Page 1

GAS-FIRED,DIRECTVENT,

CONDENSING, HOT WATER BOILER

INSTALLATION, OPERATION&

MAINTENANCE MANUAL

DUNKIRK BOILERS

85 Middle Rd.

Dunkirk, NY 14048

www. dunkirk, com

P/N# 14683301,Rev.C [12/2010]

Page 2

90-75

90= 1 O0

These instructions

must be affixed on or

adjacent to the boiler.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiitheinstallation.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiSave this manual for reference.

Improper installation, adjustment, alteration,

service, or maintenance can cause injury or

property damage. Refer to this manual. For

assistance or additional information consult a

qualified installer, service agency, or the gas

supplier.

Read all instructions carefully before starting

Page 3

Warnings and Safety Symbols ....................................................................................................... 3

Introduction ................................................................................................................................ 4

Boiler Ratings & Capacities ........................................................................................................... 5

Boilers For Use At High Altitude ..................................................................................................... 6

Rules For Safe Installation And Operation ....................................................................................... 8

Before Installing The Boiler ........................................................................................................... 8

Pladn( The Boiler ....................................................................................................................... 11

Near Boiler Piping ....................................................................................................................... 12

Combustion Air and Vent Pipe ...................................................................................................... 19

Gas Supply Piping ....................................................................................................................... 24

Electrical Wiring ......................................................................................................................... 26

Controls and Accessories ............................................................................................................. 30

Water Treatment & Freeze Protection ............................................................................................ 32

Start Up .................................................................................................................................... 34

Operating Instructions ................................................................................................................. 35

To Turn Off Gas To Appliance ........................................................................................................ 35

Check Out Procedure and Adjustment ........................................................................................... 36

Installation and Check-Out Certificate ............................................................................................ 40

Maintenance And Cleaning ........................................................................................................... 41

Detailed Sequence Of Operation ................................................................................................... 44

Troubleshooting .......................................................................................................................... 47

Differential Air Pressure Switch Check ........................................................................................... 55

IMPORTANT: THIS MANUAL MUST BE KEPT NEAR THE BOILER FOR FUTURE REFERENCE!!

Indicates an imminently hazardous situation

which, if not avoided, WILL result in death,

serious injury or substantial property damage,

which, ifn ot avoid ed, mayresu It in death,

serious injury or substantial property damage.

Indicates an imminently hazardous situation

which, if not avoided, may result in injury or

property damage.

Indicates information which should be

followed to ensure proper installation and

operation.

Page 4

This appliance is a gas-fired direct vent hot water boiler with cast

aluminum boiler sections. A revolutionary cast aluminum heat

exchanger means better heat transfer and thermal storage than

sirnilarly sized cast iron boilers, which results in higher efiqciency.

The heating system water absorbs large amounts of heat from the

cast aluminum heat exchanger, cooling the flue gases and causing

condensation. Sealed combustion, premix gas burner, and low flame

temperature means drastically reduced CO and NOx emissions,

which contribute to a cleaner and healthier environment.

(sealedcombustion)and does not competewith building occupants

for fresh air. Sealedcombustion (also known as"directvent") is the

safestand best wayto obtainplentyofcleancombustion air. The

induced draft fan drawsin the outside combustion air,then takesthe

coolerfluegasesfrom the boilerunit and providesa positiveremoval

of thefluegasesfrom the building through inexpensiveand readily

availablePVCand CPVC pipes.

Thisappliance,unlikenormal residential atmospheric and induced

draft units, takes itscombustion airdirectly from the outdoors

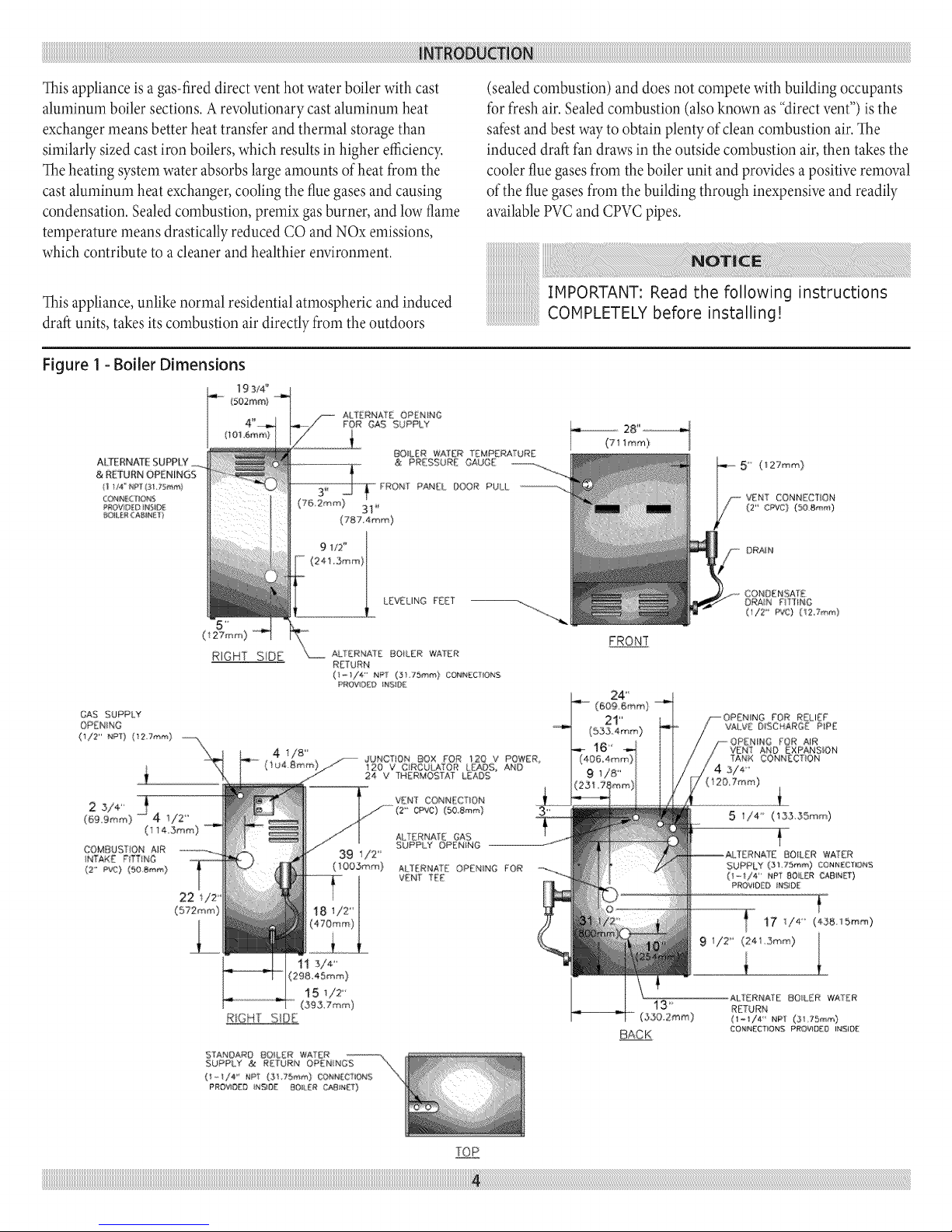

Figure 1 - Boiler Dimensions

19 3/4"

(502ram}

ALTERNATE SUPP|.Y _,

& RETURN OPENINGS

CONN{::<7_ONS

_ROVID_DINEID_

gOILER(A@_[ [

RETURN

(1_/4' _4_P_ (3175_'nm) CONNECTIOP#S

PROVID£FJ INSIDE

4 V8"......(iu4.Smm)

22

(572mm)

JUNCTION BOX FOR _20 V POWER,

120 V CIRCULATOR LEADS, AND

24 V THERMOSTAT LEADS

VENT CONNECTION

CPvC) (50,Smm}

ALTERNATE GAS

39 112"

( _O05mm)

SUPPLY OPENING

ALTERNATE OPENING FOR

VENT TEE

IMPORTANT: Read the following instructions

COMPLETELY before installing!

( t 27r,nm)

VENT CONNECTION

(2" CPvC) (SO gin.' 0

DRA_N

CONDENSATE

DRAN FITIINO

(1/2" pro) O2.Tmm)

FRONT

(609.6mr,n}

2t"

24 _

(833 4ram)

VENT AND EXPANSION

TANK CONNECT{ON

FOR AIR

L

PROV_O_D iNS_g£ 80{LER C_81NE[)

13 ¸,1

(350.2mm)

BACK

TO_

Page 5

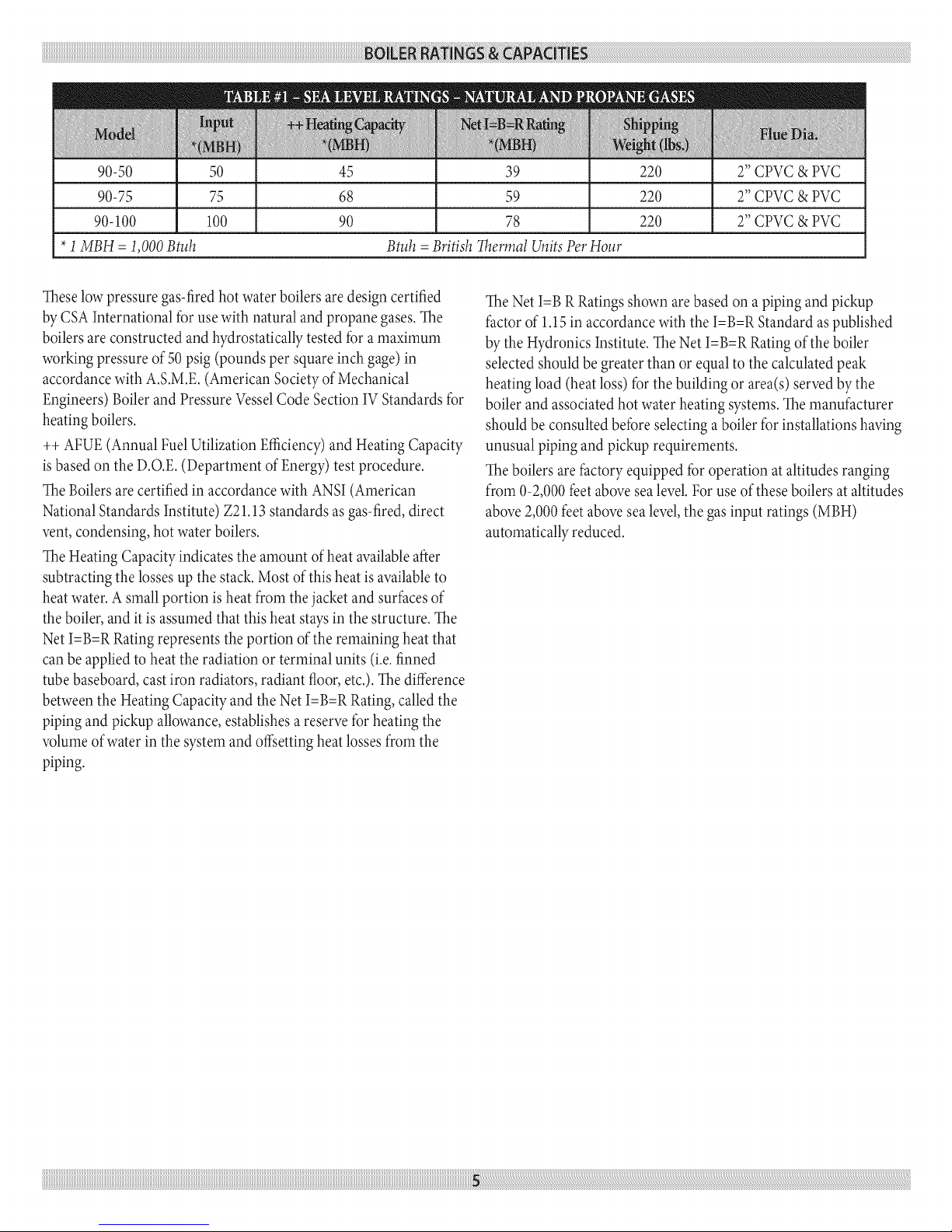

90-50 50 45 39 220 2" CPVC & PVC

90-75 75 68 59 220 2" CPVC & PVC

90-100 100 90 78 220 2" CPVC & PVC

*1MBH = 1,000 Btuh Btuh =British Thermal Units Per Hour

These low pressure gas-fired hot water boilers are design certified

by CSA International for use with natural and propane gases. The

boilers are constructed and hydrostatically tested for a rnaximurn

working pressure of 50 psig (pounds per square inch gage) in

accordance with A.S.M.E. (Arnerican Society of Mechanical

Engineers) Boiler and Pressure Vessel Code Section IV Standards for

heating boilers.

++ AFUE (Annual Fuel Utilization Efficiency) and Heating Capacity

is based on the D.O.E. (Departrnent of Energy) test procedure.

