Page 1

INSTALLATION INSTRUCTIONS

These instructions must be affixed on or adjacent to the boiler

Dml'v' ¢

MODEL PVSB

Continuous Pilot

Gas-Fired

Steam

Boilers

These Gas-Fired Water Boilers are low pressure, sectional

cast iron boilers Designed Certified by C.S.A. (Canadian

Standards Association) for use with Natural and Propane

Gases. They are constructed and hydrostatically tested for a

maximum working pressure of 50 psi (pounds per square

inch) in accordance with AS.ME. (American Society of

Mechanical Engineers) Boiler and Pressure Vessel Code

Section IV Standards for cast iron heating boilers.

MODEL PSB

Electronic

Intermittent

Ignition

Warning: Improper installation, adjustment, alteration, service or maintenance can cause injury or

property damage. Refer to this manual. For assistance or additional information consult a qualified

installer, service agency or the gas supplier

Page 2

Boiler Ratings and Capacities ...................... 2

Before You Start........................................ 3

Locating the Boiler .................................... 3

Fresh Air for Combustion ............................ 4

Installation - System Piping ......................... 5

Chimney and Vent Pipe Connection .............. 8

Vent Damper Operation .............................. 9

Gas Supply Piping .................................... 10

Electrical Wiring ....................................... 11

Controls and Accessories - What They Do ..... 17/

For Your Safety - Read Before Operating ....... 18

Operating Your Boiler ................................ 20

Checking and Adjusting ............................. 21

Cleaning Your Boiler ................................... 22

Maintaining Your Boiler .............................. 23

Service Hints ........................................... 24

Repair Parts ............................................. 25

LI

PRESSURE

GAUGE

r _T /_ "SWITCH I

....... SPILL

I I I_" l

WATER

I I L.E----I----

I [ ]L_\ /

LOW WATER

I _ CUT-OFF

- - -- ± _ -- PRORE

_ SW_TCH

L

GAS

;-.....A __ L,.E

'_'m RE_URE I

oo.TROL|

TRANSFORMER ------

_GAUGE

LOW WATER

_ $8600 CUT-OFF

VALVE

_u

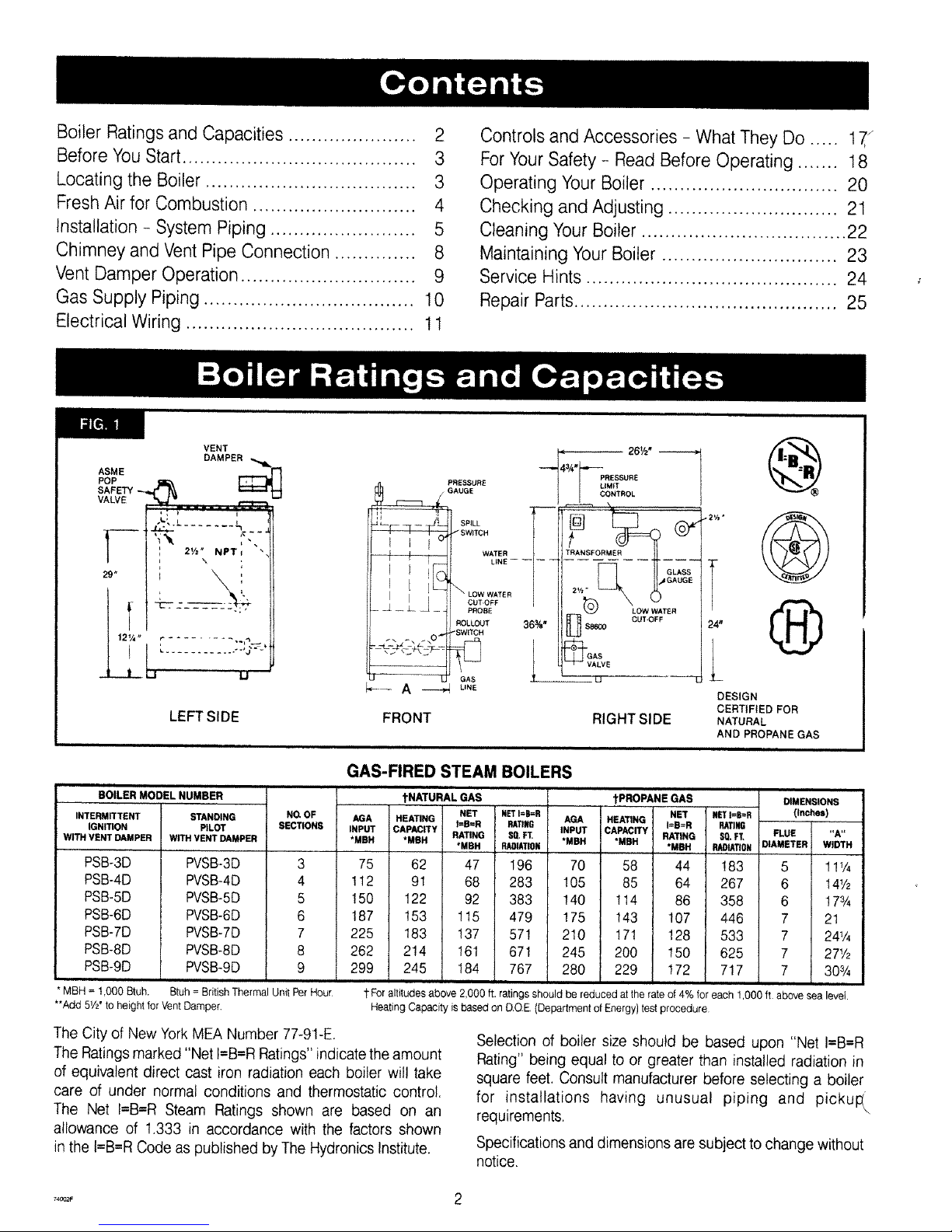

LEFT SIDE FRONT RIGHT SIDE

24"

DESIGN

CERTIFIED FOR

NATURAL

AND PROPANE GAS

GAS-FIRED STEAM BOILERS

BOILER MODEL NUMBER tNATURAL GAS tPROPANE GAS

INTERMITTENT STANDING NG OF AGA HEATING NET #£T I=B=R NET

IGNITION PILOT SECTIONS INPUT CAPACITY I=B=R RATING AGA HEATING I=B=R

WITH VENT DAMPER WITH VENT DAMPER *MBH *MBH RATING,MBH PJ_IATIONS0'FT. INPUT,MBH CAPACITY,MBH RATING

*MBH

PSB-3D

PSB-4D

PSB-5D

PSB-6D

PSB-7D

PSB-8D

PSB-9D

PVSB-3D

PVSB-4D

PVSB-5D

PVSB-6D

PVSB-7D

PVSB-8D

PVSB-9D

3

4

5

6

7

8

9

75 62 47 196 70 58

112 91 68 283 !05 85

!50 122 92 383 !40 114

187 153 115 479 !75 143

225 183 137 571 210 !71

262 2!4 161 671 245 200

299 245 184 767 280 229

DIMENSIONS

_T I=B=R (Inches)

_TI_

_. F_ F_E "A"

PJW_TION D_METER WIDTH

44 !83 5 11%

64 267 6 14½

86 358 6 !7¾

107 446 7 21

!28 533 7 24¼

150 625 7 27½

172 717 7 30¾

* MBH = 1,000 Btuh. Btuh = British Thermal Unit Per Hour

**Add 5V_' to height for Vent Damper.

t For altitudes above 2,000 ft. ratingsshould be reduced at the rate of 4% for each 1,O00 ft above sea level.

Heating Capacity is based on DOE {Department of Energy} test procedure

The City of New YorkMEA Number 77-91-E.

The Ratingsmarked "Net I=B=RRatings" indicate the amount

of equivalent direct cast iron radiation each boiler will take

care of under normal conditions and thermostatic control.

The Net I=B=R Steam Ratings shown are based on an

allowance of 1.333 in accordance with the factors shown

in the t=B=RCode as published by The Hydronics Institute.

Selection of boiler size should be based upon "Net I=B=R

Rating" being equal to or greater than installed radiation in

square feet. Consult manufacturer before selecting a boiler

for installations having unusual piping and picku!_\

requirements.

Specifications and dimensions are subject to change without

notice.

Page 3

Checktobesureyouhavetherightsizeboilerbeforestartingtheinstallation.

_,eeratingandcapacitytableonpreviouspage.Alsobesurethenewboileris

_orthetypeofgasyouareusing.Checktheratingplateontherightsideofthe

boiler.

Youmustseethattheboilerissuppliedwiththecorrecttypeofgas,freshair

forcombustion,andasuitableelectricalsupply.Also,theboilermustbecon-

nededtoasuitableventingsystemandanadequatepipingsystem.Finally,a

thermostat,properlylocated,isneededforcontroloftheheatingsystem.Ifyou

haveanydoubtsastothevariousrequirements,checkwithlocalauthorities

andobtainprolessionathelpwhereneeded.Takethetimetocompleteallof

thestepsforSAFEandPROPERoperationoftheheatingsystem.

Ifthisboilerisinstalledinabuildingunderconstruction,specialcaremustbe

takentoinsureacleancombustionairsupplyduringtheconstructionprocess.

Airborneparticulatessuchasfromdrywalldustandfromfiberglassinsulation

canclogtheburnerportsandcauseincompletecombustionandsooting,

Theseboilersaredesignedforuseinclosedheatingsystemswhereallofthe

steamisreturnedtotheboilerascondensateandtheamountofmake-upwater

requiredisminimal.Theseboilersarenotdesignedfororintendedforusein

opensystemsofprocessapplicationsusing100%make-upwater.Damageto

theboilerresultingfromsuchuseshallnotbecoveredunderthewarranty.

Whererequiredbytheauthorityhavingjurisdiction,theinstallationmustcon-

formtoAmericanSocietyofMechanicalEngineersSafetyCodeforControls

andSafetyDevicesforAulomaticallyFiredBoilers,No.CSD-1.

Theinstallationmustconformtotherequirementsof theauthorityhaving

jurisdictionor,intheabsenceofsuchrequirements,totheNationalFuelGas

Code,ANSIZ223.1-1atestrevision.

Thefollowingstepsareallnecessaryforproperinstallationandsafeoperation

ofyourboiler.

1. LOCATINGTHEBOILER 5. GASSUPPLYPIPING

2. FRESHAIRFORCOMBUSTION 6. ELECTRICALWIRING

3, INSTALLATION- SYSTEMPIPING 7. CHECKING&ADJUSTING

4. CHIMNEY& VENTPIPECONNECTION

KEEP BOILER AREA CLEAN AND FREE FROM COMBUSTIBLE MATERIALS,

GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS

1.Selectlevellocationascentralizedwithpipingsystem,andasnearchim-

neyaspossible.

2.Placecratedboilerat selectedlocation,removecratebypullingcrate

sidesfromtopandbottomboards.Combustiblefloors:Whenboileristo

beinstalledonacombustiblefloor,aSpecialBasePlatemustbeused-

1.46-14-031(2-6Section)or146-14-032(7-9Section).Thisboilermust

notbeinstalledoncarpeting.

3.I1thisboilerisequippedwithcastironburners,it isalsoequippedwith

stainlesssteelwiretiestoholdlhebackendolthecastironburnersin

placeduringshipping.Inorderto removetheburnersforcleaningor

inspection,thewiretiesmustbecutandremoved.Thewiretiesare

accessedthroughthecombustionair openingonthebacksideofthe

boileratthebottomoftherearjacketpanel,andmaybecutwithanywire

cuttingpliers.Iftheboilerisinstalledatitsminimumclearancesit may

bedifficultto reachthewiretiesaftertheboilerisinstalled,andthewire

tiesshouldbeculnow.Thewireliesareonlyneededduringshipping,

anddo notneedtobereplaced.Boilersequippedwilh stainless

steelburnersdonothavewiretiesandthisinformationdoes

notapply.

4.Boileristobelevel.Metalshimsmaybeusedunderbaselegsforfinal

leveling.

5.Equipmentshallbeinstalledina Iocalioninwhichthefacilitiesforven-

tilationpermitsatisfactorycombustionofgas,properventing,andmain-

tenanceofambienttemperatureatsalelimitsundernormalconditionsof

use,Equipmentshallbelocatedsoasnottointerferewithpropercircu-

lationofair.Whennormalinfiltrationdoesnotprovidethenecessaryair,

outsideair shall be introduced(See Page4 - "FreshAir for

Combustion").

6.Adviseownerto keepairpassagesfreeofobstructions.Ventilatingand

combustionairmustenterboilerroomwithoutrestrictions.

7. Theboilershallbeinstalledsuchthattheautomaticgasignitionsystem

componentsareprotectedfromwater(dripping,spraying,rain,etc.)dur-

ingapplianceoperationandservice(condensatetrap,controlreplace-

ment,etc.).

