclewithunusualdimensions.

Supply

Supply

Supply

Supplyat

a t

at

atthe

t he

the

thesame

s ame

same

sametime

t ime

time

time

-Connecttothepowersupplyjackofcontrolbox(400Vor230V15A)

Requirements:

Requirements:

Requirements:

Requirements:

-Concretetype425#,theperiodofdesiccationis15days

-Cleanthebasiclayer,thicknessofconcrete≥150mm,thelevelingofwholelength≤5mm.

Picture4(Grounddrawing)

Page 10

DTSL3/FRMKIIUSER’SMANUAL

10

Chapter

C hapter

Chapter

Chapter3

3

3

3SAFETY

S AFETY

SAFETY

SAFETY

Readthischaptercarefullyandcompletelysinceimportantinformationforthesafetyoftheoperatororothersincaseofimproper

useoftheliftisincluded.

Inthefollowingtextthereareclearexplanationsregardingcertainsituationsofriskordangerthatmayariseduringtheoperationor

maintenanceofthelift,thesafetydeviceinstalledandthecorrectuseofsuchsystems,residualrisksandoperativeprocedurestouse

(generalspecificprecautionstoeliminatepotentialhazards).

Liftsaredesignedandbuilttoliftvehiclesandholdthemintheelevatedpositioni nanenclosedworkshop.Allotherusesofthelifts

areunauthorised.Inparticular,theliftsarenotsuitablefor:

-Washingspraywork;

-Creatingraisedplatformsforpersonnelorliftingpersonnel;

-Useasapressforcrushingpurposes;

-Useaselevator;

-Useasaliftjackforliftingvehiclebodiesorchangingwheels.

Themanufacturerisnotliableforanyinjurytopersonsordamagetovehiclesandotherpropertycausedbytheincorrectand

unauthoriseduseofthelifts.

Duringliftinganddescent,theoperatormustremaininthecontrolstationasthediagramsillustrated.

Asthediagramsillustrated,thepresenceofpersonsinsidethedangerzoneindicatedisstrictlyprohibited.Duringoperationspersons

areadmittedtotheareabeneaththevehicleonlywhenthevehicleisalreadyintheelevatedposition,whentheplatformsare

stationary,andwhenthemechanicalsafetydevicesarefirmlyengaged.

DONOTUSETHELIFTWITHOUTPROTECTIONDEVICESORWITHTHEPROTECTIONDEVICESINHIBITED.

FAILURETOCOMPLYWITHTHESEREGULATIONSCANCAUSESERIOUSINJURYTOPERSONS,ANDIRREPARABLE

DAMAGETOTHELIFTANDTHEVEHICLEBEINGLIFTED.

Picture5

Page 11

DTSL3/FRMKIIUSER’SMANUAL

11

Chapter

C hapter

Chapter

Chapter3

3

3

3SAFETY

S AFETY

SAFETY

SAFETY

GENERAL

GENERAL

GENERAL

GENERALPRECAUTIONS

P RECAUTIONS

PRECAUTIONS

PRECAUTIONS

Theoperatorandthemaintenancefitterarerequiredtoobservetheprescriptionsofsafetyregulationinforceinthecountryof

installationofthel ift.

Furthermore,theoperatorandmaintenancefittermust:

-Alwaysworkinthestationsspeci fiedandillustratedinthismanual;

-Neverremoveordeactivatetheguardsandmechanical,electrical,orothertypesofsafetydevices;

-Readthesafetynoticesplacedonthemachineandthesafetyinformationinthismanual.

Inthemanualallsafetynoticesareshownasfollows:

WARNING:

WARNING:

WARNING:

WARNING:indicatesfollowingoperationsthatareunsafeandcancauseminorinjurytopersonsanddamagethelift,thevehicleor

otherproperty.

CAUTION:

CAUTION:

CAUTION:

CAUTION:indicatespossibledangerthatcanresultinseriousinjurytopeopleanddamageproperty.

RISK

RISK

RISK

RISKOF

O F

OF

OFELECTRIC

E LECTRIC

ELECTRIC

ELECTRICSHOCK:

S HOCK:

SHOCK:

SHOCK:aspecificsafetynoticeplacedontheliftinareaswheretheriskofelectricshockisparticularlyhigh.

RISKANDPROTECTIONDEVICES

Weshallnowexaminetherisksthatoperatorsormaintenancefittersmaybeexposedtowhenthevehicleisstandingonthe

platformsintheraisedposition,togetherwiththevarioussafetyandprotectiondevicesadoptedbythemanufacturertoreduceall

suchhazardstotheminimum:

Foroptimalpersonalsafetyandsafetyofvehicles,observethefollowingregulations:

-Donotenterthedangerareaswhenvehiclesarebeinglifted.(Picture5)

-Makesurethevehicleispositionedcorrectly.(Picture6)

-Besuretoliftonlyapprovedvehicles,neverexceedthespecifiedcarryingcapacity,maximumheight,andprojection(vehiclelength

andwidth);

-Makesurethatthereisnopersonontheplatformsduringupanddownmovementsandduringstanding.

GENERALRISKSFORLIFTINGORDESCENT:

Thefollowingsafetyequipmentsareusedtoprotectoverloadingorthepossibilityofenginefailure.