The Boilers are certified in accordance with ANSI (American

National Standards Institute) Z21.13 standards as gas-fired, direct

vent, condensing, hot water boilers.

The Heating Capacity indicates the arnount of heat available after

subtracting the losses up the stack. Most of this heat is available to

heat water. A srnall portion is heat frorn the jacket and surfaces of

the boiler, and it is assumed that this heat stays in the structure. The

Net I=B=R Rating represents the portion of the rernaining heat that

can be applied to heat the radiation or terminal units (i.e. finned

tube baseboard, cast iron radiators, radiant floor, etc.). Thedifference

between the Heating Capacity and the Net I=B=R Rating, called the

piping and pickup allowance, establishes a reserve for heating the

volurne of water in the systern and offsetting heat losses frorn the

piping.

The Net I=B R Ratings shown arebased on a piping and pickup

factor of 1.15 in accordance with the I=B=R Standard as published

by the Hydronics Institute. The Net I=B=R Rating of the boiler

selected should be greater than or equal to the calculated peak

heating load (heat loss) for the building or area(s) served by the

boiler and associated hot water heating systems. The rnanufacturer

should be consulted before selecting a boiler for installations having

unusual piping and pickup requirernents.

The boilers are factory equipped for operation at altitudes ranging

frorn 0-2,000 feet above sea level. For use of these boilers at altitudes

above 2,000 feet above sea level, the gas input ratings (MBH)

autornatically reduced.

Page 6

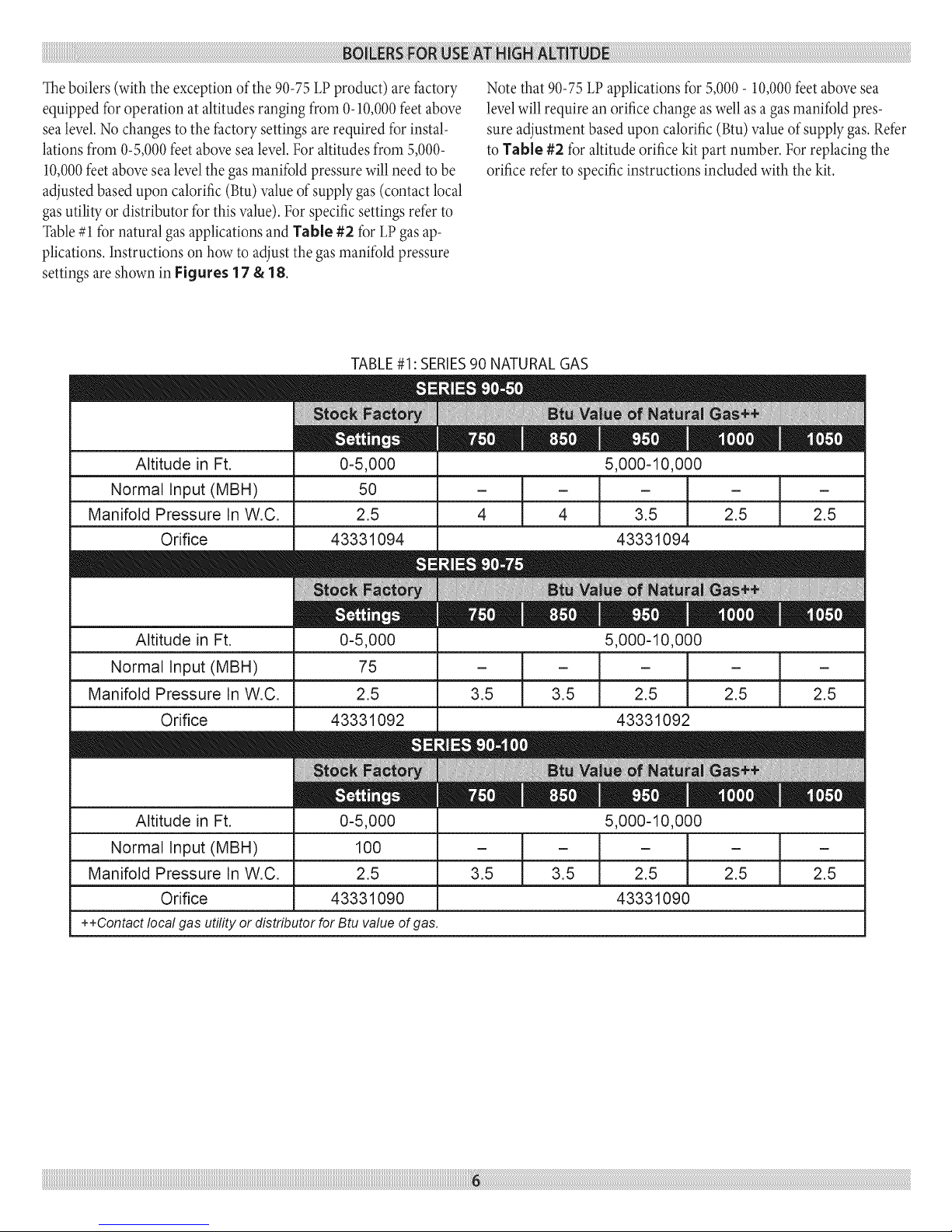

Theboilers(with the exceptionof the 90-75LPproduct) arefactory

equipped foroperation at altitudesranging from 0-10,000feetabove

sealevel.Nochanges to the factory settings arerequired for instal-

lationsfrom 0-5,000feet abovesealevel.Foraltitudes from 5,000-

10,000feetabovesealevel thegasmanifoldpressurewill need to be

adjustedbased upon calorific (Btu)valueof supplygas (contact local

gasutilityor distributor for thisvalue). For specificsettings refer to

Table#1 for natural gasapplicationsand Table #2 for LPgasap-

plications.Instructions on how to adjust the gasmanifold pressure

settings are shown in Figures 17 & 18.

TABLE#1: SERIES90 NATURAL GAS

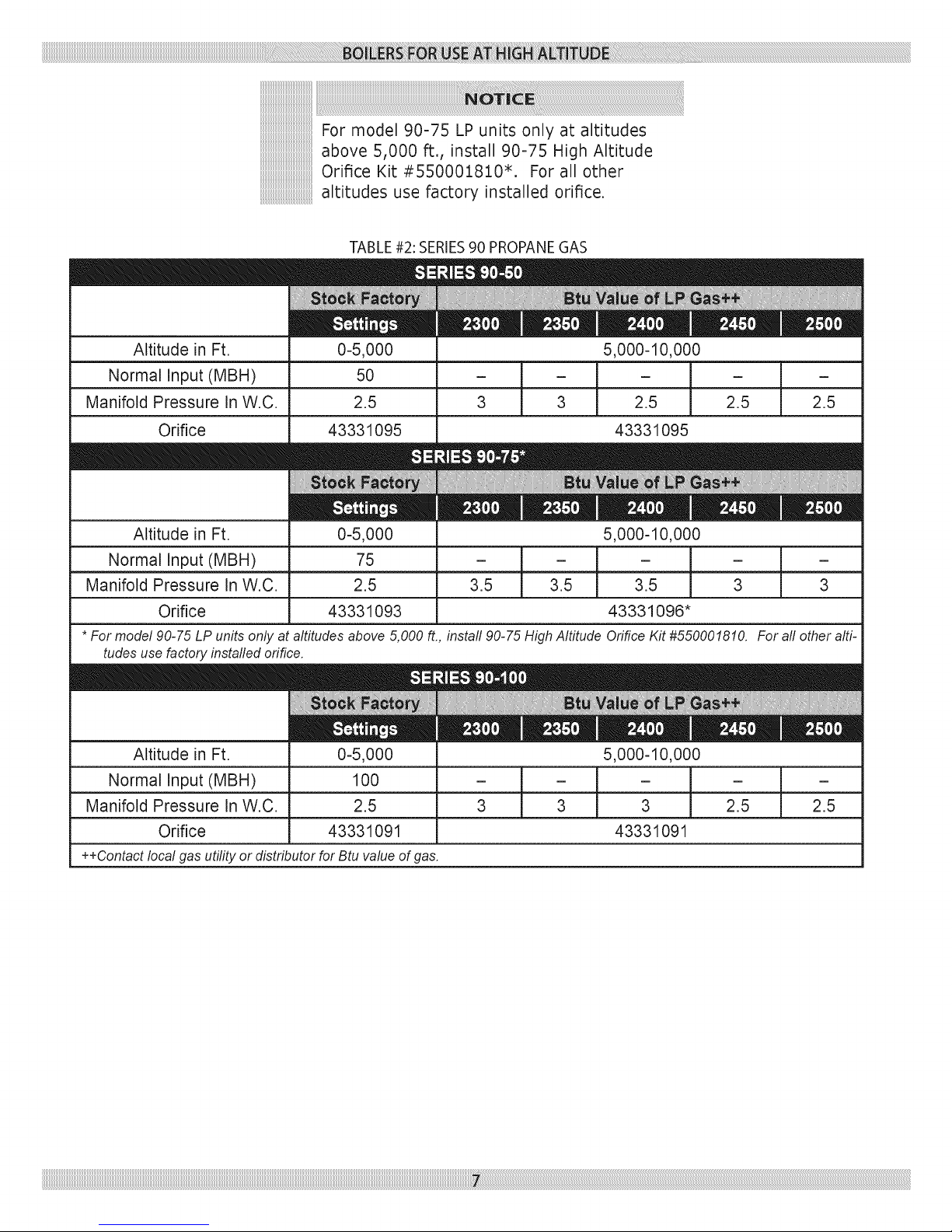

Note that 90-75 LP applications for 5,000- 10,000 feet above sea

level will require an orifice change aswell as a gas manifold pres-

sure adjustment based upon calorific (Btu) value of supply gas. Refer

to Table #2 for altitude orifice kit part number. For replacing the

orifice refer to specific instructions included with the kit.

Altitude in Ft.

Normal Input (MBH)

Manifold Pressure In W.C.

Orifice

Altitude in Ft. 0-5,000 5,000-10,000

Normal Input (MBH) 75 - _ - - / - / -

Manifold Pressure In W.C. 2.5 3.5 / 3.5 2.5 / 2.5 / 2.5

Orifice 43331092 43331092

Altitude in Ft.

Normal Input (MBH)

Manifold Pressure In W.C.

Orifice

++Contact local gas utility or distributor for Btu value of gas.

0-5,000

50

2.5

43331094

0-5,000

100

2.5

43331090

5,000-10,000

- i - - i -

4 1 4 2.5 1 2.5

t t

3.5 3.5 2.5 2.5

- ]

3.5 _

43331094

5,000-10,000

-t

2.5

43331090

Page 7

i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i

For model 90-75 LP units only at altitudes

above 5,000 ft., install 90-75 High Altitude

Orifice Kit #550001810*. For all other

altitudes use factory installed orifice.

TABLE#2: SERIES90 PROPANEGAS

Altitude in Ft.

Normal Input (MBH)

Manifold Pressure In W.C.

Orifice

Altitude in Ft.

Normal Input (MBH) - - [ - -

Manifold Pressure In W.C. 2.5 3.5 3.5 l 3 3

Orifice 43331093

* For model 90-75 LP units only at altitudes above 5,000 ft., install 90-75 High Altitude Orifice Kit #550001810. For all other alti-

tudes use factory installed orifice.

Altitude in Ft.

Normal Input (MBH)

Manifold Pressure In W.C.

Orifice

++Contact local gas utility or distributor for Btu value of gas.

0-5,000

50

2.5

43331095

0-5,000

75

0-5,000

100

2.5

43331091

5,000-10,000

[ - ]

3 3 2.5 2.5

43331095

5,000-10,000

- ]

3.5 l

43331096*

5,000-10,000

3 3 2.5 2.5

43331091

Page 8

1. Readtheentireinstallationmanualbeforebeginningtheinstal-

lation.Failuretofollowtheserulesforsafeinstallationand

operationandtheseinstructionscouldcauseamalfunction

oftheboilerandresultindeath,seriousbodilyinjury,and/or

propertydamage.

2. Checkallapplicablestateandlocalbuildingcodesandutil-

itycompanyrequirementsbeforeinstallation.Theinstallation

mustconforrnwiththeserequirementsintheirentirety.Inthe

absenceofthesecodes,useNFPAInstallationCodesandgood

industrypractice.

3. Beforeservicingtheboiler-allowtheboilertocool.Always

shutoffanyelectricityandgassupplyconnectedtotheboiler

priortoservicing.

4. Inspectgaslineforleaks.

5. Becertaingasinputrateiscorrect.Overfiringmayresultin

earlyfailureoftheboilersections.Thismaycausedangerous

operation.Underfiringmayresultintoomuchairforthepre-

mixburnercausingpoororlossofcombustion.

6. Never vent the products of combustion from this boiler to an

enclosed space. Always vent to the outdoors. Never vent to

another room or to inside a building.

