Page 1

XEB Series

Gas-FiredHot Water

Induced Draft Boilers

INSTALLATION, OPERATION &

MAINTENANCE MANUAL

DUNKIRK BOILERS

85 Middle Rd.

Dunkirk, NY 14048

www. dunkirk, corn

P/N14683001 Rev.B[11/09]

Page 2

Safety Symbols ........................................................................................................................................................ 2

Installation Instructions ......................................................................................................................................... 3

Boiler Ratings And Capacities ................................................................................................................................ 3

Before You Start ...................................................................................................................................................... 4

Locating The Boiler ................................................................................................................................................. 5

Fresh Air For Combustion ....................................................................................................................................... 6

Installation System Piping .................................................................................................................................. 10

Chimney & Vent Pipe Connection ....................................................................................................................... 12

Horizontal Venting Instructions ....................................................................................................................... 15

Optional Horizontal Venting Instruction ........................................................................................................... 20

Gas supply Piping ................................................................................................................................................ 21

Electrical Wiring ................................................................................................................................................... 22

Sequence of Operation ........................................................................................................................................ 22

Wiring Diagrams .................................................................................................................................................. 23

Equipment & Optional Accessories .................................................................................................................... 24

Starting Your Boiler ............................................................................................................................................. 26

Checking and Adjusting ...................................................................................................................................... 27

Initial Operational Boiler Test Check-Out Procedure ........................................................................................ 29

Maintaining Your Boiler ...................................................................................................................................... 31

Service Hints ......................................................................................................................................................... 32

IMPORTANT:Readthe followinginstructions COM-

PLETELYbeforeinstalling!

Keepthis manual near boiler and retainfor future refer-

ence.

Thefollowingdefined symbolsareused throughout this manual to notify the reader ofpotential hazards ofvarying risk levels.

Indicates an imminently hazardous situation which, ifnot

avoided,WILLresult in death, serious injury or substantial

property damage.

Indicates an imminently hazardous situation which, ifnot

avoided,may result in injury or property damage.

Indicates an imminently hazardous situation which, ifnot

avoided,may result in death, serious injury or substantial

property damage.

Indicates information which shouldbe followedto ensure

proper installationand operation.

C.S.A. Certified for

Natural gas or Propane

Tested for 50 Ibs. ASME

Working Pressure

Page 3

Theseinstructions must be affixedon or adjacent to the boiler.

Thisboiler cannot be usedwith alltypes ofchimneys.Read these

instructions carefullybefore installing.

TheseGas-Fired HotWater Boilersare lowpressure, sectionalcast

iron boilers Design Certifiedby C.S.A.(Canadian StandardsAssoci-

ation) foruse with Natural and Propane Gases.Theyare constructed

and hydrostaticallytested for amaximum workingpressure of 50psi

in accordancewith A.S.M.E.Boilerand PressureVesselCode Sec-

tion IV Standardsfor castiron heating boilers.

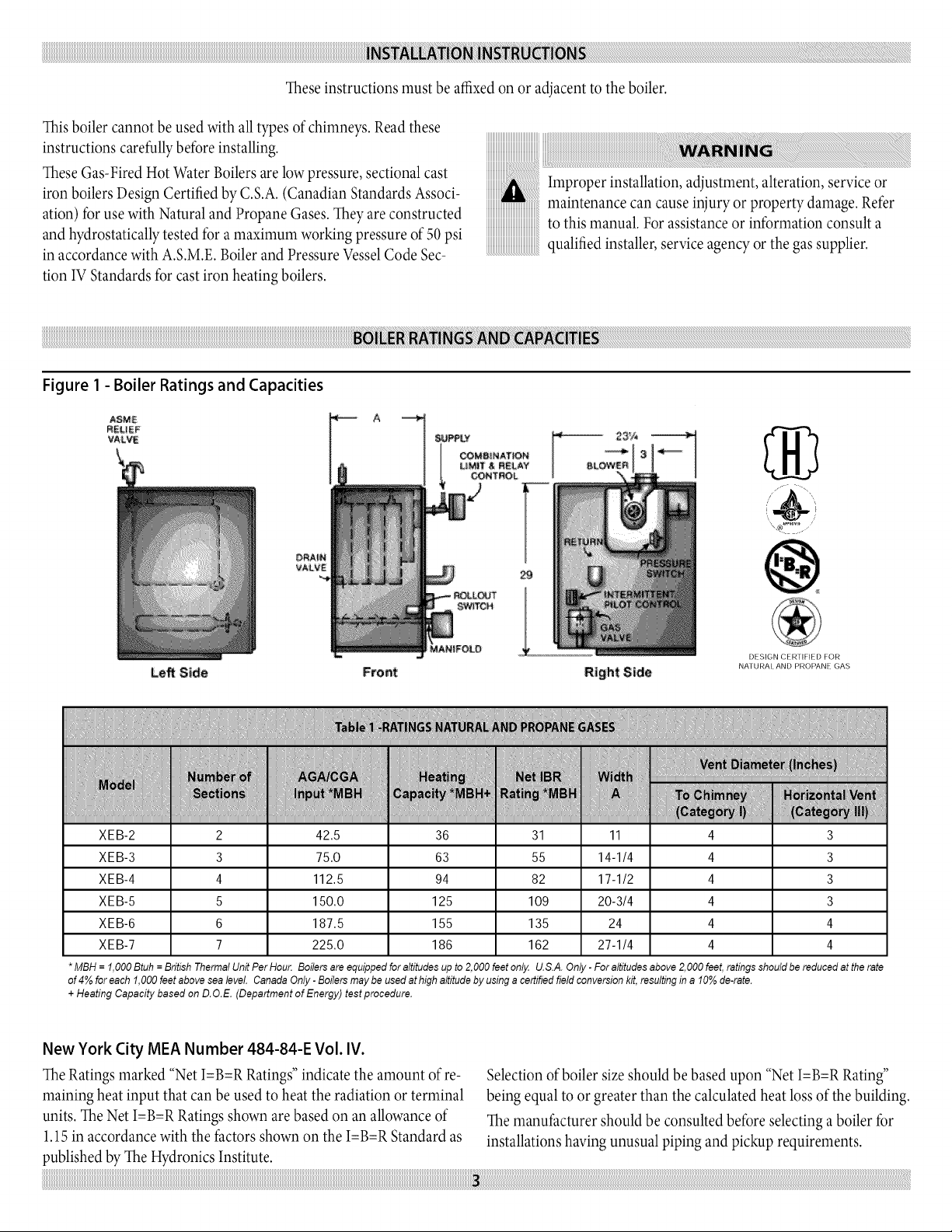

Figure 1 - Boiler Ratings and Capacities

ASME

R_LIEF

VALVE

iiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

Improper installation, adjustment, alteration, serviceor

maintenance can cause injuryor property damage.Refer

to this manual. For assistanceor information consult a

qualifiedinstaller,serviceagency or thegas supplier.

\,® .

VALVE

DESIGN CERTIFIED FOR

LeR Si_e Fro_t Right Side

XEB-2 2 42.5 36 31 11 4 3

XEB-3 3 75.0 63 55 14-1/4 4 3

XEB-4 4 112.5 94 82 17-1/2 4 3

XEB-5 5 150.0 125 109 20-3/4 4 3

XEB-6 6 187.5 155 135 24 4 4

XEB-7 7 225.0 186 162 27-1/4 4 4

*MBH = f,O00 Btuh = British Thermal Unit Per Hou_ Boilers areequipped foraltitudes up to 2,000 feet on!_ U.S.A. Only - For altitudes above 2,000 feet, ratings should be reducedat therate

of 4% for each f,O00feet above sealevel. Canada Only -Boilers may be used at high altitude by using a certified field conversion kit, resulting in a 10%de-rate.

+ Heating Capacity based on D.O.E. (Department of Energy) testprocedure.

NATURAt AND PROPANE GAS

New York City MEA Number 484-84-E Vol. IV.

TheRatingsmarked "Net I=B=RRatings"indicate the amount of re-

maining heat input that can be usedto heat the radiation or terminal

units. The Net I=B=RRatingsshown are based on an allowanceof

1.15in accordancewith thefactors shownon the I=B=RStandard as

publishedby TheHydronicsInstitute.

Selectionofboiler sizeshould be basedupon "NetI=B=RRating"

being equalto or greaterthan the calculated heat lossofthe building.

Themanufacturer shouldbe consulted before selecting a boiler for

installations havingunusual piping and pickup requirements.

Page 4

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_¸i__i_!_!_l_i_!i!!_i_i_!!i_!i_!i_!i_!!_iii_i_ii_ii_i_ii_i!i__!i_!i_!ii!i_i_i__i_!i!i_!i!i_i!_i!_i¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii¸_iiiiii¸_ii

Theseboilers must stand on a noncombustible floor.If installed on

a combustiblefloor,pleaserefer to the Repair Parts manual for the

appropriate CombustibleFloor Basepart number.

TheseGas-Fired HotWater Boilersare lowpressure, sectionalcast

iron boilers Design Certifiedby CSA(Canadian StandardsAssocia-

tion) foruse with Natural and Propane Gases.Theyare constructed

and hydrostaticallytested for amaximum workingpressure of 50psi

(pounds per square inch) in accordance with A.S.M.E.(American

Societyof Mechanical Engineers)Boilerand PressureVesselCode

Section IV Standards forcast iron heating boilers.

Boilers For UseAt High Altitude

Thisboiler is factory equipped for useat altitudesof 0-2,000feet

abovesealevel.For useat altitudes above2,000feet abovesea level,

the input ratings arereducedby a change in main burner orificesize.

U.S.A.Only- For altitudesabove2,000feet abovesea level,input

ratingsshould be reduced atthe rateof 4% for each 1,000feet above

sealevel.Consult the NationalFuel GasCode (NFPA54/ANSI

Z223.l-latest revision), orthe manufacturer for correct orifice siz-

inginformation. Highaltitude orificesare availablefrom theboiler

manufacturer.

Canada Only - For altitudes in the rangeof2,000-4,500feetabove

sealevel,boilers maybe fieldequipped foruse at high altitudeby

usinga certified fieldconversion kit.Thechangein main burner

orifice size results in the boiler'sinput rating beingreduced by 10%.

Theconversionshall be carried out by a manufacturer'sauthorized

representative,in accordancewith the requirements of the manufac-

turer, provincialor territorial authorities havingjurisdiction and in

accordancewith the requirements of the CSA-B149.1and CSA-

B149.2Installation Codes. Thecertifiedfield conversionkit includes

aconversion data plate,which must beattached to the boileradja-

centto the ratingplate, indicatingthat the boiler hasbeen converted

for high altitude use.The conversiondata platemust be filledin with

the correct conversioninformation.