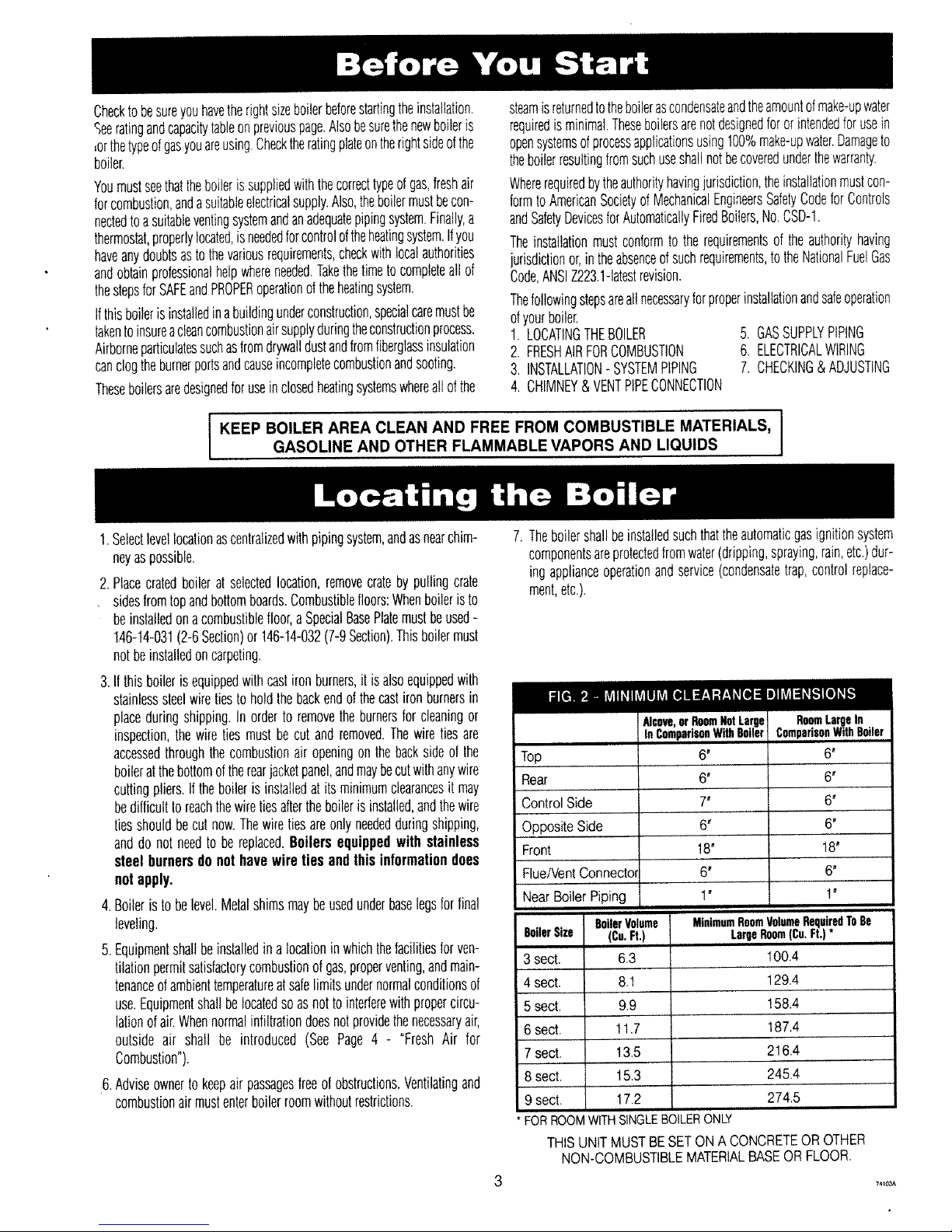

Top

Rear

Control Side

Opposite Side

Front

Flue/Vent Connectol

Near Boiler Piping

BoilerVolume

BoilerSize (Cu.Ft.)

3 sect. 6.3

4 sect. 8,1

5 sect, 9.9

6 sect. 11,7

7 sect. 13.5

8 sect. 15.3

9 sect. 17.2

* FOBROOMWITHSINGLEBOILERONLY

Alcove,orRoomNotLarge

InComparisonWith6oiler

6" 6"

6" 6'

7" 6"

6" 6'

18" 18'

6" 6'

1' 1"

MinimumRoomVolumeRequiredToBe

LargeRoom(Cu.Ft.)*

100.4

129.4

!58.4

187,4

216,4

245,4

274,5

RoomLargeIn

ComparisonWithBoiler

THIS UNIT MUST BESET ON A CONCRETEOR OTHER

NON-COMBUSTIBLEMATERIALBASEOR FLOOR.

?4_oaA

Page 4

Provisionfor combustionandventilationair mustbe in accordancewithSection5.3, Air for CombustionandVentilation,of I

the National Fuel Gas Code, ANSIZ223.1-1atest revision, or applicable provisions of the local building codes.

i

WARNING

Be sure to provide enough fresh air for combustion.

Enough air insures proper combustion and assures that

no hazard will develop due to the lack of oxygen.

NOTE

if you use a fireplace or a kitchen or bathroom exhaust

fan, you should install an outside air intake. These

devices will rob the boiler and water heater of combus-

tion air.

Youmustprovideforenoughfreshairtoassurepropercombustion.Thefire

in theboilerusesoxygen.It musthavea continuoussupply.Theairin a

housecontainsonlyenoughoxygentosupplytheburnerfor ashorttime.

Outsideair mustenterthehouseto replacethatusedbytheburner.Study

followingexamples1and2todetermineyourfreshairrequirements.

EXAMPLE1: BoilerLocatedin UnconfinedSpace

Anunconfinedspaceis definedasa spacewhosevolumeisnotlessthan

50cubicfeetper1,000Btuperhourofthetotalinputratingofallappliances

installedinthatspace.

Ifyourboilerisinanopenarea(unpartitionedbasement)in aconventional

house,theairthatleaksthroughthecracksarounddoorsandwindowswin

usuallybeadequatetoprovideairforcombustion.Thedoorsshouldnotfit

tightly.Donotcaulkthecracksaroundthewindows.

Equipmentlocatedinbuildingsofunusuallytightconstructionshallbepro-

videdwithairforcombustion,ventilation,anddilutionoffluegasesusing

themethodsdescribedinexample2Borshallbespeciallyengineered.The

authorityhavingjurisdictionmustapprovespeciallyengineeredinstalla-

tions.

EXAMPLE2: BoilerLocatedin ConfinedSpace

A.All Air fromInsidethe Building:Theconfinedspaceshallbepro-

videdwithtwopermanentopeningscommunicatingdirectlywithanaddi-

tionalroom(s)of sufficientvolumeso thatthecombinedvolumeof al!

spacesmeetsthecriteriaforanunconfinedspace.Thetotalinputofall

gasutilizationequipmentinstalledinthecombinedspaceshallbecon-

sideredin makingthisdetermination.Eachopeningshallhavea mini-

mumfreeareaofonesquareinchper1,000Btuperhourofthetotalinput

ratingofal!gasutilizationequipmentintheconfinedspace,butnotless

that100squareinches.Oneopeningshallbewithin12inchesofthetop

andonewithin12inchesofthebottomoftheenclosure.Theminimum

dimensionofairopeningsshallnotbetessthan3 inches.

B.AllAirfromOutdoors:Theconfinedspaceshallcommunicatewiththe

outdoorsinaccordancewithmethods1or2.Theminimumdimensionof

airopeningsshallnotbelessthan3 in.Whereductsareused,theyshall

beofthesamecross-sectionalareaasthefreeareaoftheopeningsto

whichtheyconnect.

1.Twopermanentopenings,onecommencingwithin12 inchesofthe

top,andonecommencingwithin12inchesofthebottom,oftheenclo-

sureshallbeprovided.Theopeningsshallcommunicatedirectly,orby

theducts,withtheoutdoorsorspaces(crawlorattic)thatfreelycom-

municatewiththeoutdoors.

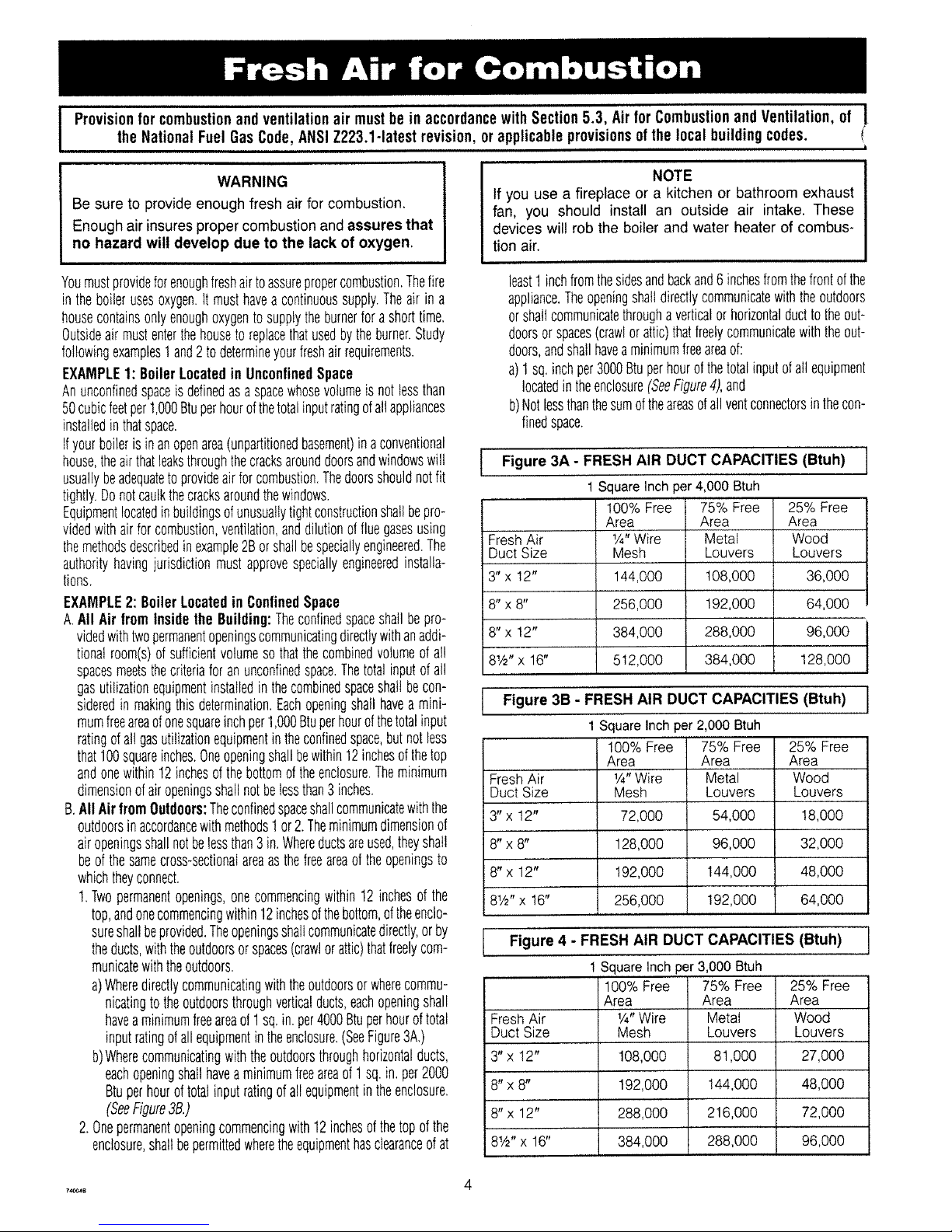

a)Wheredirectlycommunicatingwiththeoutdoorsorwherecommu-

nicatingtotheoutdoorsthroughverticalducts,eachopeningshall

haveaminimumfreeareaof1sq.in.per4000Btuperhouroftotal

inputratingof allequipmentintheenclosure.(SeeFigure3A.)

b)Wherecommunicatingwiththeoutdoorsthroughhorizontalducts,

eachopeningshallhaveaminimumfreeareaof 1sq.in. per2000

Btuperhouroftotalinputratingofallequipmentintheenclosure.

(SeeFigure3B.)

2.Onepermanentopeningcommencingwith12inchesof thetopofthe

enclosure,shallbepermittedwheretheequipmenthasclearanceofat

least1inchfromthesidesandbackand6inchesfromthefrontofthe

appliance.Theopeningshalldirectlycommunicatewiththeoutdoors

orshaltcommunicatethroughaverticalorhorizontalducttotheout-

doorsorspaces(crawlorattic)thatfreelycommunicatewiththeout-

doors,andshallhaveaminimumfreeareaof:

a)1sq.inchper3000Btuperhourofthetotalinputofallequipment

locatedintheenclosure(SeeFigure4),and

b)Notlessthanthesumoftheareasofallventconnectorsinthecon-

finedspace.