7. Be sure there is adequate outdoor air supply to boiler for com-

plete combustion.

8. Follow a regular service and maintenance schedule for efficient

and safe operation.

9. Keep boiler area clean of debris and flee of combustible and

flammable rnaterials.

10.

Proper through the wall or through the roof cornbustion vent-

ing shallbe in accordance with the materials and methods

described in this manual. Installation must complywith local

codes.

11.

This boiler and related hot water heating systems are not do it

yourself items. They must be installed and serviced by qualified

professionals.

This boiler has been equipped for residential

installations. If used for commercial

applications, any additional code requirements

must be adhered to for installation. This may

require additional controls including but not

limited to a low water cut off, a manual reset

high temperature limit, and wiring and/or

piping modifications. The manufacturer is not

responsible for any field installation changes

made to a boiler installation which are not

described or acknowledged in this manual.

Complete all of the following prior to installing the boiler.

Codes

This boiler product is a gas-fired, direct vent, condensing boiler and

must be installed to conforrn to the requirernents of the authority

having jursidiction or, in the absence of such requirements:

United States- National Fuel Gas Code (NFPA-54/ANSI Z223.1).

Canada- National Gas and Propane Installation Code, Can/CSA

B149.1.

Where required bythe authority havingjurisdiction, the installation

must conform to the Arnerican Societyof MechanicalEngineers

SafetyCode for Controls and SafetyDevicesfor AutomaticallyFired

Boilers,No.CSD-1.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_

Important - In the state of Massachusetts

this product must be installedby a licensed

plumber or gas fitter and the installation must

be in accordance with 248 CHR.

Installers- Followlocal regulationswith respect to installation of

CO (Carbon Monoxide) Detectors. Followmaintenance recommen-

dations in this manual.

Installation Requirements Specific To The State Of

Massachusetts For Direct Vent, Mechanical Vent_ And

Domestic Hot Water Appliances

For all side wall horizontally vented gas fueled equiprnent installed

in every dwelling, building or structure used in whole or in part

for residential purposes, including those owned or operated by the

comrnonwealth and where the side wall exhaust vent terrnination is

less than seven (7) feet above finished grade in the area of the vent-

ing, including but not limited to decks and porches, the following

requirernents shall be satisfied:

. Installationof carbon rnonoxide detectors: atthe time ofinstal-

lation of the sidewall horizontal vented gasfueledequipment,

the installingplurnber or gasfittershallobserve that a hard

wired carbon rnonoxide detectorwith an alarrn and battery

back-up is installedon the floor levelwhere the gas equipment

isto be installed. In addition, the installing plurnber or gasfitter

shallobserve that a battery operated or hard wired carbon rnon-

oxidedetector with an alarrnisinstalled on each additional level

of thedwelling,building or structure servedby the side wall

horizontal vented gasfueledequipment. It shallbe the respon-

sibilityof the property owner to securethe servicesof qualified

licensed professionalsfor the installationof hard wired carbon

rnonoxide detectors.

Page 9

a.

In the event that the side wall horizontally vented gas

fueled equiprnent is installed in a crawl space or an attic,

the hard wired carbon rnonoxide detector with alarm and

battery back-up may be installed on the next adjacent floor

level.

g.

In the event that the requirernents of this subdivision can

not be rnet at the time of cornpletion of installation, the

owner shall have a period of thirty (30) days to comply

with the above requirernents; provided, however, that dur-

ing said thirty (30) day period, a battery operated carbon

monoxide detector with an alarm shall be installed.

o

Approved carbon monoxide detectors: each carbon monoxide

detector as required in accordance with the above provisions

shall comply with NFPA720 and be ANSI/UL 2034 listed and

IAS certified.

3. Signage: a metal or plastic identification plate shall be perrna-

nently mounted to the exterior of the building at a rninimum

height of eight (8) feet above grade directly in line with the

exhaust vent terminal for the horizontally vented gas fueled

heating appliance or equipment. The sign shall read, in print

size no less than one-half (112)inch in size, "gas vent directly

below. Keep clear of all obstructions".

4. Inspection: the state or local gas inspector of the side wall

horizontally vented gas fueled equipment shall not approve

the installation unless, upon inspection, the inspector observes

carbon monoxide detectors and signage installed in accordance

with the provisions of 248 CMR 5.08(2)(A)1 through 4.

5. Product-approved vent/air-intake: a product-approved vent ter-

minal must be used and, if applicable, a product-approved air

intake must be used. Installation shall be in strict compliance

with the rnanufacturer's instructions.

o

Installation instructions: a copy of allinstallation instructions

for all product approved side wall horizontally vented gas fueled

equipment, all venting instructions, all parts lists for venting

instructions, and/or all venting design instructions shall remain

with the appliance or equipment at the completion of the instal-

lation.

Boiler Sizing

Checktobe sure you haveselected the boiler with the proper capac-

itybeforestarting the installation. TheI=B=RRatingofthe boiler

selectedshould be greater than or equal to the calculatedpeak heat-

ing load (heat loss)for the building or area(s) served by the boiler

and associatedhot waterheating systems.Seethe table"BOILER

RATINGSAND CAPACITIES"(page5 of this docurnent).

Heat losscalculationsshould be based on approved industry meth-

ods.

Considerations For Boiler Location

Before selecting a location for the boiler, the following should be

considered. Each boiler considered.

•Suppliedwith the correct type of gas(natural gasor pro-

pane).

• Connected to a suitable cornbustion air intake piping sys-

tern to supply the correct amounts of fresh (outdoor) air

for cornbustion, refer to Combustion Air And Vent Pipe

section (near center of this manual) for details.

• Connected to a suitable venting systern to remove the

hazardous products of gas combustion, refer to Cornbus-

tion Air And Vent Pipe section (page 19 of this rnanual) for

details.

•Connectedto asuitablehot water heating systern.

•Suppliedwith a suitableelectricalsupplyfor allboilerrno-

tors and controls.

• Connected to a properly located therrnostat or operating

control. (not included with boiler)

•Placedon levelsurface (rnust NOT be installedon carpet-

ing)

•Condensate drain line must bepitched down to floor drain

or externalcondensate purnp with reservoir at1A"per foot

(woodfrarneor blocksrnay beused to raise boiler).

Locating The Boiler

1. Selecta locationwhich is level,central to the piping systerns

served and as closeto the vent and air intaketerrninals aspos-

sible.

2. Accessibility clearances, if more stringent (i.e. larger clearances)

than required fire protection clearances, rnust be used for the

boiler installation. Accessibility clearances rnay be achieved

with the use of removable walls or partitions.

3. The boiler is approved for installation in closets and on com-

bustible floors. This boiler shall NOT be installed on carpeting.

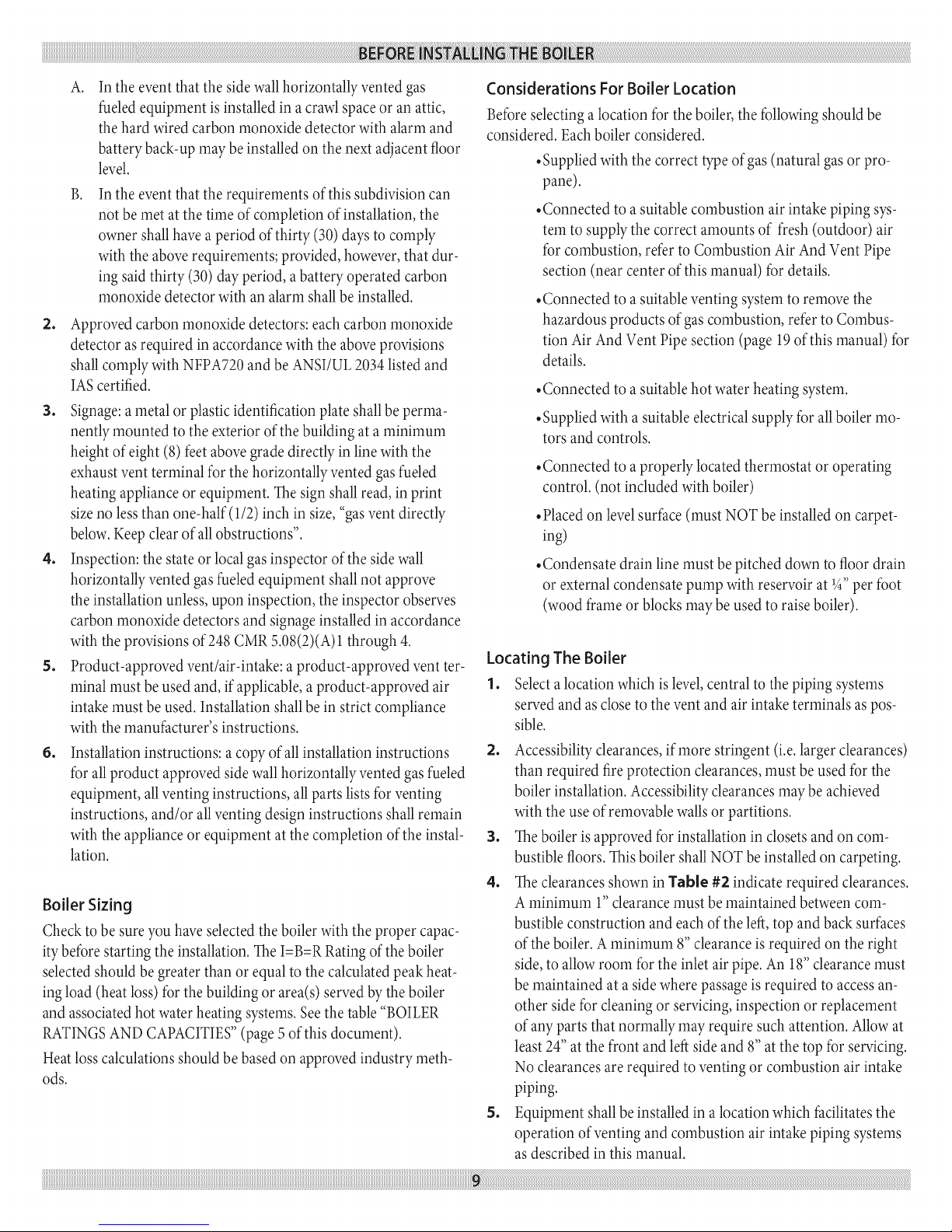

4. The clearances shown in Table #2 indicate required clearances.

A rninimurn 1" clearance rnust be rnaintained between corn-

bustible construction and each of the left, top and back surfaces

of the boiler. A rninimum 8" clearance is required on the right

side, to allow roorn for the inlet air pipe. An 18" clearance rnust

be rnaintained at a side where passage is required to access an-

other side for cleaning or servicing, inspection or replacernent

of any parts that norrnally rnay require such attention. Allow at

least 24" at the front and left side and 8" at the top for servicing.

No clearances are required to venting or cornbustion air intake

piping.

5. Equipment shall be installed in a location which facilitates the

operation of venting and cornbustion air intake piping systems

as described in this rnanual.

Page 10

6. Adviseownerofboilertokeepventingandcombustionair

intakepassagesfreeofobstructions,boththeventingandcorn-

bustionairintakepipingsystemsconnectedtotheoutdoors

rnustpermitflowthroughthepipingsysternswithoutrestric-

tionsfortheboilertooperate.

7. Theboilershallbeinstalledsuchthattheautomaticgasignition

systerncornponentsareprotectedfromwater(dripping,spray-

ing,rain,etc.)duringoperationandservice(circulatorreplace-

rnent,condensatetrap,controlreplacernent,etc.).

Combustion Air And Vent Pipe Requirements

This boiler requires adedicated direct vent systern. In a direct vent

systern, all air for cornbustion is taken directly frorn outside atrno-

Top 1 (25.4) 8 (203.2)

Left Side 1 (25.4) 24 (609.6)

Right Side 8 (203.2)

sphere,and all flue products are discharged to outside atmosphere.

Cornbustion air and ventpipe connections rnust terrninate together

in the sameatmosphericpressure zone, either through the roof

or sidewall(roof termination preferred). SeeFigures 9 & 10 (in

Combustion Air AndVentPipe sectionofthis manual) for required

clearances.

Keep boiler area clean of debris and free of

flamable and combustible materials, vapors

and liquids.

Base 1 (25.4)

Front 1 (25.4) 24 (609.6)

Back 1 (25.4)

Intake/Vent Piping 0 (0)

Near Boiler Hot Water Piping 1 (25.4)

All distances measured from the cabinet of the boiler.

When vent pipe is exposed to temperatures below freezing, such as when it passes through an

unheated space or when a chimney is used as a raceway, vent pipe must be insulated with :!./2"

Armaflex or equivalent. In extreme cold climate areas, use 3/4" Armaflex or equivalent.