Checkto be sureyou havethe right sizeboiler beforestarting the

installation. Seerating and capacitytable on previous page.Also be

sure thenew boileris for thetype of gas youare using. Checkthe

rating plateon the right side of the boiler.

Verifythat the boiler is suppliedwith the correct type ofgas,fresh air

for combustion,and a suitableelectricalsupply.Also,the boilermust

be connectedto a suitablechimney or horizontal venting systemand

an adequatepiping system. Finally,athermostat, properly located,is

needed for controlof the heating system.Ifyou haveanydoubts as

to the variousrequirements, checkwith localauthorities and obtain

professionalhelp whereneeded. Takethe time to completeallof the

stepsfor SAFEand PROPERoperation ofthe heating system.

Ifthis boiler is installed in a building under construction, special

caremust be taken to insure a clean combustion air supplydur-

ing the construction process.Airborne particulates such asfrom

drywalldust and from fiberglassinsulation can clogthe burner ports

and causeincompletecombustion and sooting. Where required by

the authority having jurisdiction, theinstallation must conform to

American SocietyofMechanicalEngineers SafetyCode for Controls

and SafetyDevicesfor AutomaticallyFired Boilers,No. CSD-1.

Theinstallationmust conformto the requirements ofthe authority

havingjurisdiction or,in the absence of suchrequirements, to the

NationalFuel GasCode, ANSIZ223.l-latest revision.

In Canada,the boiler shallbe installed accordingto CSA-B149.1and

.2,Installation Code for GasBurning Appliancesand Equipment.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

als, gasoline and other flammable vapors and liquids

Keep boiler area clean and free from combustible materi-

Page 5

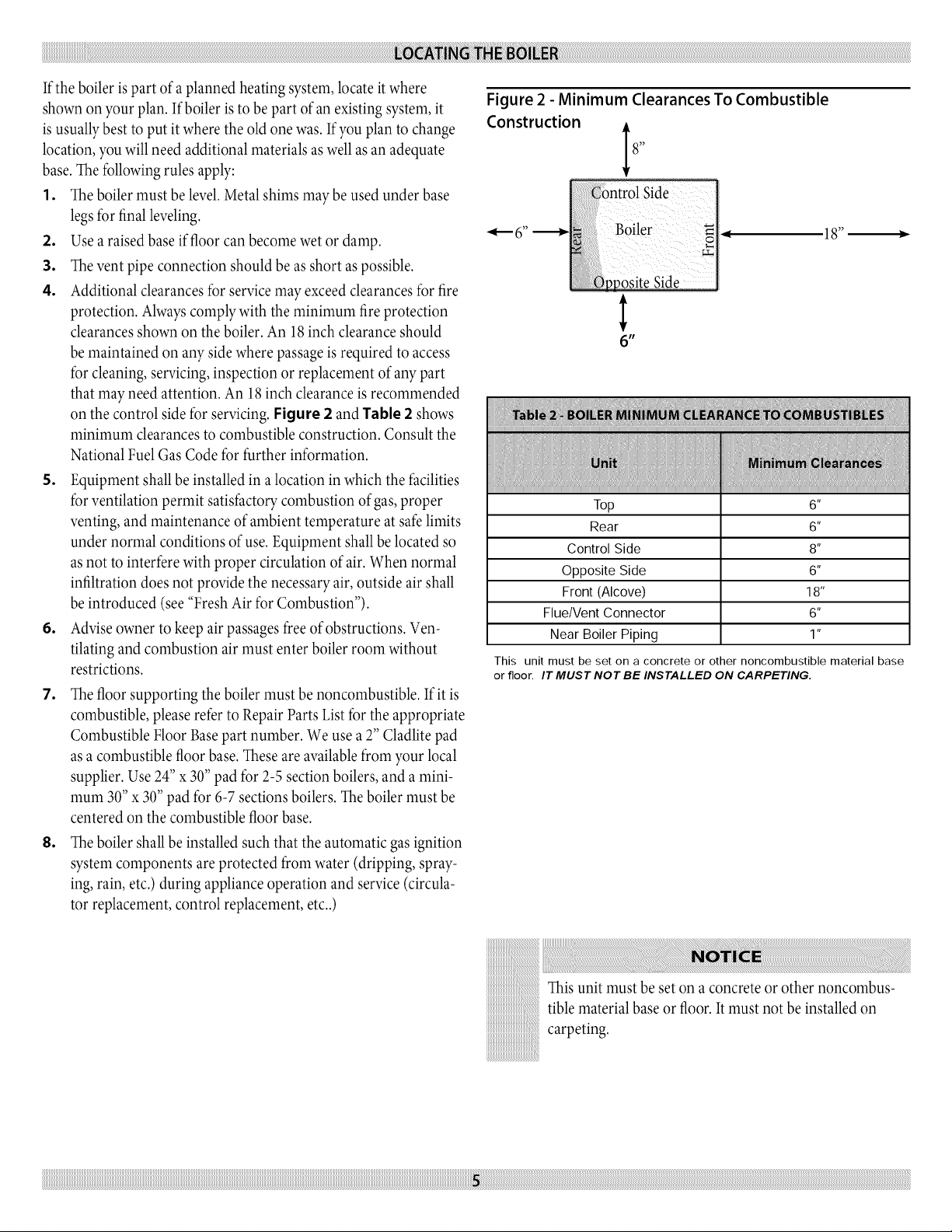

Ifthe boiler is part of a planned heatingsystem, locateit where

shown on your plan. If boiler isto be part of an existingsystem,it

is usuallybest to put it where the oldone was. Ifyou plan to change

location,you willneed additionalmaterials aswellas an adequate

base.Thefollowingrules apply:

1. Theboiler must be level.Metal shimsmay be used underbase

legsfor finalleveling.

2. Use a raised baseif floor canbecomewet or damp.

3. The vent pipe connection should be asshort aspossible.

4. Additional clearancesfor servicemay exceedclearancesfor fire

protection. Alwayscomplywith theminimum fireprotection

clearancesshownon the boiler.An 18inchclearance should

bemaintained on anyside where passageisrequired to access

for cleaning,servicing,inspection or replacement ofany part

that may need attention. An 18inch clearanceis recommended

on the control sidefor servicing. Figure 2 and Table2 shows

minimum clearances to combustible construction. Consult the

National Fuel Gas Code for further information.

5. Equipment shallbe installedin alocation in whichthe facilities

forventilation permit satisfactorycombustion ofgas,proper

venting,and maintenance of ambient temperature atsafelimits

under normal conditions ofuse. Equipment shallbe located so

asnot tointerfere with proper circulation ofair. When normal

infiltration doesnot provide the necessaryair, outside airshall

beintroduced (see"Fresh Air for Combustion").

6. Adviseowner tokeep airpassagesfree ofobstructions. Ven-

tilating and combustion air must enter boiler room without

restrictions.

.

Thefloorsupporting the boilermust benoncombustible. If itis

combustible,pleaserefer to RepairParts Listfor the appropriate

Combustible Floor Basepart number. We usea 2" Cladlitepad

asa combustible floorbase. Theseare availablefrom your local

supplier. Use24" x30"pad for 2-5 sectionboilers,and amini-

mum 30"x 30"pad for 6-7sections boilers. Theboiler must be

centered on the combustible floor base.

8,

Theboilershall be installedsuch that the automatic gasignition

systemcomponents are protected from water (dripping, spray-

ing,rain, etc.) during applianceoperation and service(circula-

tor replacement, control replacement,etc..)

Figure 2 - Minimum Clearances To Combustible

Construction i8,,

_1_ 6 _'

Boiler _ ,_

18"

_ositeSide

6"

Top 6"

Rear 6"

Control Side 8"

Opposite Side 6"

Front (Alcove) 18"

Flue/Vent Connector 6"

Near Boiler Piping 1"

This unit must be set on a concrete or other noncombustible material base

or floor. IT MUST NOT BE INSTALLED ON CARPETING.

Thisunit must be set on a concreteor other noncombus-

tiblematerial base or floor.It must not be installed on

carpeting.

Page 6

Provisionforcombustionandventilationairmustbe

inaccordancewiththeNationalFuelGasCode,ANSI

Z223.1-latestrevision,orapplicableprovisionsofthelocal

buildingcodes.

Besuretoprovideenoughfreshairforcombustion.

Enoughairinsurespropercombustionandassuresthatno

hazardwilldevelopduetothelackofoxygen.

Youmustprovideforenoughfreshairtoassurepropercombustion.

Thefireintheboilerusesoxygen.Itmusthaveacontinuoussupply.

Theairinahousecontainsonlyenoughoxygentosupplytheburner

forashorttime.Outsideairmustenterthehousetoreplacethat

usedbytheburner.Studyfollowingexamples1and2todetermine

yourfreshairrequirements.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_

Ifyou use afireplaceor a kitchen or bathroom exhaustfan,

you should installan outside air intake. These deviceswill

rob theboiler and water heater of combustion air.

Sizing Air/Ventilation Openings

Airopenings must be sized to handle allappliances and

air movers(exhaust fans,etc.) usingthe air supply.For

air openingsinto spaces containing other appliancesin

addition to the boiler referto the NationalFuel GasCode,

ANSIZ223.1for sizing.

If NoOther GasAppliances InThe Same Space

Provide air openings intothe boiler spaceas describedin this sec-

tion and the National FuelGasCode,ANSI Z223.1.Direct exhaust

installationsrequire airfor combustion and ventilation. Directvent

installationsmay require air openings for ventilation(to prevent

overheatingof boiler controls and boiler space).

When Other GasAppliances Sharethe Same Space

For airopenings into spaces containing other appliancesin addition

to the boiler referto the NationalFuel GasCode,ANSI Z223.1for

sizing.

Page 7

EXAMPLE 1: Boiler Located In Unconfined Space

An unconfined space is defined as a space whose volume is not less than 50 cubic feet per 1,000 Btu per hour of the total input rating of all

appliances installed in that space.

If your boiler is in an open area (non-partitioned basement) in a conventional house, the air that leaks through the cracks around doors and

windows will usually be adequate to provide air for combustion. The doors should not fit tightly. Do not caulk the cracks around the win-

dows.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_

Equipment located in buildings of tight construction shall be provided with air for combustion, ventilation, and dilution of flue

gases using the methods described in example 2 (below) or shall be specially engineered. The authority having jurisdiction must

approve specially engineered installations, a building of tight construction is defined as: 1)walls exposed to the outdoor atmo-

sphere have a continuous water vapor retarder with a rating of one perm or less with openings gasketed or sealed; and 2) openable

windows and doors which meet the air leakage requirements of the International Energy Conservation Code, Section 502.1.4; and

3) caulking or sealants are applied to areas such as joints around window and door frames, between sole plates and floors, between

wall-ceiling joints, between wall panels, at penetrations for plumbing, electrical and gas lines, and at other openings.