Intheconditionofoverloading,theoverflowvalvewillopenanddirectlyreturnoiltotheoiltank.(SeePicture7)

Eachbottomofoilcylinderisequippedwithantiknockvalve.Whentheoilpipeisburstinthecircuitofhydraulicpressure,the

relevantantiknockwillworkandlimitthespeedinessofplatform.(SeePicture8)

Whenthe

oil

pipegetsbustorthere'ssomeobstacletostoponeoftheplatformsfromliftingorlowering,anotherplatformwillstop

atthesametimeduetothedeviceaspicture9.

Picture6

Picture9

Picture7

Picture8

Page 12

DTSL3/FRMKIIUSER’SMANUAL

12

Chapter

C hapter

Chapter

Chapter3

3

3

3SAFET

S AFET

SAFET

SAFETY

Y

Y

Y

RISKSFORPERSONNEL

Thisheadingillustratespotentialrisksfortheoperator,maintenancefitter,oranyotherpersonpresentintheareaaroundthelift,

resultfromincorrectuseofthelift.

RISKSFOREXTRUSION

Duringupanddownoperations,personnelleavethesaidareawithoutfollowingtheruleandinstruction.

Duringupanddownoperations,nopersonisadmittedtoworkbeneaththemovablepartsofthelift,shouldworkinthesafezone.

(Picture5).

RISKOFIMPACT(Picture10)

Beforetheoperatorbeginsupanddownmovements,makesurethattherearenopersonnelinsidethedangerzone.When,

duetooperationalreasons,theliftisstoppedatrelativelylowelevations(lowerthan1.75mabovetheground)personnel

mustbecarefultoavoidimpactwithpartsofthemachinenotmarkedwithspecialcolors.

RISKOFFALLINGOFF(PERSONNEL)

Duringupanddownoperations,personnelareprohibitedfromenteringtheplatformsandthevehicletoavoidfallingoff.

RISKOFFALLING(VEHICLE)(Picture11)

Thishazardmayariseinthecaseofi ncorrectpositioningofthevehicleontheplatforms,overweightofthevehicle,orinthecaseof

vehiclesofdimensionsthatarenotcompatiblewiththecapacityofthelift.

Whentheplatformisbeingtested,thevehicleenginecannotbeturnedon.

Thereisnothingshouldbeplacedonthelift-loweringareaandthemovablepartsofthelift.

RISKOFSLIPPING(Picture12)

Thefloorcausedbylubricantcontaminationofaroundthelift.Theareabeneathandimmediatelysurroundingtheliftandalsothe

platformsmustbekeptclean.Removeanyoilspillsimmediately.

RISKOFELECTRICSHOCK

Riskofelectricshockoftheareasofinsulatedinelectricequipmentswereshattered.

Donotusejetsofwater,steamsolventsorpaintnexttothelift,andtakespecialcaretokeepsuchsubstancesclearoftheelectrical

controlpanel.

RISKSRELATEDTOINAPPROPRIATELIGHTING

Theoperatorandthemaintenancefittermustbeabletoassurethatalltheareasoftheliftareproperlyanduniformlyilluminate

compliancewiththelawsinforceintheplaceofinstallation.

Duringupanddownoperations,theoperatorshouldcontinuallyobservetheliftandcanoperateitonlyinthepositionofoperator .

Whenliftingandloweringthevehicle,thecushionneedsbeingputinthebottomofchassis.

Thehandlingofsafetydevicesisstrictlyforbidden.Neverexceedthemaximumcarryingcapacityofthelift,makesurethevehicles

tobeliftedhavenoload.

Itisthereforeessentialtoadherescrupulouslytoallregulationsregardinguse,maintenanceandsafetycontainedinthismanual.

Picture10 Picture11

Page 13

DTSL3/FRMKIIUSER’SMANUAL

13

Chapter

C hapter

Chapter

Chapter4

4

4

4INSTALLATION

I NSTALLAT ION

INSTALLATION

INSTALLATION

SKILLED

SKILLED

SKILLED

SKILLEDAND

A ND

AND

ANDAUTHORISED

A UTHORISED

AUTHORISED

AUTHORISEDPERSONNEL

P ERSONNEL

PERSONNEL

PERSONNELONLY

O NLY

ONLY

ONLYSHOULD

S HOULD

SHOULD

SHOULDBE

B E

BE

BEALLOWED

A LLOWED

ALLOWED

ALLOWEDTO

T O

TO

TOPERFORM

P ERFORM

PERFORM

PERFORMTHESE

T HESE

THESE

THESEOPERATIONS,

O PERATIONS,

OPERATIONS,

OPERATIONS,

FOLLOW

FOLLOW

FOLLOW

FOLLOWALL

A LL

ALL

ALLINSTRUCTIONS

I NSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONSSHOWN

S HOWN

SHOWN

SHOWNBELOW

B ELOW

BELOW

BELOWCAREFULLY ,

C AREFULLY ,

CAREFULLY ,

CAREFULLY ,IN

I N

IN

INORDER

O RDER

ORDER

ORDERTO

T O

TO

TOPREVENT

P REVENT

PREVENT

PREVENTPOSSIBLE

P OSSIBLE

POSSIBLE

POSSIBLEDAMAGE

D AMAGE

DAMAGE

DAMAGETO

T O

TO

TO

THE

THE

THE

THECAR

C AR

CAR

CARLIFT

L IFT

LIFT

LIFTOR

O R

OR

ORRISK

R ISK

RISK

RISKOF

O F

OF

OFINJURY

I NJURY

INJURY

INJURYTO

T O

TO

TOPEOPLE.