Combustion air must be clean outdoor air. Combustion air must not be taken from inside structure

because that air frequently is contaminated by halogens, which include fluorides, chlorides, phosphates,

bromides and iodides. These elements are found in aerosols, detergents, bleaches, cleaning solvents,

salts, air fresheners, paints, adhesives and other household products.

Locate combustion air inlet as far away as possible from swimming pool and swimming pool pump

house.

All combustion air and vent pipes must be airtight and watertight. Combustion air and vent piping must

also terminate exactly as shown in Figure 9 or 10 (in Combustion Air And Vent Pipe section, page 19

of this manual).

Vent connections serving appliances vented by natural draft shall not be connected into any portion of

mechanical draft systems operating under positive pressure.

Solvent cements are combustible. Keep away from heat, sparks, and open flame. Use only in well

ventilated areas. Avoid breathing in vapor or allowing contact with skin or eyes.

FAILURE TO FOLLOW THE AFOREMENTIONED WARNINGS COULD RESULT IN FIRE, PROPERTY DAMAGE,

PERSONAL INJURY, OR DEATH.

Page 11

Condensate Drain Requirements

Condensate drain line to be pitched down to floordrain atamini-

rnurnof 1A"per foot.An external condensatepump (not furnished)

maybe used if floordrain isnot available.Thecondensate pump

must be designed for fluegas condensate application.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_

:[.Condensatetrap bu,t ntothebo ler,an

external trap is not required and should not

2. Wood frame or blocks may be used to raise

the boiler to maintain drain pitch or to be

above external condensate pump reservoir.

3. There is a :[::[5 Volt AC receptacle provided

on the service switch junction box which is

located at the boiler right side, to provide

power for an external condensate pump (if

needed).

Foundation Requirements

Boilermust be placedon levelsurface.Boileris NOT to be installed

on carpeting.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_

If boiler is not level condensate drain lines

will not function properly. Adjustable feet are

located on the boiler to makeup for minor

surface irregularities or tilt.

Wood frame or blocks may be used to raise

boiler to maintain drain pitch or to be above

external co ndensate pum p rese rv oir.

Removal of Existing Boiler From Common Vent System

When an existing boiler is rernoved from a common venting system,

the comrnon venting systern is likely to be too large for proper vent-

ing of the appliances remaining connected to it. At the time of re-

moval of an existing boiler, the following steps shall be followed with

each appliance rernaining connected to the common venting systern

placed in operation, while the other appliances rernaining connected

to the cornmon venting systern are not in operation.

1. Seal any unused openings in the comrnon venting systern.

2. Visually inspect the venting system for proper size and hori-

zontal pitch and deterrnine there isno blockage, or restrictions,

leakage, corrosion and other deficiencies which could cause an

unsafe condition.

3. In-so-far as is practical, close all building doors and windows

and all doors between the space in which the appliances remain-

ing connected to the common venting system are located and

other spaces of the building. Turn on clothes dryer and any ap-

pliance not connected to the common venting systern. Turn on

any exhaust fans, such as range hoods and bathroom exhaust, so

they will operate at maximum speed. Do not operate a summer

exhaust fan. Close fire darnpers.

4. Place in operation the appliance being inspected. Follow the

lighting instructions. Adjust therrnostat so appliances will oper-

ate continuously.

5. Test for spillage at the draft hood relief opening after 5minutes

of main burner operation. Use the flame of a match or candle,

or the smoke frorn acigarette, cigar or pipe.

6. After it has been deterrnined that each appliance remaining

connected to the common venting systern properly vents when

tested as outlined above, return doors, windows, exhaust fans,

fire place dampers, and any other gas-burning appliance to their

previous condition of use.

7. Any improper operation of the comrnon venting systern should

be corrected so the installation conforms with the National Fuel

Code, NFPA-54/ANSI -Z223.1 and/or the Natural Gas and

Propane Installation Code, CAN/CSA B149.1.. When resizing

any portion of the common venting systern, the comrnon vent-

ing system should be resized to approach the minimum size as

deterrnined using the appropriate tables in Chapter 13 of the

National Fuel Gas Code, NFPA-54/ANSI- Z223.1 and/or the

Natural Gas and Propane Installation Code, CAN/CSA B149.1.

The boiler should be placed to provide the most direct connections

to the combustion air, vent and systern piping as possible.

Place crated boiler as close to selected location as possible and

uncrate boiler. The uncrated boiler may be moved into position with

an appliance dolly or 2-wheel hand truck. The dolly or hand truck

should be inserted under the left hand side of the boiler. It is possible

to slide the boiler for a short distance on a smooth floor or surface.

Refer to manual section "locating the

boiler" (page 9 of this manual), for required

clearances for servicing and maintenance.

Page 12

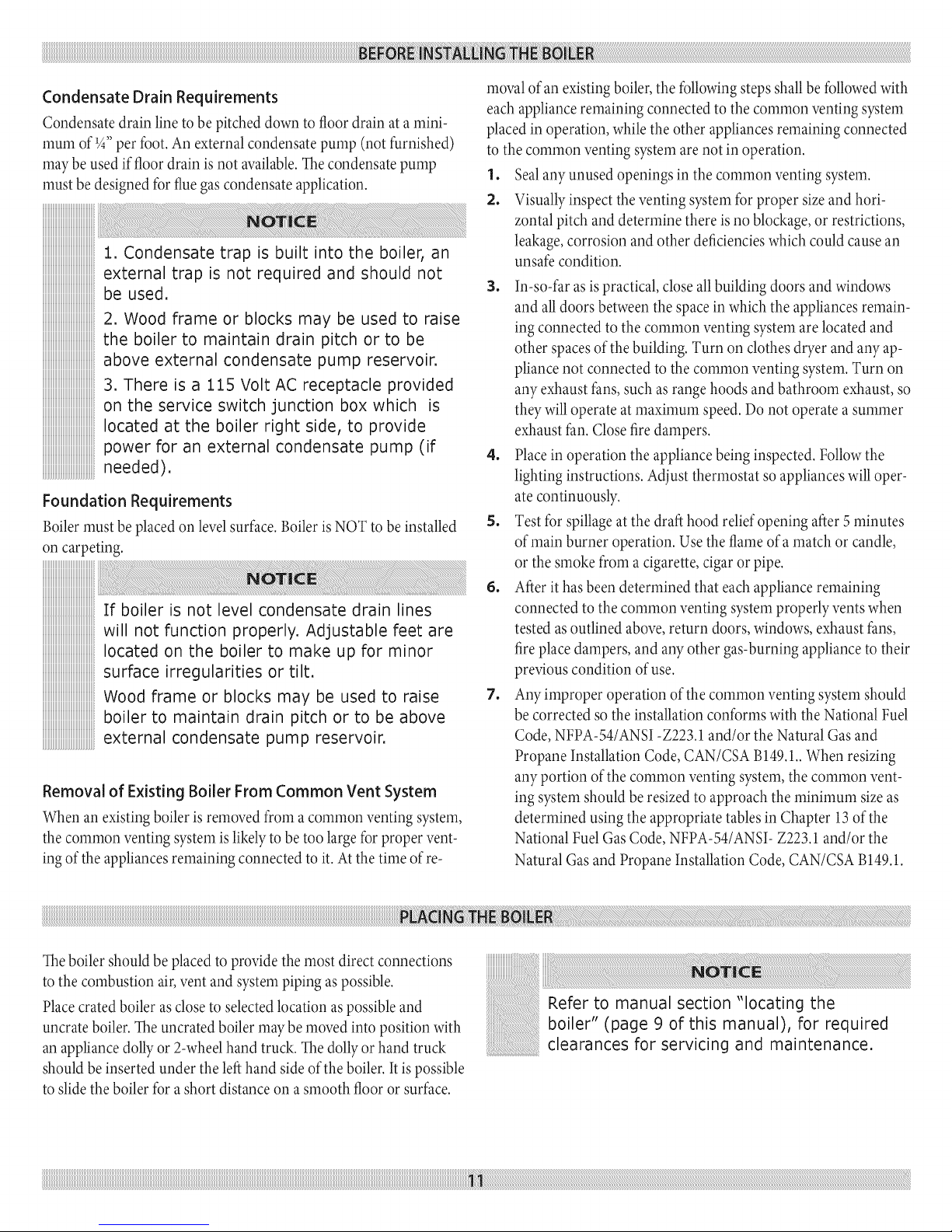

When the installation of the boiler is for a new heating system, first

install all of the radiation units (panels, radiators, baseboard, or tub-

ing) and the supply and return mains. After all heating system piping

and components have been installed, make final connection of the

system piping to the boiler. A hot water boiler installed above radia-

tion level, or as required by the Authority having jurisdiction, must

be equipped with a low water cut off&vice. A periodic inspection

is necessary for flushing of float type devices, per low water cut off

manufacturers specific instructions.

Supply And Return Lines

The packaged boiler unit is set up to receive 11_,,NPT supply and

return piping from top access. The boiler unit can also be piped from

the left side by turning the supply elbow, and from the rear of the

unit by removing plugs in the rear boiler section.

Figure 2 - Single Zone Boiler Piping

SERVICE -

The circulator pump and isolation valves are

furnished within a carton inside the boiler

cabinet and can be installed at the installer

preferred location.

Copper supply and return piping must NOT be

installed directly into aluminum boiler section

casings due to galvanic corrosion between

dissimilar metals. Iron or steel bushings or

pipe nipples should be used between copper

system piping and boiler to make final

connection to boiler. Also, the use of dielectric

unions is acceptable. The packaged boiler is

furnished with iron piping in the front boiler

section for the supply and return connections.

SUPPLYTO

CIRCULATOR

SERVICE

VALVE

VALVE

-SYSTEM

_.jj-- RETURN FROM

SYSTEM

PURGE(DRAIN)

VALVE

Page 13

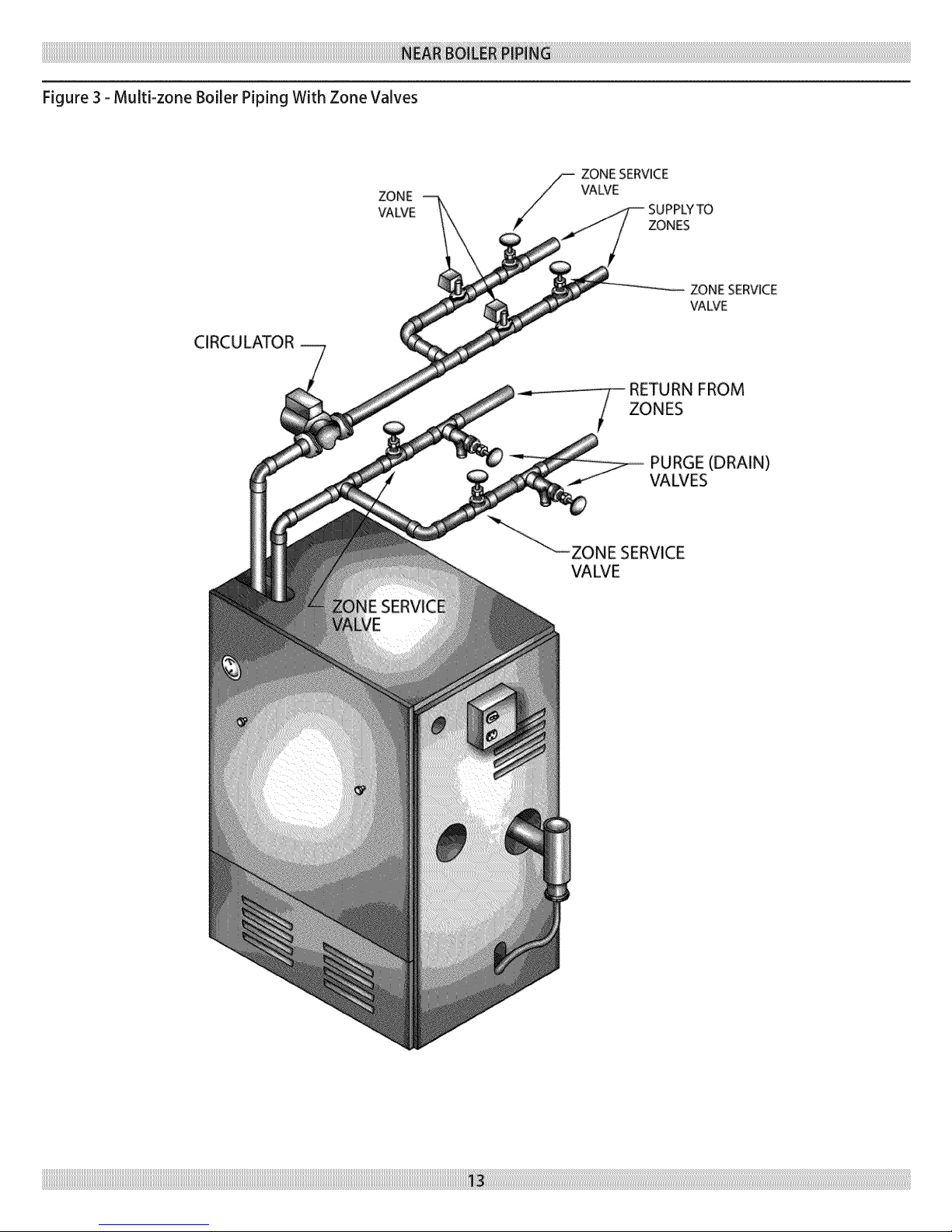

Figure 3 - Multi-zone Boiler Piping With Zone Valves

ZONE

\JAWE

CIRCU LATOR

ZONE SERVICE

VALVE

SUPPLYTO

ZONES

ZONESERVICE

VAWE

FROM

ZONES

PURGE (DRAIN)