EXAMPLE 2: Boiler Located in Confined Space

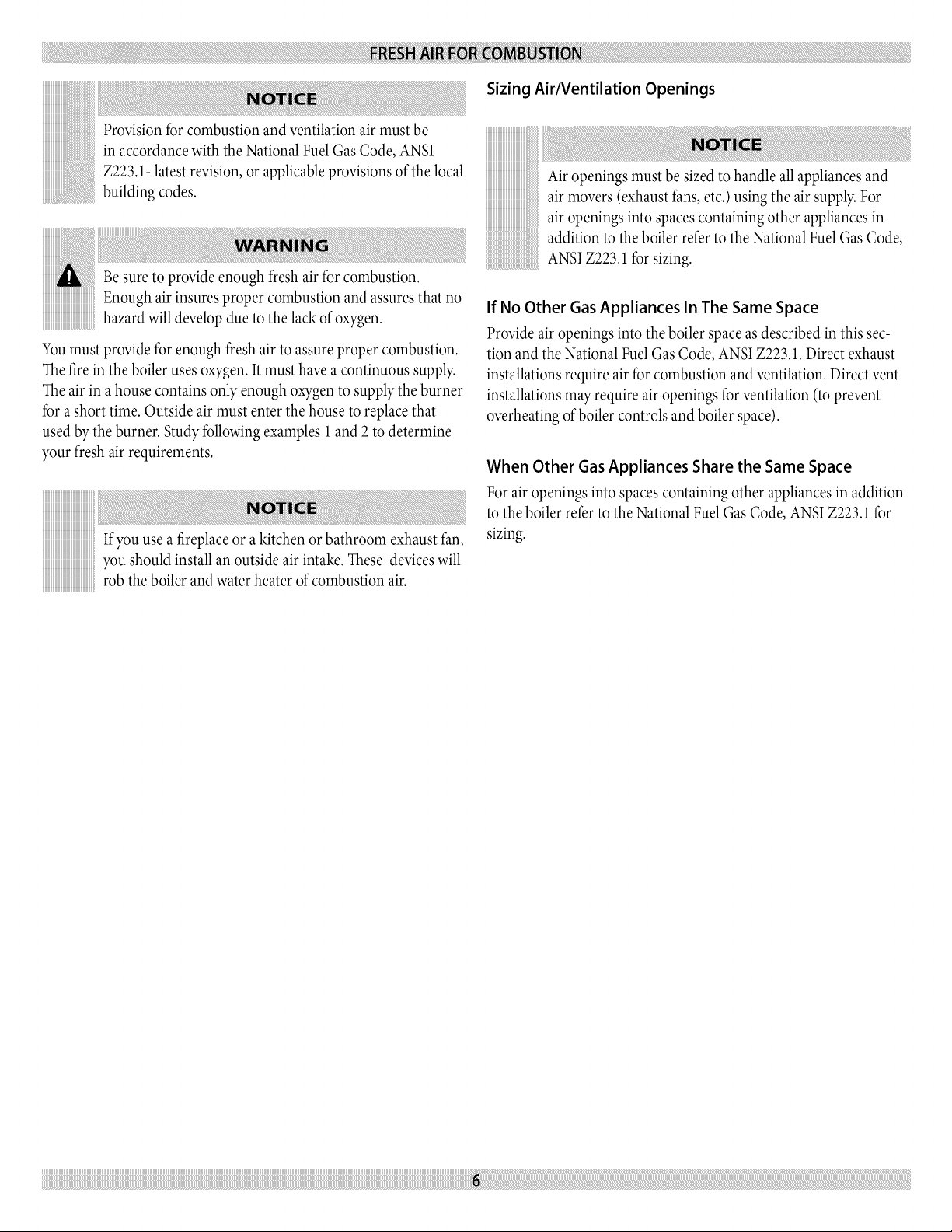

1. All Air from Inside the Building: The confined space shall be provided with two permanent openings communicating directly with

an additional room(s) of sufficient volume so that the combined volume of all spaces meets the criteria for an unconfined space. The

total input of all gas utilization equipment installed in the combined space shall be considered in making this determination. Eachopen-

ing shall have a minimum free area of one square inch per 1,000 Btu per hour of the total input rating of all gas utilization equipment in

the confined space, but not less that 100 square inches. One opening shall be within 12 inches of the top and one within 12 inches of the

bottom of the enclosure. The minimum dimension of air openings shall not be less than 3 inches (see Figure 3A).

Figure 3A - Boiler Located in Confined Space

f

Chimney

Or

GasVent

Vent Pipe_

) Openings

Page 8

o

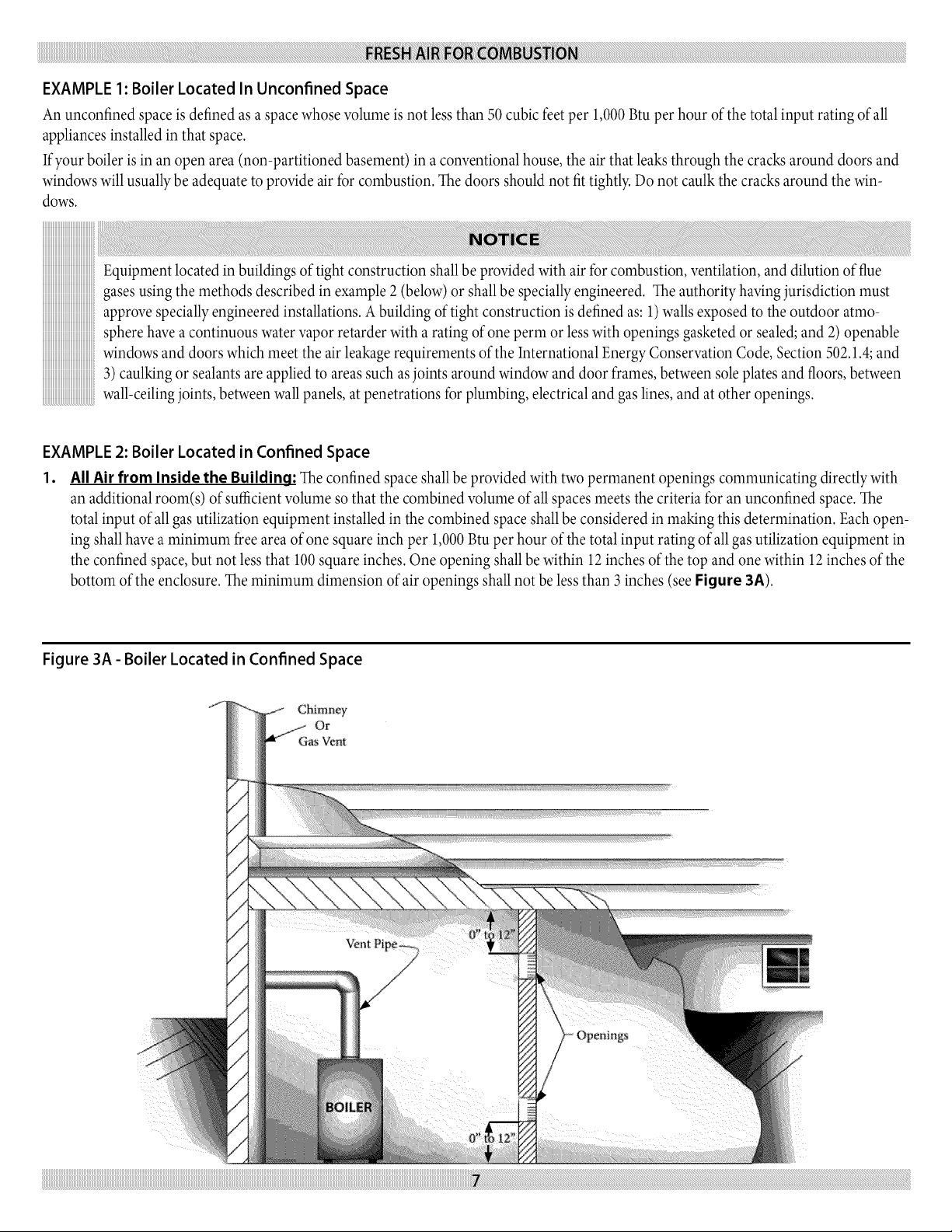

All Air from Outdoors: The confined space shall communicate with the outdoors in accordance with Methods A or Bbelow. The

minimum dimension of air openings shall not be less than 3 in. Where ducts are used, they shall be of the same cross-sectional area as

the free area of the openings to which they connect.

Method A: Two permanent openings, one commencing within 12 inches of the top, and one commencing within 12inches of the bot-

tom, of the enclosure shall be provided. The openings shall communicate directly, or by the ducts, with the outdoors or spaces (crawl or

attic) that freely communicate with the outdoors.

1. Where directly communicating with the outdoors (see Figure 3B) or where communicating to the outdoors through vertical ducts

(see Figure 3C), each opening shall have aminimum free area of 1 sq. in. per 4000 Btu per hour of total input rating of all equip-

ment in the enclosure.

Figure 3B - Directly Communicating to the Outdoors Figure 3C - Vertical Ducts Communicating to the Outdoors

Air

Pipe

3"x 12" 144,000 108,000 36,000

8"x 8" 256,000 192,000 64,000

8"x 12" 384,000 288,000 96,000

8 ½"x16" 512,000 384,000 128,000

Louver Allowance

The free areas of openings means the area after reduction for any installed louvers or grilles. Be

sure to consider this reduction when sizing the air openings.