P EOPLE.

PEOPLE.

PEOPLE.

Skilledtechniciansonlyappointedbythesamemanufacturerorbyauthoriseddealers,areallowedtoinstallthecarlift.

INSTALLATIONREQUIREMENTS

�Thecarliftmustbeinstalledaccordingtothespecifiedsafetydistancesfromwalls,poleandwhatotherequipmentsstated.

(Picture12)

�Thespecifiedsafetydistancesfromwallsmustbe1000mmatleast,takingintoconsiderationthenecessaryspacetowork

easily.Becausespaceforthecontrolsiteandforpossiblerunwaysincaseofemergencyisalsonecessary.

�Theroommustbepreviouslyarrangedforthepowersupplyandpneumaticfeedofthecarlift.

�Theroommustbe4000mminheight,atleast.

�Thecarliftcanbeplacedonanyfloor,aslongasitisperfectlylevelandsufficientlyresistant.(≥250kg/cm²,thethicknessof

concrete≥150mm)

Allpartsofthemachinemustbeuniformlylitwithsufficientlighttomakesurethattheadjustmentandmaintenanceoperationscan

beperformedsafely,andwithoutreflectedlight,glarethatcouldgiverisetoeyefatigue.

�Theintegralityofarrivedgoodsshouldbecheckedbeforetheliftisinstalled.

�Movingandinstallingliftshouldfollowtheprocessasthepictureinstructs.

The

The

The

Thetransport

t ransport

transport

transportand

a nd

and

andstorage

s torage

storage

storageof

o f

of

ofmachine

m achine

machine

machinerefers

r efers

refers

refersto

t o

to

to“

“

“

“TRANSPORT

T RANSPORT

TRANSPORT

TRANSPORTAND

A ND

AND

ANDSTORAGE

S TORAGE

STORAGE

STORAGE”

”

”

”on

o n

on

onpage

p age

page

page4.

4 .

4.

4.

Platform

Platform

Platform

PlatformInstallation:

I nstallation:

Installation:

Installation:

-Placetwoplatformsonthepositionofthelocation.

-Thebottomofoilcylinderislocatedi nthefrontageofmachine(thedirectionofgettingonthevehicle)

-Useforkcarorotherliftingequipmentstolifttheplatform(Picture13)andmakesurethatthesafetyequipmentofmachineisboth

turnedonandlocked.

To

avoidfailureofmachinesafetyequipment,caninsertawoodinthemiddlepartofjoint-pole.

Prohibitworkingbeneaththeliftwhenhydraulicsystemisnotcompletelyequippedwithhydraulicoilandtaketheactionofupand

downoperations.

-Whenmovingtheliftplatform,adjustthespacebetweentwoplatforms;makesurethatthetwoplatformsareparallel.

LINE

LINE

LINE

LINECONNECTION

C ONNECTION

CONNECTION

CONNECTION

Connecttheelectricalandoillineaccordingto‘theelectric aldiagram’and‘oilpipeconnectiondiagram’.

Intheprocessofconnectingoilpipes,payparticularlyattentiontotheprotectionofpipetie-intopreventabnormalthingfrom

enteringoilloop,thendamaginghydraulicsystem.

Picture13

Picture12

Page 14

DTSL3/FRMKIIUSER’SMANUAL

14

Chapter

C hapter

Chapter

Chapter4

4

4

4INSTALLATION

I NSTALLAT ION

INSTALLATION

INSTALLATION

ELECTRIC

ELECTRIC

ELECTRIC

ELECTRICCIRCUIT

C IRCUIT

CIRCUIT

CIRCUITCONNECTION:

C ONNECTION:

CONNECTION:

CONNECTION:

Followthestatedline-pathwayandline-numberofthe‘electricaldiagram’toconnectelectriccircuit.

Onlyskilledpersonisallowedtoperformtheoperations.

-Openthecontrolboxfrontcover.

-C

C

C

Connection

onnection

onnection

onnectionof

o f

of

ofpower

p ower

power

powersupply:

s upply:

supply:

supply:the400Vthree-phaseandfive-lineconnectionwires(3×2.5mm2+2×1.5mm

2

cablewire)for

powersupplyareconnectedtocontrolboxL1,L2,L3,Nandentering-wireterminal.ThePEgroundwireisconnectedunderthebolt

markedgroundfirstly(Picture15)andthenconnectedundertheboltmarkedgroundoftwoplatforms.

-Iftheliftisoperatedat230Vthree-phase,changetheconnectiononthetransformerandmotor.(Picture15)

-

-

-

-C

C

C

Connection

onnection

onnection

onnectionof

o f

of

ofup

u p

up

uplimit

l imit

limit

limitswitch

s witch

switch

switch:uplimitswitchislabeled102#and100#,toconnectthemtothesameno.inthecontrolbox.