1

Figure 3A - FRESH AIR DUCT CAPACITIES (Btuh) I

FreshAir

Duct Size

3"x 12"

8"x 8"

8"x 12"

= 1 tt

18Y2 x 16"

1 Square Inch per 4,000 Btuh

100% Free 75% Free

Area Area

1/4"Wire Metal

Mesh Louvers

144,000 108,000

256,000 192,000

384,000 288,000

5t2,000 384,000

25% Free

Area

Wood

Louvers

36,000

64,000

96,000

128,000

Figure 3B- FRESH AIR DUCT

1SquareInchper2,000Btuh

Fresh Air

Duct Size

3" x 12"

8" x 8"

8" x 12"

81/2"x 16"

100% Free

Area

1/4"Wire

Mesh

72,000

128,000

192,000

256,000

CAPACITIES (Btuh) I

75% Free

Area

Metal

Louvers

54,000

96,000

144,000

192,000

25%Free

Area

Wood

Louvers

18,000

32,000

48,O0O

64,000

Figure 4 - FRESH AIR DUCT CAPACITIES (Btuh)

1Squaretnch per3,000 Btuh

100%Free 75% Free 25% Free

Area Area Area

FreshAir 1/4"Wire Metal Wood

Duct Size Mesh Louvers Louvers

3"x !2" 108,000 81,000 27,000

8"x8" 192,000 144,000 48,000

8"x 12" 288,000 216,000 72,000

8½"x 16" 384,000 288,000 96,000

I

7,_8 4

Page 5

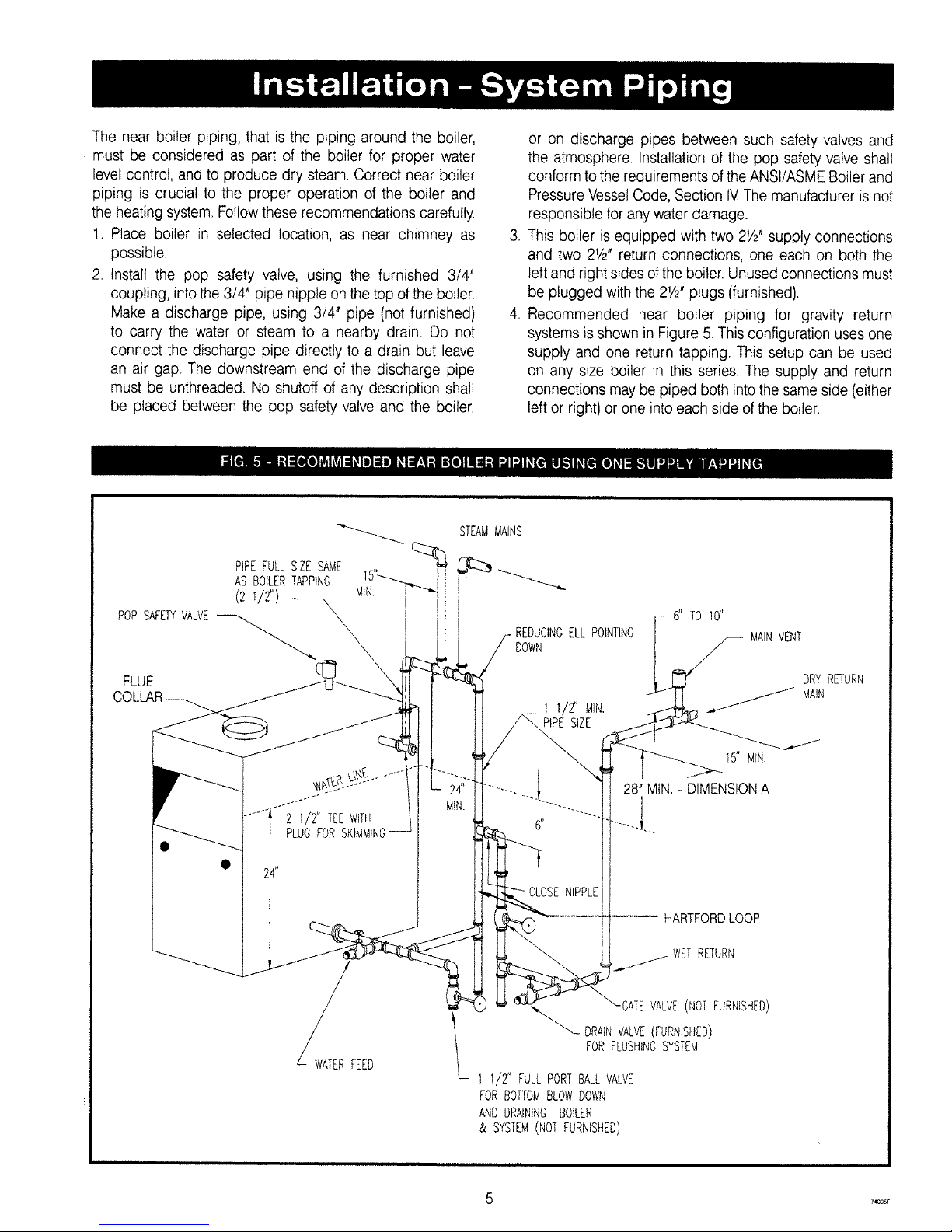

The near boiler piping, that is the piping around the boiler,

must be considered as part of the boiler for proper water

level control, and to produce dry steam. Correct near boiler

piping is crucial to the proper operation of the boiler and

the heating system. Followthese recommendations carefully.

1. Place boiler in selected location, as near chimney as

possible.

2. Install the pop safety valve, using the furnished 3/4"

coupling, intothe 3/4" pipe nipple on the top of the boiler.

Make a discharge pipe, using 3/4' pipe (not furnished}

to carry the water or steam to a nearby drain. Do not

connect the discharge pipe directly to a drain but leave

an air gap. The downstream end of the discharge pipe

must be unthreaded. No shutoff of any description shall

be placed between the pop safety valve and the boiler,

,

,

or on discharge pipes between such safety valves and

the atmosphere. Installation of the pop safety valve shall

conform to the requirements ofthe ANSltASME Boiler and

Pressure Vessel Code, Section IV The manufacturer is not

responsible for any water damage.

This boiler is equipped with two 21/2"supply connections

and two 21/2"return connections, one each on both the

left and right sides ofthe boiler. Unused connections must

be plugged with the 21/2_ plugs (furnished}.

Recommended near boiler piping for gravity return

systems is shown in Figure 5. This configuration uses one

supply and one return tapping. This setup can be used

on any size boiler in this series. The supply and return

connections may be piped both into the same side (either

left or right} or one into each side ofthe boiler.

POPSAFETYVALVE

FLUE

PIPEFULLSIZESAME

AS BOILERTAPPING

(2ii2")_ MIN'

2 1/2" TEEWiTH

PLUGFOR

• 24"

FEED

STEAMMAINS

REDUCINGELL POINTING

DOWN

6" TO 10"

MAINVENT

1 1/2" MtN.

PIPESiZE

NIPPLE

15' MIN,

28' MIN.- DIMENSIONA

I

-- HARTFORD LOOP

WET RETURN

GATEVALVE(NOTFURNISHED)

_"'--DRAiN VALVE(FURNISHED)

FORFLUSHINGSYSTEM

I t/2" FULLPORTBALLVALVE

FORBOTTOMSLOWDOWN

ANDDRAININGBOILER

& SYSTEM(NOT FURNISHED}

DRYRETURN

MAIN

Z4OCBF

Page 6

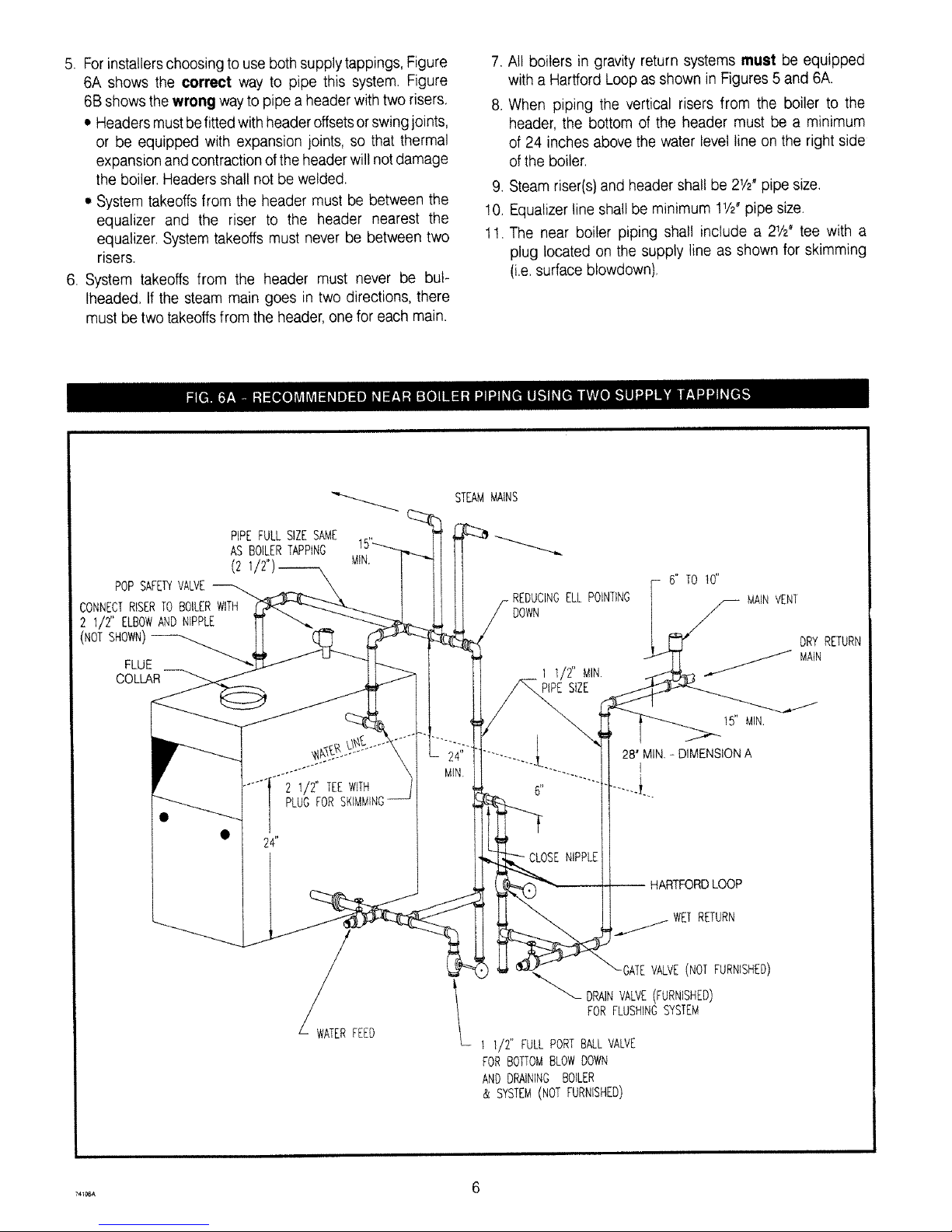

5. For installerschoosing to use both supply tappings, Figure

6A shows the correct way to pipe this system. Figure

6B showsthe wrong way to pipe a header with two risers.

• Headers mustbefittedwithheaderoffsetsorswing joints,

or be equipped with expansion joints, so that thermal

expansion and contraction of the header wilt notdamage

the boiler. Headers shall not be welded.

• System takeoffs from the header must be between the

equalizer and the riser to the header nearest the

equalizer. System takeoffs must never be between two

risers.

6. System takeoffs from the header must never be bul-

lheaded. If the steam main goes in two directions, there

must betwo takeoffsfrom the header, one for each main.

,

8.

All boilers in gravity return systems must be equipped

with a Hartford Loop as shown in Figures 5 and 6A.

When piping the vertical risers from the boiler to the

header, the bottom of the header must be a minimum

of 24 inches above the water level line on the right side

ofthe boiler.

9. Steam riser(s) and header shall be 21/2"pipe size.

!0. Equalizerline shall be minimum 11/2"pipe size.

11. The near boiler piping shall include a 21/2"tee with a

plug located on the supply line as shown for skimming

(i.e.surface blowdown).

PiPEFULL SIZESAME

AS BOILERTAPPING

(2

POPSAFE_ VALVE

CONNECTRISERTO BOILERWITH

2 I/2" ELBOWANDNIPPLE

(NOTSHOWN)

FLUE

COLLAR

MIN,

....{"2112" W TN

PLUGFORS

24"

W_AT_RFEED

STEAMMAINS

REDUCINGELL POINTING

DOWN

6" TO t0"

I1/2" MIN.