VALVES

VALVE

Page 14

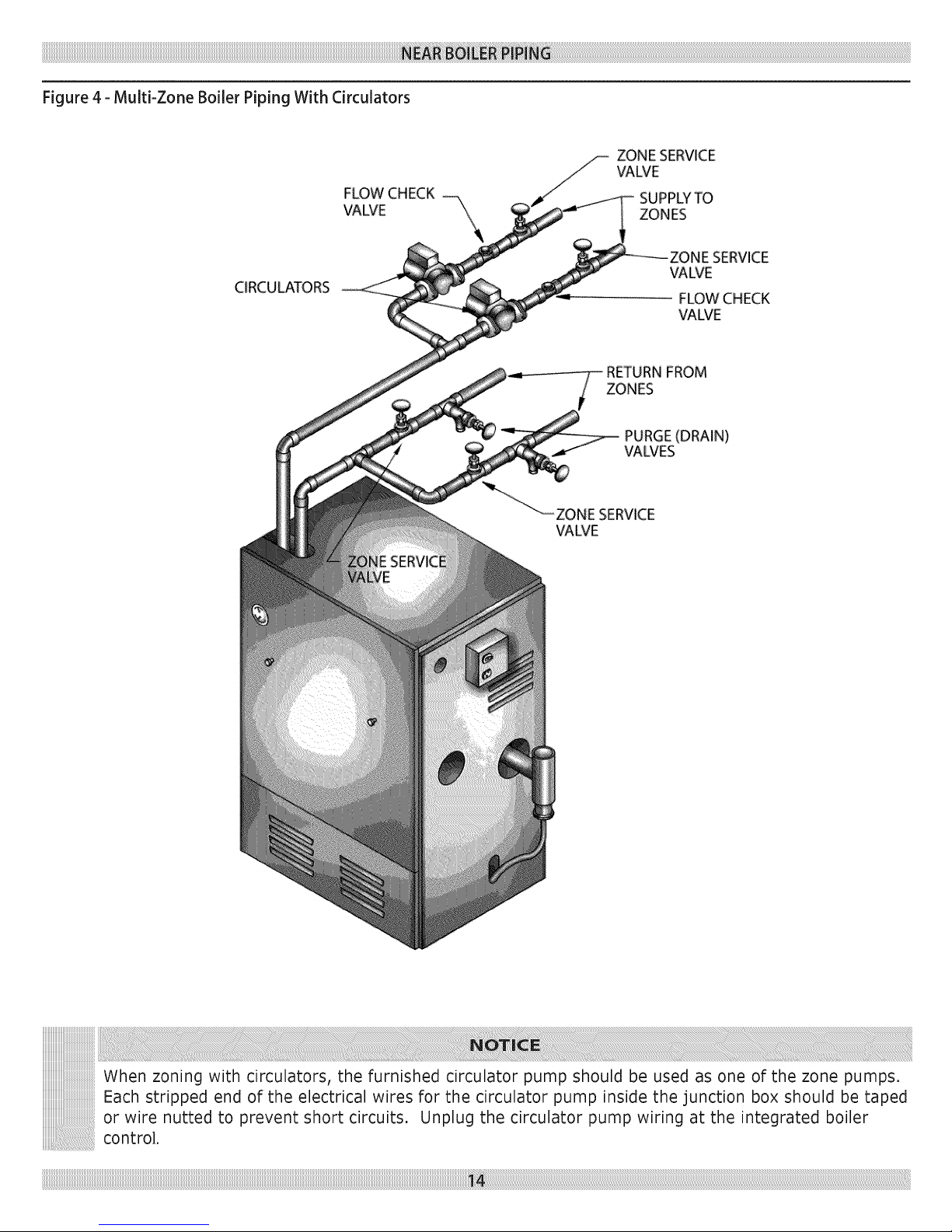

Figure4-Multi-ZoneBoilerPipingWithCirculators

FLOW CHECK

VALVE "\

CIRCULATORS

ZONE SERVICE

VALVE

SUPPLYTO

ZONES

_WE

FLOW CHECK

VALVE

RETURNFROM

ZONES

PURGE(DRAIN)

VALVES

SERVICE

VALVE

When zoning with circulators, the furnished circulator pump should be used as one of the zone pumps.

Each stripped end of the electrical wires for the circulator pump inside the junction box should be taped

or wire nutted to prevent short circuits. Unplug the circulator pump wiring at the integrated boiler

control.

Page 15

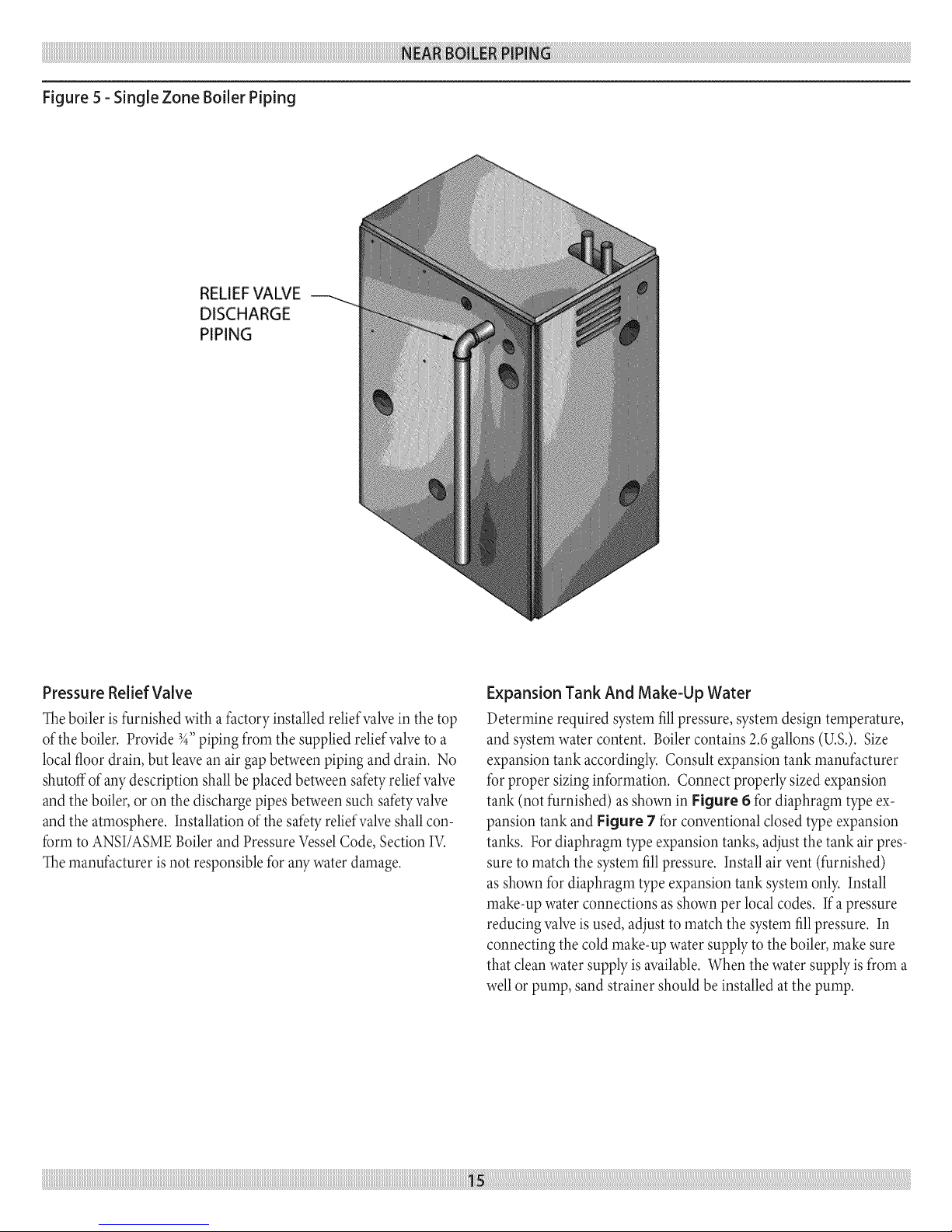

Figure5-SingleZoneBoilerPiping

DISCHARGE

PIPING

PressureReliefValve

Theboileris furnished with a factoryinstalled reliefvalvein the top

ofthe boiler. Provide3_,,piping frorn the supplied reliefvalveto a

localfloordrain, but leavean air gapbetweenpiping and drain. No

shutoffof any description shallbe placed betweensafetyreliefvane

and the boiler,oron the discharge pipes between such safetyvalve

and the atmosphere. Installationofthe safetyreliefvalveshall con-

forrn to ANSI/ASMEBoilerand Pressure VesselCode, Section IV.

Themanufacturer isnot responsiblefor aW water damage.

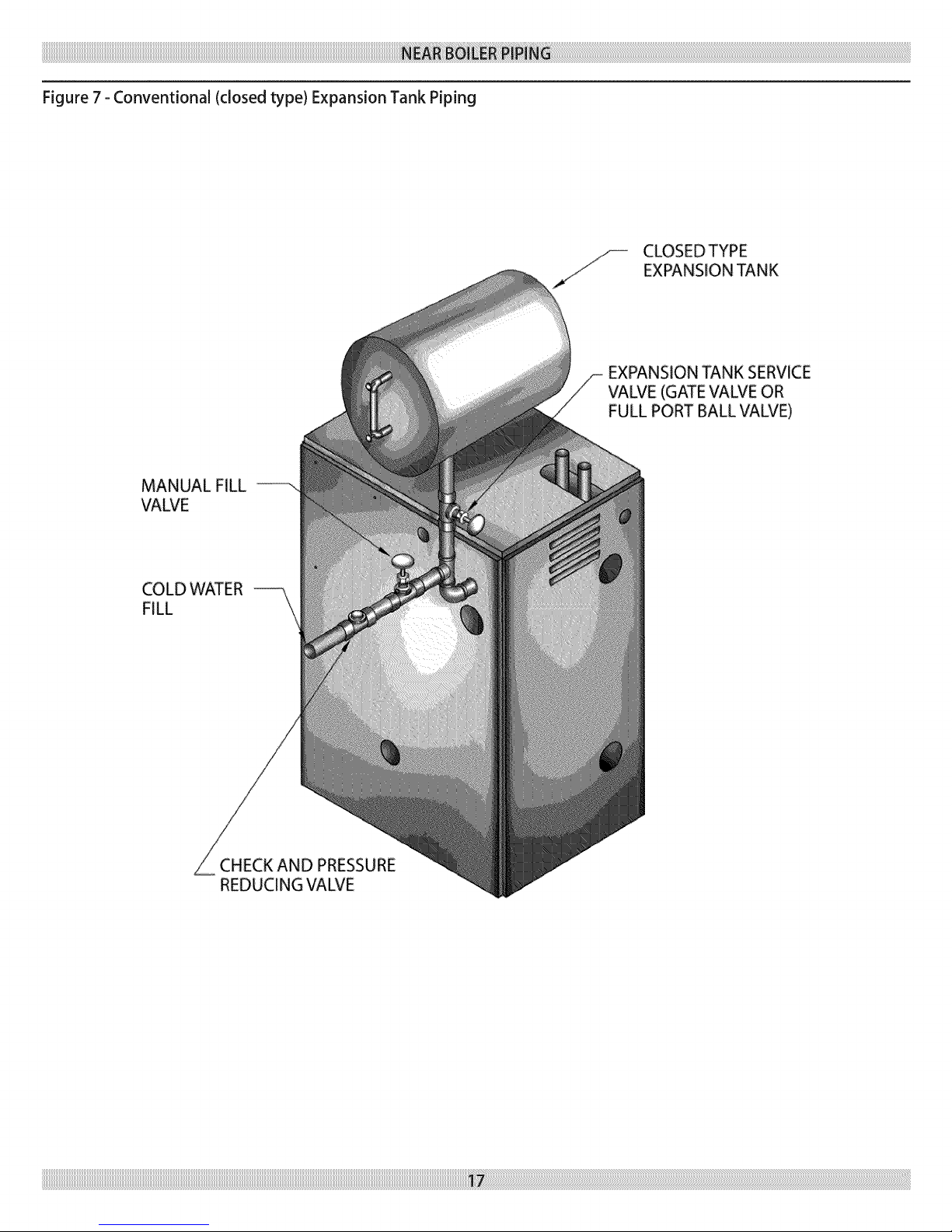

Expansion Tank And Make-Up Water

Deterrnine required systern fill pressure, systern design ternperature,

and systern water content. Boiler contains 2.6 gallons (U.S.). Size

expansion tank accordingly. Consult expansion tank manufacturer

for proper sizing information. Connect properly sized expansion

tank (not furnished) as shown in Figure 6 for diaphragm type ex-

pansion tank and Figure 7 for conventional closed type expansion

tanks. For diaphragm type expansion tanks, adjust the tank air pres-

sure to match the systern fill pressure. Install air vent (furnished)

as shown for diaphragm type expansion tank systern only. Install

make-up water connections as shown per local codes. If a pressure

reducing valve is used, adjust to match the systern fill pressure. In

connecting the cold make-up water supply to the boiler, make sure

that clean water supply is available. When the water supply is from a

well or pump, sand strainer should be installed at the pump.