-

-

-

-C

C

C

Connection

onnection

onnection

onnectionof

o f

of

oflower

l ower

lower

lowerlimit

l imit

limit

limitswitch

s witch

switch

switch:lowerlimitswitchislabeled105#,107#and109#,toconnectthemtothesameno.insidethe

controlbox.

Oil

Oil

Oil

OilPIPE

P IPE

PIPE

PIPECONNECTION:

C ONNECTION:

CONNECTION:

CONNECTION:

Follow“oilpipediagram“toconnecttheoilpipes.

Onlyskilledandauthorisedpersonisallowedtoperformtheoperations.Andpayparticularlyattentiontotheprotectionofoil

pipefitting.Referto“oilpipediagram

:

-Whenconnectingoilpipes,payattentiontotheprotectionofoilpipetie-intopreventimpuritiesfromenteringhydrauliccircuit.

-Whenconnecttheoilpipes,becarefulnottomistakeeachoilpipenumber.

-Duringthestandardinstallation,controlboxisinthenearsideofvehicle-enteringdirection.Ifplacedontherightshouldadjust

relevantoilpipe.

Picture20

Picture17uplimitswitch

Picture18lowerlimitswitch

Picture19positiontofixthelimitswitch

Picture14 Picture15

Picture16

Page 15

DTSL3/FRMKIIUSER’SMANUAL

15

Chapter

C hapter

Chapter

Chapter5

5

5

5ADJUSTMENT

A DJUSTMENT

ADJUSTMENT

ADJUSTMENT

Add

Add

Add

Addoil

o il

oil

oiland

a nd

and

andcheck

c heck

check

checkthe

t he

the

theorder

o rder

order

orderof

o f

of

ofphase

p hase

phase

phase.

AfterinstallingliftasPicture4requiredandconnectinghydrauliccircuitandelectriccircuit,operateitasfollowing:

-openthehydraulic

oil

tank,add18Lofhydraulicoilintotheoiltank,thehydraulic

oil

isprovidedbytheuser.

Makesurethecleanofhydraulicoil,preventanyimpurityintotheoilline,leadthedigestofthe

oil

lineandnoworkingofthe

solenoidvalve.

-Turnon"MAIN

MAIN

MAIN

MAINSWITCH

S WITCH

SWITCH

SWITCH"toturnonpower,clickingthe‘UP’button,checkwhetherthemotorturnsclockwise(looking

downward),ifnotturnoff"MAINSWITCH",thentochangethephaseofthemotor.

When

When

When

Whenturn

t urn

turn

turnon

o n

on

onpower,

p ower,

power,

power,t

t

t

there

h ere

here

herewill

w ill

will

willbe

b e

be

behigh

h igh

high

highvoltage

v oltage

voltage

voltageexist

e xist

exist

existin

i n

in

inthe

t he

the

thecontrol

c ontrol

control

controlbox,

b ox,

box,

box,only

o nly

only

onlyauthori

a uthori

authori

authoris

s

s

sed

e d

ed

edperson

p erson

person

personcan

c an

can

canoperate

o perate

operate

operateit.

i t.

it.

it.

Oil

Oil

Oil

Oilmake-up

m ake-up

make-up

make-upadjustment

a djustment

adjustment

adjustment

1Press‘UP

UP

UP

UP’button,andthenmotorstartstolifttwoplatformstogouptotheapex.

2Openthecontrolboxofdoor,andpress“UP

U P

UP

UP”buttonand“SB4"aspicture21forsomeminutes

3Press‘DOW N

DOWN

DOWN

DOWN’buttontoletthetwoplatformsgodownuntiltheplatformsstopatthelowerlimitswitchactionposition,andthen

press"SECOND

SECOND

SECOND

SECONDDOWN

D OWN

DOWN

DOWN"buttontogether,andtheplatformswillgodowntothelowestposition.

4Theoilmake-upadjustmentprocessisover.

GROUND

GROUND

GROUND

GROUNDBOLTS

B OLTS

BOLTS

BOLTSINSTALLATION:

I NSTALLA TION:

INSTALLA TION:

INSTALLA TION:

Thegroundboltsinstallationmuststartaftertheexpirydateonthemaintenanceofconcert,otherwise,itwillaffectthequalityof

solidity.

-AdjusttheparalleloftheplatformandthedistanceoftwoplatformsasPicture4requires.

-Fixtheanchorboltswithapercussionelectricdrill(percussiondrillbitisof16),drillto120mmholeandcleanthehole.

(Picture22)

-UselighthammertoinstallthegroundHoltsintothehole(neednotinstallthe

Centralexpandednailofgroundbolts,installitafterleveladjustment.)

Picture22

Picture20adjustlevelbutton(SB4)

Page 16

DTSL3/FRMKIIUSER’SMANUAL

16

Chapter

C hapter

Chapter

Chapter5

5

5

5ADJUSTMENT

A DJUSTMENT

ADJUSTMENT

ADJUSTMENT

Level

Level

Level

Leveladjustment

a djustment

adjustment

adjustment

:

-Byusingalevelbarandthehorizontalpipeandadjustingtheadjustmentscrewsattowsidesofthebaseplate.