Page 9

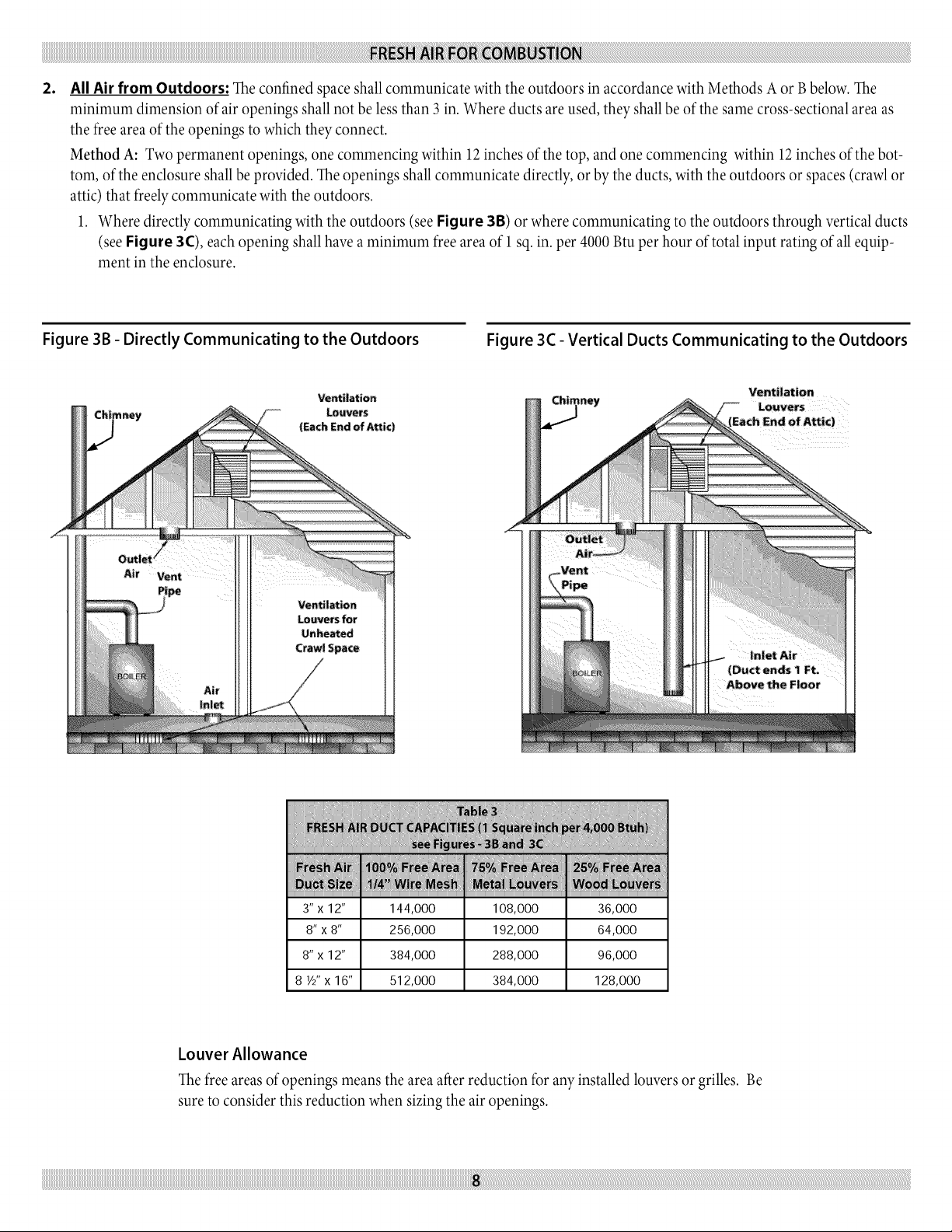

2. Wherecommunicatingwiththeoutdoorsthroughhorizontalducts(seeFigure 3D), each opening shall have a minimum free area

of 1area ofsq. in. per 2000 Btu per hour of total rating of all equipment in the enclosure.

Figure 3D - Horizontal Ducts Communicating to the Outdoors

Louver Allowance

The free areas of openings means the area after reduction for any

installed louvers or grilles. Be sure to consider this reduction when

3"x 12" 72,000 54,000 18,000

8"x 8" 128,000 96,000 32,000

8"x 12" 192,000 144,000 48,000

8 ½"x16" 256,000 192,000 64,000

sizing the air openings.

Method B:One permanent opening commencing within 12 inches of the top of the enclosure shall be permitted where the equipment has

clearance of at least 1inch from the sides and back and 6 inches from the front of the appliance. The opening shall directly communicate

with the outdoors or shall communicate through a vertical or horizontal duct to the outdoors or to a crawl space or attic that freely com-

municate with the out doors, and shall have a minimum free area off

1. 1 sq. inch per 3000 Btu per hour of the total input of all equipment located in the enclosure (see chart below).

2. Not less than the sum of the areas of all vent connectors in the confined space.

Louver Allowance

The free areas of openings means the area after reduction for any

3"x12" 108,000 81,000 27,000

8"x 8" 192,000 144,000 48,000

8"x12" 288,000 216,000 72,000

8 ½"x 16" 384,000 288,000 96,000

installed louvers or grilles. Be sure to consider this reduction when

sizing the air openings.

Page 10

To avoid burns, scalding, or water damage due to discharge of steam and/or hot water during operation, a discharge

line shall be installed to relief valve outlet connection.

The discharge line shall:

•connect to relief valve outlet and piped down to safe point of disposal.

•be of pipe size equal to or greater than that of the relief valve outlet over the entire length of discharge line;

•have no intervening shutoffvalve between safety relief valve and discharge to atmosphere (do not plug or

place any obstruction in discharge line.

iiiiiiiiiiii_iiiiiiiiiii_

•terminate freely to atmosphere where any discharge will be clearly visible and at no risk of freezing;

•allow complete drainage of the valve and the discharge line;

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

•be independently supported and securely anchored to avoid applied stress on the relief valve;

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiii

Refer to local codes and appropriate ASME Boiler and Pressure Vessel Code for additional installation requirements.

1. Place boiler in the selected location (as near chimney as pos- 3.

sible). Your boiler is shipped assembled. You need only to

install the circulator, ball valves, the relief valve with a drain line

to carry any water to a drain, and the drain valve.

o

Install relief valve on 3/4" pipe nipple in tapped boiler opening.

Pipe the discharge line following guidelines in the preceding

line pipe size shall be equal or greater than that of the relief

valve outlet over the entire length of discharge line with no

intervening shutoffvalve between the safety relief valve and dis-

charge to atmosphere. Thedischarge line shall terminate with

a plain end to atmosphere where any discharge will be clearly

visible and is at no risk of freezing. The discharge line shall be

independently supported to avoid applied stress on the relief

valve. The installation shall allow complete drainage of the

relief valve and the discharge line. The discharge line shall be as

short and straight as possible and constructed of a material suit-

able for exposure to temperatures of 375° F or greater.

•be as short and straight as possible;

•terminate with plain end (not threaded);

•be constructed of material suitable for exposure to temperatures of 375° F;

•or greater.

Referto localcodes and appropriate ASMEBoilerand Pressure

VesselCode for additional installation requirements.

o

Install Drain Valveon lowerleftside ofboiler as marked.

5.

Install Temperature and Pressure Gauge into 1A,,bushing

threaded in tee furnished with supply piping See Figures 5

Refer to example shown in Figure 4. The discharge

and 6).

6,

Connect Supply and Return Lines to boiler, as shown in Fig-

ures 5 and 6. The connections may require certain additional

fittings and parts.

Page 11

Figure 4 - Relief Valve Discharge Piping

RELIEFVALVE

DISCHARGE

PIPING

Check local code_

for maximum

distance from

floor or other al-

lowable safe point

of discharge

Figure 6 - Forced Hot Water Typical Piping With Zone

Control Valve

ZONE VALVE o,

Figure 5 - Forced Hot Water Typical Piping

MAiN

T_K

Page 12

Ifyou areinstalling an entire new heating system,first install allof

yourradiation units (panels,radiators or cabinets)andthe Supply

and Return Mains - then make the connections atthe boiler.

In connecting the cold water supply to the water vane, make sure

that a clean water supply is available. When the water supply is from

a well or pump, a sand strainer should be installed at the pump.

A hot water boiler installed above radiation level must be equipped

with a low water cutoffdevice. A periodic inspection is necessary, as

is flushing of float type devices, per manufacturers specific instruc-

tions.

When the boiler is used in connection with refrigeration systems

it shall be installed so that the chilled medium is piped in parallel

with the heating boiler with appropriate vanes to prevent the chilled

medium from entering the heating boiler (Figure 7).

If the boiler is connected to heating coils located in air handling

units where they may be exposed to refrigerated air circulation, the

piping system shall be equipped with flow control valves or other

automatic means to prevent gravity circulation of the boiler water

during the cooling cycle.

Low Design Water Temperature Systems (Below 140° F)

And Large Water Content Systems:

Significant condensation may form in this boiler and/or

the venting system if the boiler is operated with return

temperatures of less than 120° E

Thiscondensation is corrosiveand can eventuallycauseseveredam-

ageto the boilerand venting system.The minimum designreturn

watertemperature toprevent this condensation in the boilerand

venting is 120°ETheminimum high limit setting is 140°E

Ifthe boileris to be usedin aheating systemwheredesign water

temperatures below 140°Faredesired (e.g.radiant floor heating),

a3-wayor 4-waymixingvane or suitablealternative is required

to prevent lowtemperature return waterfrom entering the boiler.

When using amixing vane, followthe manufacturer's installation

instructions.

If the boiler is to be connected to a system having a large water con-

tent (such as aformer gravity system), it is suggested to use bypass

piping shown in Figure 8.

Figure 7 - Piping Arrangements For Boiler When Used In

Connection With Refrigeration System

VALVESA& B_OPENFORHEATmNG;CLOSEDFORCOOLING

VALVESC& D- CLOSEDFORHEATING;OPENFORCOOUNG

TOSYSTEM

Figure 8 - Bypass Piping

ReturnFromSystem

Thermometer

Aquastat Water To System

Front

Throttling

Feed

Fi_Rro_With

Air Purger

[ Adi_stthe twoth_ttli_g valvesto maintainat leas_i20_F i:ntheboilerreLum

Page 13

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_

For boilers for connection to gas vents or chimneys, vent

installations shall be in accordance with the National Fuel

Gas Code, ANSI Z223.1-latest revision and applicable

provisions of the local building codes.

CheckYour Chimney

Thisis avery important part ofyour heating system.It must be

clean,the right size,properly constructed and in GOOD CONDI-

TION.No boiler can function properly with abad chimney.

1. Uselocal codes forinstallation or National Fuel GasCode

Z223.l-latest revision.In Canada, followCSAB149.1or .2

Installation Codes.It isvery important to properly sizethe

venting systemfor induced draft appliances.Consult the Vent

SizingTables,in the National FuelGas Code ANSIZ223.l-

latest revision for correct sizinginformation. In Canada, consult

the Vent SizingTables,Amendment #1 toCSA-B149.1and .2

Installation Codes.