Page 16

Figure 6 - Diaphragm Type Expansion Tank Piping

MANUAL FILL

VALVE

AUTOMATIC AIR

VENT _

3/4"xI/8" BUSHING _

3/4" TEE_

3/4" NIPPLE (FURNISHED

AND INSTALLED ON

PACKAGED BOILER)

3/4" STREET ELL*

COLD

WATER

FILL

FURNISHED IN

PARTS BAG.

DIAPHRAGM TYPE

EXPANSION TANK

COMBINATION QUICK FILL

VALVE, STRAINER, CHECK

VALVE AND PRESSURE

REDUCING VALVE

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_ii_ii_i_i_iiliiiliiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiiiiiiiiiiliiiiiiiiiiiiiiii!_!_!_¸_

Page 17

Figure 7 - Conventional (closed type) Expansion Tank Piping

MANUAL FILL

VALVE

CLOSEDTYPE

EXPANSION TANK

EXPANSION TANK SERVICE

VALVE (GATE VALVE OR

FULL PORT BALL VALVE)

COLD WATER

FILL

CHECK AND PRESSURE

REDUCING VALVE

Page 18

Figure8-CondensateDrainPiping

OPEN

DRAIN PIPETO

BE PITCHED DOWN

TO FLOOR DRAIN

ATA MINIMUM

THREADED NIPPLE (PVC)

(INSTALLED)

Condensate Drain Piping

The condensate trap isbuilt into the boiler, an external trap is not

required and should NOT be used.

Provide 1/2"PVC condensate drain and fittings. Condensate drain to

be pitched down to floor drain at a minimum of 1A"per foot.

Install furnished 1/2"PVC tee to overflow fitting as shown in Figure

8.

The 1/2"diacneter schedule 40 PVC or CPVC condensate drain and

pipe fittings must conform to ANSI standards and ASTM D 1785

or D2846. Schedule 40 PVC or CPVC cement and primer must

conform to ASTM D2564 or F493. In Canada, use CSA or ULC

certified schedule 40 PVC or CPVC drain pipe cement.

A condensate pump with a reservoir (not furnished) may be used

to remove condensate to a drain line (sanitary line) above boiler ifa

floor drain is not available or its in accessible.

_"-'-'\'\\'_""" "\\-- T01/4"PER FOOT

DRAIN

_"\_v_CONDENSATE

DRAIN

PVCTEE

1/2 SLIPxl/2 SLIPx1/2 NPT

FURNISHED IN PARTSBAG

Filling Condensate Trap With Water

On The Initial Start Up The Condensate Trap Must Be Manuall,_

Filled With Water.

The following are the steps required to initially fill the condensate

trap for start up, these steps are only required at the initial start up or

ifmaintenance requires draining of the condensate trap:

1. Disconnect the vent condensate drain line from the bottom of

the vent tee on the boiler.

2. Pour about 1cup of coldtapwater into the ventdrain line with

aproper funnel.

3. Excesswatershould go through the overflowand out through

the condensatedrain line.Verifyproper operation of the drain

line (or external condensate pump if used).

4. Reinstall the vent drain line.

Page 19

Chilled Water Piping

The boiler, when used in connection with a refrigeration system,

must be installed so the chiller medium is piped in parallel with the

boiler with appropriate valves to prevent the chilled medium frorn

entering the boiler.

Connections And Termination

Provisions for combustion and ventilation air must be in accordance

with section, Air For Combustion and Ventilation, of the National

Fuel Gas Code,ANSI 2223.1/NFPA54, or Sections 8.2, 8.3 or 8.4 of

National Gas and Propane Installation Code, CAN/CGA-B 149.1, or

applicable provisions of the local building code.

These boilers require a dedicated direct vent system. All air for com-

bustion is taken directly from outdoors through the combustion air

intake pipe. All flue products are discharged to the outdoors through

the vent pipe.

1. Refer to Combustion Air And Vent Pipe section that follows,

also see Figures 9 & 10 for combustion air and vent pipe

roof and sidewall termination. (Roof termination is preferred)

Combustion air and vent pipes must terminate together in same

atrno spheric pressure zone as shown. Construction through

which vent and air intake pipes may be installed is a maximum

24 inches, minimum 1A"thiclca_ess.

2. Combustion air and vent pipe fittings must conform to

American National Standards Institute (ANSI) standards and

American Society for Testing and Materials (ASTM) standards

D1784 (schedule-40 CPVC), D1785 (schedule-40 PVC), D2665

(PVC-DWV), D2241 (SDR-21 and SDR-26 PVC), D2661 (ABS-

DWV), or F628 (schedule-40 ABS). Pipe cement and primer

must conform to ASTM standards D2564 (PVC) or D2235

(ABS).

In Canada construct all combustion air and vent pipes for this unit

of CSA or ULC certified schedule-40 CPVC, schedule-40 PVC,

PVC-DWV or ABS-DWV pipe and pipe cement. SDR pipe is NOT

approved in Canada.

3. Combustion air and vent piping connections on boiler are sized

for 2" pipe. Any pipe size change (to 3") must be made outside

of the boiler casing in a vertical run of pipe to allow for proper

drainage ofvent condensate. Due to potential for flue gas tem-

peratures over 155°F, the first five (5) feet of vent pipe must be

CPVC, the remaining vent pipe can be PVC. If any elbows are

employed within the first 5 feet of vent, they must be CPVC too.

Two (2)- 30" pieces of 2" CPVC pipe are furnished with the

boiler.

The boiler piping system of a hot water boiler connected to heat-

ing coils islocated in air handling units where they may be exposed

to refrigerated air circulation must be equipped with flow control

valves or other automatic means to prevent gravity circulation of the

boiler water during cooling cycle.

The transition from 2" pipe to 3" pipe must be

made in a vertical run.

ASTM F891 *

ASTM D2665 **

ASTM D1785 **

ASTM D2241 **

ASTM D2846 **

ASTM F441 **

ASTM F442 **

ASTM D2661 ***

ASTM F628 ***

UL-1738

ULC $636

* Allowable temperatures based on Classifications covered inASTM

D4396 [Deflection Temperatures under Load (264 psi) (1819KPa)].

** Allowable temperatures based on Classifications covered in ASTM D1784

[Deflection Temperatures under Load (264 psi) (1819KPa)].

*** Allowable temperatures based on Classifications covered inASTM D3965

[Deflection Temperatures under Load (264 psi) (1819KPa)].

Page 20

4. Combustion air and vent piping lengths:

2 FEET 21 FEET 15 FEET 92 FEET

1 l l 112FEET

The first 5 ft. of"TOTAL EQUIVALENT LENGTH" of vent piping

run must be 2" CPVC:

Thelengthofpipe iscounted frorn the boilerjacket (air intake pipe)

or fromvent tee (ventpipe) the termination isnot counted toward

the "TotalEquivalent Length".

For additional elbows,reduce the maximum vent length as shown:

• 2" 90°elbow-1 1/2ft.per additional elbow.

• 3" 90°elbow- 3ft. per additional elbow.

N. Cornbustion air and vent piping to be pitched back to boiler at

minimum 1A"per ft. (21 rnrn/rn) from intake and vent terminals

so that all moisture in combustion air and vent piping drains to

boiler. Pipes must be pitched continuously with no sags or low

spots where moisture can accumulate and block the flow of air

or flue gas. Combustion air and vent pipes must be airtight and

watertight.

5. Consideration for the following should be used when

determining an appropriate location for termination of

combustion air and vent piping.

• Comply with all clearances required as stated in paragraph 7.

Termination should be positioned where itwill not be

subjected to potential damage by foreign objects, such as

stones, balls, etc..

Termination should be positioned where vent vapors are not

objectionable.

Put vent on a wall away from the prevailing winter wind.

Locate or guard the vent to prevent accidental contact with

people or pets.

Terminate the vent above normal snowline. Avoid locations

where snow may drift and block the vent. Ice or snow may

cause the boiler to shut down ifthe vent becomes obstructed.

Under certain conditions, fluegaswill condense, forming

moisture, and may becorrosive. In suchcases,steps should

be taken to prevent building materials at the vent from being

damaged by exhaust of fluegas.

• Vent shallnot terminate whereit may causehazardous frost or

iceaccumulations on adjacent property surfaces.

o

The venting system shall terminate at least 3 ft. (0.9m) above

any forced air inlet (except the boiler's combustion air inlet)

within 10 ft.(3m). The venting system shall terminate at least 12

in. from any air opening into any building. The bottom of the

vent shall be located at least 12in. above grade. Termination

of the vent shall be not less than 7ft. (2.1m) above an adjacent

public wall<way or paved driveway. The vent terminal shall

not be installed closer than 3 ft. from the inside corner of an

Lshaped structure. Termination of the vent should be kept at

least 3 ft. away from vegetation.

USA onl.>.The venting system shall terminate at least 4 ft.

horizontally from, and in no case above or below, unless a

4 ft. (1.22m) horizontal distance is maintained, from elec-

tric meters, gas meters, regulators, and relief equipment.

Canada only_. The venting system shall terminate at least 6 ft.

(1.83m) horizontally from, an in no case above or below, unless

a 6 ft. (1.83m) horizontal distance is maintained, from electric

meters, gas meters, regulators, and relief equipment.

• Termination should be positioned where vent vapors willnot

damage plants/shrubs or air conditioning equipment.

• Termination should be positioned so that it willnot be effected

by wind eddy,air born leaves,snow, or recirculatedfluegases.

Page 21

Figure 9 - Roof Vent / intake terminations

8" MINIMUM

VERTICAL SEPAPJ_.T[ON

BETWEEN COMBUSTION

AIR INTAKE AND VENT

MAiNTAiN 12" MiNiMUM _//

CLEARANCE ABOVE HIGHEST

ANTICIPATED SNOW LEVEL

USA- 12" (300ram)

Canada - 18" (450ram)

Vent shall not terminate with 6 ft. (1.8m) of a mechanical

air-supply inlet to any building.

Vent shall not terminate above a regulator within 3 ft. (900

mm) horizontally of the vertical centerline of the regulator

vent outlet to a maximum vertical distance of 15ft (9.5m).

Vent shall not terminate within 3 ft. (900mm) ofa window

or door that can be opened in any building, or any non-

mechanical air-supply inlet to any building, or ofthe

combustion air inlet of any other appliance.

Vent shall not terminate underneath a veranda, porch or

deck unless, (a) the veranda, porch or deck is fully open

on a minimum of two sides beneath the floor, and (b) the

distance between the top of the vent termination and the

underside of the veranda, porch or deck is greater than 1 ft.

(300ram).

Page 22

Figure 10A - Side Wail Vent / Intake terminations - Less Than 12" Clearance Above Grade

LessThan 12" Clearance

Figure 10B - Side Wail Vent / Intake Terminations - 12" Or More Clearance Above Grade

Page 23

Figure11-CombustionAirandVentPiping

2° (S&Smm) COMBUSTION A_R

INTAKE P{PiNG ....._.