-Ifplatformunevennessisresultedfrombasicunevenness,useironblocktofillupthelowplace.

-Afterleveladjustment,insertthecentralexpandednailofgroundboltsanduseheavyhammertohammer

it.

-Screwdownthegroundboltscap.

Whentheexpirydateonthemaintenanceofconcretehasn’tarrived,onecannotinstallthecentralexpandednailofgroundbolts.

Thegapbetweenthebaseplateandgroundafteradjustmentmustbefilledwithironplateorconcrete.

No

No

No

Noload

l oad

load

loadof

o f

of

ofmain

m ain

main

mainmachine

m achine

machine

machinetest:

t est:

test:

test:

-TurnonthepowerQSof"MAINSWITCH".

-Press“UP”button,payattentiontothesynchronizationandplacidityofthelifting.

-Checkandensuretherearenoleakageontheoilline.

Whentestingthel ift,nopersonorotherthingsareallowedtostandorbeputnearthetwosidesandbeneaththemachine.Ifany

abnormalisfound,pressbutton“EMERGENCY

E MERGENCY

EMERGENCY

EMERGENCYSTOP

S TOP

STOP

STOP”tostopitimmediately.Afterclearingobstacles,dothetestagain.

Load

Load

Load

Loadof

o f

of

ofmachine

m achine

machine

machinetest:

t est:

test:

test:

-Drivethevehiclewhoseweightdoesn’texceedmaximumliftweighttotheplatform,andthenthedriverleaveit.

-Puttheliftrubbercushionontheplatform.

-Press‘UP’button,lifttheplatformandpayattentiontothesynchronizationandplacidityofthelifting.

-Checkandensurenooill eakage.

Whenbeginningloadofmachinetest,nopersonorotherthingsareallowedtostandorbeputnearthetwosidesandbeneaththe

machine.

Testvehiclewhoseweightdoesn’texceedmaximumliftweight.

Checkandensurethere'snoleakageonoilline.Ifanyabnormalisfound,pressbutton"EMERGENCY

E MERGENCY

EMERGENCY

EMERGENCYSTOP

S TOP

STOP

STOP"tostop

it

immediately.Afterclearingobstacles,dothetestagain.

Picture23

Page 17

DTSL3/FRMKIIUSER’SMANUAL

17

Chapter

C hapter

Chapter

Chapter6

6

6

6OPERATION

O PERATION

OPERATION

OPERATION

Only

Only

Only

Onlyskilled

s killed

skilled

skilledand

a nd

and

andhaving

h aving

having

havingbeen

b een

been

beentrained

t rained

trained

trainedpersonnel

p ersonnel

personnel

personnelis

i s

is

isallowed

a llowed

allowed

allowedto

t o

to

toperform

p erform

perform

performthe

t he

the

theoperations.

o perations.

operations.

operations.Check

C heck

Check

Checkproceedings

p roceedings

proceedings

proceedingsas

a s

as

asfollowing.

f ollowing.

following.

following.

Operation

Operation

Operation

OperationNotices:

N otices:

Notices:

Notices:

-Clearobstaclesaroundtheliftbeforeoperation.

-Duringliftingorlowering,nopersonisallowedtostandnearthetwosidesandbeneaththemachine,andnopersonisallowedon

thetwoplatforms.

-Avoidtoliftingoverweightvehiclesorothergoods.

-Whenl iftingvehicle,thechassisofthevehicleshouldbefilledupwithrubbercushion.

-Payattentiontothesynchronizationoftheliftingandlowering.Ifanyabnormalisfound,stopthemachinetimely,checkand

removethetrouble.

-Whentheequipmentisnotusedforalongtimeorovernight,themachineshouldbeloweredtothelowestpositiononground,and

removevehicle,andcutoffpowersupply.

Instructions

Instructions

Instructions

Instructionson

o n

on

onelectric

e lectric

electric

electricoperation:

o peration:

operation:

operation:(see

( see

(see

(seethe

t he

the

theoperation

o peration

operation

operationpanel

p anel

panel

panelpicture

p icture

picture

picture24

2 4

24

24)

)

)

)

LIFTING:

LIFTING:

LIFTING:

LIFTING:

-Press‘UP

U P

UP

UP’button,theplatformsgoup.Andtheplatformswillstopliftingwhenreachtheuplimitswitch.

-Release‘UP

U P

UP

UP’button,theoilpumpwillstopimmediately.Andtheplatformsstopslifting.

LOWERING

LOWERING

LOWERING

LOWERING:

:

:

:

-Press"DOWN

D OWN

DOWN

DOWN"button,theplatformsdescend.

-Andtheplatformswillstoploweringautomaticallyaround200~300mmheightwhenreachthelowerlimitswitch.Release

"DOWN

DOWN

DOWN

DOWN"button,thenpress"SECOND

S ECOND

SECOND

SECONDDOWN

D OWN

DOWN

DOWN"buttontoletplatformsgodowntothelowestposition.

EMERGENCY

EMERGENCY

EMERGENCY

EMERGENCYSTOP:

S TOP:

STOP:

STOP:

Whenthemachinehasabnormalduringcarmaintenance,press"EMERGENCY

E MERGENCY

EMERGENCY

EMERGENCYSTOP

S TOP

STOP

STOP"buttonandlock,tocutoffalltheoperation

circuit,sootheroperationcannotbework.