2. The boiler's induced draft blower has a 3" outlet. A 3" X 4"

increaser fitting is included in the parts bag. Locate the in-

creaser fitting on the outlet of the induced draft blower, and

secure gastight with a bead of the furnished silicone sealant. The

increaser fitting is required on this boiler for Category I venting,

and 4" is the minimum permissible vent diameter. This does

not imply that the vent connector is intended to be 4" diam-

eter pipe. The vent connector shall be sized according to the

appropriate venting tables in the National Fuel Gas Code or the

Canadian Installation Codes, and may be required to be larger

than 4" diameter.

The boiler installation for chimney venting is not complete

unless the Y'x 4" increaser fitting islocated and secured.

3.

Theseare highefficiencyboilers withalow stackor exhaust

temperature.

.

Ifventing into amasonry chimneywithout aliner, linethe

chimneyfrom top to bottom with either:

A. ListedType Bvent pipe

B. Listedflexiblevent liner

C. Poured ceramicliner.

5. Outside chimneysshould not be used unlessthey are (choose

one ofthe following):

A. Enclosedin a chase

B. Lined with TypeBvent pipe

C. Usea listedflexiblevent liner

D. Usea certified chimney lining system

6. The vent connector from the boiler tothe chimney should run

asdirectlyas possiblewith asfewelbowsas possible.

7. Where possible,it is recommended to common vent the water

heater andboiler. Consult the appropriate Vent SizingTablesin

either the National FuelGasCode, or the Canadian Installation

Codesfor specificrequirements ofmultiple appliance venting.

8. If the boiler isthe onlyappliance connected to the vent, Type B

vent pipe is recommended forthe vent connector.

9. Slopepipe up from boiler to chimney not lessthan 1/4"per

foot.

10. End ofvent pipe must be flushwith theinside faceof the chim-

ney flue.Use asealed-in thimble for the chimney connection.

11. The sections ofvent pipe should be fastenedwith sheetmetal

screwsto make the piping rigid. Use stovepipewires to support

the pipe from above.

12. Do not connect to fireplaceflue.

13. Do not installa damper on this boiler.

Minimum Vent Pipe Clearance

If the vent pipe must go through a crawl space, Type Bvent pipe

should be used. Where vent pipe passes through a combustible wall

or partition, use a ventilated metal thimble. The thimble should be 4

inches larger in diameter than the vent pipe.

If boiler is installed with single wall vent, it must have a 6" clear-

ance between its surface and any combustible material. A new Type

B gas vent or flexible liner must be installed in accordance with the

instructions furnished with the vent. Maintain clearances as speci-

fied for the vent pipe.

Check the vent pipe to see if it is fire-stopped where it goes through

the floor or ceiling. It should have an approved vent cap with clear-

ances from the roof as shown in Figure 9. If clearances are less

than shown in Figure 9, have the vent checked by local authorities.

For boilers for connection to gas vents or chimneys, vent installa-

tions shall be in accordance with the National Fuel Gas Code, ANSI

Z223. l-latest revision and applicable provisions of the local building

codes. In Canada, follow CSA B149.1 or .2 Installation Codes.

Vent connectors serving appliances vented by natural draft shall not

be connected into any portion of mechanical draft systems operating

under positive pressure.

Removing Existing Boiler From Common Venting System

When an existing boiler is removed from a common venting system,

the common venting system is likely to be too large for proper vent-

ing of the appliances remaining connected to it.

At the time of removal of an existing boiler, the following steps shall

be followed with each appliance remaining connected to the com-

mon venting system placed in operation, while the other appliance

remaining connected to the common venting system are not in

operation.

1. Seal any unused openings in the common venting system.

2. Visually inspect the venting system for proper size and hori-

Page 14

Figure 9 - Type B Gas Vent

Liner

Chimney

Sheet Metal

Vent System

Cleanout

CHECK YOUR CHIMNEY

This is a very important part of your heating system.

It must be clean, the right size, properly constructed

and in GOOD CONDITION. No boiler can function

properly with a bad chimney. Use local codes for instal-

lation or National Fuel Gas Code Z223. l-latest revision.

In Canada, follow CSA B149.1 or .2 Installation Codes.

It is very important to properly size the venting system

for induced draft appliances. Consult the Vent Sizing

Tables, in the National Fuel Gas Code ANSI Z223. l-

latest revision for correct sizing information. In Canada,

consult the Vent SizingTables, Amendment # 1to CSA-

B149.1 and.2 Installation Codes.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiil_i_i¸iiii_ii_ii_ii_il_il_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_i_i_i

Page 15

zontal pitch and determine there is no blockage or restriction,

leakage, corrosion and other deficiencies which could cause an

unsafe condition.

3,

Insofar asispractical, closeallbuilding doors and windows and

alldoors between the spacein which the appliancesremaining

connected to the common venting systemare locatedand other

spacesof the building. Turn on clothesdryers and any appli-

ancenot connected to the common venting system.Turn on

anyexhaust fans,such as range hoods and bathroom exhausts,

so theywill operate at maximum speed. Closefireplacedamp-

ers.

4. Place in operation the appliance being inspected. Follow the

lighting instructions. Adjust thermostat so appliance will operate

continuously.

5. Test for spillage at the hood relief opening after 5minutes of

main burner operation.

G. After it has been determined that each appliance remaining con-

nected tothe commonventingsystemproperlyventswhentested

asoutlinedabove,returndoors,windows,exhaustfans,fireplace

dampers andany other gas-burningapplianceto their previous

conditionsof use.

,

Anyimproper operation of the common venting systemshould

be corrected so the installationconforms with the National

FuelGas Code, ANSIZ223.l-latest revision.When resizing any

portion ofthe common ventingsystem,the common venting

systemshould be resizedto approach the minimum sizeas

determined usingthe appropriate tables in the National Fuel

GasCode,ANSIZ223.l-latest revision.In Canada, followCSA

B149.1or.2 Installation Codes.

NOTE:It is recommended that existinggasvents be

checkedto be sure theymeet localcodes.

Page 16

INDUCED DRAFT HIGH EFFICIENCY BOILERS

Maximum Horizontal Vent Length ForStainlessSteelVentPipe - 30'

PlusOne 90° ElbowPlusVent Terminal.

Minimum Horizontal VentLength- 2' PlusOne 90° ElbowVent

Termination.

Additional elbowsare equivalent to 6 feetof straightpipe for 4" di-

ameter 90° elbowor 3 feetof straight pipefor 3"diameter 90°elbow.

2,3,4, 5,Section Boilersuse 3"vent pipe;for 6, 7 SectionBoilersuse

4"vent pipe.

Figure 10 - Induced Draft High Efficiency boilers

Optional Termination Fitting

T Jemlund S_deWall Vent Hood

VHolo3"for 2, 3, 4& 5 Section Boilers

VH-I_4" for 6 & 7 Section _i|ers

CHOICE OF VENT PIPE MATERIAL

1. U.L. ListedZ-FlexZ-VentStainlessSteelVentPipe.

2. U.L.ListedHeat-Fab Saf-T-VentStainless SteelVent Pipe.

3. U.L. ListedFlex-LStar-34StainlessSteelVentPipe.

4. U.L. ListedProTechSystemsFasNSealStainlessSteelVent Pipe.

Termination Fitting

_° Elbow, pointing down, same matetiai and

pipe size as venting systems equtped with

screen (Min, I/4" Mesh) to keep birds outs

Fot a combustib|e wa|l, use a thimb|e_ Select as

fo|iows:

Vent Pipe: Z-Vent, SafoT_Vent,Star 34

_tmble: Simpson Duravent Thimb|e --

# 3G_¢_,/T(3% # 4GV_t#T (4")

Vent Pt_: FasNSeal

Thimble: FasNSea| Wal| Thimble

#FSWT03-3'; FSWT04-4 _'

PRchDown Toward

Outside 1i4" Per Foot

Pitch Down Towa_

Outside 1/4" Per Foot

_vel

Page 17

1,

Theseboilers maybe vented horizontally as shown in

Figure 10.Thevent pipe is pitched down from the boiler to

thevent termination. Do not connect other appliances tothis

vent.

,

Vent Pipe Material:

A. ULListedZ-FlexZ-Vent stainlesssteelvent pipe from

boilerto vent termination,

-or-

B. ULListedHeat-FabSaf-T-Vent stainless steelvent pipe

fromboiler to vent termination,

-or-

C. UL ListedFlex-LStaR-34stainless steelvent pipe from

boilerto vent termination,

6,

Vent Termination Fitting: For allvent pipe materials,you may

useeither:

A. A 90° elbowpointing down, fittedwith aminimum 114"

mesh screen to keepout rodents and birds. Theelbow shall

be ofthe same material and size as ventpipe. The elbow

exit should be at least 6" awayfrom exterior wall asshown

in Figure 10.

-0r-

B.

Tjernlund VH-1Seriessidewall vent hood. For 2,3,4, 5

sectionboilers use VH-1-3",For 6, 7section boilers use

VH-1-4".

7. Vent PipeTermination Location (Figure 10):

-or-

D. ULListedProTech FasNSealstainlesssteelvent pipe from

boilerto vent termination.

3,

Clearanceto CombustibleMaterials: Forstainless steelvent

pipemaintain 6" minimum airspaceclearanceto combustible

materials.

,

Vent Pipe Size:

A. 2, 3, 4 and 5 section boilers use 3" vent pipe connected

directly to the outlet of the induced draft blower.

B.

6 and 7 sectionboilers use4" ventpipe, starting with a3"

to 4"stainless steelvent pipe transition that is connected

directlyto the outlet of the induced draft blower.Do not

use3" ventpipe on 6or 7 sectionboilers.

5,

Vent Pipe Length:

A. For stainlesssteelvent pipe,the maximum horizontal vent

length is 30feet plus one 90°elbowplus termination fitting.

B.

Minimum horizontal vent length forall ventmaterials is 2

feetplus one 90° elbowplus termination fitting.

C.

For additional elbowsreduce the maximum vent length as

shown:

•3" - 90° elbow - reduce vent length 3 feet per each 3" elbow

•4" - 90° elbow - reduce vent length 6 feet per each 4" elbow

a.

When venting through combustible walls, combustible

clearancesmust be considered. TheVH-1 Sidewallvent

hood provides both the outside vent termination and a

double wallpipe for passing through a combustiblewall

up to 8"thick (VH-1-4")or 9" thick (VH-1-3").Thehole

in thewall must be 61_'' square for 3"vent pipe and 7 1/2"

square for 4" vent pipe, in order to insert theVH-1 side

wallvent hood. TheVH-1may alsobeused in noncombus-

tible walls.