PiPEStZE

15" MIN,

28" MIN - DIMENSION A

I

i

NIPPLE

HARTFORDLOOP

RETURN

-GATEVALVE(NOTFURNISHED)

_-- DRAINVALVE(FURNISHED)

FORFLUSHINGSYSTEM

I ;/2" FULLPORTBALLVALVE

FORBOTTOMBLOWDOWN

ANDDRAINING BOILER

& SYSTEM(NOT FURNISHED)

MAINVENT

ORYRETURN

MAiN

_4106A 6

Page 7

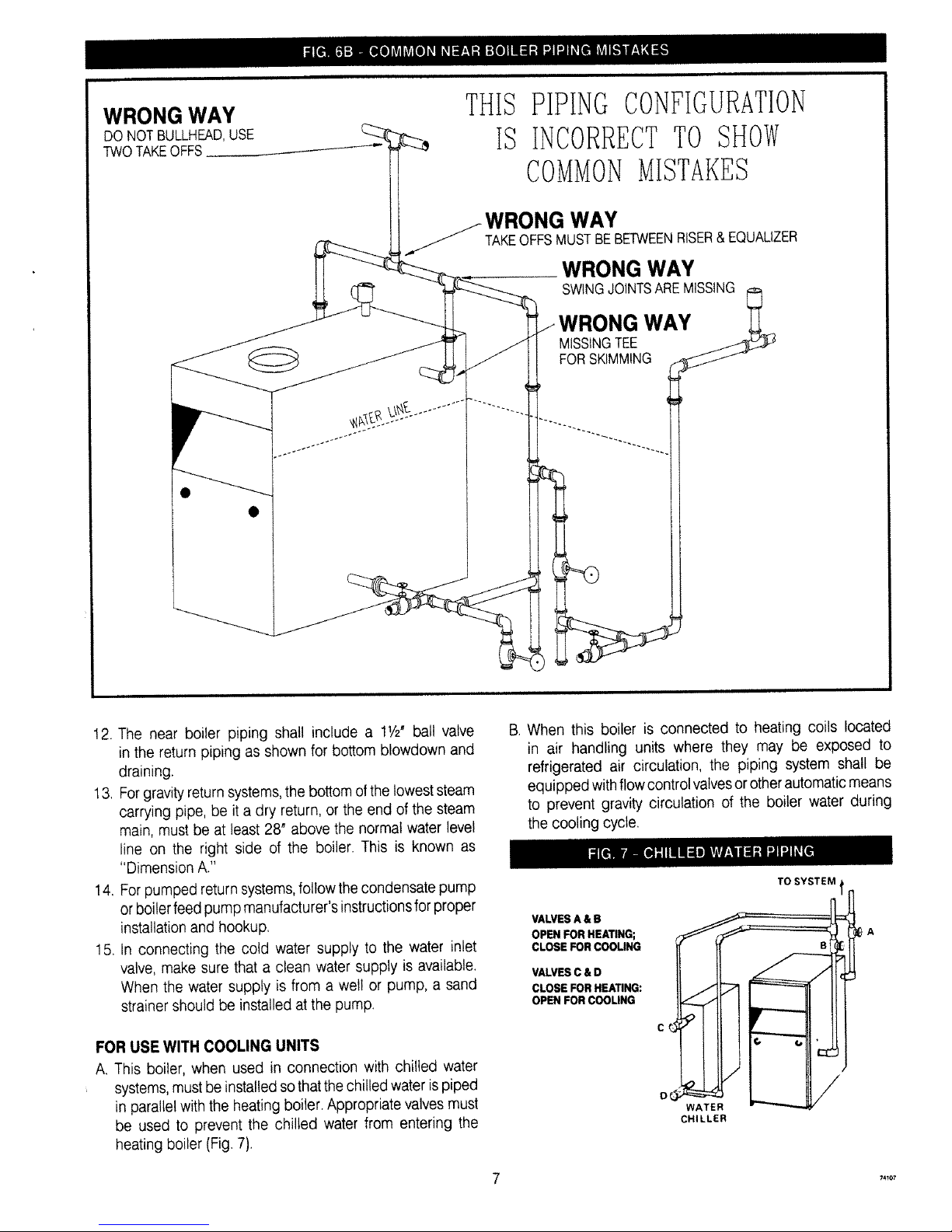

WRONG WAY

DONOTBULLHEAD,USE

TWOTAKEOFFS

THIS PIPING CONFIGURATION

tS INCORRECTTO SHOW

COMMONMISTAKES

WAY

TAKEOFFSMUSTBEBETWEENRISER&EQUALIZER

WRONG WAY

SWINGJOINTSAREMISSING

WRONG WAY

MiSSiNGTEE

FORSKIMMING

12. The near boiler piping shall include a 11h"ball valve

in the return piping as shown for bottom blowdown and

draining.

13. Forgravity returnsystems,the bottom ofthe lowest steam

carrying pipe, be it a dry return, or the end of the steam

main, must be at least 28" above the normal water level

line on the right side of the boiler. This is known as

"Dimension A."

14. For pumped returnsystems,follow the condensate pump

or boiler feed pump manufacturer's instructionsfor proper

installation and hookup.

15. In connecting the cold water supply to the water inlet

valve, make sure that a clean water supply is available.

When the water supply is from a welt or pump, a sand

strainer should be installed at the pump.

FOR USE WITH COOLING UNITS

A. This boiler, when used in connection with chilled water

, systems,mustbe installed sothat thechilled water ispiped

in parallel with the heating boiler. Appropriate valves must

be used to prevent the chilled water from entering the

heating boiler (Fig.7).

B When this boiler is connected to heating coils located

in air handling units where they may be exposed to

refrigerated air circulation, the piping system shall be

equipped with flowcontrol valvesor otherautomaticmeans

to prevent gravity circulation of the boiler water during

the cooling cycle.

VALVES A & B

OPEN FOR HEATING;

CLOSE FOR COOLING

VALVES C & O

CLOSE FOR HEATING:

OPEN FOR COOLING

WATER

CHILLER

TO SYSTEM t

74_o7

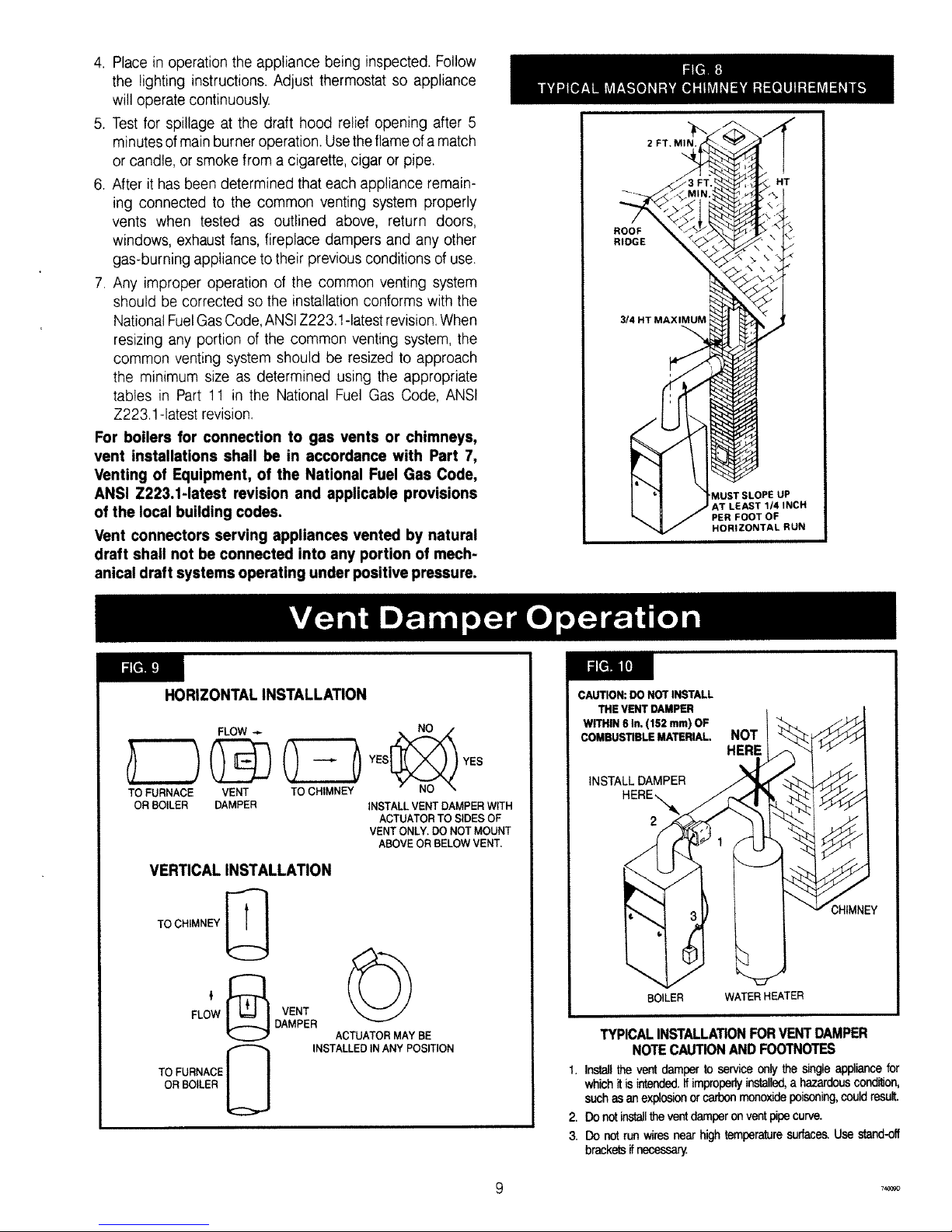

Page 8

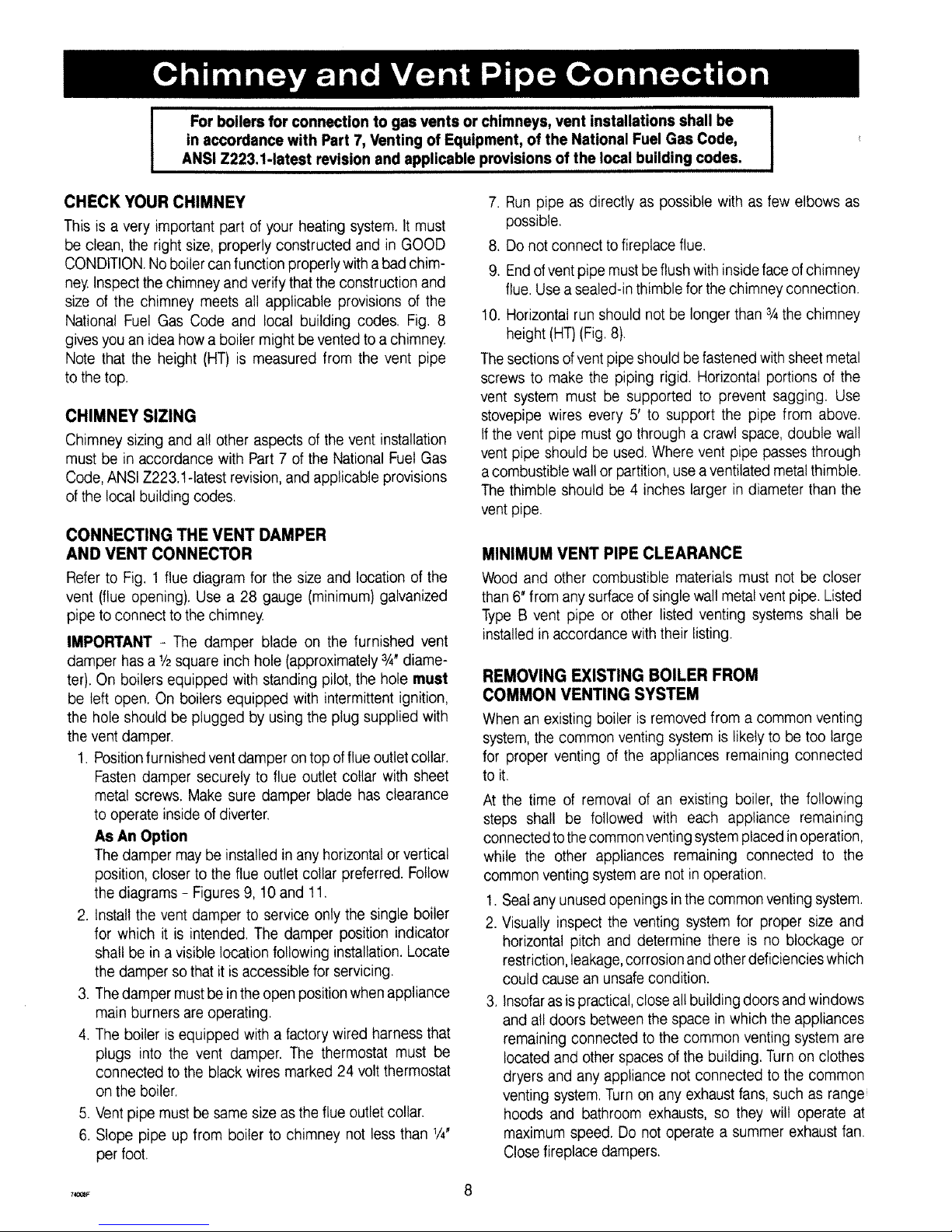

For boilers for connection to gas vents or chimneys, vent installations shall be I

in accordance with Part 7, Venting of Equipment, of the National Fuel Gas Code,

I

ANSI Z223.1-1atest revision and applicable provisions of the local building codes.