NOT

NOT

NOT

NOTIN-PHASE

I N-PHASE

IN-PHASE

IN-PHASESTOP

S TOP

STOP

STOPMACHINE:

M ACHINE:

MACHINE:

MACHINE:

Whentwoplatformsarenotatthesameheightduringliftingandloweringoperations,photo-electricitylevelingequipmentwillstop

workingimmediately.Accordingtothefollowingprocesstoadjusttheplatformlevel,onlyaftertwoplatformsareatthesameheight

canputthemintouse.

Oil

Oil

Oil

Oilmake-up

m ake-up

make-up

make-up“

“

“

“adjust

a djust

adjust

adjust”

”

”

”operation

o peration

operation

operation(normal

( normal

(normal

(normalservice

s ervice

service

serviceperiod):

p eriod):

period):

period):

Aftercompletionofmachineinstallationandadjustmentintheapplicationprocess,therightplatform

islowerthantheleftonebecauseofairintheoilcylindernotbeingexcludedcompletelynormal

loosesorleakageofthehydraulicoil.

Whenconductingoilmake-upoperation,theplatformsmustnot load.

Adjustmentprocessisasapproach‘5’and‘6’of‘Oilmake-upadjustment’.

EMERGENCY

EMERGENCY

EMERGENCY

EMERGENCYMANUAL

M ANUAL

MANUAL

MANUALOPERATION

O PERATION

OPERATION

OPERATIONFOR

F OR

FOR

FORLOWERING

L OWERING

LOWERING

LOWERING(POWER

( POWER

(POWER

(POWERFAILURE):

F AILURE):

FAILURE):

FAILURE):

Whenloweringthroughmanualoperation,shouldobservetheconditionofplatformat

Anytimebecausethereisvehicleontheplatforms.Ifthereissomethingabnormal,screw

Picture

Picture

Picture

Picture24

2 4

24

24(control

( control

(control

(controlpanel)

p anel)

panel)

panel)

Picture25

Page 18

DTSL3/FRMKIIUSER’SMANUAL

18

Chapter

C hapter

Chapter

Chapter6

6

6

6OPERATION

O PERATION

OPERATION

OPERATION

Downoilloopvalveimmediately.

Theprocessofmanualoperation:

-Switchoffthepowerbutton(avoidabruptlyincomingelectricity).

Openthesmallroundcoverofcontrolboxtofindtheel ectromagneticvalveAforlowering.

-Loosenmanualoilloopstudattheendofloweringelectromagneticdescentvalvecore,

Andthentheplatformsbegintodescend.

-Afterthemachinehasbeendescended,screwdowndescentvalve’sstudtimely.Theprocessofmanualloweringcomestotheend.

Chapter

Chapter

Chapter

Chapter7

7

7

7MAINTENANCE

M AINTENANCE

MAINTENANCE

MAINTENANCEAND

A ND

AND

ANDC ARE

C ARE

CARE

CARE

Skilled

killed

killed

killedpersonnel

p ersonnel

personnel

personnelonly

o nly

only

onlyare

a re

are

areallowed

a llowed

allowed

allowedto

t o

to

toperform

p erform

perform

performthe

t he

the

theoperations.

o perations.

operations.

operations.

-Allbearingsandhingesonthismachinemustbelubricatedonceaweekbyusinganoilier.

-Theupperandlowerslidingblocksandothermovablepartsmustbelubricatedonceomonth.

-Thehydraulicoilmustbereplacedonetimeeachyear.Theoillevelshoul dalwaysbekeptatupperlimitposition.

Themachineshouldbelowertothelowestpositionwhenreplacehydraulicoil,thenlettheoldoilout,andshouldbefilteringthe

hydraulicoil.

-Eachteamcheckstheagilityandreliabilityofpneumaticsafetyequipment.

Chapter

C hapter

Chapter

Chapter8

8

8

8TROUBLESHOOTING

T ROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

Skilledpersonnelonlyareallowedtoperformtheoperations.

Troubleshooting

Troubleshooting

Troubleshooting

Troubleshooting

Symptom

Symptom

Symptom

SymptomCause

C ause

Cause

CauseTroubleshooting

T roubleshooting

Troubleshooting

Troubleshooting

Themotordoesnot

runinlifting

operation.

①Connectionofpowersupplywiresis

notcorrect.

Checkandcorrectwireconnection

②TheACcontactorinthecircuitof

themotordoesnotpickup.

Ifthemotoroperateswhenforcingthecontactordownwithan

isolationrod,checkthecontrolcircuit.Ifthevoltageattwoendsof

thecontactorcoilisnormal,replacethecontactor.

③

Thelimitswitchisnotclosed.Checkthelimitswitch,wiresandadjustorreplacethelimitswitch.

Inliftingoperation,

themotorruns,but

thereisnolifting

movement

①Themotorturnsreverse.Changethephasesofthepowersupplywires.

②Liftingwithlightloadisnormalbut

noliftingwithheavyload.