B.

Ifthe 90° elbow isthe termination fittingof choice,then

the singlewallpipe will be passingthrough the sidewall.

For combustiblewalls, a ULlisted thimble shall be used

where the singlewallpipe passes through the wall.For

combustiblewalls usingZ-Vent, Saf-T-Vent,or StaR-34

vent pipe, usethe following:

• 3" vent pipe - use Simpson's Duravent 3" thimble

•4" vent pipe -use Simpson's Duravent4" thimble. Maxi-

mum wallthickness with this thimble is 7inches.

For combustiblewallsusing ProTechFasNSealwhere the singlewall

vent pipe must pass through the sidewall,a ULListedFasNSealwall

thimble shallbe used.

Thethimble isadjustable for differentwall thickness,with amaxi-

mum wallthickness of 7 inches.Sealthe thimble along the outside

edgeof the platewith caulkor siliconeand fasten to the wallwith

screwsor nails.

Example: 6 section boiler has 3 elbows plus the termination fitting.

This means 2 additional 4" elbows will be used, at 6 feet per elbow.

This is equivalent to 12 feet of pipe (2 x 6 =12), therefore maximum

vent length is now 18 feet (30 -12 =18).

C. For singlewallpipe through non-combustible walls, the

hole through the wallneed onlybe large enough to main-

tain the pitch of thevent pipe, and provide proper seal-

ing.A thimble isnot required for singlewall pipe passing

through noncombustible walls.

D. Theventing systemshall terminate at least 3feet above

Page 18

Figure 11 - Horizontal Venting Clearances

NOTE: _ THERE IS A POTENTIAL POR EXCES:S_VE WINDS, SPECIAL

CONSIDERATION _NOULD BE GIVEN TO LOCATE THE VENT TERMINATION

AWAY FROM THE WINDWARD Si:DE OR THE BUILD_NG,

ing system shall terminate at least 4 feet below, 4 feet

horizontally from, or 1 foot above any door, window,

or gravity air inlet into any building. The bottom of

the vent shall be located at least 12 inches above grade.

Termination of the vent shall be not less than 7 feet above

an adjacent public walkway. The vent terminal shall not be

installed closer than 3 feet from the inside corner of an L

shaped structure. Termination of the vent should be kept

at least 3 feet away from vegetation. The venting system

shall terminate at least 4 feet horizontally from, and in no

case above or below, unless a 4 foot horizontal distance is

maintained, from electric meters, gas meters, regulators,

and relief equipment. (See Figure 11)

E,

The venting system shall terminate at least 4 feet below any

eve, soffit, or roof overhang.

F. The venting system shall not terminate underneath any

deck, patio, or similar structure.

G. Put vent on awall away from the prevailing winter wind.

LOCATE VENT CAP TO ALLOW

_2" (3_ CM) MIN ABOVE: ORADE

Locate or guard the vent to prevent accidental contact with

people or pets.

H,

Terminate the vent above normal snow-line. Avoid loca-

tions where snow may drift and block the vent. Ice or snow

may cause the boiler to shut down if the vent becomes

obstructed.

Under certain conditions, flue gas will condense, forming

moisture. In such cases, steps should be taken to prevent

building materials at the vent terminal from being dam-

aged by exhaust of flue gas.

8_

Joining and Sealing the Vent Pipe:

The vent pipe needs to be both watertight and gastight. Seal all

joints and seams as follows:

A. For Z-Flex Z-Vent stainless steel vent pipe use a high tem-

perature silicone sealant rated for 550°F. The outside of the

male end and inside of the female end of the pipe must be

cleaned with brake cleaner before applying silicone bead.

Page 19

For 3"vent pipe runs beginwith the male endof the vent

pipeover the boilersinduced draft bloweroutlet. For 4"

ventpipe runs begin with a 6" lengthof 3"Z-Vent over the

boiler's induced draft blower outlet, to which an evenbead

ofhigh temperature silicone sealantshouldbe applied.

Thenconnect the 3" Z-Ventto a Z-Vent 3"to 4"reducer.

Thencontinue the 4"Z-Vent piperun byconnecting the

4" male end of the Z-Ventto the reducer. (A locking band

maybe used around this joint for additional support.) Then

followingthe sealinginstructions, push the4" male end of

the Z-Vent overthe 4" increaserfitting. When using the

Tjernlund VH-1 vent hood, the femaleend (flaredend) of

thevent pipe willbe connected to the termination hood.

Themale endof thevent hood must be crimped before

pushing the Z-Vent over thevent hood's connecting pipe.

Beforethe pipes are joined, applya ¼" bead of siliconeone

inch from the endof the male end. Then pushthe pipes

together asfar asthey willgo makingsure any seamsare

alignedand oriented upward. Now apply another beadof

silicone around this joint and smooth out. Then use a Z-

Flexlockingband around the center of the joint.

1. Apply the high temperature silicone approximatelyone

inchfrom the end, around the male end ofthe pipe in

an even ¼" bead.

,

Pipescan now be pushed together asfar as they will

go. Theseams onpipe should be alignedand oriented

upward in allhorizontal appliances. Applyanother bead

of siliconearound this joint and smooth out.

,

Slidelockingband overcenter of joint and tighten gear

clamps.Makesure locking band is centered onjoint.

,

Checkalljoints and seams for gastightness.

5.

Horizontal ventingshall haveaslope notless than ¼"

(6.4mm) every12inches (305mm)downward away

from the boilerto preventcollectionof condensate

throughout the assembly.

,

Allowthe sealant to cure for 24hours before operating

the appliance.

B,

For Heat-Fab Saf-T-Ventstainlesssteelvent pipe use

ahigh temperature siliconesealantrated for 550°F

Theoutside ofthe male end and inside ofthe female

end ofthe pipe must becleanedbefore applyingthe

siliconebead. For 3"vent pipe runs, the male endof

thevent pipe which goes overthe outlet of theboiler's

induced draftblower must be crimped. Thevent pipe

should be crimpedas minimal aspossible to provide

atight fit overthe outlet. After crimping is completed

followthe instructions forapplying siliconesealant.

For 4"vent pipe runs, begin with a Saf-T-Vent3"to 4" in-

creaserfittingoverthe boiler'sinduced draft bloweroutlet,

to which an even bead of high temperature siliconesealant

shouldbe applied. Thencontinue the 4" Saf-T-Ventpipe

run by connecting the 4" male end of the Saf-T-Ventto the

increaser.(Alockingband maybe usedaround thisjoint

for additional support.) Thevent flowmust be in the direc-

tion indicatedon the ventpipe. When usingthe Tjernlund

VH-1 vent hood, the femaleend (flared end) ofthe vent

pipe willbeconnected to the termination hood. Applyhigh

temperature silicone in an even ¼"bead approximately¼"

to 3/8"from the end of the venthood's connecting vent pipe.

Also,run asimilar sizebead ofsilicone sealantdown the

seamweldofthe vent pipe. Then push the femaleend over

the vent hood'sconnecting vent pipe.

1. Apply thehigh temperature siliconearound the male

end ofthe pipe (without the tabs) in an even ¼"bead.

Siliconebead should be approximately¼"to 3/8"from

the end ofthe male end. Also,run a similarsizebead of

silicone sealantdown the seam weld at the end of each

joint.

,

Pipes cannow be pushed together asfar as theywill

go. Theseams onthe vent pipe should be alignedand

oriented upward in allhorizontal appliances.With a

moistened fingeror fiat tool, spreadany sealant that

squeezesout around the circumference of the joint.

,

Attach the sectionstogether with the locking rings and

tabs (exceptat the bloweroutlet where no locking ring

exists.) Inspectthe joint to ensurethat fluegaseswill

not leak.If necessaryapplyadditional sealantaround

thejoint.

,

Horizontal venting shallhave a slopenot lessthan ¼"

(6.4mm) every 12inches (305mm) downwardaway

from the boilerto prevent collectionof condensate

throughout the assembly.

5. Allowthe sealantto cure for 24 hours beforeoperating

the appliance.

C,

For Flex-LStaR-34stainless steelvent pipe use ahigh

temperature siliconesealant rated for 550°F.Beforeapply-

ing silicone,the outside of themale end and inside ofthe

femaleend of the pipe must be cleaned using acleaner,

suchas methyl ethyl ketone (MEK)or naptha. For 3"

vent pipe runs, beginwith the male endof the vent pipe

over the boiler'sinduced draftbloweroutlet. For 4"vent

pipe runs begin with aStaR-34 3"to 4"increaser fitting

over the boiler'sinduced draftbloweroutlet. For both

3" and 4"vent pipe runs,apply a bead ofsilicone seal-

ant around the blower outlet and around the inside of

the male end ofvent pipe going overthe blower's outlet.

When usingthe Tjernlund VH-1 vent hood,the

femaleend (flaredend) ofthe vent pipe

willbe connected to the termination hood.

Page 20

Applyhigh temperature siliconein an even ¼"bead ap-

proximately 1/4"from the end ofthe vent hood's connecting

ventpipe. Also,run a similar sizebead of siliconesealant

down the seam weldof the vent pipe. Then push the female

end over thevent hood's connecting vent pipe. Now fillin

the channel inlet with siliconesealant.Do not try to insert

thejoiner band, instead fastenthe vent pipe tothe vent

hood's pipe with a steelgear clamp.

1. Apply the high temperature silicone around the male

endof the pipe in an even ¼" bead. Siliconebead

shouldbe approximately ¼" fromthe end of the male

end. Also,run a similarsize bead of siliconesealant

down the seamweld at the end of each joint.

2. The seams on the vent pipe should be alignedand ori-

ented upwardin allhorizontal vent pipe runs.

3. Insert the maleend ofone into thefemaleend of the

other. Push the pipe together sothe female end rests up

againstthe stop bead of themale end.

.

Insert a StaR-Joiner Band into the inlet of the beaded

channel. Feed the Joiner Band in so it makes its way

around the pipe, back to the channel inlet and it over-

laps itself by about 1/2".

.

Cutthe excessJoiner Band soit lays fiatin the beaded

channel.Fillthe inlet ofthe beaded channel withhigh

temperature silicone.Smooth outthe siliconeover the

channel inlet and the siliconebetween the female end

and thestop bead of the male end.

.

Horizontal ventingshall haveaslope notless than ¼"

(6.4mm) every12inches (305mm)downward away

from the boilerto preventcollectionof condensate

throughout the assembly.

7. Allowthe sealant to cure for 24hours before operating

the appliance.

D.