CHECK YOUR CHIMNEY

This is a very important part of your heating system. It must

be clean, the right size, properly constructed and in GOOD

CONDITION.Noboilercan function properly with a bad chim-

ney.Inspect the chimney and verify that the construction and

size of the chimney meets all applicable provisions of the

National Fuel Gas Code and local building codes. Fig. 8

gives you an idea how a boiler might be vented to a chimney.

Note that the height (HT} is measured from the vent pipe

to the top.

CHIMNEY SIZING

Chimney sizing and all other aspects of the vent installation

must be in accordance with Part 7 of the National Fuel Gas

Code, ANSI Z223.1-latest revision, and applicable provisions

ofthe local building codes.

CONNECTING THE VENT DAMPER

AND VENT CONNECTOR

Refer to Fig. 1 flue diagram for the size and location of the

vent (flue opening). Use a 28 gauge (minimum) galvanized

pipe to connect to the chimney.

IMPORTANT - The damper blade on the furnished vent

damper has a 1/2square inch hole (approximately 3/4"diame-

ter). On boilers equipped with standing pilot, the hole must

be left open. On boilers equipped with intermittent ignition,

the hole should be plugged by using the plug supplied with

the ventdamper.

1. Positionfurnished vent damper on top offlue outletcollar.

Fasten damper securely to flue outlet collar with sheet

metal screws, Make sure damper blade has clearance

to operate inside ofdiverter.

As An Option

The damper maybe installed in any horizontal or vertical

position, closer to the flue outlet collar preferred. Follow

the diagrams - Figures 9, 10 and 11.

2. Install the vent damper to service only the single boiler

for which it is intended. The damper position indicator

shall be in avisible location following installation. Locate

the damper so thatit is accessible for servicing.

3. Thedamper mustbeintheopen position whenappliance

main burners are operating.

4. The boiler is equipped with a factory wired harness that

plugs into the vent damper. The thermostat must be

connected to the black wires marked 24 volt thermostat

on the boiler.

5. Vent pipe must be same size as the flue outlet collar.

6. Slope pipe up from boiler to chimney not less than 1/4'

per foot.

7. Run pipe as directly as possible with as few elbows as

possible.

8. Do not connect tofireplace flue.

9. Endofvent pipe must be flush with insideface ofchimney

flue. Usea sealed-in thimblefor the chimney connection.

10. Horizontal run should not be longer than 3/4the chimney

height (HT}(Fig.8}.

The sectionsofventpipeshould be fastenedwith sheet metal

screws to make the piping rigid. Horizontal portions of the

vent system must be supported to prevent sagging. Use

stovepipe wires every 5' to support the pipe from above.

If the vent pipe must go through a crawl space, double wall

vent pipe should be used. Where vent pipe passes through

a combustible wall or partition, use a ventilatedmetal thimble.

The thimble should be 4 inches larger in diameter than the

vent pipe.

MINIMUM VENT PIPE CLEARANCE

Wood and other combustible materials must not be closer

than 6" from anysurfaceof single wall metal vent pipe. Listed

Type B vent pipe or other listed venting systems shall be

installed in accordance with their listing.

REMOVING EXISTING BOILER FROM

COMMON VENTING SYSTEM

When an existing boiler is removed from a common venting

system, the common venting system is likely to be too large

for proper venting of the appliances remaining connected

to it.

At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining

connectedto the commonventingsystemplaced inoperation,

while the other appliances remaining connected to the

common venting systemare not in operation.

1. Sealany unused openings in the common venting system.

2. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction,leakage,corrosionand otherdeficiencies which

could cause an unsafecondition.

3. Insofaras is practical,close all building doors and windows

and atl doors between the space in which the appliances

remaining connected to the common venting system are

located and other spaces of the building. Turnon clothes

dryers and any appliance not connected to the common

venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at

maximum speed. Do not operate a summer exhaust fan.

Close fireplace dampers.

7_ 8

Page 9

4. Place in operation the appliance being inspected. Follow

the lighting instructions. Adjust thermostat so appliance

will operate continuously.

5. Test for spillage at the draft hood relief opening after 5

minutesofmain burner operation. Usetheflameofamatch

or candle, or smoke from a cigarette, cigar or pipe.

6. After it has been determined that each appliance remain-

ing connected to the common venting system properly

vents when tested as outlined above, return doors,

windows, exhaust fans, fireplace dampers and any other

gas-burning appliance to their previous conditions of use.

7. Any improper operation of the common venting system

should be corrected so the installation conforms with the

National FuelGasCode,ANSIZ223.1-latestrevision. When

resizing any portion of the common venting system, the

common venting system should be resized to approach

the minimum size as determined using the appropriate

tables in Part 1! in the National Fuel Gas Code, ANSI

Z223.1 -latestrevision.

For boilers for connection to gas vents or chimneys,

vent installations shall be in accordance with Part 7,

Venting of Equipment, of the National Fuel Gas Code,

ANSI Z223.1-1atest revision and applicable provisions

of the local building codes.

Vent connectors serving appliances vented by natural

draft shall not be connected into any portion of mech-

anical draft systems operating under positive pressure.

ROOF

RIDGE

3t4 HT MAXIMUM

J

MUST SLOPE UP

AT LEAST 1/4 INCH

PER FOOT OF

HORIZONTAL RUN

HORIZONTAL INSTALLATION

YES YES

TO FURNACE VENT TO CHIMNEY

OR BOILER DAMPER INSTALL VENT DAMPER WITH

ACTUATOR TO SIDES OF

VENT ONLY, DO NOT MOUNT

ABOVE OR BELOW VENT,

VERTICAL INSTALLATION

TO CHIMNEY

€ _ VENT

FLOW uDAMPE R

TO FURNACE N

OR BOILER U

ACTUATOR MAY BE

INSTALLED IN ANY POSITION

CAUTION: DO NOT INSTALL

THE VENT DAMPER

WITHIN 6 In. (152 ram) OF

COMBUSTIBLE MATERIAL.

INSTALL DAMPER

NOT

HERE

_'HtMNEY

BOILER WATER HEATER

TYPICAL INSTALLATION FOR VENT DAMPER

NOTE CAUTION AND FOOTNOTES

1. Install the vent damper to service only the singleappliance for

which it is intended.Ifimproperly installed,a hazardous condition,

such as an explosion or carbon monoxidepoisoning,could result.

2. Do not installthevent damper on vent pipecurve.

3. Do not run wires near high temperature surfaces. Use stand-off

brackets ifnecessary.

7_c090

Page 10

For safe, efficient operation, the vent damper and all flue

product carrying areas of the appliance must be checked

annually byyou, with particular attention given to deterioration

from corrosion or other sources. If you see corrosion or other

deterioration,contactyour heating contractorfor repairs. Check

vent damper operation as follows:

1. When theboilerisoff,check thattheventdamperpositions

indicator points to theclosed position, Fig. 11.

2. Turn the thermostat or controller up to call for heat and

check the vent damper indicator points to the open

position, Fig. 11.

3. Turn the thermostat or controller down again and check

that the damper position indicator returns to the closed

position.

4. If you have central air conditioning, set the thermostat

to COOL and turn it down to call for cooling. Cooling

system should operate.

5. Return thermostat to desired position.

The vent damper must be inspected at least once a year

by a trained, experienced service technician. The name

ofthe person who originally installed your vent damper is

shown on the installation label.

MANUAL OPERATION OF THE VENT DAMPER

The ventdamper may be placed in the open position to permit

burner operation by usingthe "HOLD DAMPER OPEN" switch,

located on the damper controller. The thermostat will control

the burnerfiring as before, whilethe damper will remain open.

DO NOT turn damper open manually or motor damage will

result. Set switchto "AUTOMATIC OPERATION" to close vent

damper during burner off cycle.

Forfurther information, and for a vent damper troubleshooting

guide, refer to the manual that was packaged with the vent

damper.

z

DAMPER CLOSED DAMPER DPEN

SHOWING OPEN AND CLOSED POSITION

CHECK GAS SUPPLY

The gas pipe to your boiler must be the correct size for the

length of the run and for the BTU per hour input of all gas

utilizationequipment connected to it. See Fig. 12for the proper

size. Besure your gas line complies with local codes and gas

company requirements.

The boilerand its individualshut-off valve must bedisconnected

from the gas supply piping system during any pressure testing

of that system attest pressures inexcess of ½ psig (3.5 kPa).

This boiler must be isolated from the gas supply piping system

by closing its individual manual shut-off valve during any

pressure testing of the gas supply piping system at test

pressures equal to or tessthan ½ psig (3.5 kPa).

CONNECTING THE GAS PIPING

Refer to Fig. 13 for the general layout at the boiler. It shows

the basic fittings you will need. The gas line enters the boiler

from the right side.

The following rules apply:

1. Use only those piping materials and joining methods

listed as acceptable bythe authority havingjurisdiction,

or in the absence of such requirements, by the National

Fuel Gas Code, ANSI Z223.1-1atestrevision.

2. Use pipe joint compound suitable for LP gas on male

threads only.

3. Use ground joint unions.

4. Install a sediment trap upstream of gas controls.

5. Use two pipe wrenches when making the connection to

the gas valve to keep it from turning.

6. Install a manual shut-off valve in vertical pipe about 5

feet above floor.

7. Tighten all joints securely.

8. Propane - gas connections should only be made by a

licensed propane installer.

9. Two-stage regulation should be used by the propane

installer.

10. Propane - gas piping should be checked out by the

propane installer.

CHECKING THE GAS PIPING

Upon completion of piping, check immediately for gas leaks.

Open the manual shut-off valve. Test for leaks by applying

soap suds (ora liquiddetergent) to eachjoint. Bubblesforming

indicate a leak. CORRECT EVENTHE SMALLEST LEAKAT

ONCE.

I WARNING I

Never use a match or open flame to test for leaks

10

Page 11

Length of

Pipe - Ft.

2O

4O

60

NATURAL GAS

Pipe Capacity - BTU Per Hour Input

includes Fittings

Y2" 314" 1"

92,000 190,000 350,000

63,000 130,000 245,000

50,000 105,000 195,000

1¼"

625,000

445,000

365,000

Length of

Pipe- Ft.

20

40

60

PROPANE GAS

Pipe Capacity - BTU Per Hour input

includes Fittings

CopperTubing*

%- ¾-

131,000 2!6,000

90,000 145,000

72,000 121,000

Iron Pipe

½- ¾-

189,000 393,000

129,000 267,000

103,000 217,000

*Outside diameter

The length of pipe or tubing should be measured from the gas meter or propane

second stage regulator.

VALVE

iZT'" tl

\ o=oLL

FLOOR SEDIMENT TRAP

LINE ........."___

ELECTRIC POWER SUPPLY

All electrical work must conform to local codes, as wel! as

the National Electrical Code, ANSt/NFPA-70, latest revision.

Run a separate 120 volt circuit from a separate overcurrent

protective device in your electrical service entrance panel.

This should be a 15 ampere circuit. Locate a shut-off switch

at the boiler. It must be turned off during any maintenance.

Connect 120 volt electrical supply to the primary leads on

the 24 volt transformer. Solder and tape or securely fasten

these connections with wire nuts.

The boiler, when installed, must be electrically grounded in

accordance with the requirements of the authority having

jurisdiction or, in the absence of such requirements, with the

National Electrical Code, ANSI/NFPA No. 70-latest revision.

Run a 14 gauge or heavier copper wire from the boiler to

a grounded connection in the service panel or a properly

driven and electrically grounded ground rod.

WARNING

Turn off electric power at fuse box before making any

line voltage connections. Follow local electrical codes.

INSTALL YOUR THERMOSTAT

The thermostat location has an important effect on the

operation of your boiler system. BE SURETO FOLLOW THE

INSTRUCTIONSINCLUDEDWITHYOURTHERMOSTAT,

Locate the thermostat about five feet above the floor on an

inside wall. It may be mounted directly on the wall or on

a vertically mounted outlet box. It should be sensing average

room temperature, so avoidthe following:

DEAD SPOTS:

Behind doors

Corners and alcoves

HOTSPOTS:

Concealed pipes

Fireplace

TVsets

Radios

Lamps

Direct sunlight

Kitchens

COLD SPOTS:

Concealed pipes or ducts

Stairwells - drafts

Doors - drafts

Unheated rooms on other side of wall

Set heat anticipator at 0.4 amps for boilers equipped with

standing pilot, and at 0.6 amps for boilers equipped with

intermittent ignition. The 24 volt thermostat leads shall be

connected to the two wires tagged "24 volt thermostat" on

the boiler. For boilers with 67D-1 float type tow water cut-

off, the two wires are black. One wire is located on the

secondary of the 24 volt transformer, the second wire is

located on the pressure limit control. For boilers with PS-

802 probe type low water cut-off, one wire is green and

is located on terminal B of the PS-802, the second wire is

black and located on the pressure limit control.