Thesetsafepressureoftheover-flowvalvemaybeincreasedby

turningthesetknobrightwardslightly.

Thespooloftheloweringsolenoidvalveisstuckbydirt.Cleanthe

spool.

③Theamountofhydraulicoilisnot

enough.

Addhydraulicoil.

④Thedescentvalveisenergizedbut

doesnotwork.

Checktheplugandcoilofthedescentvalveandchecktherightturn

tightnessofitsendcoppernutandsoon.

⑤

The“antiknockvalve”isblocked.

Removethe“antiknockvalve”fromtheoilsupplyholeatthe

bottomoftheoilcylinder,andcleanthe“antiknockvalve”.

Themachinelowers

extremelyslowly

undernormalloads.

①Thehydraulicoilhastoohigh

viscosityorfrozen,deteriorated(in

Winter).

Replacewithhydraulicoilinaccordancewiththeinstructionbook.

②The“antiknockvalve”for

preventing

oil

pipeburstisblocked.

Removethe“antiknockvalve”fromtheoilsupplyholeatthe

bottomoftheoilcylinder,andcleanthe“antiknockvalve”.

Therightandleft

platformsarenot

synchronousandnot

inthesameheight.

①

The

air

intheoilcylinderisnotvent

completely.

Referto“Ⅶ.OilMake-up‘Adjust’Operation”.

②Oilleakageon

oil

pipeoratits

connections.

Tightenoilpipeconnectionsorreplace

oil

sealsandthenmake-up

oilandadjustlevelness.

Noisyliftingand

lowering.

①Lubricationisnotenough.

Lubricateallhingesandmotionparts(includingpistonrod)with

machineoil

②Thebaseorthemachineistwisted.Adjustagainthelevelnessofthemachine,andfillorpadthebase.

Table2

Page 19

DTSL3/FRMKIIUSER’SMANUAL

19

ACCESSORY

A CCESSORY

ACCESSORY

ACCESSORY

Hydraulic

Hydraulic

Hydraulic

Hydraulicpressure

p ressure

pressure

pressureschematic

s chematic

schematic

schematicdiagram

d iagram

diagram

diagram:

:

:

:

Page 20

DTSL3/FRMKIIUSER’SMANUAL

20

ACCESSORY

A CCESSORY

ACCESSORY

ACCESSORY

Oil

Oil

Oil

Oilpipe

p ipe

pipe

pipeconnection

c onnection

connection

connectiondiagram

d iagram

diagram

diagram

:

Page 21

GC-3.0SSV(without

GC-3.0SSV(without

extension

extension

extension

extension ramp )

ramp)

ramp)

ramp)

EXPLODED

EXPLODED

EXPLODED

EXPLODED DRAWING

DRAWING

DRAWING

DRAWING

A---------------PLATFORM

A---------------PLATFORM

A---------------PLATFORM

A---------------PLATFORM

DTSL3 MKII

Page 22

B---------------CYLINDER

B---------------CYLINDER

B---------------CYLINDER

B---------------CYLINDER

See

See

See

Seeabove

a bove

above

abovepicture!

p icture!

picture!

picture!

Page 23

C---------------CONTROL

C---------------CONTROL

C---------------CONTROL

C---------------CONTROLBOX

B OX

BOX

BOX

Page 24

D---------------PUMP

D---------------PUMP

D---------------PUMP

D---------------PUMP

Page 25

GC-

DTSL3 MKII

(without extension ramp)

Parts list

2012.10.17

A

A

A

A-

-

-

--

-

-

--

-

-

--

-

-

--

-

-

-PLATFORM

PLATFORM

PLATFORM

PLATFORM

&

&

&

&

B

B

B

B-

-

-

--

-

-

--

-

-

--

-

-

--

-

-

-CYLINDER

CYLINDER

CYLINDER

CYLINDER

No.

Description

Description

Description

Description GC

GC

GC

GC

parts

parts

parts

parts

CODE

CODE

CODE

CODE

QTY

(pcs)

Unit

Unit

Unit

Unit

price

price

price

price

(USD)

(USD)

(USD)

(USD)