For ProTechSystemsFasNSealstainlesssteel vent pipe

no cleaningfluid isrequired. For 3" vent pipe runs on 2,

3,4 and 5 section boilers,begin bylocating the FasNSeal

AmetekAdapter overthe boiler's induced draft blower.

Continue the vent piperun with 3" FasNSealvent pipe.

For 6and 7 section boilers, begin by locatingthe FasNSeal

AmetekAdapter over the boiler'sinduced draft blower.

Thenconnect a FasNSeal3"to 4" increaserto the 3"

adapter outlet.Continue thevent piperun with 4"FasNSeal

ventpipe. Other than the Ametek Adapter and increaser

fitting,DO NOT use 3"vent pipe on 6or 7 sectionboilers.

FasNSealventpipe isjoined and sealedby the useof an

internal sealinggasketand alocking band on the female

end ofeachvent pipe.Allcomponents should be examined

for possibleshippingdamage prior to installation. Align

allvent pipe seamsand orient upward in allhorizontal

applications.Adjustablevent lengths areavailablefor4"

diameter vent piping.For 3" diameter vent piping, square

cutmale end at the desired length. For2, 3,4 and 5 section

boilers usingthe VH-1-3" vent hood, connect the FasNSeal

Ventto the VH-1-3"vent hood using FasNSealAdapter

#FSC-DUN-3.Thisadapter has no internal sealinggasket.

Toattach the adapter to the vent hood, crimp the 3"vent

hood pipe,apply a 1/4"bead ofhigh temperature silicone

sealantaround the outside of the venthood's crimped

connecting pipeand asimilar bead of high temperature

siliconearound theinside ofthe FasNSealadapter. After

pressing thetwo pipestogether and tightening the locking

band, finish creatinga complete sealby fillingthe FasNSeal

adapter'snotched holewith hightemperature silicone.

For 6 and 7 sectionboilers using the VH-1- 4"vent hood,

an adapter isnot required. The 4" FasNSealventpipe con-

nects directlyto the VH-1-4" venthood, and is joined and

sealedby the internal gasketand lockingband.

Tojoin and seal the FasNSealvent pipe:

1. Insert maleend into female section.

2. Push the units together as faras possible.

3. Firmly tighten locking band with anut driver.

4. DO NOT penetrate theFasNSealvent pipe with fasten-

ers.

.

Horizontal venting shallhave a slopeof not less than

¼"(6.4mm) every12inches (305mm)downward away

from the boilerto prevent the collectionof condensate

throughout the assembly.

o

Support Spacing:

Donot restrict thermal expansion movement of the vent. The

vent pipe must expand and contract freely with temperature

change.Eachrun ofventpiping shallbe supported asfollows:

A. Z-Flexstainlesssteel ventpiping requires a loosefitting

metal strap or similar support at eachjoint at a maximum

of 4 feetbetween supports.

B. Heat-Fab stainlesssteelvent piping requiresa support for

every6 feet ofhorizontal piping run. Thesupport must be

securedusing at least#10fastenersto asolid material (solid

masonry or wood framing or blocking.)Do not fastento

drywall sheathingusing hollowwall anchors. Each sup-

port willbe 11/2inch lowerthan the previous support when

spaced6feet apart.

C. Flex-Lstainlesssteelvent piping requires aloose fitting

metal strap or similar support at eachjoint at a maximum

of 4 feetbetween supports.

D. ProTech stainlesssteelvent piping requires one loose fit-

ting FasNSealsupport strap for every6' ofhorizontal vent.

Page 21

10. If the horizontal vent must go through a crawl space or other

unheated space, the cool temperatures will likely cause the flue

gases to continuously condense inside the vent pipe. Do not

insulate the vent pipe. It must be visible for monthly inspec-

tion. Insure that the vent pipe is properly pitched away from

the boiler, with no low spots, sothat condensate in the vent will

drain away from the boiler. An insulated enclosure or chase,

with access for inspection and servicing of the vent, may be

required to prevent freezing of liquid condensate. Consult the

vent pipe manufacturer's instructions for specific guidelines.

11. At the beginning of each heating season and monthly during

the heating season, check all vent pipes and the vent terminal

to make sure there are no obstructions. Periodically clean the

screen in the vent terminal.

Horizontal ventingwith apower venter is an alternatemethod of

sidewallventing. Thisboiler is CSAlisted for sidewallventing with

standard singlewallgalvanized or TypeBvent pipe when usingthe

followingpower venterkits, which werespecificallysizedfor these

boilers:

2,3, 4,5 SWG-4D

6,7 SWG-SD

Somepossiblereasons for using apower venterfor sidewallventing:

1. May be preferred by localcodes.

2. Need avent pipingrun beyond 30' (butnot more than 50').

3. The boiler installation site experiencesgusting or high winds.A

power venter canhelp prevent the boiler from short cyclingdue

to gusting or high winds byproviding ventexhaust pressures

greater than the boiler'sinduced draft blower alone.

4. When installersor homeowners prefera negativepressure vent

systeminstead of a positive pressure vent system.

5. May bemore costeffectivethan stainlesssteel

venting,particularly at longer vent lengths.

TheFieldControls powervent kit includeseither a SWG-II-

4HD or SWG-II-5power venter,a MG-1 4" barometric draft

controller,and the CK-43Dcontrols kit.

Confirm that installingapower venter isan option allowedby local

codes.Followthe specificpowerventer installation instructions

issuedwith the power venter kits. Although the powerventer is

equippedwith itsownfan, the fanon the boiler remains in place and

isunaltered whena power venter isused.

When sidewallventing, fluegasesmust be vented to apoint in rela-

tion tothe prevailingwind so that they may freelydisperse without

being blown backat the building causingdiscoloration, orinto the

building through doors or windows causingodors. Also,under cer-

tain conditions fluegaseswill condense, forming moisture. In such

cases,steps should be taken to preventbuilding materialsat the vent

terminal frombeing damaged by the exhaustedfluegas.

When installing singlewall galvanizedvent pipe forpower venting

followthe specificpower venter installation instructions for layout,

location ofthe barometric draft control and termination connec-

tions.

When joining and sealingthe singlewall galvanizedor Type Bvent

piping, use RTVsilicone sealantwith aminimum temperature rating

of 400°EFor 3"vent pipe runs, begin with the female end of the vent

pipe overthe boiler'sinduced draft bloweroutlet. For4" ventpipe

runs begin with the galvanized3" to 4" increaser fitting (included in

the boiler'sparts bag)over the induced draft bloweroutlet. Thenfol-

low by placingthefemale end of the 4"vent pipe overthe increaser

fitting.

When joining piecesofsinglewall galvanizedvent pipe,a substan-

tial bead ofsiliconeshould be used atthe joint to insure aleakproof

connection.

Page 22

Connecting The Gas Piping

Refer to Figure 12 for the general layout at the boiler. It shows the

basic fittings you will need. The gas line enters the boiler from the

right side. Flexible gas connectors must never breach any boiler

openings.

Figure 12 - GAS PIPING AT BOILER

Never use a match or open flame to test for leaks.

9. Two-stage regulation should be used by the propane installer.

10. Propane gas piping should be checked out by the propane

installer.

Checking The Gas Piping

Upon completion of piping, check right away for gas leaks. Open

the manual shut-offvalve. Test for leaks by applying soap suds (or

a liquid detergent) to each joint. Bubbles forming indicate a leak.

CORRECTEVENTHE SMALLEST LEAK AT ONCE.

Manifold

Automatic Ground

GasValve, Joint

Check Gas Supply

The gas pipe to your boiler must be the correct size for the length

of the run and for the total BTU per hour input of all gas utilization

equipment connected to it. See Gas Table 8 for the proper size.

Be sure your gas line complies with local codes and gas company

requirements.

Tmp

Floor Line

.iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

20 92,000 190,000 350,000 625,000

40 63,000 130,000 245,000 445,000

MIN. SUPPLY 5" w.c. 11" w.c.

MAX. SUPPLY 14" w.c. 14" w.c.

MANIFOLD 3.5" w.c. 10" w.c.

The following rules apply:

1. Use only those piping materials and joining methods listed

as acceptable by the authority having jurisdiction, or in the

absence of such requirements, by the National Fuel Gas Code,

ANSI Z223.1- latest revision. In Canada, follow the CSA B149.1

and .2 Installation Codes for Gas Burning Appliances and

Equipment.

2. All pipe compound must be resistant to liquefied petroleum gas.

3. Install ground joint union in gas supply line between shut-off

vane and boiler controls.

4. Install a sediment trap upstream of gas controls.

5. Use two pipe wrenches when making the connection to the gas

vane to keep it from turning.

6. Install manual shut-offvaNe in vertical pipe about 5 feet above

floor.

7. Tighten alljoints securely.

8. Propane gas connections should only bemade bya licensed

propane installer.

60 50,000 105,000 195,000 365,000

216,000 189,000 393,000

145,000 129,000 267,000

121,000 103,000 217,000

The length of pipe or tubing should be measured j?om the gas meter or propane

second stage regulatoc

The boiler and its individual shutoffvaNe must be disconnected

from the gas supply piping system during any pressure testing of that

system at test pressures in excess of 1/2Psig (3.5 kPa).

The boiler must be isolated from the gas supply piping system by

closing its individual manual shutoff vane during any pressure test-

ing of the gas supply piping system at test pressures equal to or less

than 1/2Psig (3.5 kPa).

Page 23

All electrical work must conform to local codes as well as the Na-

tional Electrical Code, ANSI/NFPA-70, latest revision. In Canada,

electrical wiring shall comply with the Canadian Electrical Code,

CSA-C22.1.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiTurn offelectricpower atfuseboxbefore makinganyline

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiivoltageconnections. Followlocalelectricalcodes.

Electric Power Supply

Run a separate 120volt circuit from a separate over current protec-

tive device in the electrical service entrance panel. This should be a

15 ampere circuit. Locate a shut-off switch at the boiler. It must be

turned offduring any maintenance. Connect 120 volt power supply

to aquastat terminals L1 (HOT) and L2.

The boiler, when installed, must be electrically grounded in accor-

dance with the requirements of the authority having jurisdiction or,

in the absence of such requirements, with the National Electrical

Code, ANSI/NFPA No. 70 - latest revision. Run a 14gauge or heavier

copper wire from the boiler to a grounded connection in the service

panel or a properly driven and electrically grounded ground rod.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

Label allwires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing.

Install Your Thermostat

The thermostat location has an important effect on the operation of

your boiler system. BE SURE TO FOLLOW THE INSTRUCTIONS

INCLUDED WITH YOUR THERMOSTAT. Locate the thermo-

stat about five feet (5') above the floor on an inside wall. It may be

mounted directly on the wall or on a vertically mounted outlet box.