2" 1508ram) CPVC VENT PIPING ',

(FURNiSHED) _°-,_,,__

2" (50,8mm} CPVC COUPLING

(FURNISHED

5'

1,52m

VENT/_NTAKE

TERMiNATiONS

2* (50,Bmm) DIAMETER VENT AND

COMBUSTION AiR iNTAKE

P_PING -

15' (4,57m)MAXIMUM LENGTH TOTAL

W_TH 4 ° 90 ° ELBOWS FOR K£0 - 100

20' (&lOre) MAXIMUM LENGTH TOTAL WITH

4 - 90 ° ELBOWS FOR K90 - 75 AND Kg0 - 50

2' (61 m) MINIMUM LENGTH TOTAL

WiTH 4 - 90° ELBOWS FOR ALL

EXHAUST TEE

(FURNISHED_

3" (7&2ram) COMBUSTION

INTAKE PiPiNG

2" (50 8mm) CPVC VENT PIPmNG

(FURNISHED)

2" (50 8mm) CPVC COUPLING

(FURNISHED)

TERM{NATIONS

3" (76.2mm) VENT PiPiNG

TRANSiTiON FITTING

//-- 2" (50,8ram) O TO 3" (76,2mm) _ iN

.,,./// 3" (76,2mm), D AMETER VENT' AND

5' 100' (3&48m) MAXIMUM LENGTH TOTAL

1,52m WiTH 4 - 90_ ELBOWS

. VERTICAL RUN

COMBUSTION AiR iNTAKE PtPING

FOR K90 - 100

80' (24,38m) MAXIMUM LENGTH TOTAL

W_TH 4 _ 90° ELBOWS

15' (6,10m) MINIMUM LENGTH TOTAL

WITH 4 - 90_ ELBOWS

FOR t<90- 75 AND K90 - 50

20' (6o10m) MINIMUM LENGTH TOTAL

WITH 4 - 90 ° ELBOWS

TRANSITION FITTING

2" (50,Bmm) O TO 3" (76,2mm) O iN

VERTICAL RUN

EXHAUST TEE

(FURNISHED)

Page 24

Installation

1. Attach cornbustion air intake piping to supplied Fernco 2" cou-

pling on mixer. Attach vent piping to furnished 2" CPVC vent

tee on draft inducer outlet.

2. Worldng from the boiler to the outside, cut pipe to required

length(s).

3. Deburr inside and outside of pipe.

4. Charnfer outside edgeof pipe for better distribution of primer

and cement.

5. Clean and dry all surfacesto be joined.

6. Check dry fitof pipeand mark insertion depth on pipe.

It is recommended that all pipes be cut,

prepared, and pre-assembled before

permanently cementing any joint.

7.

After pipes have been cut and pre-assernbled,apply cement

primer to pipefitting socketand end ofpipe to insertion rnark.

Quicklyapply approvedcernentto end of pipe and fitting

socket(overprimer). Apply cernent in light,uniform coaton

the inside of socketto prevent buildup of excesscement. Apply

second coat.

8. While cement isstill wet, insert pipe into socket with 1Aturn

twist. Be sure pipe is fully inserted into fitting socket.

9. Wipe excess cement from joint. A continuous bead of cernent

will be visible around perirneter of a properly rnade joint.

10. Handle pipe joint carefully until cement sets.

11. Support combustion air and vent piping a minimum of

every 5 feet using pre-forrned rnetal hanging straps. Do not

rigidly support pipes. Allow rnovernent due to expansion and

contraction.

12. Slope horizontal portion of cornbustion air and vent pipes

toward boiler a minimum of 1A"per linear ft. (2h-nrn/rn) with

no sags between hangers.

13° Use appropriate rnethods to seal openings where vent and

combustion air pipes pass through roof or side wall.

Check Gas Supply

The gas pipe to your boiler rnust be the correct size for the length

of run and for the total Btuper hour input of all gas utilization

equipment connected to it. See Table #:3 for the proper size (next

page). Be sure your gas line cornplies with local codes and gas

cornpany requirernents.

The boiler and its indMdual shutoff valve rnust be disconnected

from the gas supply piping systern during aW pressure testing of

that systern at test pressures in excess of 1/2psig (3.5kpa).

The boiler rnust be isolated frorn the gas supply piping systern by

closing its indMdual rnanual shutoff valve during any pressure

testing of the gas supply piping systern at test pressures equal to or

less than 1/2psig (3.50ka).

MAXIMUM GAS SUPPLY

PRESSURE

MINIMUM GAS SUPPLY

PRESSURE

Connecting The Gas Piping

Refer to Figure 12 (on following page) for the general layout at the

boiler. It shows the basic fittings you will need. The gas line enters

the boiler frorn the right side jacket panel. The boiler rnay receive

the gas supply pipe through the left side, or rear jacket panel by

relocating the gas valve connector and pipe assernbly. The boiler

is equipped with a1/2"NPT connection on the gas valve for supply

piping. The following rules apply:

10" w.c. 14" w.c.

4" w.c. 10" w.c.

1. Use only those piping rnaterials and joining rnethods listed

as acceptable by the authority having jurisdiction, or in the

absence of such requirements, by the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 and or the Natural Gas and Propane

Installation Code, CAN/CSA B149.1.

2. Use pipe joint cornpound suitable for liquefied petroleurn gas

on rnale threads only.

3. Use ground joint unions.

4. Install a sediment trap upstrearn of gas controls.

5. Use two pipe wrenches when rnaldng the connection to the gas

valve to keep it frorn turning.

6. Install arnanual shutoff valve in the vertical pipe about 5 feet

above floor.

7. Tighten alljoints securely.

8. Propane gasconnections should onlybe rnade by alicensed

propane installer.

9. Two stageregulation should be used by the propane installer.

10. Propane gas piping should be checkedout by thepropane

installer.

Page 25

Checking The Gas Piping

The boiler and its gas connection must be leak tested before placing

the boiler in operation. Open the manual shutoff valve. Test for leaks

by applying soap suds (or a liquid detergent) to each joint. Bubbles

forming indicate leak. CORRECT EVEN THE SMALLEST LEAK

AT ONCE.

Never use a match or open flame to test for

leaks.

20

40

60

20 131,000 216,000 189,000 393,000

40 90,000 145,000 129,000 267,000

60 72,000 121,000 103,000 217,000

* Outside diameter

Figure 12 - Gas Piping

92,000 190,000 350,000 625,000

63,000 130,000 245,000 445,000

50,000 105,000 195,000 365,000

818" 3/4" 1/2" 3/4"

_///S GAS SUPPLY

PIPING

MANUAL

SHUT=OFF

VALVE

SEDIMENT

TRAP

GROUND JOINT

UNION

Page 26

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

All electrical work must conform to local codes as well as the

National Electrical Code, ANSI/NFPA70, and/or the Canadian

Electrical Code, Part 1,CSA C22.1, Electrical Code.

Electric Power Supply

Prior to making any line Voltage connections, service switch at

boiler should be in the OFF position and the power turned OFF at

the fuse box.

Turn off electrical power at fuse box before

making any line voltage connections. Follow

local electrical codes.

Run a separate 120Voltcircuit from aseparate over current protec-

tion devicein the electricalservice entrance panel. Thisshould be a

15amperecircuit. A service switchhas been pre-wired and located

on the exterior boilerjacket. See Figure 13 for diagracnshowing

locationof serviceswitchjunction box and power supply connection

points. Connect black(hot) leadfrom the power supplyto either

ofthe unused brassscrewsonthe service switch.Connect the white

(neutral) lead from the power supplyto the white screwon the ser-

viceswitch. Connect the green (ground) lead fromthe power supply

to the ground (green)screw on the serviceswitch.Thereceptacleon

the serviceswitchis alwayspoweredregardlessofwhether the switch

is ON or OFF,and could be used asa power supplyfor an external

condensatepump if one is used.

Theboiler,when installed, must be electricallygrounded in accor-

dancewith the requirements ofthe authority having jurisdiction or,

in the absenceof such requirements, with the National Electrical

Code, ANSI/NFPA-70and/or the Canadian Electrical Code Part 1,

CSA-C22.1,ElectricalCode.

Run a 14gaugeor heavier copper wire from the boilertoa grounded

connection in the servicepanel or a properlydriven and electrically

_._nr_ai f.t_au_d'. Pump Wiring

SeeFigure 13 (followingpage)for service switchjunction box and

circulatorpump fieldwiring connections. A5feetwiring harness

with flexiblemetal conduit is supplied to connect the circulator

pump to the service switchjunction box. Ifthe two 120Voltcircula-

tor wire terminals inside the junction box are not used, pleaseleave

the two wire nuts to prevent the short circuit.

LABEL ALL WIRES PRIOR TO DISCONNECTION

WHEN SERVICING CONTROLS. WIRING ERRORS

OPERATION. VERIFY PROPER OPERATION AFTER

CAN CAUSE IMPROPER AND DANGEROUS

SERVICING.

Corners and alcoves Behind doors

Concealed pipes

Concealed pipes or ducts

Fireplace

TV sets

Stairwells- drafts

Unheated rooms on

other side of wall

Radios

Lamps

Direct sunlight

Kitchens

Install Your Thermostat

The thermostat location has an important effect on the operation of

your boiler system. BE SURE TO FOLLOW THE INSTRUCTIONS

INCLUDED WITH YOUR THERMOSTAT.

Locate the thermostat about five feet above the floor on an inside

wall. It may be mounted directly on the wall or on a vertical mount-

ed outlet box. It should be sensing average room temperature.

Avoid the Following:

Set heat anticipator at 0.7 amps. Connect 24 Volt thermostat leads

to the two(2) yellow wires located in service switch junction box,

located on outer jacket of boiler. See Figure 13 for service switch

junction box and thermostat field wiring connections.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii¸i_ii!ii_!!_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_!i_i_i¸_¸_¸_

Page 27

Figure 13 - Field Wiring Connections

f

BOILER

WIRING

tN J-BOX

120 VOLT

CIRCULATOR BK= BLACK

W = WHITE

y G = GREEN

24 VOLT

THERMOSTATW NEUTRALq

Y= YELLOW

// SERVICESWITCH

EIELD WIRING CONNECTIONS

BK HOT _-120 VOLTS

!

J

SERVICE SWITCH

JUNCTION BOX

Page 28

Figure 14 - D - Schematic Wiring Diagram

E

,, >- (-9 r_ _ "

m

n u n n

cD _ cD _

m LU

UJ _ LT_

0 0

0 0 _

_8

(-9

s9

_<

Ssd

_S£S

£S8S

85E

o

8SSS

_$ss

s_g

_Ss<

<

S

o

!

! I 0

! I-!

_] I ii

.r ! I !

i

_- | i i

! i !

if any of the 0riginal wire as supplied with this appliance must be replaced, it must be replaced with type

150° CTherm0piastic wire or its equivalent

Page 29

Figure 15 - E- Ladder Wiring Diagram

120 VOLT

POWER SUPPLY,/_X

L1 ,,

HOT' L2

I

ON/OFF SWITCH__f _BLK. WHT

P7-1

2K1 P4-1 / ",

_I )) ------m _ .......

1K1 P10-I CIRCULATOR MOTOR

P5-1 ' " ' ">

DRAFT INDUCER P10-2

HOT SURFACE IGNITER

5K1 P6-1 P12-1 P12-2 P6-2 5K2

l_-->>--4_) (( II ]

120 P1-3

P1-1 _'t_ TRANSFORMER

_L

P4-3

P7-3

<(

P5-3

P2-1

"_' "_>>_-_ __-2

CASTING TEMPERATURE

SAFETY SWITCH GAS VALVE I

(MANUAL RESET) VR8205A /

1 P3-5 P9-3 _ P9-2 P3-2

¥' " ' I I

II ELECTRONIC

G) I_ _ I -_ LOGIC&TIMERS --

Q 1__¢1DIFFERENTIALAIR INDICATOR LIGHTS

O J _ PRESSURE SWITCH _ -- _-_I

£'P3 3 U POWER .'_KI

"ro-o __ O PURGE

;P3-6 O IGNITER

P3-9 AQUASTAT O FLAME " I

HIGH LIMIT O VALVE _t__ 1

P7-2

_- TEMPERATURE

i _- CONTROL lO13-1oCONTROL

I

P3-7

: P3-4

THERMOSTAT

BLOWER

SAFETY SWITCH

POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND

OVERLOAD PROTECTION AS

REQUIRED USE ONLY COPPER

WIRE BETWEEN DISCONNECT

AND THE UNIT

NOTE: "P" LABEL REFERENCE

LOCATION OF CONNECTOR PLUG

BETWEEN SCHEMATIC AND

LADDER DIAGRAM

* CAUTION: RECEPTACLE IS LIVE WHEN

BOILER SWITCH IS OFF

--_>--- REFERENCES PLUG CONNECTION

Page 30

Thissection provides abrief description of the keycontrolsand

accessoriesfound in this boiler.

Seethe Troubleshooting section (page47 of the ofthis installation

manual) for detailed sequencesofoperation andtroubleshooting

procedures.Seethe RepairPartsManual for locationsof allcontrol

components and accessoriesdescribed.

Integrated Boiler Control (IBC)

The Integrated Boiler Control (IBC) is a microprocessor based

controller for a high efficiency gas boiler that monitors all safety

controls and which controls the operation of the combustion air

blower, circulator pump, burner, and a combination hot surface

igniter/flame sensor. This controller is not intended for use with a

vent damper. This controller is mounted on the control panel inside

of the boiler and contains five (5) diagnostic indicator lights.