1 Base frame SSA0100 2 125

2 Bolt LS-GS-M16140 8 4

3 Bush ZC-AT-2520 4 3

4 Down support stand SSA0107 4 9

5 Bolt LS-SCS-M1050 8 3

6 Snap ring PD-CR-30 8 1

7 Axle SLB1200 2 5

8 Slide block SSB0500 8 9

9 Bolt LD-PCS-M816 8 1

10 Axle block SLB0600 4 1

11 Axle SSB0400 2 6

12 Axle SSB0900 2 6

13 Roller SSB1100 4 4

14 Small lock device SSB0700 2 13

15 Bush ZC-AT-3030 4 3

16 Bush ZC-AT-3040 4 3

18 Snap ring PD-CR-32 4 1

19 Axle SLB1300 2 6

20 Alignment knot SSE0200 2 4

21 Outer scissor SSB0100L-30SLV

1 14

5

21a Outer scissor SSB0100R-30SLV 1 145

22 Inner scissor SSB0200L-30SLV 1 155

22a Inner scissor SSB0200R-30SLV 1 155

23 Snap ring PD-CR-20 4 1

24 Axle SSB0600 4 4

25 Bush ZC-AT-2020 4 3

28 Snap ring PD-CR-16 16 1

29 Axle SSC0400 4 3

30 Snap ring PD-CR-12 8 1

31 Axle SSC0300 4 3

32 Roller SLC1200 8 5

33 Ramp(RR/FL) SSC0200-30SS 2 29

34 Top plate SSC0100-30SS 2 108

35 Ramp(RL/FR) SSC0200-30SS 2 29

37 Cylinder 75 SSD0100 2 130

38 Cylinder 60 SSD0200 2 115

48 Dust proof ring MF-DR-45-53 4 4

49 Guide belt MF-G-6 4 3

50 U ring MF-U-45-55 4 7.5

51 Cylinder cover

75 SLD

0101a-30SLV 2 15

52 O ring MF-R-71-2.65 2 1.5

53 Cylinder canister SSD0101-30SSV 2 40

Page 26

54 Bush ZC-AT-3030 4 3

55 Washer MF-F-14 4 1

56 Oil pipe fitting GHC-14-19-14 4 3.5

57 Piston pole ring SLD0300 2 9

58 Bush ZC-AT-3250 4 3

59 Piston pole 45 SSD0102 4 26

60 Piston 75 SLD0102 2 13

61 Assemble seal kit MF-P-75-55 2 15

62 Guide belt MF-G-6 4 3

63 Cylinder cover 60 SLD0201a-30SLV 2 7

64 Cylinder canister 60 SSD0201 2 36

65 Piston 60 SLD0202 2 12

66 Assemble seal kit MF-P-60-44 2 13

70 Cam SSB0800 2 10

71 Micro limit switch--3cable LS-166S

1

17

71a Micro limit switch--2cable LS-166u

1

17

C

C

C

C-

-

-

--

-

-

--

-

-

--

-

-

--

-

-

-CONTROL

CONTROL

CO

NTROL

CONTROL

BOX

BOX

BOX

BOX

Item Description GC part CODE

QTY

(pcs)

Unit

Unit

Unit

Unit

price

price

price

price

(USD)

(USD)

(USD)

(USD)

1

Control cover(with panel but

no buttons)

WS-CC-285-445 1 20

2 Buzzer WS-B-01 1 4

3 Power lamp WS-LW-01 1 4

4 UP button WS-BT-06 1 3

5 Main switch WS-SW-02 1 16

6 Emergency stop button WS-SW-03 1 5

7 "LOCK.DOWN" button WS-BT-06 1 3

8 DOWN button WS-BT-06 1 3

9

Circuit board(with wiring and

electrical parts)

CNJ0400 1 85

10

Fuse WS-F-8 3 1

Fuse WS-F-2 1 1

Fuse box WS-FB-01 4 1

11

AC contactor WS-KM-01 1 22

Thermal relay WS-KM-04 1 21

12 Time relay WS-KT-0101 1 17

13

Transformer

(pls

(pls

(pls

(pls

advise

advise

advise

advise

voltage

voltage

voltage

voltag

e

)

WS-TC-4 1 20

14 Diode bridge WS-DB-01 1 7

15 Connection terminal WS-TBC-UK-2.5 1 9

16 Wire lock head WS-PG-9 5 1

17 Up body cover CNJ0100 1 33

18 Back door of oil tank CNJ0200 1 5

19 Working valve WS-SV-03 1 80

Page 27

20 Bolt LS-SCS-M690 4 3

21 Valve block VB-100-80-72 1 60

22 Filter TKC-01 1 7

23 Motor(

pls

pls

pls

pls

advise

advise

advise

advise

voltage

voltage

voltage

voltage

) 1 200

24 Hydraulic pump 1 380

25 Descent valve WS-SV-09 1 80

26 oil tank CNJ0300 1 50

27 Bolt LS-SCS-M616 4 3

28 Washer MF-F-14 1 1

29 Stopple CNJ0600 1 1

D

D

D

D-

-

-

--

-

-

--

-

-

--

-

-

--

-

-

-PUMP

PUMP

PUMP

PUMP

Item Description GC part CODE

QTY

(pcs)

Unit

Unit

Unit

Unit

price

price

price

price

(USD)

(USD)

(USD)

(USD)

1

Stopple of pump PC-02 1 2

2

Connecting axle 32017 1 7

3

Socket cap screw LD-SCS-M640 4 3

4

Stopple of oil tank LS-HHB-M2010 1 3

5

Throttling valve PV-06 1 25

6

Overflowing valve PV-03 1 35

7

Valve block VB-100-80-72 1 60

8

Oil hose 32023A 1 8

9

Oil hose 32023B 1 6

10

Filter 32024 1 20

11

Gear pump 32012-B 1

240

Socket cap screw

LD-SCS-M850/LD-SCS-

M870

2

12

Oil hose 32020A 1 10

13

O ring MF-R-115-3.5 1 No supply!

14

Check valve PV-04 1 50

15

Coil of descent valve WS-SV-04 1 28

16

Plug of descent valve WS-SV-0401 1 10

17

Valve core of descent valve WS-SV-0301 1 58

18

Plastic cap 32012-D 1 1

第 3 ,共 3

Loading...

Loading...