ELECTRONIC THERMOSTATS

Certaintypes ofelectronic thermostatsmay losetheirmemory

or shut down. With 67D-1 float type low water cut offs,

this may occur each time the thermostat calls for heat,

due to the internal circuit in the vent damper. With PS-802

t 74o11F

Page 12

probe type low water cut offs, this may occur each time the

low water cut off detects a low water condition. If this is the

case, an isolation relay is required for the thermostat circuit.

A 24 volt single pole single throw (SPST)normally open (NO)

relay is required, such as the Honeywell R8222A or

equivalent. Wire as shown in Fig. 14A or Fig. 14B.

VENT DAMPER

The boiler is equipped with a factory wired harness with 4

pin molex plug, that plugs into the 4 pin molex receptacle

inside the vent damper operator.

Theventdamper must beconnected for theboiler to operate.

Wiring diagrams follow for the various different models.

CAUTION

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

VENT DAMPER

4 PIN

24 VOLT

TRANSFORMER

T "_\_ ELECTRONIC

TO LWCO AND THERMOSTAT

IGNITION SYSTEM

..... FIELD WIRING

VENT DAMPER

4 PIN

MOLEX PLUG

__y _ ISOLATION RELAY 24V.

\SPST N,O, HONEYWELL

I J \R8222A OR EQUIVALENT

\

24 VOLT IIF .... _::__ -K---_ -_0

TRANSFORMER !m Z-IPRESSURELIMIT

wBT, Ti

I / _t" _"'--_ TERMINAL B

/ _- c<o--- G OF LWCO

1 _- ELECTRONIC

TO WCO AND THERMOSTAT

IGNITION SYSTEM --- FIELD WIRING

..... 12

Page 13

i

15 7/i OH2,/I _ i

PO¢,'E_ BK

SUPPL

NEUT --

ov'£ cI R NI P_O EC]£

{}15C NNEC

i / ......

',(}} .£................

OPI_O_',A[ WF 2U 24

F EX:::t

NOTE:TE2MN-_ NO "_ Af'r;r'hR_: ONY

)ld V'AIq r< Ir_ED[_ MOIIt[5 WrH

M/,N'JAL F_ED PUSH BUWON

INTERMITTENT IGNITION

vl[iqT DAMPER

M©LEX PLUG

i

<:'i >i

_, ] o '

i ............ ] o

.... i ,. t _K

L _...................

Y

_4 I(X ! CON/4!:(: Ol_

//

\N

SHUTOFF

BL)CKED 4ENT li_L

SAFEF!'

SHIJTOF_ ¸

15V/6OHZi i ¢,

OVERCIJRREN] PROIEC] ED

/;ISC()NNECT

JT 1OO3-620 SERIES

_TERMI_TENT PLOT CONTROL

..... _: ]

O_ERAHO/_ / HOLD DAMPER OPEN W CI4 i ::: ©ND

J

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THIS APPLIANCE MUST BE REPLACED,

IT MUST BE REPLACED WITH TYPE 105°C THERMOPLASTIC WIRE OR ITS EQUIVALENT.

13

Page 14

STANDING PILOT

Will lAMP R

M(L {7, 'L U(

f: :77: .....

i ( ) /} t) t_}

NEU/ i I _

• "?'7" ...... .......

r j ) k i i i ']' i LJ] Orl

f +7 ............................................................................g 1 r' kfls: , !

t,;:i .................................i................................................................[ii_'

W/-TER

F£E[,_:R

rqol[:

rER_AL NO_ 5 APPEAR_o ONP,"

ON WAr_R FEEr,ER MOOEP, WI01

M.tr_A} v_r) Pu%H BUmrOq

WIRE }_UT

COLOR C3:,E

_R BROWN

O OP.AN{SE

BI¸ 8'_,_7d WiTH IAAO_R

_Si:7 (_s7

{W

i i

i ..... 7:: .........................

Tr_

, {>

i }

;AFE[ f HUT)Fr I'

H

vJLO i O ,i!l

"D]: : " HU i)f:

/oooo-4 POI E CON'\lICTOR

/

/ _......................................VENT DAMPER CA[7_ E

//

/

/

\

T}

VENT <"

DAMPER

/

\

,!,., I <w,_/<"

£2 TFWRMO TAT

i " ' - W /

i "

_ II _F_ I

i

:_/-=:),i i_K

OVERCURREN I

PAOT CTED

GA*g Ol COHNFCI

VA_ _

NOTE:

SIA AND S1B ARE TtE AUIOMAIC OPERA-ION / itO/D DAMPER OPEN >W!TCH

SWICI SIOWN N AUrOMA C POS11ON,

$2, $5, AND £4 ARF CAM ACTUATED SNAP SYqTC i8S

1i }V!60 t !//¢

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THIS APPLIANCE MUST BE REPLACED,

IT MUST BE REPLACED WITH TYPE 105°C THERMOPLASTIC WIRE OR ITS EQUIVALENT.

14

Page 15

2¢ VOLT

TRANSFORMER --_

N

11 S///6OHZ/1 ¢

POWER SUPPLY

HOT ----._

OVERCDRRENT PROTECTED

DISCONNECT

W

NEUT

VENT DAMPER

MOLEX PLUG

Y

INTERMITTENT IGNITION

THEI44r)gT4]'

__4//

P RESSLIRE LIMIT

OPTIONAL WF-2U-24

WATER FEEDER

NOTE:

TERMINAL NO. 5 APPEARS ONLY

ON WATER FEEDER b4ODELS WITH

MANUAL FEED PU£H BUTTON

I'

BK

LOW WATER

OUT OFF

BK

FbkblE ROLLOUT

SAFETY SHUTOFF

_i--W_RE NUT

COLOR CODE

BK--BLACK

BR-BROWN

0 -ORANGE

Y -YELLOW

R -RED

BT-BLACK WiTH TRACER

W -WHITE

G -GREEN

UT 1003-620 SERES

NTERt,4[TTENT PILO'TCONTROL

" 4 POLE CONFECTOR

/

j/"

'\

THERMOSTAT

_o_i Io¸ _Z

H_SSURE

i_qT

/ BKi

PI-04I i j 24- V

j SECONDAR f

I y i BK

t..............................I . i

\x o9 i

I_/! LiT fOG3 620 SERIEb '_

I I

/

I

l

7 A_,_m ROL' O [ ffTERbdll] NI PI O1 CONTROL F. (J 7AI

SARET¢ ",, F ] l _ _._- Ho

_H iTCFF < ) - i I

{7OL! ED vE _ _ _

SHt TOFF / _IGI/wl IBK r i_,_,KB[ [O FlOg [} JR'/ R

NO/: J _ i J pK

M/M........................,

OPERATION / HOD DAMPER OPEN SWITCI i I _._i i_c/il) I#s/

SW_TCH SHOWN IN AUTOMATC POSTIO"/ l iNi2 pv / GAS VAVE

S2 $3 AND $4 ARE CAM ACLAi D SNAP SWfC4ES _ PV/MV VR8204A / 'vR:_3OaM

/ 15V!601 'Z,//¢

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THIS APPLIANCE MUST BE REPLACED,

IT MUST BE REPLACED WITH TYPE 105°C THERMOPLASTIC WIRE OR ITS EQUIVALENT.

15

Page 16

24 _OL1

TRAHSFORMER _\

" Bi<

1 15Vi@HZ/1 r,_ '\,

\

POWER SUPPM

lOT

OVER( U RI:_E'\! PROYEC El

01SCOk qECT

W

NEUT

I,lO :

fERb'INA NO 3 APPEARS Ob_ Y

ON WATER FEEDER MODEl> WiTII

MANbAt FEE{) PUSH BtlTION

VE:i\I7 )/¢4 Y'{ I:,

I/0i E:X /:i tJ(,

STANDING PILOT

PRES _URE /IMIi

1,

BK

WiRE NUT

COLOR CODE

BK BLACK

BR BROW!N

0 Or#Ai,,OE

Y YELOW

_< Ik<ED

BT B_ACK WFH TRACER

W WIE

O GREEN

FLAME ROILOLIT BLOCKED VENT

.<;AFE]Y SHUF)F: SAFELY SHU OSF

, +i PX)L[ COl N(:(:} OR

/

//

i /

TO /_

'/Nl <"

I)/kIP R

PI 02i I0 I _ THFRMOSTAT

PRESSt.iR£

NOTE:

i} SIA AND SI[J ARE THE AU}OM£]IC

Ol EI_£10N / I/(}LI3 DAMPER OPEN SWFCI_

_Wi[C/i Siq©WN IN A_f[(>MATiC POSIHON

$2, $3, AND $4- ARE CAM A¢_UAilED SI/AP SWI/CHES

OVERCIiRRE} T

PROTECED

DIS/,: ( N qEC i

1 / 5V/ iO Ei'I ¢

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THIS APPLIANCE MUST BE REPLACED,

IT MUST BE REPLACED WITH TYPE 105°C THERMOPLASTIC WIRE OR ITS EQUIVALENT.

16

Page 17

POP SAFETY VALVE

The pop safetyvalve should open automatically if the boiler

steam pressure exceeds the pressure rating ofthe valve (15

psig). Should it ever fail to open under this condition, shut

down your boiler. If valve discharge occurs, or valve fails

to open asdescribed above, contact an authorizedcontractor

or qualified service technician to replacethe pop safety valve

and inspect the heating system to determine the cause, as

this may indicate an equipment malfunction.

Run a pipe from the safety valve outlet (pipe must be same

size as outlet and open end must not be threaded) to an

open drain, tub or sink, or other suitable drainage point not

subject to freezing. Failuretodo so maycausewater damage

or injury should relief valverelease. Do not cap off the drain

line from this valve!

STEAM PRESSURE GAUGE

Every system should havea pressure gauge installed in the

boiler. This gauge enables you to monitor the pressure in

the system. If the safety devices fail to shut off your boiler

atthe proper settings,notify your serviceman immediately.

WATER LEVEL GAUGE

The water level in the boiler can be seen through the glass

tube in the water level gauge at side of boiler. Correct cold

boiler water level isstamped on side jacket panel. The water

level should be checked regularly for the proper level.

On the right side jacket panel of the boiler, there are three

holesforthe glass water level gauge.Thetop hole is common

for both types of low water cut off, and is used for the upper

gauge glass fitting. The middle hole, 9" down from the top

hole, is used for the bottom gauge glass fitting for the Model

67D-1 and 47-2 float type low water cut off.The lowest hole,

12¼_down from the top hole, is used for the bottom gauge

glass fitting for the Model PS-802 probe type low water cut

off. The hole that is not being used is covered with a sheet

metal knockout.

STEAM PRESSURE CONTROL

The steam pressure limit control (pressuretrol)shuts off the

gas to the main burners when the steam pressure in the

boiler reaches the cut-off setpoint (i.e. the sum of the cut-

inand thedifferentialsetpoints).Burnersretirewhen the steam

pressure drops to the cut-in setpoint. System pressure

requirements are based on the size and condition of the

pipes, and the load.

LOW WATER CUT-OFF

1. Model 67D-1

This isa float operated switch which shuts down the gas

burner if waterfalls below the visible bottom of the gauge

glass.

2. Model PS.802

This is an electronic probe type LWCO.The probe is

located inside the boiler. The LWCOwill shut down the

burners if the water loses contact with the probe for a

period of 10 seconds.

Refer to manufacturer's instructions (enclosed) for more

information.

WATER FEEDER (Optional)

TheModel WF-2U-24water feeder maybe used with either

of the available low water cut-offs. The water feeder's job

is to maintain a safe minimum water level. It's used to

keep the boiler running by compensating for minor

evaporative steam leaks,and to prevent freeze-ups if the

homeowners are away and a return line should spring

a leak.

McDonnell and Miller Model 10t water feeders may be

used, howeverthe water feed ratesare too high and need

to be regulated or throttled, and wiring will have to be

revised.Consultthe boiler manufacturerbefore usingthese

or any other non-standard types of controls.

The automatic water feeder is a safety device, not a

convenience item.Itisnotdesigned to maintaina "normal"

water line. The water feeder does not take the place of

a responsible person monitoring and maintaining the

normalwaterline.Steam boilers require personal attention.