It should be sensing average room temperature.

Behinddoors

Corners&

alcoves

Concealed pipes

Fireplace

TV sets

Radios

Lamps

Direct sunlight

Kitchens

Concealed pipes

or ducts

Stairwells-drafts

Doors- drafts

Unheated room on

other side of wall

Sequence of Operation - Refer to Figure 13

1. Thermostat calls for heat, powering the 1Krelay coil and closing

contacts 1K1and 1K2.

2. Circulator pump ispowered through terminals C1and C2.

3. Induced draft blower and transformer primary arepowered

through terminals B1and B2.

4. When blowergets up to speed andblower suction pressure

reaches pressure switchset point, pressure switchcontacts close

sending 24 voltsto intermittent pilot control from transformer

secondary.

5. Pilot gasvalve opens and spark initiates to light pilot burner.

6. When pilotflame isproven, sparkdrops out.

7. Main gasvalveopens and pilot burner ignites main burners.

Setheat anticipator at .2amps. The 24 voltthermostat connects

to aquastat terminals T and T.

8. If boiler water temperature reaches high limit setpoint, high

limit contacts B-Ropen, cutting powerto blower and intermit-

tent pilot control. Burnersextinguishand blower stops.Circula-

tor pump continues to run aslong asthe thermostat continues

to call for heat. When boilerwater temperature drops pastthe

high limit set point and through the differential,high limit

contacts B-Rclose,repeating steps3-7.

9. If venting systembecomesblocked, blower suction pressurewill

drop belowthe pressure switchset point, opening the pressure

switch contacts and cutting power to the intermittent pilot con-

trol. Burners willextinguish, butblower willremain powered

aslong asthe thermostat continuesto callfor heat. Ifventing

systemclears,steps 4-7will repeat.

10. Thermostat is satisfied,ending callfor heat. Relaycoil 1Kisde-

energized,opening 1K1and 1K2contacts. Burners extinguish.

Blowerand circulator pump stop.

Page 24

Figure #13 -Intermittent Ignition

120/60/1

POWER SUPPLY

NEUT 24V

HOT_ I THERMOSTAT

,Olw7:DISCONNEC 1

;1)/L. q <T_

\_>' _'/ \/

-!_ L8148A

AQUASTAT G

LINE VOLTAGE WIRING

LOW VOLTAGE WIRING

LOW VOLTAGE FIELD WIRING

B BLACK

BT BLACK WITH TRACER

W WHITE

G GREEN

R RED

BL BLUE

INDUCER

DRAFT

/

AT 140C TRANSFORMER

7

B

B

CIRCULATOR

HOT

B

FUSED

fll_ +DISCONNECT

i ,

1K1

?_ HIGHLIMIT

B_ B

l

INTERMITTENT PILOT CONTROL

> -_s-2_ l

>5> >_ z_Z_ I

I I

_(_ TBKTBKTBT_Bk--TOPILOT

/// / / / _" BURNER

PRESSURE ROLLOUT/// 'Ln_in

SWITCH SWITCH // W _.- GAS VALVE

/VR8204A/VRS,04M

170/60/1P?WERSUPPLY

120 V PRIMARY

[ 24ZVrSEC%NDARY _IK

.) \. _/ -

24 V THERMOSTAT O

II

1K2

¥_L31

PRESSURE ROLLOUT

SWITCH SWITCH

B _ w

G

'\S

DRAFT INDUCER

120V PRIMARY

\)_/,),..J

24 V SECONDARY

CIRCULATOR

AT 140C TRANSFORMER

w

INTERMITTENT

PILOT CONTROL

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

NEUT

W

(LL"i

\l j'

1/c2

\j'

TO GAS

VALVE

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii!Ifanyoftheoriginalwireassuppliedwiththisappliance

must be replaced,it must be replacedwith type 105° C

thermoplastic wireor its equivalent.

NOTE:Thecirculatorharness isfactorywired to the

aquastat.Thisharness needs to beconnected to the circu-

latorin thefield.

Page 25

Relief Valve

Youmust havea reliefvalve on your boiler.Water expands asit is

heated. Ifthere is no placefor thewater to expand into,waterpres-

surewill build up insidethe boiler and system. Should this happen,

the ReliefValvewillautomaticallyopen ata pre-determined pres-

sure. Thiswillrelievethe strain on the boilerand system.Run apipe

from thereliefvalveoutlet (pipemust be samesizeasoutlet and the

open end must not be threaded) to anopen drain, tub or sink,or

other suitabledrainagepoint not subject tofreezing. Failure to do so

maycausewater damageor injuryshould reliefvalverelease.

Expansion Tank

In aproperly assembledsystem, the expanding water flowsinto an

ExpansionTank.This tank should be ofthe correct size.

Thetank ispartially filledwith air.Asthe water expandsit compress-

esthe air in the tankto form an airpressure cushion. This"spring-

like"cushion servesto maintain correct operating water pressure

regardlessof watertemperature. Thisassuresa "fullmeasure"ofwa-

ter, evenin the highest radiation unit ofthe system.It alsoprevents

blowingoffof the reliefvalve.

Theair in the tank inthe beginning (with systemfilledwith cold wa-

ter) issufficientfor proper operation. Thetank also servesasa trap

for excessair in the system. The air would causegurgling in the pipes

and inefficientcirculation in the radiators ifleft in the system.

It ispossible fora tank to become "waterlogged"(filledwith water).

It can alsobecome overfilledwith air.Thiscan happen afterfilling

the systemwith newwater.Fittings provided on the tank and inthe

line to the tank are for bleeding offexcesswater or air.

When installingthis tank, itis important:

1)Thatthe tank be higher than the boiler top.

2)That the pipe to the tank continuouslyrises up to the tank (so that

air can "bubble"up toit).

Diaphragm Type Expansion Tank

TheDiaphragm Type Expansion Tank (EX-TROL)takes the place

ofthe conventionalexpansion tank. Carefullyread the instructions

packedwith your EX-TROLTank Assembly.The EX-TROLTank

comesto youwith a 10-12pounds per squareinch air charge.Thisis

the sameasthe pressure produced inthe systemby the automatic fill

valve.When the systemis firstfilled,the EX-TROLTankwillcontain

littleor no water.

Asthe water is heated itspressure increases.It expands into the EX-

TROLTank,compressing the air in the tank. Thiscompressed air

cushion permits the waterin the systemto expand asthe tempera-

ture changes.

Air Eliminating Fitting (Air Purger)

AnAir Purger is usedto remove excessairfrom the system. It is in-

stalledin the supplyline.It willhelp to eliminateairfrom the water

before it reachesthe radiators andbleed offthis air.

Main Air Vent For Down Flow Systems Or Diaphragm Type

Expansion Tank

Beforeasystem isfilledwith water,there is air in the pipesand

radiation units. Someof itwill be trapped as the systemis filled.It

ispossible to eliminatemost of this airthrough the airvents on the

radiation units.A Main AirVent will speed and simplifythis. It

shouldbe installed on the highest point inthe main when allradia-

tion isbelowtop ofboiler.

Automatic Fill Valve

For safe,efficientoperation, a hotwater systemmust befilledwith

water.Adding new water,when needed canbe done manually(by

useof a hand valvein thewater supplyline). Thisrequires regular at-

tention to thesystem'sneeds. AnAutomaticFillValveaccomplishes

this without attention. It isinstalled in the Supply Lineon hot water

boilers only.TheValveoperates through water pressure differentials.

It does not require an electricalconnection.

Drain Valve

This manual valve provides a means of draining all water from the

boiler and system. It isoften installed in the _" Tapping at the bot-

tom of the left boiler section. Or it can be installed in a tee where the

return line enters the boiler.

Water Temperature Control

The water temperature limit control in the relay is adjustable and

may be set as necessary. It may be set as low as 140° F, or as high as

240° E This depends on the type and amount of radiation involved

and weather conditions.

Circulating Pump

EveryForcedHot-Water Systemrequires a Circulating Pump. A

separatepump or zonevalveis requiredfor eachZone, ifyou have

atwo or more Zone System.Thispump must havethe capacityto

provide the circulation required byyour system.

Thepump does notcome pre-installed on theboiler. It must be con-

nected to the circulator harness in the fieldaccording to the pump

manufacturer's instructions andthe wiring diagrams inthis manual.

Page 26

Blower (Draft Inducer)

Rollout Switch

The blower provides a means for pulling air through the boiler and

exhausting the flue gasses into the vent system. The blower shuts off

when the burners are not firing. This keeps heat in the house rather

than having it go up the chimney.

Pressure Switch

The air pressure switch works on a negative pressure. When the

blower comes on the air pressure switch operates the intermittent pi-

lot and gasvalve. The air pressure switch is factory set and will only

work when the blower operates properly. It will not allow the boiler

to come on if the blower does not generate enough pressure or if the

venting system is blocked.

Factory Pressure Switch Set point:

-0.4" wc. for 2-5 section boilers.

-0.5" w.c. for 6-7 section boilers.

(Flame Rollout Safety Shutoff)

The rollout switch is a temperature-sensitive fuse link device. It is lo-

cated on the boiler base just outside the fire box. In the event of heat

exchanger flueway blockage causing flame to roll out of the fire box,

the fuse will blow, shutting down the flow of gas to the main burners.

The fuse does not change in appearance when blown.

If the rollout switch blows, it must be replaced with an exact replace-

ment. Check heat exchanger flueways for blockage when restoring

system to operating condition. Do not operate system without a

rollout switch.

Page 27

HowA Hot Water System Operates

Your entire heating system (boiler, piping and radiation units) is

filled with water. As the water in the boiler is heated, it is pumped

from the top of the boiler through the supply main to the radia-

tion units. The cooler water in them flows back through the return

main to the boiler. This provides positive and rapid response to the

thermostat.

Filling System With Water

Close the Air Vents on all radiation units. Open the Valves to these

units. Make sure the boiler and Expansion Tank Drain Cocks are

closed. The Air Bleed Screw on the tank Drain Fitting should be

closed. Open the valve in the line from the boiler to the expansion

tank. Open the water inlet to your boiler and leave it open. Start with

the lowest radiation unit. Open the air vent on this unit. When all

the air has escaped and water starts to flow from the vent, close it.

Go to the next radiation unit, and repeat this process. Repeat until

you have covered every radiation unit in the system (ending up at

the highest unit in the system). If your units have automatic vents,

this manual venting is unnecessary but it will speed up the proper

filling of your system.