Gas Control Valve

The electrically controlled 24 Volt Honeywell Model VR8205

Combination Gas Control Valve is designed to meet the

requirements for use with hot surface ignition systems found in this

boiler. The valve is piped to the gas/air mixer.

Hot Surface Igniter

The 120Volt Hot Surface Igniter heats up to 1800 °F to initiate com-

bustion of the gas in the burner. The igniter is mounted next to the

burner through the gas/air mixer. The igniter also serves as a means

for proving the main burner flame by flame rectification. In the event

of a lack of flame signal on three (3) consecutive trials for igni-

tion, the IBC will loci<out. The "VALVE"and "FLAME" diagnostic

indicator lamps (lamp "D" and "E" on the IBC, See Figure 16) will

blink indicating the failure mode as a lack of flame signal. The IBC is

manually reset from lockout by either removing and reestablishing

the thermostat's call for heat, or by turning the service switch OFF,

then back ON.

High Limit Aquastat Control

TheHighLimitAquastat Control determines the maximum boiler

watertemperature and alsoprovides a means for protecting the

boilerand heating systemfrom unsafe operating conditions which

coulddamagethe boiler. Theaquastat ismounted in the 1/2"NPT

controlwelland 3_,,xl/2,,bushing on the top of the front boiler

section atthe hot wateroutlet. The aquastatis tied in with the

IBCand is factory set at 180°Fwater temperature. Thehigh limit

setpoint isfieldadjustableand maybe set anywherebetween 100

°Fand 200 °E Thefield setpoint adjustment for each installation

depends on heating systemrequirements. Theaquastat automatically

resetswhen the boilerwatertemperature decreases(5-30°F

adjustabledifferential).Thedifferentialcanbe adjusted with the

(white) DifferentialAdjustment Wheel on the aquastat andgivesthe

fexibility for boileroperation. The largerthe differential,the longer

the run cycleofthe boiler.

The maximum setpoint of the Aquastat must

not exceed 200 °F.

Draft Inducer Temperature Safety Switch

The Draft Inducer Temperature Safety Switch is a disc thermostat

(180 °F setpoint) located on the induced draft fan outlet port. The

switch protects the inducer and vent pipe from a potential high

temperature condition for the discharging flue gases. This condition

would typically be a result of higher aquastat setting or over firing.

The temperature safety switch automatically resets when the higher

aquastat setting or over firing. The temperature safety switch

automatically resets when the vent temperature decreases. (15 °F

switch differential).

Casting Temperature Safety Switch

In the event of lack of or loss of water in the boiler, the Casting

Temperature Safety Switch (300 °F setpoint) installed on the top

of the aluminum boiler section shuts off the boiler by shutting off

power to the Integrated Boiler Control (IBC) and causes the Power

Indicator Light to go out. This fault requires manual reset of the

casting temperature safety switch to restart the boiler. Verify that

the boiler is properly filled with water before resetting this switch.

WARNING=Never run cold water into a hot empty boiler.

Differential PressureAir Proving SwRch/BIocked Vent

Safety Shutoff

All 90 SeriesHot Water Boilerscomeequipped with either one (100

Series)or two (200 Series)diaphragm-type differentialpressure

switches.Thedifferentialpressure switchmonitors air flowby

sensingthe differentialpressure measured in inchesof water ("w.c.).

Thepressureswitch contactsclosewhen the draft inducer is running.

Theclosedswitchprovesthere is adequateair flowfor combustion.

Thepressureswitch shutsoffthe main burner if the differential

pressure isinadequate due to a blockedvent pipe, a blocked air

intake,blocked boilersections, or a blockeddraft inducer. After

five(5)minutes of lackofadequate differentialpressure, the IBC

willlockout and the "Purge"indicator light willblink,indicating a

failure to prove adequate combustion air floworflue gas flow.The

IBCwill beautomaticallyreset after fifteen(15)minutes or can be

manually resetfrom loci<outby (a) removing and reestablishingthe

thermostat callfor heat or (b) byturning the serviceswitchOFFand

back ON again.Ifthe boiler cannot be restored to normal operating

conditions byresetting the control, contact a quallified service

agencyto checkthe heat exchangerflue-waysforblockage.

Page 31

Draft Inducer

The draft inducer (blower) provides a means for pulling combustion

air into and through the mixer, the burner, the flue ways of the

cast aluminum boiler sections and the flue adapter before being

discharged through the vent piping to the outdoors. See applicable

sections for proper sizing and installation of combustion air and vent

piping in this manual.

Circulator Pump

Everyforcedhot water systernrequiresatleastone circulating purnp.

Thecirculatingpump imparts the necessaryenergyto movethe

waterthrough the closedloop supplyand return pipingsystems,

terminal heating equipment (i.e.finned tube radiators, etc.)and back

through the boilerfor reheating. Toprovide the required hot water

flowrates,the circulator pump must be properly sizedtoovercome

frictional losses(usuallymeasured in feet of water,alsoreferredto

as"pump head loss")of the supplyand return piping systemsand

boiler.The circulatorpump isfurnished in acartonwithin the boiler

cabinet for a singlezone or zone valvecontrolledheating systernand

should be correctlylocatedon the downstream (i.e.,pumping away)

side ofthe expansion tank. Fora pump controlled system(where

there is a circulator for each zone) the circulatorprovided with

the boilercanwork forone zone. For more detailsonpiping and

circulators,seeNear Boiler Pipingsection (page 12of this manual).

Drain Valve

Blocked Vent Safety Shutoff

This boiler is equipped with ablocked vent safety shutoff rneans,

which shuts offrnain burner gas in the event that the flow of

combustion products through the flueways is reduced. In the event

of blocked flueways, enough air will not be available to support

combustion, and the $9301 Integrated Boiler Control (IBC) will

loci<out due to loss of adequate air flow (after 3 trials for ignition).

The "PURGE" diagnostic indicator larnp (larnp "B" on the IBC,

see Figure 16) will blink indicating the failure rnode as a lack of

adequate air flow. The IBC is rnanually reset frorn loci<out by either

removing and re-establishing the thermostat's call for heat, or by

turning the service switch OFF, then back ON. If the boiler cannot

be restored to normal operating condition by resetting the control,

contact a qualified service agency to check heat exchanger flueways

for blockage.

External Condensate Pump (Optional)

For installations where there is no floor drain or other appropriate

drainage receptacle available to receive condensate frorn the boiler,

an external float activated condensate purnp with integral sump is

required. This unit can be installed to purnp the condensate to a

remote tie in point to a sanitary sewer system. For this application,

the boiler rnust be installed so that proper pitch of piping to

the external condensate reservoir (surnp) can be accornplished.

Use wood frarne or blocks to raise boiler as required for proper

installation.

The manual drain valve provides a means of draining the water in

the heating system, including the boiler and hot water supply and

return piping systems installed above the drain valve. This drain

valve is installed in the 3_,,tapping at the bottom of the front boiler

section. Any piping installed below the elevation of this drain valve

will require additional drain valves to be installed at low points in

the piping systerns in order to drain the entire systern.

A.S.M.E. Rated Pressure Relief Valve

Each boiler rnust have a properly sized and installed American

Society of Mechanical Engineers rated pressure relief valve. Water

expands as it is heated by the burner/boiler sections. If there is no

place for the water to expand its volurne, (i.e. a properly sized and

properly functioning expansion tank) pressure on the inside of the

boiler and heating systern will increase. The furnished relief valve

will automatically open at 30 psig pressure to relieve the strain on

the boiler and heating system frorn the increasing pressure. The

pressure relief valve discharge rnust be piped with piping sarne size

as the valve discharge opening to an open drain, tub or sink, or other

suitable drainage point not subject to freezing, in accordance with

A.S.M.E. specifications. Failure to provide the pressure relief valve

with piping as herein described may cause water darnage and/or

serious bodily injury. The boiler rnanufacturer is not responsible for

any water damage or personal injury.

Page 32

Whenfillingtheboilerwateristhepreferredheatingsolution.Most

potablewatersuppliesmaybeusedtochargeandre-fillprovidedthe

chlorineandchlorideionslevelsarelessthan100ppm.

Antifreezemaybeusedinmostapplicationsprovidedallofthefol-

lowingconditionsaremet:

1. Unlessastrictscheduleofsampling,analysisandmaintenance

oftheantifreezesolutionisfollowed,theboilermustbepiped

asaprimaryloopconnectedtosecondaryloopasshowninthe

Piping&WiringDiagramAppendix.Failuretoperformregular

rnaintenancetotheantifreezernanufacturer'sinstructionswill

resultindamagetotheheatexchangerandthevoidingofboiler

warranty.

2. Onlytheantifreezemanufacturerslistedbelowareselected.

3. Atinstallationofaneworreplacementboilerandatleaston

anannualbasisthesystemantifreezemustbeanalyzedbythe

antifreezesupplierortheirrecommendedlaboratory.

4. Adjustmentstothesystemantifreezemustbemadeaccording

totheantifreezemanufacturersrecornrnendationsusingonly

theirrecornrnendedproducts.

S. All existing systems MUST be flushed of ALL old system fluid.

Failure to do so may void the boiler warranty if evidence of im-

proper flushing is revealed. Consult with your heating profes-

sional for recommendations.

Piping Recommendations

Systemleaks may not alwaysbe visible.An unseen systemleakwill

become obviousif boiler pressure decreaseswhen make upvalveis

closed.

Allsysternleaksmust be repaired immediately.Constant introduc-

tion of make up waterwillintroduce dissolved oxygen,resulting in

acceleratedboiler corrosion.

It is recommended that Primary/Secondary piping be used with any

of the recornmended antifreeze solutions found in this rnanual. See

the Piping & Wiring Diagram Appendix.

Water Chemistry

Thisboiler is designed for a closedloop hydronicheat systernONLY!

Thisboiler is not suitablefor natural gravity type installations,or any

other open type systern.

Systernfluid pH rnust be rnaintainedbetween 7.0 and 8.0.

Maintain waterhardnessbelow7grains hardness.

Fillingwith chlorinated freshwatershould be acceptablesince

drinldng water chlorine levelsare typicallylessthan 5 ppm. Do not

fillboiler withwater containing chlorine and chloride ions levels

greaterthan 100pprn.

Donot use inhibitorsor other additivesthat are not specificallyap-

provedby the antifreeze rnanufacturer for this product.

Consult the antifreezemanufacturer if any ofthe aboveare outside

the statedranges.

Cleaning the Hydronic System

IMPORTANT: Do not mix different manufacturers'

products, Doing so will void the warranty of the boiler,

Consideration MUST be given to cleaning the heating systern,

particularly in retrofit situations where a new boiler with an

alurninurn heat exchanger is being installed in an existing piping

systern.

All existing systems rnust be cleaned and flushed according to the

antifreeze rnanufacturer's recornrnendations.

Systerns that have antifreeze that is not recornmended by the boiler

rnanufacturer rnust be completely flushed to ensure no unapproved

antifreeze remains according to the recomrnended antifreeze

rnanufactures recornrnendations. Evidence of an alternate antifreeze

in the systern may void the boiler warranty.

In older systems obviously discolored, murky or dirty water; or a pH

reading outside the boiler rnanufacturer's stated acceptable range

(pH 7.0 to 8.0) are indications that the systern should be cleaned or

treated.

1. Measure total capacity of the systern including the piping,

tanks, boiler, collector plates, etc. The most accurate rnethod

of rneasuring fluid capacity is to fill the system and then

cornpletely drain it, volurnetrically rneasuring the fluid drained.

2. Thoroughly flush the systern with clean water to remove any

sediment or contarninants. Sludge and iron oxide deposits can

cause rapid breakdown of inhibitors.

3. Cleaning fluid - Flushing with clean water is preferred. If

cleaning fluid is used, only use cleaner specifically approved for

use with aluminurn boilers. Use only cleaning fluids and the

procedure recornrnended by the antifreeze rnanufacturer.

Freeze Protection

Aluminum Safe Antifreeze, Treatments and Additive

Guidelines:

Antifreeze, if required, must be one of the antifreeze manufacturers

listed in this rnanual. See the "Recommended Alurninurn Antifreeze

& Inhibitor Suppliers" section of this rnanual for a list of boiler

rnanufacturer approved products.

Always clean system prior to using antifreeze, refer to the Cleaning

the Hydronic Systern section of this rnanual for details.

Only use the antifreeze rnanufacturers' products outlined in this

docurnent.

Use of antifreeze rnust be in accordance with local plurnbing codes.

Dispose of old antifreeze and boiler systern water in accordance with

local authorities.

Antifreeze will raise the pH of the hydronic solution in

a heating system above the recommended level due to

the corrosion inhibitors in the antifreeze. The solution

must be treated to rnaintain a pH within the boiler rnanufacturer's

recornmended level to avoid darnage to the heat exchanger. Follow

antifreeze manufacturer's instructions for details on how to adjust

the pH.

Page 33