VENT DAMPER

This is an automatic, motorized stack damper that has

been developed to increase the efficiency of heating

systems by reducing standby losses from the boiler and

the conditioned air space.The damper closes thechimney

vent when the burner is off and fully opens it when

combustion is required.

ROLLOUT SWITCH

(FLAME ROLLOUT SAFETY SHUTOFF)

The rollout switch is a temperature-sensitive fuse link

device. It is located on the boiler base just outside the

fire box. In the event of heat exchanger flueway blockage

causing flame to roll out of the fire box, the fuse will blow,

shutting down the flow of gas to the main burners. The

fuse does not change in appearance when blown.

If the ro!!out switch blows, it must be replaced with an

exact replacement. Check heat exchanger flueways for

blockage when restoring system to operating condition.

Donot operate system without a rollout switch.

SPILL SWITCH

(BLOCKED VENT SAFETY SHUTOFF)

The spil! switch is a manual reset disc thermostat with

a fixed setpoint (280° F}, and normally closed contacts.

It is located at the relief opening of the draft diverter. In

the event of chimney or venting system blockage causing

products of combustion to spill out of the relief opening,

the spill switch disc heats up and the spill switch contacts

willopen, shuttingdown theflow ofgas tothe main burners

by removing power to the gas valve.

In the event that the spill switch contacts open, the reset

button on the back of the switch will pop up. The spill

switch must be reset manually,after theswitch hascooled

off, by pushing the reset button down. Check the venting

system and chimney for blockage when restoring the

system to operating condition. DO NOT operate the boiler

without a spill switch.

7 74_

Page 18

WARNING: If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

A. Some boilers are equipped with an intermittent ignition

device which automatically lights the pilot. Do not try to

light the pilot by hand.

Some boilers are equipped with a continuous pilot and

must bemanuallylighted. (Seelighting instructionson page

18-19.) A match holder is included in the parts bag.

B. BEFOREOPERATINGsmell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavierthan air and will settle on the floor.

WHATTO DO IFYOUSMELLGAS

• Do nottry to light any appliance,

• Do not touch any electric switch; do not use any phone

in your building.

C.

U.

• Immediately call your gas supplier from a neighbor's

phone. Followthe gas supplier's instructions.

elf you cannot reach your gas supplier, call the fire

department.

Use only your hand to push in or turn the gas control

knob. Never use tools, tf the knob will not push in or turn

by hand, don't try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect theappliance and toreplace any partofthecontrol

system and any gas control which has been under water.

1. STOP!Readthe safety information on this page.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance isequipped withan ignition device which

automatically lights the pilot. Do not try to light the pilot

by hand,

aB

GAS _,INLET

GAS CONTROL KNOB

SHOWN IN "ON" POSITION

5. Remove lower front panel.

6. Rotate the gas control knob clockwise _ to"OFE"

7. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. If you smell gas, STOP!

Follow "B" in the safety information on this page. If you

don't smell gas, go to next step.

Rotatethe gascontrolknob counterclockwise If to"ON."

Replace lowerfront panel.

Turn on all electric power to the appliance.

Setthermostat to desired setting.

If the appliance wilt not operate, follow the instructions

"To Turn Off Gas To Appliance" and call your service

technician or gas supplier.

TURN OFF GAS TO APPLIANCE

1_Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is

to be performed.

3. Push in gas control knob slightly and turn clockwise

to "OFE" Do notforce.

,

9.

10.

11.

12.

TO

..... 18

Page 19

1.STOP!Readthesafetyinformationonpage18.

2.Setthethermostattolowestsetting.

3.Turnoffallelectricpowertotheappliance.

4.Removelowerfrontpanel.

5.Rotategascontrolknobslightlyandturnclockwise

GAS CONTROL KNOB

to "OFE" F SHOWNIN''ON"POSIT!ON

GAS

INLET

• o

RESET BUTTON

6. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. If you smell gas, STOP!

Follow "B" in the safety information on page 18. If you

don't smell gas, go to next step.

7. Find pilot - follow metal tube from gas control. The pilot

is betweentwo burner tubes as shown in Fig. 15.

8. Turn knob on gas control counterclockwise _ to

"PILOT."

9. Rotate the gas control knob counterclockwise i_ to

"PILOT."Pushdown and hold the red reset button while

you light pilot burner with a match.

After about one minute, releasereset button.Pilotshould

remain lit. If it goes out, turn gas control knob clockwise

'W to OFF Torelight, repeat steps 5-9.

* If button does not pop up when released, stop and

immediately callyourservice technicianorgassupplier.

* If the pilot will not stay lit after several tries, turn the

gas control knob to "OFF" and call your service

technician or gas supplier.

10. After pilot remains lit when red reset button is released,

turn gas control knob counterclockwise t_ to "ON."

11. Replace lowerfront panel.

!2. Turnon all electric power to the appliance.

13. Set thermostat to desired setting.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostatto lowestsetting.

2. Turn off all electric power to the appliance if service is

to be performed.

3. Push in gas control knob slightly and turn clockwise

_i to "OFF" Do not force.

i_ATCH HOLDER

PRESSURE REGULATOR CONVENIENCE WIRING

ADJUSTMENT TERMINALS(2} /TERMINALS (2)

(UNDER CAP SCREW)*, (OPTIONAL) | / OUTLET PRESSURE

PRESSURE TAP

THERMOCOUPLB PILOT ADJUSTMENT

CONNECTION .B/ \RR[_ET _GAS (UNDER CAP SCREW}

BU'i'FON CONTROL/VALVE

1L62aA KNOB

PRESSURE REGULATOR

ADJUSTMENT

(UNDER CAPSCREW

INLET _

PRESSURETA

IZ.160

WIRING

TERMtNALS(3)

OUTLETPRE$SURE

,,, TAP

GROUND

n TERMINALS(2)

1_ OUTLET

._PILOT OUTLET

_PILOT ADJUSTMENT

(UNDER CAPSEREW)

_GA$

CONTROL

KNOB

1 g 7_o17J

Page 20

HOW A STEAM SYSTEM OPERATES

The water in the boiler is heated until it reaches the boiling

point. As the water boils it turns into steam.The steam rises

from the top of the water through the supply main to the

radiation units. As it passesthrough the radiators it releases

its heat and condenses into water. The water returns to the

boiler through the return main. Most residential systems

operate at less than 1 pound steam pressure.

FILLING SYSTEM WITH WATER

On steam heating systems the boiler is partially filled with

water.Itis very importantto the proper operation of the entire

system thatyour boilerbe filled tothe proper level.The correct

water level is about halfway up the glass water level gauge

as marked on the boiler jacket. Tofill:

1. Close the boiler drain valve.

2. Open the valvesat the top and bottom of the glass water

level gauge. Also open the drain valve at the bottom of

the gauge.

3, Open the fill valve and allow waterto run into the boiler.

WARNING - Neverrun waterintoa hotemptyboiler. I

4. Allow boiler to fill until water runs out the gauge drain

valve.Then close the gauge drain valve.

5. Continuetofill boiler until water reachesthe indicated water

line. This isabout halfwayup the glasstube.

WATER LEVEL

The normal water level is shown on the right side of the

boiler and is 24" above the floor. The normal water level

is determined when the boiler is off and cold, i.e. when all

of the water in the system is inside the boiler and the return

piping below the water line, and everything above the water

line is air, no steam. When the boiler is making steam, the

water level will drop two to three inches below the normal

water line.

AUTOMATIC GAS VALVE

The Automatic Gas Valve opens or closes according to the

heat requirements of the thermostat and temperature limit

control. It closes ifthe pilot goes out. Each individual control

must be operating correctly before any gas can pass to the

burners. Any one control can hold the gassupply from burner

regardless ofthe demand of any other control.

THERMOSTAT

Keep it set at a desired room temperature. If windows are

to beopened or heatis not needed, move thermostat pointer

to alower setting.

NOTE

In the event of failure of any component, the system

will not operate or will go intosafetylockout. Thesystem

iscompletely self-checking. On every callfor heat, each

component must be functioning properly to permit

operation. On safety lockout the system has to be reset

by turning the thermostat to the lowest setting for one

minute,then back tothe normal setting.

Safe lighting and other performance criteria were met with

the gasmanifold and control assembly provided on the boiler

when the boiler underwent tests specified in ANSI Z21.13

- latestrevision.

...... 20

Page 21

ADJUST PILOT BURNER

Pilotflameshouldsurround3/8" to 1/2" ofthepilot sensor.Refer

to Fig.19.Ifflameneedsadjusting,doit asfoltows:

1.Removescrewcoveroverpilotadjustingscrew.

2.Insertsmallscrewdriverandadjustflameasneeded.Turnscrew

counterclockwiseto increaseflame,clockwiseto decrease.

3.Replacescrewcoveroverpilotadjustingscrew.

MAIN BURNER(S)

Themainburnersdo not requireprimaryair adjustmentandare

notequippedwith primaryair shutters.Mainburnerflamesshould

form sharpblueinnerconesin a softer blueoutermantel,with no

yellow.Puffsof air from blowingon theflameor stampingonthe

floor will causetheflamesto turn orangemomentarily.Thisis not

unusual.Remainstill when observingthe mainburnerflames.If

theflameappearanceis notcorrect,checkmainburnerorificesand

the burnerthroatandflame portsfor dustand lintobstruction.It

maybenecessaryto removethe rolloutshieldtoobservethe main

burnerflames.Replacerollout shieldafterobservation.Referto

Figure18.

ARPINNERCONES

GAS VALVE SAFETY SHUTDOWN TEST

1. For boilers equipped with continuous pilot, with main

burners firing, disconnect the thermocouple from the gas

valve.The gas valve should immediately shut off the main

burners and the pilot.

2. For boilers equipped with intermittent ignition, with main

burners firing, disconnect the ignition cable from the

intermittent pilot control box. The gas valve should shut

off the main burners. TURN OFF ELECTRICPOWERto

boiler before reconnecting ignition cable, to prevent

electric shock.

ADJUST STEAM PRESSURE CONTROL

The steam pressure limit control (pressuretro!) shuts off the

gas to the main burners when the steam pressure in the

boiler reaches the cut-off setpoint (i.e. the sum of the cut-

inand thedifferentialsetpoints).Burners retirewhen thesteam

pressure drops to the cut-in setpoint. System pressure

requirements are based on the size and condition of the

pipes, and the load.

For good system operation, the cut-in setting of the

pressuretrol should never be less than twice the system

pressure drop. In a typical single family residence with a

clean one pipe heating system and cast iron radiation, this

meansthatthecut-in will usuallybe setat theminimum setting,

i.e. '/2psi.

Steam radiation is usually sized based on square feet of

equivalent direct radiation (EDR). This is based on a steam

pressure in the radiator of just tess than 1 psi. Therefore,

in our example system from above, we would set the

differential adjustment at 1 psi, i.e. the steam pressure

required in the radiators. This will give us a cut-off setpoint

of 11/2psi.

The above is an example of a typical one pipe system. For

larger systems or other types of systems such as two pipe

systems, or systems with convectors or fan coil units, the

pressuretrol settings will need to be determined on a system-

by-system basis.

The cut-in setpoint is determined by the system pressure

drop tothefurthestradiatororterminal unit.Doublethesystem

pressure drop as a safety factor, resulting in the rule that

the cut-in setting should never be less than twice the system

pressure drop.

The differential setpoint is the steam pressure required at

the terminal heating units.

Now your boiler wil! operate in the correct pressure range.

It will maintain enough steam pressure to send the steam

out to the furthest radiator, and not go over the optimum

steam pressure that is required at the radiators.

CHECKING CONTROLS

Tocheck the Low Water Cut-Off,turn off power to the boiler

or turn the thermostatdown tothe lowest setting. Drain water

to below the visible bottom of the water gauge glass. Turn

power on and turn the thermostat to call for heat. When the

boiler is equipped with the float type LWCO,the gas valve

should not open on a cal! for heat when the water is low.

When the boiler is equipped with a probe type LWCO,the

gas control should be powered for approximately 10seconds

(thetime delay on the probe type LWCO),then the gas valve

wil! close and the red indicator will illuminate on the LWCQ

If your boiler is equipped with the optional WF-2U-24 water

feeder, continue to keep the thermostat calling for heatafter

the lowwatercut off recognizes the low watercondition. After

a one minute time delay,thewaterfeeder should start feeding

water to the boiler. The feeder should feed for one minute,

and then go into another one minute waiting period. This

cycle ofalternately waiting and feeding should repeat until:

1. For Model 67D-1 float type low water cut offs - as the

water level raises the float above the burner cut off switch

level, the burners should ignite. Thewaterfeeder remains

powered until the water level raises the float to the water

feeder switch level,satisfying the water feeder.

2. For Model PS-802 probe type low water cut offs - the

water levelwill rise until waterin the boiler makes contact

with the probe, satisfying the water feeder, and igniting

the burners.

Ineither case, there should be between one and two inches

ofwatervisible in thegauge glass when both the waterfeeder

issatisfied, and the burners are allowed to ignite.

The time delays in the feed cycles are designed to prevent

the boiler from flooding due to slow return lines.

To check the pressure limit, run the boiler untilthe pressure

reaches system demand. Then turn the pressure screw and

1 z4o_eH

Page 22

drop the pressure setting until the boiler shuts down. This

wilt show that the pressure limit isoperating properly

Refer to control manufacturer's instructions (enclosed) for

more information.

Check thermostat operation, When set above temperature

indicated on the thermometer, boiler should ignite. Make

certain the thermostat turns off the boiler when room

temperature reachesthe selected setting and startsthe boiler

operating when room temperature falls a few degrees,

Finally set thethermostatfor thedesired temperature. Special

conditions in your home and the location of the thermostat

will govern this setting.

It is very important to clean a new steam boiler after it has

been installed and put into continuous operation. This must

be done to remove any accumulation of oil, grease, sludge,

etc., that may have been present in the system. These

substances may cause the boiler water to foam and surge,

thus producing a very unsteady water line, throwing water

into the steam header, and possibly preventing steam

generation. Follow these steps in order to remove these

contaminants.

SKIMMING AND BLOWDOWN

New boilers must be skimmed at the time of installation to

remove threading oil and other impurities that float on the

surface of the water.

1. Remove the plug from the skimmer tapping and pipe to

a floor drain or bucket.

2. Raise the water levelto the skimmer tapping.

3. Fire the boiler to maintain a water temperature of !80-

200 degrees.

4. Feed water to the boiler to maintain the water level.Adjust

the water feed rate to keep water continuously flowing

out of the skimmer tapping without the water level going

above or falling betow the tapping. Cycle the burners to

prevent boiling.

5. Continue skimming until the water runs clear, This may

take several hours.

6. Float type low water cut offs must be blown down after

skimming. Thefloatchamber of the lowwater cut off must

be flushed clean and maintained clear of sediment to allow

free movement of the float. This must be done frequently

during initial operation of the boiler, and at least once

a week thereafter. Follow the instructions on the tag

attached to the control.

Probe type low water cut offs require no maintenance

at this time.

7. After blowing down the !ow water cut off and before

blowing clown the boiler, fil! the boiler to the water line.

Firethe burners and allow normal steam pressure to build

up. Run a connection from the boiler blowdown valve to

a nearby sewer or floor drain or to a safe discharge point

outside. Shut off the gas burners, open the blowdown

valve, and allow all of the water in the boiler to drain out.

Close the blowdown valve. Allow the boiler to cool

thoroughly, and then slowly refill the boiler to the water

line. Repeat this step as many times as necessary until

the blowdown water is clear.

8. Followingthe finalbtowdown, allowthe boiler tothoroughly

cool, and then add fresh water slowly up to the normal

water line. Start the burners and maintain at least 180

degrees for 15 minutesto remove dissolved gasses from

the fresh water. Shutoff burners.

Now,let the boiler steam for a few days, to give the majority

of the system dirt a chance to work its way back to the boiler.

Then check the water in the gauge glass. The gauge glass

should be dry above the water line. The water line should

not bounce more than one inch when the boiler issteaming.

tf you see water droplets carrying over from the top of the

gauge glass, or excessive bouncing of the water line, the

boiler needs further cleaning. Take a water sample and boil

it on the stove, to see if itfoams. If it does, this also indicates

the boiler needs to be cleaned.

Ifcleaning isnecessary, repeat the skimming and blow down

procedure from above. Usually,a tong skim will be all you

need to clean the boiler.

In more troublesome cases it may be desirable to flush the

system as well. This is accomplished by closing the gate

valve in the Hartford Loop, and opening the drain(s) at the

end of the wet return(s). Run a hose from the drain valve

on the wet return to a nearby floor drain or bucket. Run

the boiler attwopounds ofsteam pressure. Feedjust enough

water to compensate for the waste condensate going down

the drain, and to keep the boiler from going off on low water

cut off.Run the boiler until all waste condensate runs clear.

NOTE

Boiler cleaners and chemical cleaning additives are not

recommended. If used and not rinsed properly they

will do more harmthan good. The cleaning procedures

laid outabovewill clean outthe typicaloils and impurities

found in new boilers and in residential heating systems.

The best thing for your boiler and heating system is

clean water with no additives.

In very extreme cases it may be necessary to chemically

clean and flush the heating system. Consult the boiler manu-

facturer before introducing any chemicals intothe boiler.

,,= 22

Page 23

Checkthewaterleveleverydayortwo.Verifythewaterlineshownby

operatingthedrainvalveonthegauge.BESURETOPANDBOTTOM

VALVESONGAUGEAREALWAYSOPENSOTHATACTUALWATERLEVEL

WILLBESHOWNATALLTIMES.

Thegaugeglassshouldbedryabovethewaterline.Thewaterlineshould

notbouncemorethanaboutoneinchwhentheboilerissteaming.If

youseewaterdropletscarryingoverthroughthetopofthegaugeglass,

orexcessivebouncingofthewaterline,theboilerneedstobecleaned.

Followtheinstructionsunder"CleaningYourBoiler."

POP SAFETY VALVE

Beforetesting,makecertaindischargepipeisproperlyconnectedtovalve

outletandarrangedto containandsafelydisposeol boilerdischarge.

Undernormaloperatingconditionsa "try levertest"mustbeperlormed

everymonth.A "try levertest" mustalsobeperformedattheendof

anynon-serviceperiod.Testatnormalsystemoperatingpressurebyholding

thetestleverfullyopenforatleastfivesecondsto flushthe valveseat

free of sedimentanddebris.Thenreleaseleverandpermitthevalve

to snapshut.II lift leverdoesnotactivate,or thereis no evidenceol

discharge,turnoffboilerimmediatelyandcontacta licensedcontractor

orqualifiedservicepersonnel.

LOW WATER CUT-OFF

TheLowWaterCut-Offwill interrupttheelectricalcurrentto theburner

whenthewaterlineintheboilerdropstoa lowlevel.

Onfloattypelowwatercut-offs,it is very importantto keepthefloat

chamberfreefromsediment,a conditionessentialto dependabilityTo

keepanyaccumulationfrominterferingwithfloatactionisto"BLOWDOWN"

orflushoutthecontrolregularlyThismustbedonetwoto threetimes

duringthefirstweekafterinstallationandoncea weekthereafterduring

theheatingseason.Doit whiletheboilerisinoperation.Firstnotewater

levelin gaugeglass.Openblow-offvalveat bottomof control;water

will pourout,flushingawaysediment.Drainuntilwateris clear,about

a pailful,thenclosevalve.If waterlevelin gaugeglasshas dropped,

addwaterto boilertorestorelevel.Consultlowwatercut-offmanufacturer's

instructionsincludedwithboiler.

NOTE: Openingblow-offvalvecheckscut-offoperationtoo.As float

dropswithfallingwaterlevel,burnerswill shutoff.Aftervalveisclosed

andnormaloperatingconditionsarerestored,burnerswillresumefiring.

ForprobetypeLowWaterCut-Offs,checkactionof theLowWaterCut-

Offmonthlytomakesureit isprovidingtheproperprotection.See"Checking

andAdjusting"onpage19. LowWaterCut-Oflremoteprobesmustbe

removedforperiodicinspectionandcleaning,preferablyat thebeginning

ofeachheatingseason.Morefrequentcleaningmayberequiredonboilers

requiringconstantorveryfrequentadditionsofmakeupwater.

BURNERS

A visualcheckofthepilotandmainburnerflamesshouldbe madeat

leastonceeachyear,preferablyat thebeginningof theheatingseason.

Seepage19.

BOILER FLUE PASSAGES

Undernormaloperatingconditions,withtheburnersproperlyadjusted,

itshouldnotbenecessarytocleantheboilerfluegaspassages,However,

to assuretrouble-freeoperation,werecommendthatyou havetheflue

passages,burneradjustment,andoperationofthecontrolscheckedonce

eachyearbyacompetentServiceTechnician.

Beforethestartofeachseason(orwheneversystemhasbeenshutdown

for sometime)recheckthewholesystemfor leaks... andrecheckthe

boilerandventpipeforleaks.

VENT PIPE

Theventingolthisunitisveryimportantandthepipingshouldbechecked

at leastoncea season.If the ventpipingshowsany signof leaking,

replaceitimmediately

CLEANING YOUR BOILER FLUE PASSAGES

AND BURNERS

FluePassagesbetweensectionsshouldbe examinedyearlyandcleaned,

il necessaryToclean,removeburners,pilot,andventpipe.Removetop

andfrontjacketpanels.Removethetwoscrewsattachingtheintermediate

front panelto theleft andrightsidejacketpanels.Removethedraft

diverterandintermediatefrontpanelasaunit.Carefullyremovethecerafelt

gasketstrips.Cleanpassagewaysbetweensectionswithaflexiblehandle

wirebrush.Removedirtfrombottomol boilerandfrombetweensections

by vacuuming.Makesureallflameportsin burnersareopenandclear.

Shakeout or blowoutallloosedirtin burners.Resealseamsbetween

adjacentsectionsasnecessarywith400FRTVsiliconesealant.Reassemble

all parts.Besuretochecktightnessof pilotconnectionsandcondition

ofburnerflamesafterreassembly(seeFigures18and19).Besurevent

pipeconnectionstochimneyaresecureandnoobstructionsarepresent.

FOAMING, PRIMING OR SURGING

Thesetermsareusedto describea fluctuatingwaterline- whenwater

leavestheboilerwiththesteam.

Itiscausedbyanycombinationofthefollowing:

1. Threadingoil andorganicmatterintheboilerwater.(Mineraloil, or

coresanddoesnotcausesurging.)Followinstructionsunder"Cleaning

YourBoiler."

2. Faultyquickventsthatdo notreleaseair untila sizeablepressure

is builtup- if oldstyle,replace- if dirty cleansoyoucaneasily

blowthroughvalve.

3. Improperheaderdesign- whensteamflowsin oppositedirection

of equalizerlineon "HartfordLoop."Generallya 15"horizontalrun

betweenriserandmaintakeoffwillallowentrainedwaterto fall out

of thesteamvaporso it canreturnto boiler.(SeeFigures5, 6A

&6Bonpages5 and6).

4. Adjustmentofsteamtimitcontrolto awidedifferentialincreasesdifliculty

if quickventsareoldstyle,slow-releasingtypeor dirty Alwaysset

steamlimitcontroldifferentialaslowaspossible.

5. Soapanddetergentsintheboilerwatercauseextremesurging.Boiler

cleanersandchemicalcleaningadditivesarenotrecommended.Ifused

andnotrinsedproperlytheywilldomoreharmthangood.Thecleaning

procedureslaid out in theseinstructionswill cleanoutthetypical

oilsandimpuritiesfoundinnewboilersandinresidentialheatingsystems.

Thebestthingfor yourboilerandheatingsystemis cleanwaterwith

noadditives.

CAUTION

Never refill a hot boiler with cold water - the danger

of thermal shock may crack a section.

iii

BOILER WATER TREATMENT (Other Than Cleaners)

in steamsystemswherethe systemis tight,freefrom leaks,andall

thesteamis returnedto theboileras condensate,the amountof make

upwaterissmall.Watertreatmentis generallynotrequired.

In steamsystemswithlessthan90% of the steambeingreturnedas

condensate,orwithveryhardorcorrosivemakeupwater,treatmentmay

bedesirable.Followtherecommendationsofyourlocalboilerwatertreatment

specialist.

BETWEEN HEATING SEASONS

Boilersshouldnotbedrainedbetweenheatingseasons.Steamboilersshould

beentirelylilledwithwaterduringthesummermonthstoexcludeair.

23

Page 24

You may avoid inconvenience and service calls by checking these points before you call for service.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

1. Do Not try to light any appliance.

2. Do not touch any electric switch, do not use the phone.

3. Leave the building immediately, then call your gas supplier.

4. If you cannot reach the gas supplier, call the fire department.

Possible Cause

Thermostatisnot set correctly

Burner is not operating properly

No electric powerto boiler

Controls out ofadjustment

Radiators not heating

Poor electrical contact

Rollout switch blown

Chimney flue is blocked

Vent damper not operating

Possible Cause

Gas input amount is incorrect

Possible Cause

Notenough ventilation

Chimney flue is blocked

Possible Cause

Air insystem

What to do

Resetthermostat above room temperature.

Check flame. If it is yellow, the burner is not getting enough air. Or, if flame

is blue and noisy and seems to lift off the burner, the burner is getting too

much air.Contact your service technician.

Check overcurrent protection. Check to be sure electric power supply circuit

is "ON."

Resetaccording to instructions.

Steam air vents are not operating properly Check flow control valve (if used).

It may be in closed position.

Check all control terminals and wire joints.